Patents

Literature

788results about "Perfluorocarbons/hydrofluorocarbons capture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

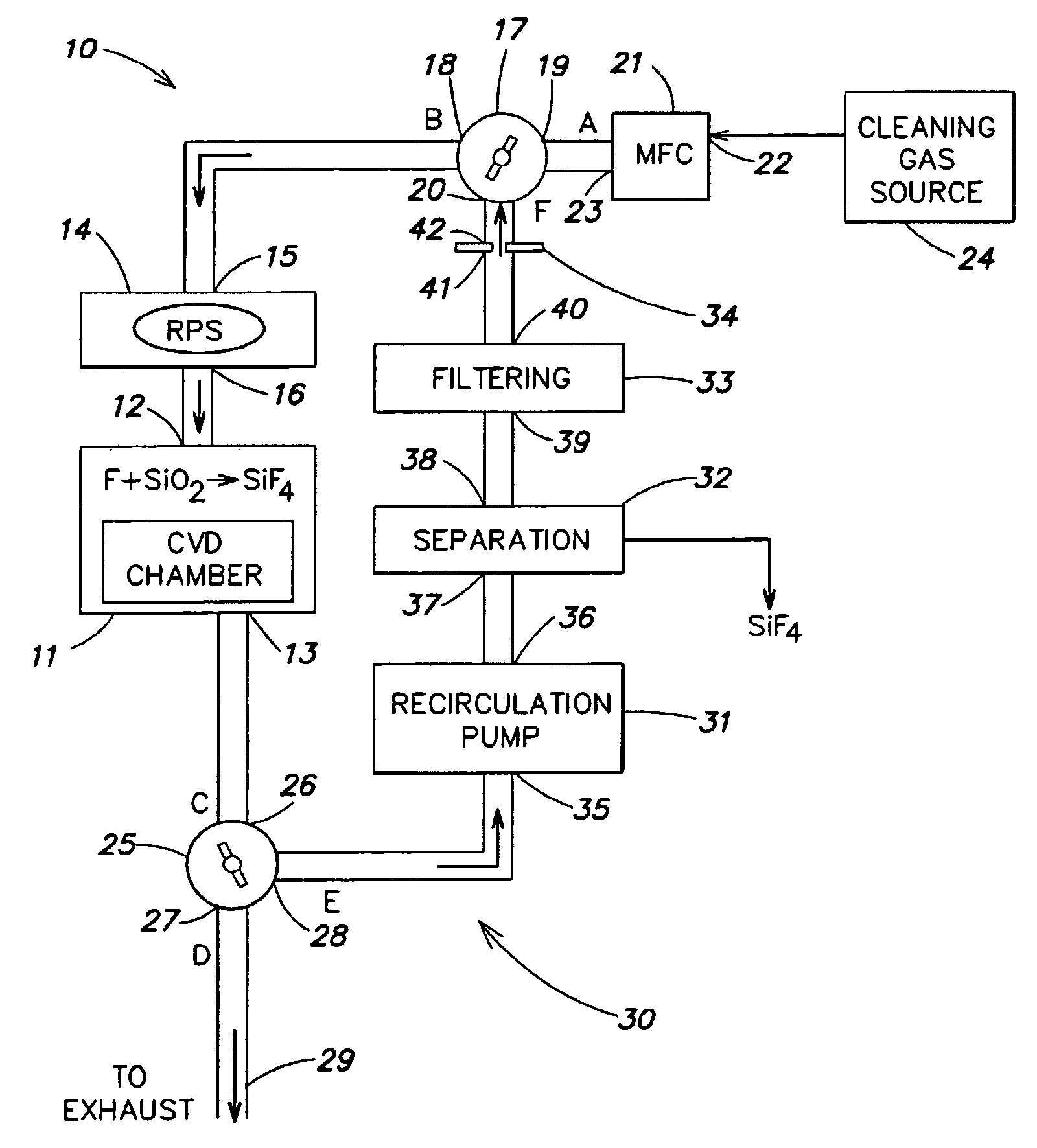

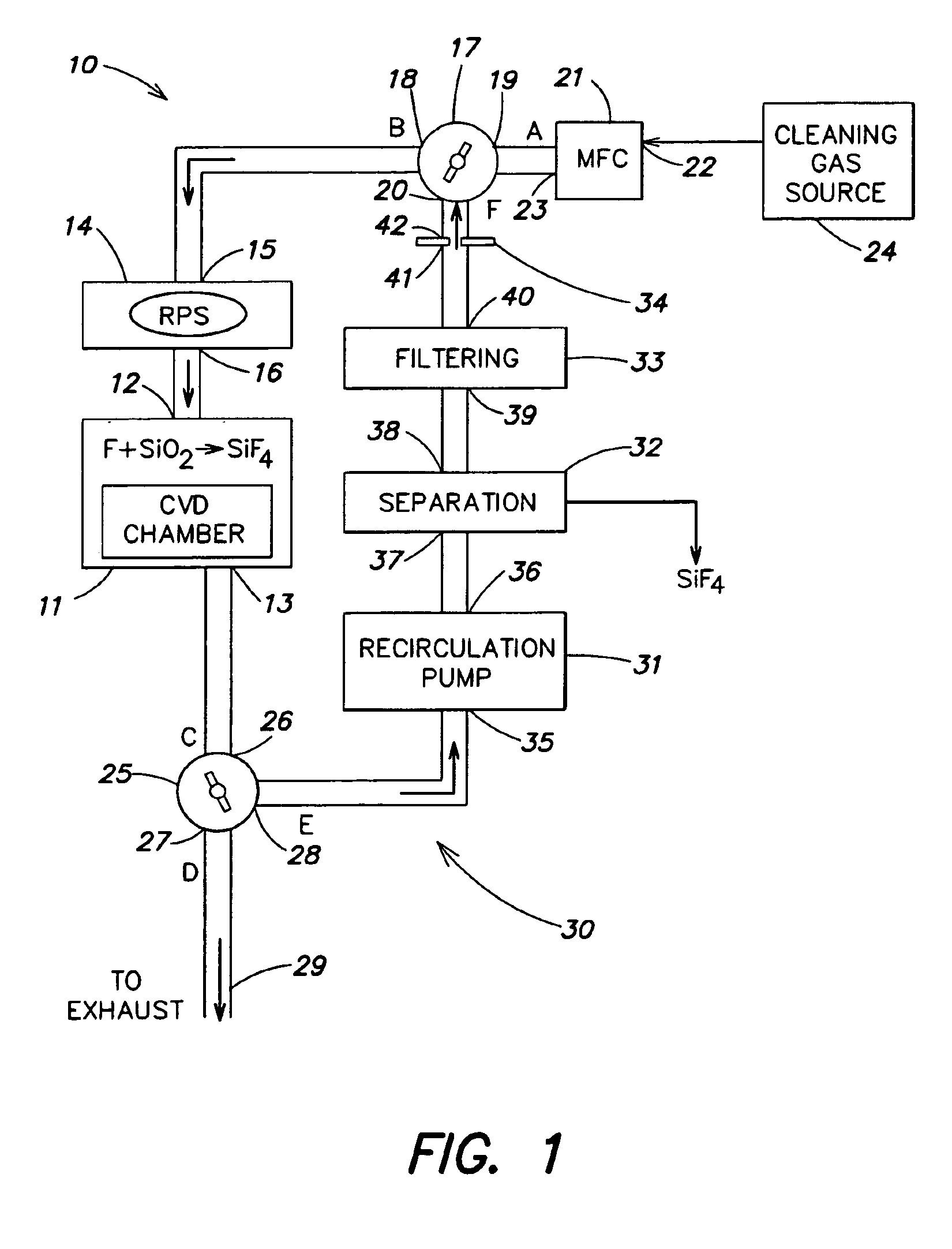

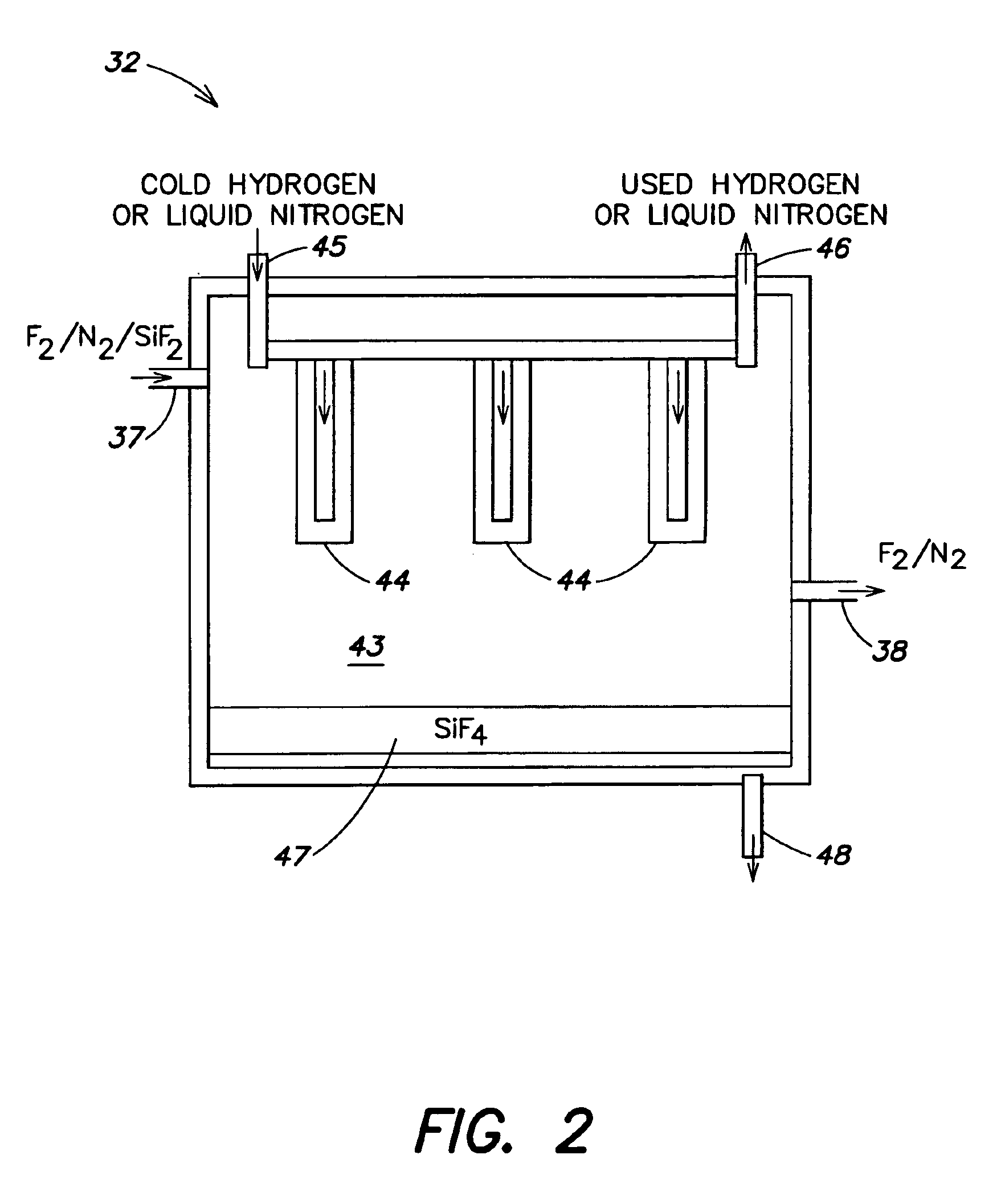

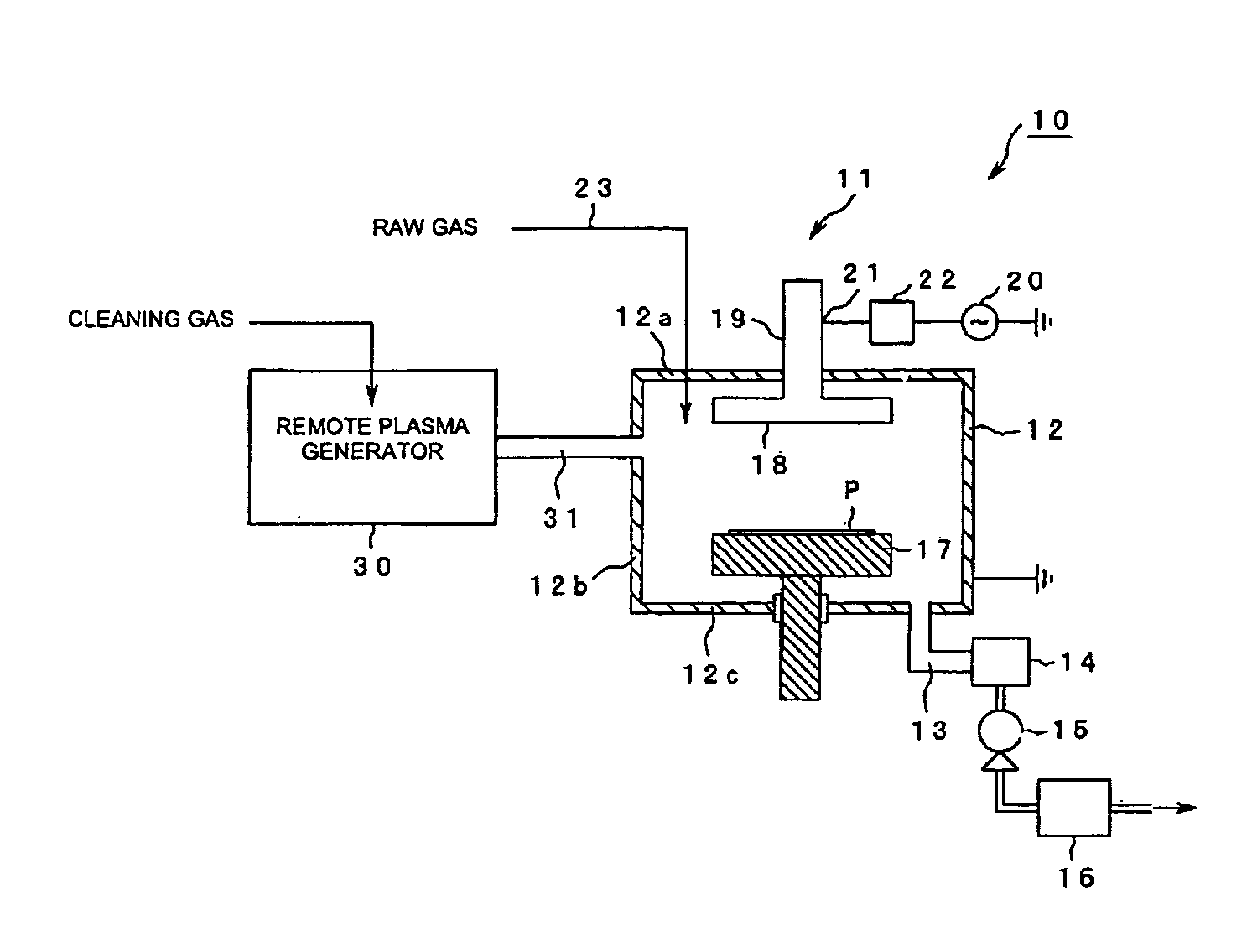

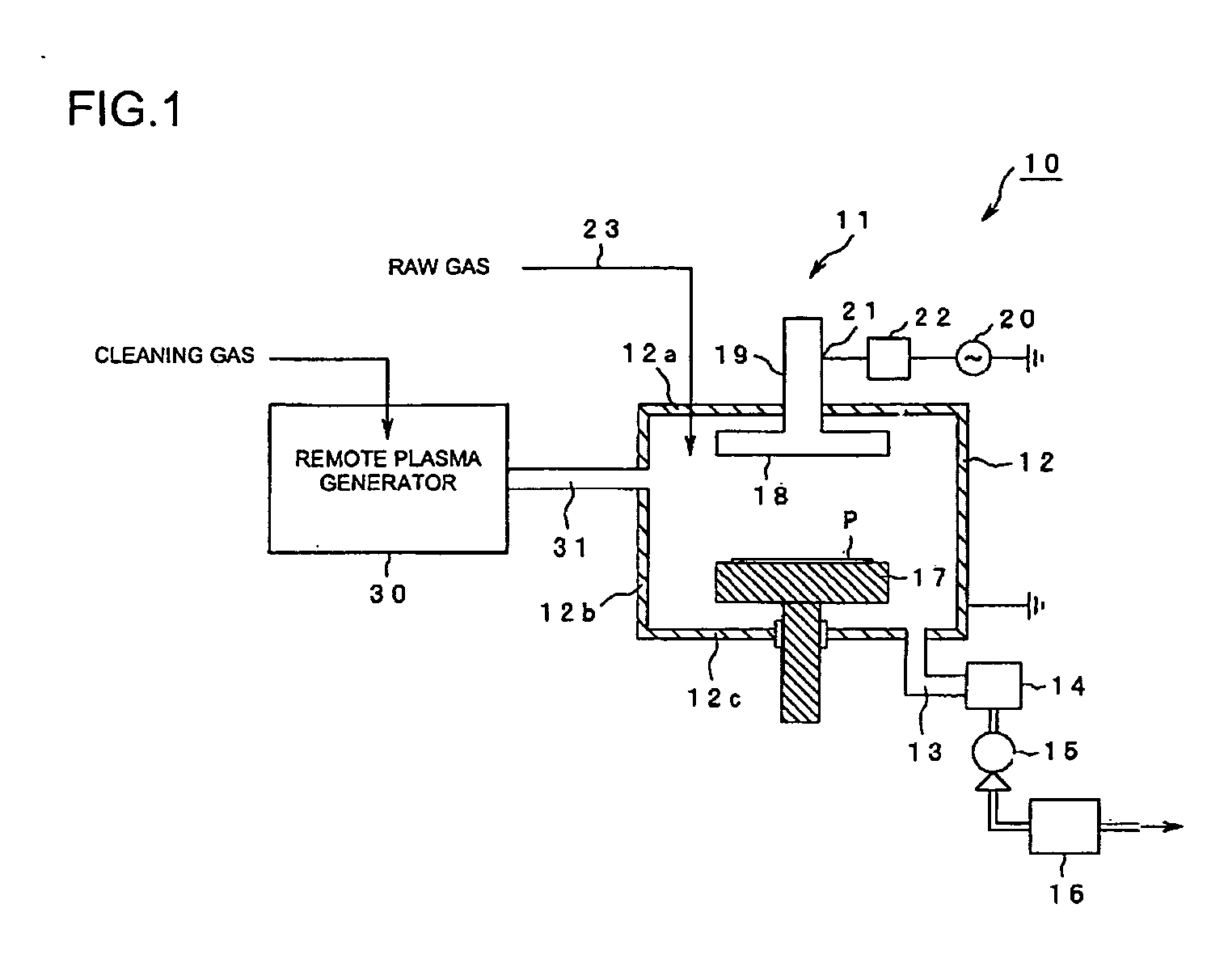

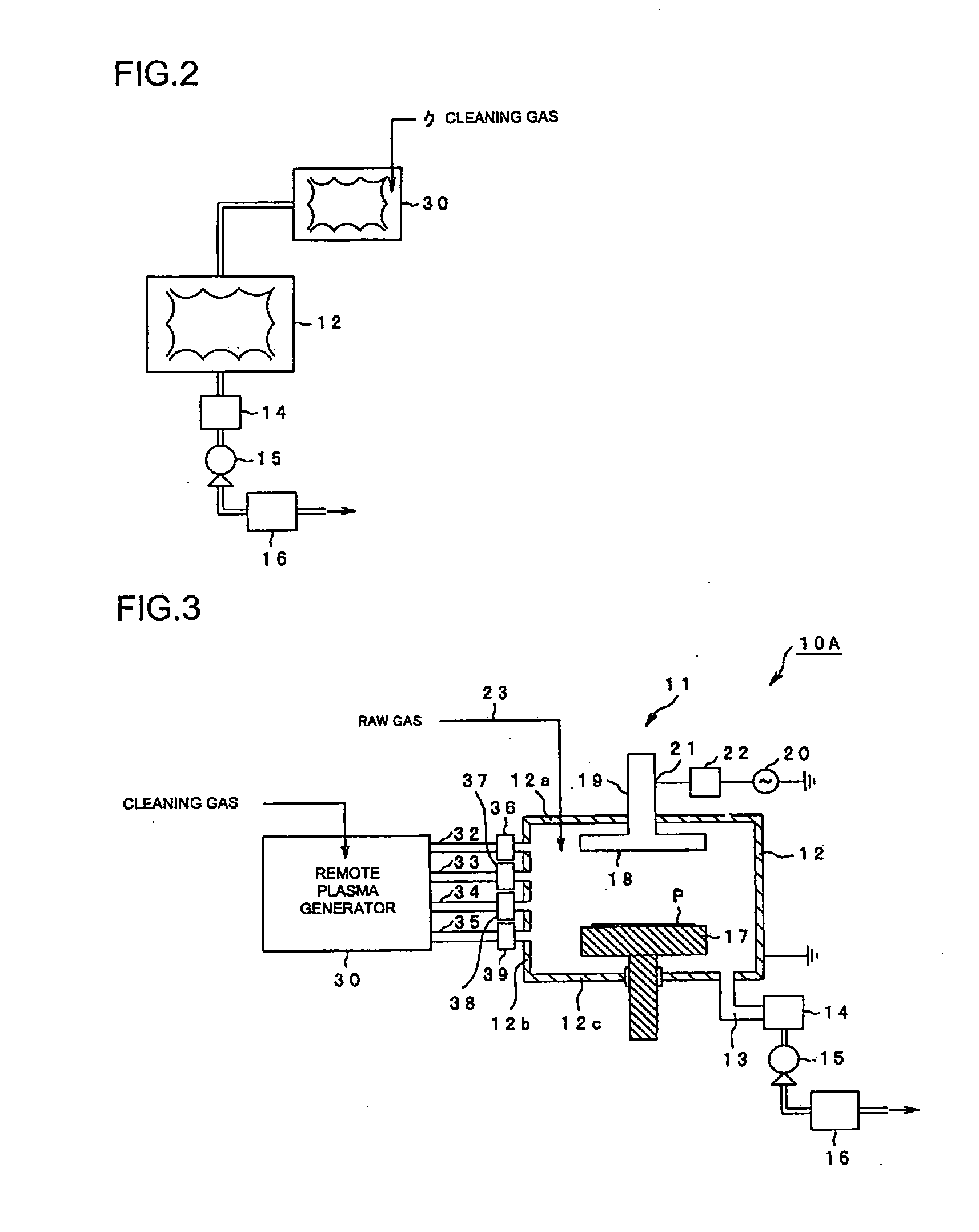

Semiconductor device fabrication chamber cleaning method and apparatus with recirculation of cleaning gas

InactiveUS6863019B2Low costReduce consumptionElectric discharge tubesElectrostatic cleaningNuclear engineeringProduct gas

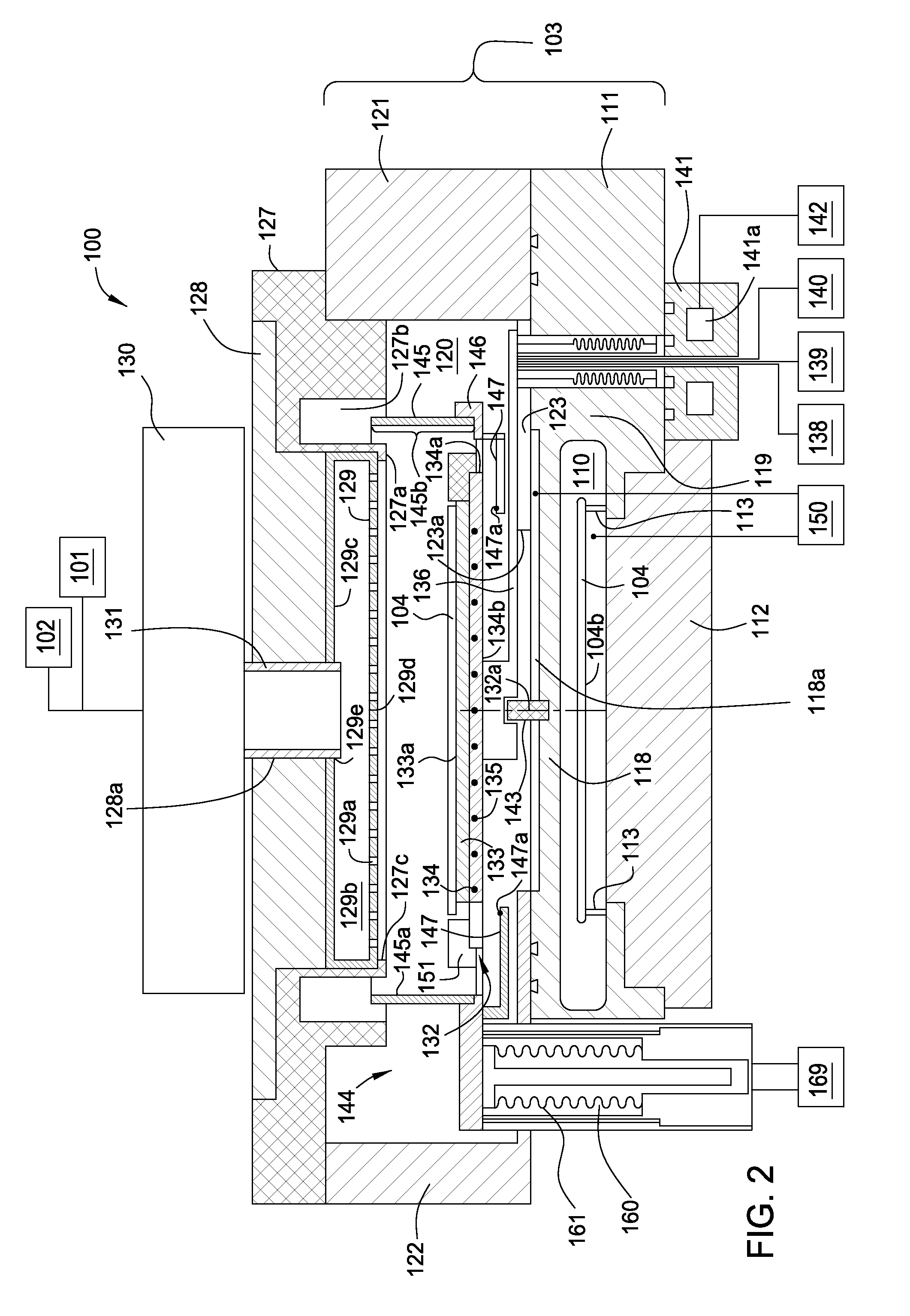

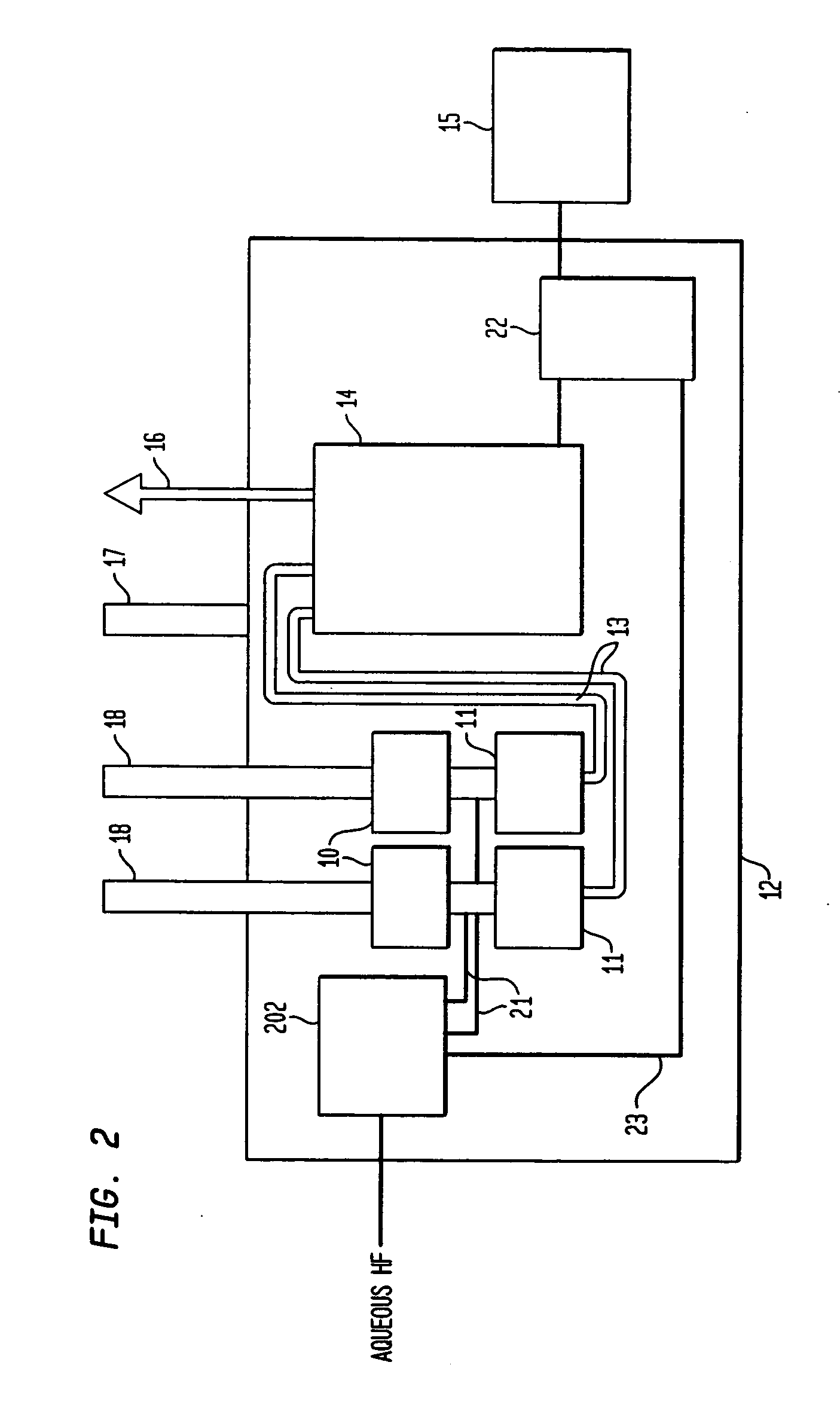

A method of cleaning a semiconductor fabrication processing chamber involves recirculation of cleaning gas components. Consequently, input cleaning gas is utilized efficiently, and undesirable emissions are reduced. The method includes flowing a cleaning gas to an inlet of a processing chamber, and exposing surfaces of the processing chamber to the cleaning gas to clean the surfaces, thereby producing a reaction product. The method further includes removing an outlet gas including the reaction product from an outlet of the processing chamber, separating at least a portion of the reaction product from the outlet gas, and recirculating a portion of the outlet gas to the inlet of the processing chamber.

Owner:APPLIED MATERIALS INC

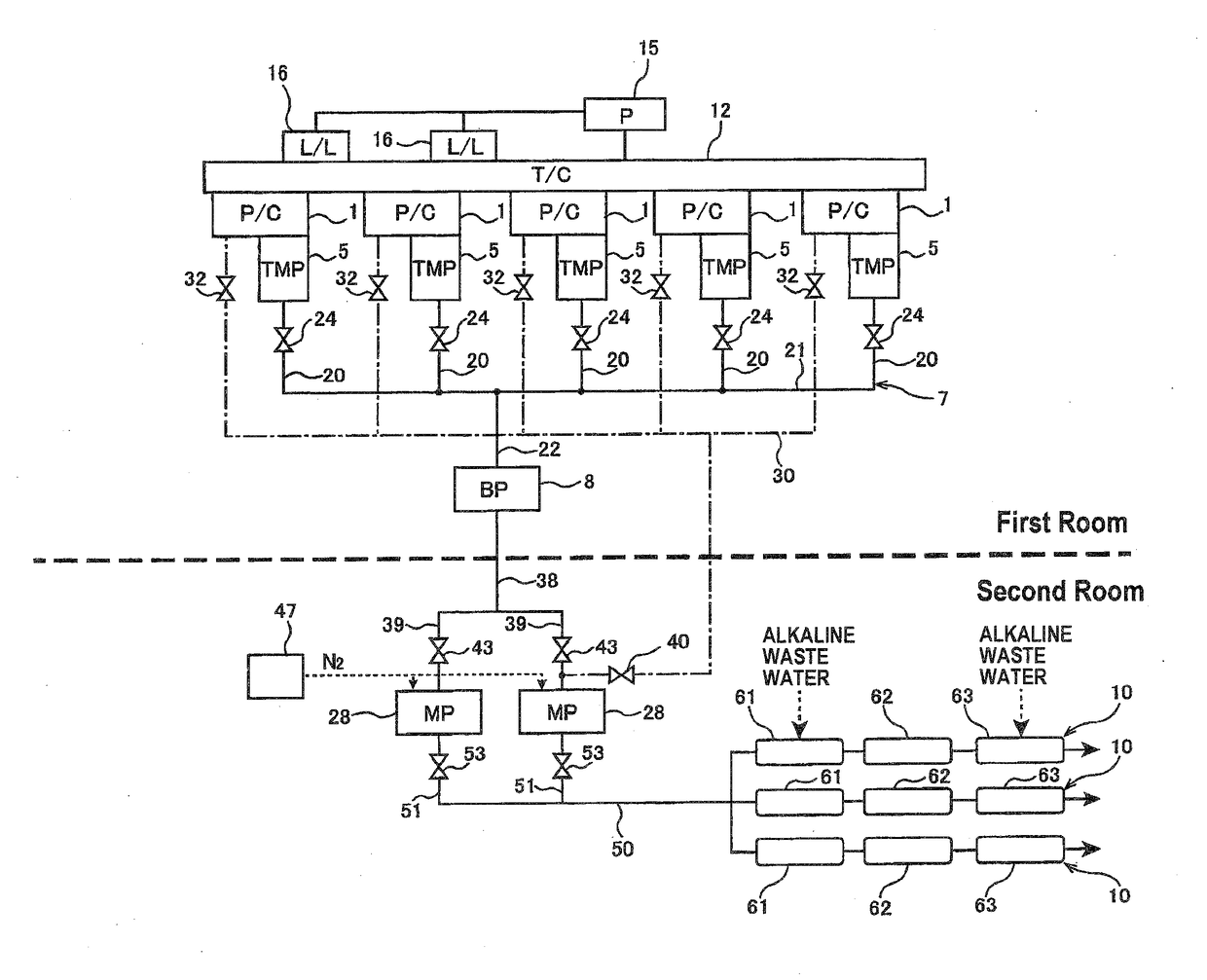

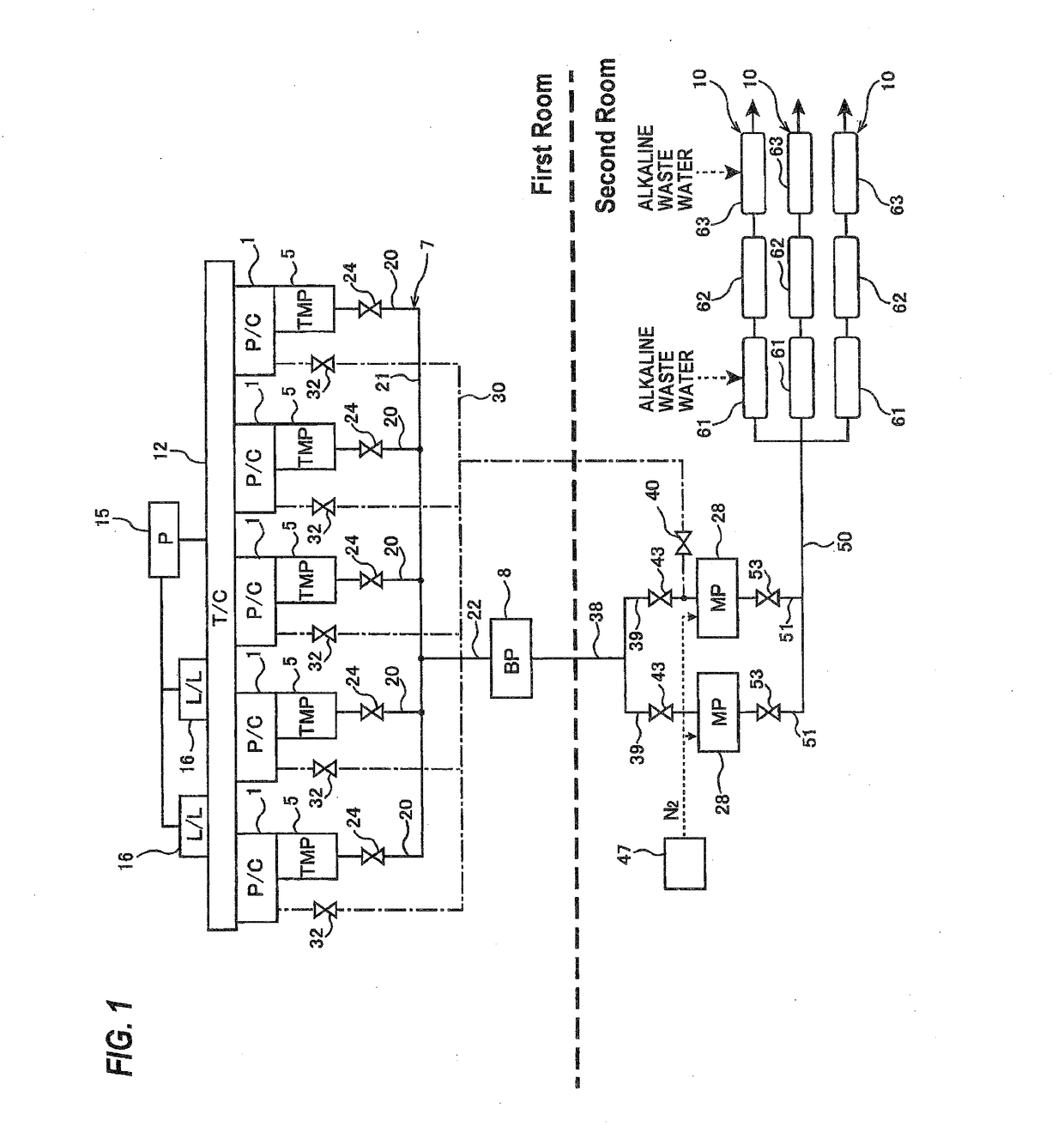

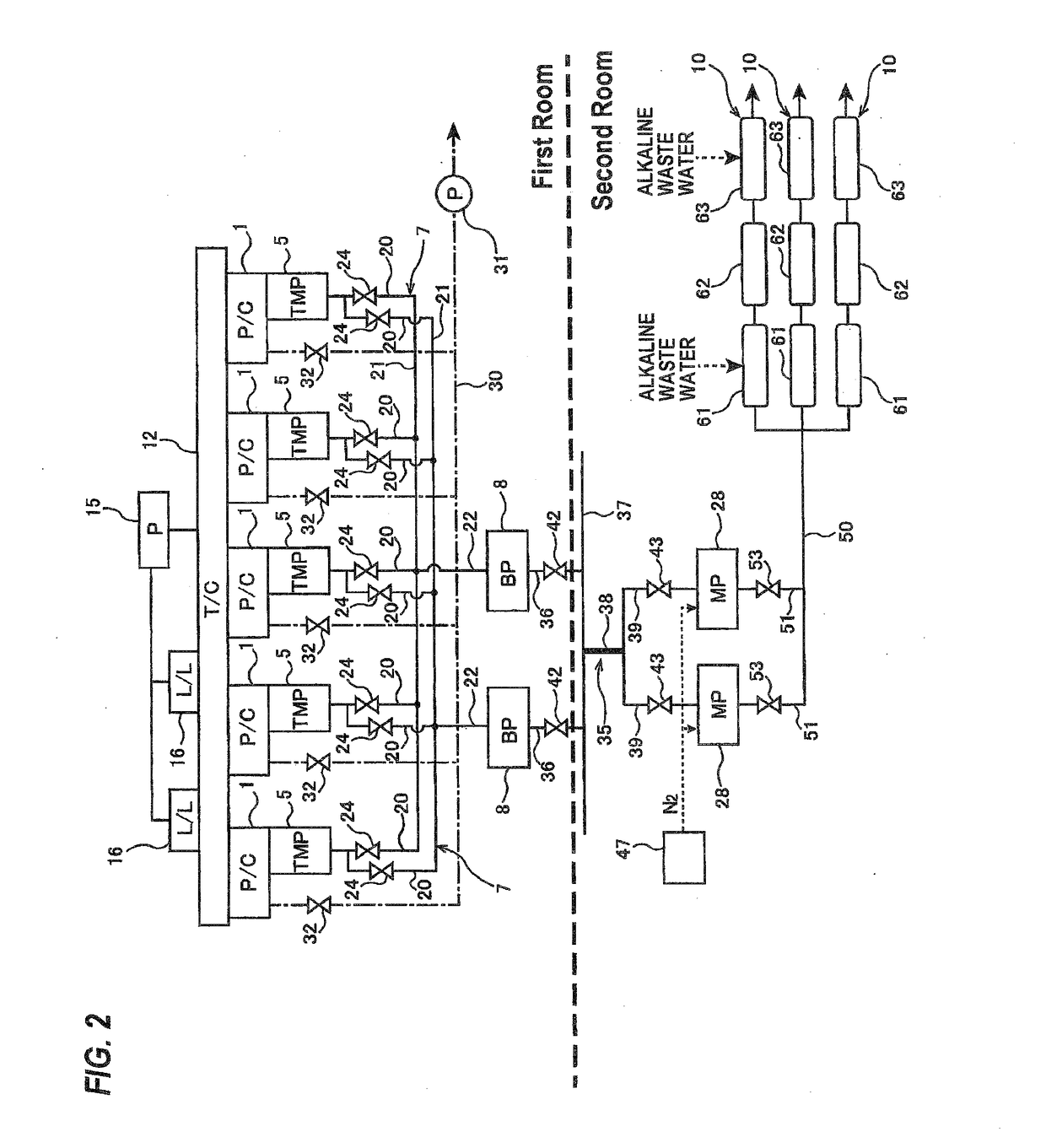

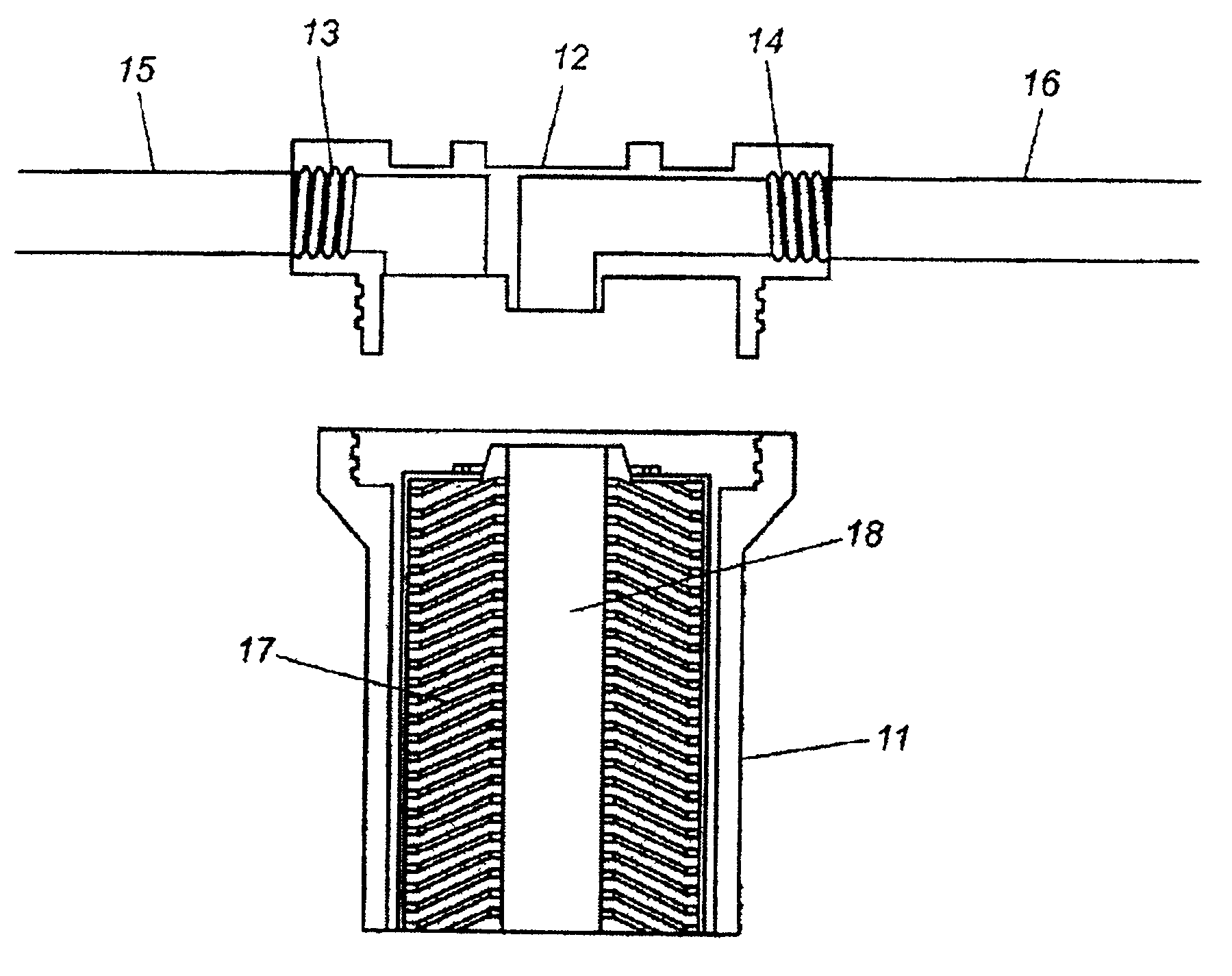

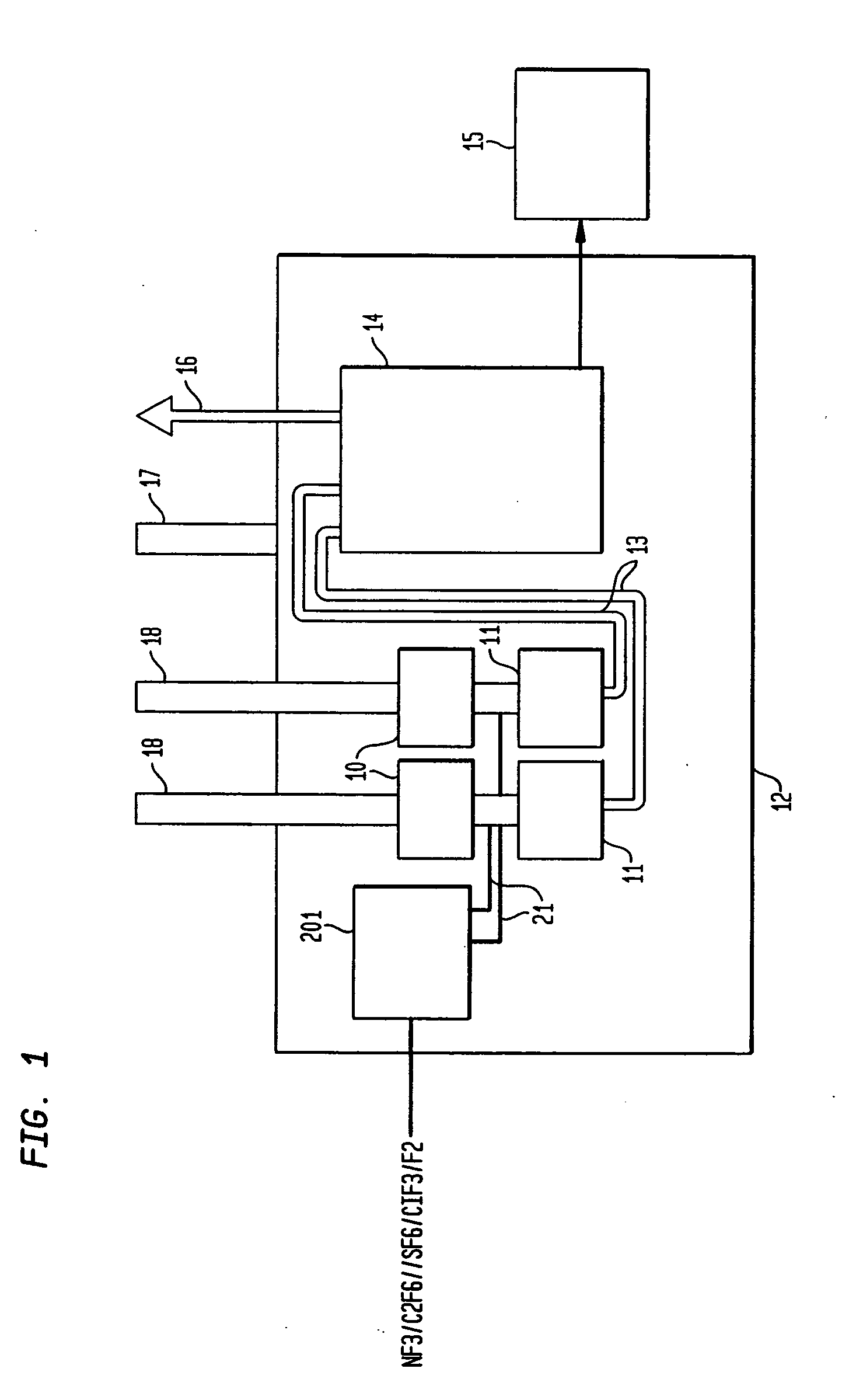

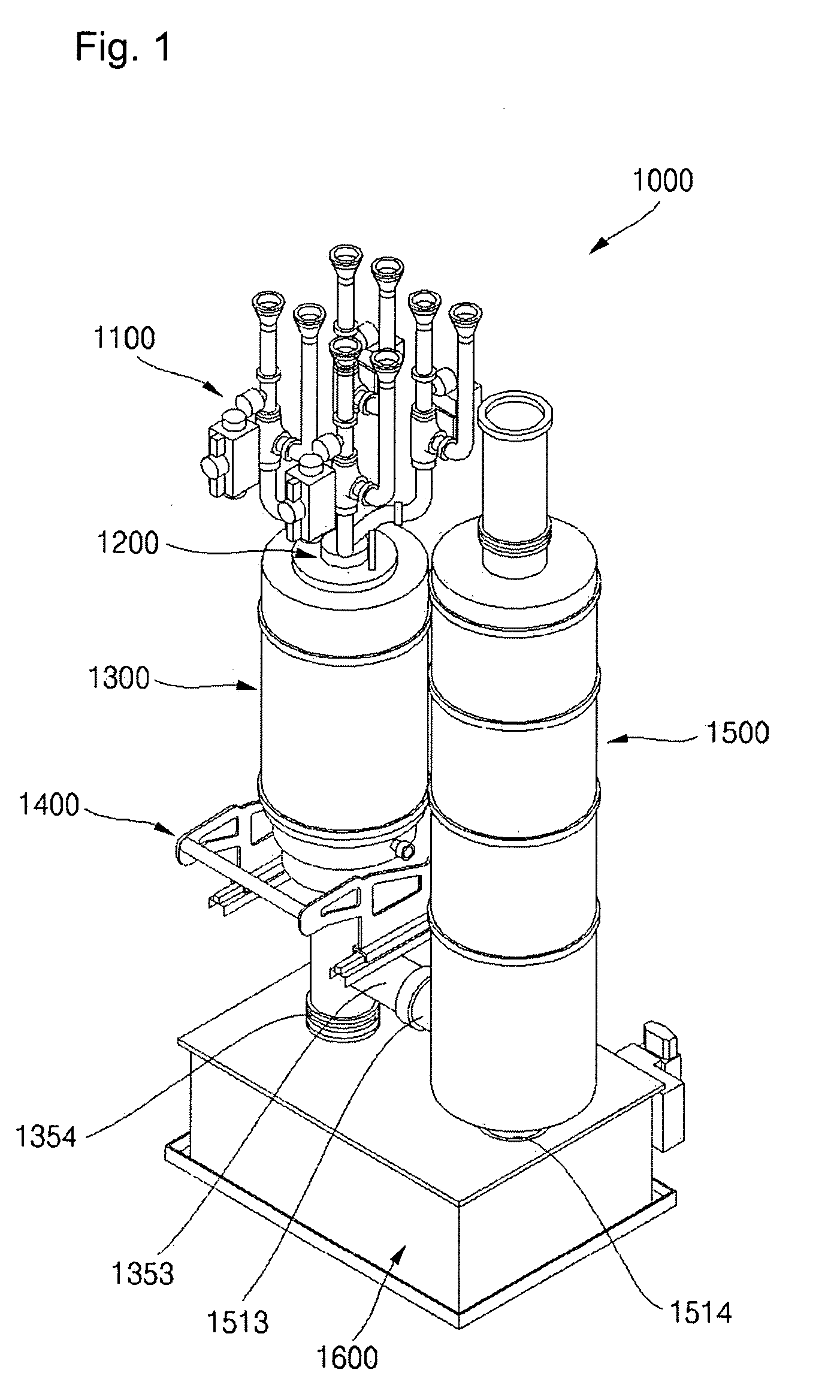

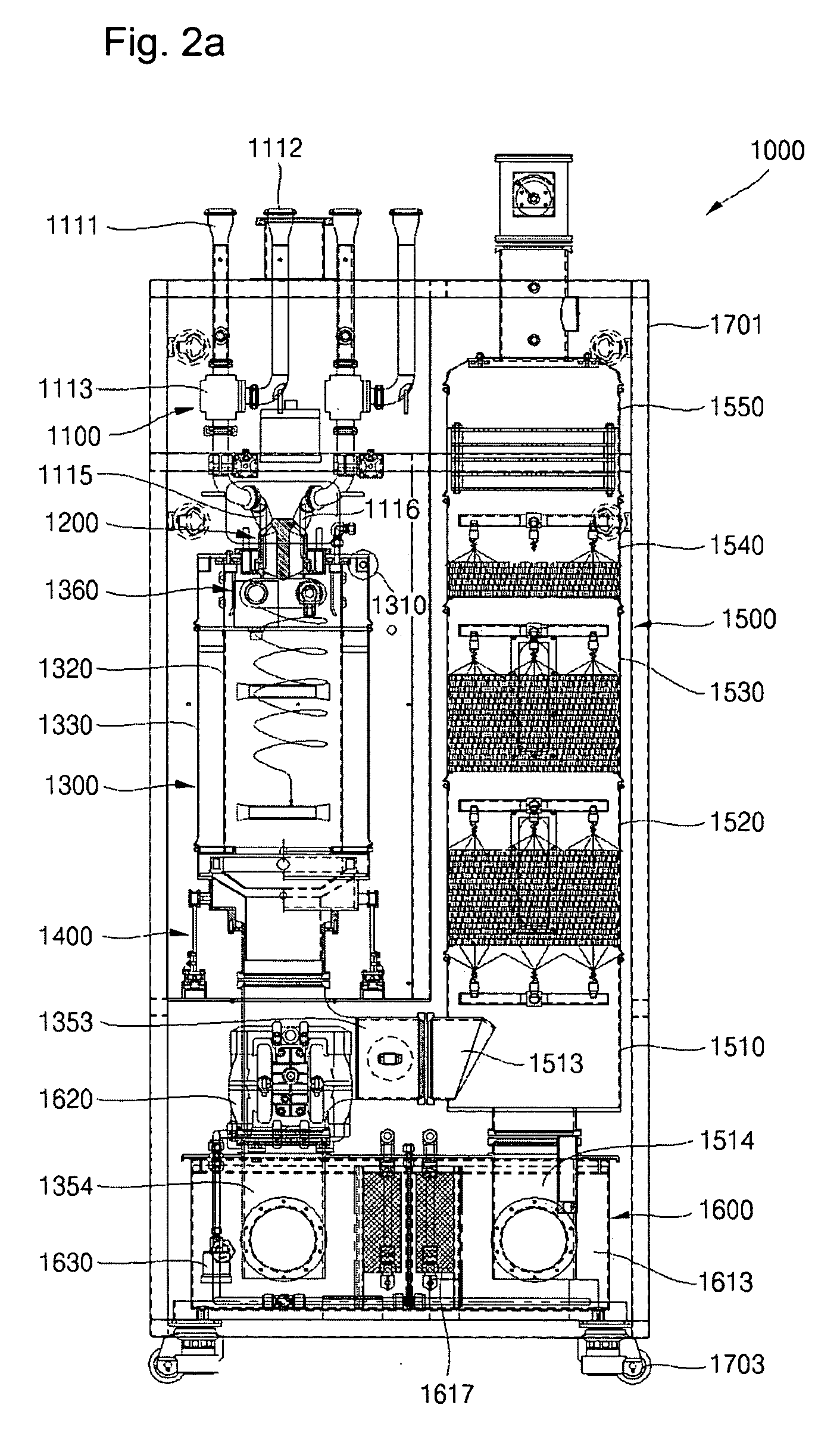

Vacuum evacuation system

ActiveUS20170200622A1Reduce installation costsIncrease pressureElectric discharge tubesFinal product manufactureProcess engineeringVacuum pump

The present invention relates to a vacuum evacuation system used to evacuate a processing gas from one or more process chambers for use in, for example, a semiconductor-device manufacturing apparatus. The vacuum evacuation system is a vacuum apparatus for evacuating a gas from a plurality of process chambers (1). The vacuum evacuation system includes a plurality of first vacuum pumps (5) coupled to the plurality of process chambers (1) respectively, a collecting pipe (7) coupled to the plurality of first vacuum pumps (5), and a second vacuum pump (8) coupled to the collecting pipe (7).

Owner:EBARA CORP

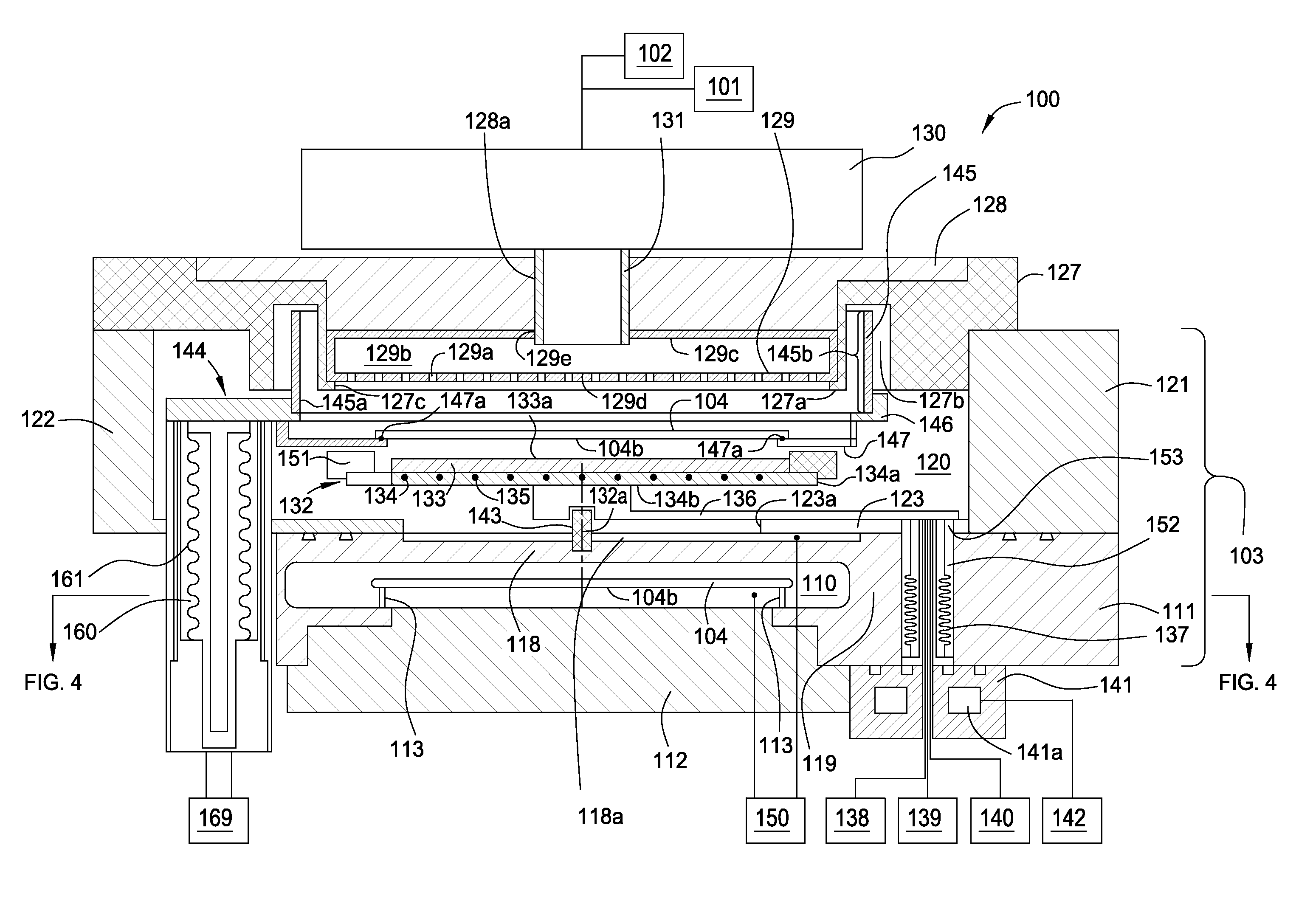

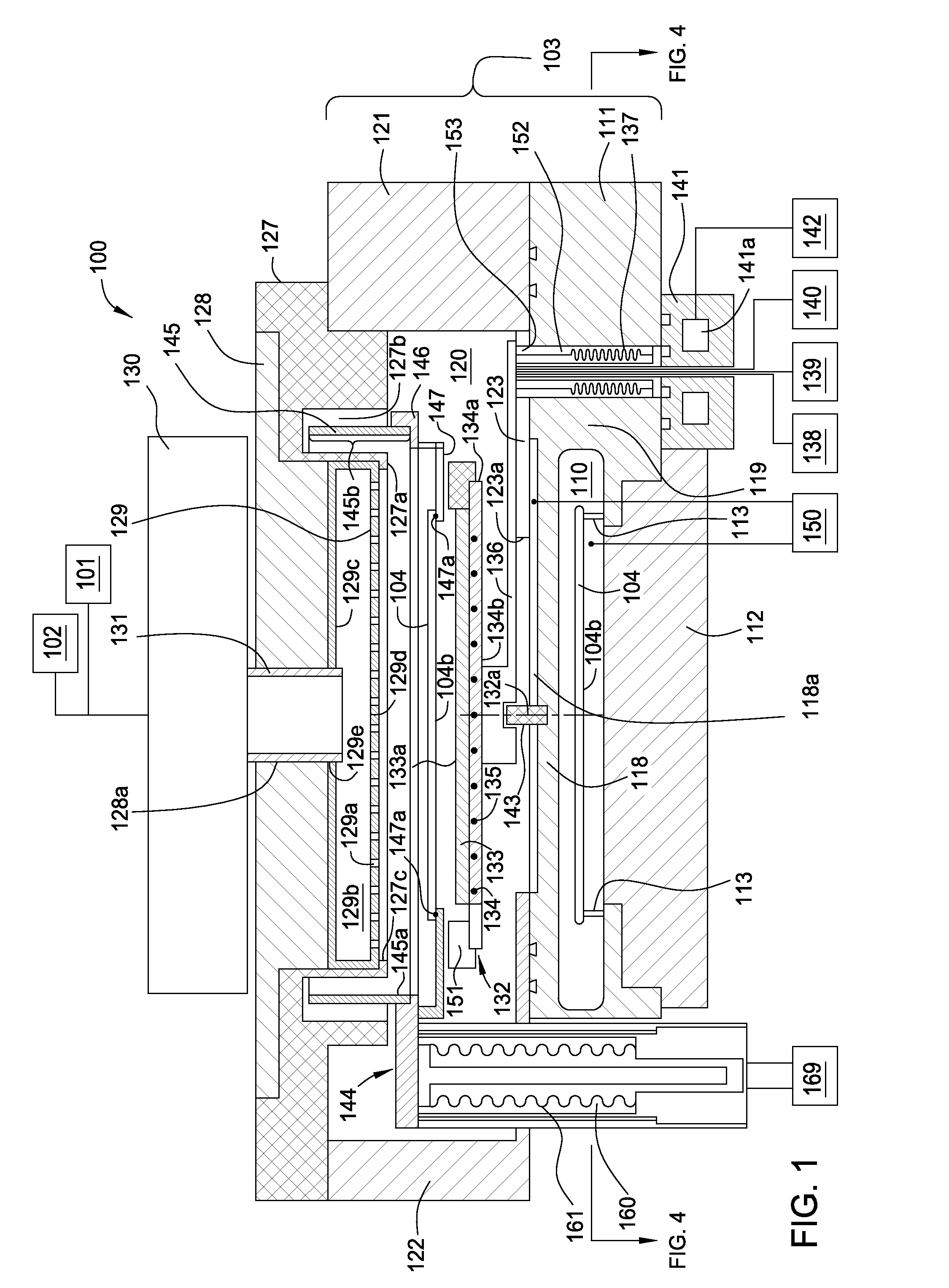

Abatement and strip process chamber in a dual loadlock configuration

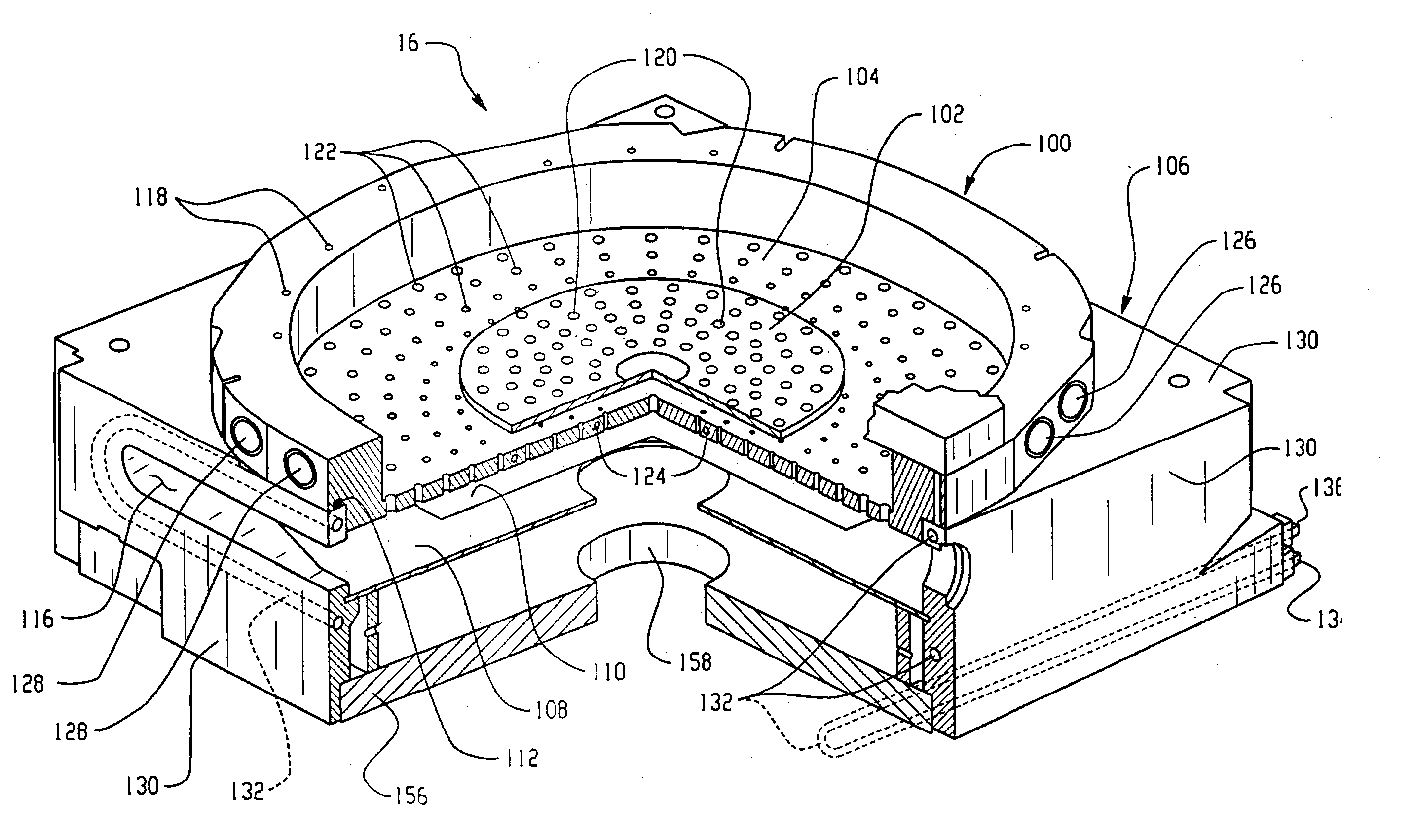

Embodiments of the present invention provide a dual load lock chamber capable of processing a substrate. In one embodiment, the dual load lock chamber includes a chamber body defining a first chamber volume and a second chamber volume isolated from one another. Each of the lower and second chamber volumes is selectively connectable to two processing environments through two openings configured for substrate transferring. The dual load lock chamber also includes a heated substrate support assembly disposed in the second chamber volume. The heated substrate support assembly is configured to support and heat a substrate thereon. The dual load lock chamber also includes a remote plasma source connected to the second chamber volume for supplying a plasma to the second chamber volume.

Owner:APPLIED MATERIALS INC

Plasma apparatus, gas distribution assembly for a plasma apparatus and processes therewith

ActiveUS20040238123A1Maintain good propertiesHigh ashing selectivityElectric discharge tubesSemiconductor/solid-state device manufacturingHydrogenNitrogen

A plasma apparatus, various components of the plasma apparatus, and an oxygen free and nitrogen free processes for effectively removing photoresist material and post etch residues from a substrate with a carbon and / or hydrogen containing low k dielectric layer(s).

Owner:LAM RES CORP

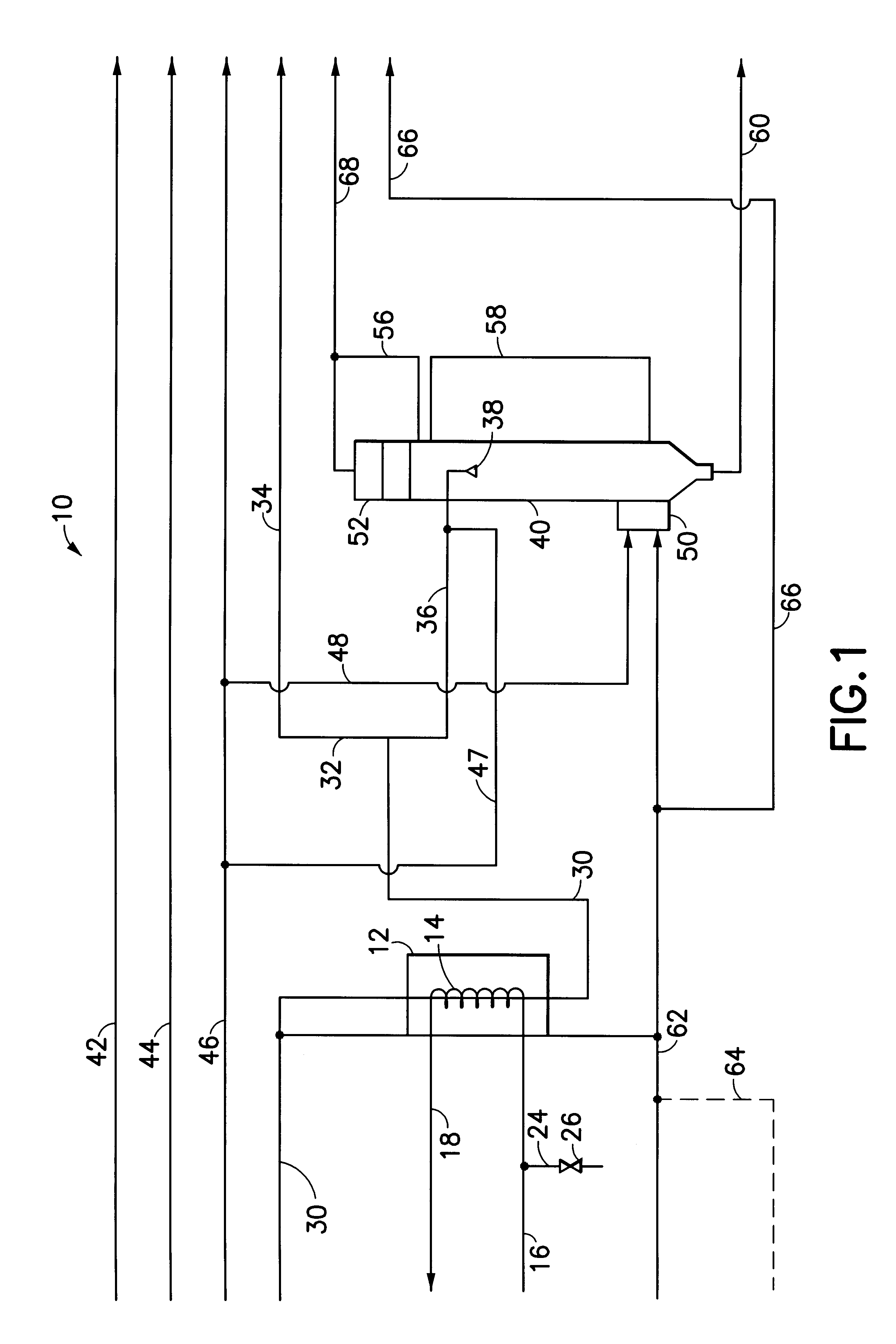

Effluent gas stream treatment system having utility for oxidation treatment of semiconductor manufacturing effluent gases

InactiveUS6322756B1Reduce sensitivityReduces water requiredCombination devicesExhaust apparatusOxygenOxidative treatment

An effluent gas stream treatment system for treatment of gaseous effluents such as waste gases from semiconductor manufacturing operations. The effluent gas stream treatment system comprises an oxidation unit to which an oxygen-containing gas such as ozone may be added, with input of energy (e.g., thermal, radio frequency, electrical, microwave, etc.), to effect oxidation of oxidizable species in the effluent, such as halocompounds (e.g., chlorofluorocarbons, perfluorocarbons), CO, NF3, nitrogen oxides, and sulfur oxides). The effluent gas stream treatment system may include a wet scrubber associated with the oxygen-containing gas source, so that the gas stream is contacted with the oxygen-containing gas during the wet scrubbing operation, to enhance removal of oxidizable species in the gas stream during treatment.

Owner:BHT SERVICES PTE LTD

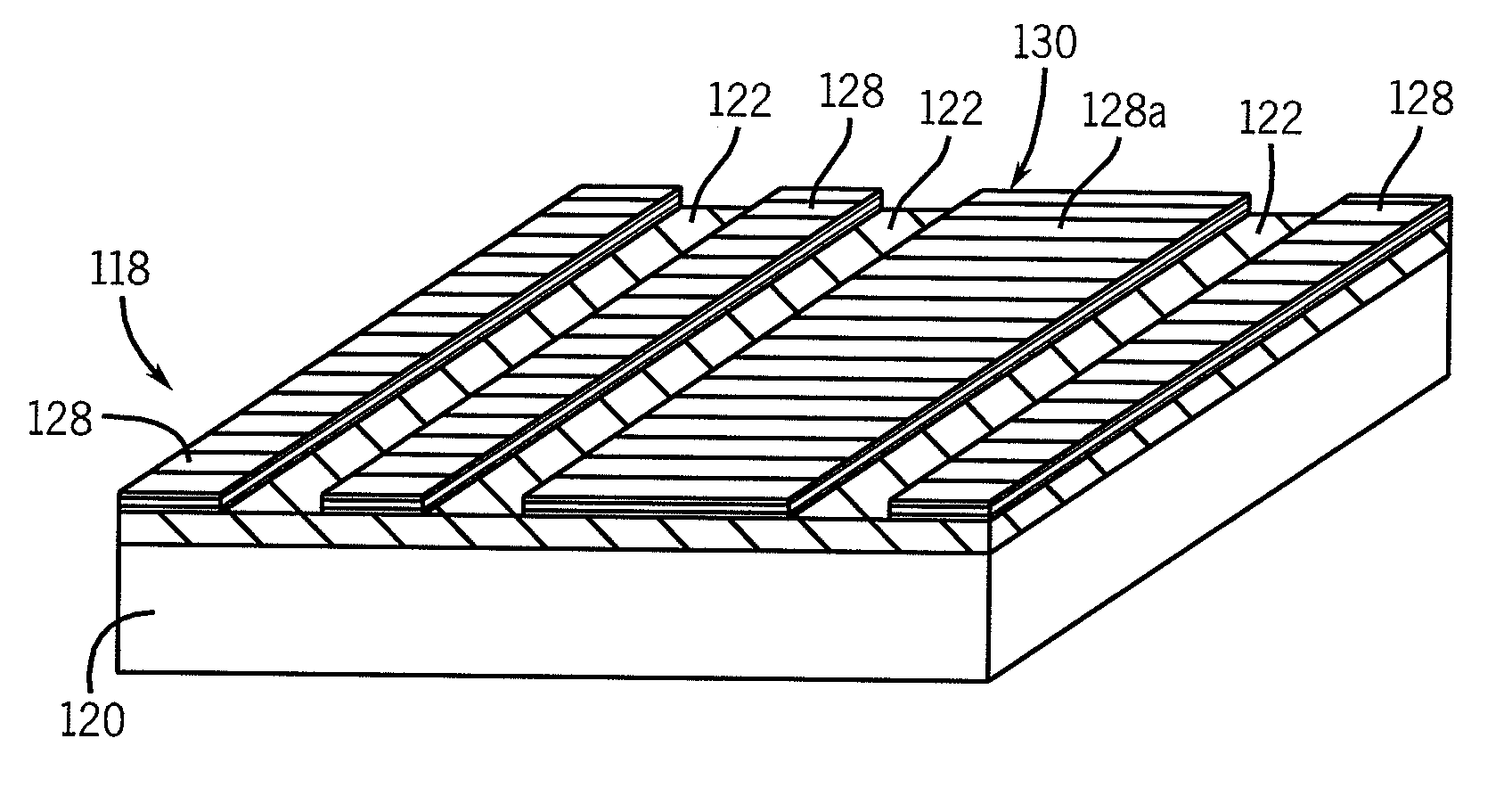

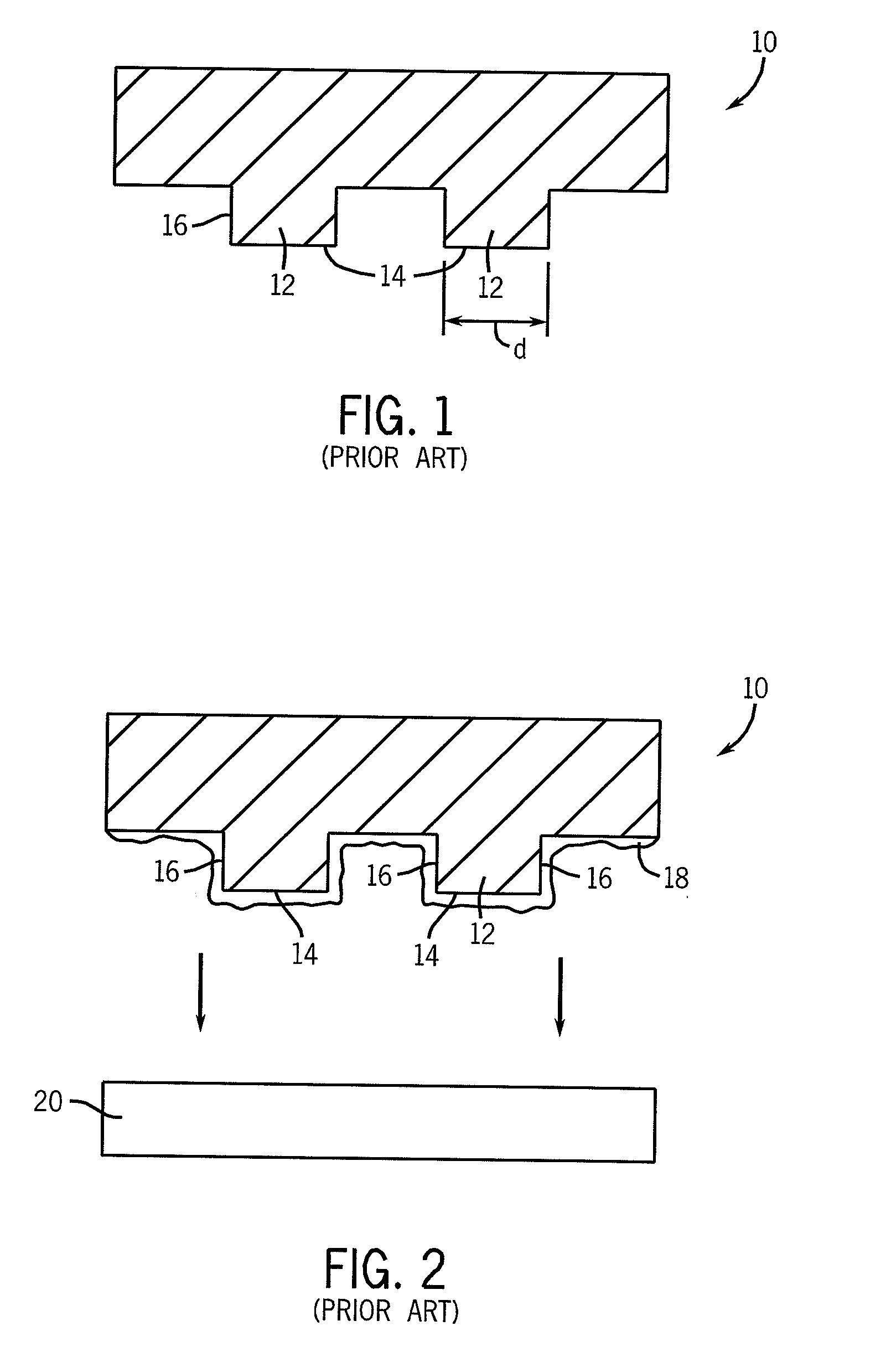

Method to Produce Nanometer-Sized Features with Directed Assembly of Block Copolymers

Owner:MICRON TECH INC

Solvent compositions containing chlorofluoroolefins or fluoroolefins

Compositions and methods based on the use of fluoroalkene containing from 3 to 4 carbon atoms and at least one carbon-carbon double bond, such as HFO-1214, HFO-HFO-1233, or HFO-1354, having properties highly beneficial in solvent cleaning applications.

Owner:HONEYWELL INT INC

Reactive compositions for fluid treatment

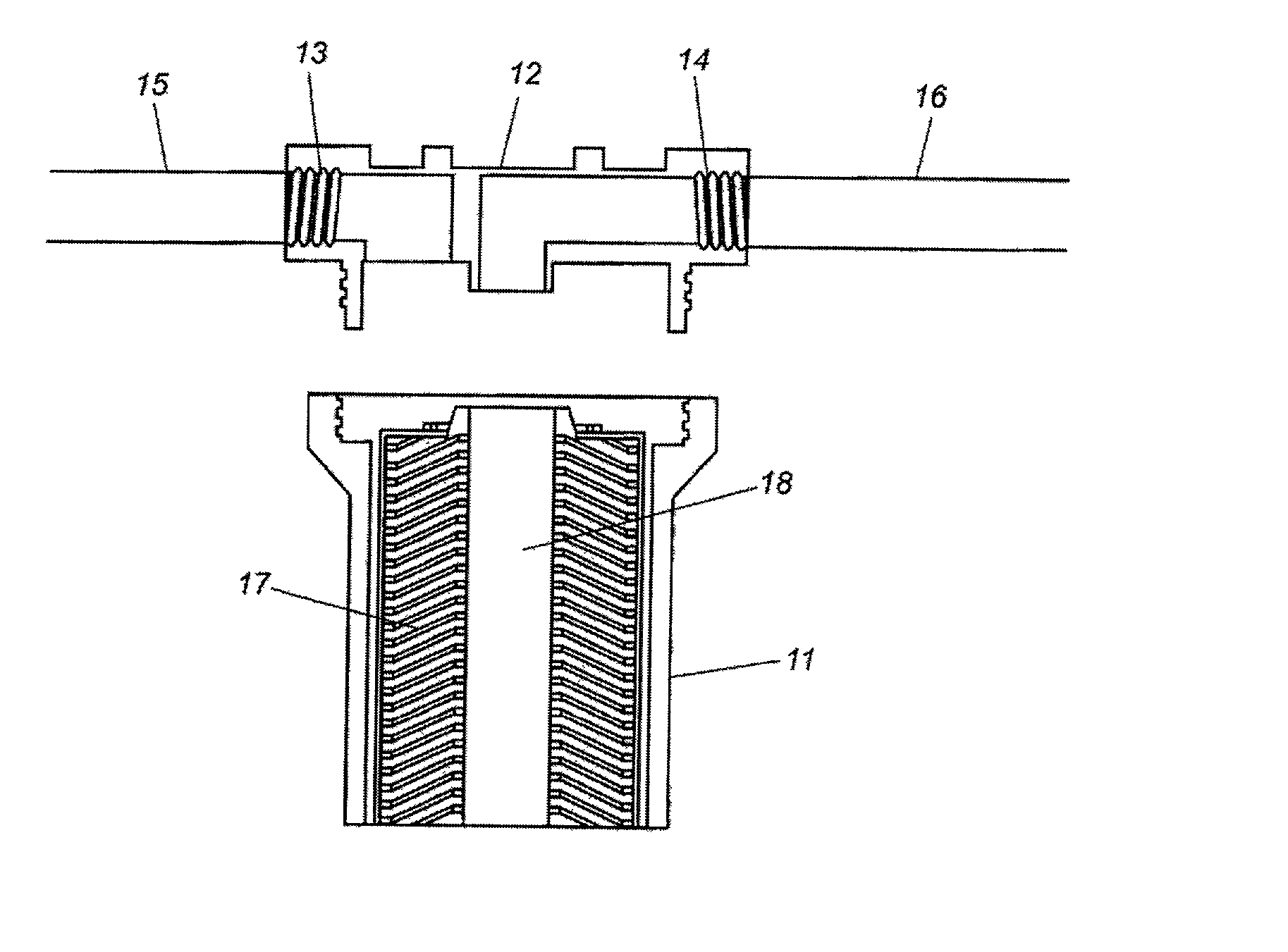

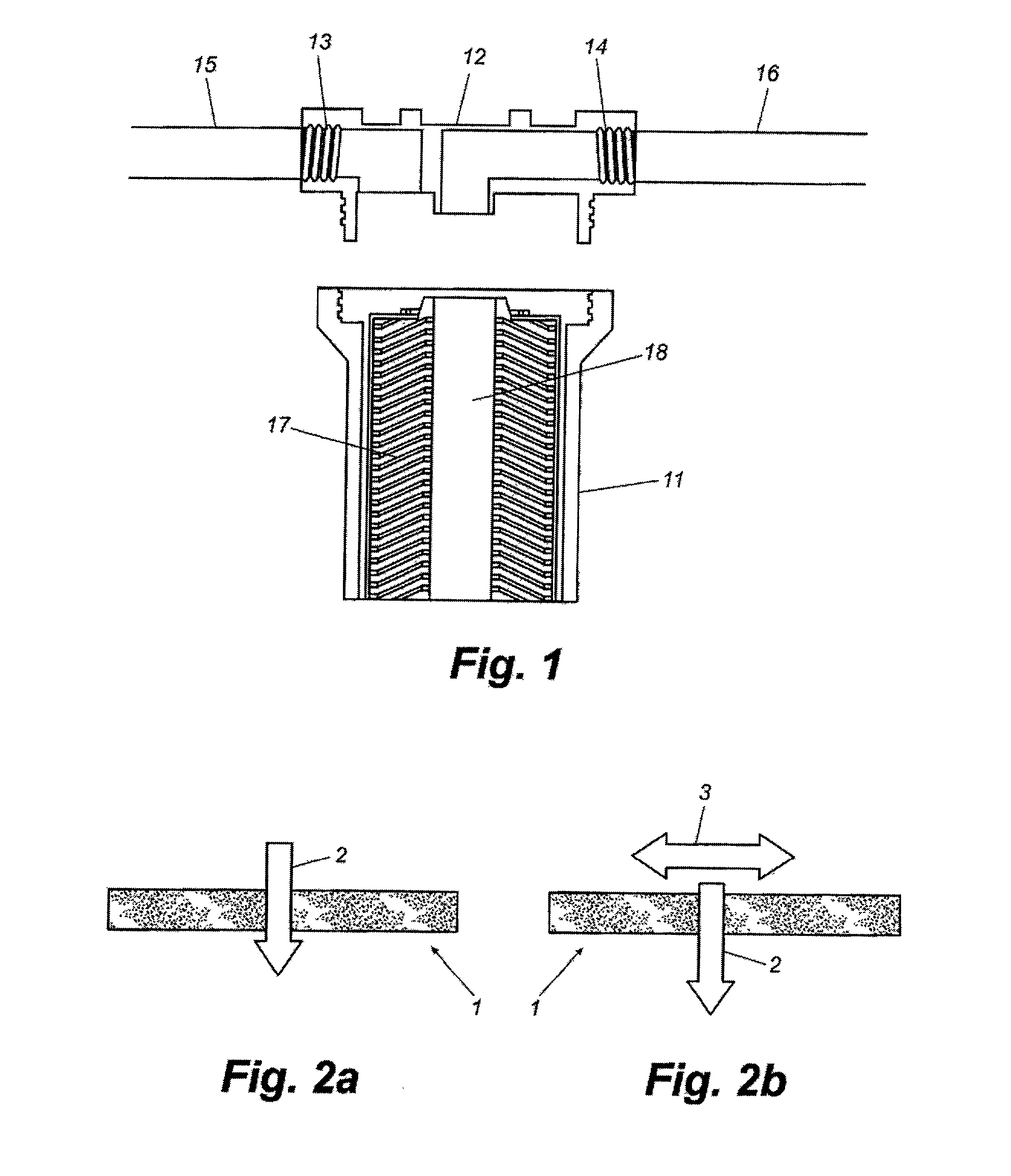

InactiveUS6861002B2Easy to disassembleImprove efficiencyPerfluorocarbons/hydrofluorocarbons captureLoose filtering material filtersCystFiltration

A method and device for the chemical conversion, filtration and / or purification of fluids water or other solutions containing microbiological and chemical contaminants, such as fluids containing arsenic, chlorine, bacteria, viruses, and cysts, where the fluid is passed through a purification material composed of fluid treatment carbon, metal phosphates, metal oxides, reduced metals, metal silicates, metal sulfates, metal carbonates, metal hydroxides, or combinations thereof. The material may be included in a fixed binder matrix.

Owner:WATERVISIONS INT

Reactive compositions for fluid treatment

InactiveUS20030196966A1Perfluorocarbons/hydrofluorocarbons captureLoose filtering material filtersFiltrationPhosphate

A method and device for the chemical conversion, filtration and / or purification of fluids water or other solutions containing microbiological and chemical contaminants, such as fluids containing arsenic, chlorine, bacteria, viruses, and cysts, where the fluid is passed through a purification material composed of fluid treatment carbon, metal phosphates, metal oxides, reduced metals, metal silicates, metal sulfates, metal carbonates, metal hydroxides, or combinations thereof. The material may be included in a fixed binder matrix.

Owner:WATERVISIONS INT

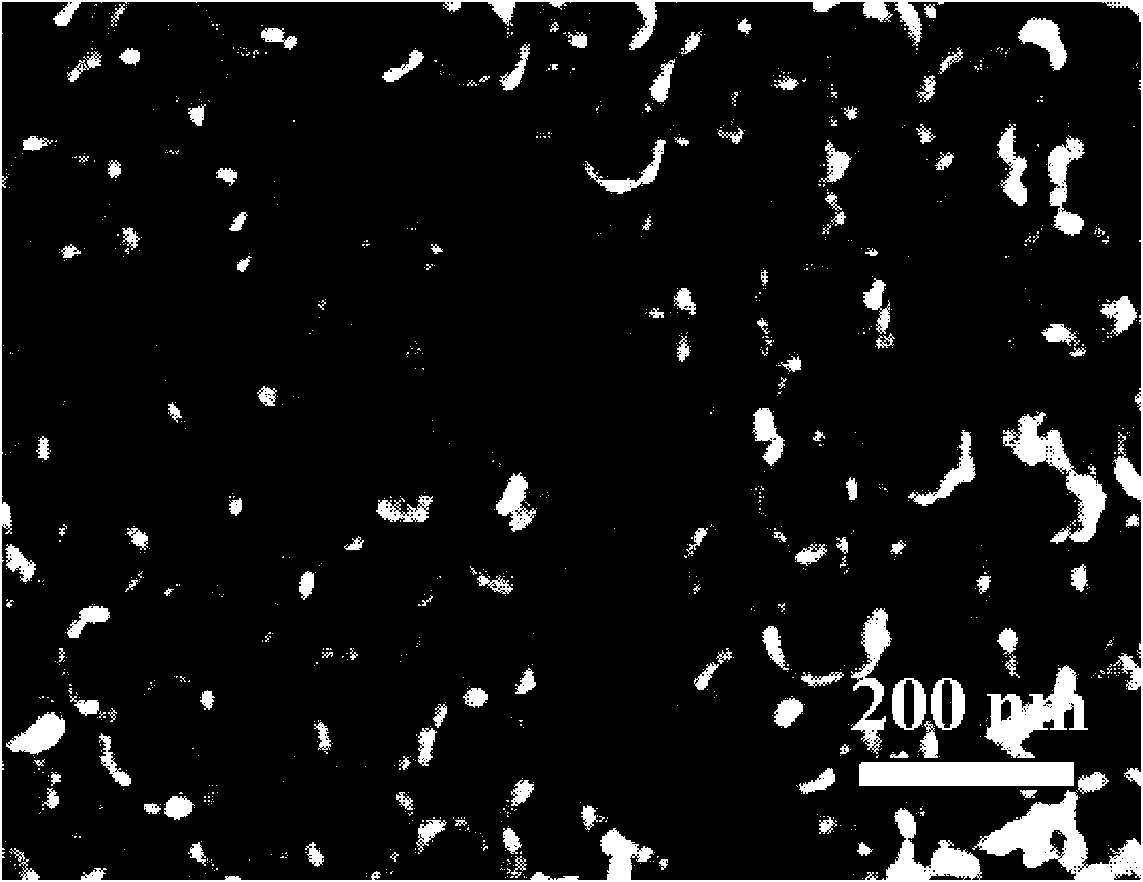

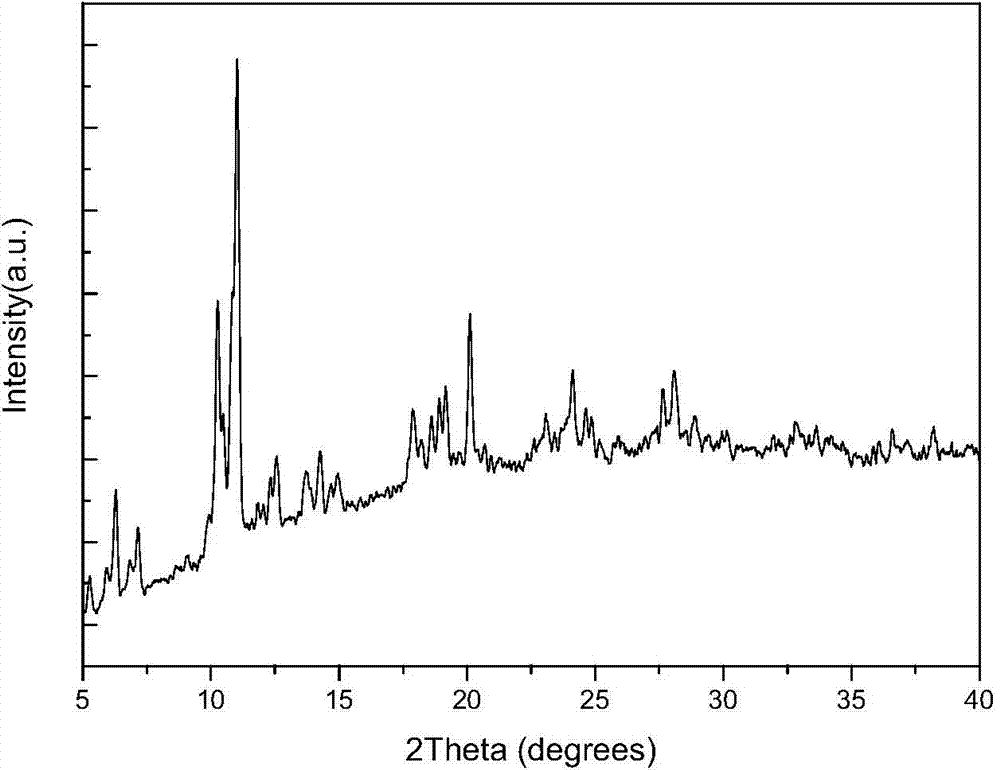

Manganese-based composite oxide catalyst for catalytically decomposing ozone, and preparation method of manganese-based composite oxide catalyst

ActiveCN102600861AAchieve decentralizationAchieve catalytic effectDispersed particle separationPerfluorocarbons/hydrofluorocarbons captureAir treatmentHydrothermal synthesis

The invention relates to a manganese-based composite oxide catalyst for catalytically decomposing ozone, and a preparation method of the catalyst. The catalyst comprises manganese oxide and at least one transition metal oxide. The preparation method is a homogeneous precipitation method or a hydrothermal synthesis method. The manganese-based composite oxide catalyst adopts innocuous and non-poisonous materials, prepares a manganese-based composite oxide catalyst with high catalytic activity, good wet resistance and high catalytic deposition content by the simple and easy method, so that the catalyst is suitable for catalytically decomposing ozone produced in water or air treatment and modern industry and home appliance.

Owner:上海棕晟企业管理合伙企业(有限合伙)

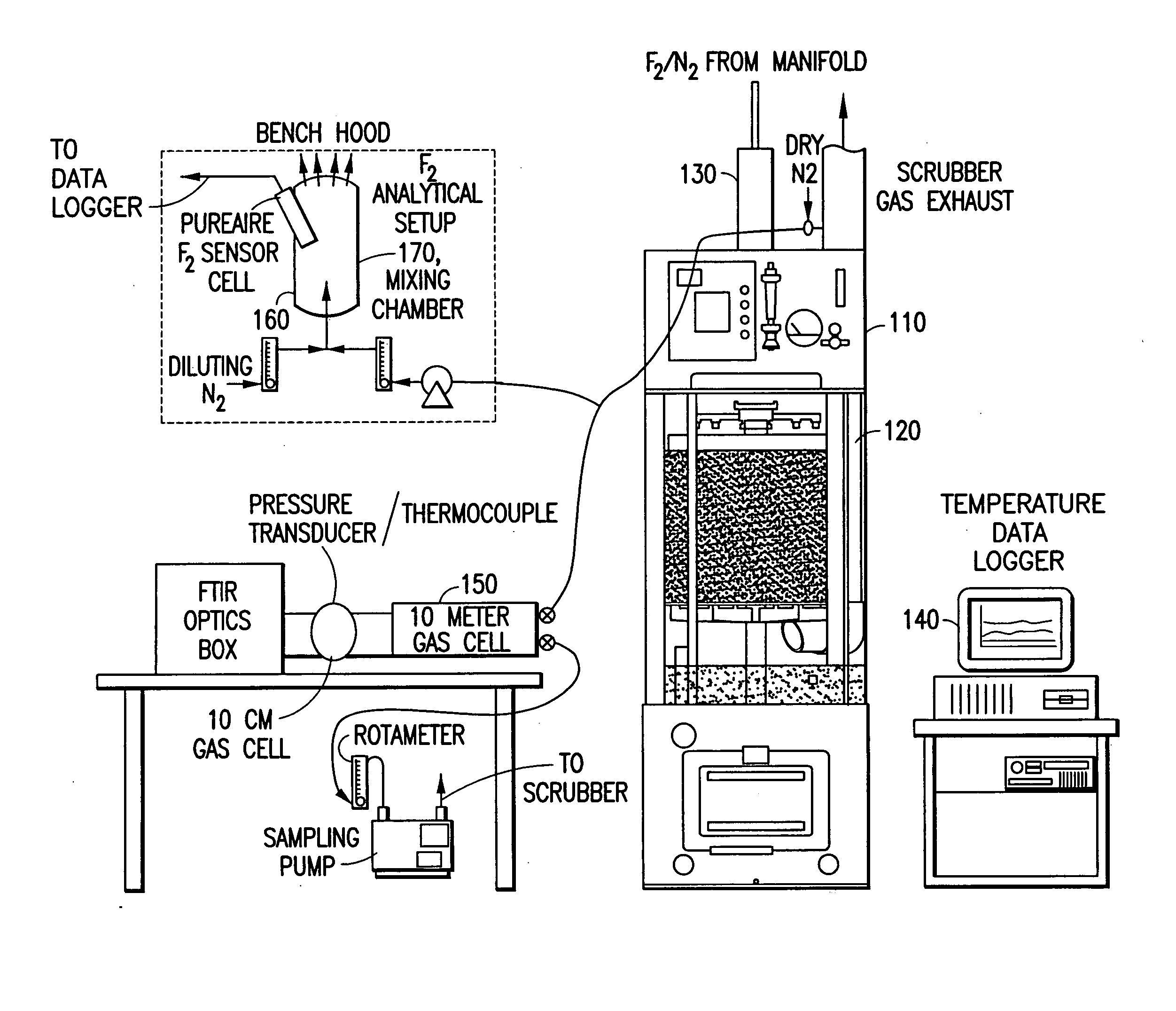

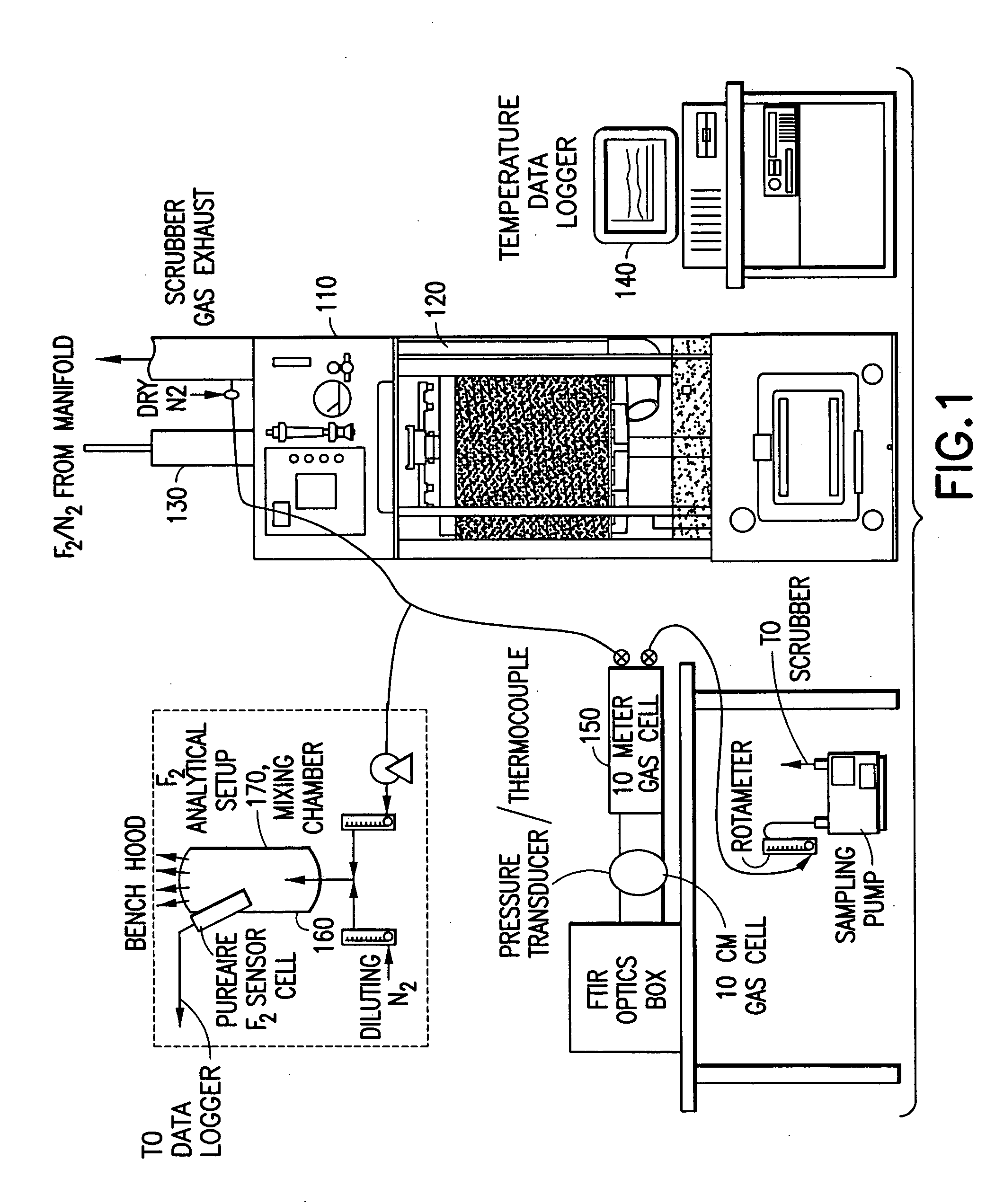

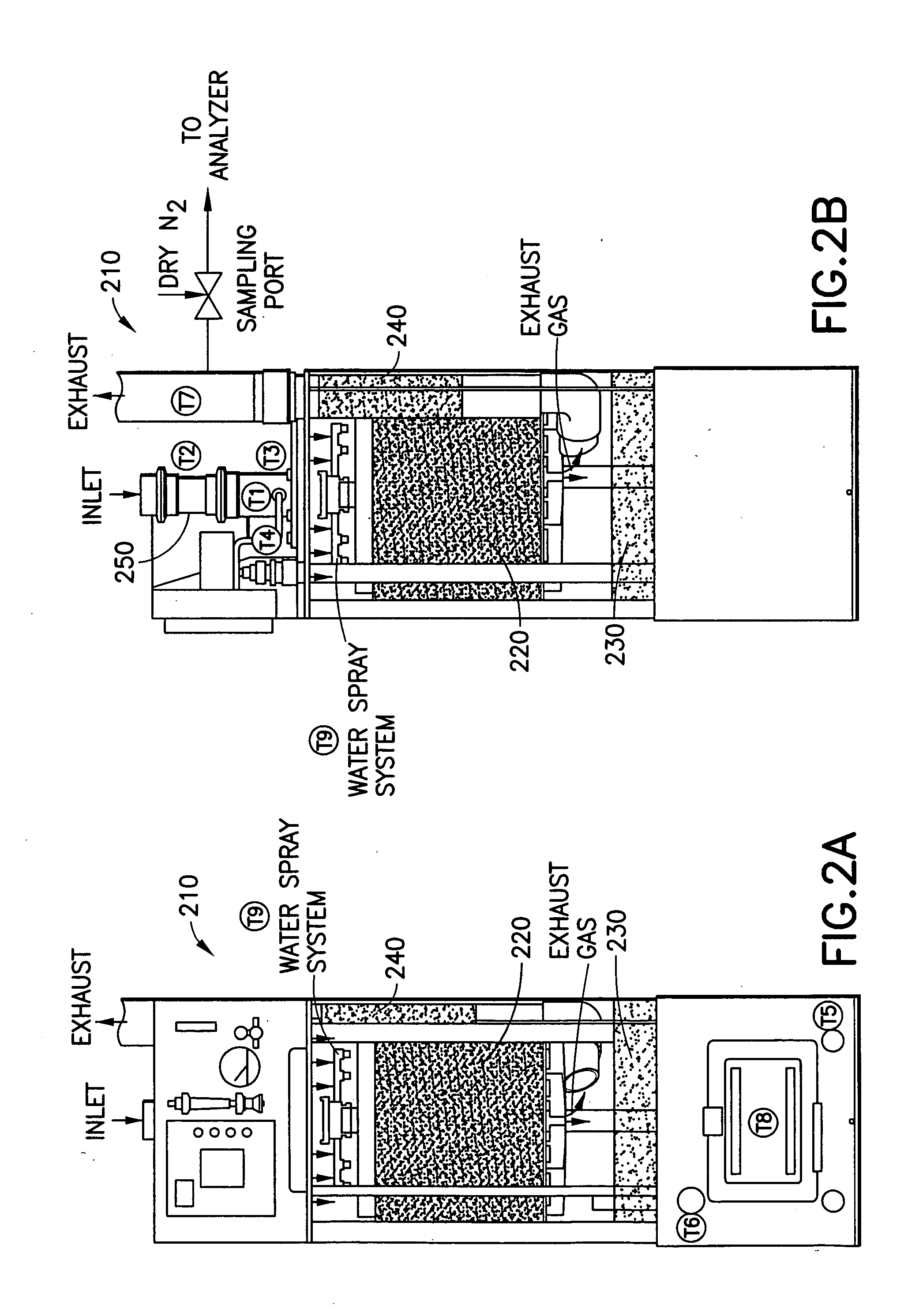

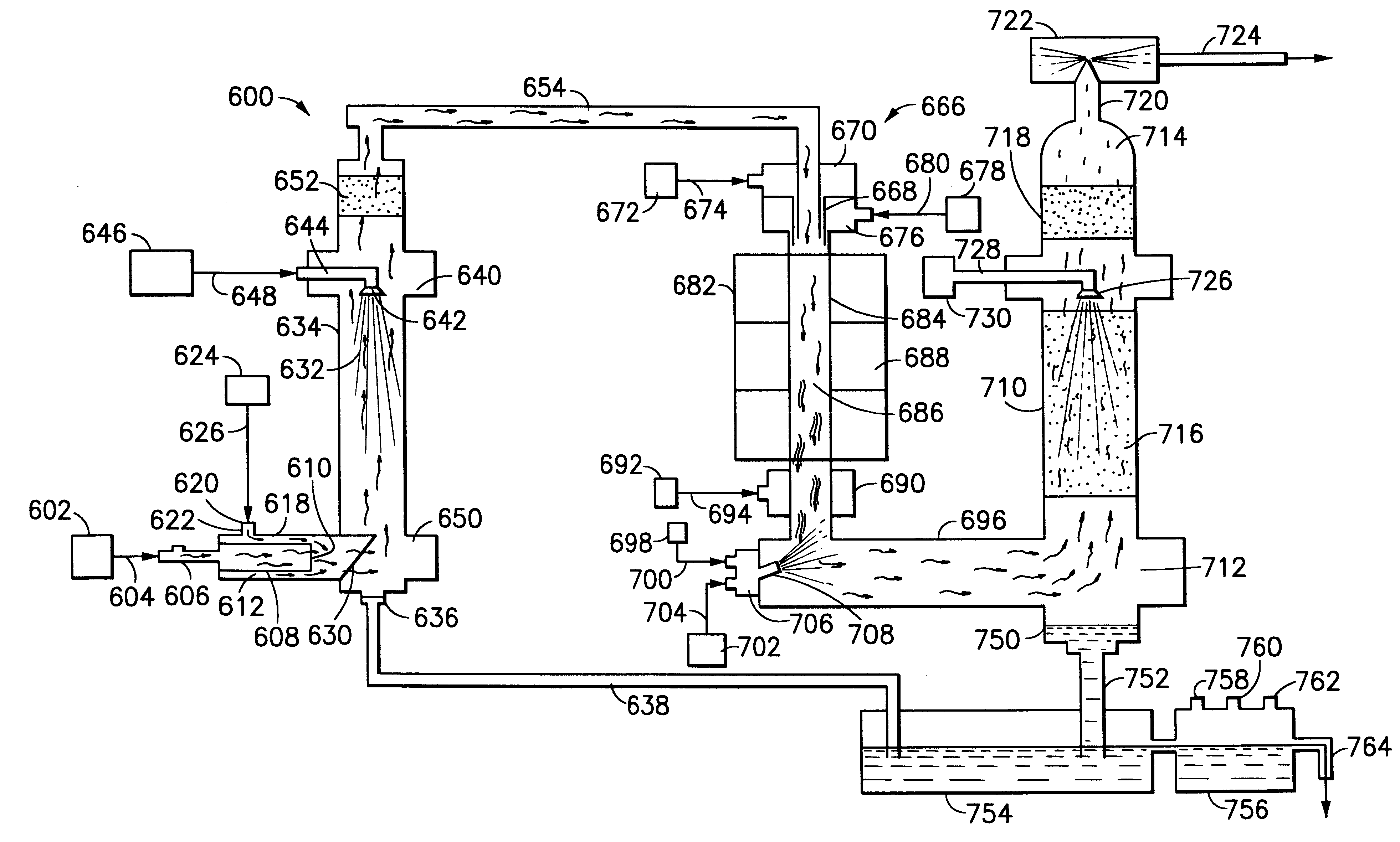

Apparatus and method for point-of-use treatment of effluent gas streams

InactiveUS20040213721A1Highly efficient mannerReduce foaming in the scrubbing systemProcess control/regulationHydrogenSilanesChlorofluorocarbon

A system for abating undesired component(s) from a gas stream containing same, such as halocompounds, acid gases, silanes, ammonia, etc., by scrubbing of the effluent gas stream with an aqueous scrubbing medium. Halocompounds, such as fluorine, fluorides, perfluorocarbons, and chlorofluorocarbons, may be scrubbed in the presence of a reducing agent, e.g., sodium thiosulfate, ammonium hydroxide, or potassium iodide. In one embodiment, the scrubbing system includes a first acid gas scrubbing unit operated in cocurrent gas / liquid flow, and a second "polishing" unit operated in countercurrent gas / liquid flow, to achieve high removal efficiency with low consumption of water. The scrubbing system may utilize removable insert beds of packing material, packaged in a foraminous containment structure. The abatement system of the invention has particular utility in the treatment of semiconductor manufacturing process effluents.

Owner:APPLIED MATERIALS INC

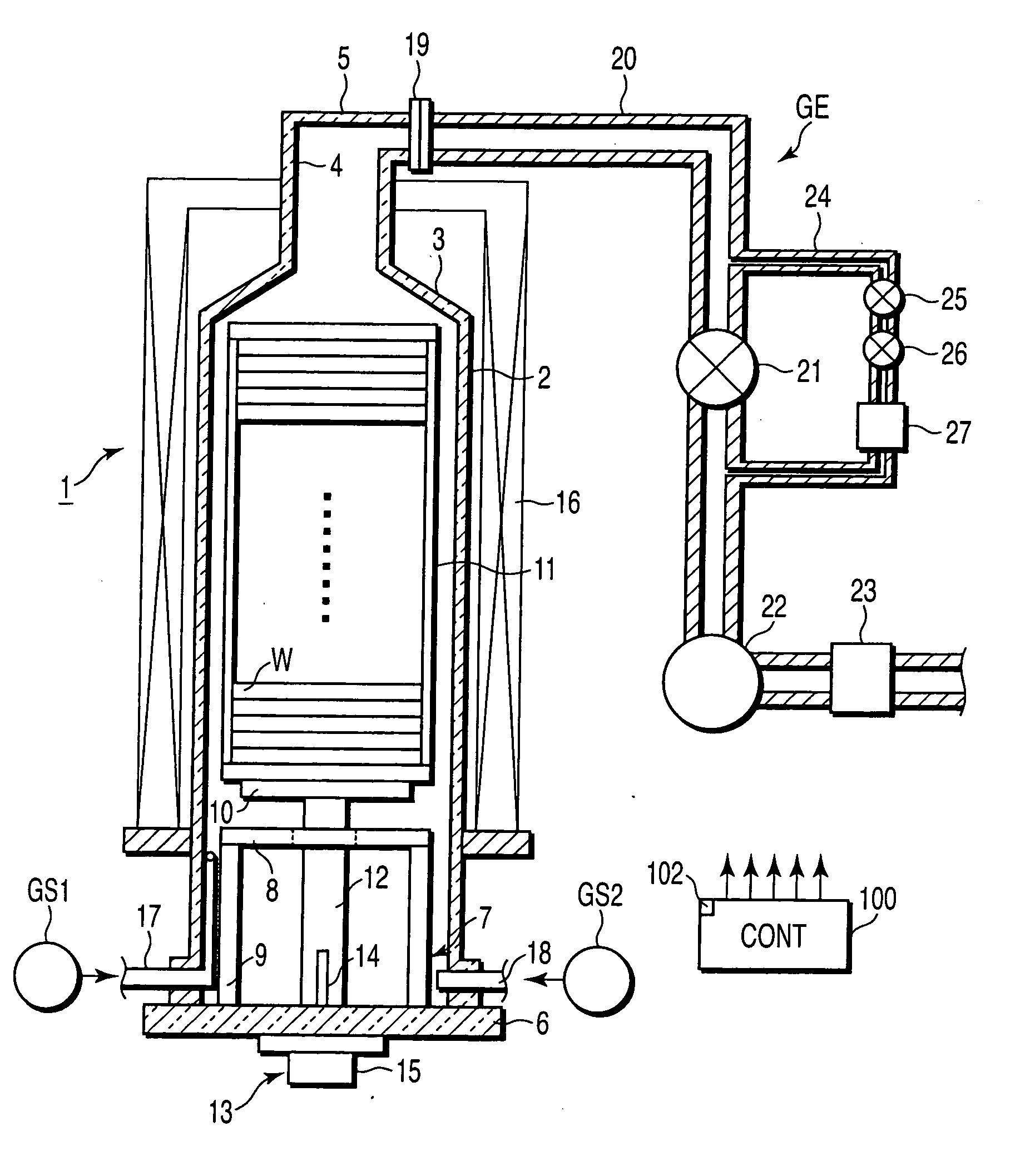

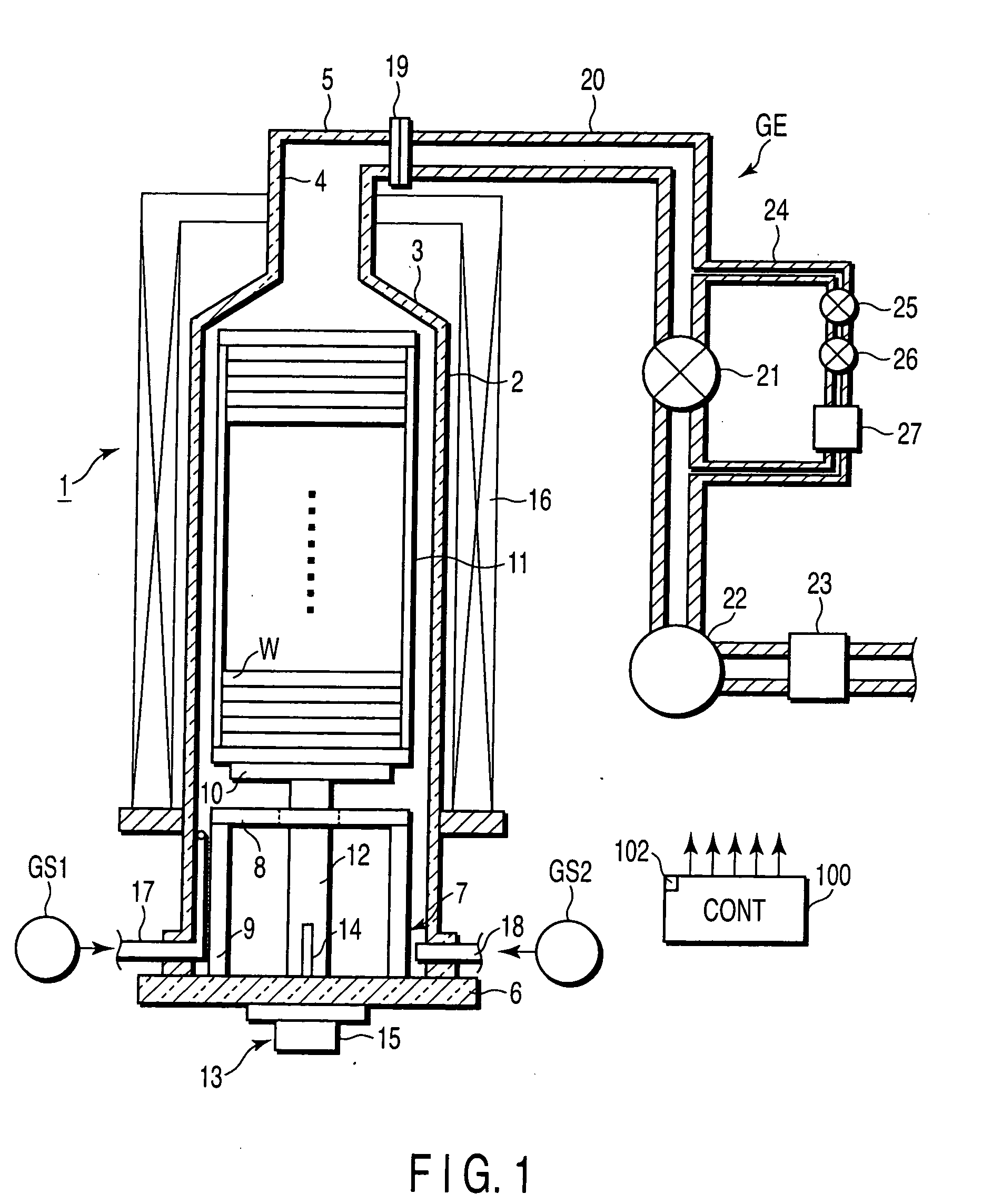

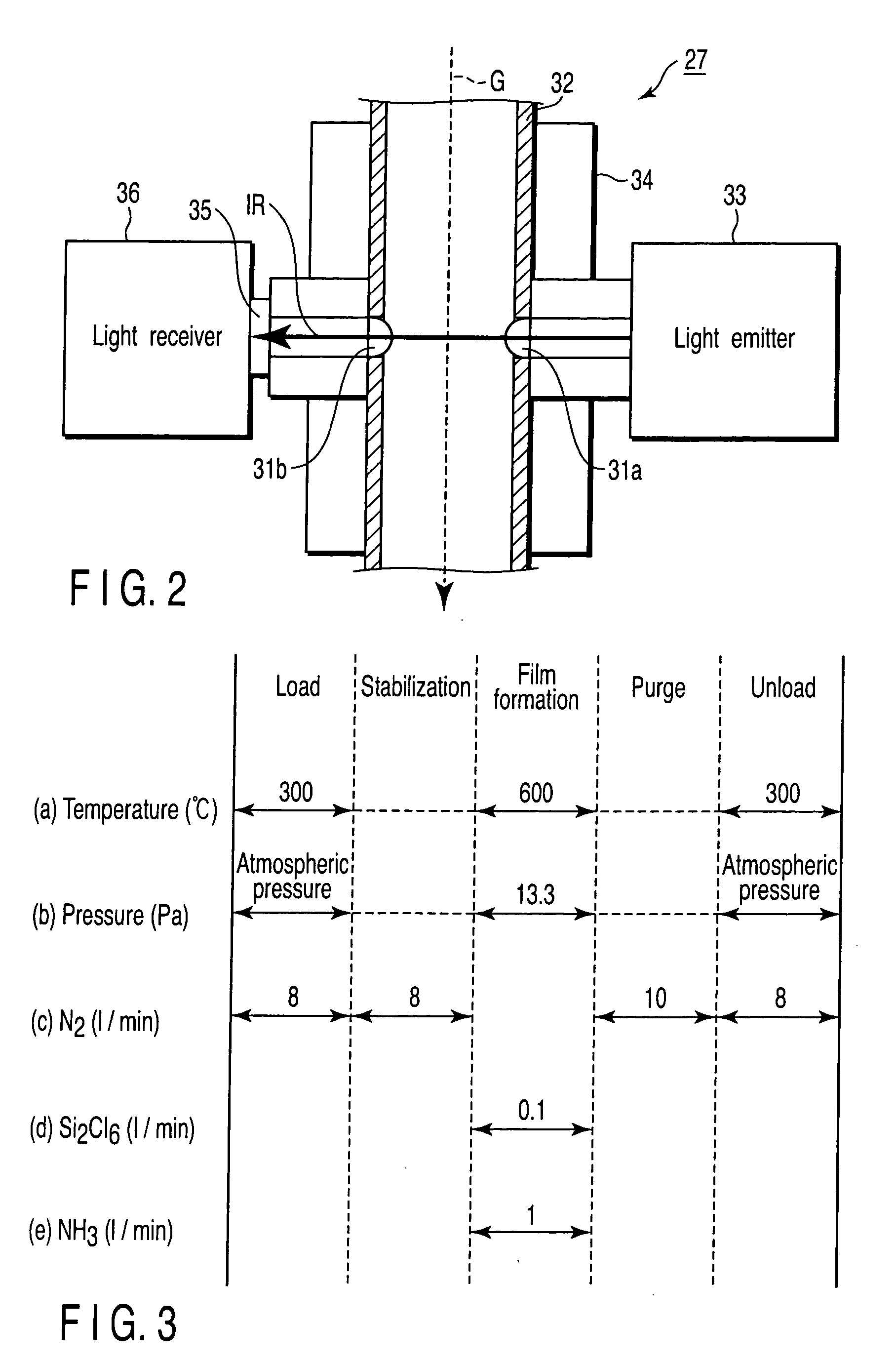

Film formation apparatus and method of using the same

InactiveUS20060042544A1Great period of timeFinal product manufactureElectrostatic cleaningEngineeringInformation processor

A film formation apparatus for a semiconductor process includes a cleaning gas supply circuit, a concentration measuring section, and an information processor. The cleaning gas supply circuit is configured to supply a cleaning gas into a reaction chamber to perform cleaning of removing from an inner surface of the reaction chamber a by-product film derived from a film formation gas. The concentration measuring section is disposed in an exhaust system to monitor concentration of a predetermined component contained in exhaust gas from the reaction chamber. The information processor is configured to compare a measurement value obtained by the concentration measuring section with a preset value and to thereby determine an end point of the cleaning.

Owner:TOKYO ELECTRON LTD +1

Treatment of effluent gases

A method is described for recovering a noble gas, such as xenon or krypton, from a first gas mixture comprising a plurality of components, one of which is the noble gas and the others are typically helium and / or nitrogen, argon, and relatively light fluorocarbons. The gas mixture is first conveyed to a gas chromatography column for separating the noble gas from the other components of the gas mixture. As the noble gas travels relatively slowly through the column, the other components are exhaust from the column before the relatively slow noble gas. Following the exhaust of these other components, a purge gas is supplied to the column to flush the noble gas therefrom. A second gas mixture comprising the noble gas and the purge gas is conveyed from the column to a membrane separator to separate the second gas mixture into a noble gas-rich gas stream and a purge gas-rich gas stream, which may be recirculated back to the column for re-use.

Owner:THE BOC GRP PLC

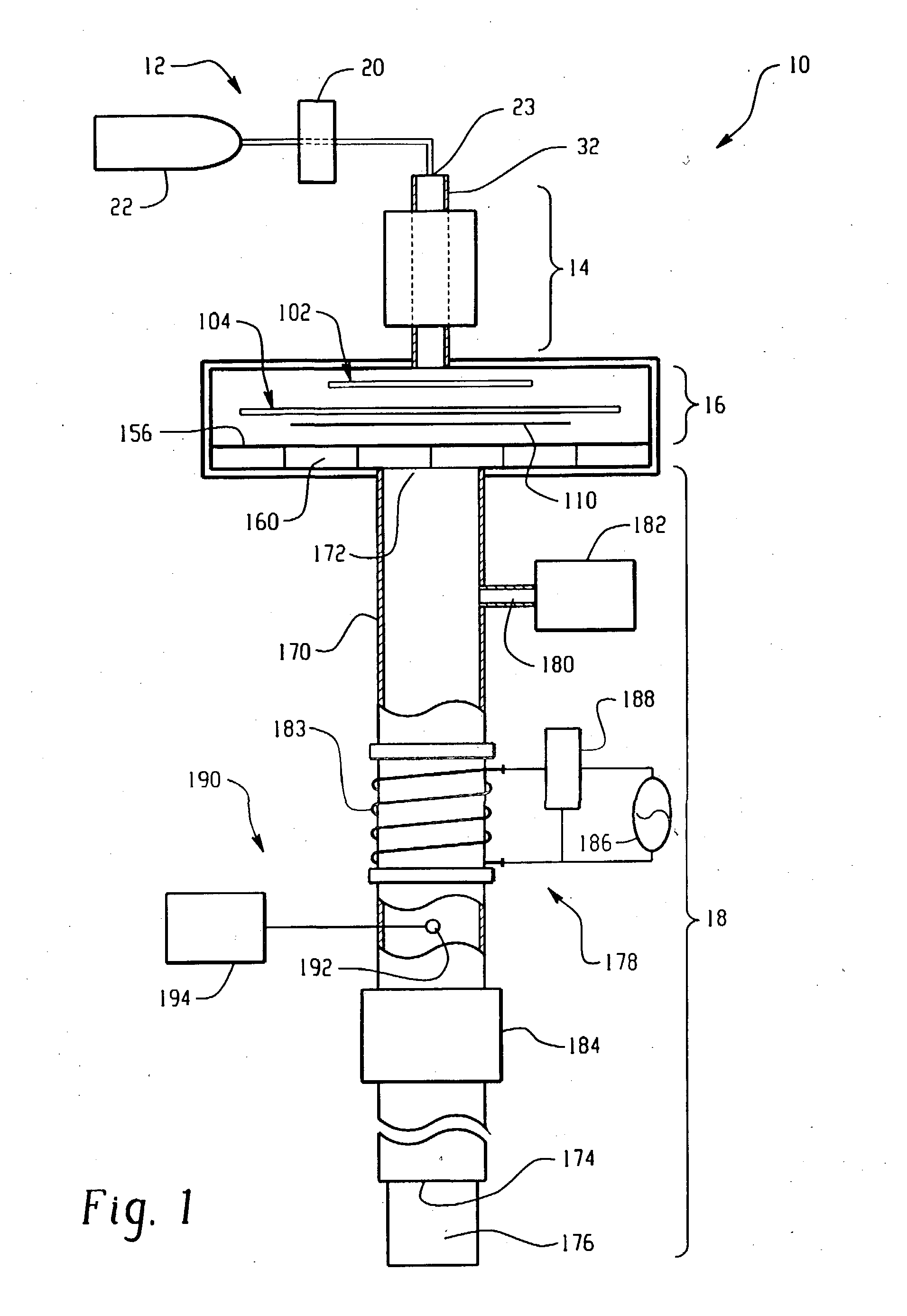

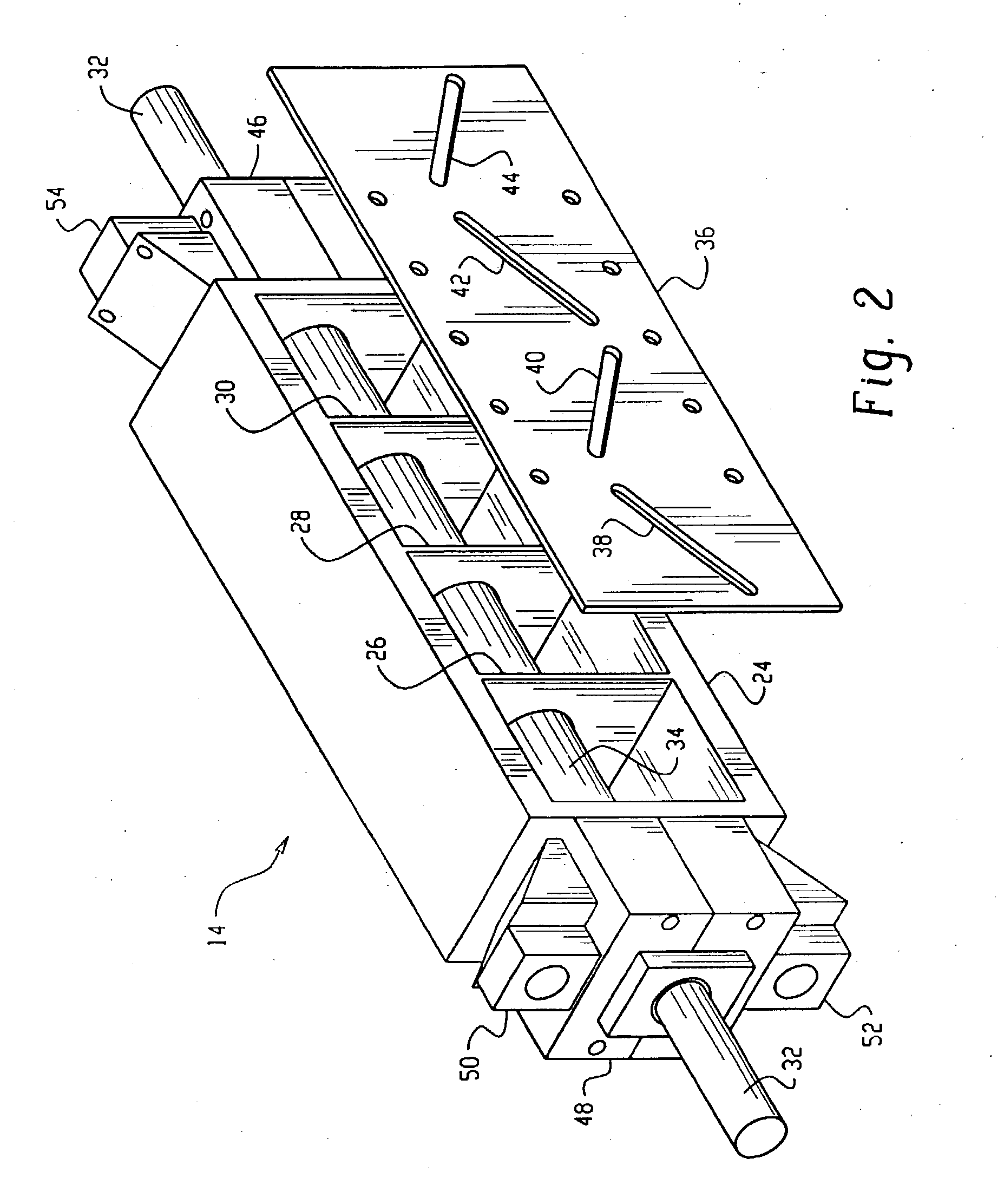

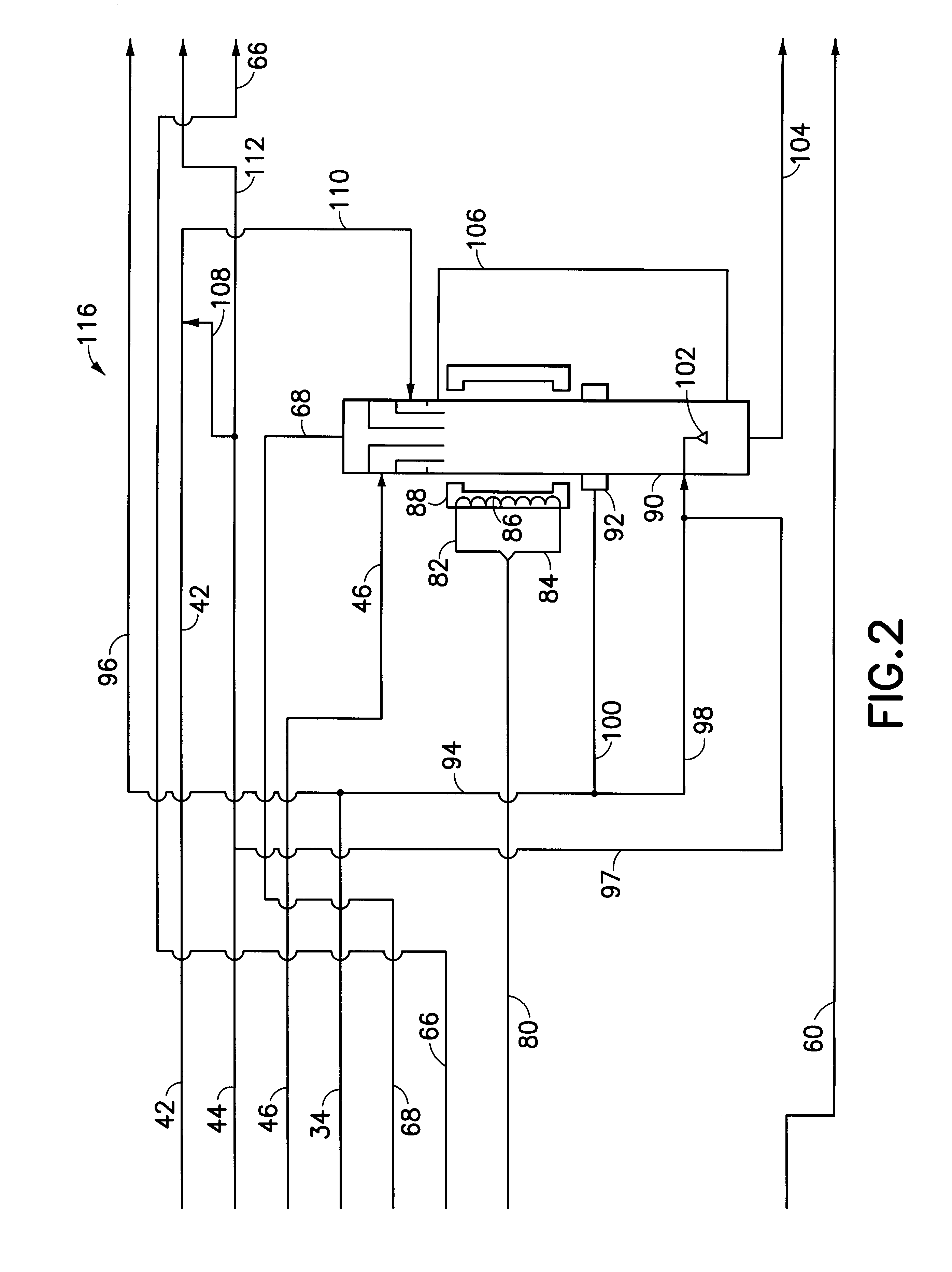

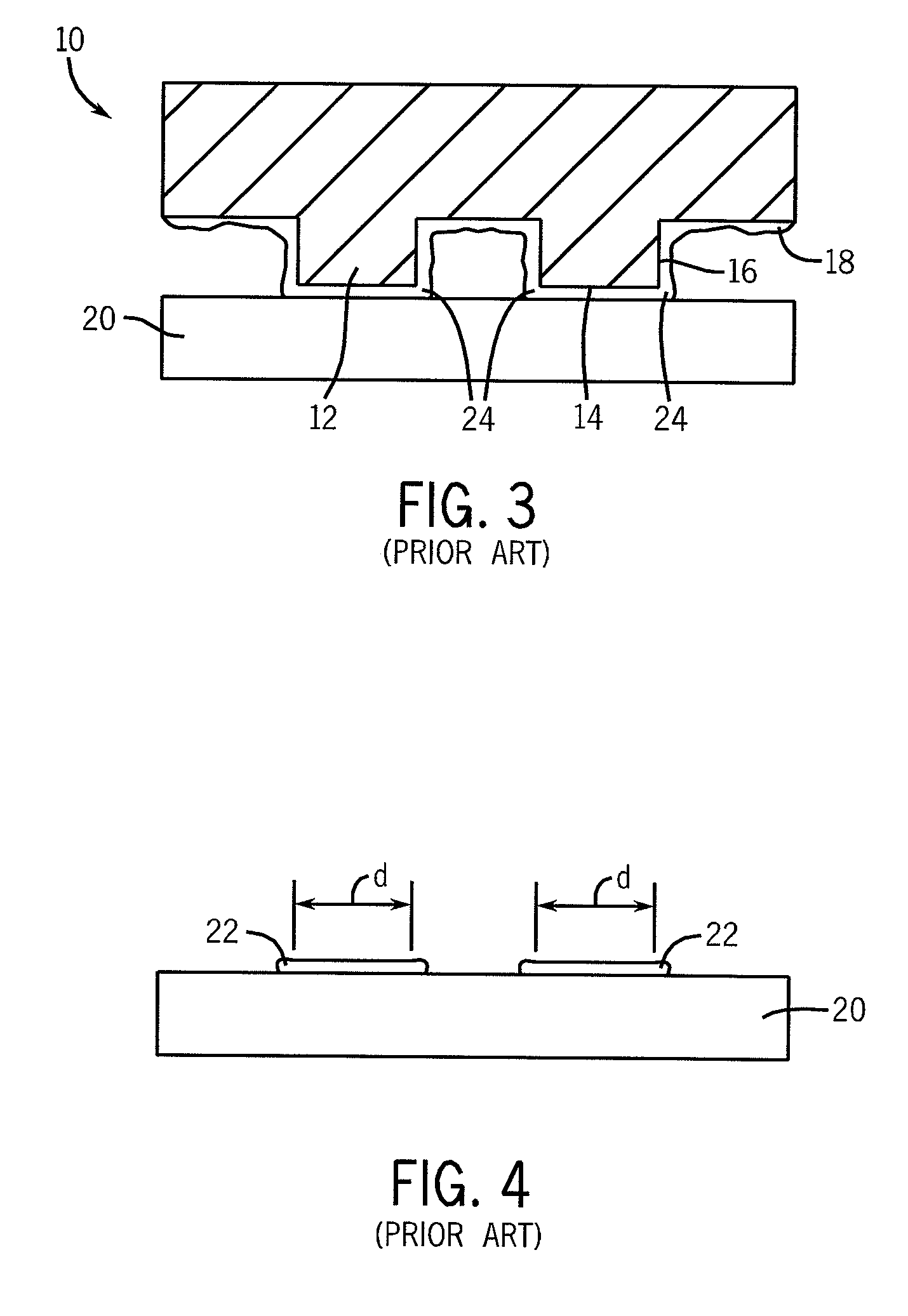

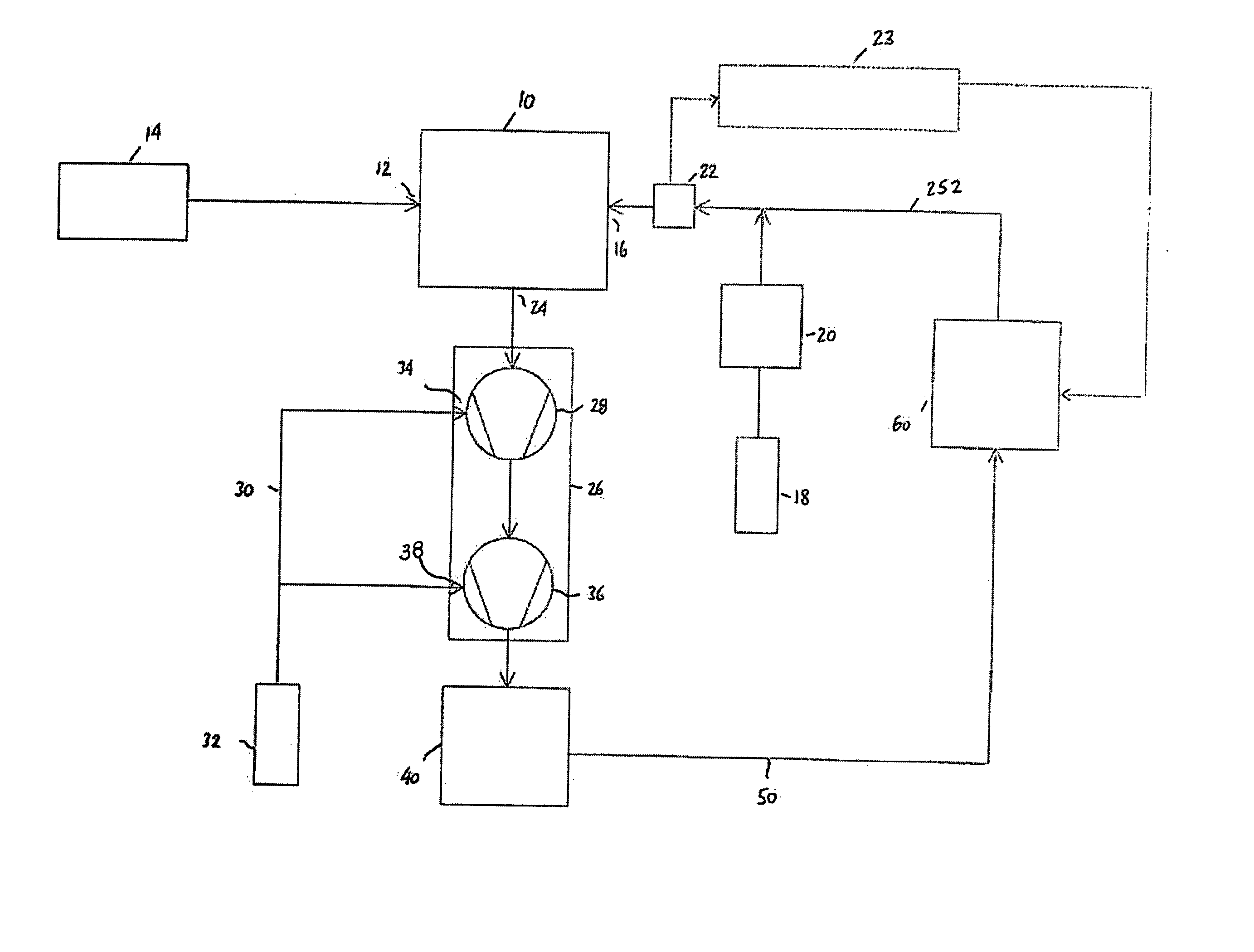

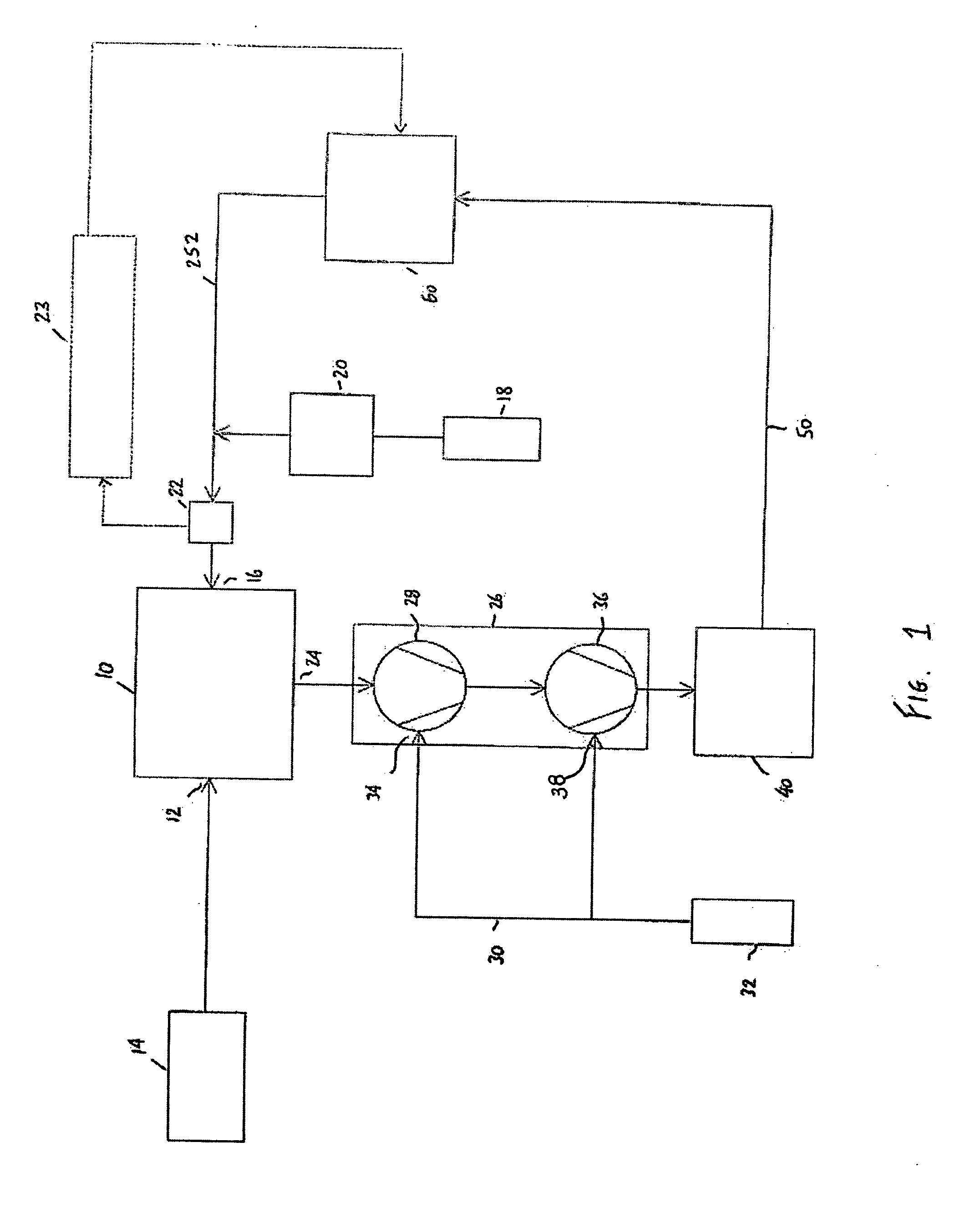

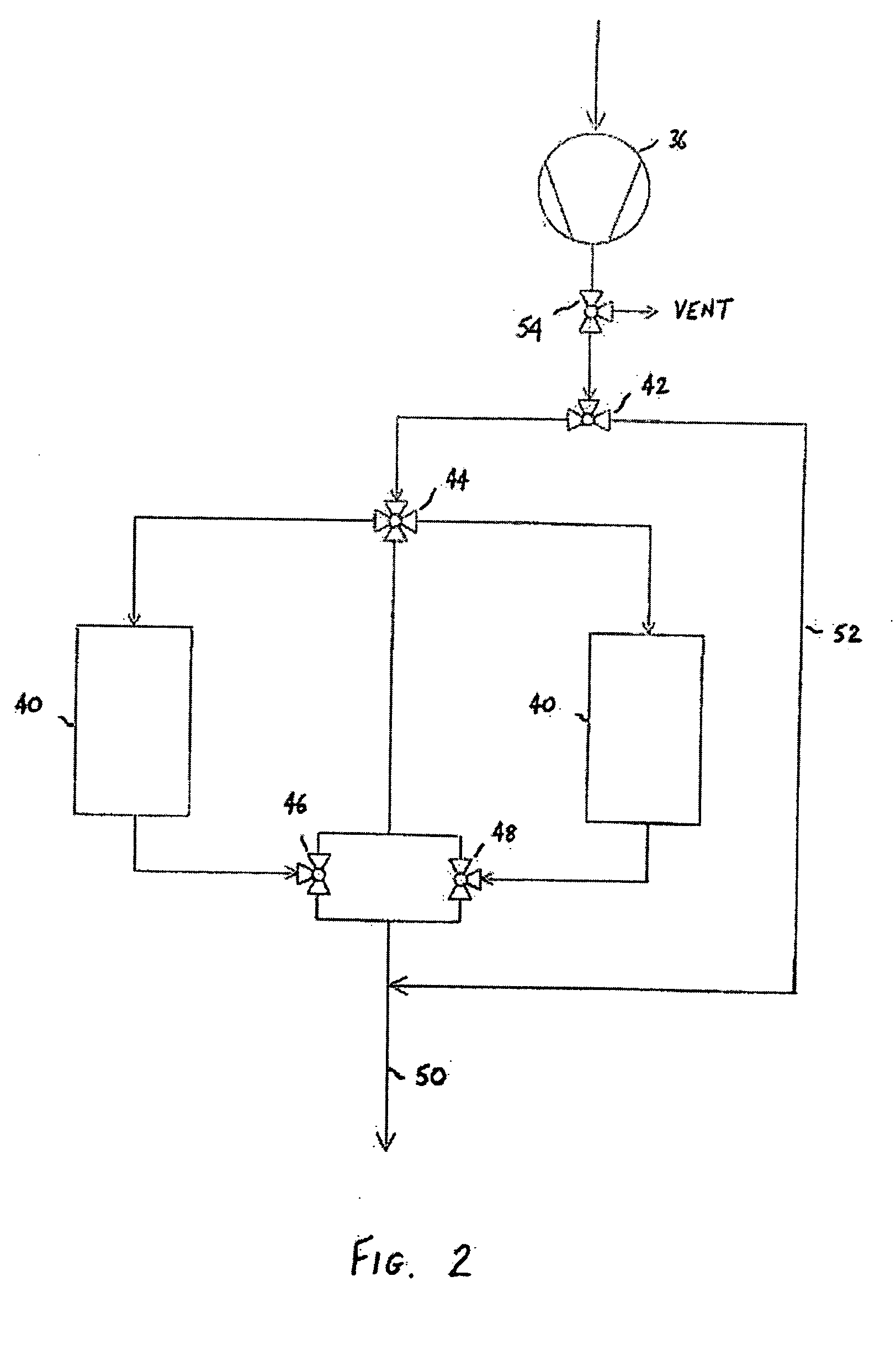

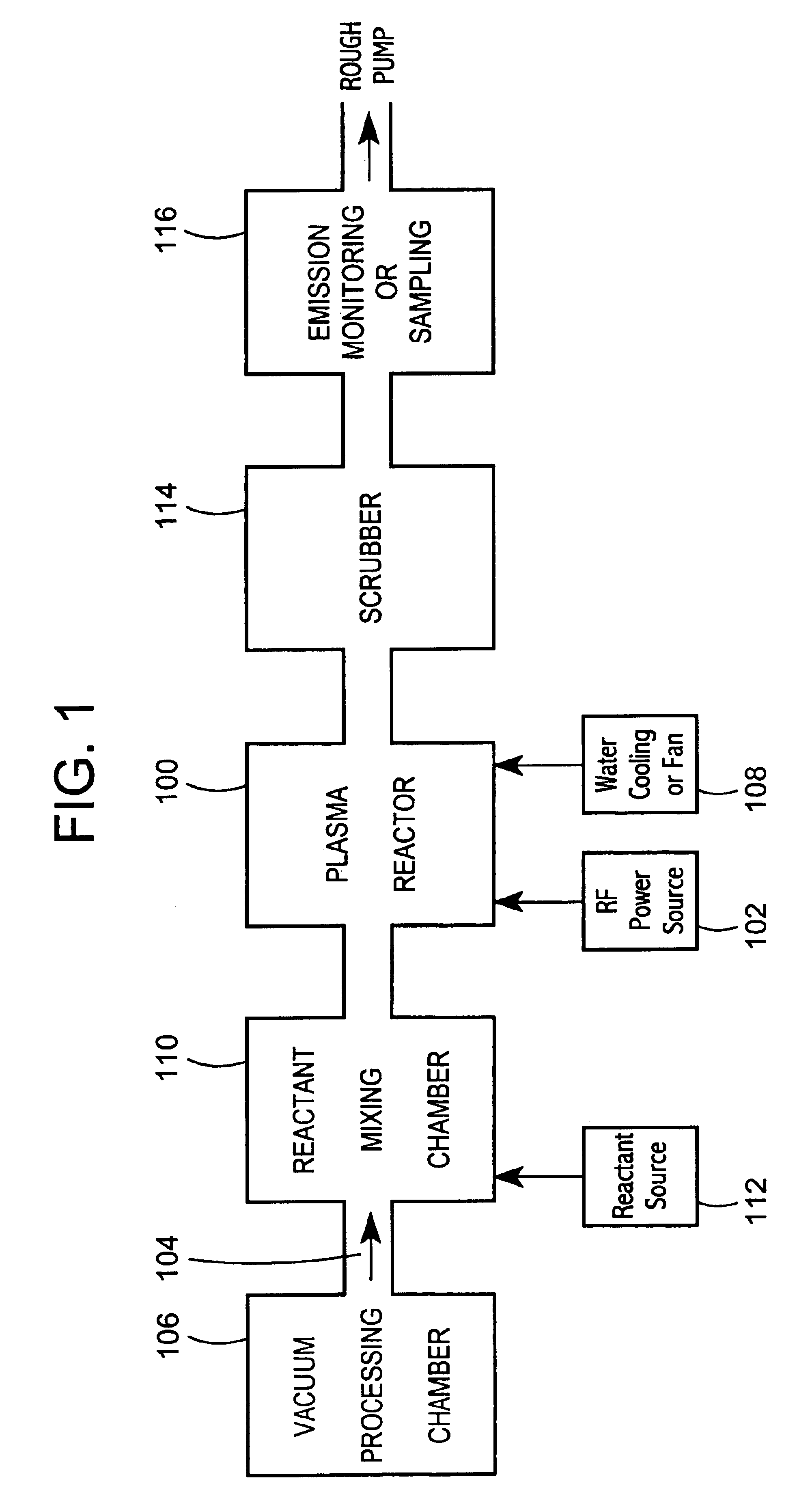

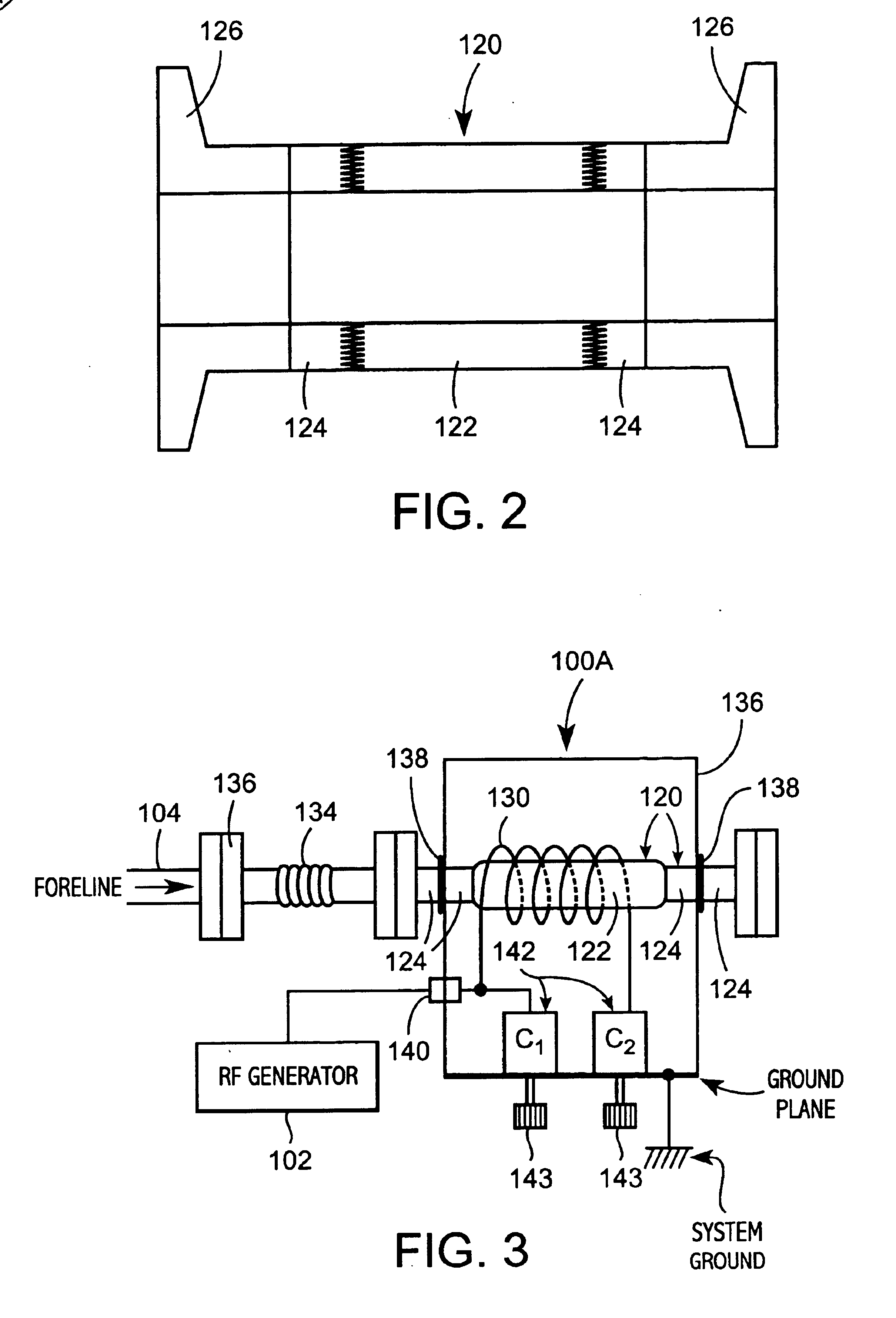

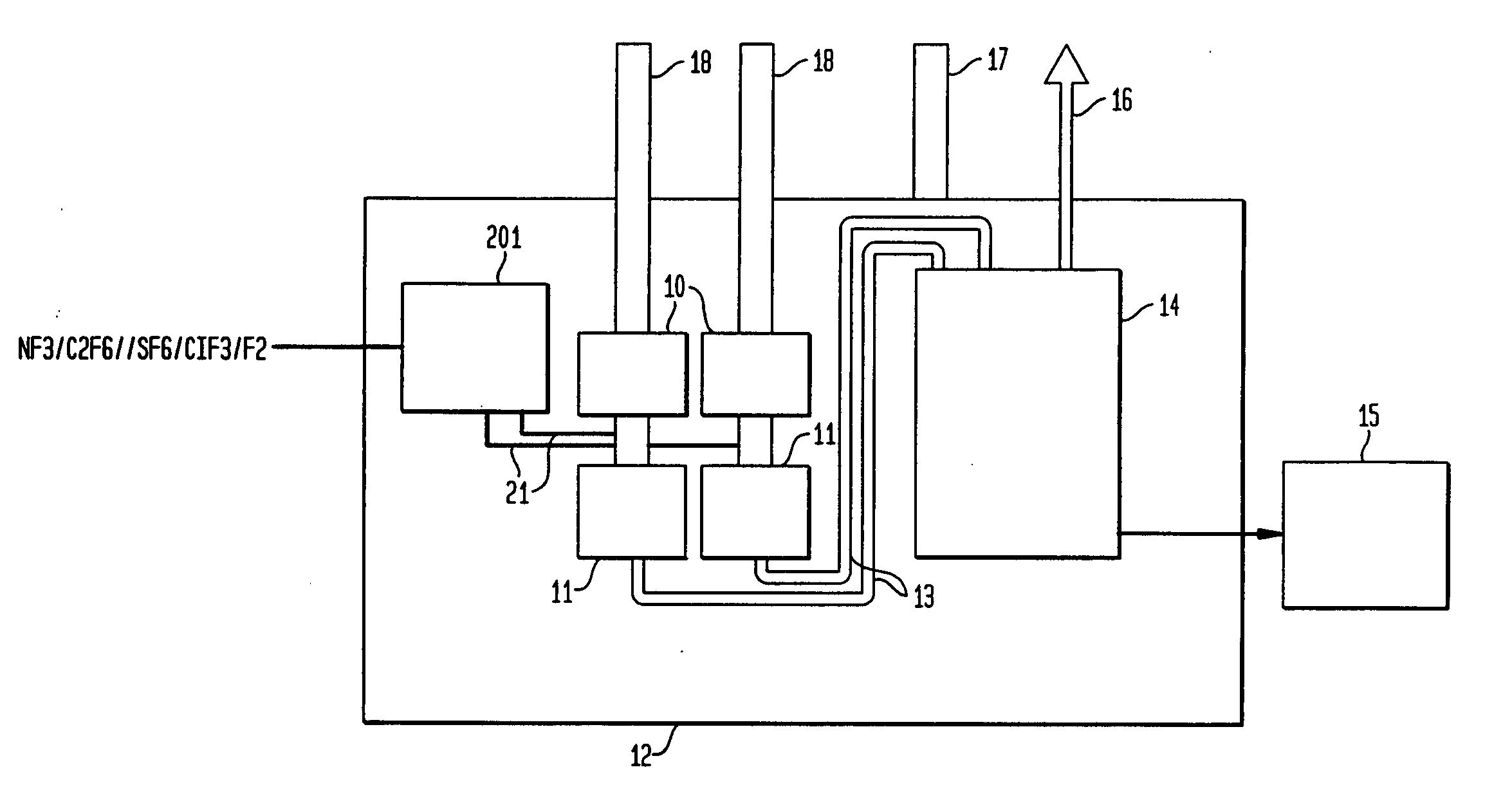

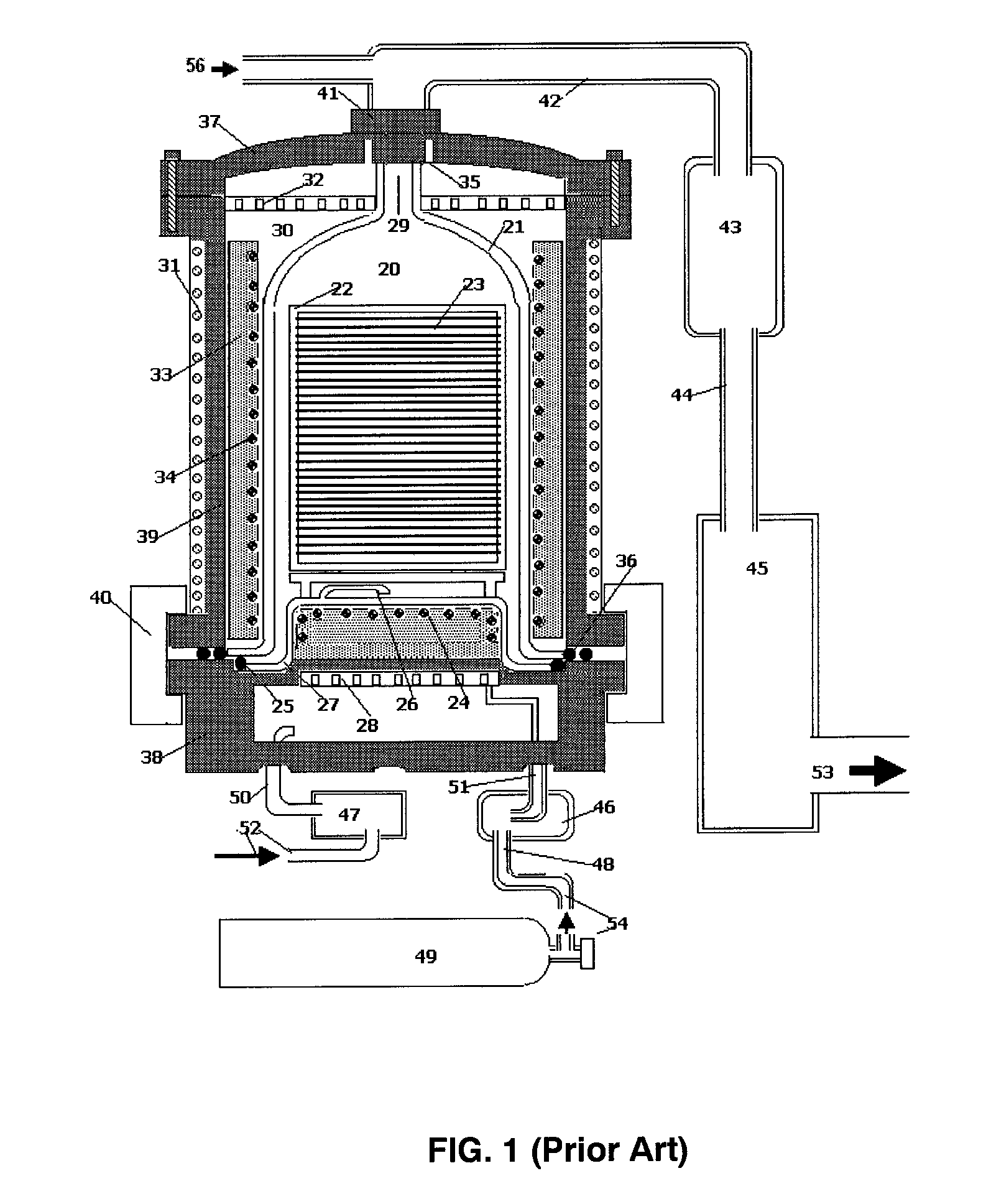

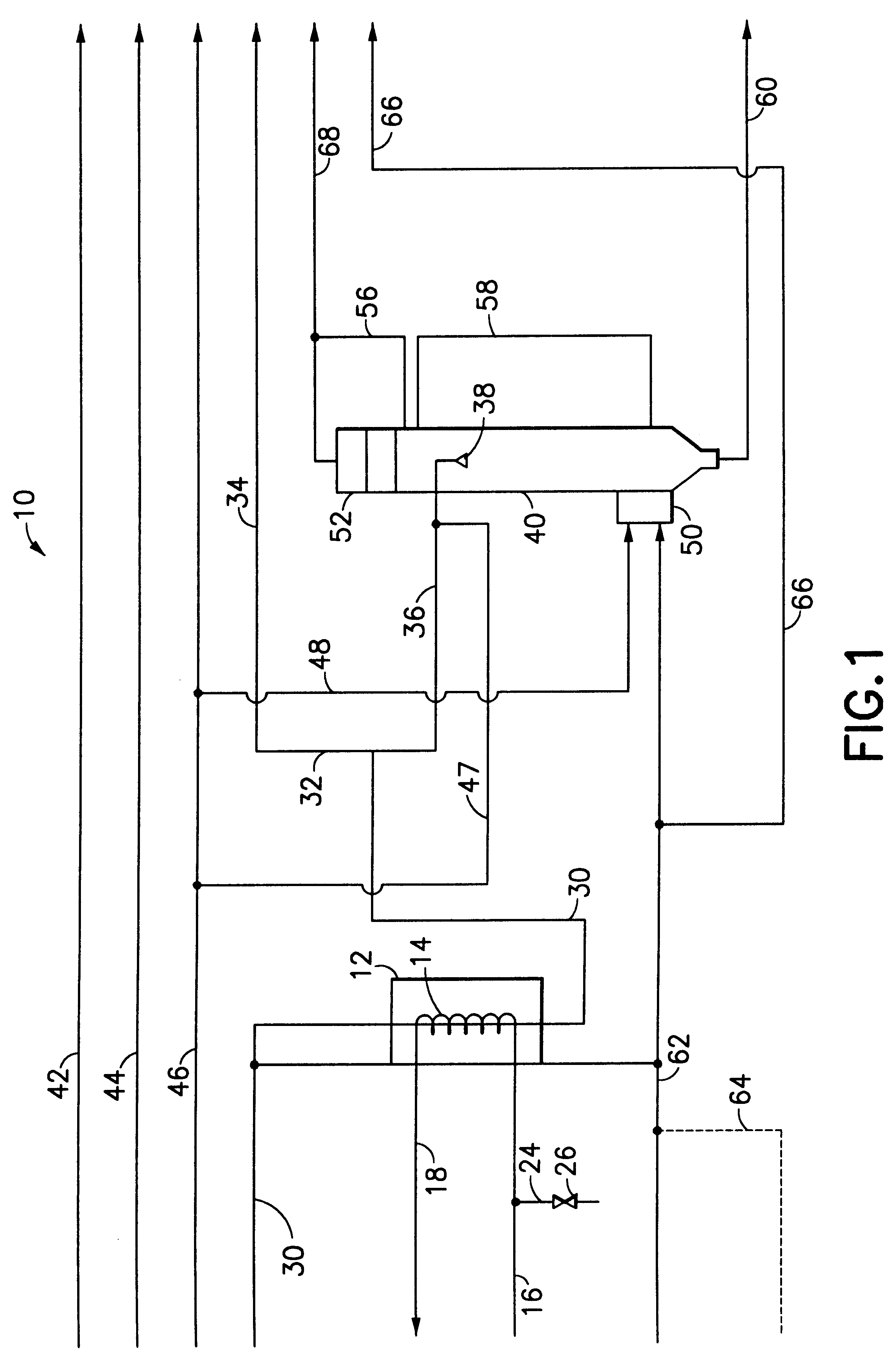

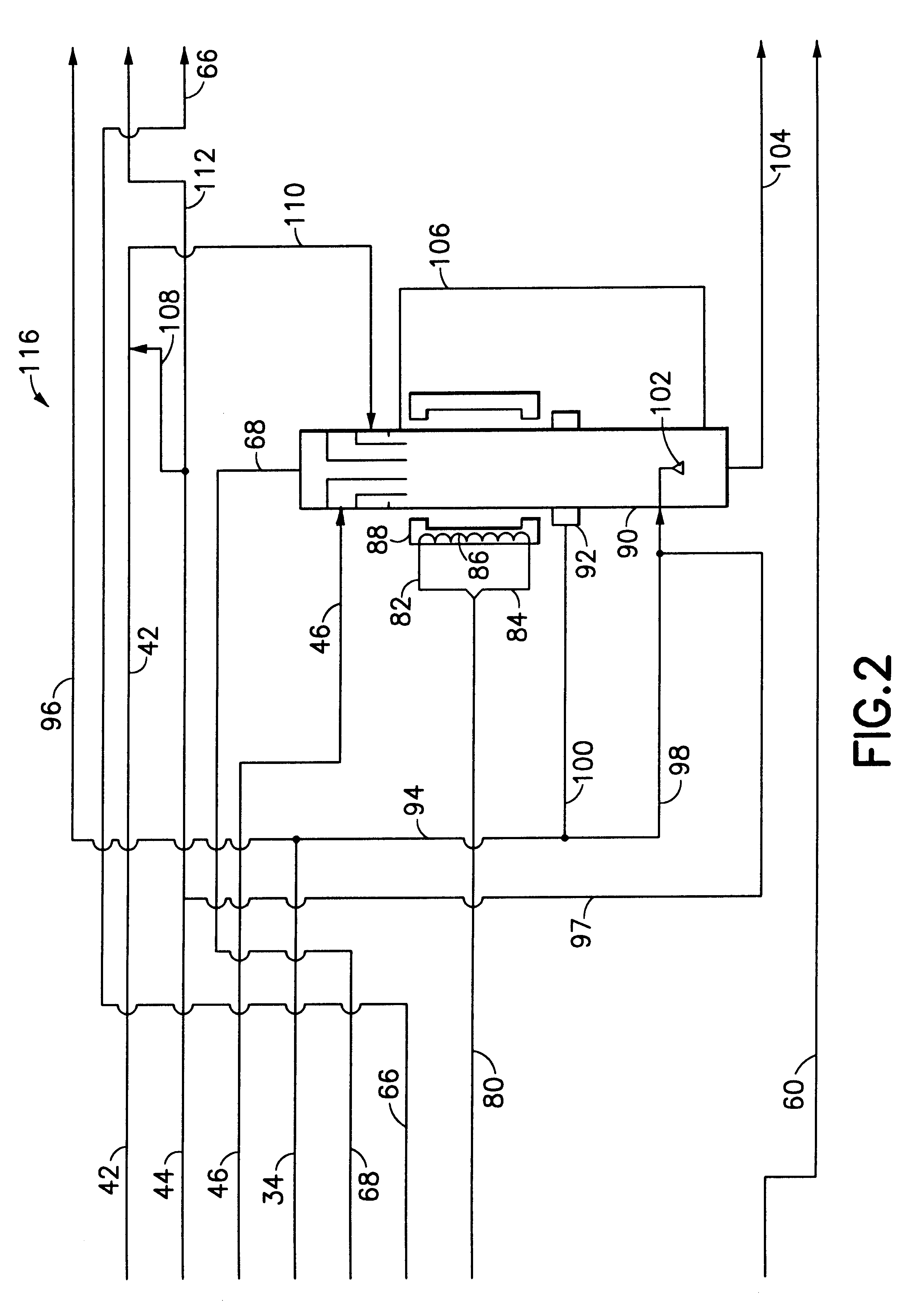

Method and apparatus for abatement of reaction products from a vacuum processing chamber

InactiveUS6888040B1Increase plasma densityHigh operating requirementsGas treatmentUsing liquid separation agentHydrofluorocarbonReaction chamber

An exemplary method and apparatus for abating reaction products from a vacuum processing chamber includes a reaction chamber in fluid communication with the vacuum processing chamber, a coil disposed about the reaction chamber, and a power source for supplying RF energy to the coil. The coil creates a plasma in the reaction chamber which effectively breaks down stable reaction products from the vacuum processing chamber such as perfluorocarbons (PFCs) and hydrofluorocarbons (HFCs) which significantly contribute to global warming. According to alternative embodiments, the plasma may be generated with grids or coils disposed in the reaction chamber perpendicular to the flow of reaction products from the vacuum processing chamber.

Owner:LAM RES CORP

Method and apparatus for maintaining by-product volatility in deposition process

InactiveUS20050250347A1Improve deposition efficiencyReduce the amount requiredElectric discharge tubesFinal product manufactureDeposition processFluorine containing

A method and apparatus for introducing a fluorine-containing flow stream to a deposition process to maintain process by-product volatility and reduce or eliminate by-product formation and / or interference.

Owner:EDWARDS VACUUM INC

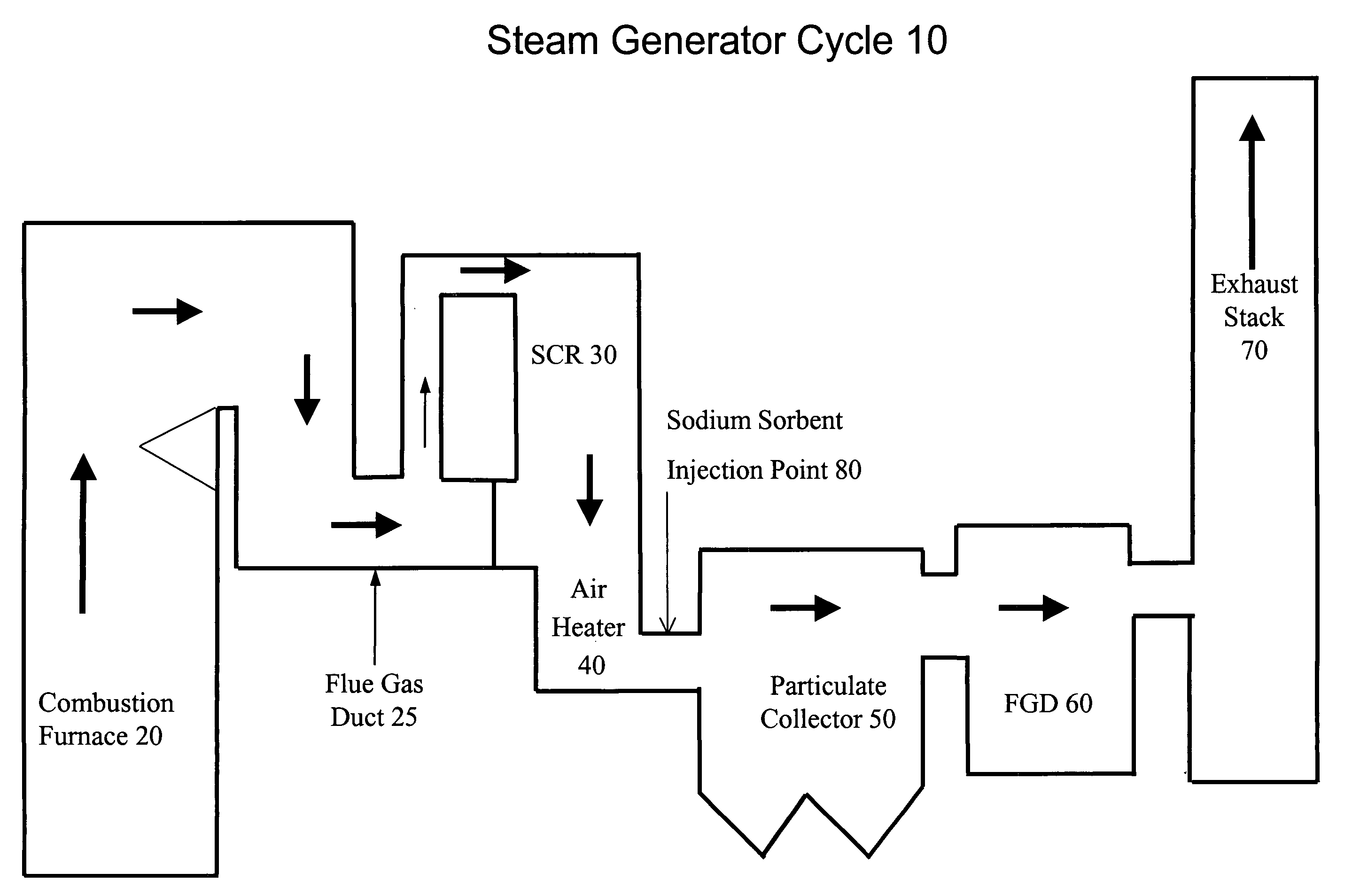

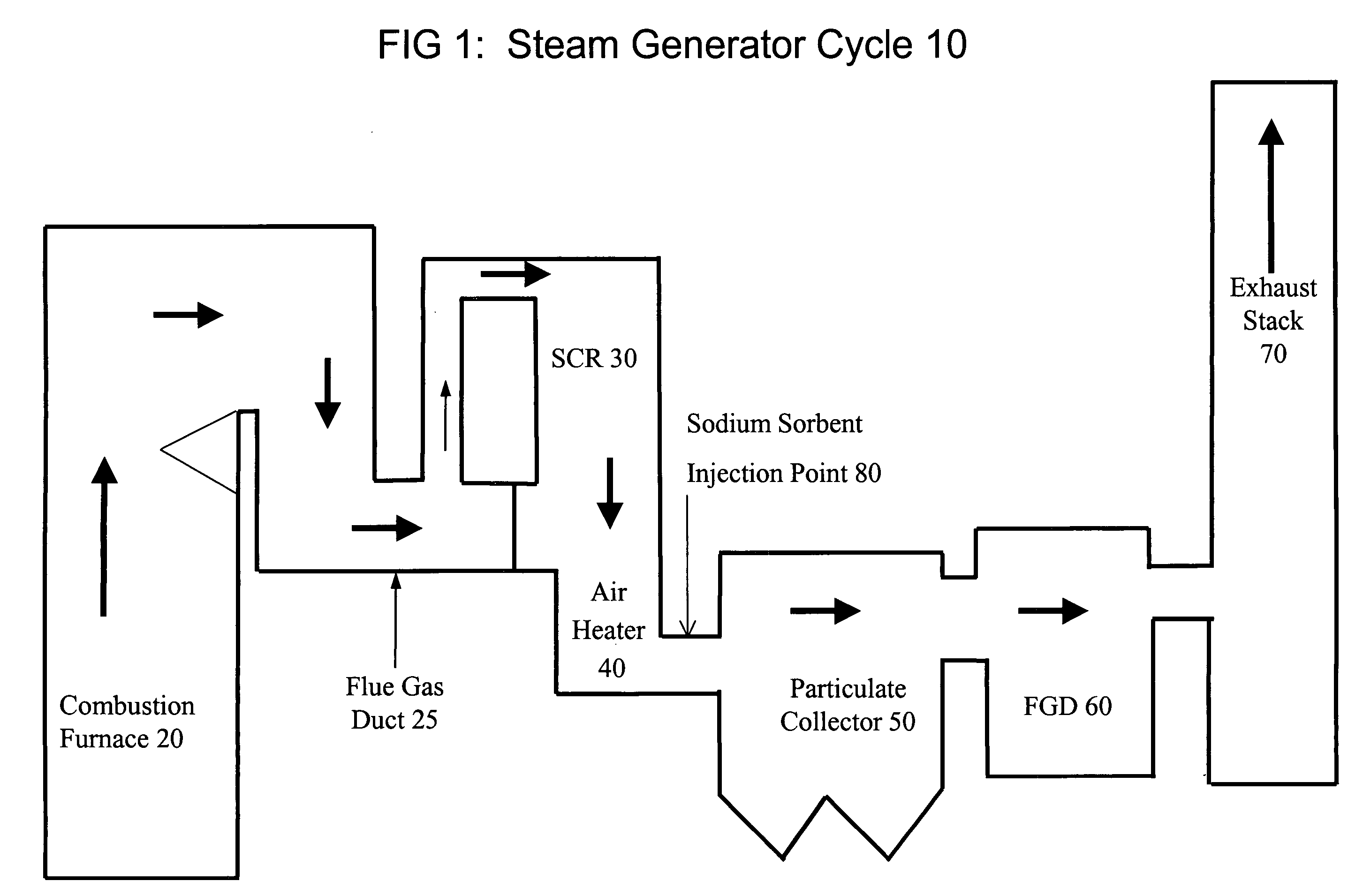

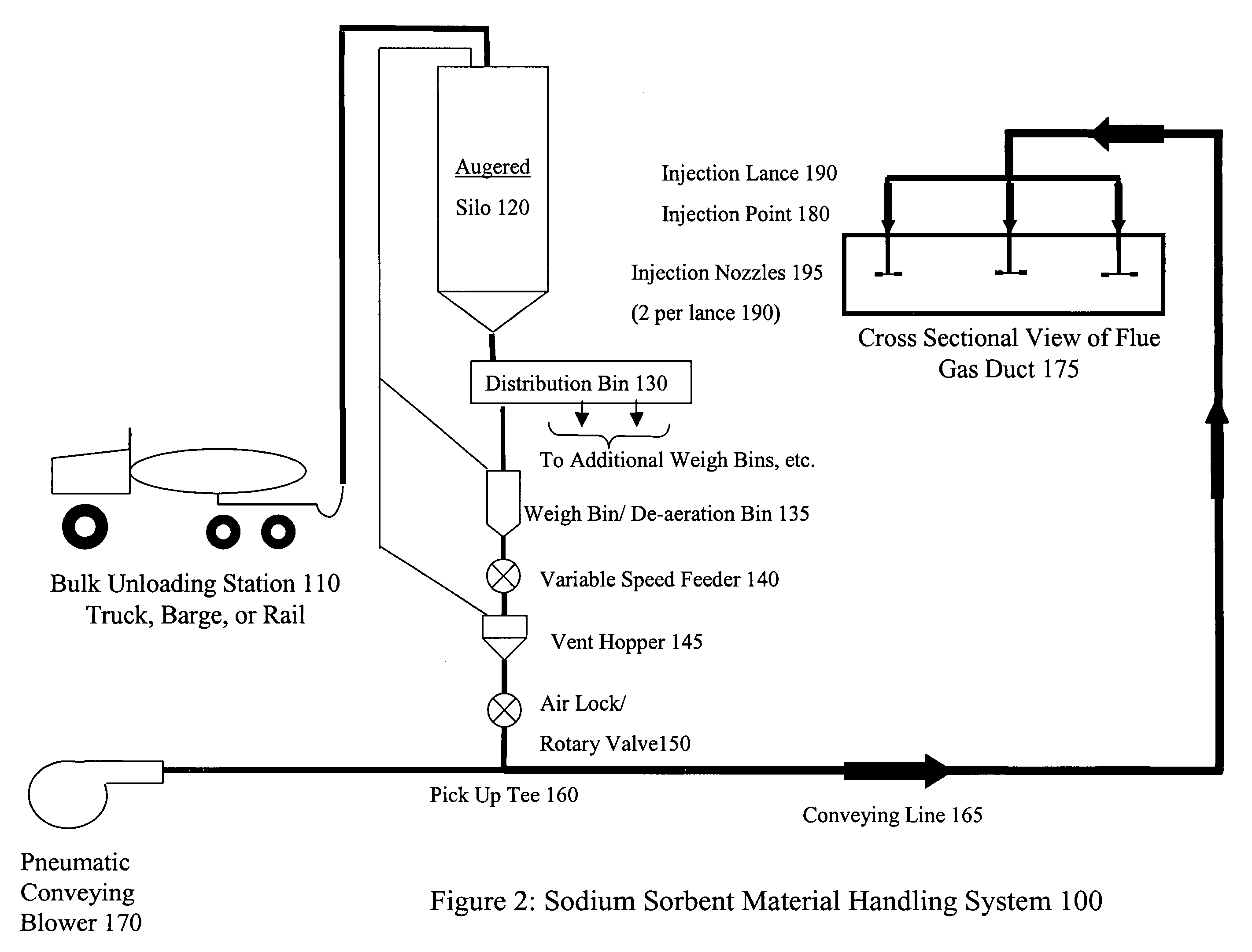

System and method for treating a flue gas stream

PendingUS20050201914A1Lower volume resistivityEfficient removalCombination devicesGas treatmentParticulatesDicarbonate

The present invention is a system and method for treating a flue gas stream to remove strong acid compounds selected from the group consisting of hydrofluoric acid (HF), hydrochloric acid (HCl), sulfuric acid (H2SO4), and sulfur trioxide (SO3) by injecting a sodium sorbent selected from the group consisting of sodium sesquicarbonate, sodium carbonate-bicarbonate, trona ore, mechanically refined trona ore, and trona into the flue gas stream, calcining substantially all of the sodium sorbent in the presence of the flue gas stream to form a soda ash, reducing the concentration of the at least one strong acid compound in the flue gas stream by reacting the at least one strong acid compound with the soda ash to form a sodium based by-product; and changing the chemistry of the flue gas stream to reduce the overall average resistivity of the particulate matter.

Owner:AMERICAN ELECTRIC POWER CO INC

Substantially Non-Oxidizing Plasma Treatment Devices and Processes

InactiveUS20110136346A1Avoid insufficient temperatureAvoid reactionElectric discharge tubesFinal product manufactureCopperSemiconductor

Non-oxidizing plasma treatment devices for treating a semiconductor workpiece generally include a substantially non-oxidizing gas source; a plasma generating component in fluid communication with the non-oxidizing gas source; a process chamber in fluid communication with the plasma generating component, and an exhaust conduit centrally located in a bottom wall of the process chamber. In one embodiment, the process chamber is formed of an aluminum alloy containing less than 0.15% copper by weight; In other embodiments, the process chamber includes a coating of a non-copper containing material to prevent formation of copper hydride during processing with substantially non-oxidizing plasma. In still other embodiments, the process chamber walls are configured to be heated during plasma processing. Also disclosed are non-oxidizing plasma processes.

Owner:LAM RES CORP

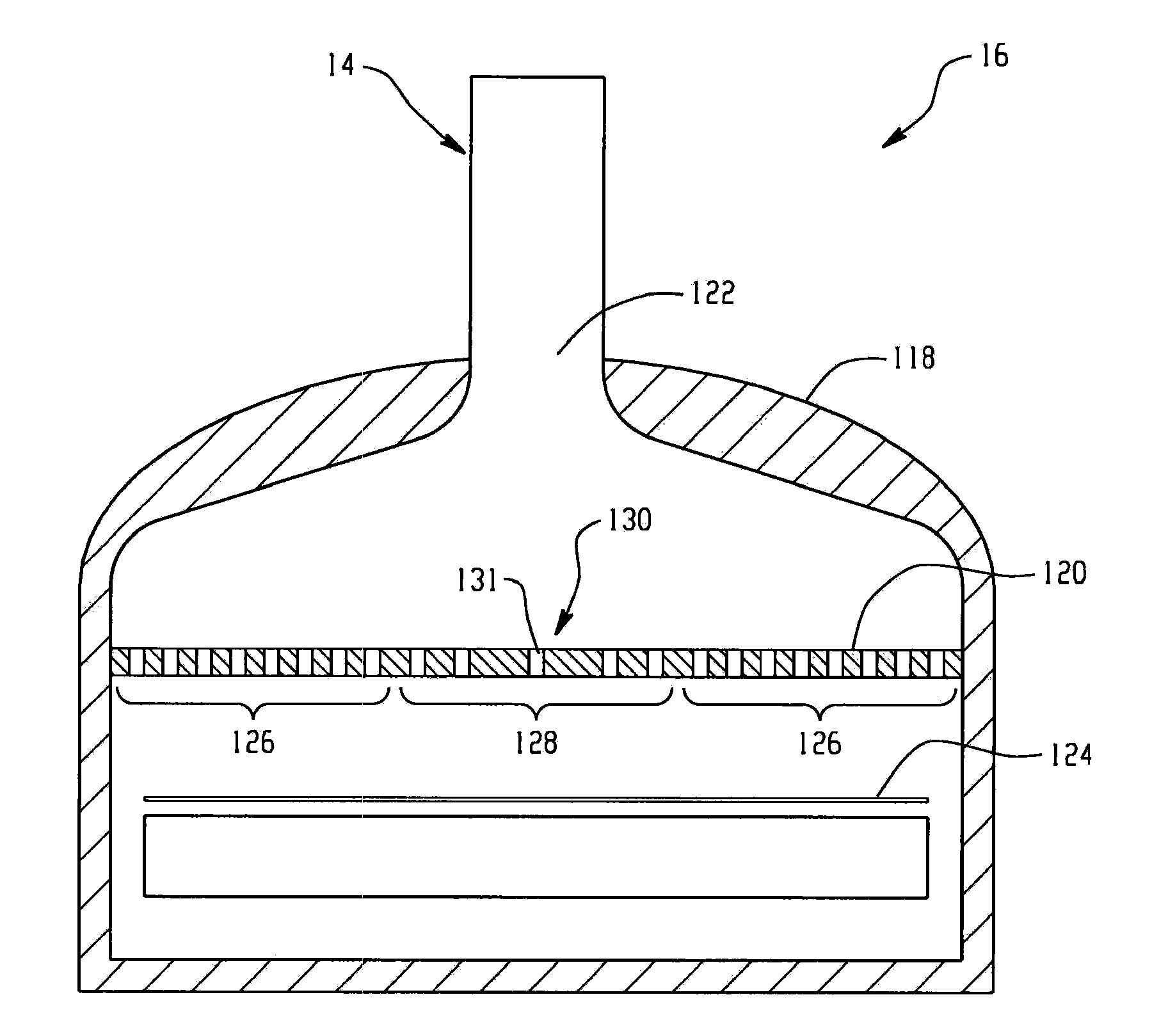

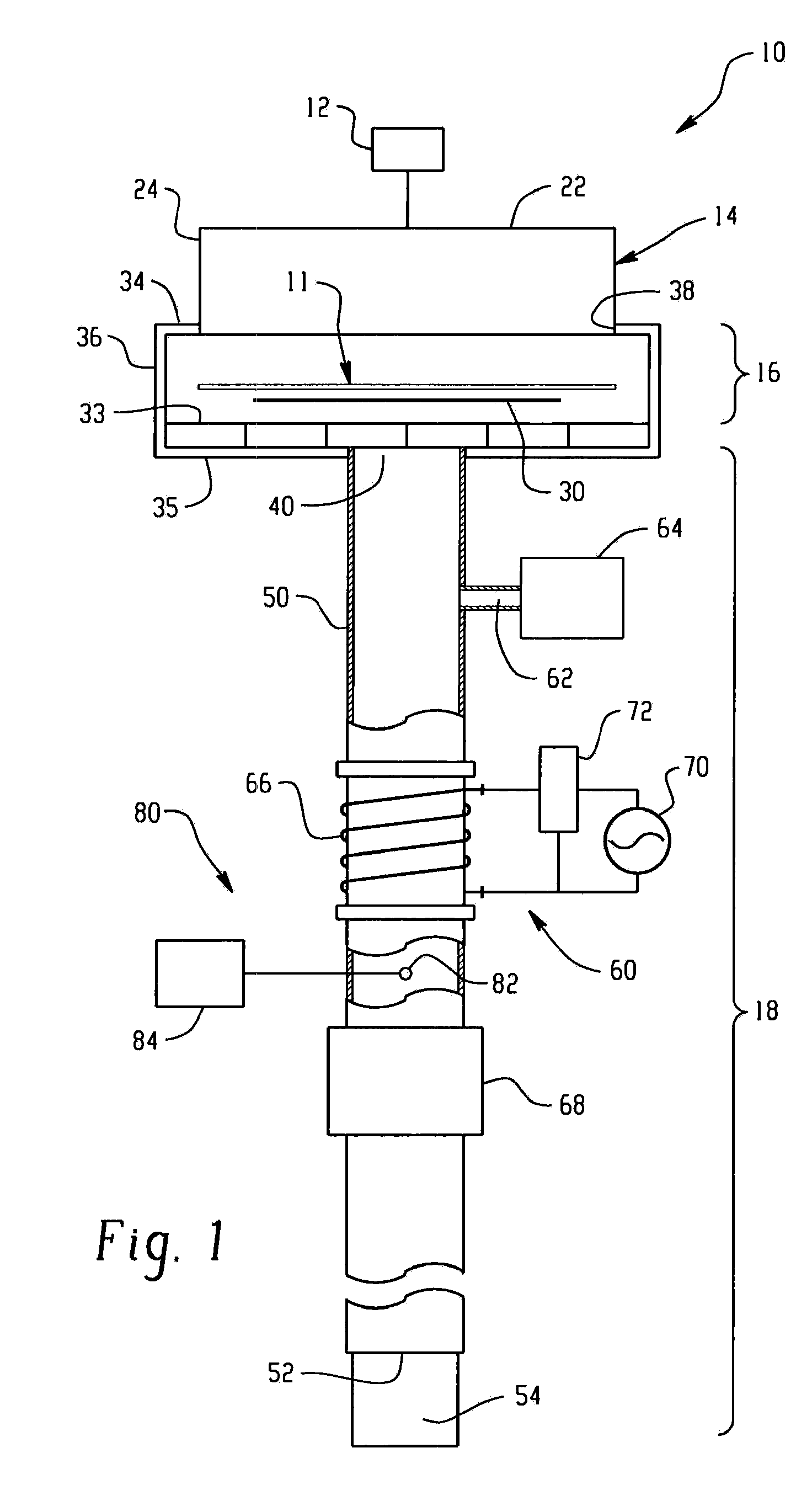

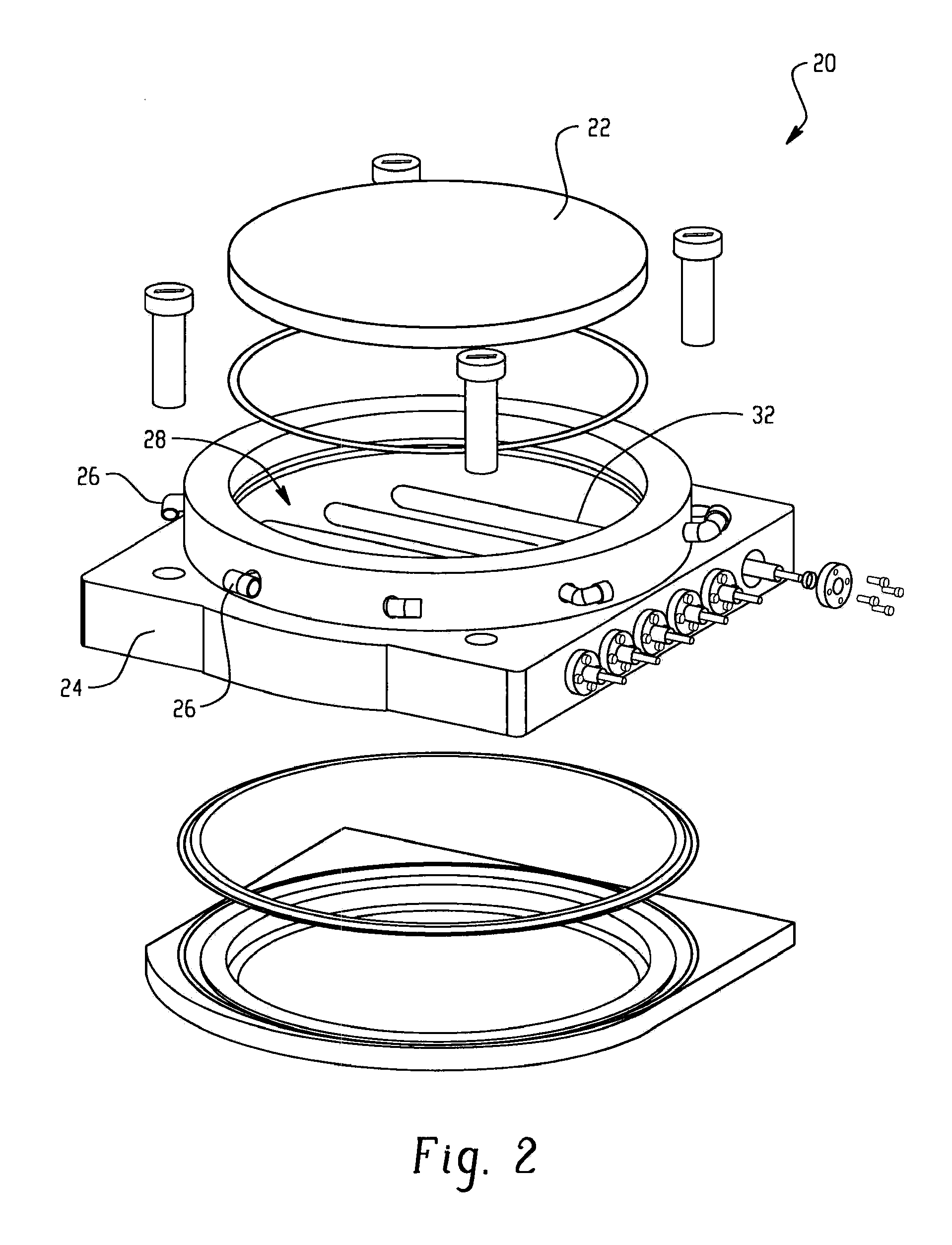

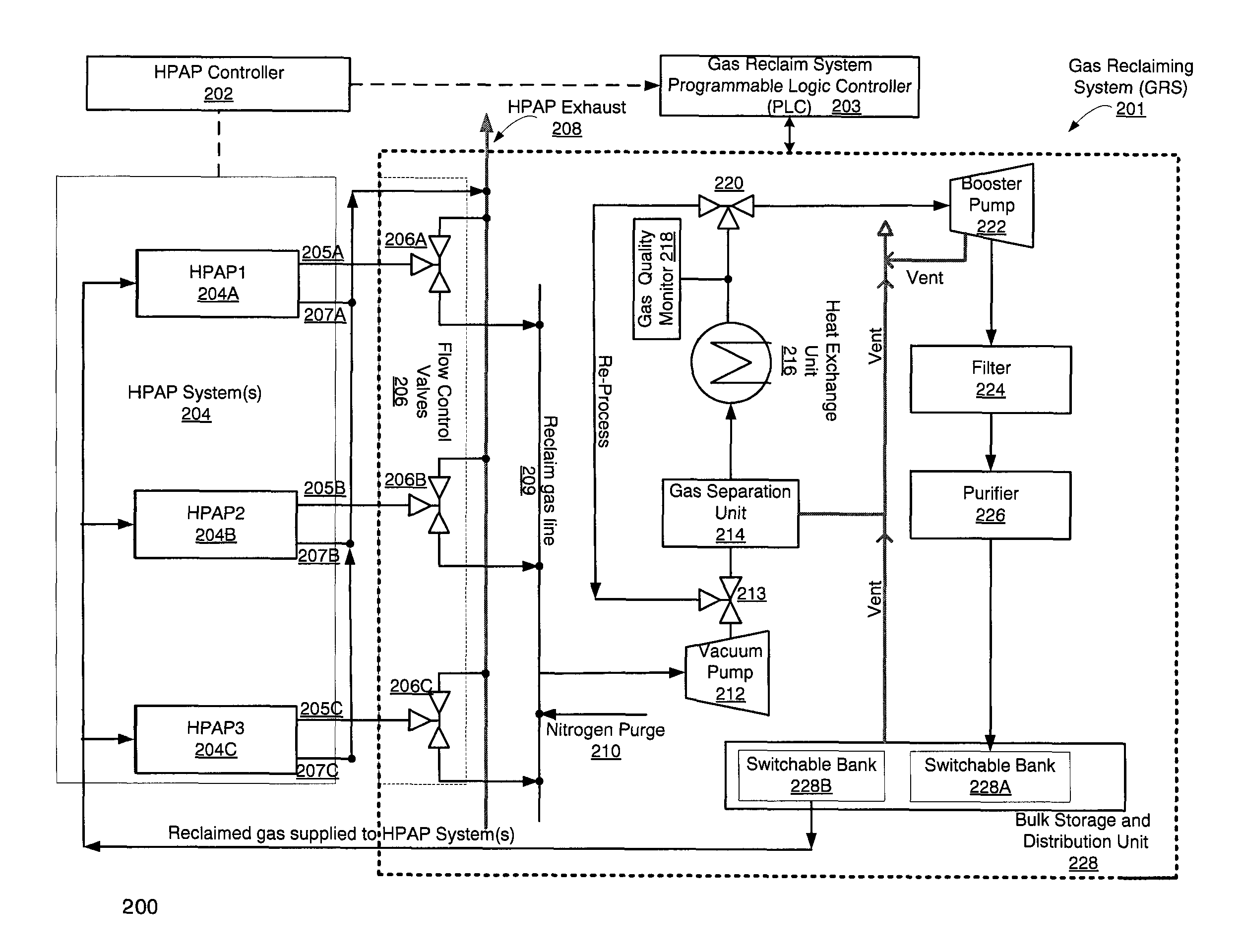

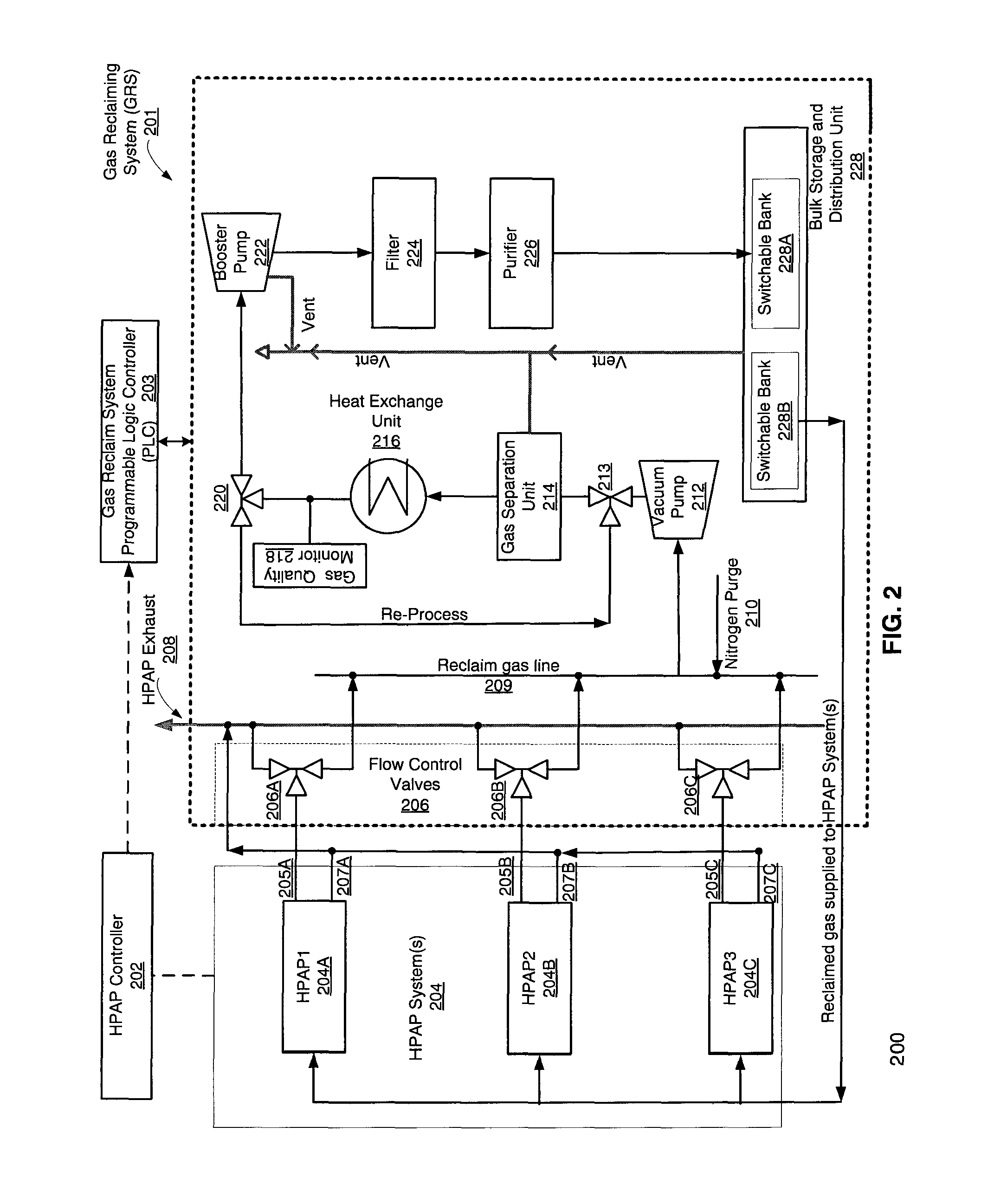

Methods and apparatuses for deuterium recovery

Novel methods, systems, and apparatuses for reclaiming annealing gases from a high pressure annealing processing system are disclosed. According to an embodiment, the exhaust gasses from the high pressure annealing processing system are directed into a gas reclaiming system only when a precious gas, e.g., deuterium is used. The annealing gas is the separated from other gasses used in the high pressure annealing processing system and is then pressurized, filtered, and purified prior to transferring the gas to a bulk storage distribution unit. In one embodiment, the reclaimed gas is then again provided to the high pressure annealing processing system to anneal the wafers.

Owner:HPSP CO LTD

Solvent compositions containing chlorofluoroolefins

InactiveUS20050096246A1Satisfies needOvercome deficienciesCompressorTransportation and packagingDouble bondSolvent composition

Compositions and methods based on the use of fluoroalkene containing from 3 to 4 carbon atoms and at least one carbon-carbon double bond, such as 1,2,-dichloro-3,3,3-trifluoropropene (HFO-1223xd) having properties highly beneficial in solvent cleaning applications.

Owner:HONEYWELL INT INC

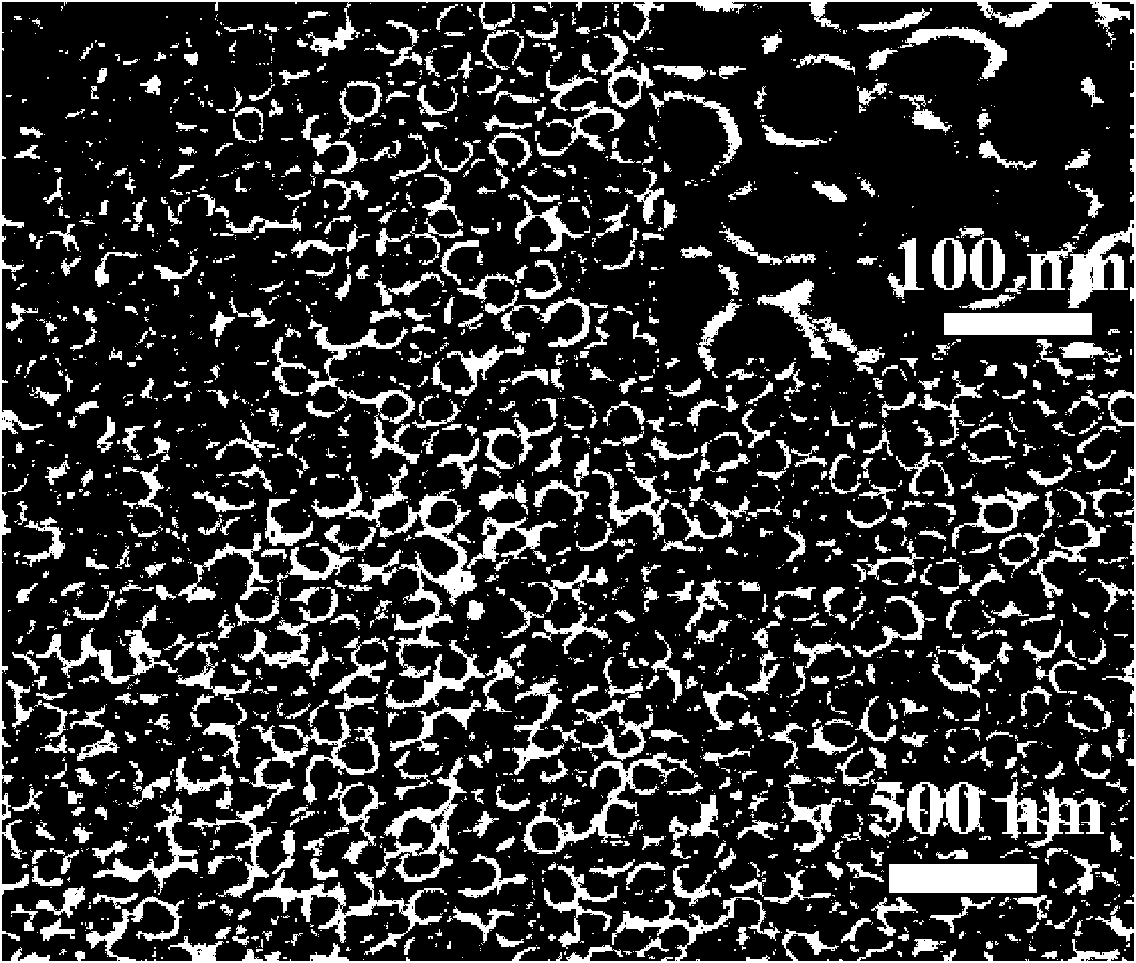

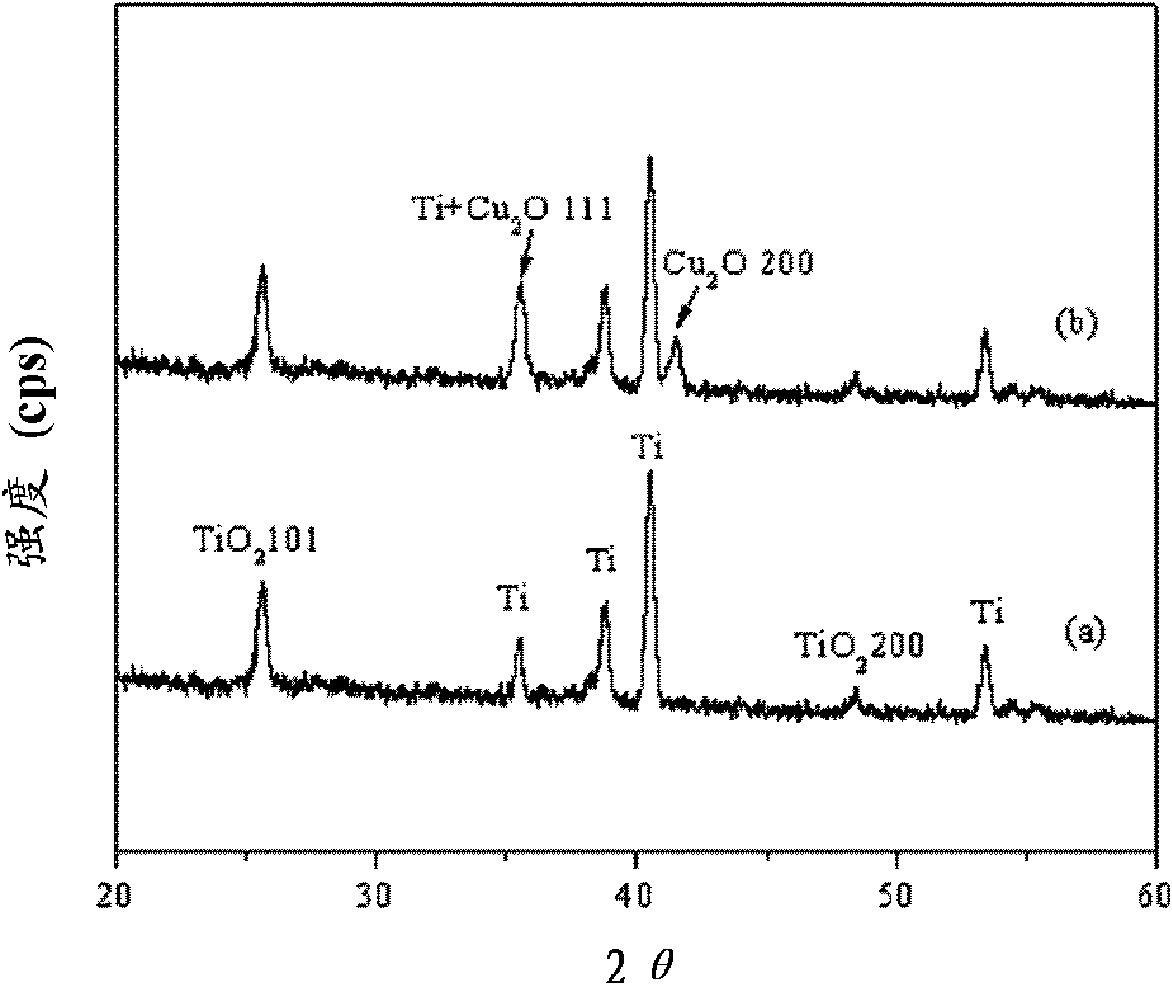

Preparation method of visible-light activated cuprous oxide/titanium dioxide nano-composite photocatalyst and applications thereof

InactiveCN101537354ASimple processLarge specific surface areaWater/sewage treatment by irradiationWater contaminantsPhotocatalytic degradationLight response

Owner:DALIAN UNIV OF TECH

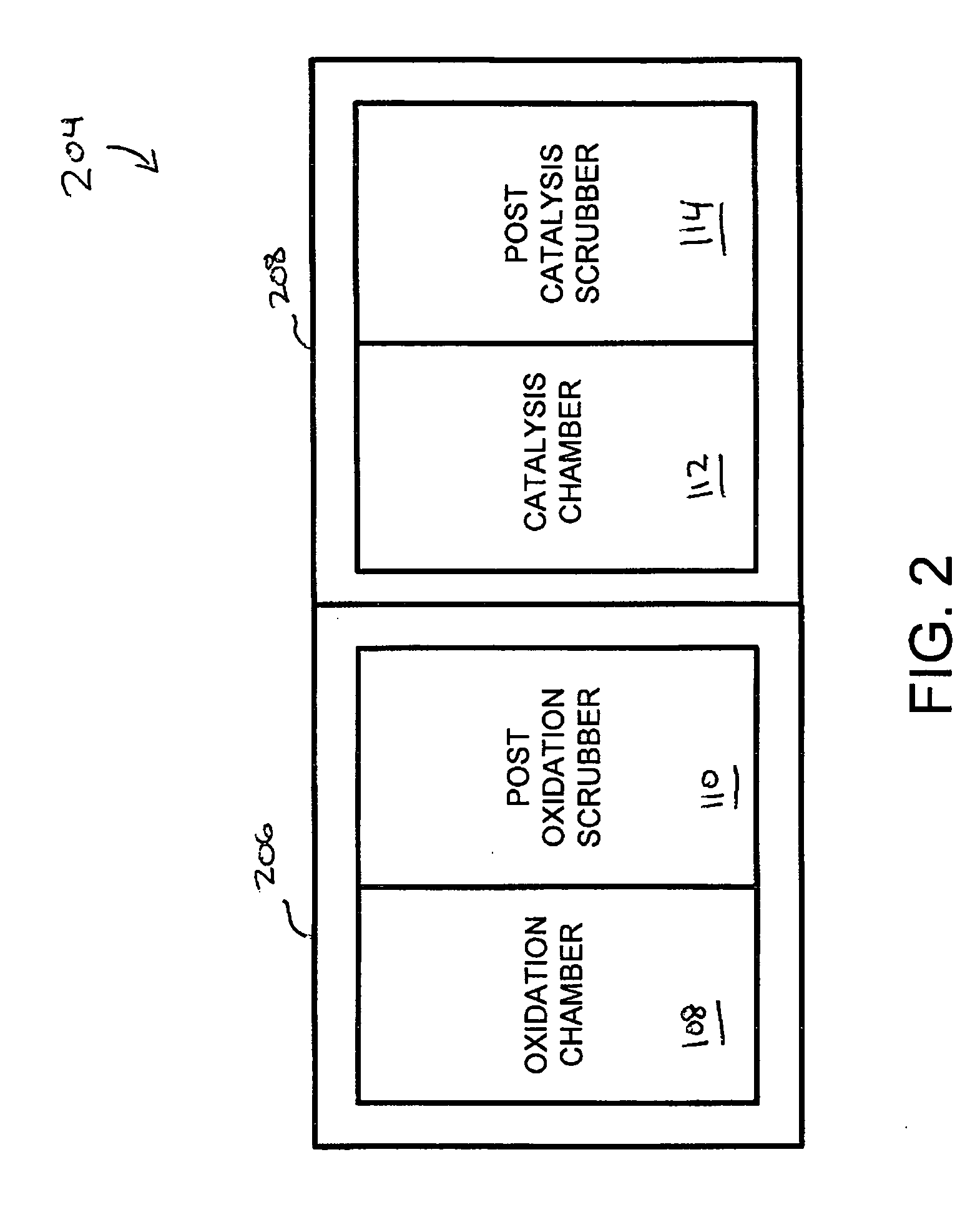

Effluent gas stream treatment system having utility for oxidation treatment of semiconductor manufacturing effluent gases

InactiveUS6333010B1Reduce sensitivityReduced water requirementsCombination devicesGas treatmentEnvironmental engineeringProduct gas

An effluent gas stream treatment system for treatment of gaseous effluents such as waste gases from semiconductor manufacturing operations. The effluent gas stream treatment system comprises a pre-oxidation treatment unit, which may for example comprise a scrubber, an oxidation unit such an electrothermal oxidizer, and a post-oxidation treatment unit, such as a wet or dry scrubber. The effluent gas stream treatment system of the invention may utilize an integrated oxidizer, quench and wet scrubber assembly, for abatement of hazardous or otherwise undesired components from the effluent gas stream. Gas or liquid shrouding of gas streams in the treatment system may be provided by high efficiency inlet structures.

Owner:BHT SERVICES PTE LTD

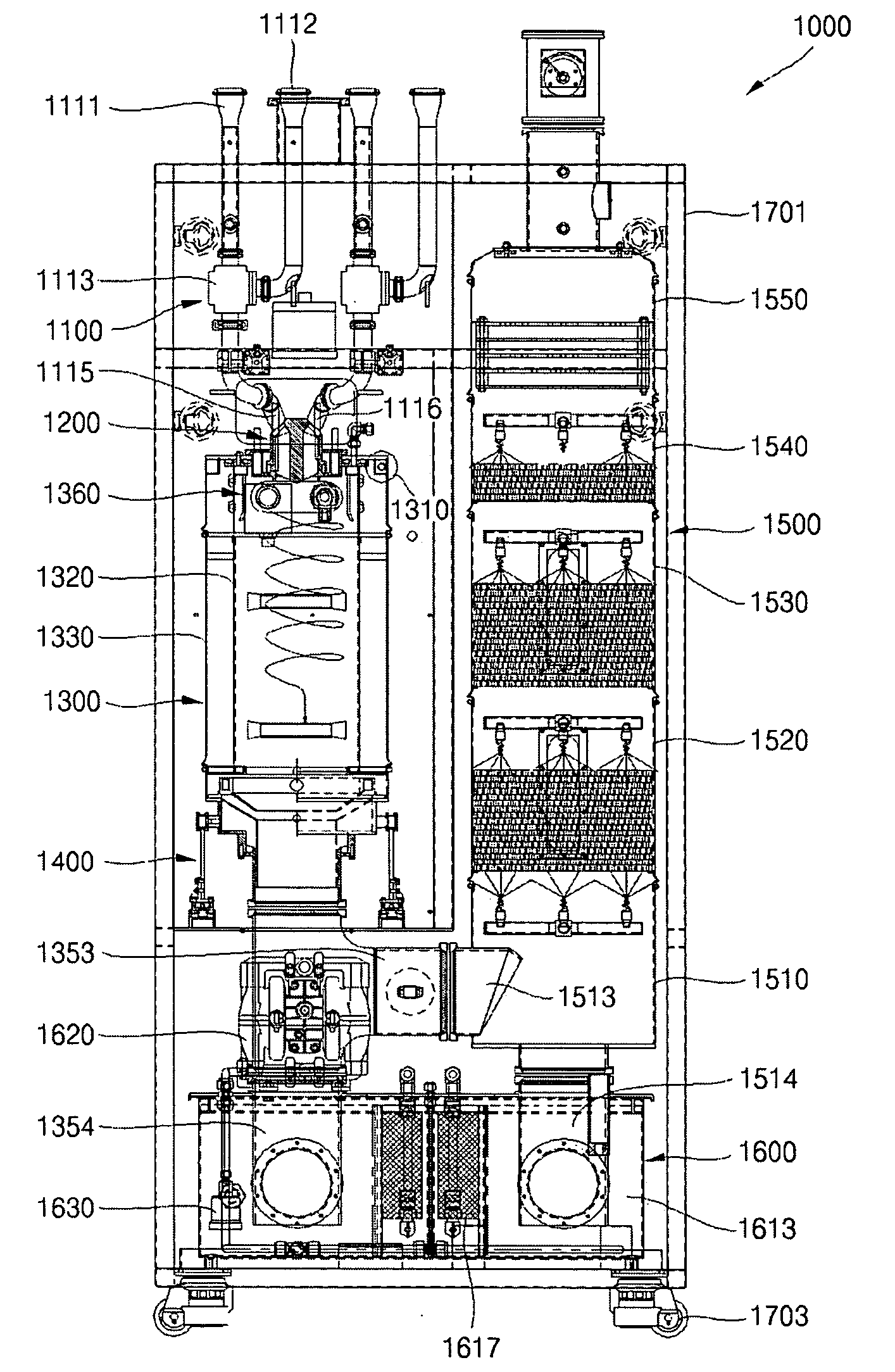

Scrubber for processing semiconductor waste gas

ActiveUS20070053803A1Improved efficiency of burning semiconductor waste gasImprove efficiencyCombination devicesGas treatmentParticulatesCombustor

Disclosed is a scrubber for processing semiconductor waste gas produced in a semiconductor fabricating process, wherein the scrubber burns the waste gas with a flame of a high temperature, filters and captures particles produced after the waste gas is burnt, and discharges particle-filtered waste gas to the atmosphere. The semiconductor waste gas processing scrubber includes: a supply section for supplying semiconductor waste gas, fuel and oxygen; a burner connected to the supply section so as to burn the semiconductor waste gas by flame; a burning chamber joined to the burner so as to cause particles, which are produced as the semiconductor waste gas is burnt, to drop; a wet tower installed at a side of the burning chamber so as to cause the particles, which are transferred from the burning chamber after adsorbing the particles using water, to drop; and a water reservoir tank connected to the burning chamber and the wet tower so as to capture the particles which have dropped from the burning chamber and the wet tower.

Owner:CLEAN SYST KOREA

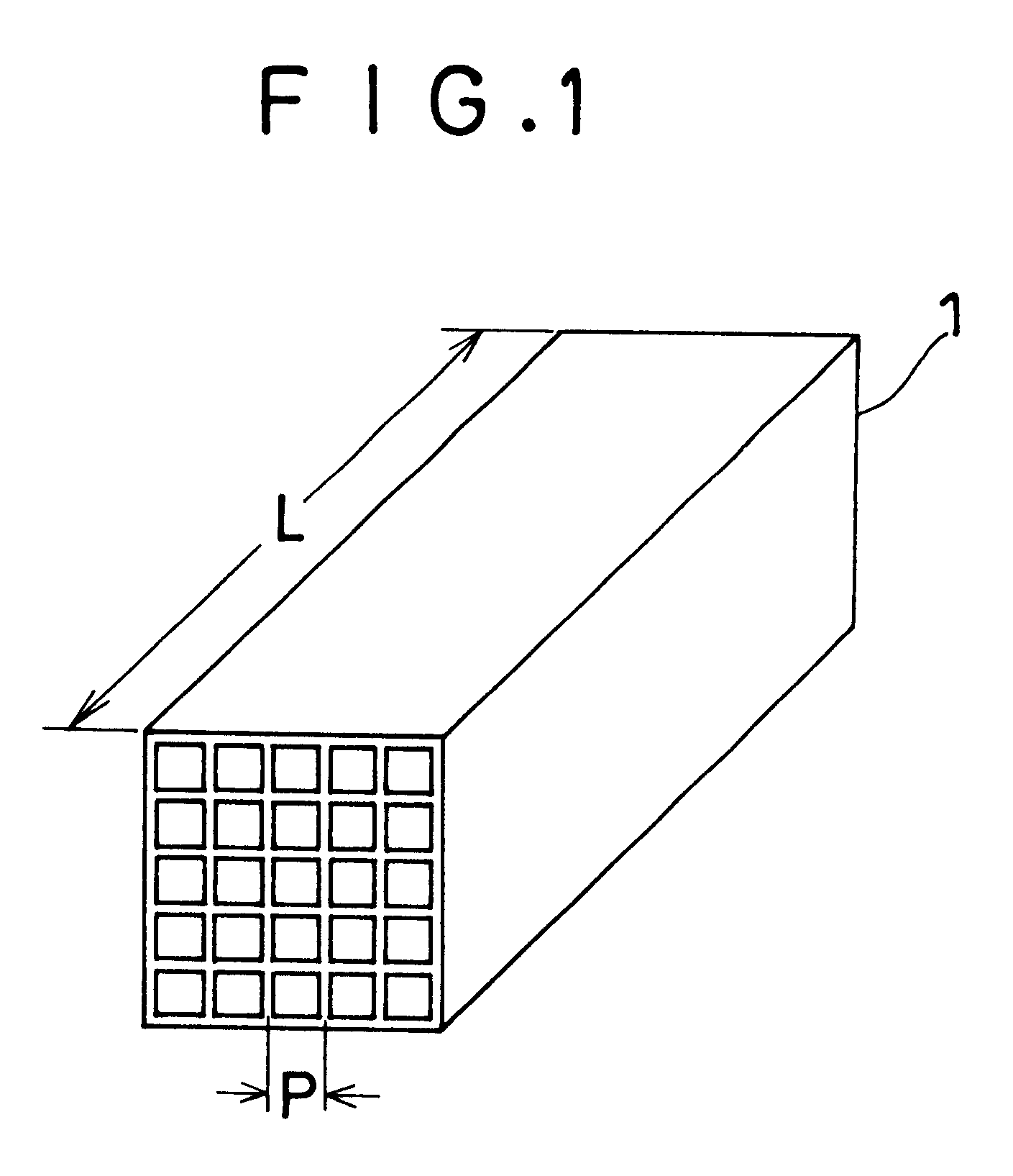

Methods for the regeneration of a denitration catalyst

InactiveUS6395665B2Reduce catalysisReduce the required powerOther chemical processesDispersed particle separationActive componentBiological activation

This invention provides a method for the regeneration of a denitration catalyst which comprises cleaning a denitration catalyst having reduced denitration power with an aqueous alkaline solution to remove the substances deposited thereon, and subjecting the catalyst to an activation treatment with an aqueous acid solution; a method for the regeneration of a denitration catalyst which comprises cleaning a denitration catalyst having reduced denitration power with a cleaning fluid comprising an aqueous solution containing sulfuric acid or ammonia at a concentration of 0.05 to 20% by weight and maintained at a temperature of 10 to 90°C.; and a method for the regeneration of a denitration catalyst which comprises cleaning a denitration catalyst having reduced denitration power under the above-described conditions, and impregnating the denitration catalyst with a catalytically active component so as to support it on the catalyst.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

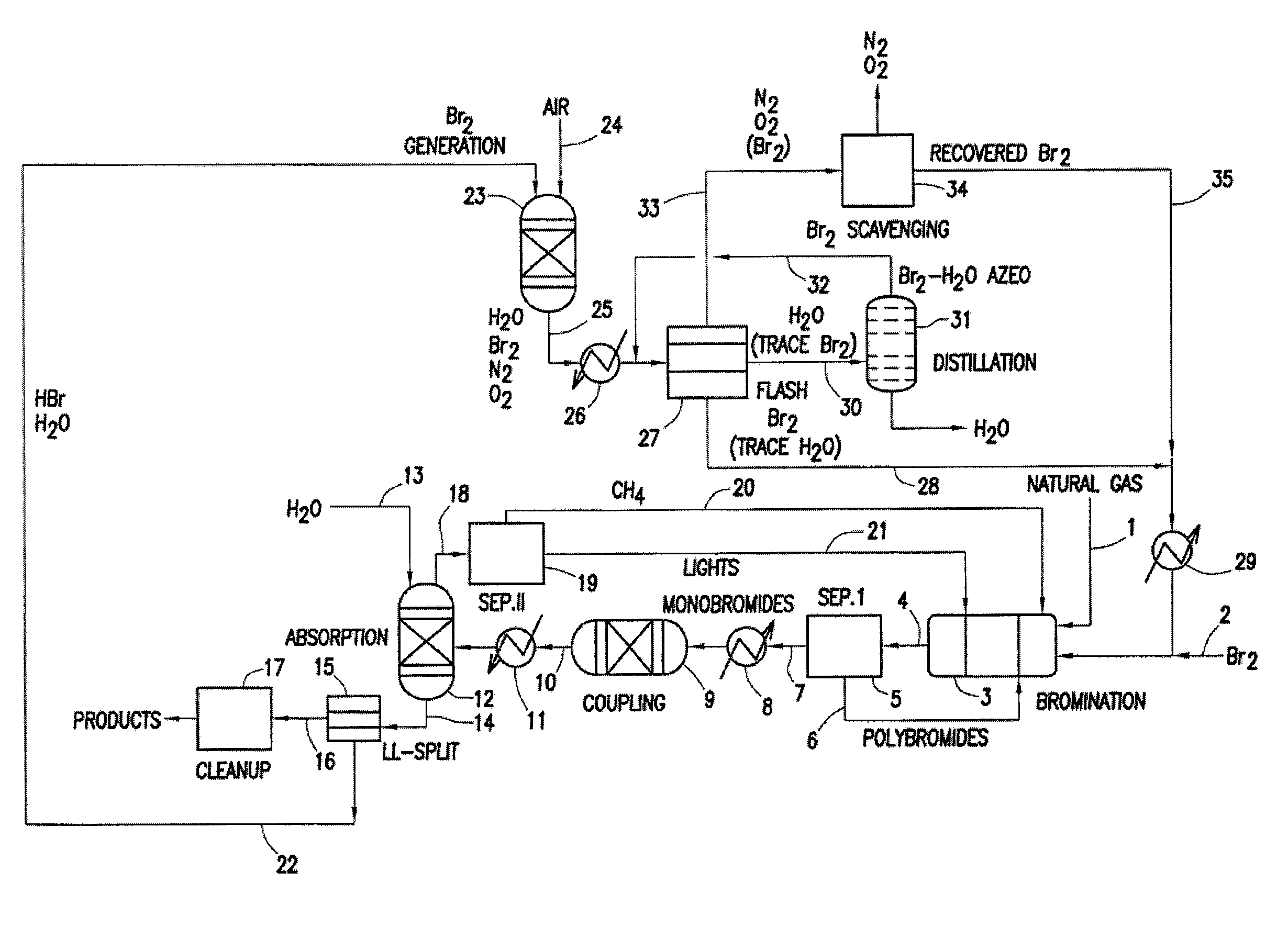

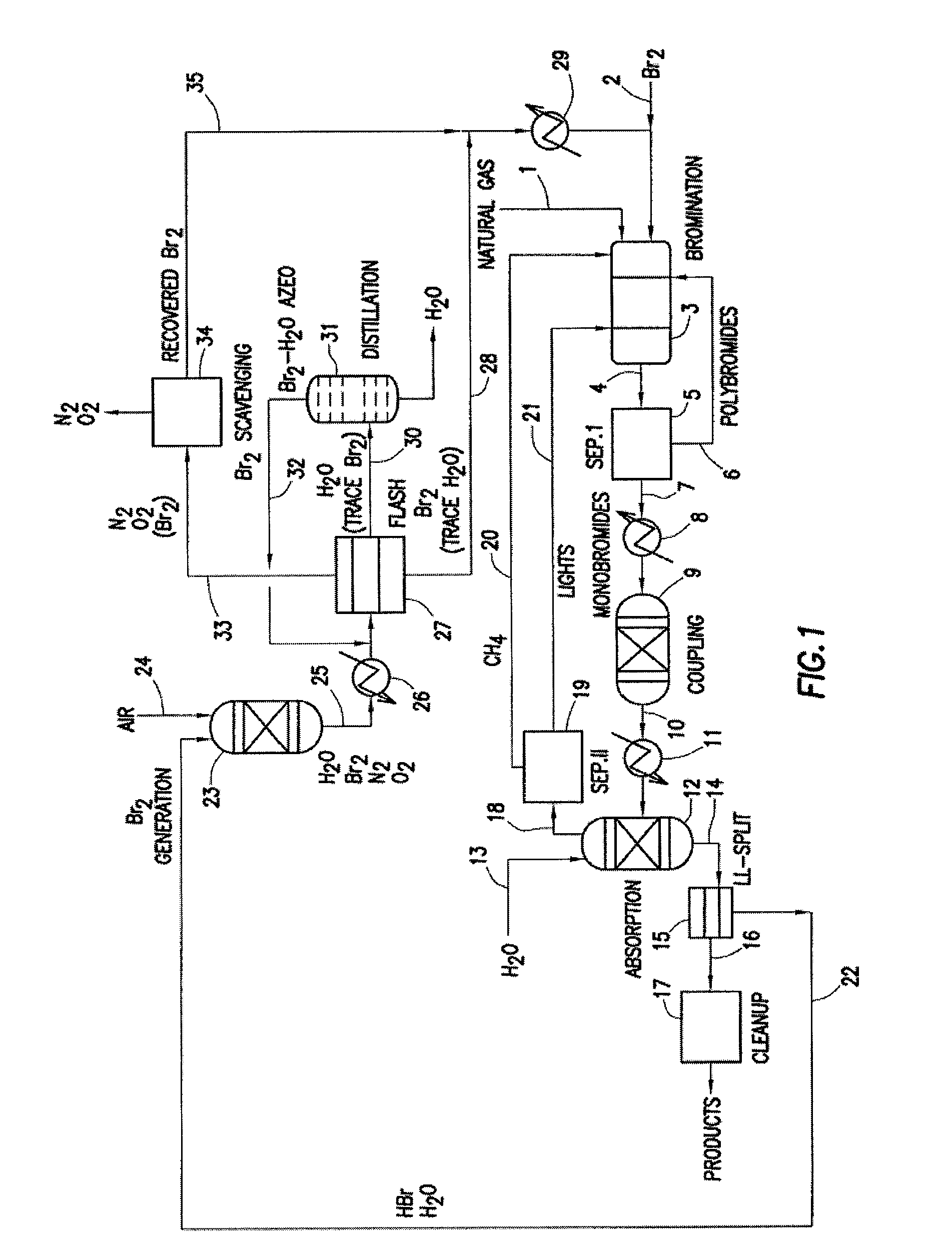

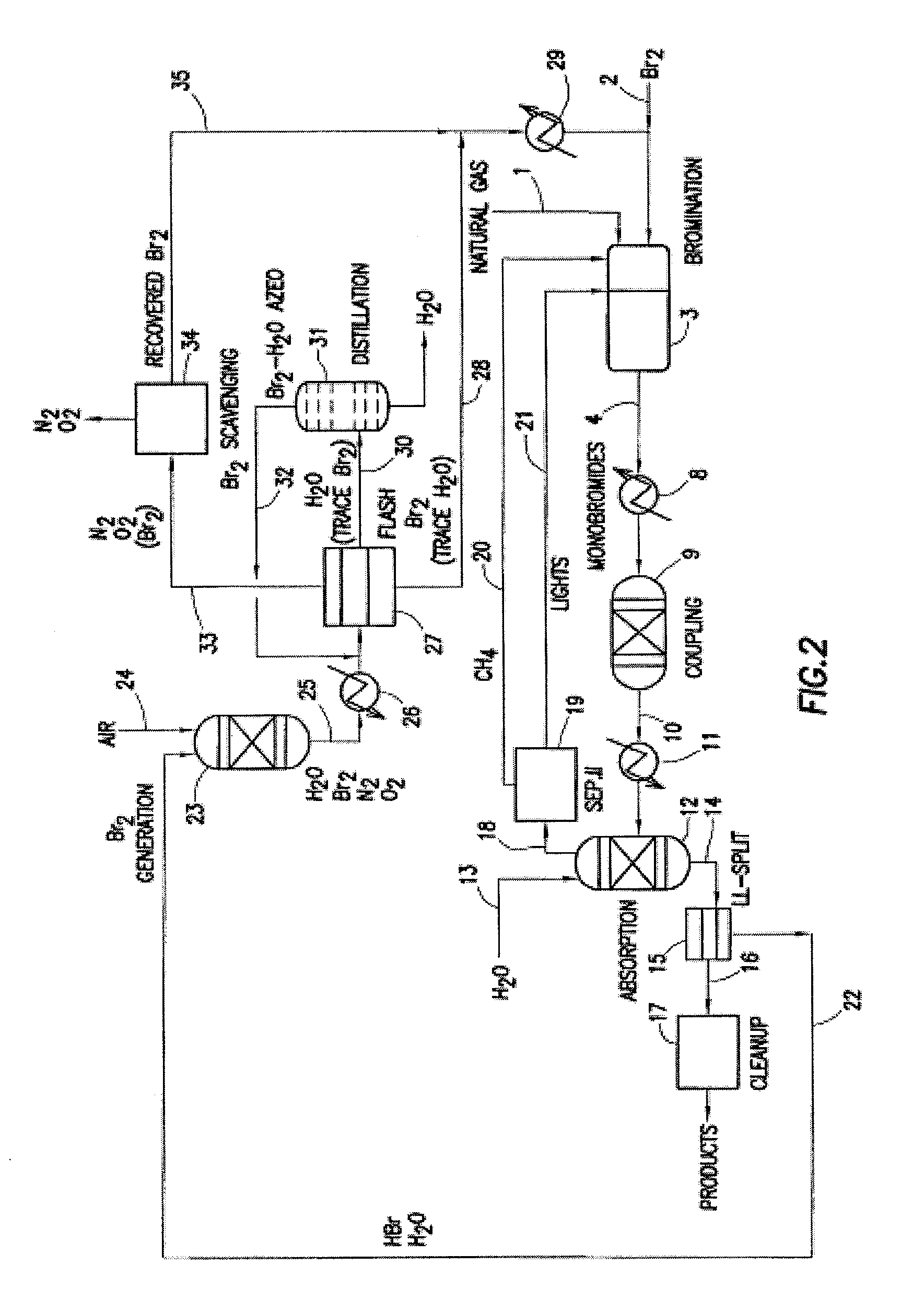

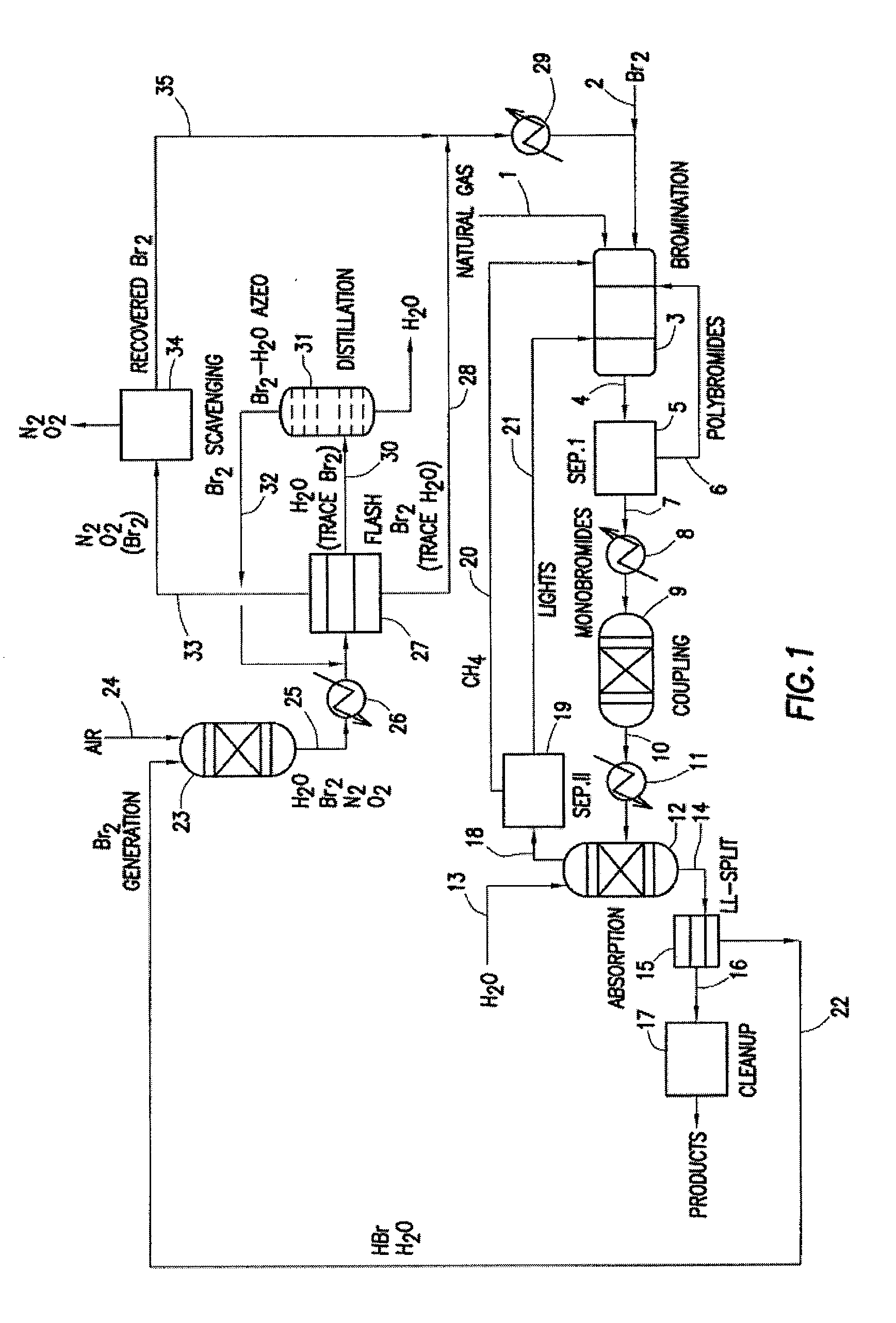

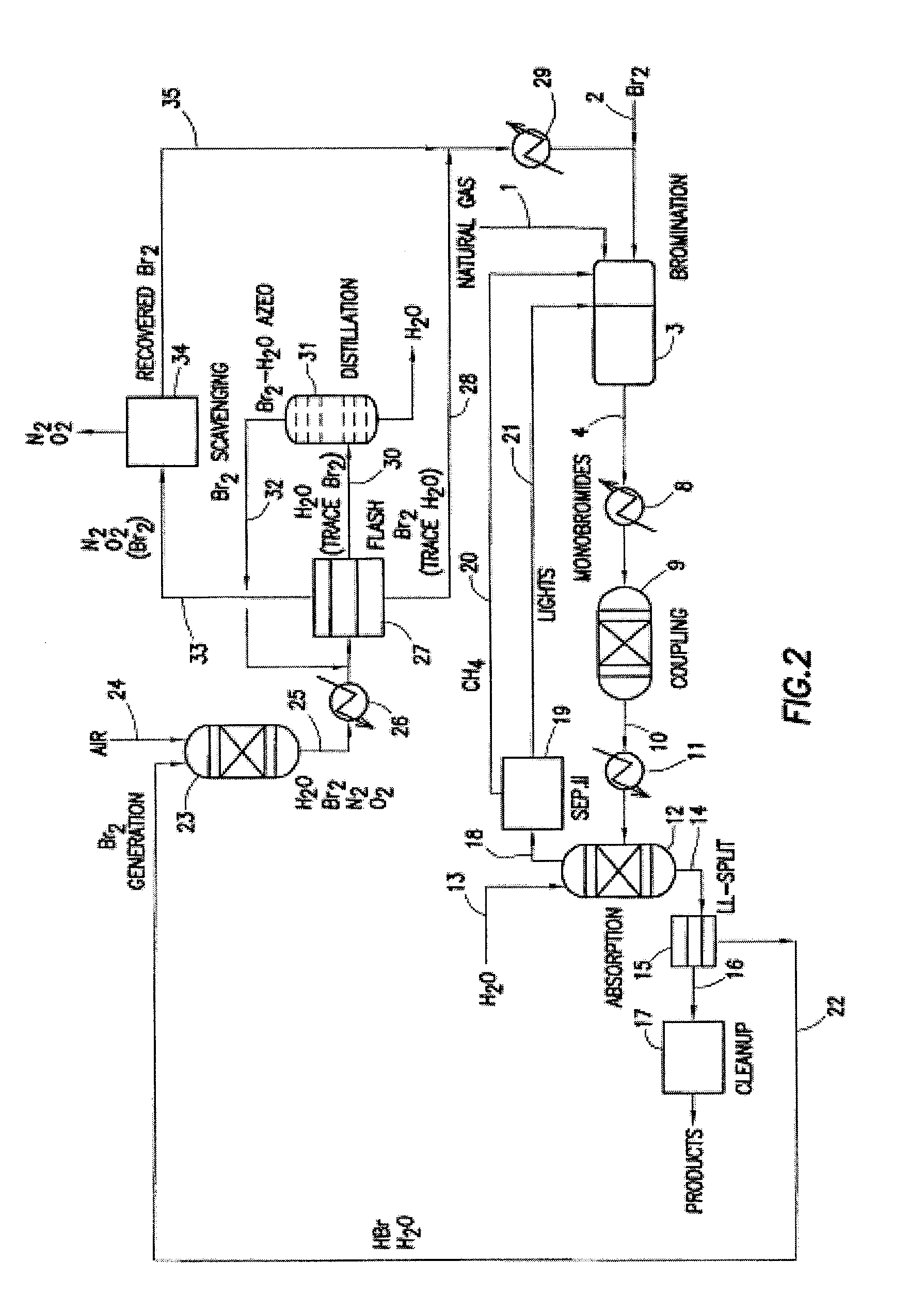

Continuous Process for Converting Natural Gas to Liquid Hydrocarbons

A method comprising: providing an alkyl halide stream; contacting at least some of the alkyl halides with a coupling catalyst to form a product stream comprising higher hydrocarbons and hydrogen halide; contacting the product stream with a solid reactant to remove at least a portion of the hydrogen halide from the product stream; and reacting the solid reactant with a source of oxygen to generate a corresponding halogen.

Owner:REACTION 35 LLC

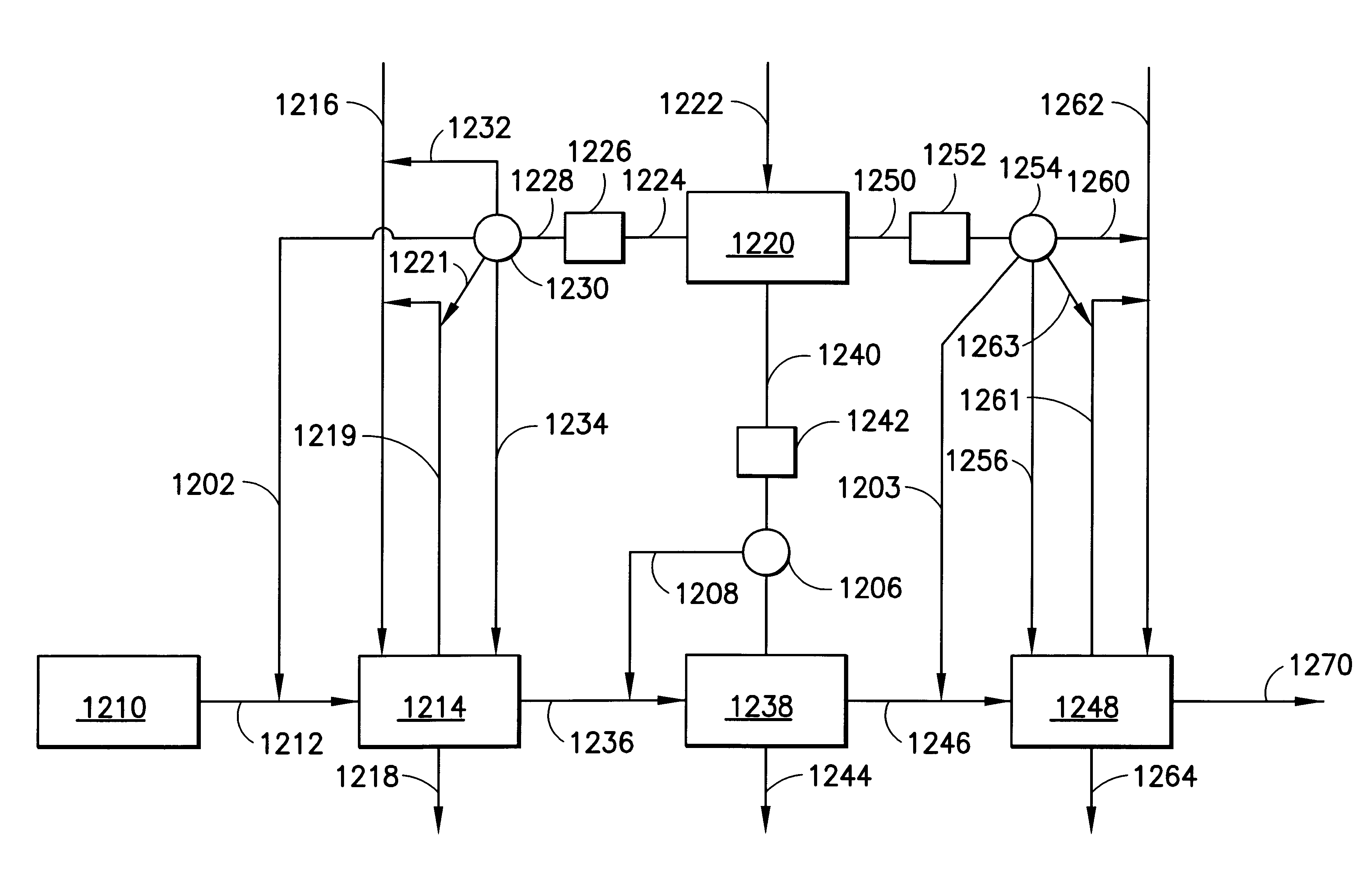

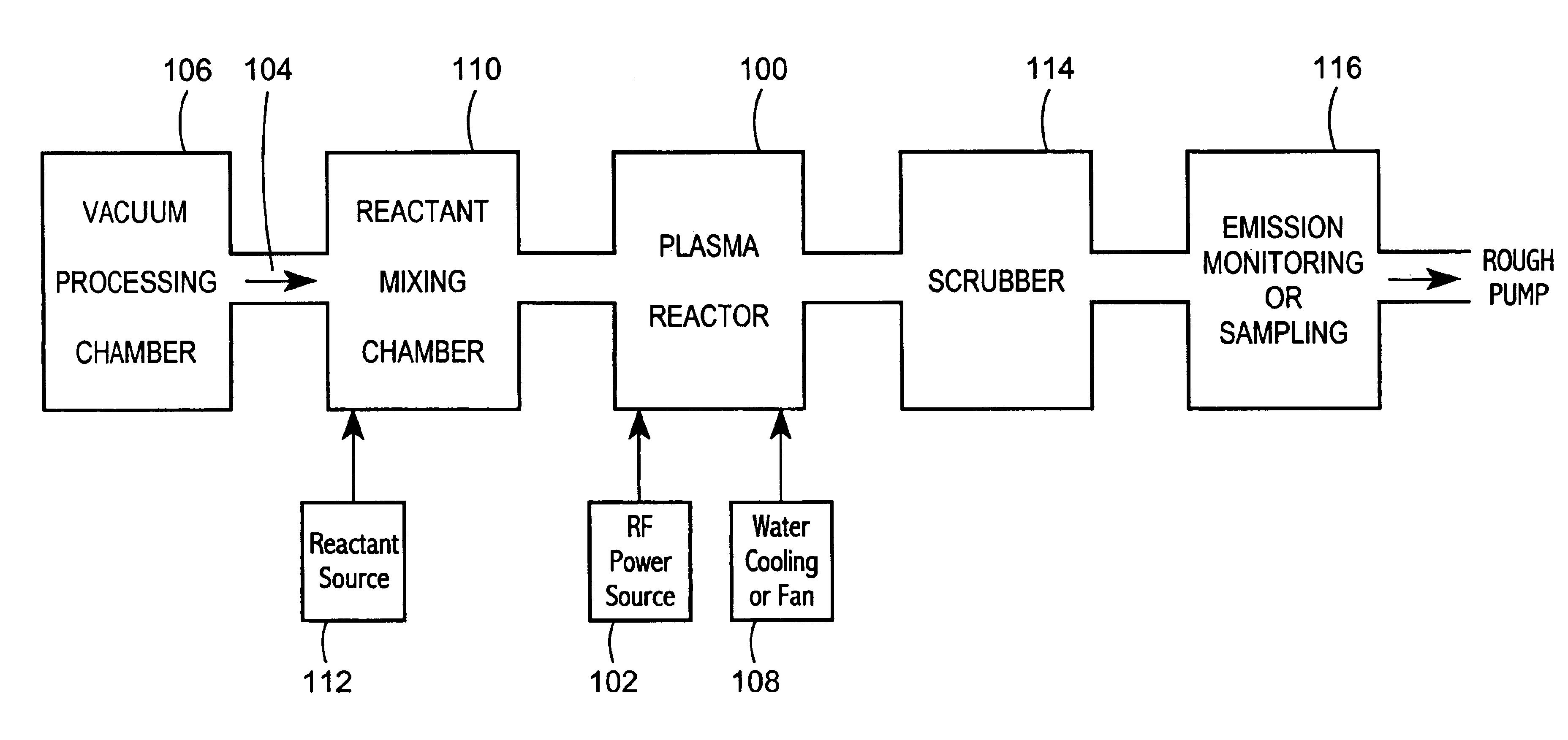

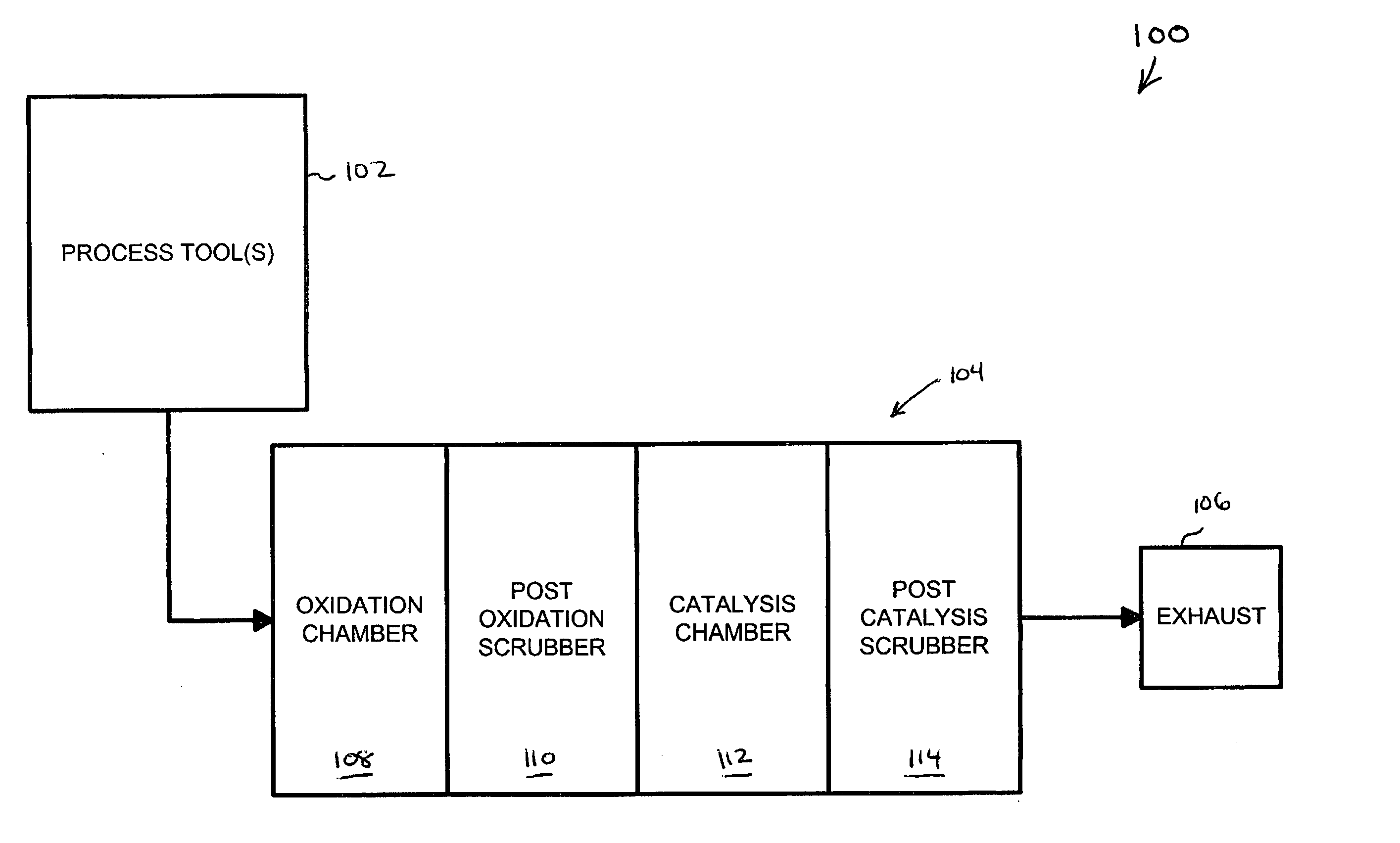

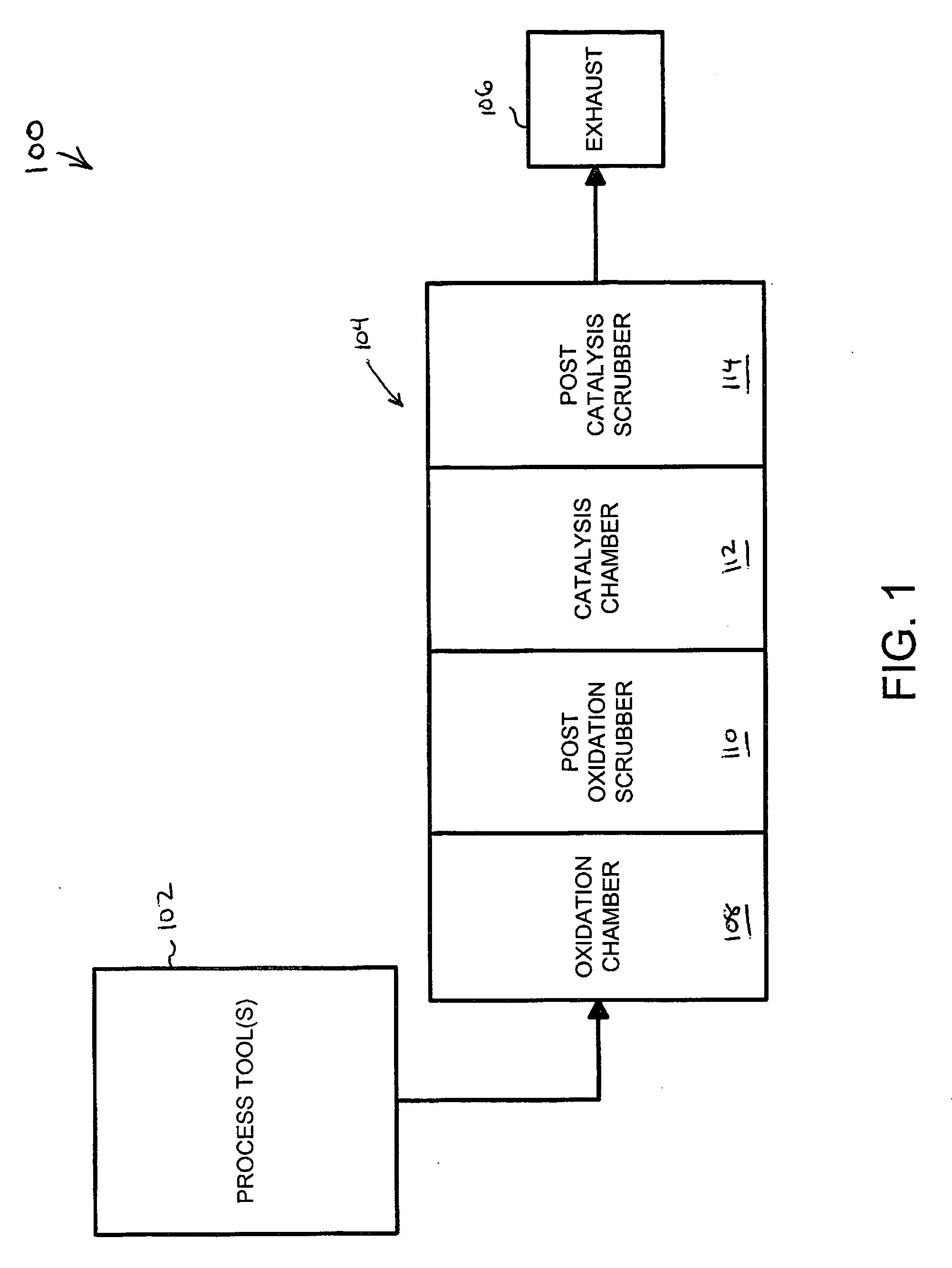

Methods and apparatus for process abatement

In a first aspect, a first abatement apparatus is provided. The first abatement apparatus includes (1) an oxidation unit adapted to receive an effluent stream from a semiconductor device manufacturing chamber; (2) a first water scrubber unit adapted to receive the effluent stream from the oxidation unit; and (3) a catalysis unit adapted to receive the effluent stream from the first water scrubber unit. Numerous other aspects are provided.

Owner:APPLIED MATERIALS INC

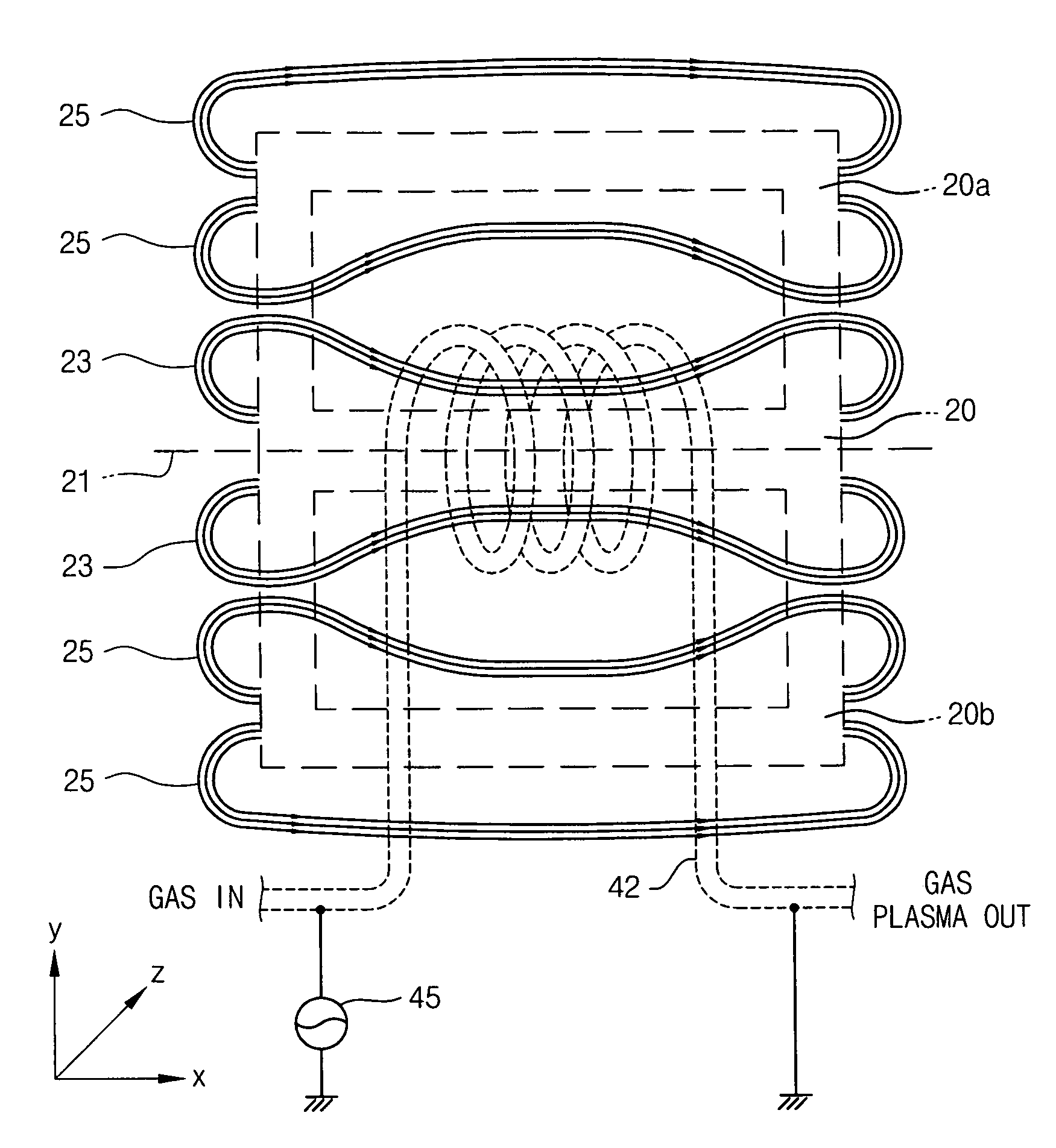

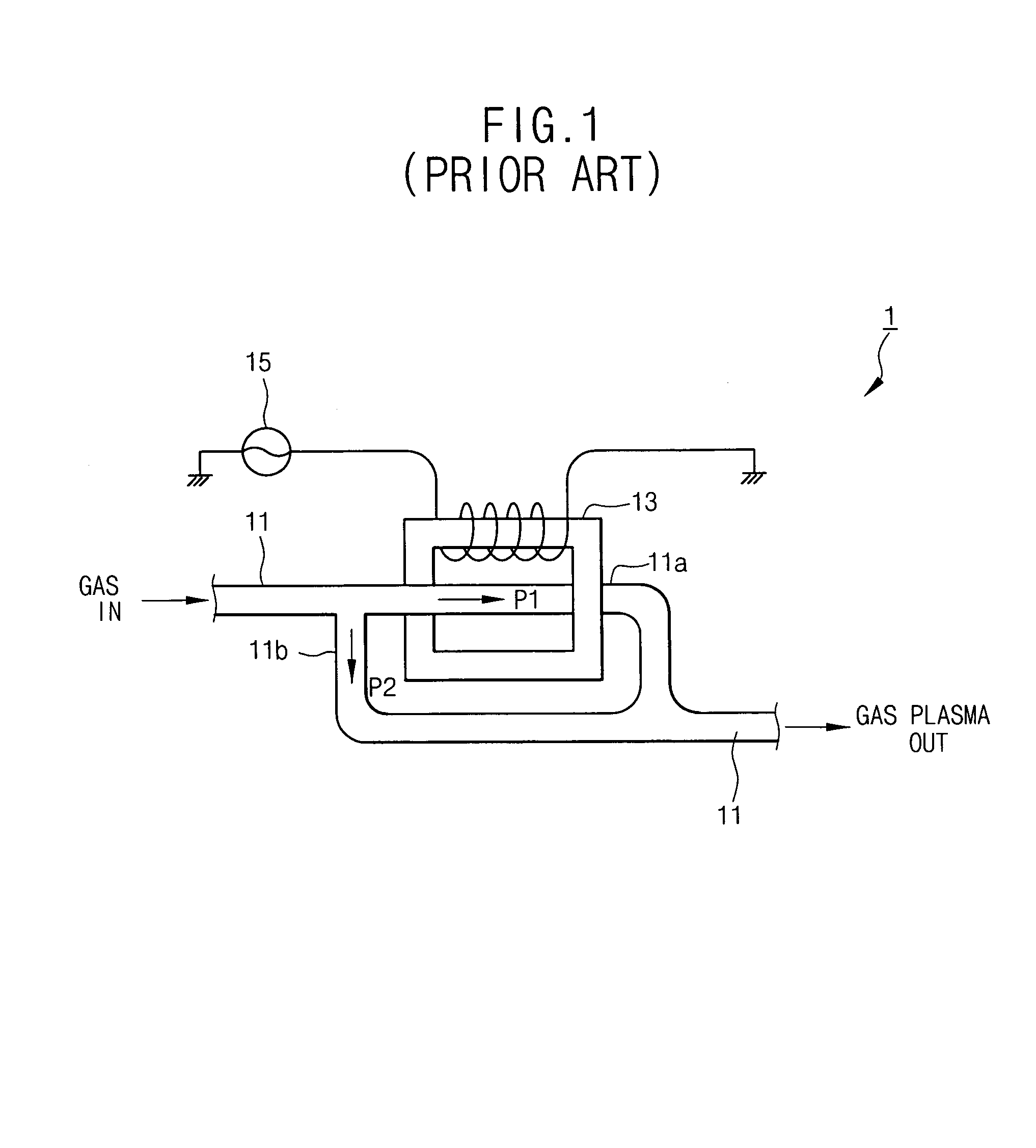

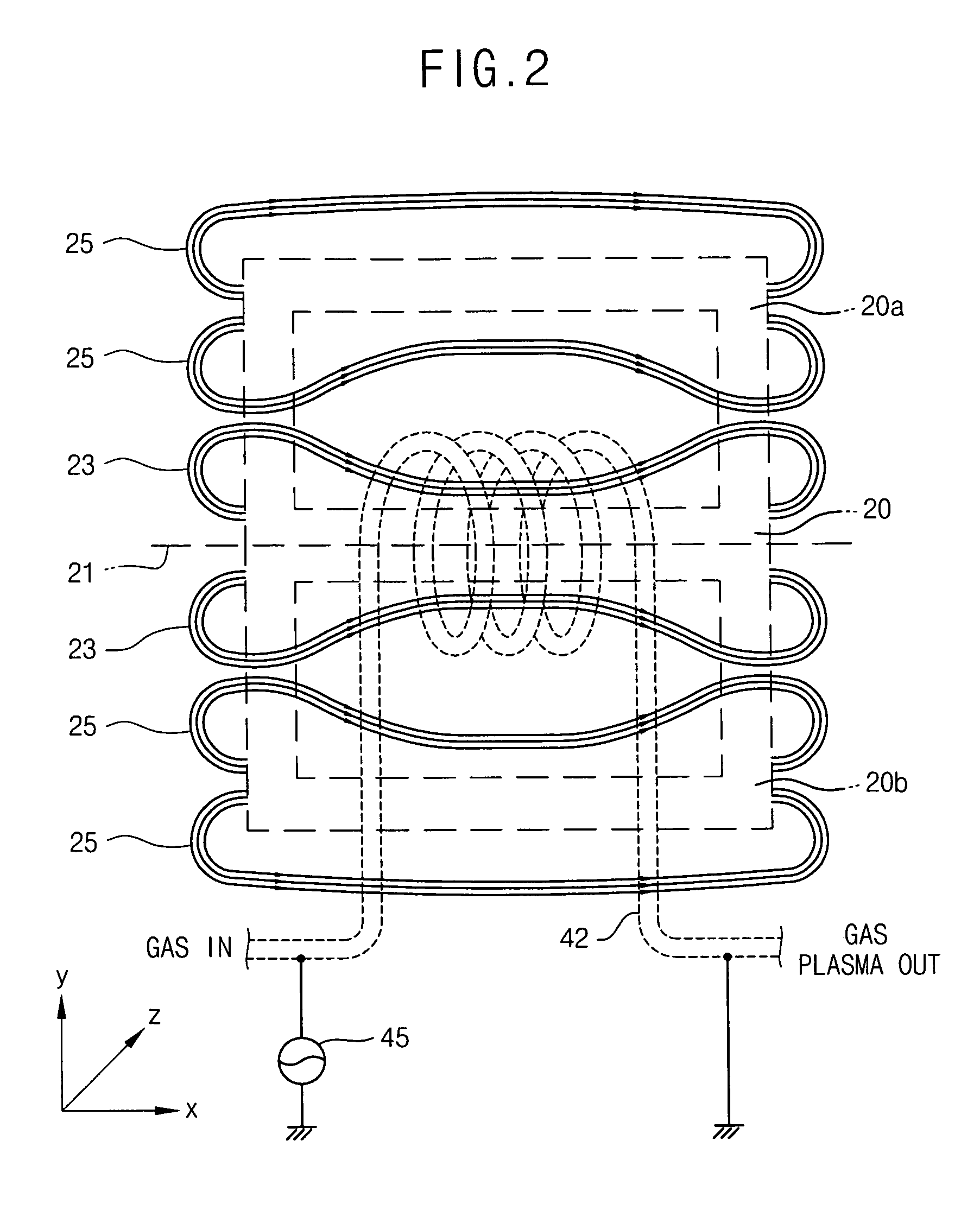

Method for generating gas plasma

InactiveUS7193369B2Improve power generation efficiencyReduce manufacturing costElectric discharge tubesFinal product manufactureElectricityAlternating current

A method for generating a plasma. A gas flows along a flow path having the displacement identical to the lines of magnetic force of the main magnetic field, and high frequency alternating current is applied to the gas, thereby generating a gas plasma. For example, a gas is flowed through a pipe in a first direction. Electricity is conducted through the pipe in substantially the first direction. And a magnetic field is applied along a second direction (e.g., perpendicular to the first direction) to the gas flowing in the pipe such that a plasma is induced in the pipe.

Owner:SAMSUNG ELECTRONICS CO LTD

Cleaning method and cleaning device

InactiveUS20050082001A1Improve efficiencyEasy to useElectric discharge tubesFinal product manufactureRemote plasmaCleaning methods

A method for cleaning a process chamber of a plasma treatment device includes introducing gas that has been activated with a remote plasma source into a process chamber, reactivating the activated gas in the process chamber, reacting the reactivated gas with a deposit inside the process chamber and exhausting the reacted gas.

Owner:SEIKO EPSON CORP

Preparation method and application of metal organic framework material

ActiveCN104497055ALarge specific surface areaReduce contentOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsRefluxOrganic dye

The invention provides a preparation method of a metal organic framework material. The metal organic framework material is synthesized by virtue of a hydrothermal method or a heating reflux method and is a metal organic framework MOF(Fe) material. The invention also discloses a cigarette filter tip added with the metal organic framework MOF(Fe) material. According to the preparation method and application of the metal organic framework material, by adding the metal organic framework MOF(Fe) material into the cigarette filter tip, the contents of harmful ingredients such as ammonia and benzo[a]pyrene in cigarette mainstream smoke can be effectively decreased; the environmental friendliness is achieved and the safety to a human body after the material is added into the cigarette is ensured. Meanwhile, the metal organic framework MOF(Fe) material has super-strong adsorption capacity to organic dye pollutants and is worthy of popularization and application.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

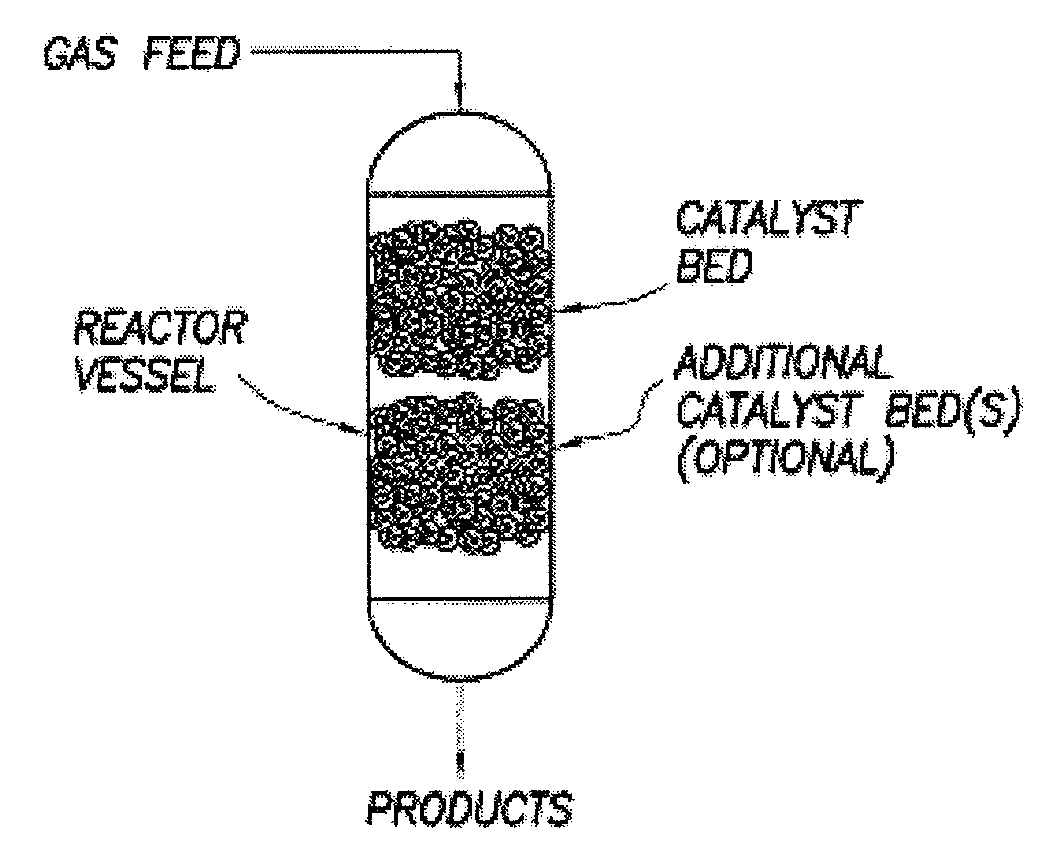

Catalyst composition and method of controlling PFC and HFC emissions

The present invention relates to a catalytic process for the destruction of PFC's and HFC's using a catalyst which comprises aluminum oxide that has preferably been stabilized through the addition of a stabilizing agent (such as, titanium, zirconium, or cobalt, or mixtures of these elements). The addition of these elements to the aluminum oxide unexpectedly enhances the catalyst's stability without significantly altering its reactivity. The total amount of stabilizing agent added to the catalyst can be as low as 0.005 parts (by weight) stabilizing agent per part (by weight) aluminum oxide (Al2O3) or as great as 2 or more parts (by weight) stabilizing agent per part (by weight) aluminum oxide; so long as there is sufficient aluminum oxide available to effectively catalyze the destruction of the target PFC's and / or HFC's. An oxidizing agent, such as, for example, platinum, palladium, rhodium, iridium, silver, nickel, copper, iron, vanadium, and / or cerium, may be added to the catalyst to effectively convert any carbon monoxide to carbon dioxide.

Owner:GUILD ASSOCS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com