Vacuum pumping system

A vacuum pump, vacuum technology, applied in the direction of pump, pump components, pump control, etc., can solve the problems of multi-power, consumption and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

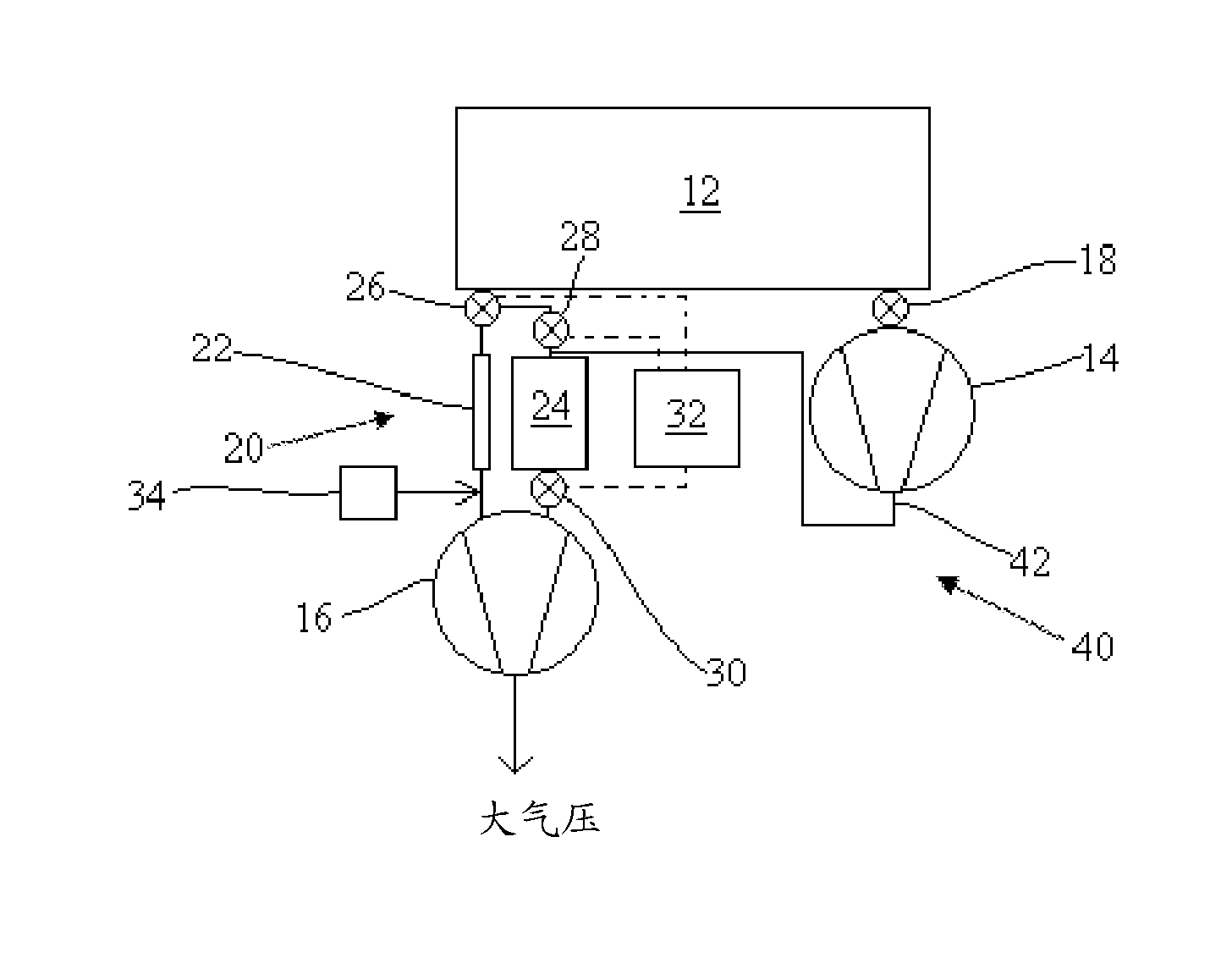

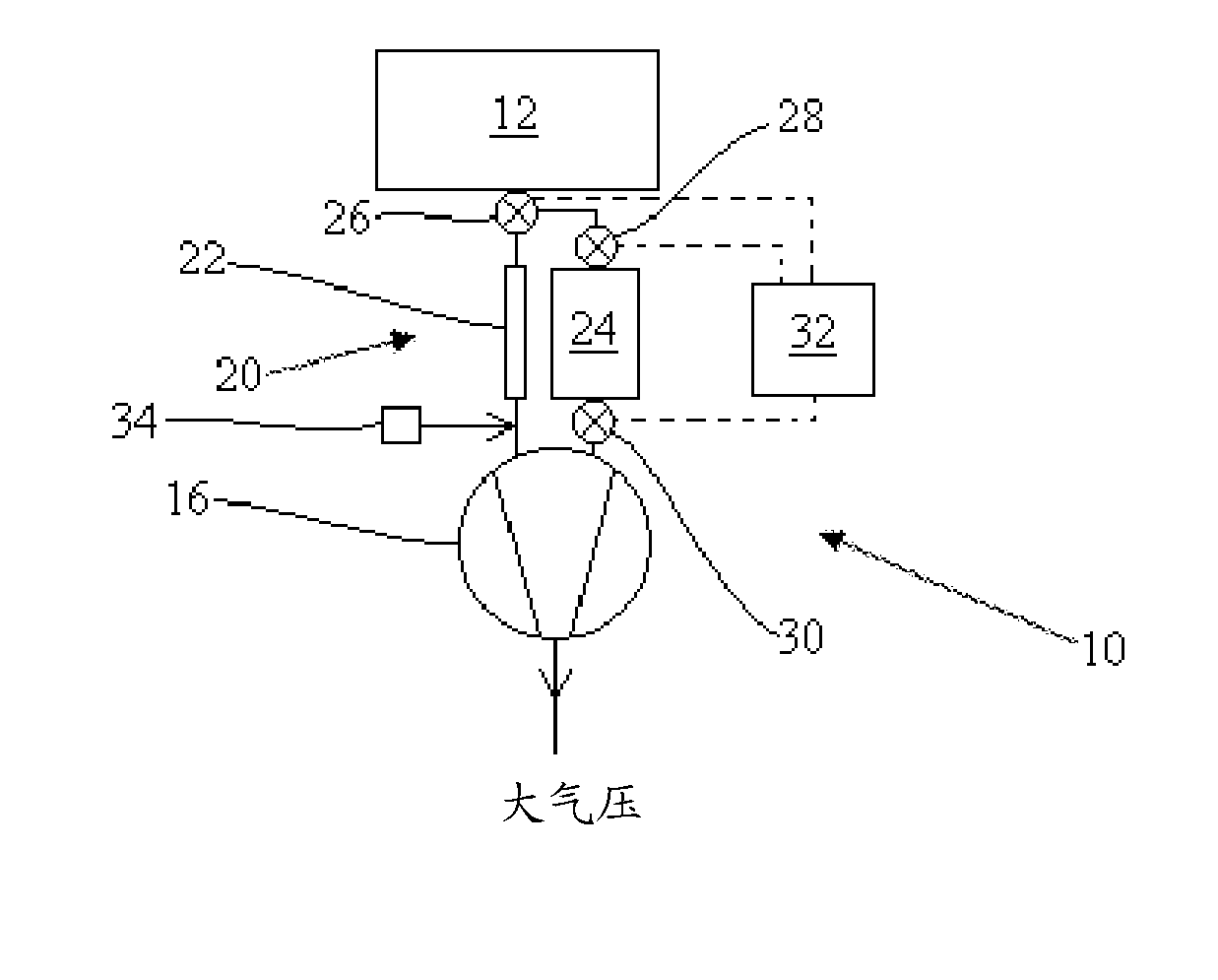

[0013] Referring to FIG. 1 , a vacuum pumping system 10 is shown for evacuating a vacuum chamber 12 . The vacuum pumping system includes a vacuum pump 16, such as a Roots pump, a claw pump or a scroll pump, for evacuating the vacuum chamber 12 to between about 1 mbar and 0.01 mbar. Two or more such pumps can be arranged in series or in parallel, and the term vacuum pump should be interpreted accordingly. A plurality of forelines 20 or conduits connect the vacuum pump 16 to the vacuum chamber 12 for delivering fluid from the chamber to the vacuum pump. The first foreline arrangement includes one or more forelines and has a first overall cross-sectional area for conveying fluid. During the rough vacuum phase of chamber evacuation, a first foreline arrangement may be connected for delivering gas to the vacuum pump. The second foreline arrangement includes one or more forelines and has a second overall cross-sectional area. During the higher vacuum phase of chamber evacuation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com