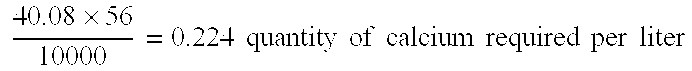

Patents

Literature

437results about How to "Improve pumping capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

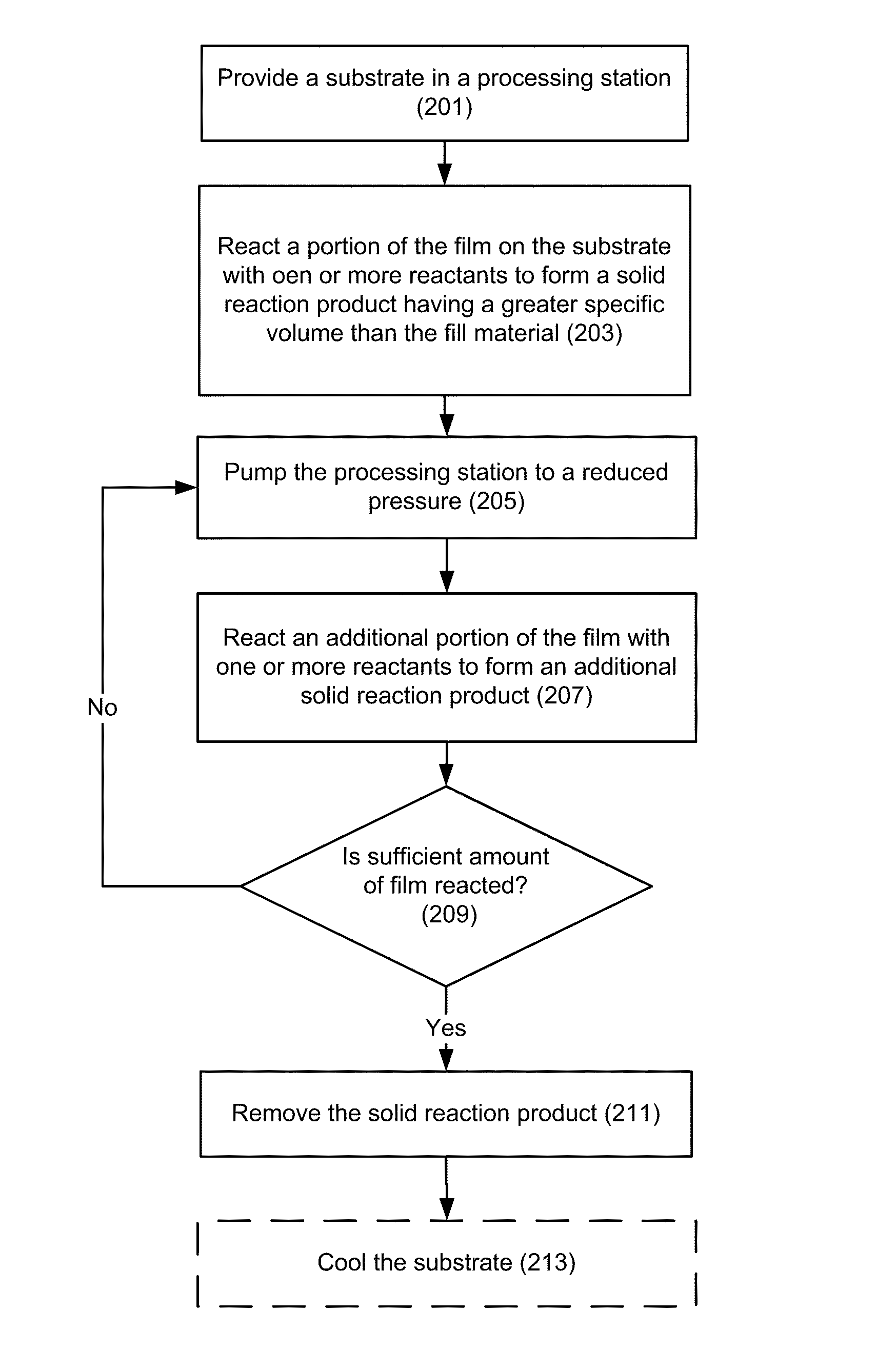

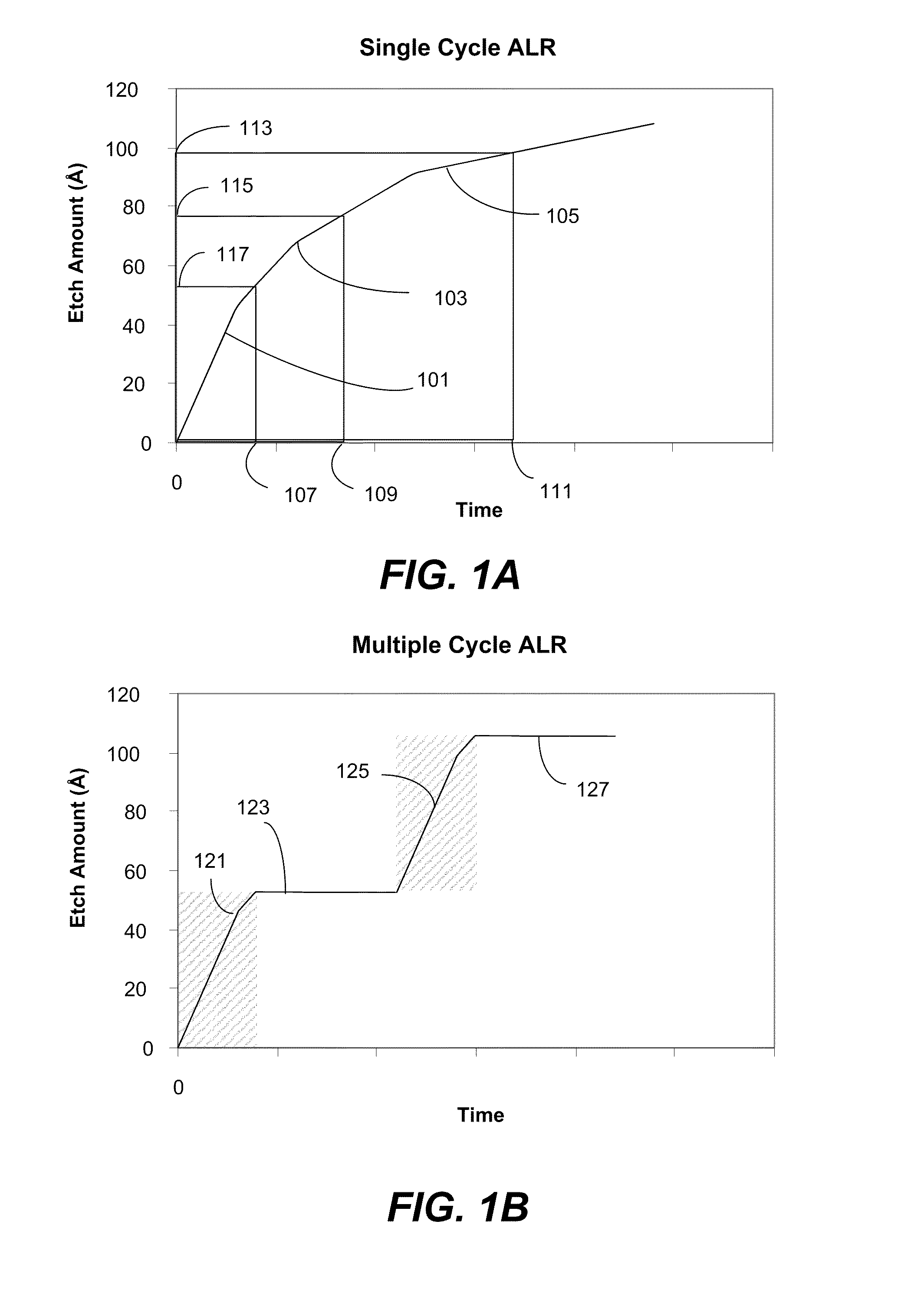

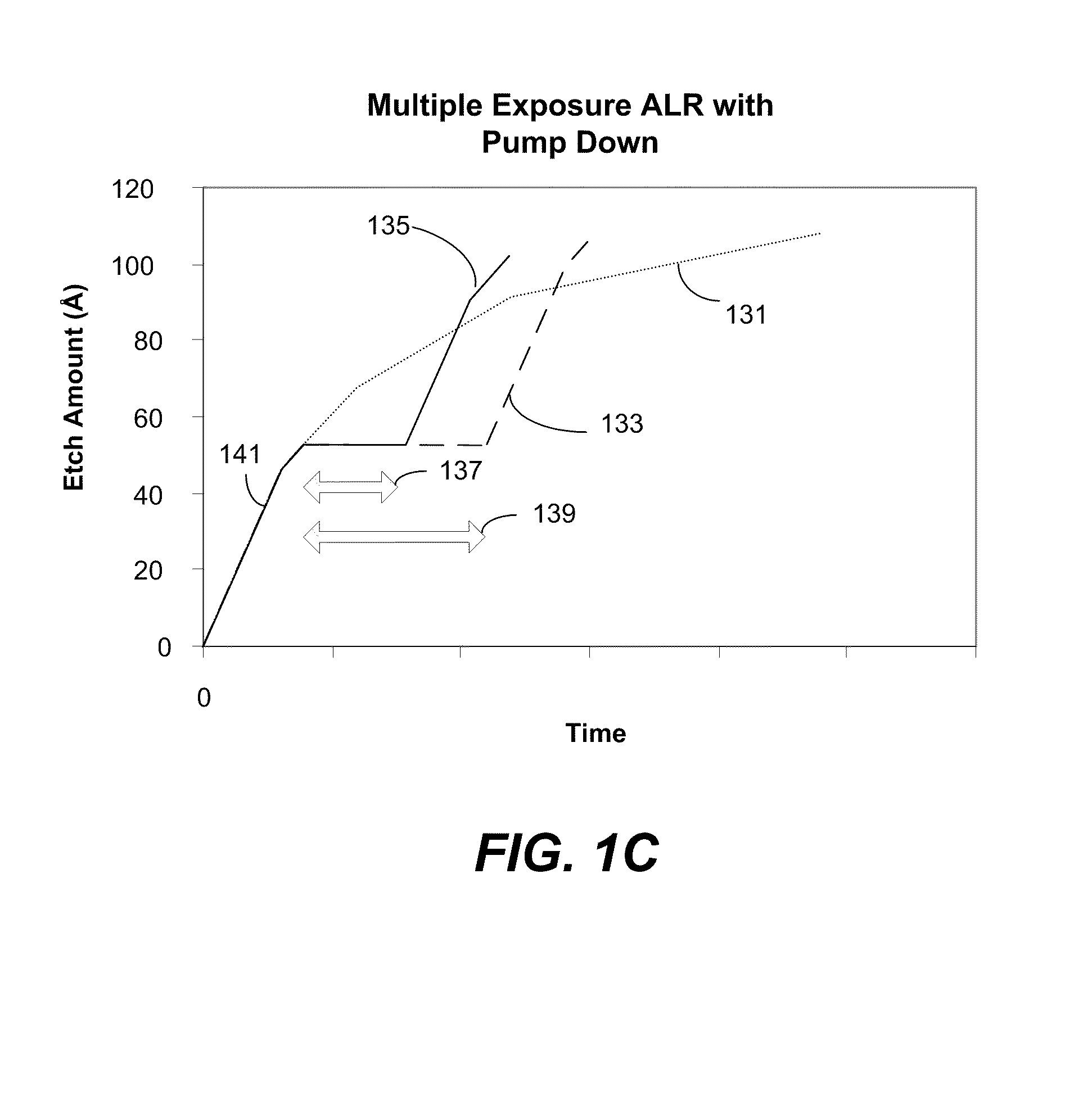

Atomic layer removal process with higher etch amount

InactiveUS8058179B1Easy to controlLimit amount of materialSemiconductor/solid-state device manufacturingSelf limitingLayer removal

Higher overall etch rate and throughput for atomic layer removal (ALR) is achieved. The reaction is a self-limiting process, thus limiting the total amount of material that may be etched per cycle. By pumping down the process station between reacting operations, the reaction is partially “reset.” A higher overall etch rate is achieved by a multiple exposure with pump down ALR process.

Owner:NOVELLUS SYSTEMS

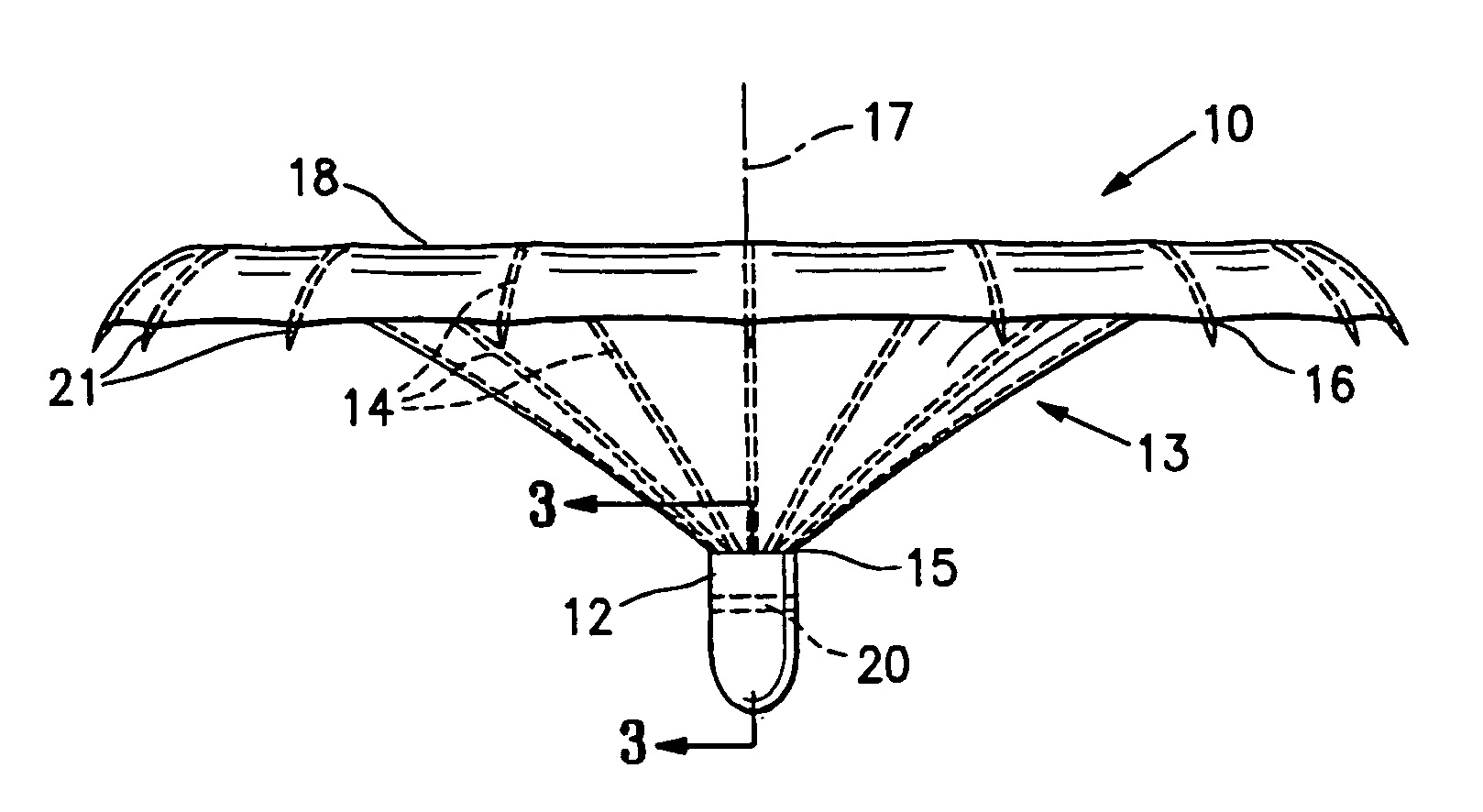

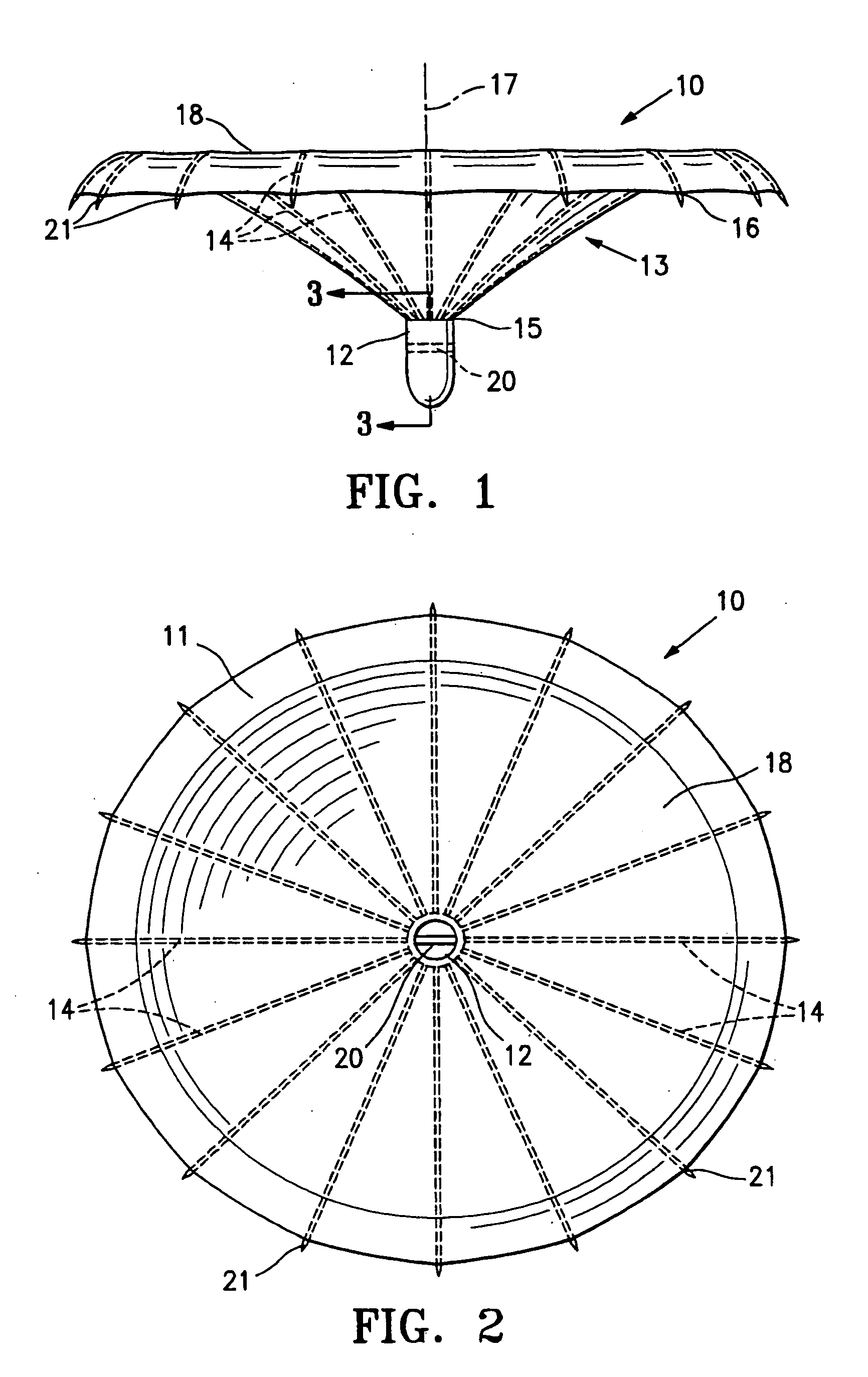

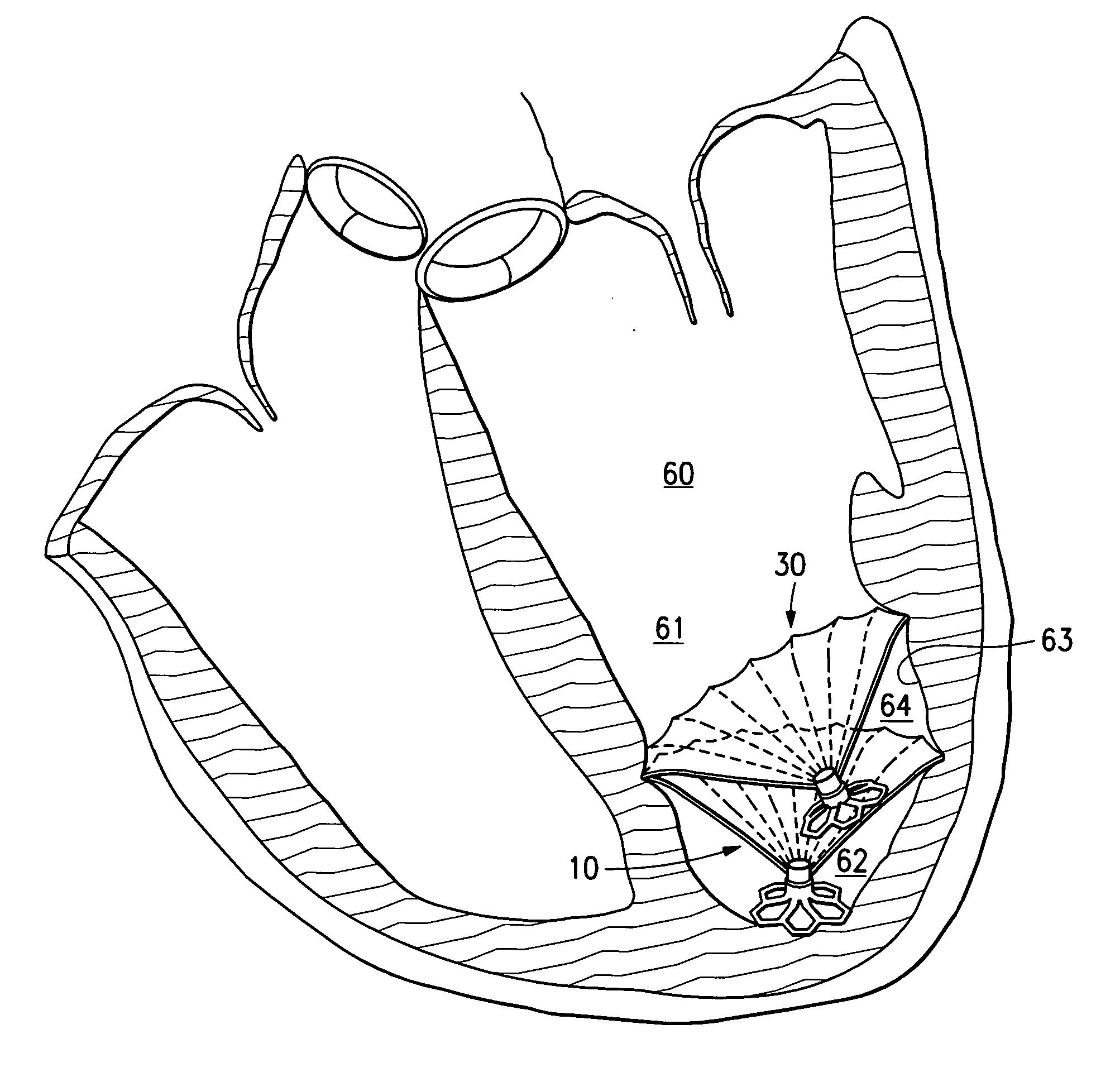

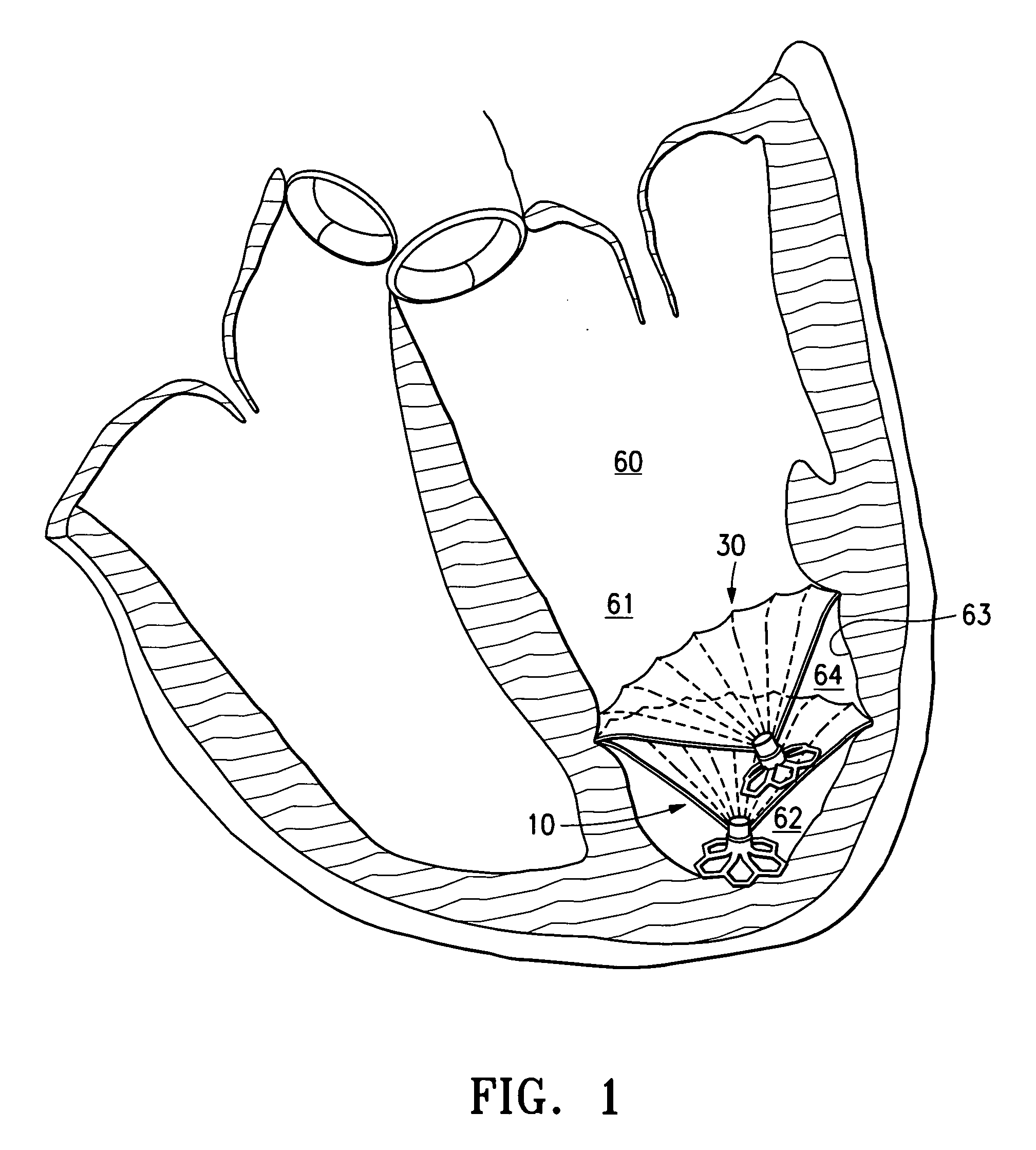

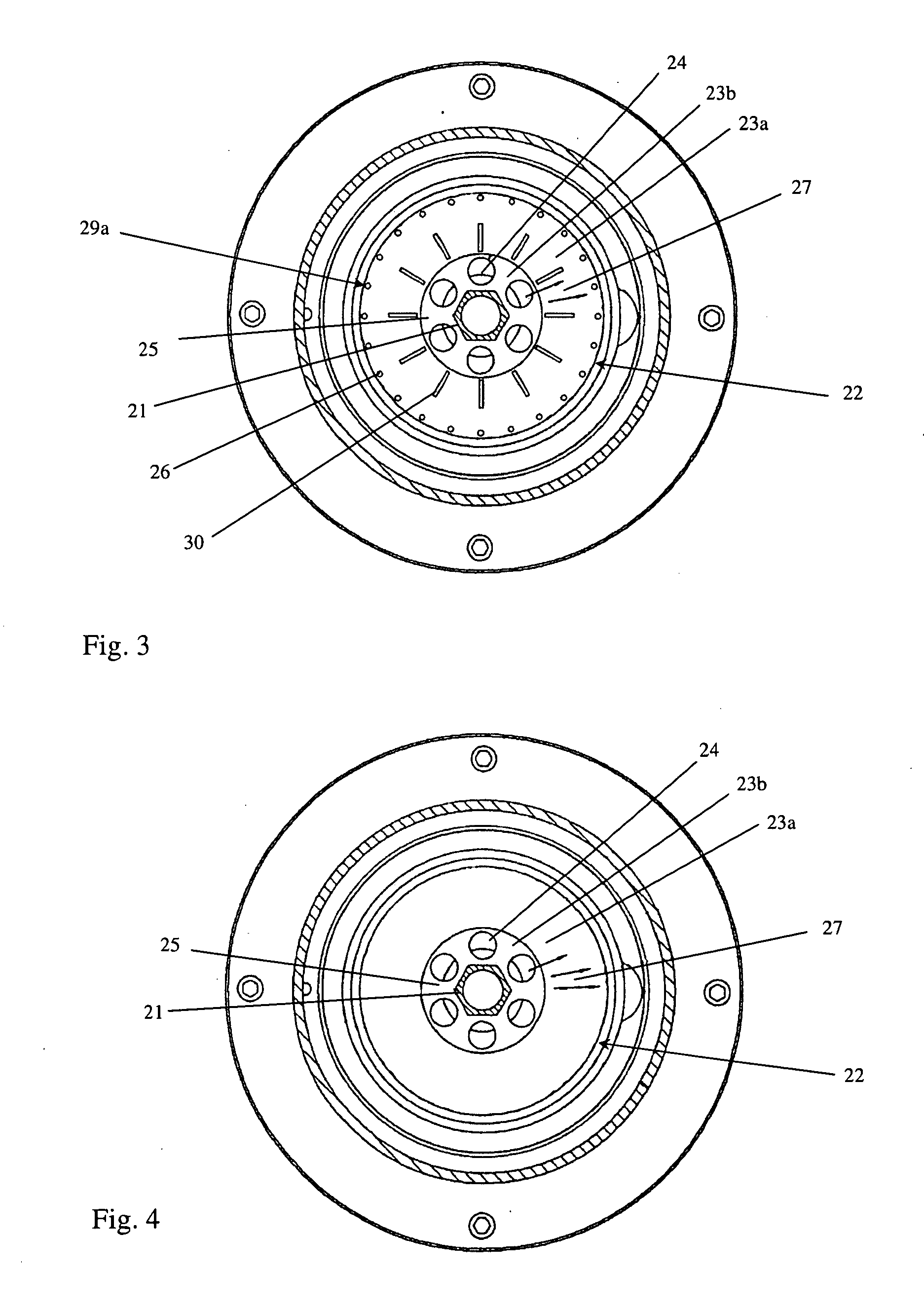

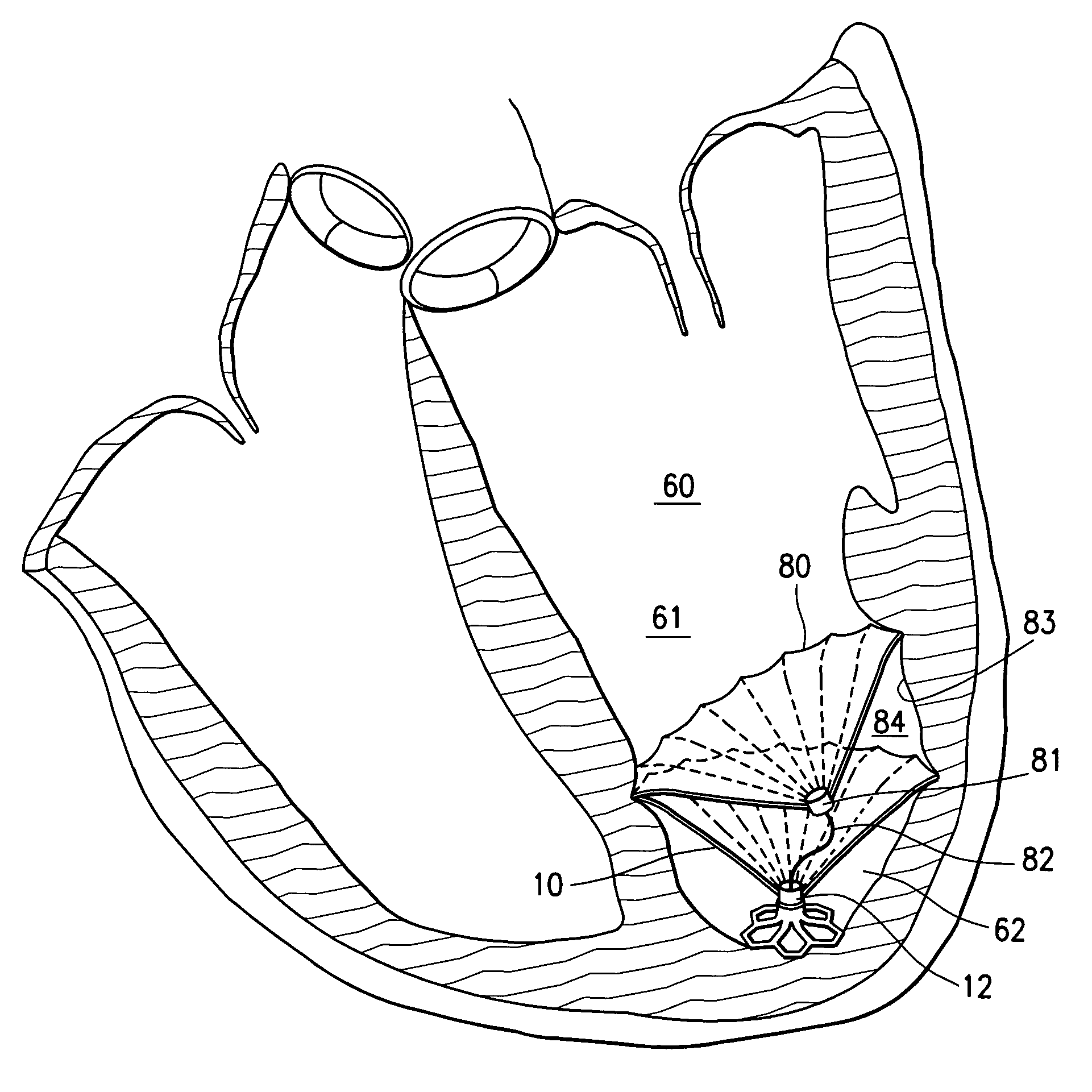

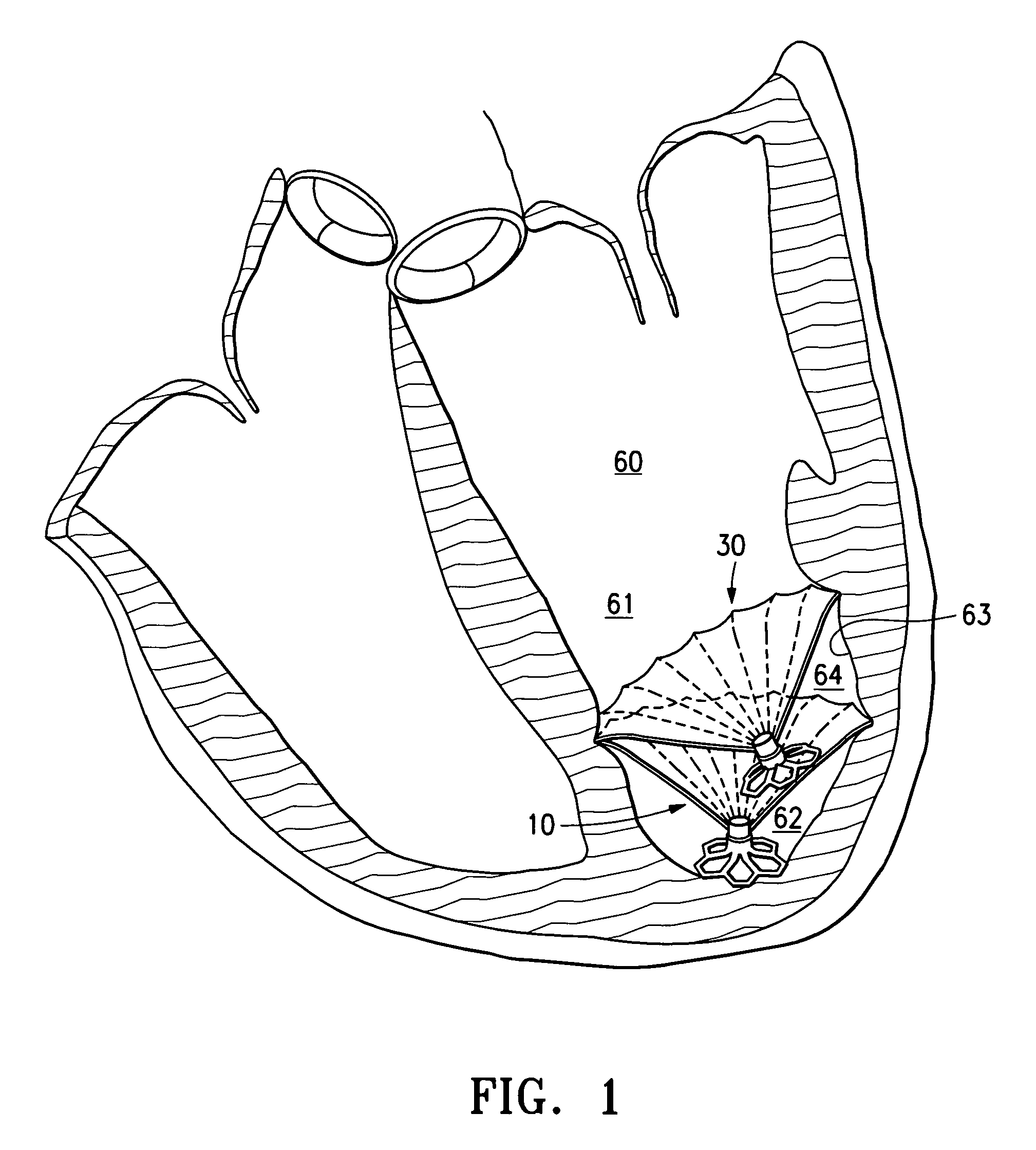

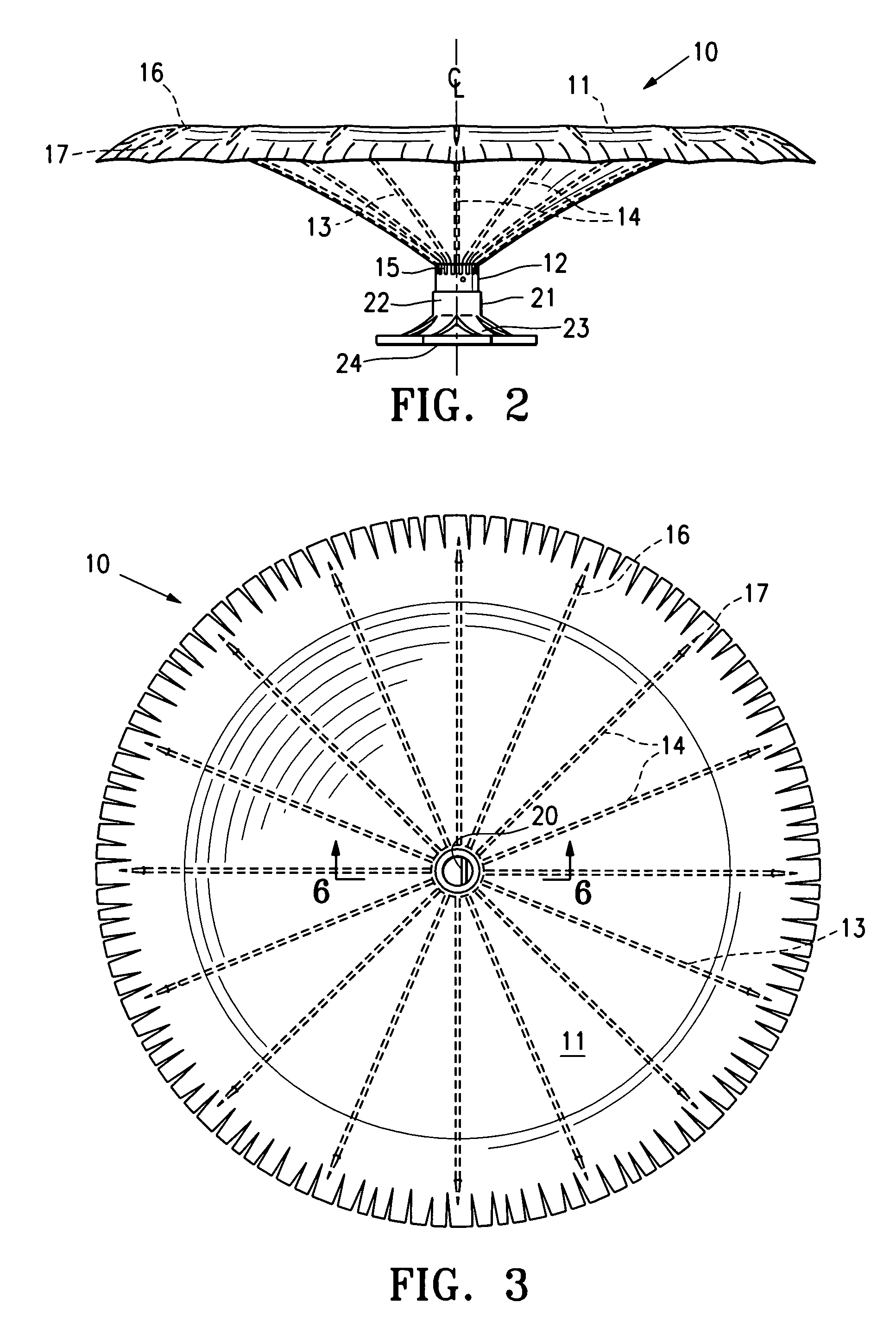

Ventricular partitioning device

InactiveUS20060030881A1Lower the volumeImprove ejection fractionOcculdersSurgical veterinaryHeart chamberNon traumatic

This invention is directed to a partitioning device for separating a patient's heart chamber into a productive portion and a non-productive portion. The device is particularly suitable for treating patients with congestive heart failure. The partitioning device has a frame-reinforced, expandable membrane which separates the productive and non-productive portions of the heart chamber. The proximal ends of the ribs of the frame have tissue penetrating elements about the periphery thereof which are configured to penetrate tissue lining the heart wall at an angle approximately perpendicular to a longitudinal axis of the partitioning device. The partitioning device has a hub with a non-traumatic distal end to engage the ventricular wall.

Owner:EDWARDS LIFESCIENCES CORP

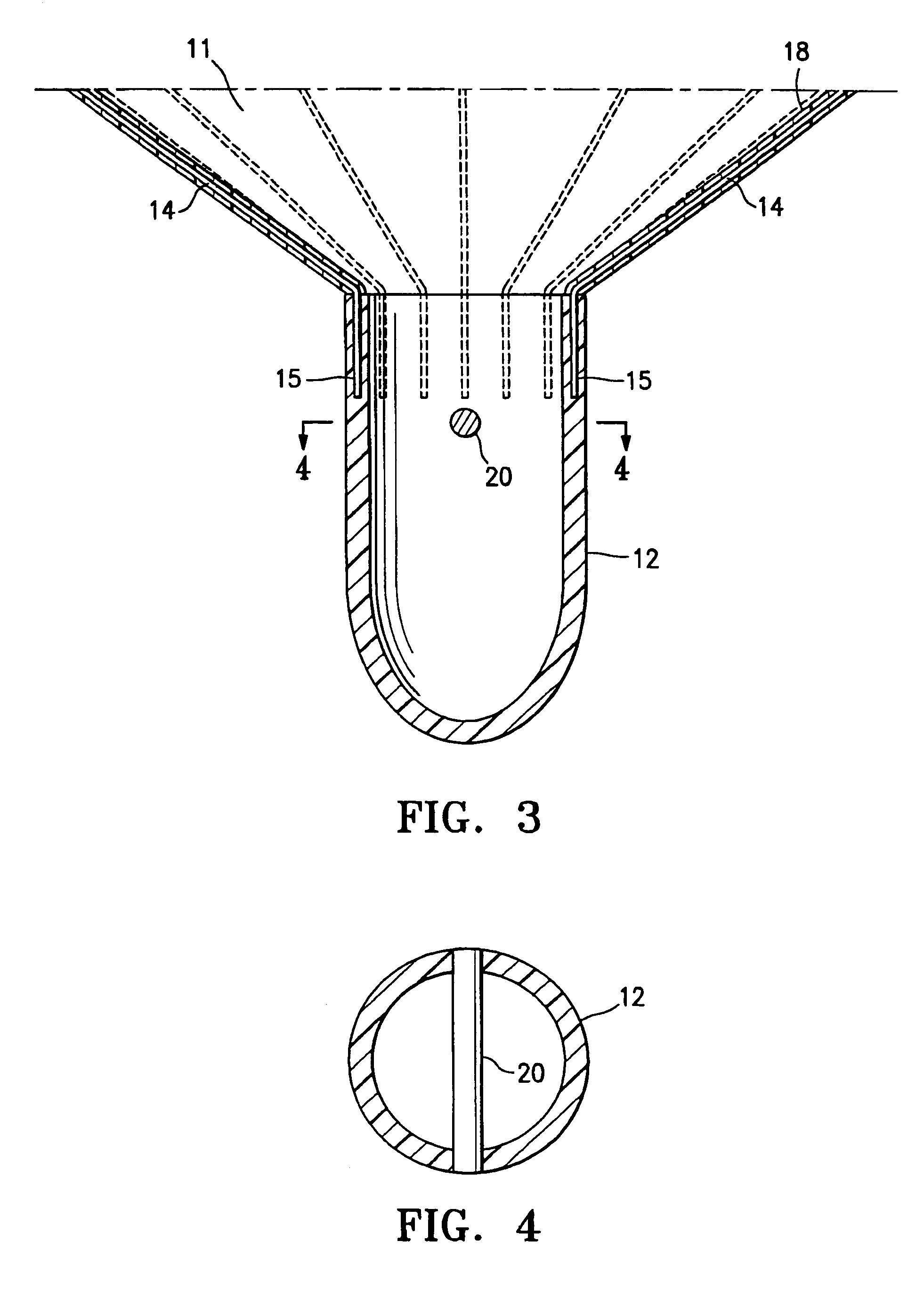

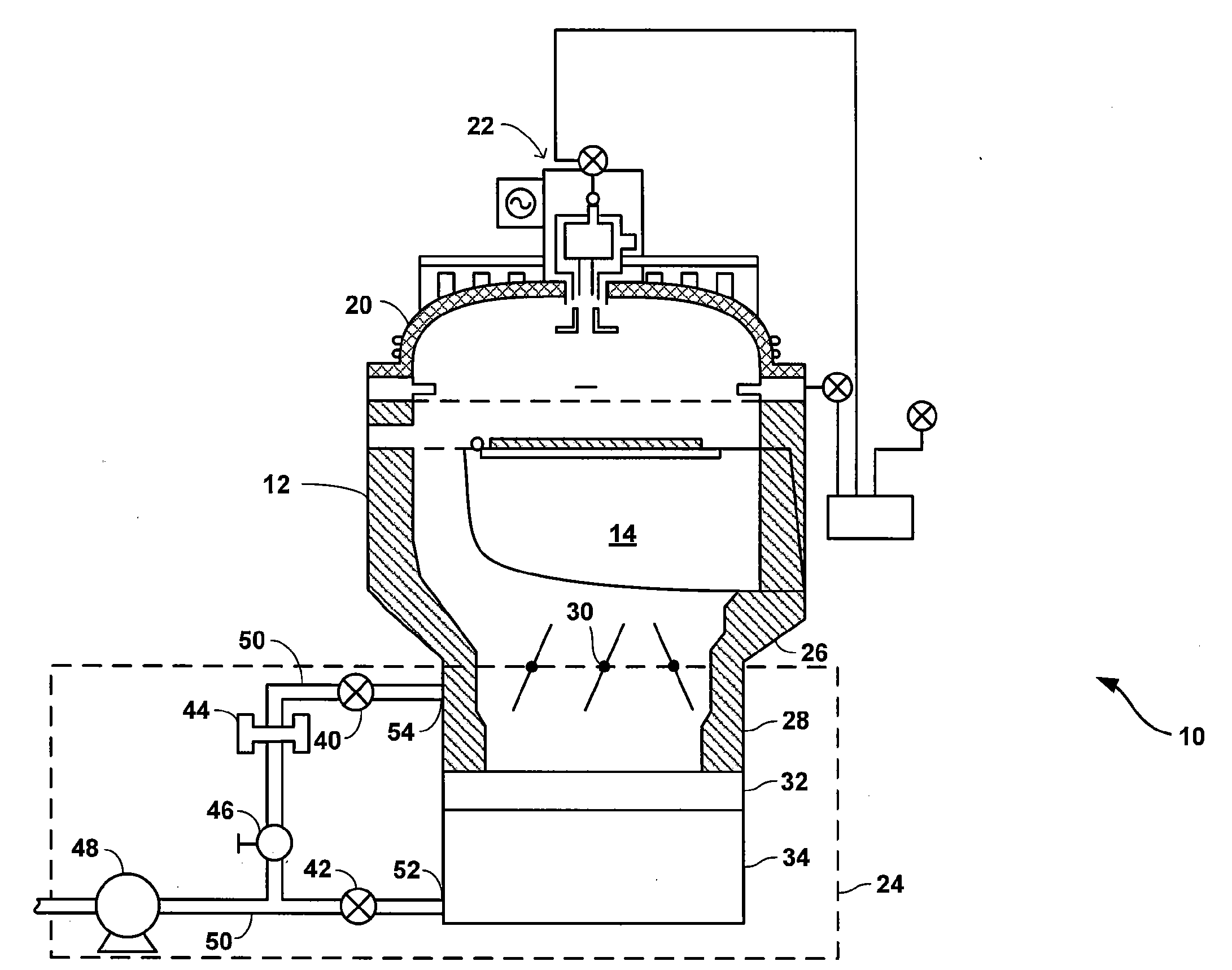

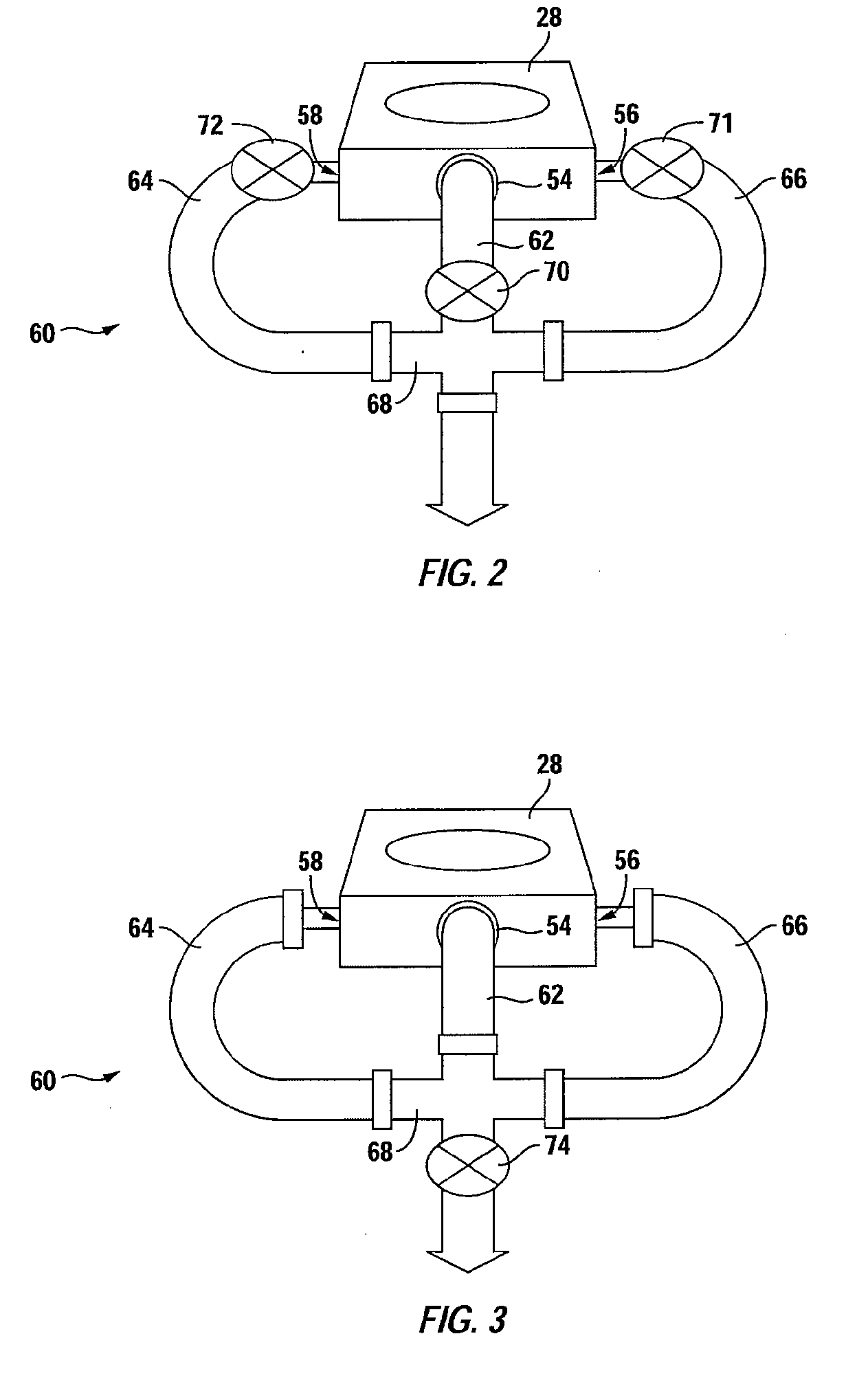

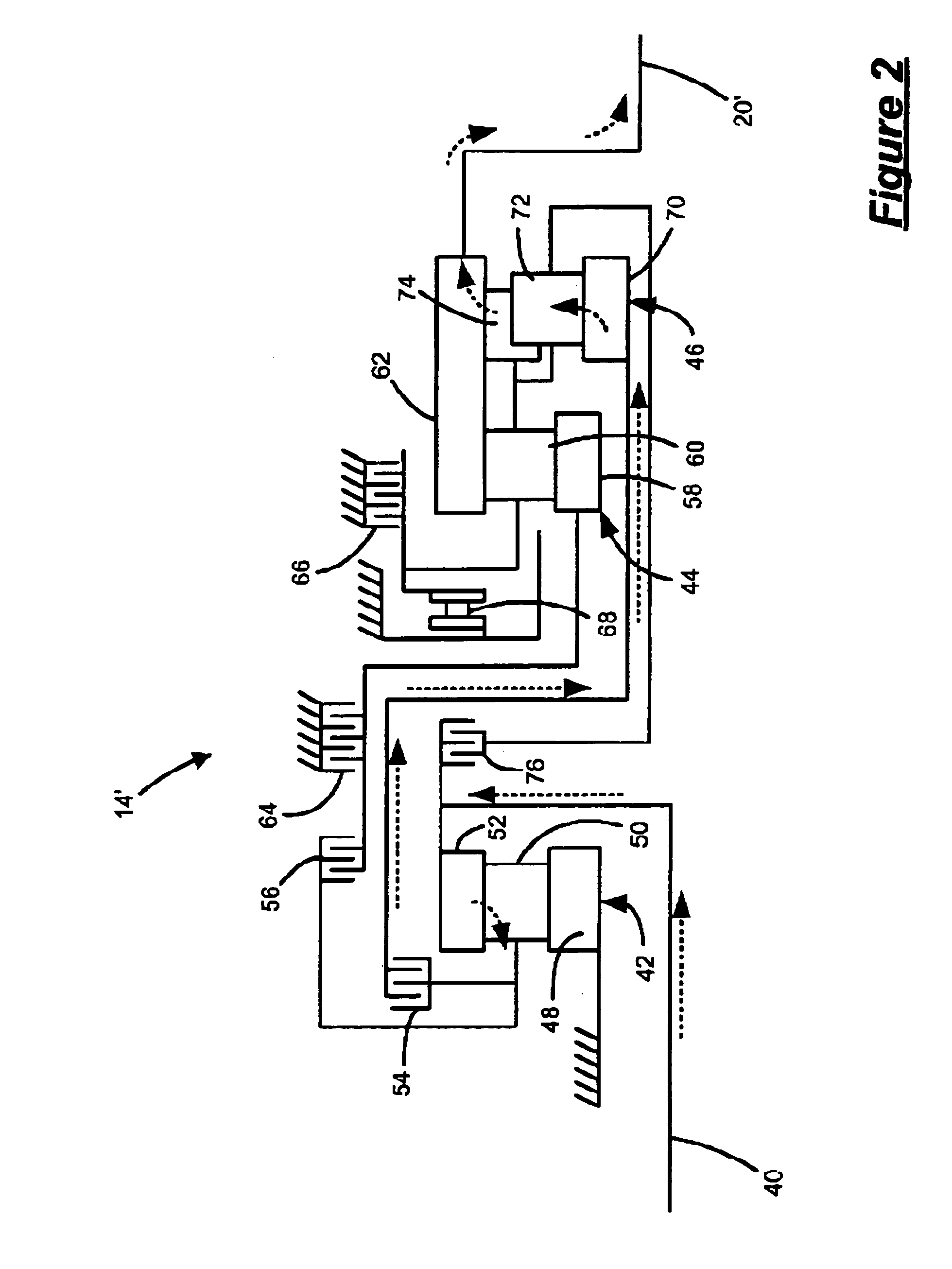

Multi-port pumping system for substrate processing chambers

InactiveUS20090120464A1Improve pumping capacityImprove rendering capabilitiesFrozen sweetsSemiconductor/solid-state device manufacturingEngineeringMulti port

An exhaust foreline for purging fluids from a semiconductor fabrication chamber is described. The foreline may include a first, second and third ports independently coupled to the chamber. A semiconductor fabrication system is also described that includes a substrate chamber that has a first, second and third interface port. The system may also include a multi-port foreline that has a first, second and third port, where the first foreline port is coupled to the first interface port, the second foreline port is coupled to the second interface port, and the third foreline port is coupled to the third interface port. The system may further include an exhaust vacuum coupled to the multi-port foreline.

Owner:APPLIED MATERIALS INC

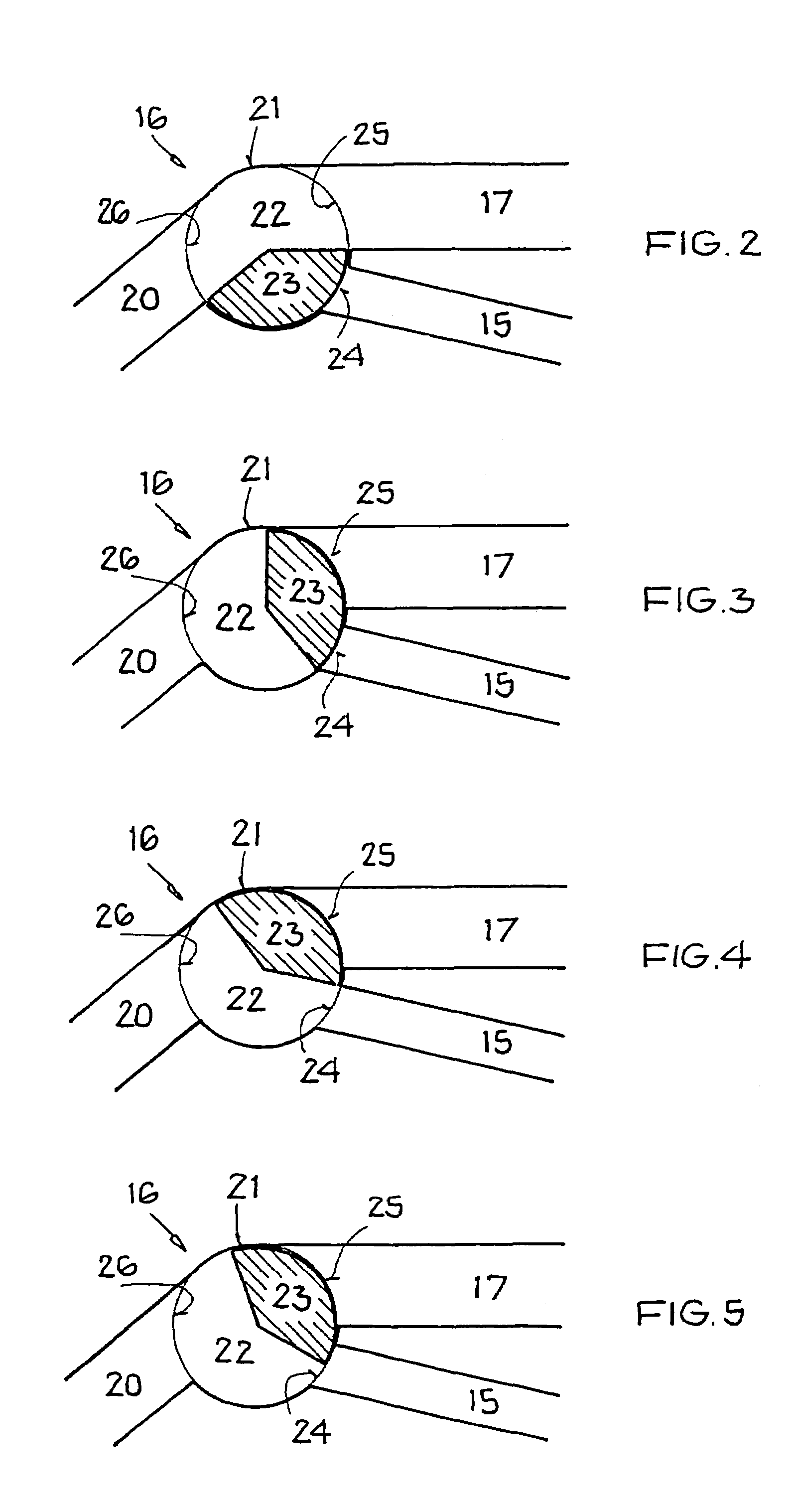

Multiple partitioning devices for heart treatment

ActiveUS20060014998A1Lower the volumeReduce stressHeart valvesHeart stimulatorsHeart chamberCongestive heart failure chf

This invention is directed to a system and method for partitioning a patient's heart chamber into a productive portion and a non-productive portion which are particularly suitable for treating patients with congestive heart failure. The partitioning system has a plurality of partitioning devices with reinforced, expandable membranes which separate the productive and non-productive portions of the heart chamber. When deployed within the patient's heart chamber, the second partitioning device is off-set from the deployed first partitioning device to cover a region of the wall defining the patient's heart chamber which is not covered by the first partitioning device. The multiple partitioning devices may be independent from each other or may be interconnected, e.g. a tether or strand.

Owner:EDWARDS LIFESCIENCES CORP

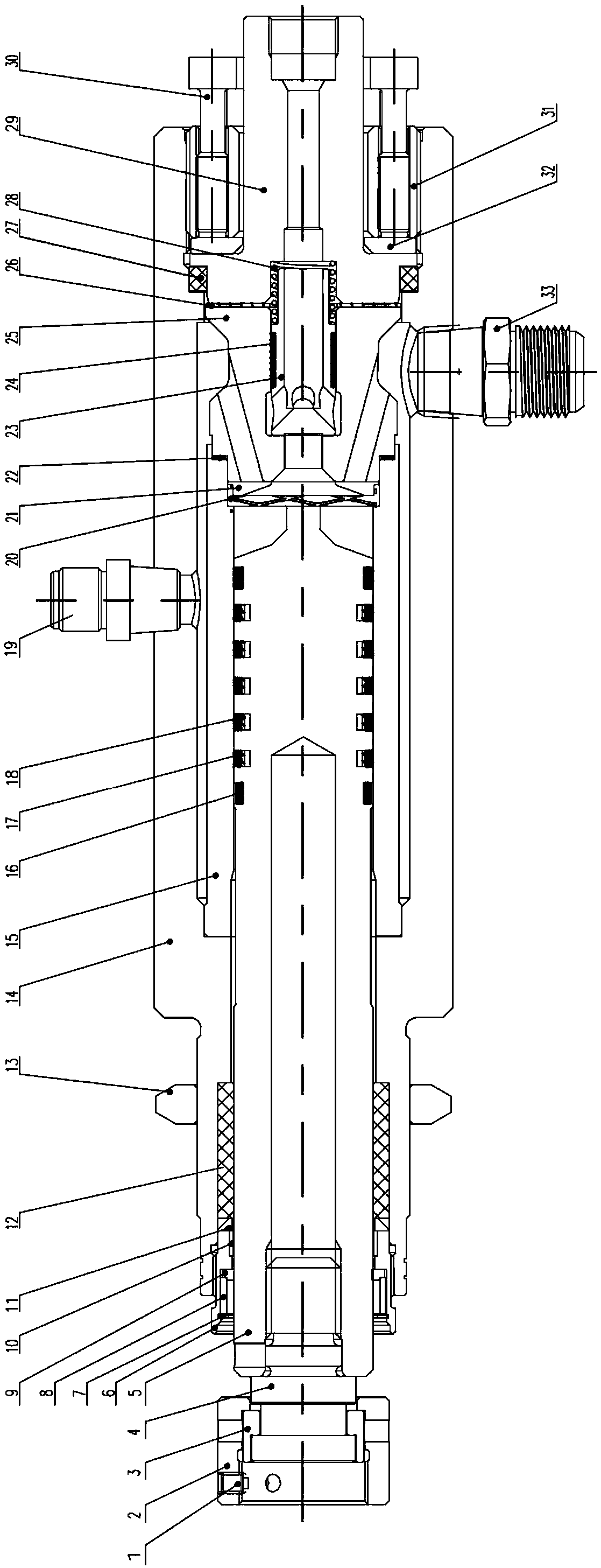

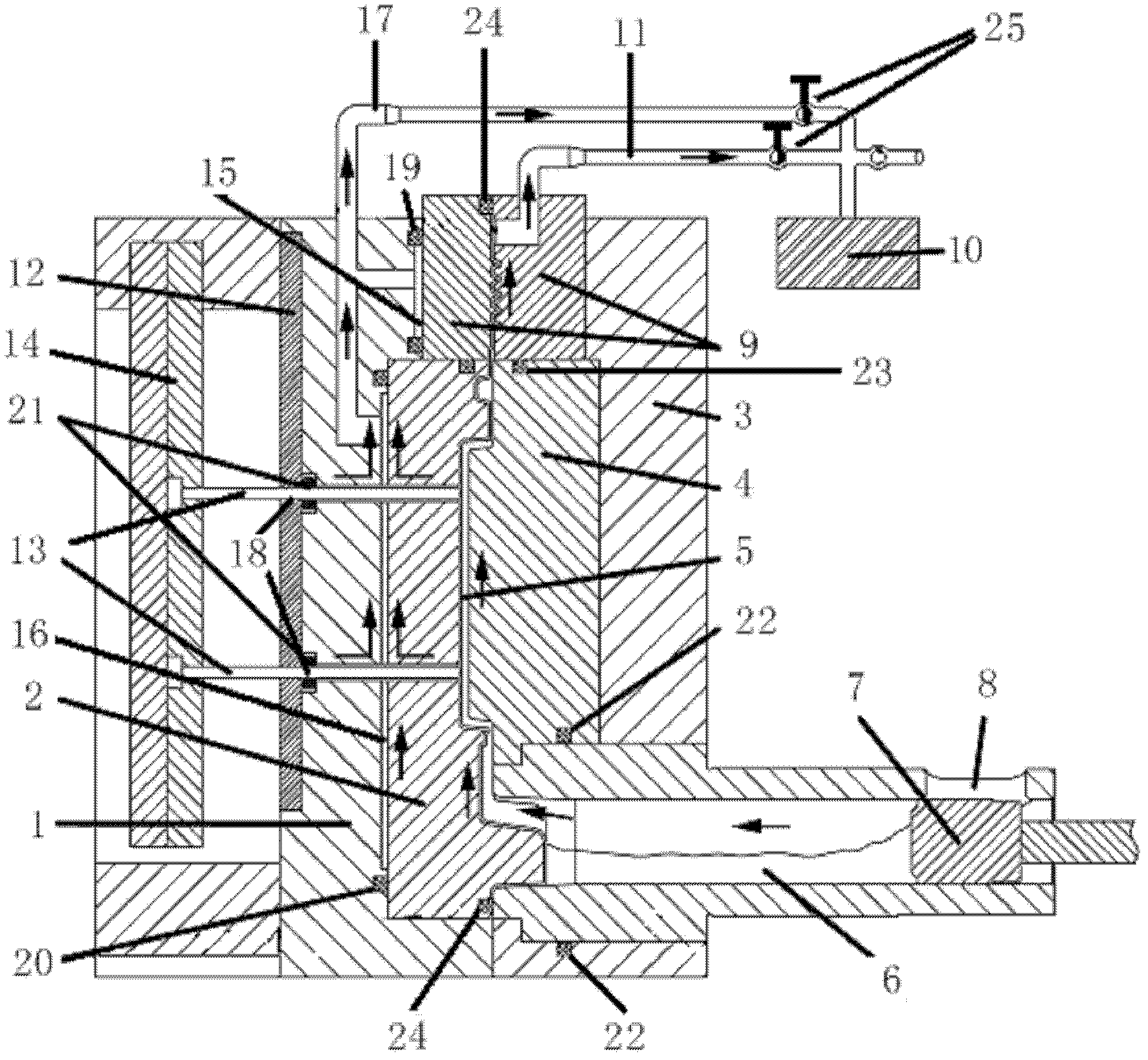

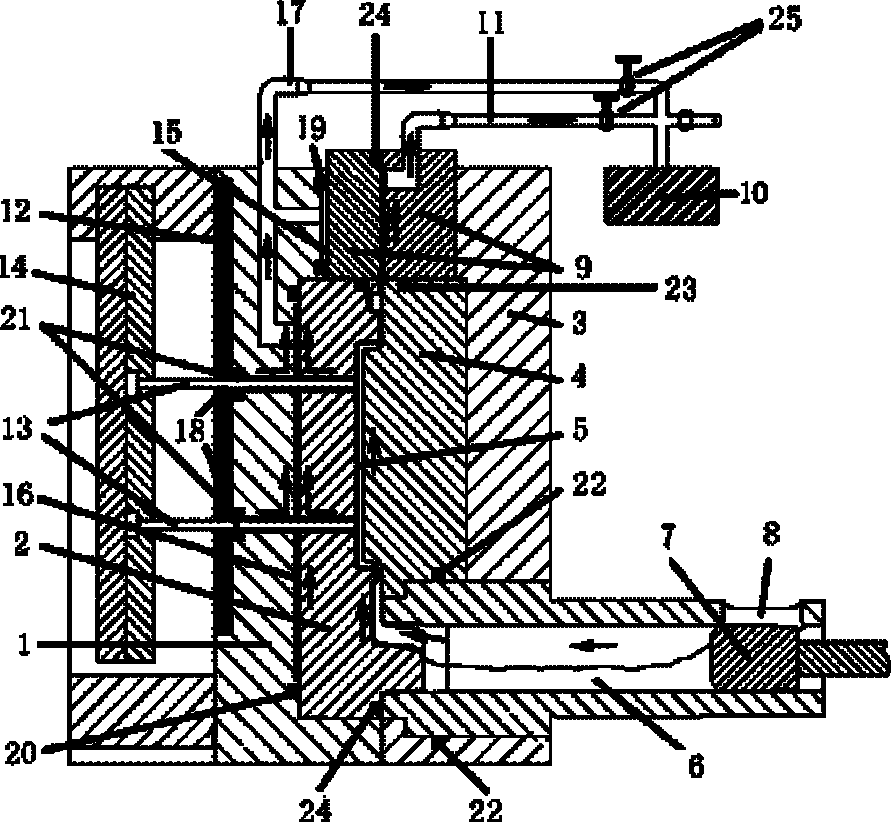

Cold end of low-temperature high-pressure plunger pump

InactiveCN109404274ASolve the problem of being unable to pump low temperature and high pressure liquid nitrogenHigh conveying medium temperaturePositive displacement pump componentsFluid removalHigh pressureLiquid nitrogen

The invention belongs to the technical field of low-temperature high-pressure plunger pumps, and particularly relates to a cold end of a low-temperature high-pressure plunger pump. The cold end comprises a cold end shell body, a plunger and a cylinder sleeve, wherein the plunger is arranged inside the cylinder sleeve, the cylinder sleeve is located inside the cold end shell body, a connecting locking device is arranged at the front end of the cold end shell body, the cold end shell body comprises a left cavity and a right cavity which communicate with each other, the right cavity internally comprises the cylinder sleeve, a valve set and a discharging flange, and the valve set comprises a valve seat, a high-pressure valve arranged in the valve seat and a low-pressure valve arranged betweenthe cylinder sleeve and the valve seat. According to the cold end of the low-temperature high-pressure plunger pump, the novel valve set structure adopts metal sealing, continuous opening and closingof the high-pressure valve and the low-pressure valve are achieved, and normal-pressure ultralow-temperature liquid nitrogen is converted into high-pressure low-temperature liquid nitrogen and is discharged so that the requirement for high-frequency opening and closing can be met, the characteristics of being low in conveying medium temperature and high in output pressure are achieved, and the problem that a common plunger pump cannot pump the low-temperature and high-pressure liquid nitrogen is solved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

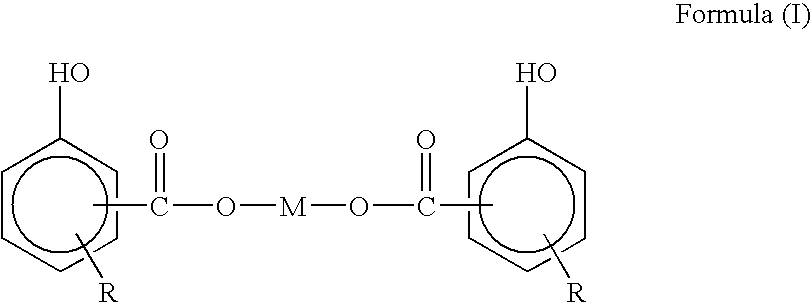

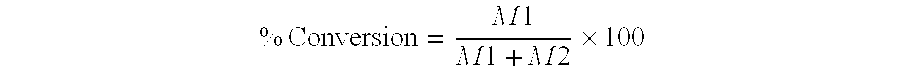

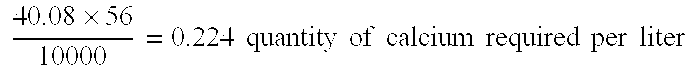

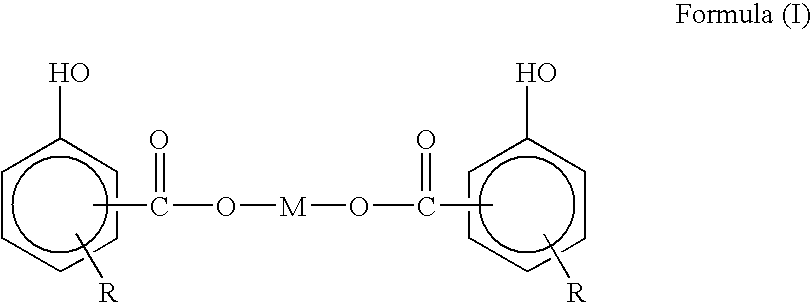

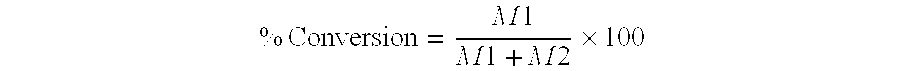

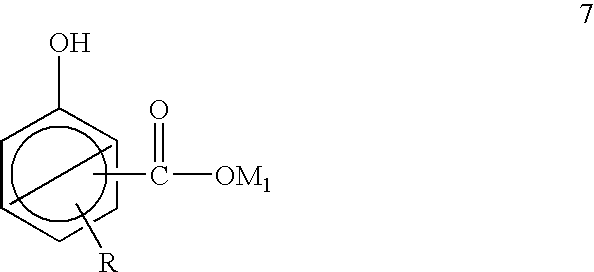

Overbased alkaline earth metal alkylhydroxybenzoates having low crude sediment

ActiveUS20070027043A1Improve low temperature viscosityImprove pumpabilityOrganic chemistryOrganic compound preparationSolventChemistry

A process for preparing an overbased alkaline earth metal alkylhydroxybenzoate, said process comprising overbasing an alkaline earth metal alkylhydroxybenzoate or a mixture of alkaline earth metal alkylhydroxybenzoate and up to 50 mole % of alkylphenol, based on the total mixture of alkylhydroxybenzoate and alkylphenol, with a molar excess of alkaline earth metal base and at least one acidic overbasing material in the presence of at least one carboxylic acid having from one to four carbon atoms and a solvent selected from the group consisting of aromatic hydrocarbons, aliphatic hydrocarbons, monoalcohols, and mixtures thereof.

Owner:CHEVRON ORONITE SA

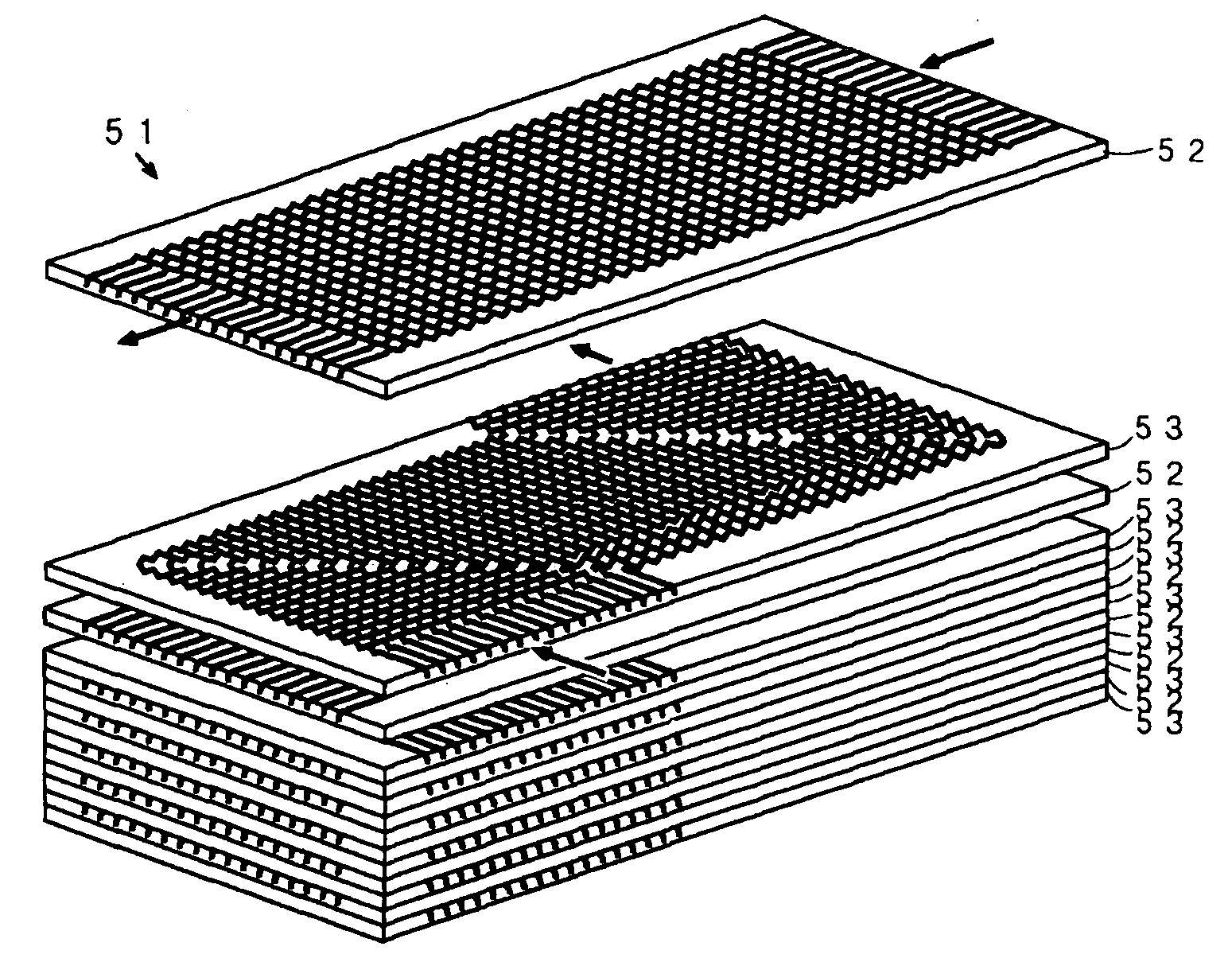

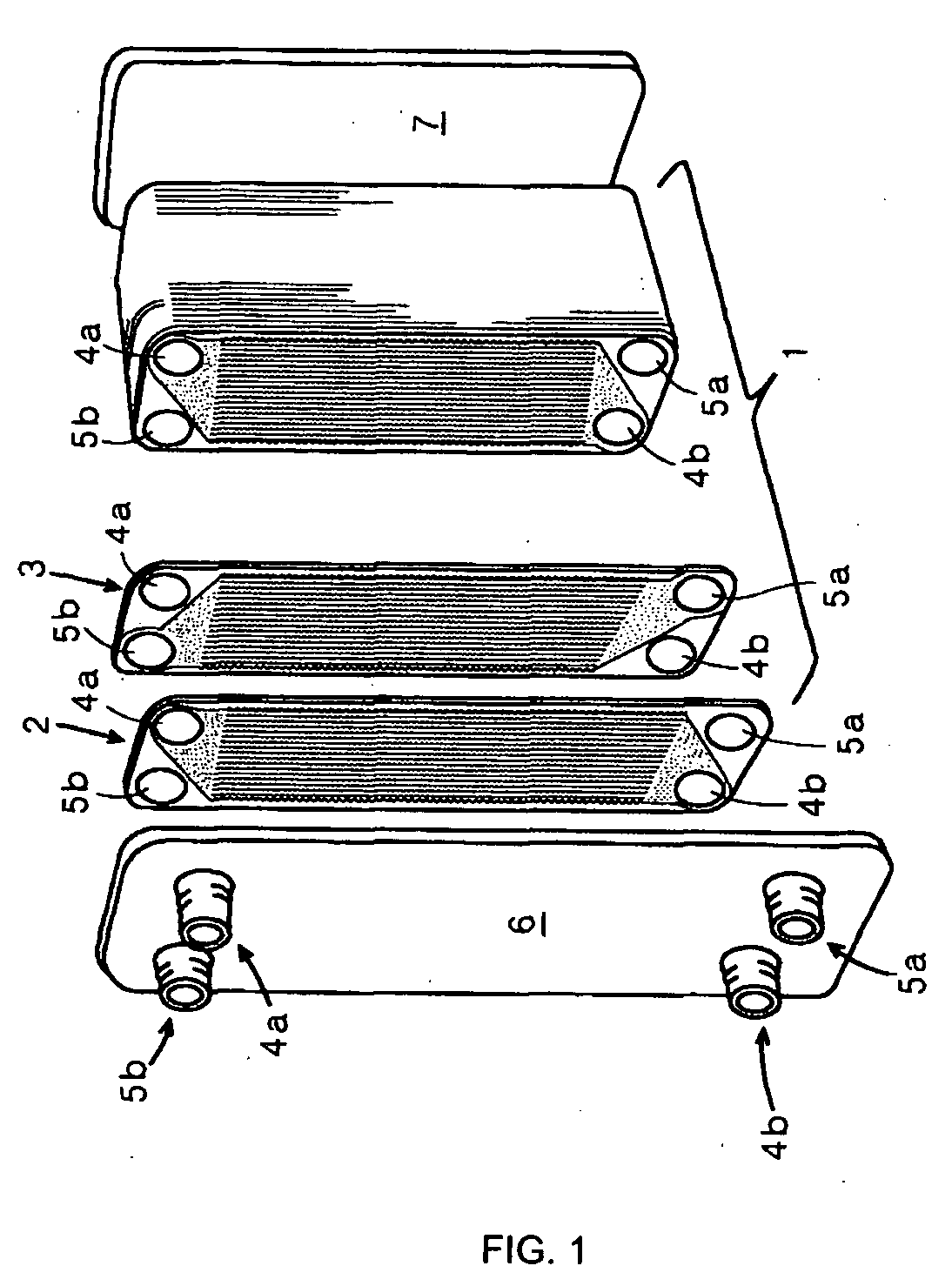

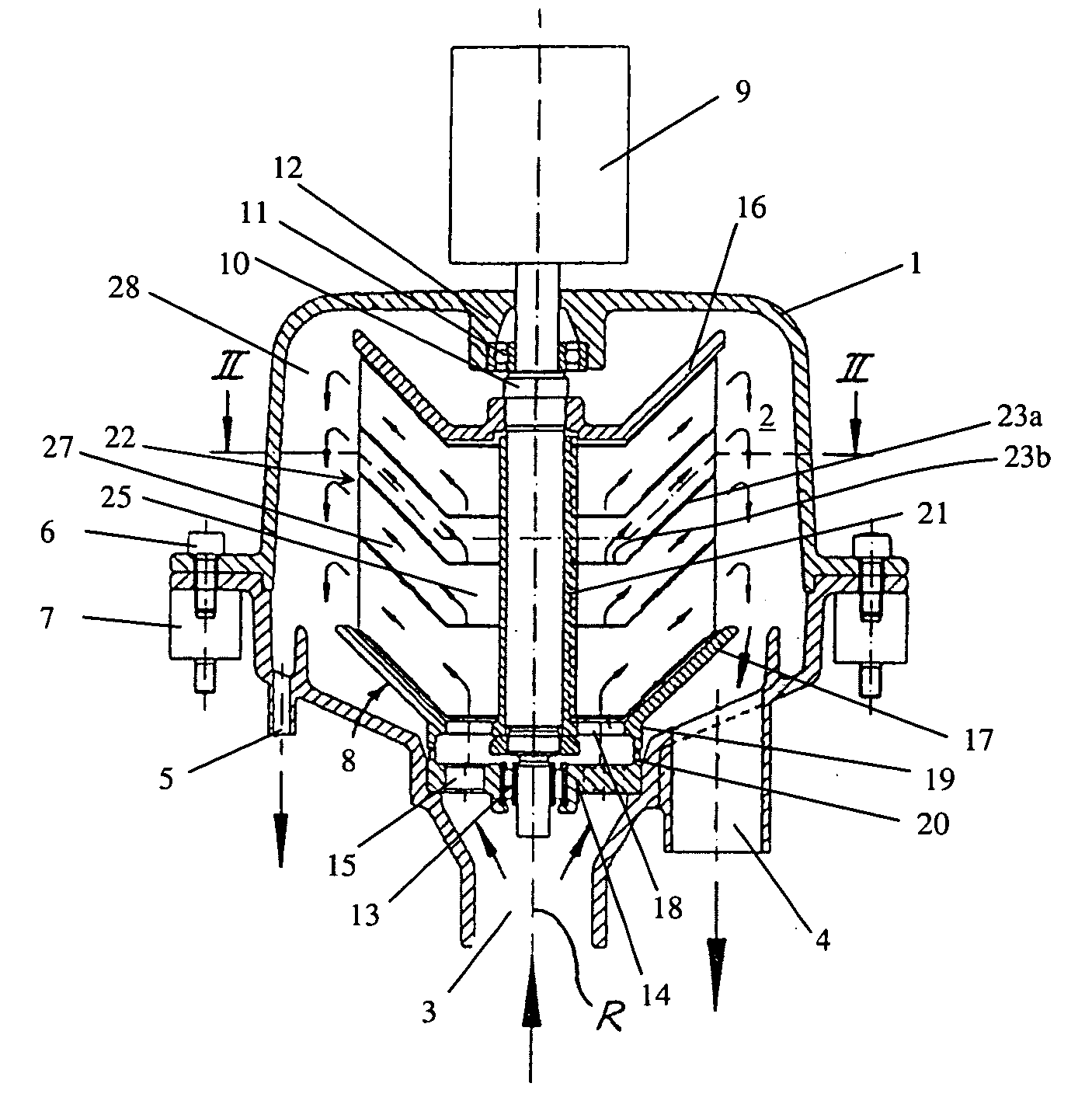

Heat exchanger

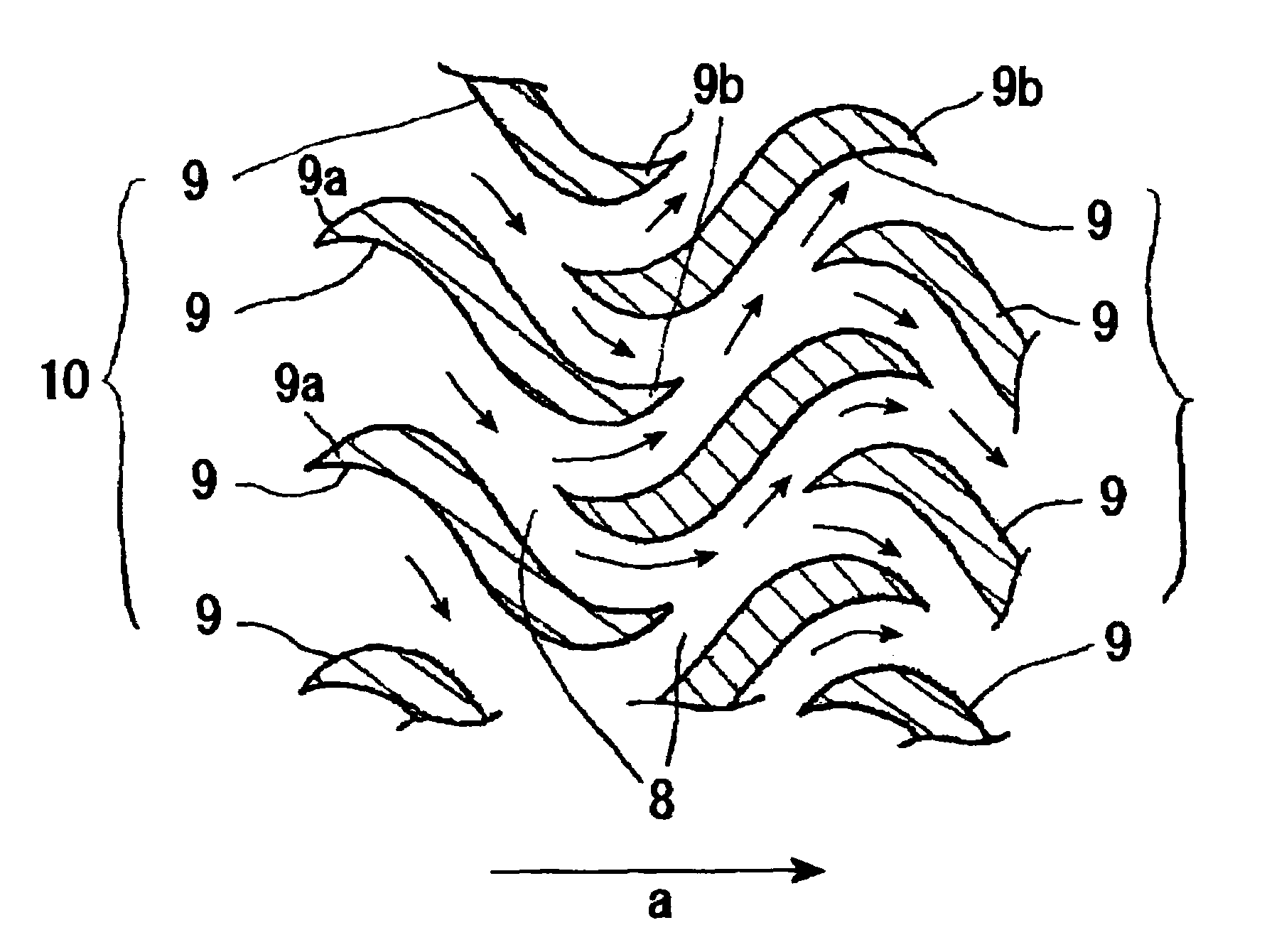

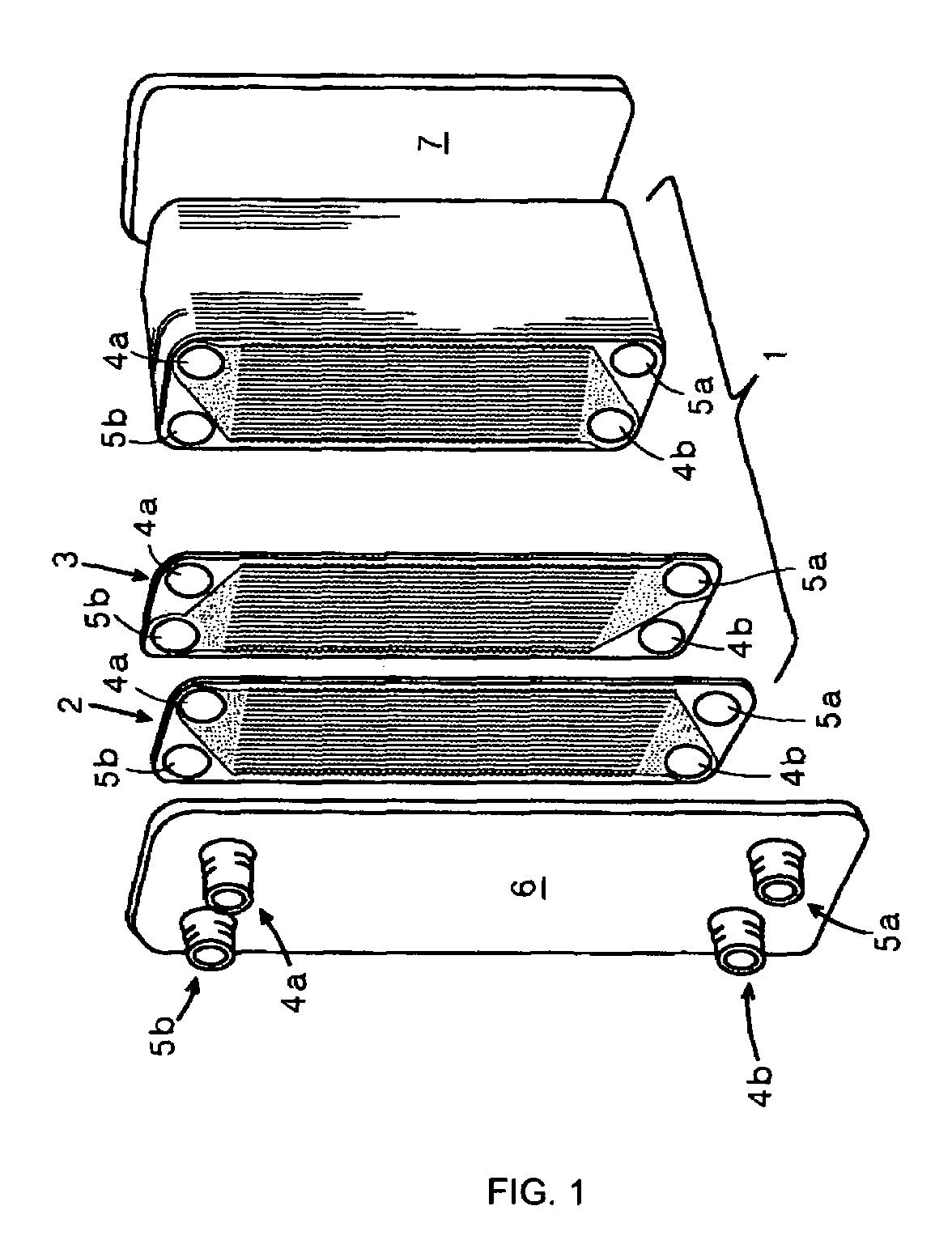

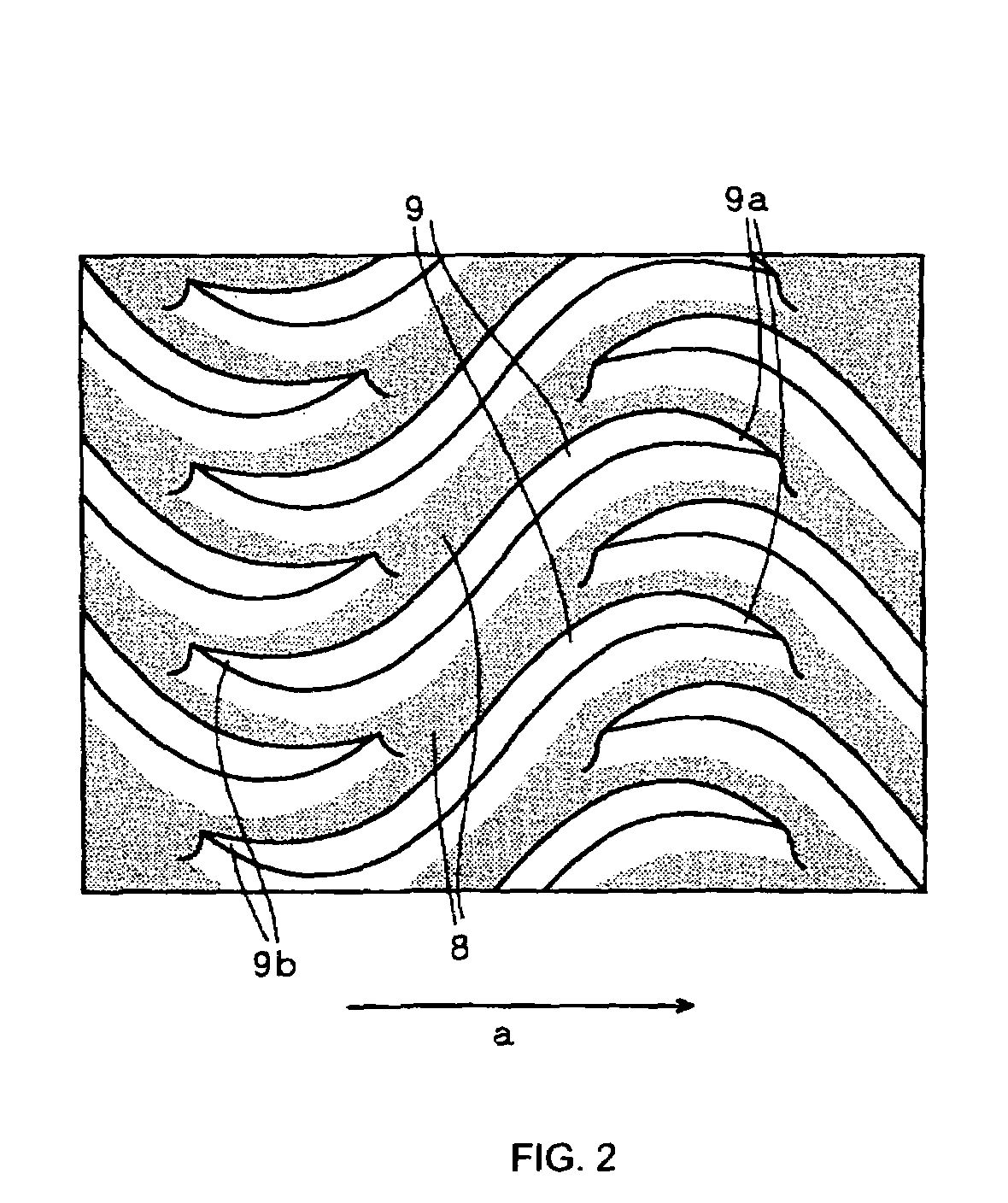

InactiveUS7334631B2Without impairment of heat transfer characteristicIncreased pressure lossHeat transfer modificationLaminated elementsThin metalPlate heat exchanger

To reduce pressure loss on a heat-exchanger fluid while downsizing a heat exchange and reducing the production cost of the heat exchanger without impairment of the heat transfer performance of the heat exchanger by forming a fluid channel in surfaces of thin metal plates such as stainless steel plates through the use of an etching technique or the like and by improving the shape of the fluid channel. In a heat exchanger in which a plurality of heat exchanger fins are provided in thin metal plates by using an etching technique or the like and a fluid channel for a heat-exchanger fluid is formed between the two opposed thin metal plates by alternately stacking the thin metal plates, the area of the fluid channel, through which the fluid flows between the heat exchanger fins, is made substantially uniform by forming the heat exchanger fins so as to have a curved cross-sectional shape from the front end thereof to the rear end.

Owner:KATO YASUYOSHI

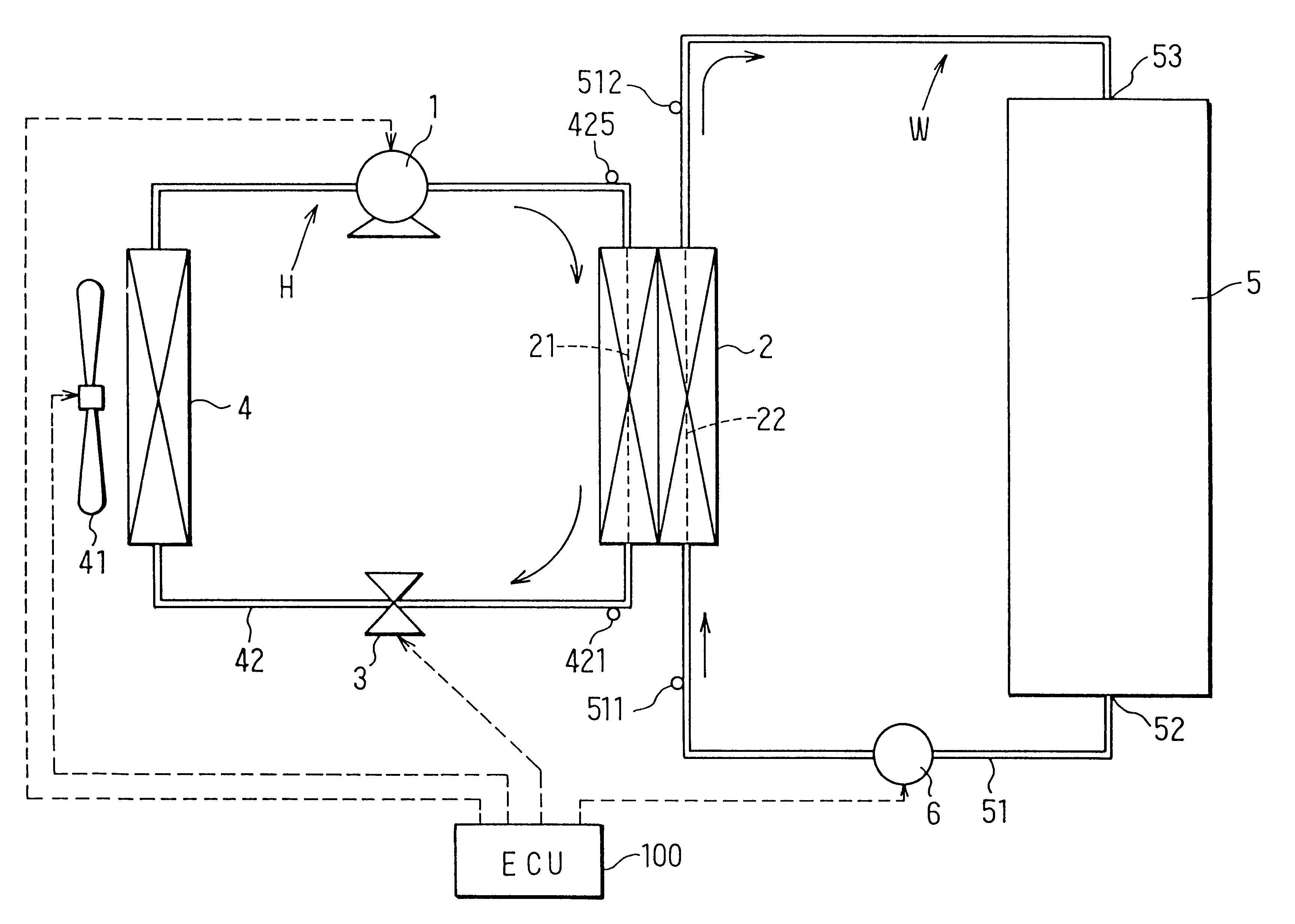

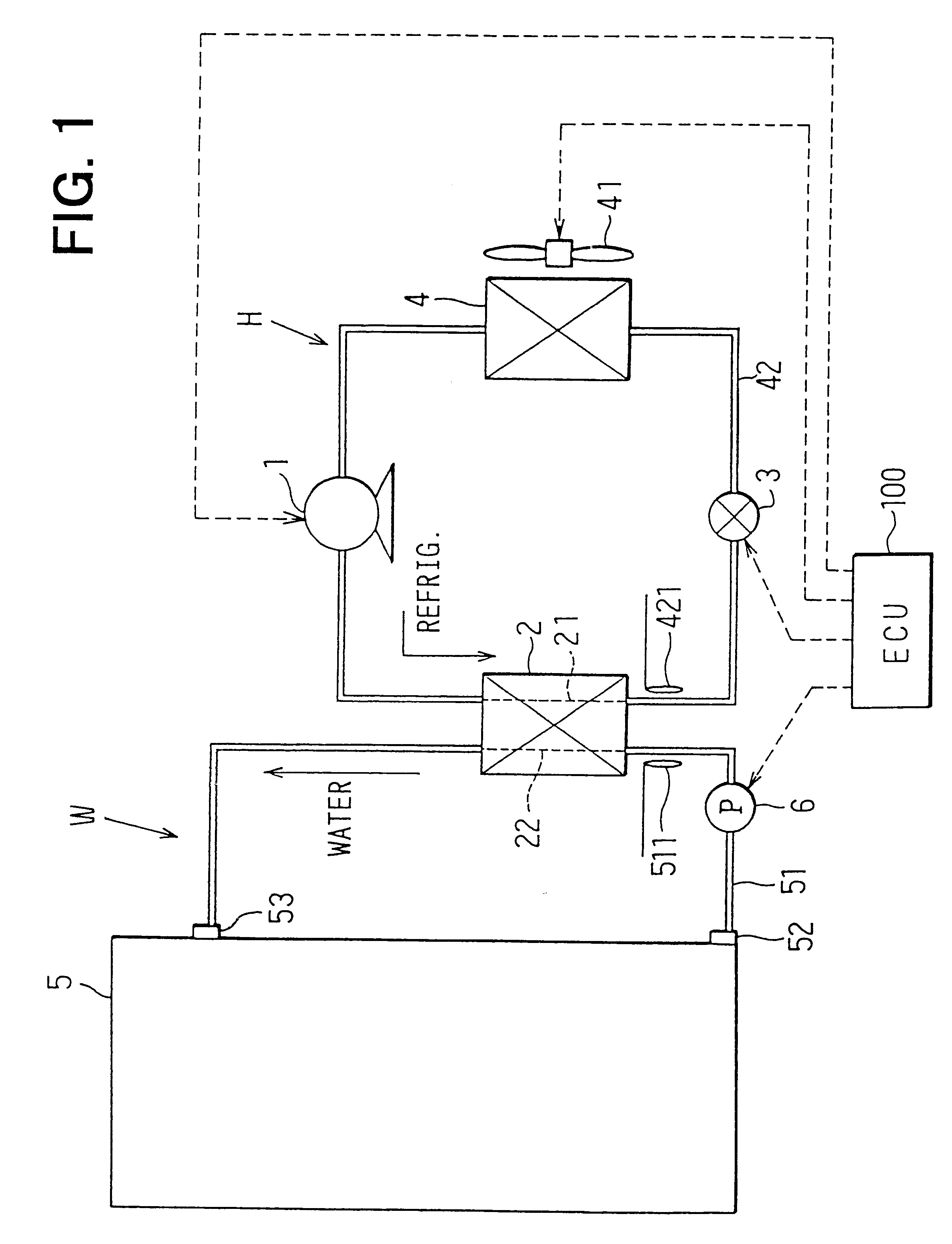

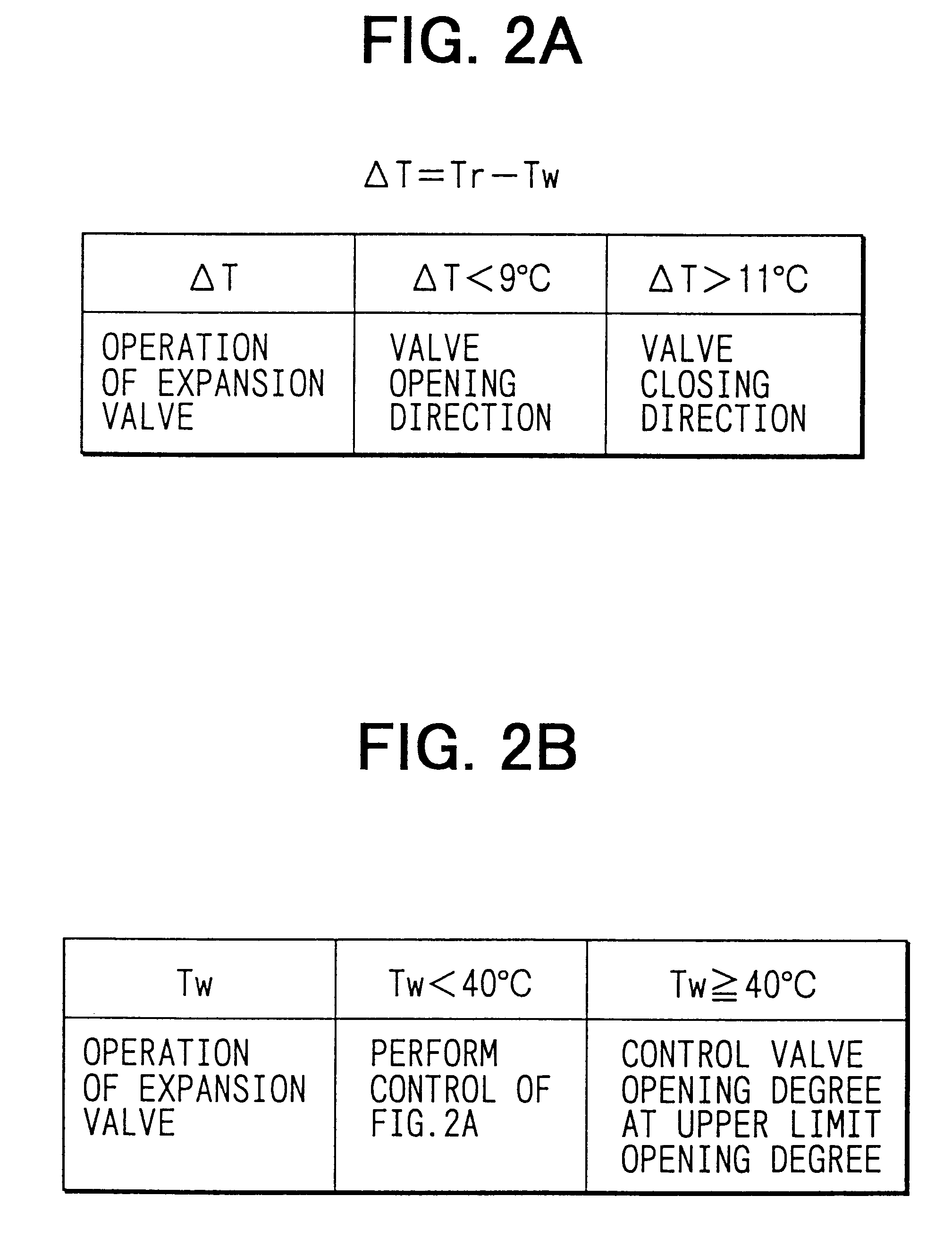

Hot-water supply system with heat pump cycle

InactiveUS6467289B2Improve stabilityImprove reliabilityMechanical apparatusHeat pumpsEngineeringTemperature difference

In a hot-water supply system with a heat pump cycle, a control unit controls operation of an expansion valve based on a temperature difference between a refrigerant temperature at an outlet side of a refrigerant passage in a water heat exchanger and a water temperature at an inlet side of a water passage in the water heat exchanger. When the expansion valve is controlled in a direction increasing a valve opening degree, the control unit sets an upper limit opening degree of the expansion valve, for obtaining a refrigerant pressure corresponding to a target hot-water temperature, and controls the expansion valve in an opening degree range smaller than the upper limit opening degree.

Owner:DENSO CORP +2

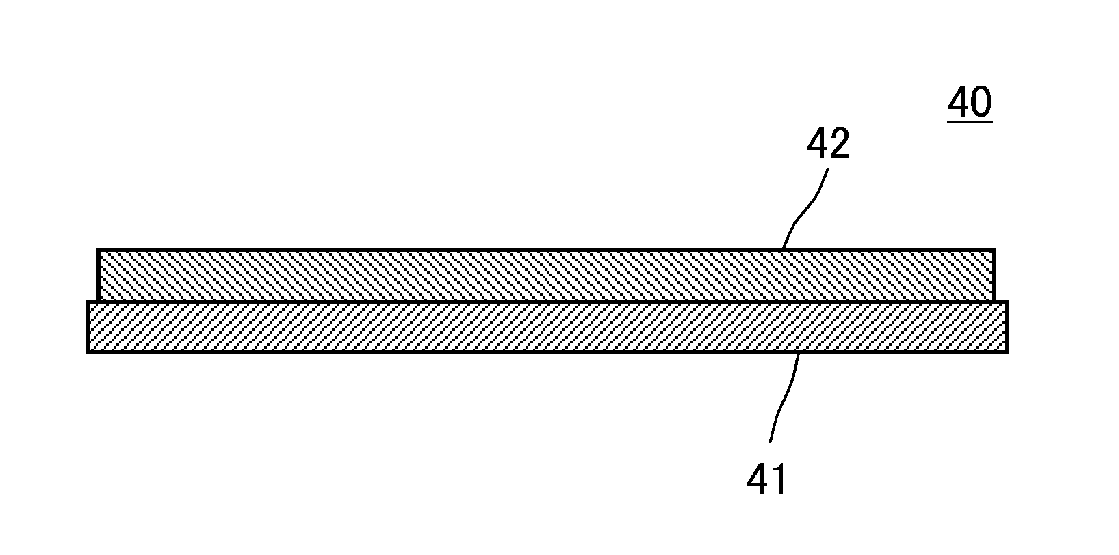

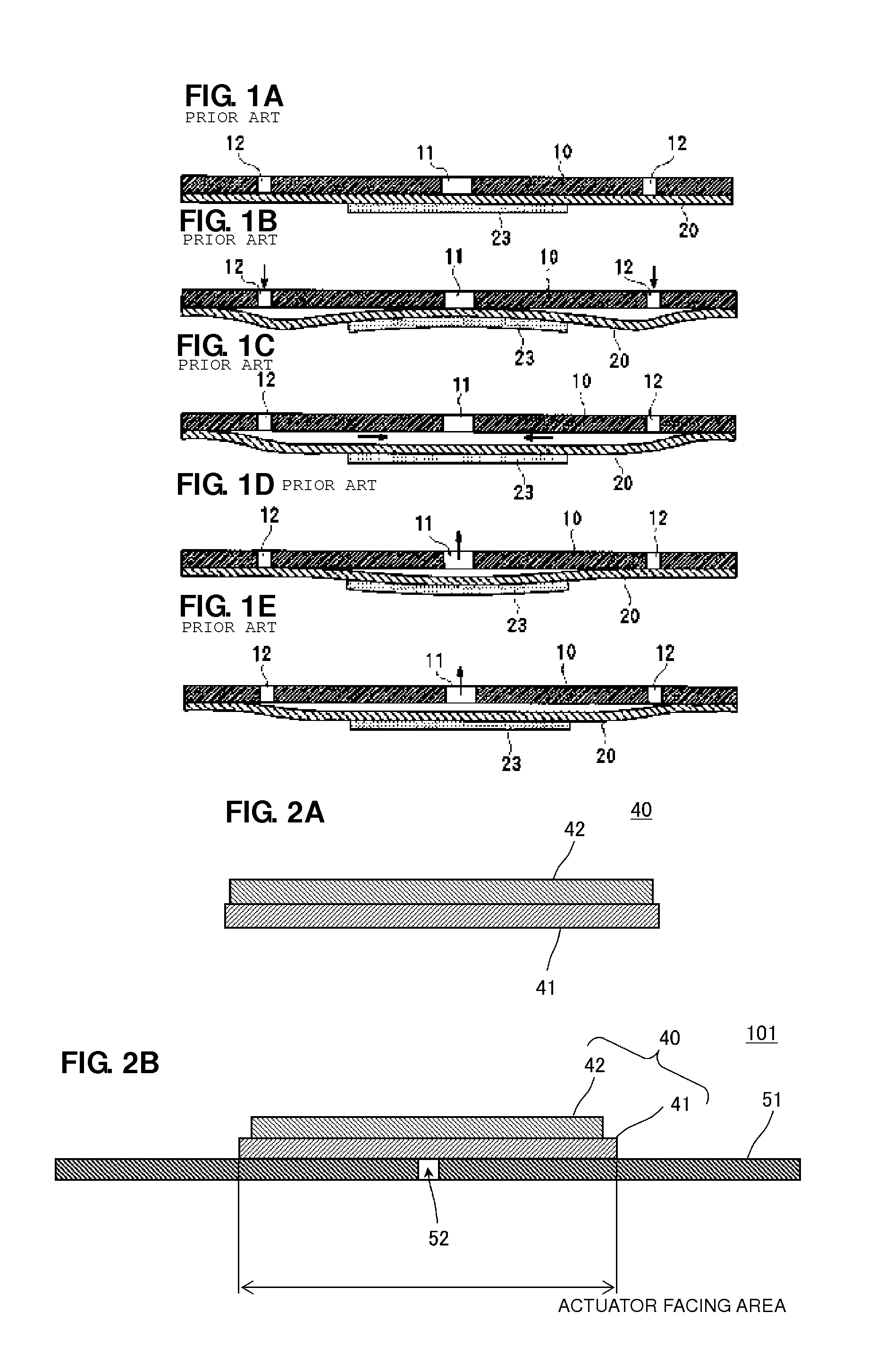

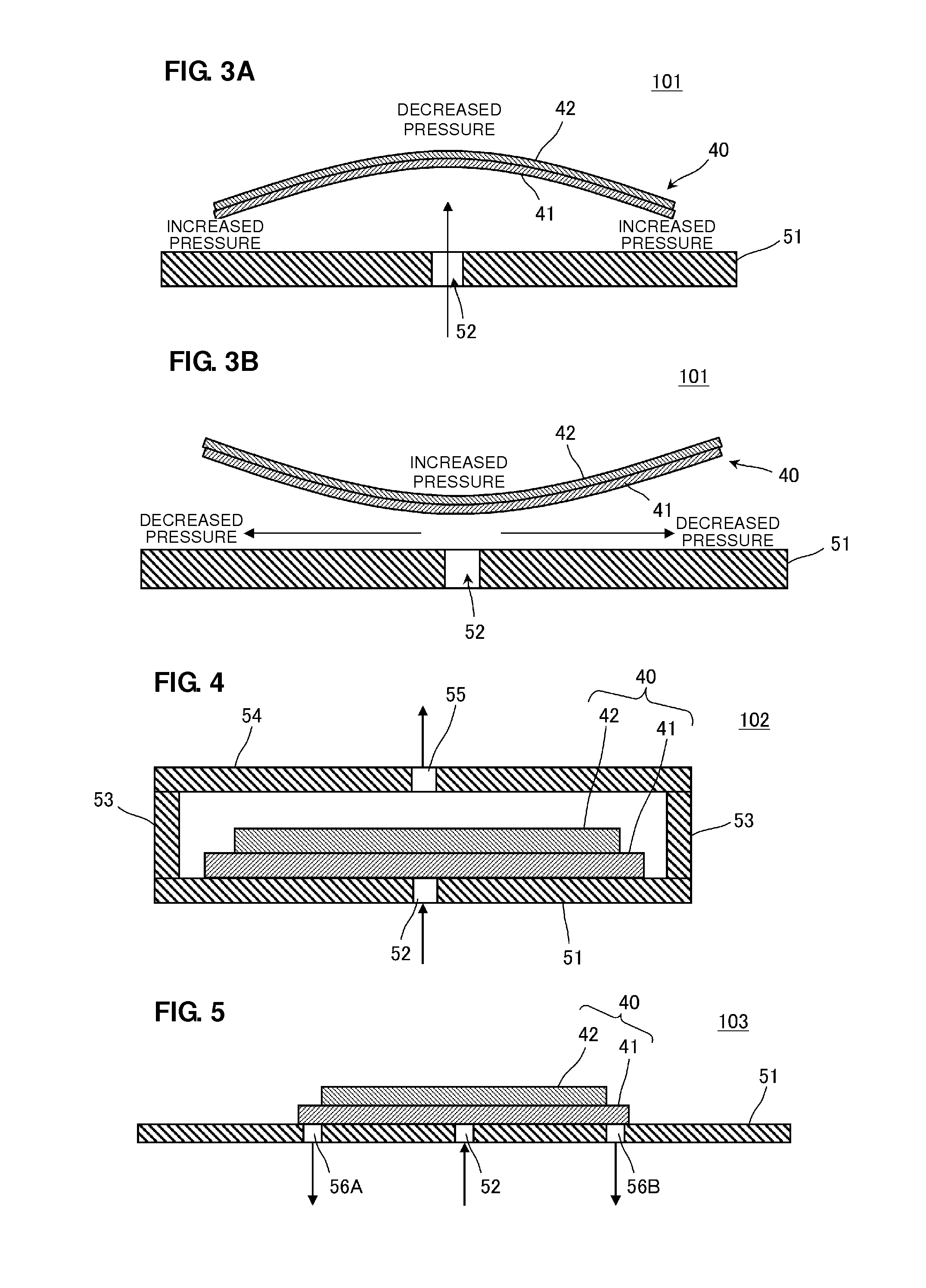

Fluid pump

ActiveUS20120171062A1Improve abilitiesPumping capability can be improvedPositive displacement pump componentsWorking fluid for enginesSquare waveformActuator

A small-sized, low-profile fluid pump having high pumping capabilities includes an actuator and a planar section including a metal plate. The actuator includes a disk-shaped piezoelectric element attached to a disk-shaped diaphragm. As a result of application of a square-wave or sine-wave drive voltage, the actuator performs a bending vibration from the central portion to the peripheral portion. The peripheral portion of the actuator is not restrained. The actuator performs a bending vibration in the state in which it is in proximity to the planar section while facing the planar section. A center vent is provided at or in an area adjacent to the center of an actuator facing area of the planar section that faces the actuator.

Owner:MURATA MFG CO LTD

Porous Particulate Material For Fluid Treatment, Cementitious Composition and Method of Manufacture Thereof

InactiveUS20080179253A1Improve machinabilityInhibit initial setting timePhysical/chemical process catalystsOther chemical processesRed mudPorous particle

A porous particulate material for treating a fluid containing a contaminant is disclosed. The particulate material comprises a cementitious matrix or binder and treated bauxite refinery residue or red mud. At least a portion of the pores in the particulate material is open cell or interconnected pores. The invention also relates to the use of a reactive permeable barrier comprising porous material, for treating a contaminated fluid. Also disclosed is a method for producing porous particulate material for treating a contaminated fluid and a method for treating a contaminated fluid, in which the porous material is used. The invention furthermore relates to a cementitious composition comprising partially neutralised red mud and cement, wherein the partially neutralised red mud has been pre-treated by contacting it with water having a total hardness supplied by calcium, magnesium or a combination thereof, of at least 3.5 millimoles per litre calcium carbonate equivalent. The cementitious composition is useful as a building and construction material.

Owner:MT ASPIRING GEOCHEMISTRY CONSULTANTS PTY LTD

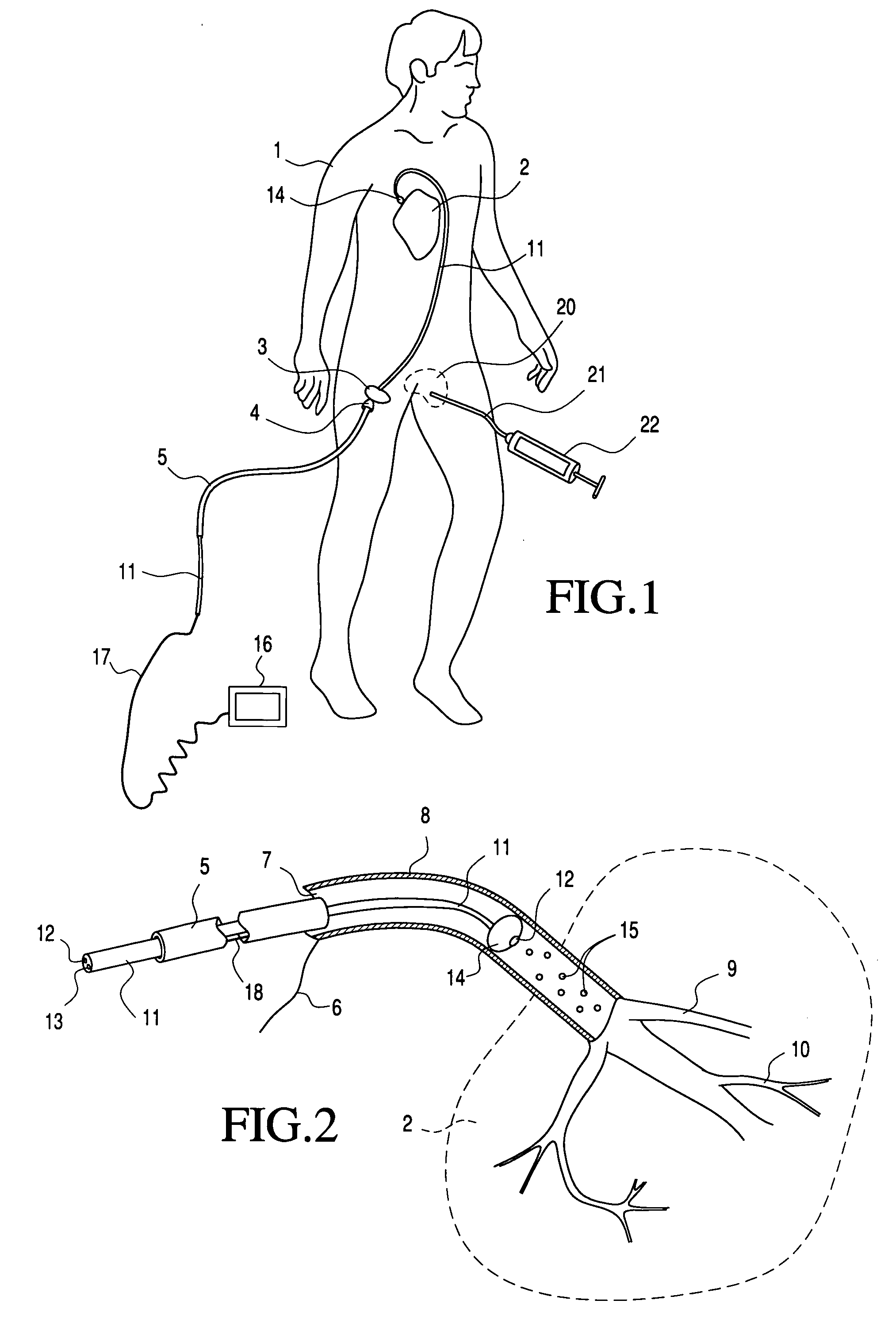

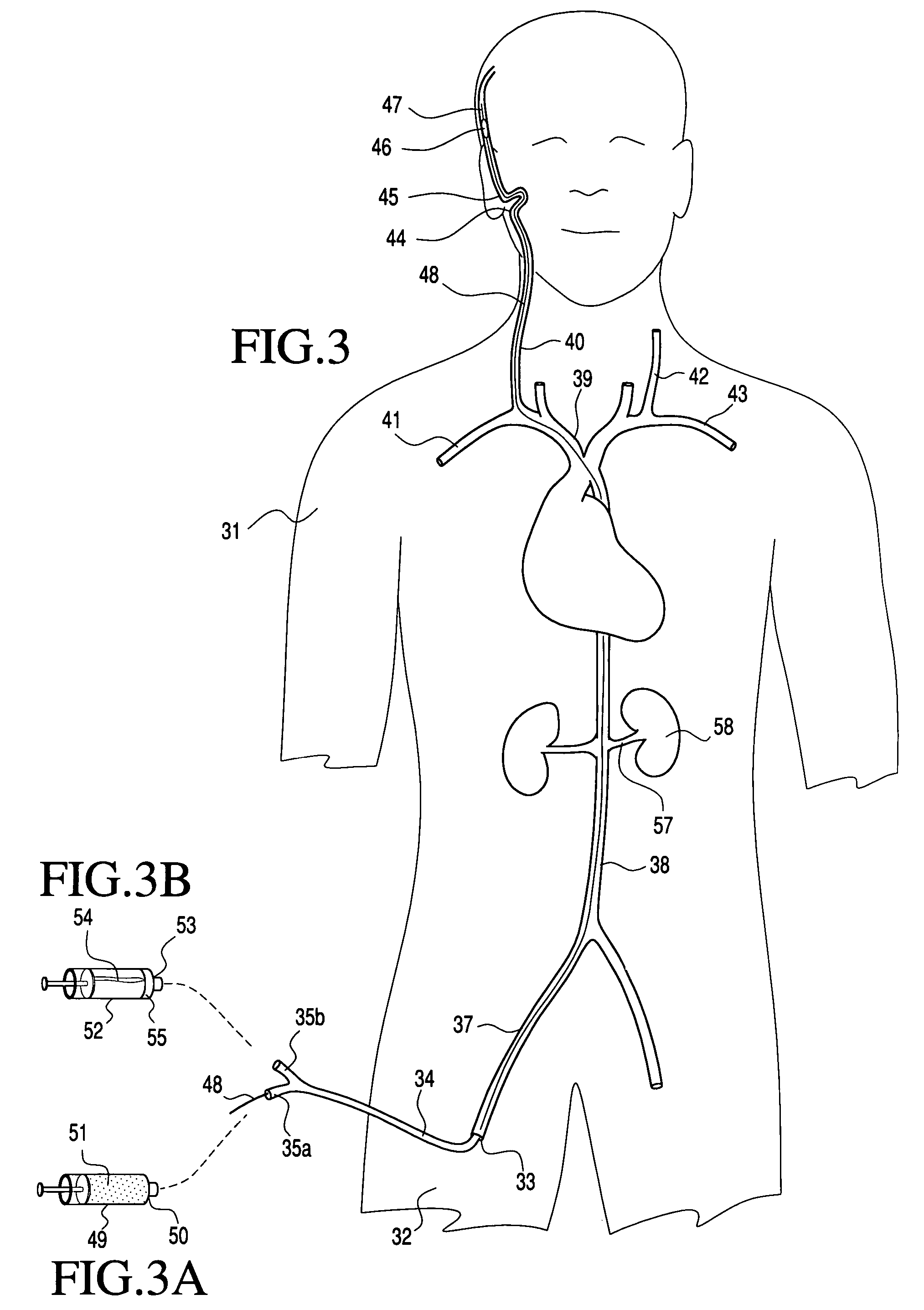

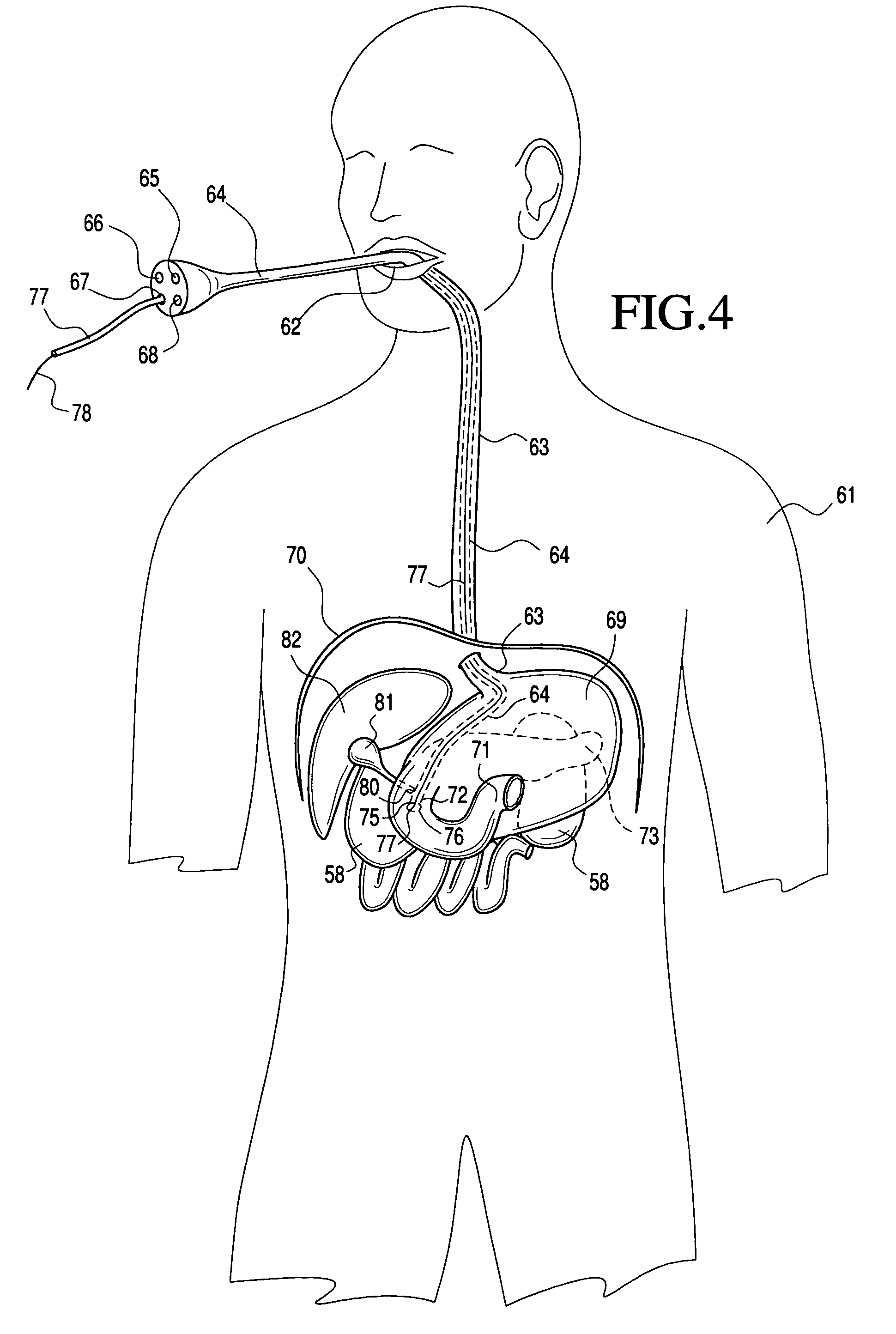

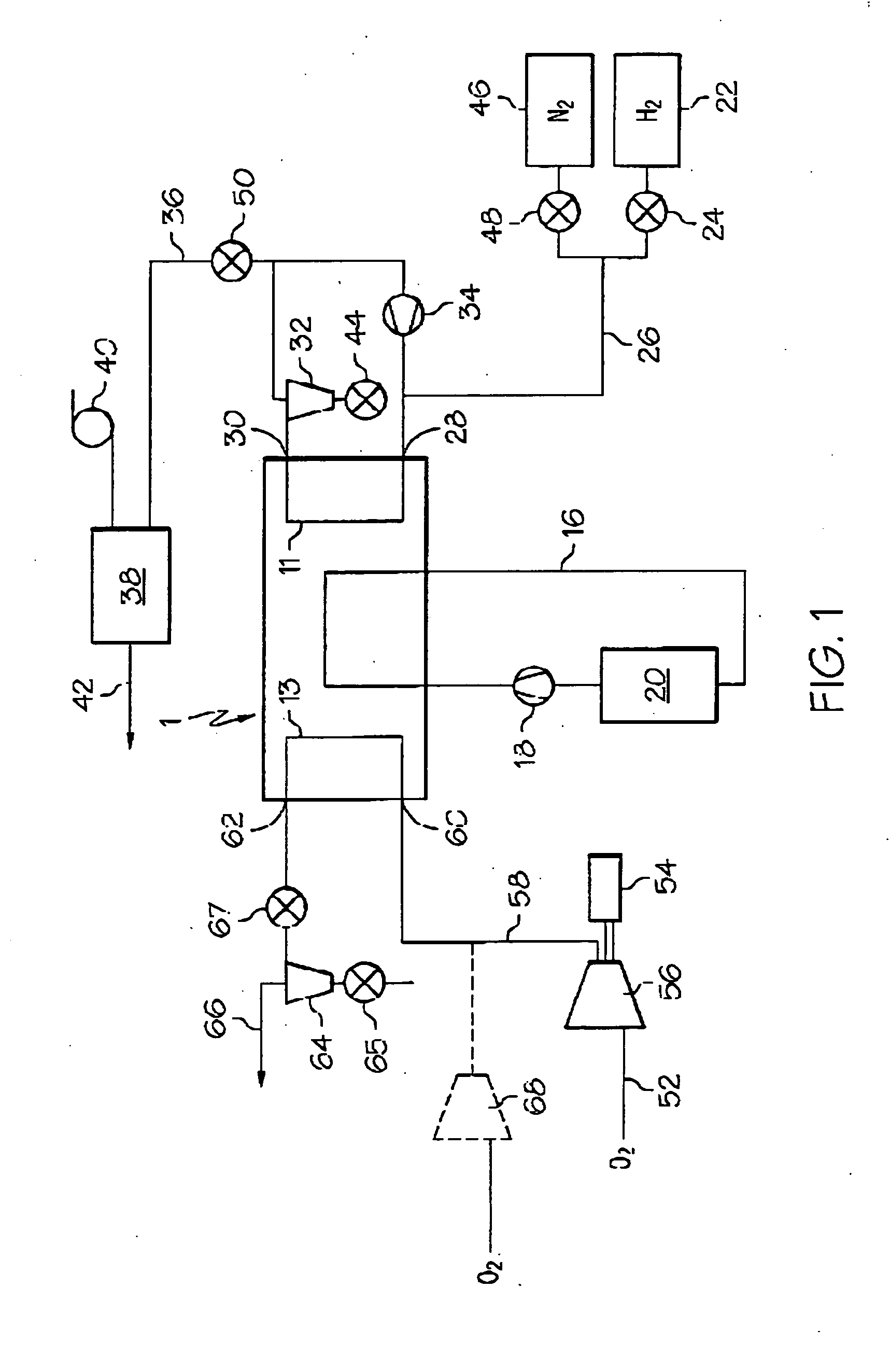

Transluminal application of adult stem cells for body organ tissue repair

InactiveUS7452532B2Improve pumping capacityEasy to implementBiocideCell differentiationBody organsTissue repair

A method for repairing tissue of a selected organ from among heart, brain, liver, pancreas, kidney, glands, and muscles in a patient's body. Adult stem cells that have the capability to repair tissue of the selected organ are recovered by harvesting from the patient's body. The harvested stem cells are then intraluminally applied through a designated natural body vessel. During the time the stem cells are being applied to the targeted tissue downstream, the designated vessel or duct is selectively occluded to increase concentration and pressure of the applied adult stem cells by the vessel.

Owner:SCICOTEC

Heat exchanger

InactiveUS20060090887A1Reduce total pressure lossReduce maintenanceHeat transfer modificationLaminated elementsThin metalEngineering

To reduce pressure loss on a heat-exchanger fluid while downsizing a heat exchange and reducing the production cost of the heat exchanger without impairment of the heat transfer performance of the heat exchanger by forming a fluid channel in surfaces of thin metal plates such as stainless steel plates through the use of an etching technique or the like and by improving the shape of the fluid channel. In a heat exchanger in which a plurality of heat exchanger fins are provided in thin metal plates by using an etching technique or the like and a fluid channel for a heat-exchanger fluid is formed between the two opposed thin metal plates by alternately stacking the thin metal plates, the area of the fluid channel, through which the fluid flows between the heat exchanger fins, is made substantially uniform by forming the heat exchanger fins so as to have a curved cross-sectional shape from the front end thereof to the rear end.

Owner:KATO YASUYOSHI

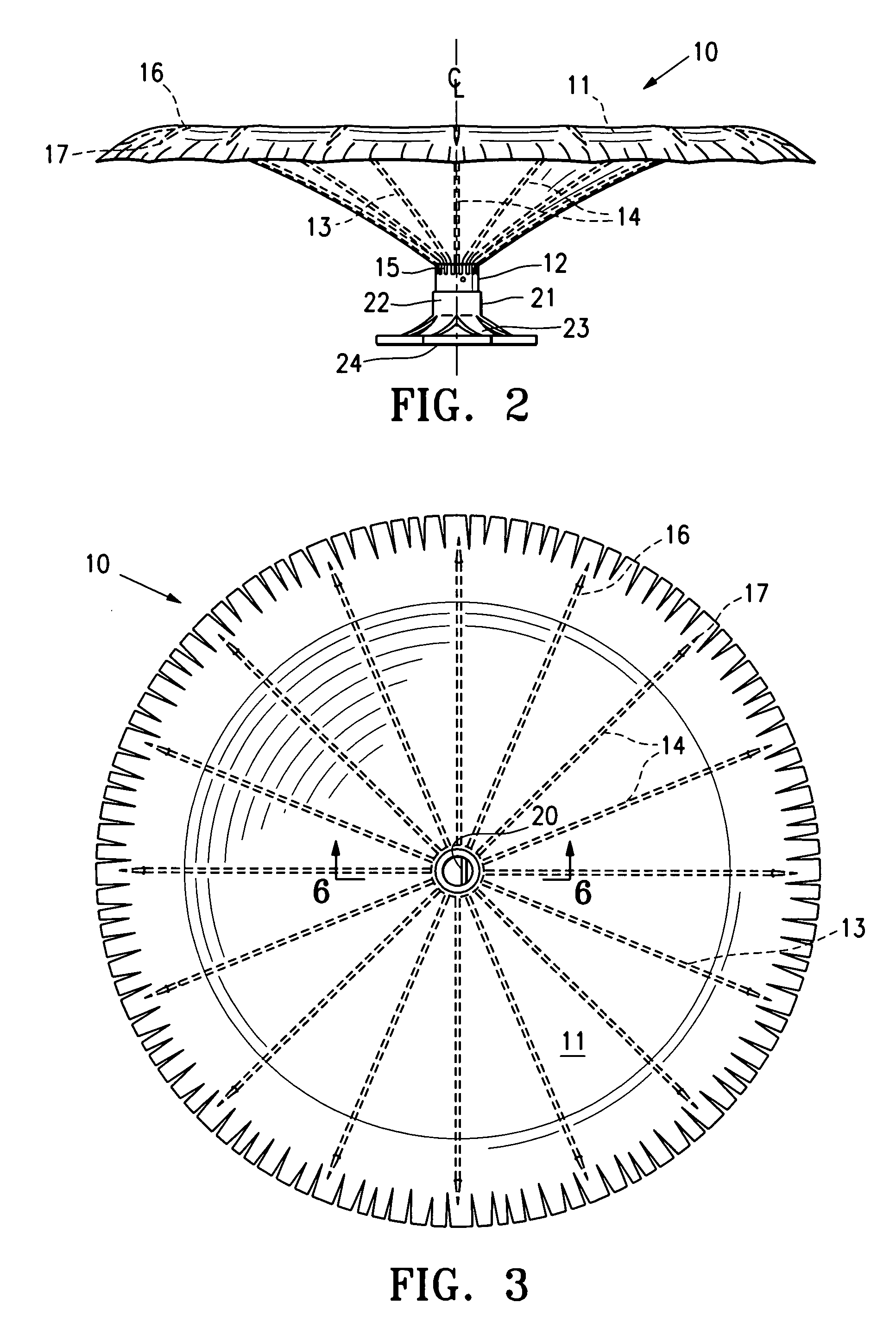

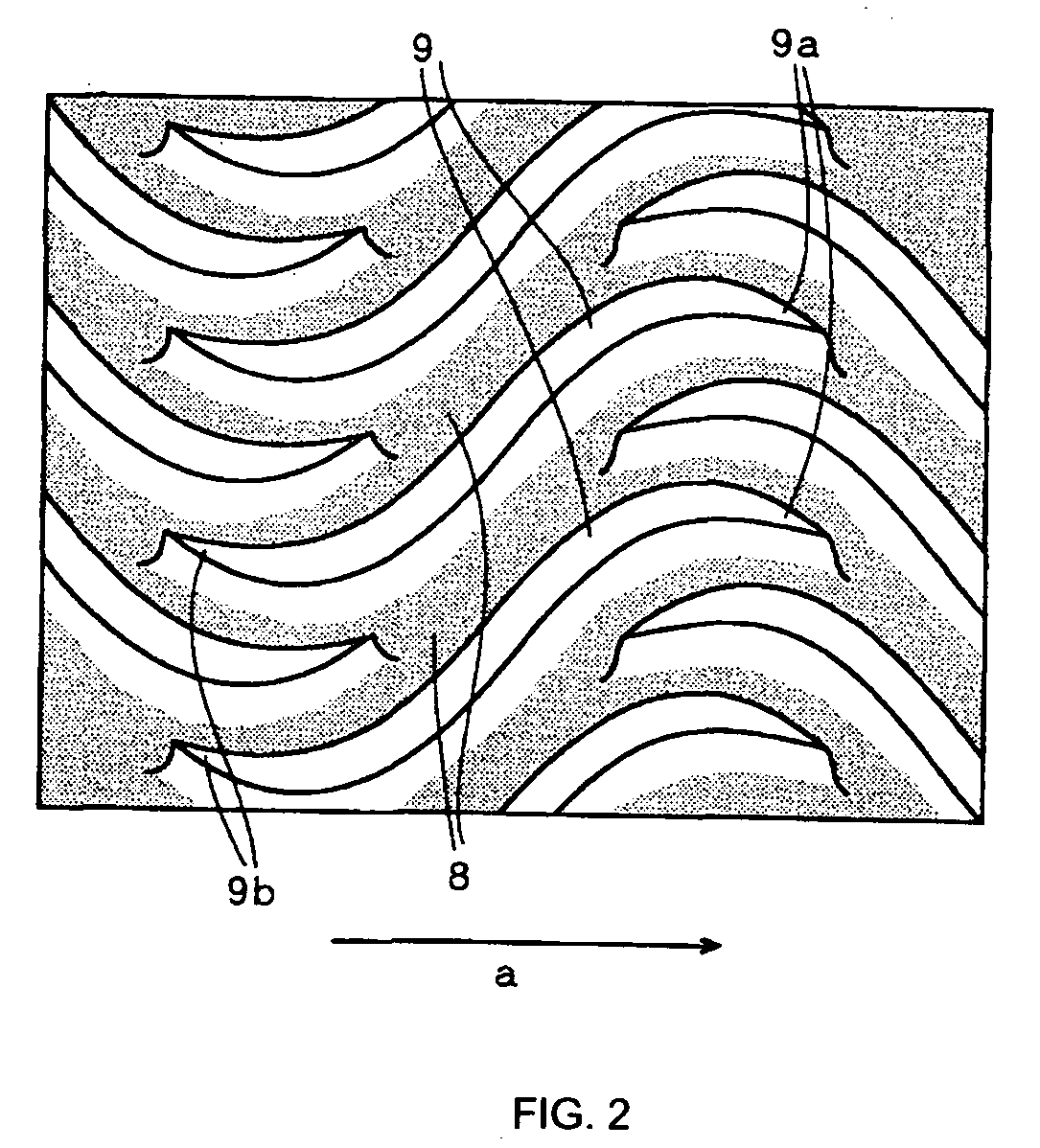

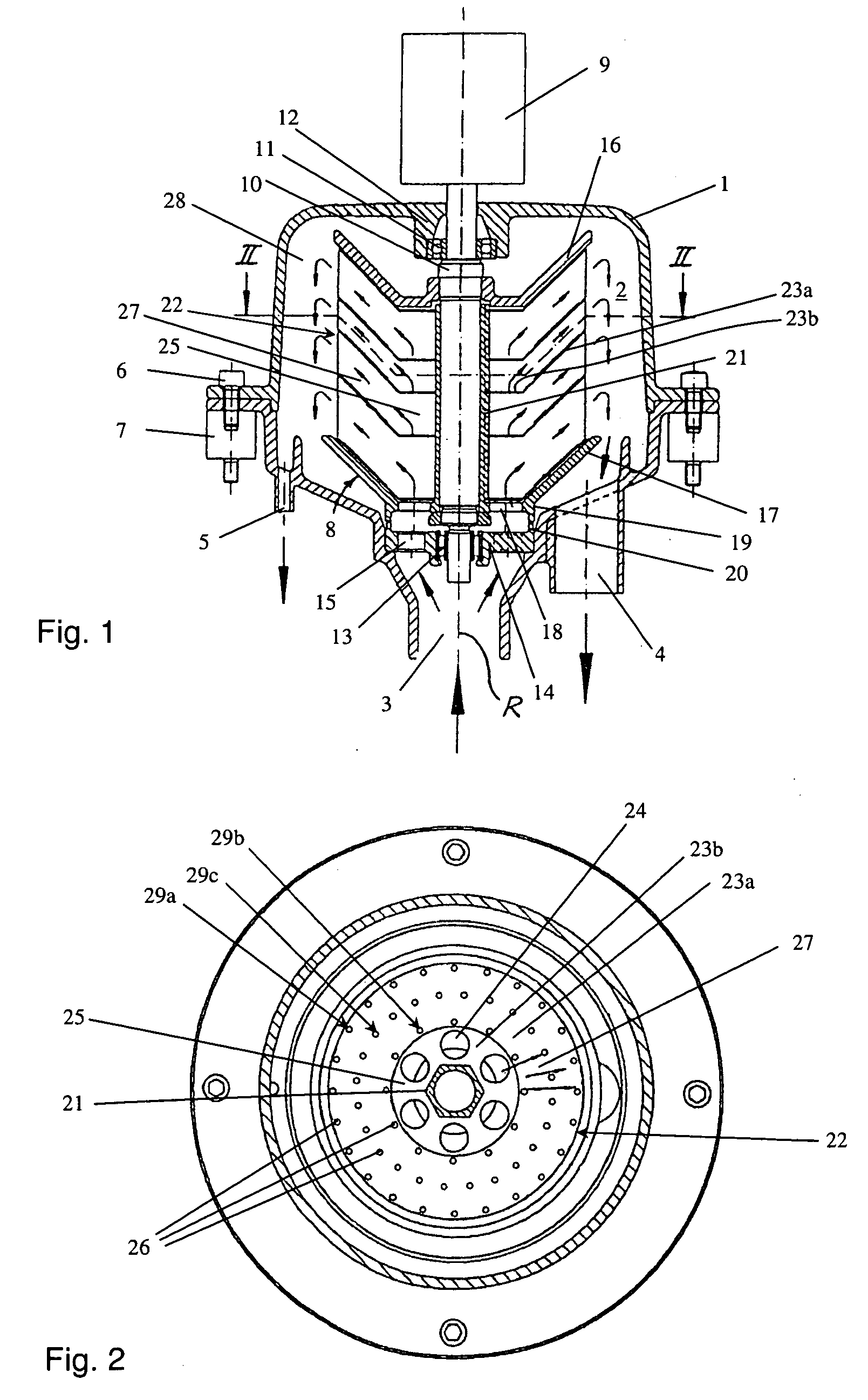

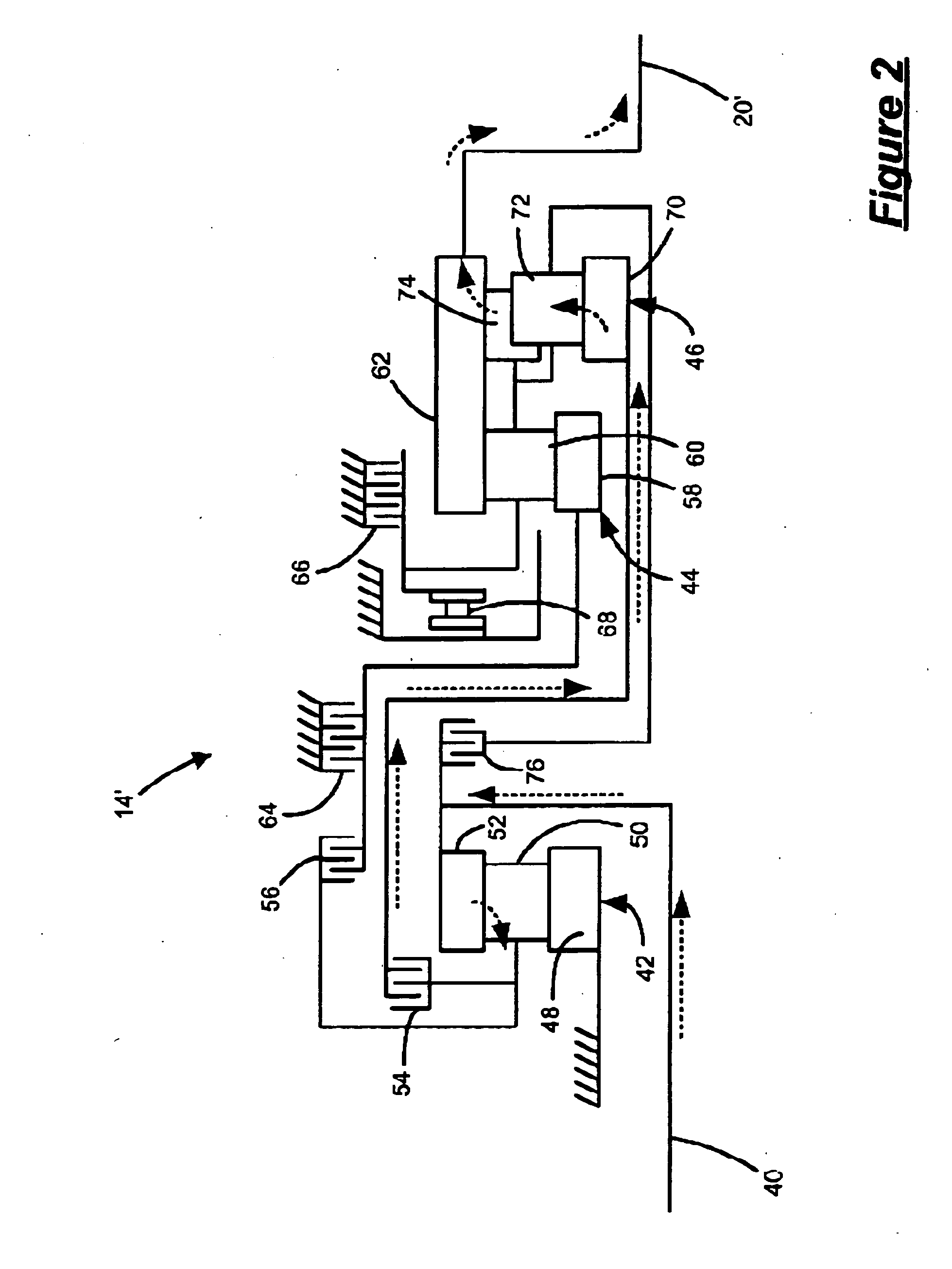

Centrifugal separator

ActiveUS20100011723A1Evenly distributedImprove pumping capacityDispersed particle separationRotary centrifugesParticulatesProduct gas

The invention relates to a centrifugal separator for cleaning of gas from solid or liquid particles suspended therein which are of greater density than the gas. A main object of the present invention is to accomplish a centrifugal separator which does not have said inactive regions and thereby achieves efficient separation of particulate contaminants from a gas. This object is achieved by the centrifugal separator initially defined, which is characterised in that the interspaces between the separation discs at least at their radially outer parts are substantially open for flow of the gas in the circumferential direction and that mutually adjacent separation discs are arranged at mutual spacing such that rotation of the rotor causes a pumping action in the interspaces, which pumping action drives the gas from the gas inlet, through the interspaces between the separation discs and out via the gas outlet.

Owner:ALFA LAVAL CORP AB

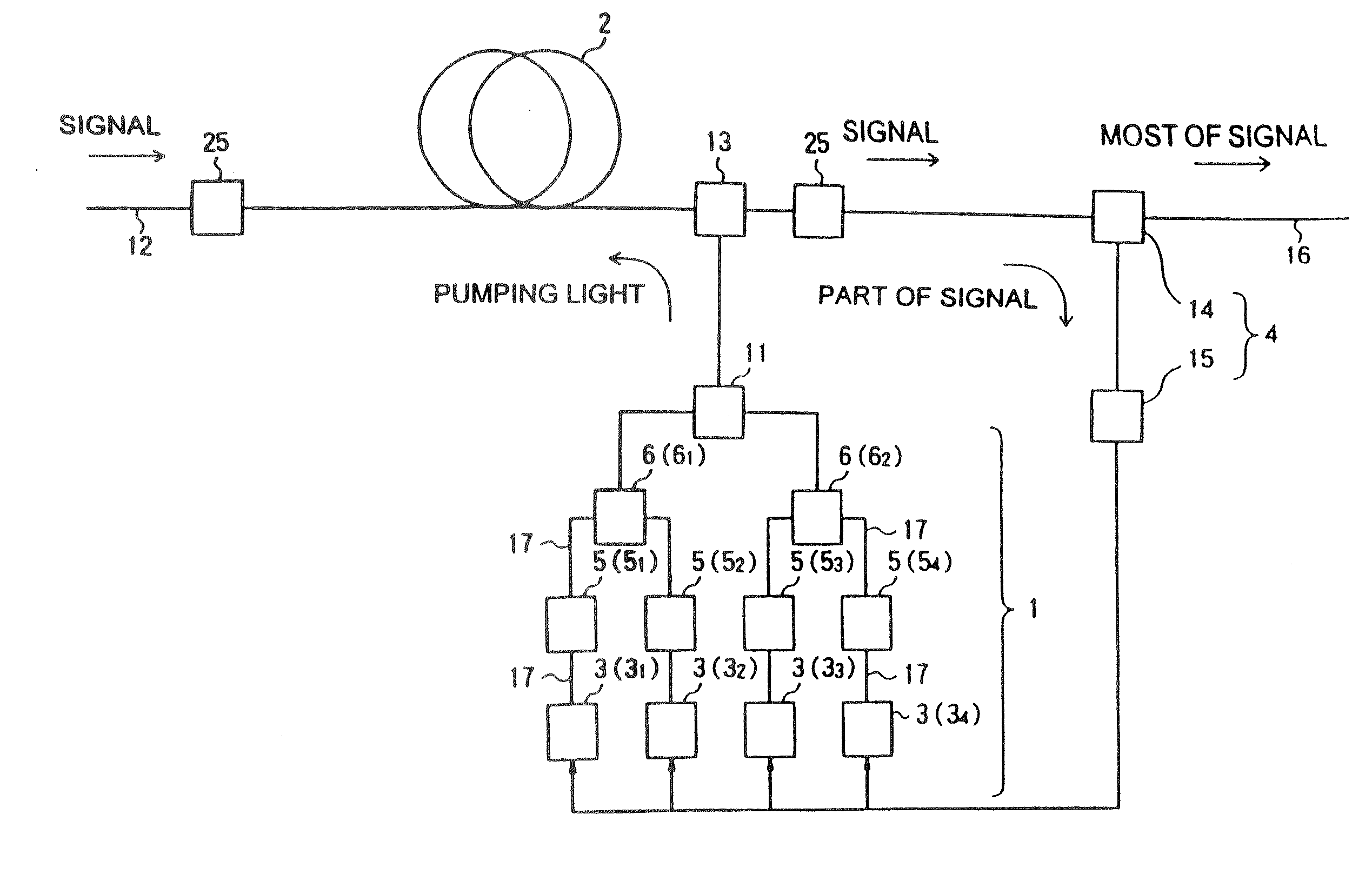

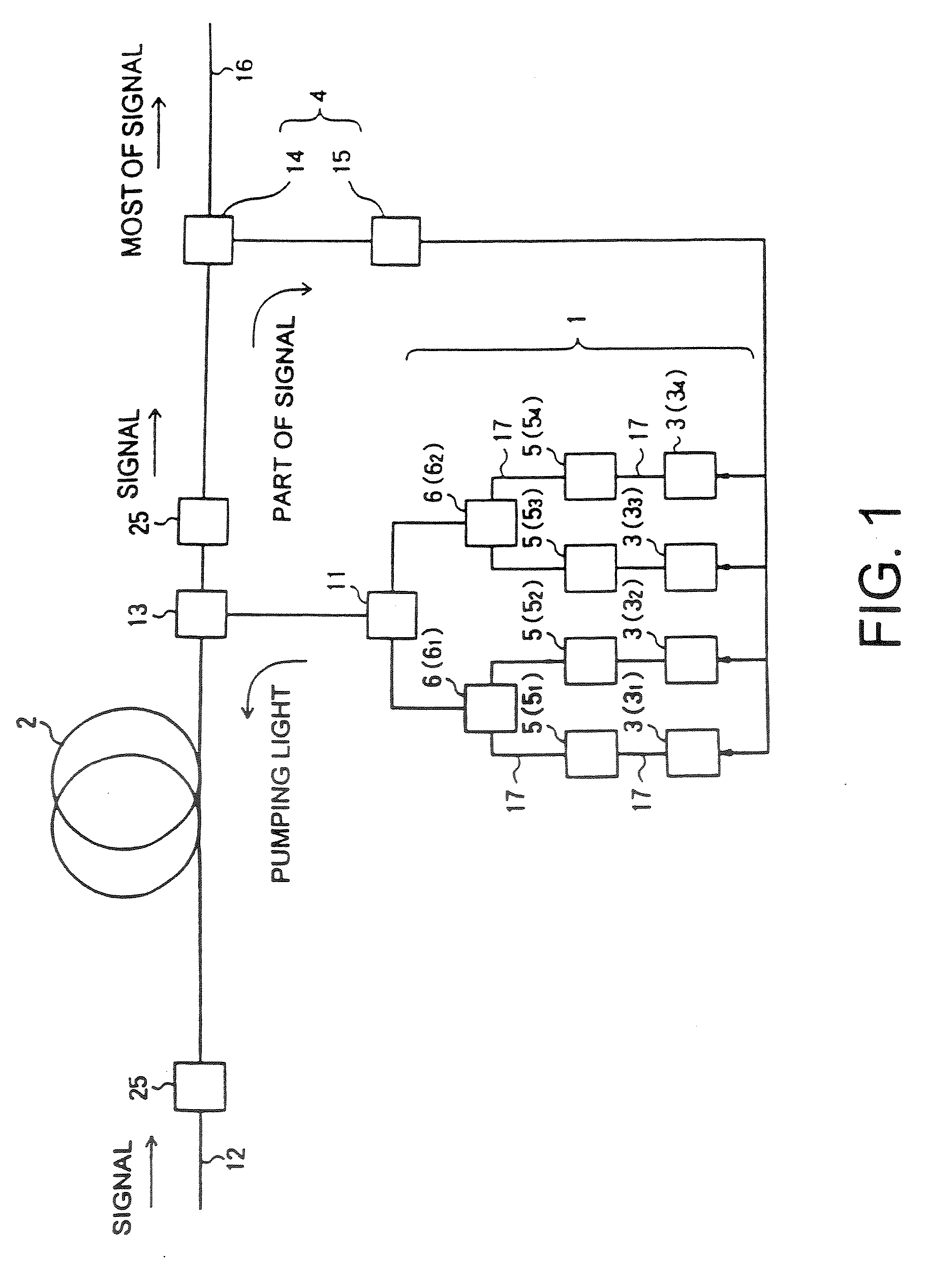

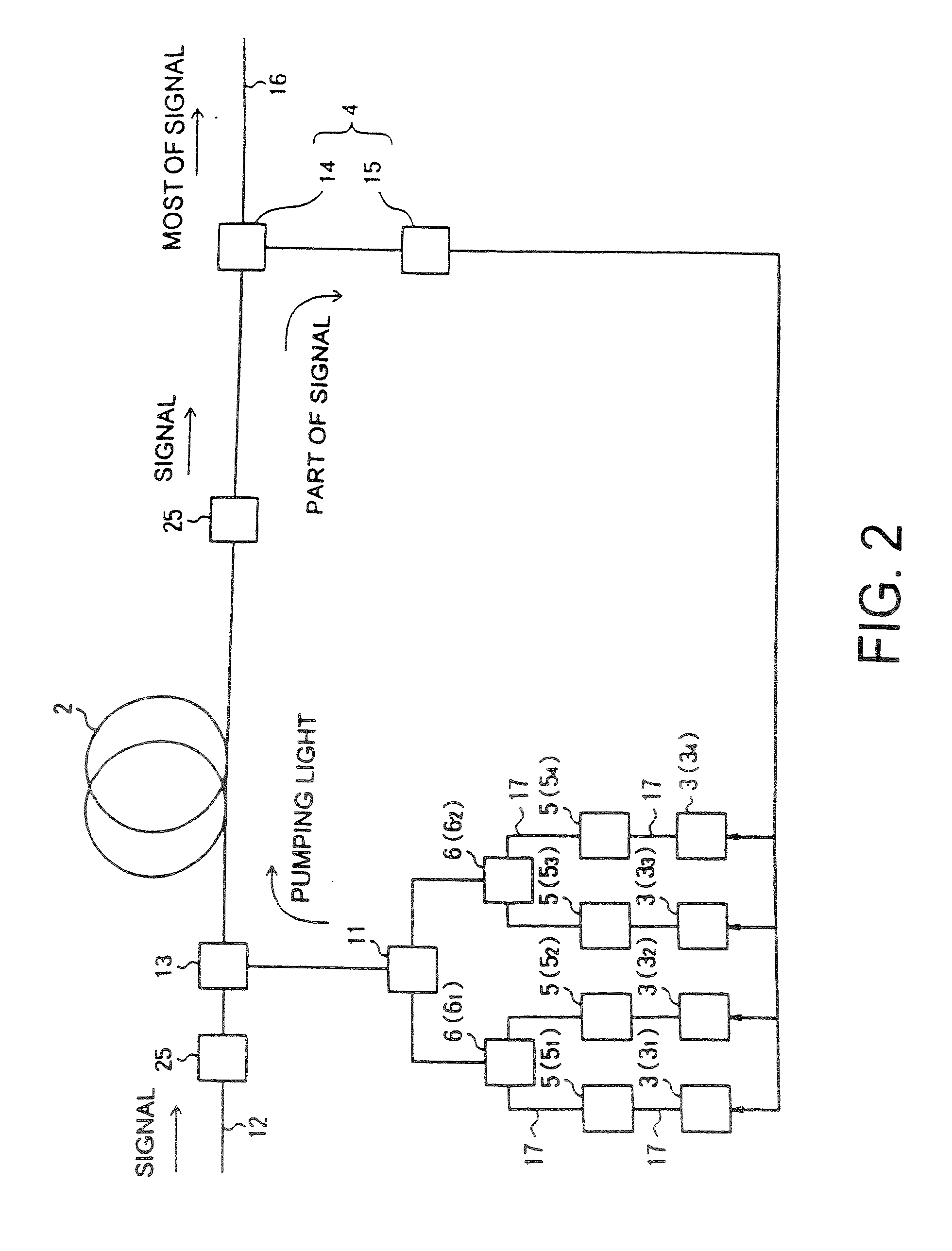

Raman amplifier, optical repeater, and raman amplification method

InactiveUS20070247701A1Soften propertyWide bandLaser using scattering effectsLaser arrangementsLong wavelengthLight source

A Raman amplifier according to the present invention comprises a plurality of pumping means using semiconductor lasers of Fabry-Perot, DFB, or DBR type or MOPAs, and pumping lights outputted from the pumping means have different central wavelengths, and interval between the adjacent central wavelength is greater than 6 nm and smaller than 35 nm. An optical repeater according to the present invention comprises the above-mentioned Raman amplifier and adapted to compensate loss in an optical fiber transmission line by the Raman amplifier. In a Raman amplification method according to the present invention, the shorter the central wavelength of the pumping light the higher light power of said pumping light. In the Raman amplifier according to the present invention, when a certain pumping wavelength is defined as a first channel, and second to n-th channels are defined to be arranged with an interval of about 1 THz toward a longer wavelength side, the pumping lights having wavelengths corresponding to the first to n-th channels are multiplexed, and an pumping light having a wavelength spaced apart from the n-th channel by 2 THz or more toward the longer wavelength side is combined with the multiplexed light, thereby forming the pumping light source. The pumping lights having wavelengths corresponding to the channels other than (n-1)-th and (n-2)-th channels may be multiplexed, thereby forming the pumping light source. The pumping lights having wavelengths corresponding to the channels other than (n-2)-th and (n-3)-th channels may be multiplexed, thereby forming the pumping light source.

Owner:FURUKAWA ELECTRIC CO LTD

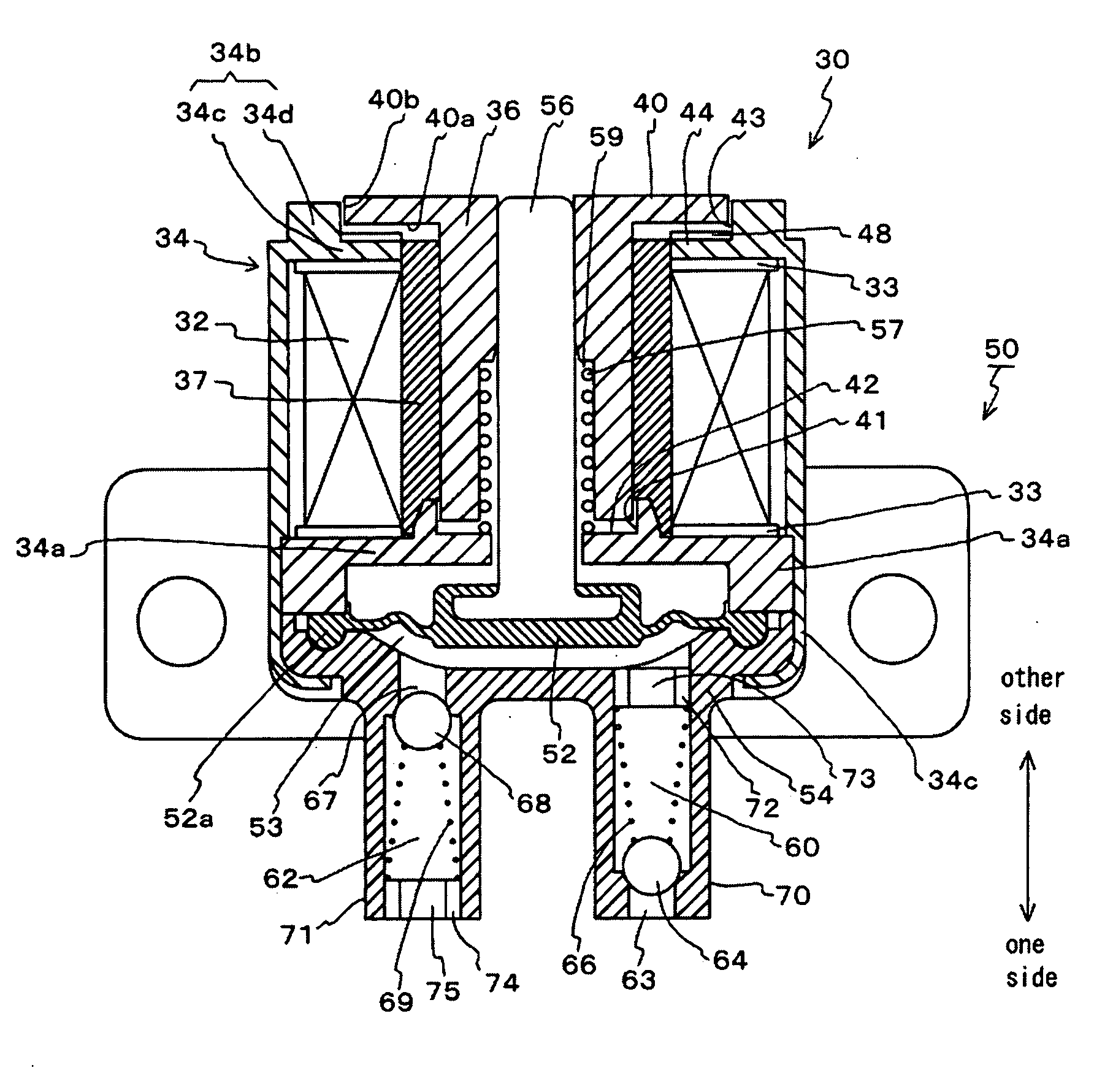

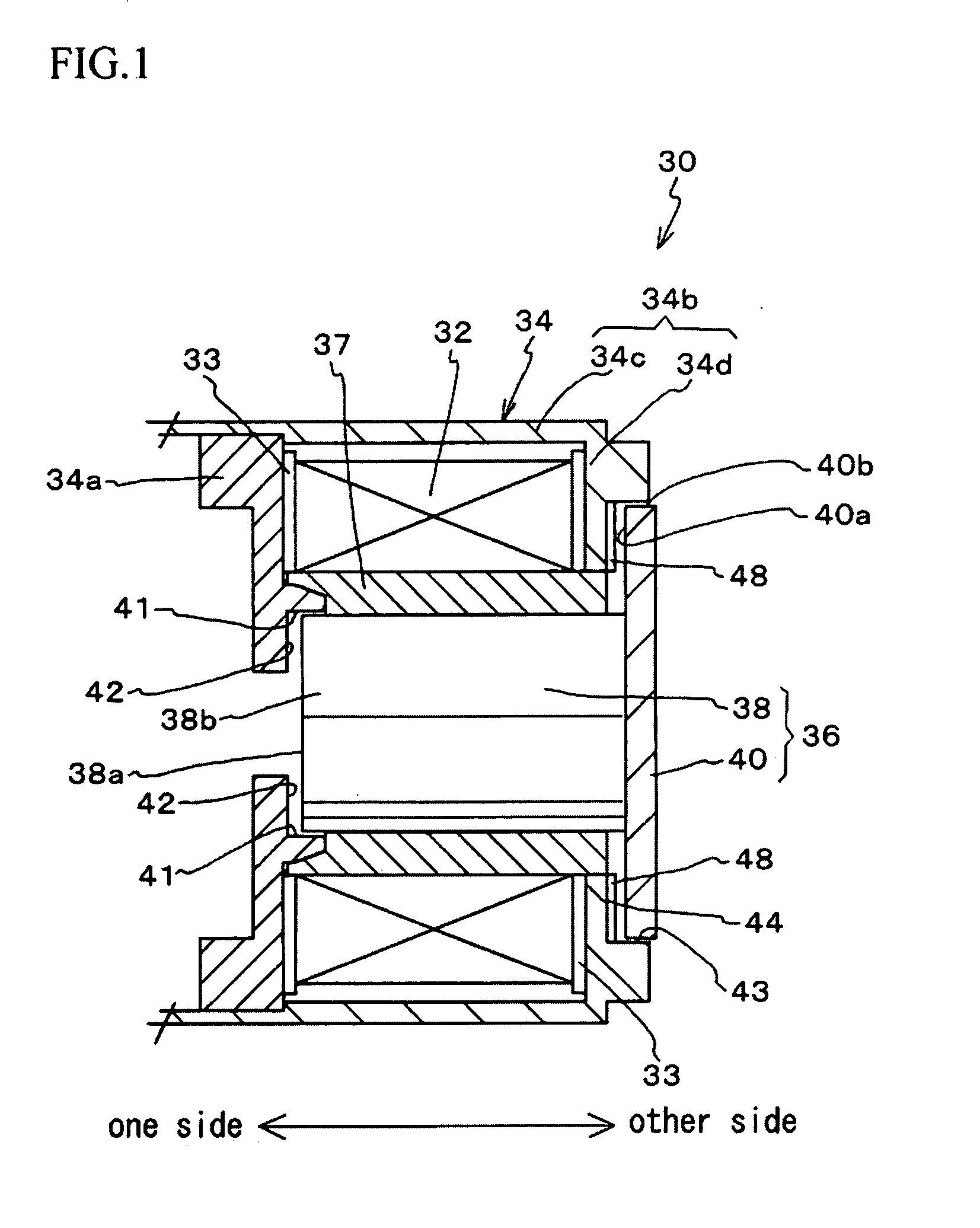

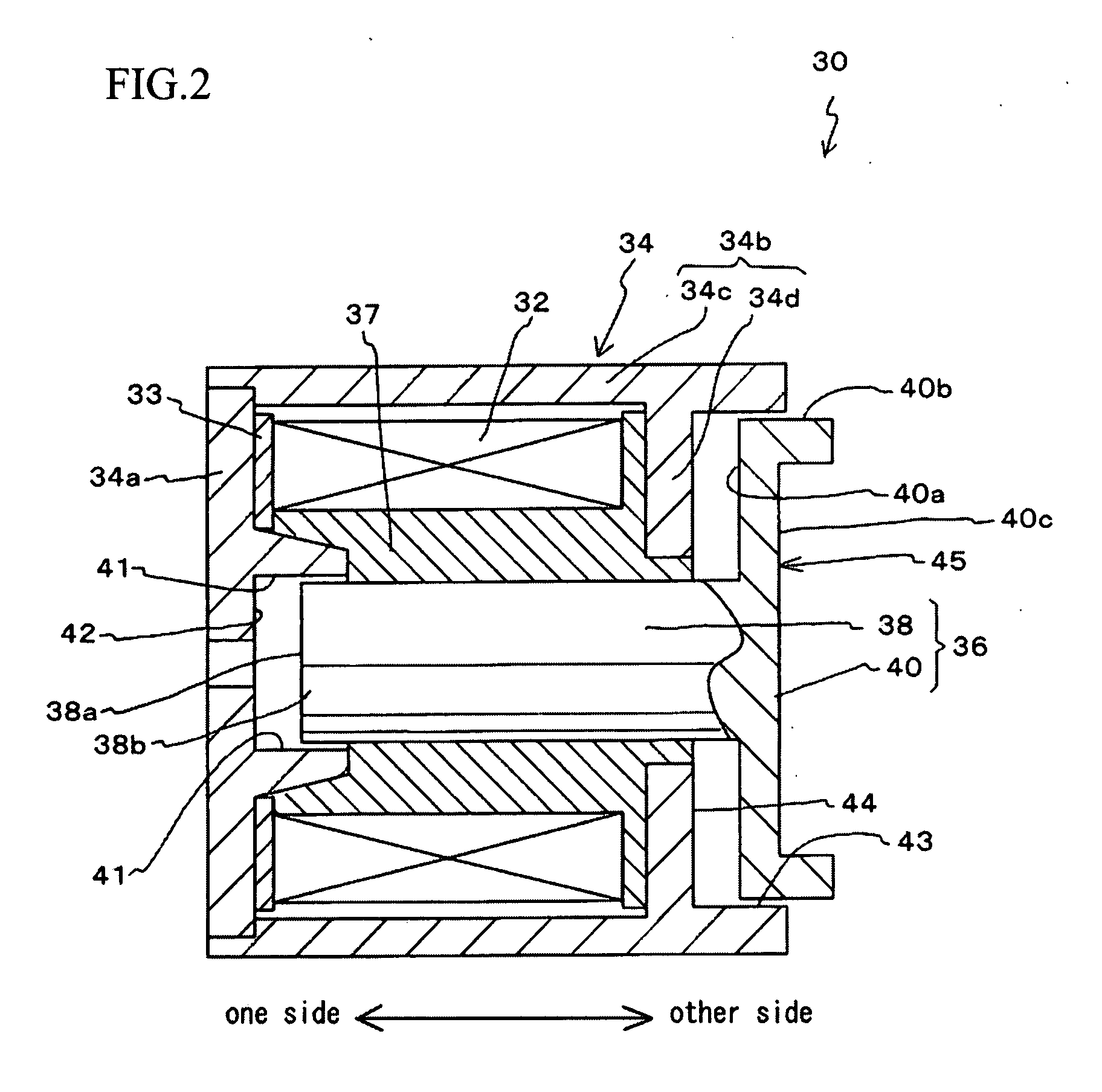

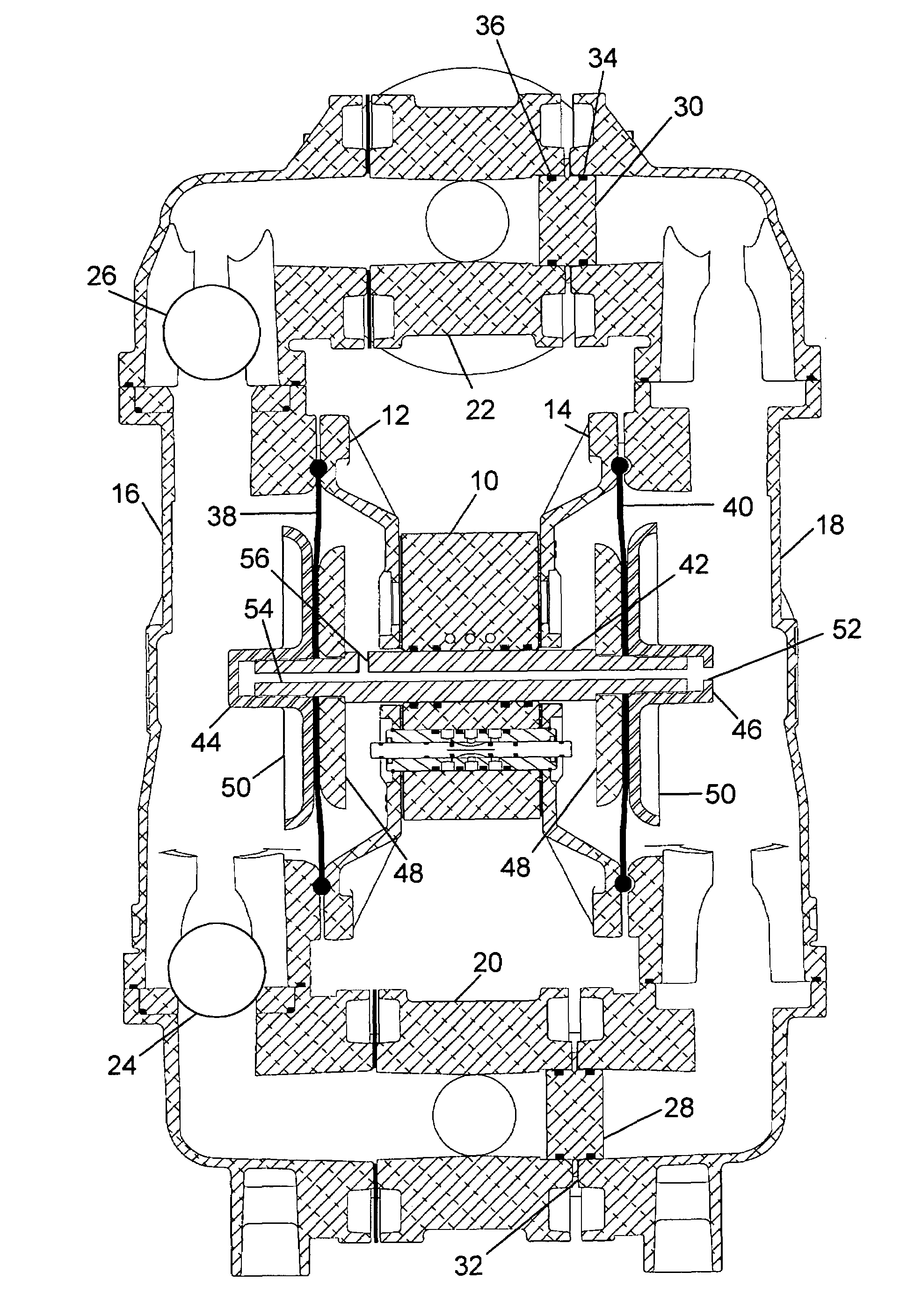

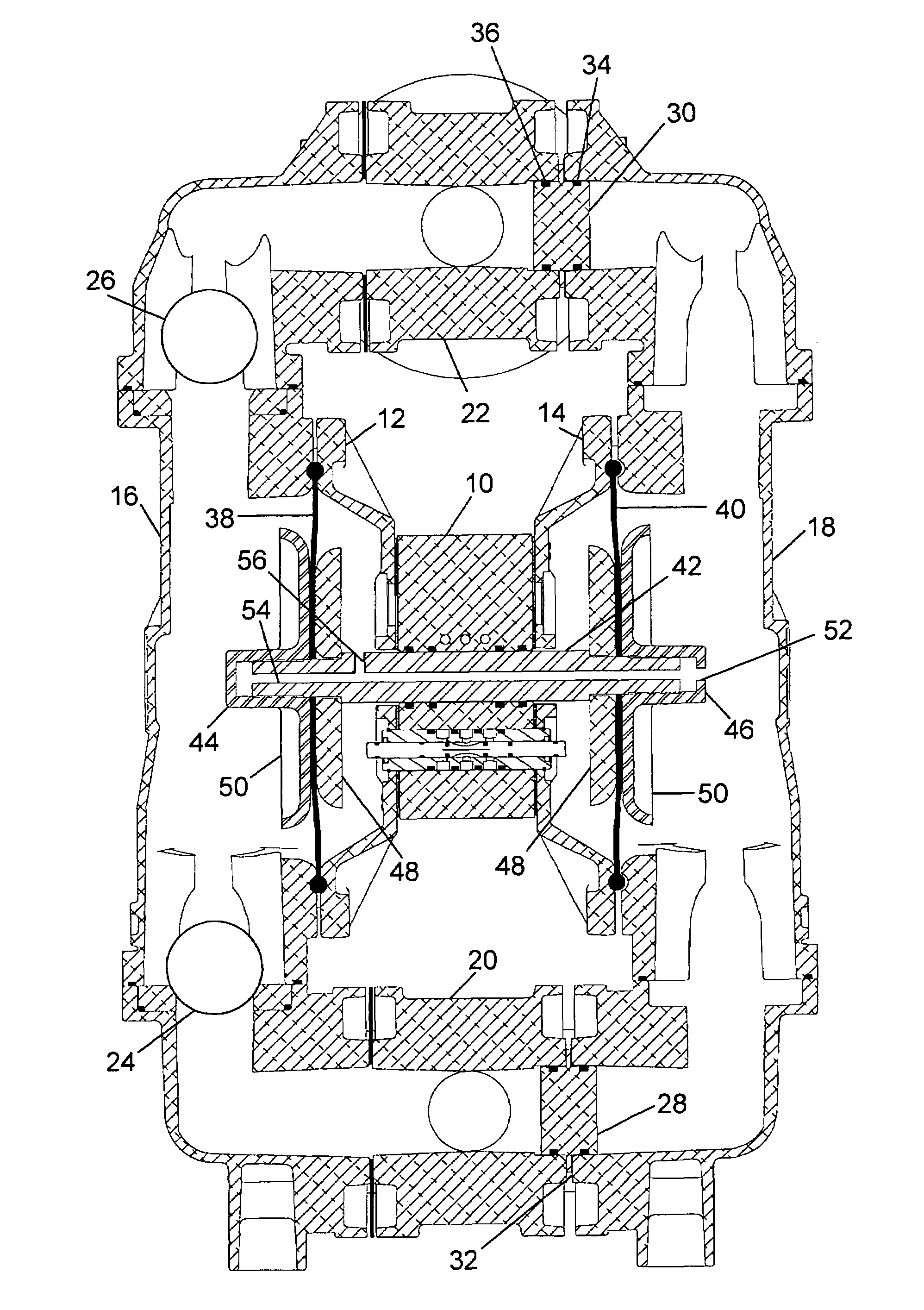

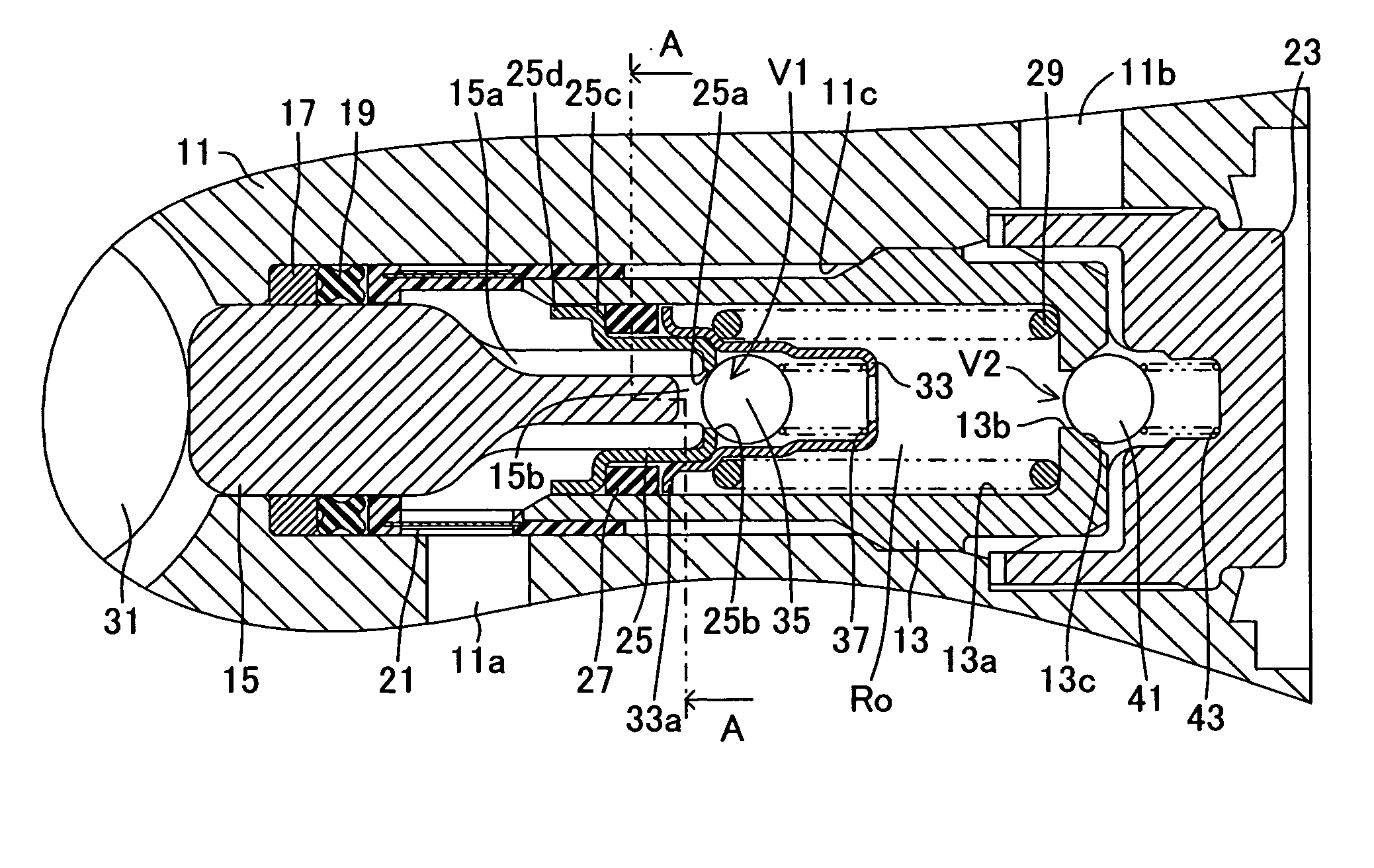

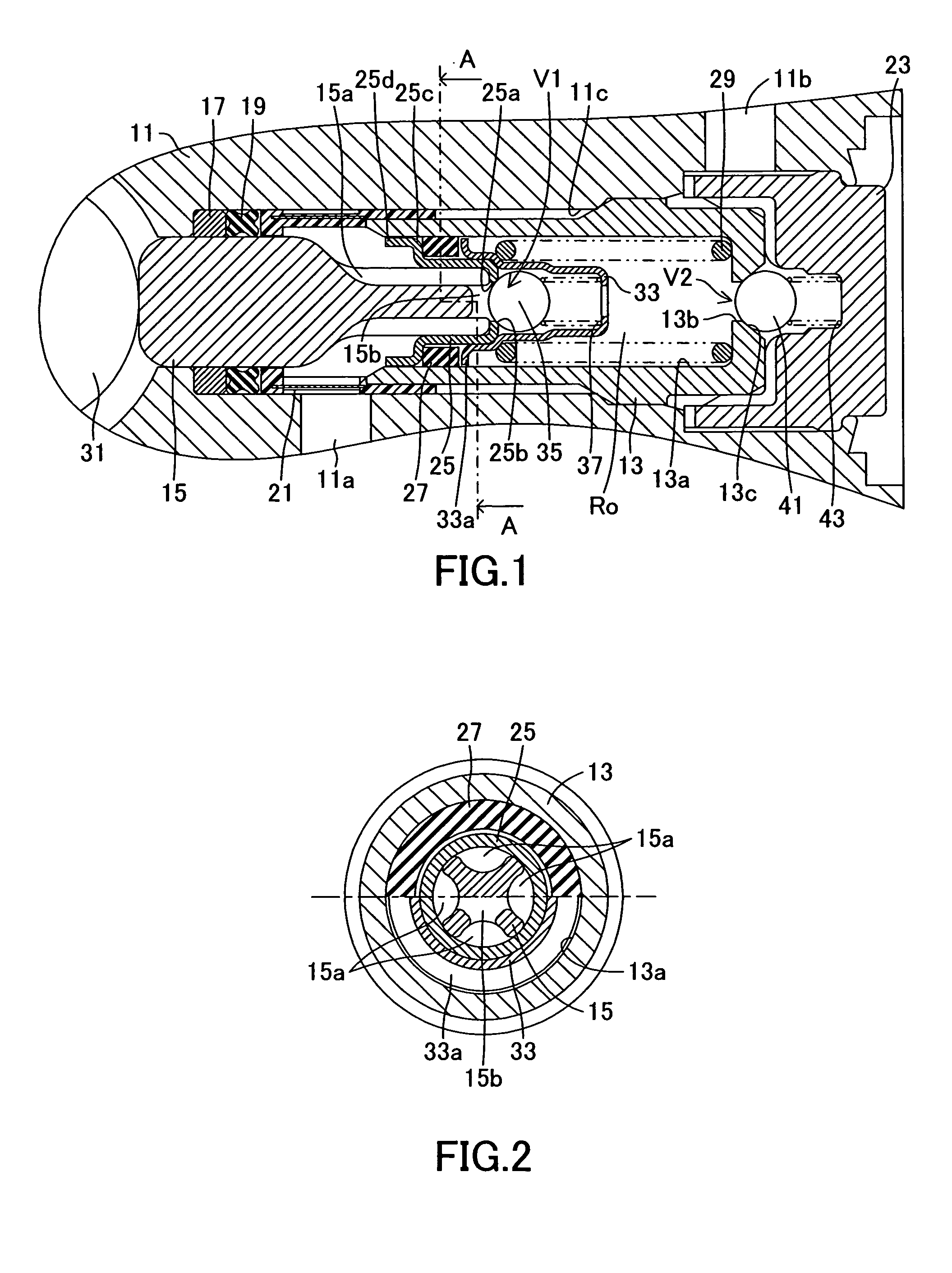

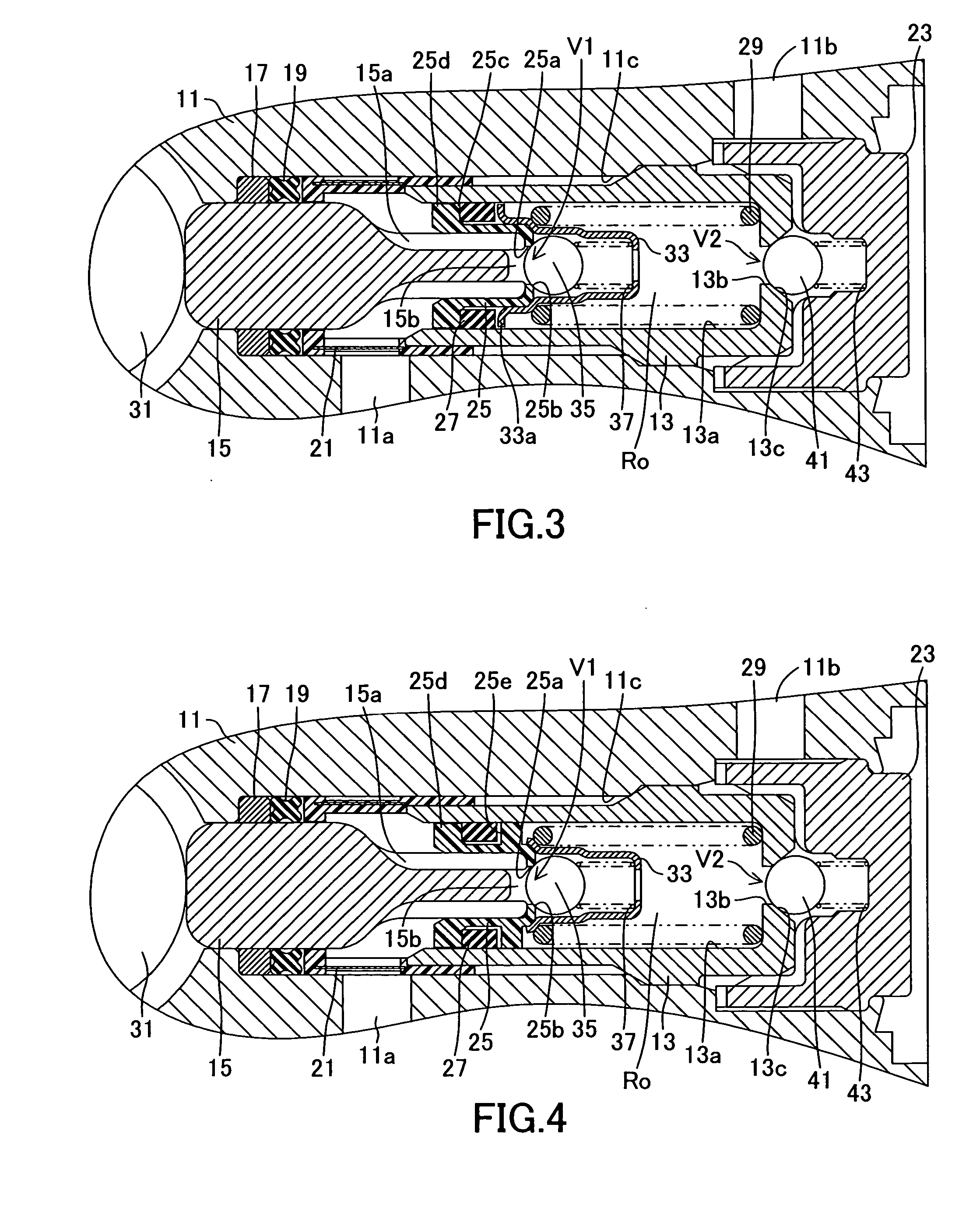

Solenoid and pump using the same

InactiveUS20070236089A1Enhanced pumpabilityImprove pumping capacityFlexible member pumpsPiston pumpsSolenoid valveEngineering

The solenoid is capable of generating great thrust and having broad-ranging thrust characteristics. The solenoid of the present invention comprises: a guide pipe formed into a cylindrical shape and provided inside of an excitation coil; a movable element having a small diameter section and a large diameter section; a first yoke part covering one end face of the excitation coil, the first yoke part having a first facing surface, which faces an outer circumferential face of the small diameter section of the movable element, and a second facing surface, which faces one end face of the small diameter section; and a second yoke part covering the other end face of the excitation coil, the second yoke part having a third facing surface, which faces an outer circumferential face of the large diameter section of the movable element, and a fourth facing surface, which faces one end face of the large diameter section.

Owner:SHINANO KENSHI

Multiple partitioning devices for heart treatment

ActiveUS7862500B2Lower the volumeReduce stressHeart valvesHeart stimulatorsHeart chamberMembrane configuration

This invention is directed to a system and method for partitioning a patient's heart chamber into a productive portion and a non-productive portion which are particularly suitable for treating patients with congestive heart failure. The partitioning system has a plurality of partitioning devices with reinforced, expandable membranes which separate the productive and non-productive portions of the heart chamber. When deployed within the patient's heart chamber, the second partitioning device is off-set from the deployed first partitioning device to cover a region of the wall defining the patient's heart chamber which is not covered by the first partitioning device. The multiple partitioning devices may be independent from each other or may be interconnected, e.g. a tether or strand.

Owner:EDWARDS LIFESCIENCES CORP

Air driven diaphragm pump

ActiveUS7399168B1Improve pumping capacityImprove stress resistanceFlexible wall reciprocating enginesFlexible member pumpsDiaphragm pumpExhaust valve

An air driven diaphragm pump includes two diaphragms affixed to a common shaft. The shaft extends through an air valve providing reciprocating pressurized air to the diaphragms through associated air chambers. A pump chamber with intake and exhaust valves is associated with one of the two diaphragms while a further air chamber replaces a pump chamber and is associated with the other of the diaphragms. A passage extends through the shaft and is in communication with the air chamber adjacent to the pump chamber and with the further air chamber converted from the pump chamber.

Owner:PSG CALIFORNIA LLC

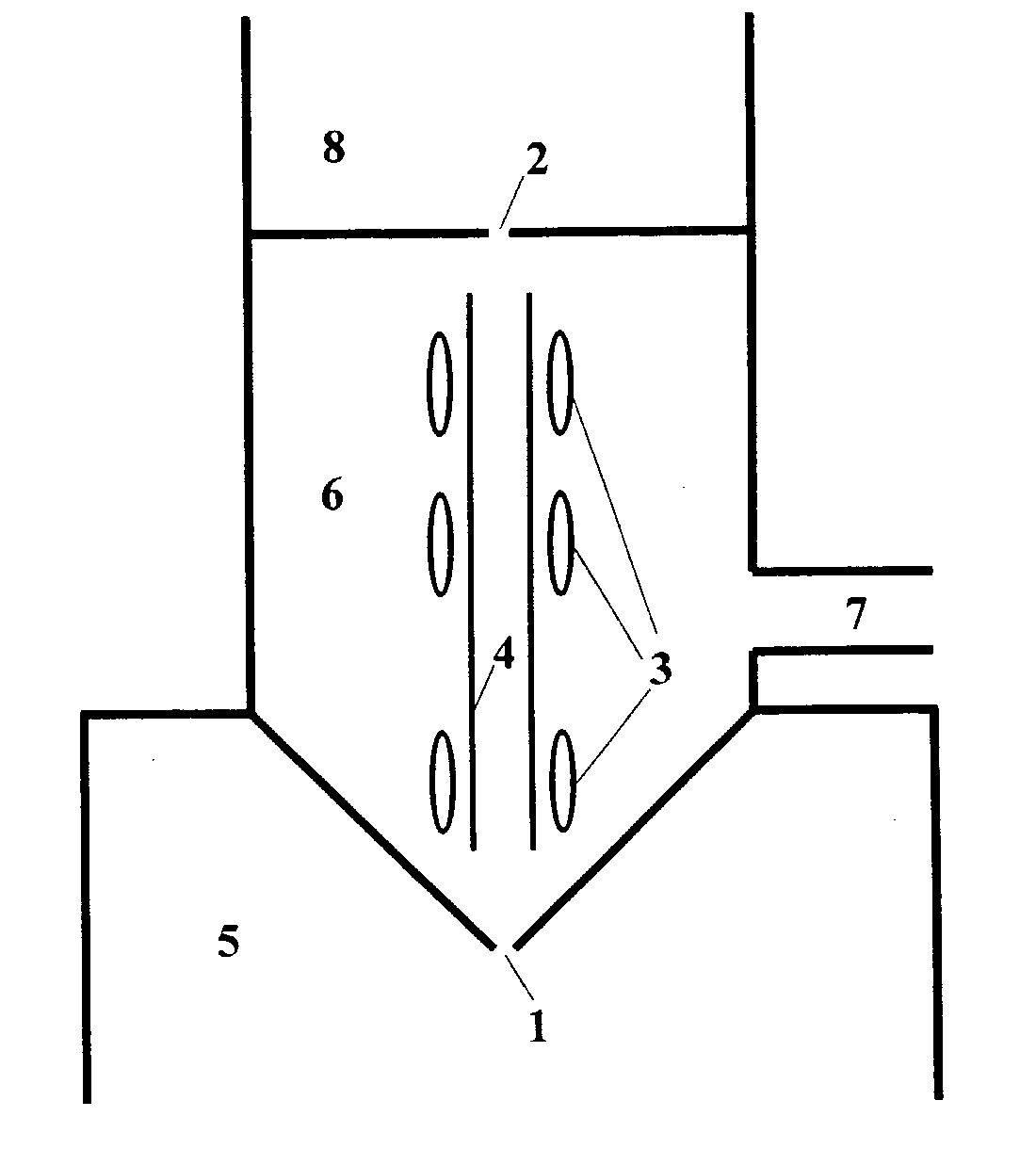

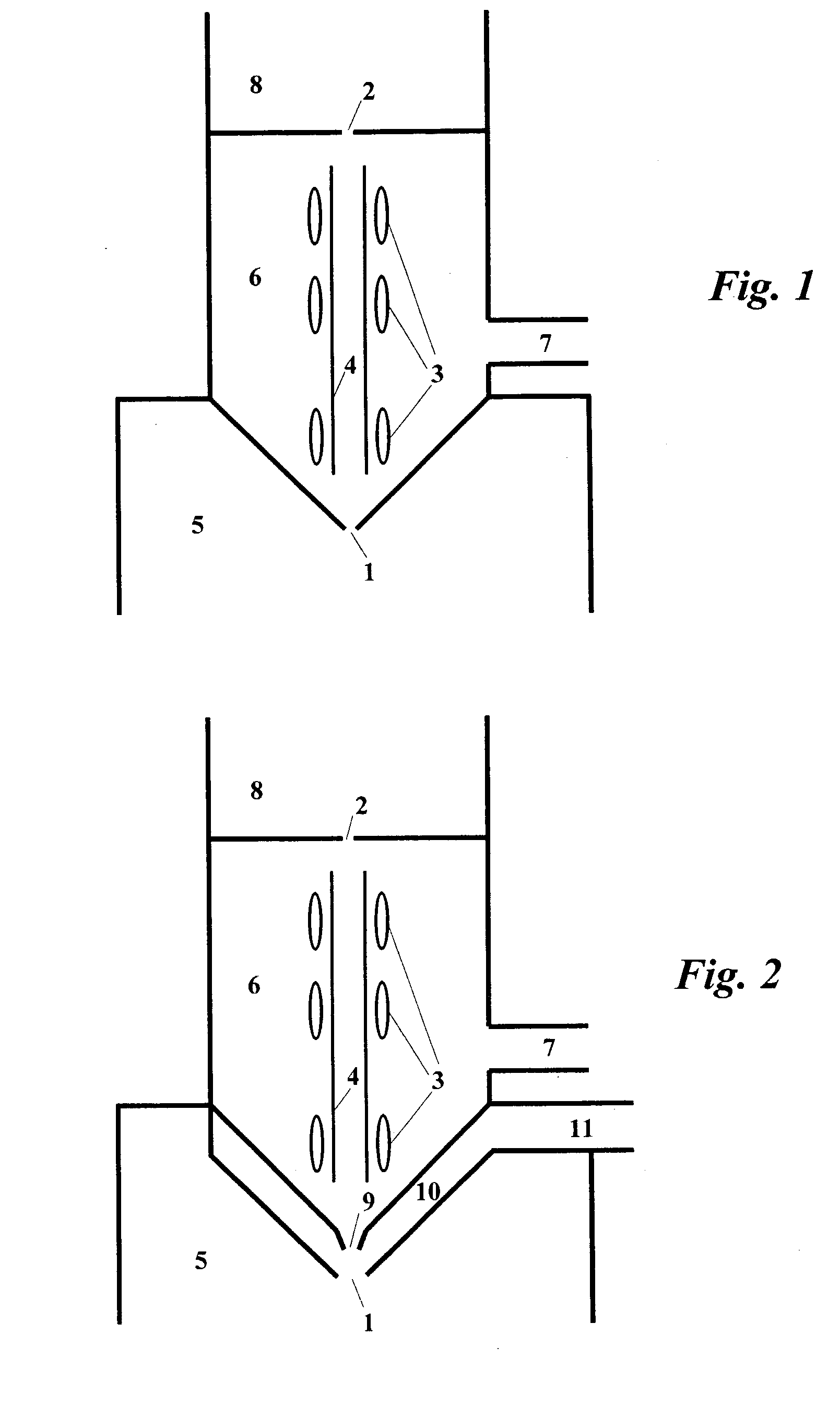

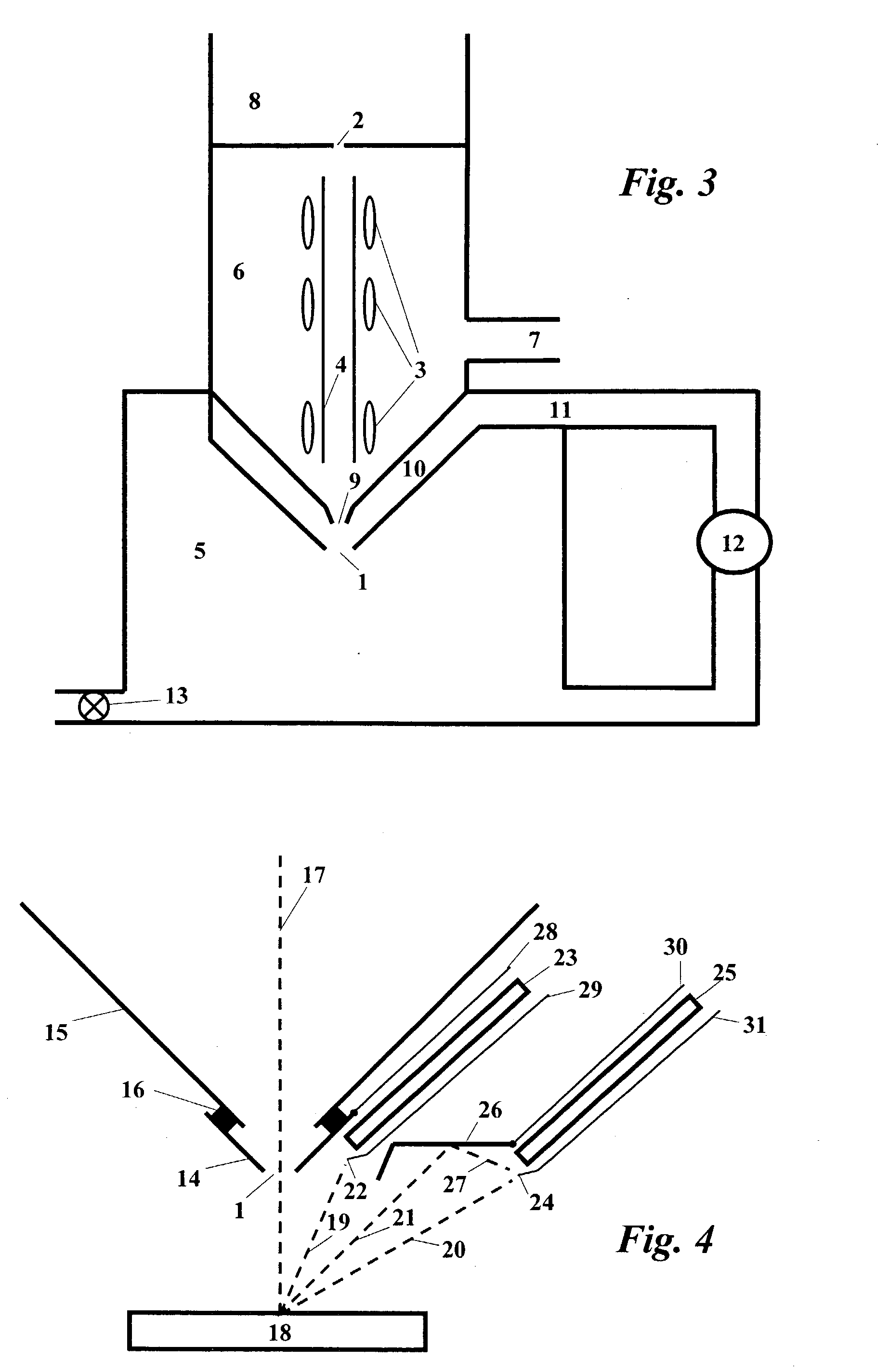

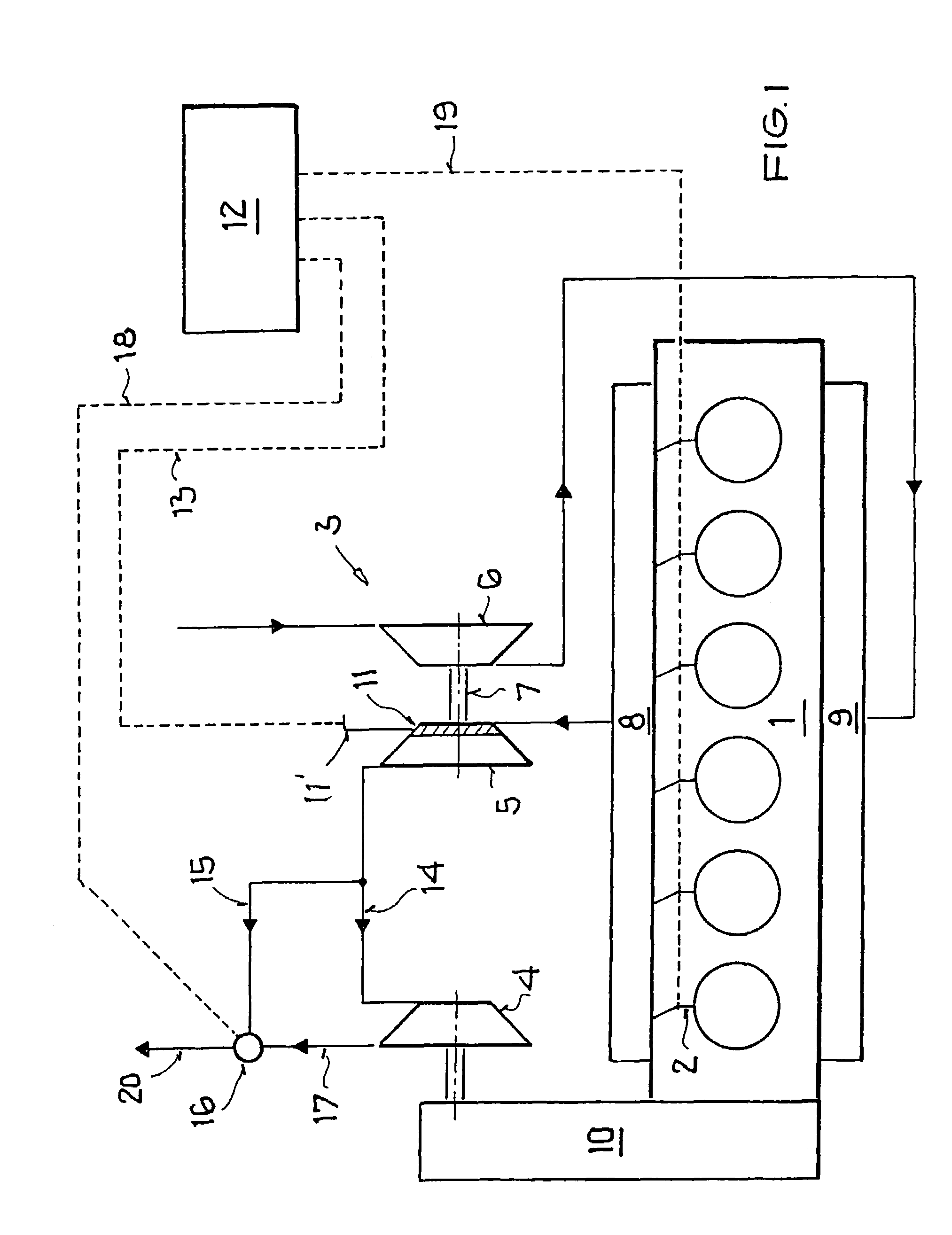

Environmental scanning electron microscope

InactiveUS20030168595A1Easy to detectExpand field of viewMaterial analysis using wave/particle radiationParticle separator tubesShock waveIon beam

The invention provides for a scanning electron or ion beam instrument capable of transferring the beam from a high vacuum chamber (8) into a high pressure chamber (5) via aperture (1) and aperture (2). The beam is deflected and scanned by coils (3) generally positioned between apertures (1) and (2). The amplitude of deflection of the beam over a specimen placed inside chamber (5) is substantially larger than the diameter of aperture (1). Leaking gas through aperture (1) is removed via port (7) by appropriate pumping apparatus. The size of aperture (1) is such that the pressure in chamber (6) combined with the supersonic jet and shock waves naturally forming therein do not result in catastrophic electron beam loss in chamber (6). The addition of appropriate detection means result in an instrument characterised by superior performance over prior art by way of better field of view at low magnification, better vacuum system and improved detection and imaging capabilities.

Owner:DANILATOS GERASIMOS DANIEL

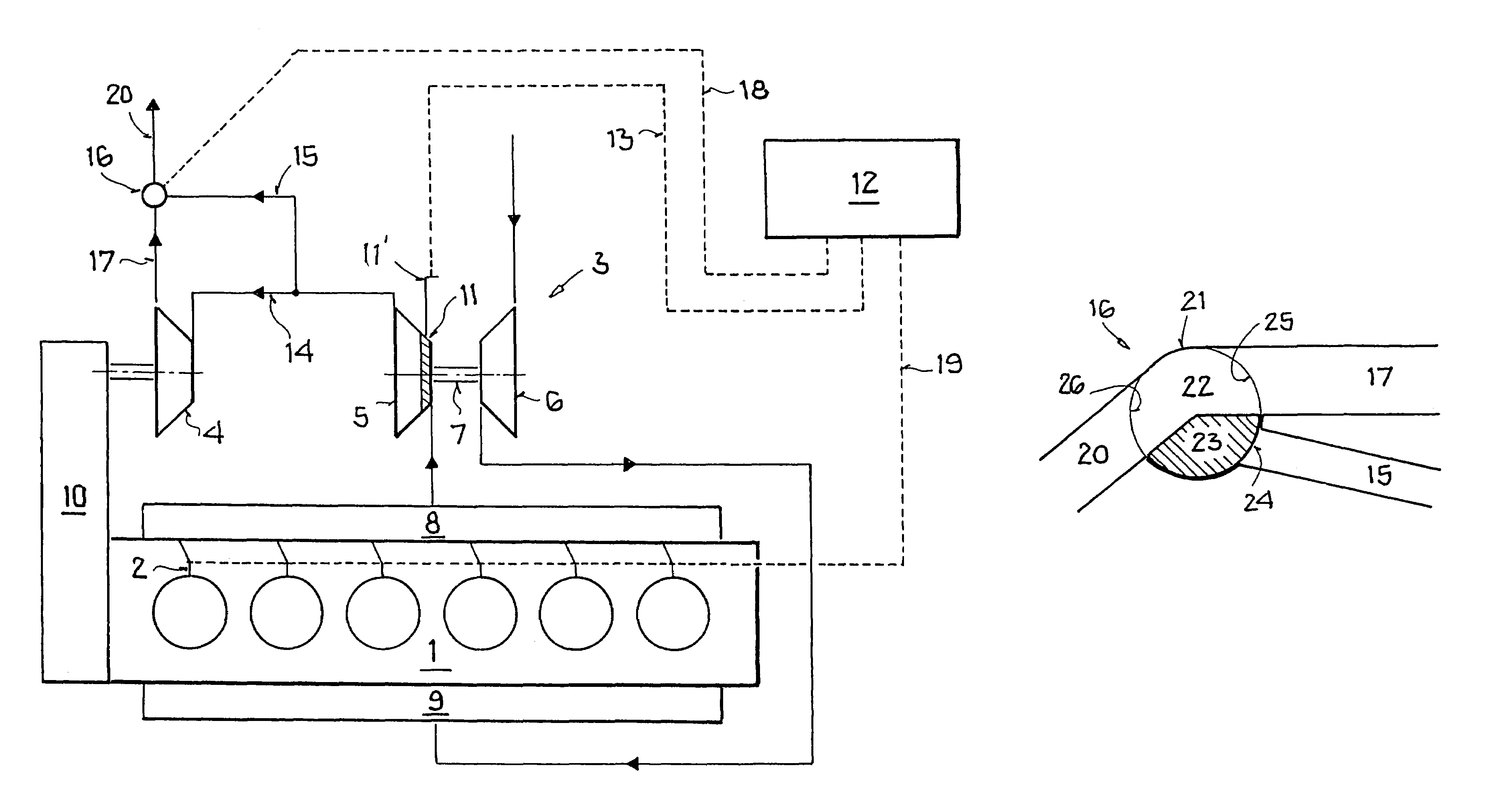

Internal combustion engine comprising an engine braking arrangement

InactiveUS7347048B2Avoid high forceEasy constructionInternal combustion piston enginesOutput powerExternal combustion engineTurbocharger

In an internal combustion engine comprising an engine braking arrangement including a constant throttle valve, an exhaust gas turbocharger with a variable turbine guide vane structure and a power turbine connected to an exhaust tract and a compressor connected to an intake tract of the internal combustion engine, the power turbine is disposed in the exhaust duct downstream of the exhaust gas turbine and is driven by the exhaust gas of the internal combustion engine and a bypass device is provided in a bypass pipe which extends around the power turbine and via which the exhaust pipe can be completely closed and the bypass pipe can be completely or partially closed so as to selectively partially or completely block the exhaust gas flow and the bypass flow to an exhaust gas discharge pipe.

Owner:DAIMLER AG

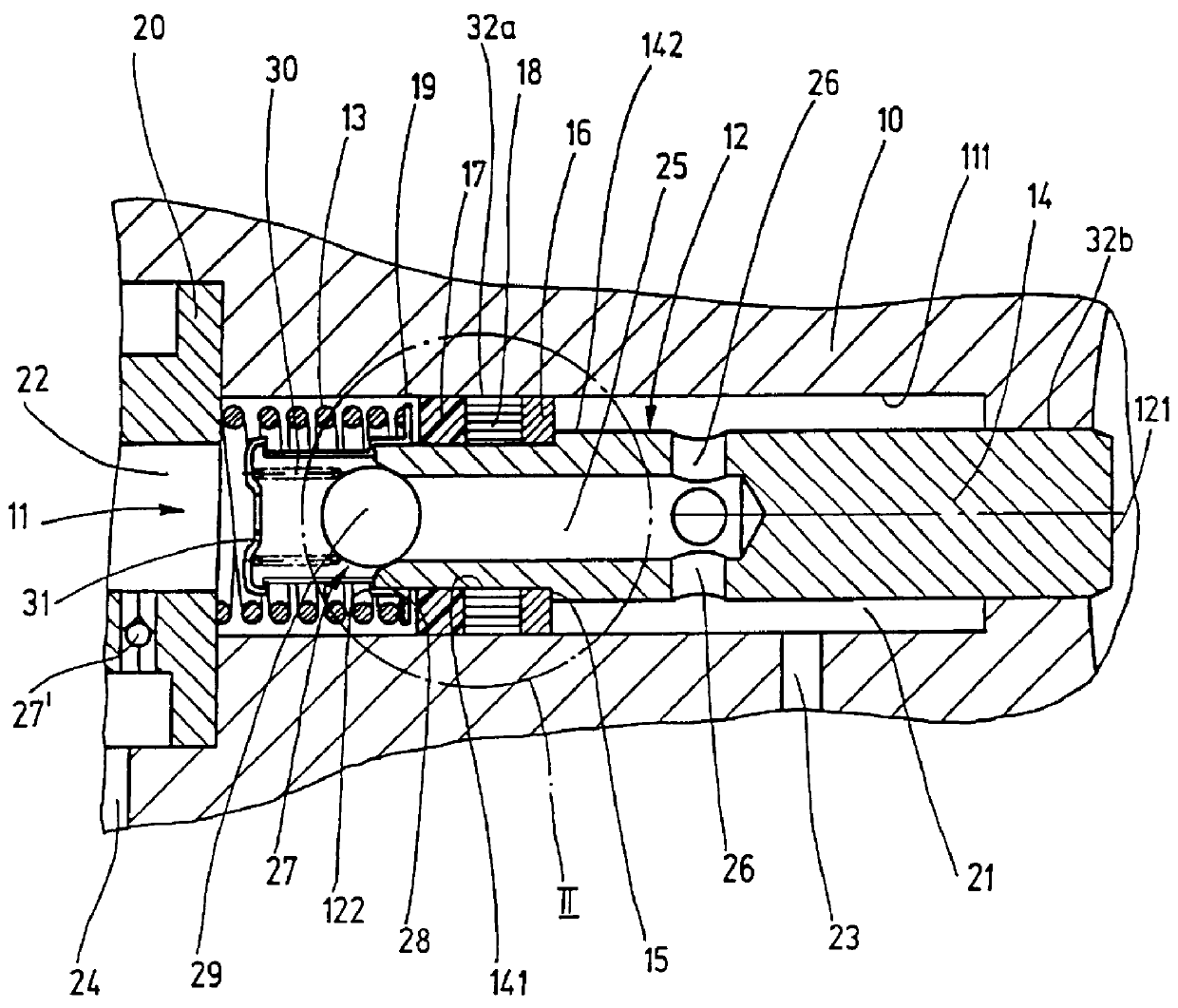

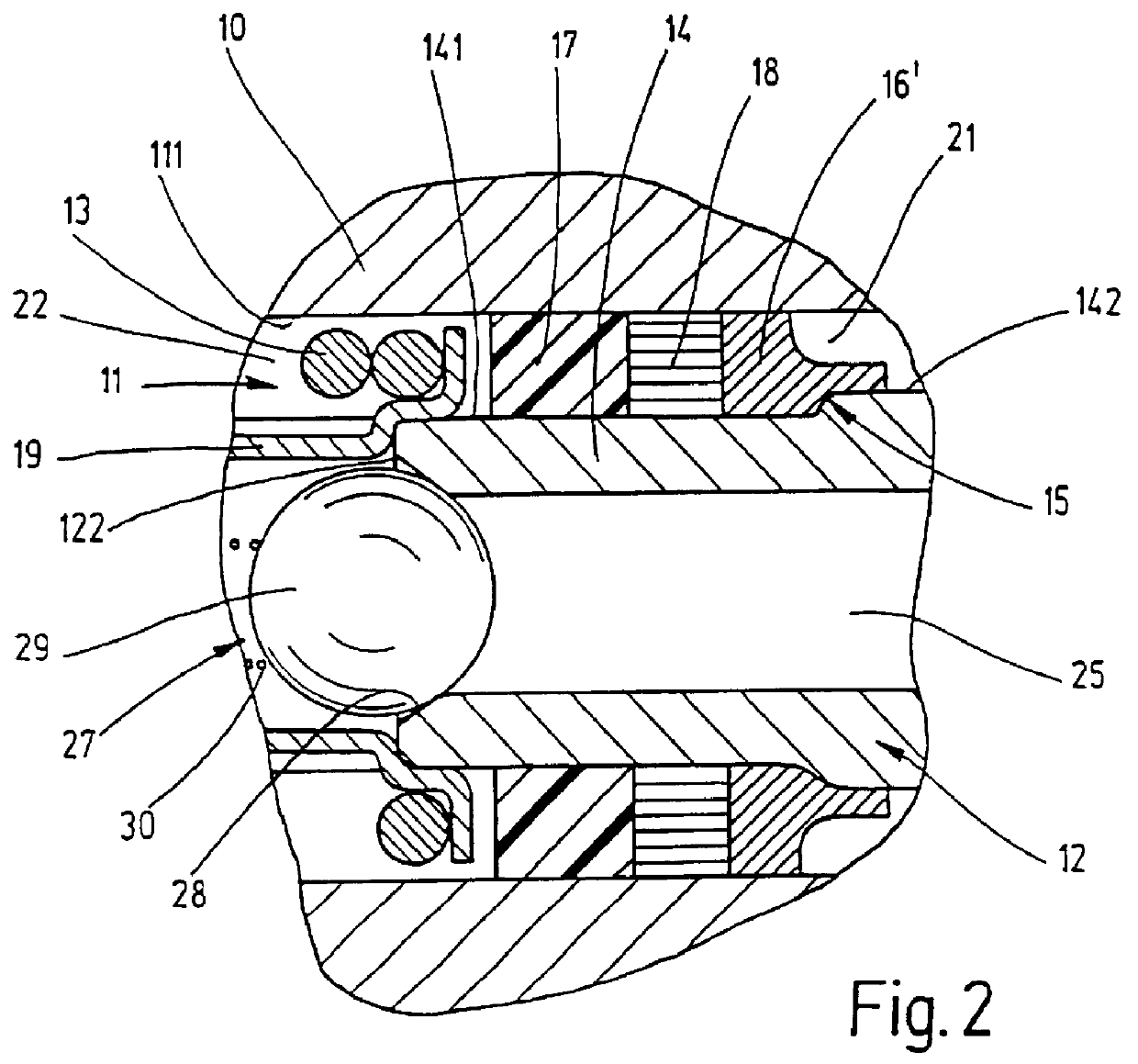

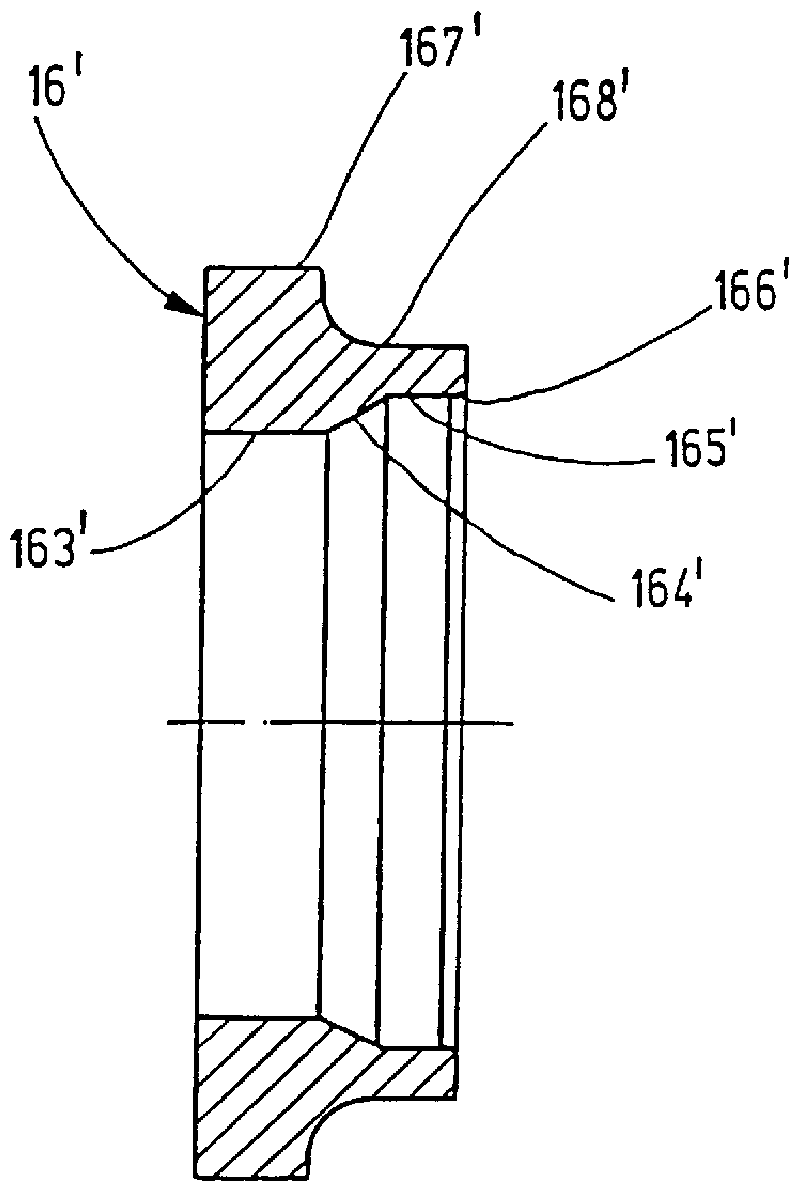

Piston pump

InactiveUS6109896AProduced economicallyCost advantagePositive displacement pump componentsPlungersElastomerPump chamber

PCT No. PCT / DE97 / 01101 Sec. 371 Date May 18, 1998 Sec. 102(e) Date May 18, 1998 PCT Filed Jun. 3, 1997 PCT Pub. No. WO98 / 12434 PCT Pub. Date Mar. 26, 1998A piston pump for pumping hydraulic fluid, especially for vehicle brake systems having a stepped piston axially displaceable in a pump space. The stepped piston in order to reduce the production costs comprises a cylinder of substantially constant outer diameter and a bush which is held axially nondisplaceably on the cylinder, by being press-fitted onto the cylinder. An elastomer seal is slipped onto a cylinder portion defined by the bush seals off the cylinder from the wall of the pump space and divides the pump space into two pump chambers of variable chamber volume.

Owner:ROBERT BOSCH GMBH

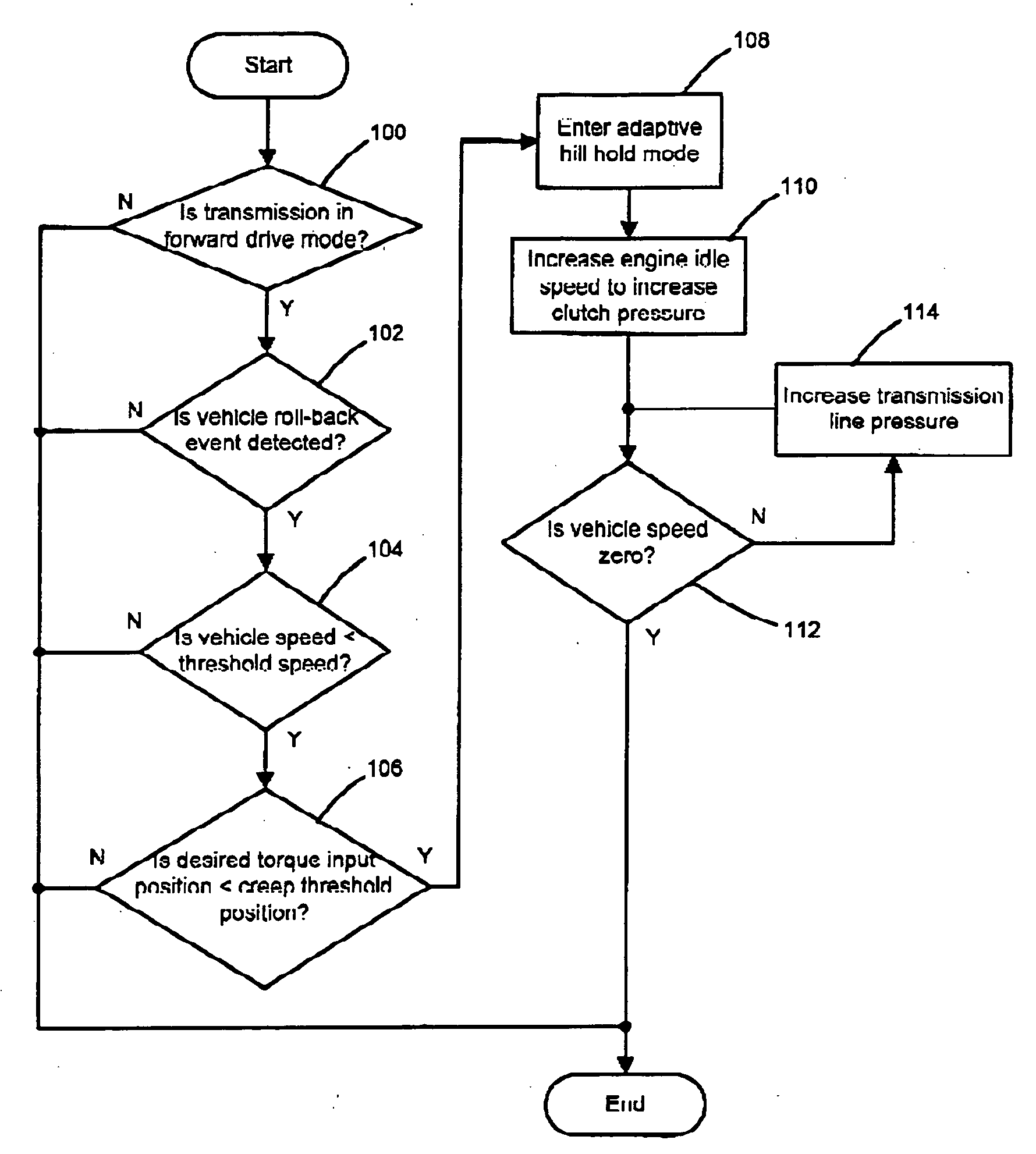

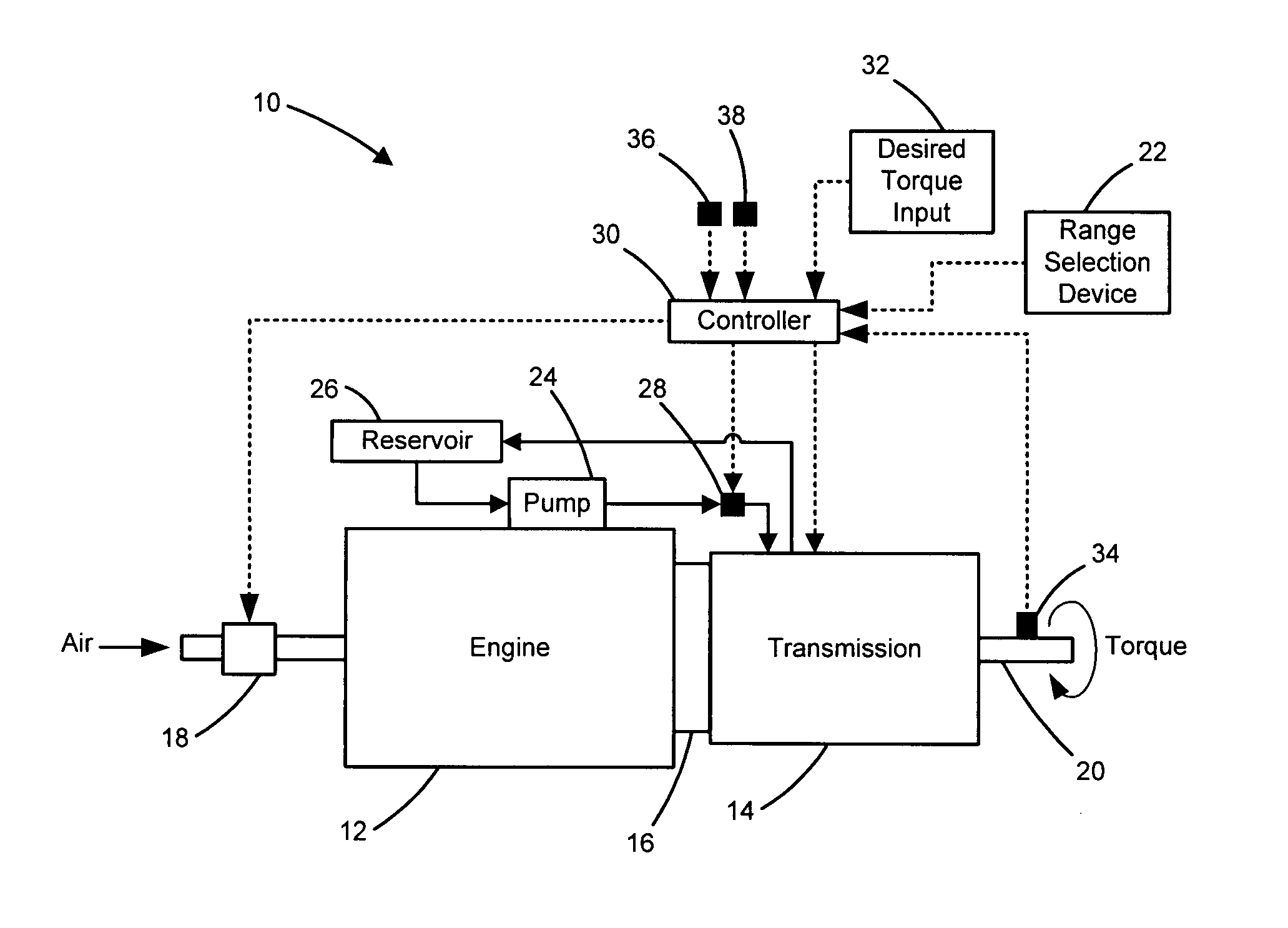

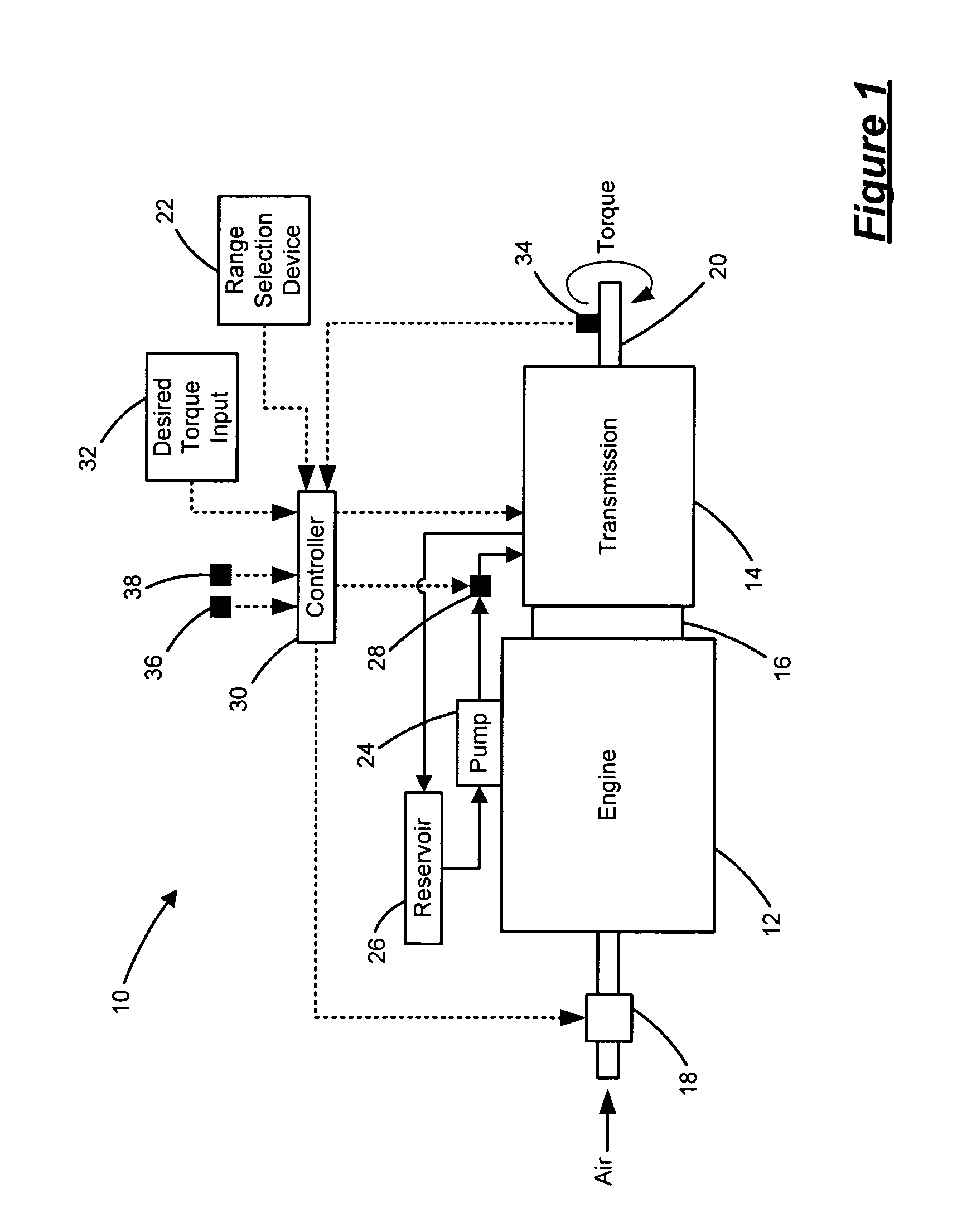

Adaptive hill hold for automobile applications by redundant clutch apply

InactiveUS20050075775A1Improve pumping capacityIncrease capacityDigital data processing detailsGearing controlSelf adaptiveDriving mode

A vehicle having an automatic transmission includes a roll-back detector that generates a roll-back signal indicating a vehicle roll-back event. A controller receives the roll-back signal and determines whether the automatic transmission is in a forward drive mode having first and second torque transfer elements engaged. The controller engages a third torque transfer element to prevent the vehicle roll-back event.

Owner:GM GLOBAL TECH OPERATIONS LLC

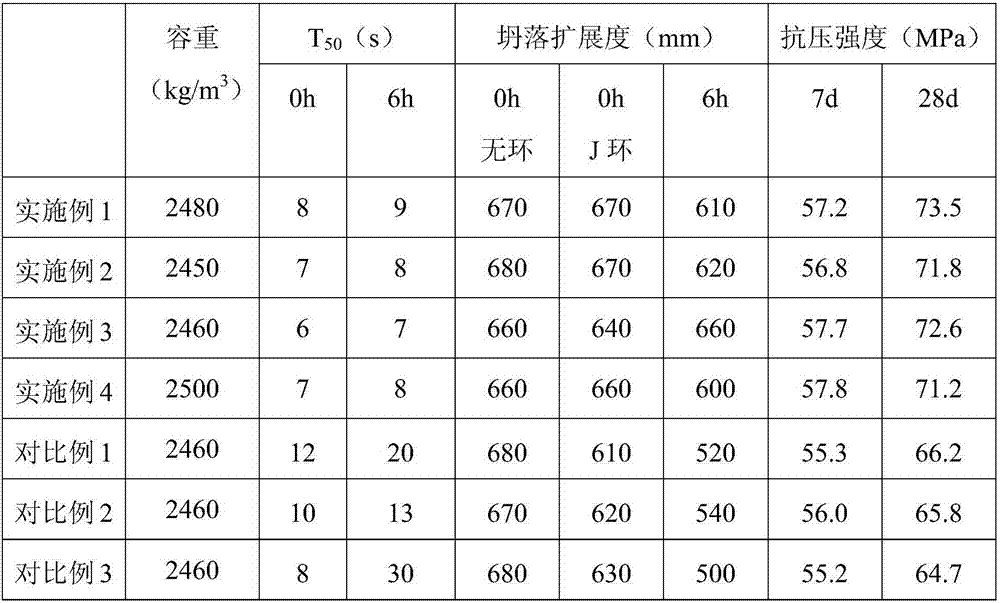

Self-compacting concrete

The invention discloses a self-compacting concrete and belongs to the technical field of concrete. The self-compacting concrete comprises the following components in parts by weight: 350-400 parts of cement, 54-80 parts of coal ash, 52-60 parts of slag powder, 50-62 parts of expanding agent, 9-13 parts of silica powder, 748-800 parts of mixed sand, 948-1020 parts of macadam, 140-165 parts of drinking water, 0-10 parts of compound additive and high-performance additive being 1-2% of the binding material in mass fraction. The concrete acquired according to the invention has excellent self-compacting property, fluidity, collapse prevention, cohesiveness and separation resistance, and meanwhile, a test proves that the compressive strength after 7 days is about 57MPa and the compressive strength after 28 days is about 70MPa, so that the concrete provided by the invention has higher compressive strength.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

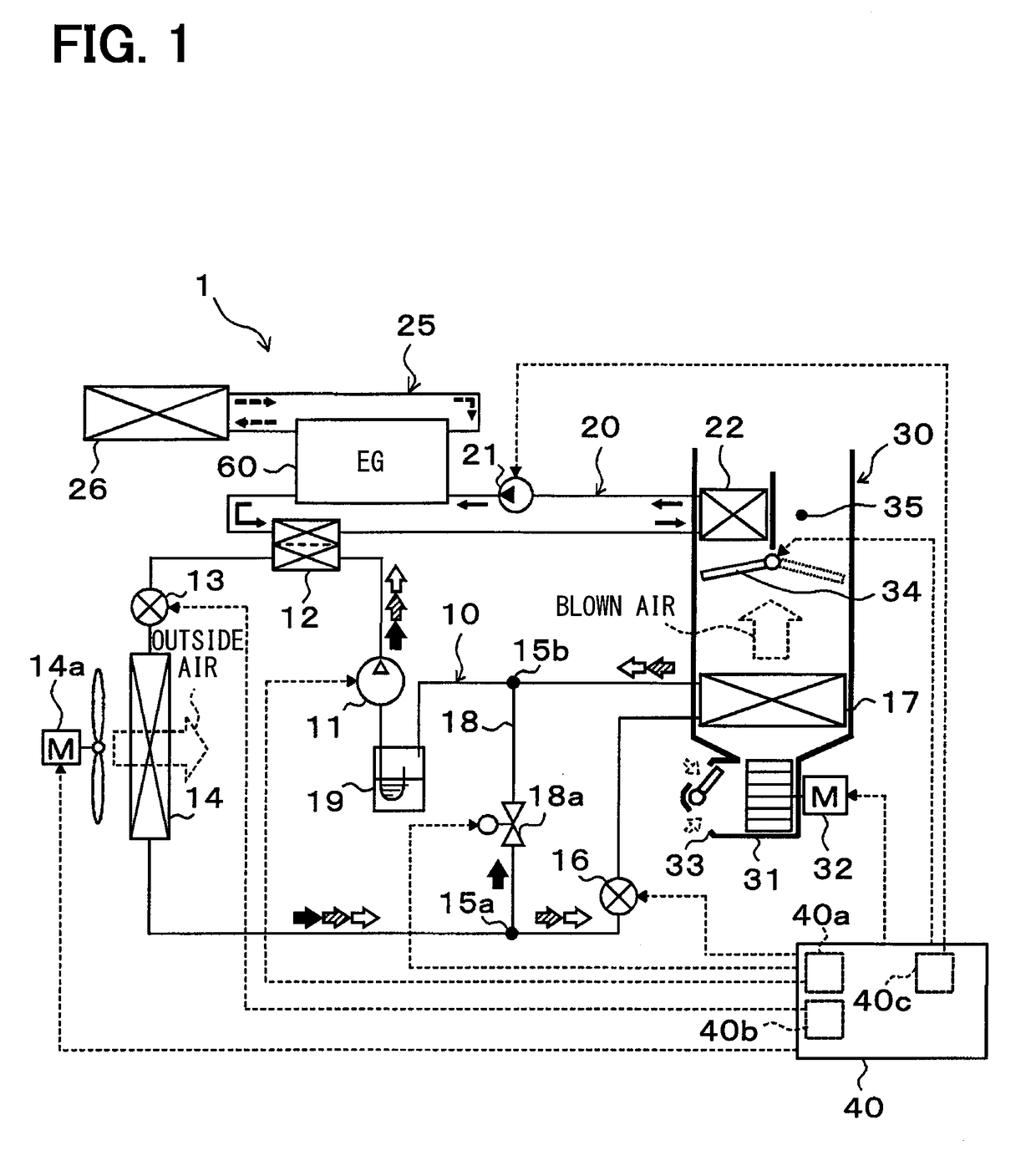

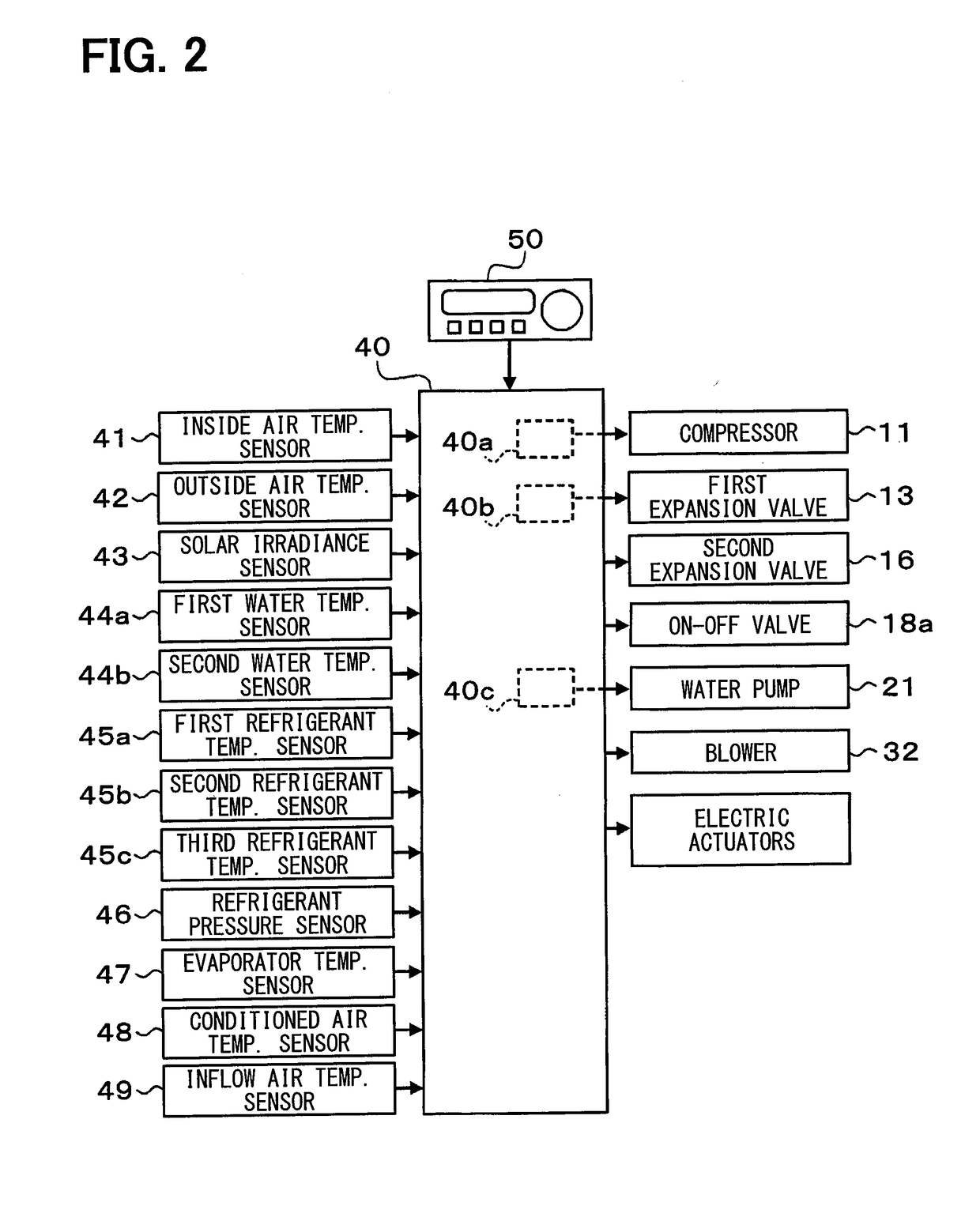

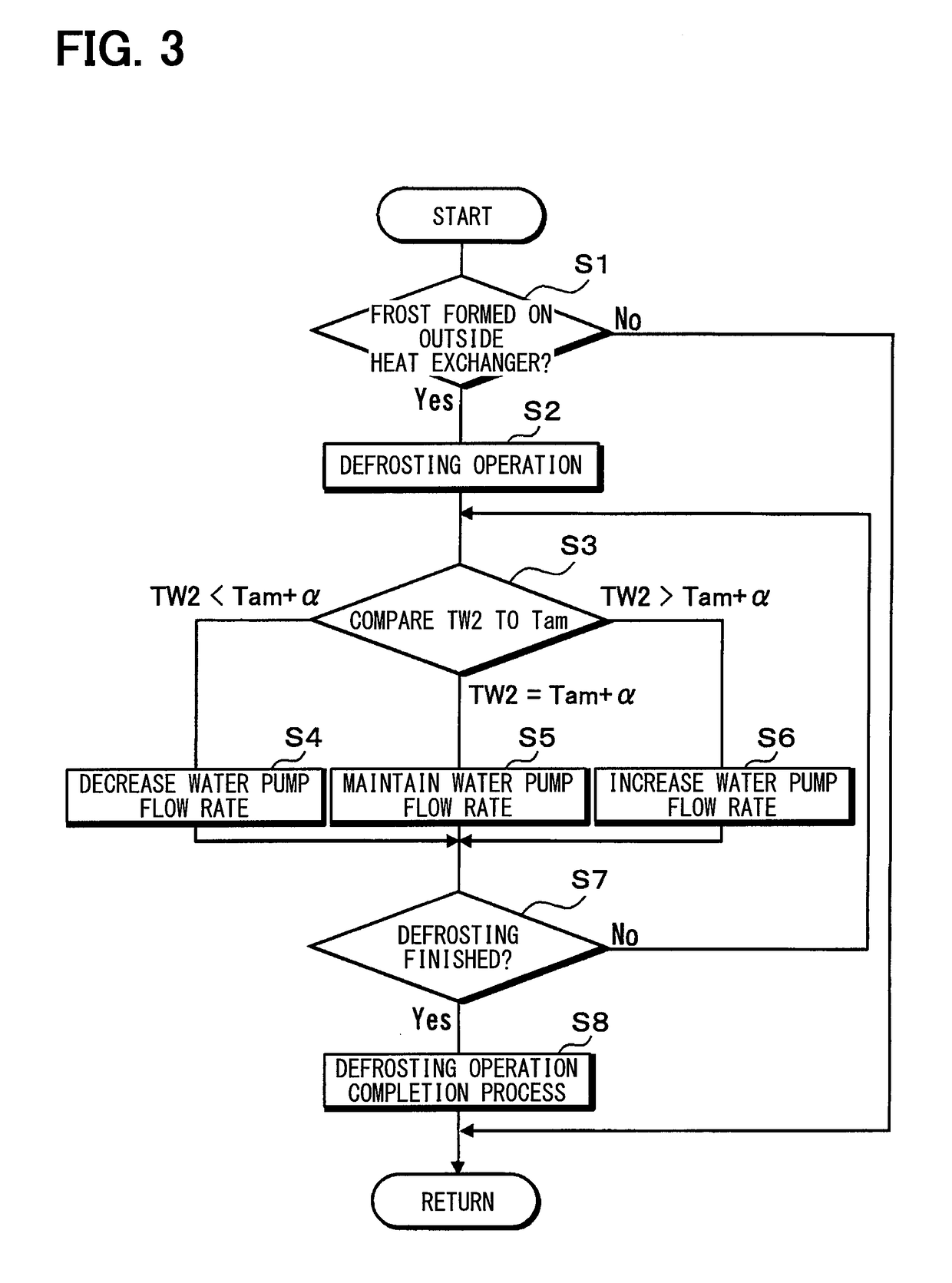

Heat pump system

ActiveUS20190030992A1High degree of opennessSuppress temperature decreaseAir-treating devicesMechanical apparatusFrostEngineering

A heat pump system includes a heat pump cycle, a heat medium circulation circuit, and a refrigeration cycle device. The refrigeration cycle device is configured to perform a defrosting operation when a frost formation determiner determines that frost is formed. A throttle opening degree controller is configured to increase an opening degree in the defrosting operation. A pumping capacity controller is configured to increase a pumping capacity in the defrosting operation with increase of a required heating capacity required for heating a heating target fluid, the pumping capacity controller increasing the pumping capacity such that heat of refrigerant discharged from a compressor is transferred to heat medium in a first heat exchanger within a range in which a temperature of the refrigerant flowing into an outside heat exchanger is capable of melting the frost formed on the outside heat exchanger.

Owner:DENSO CORP

Vacuum die casting mould

The invention relates to a vacuum die casting mould, which comprises a movable mould area and a static mould area. The movable mould area comprises a movable mould frame, a movable lining mould, a press plate and a top cover with a top rod. The static mould area comprises a static mould frame, a static lining mould and a press chamber. An air discharge valve is arranged at the top of the movable lining mould and the static lining mould and communicated with an external vacuum machine through air discharge pipelines. A gap is respectively retained between the movable mould frame and the air discharge valve and between the movable mould frame and the movable lining mould, and two rows of air cavities are formed through sealing elements and are communicated with the external vacuum machine through the air discharge pipelines. A sealing element is arranged on the inner side of a top rod hole of each top rod contacted with the press plate. Sealing elements are arranged between the static lining mould and the static mould frame and the outer circle of the material outlet end of the press chamber. A sealing element is respectively arranged between the top of the movable lining area and the bottom of the air discharge valve and between the top of the static lining mould and the bottom of the air discharge valve. A sealing element is arranged at the mould assembly position of the movable mould area and the static mould area. The vacuum die casting mould is capable of being used for die casting process production in high vacuum, and vacuum pressure of a cast piece cavity can be reduced to below 5kPa to achieve high vacuum level.

Owner:TSINGHUA UNIV

Concrete nano water-reducing super high-early-strength agent

The invention discloses a concrete nano water-reducing super high-early-strength agent which is capable of remarkably increasing early and late strength of concrete and shortening construction period and simultaneously has good water-reducing performance, plastic retaining performance, corrosion inhibiting performance and stability. The agent comprises the following ingredients: 46-52 wt% of early strength components, 26-32 wt% of water reducing components, 6-15 wt% of corrosion inhibiting components, 4-5 wt% of retarding components, and 6-8 wt% of adjustment components, wherein the early strength components comprise three or four selected from magnesium sulfate, sodium sulfate, sodium nitrite, triethanolamine, sodium thiosulfate, triisopropanolamine, and calcium formate, the water reducing components comprise one selected from naphthalene sulfonic acid high-efficiency water reducer and carboxylic acid water reducer, the corrosion inhibiting components comprise one selected from calcium nitrite, calcium nitrate, potassium chromate, and stannous chloride, the retarding components comprise one selected from sodium gluconate and citric acid, and the adjustment components comprise nano ground calcium carbonate.

Owner:DALIAN KEYKOWN TECH CO LTD +1

Overbased alkaline earth metal alkylhydroxybenzoates having low crude sediment

ActiveUS8030258B2Decrease in levelLow production costOrganic chemistryOrganic compound preparationAlkaline earth metalAliphatic hydrocarbon

A process for preparing an overbased alkaline earth metal alkylhydroxybenzoate, said process comprising overbasing an alkaline earth metal alkylhydroxybenzoate or a mixture of alkaline earth metal alkylhydroxybenzoate and up to 50 mole % of alkylphenol, based on the total mixture of alkylhydroxybenzoate and alkylphenol, with a molar excess of alkaline earth metal base and at least one acidic overbasing material in the presence of at least one carboxylic acid having from one to four carbon atoms and a solvent selected from the group consisting of aromatic hydrocarbons, aliphatic hydrocarbons, monoalcohols, and mixtures thereof.

Owner:CHEVRON ORONITE SA

Piston pump

InactiveUS20050063846A1Low costReduce manufacturing costPositive displacement pump componentsPump controlEngineeringPiston pump

A piston pump includes a piston for increasing and decreasing the volume of a pump chamber formed in a cylinder bore of a cylinder member, by means of axially reciprocating movement thereof; a suction valve provided in the piston, and opening and closing when the volume of the pump chamber increases and decreases, respectively; and a discharge valve provided at a discharge side of the pump chamber, and opening and closing when the volume of the pump chamber decreases and increases, respectively. A plurality of mutually communicating, axially extending grooves are formed on an outer circumferential portion of the piston located on the pump-chamber side. A cylindrical seat member is fixedly and externally fitted to the piston in a region of the communicating grooves. A valve port and a valve seat of the suction valve are formed at an end portion of the seat member located on the pump-chamber side.

Owner:ADVICS CO LTD

Overbased alkali metal alkylhydroxybenzoates having low crude sediment

InactiveUS20070027044A1Effective lubricationDecrease in levelOrganic chemistryOrganic compound preparationAlkaline earth metalAlkylphenol

A process for preparing an overbased alkali metal alkylhydroxybenzoate, said process comprising overbasing an alkali metal alkylhydroxybenzoate or a mixture of alkali metal alkylhydroxybenzoate and up to 50 mole % of alkylphenol, based on the total mixture of alkylhydroxybenzoate and alkylphenol, with a molar excess of alkaline earth metal base and at least one acidic overbasing material in the presence of at least one carboxylic acid having from one to four carbon atoms and a solvent selected from the group consisting of aromatic hydrocarbons, aliphatic hydrocarbons, monoalcohols and mixtures thereof.

Owner:CHEVRON ORONITE SA

Adaptive hill hold for automobile applications by redundant clutch apply

InactiveUS7136735B2Improve pumping capacityIncrease capacityDigital data processing detailsGearing controlAutomatic transmissionEngineering

A vehicle having an automatic transmission includes a roll-back detector that generates a roll-back signal indicating a vehicle roll-back event. A controller receives the roll-back signal and determines whether the automatic transmission is in a forward drive mode having first and second torque transfer elements engaged. The controller engages a third torque transfer element to prevent the vehicle roll-back event.

Owner:GM GLOBAL TECH OPERATIONS LLC

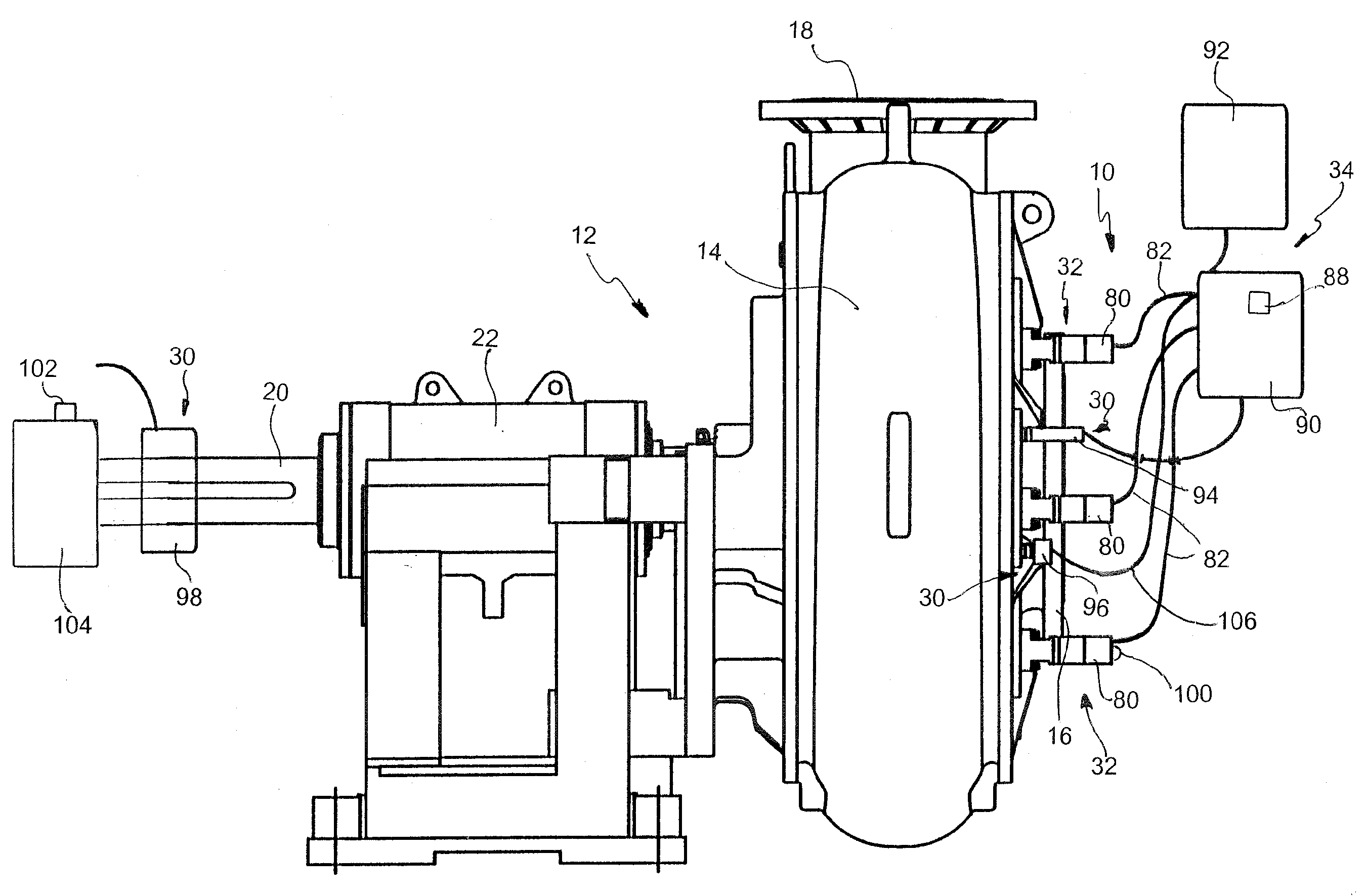

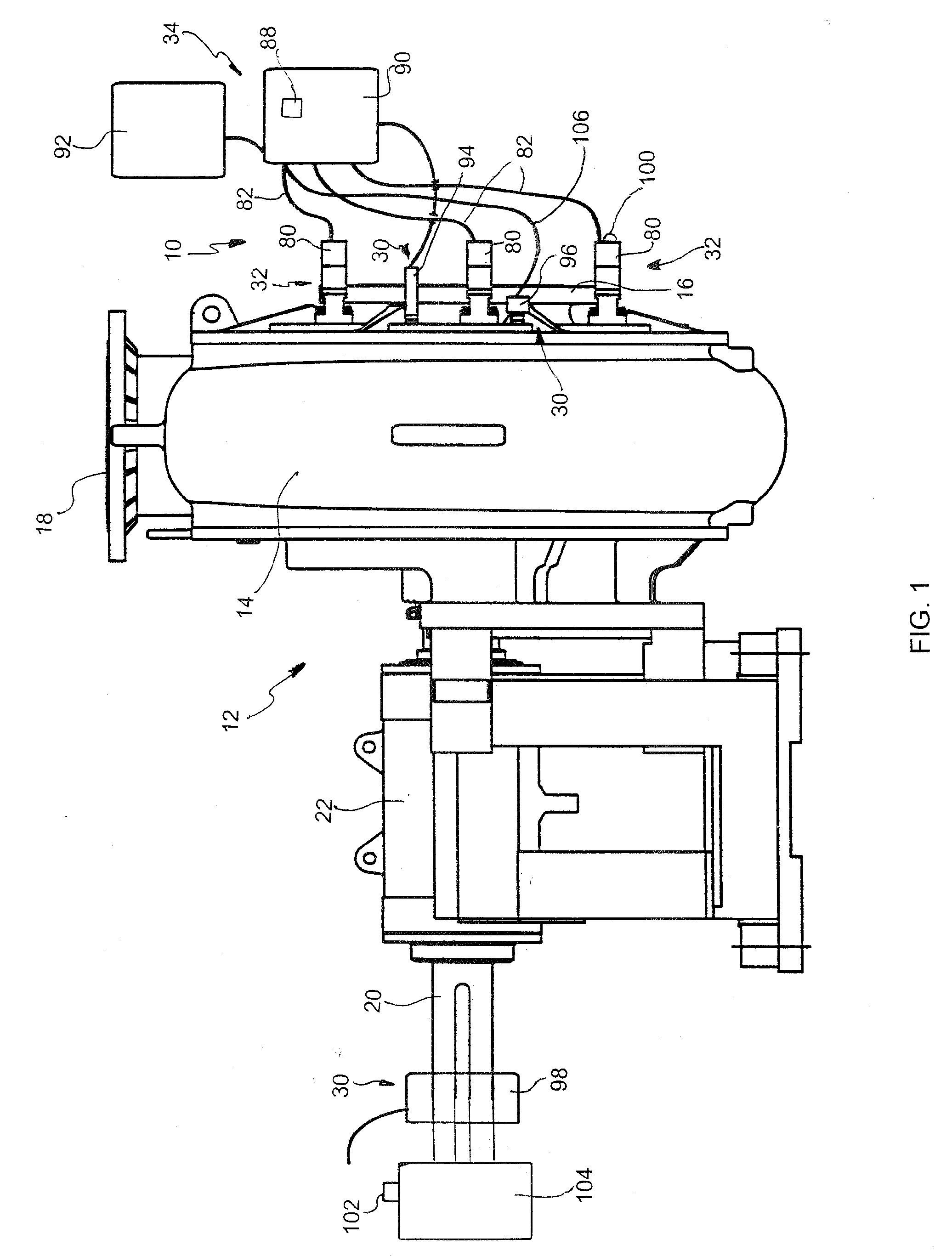

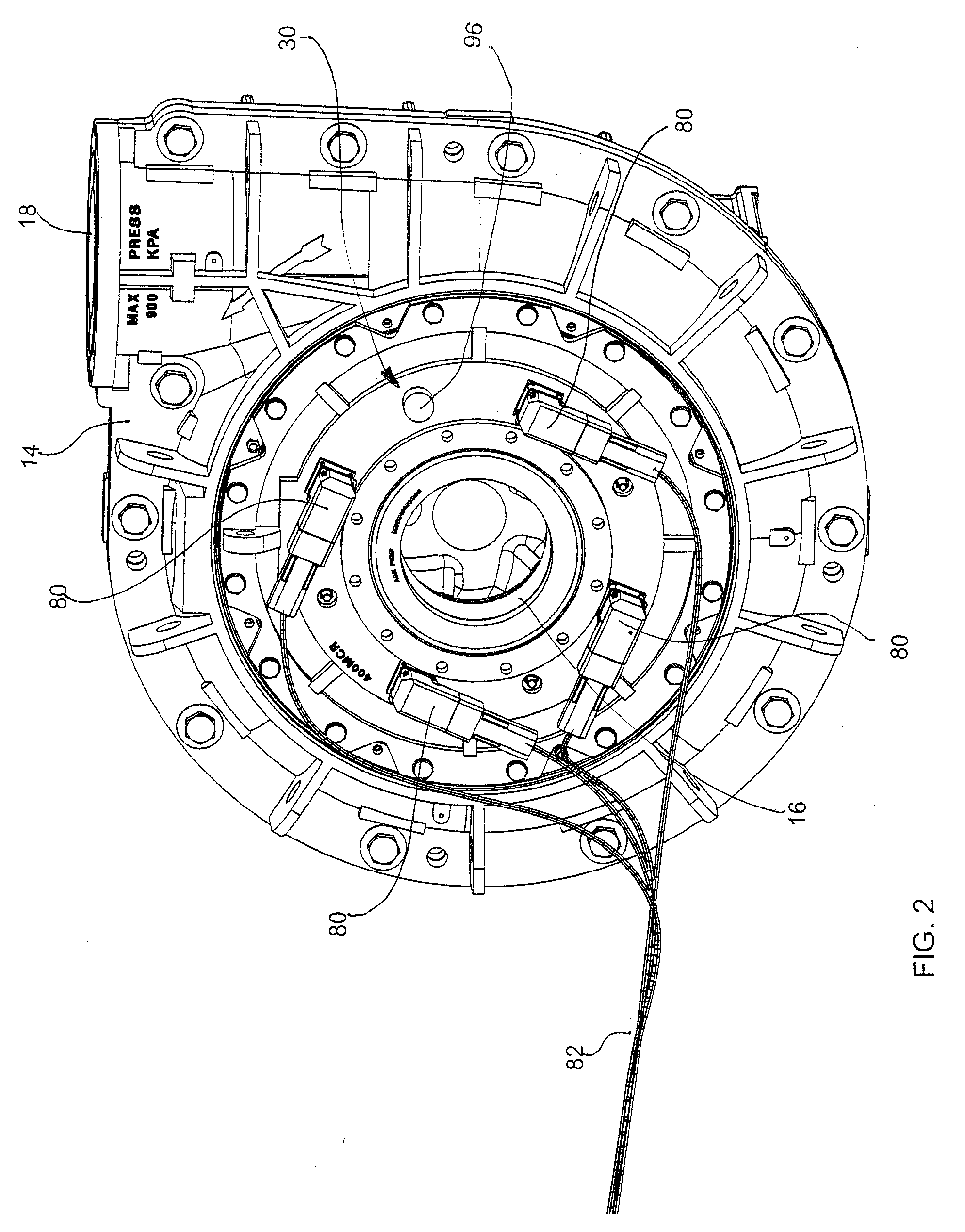

Self-monitoring system for evaluating and controlling adjustment requirements of leakage restricting devices in rotodynamic pumps

ActiveUS20090180866A1Reduce wearImprove pumping capacityPump componentsBlade accessoriesMonitoring systemRotodynamic pump

A self-monitoring adjustment system is provided for evaluating and effecting adjustment of the leakage restricting mechanism between the rotating and non-rotating elements of a rotodynamic pump to restrict leakage and to establish desired gap dimensions between the rotating and non-rotating elements of the pump. The adjustment system is structured to be self-monitoring for determination of when an adjustment of the leakage restricting mechanism is warranted by the conditions of the pump, and is structured with adjusting mechanisms that are self-adjusting responsive to the monitored conditions of the pump, though manual adjustment is also enabled.

Owner:WEIR SLURRY GRP INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com