Patents

Literature

44 results about "Foreline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A foreline is a vacuum line between the pumps of a multistage vacuum system. A pump which takes gas out of a foreline is known as a backing pump. A classic example of a foreline is the hose or tube that connects a rotary vane pump to the outlet of an oil diffusion pump. The rotary vane pump functions as a backing pump. Many other examples exist, since vacuum technology now uses a vast array of roughing pumps and high vacuum pumps. No longer exclusively used by scientists in research, vacuum systems are used in numerous industries that include food production and the manufacturing of electronic components.

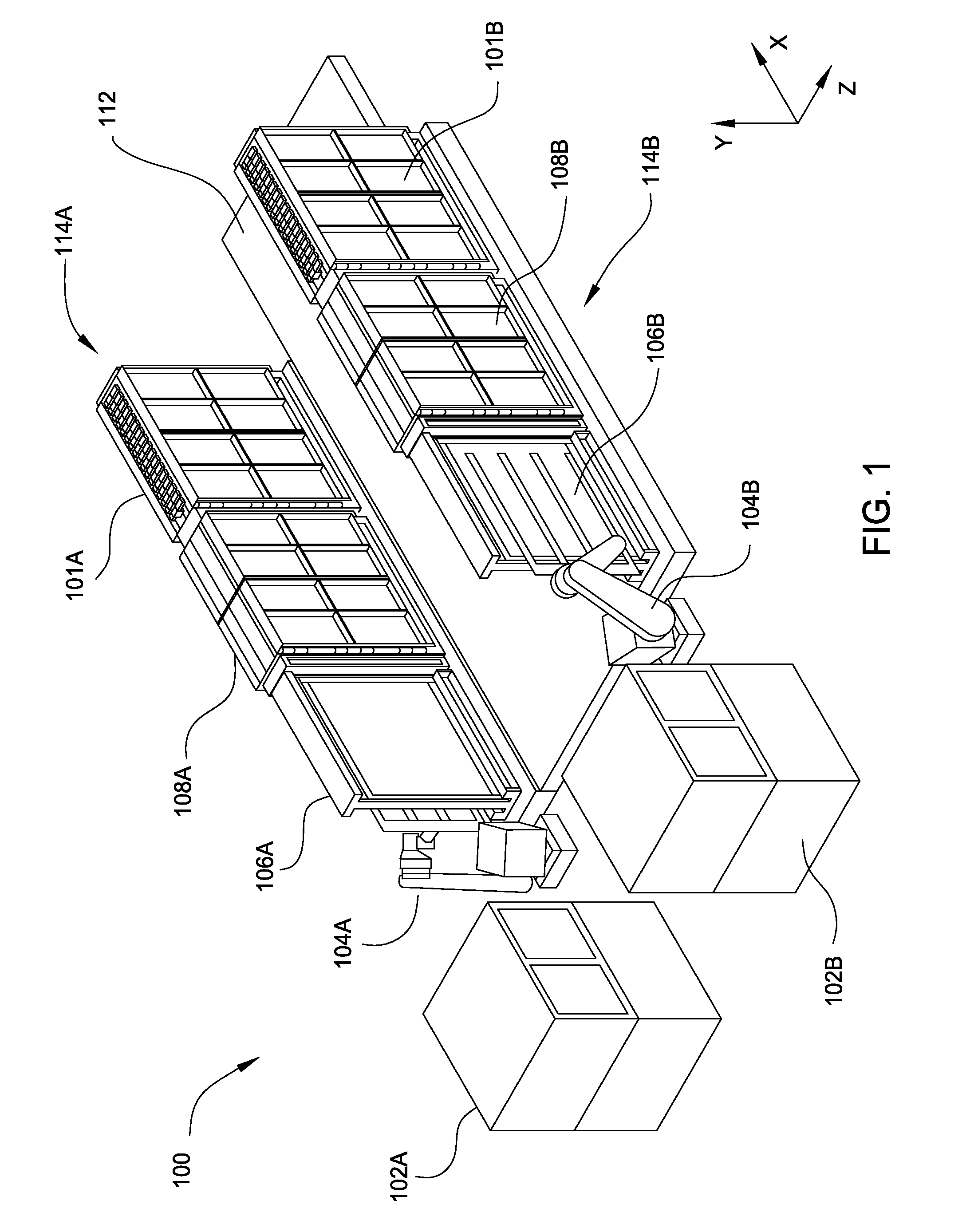

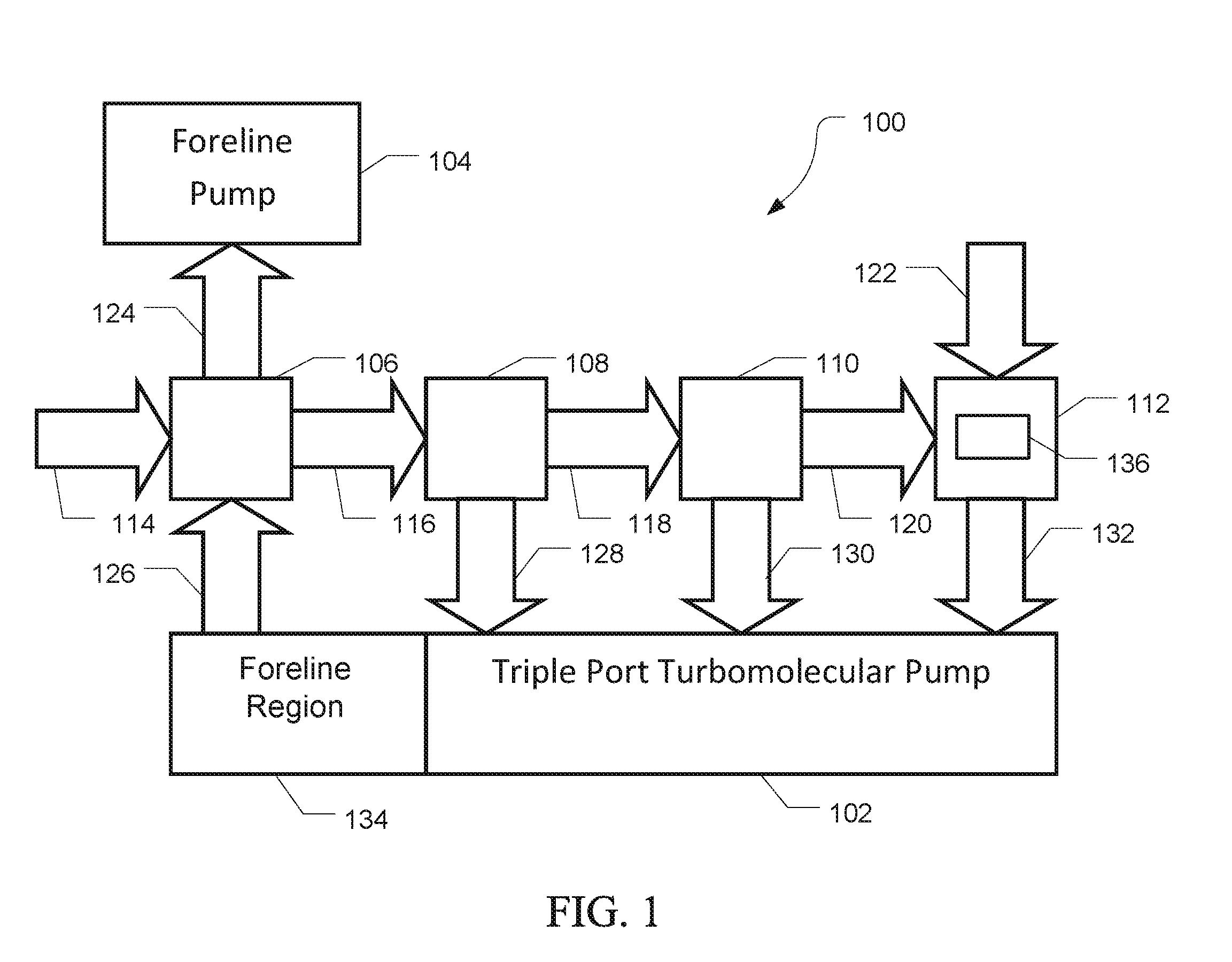

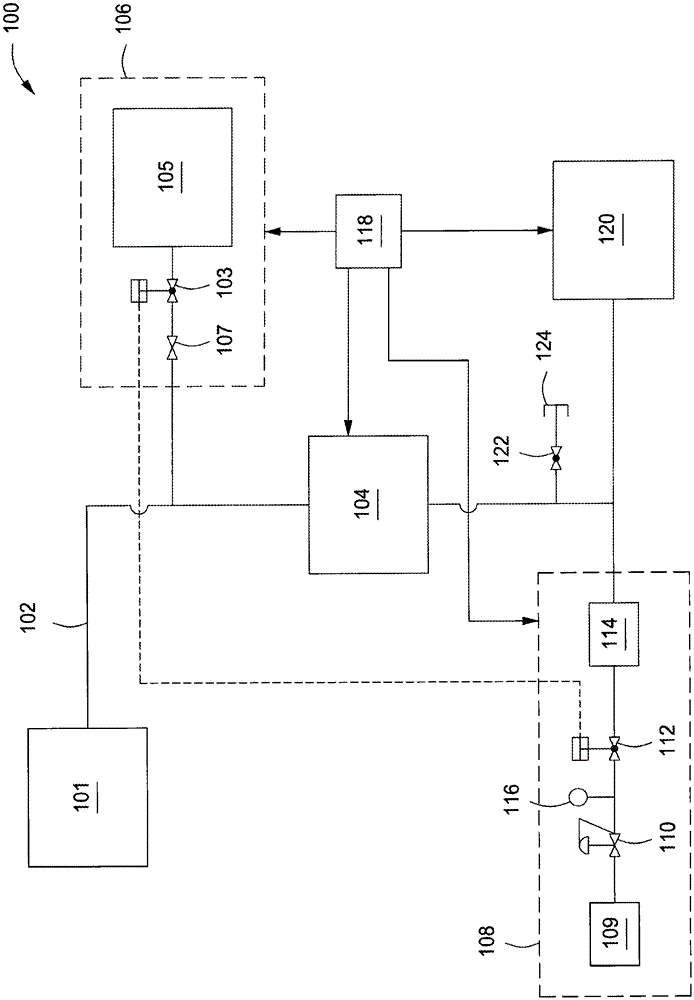

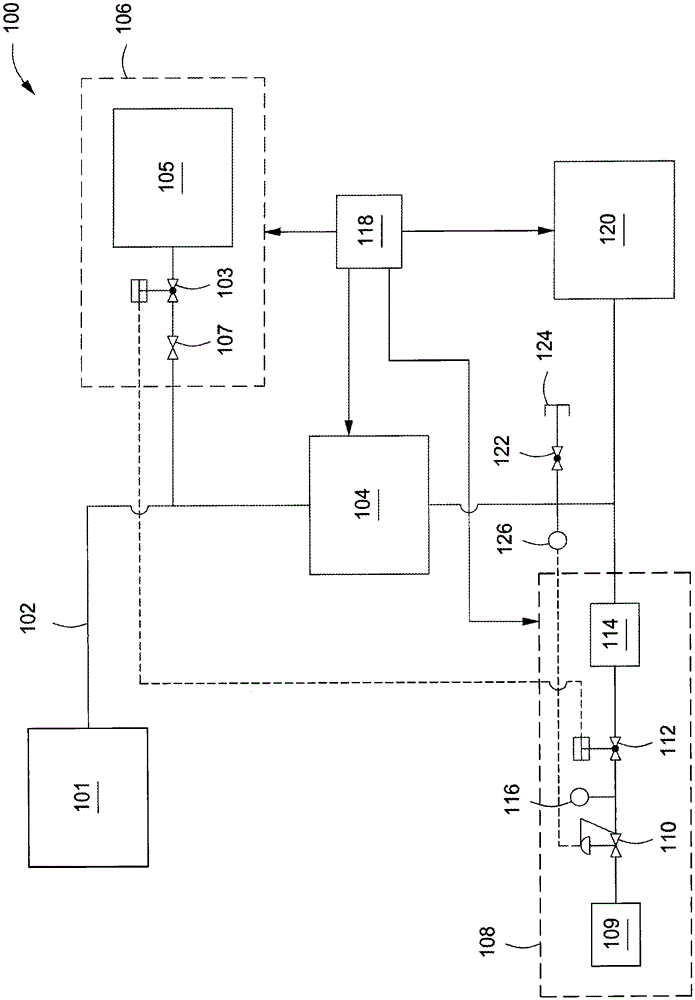

Multi-port pumping system for substrate processing chambers

InactiveUS20090120464A1Improve pumping capacityImprove rendering capabilitiesFrozen sweetsSemiconductor/solid-state device manufacturingEngineeringMulti port

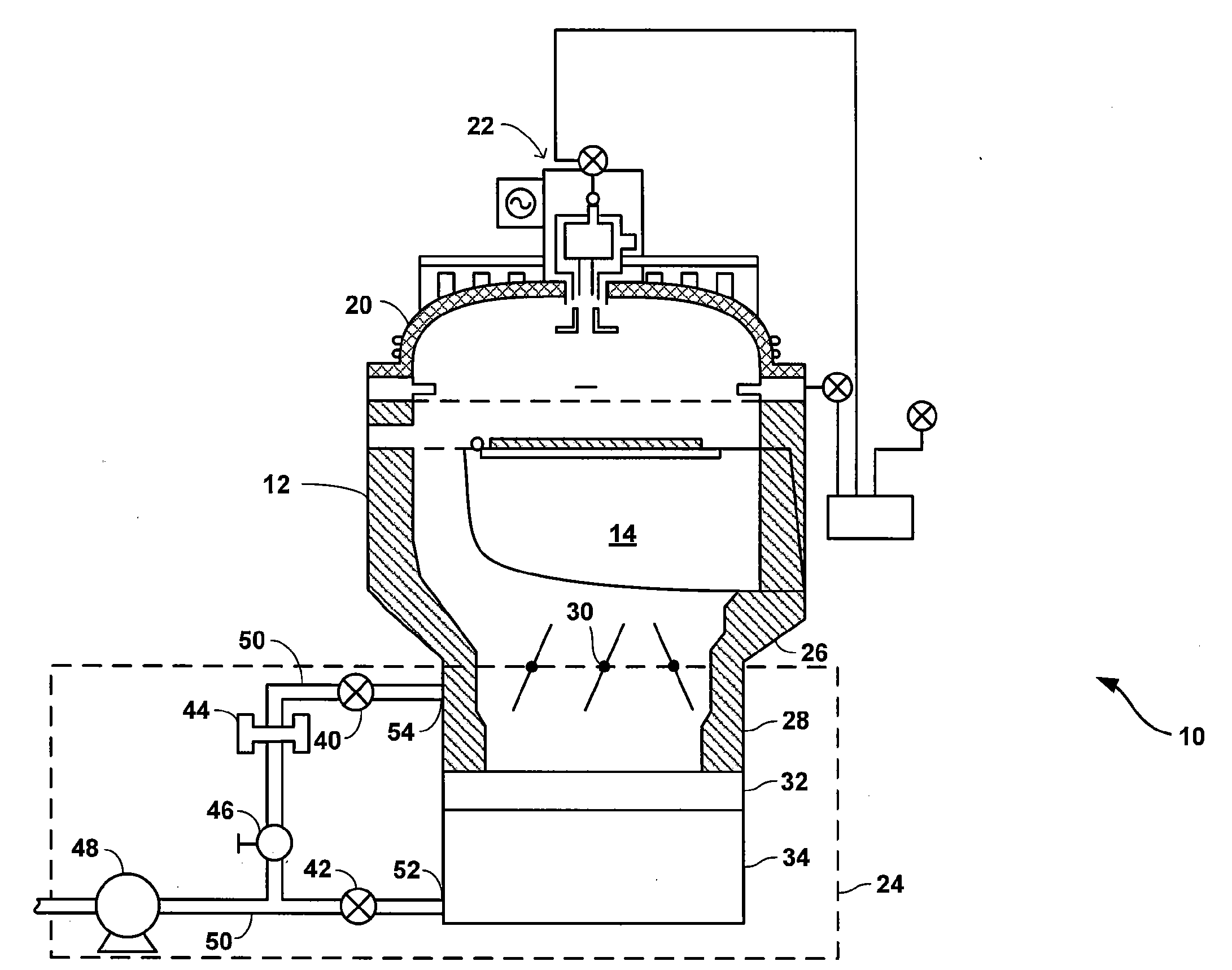

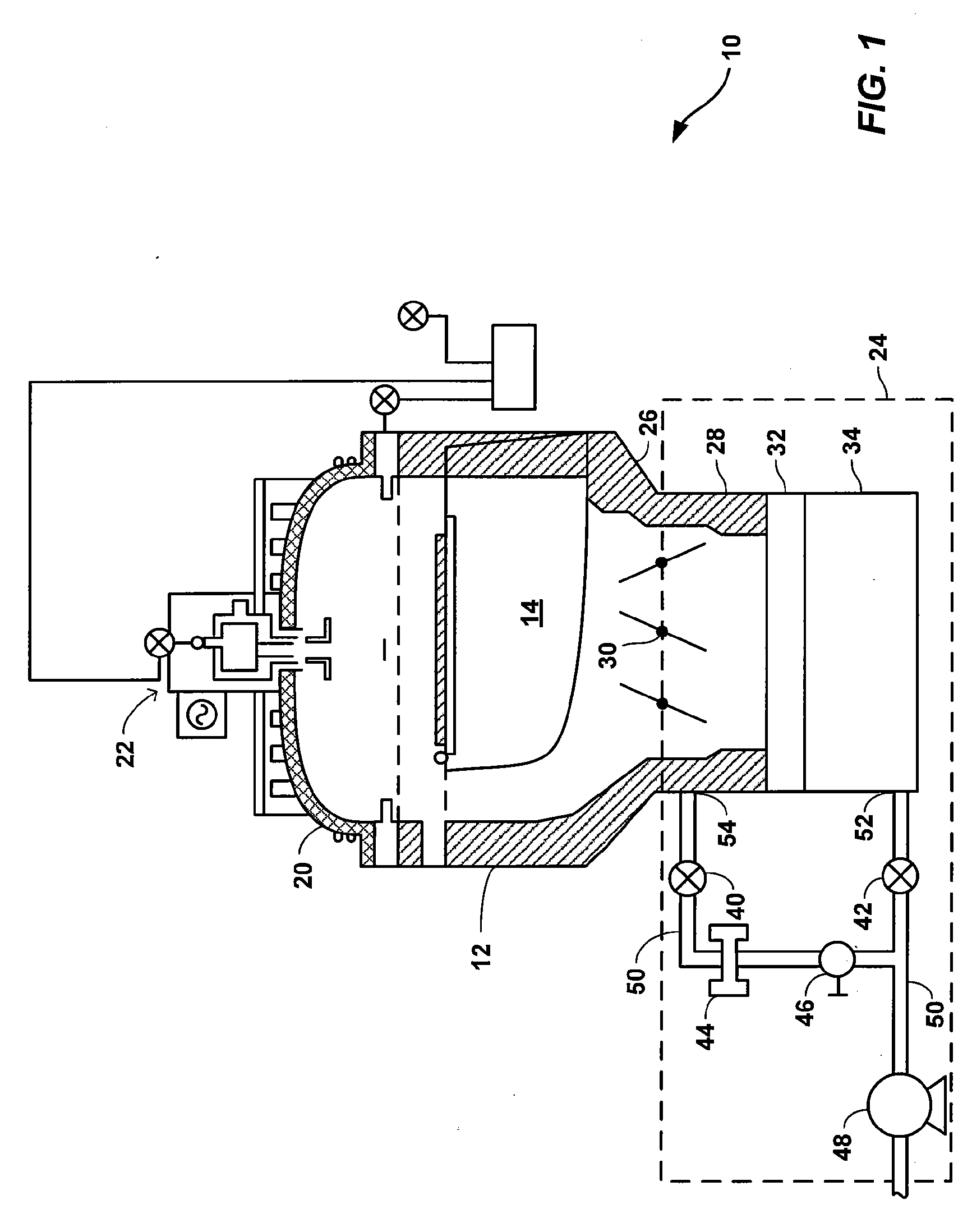

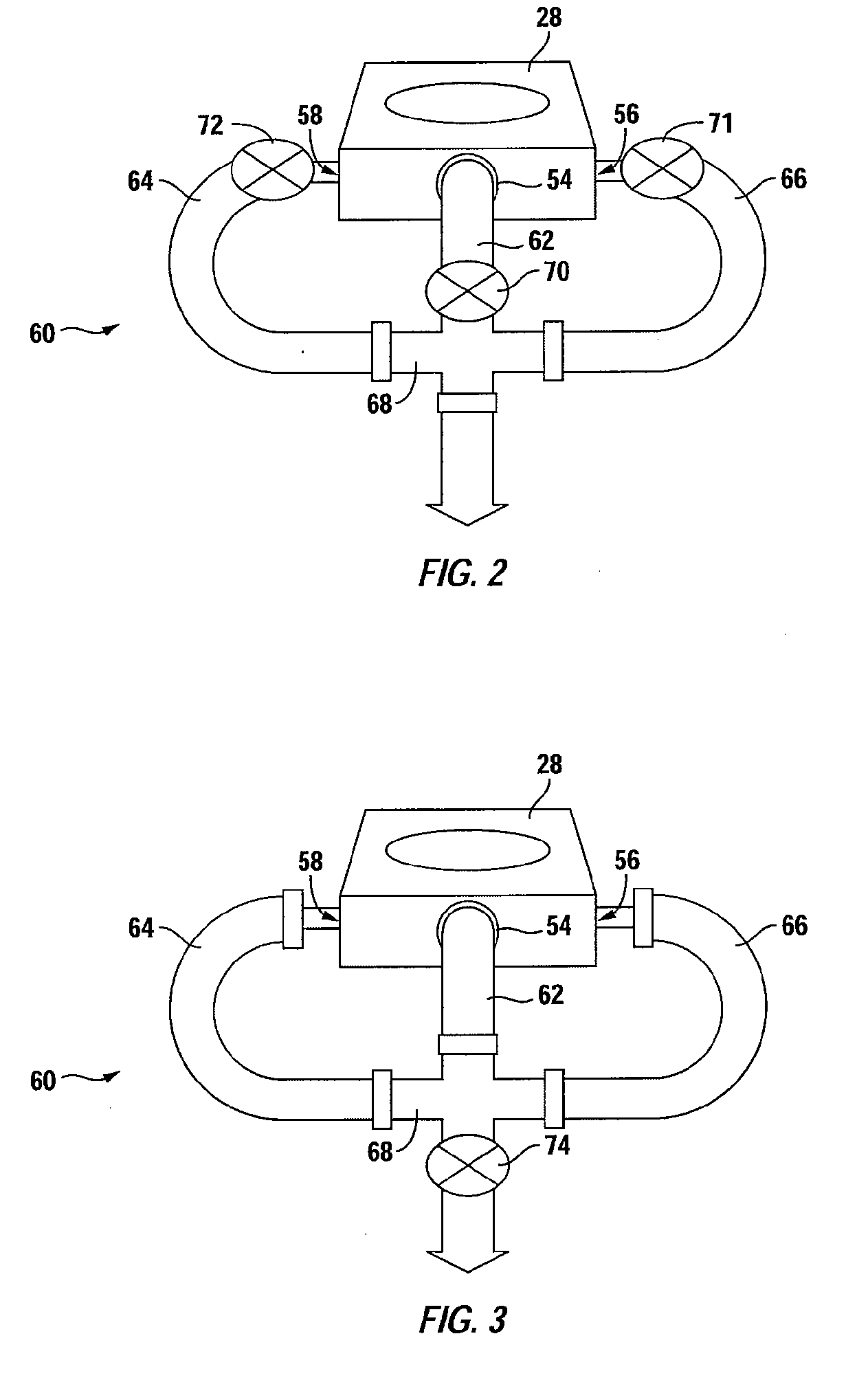

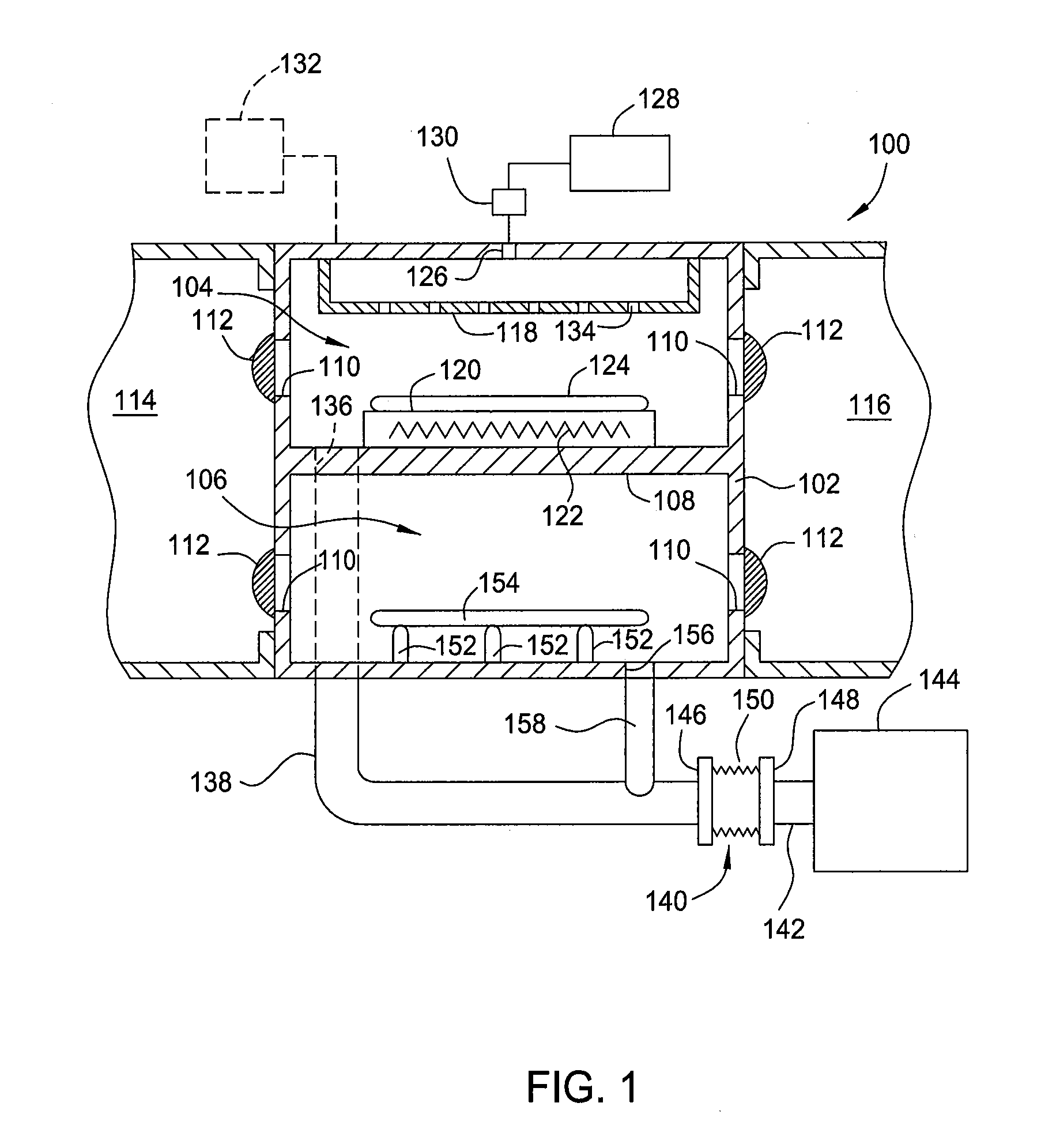

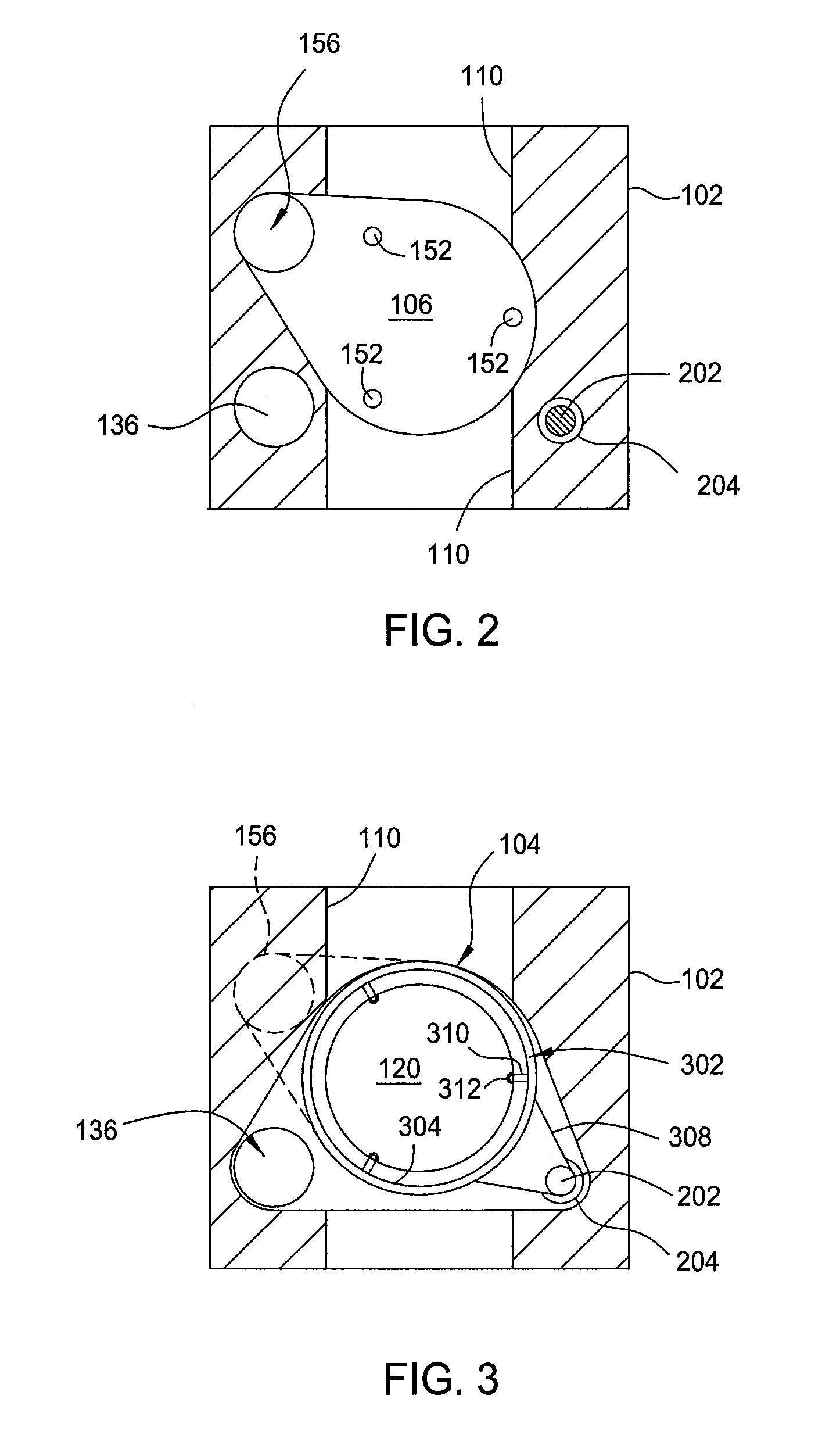

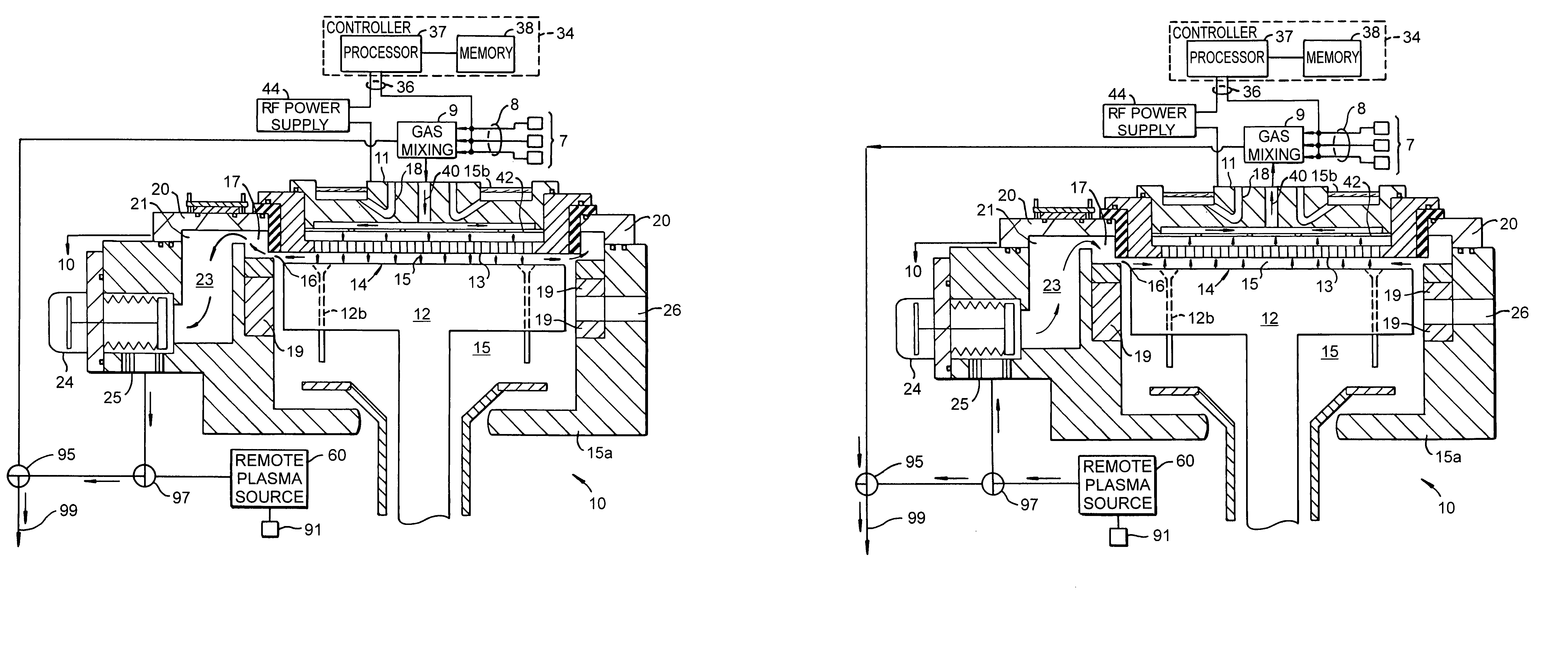

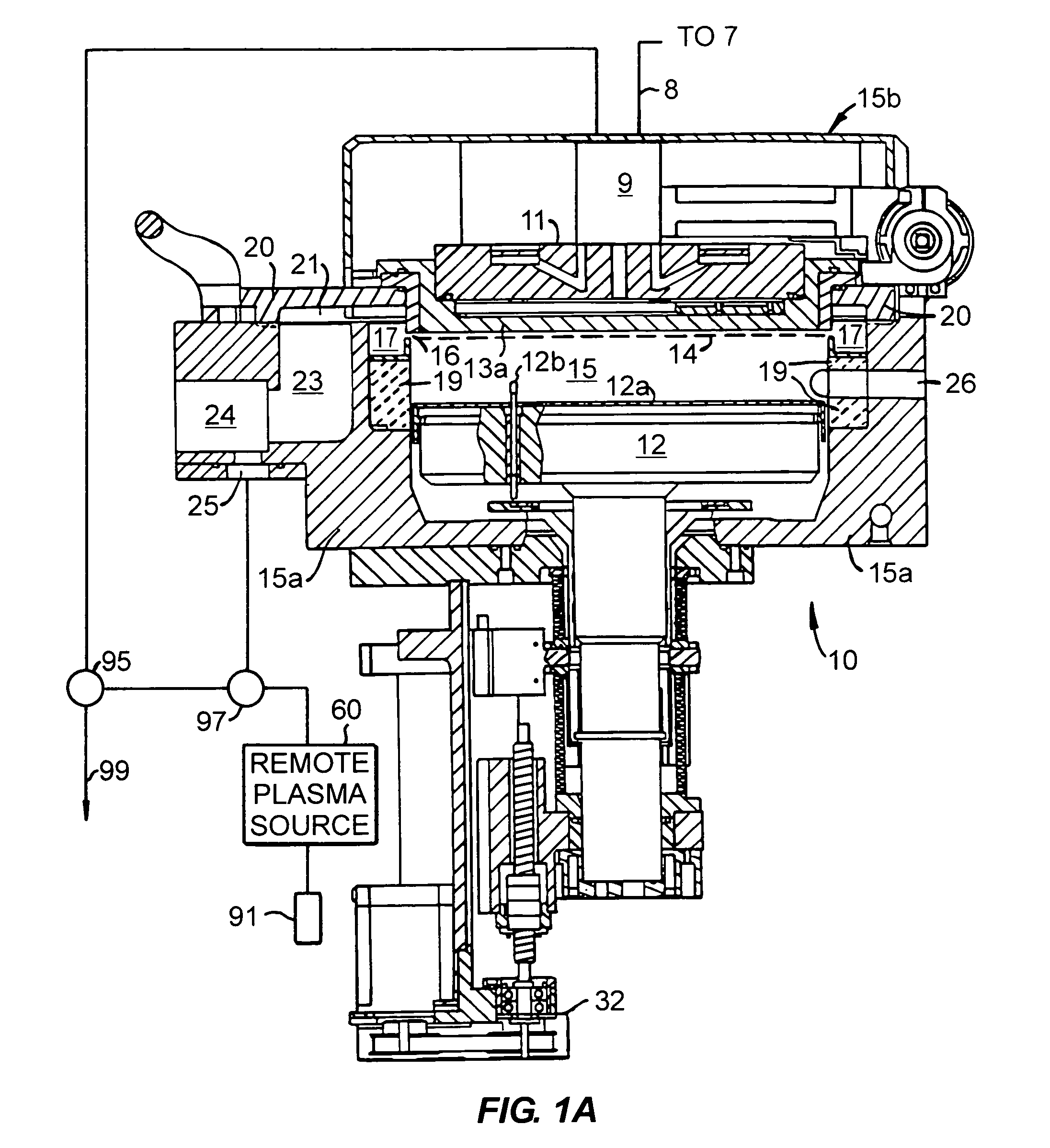

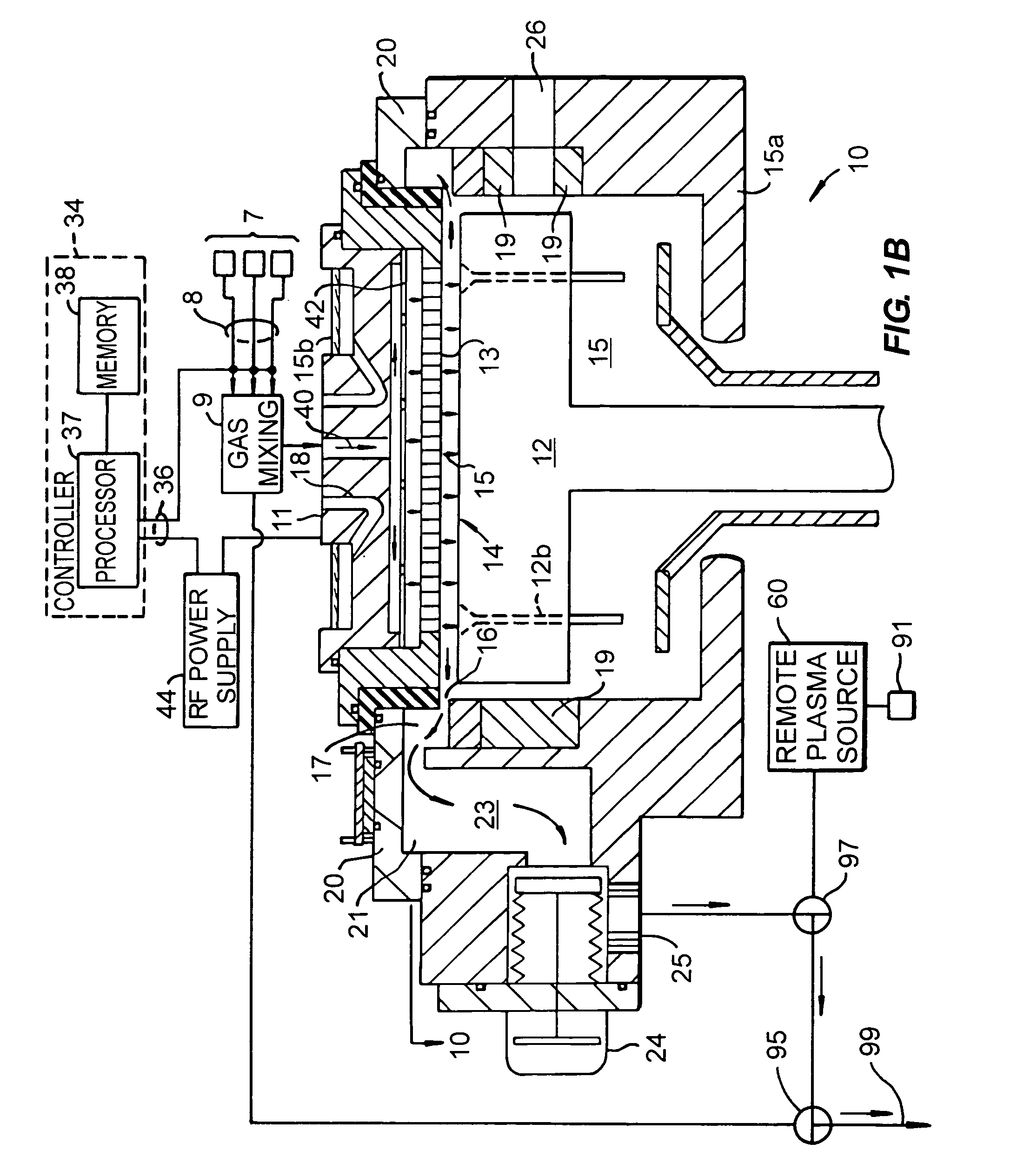

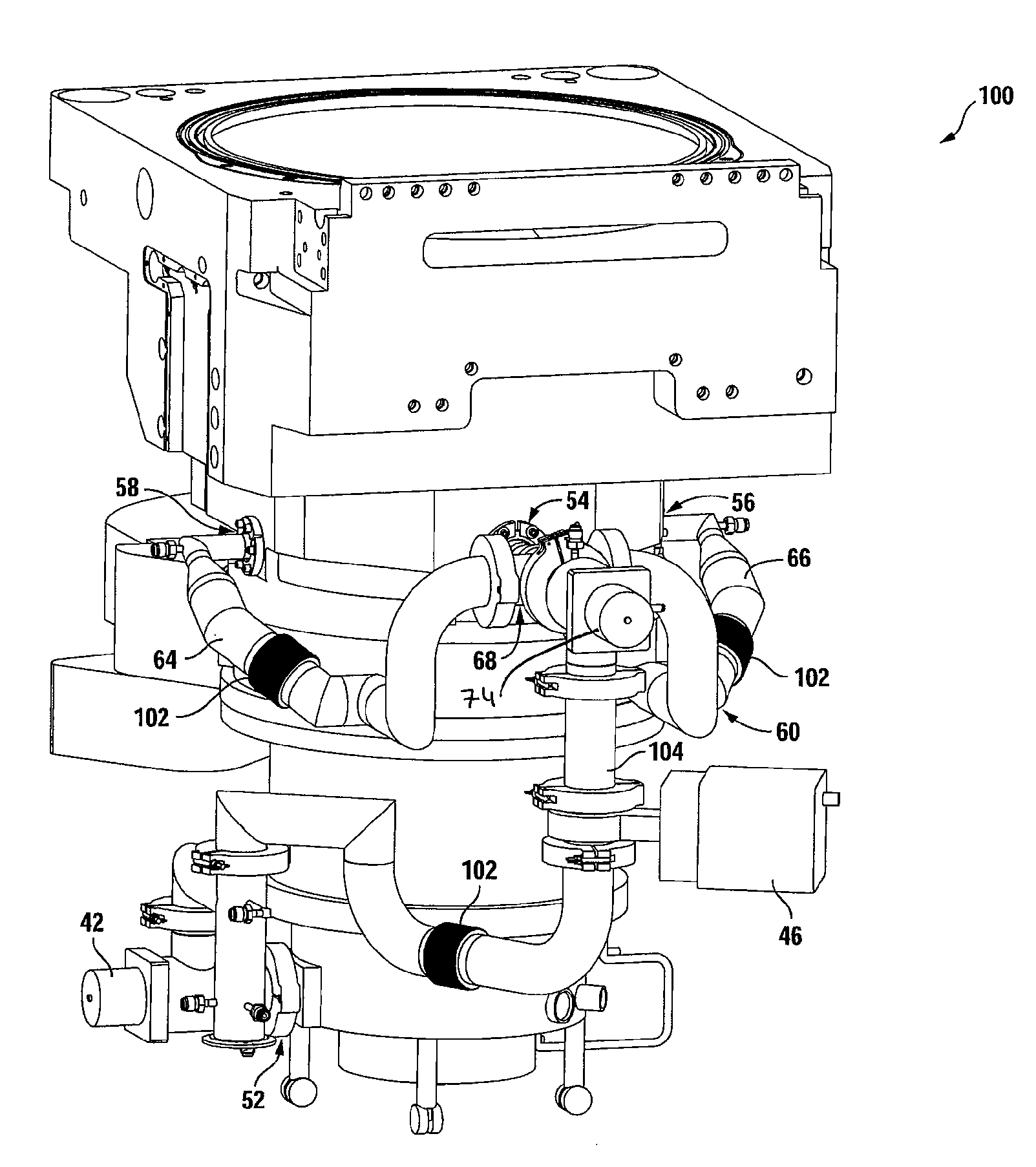

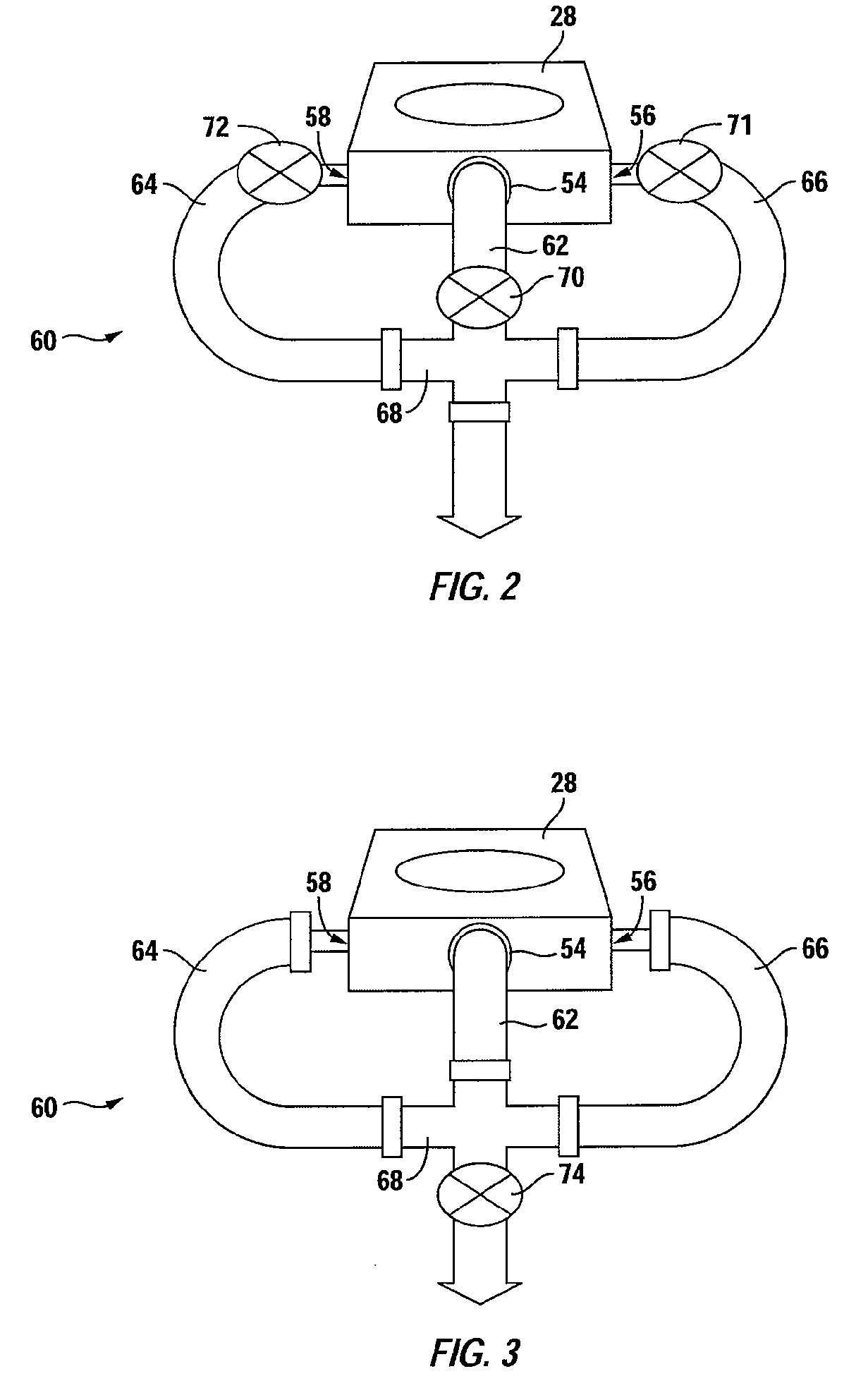

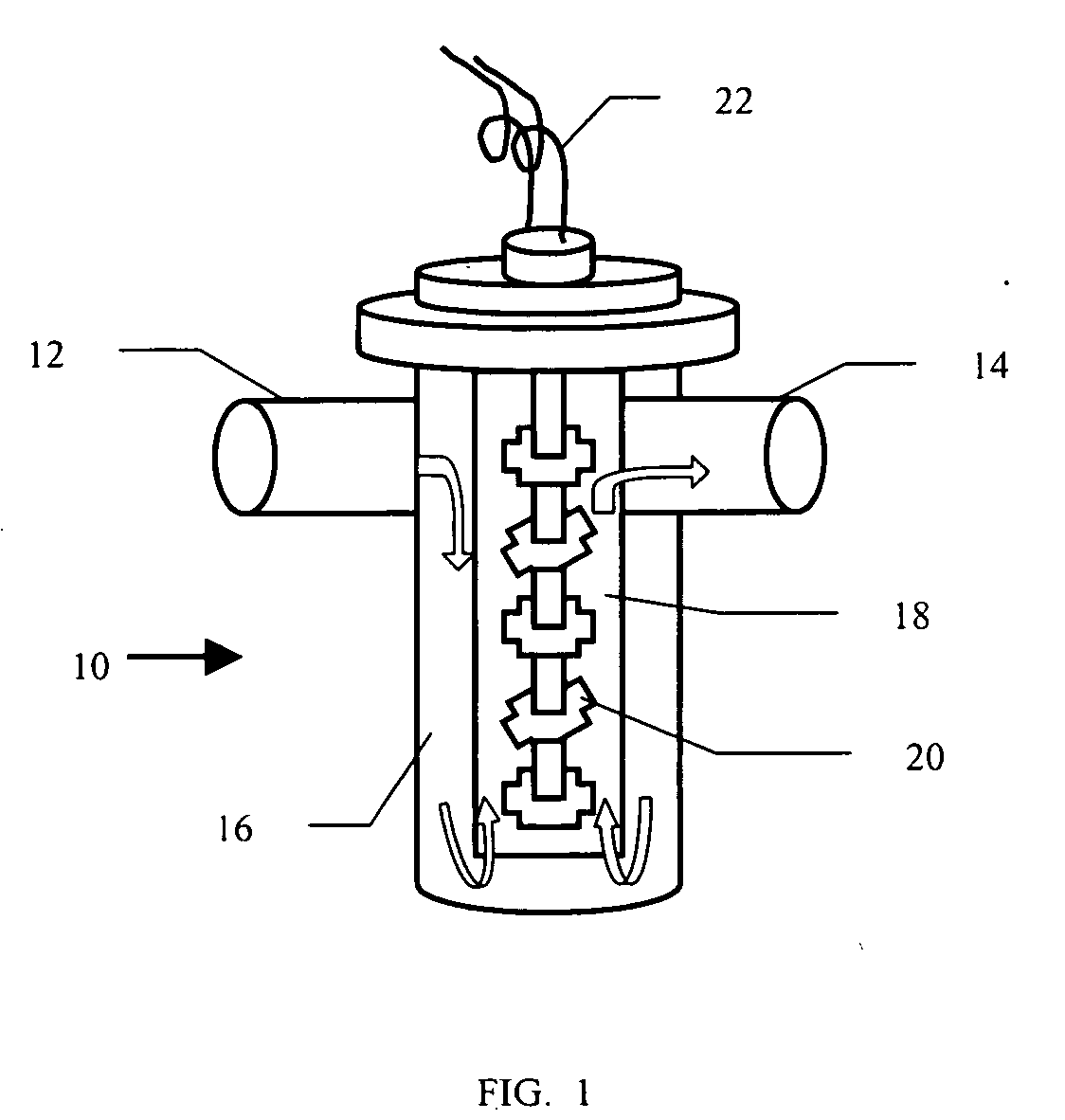

An exhaust foreline for purging fluids from a semiconductor fabrication chamber is described. The foreline may include a first, second and third ports independently coupled to the chamber. A semiconductor fabrication system is also described that includes a substrate chamber that has a first, second and third interface port. The system may also include a multi-port foreline that has a first, second and third port, where the first foreline port is coupled to the first interface port, the second foreline port is coupled to the second interface port, and the third foreline port is coupled to the third interface port. The system may further include an exhaust vacuum coupled to the multi-port foreline.

Owner:APPLIED MATERIALS INC

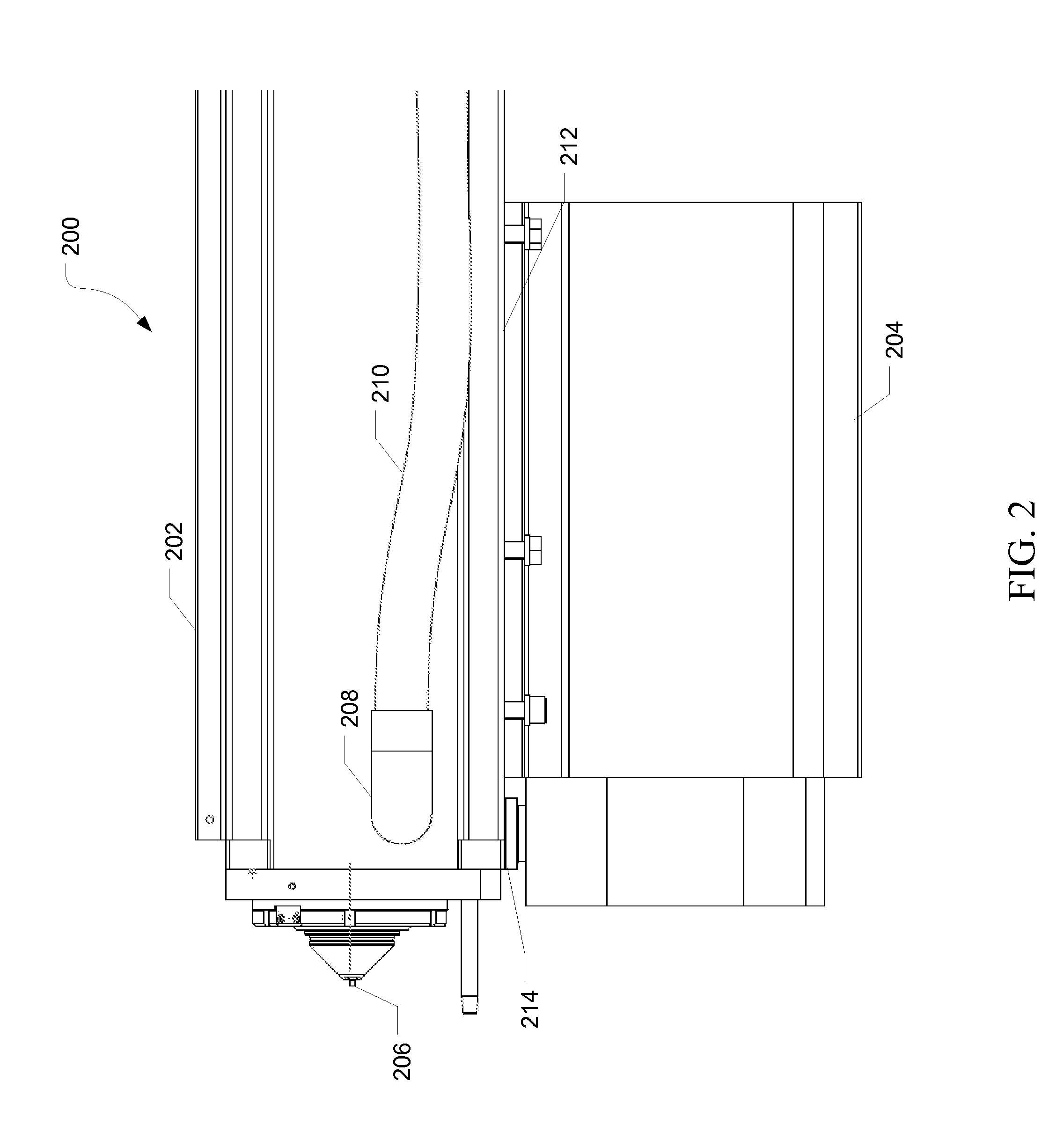

Vacuum chambers with shared pump

InactiveUS20120222813A1Liquid surface applicatorsSemiconductor/solid-state device manufacturingEngineeringVacuum chamber

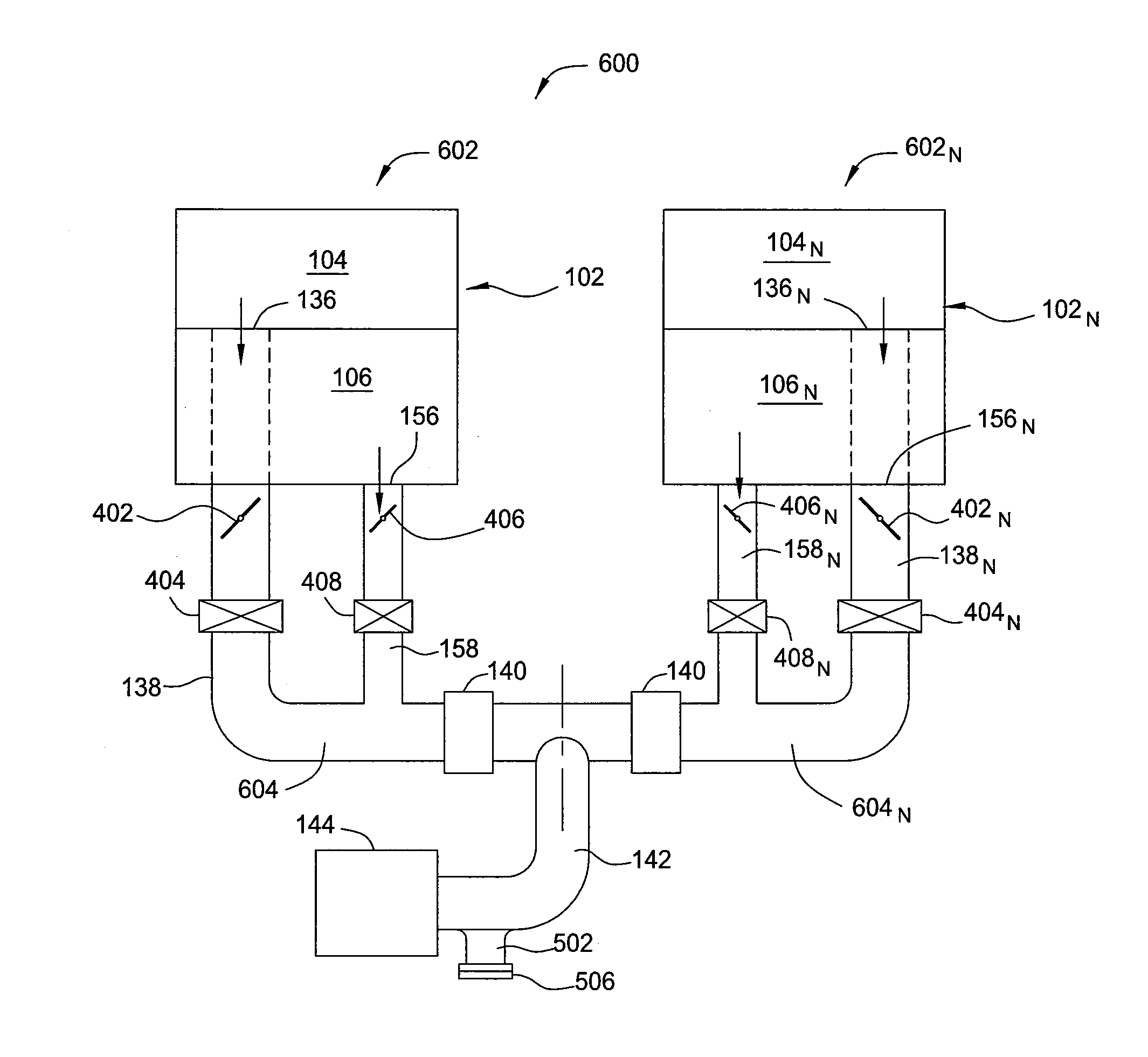

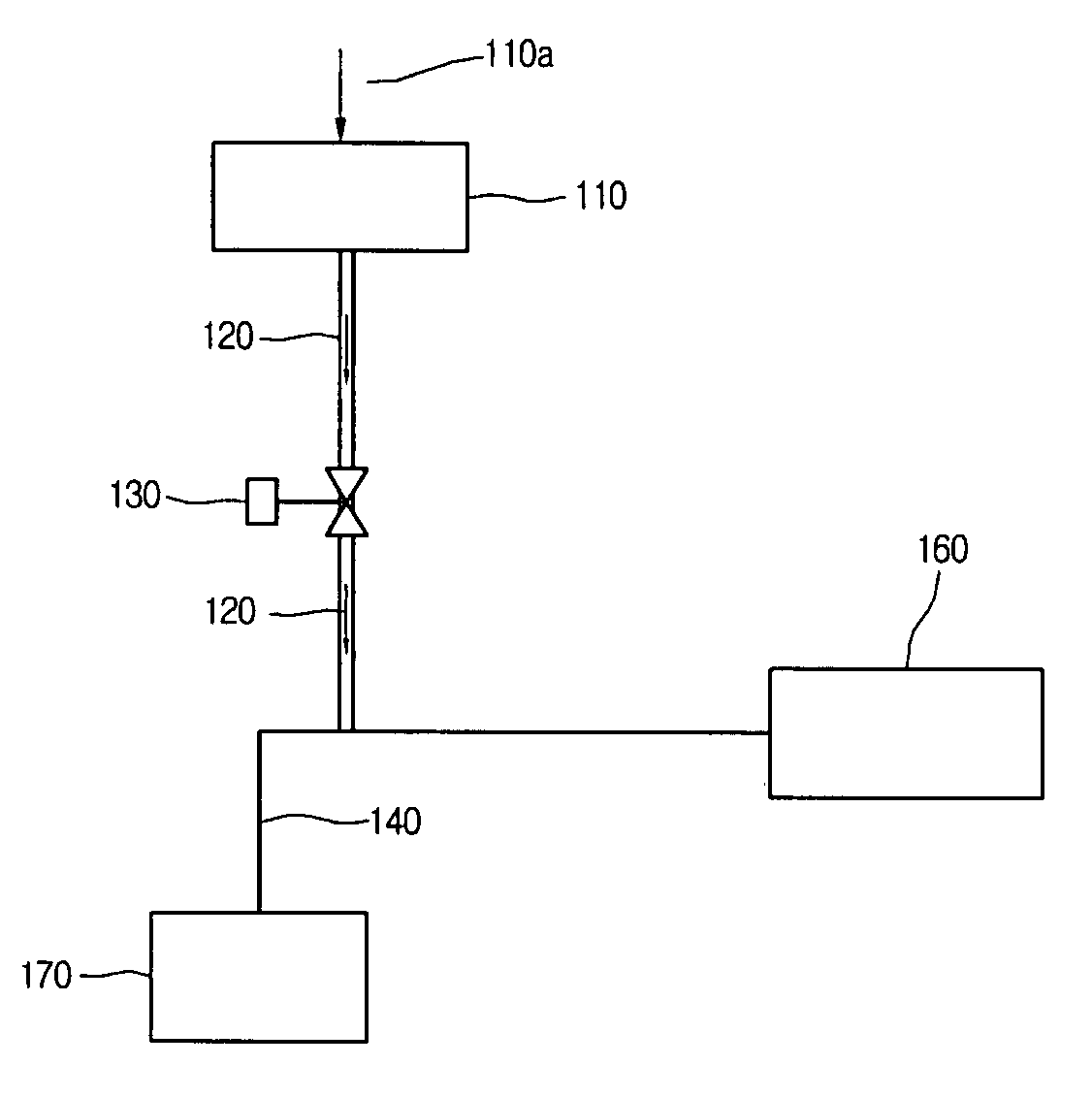

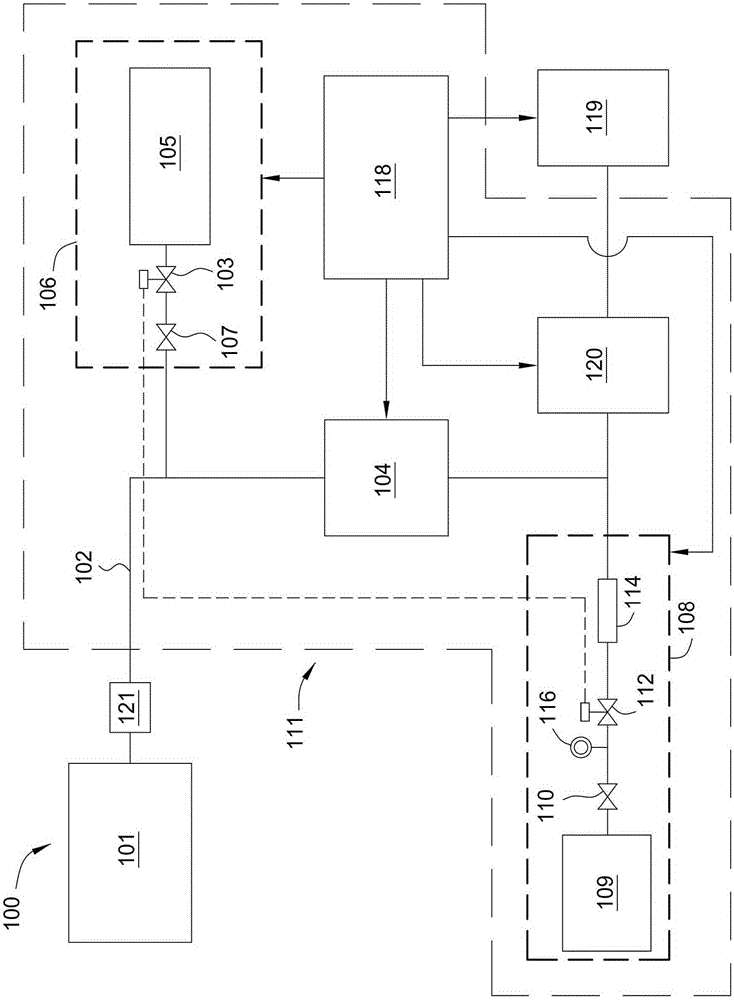

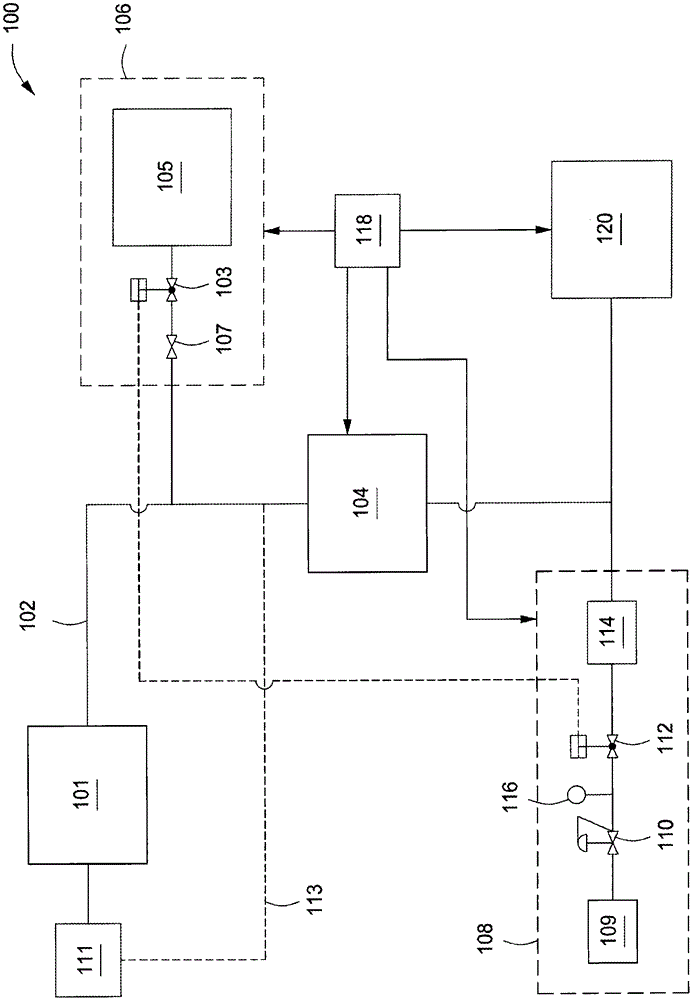

Embodiments of the present disclosure generally relate to vacuum processing chambers having different pumping requirements and connected to a shared pumping system through a single foreline. In one embodiment, the vacuum processing chambers include a high conductance pumping conduit and a low conductance pumping conduit coupled to a single high conductance foreline. In another embodiment, a plurality of unbalanced chamber groups may be connected to a common pumping system by a final foreline.

Owner:APPLIED MATERIALS INC

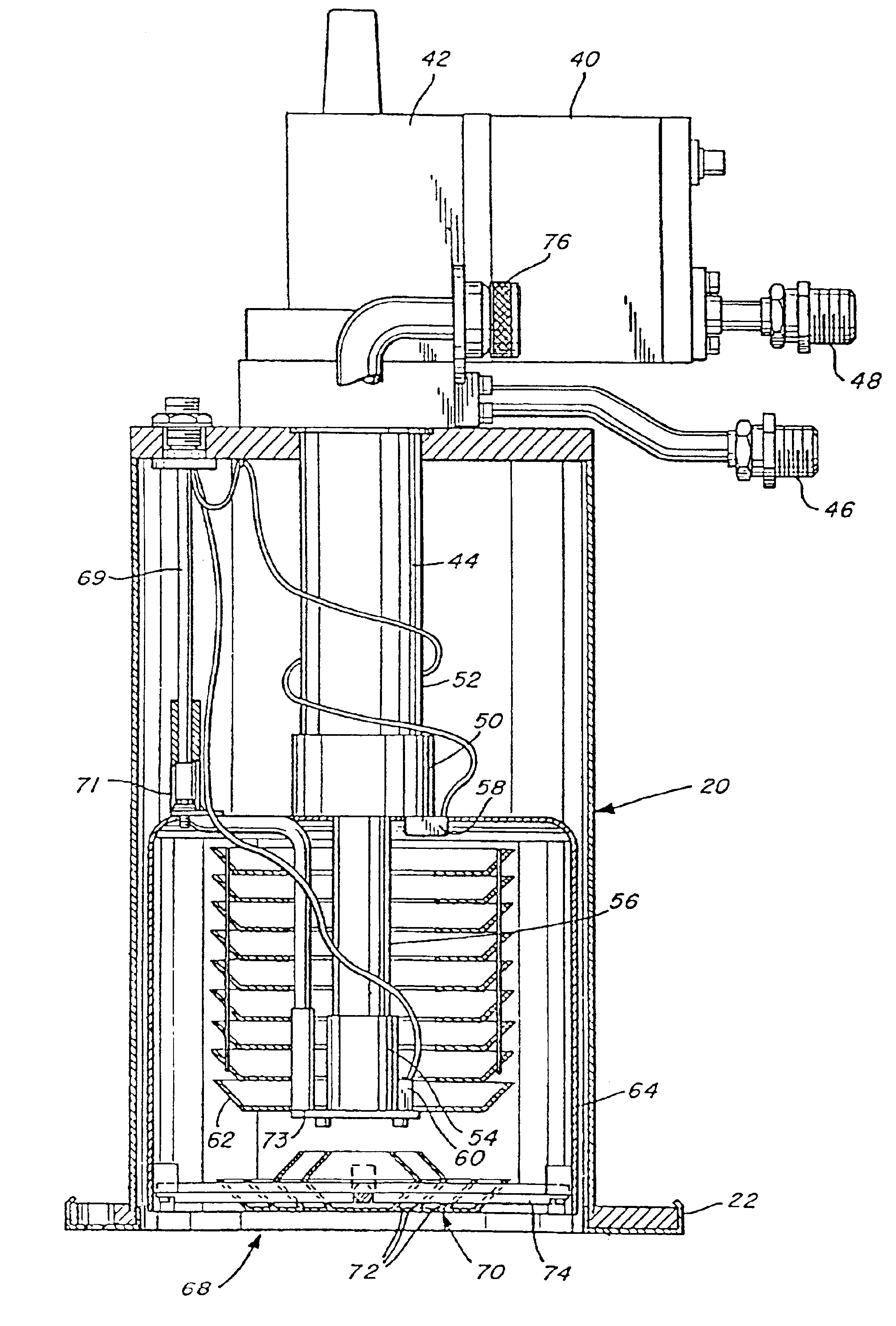

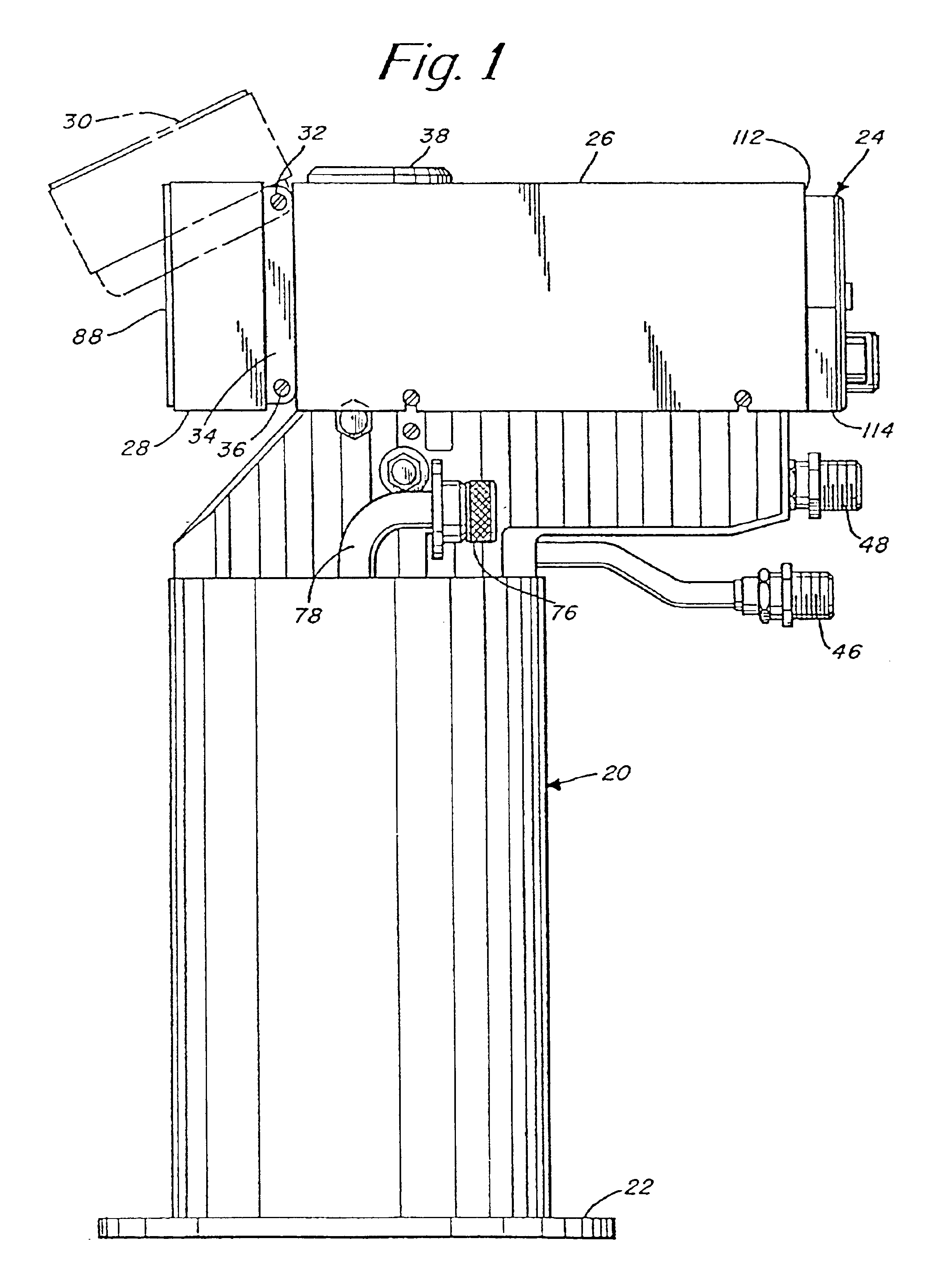

Electronically controlled vacuum pump

A vacuum system comprises, as an integral assembly, a vacuum pump with drive motor, a purge valve, a roughing valve and an electronic control module. A cryogenic vacuum pump and a turbomolecular vacuum pump are disclosed. The control module has a programmed processor for controlling the motor and valves and is user programmable for establishing specific control sequences. The integral electronic control module is removable from the assembly and is connected to the other devices through a common connector assembly. In the turbomolecular pump system proper introduction of a purge gas through the purge valve is detected by detecting the current load on the pump drive or by detecting foreline pressure. To test the purge gas status, the purge valve may be closed and then opened as drive current or pressure is monitored. After power failure, the controller will continue normal drive of the turbomolecular pump so long as the speed of the pump has remained above a threshold value. Otherwise the vent valve will have been opened, and a start-up sequence must be initiated. During shutdown, power to the pump drive motor is discontinued and the vent valve is opened before the roughing valve is closed.

Owner:BROOKS AUTOMATION INC

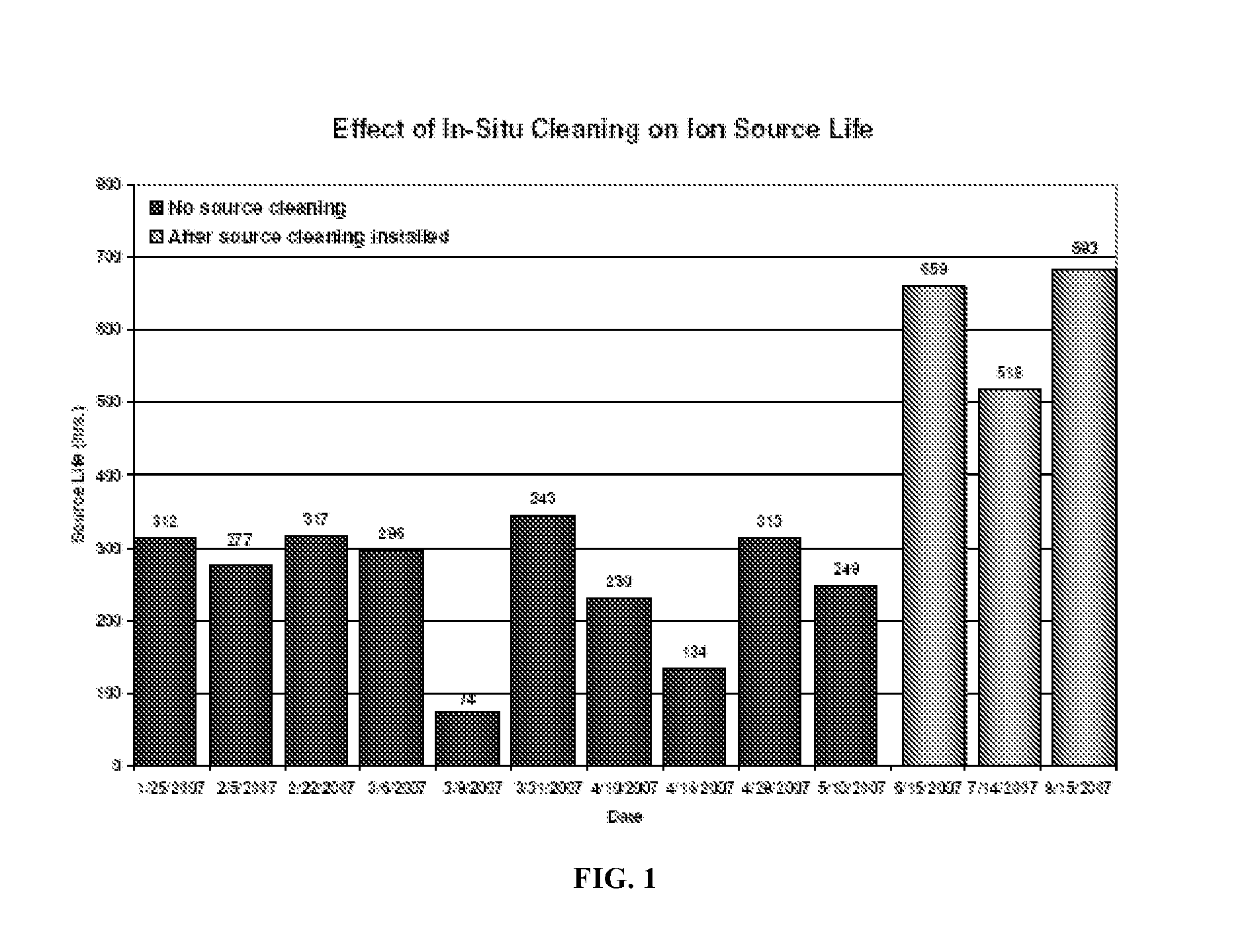

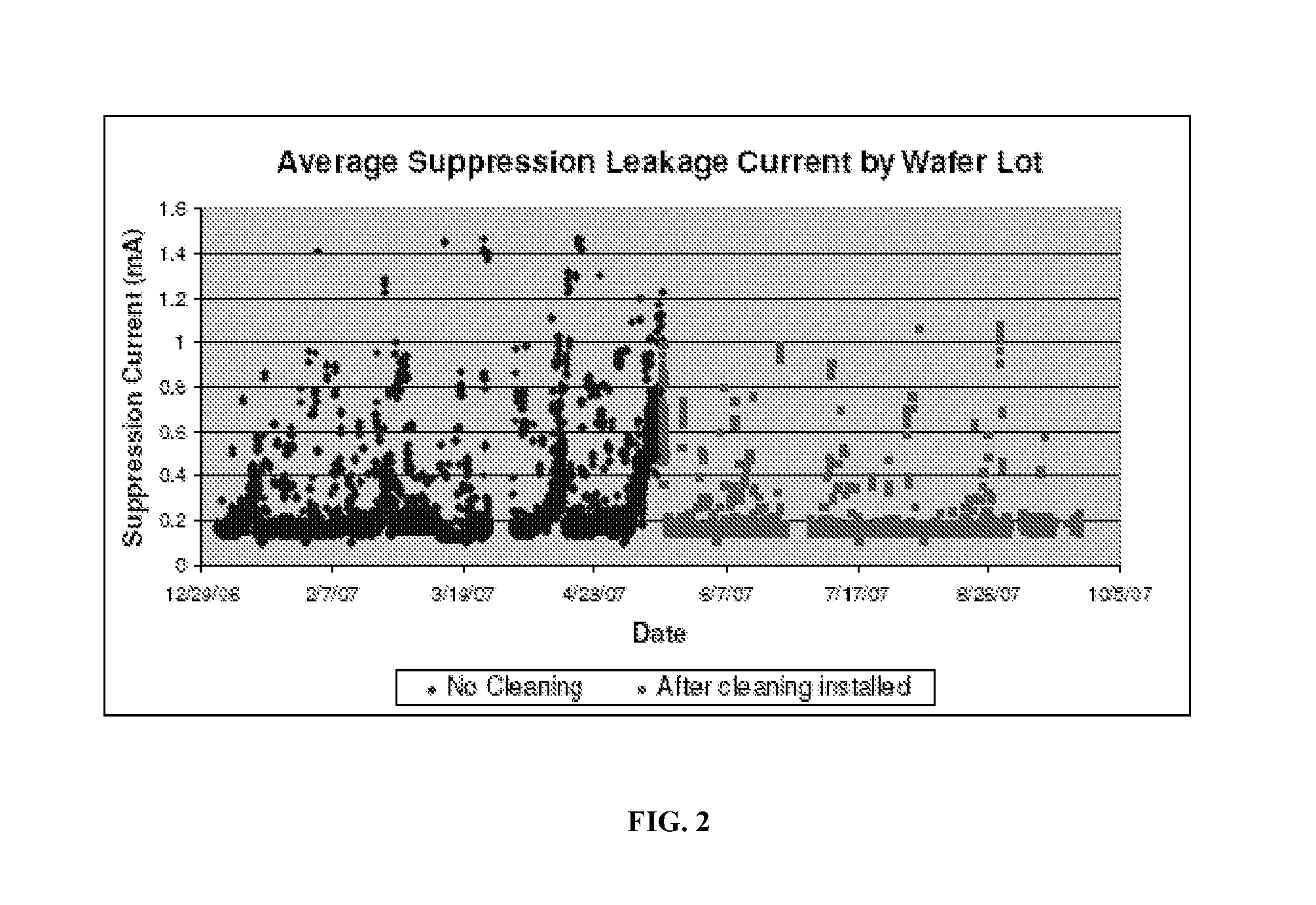

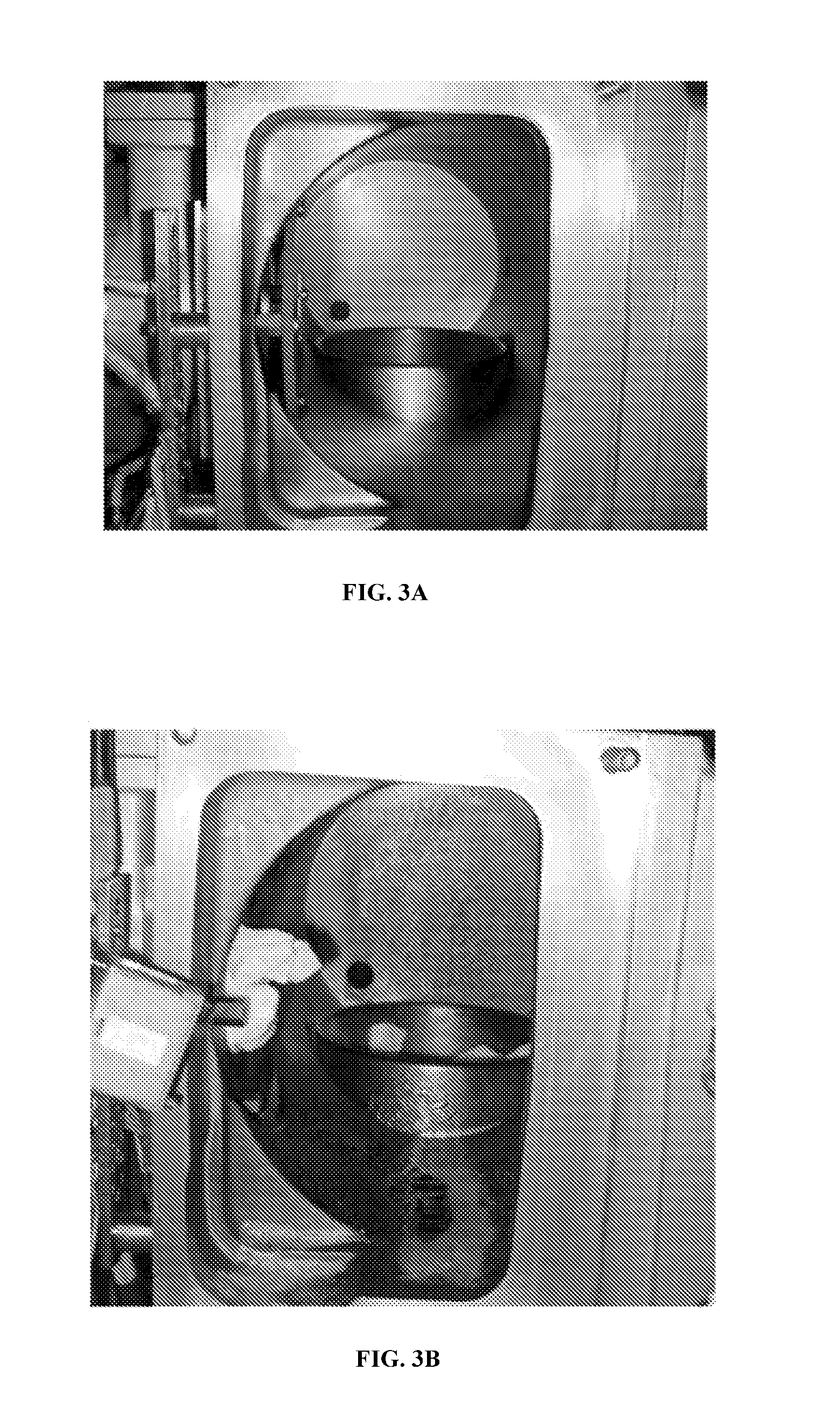

Ion source cleaning in semiconductor processing systems

InactiveUS20110259366A1Maintain resistanceImprove performanceElectric discharge tubesHollow article cleaningEtchingChemical reaction

Cleaning of an ion implantation system or components thereof, utilizing a reactive cleaning reagent enabling growth / etching of the filament in an ion source of the arc chamber, by appropriate control of temperature in the arc chamber to effect the desired filament growth or alternative filament etching. Also described is the use of reactive gases such as XeFx, WFx, AsFx, PFx and TaFx, wherein x has a stoichioimetrically appropriate value or range of values, for cleaning regions of ion implanters, or components of implanters, in in situ or ex situ cleaning arrangements, under ambient temperature, elevated temperature or plasma conditions. Among specific reactive cleaning agents, BrF3 is described as useful for cleaning ion implant systems or component(s) thereof, in in situ or ex situ cleaning arrangements. Also described is a method of cleaning the forelines of an ion implant system for at least partial removal of ionization-related deposit from said forelines, comprising contacting said forelines with a cleaning gas wherein said cleaning gas is chemically reactive with said deposit. Also described is a method of improving the performance and extending the lifetime of an ion implant system, comprising contacting the cathode with a gas mixture.

Owner:ENTEGRIS INC

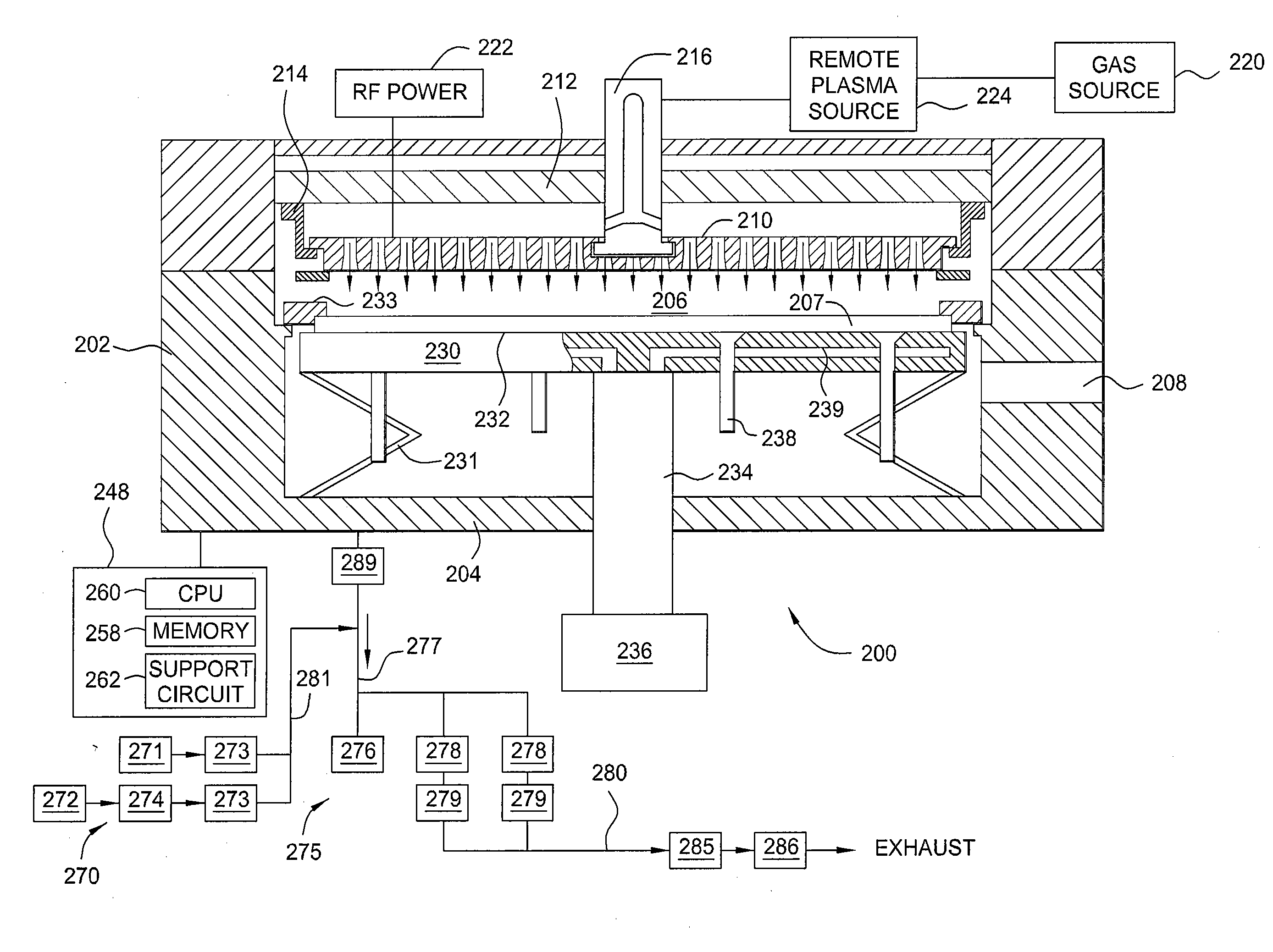

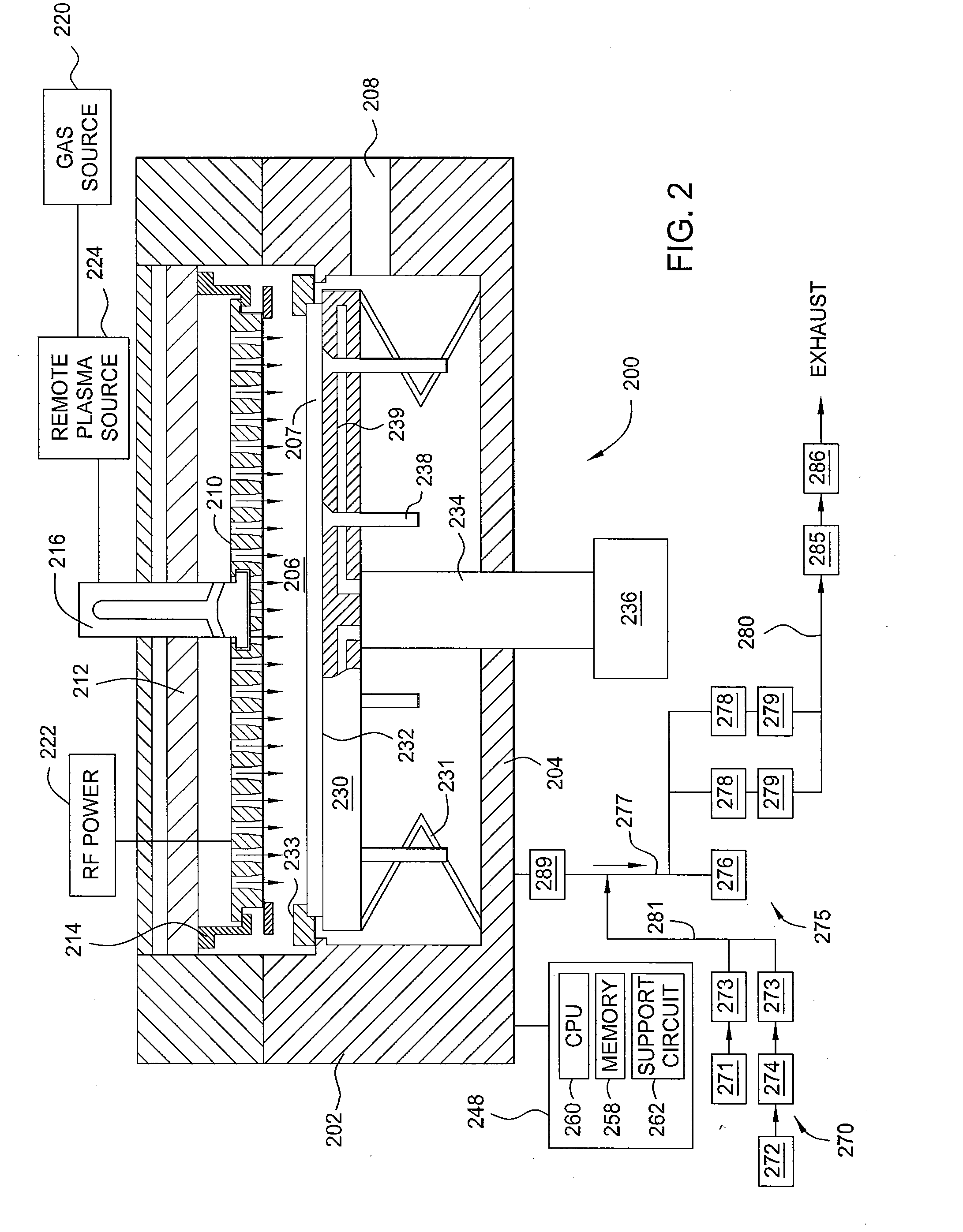

Backflush chamber clean

InactiveUS7037376B2Improve concentrationSignificant pressure increaseHollow article cleaningSemiconductor/solid-state device manufacturingRemote plasmaShower

A processing chamber may be effectively cleaned by a remote plasma flowed through the chamber in a direction opposite to the direction of gas flowed during wafer processing. Specifically, the remotely generated plasma may be introduced directly into the chamber through a processing gas exhaust or other port, and then be exhausted from the chamber by traveling through the gas distribution shower head to the foreline. In one embodiment of the present invention, this reverse flow of remote cleaning plasma is maintained for the duration of the chamber cleaning step. In an alternative embodiment, the direction of flow of the remote cleaning plasma through the chamber is alternated between this reverse flow and a conventional forward flow.

Owner:APPLIED MATERIALS INC

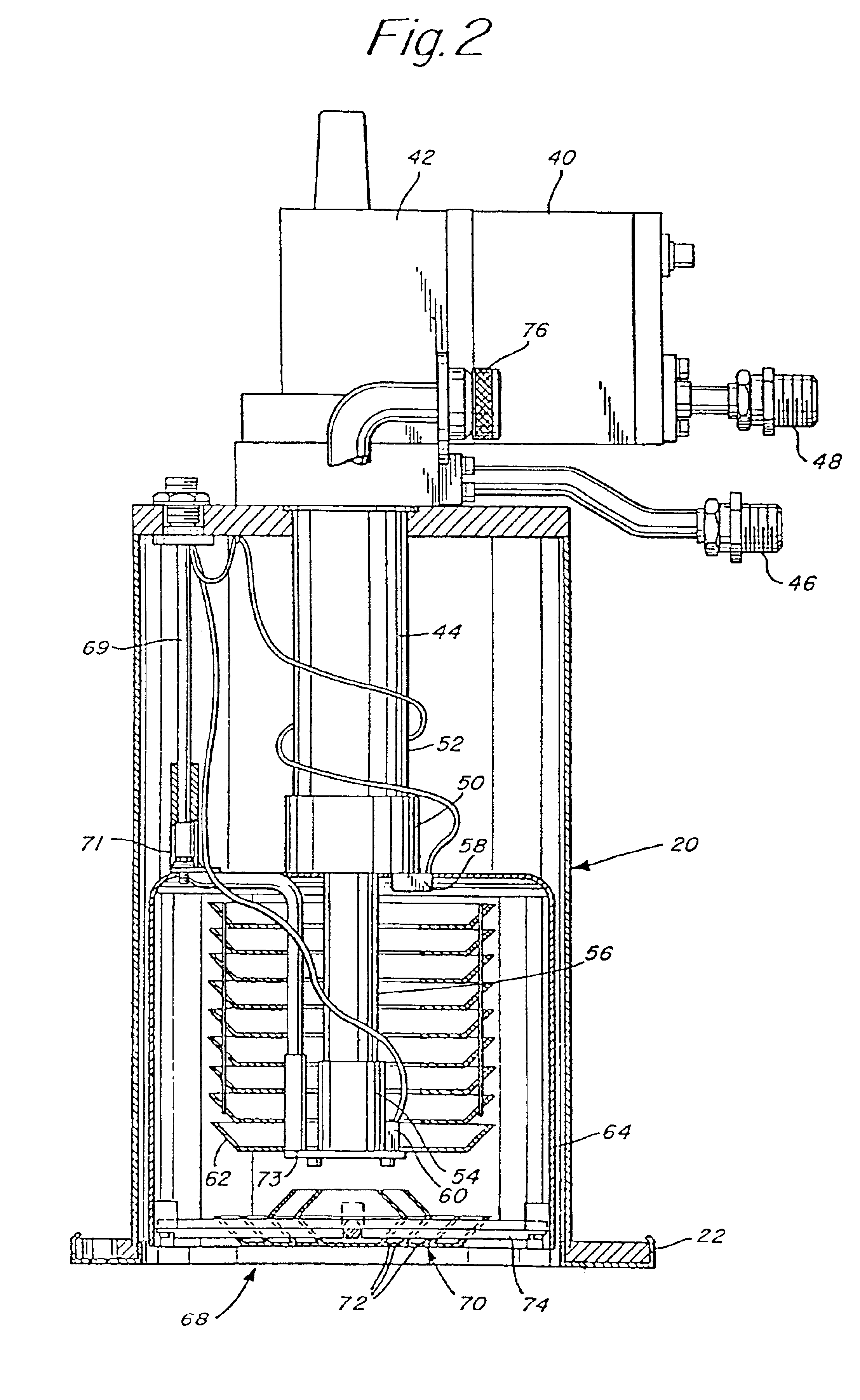

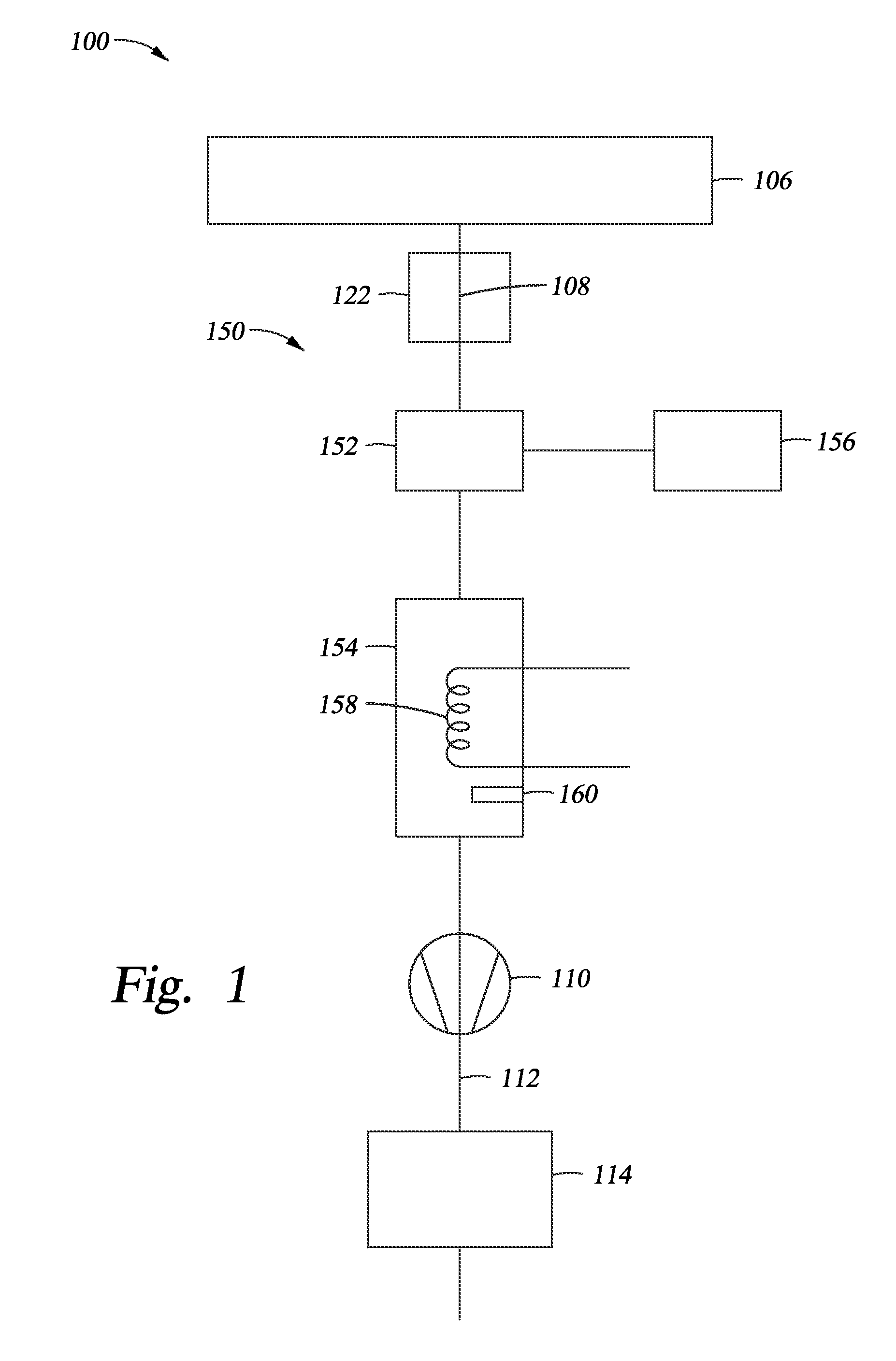

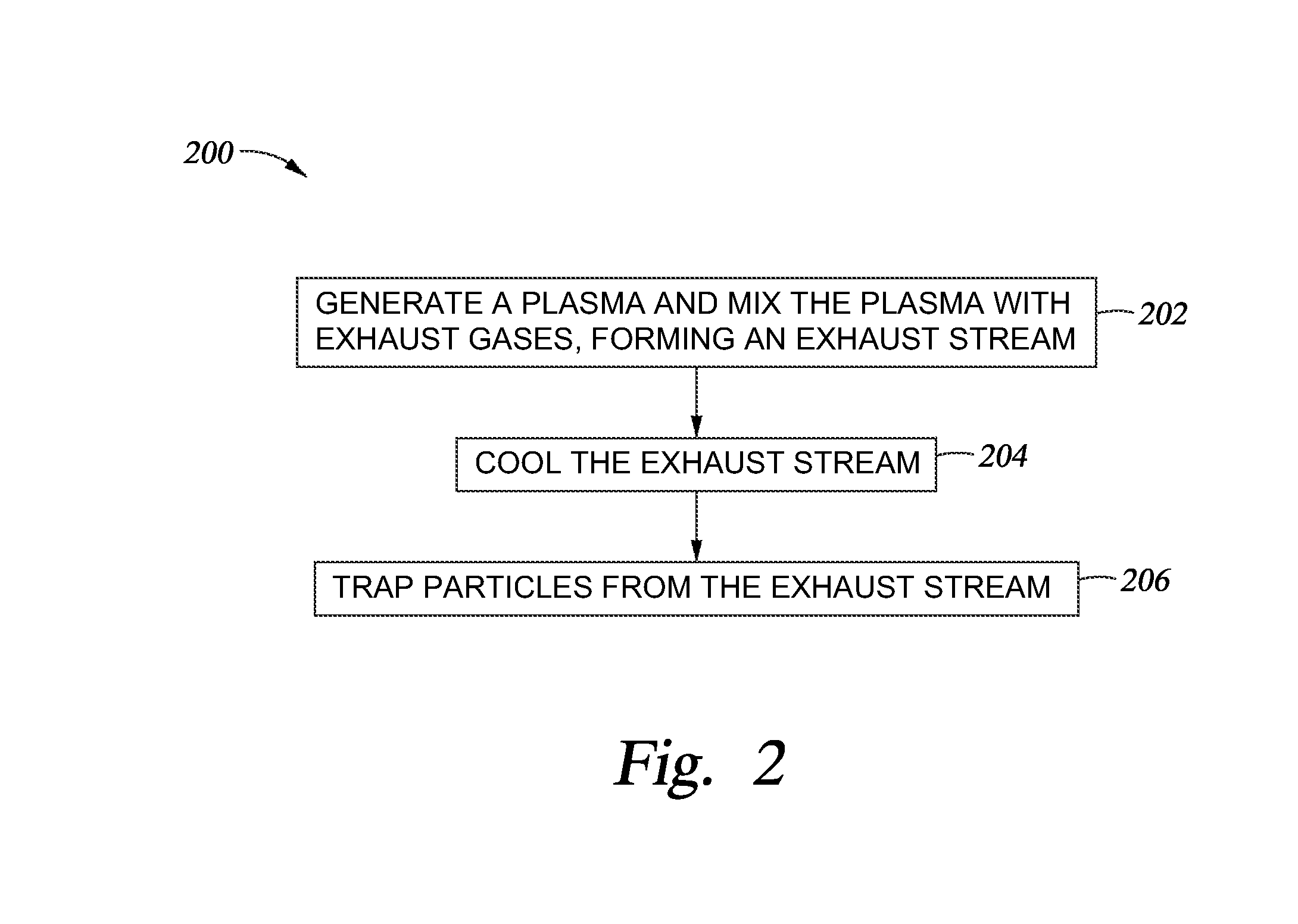

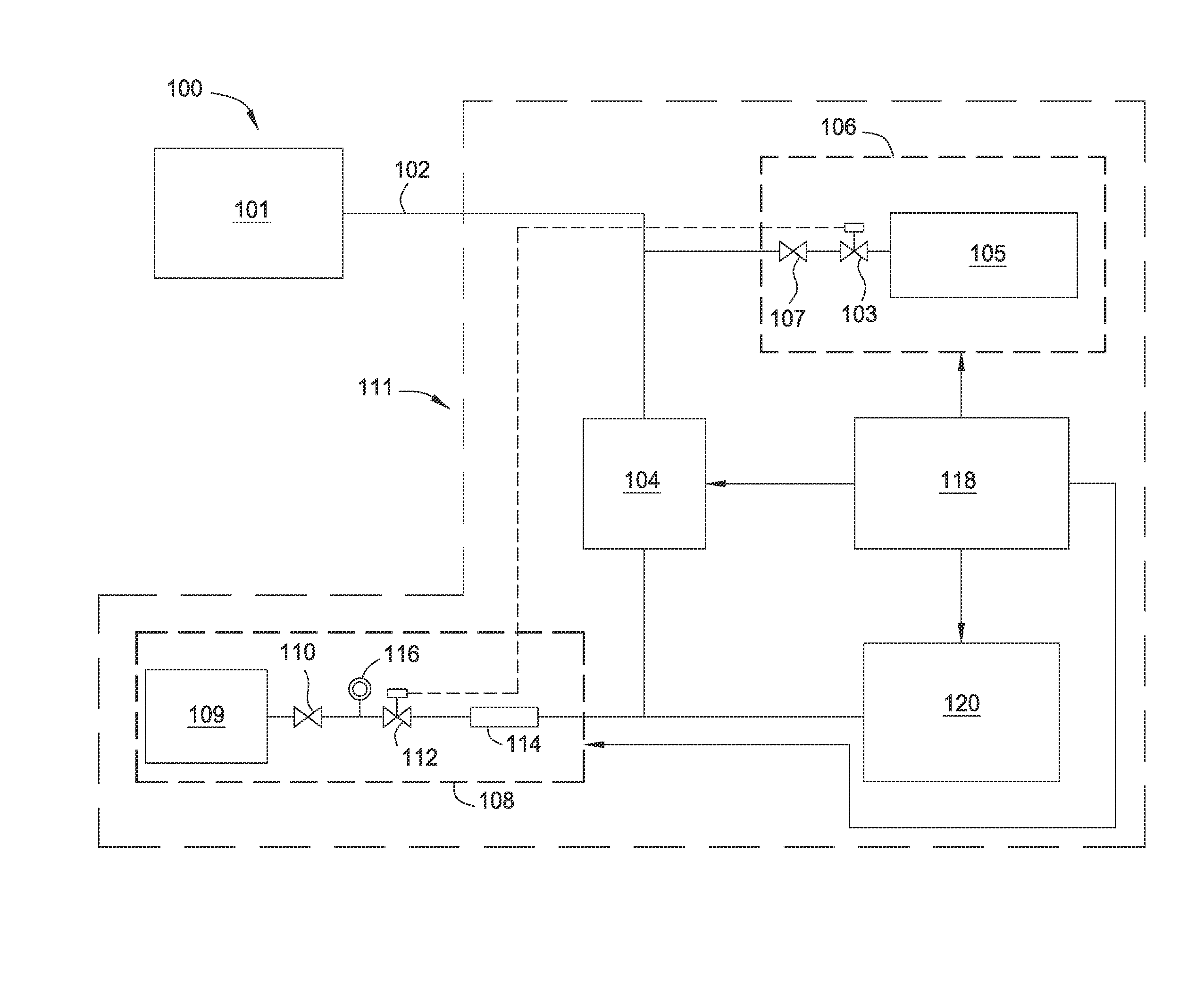

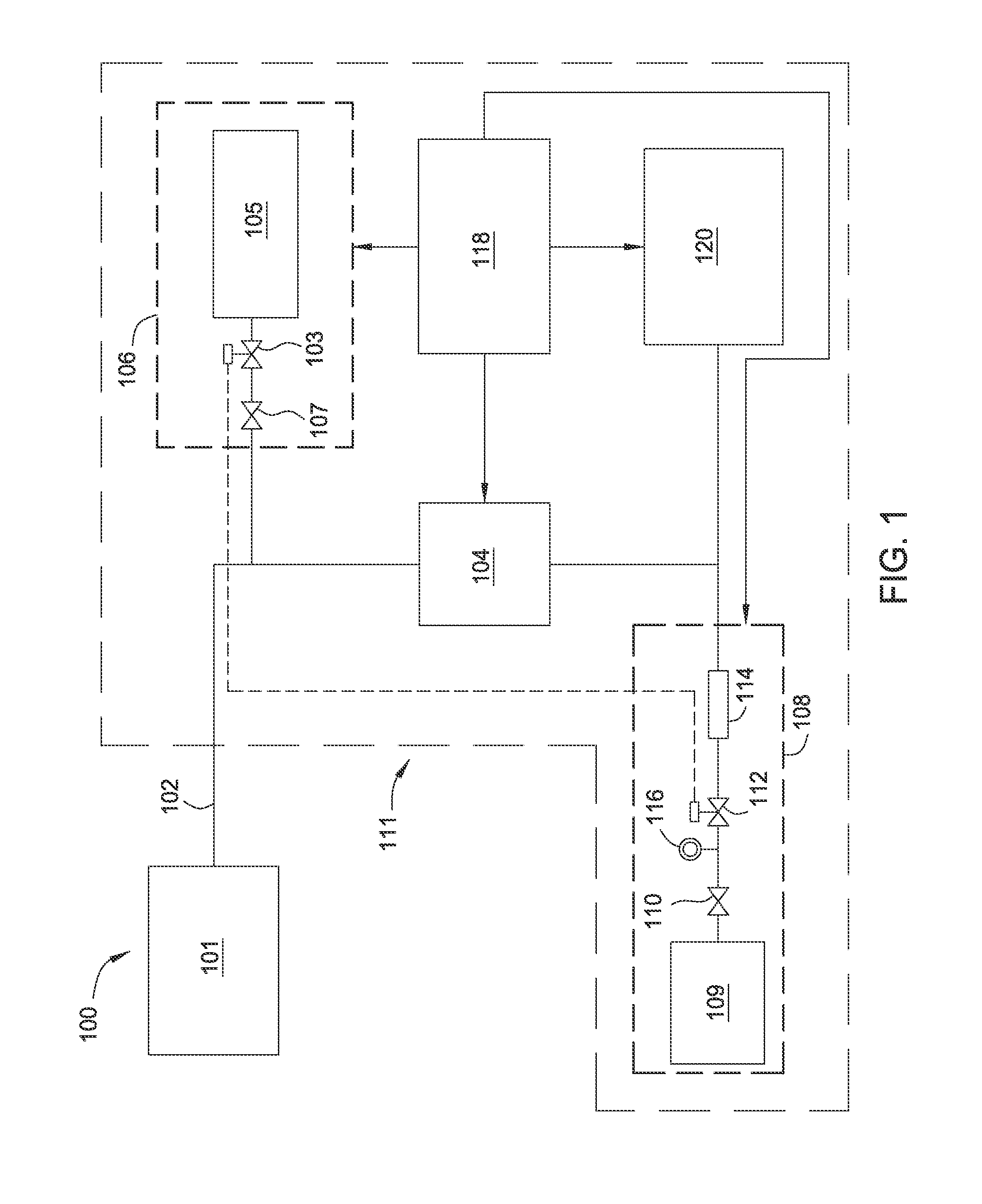

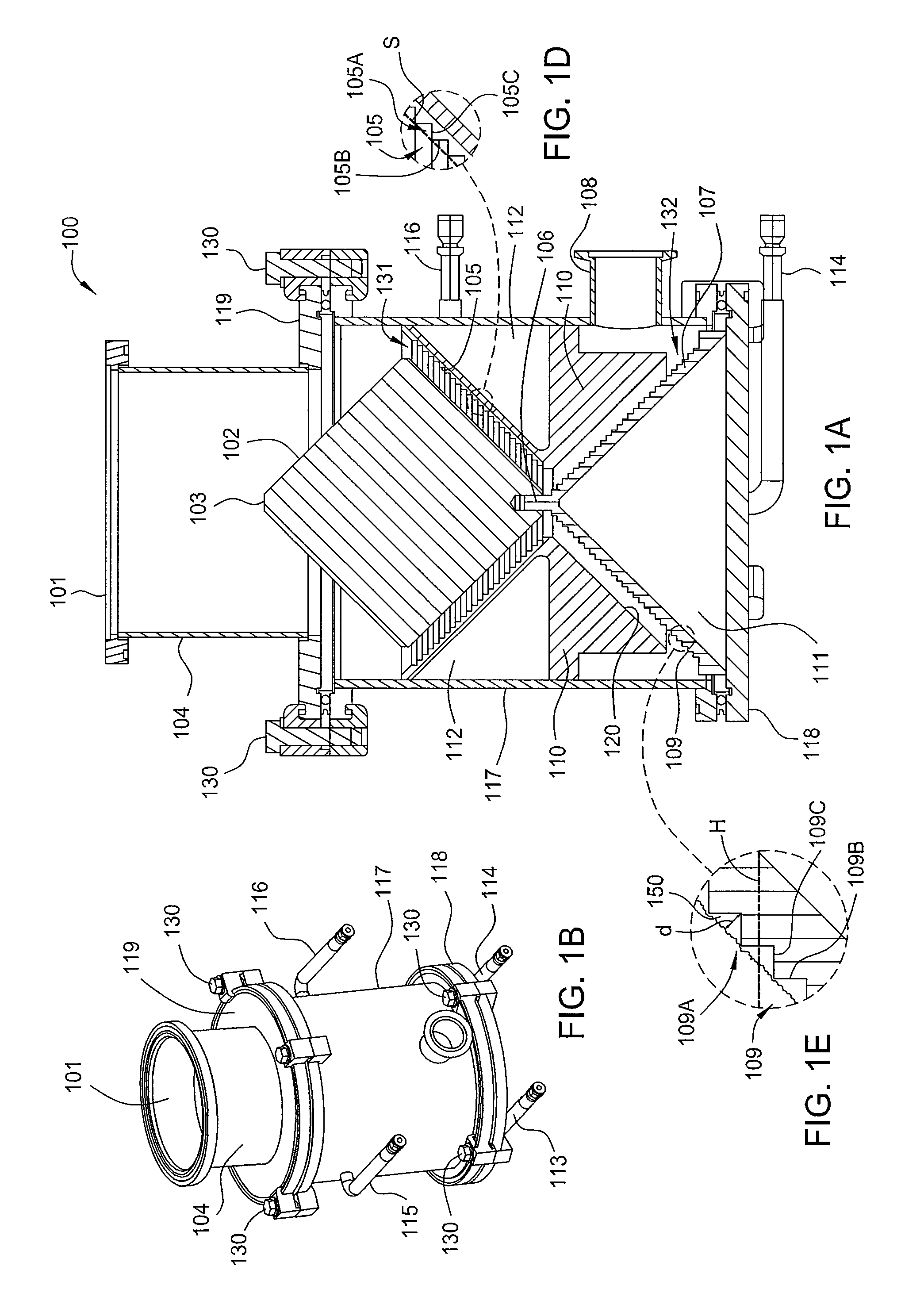

Plasma foreline thermal reactor system

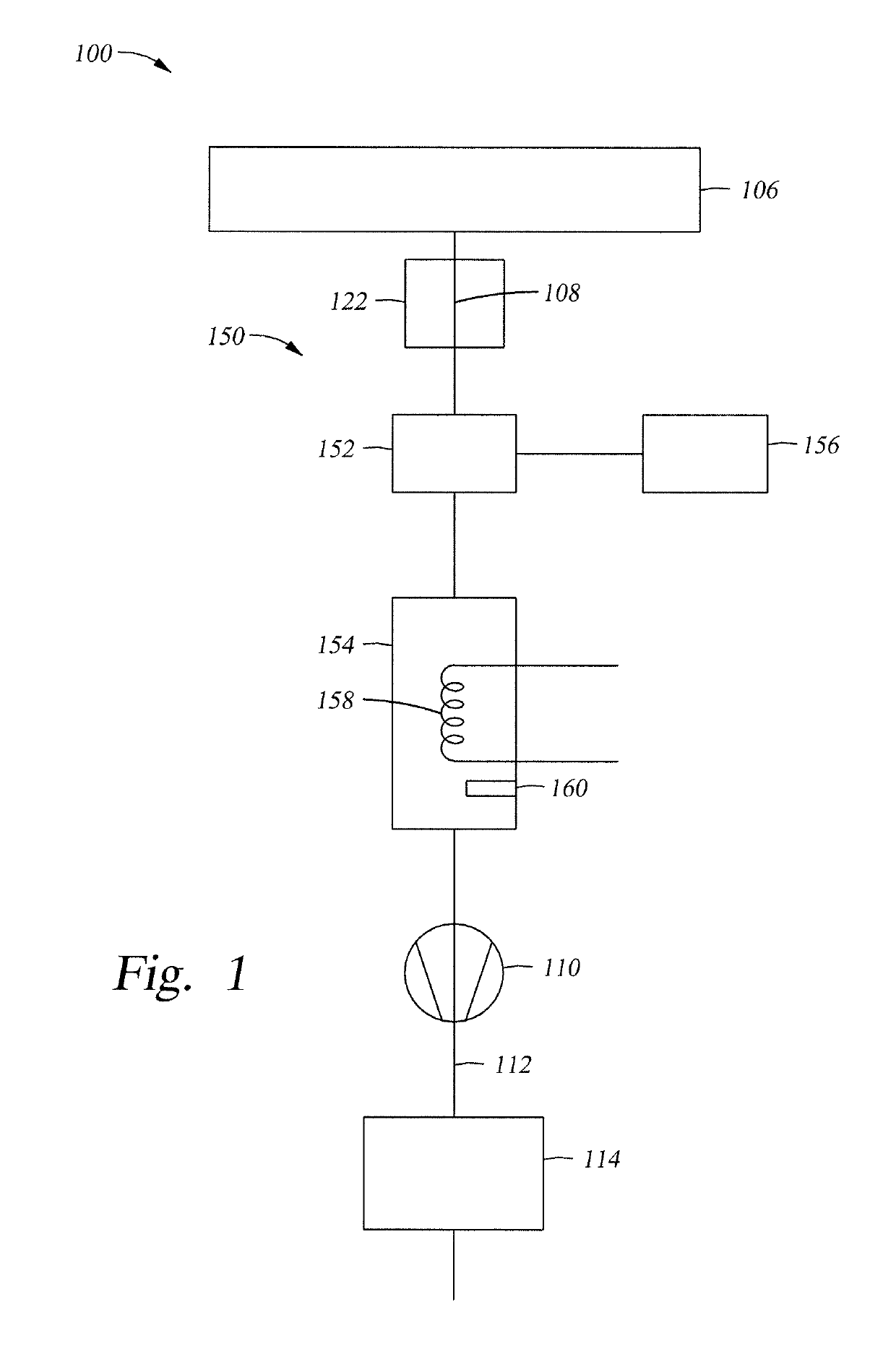

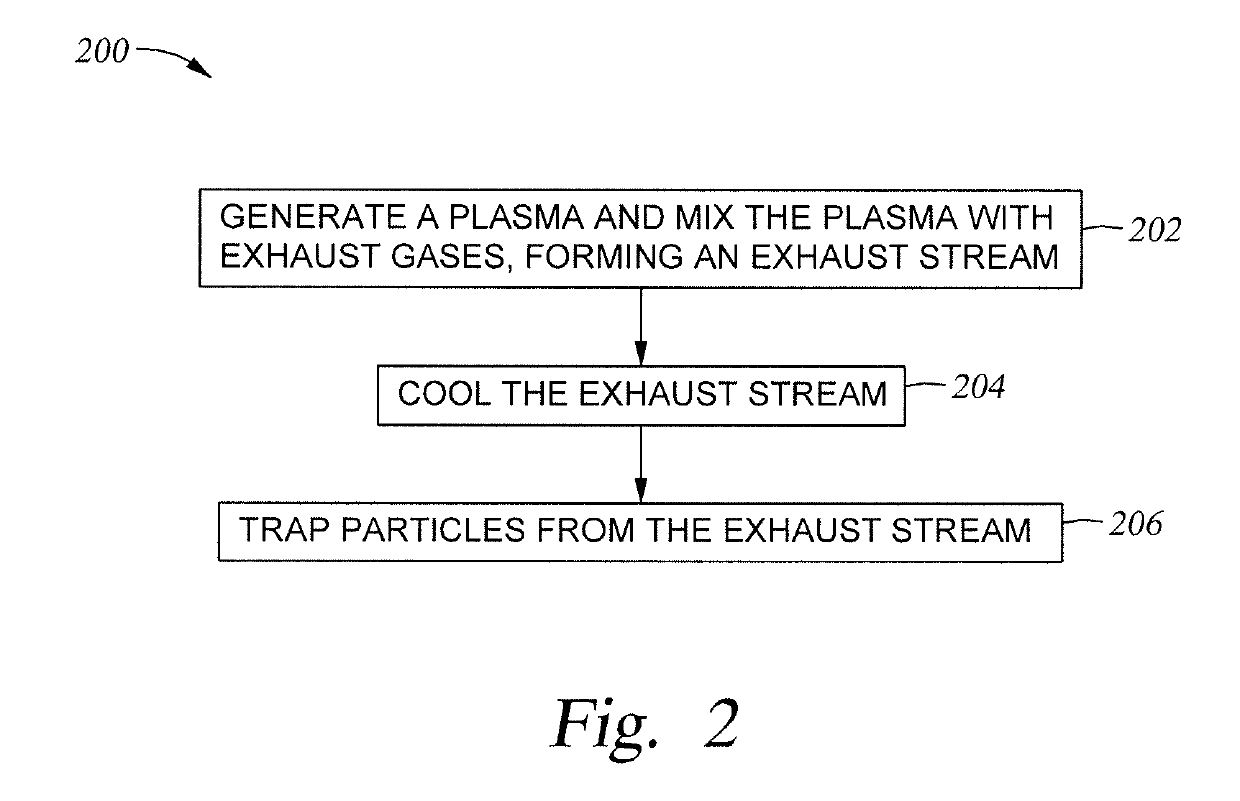

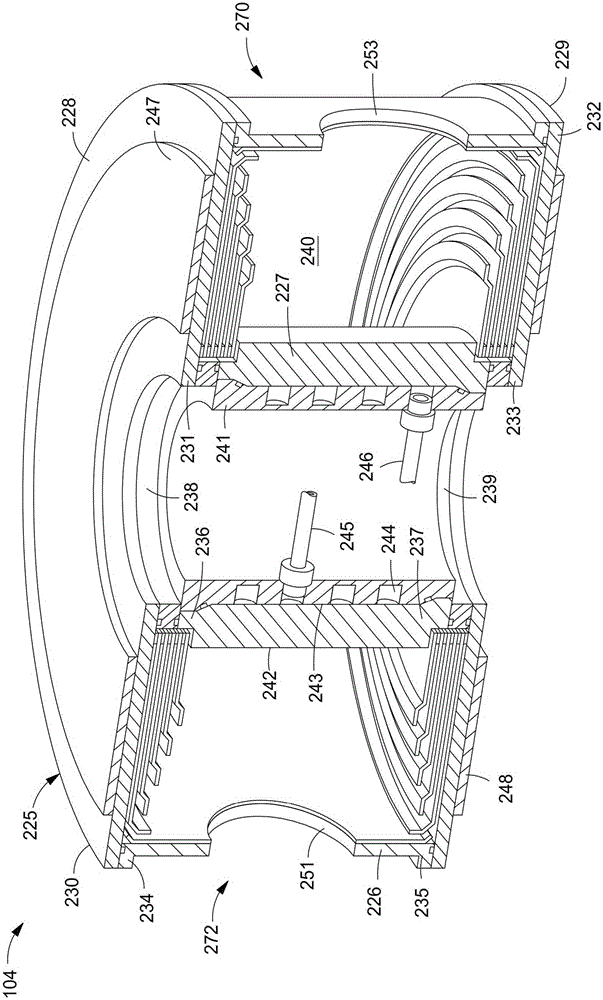

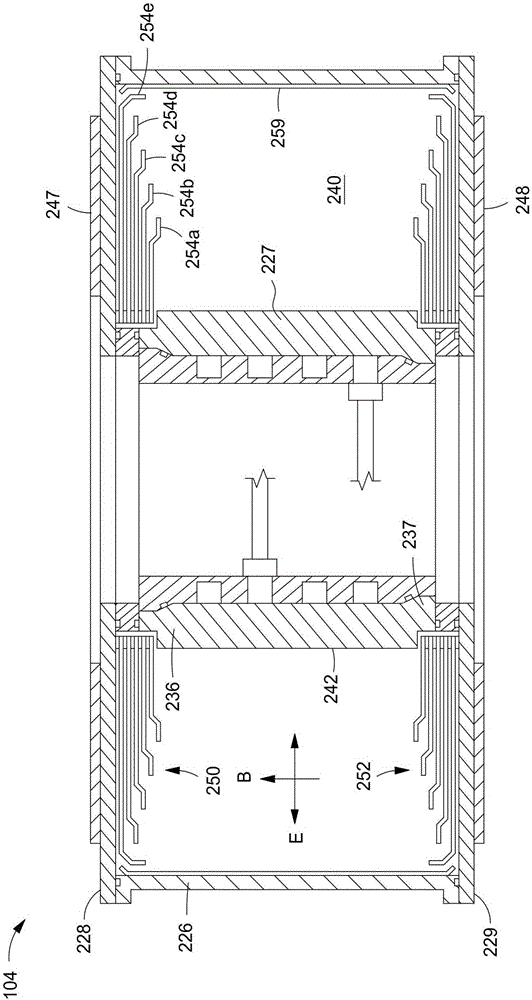

InactiveUS20150252473A1Avoid accumulationElectric discharge tubesSemiconductor/solid-state device manufacturingReactor systemEngineering

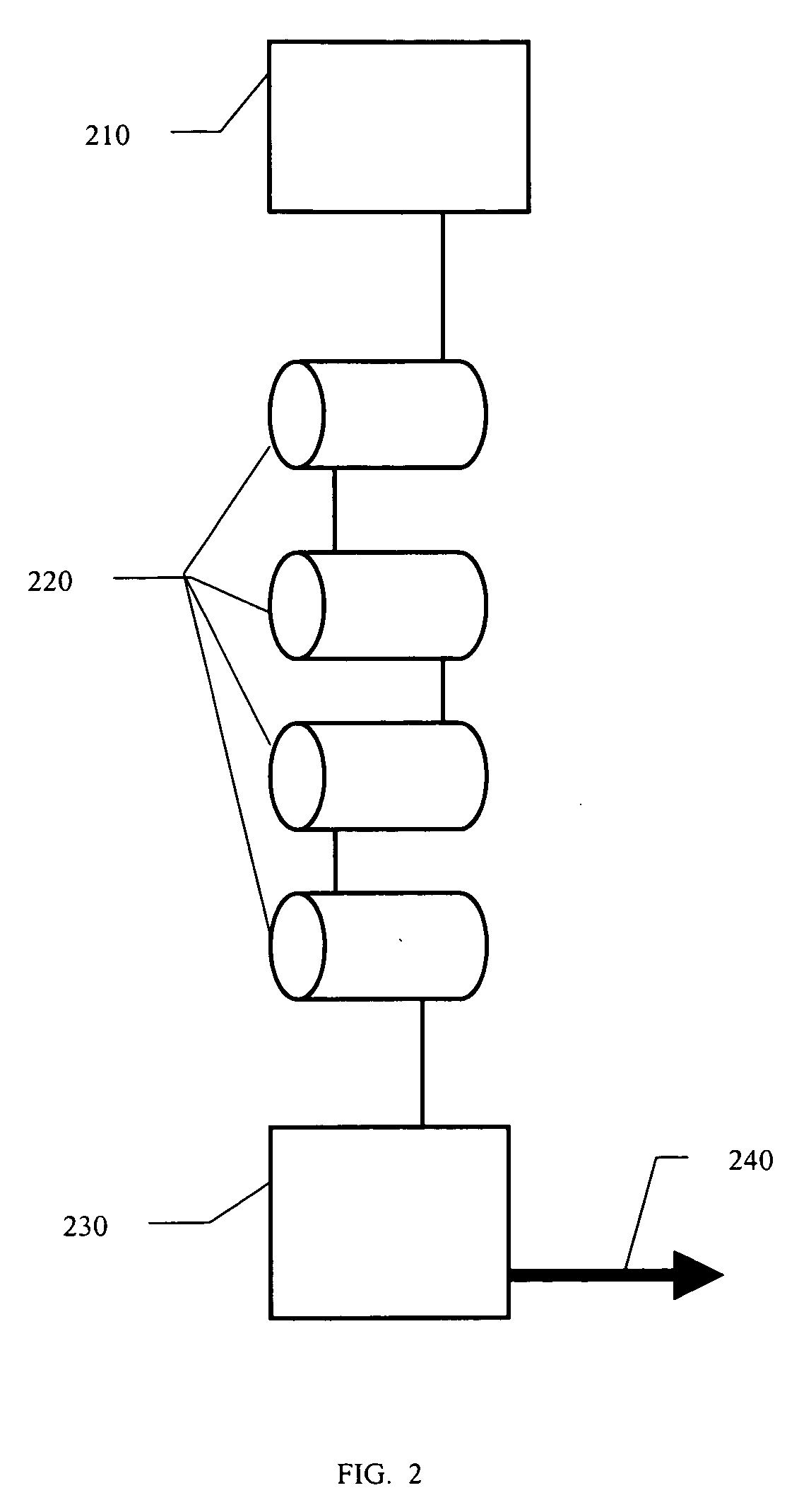

The present disclosure relates to methods and apparatus for treating vacuum processing system exhaust gases. In addition, methods and apparatus for maintenance of foreline plasma reactor subsystems are disclosed. In some embodiments, an apparatus for treating an exhaust gas in a foreline of a vacuum processing system includes a plasma source coupled with a foreline of a process chamber, a treatment agent source coupled with the plasma source, and a downstream trap to cool an exhaust stream and trap particles in the exhaust stream. In some embodiments, multiple foreline plasma reactor subsystems are used with a vacuum processing system, and one foreline plasma reactor subsystem can be isolated and maintained (e.g., cleaned) while exhaust gas treatment continues in another foreline plasma reactor subsystem and processing continues in the vacuum processing system.

Owner:APPLIED MATERIALS INC

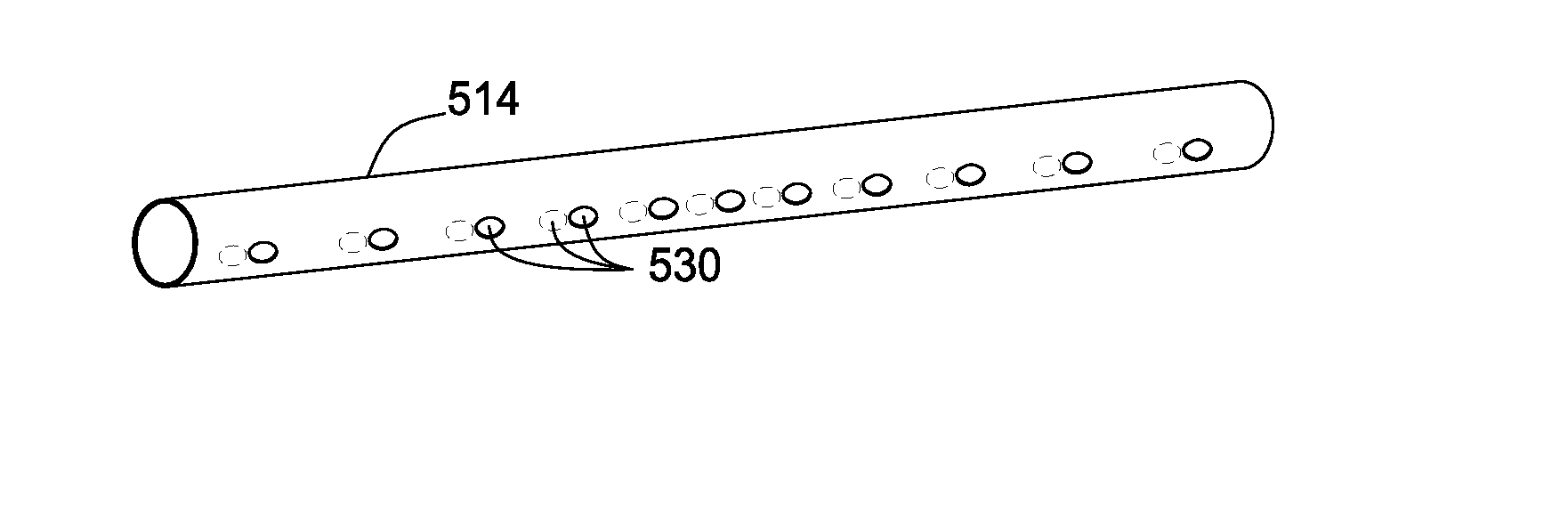

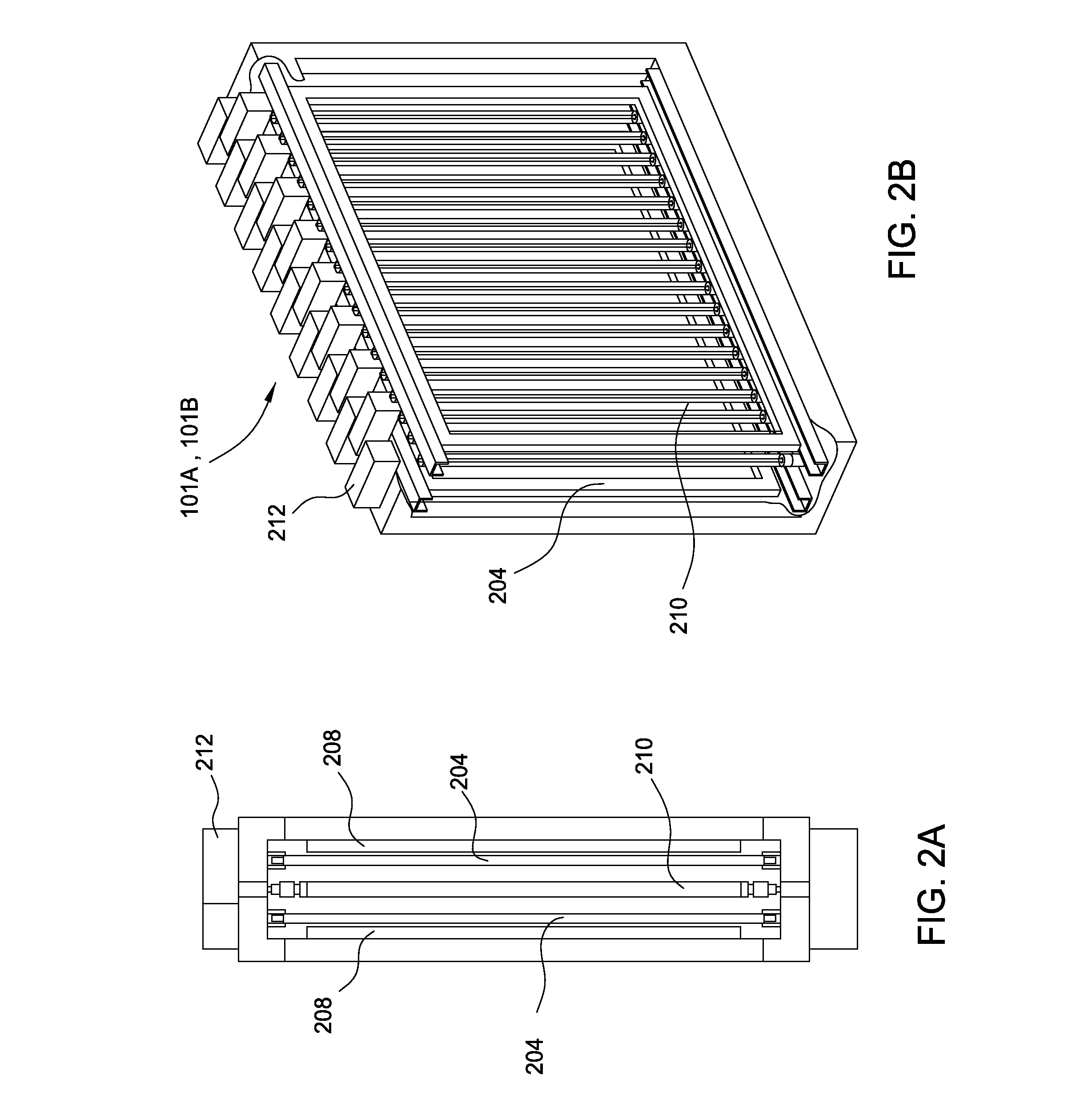

Gas delivery and distribution for uniform process in linear-type large-area plasma reactor

An apparatus for introducing gas into a processing chamber comprising one or more gas distribution tubes having gas-injection holes which may be larger in size, greater in number, and / or spaced closer together at sections of the gas introduction tubes where greater gas conductance through the gas-injection holes is desired. An outside tube having larger gas-injection holes may surround each gas distribution tube. The gas distribution tubes may be fluidically connected to a vacuum foreline to facilitate removal of gas from the gas distribution tube at the end of a process cycle.

Owner:APPLIED MATERIALS INC

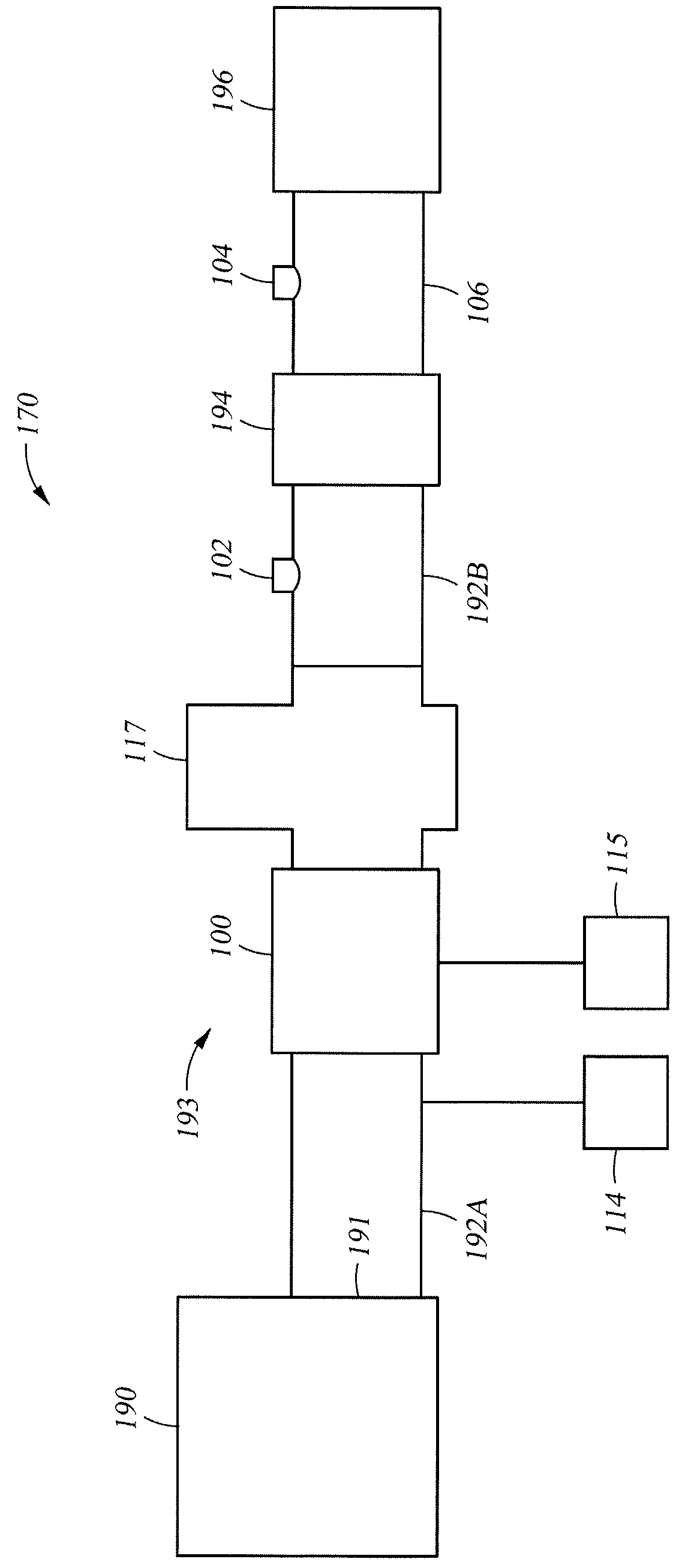

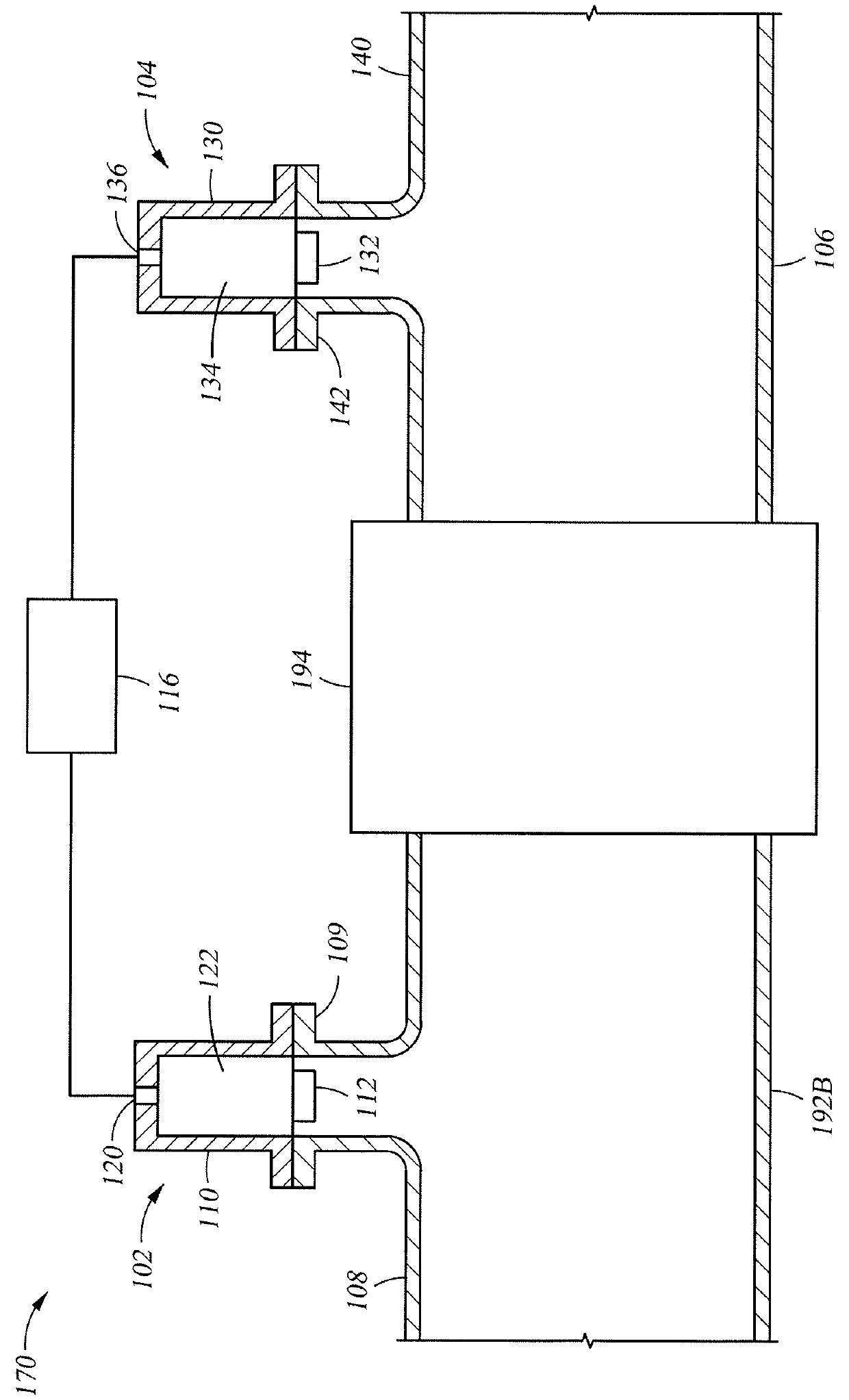

Multi-port pumping system for substrate processing chambers

InactiveUS7964040B2Improve pumping capacityImprove rendering capabilitiesElectric discharge tubesFrozen sweetsEngineeringMulti port

An exhaust foreline for purging fluids from a semiconductor fabrication chamber is described. The foreline may include a first, second and third ports independently coupled to the chamber. A semiconductor fabrication system is also described that includes a substrate chamber that has a first, second and third interface port. The system may also include a multi-port foreline that has a first, second and third port, where the first foreline port is coupled to the first interface port, the second foreline port is coupled to the second interface port, and the third foreline port is coupled to the third interface port. The system may further include an exhaust vacuum coupled to the multi-port foreline.

Owner:APPLIED MATERIALS INC

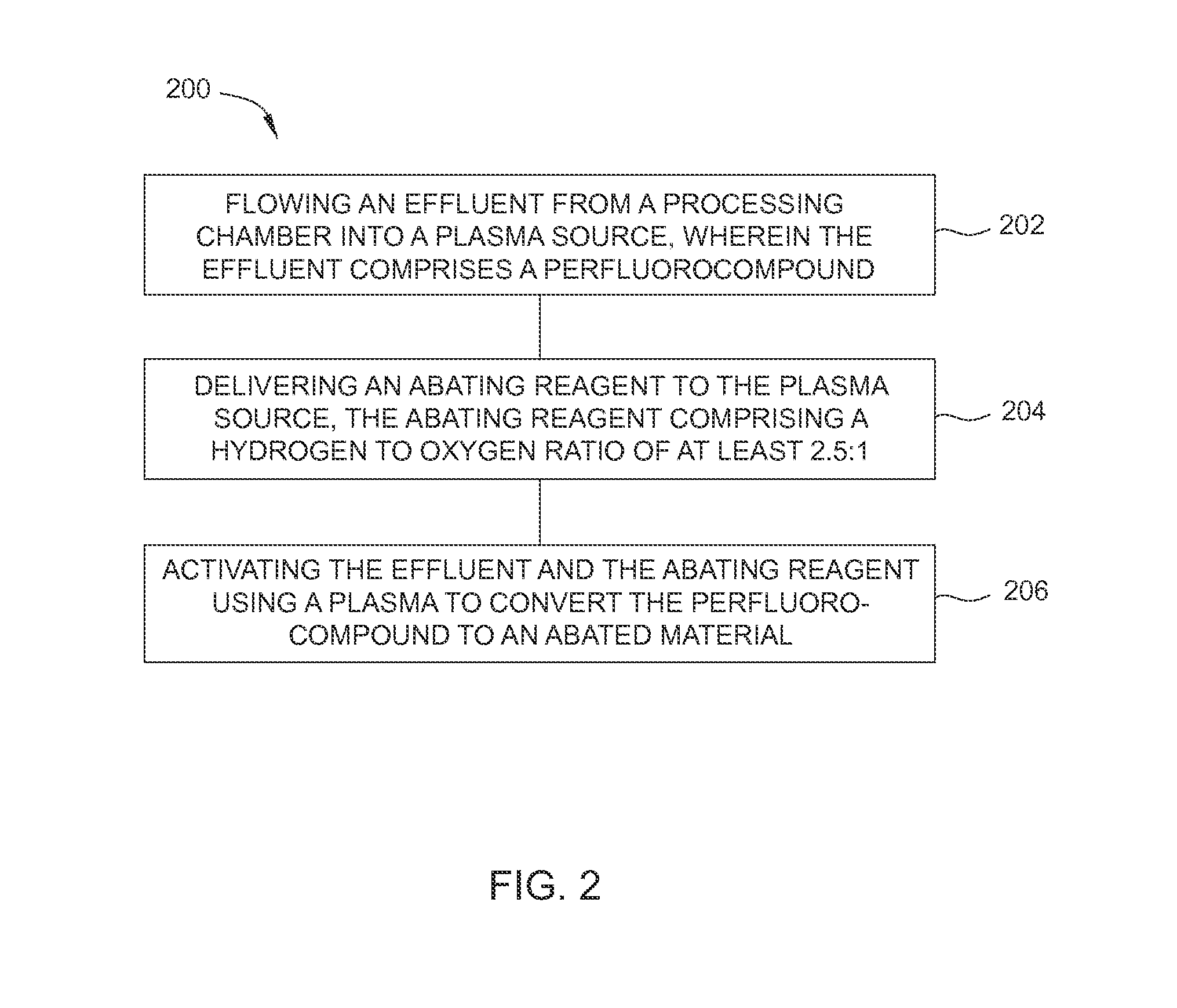

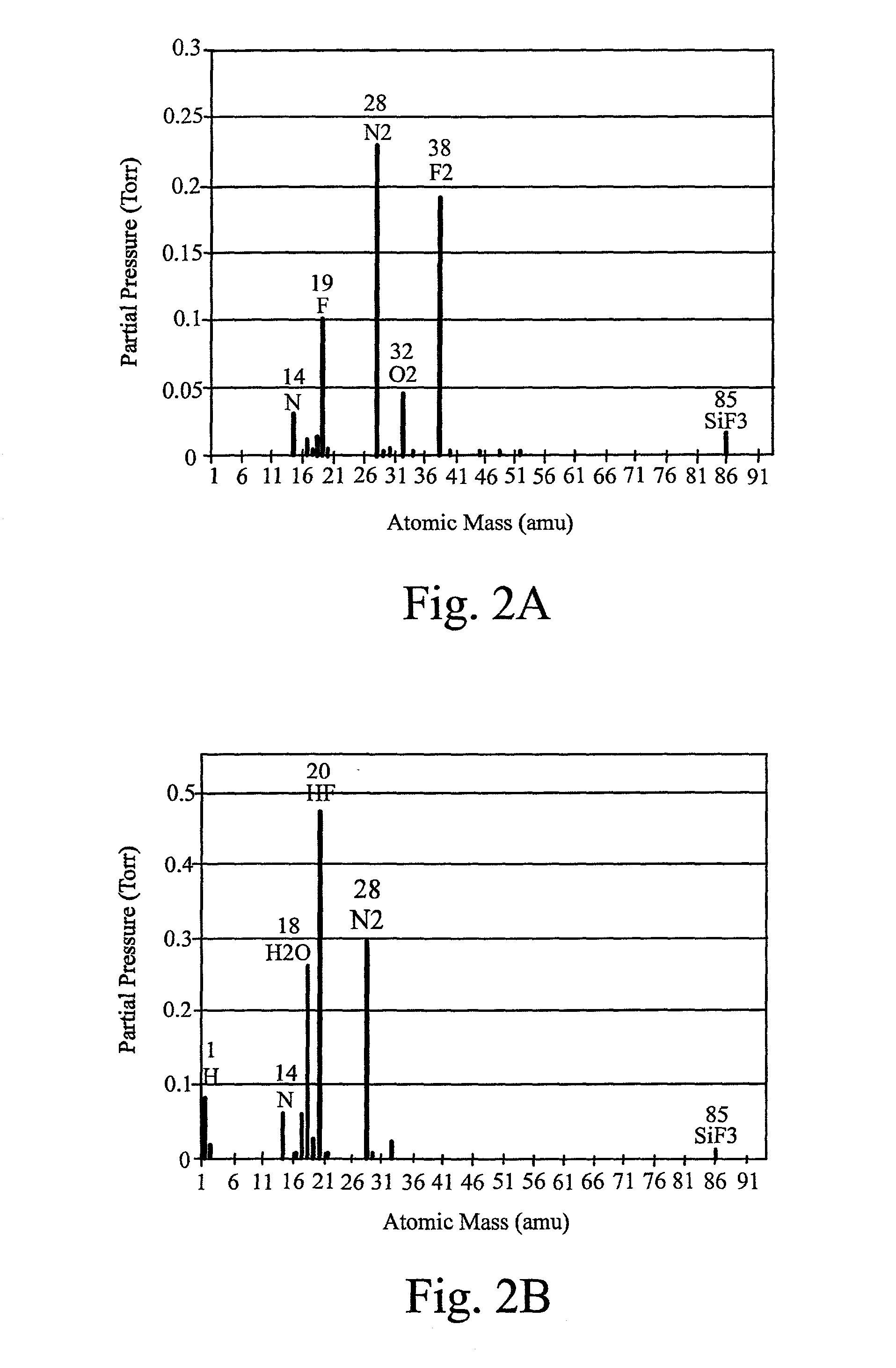

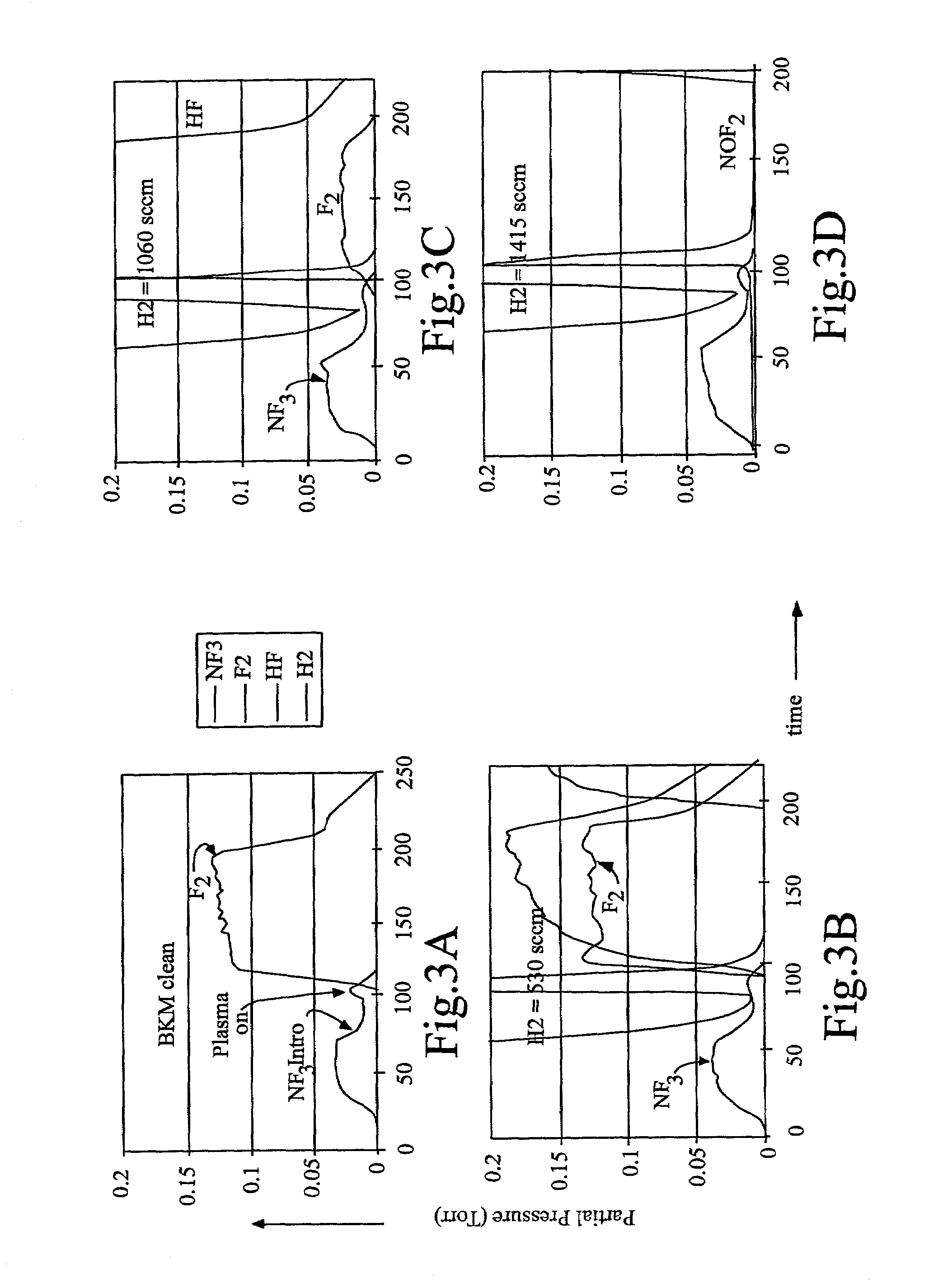

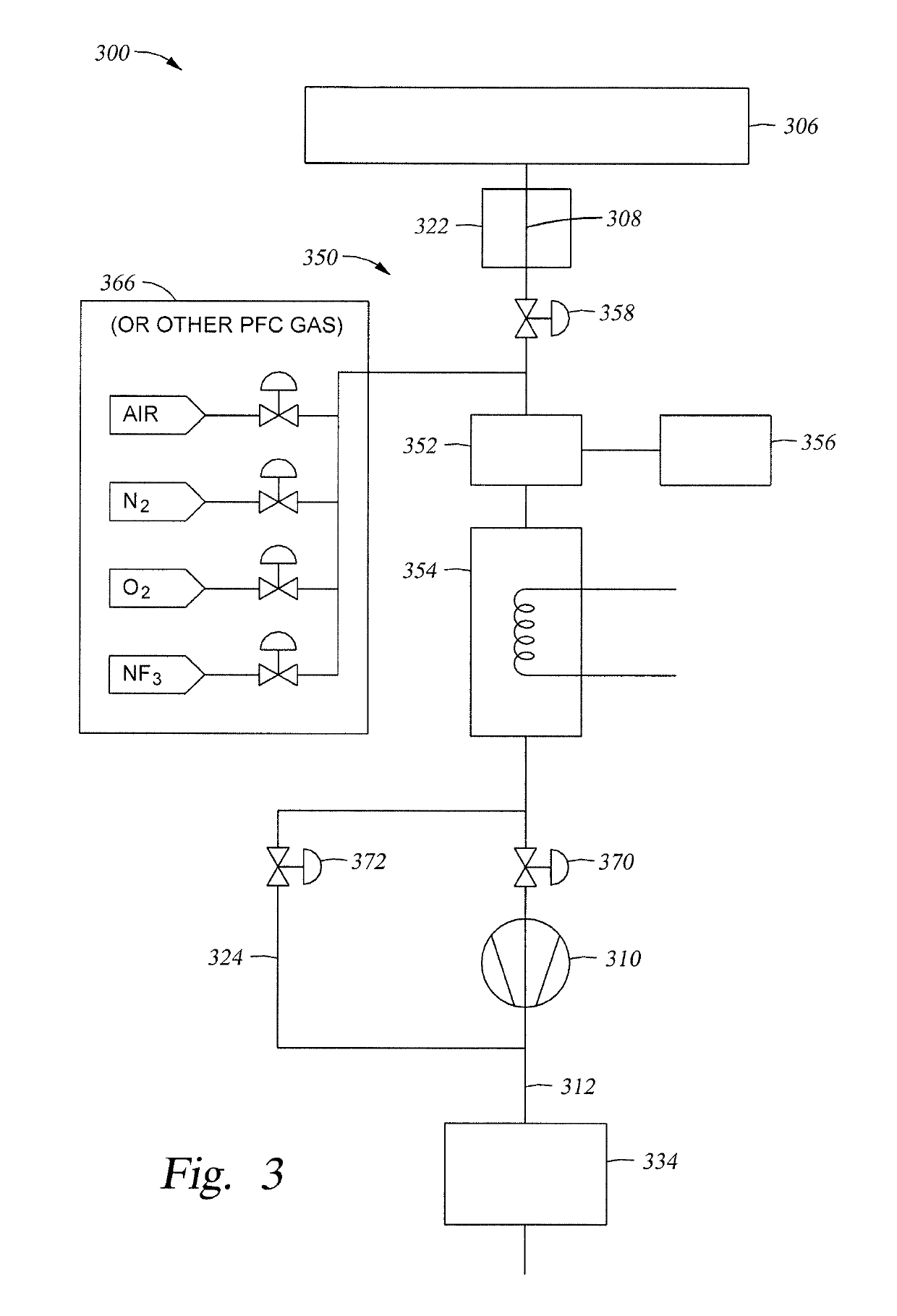

Plasma abatement using water vapor in conjunction with hydrogen or hydrogen containing gases

InactiveUS20160166868A1Maintain effective PFC abatement performanceAdd supportElectric discharge tubesPerfluorocarbons/hydrofluorocarbons captureHydrogenWater vapor

A plasma abatement process for abating effluent containing a PFC gas from a processing chamber is described. A plasma abatement process takes gaseous foreline effluent from a processing chamber, such as an etch chamber, and reacts with the effluent within a plasma chamber placed in the foreline path. The plasma dissociates the PFC gases and reacts them with a reagent, converting the effluent into compounds that are non-global warming and which may be easily removed by traditional facility water scrubbing technology. This disclosure explains methods to control the reagent hydrogen to oxygen ratio such that in addition to PFC destruction, the abated compounds have modified composition to enable extension of the maintenance interval for downstream supporting equipment.

Owner:APPLIED MATERIALS INC

High efficiency trap for deposition process

InactiveUS20060276049A1Improve efficiencyReduce accumulationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringDeposition process

The present invention provides a system, apparatus and method for improving the efficiency of a semiconductor processing system, such as a deposition system by decreasing or substantially eliminating the accumulation of by-products in the apparatus components of the semiconductor processing system. The present invention further relates to improving the efficiency of a foreline trap associated with a semiconductor processing system, wherein the trap removes substantially all of the by-products from the exhaust gas from the processing chamber. In addition, the present invention provides a system, apparatus and method for efficiently clearing traps of accumulated by-products from exhaust gas of a semiconductor processing system.

Owner:EDWARDS VACUUM INC

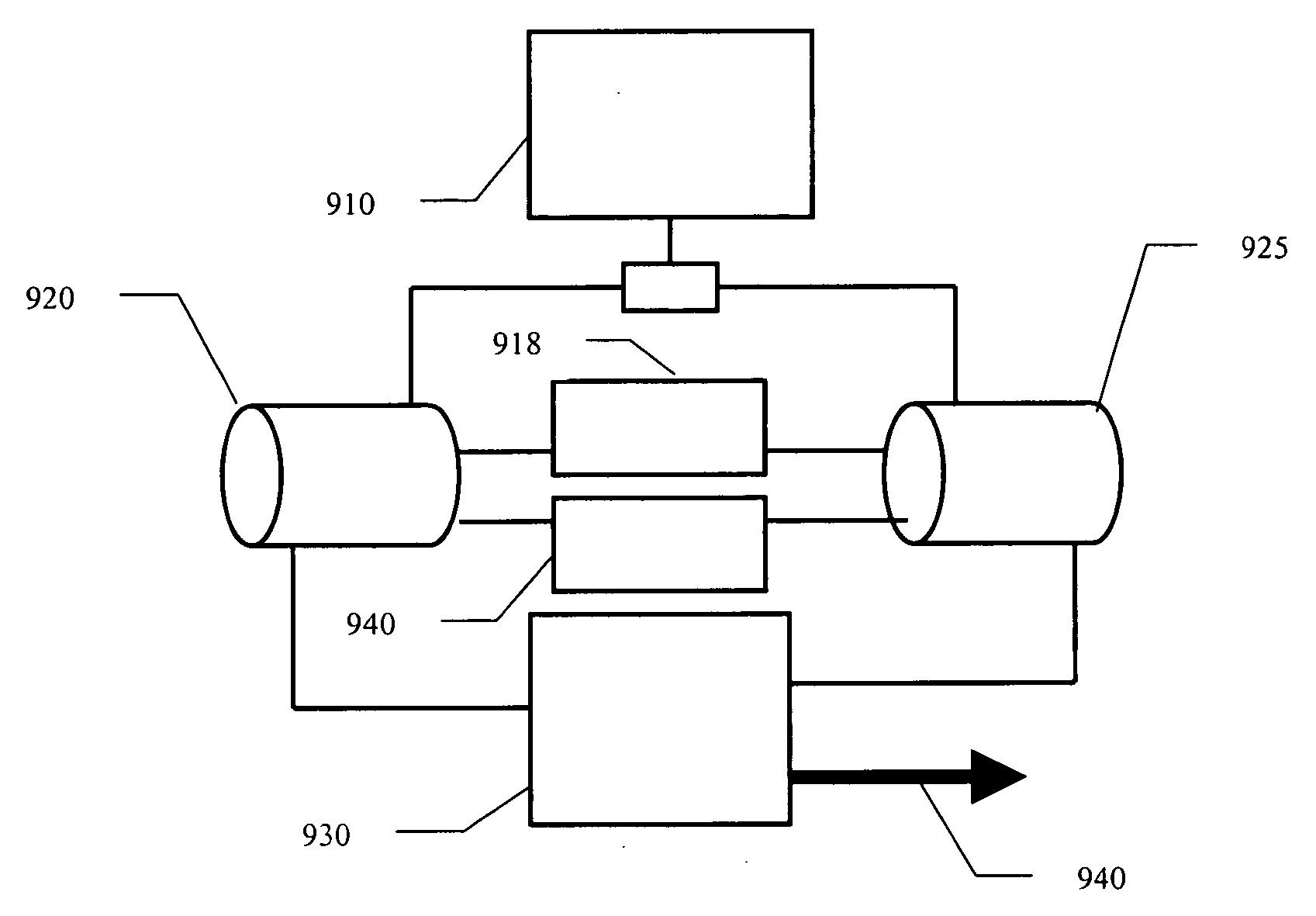

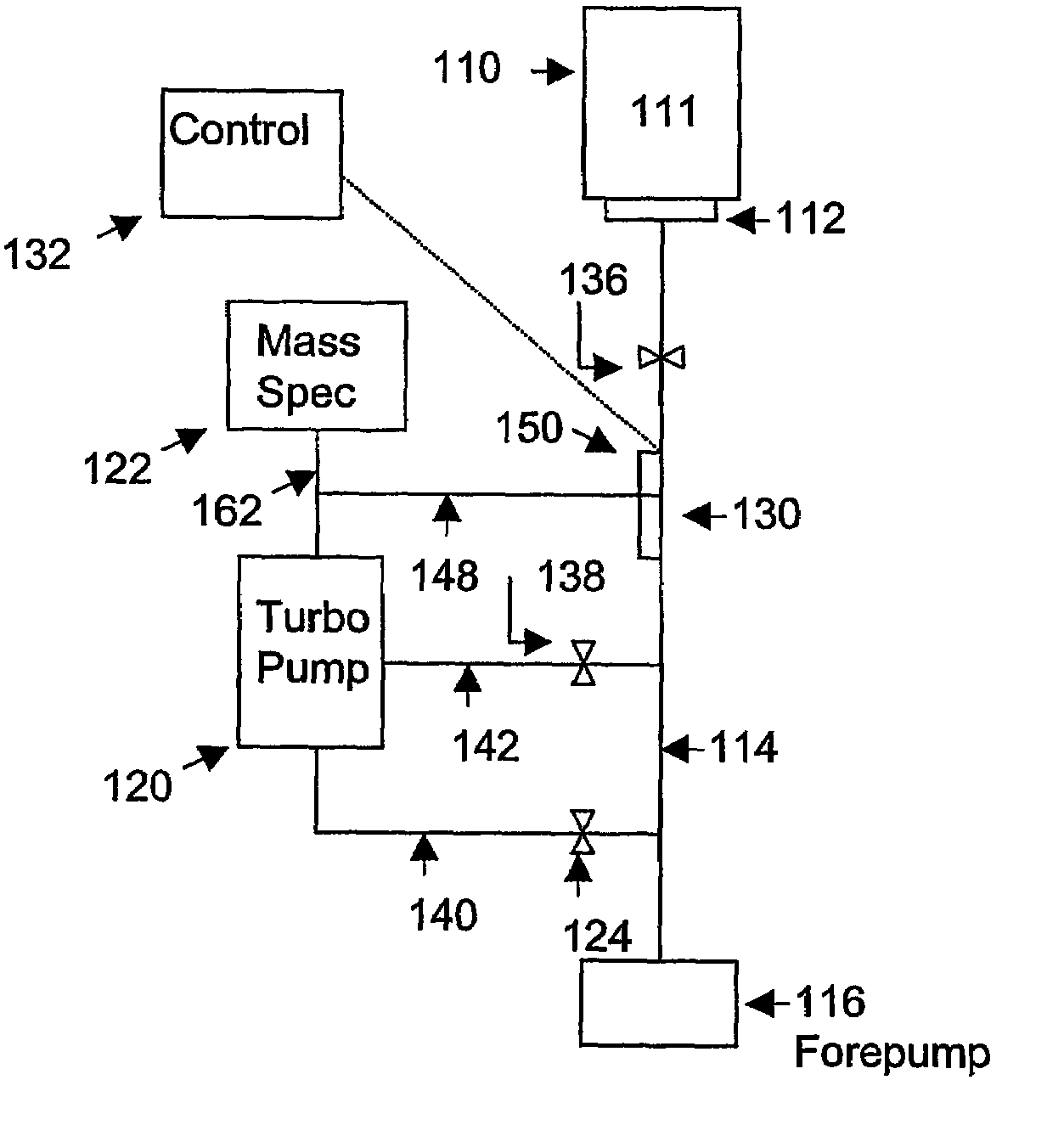

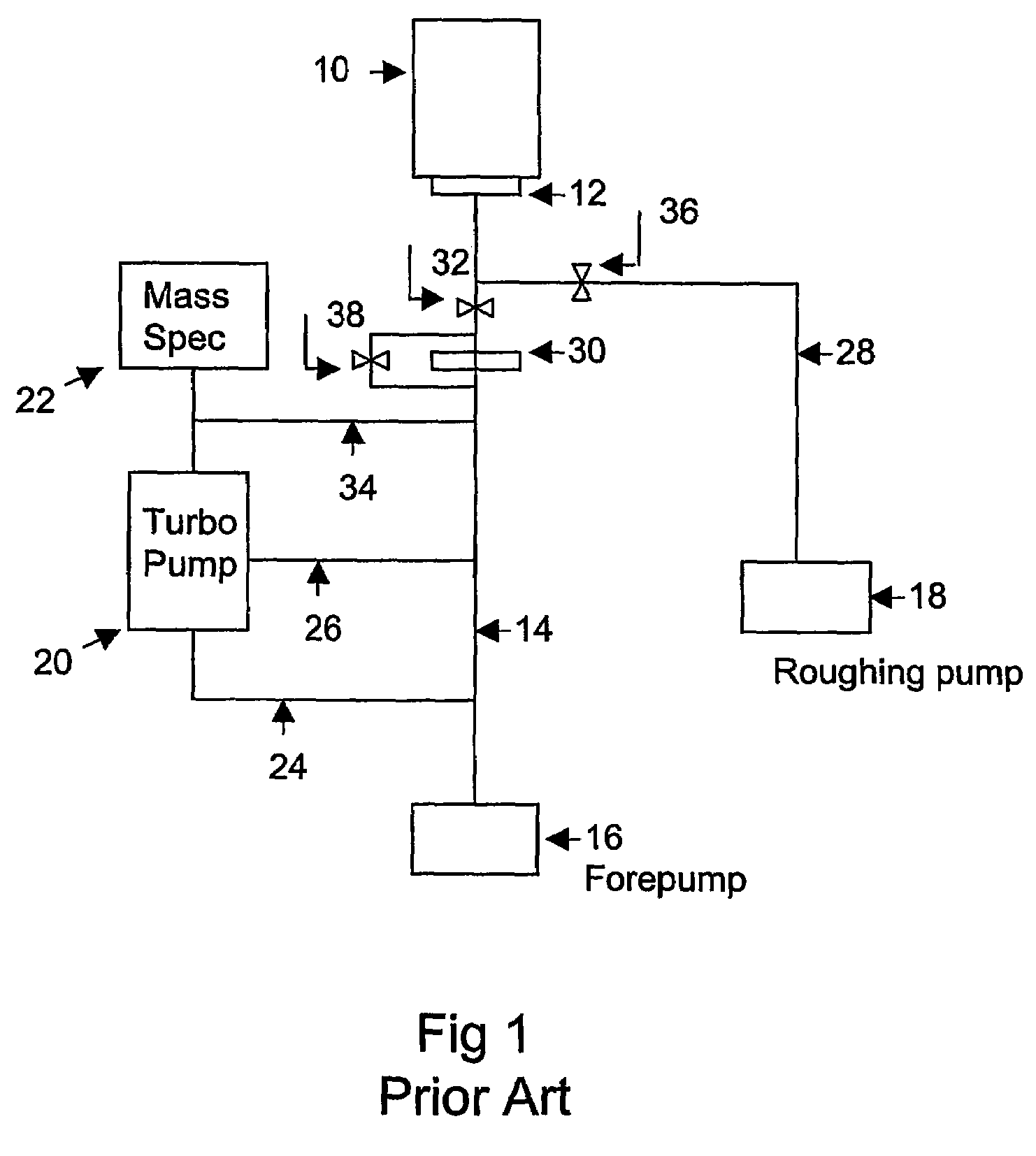

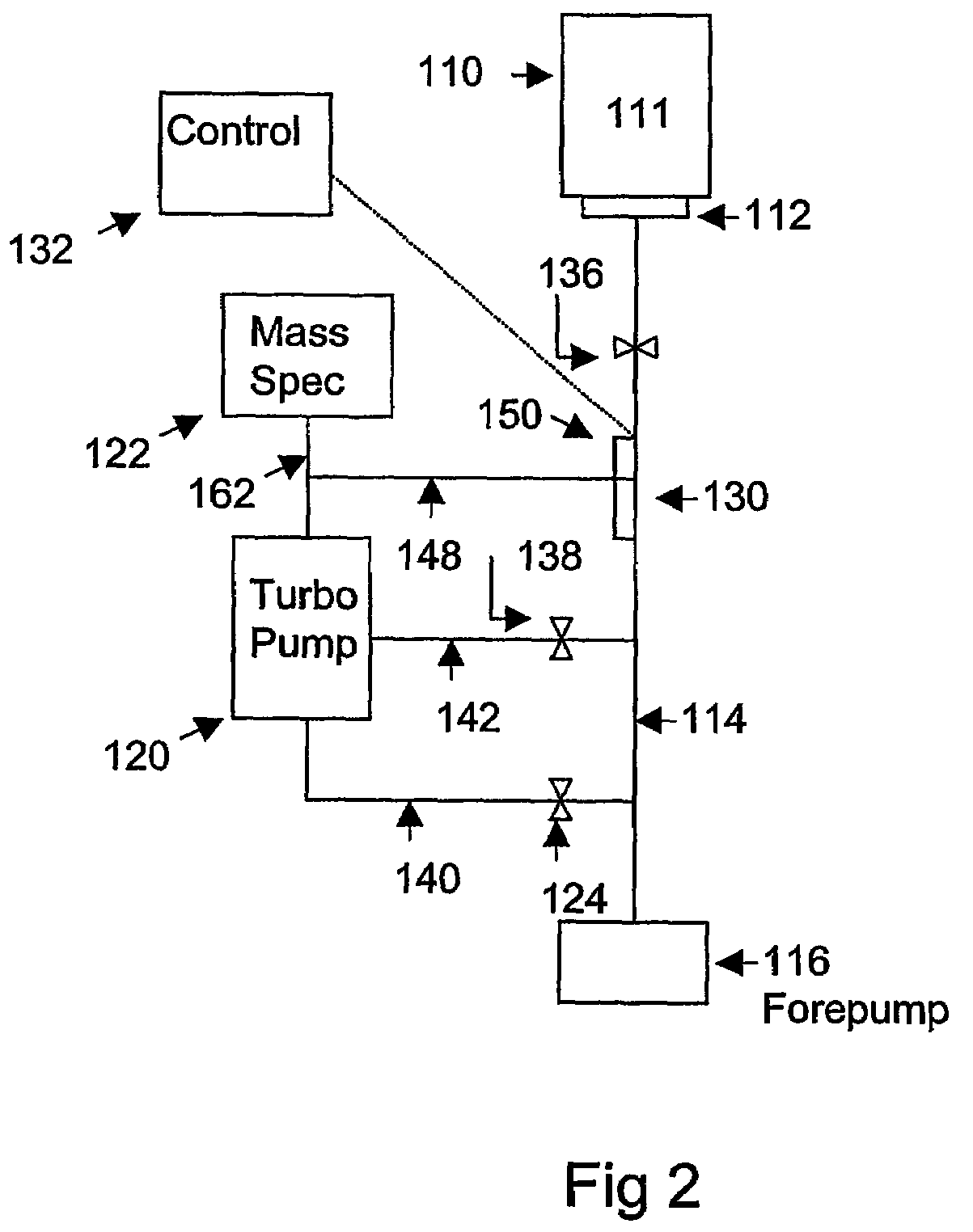

Method and apparatus for large leak testing

InactiveUS20050199042A1High reverse flow rateReduce the chance of backflowDetection of fluid at leakage pointEngineeringLeak testing

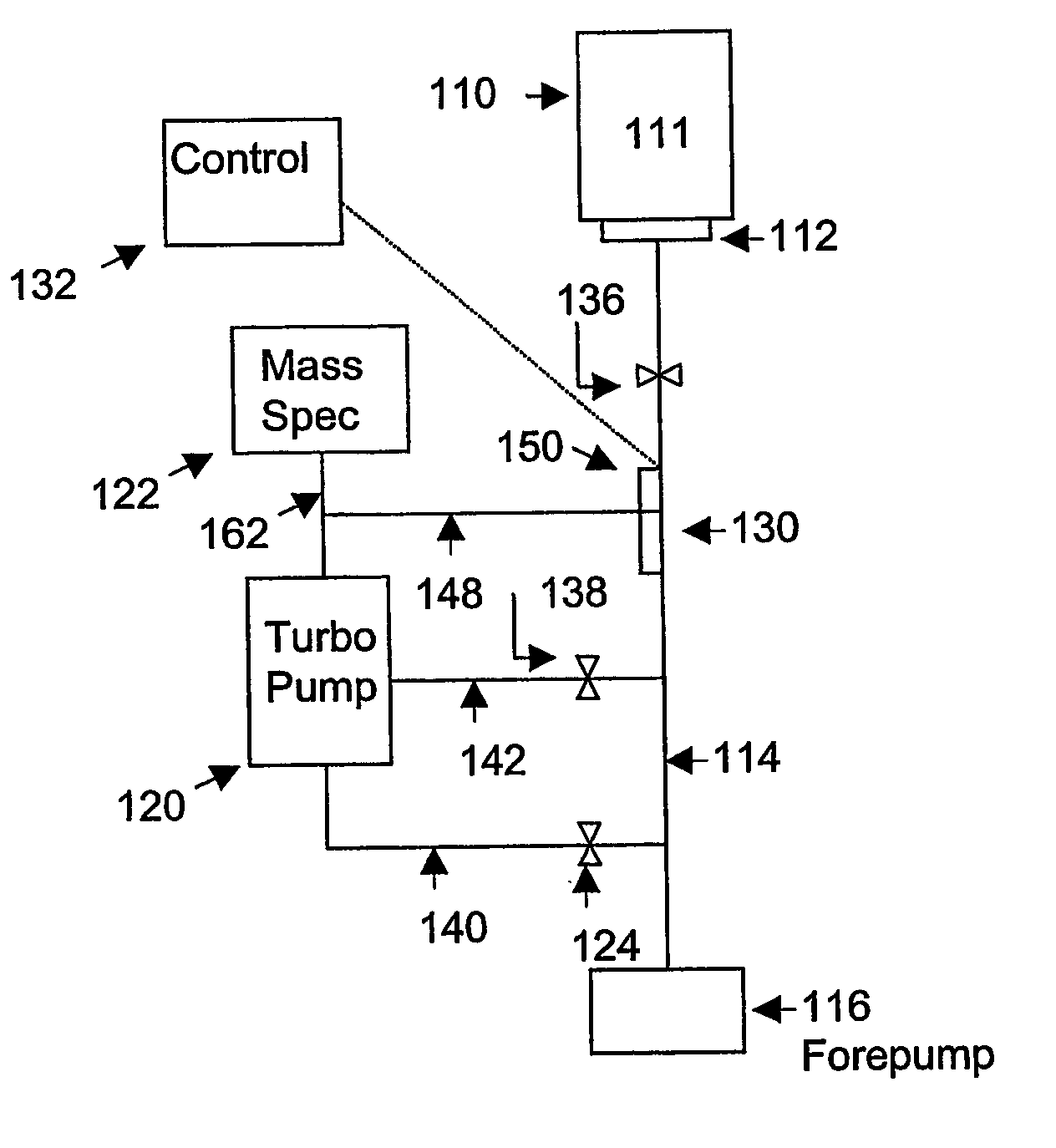

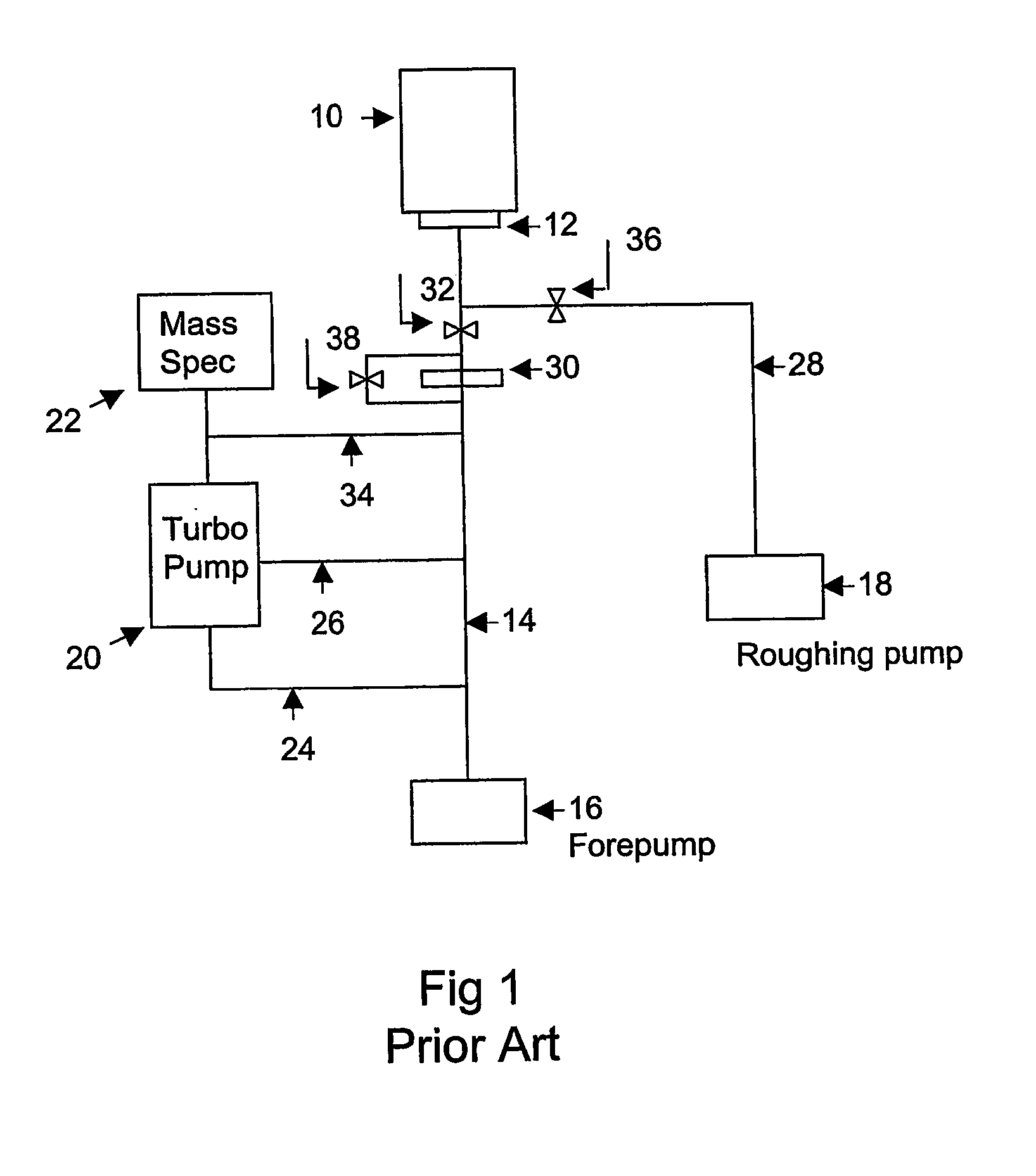

Methods and apparatus for large leak testing are provided. The apparatus includes a test line to receive a sample containing a trace gas, a mass spectrometer to detect the trace gas and having an inlet for receiving the trace gas, a first vacuum pump characterized by a relatively high reverse flow rate for light gases and a relatively low reverse flow rate for heavy gases, the first vacuum pump having a pump inlet and a foreline, the pump inlet being coupled to the inlet of the mass spectrometer, and a second vacuum pump configured to back the first vacuum pump. The apparatus further includes a trace gas permeable member coupled between the test line and the pump inlet, the foreline, or, in the case where the first vacuum pump is a turbomolecular pump, a midstage line.

Owner:AGILENT TECH INC

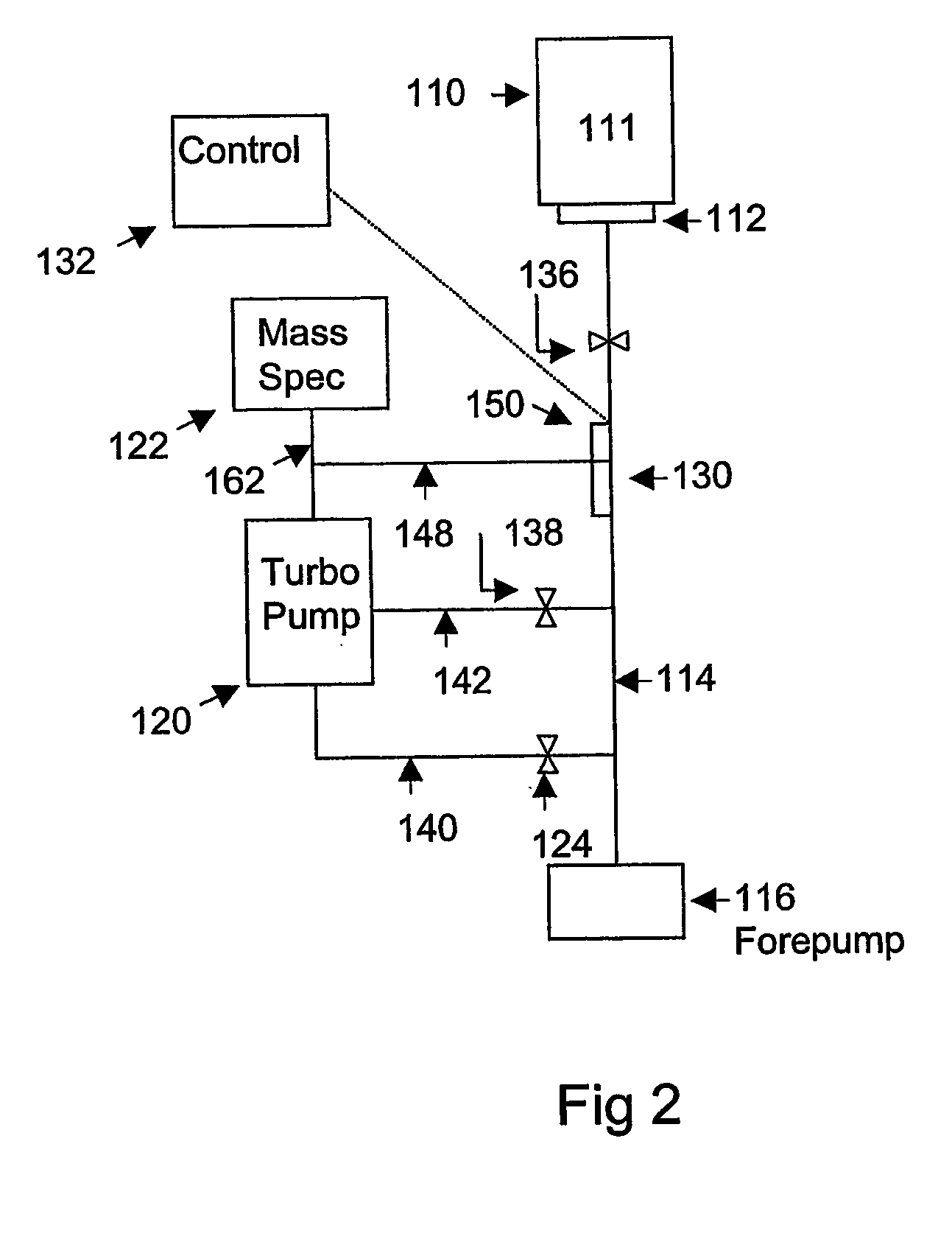

Method and apparatus for large leak testing

Methods and apparatus for large leak testing are provided. The apparatus includes a test line to receive a sample containing a trace gas, a mass spectrometer to detect the trace gas and having an inlet for receiving the trace gas, a first vacuum pump characterized by a relatively high reverse flow rate for light gases and a relatively low reverse flow rate for heavy gases, the first vacuum pump having a pump inlet and a foreline, the pump inlet being coupled to the inlet of the mass spectrometer, and a second vacuum pump configured to back the first vacuum pump. The apparatus further includes a trace gas permeable member coupled between the test line and the pump inlet, the foreline, or, in the case where the first vacuum pump is a turbomolecular pump, a midstage line.

Owner:AGILENT TECH INC

Apparatus and method for fabricating semiconductor device and removing by-products

InactiveUS20080057726A1Semiconductor/solid-state device manufacturingElectrostatic cleaningRemote plasmaProduct gas

An apparatus and a method for fabricating a semiconductor device are provided. The method can efficiently remove by-products from a foreline connected to a process chamber. The apparatus includes a remote plasma source, which generates a plasma gas. The plasma gas is guided to the foreline, so as to remove impurities formed on an inner wall of the foreline.

Owner:DONGBU HITEK CO LTD

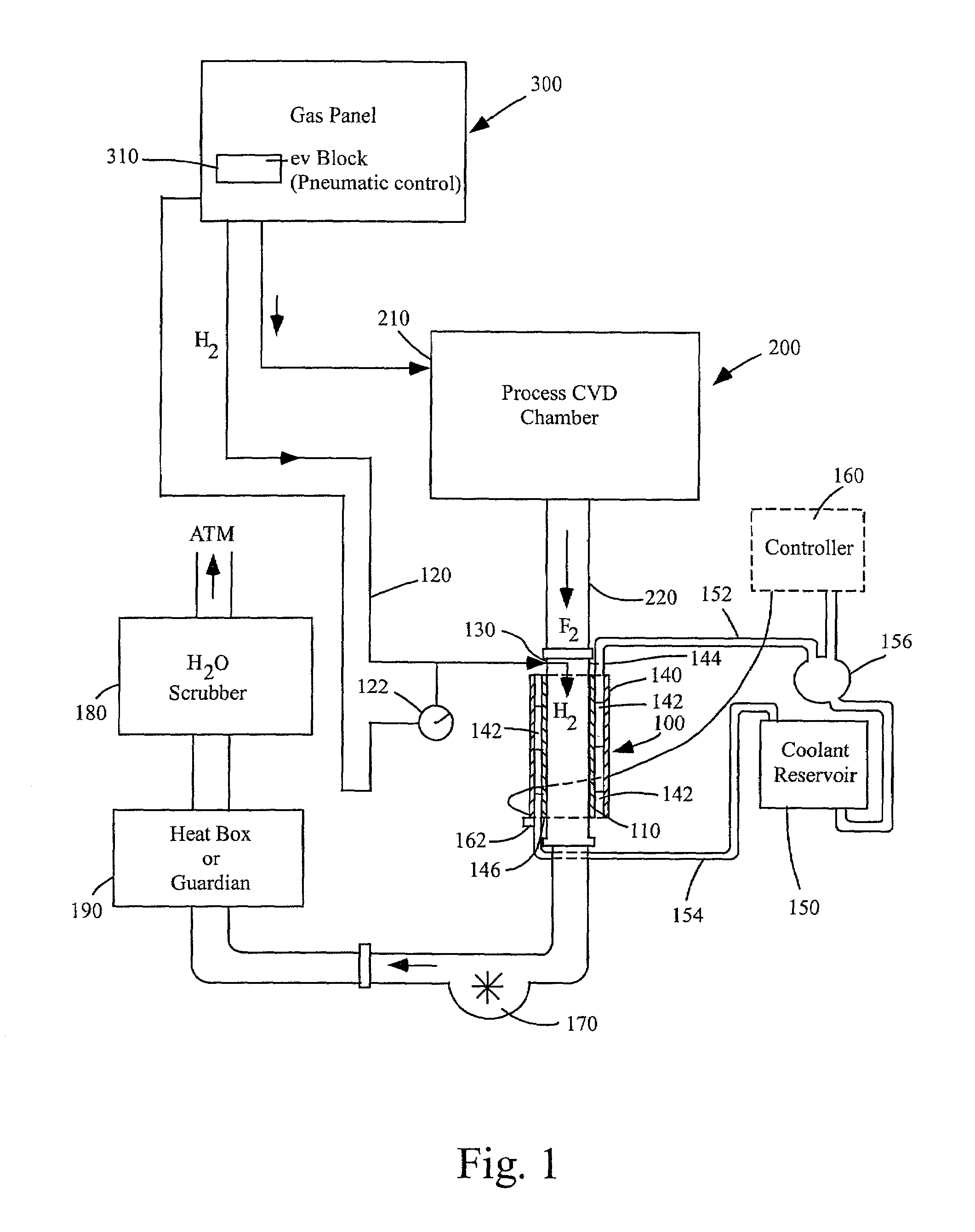

Apparatus for abatement of by-products generated from deposition processes and cleaning of deposition chambers

InactiveUS7494628B2Easy to disassembleCombination devicesGas treatmentDeposition processMechanical engineering

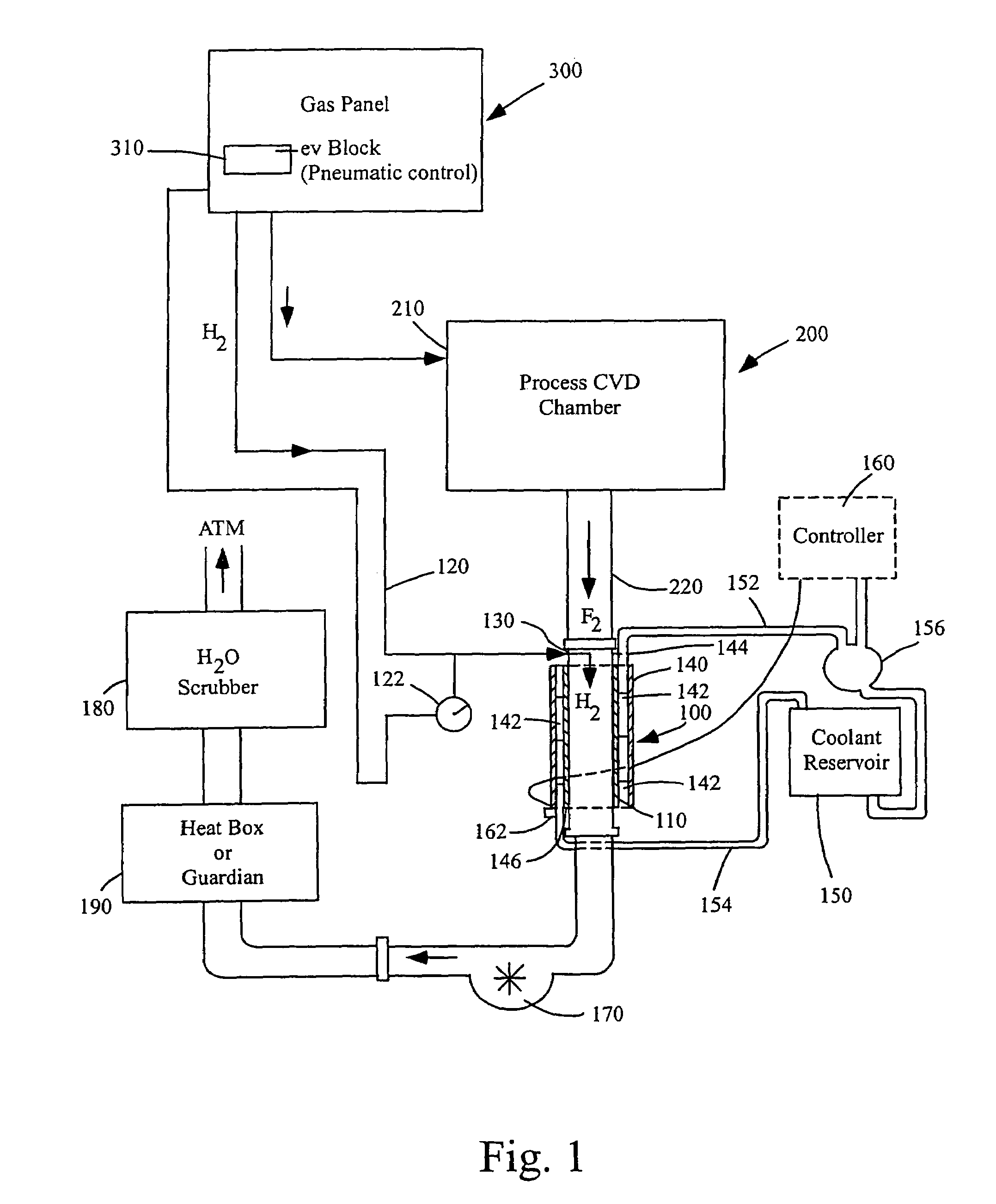

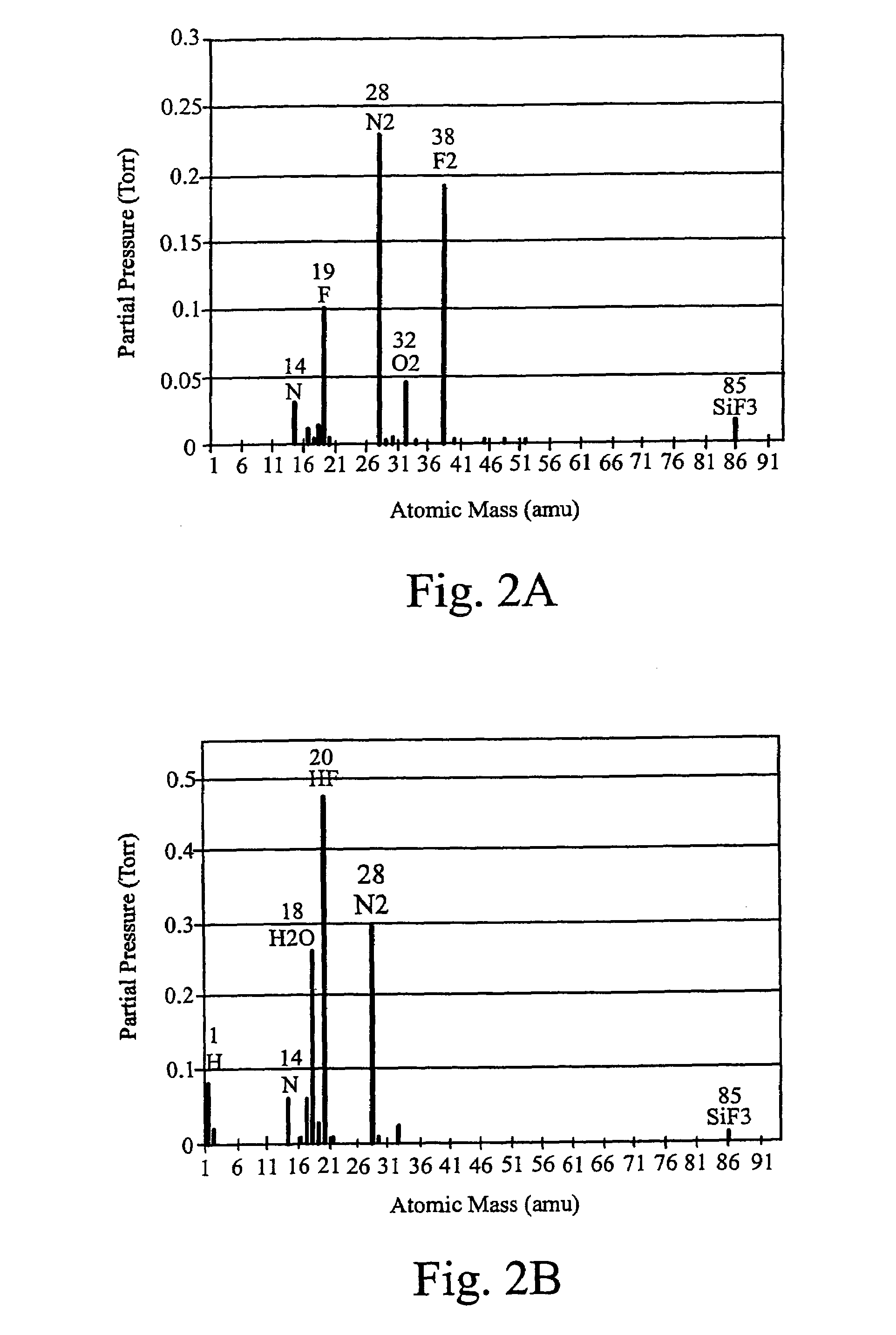

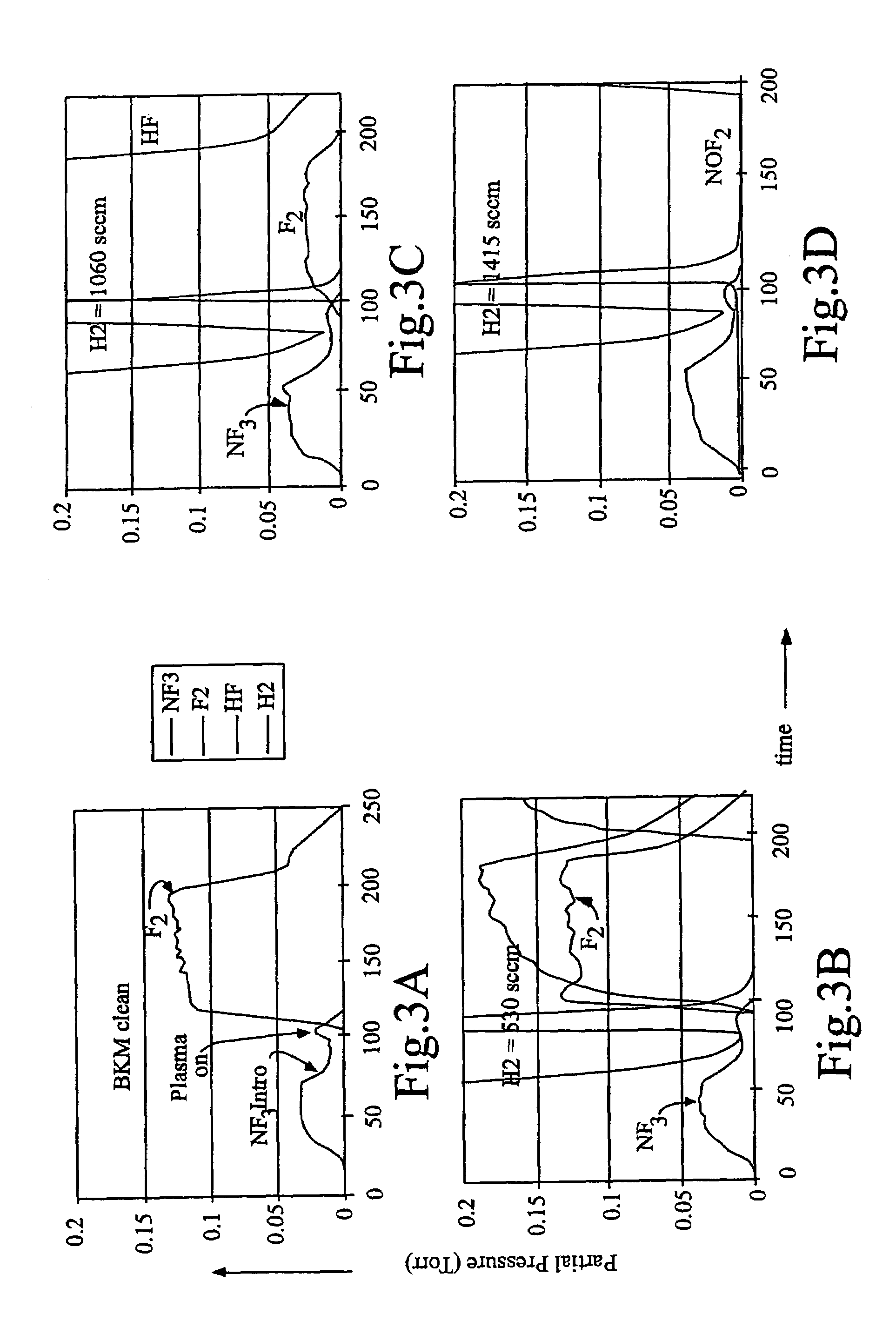

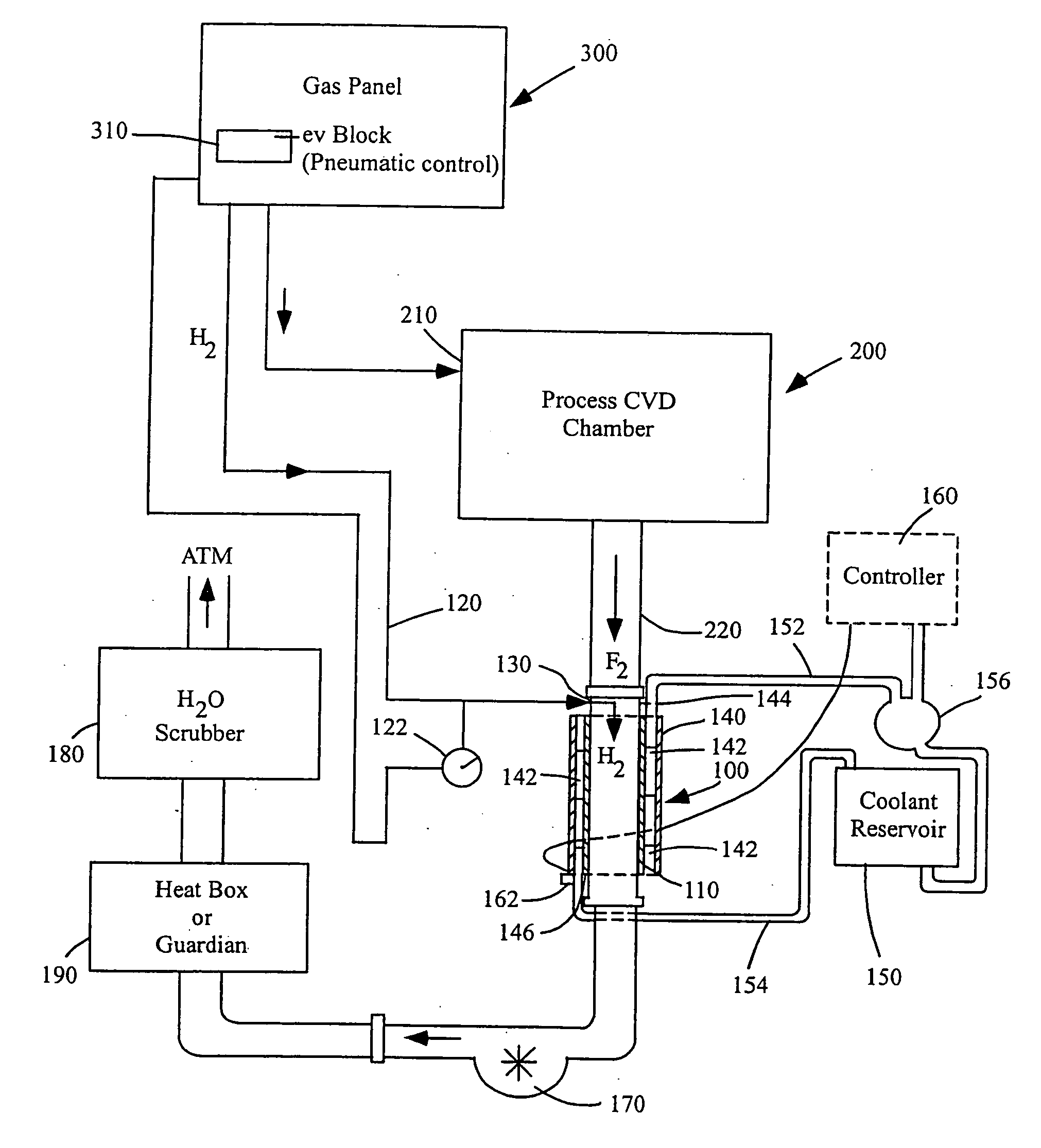

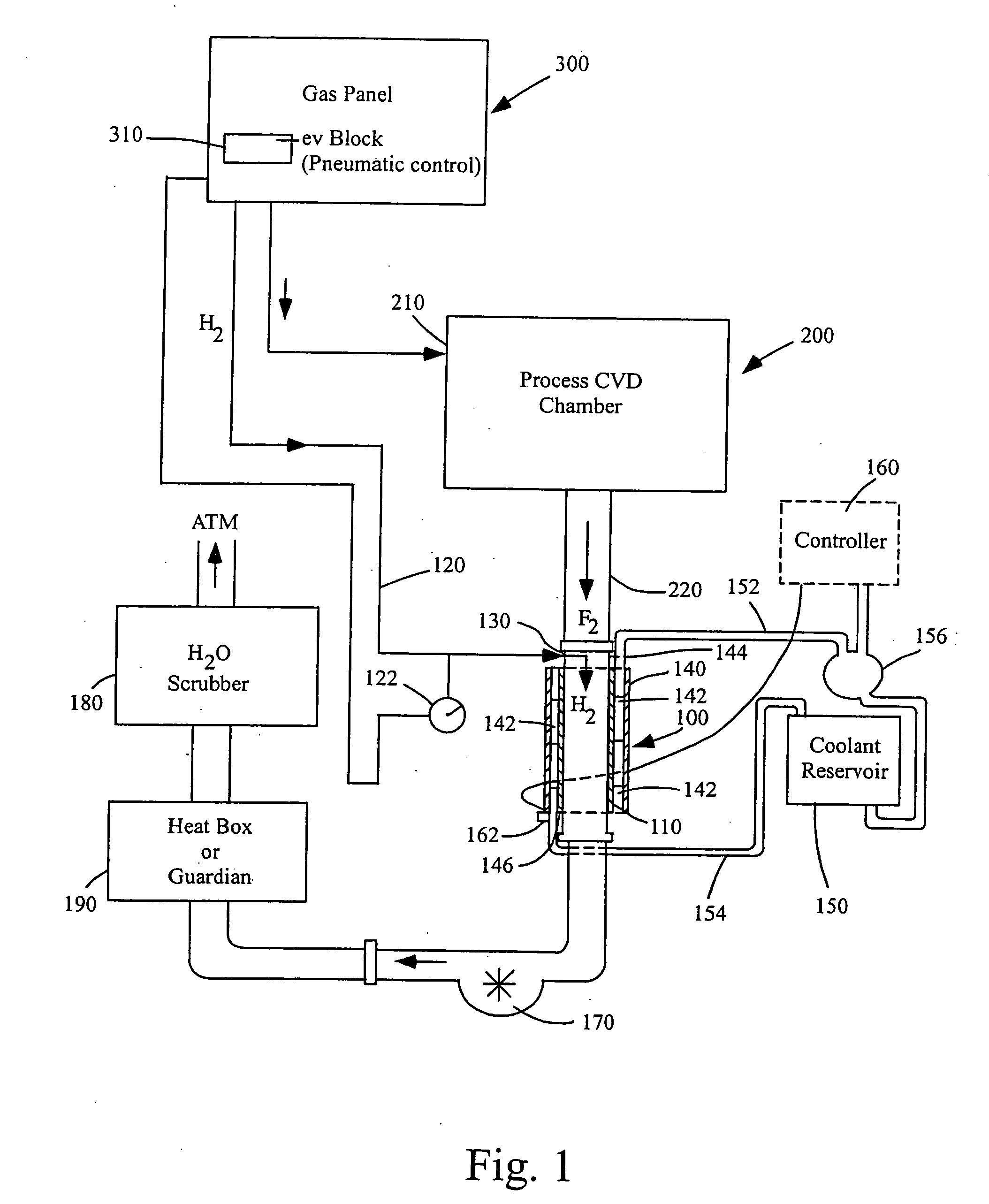

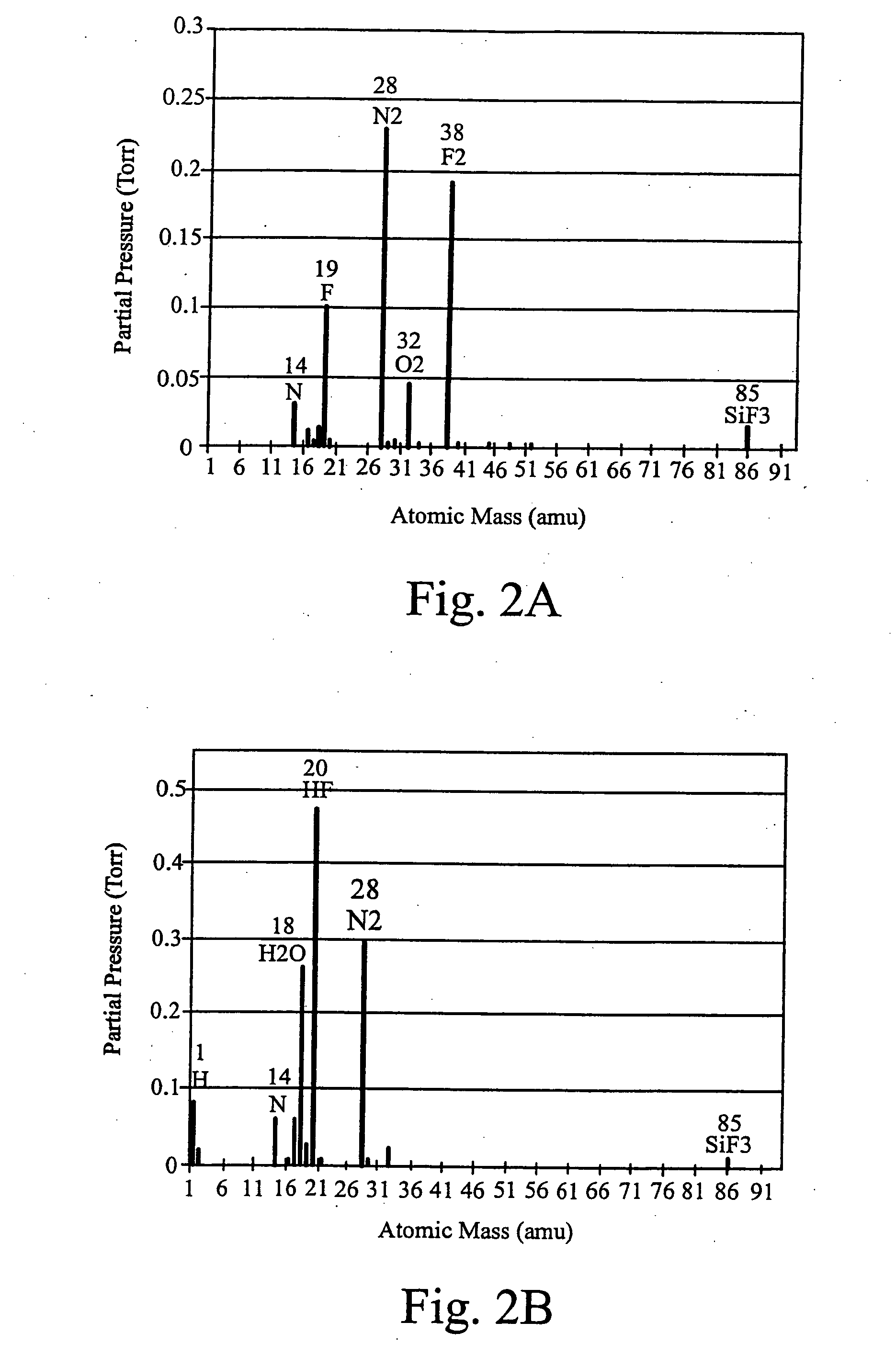

Method and apparatus for abating F2 from by-products generated during cleaning of a processing chamber. F2 abatement is efficiently performed by directly injecting H2 in line with a foreline exiting the processing chamber. A tube which is highly resistant to oxidation and corrosive gases, even at high temperature, is connected in line with the foreline as part of the exhaust line of the processing chamber. A cooling jacket may be provided for cooling the tube, since the reaction between F2 and H2 is exothermic. A pressure monitoring arrangement may also be employed to insure that pressure within a hydrogen line, that feeds the injection of H2 into the tube, does not exceed a predetermined pressure value.

Owner:APPLIED MATERIALS INC

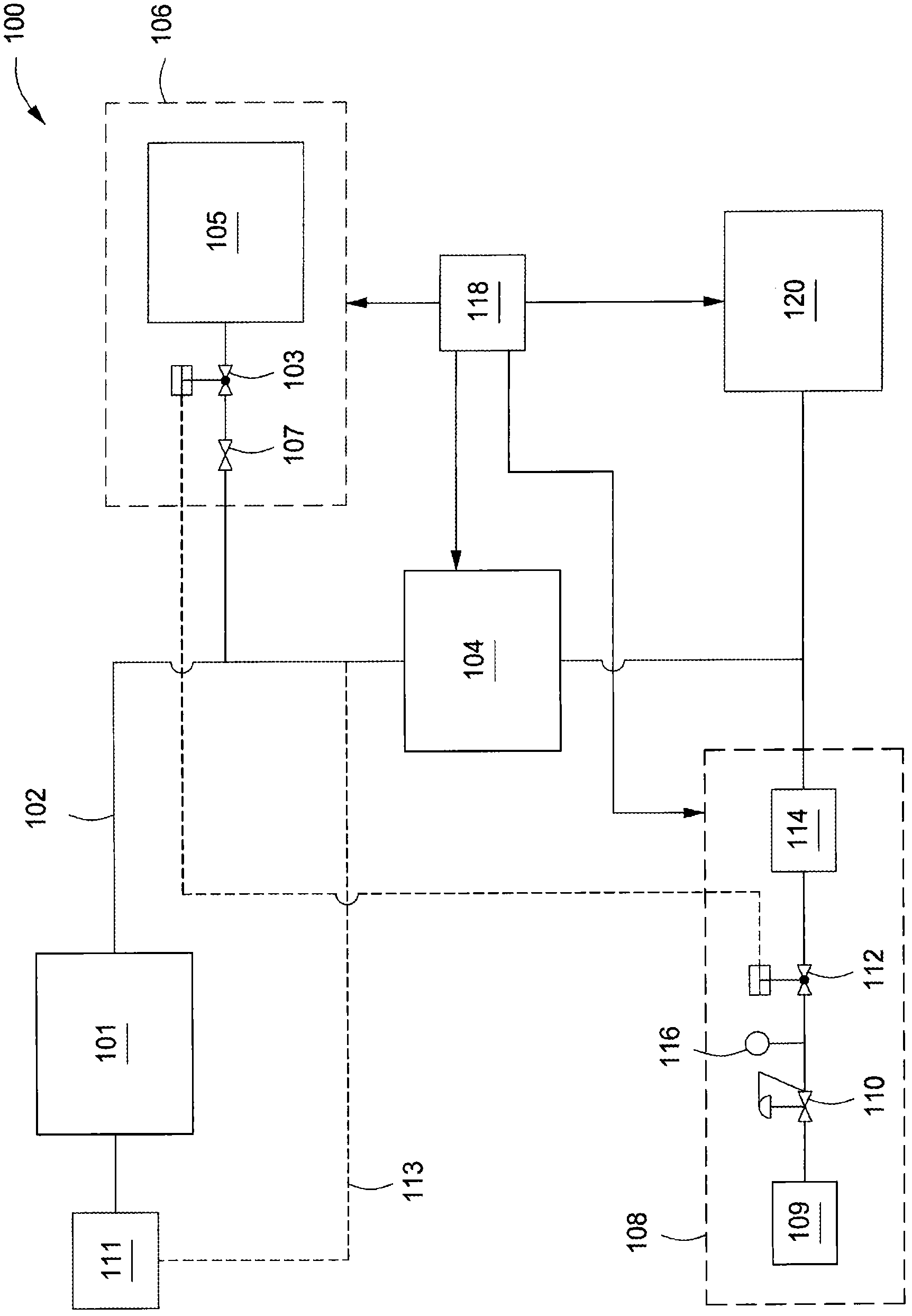

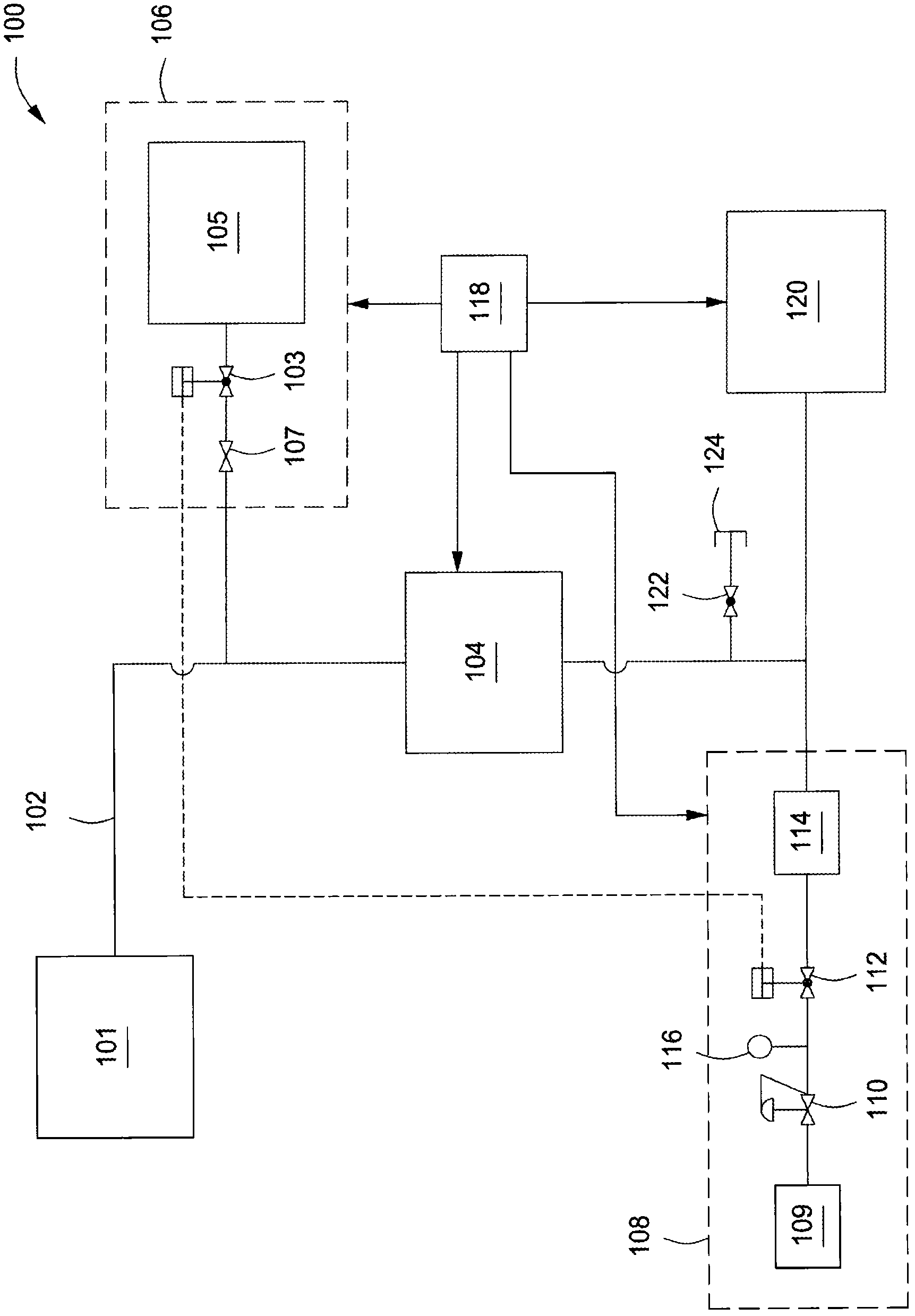

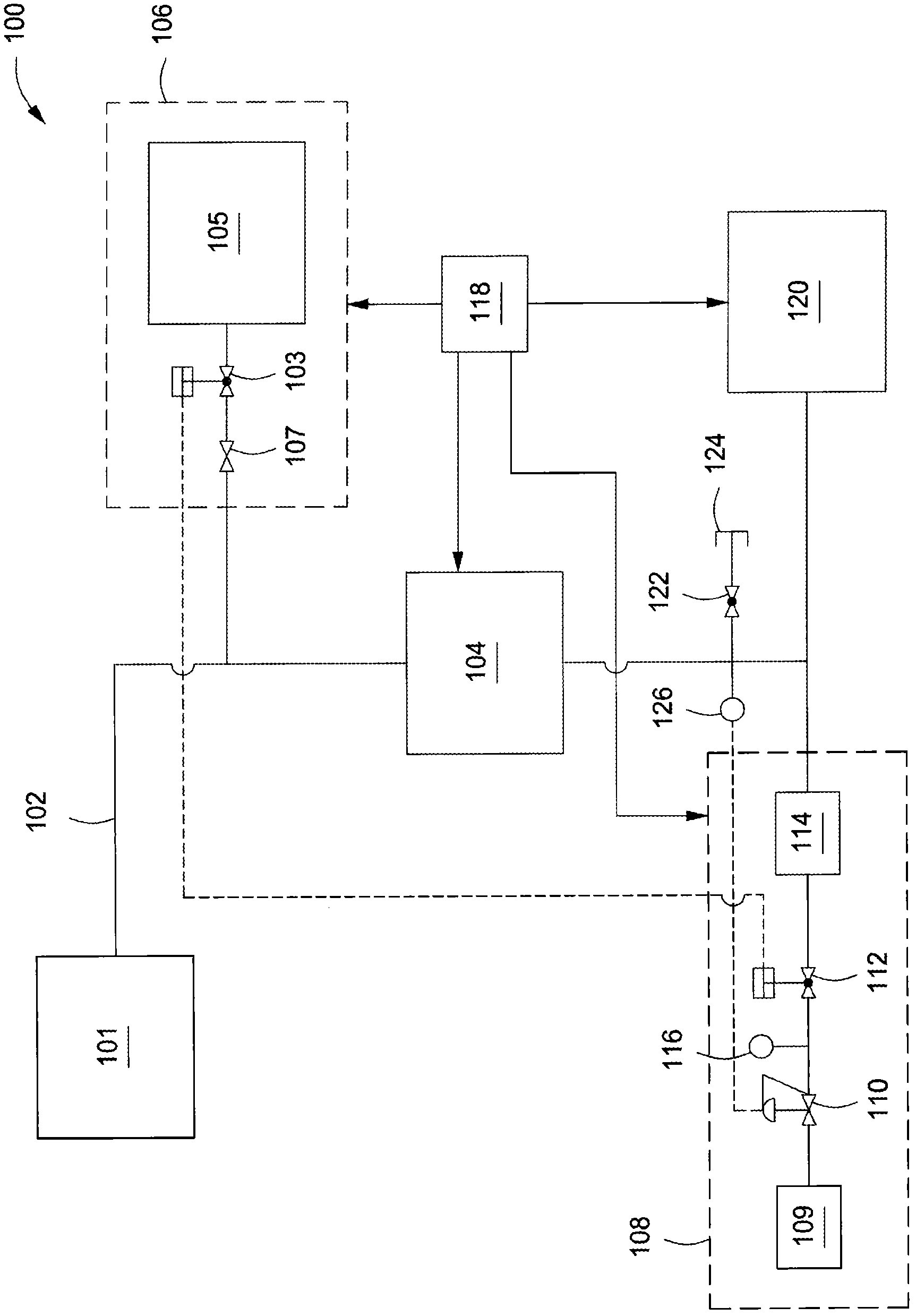

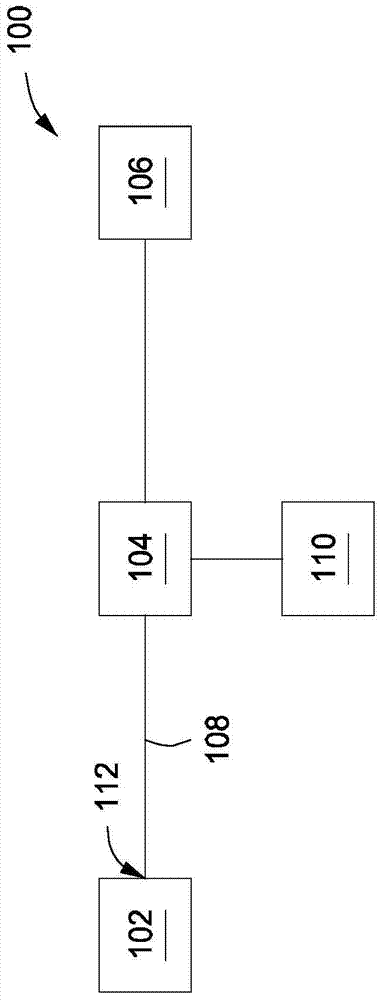

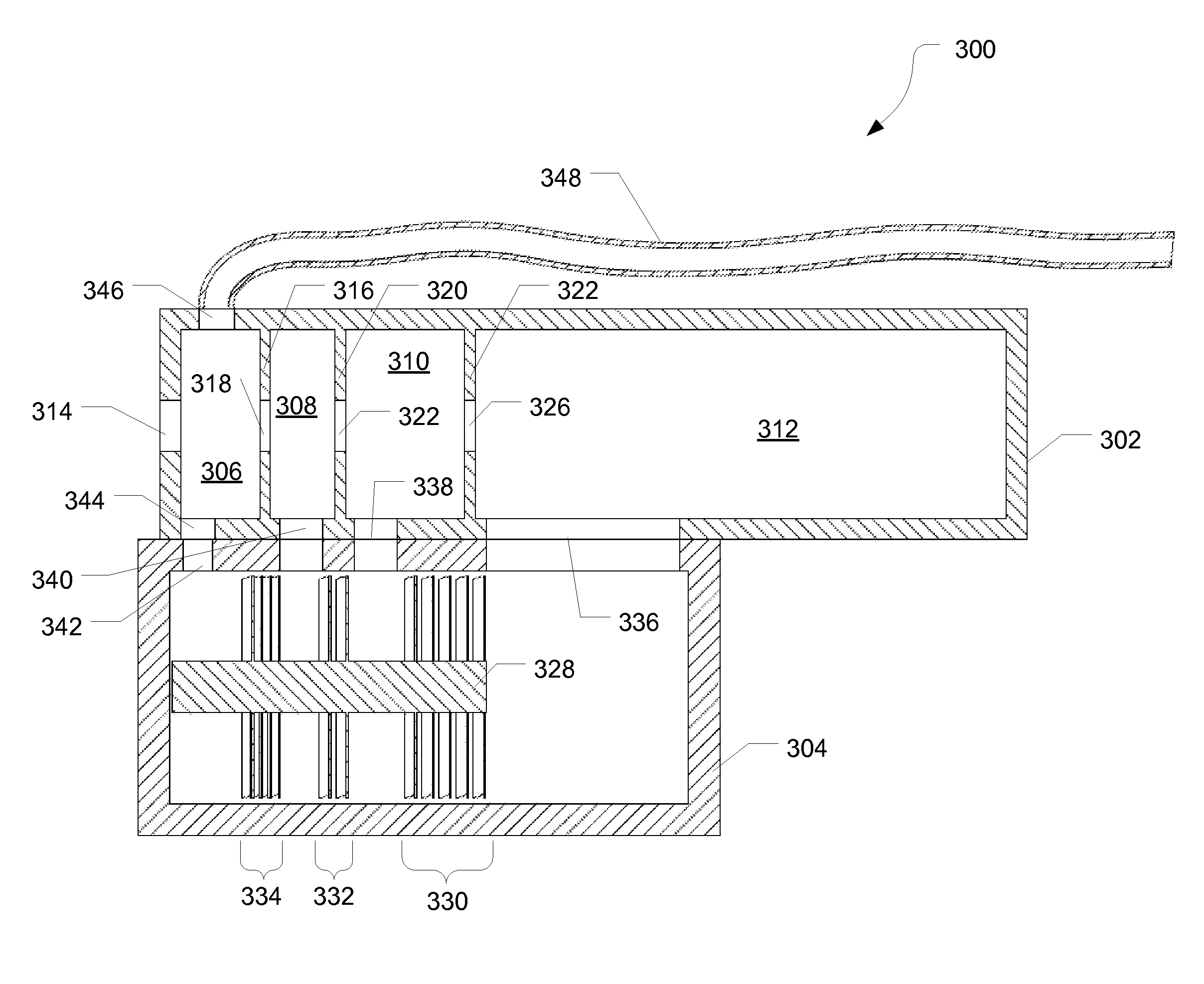

Methods and apparatus for treating exhaust gas in a processing system

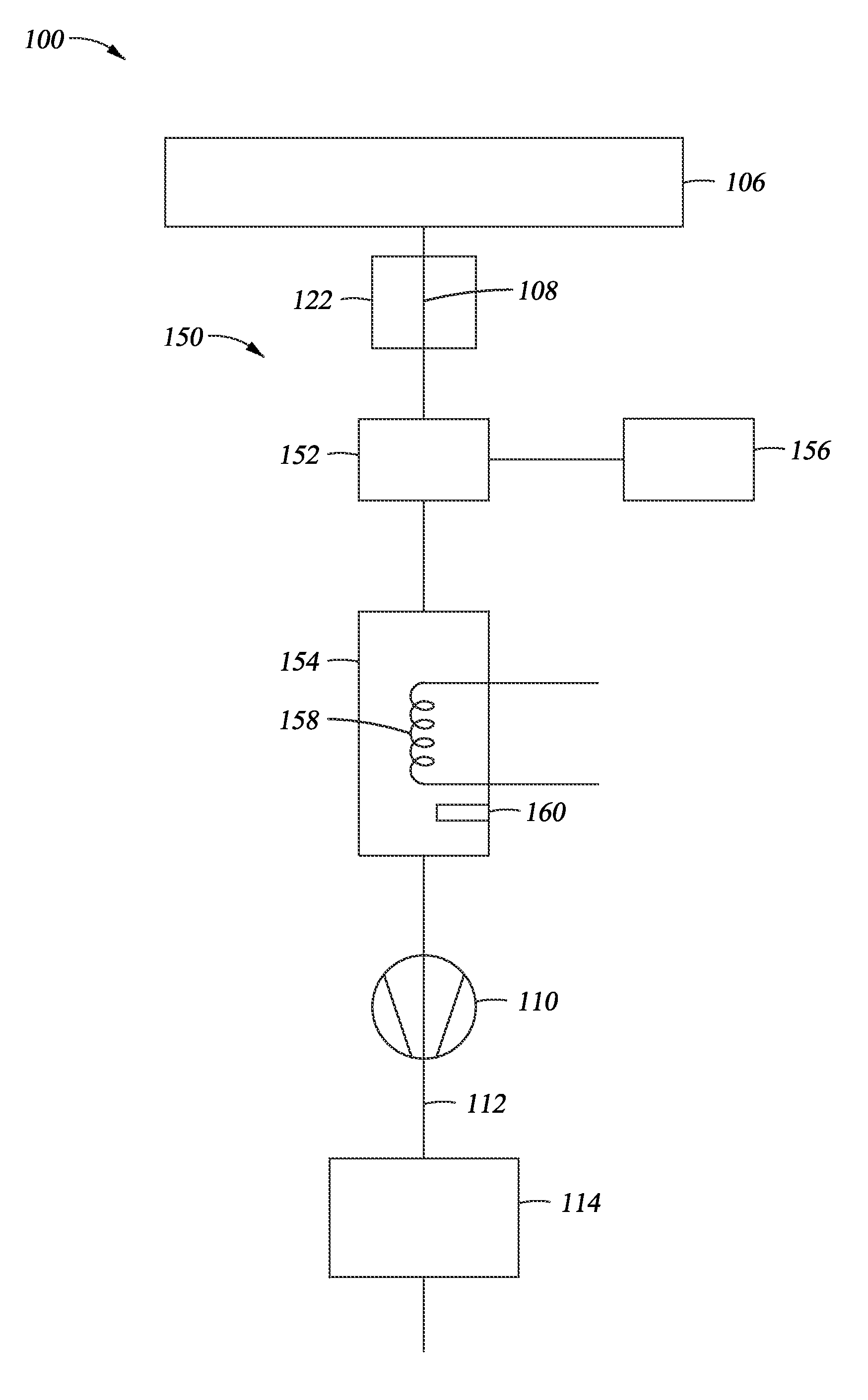

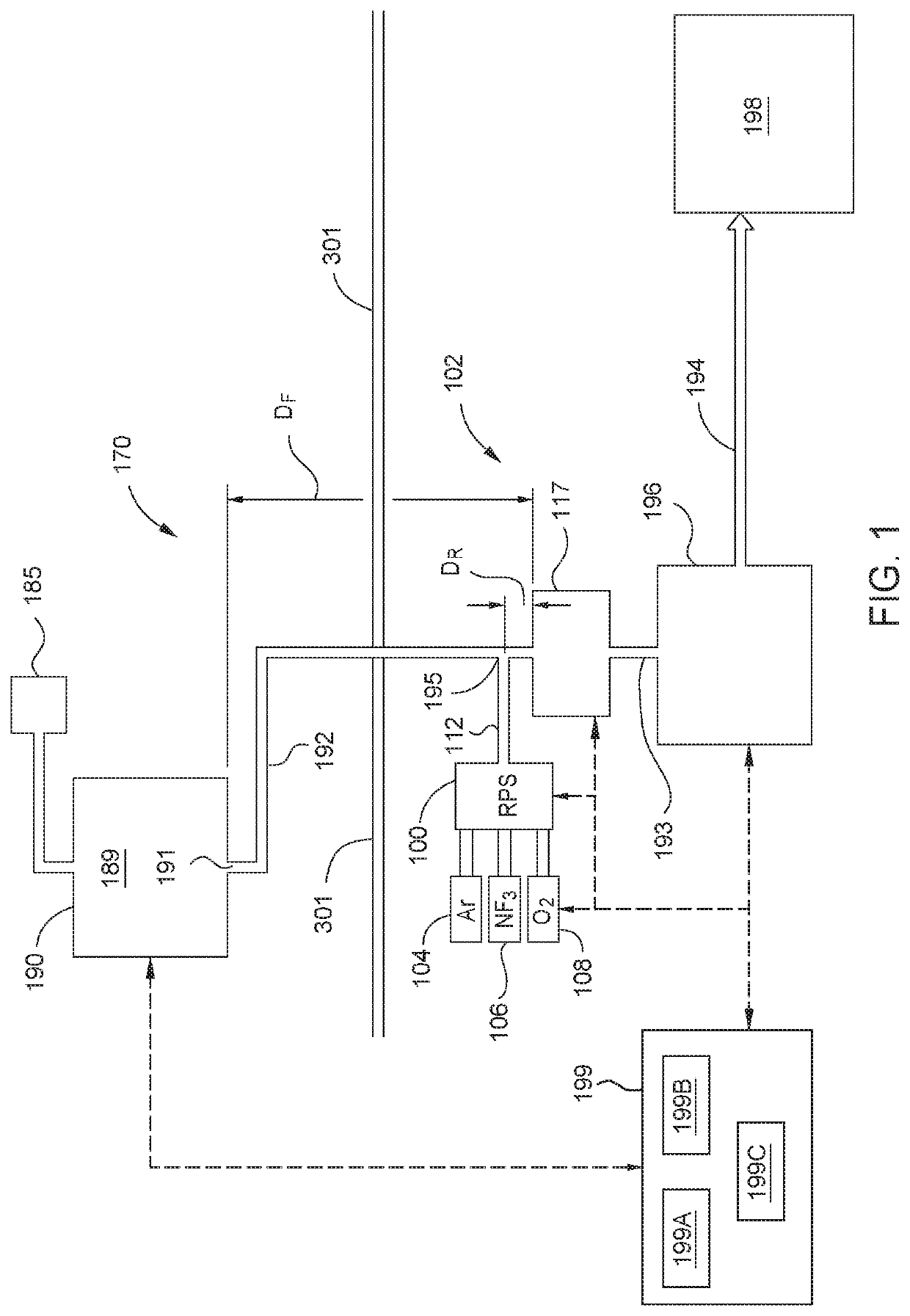

ActiveCN102640255AImprove efficiencyIncrease productionGas treatmentElectric discharge tubesEngineeringPressure regulator

Methods and apparatus for treating an exhaust gas in a foreline of a substrate processing system are provided herein. In some embodiments, an apparatus for treating an exhaust gas in a foreline of a substrate processing system includes a plasma source coupled to a foreline of a process chamber, a reagent source coupled to the foreline upstream of the plasma source, and a foreline gas injection kit coupled to the foreline to controllably deliver a gas to the foreline, wherein the foreline injection kit includes a pressure regulator to set a foreline gas delivery pressure setpoint, and a first pressure gauge coupled to monitor a delivery pressure of the gas upstream of the foreline.

Owner:APPLIED MATERIALS INC

Apparatus for abatement of by-products generated from deposition processes and cleaning of deposition chambers

InactiveUS20060198769A1Easy to disassembleCombination devicesGas treatmentEngineeringDeposition process

Method and apparatus for abating F2 from by-products generated during cleaning of a processing chamber. F2 abatement is efficiently performed by directly injecting H2 in line with a foreline exiting the processing chamber. A tube which is highly resistant to oxidation and corrosive gases, even at high temperature, is connected in line with the foreline as part of the exhaust line of the processing chamber. A cooling jacket may be provided for cooling the tube, since the reaction between F2 and H2 is exothermic. A pressure monitoring arrangement may also be employed to insure that pressure within a hydrogen line, that feeds the injection of H2 into the tube, does not exceed a predetermined pressure value.

Owner:APPLIED MATERIALS INC

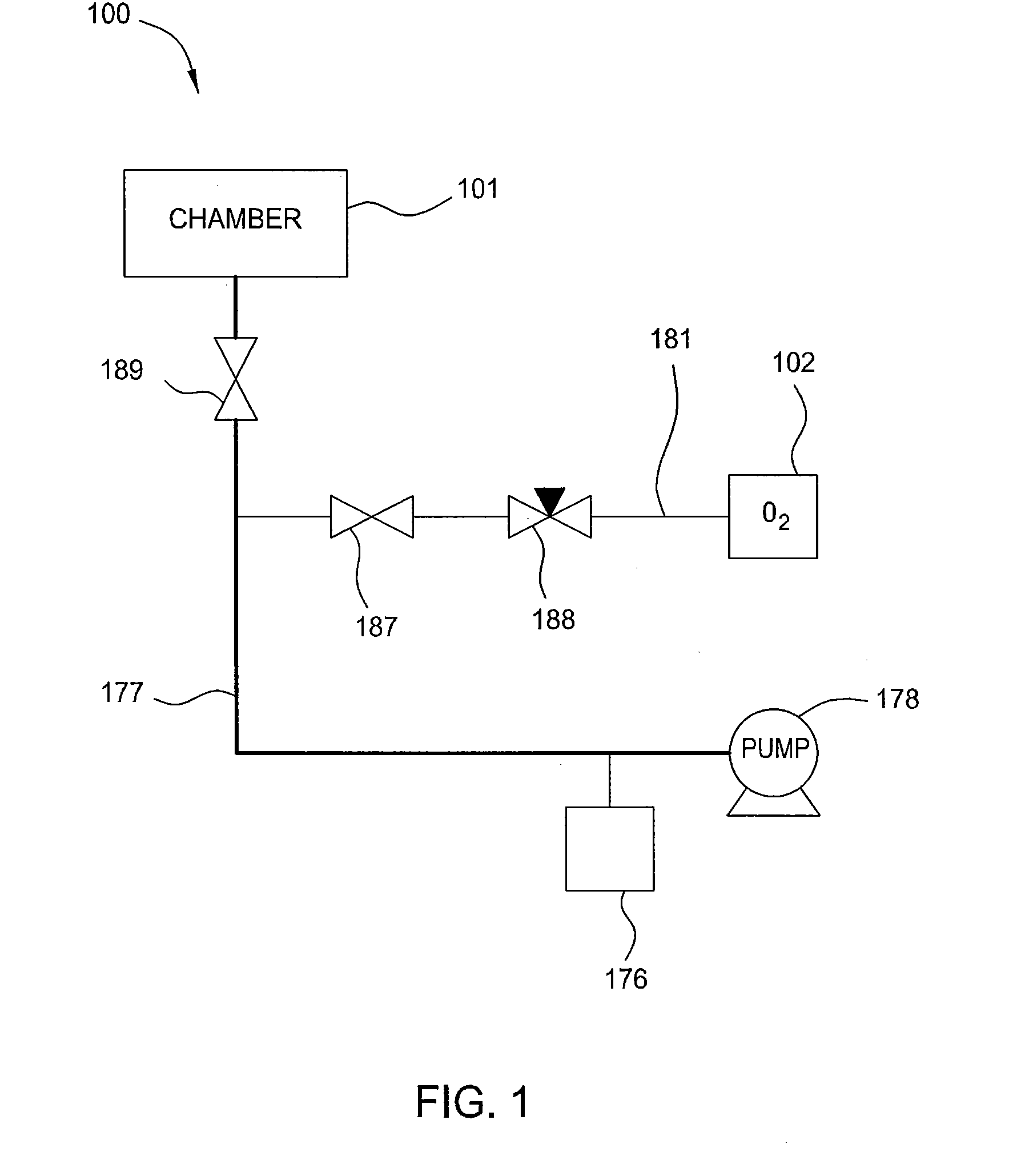

Oxygen pump purge to prevent reactive powder explosion

InactiveUS20110195202A1Avoid accumulationElectric discharge tubesChemical vapor deposition coatingEngineeringOxygen

A method of managing particles and material accumulation in exhaust components used in deposition systems is provided. More specifically, embodiments of the present invention relate to methods of preventing build-up of explosive material in vacuum forelines of deposition systems. In one embodiment, a short purge of oxygen-containing gas may be introduced into the foreline during or in between cycles of deposition of a layer on the substrate in order to oxidize at least a portion of combustible processing by-products in the foreline. In one embodiment, at least a portion of the processing by-products and oxygen-containing gas react to form silicon dioxide (SiO2).

Owner:APPLIED MATERIALS INC

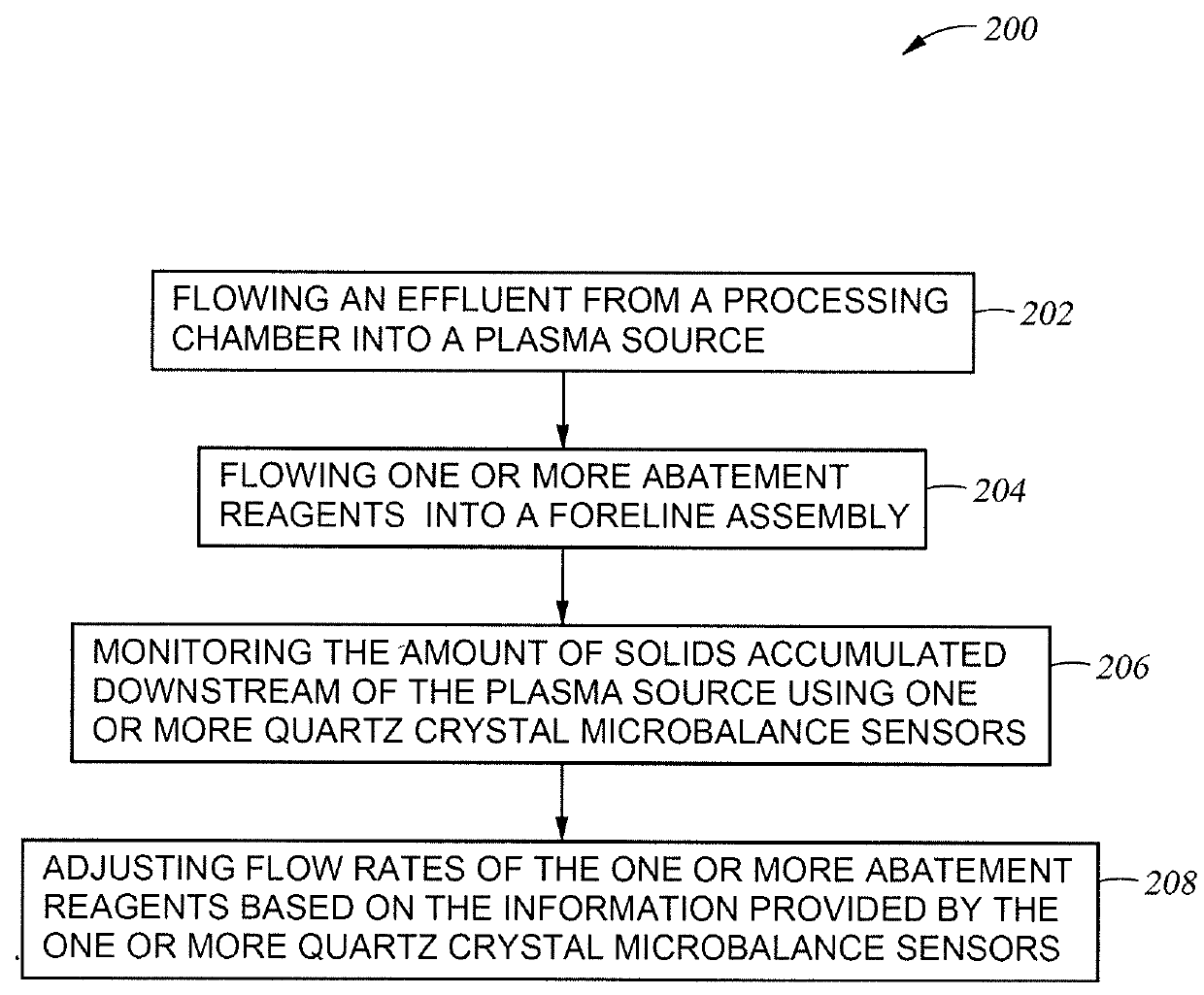

Quartz crystal microbalance utilization for foreline solids formation quantification

InactiveUS20180166306A1Electric discharge tubesFinal product manufactureQuartz crystal microbalanceEngineering

Embodiments of the present disclosure generally relate to abatement for semiconductor processing equipment. More particularly, embodiments of the present disclosure relate to techniques for foreline solids formation quantification. In one embodiment, a system includes one or more quartz crystal microbalance (QCM) sensors located between a processing chamber and a facility exhaust. The one or more QCM sensors provide real-time measurement of the amount of solids generated in the system without having to shut down a pump located between the processing chamber and the facility exhaust. In addition, information provided by the QCM sensors can be used to control the flow of reagents used to abate compounds in the effluent exiting the processing chamber in order to reduce solid formation.

Owner:APPLIED MATERIALS INC

Process and apparatus for abatement of by products generated from deposition processes and cleaning of deposition chambers

InactiveUS7060234B2Easy to disassembleCombination devicesGas treatmentDeposition processMechanical engineering

Method and apparatus for abating F2 from byproducts generated during cleaning of a processing chamber. F2 abatement is efficiently performed by directly injecting H2 in line with a foreline exiting the processing chamber. A tube which is highly resistant to oxidation and corrosive gases, even at high temperature, is connected in line with the foreline as part of the exhaust line of the processing chamber. A cooling jacket may be provided for cooling the tube, since the reaction between F2 and H2 is exothermic. A pressure monitoring arrangement may also be employed to insure that pressure within a hydrogen line, that feeds the injection of H2 into the tube, does not exceed a predetermined pressure value.

Owner:APPLIED MATERIALS INC

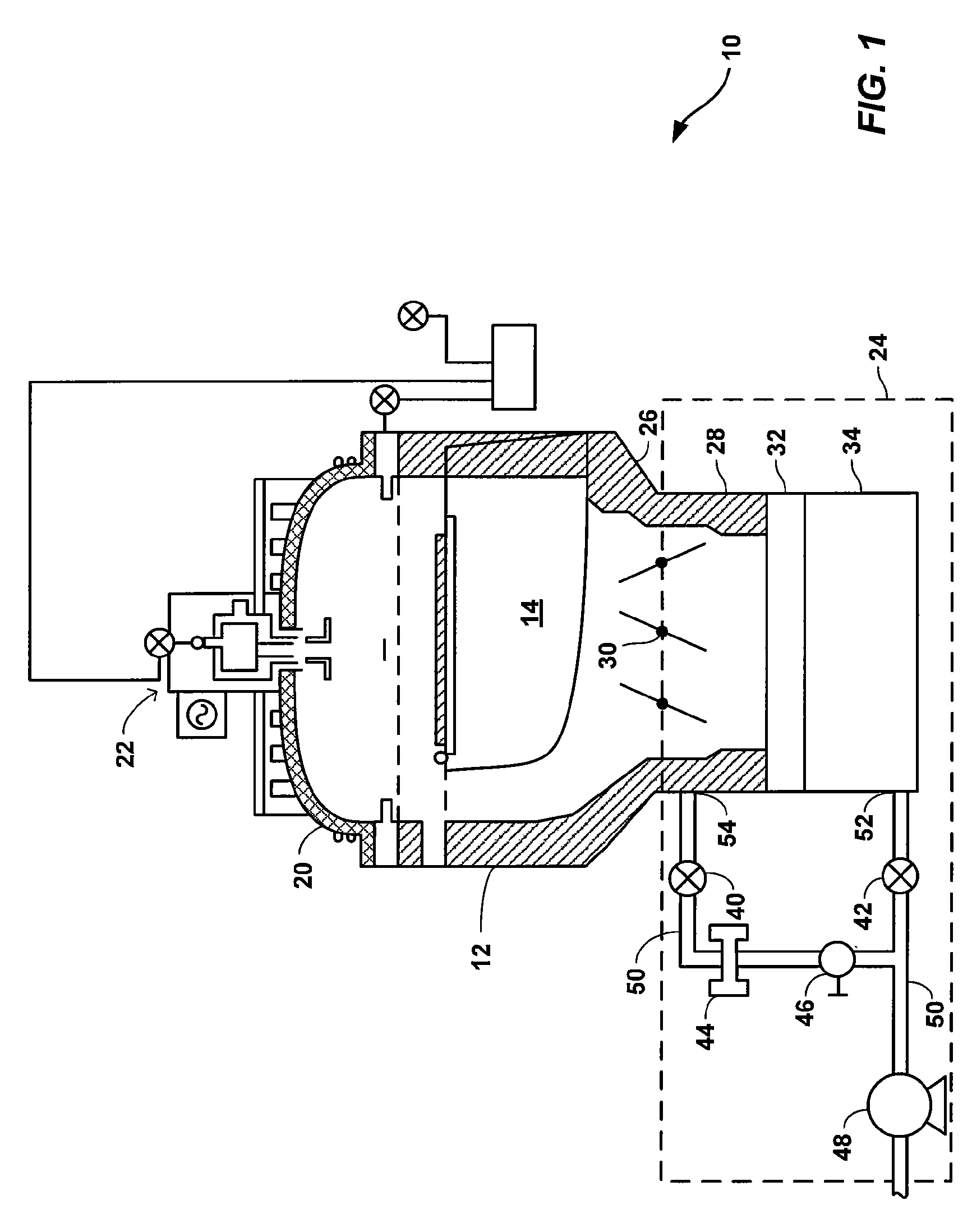

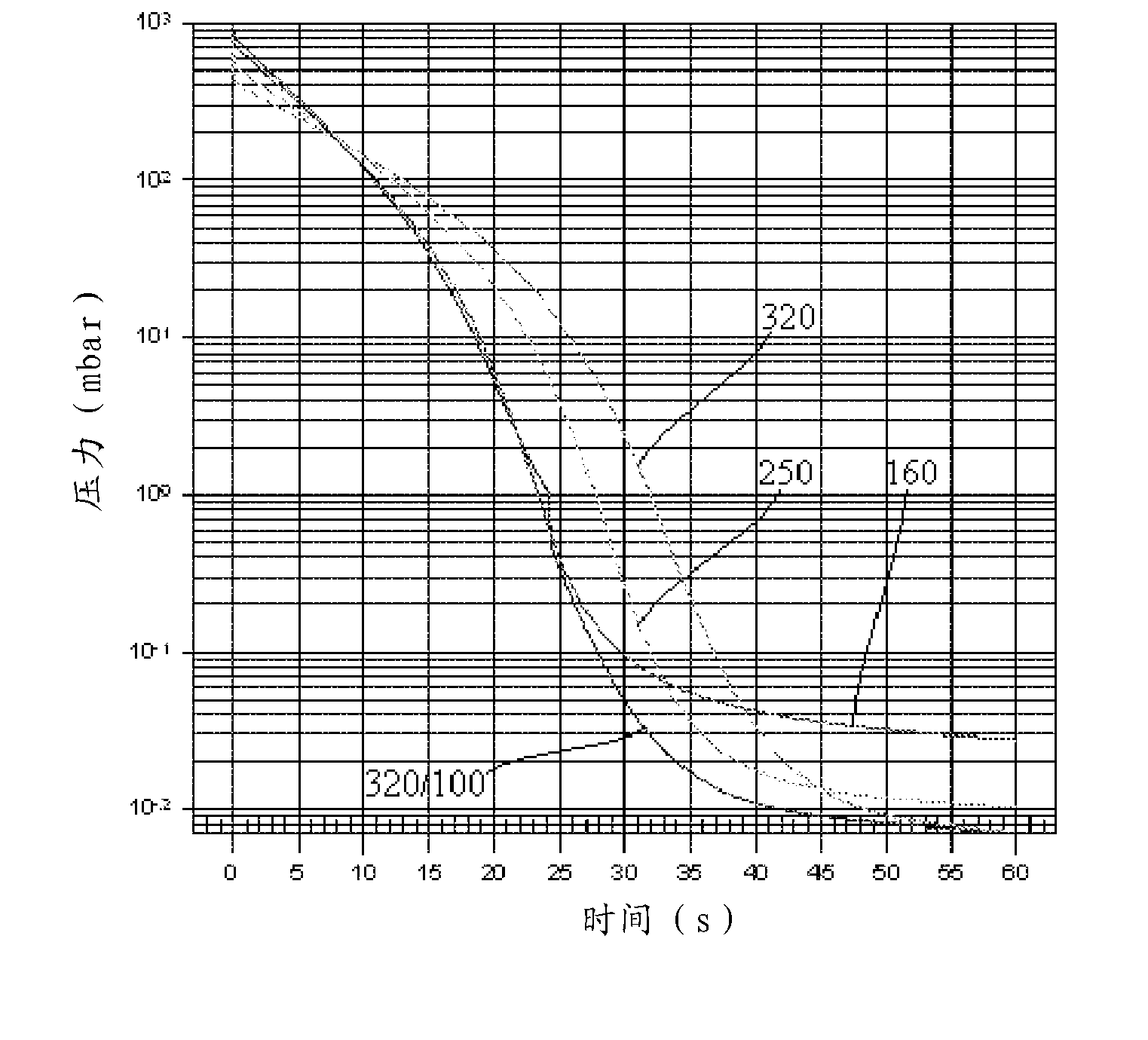

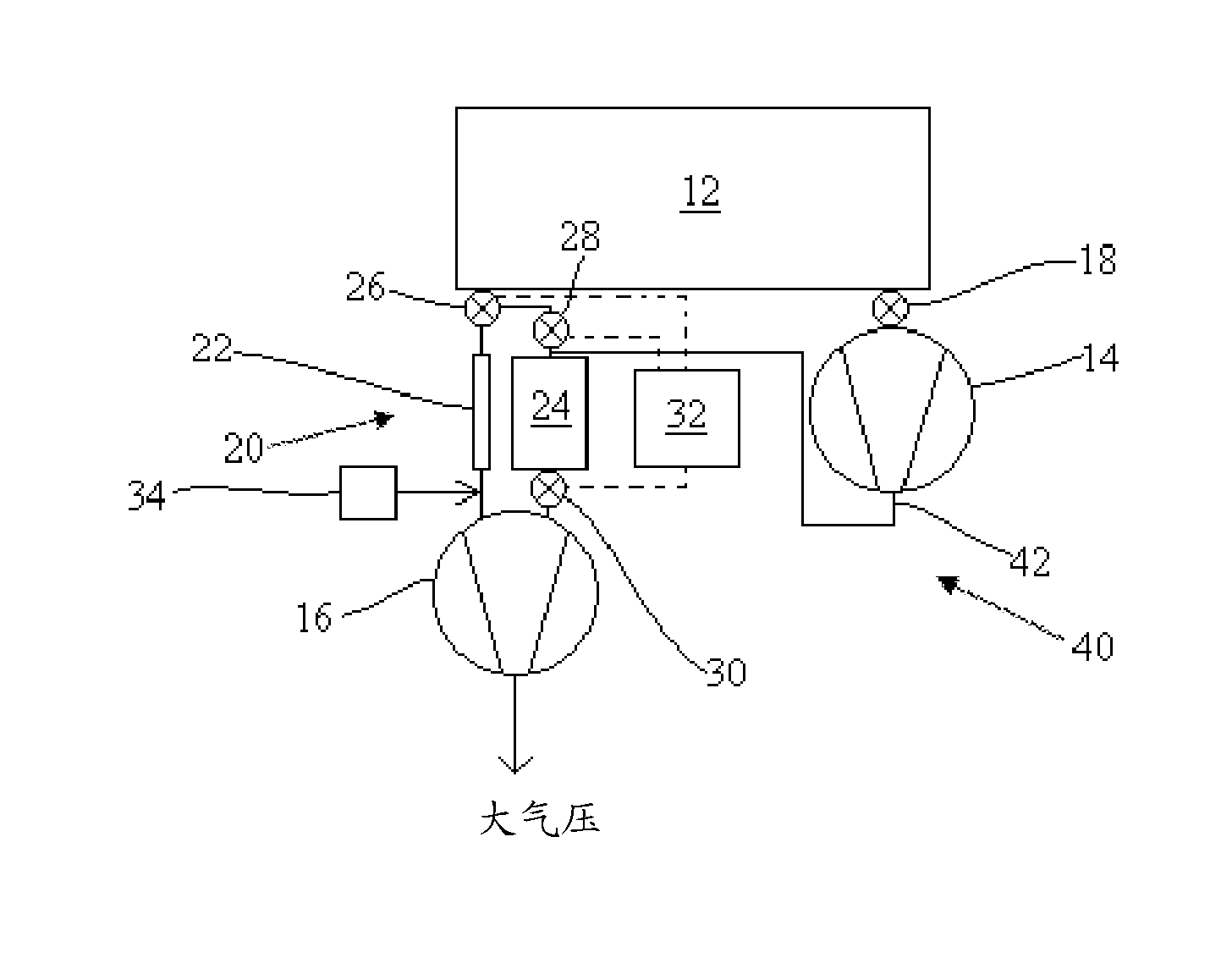

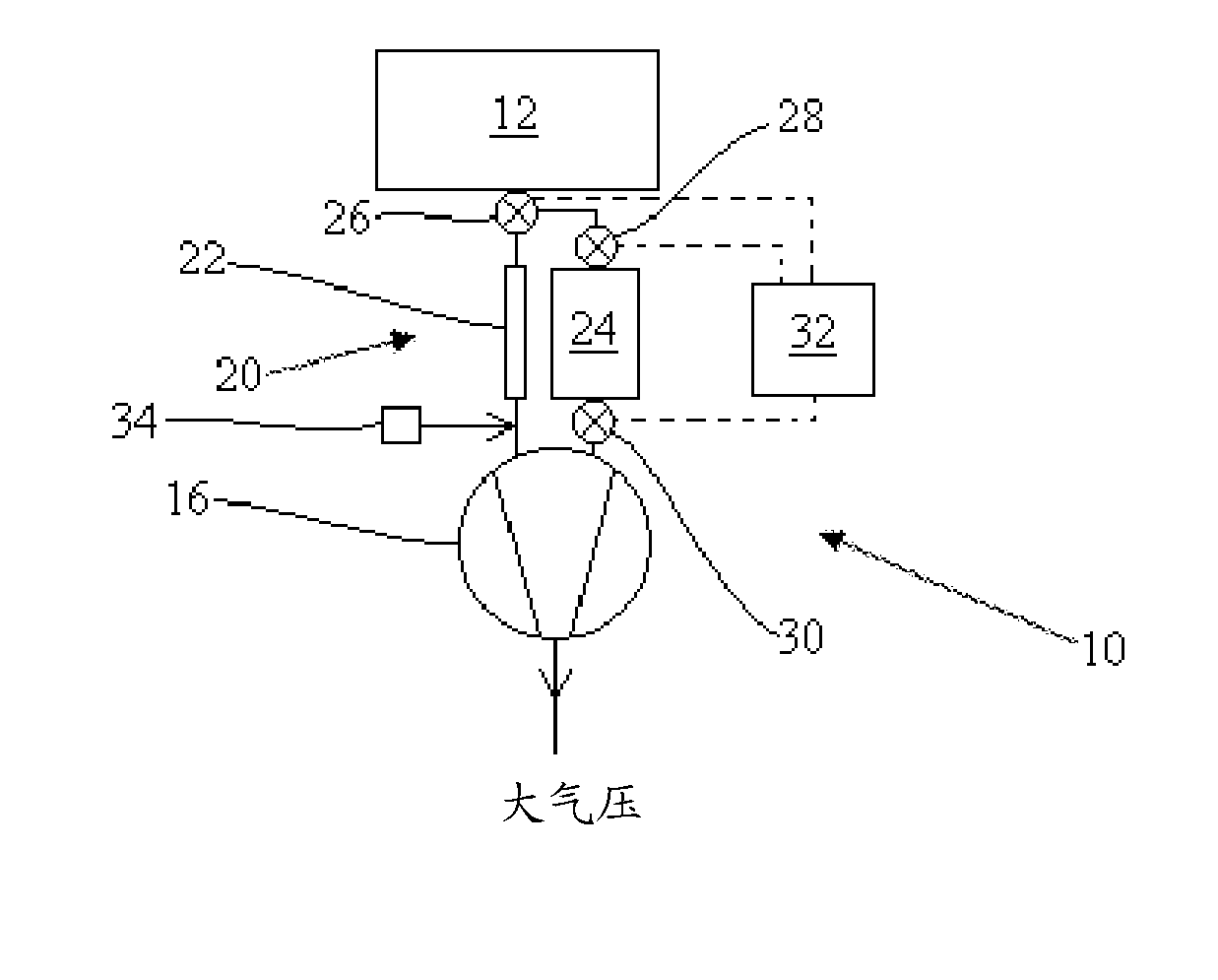

Vacuum pumping system

InactiveCN103228922AImprove conduction abilityRotary piston pumpsRotary piston liquid enginesVacuum pumpingEngineering

The present invention relates to a vacuum pumping system (10) for evacuating a vacuum chamber (12), the system comprising: a vacuum pump (16); and a plurality of forelines (22, 24) for conveying gas to the vacuum pump wherein in a first low vacuum stage of chamber evacuation a first foreline arrangement (22) can be connected for conveying gas to the vacuum pump and in a second higher vacuum stage of chamber evacuation a second foreline arrangement (22, 24) comprising one or more of said forelines can be connected for conveying gas to the vacuum pump, wherein the second foreline arrangement has a total cross-sectional area for conveying fluid which is larger than a total cross-sectional area of the first foreline arrangement.

Owner:EDWARDS LTD

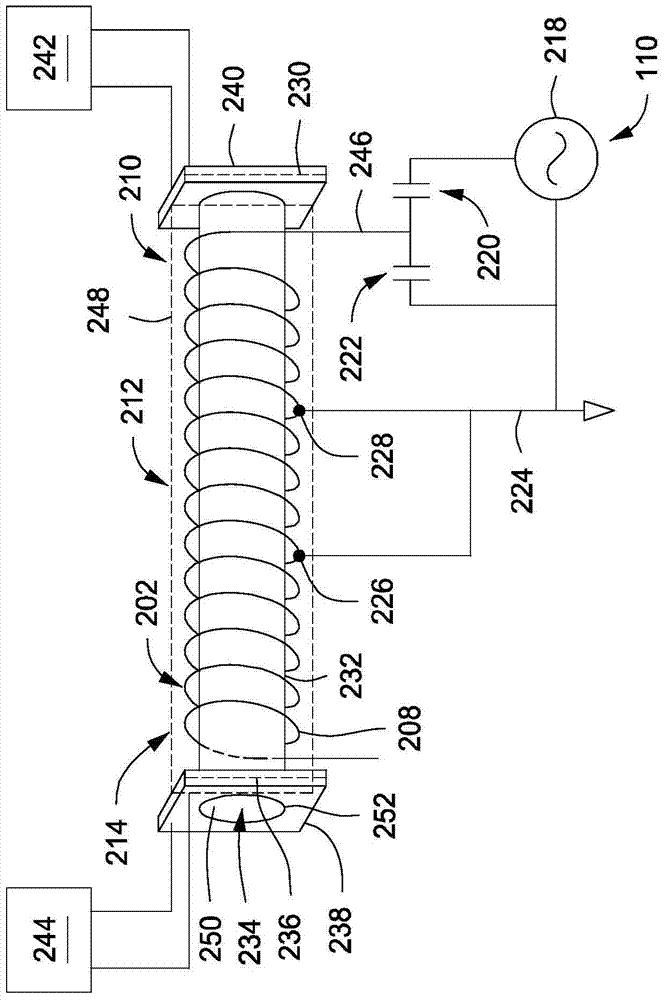

Apparatus for treating an exhaust gas in a foreline

In some embodiments an apparatus for treating an exhaust gas in a foreline of a substrate processing system may include a dielectric tube configured to be coupled to the foreline of the substrate processing system to allow a flow of exhaust gases from the foreline through the dielectric tube; an RF coil wound about an outer surface of the dielectric tube, the RF coil having a first end to provide an RF input to the RF coil, the first end of the RF coil disposed proximate a first end of the dielectric tube and a second end disposed proximate a second end of the dielectric tube; a tap coupled to the RF coil to provide an RF return path, the tap disposed between the first end of the dielectric tube and a central portion of the dielectric tube.

Owner:APPLIED MATERIALS INC

Plasma foreline thermal reactor system

ActiveUS20190226083A1Avoid accumulationElectric discharge tubesPerfluorocarbons/hydrofluorocarbons captureReactor systemEngineering

The present disclosure relates to methods and apparatus for treating vacuum processing system exhaust gases. In addition, methods and apparatus for maintenance of foreline plasma reactor subsystems are disclosed. In some embodiments, an apparatus for treating an exhaust gas in a foreline of a vacuum processing system includes a plasma source coupled with a foreline of a process chamber, a treatment agent source coupled with the plasma source, and a downstream trap to cool an exhaust stream and trap particles in the exhaust stream. In some embodiments, multiple foreline plasma reactor subsystems are used with a vacuum processing system, and one foreline plasma reactor subsystem can be isolated and maintained (e.g., cleaned) while exhaust gas treatment continues in another foreline plasma reactor subsystem and processing continues in the vacuum processing system.

Owner:APPLIED MATERIALS INC

Method and device for eliminating pyrophoric by-products from ion implantation technology

InactiveCN106298421AElectric discharge tubesSemiconductor/solid-state device manufacturingParticulatesGas phase

Owner:APPLIED MATERIALS INC

Mass spectrometer

A mass spectrometer system can include a vacuum manifold and a high vacuum pump. The vacuum manifold can include a foreline chamber and a high vacuum chamber. The foreline chamber can have a source inlet, a foreline inlet, and a foreline outlet. The high vacuum pump can have a vacuum port coupled to high vacuum chamber, and a foreline port coupled to the foreline inlet.

Owner:THERMO FINNIGAN

Removal of trapped silicon with a cleaning gas

InactiveUS20110274836A1Avoid accumulationCombination devicesLiquid surface applicatorsParticulatesSilicon tetrafluoride

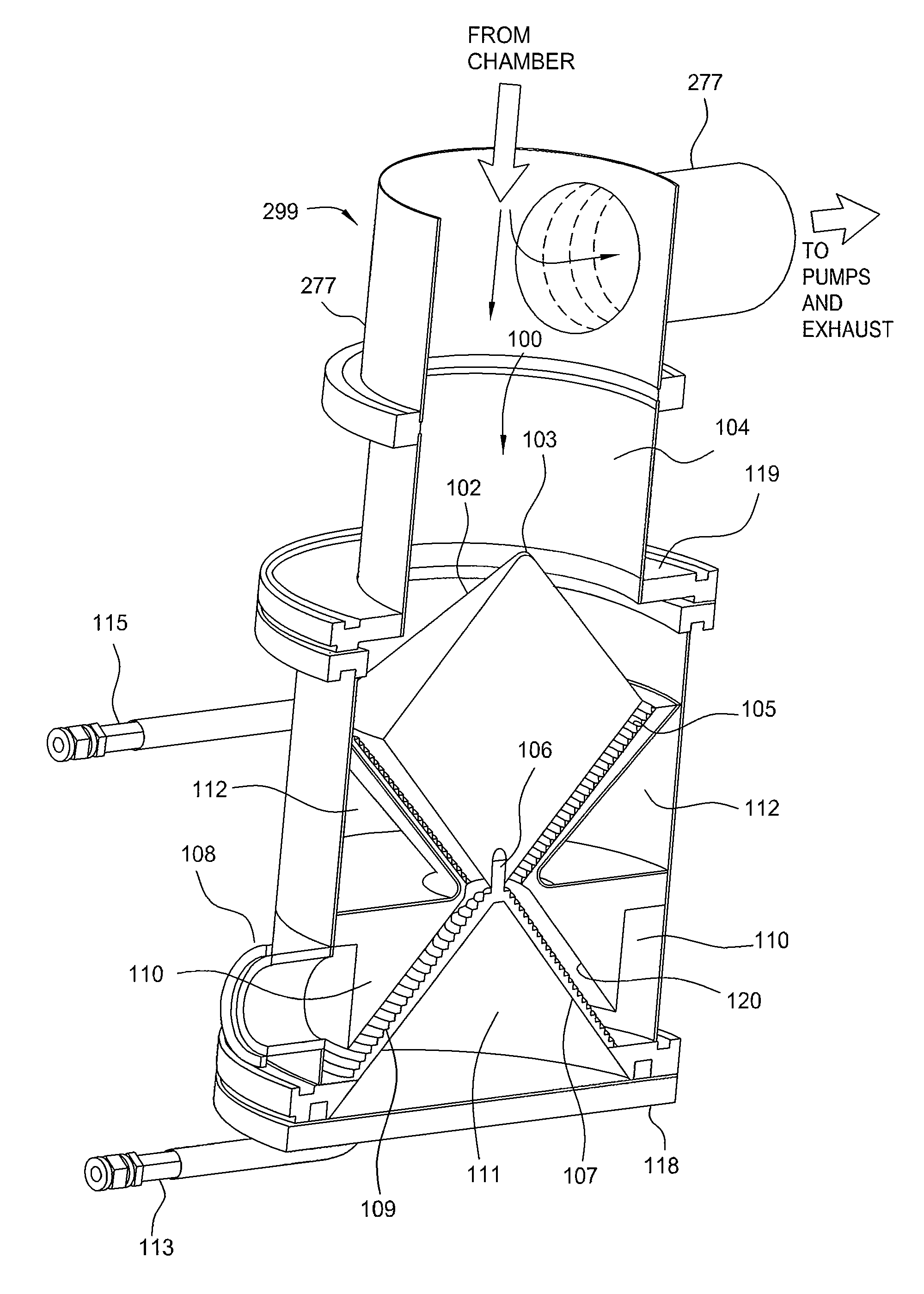

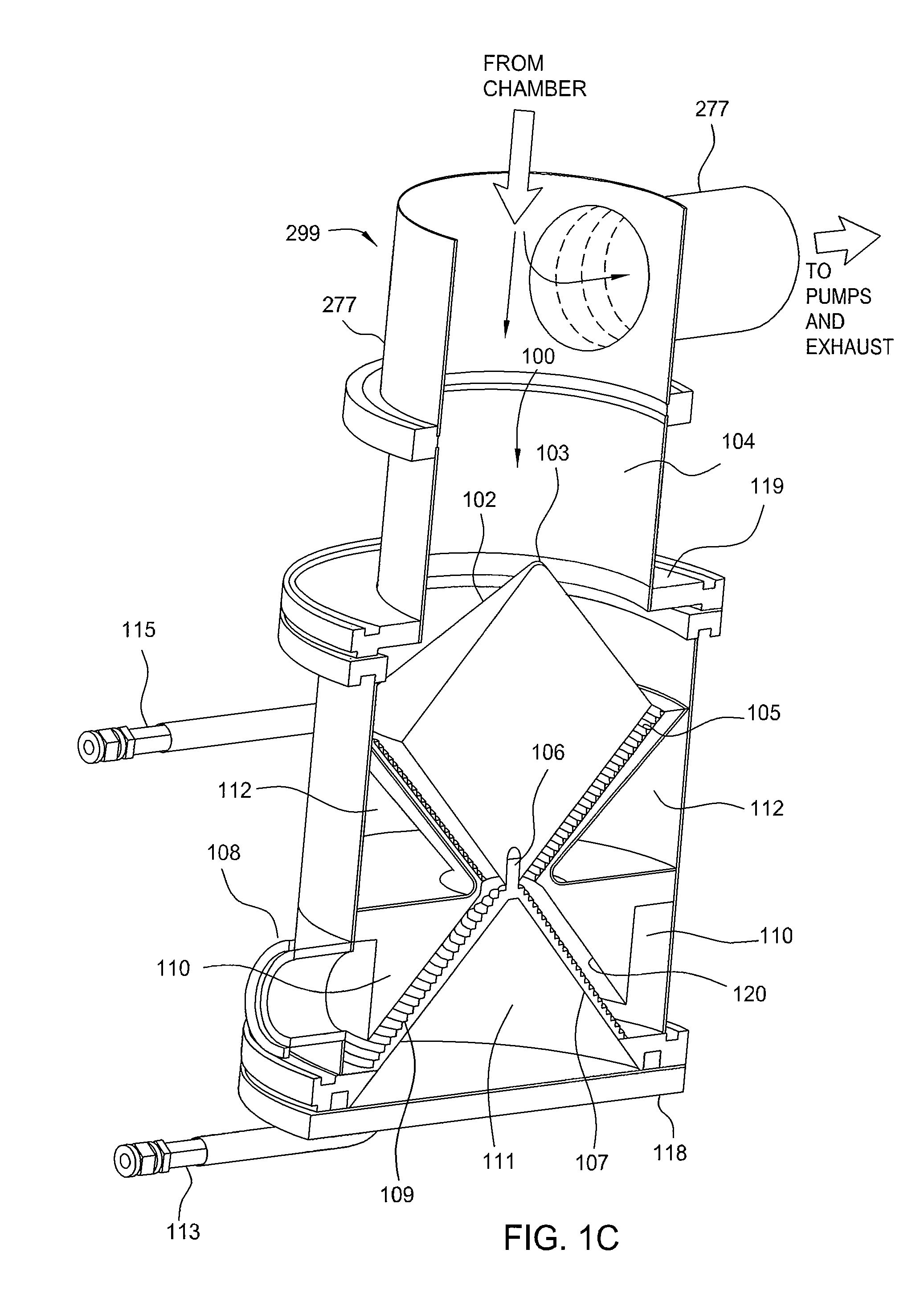

Embodiments of the present invention relate to apparatus and methods of preventing build-up of explosive material in vacuum forelines of deposition systems. A cleaning gas such as nitrogen trifluoride (NF3) may be introduced into a particulate collection device including a catchpot having a configuration comprising a sloped interior surface area that maximizes the amount of reactive silicon-containing particles that are exposed to and react with the cleaning gas stream to form silicon tetrafluoride (SiF4) and other non-reactive by-products. The degree of slope of the interior surface area may be based upon the angle of repose of the silicon-containing particles. The gaseous silicon tetrafluoride (SiF4) and other non-reactive by-products can flow out of the catchpot and into the exhaust stream towards a vacuum pump. The apparatus and method may also avoid accumulation of highly reactive and highly explosive particulates in catchpots.

Owner:APPLIED MATERIALS INC

Apparatus for gaseous byproduct abatement and foreline cleaning

ActiveUS20190338419A1Improve securityMeet the restrictionsGas treatmentElectric discharge tubesRemote plasmaEngineering

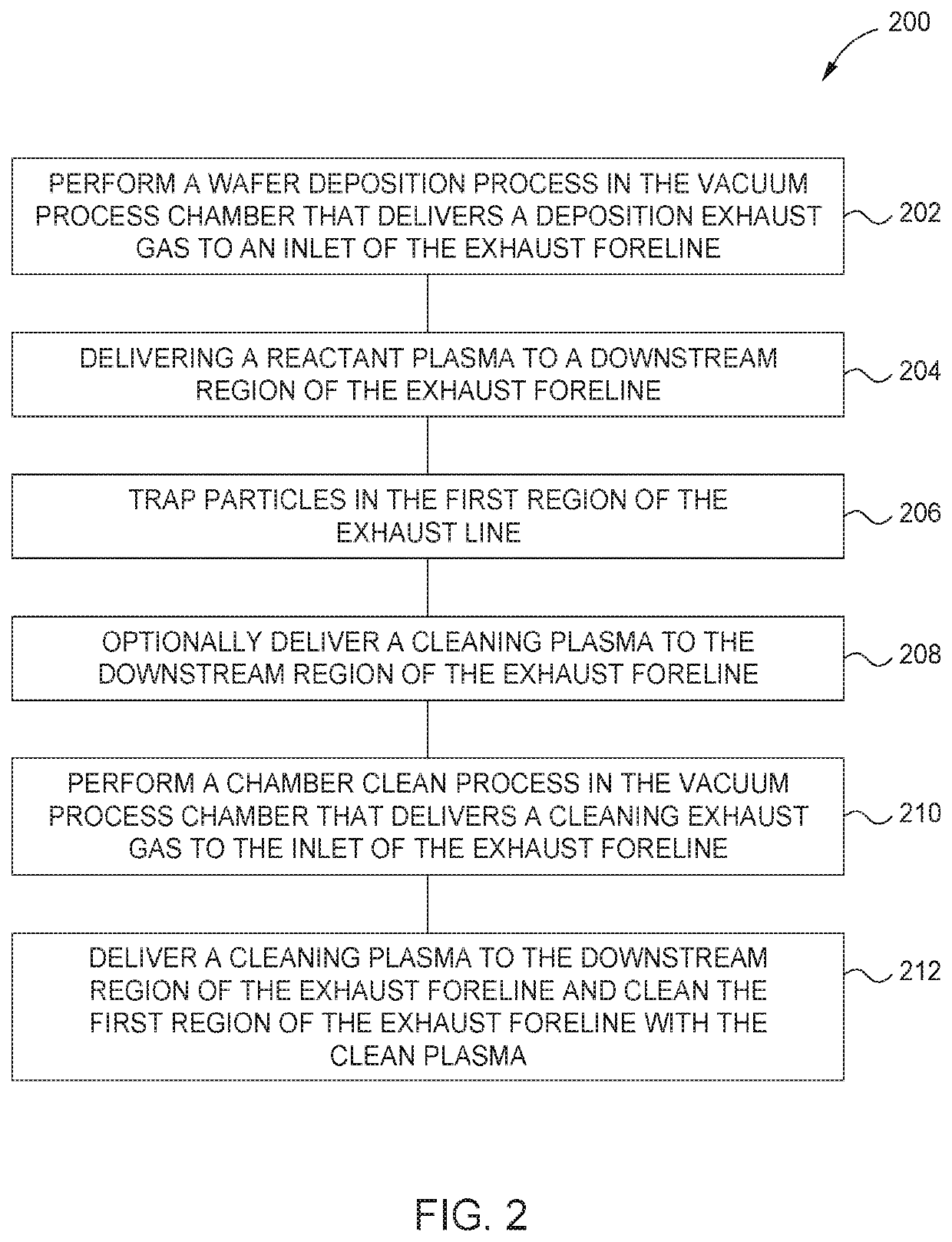

Embodiments disclosed herein include an abatement system and method for abating compounds produced in semiconductor processes. The abatement system includes a remote plasma source for generating an oxidizing plasma for treating exhaust gases from a deposition process performed in the processing chamber, the treatment assisting with the trapping particles in an exhaust cooling apparatus. The remote plasma source then generates a cleaning plasma for treating exhaust gases from a cleaning process performed in the processing chamber, the cleaning plasma reacting with the trapped particles in the exhaust cooling apparatus and cleaning the exhaust cooling apparatus.

Owner:APPLIED MATERIALS INC

Method and apparatus for treating exhaust gases in a substrate processing system

ActiveCN102640255BImprove efficiencyIncrease productionGas treatmentElectric discharge tubesEngineeringPressure regulator

Owner:APPLIED MATERIALS INC

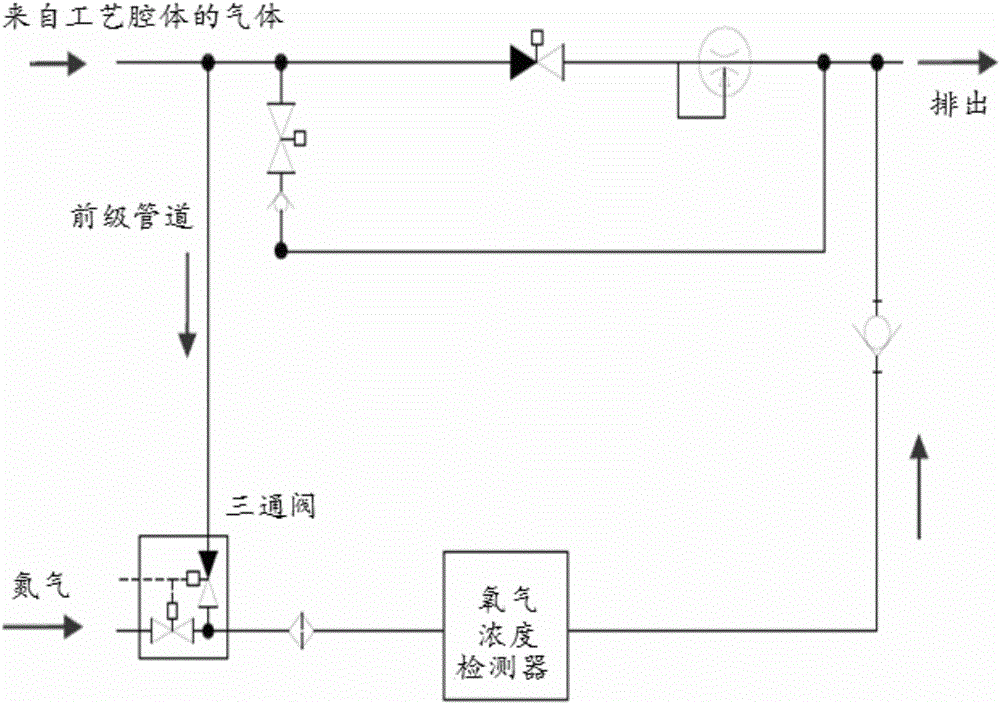

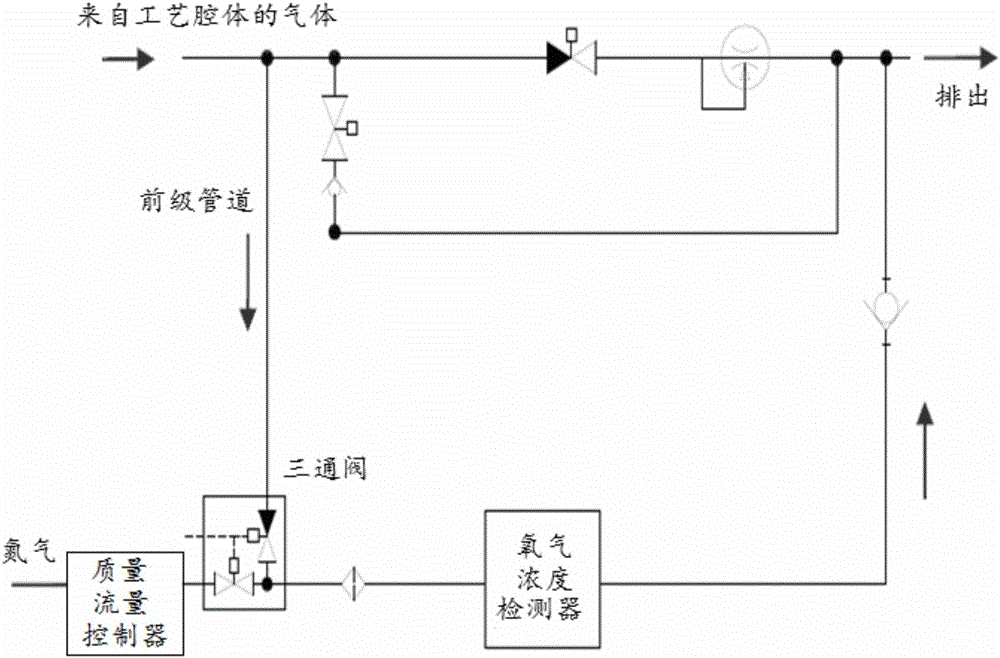

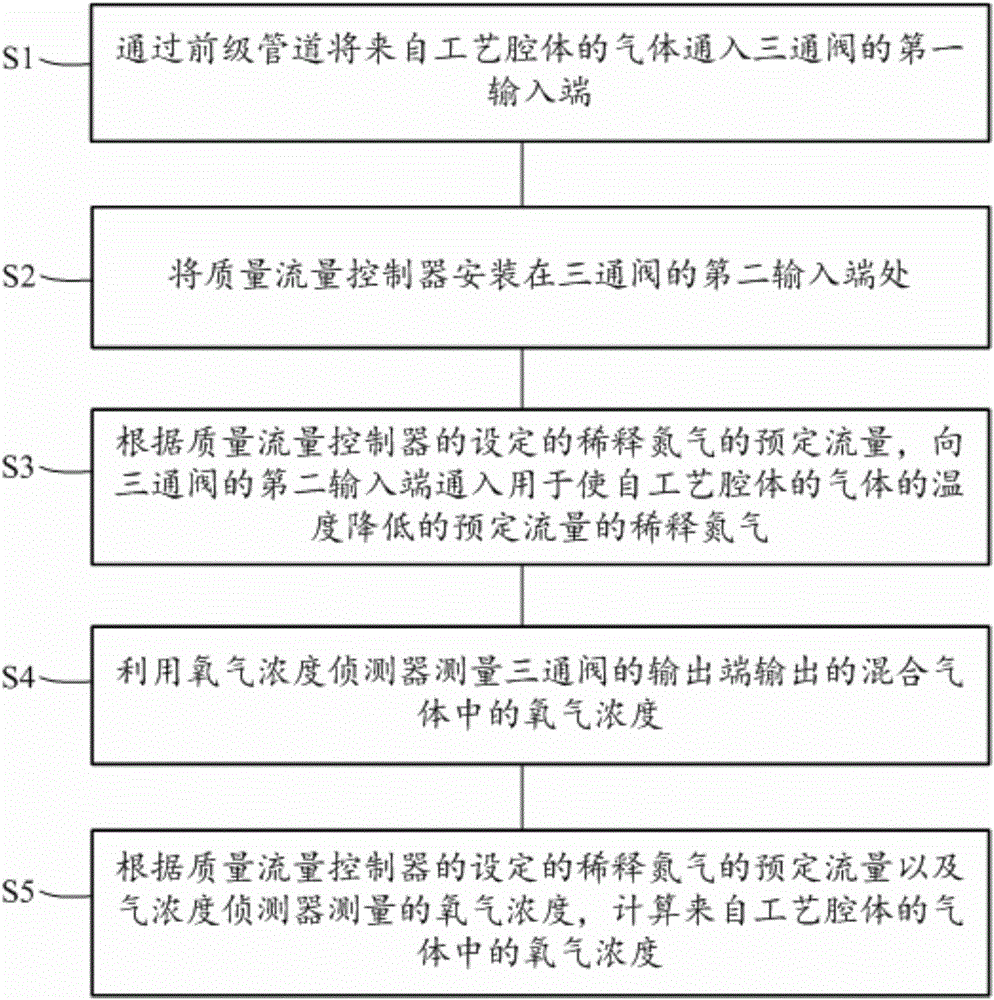

Technological cavity oxygen concentration detecting system and technological cavity oxygen concentration detecting method

InactiveCN105866348ARealize accurate detectionAchieve consistencyGas analyser construction detailsNitrogenNitrogen gas

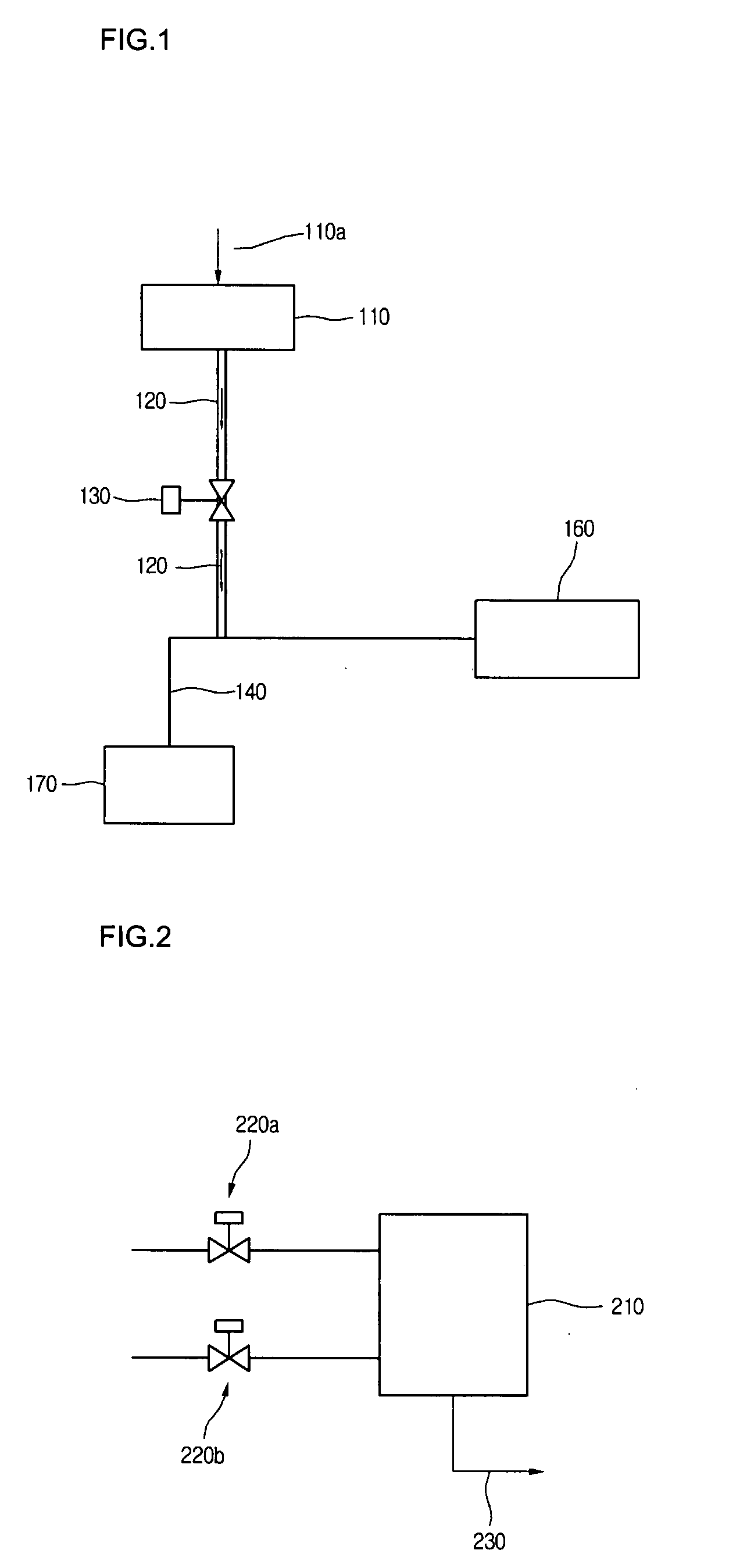

The invention provides a technological cavity oxygen concentration detecting system and a technological cavity oxygen concentration detecting method. The technological cavity oxygen concentration detecting system comprises a foreline, a three-way valve, a mass flow controller and an oxygen concentration detector. Gas from a technological cavity is introduced into the first input end of the three-way cavity through the foreline, the mass flow controller is installed at the second input end of the three-way valve, and the second input end of the three-way valve receives nitrogen making the temperature of gas from the technological cavity reduced, and the output end of the three-way valve is connected to the oxygen concentration detector.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

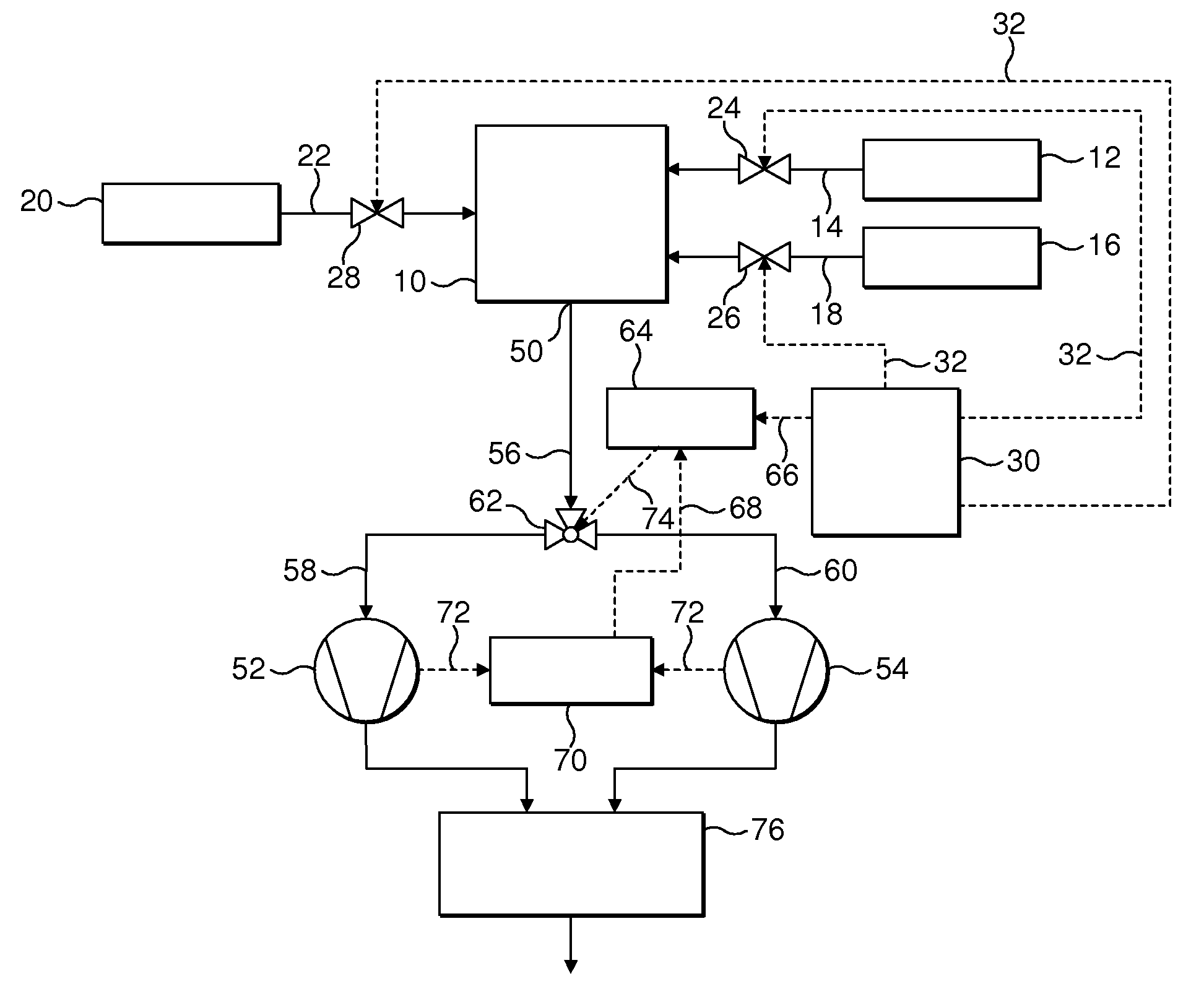

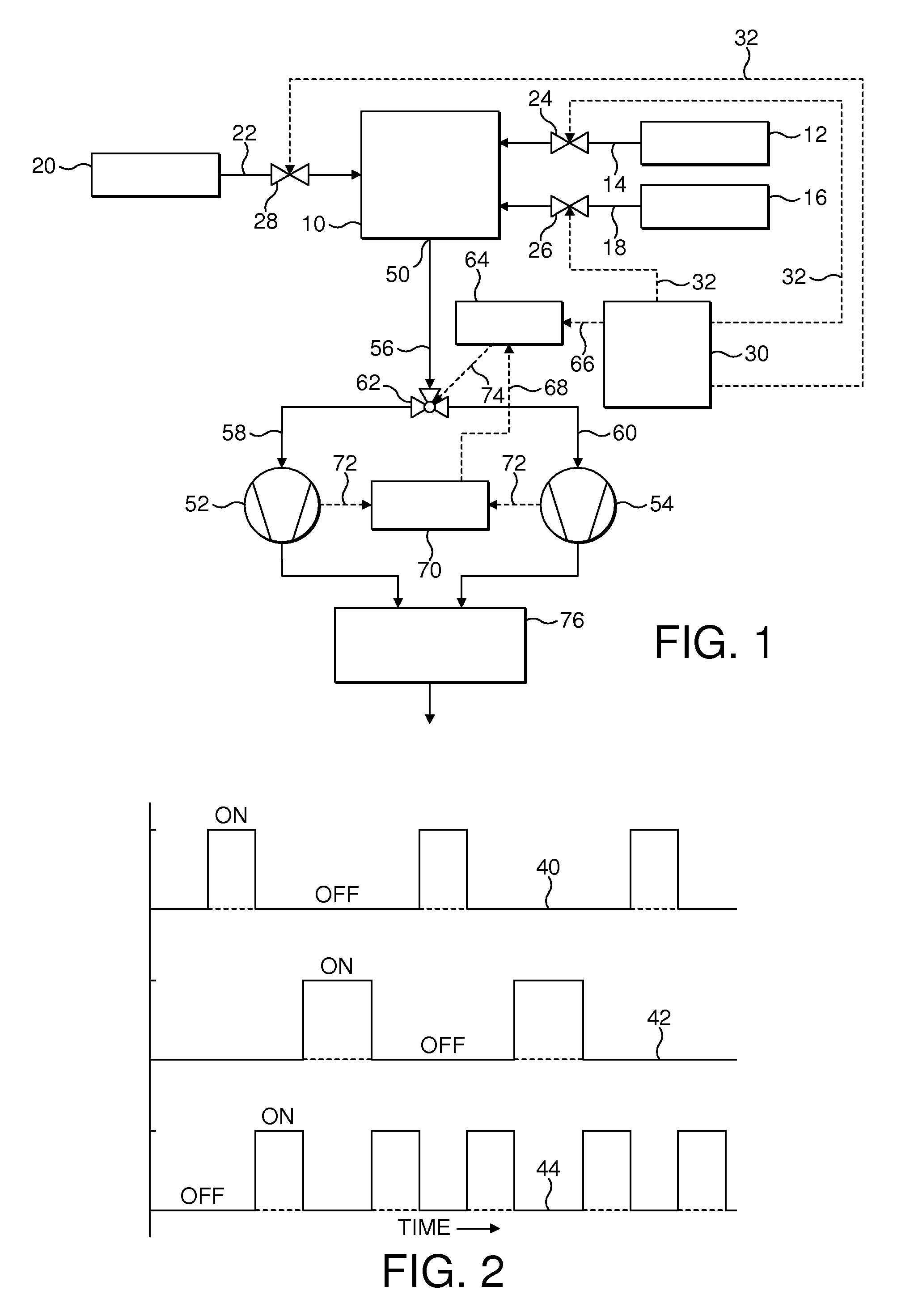

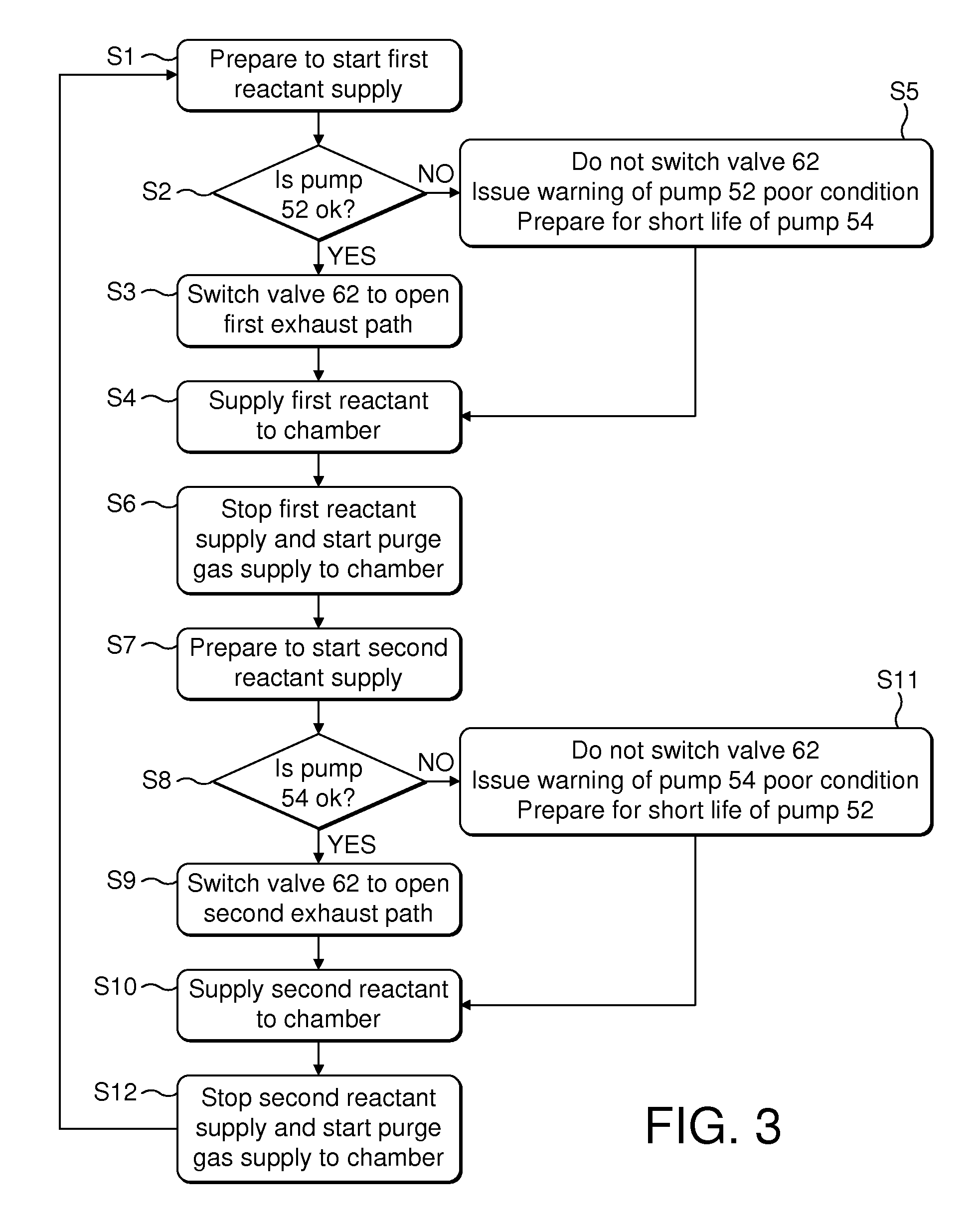

Vacuum pumping system

A vacuum pumping system comprises a primary foreline for receiving a gas stream from an outlet of a chamber, a first vacuum pump for evacuating the chamber, a second vacuum pump for evacuating the chamber, a first secondary foreline for conveying gas from the primary foreline to the first vacuum pump, a second secondary foreline for conveying gas from the primary foreline to the second vacuum pump, and valve means for selectively connecting a chosen one of the first and second secondary forelines to the primary foreline. The condition of the vacuum pumps is monitored during use. When both vacuum pumps are operating normally, the valve means is controlled to divert a first reactant-rich gas from the primary foreline into the first secondary foreline, and to divert a second reactant-rich gas from the primary foreline to the second secondary foreline, thereby inhibiting mixing of the first and second reactants within the vacuum pumps. However, in the event that the condition of one of the vacuum pumps indicates that one of the pumps is likely to fail during a current process within the chamber, the valve means is controlled to divert both the first reactant-rich gas and the second reactant-rich gas to the other vacuum pump, thereby preventing the potentially costly loss of a batch of substrates within the chamber.

Owner:EDWARDS LTD

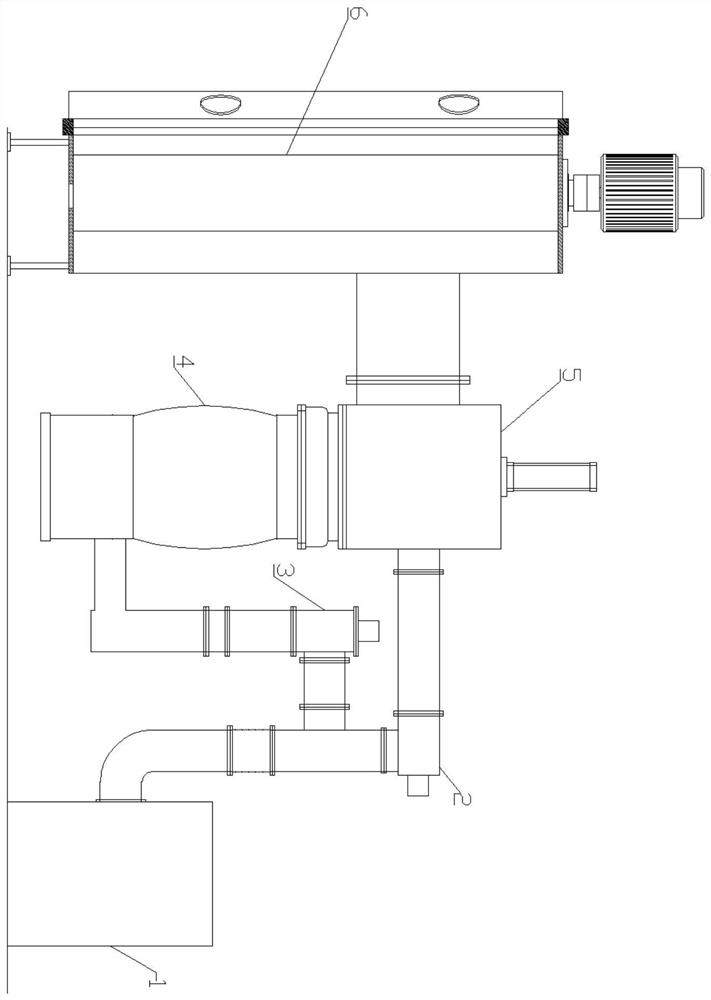

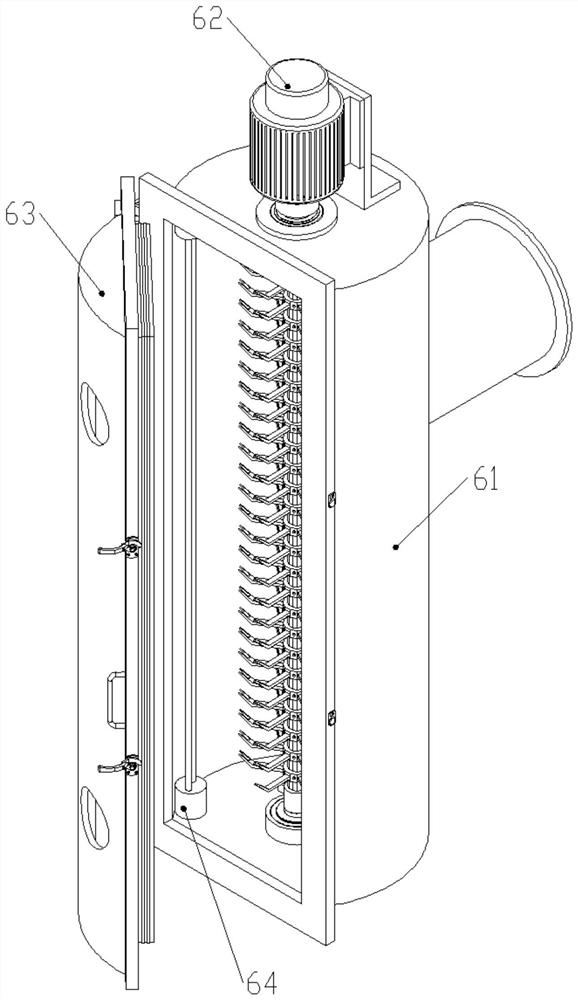

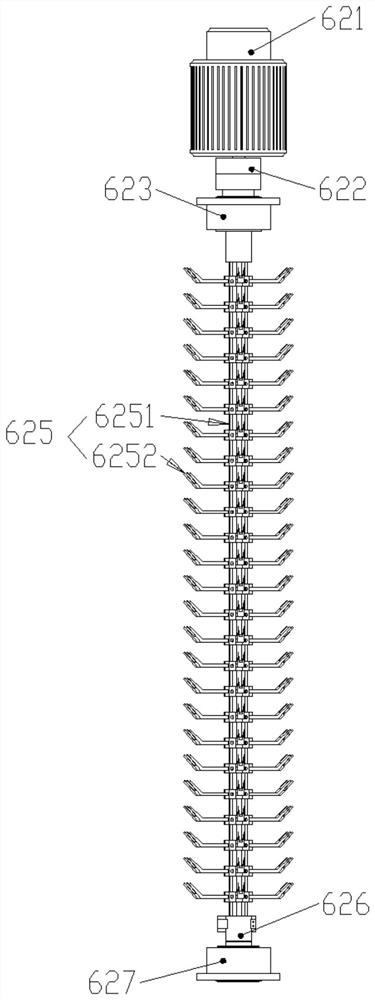

Large vacuum glow power generation nano-film coating equipment and working mode thereof

PendingCN112011772AFast depositionImprove coating uniformityMaterial nanotechnologyVacuum evaporation coatingSpool valveElectromagnetic generator

The invention discloses large vacuum glow power generation nano-film coating equipment and a working method thereof. The equipment comprises a slide valve pump, a pre-pumping valve, a foreline valve,a diffusion valve, a high valve and a vacuum coating chamber; the vacuum coating chamber comprises a coating chamber main body, a rotary hanging frame structure and a coating chamber door structure; the rotary hanging frame structure is arranged in the middle of the coating chamber main body, and the coating chamber door structure is arranged on the side edge of the coating chamber main body; andthe coating chamber door structure is of a double-layer structure, and a pulse electromagnetic generator is arranged in an interlayer. The pulse electromagnetic generator is arranged on the interlayerof the coating chamber door structure of the double-layer structure, so that the plasma energy in the chamber is multiplied, the deposition speed of coating is greatly increased, and the uniformity of a coated workpiece in the vacuum coating chamber from top to bottom is improved.

Owner:昆山立特纳米电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com