Method and apparatus for treating exhaust gases in a substrate processing system

A technology for processing systems and equipment, which is applied in the field of emission systems and can solve problems such as PFC and/or GWG weakening without foreline operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

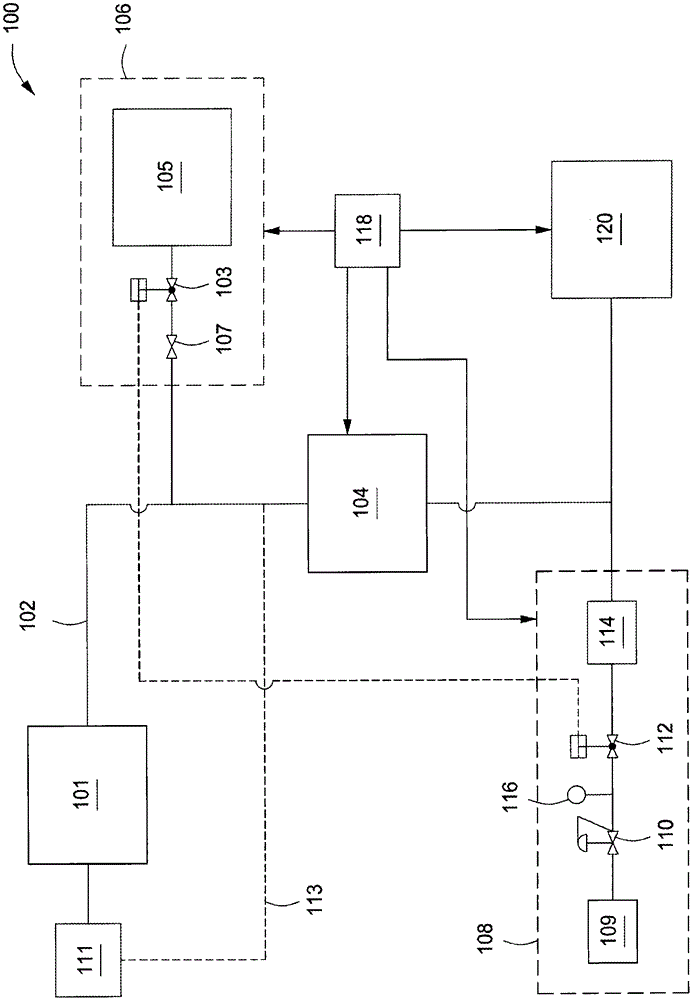

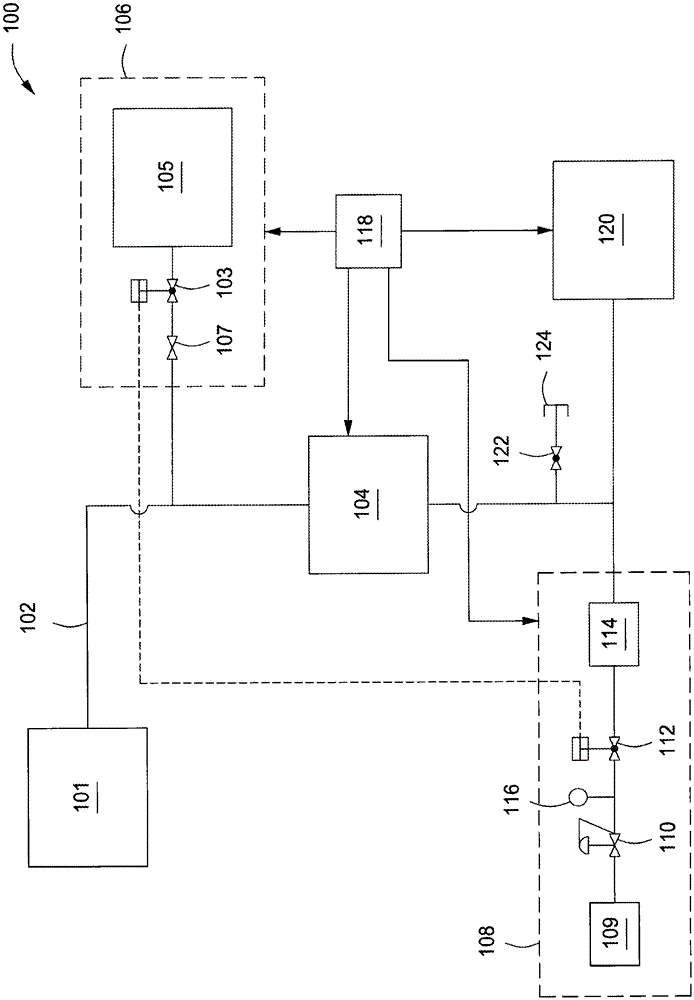

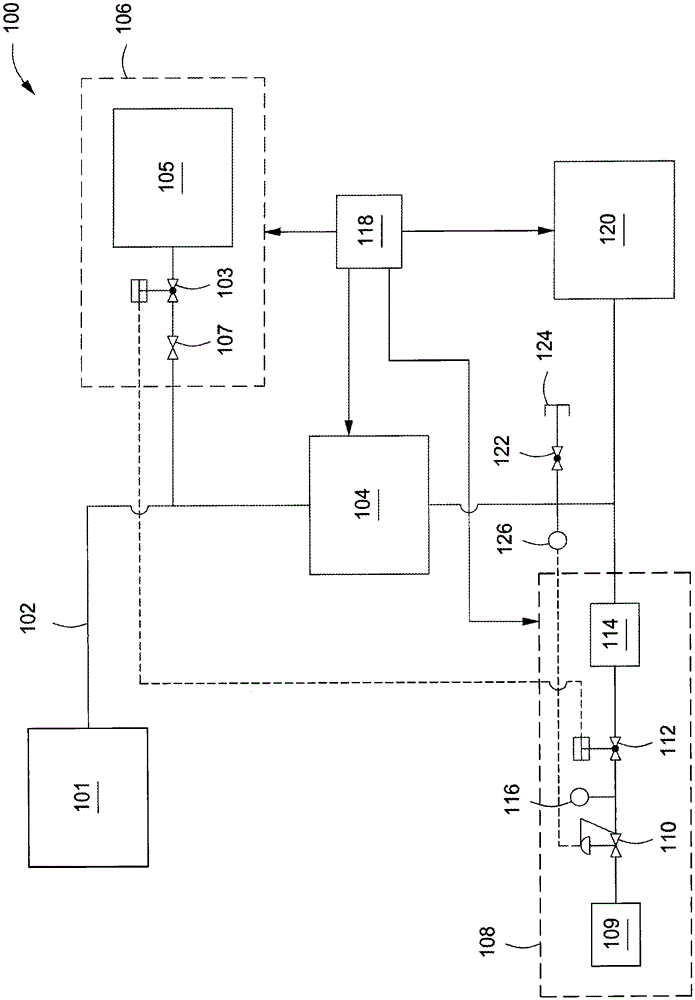

[0015] Provided herein are methods and apparatus for treating exhaust gases in the foreline of a substrate processing system. Embodiments of the present invention may advantageously provide improved perfluorocarbon (PFC) and global greenhouse gas (GWG) abatement efficiencies. Embodiments of the present invention improve abatement efficiency by, for example, reacting with one or more reactant gases to control the pressure in the foreline to optimize the decomposition of the PFC and / or GWG. For example, the pressure may be controlled in real time to maintain the pressure within a desired operating range, or may be controlled in response to one or more reactant gases injected into the foreline.

[0016] For example, in some embodiments, a plasma including a reactant (e.g., water) can be formed in or delivered to a process foreline while simultaneously controlling the pressure in the process foreline to optimize Form and / or maintain a plasma efficiently. In some embodiments, a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com