Patents

Literature

377results about "Ammonium nitrates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biochar

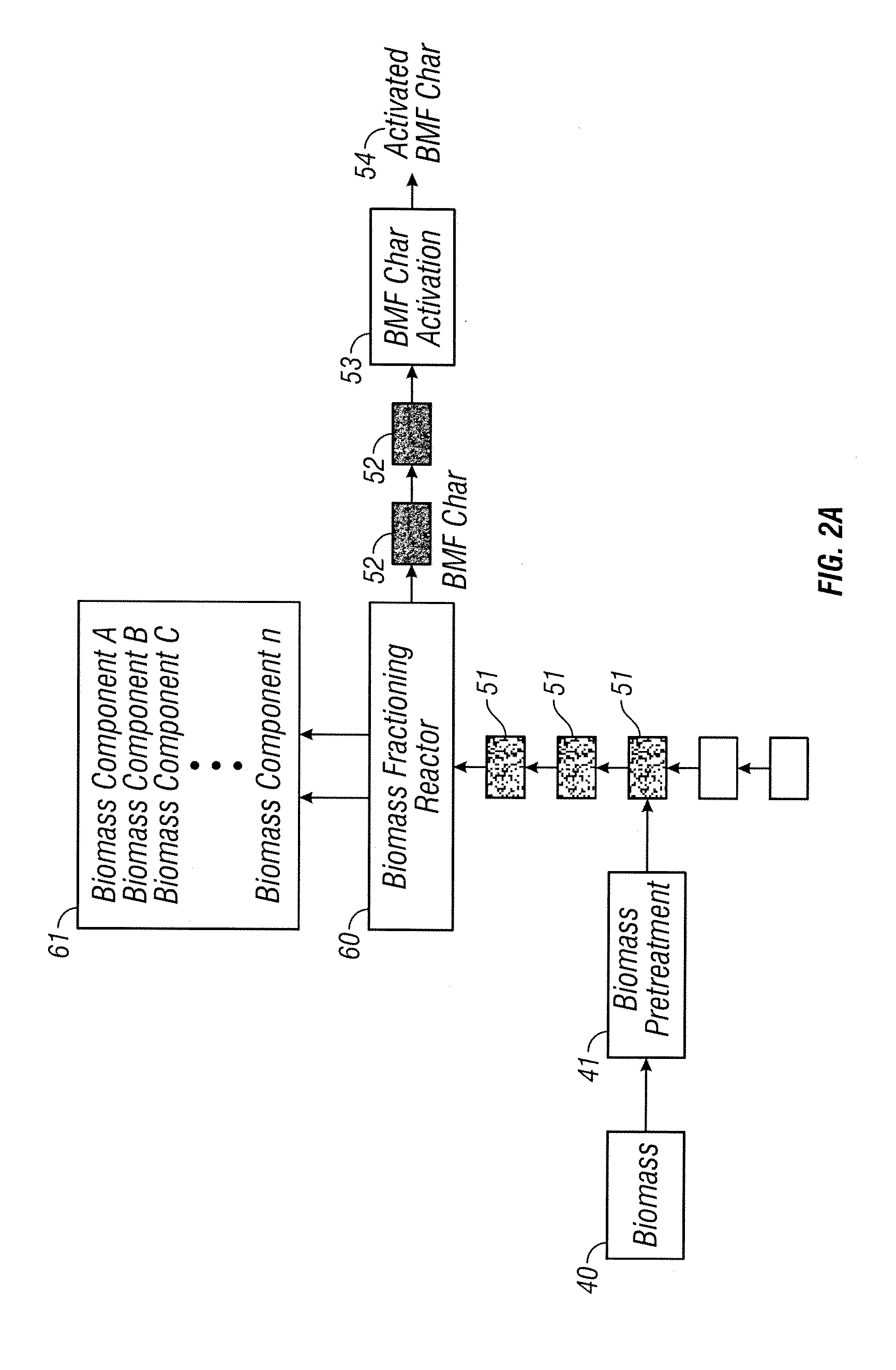

ActiveUS8361186B1Enhanced and functionalizedCalcareous fertilisersMagnesium fertilisersForming gasBiological activation

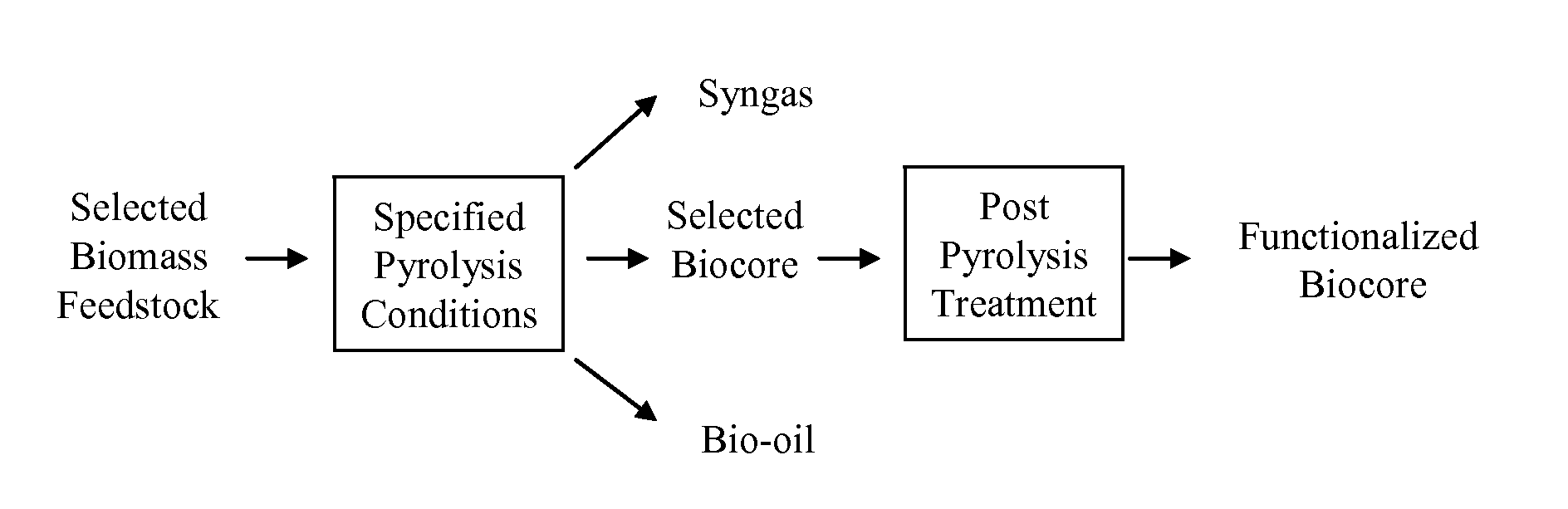

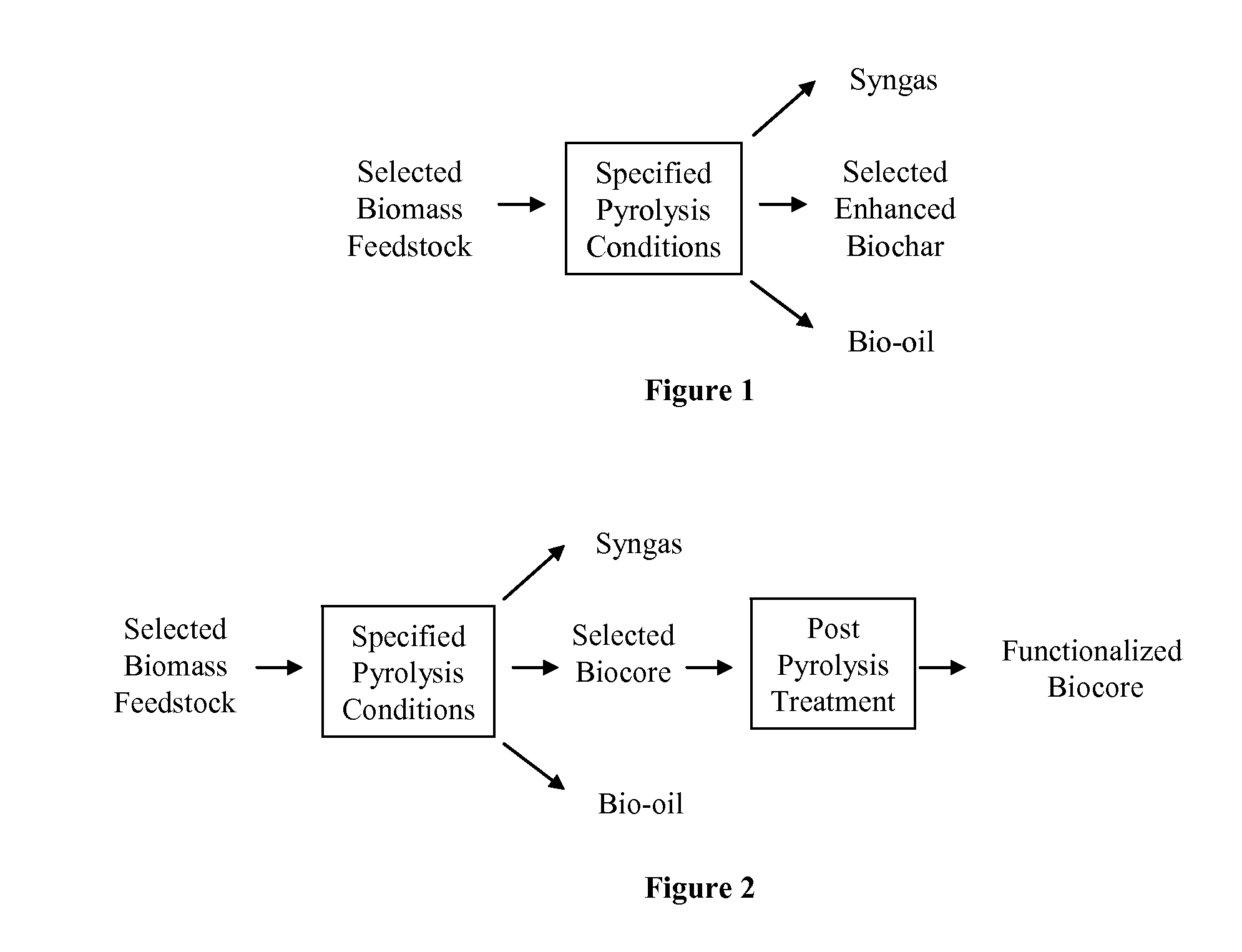

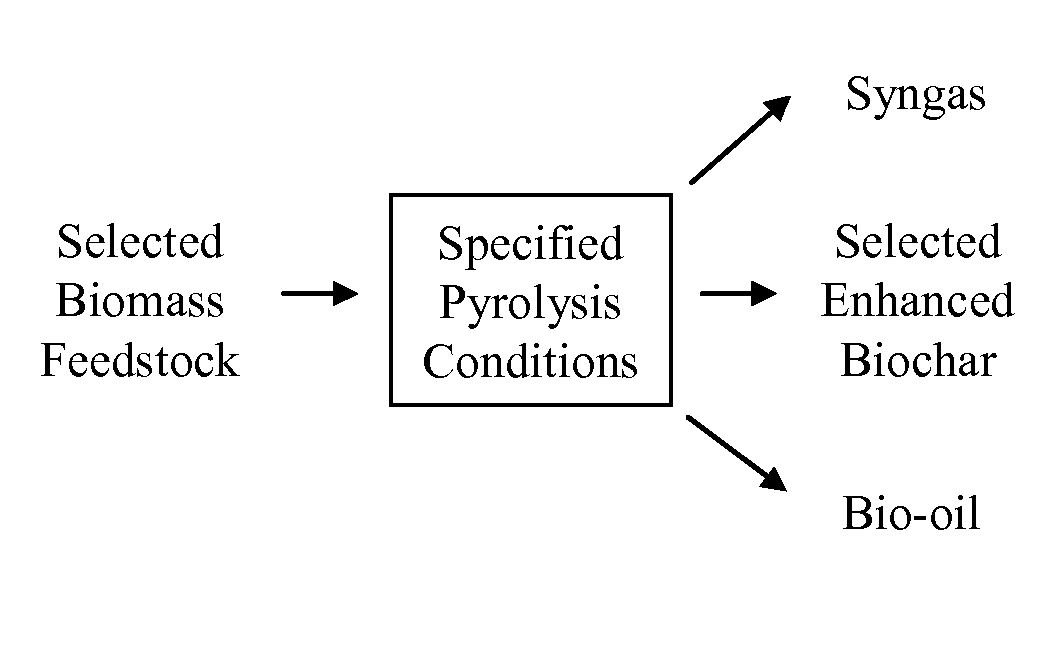

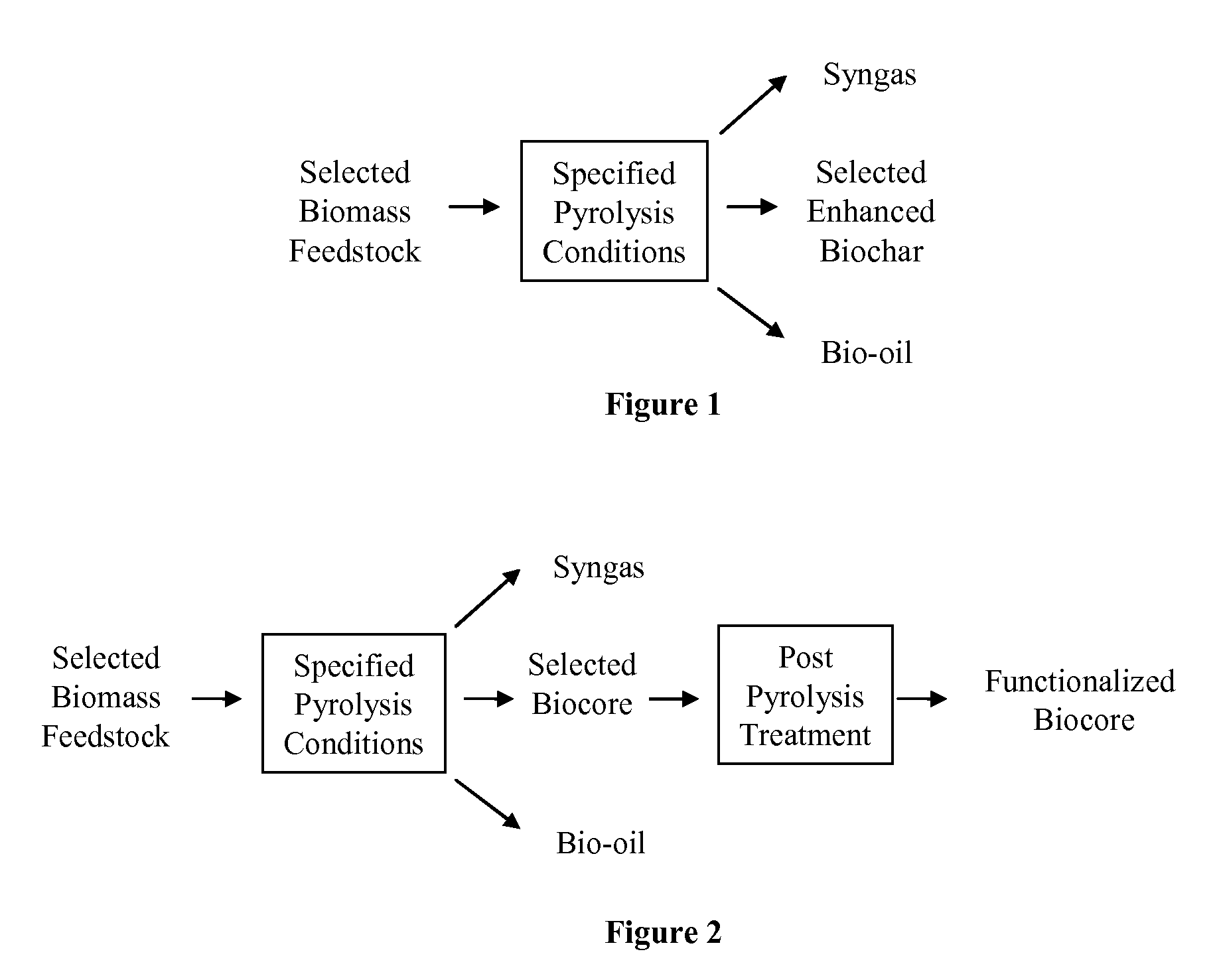

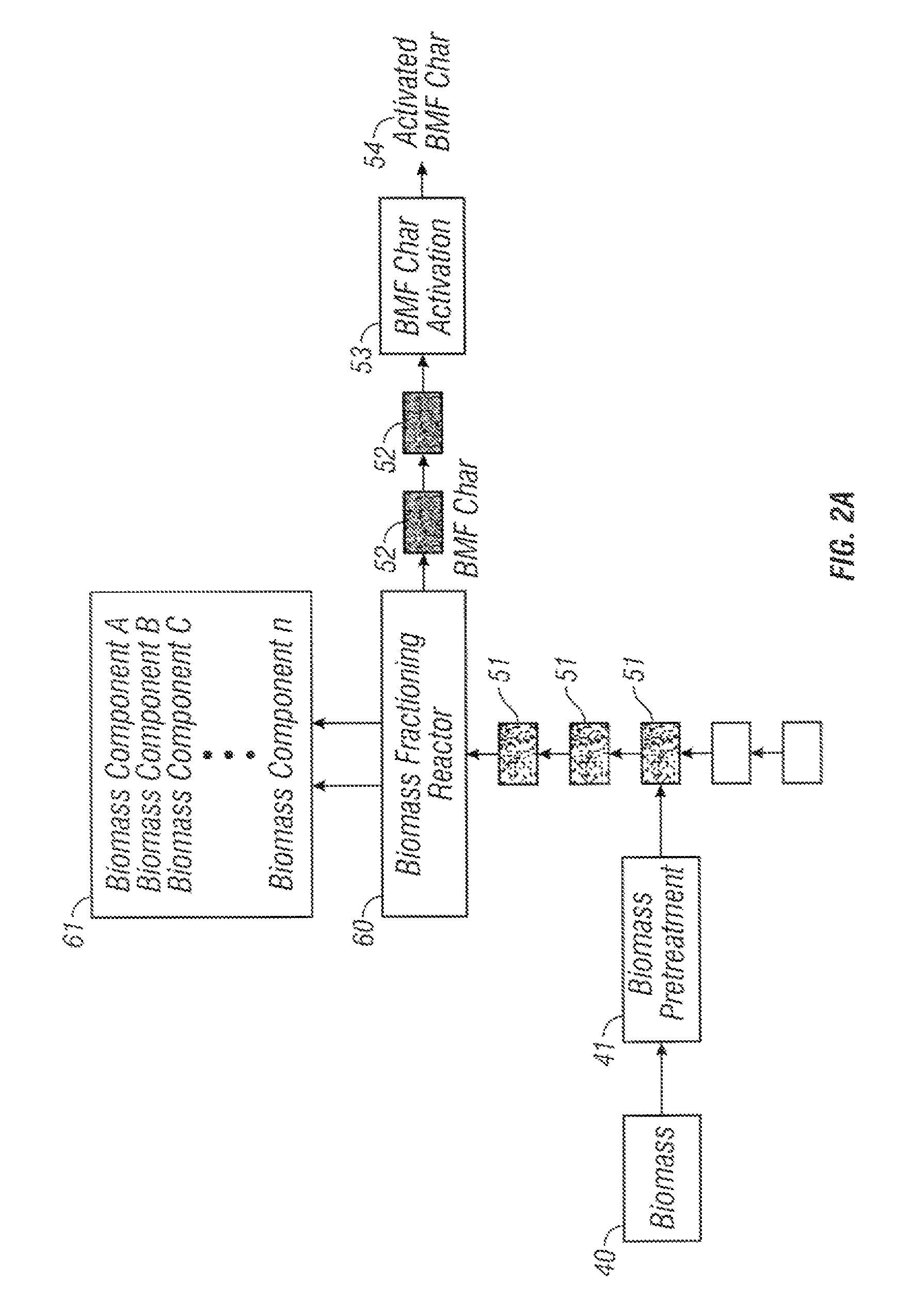

The invention provides for methods, devices, and systems for pyrolyzing biomass. A pyrolysis unit can be used for the pyrolysis of biomass to form gas, liquid, and solid products. The biomass materials can be selected such that an enhanced biochar is formed after pyrolysis. The biomass can be pyrolyzed under specified conditions such that a selected biochar core is formed. The pyrolysis process can form a stable biochar core that is inert and / or resistant to degradation. The biochar or biochar core can be functionalized to form a functionalized biochar or functionalized biochar core. Functionalization can include post-pyrolysis treatments such as supplementation with microbes or physical transformations including annealing and / or activation.

Owner:FULL CIRCLE BIOCHAR

Biochar Production Method and Composition Therefrom

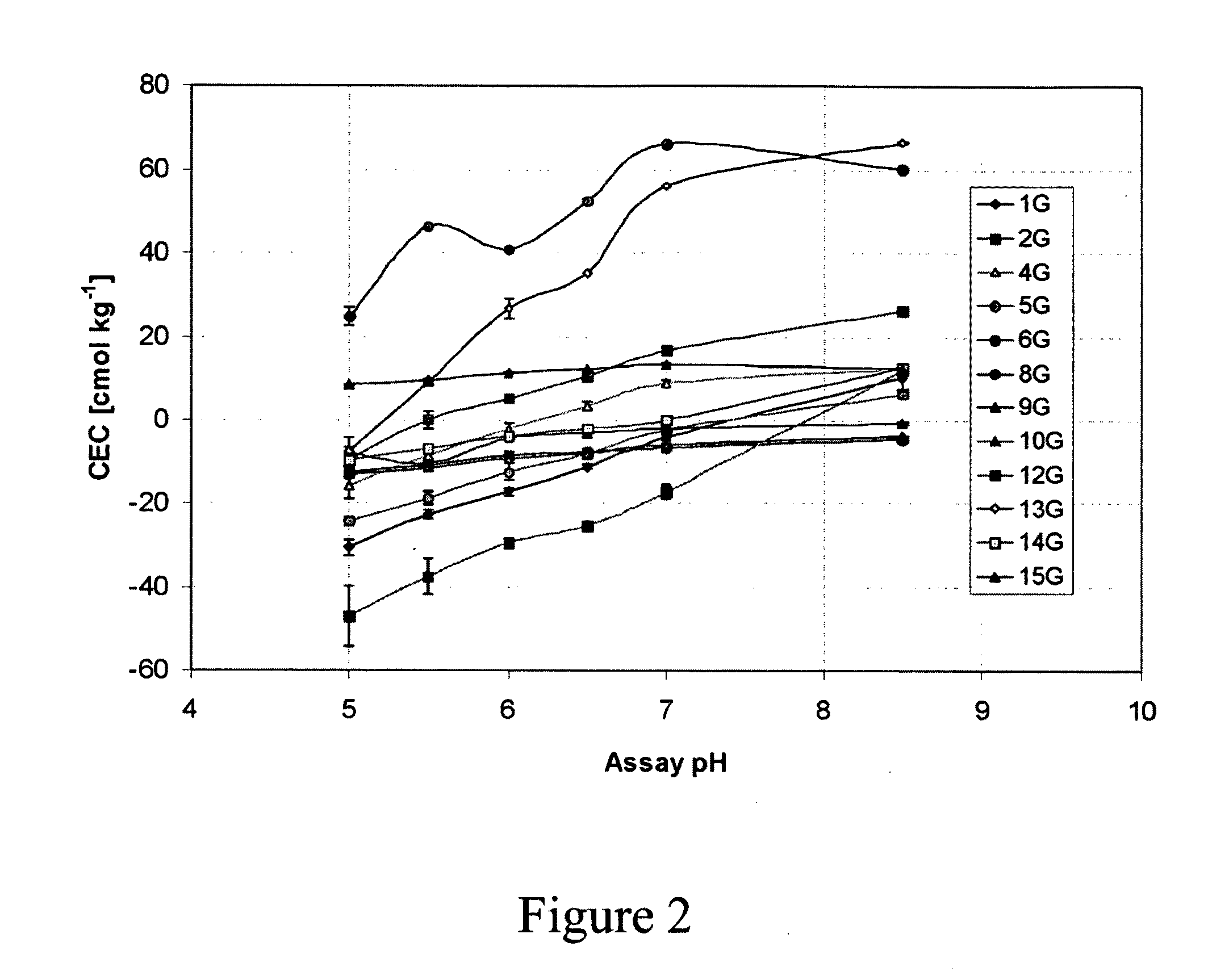

InactiveUS20110172092A1Low batch-to-batchMany of characteristicAmmonium nitratesCarbon compoundsIon exchangeOxygen

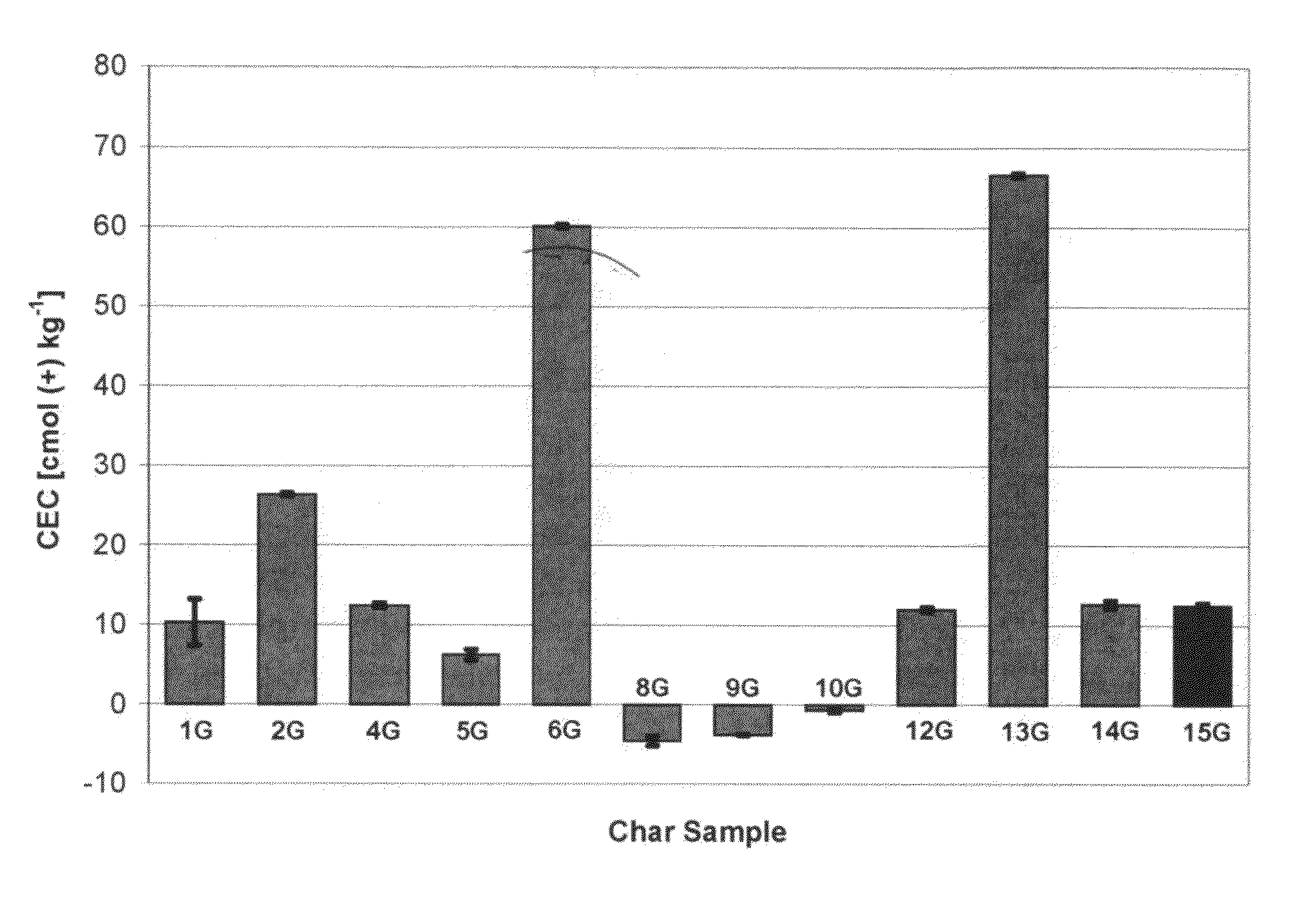

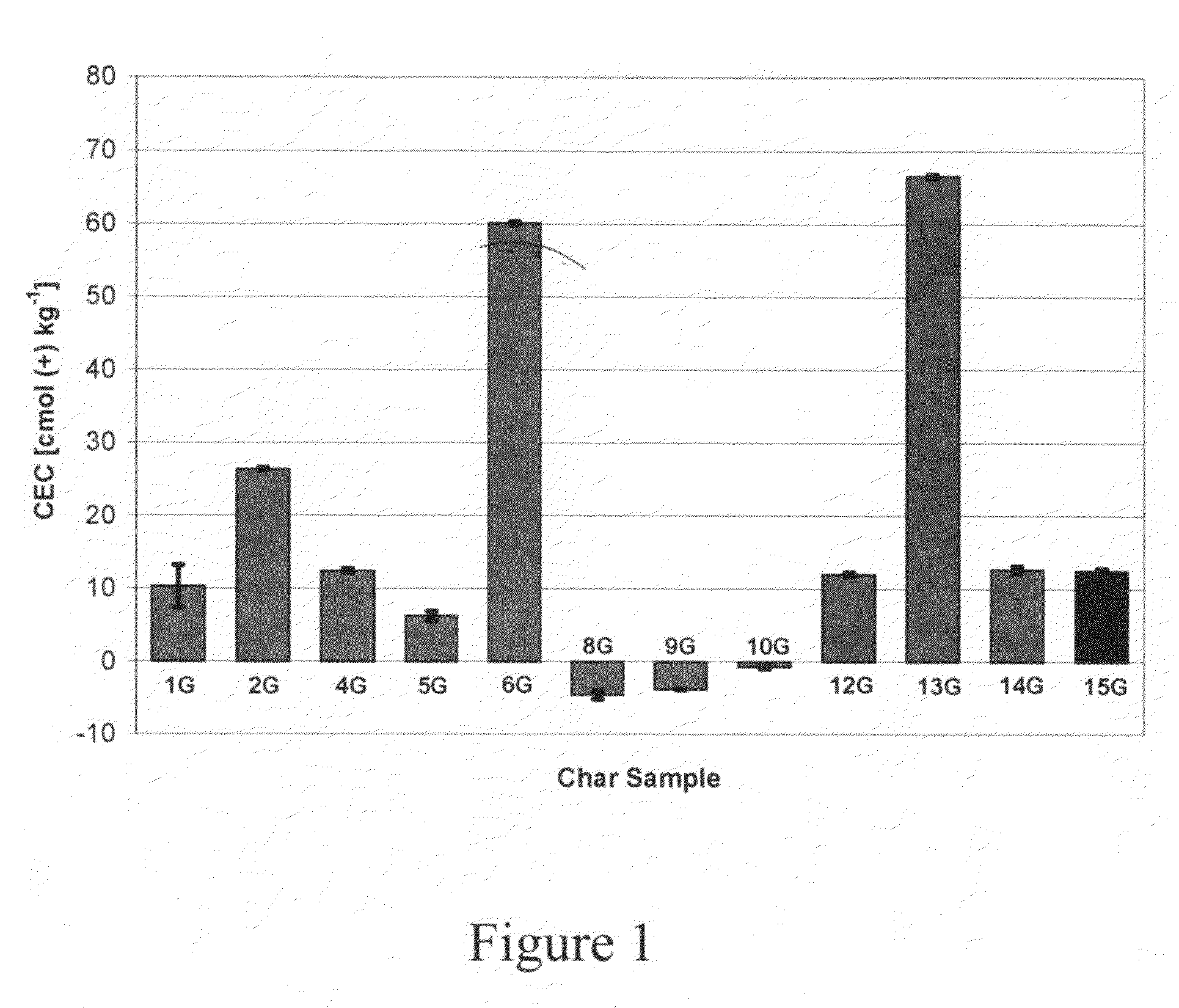

The invention is directed to a method for producing an oxygenated biochar material possessing a cation-exchanging property, wherein a biochar source is reacted with one or more oxygenating compounds in such a manner that the biochar source homogeneously acquires oxygen-containing cation-exchanging groups in an incomplete combustion process. The invention is also directed to oxygenated biochar compositions and soil formulations containing the oxygenated biochar material.

Owner:UT BATTELLE LLC

Precipitated aragonite and a process for producing it

InactiveUS20030213937A1Less expensiveEfficient and less-expensiveCalcium/strontium/barium carbonatesInorganic/elemental detergent compounding agentsParticulatesAragonite

Disclosed is a novel form of particulate precipitated aragonite, and a novel process for producing it.

Owner:3P TECH

Controlled release fertilizer composition

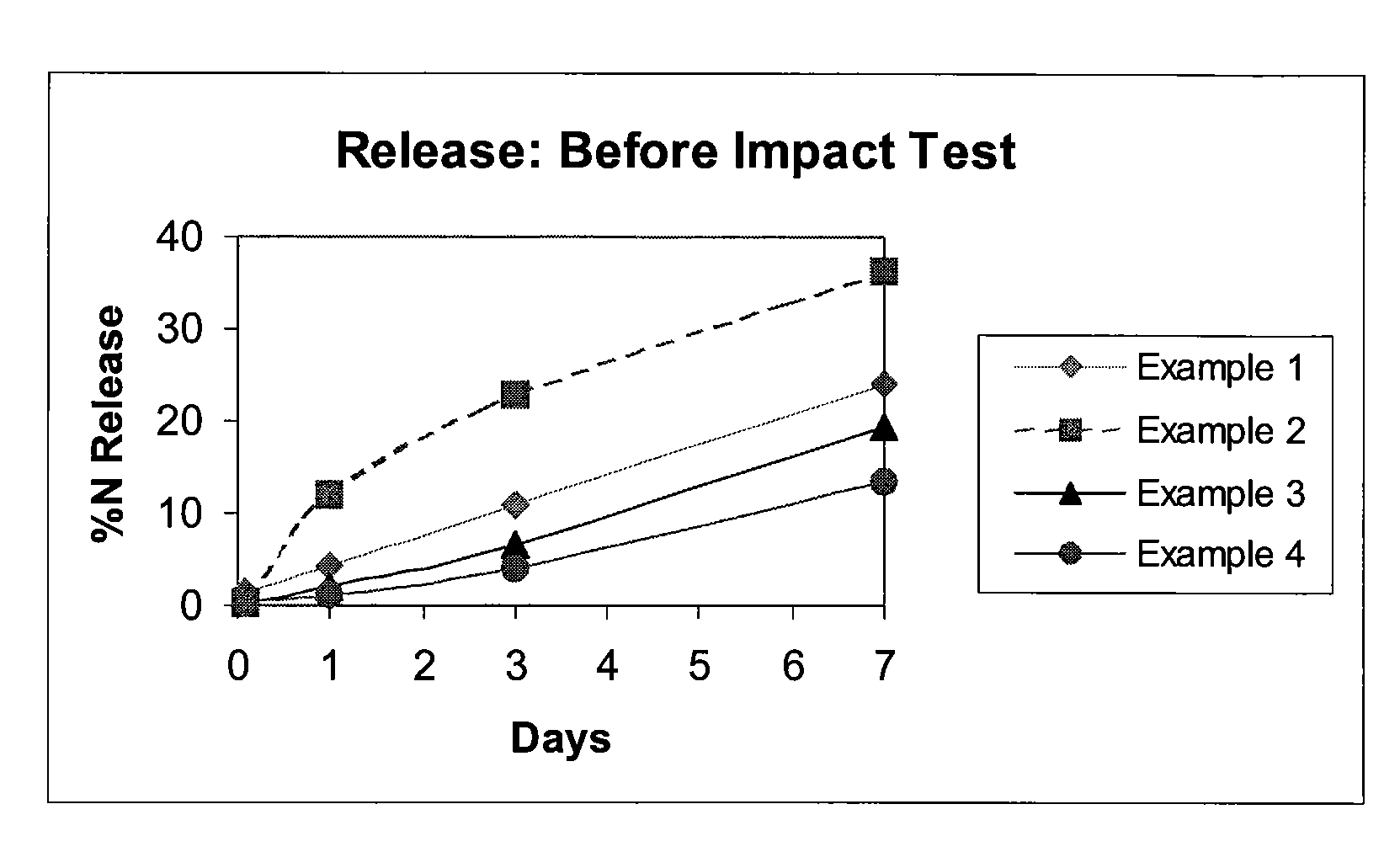

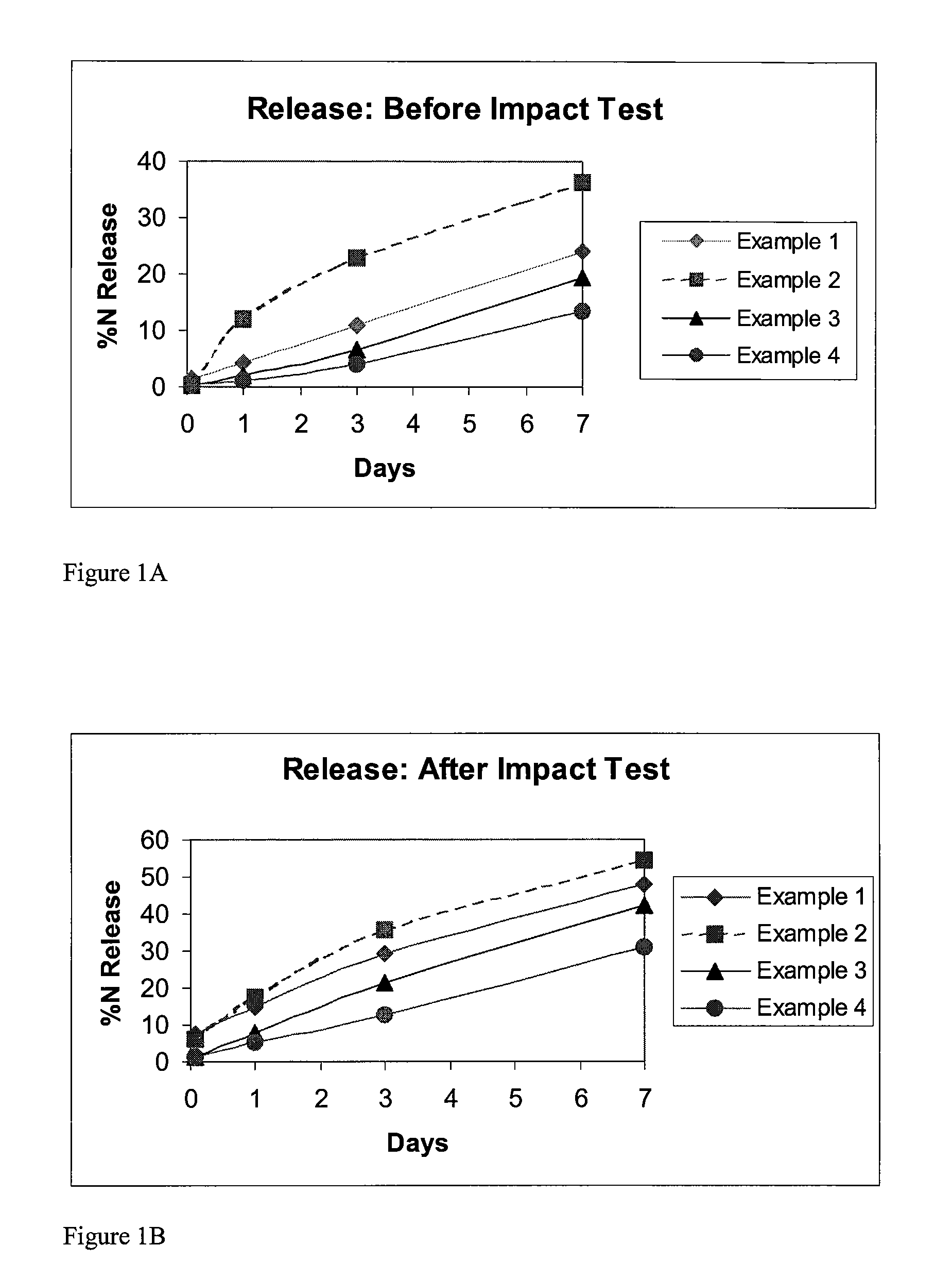

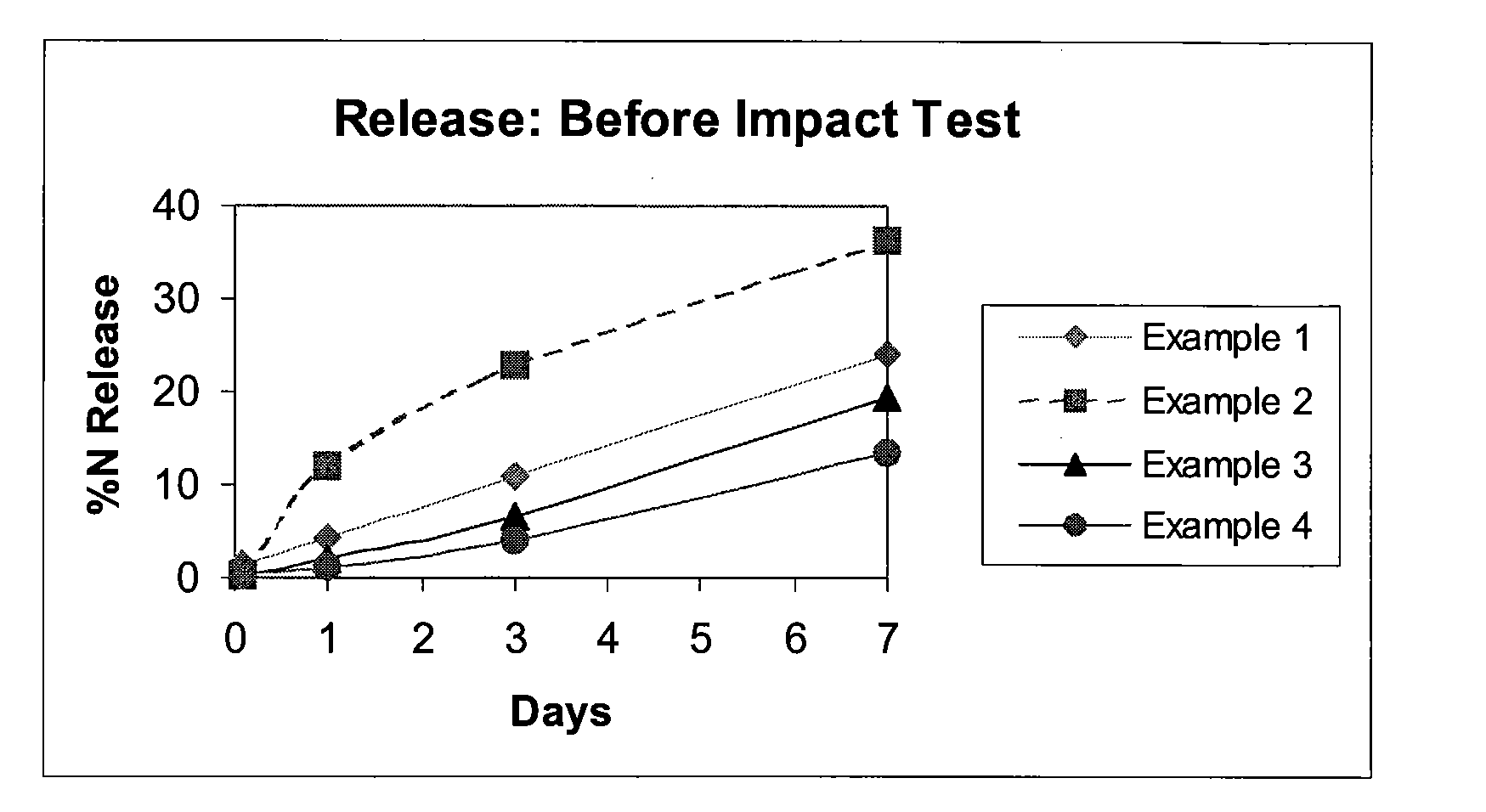

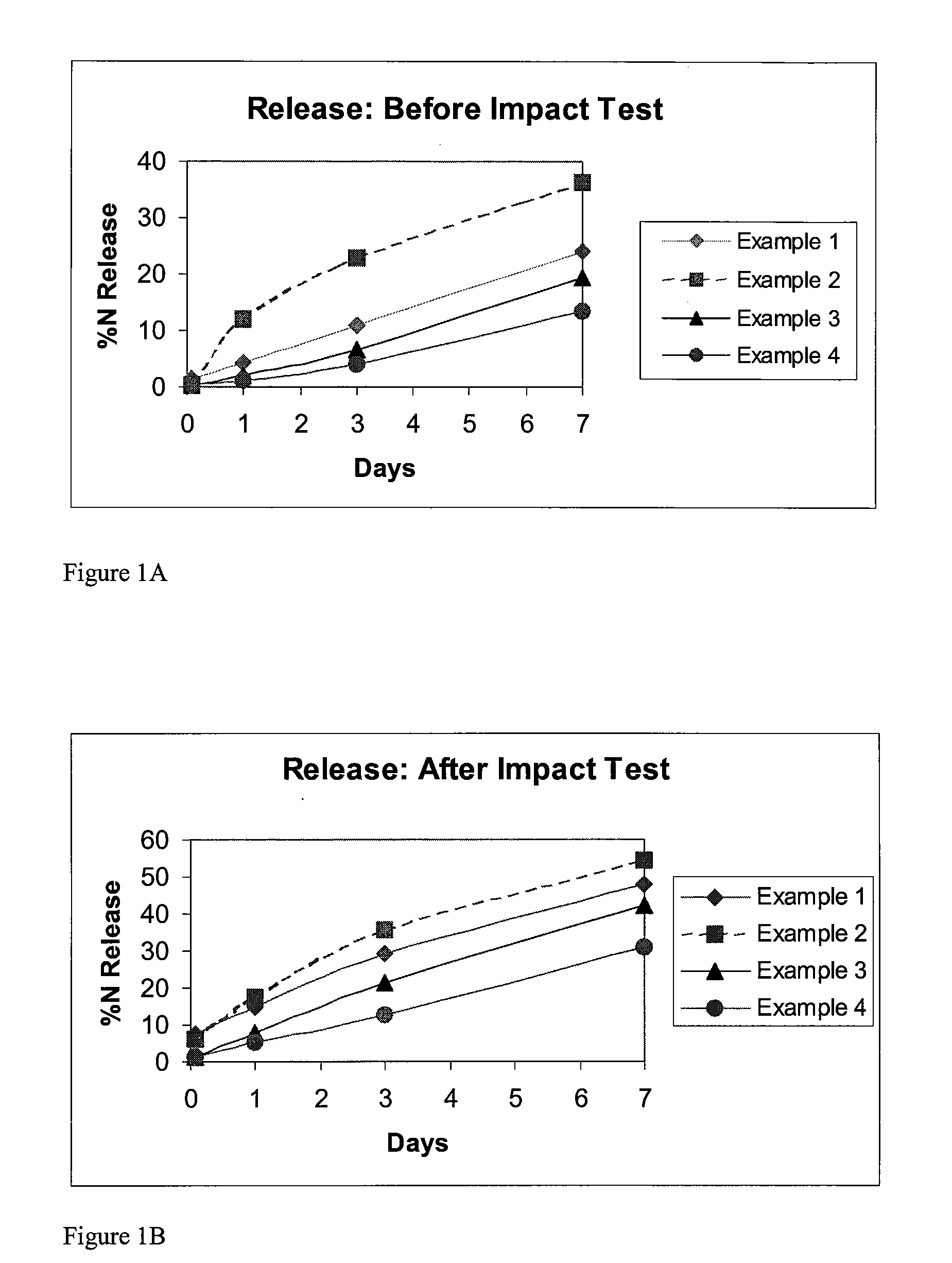

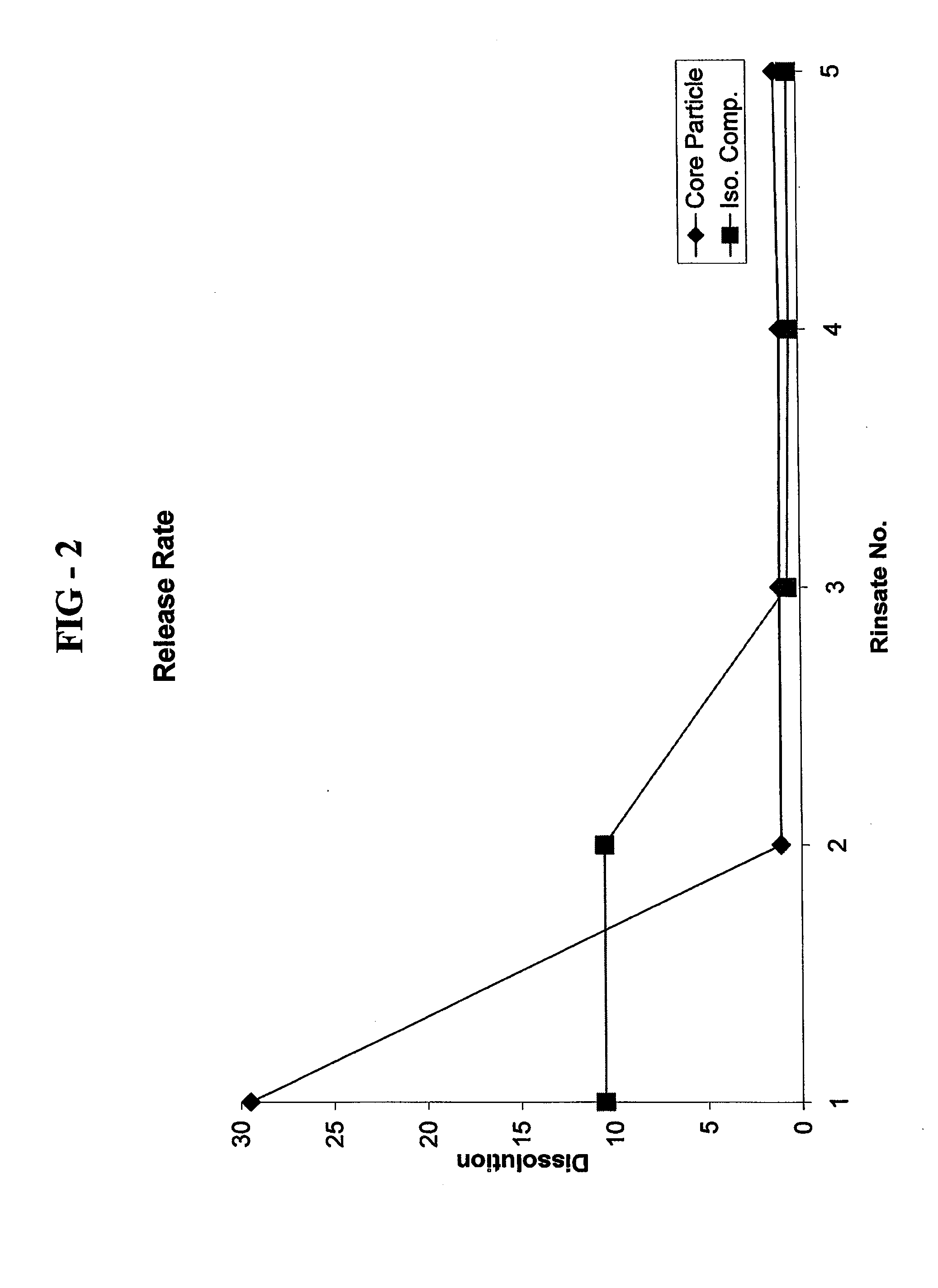

ActiveUS7771505B2Reduce manufacturing costReduce the amount requiredBiocideOrganic phosphatic fertilisersControlled releaseWater insoluble

A controlled release fertilizer composition and methods to produce the controlled release fertilizer composition are described. The controlled release fertilizer composition comprises a water soluble fertilizer core that is coated with a polymeric layer, intermediate layer, and a sulfur layer. If desired, the sulfur layer can be coated with an outer water-insoluble layer.

Owner:KOCH AGRONOMIC SERVICES LLC

Biochar

The invention provides for methods, devices, and systems for pyrolyzing biomass. A pyrolysis unit can be used for the pyrolysis of biomass to form gas, liquid, and solid products. The biomass materials can be selected such that an enhanced biochar is formed after pyrolysis. The biomass can be pyrolyzed under specified conditions such that a selected biochar core is formed. The pyrolysis process can form a stable biochar core that is inert and / or resistant to degradation. The biochar or biochar core can be functionalized to form a functionalized biochar or functionalized biochar core. Functionalization can include post-pyrolysis treatments such as supplementation with microbes or physical transformations including annealing and / or activation.

Owner:FULL CIRCLE BIOCHAR

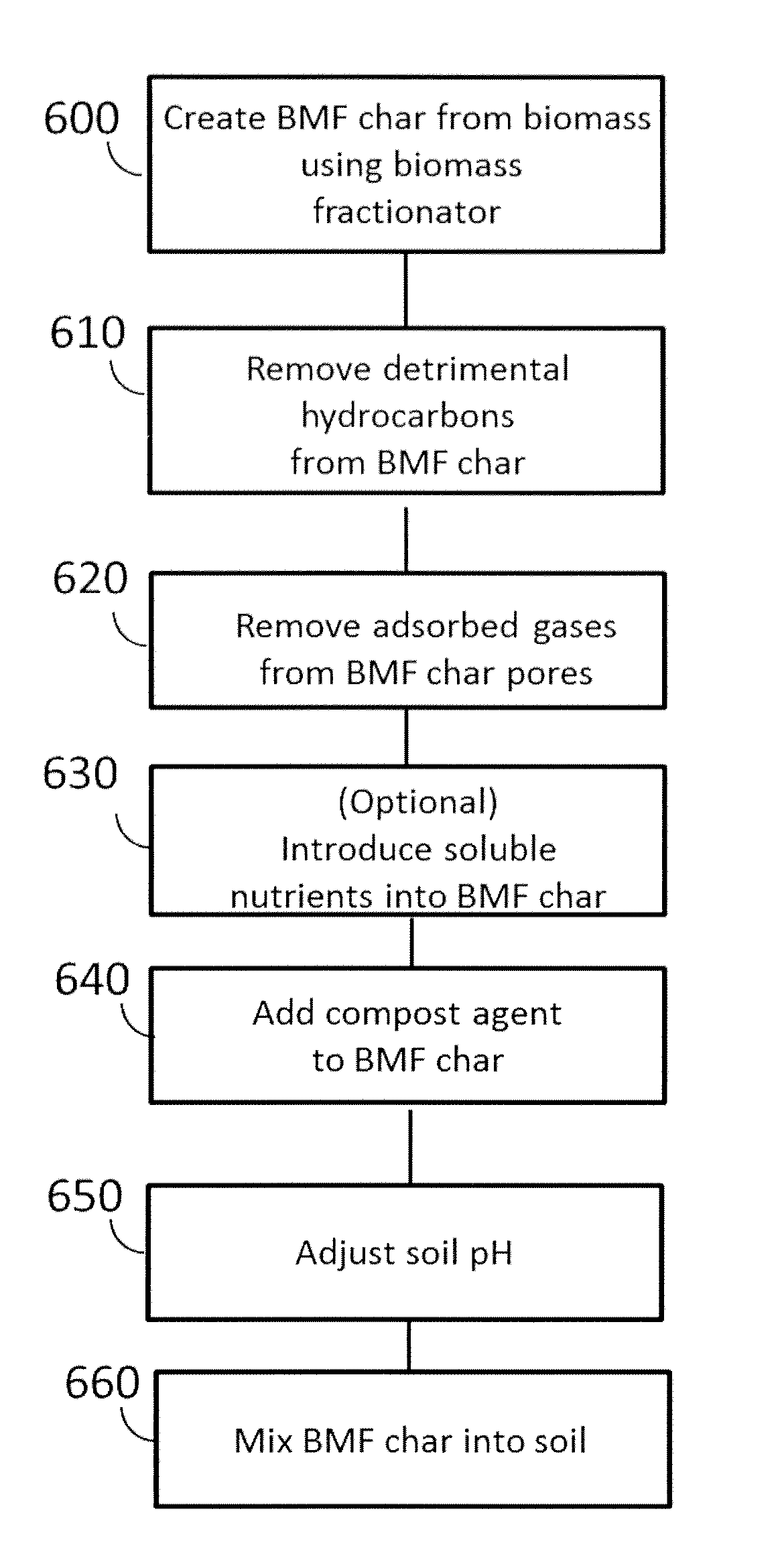

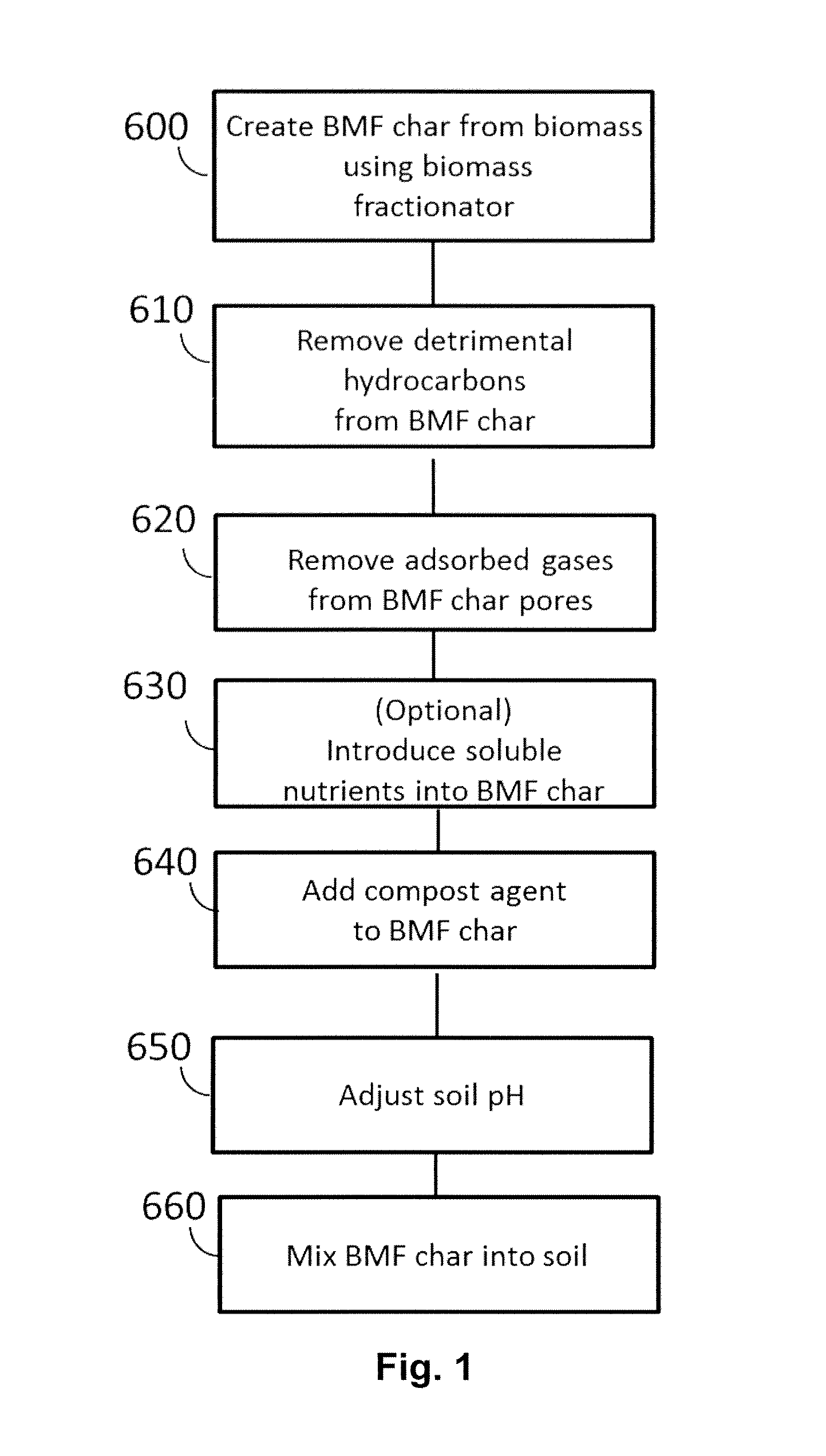

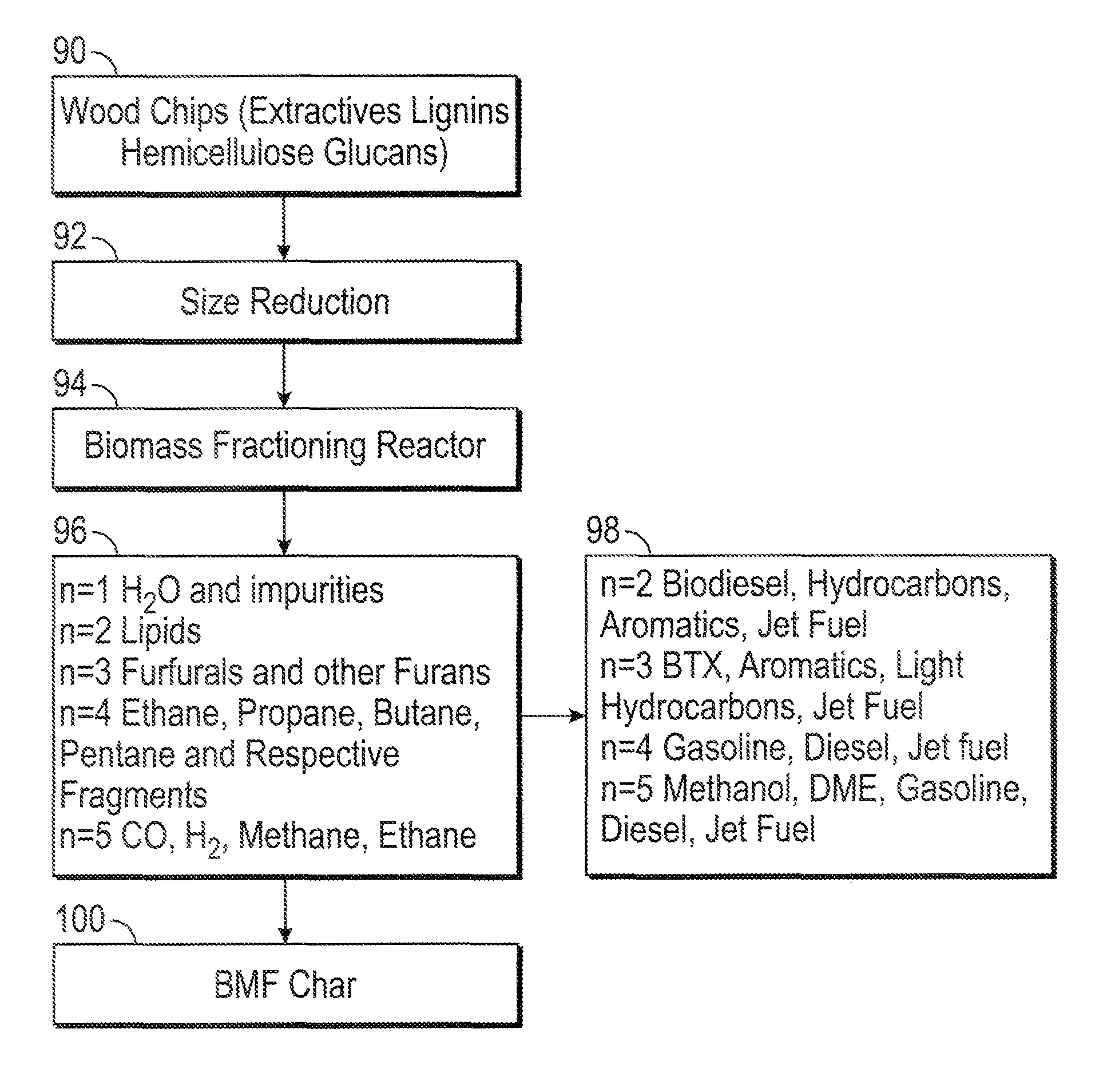

Method for enhancing soil growth using bio-char

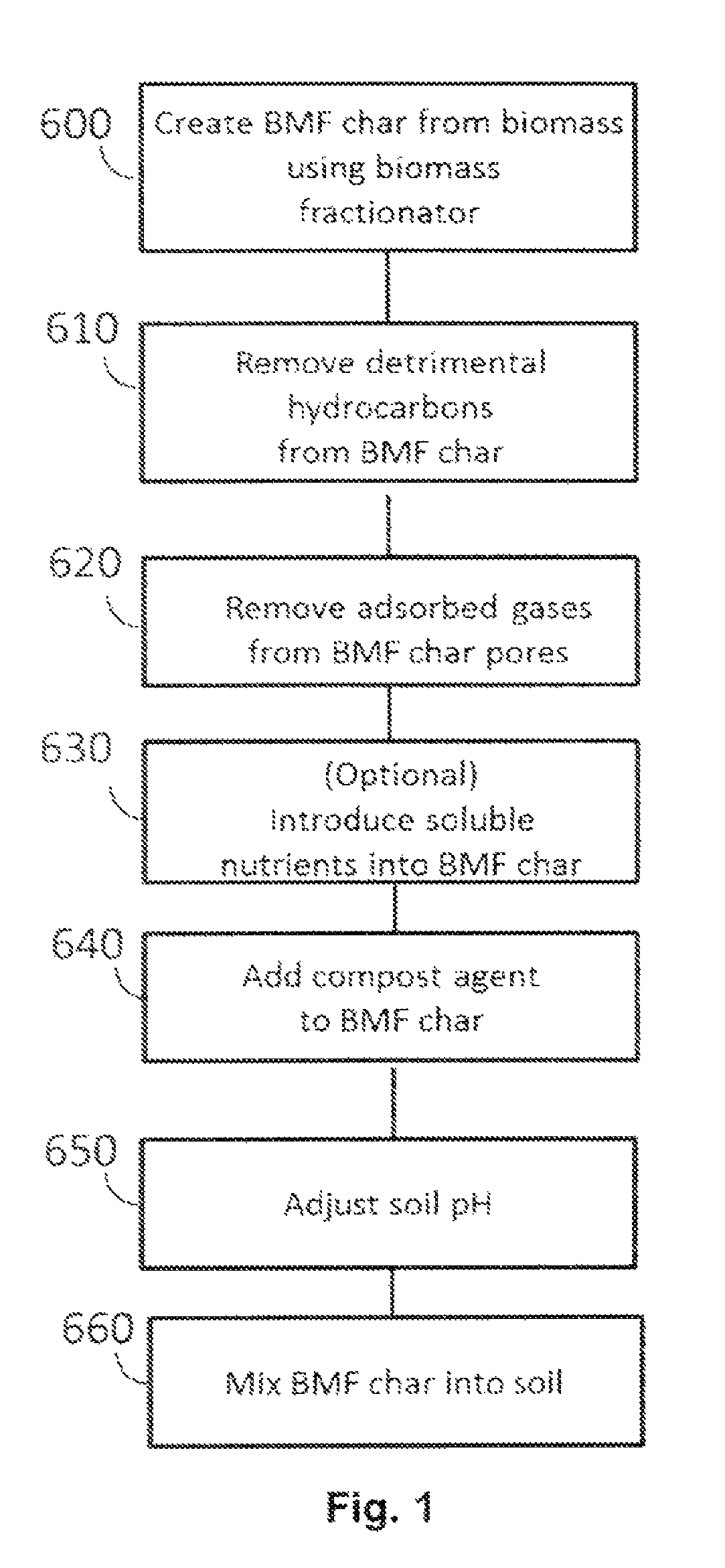

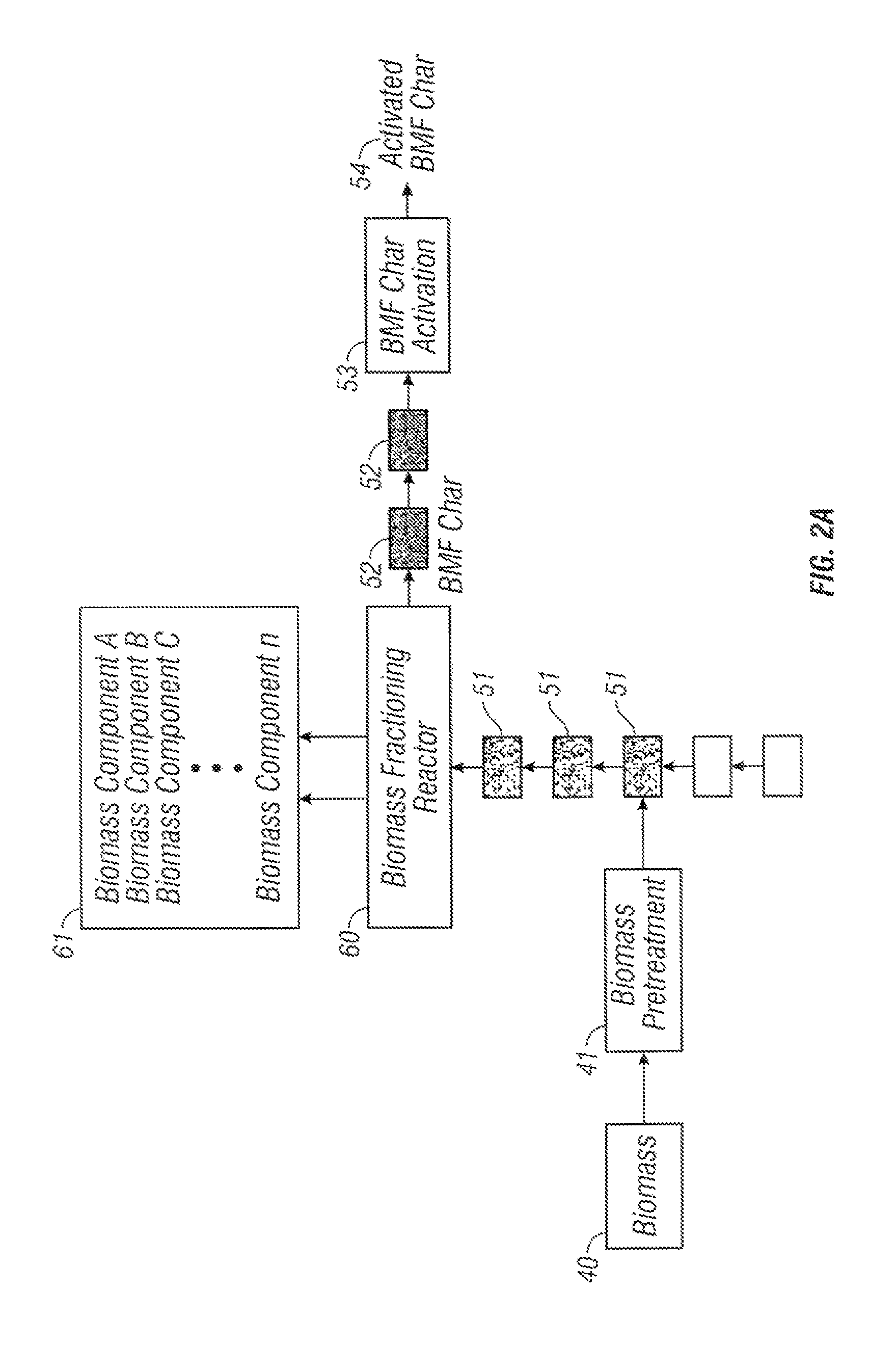

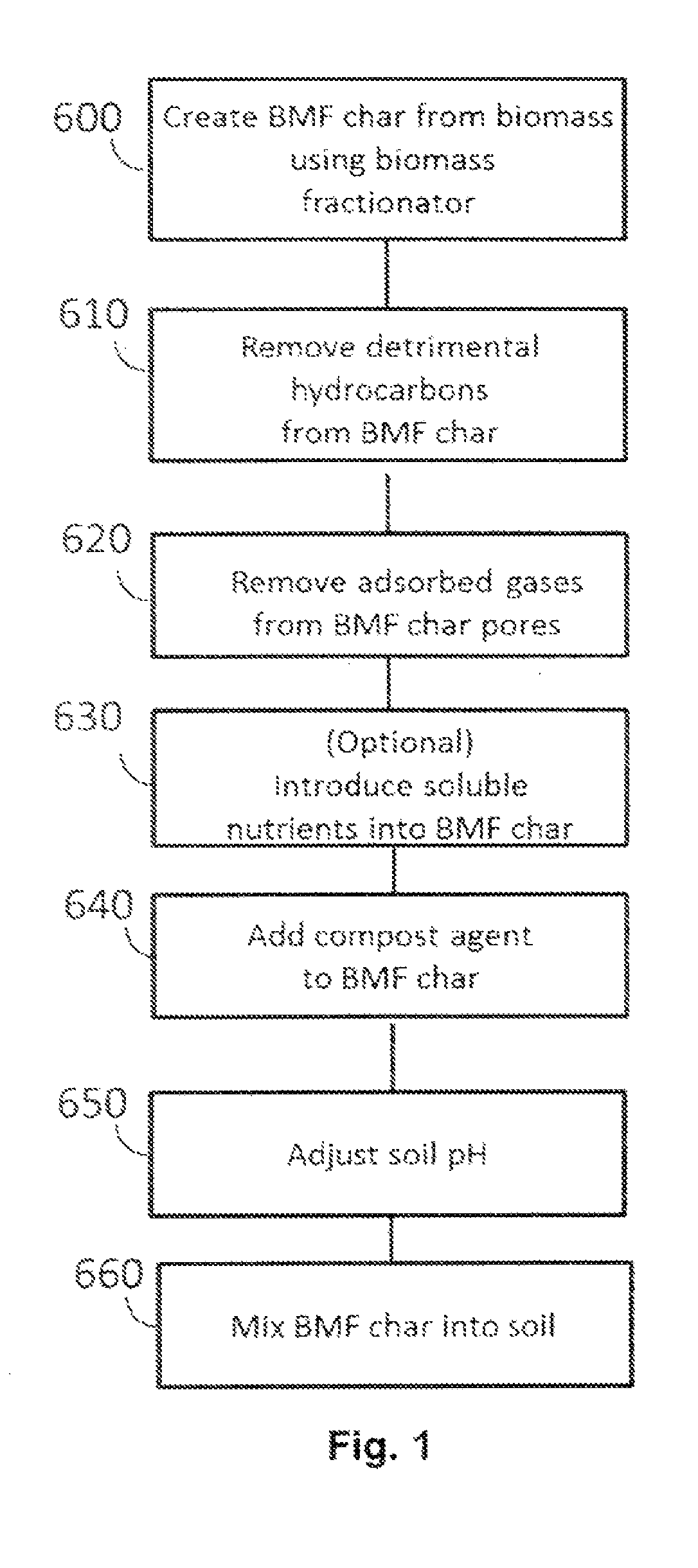

ActiveUS8317891B1Improve thermal conductivityLow densityFungiBacteriaMicroorganismHigh concentration

A method is described for rendering char from a biomass fractionator apparatus (BMF char) suitable for addition to soil in high concentrations, the method relying on multiple processes comprising removing detrimental hydrocarbons from BMF char, removing adsorbed gases from BMF char, introducing microorganisms to the BMF char, and adjusting soil pH.

Owner:CARBON TECH HLDG LLC

Method for enhancing soil growth using bio-char

ActiveUS8236085B1Improve thermal conductivityLow densityFungiBacteriaMicroorganismHigh concentration

A method is described for rendering char from a biomass fractionator apparatus (BMF char) suitable for addition to soil in high concentrations, the method relying on multiple processes comprising removing detrimental hydrocarbons from BMF char, removing adsorbed gases from BMF char, introducing microorganisms to the BMF char, and adjusting soil pH.

Owner:CARBON TECH HLDG LLC

Acicular calcite and aragonite calcium carbonate

InactiveUS6022517AReduce conductivityIncrease production costCalcium/strontium/barium carbonatesAmmonium nitratesToothpasteCalcite

The present invention relates to a calcium carbonate composition having both calcite and aragonite crystalline morphology. More particularly, the present invention relates to an acicular calcite and an acicular aragonite product and a method for the production of the same and the use of such as fillers, additives and modifiers of consumer and commercial products such as toothpaste, paper, plastics and sealants. The acicular calcite / aragonite composition of the present invention provides a balance of properties such as sheet bulk, strength, stiffness, and sizing, when employed as a filler for paper. As a coating pigment, the acicular calcite / aragonite product of the present invention provides gloss characteristics suitable for dull and matte grades of low gloss coated paper. Upon further processing such as milling, grinding, or other means of comminution, the resulting product provides gloss characteristics suitable for high gloss coated paper. For paint formulations, the acicular calcite / aragonite composition of the present invention provides properties such as low sheen and high contrast ratio. As an additive in polymers, the acicular calcite / aragonite product of the present invention imparts reinforcing properties, rigidity, and impact strength, including sealant applications.

Owner:MINERALS TECH

Liquid composition containing phosphoric or thiophosphoric triamide derivative and use thereof

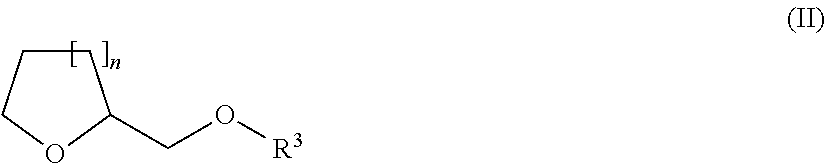

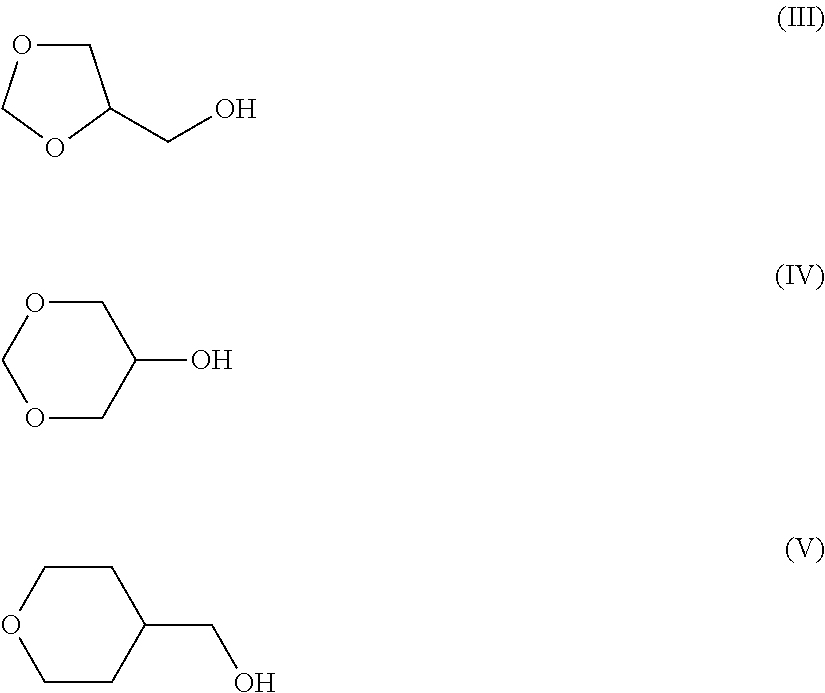

ActiveUS20110233474A1Improve stabilityIncrease concentrationCosmetic preparationsAmmonium nitratesPhosphoric acidSolvent

The invention relates to a liquid composition containing phosphoric or thiophosphoric triamide derivatives and suitable solvents selected from the group comprising esters of hydroxyacids, heterocyclic alcohols and their derivatives, cyclic carbonic acid esters and dicarboxyacid esters, optionally the composition may also contain glycol ethers and auxiliary substances. The invention further includes the use of this liquid composition as urease inhibitor in urea-containing fertilizers, in fertilizers and wastes of animal origin or in sprays masking animal urine odours.

Owner:AGRA GROUP AS

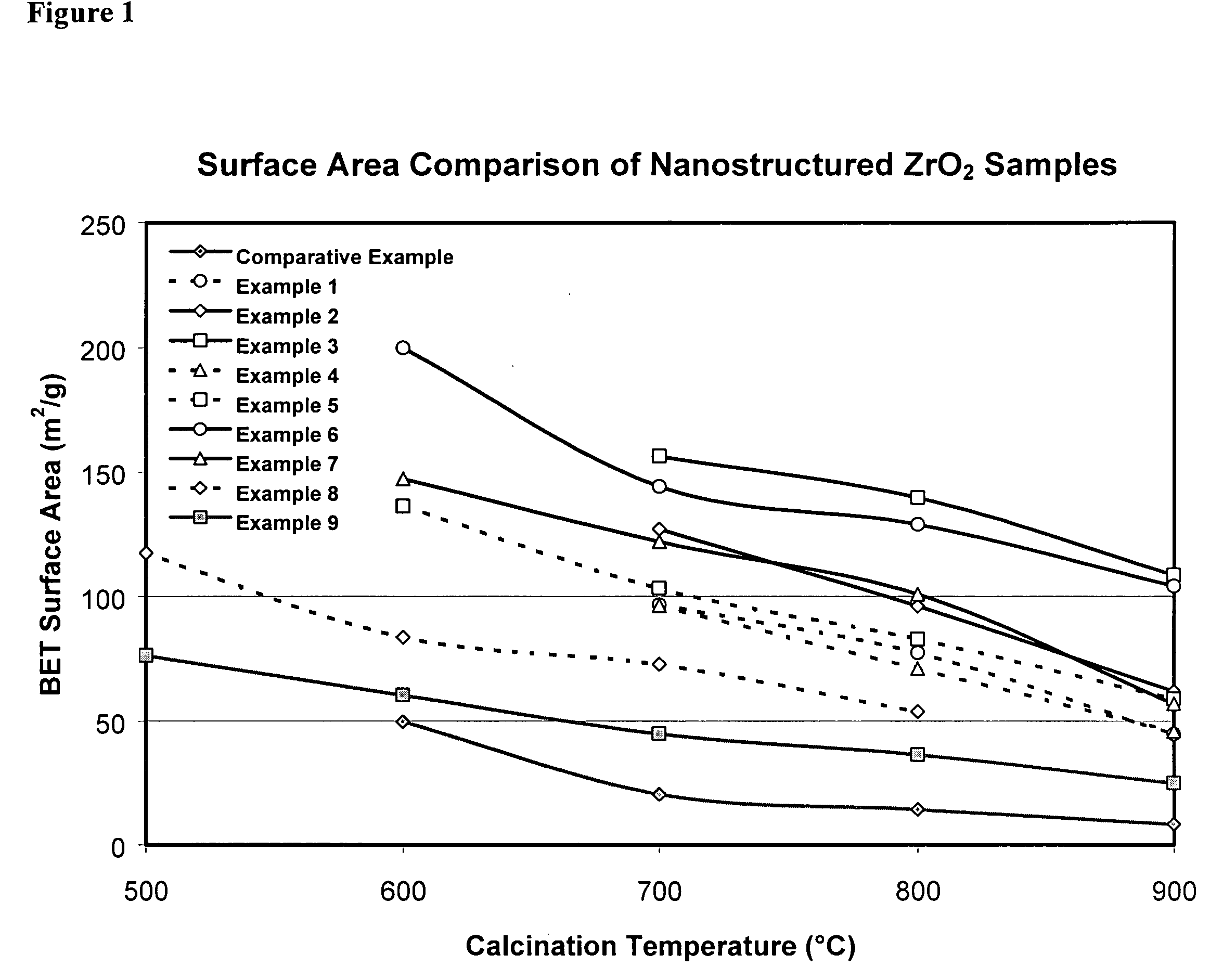

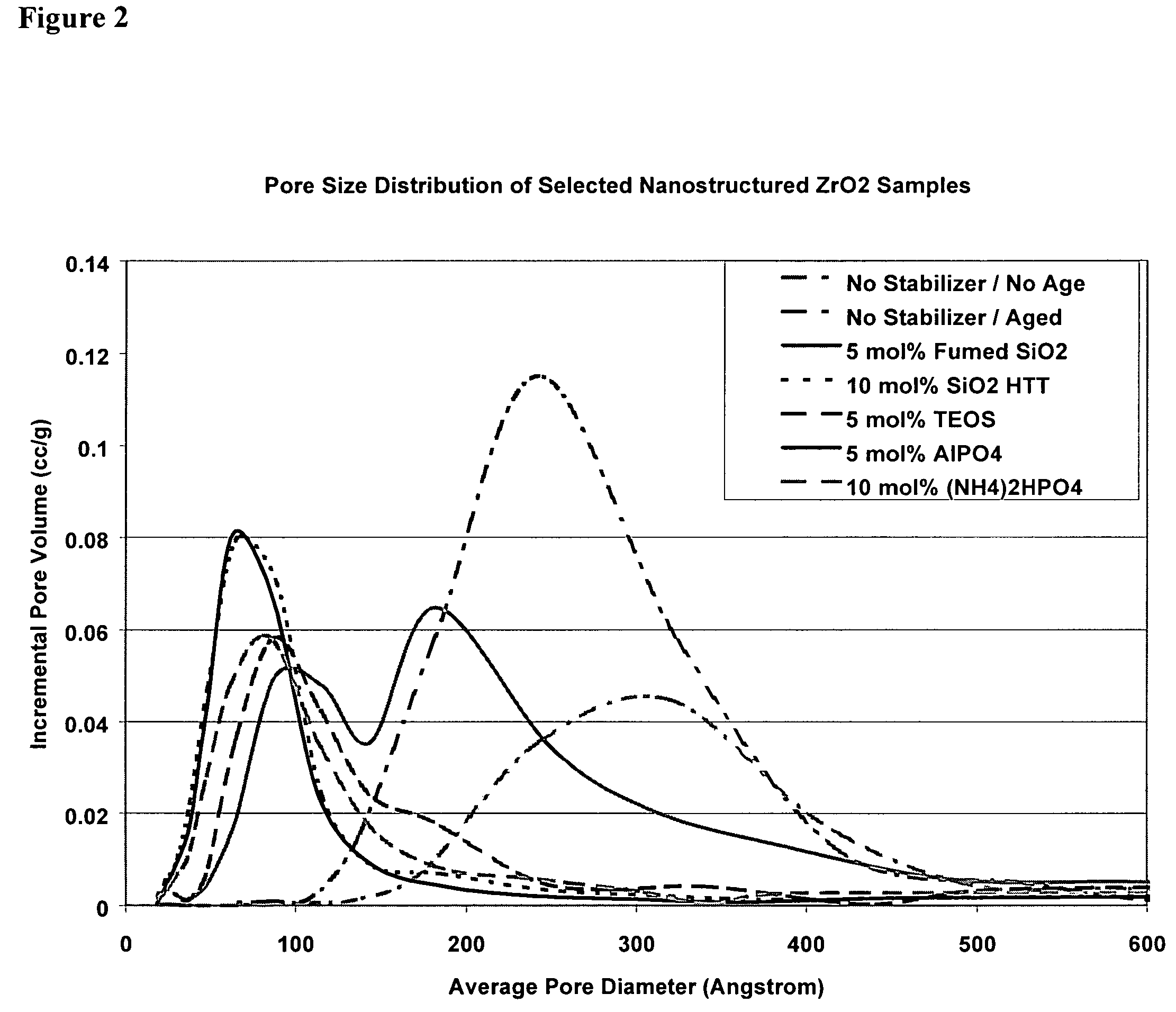

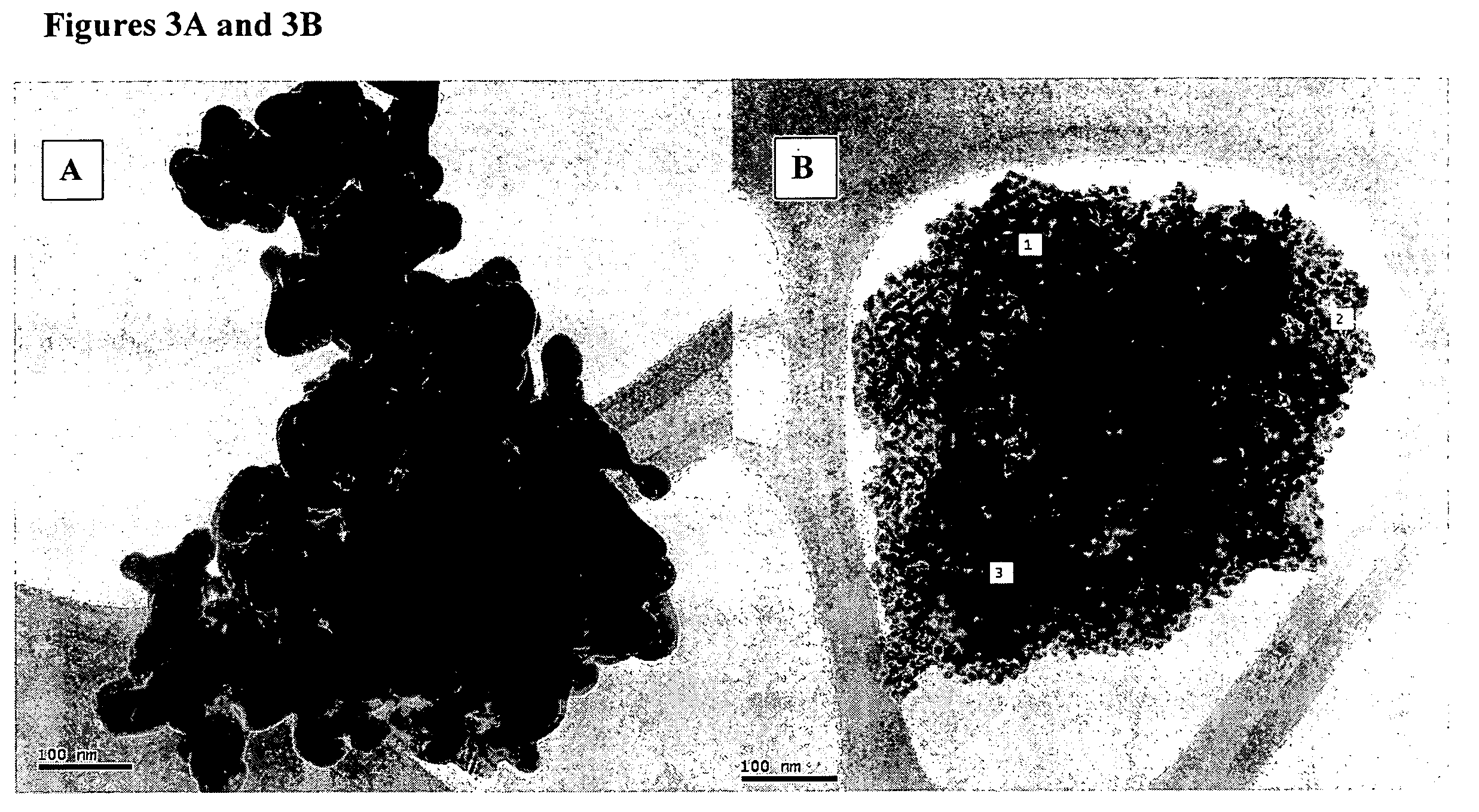

Nano-structured particles with high thermal stability

ActiveUS20050175525A1Large specific surface areaImprove thermal stabilityMaterial nanotechnologyNanostructure manufactureNanoparticleThermal stability

The present invention is directed to producing nano-structured particles that have high specific surface-areas and high thermal stability. By aging nanoparticle precursors, and processing them under appropriate conditions, one is able to generate nano-structured particles that may be used in catalysts. By adding a stabilizing agent one is able to further improve the high thermal stability. These nano-structured particle products are particularly advantageous in applications as catalysts or catalyst supports that operate at high temperatures.

Owner:TRONOX LLC

Method for enhancing soil growth using bio-char

ActiveUS8317892B1Improve thermal conductivityLow densityFungiBacteriaMicroorganismHigh concentration

A method is described for rendering char from a biomass fractionator apparatus (BMF char) suitable for addition to soil in high concentrations, the method relying on multiple processes comprising removing detrimental hydrocarbons from BMF char, removing adsorbed gases from BMF char, introducing microorganisms to the BMF char, and adjusting soil pH.

Owner:CARBON TECH HLDG LLC

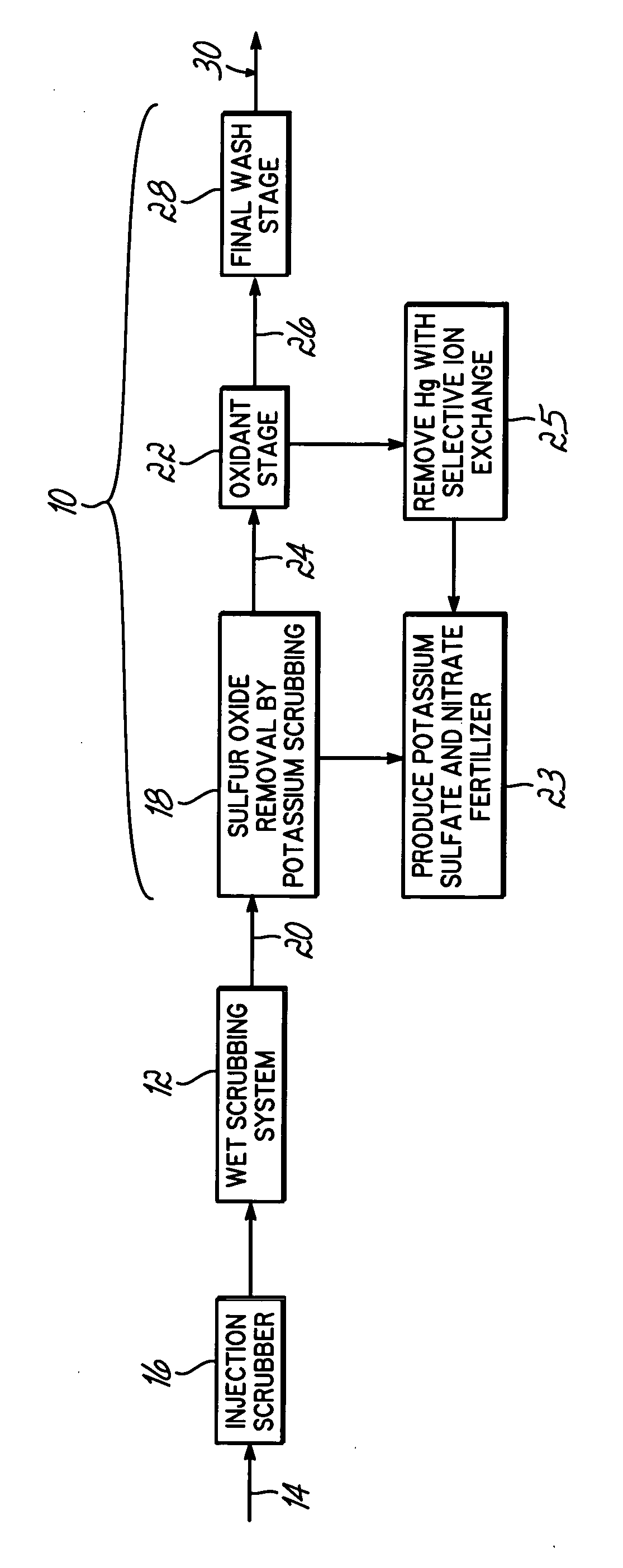

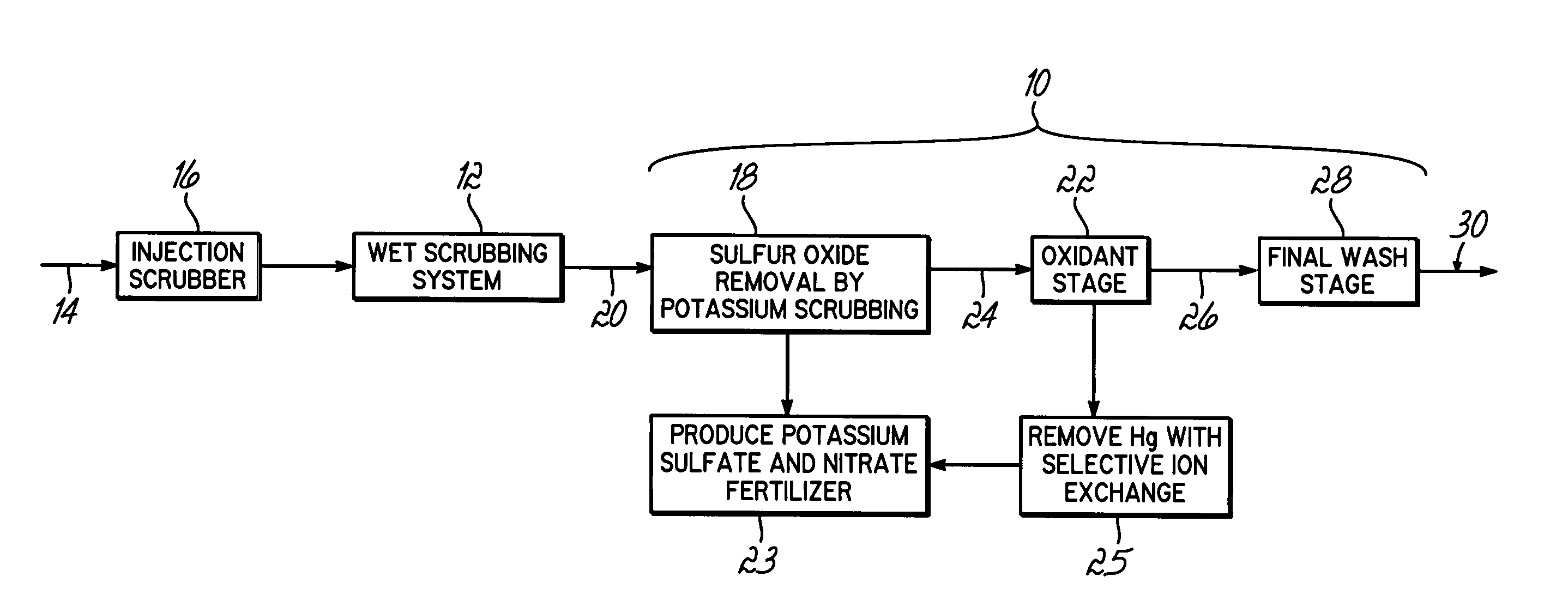

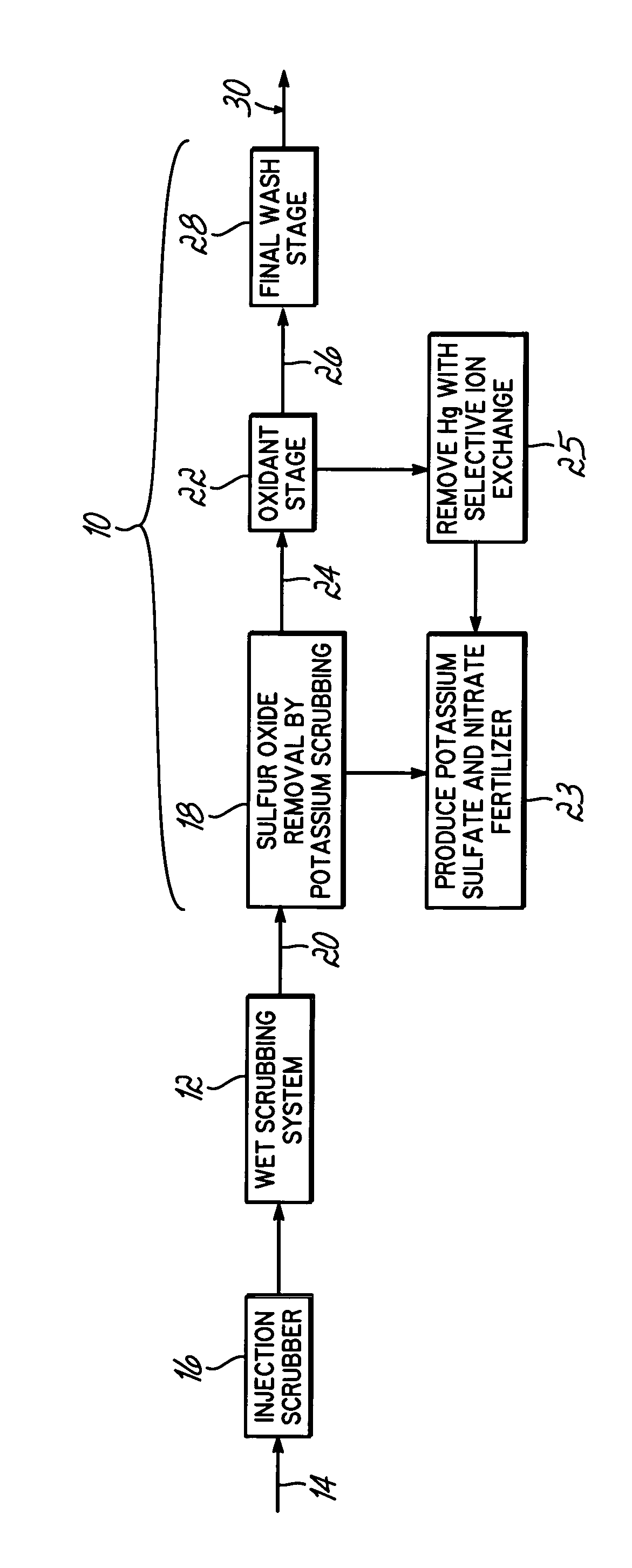

Method for removing sulfur dioxide, mercury, and nitrogen oxides from a gas stream

InactiveUS20060239877A1Low costImprove performanceAmmonium nitratesNitrogen compoundsSorbentPotassium

Methods for scrubbing gas streams to remove acid gases including sulfur dioxide, mercury-containing substances, and / or nitrogen oxides from the gas stream. The gas stream is contacted with a potassium-based sorbent effective for removing at least a portion of the acid gases. The partially cleaned gas stream is then contacted with an oxidant effective to remove at least a portion of the nitrogen oxides and / or mercury-containing substances after partially removing the acid gas substance.

Owner:ENVIROSOLV ENERGY

Pesticide compositions and methods for their use

Pesticide compositions and methods for their use are provided. Embodiments of the subject pesticide compositions include a pesticide and an assimilable carbon skeleton energy component. Embodiments of the subject compositions may include a pesticide and one or more of a macronutrient component, micronutrient component, vitamin / cofactor component and a complexing agent. Also provided are methods that include preparing an assimilable carbon skeleton energy containing-pesticide composition and methods for administering an assimilable carbon skeleton energy containing-pesticide composition to a plant. Kits for use in practicing the subject invention are also provided. The subject pesticide compositions find use in a variety of different applications, and are particularly suited for use in at least mollifying pesticide-induced phytotoxicity of a plant.

Owner:YAMASHITA THOMAS T

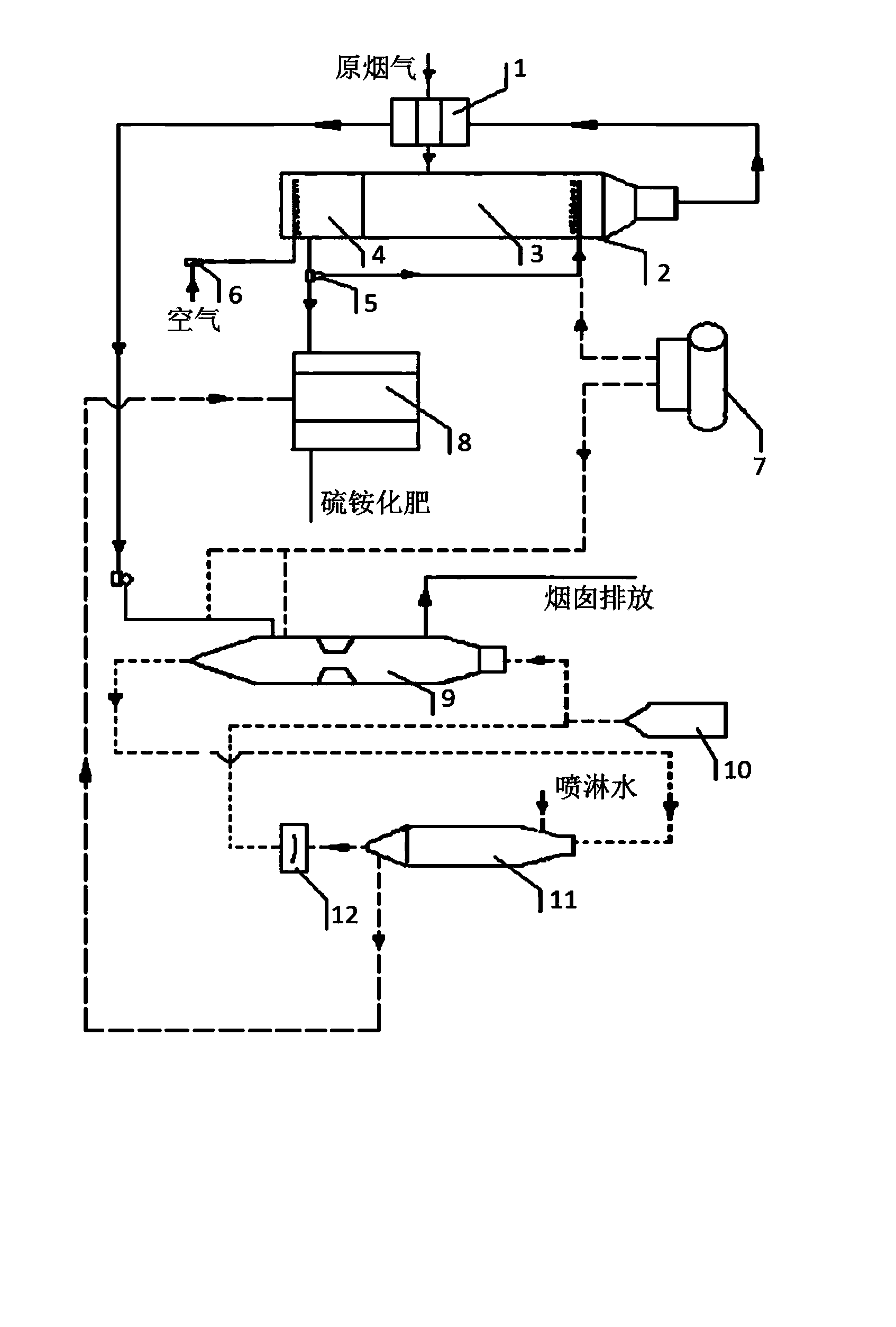

Method for simultaneously desulfurizing, denitrating and purifying flue gas

InactiveCN103861439ACompliance with emission standardsAdaptableAmmonium nitratesProductsFuranChemical industry

The invention discloses a method for simultaneously desulfurizing, denitrating and purifying flue gas and belongs to the field of flue gas purification. The method comprises the following steps: spraying the flue gas at the temperature of 50-90 DEG C by using ammonia absorption liquid to obtain a solution, and aerating and oxidizing the solution to obtain an ammonium sulfate solution; exchanging heat between the obtained flue gas and the original flue gas, heating to 120-350 DEG C, and supplementing ammonium hydroxide; converting NO and NO2 in the flue gas into N2 by addition or non-addition of an activated carbon material of a catalyst; performing reaction on the remaining SO2, ammonia and water vapor to generate ammonium sulfate; adsorbing mercury, dioxin, furan, a volatile organic compound, ammonia sol and other trace toxic substances by activated carbon; and regenerating the activated carbon after absorption and adsorption by using washing and heating methods. The method has the advantages that the process is simple and convenient, and the desulfurizing and denitrating efficiency is high; various toxic substances and fine particles in the flue gas can be adsorbed, a good prevention effect on PM2.5 pollution of industrial flue gas is achieved, ammonium sulfate and ammonium nitrate fertilizer byproducts are obtained, and resources can be recycled. The method can be applied to purification of sulfur-containing and nitrate-containing flue gas in the fields of boilers, metallurgy, chemical industry, thermoelectricity and garbage incineration power generation.

Owner:ASIA PACIFIC ENVIRONMENTAL CORP

Method for removing sulfur dioxide, mercury, and nitrogen oxides from a gas stream

InactiveUS7514053B2Improve performanceAvoid pollutionAmmonium nitratesNitrogen compoundsNitrogen oxidesSorbent

Methods for scrubbing gas streams to remove acid gases including sulfur dioxide, mercury-containing substances, and / or nitrogen oxides from the gas stream. The gas stream is contacted with a potassium-based sorbent effective for removing at least a portion of the acid gases. The partially cleaned gas stream is then contacted with an oxidant effective to remove at least a portion of the nitrogen oxides and / or mercury-containing substances after partially removing the acid gas substance.

Owner:ENVIROSOLV ENERGY

Fully compatible water-soluble fertilizer and use

InactiveUS6826866B2High retention rateReadily solubilized in waterBiocideRoot feedersAlkyl polyglycosideWater soluble

Owner:AQUATROLS HLDG +1

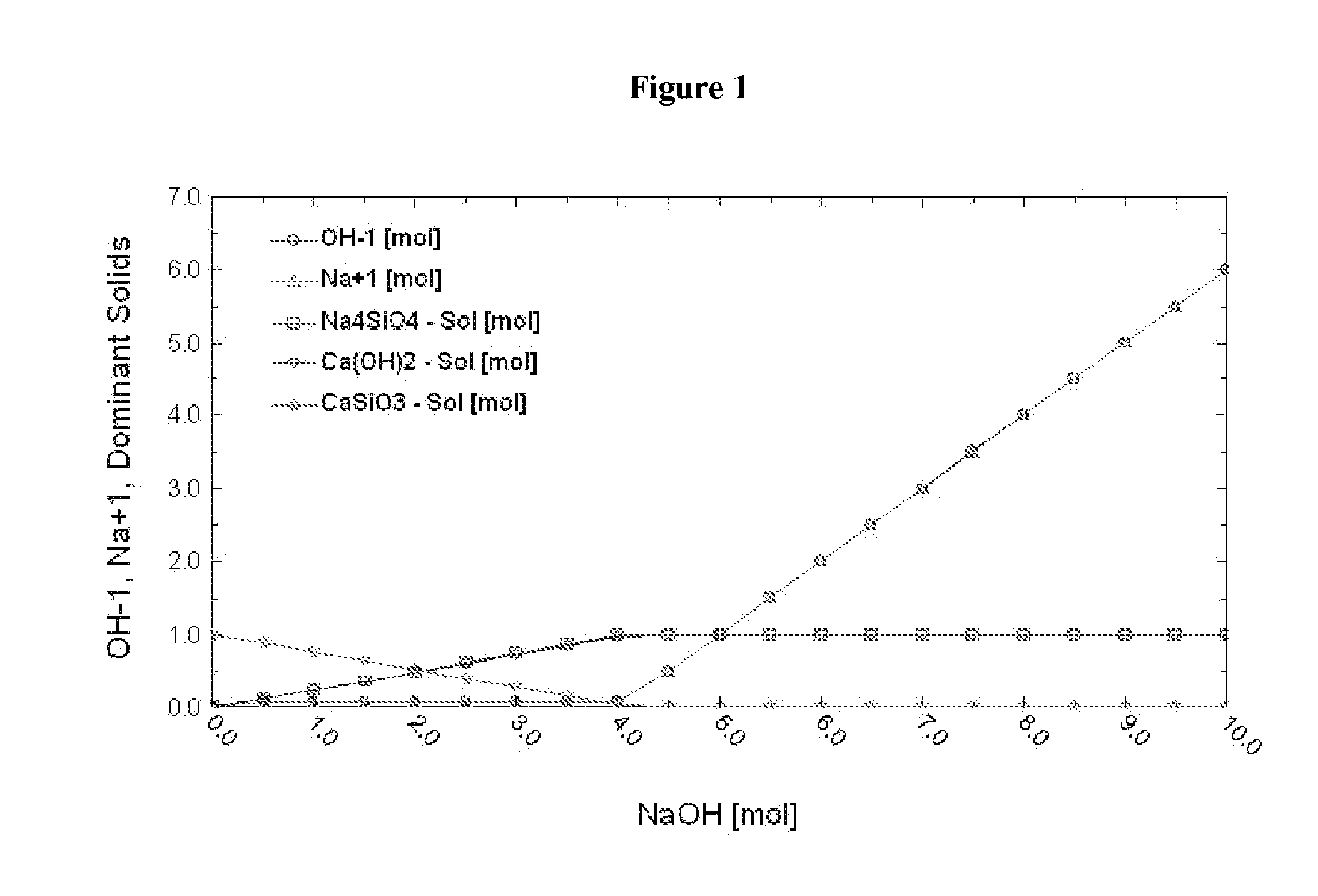

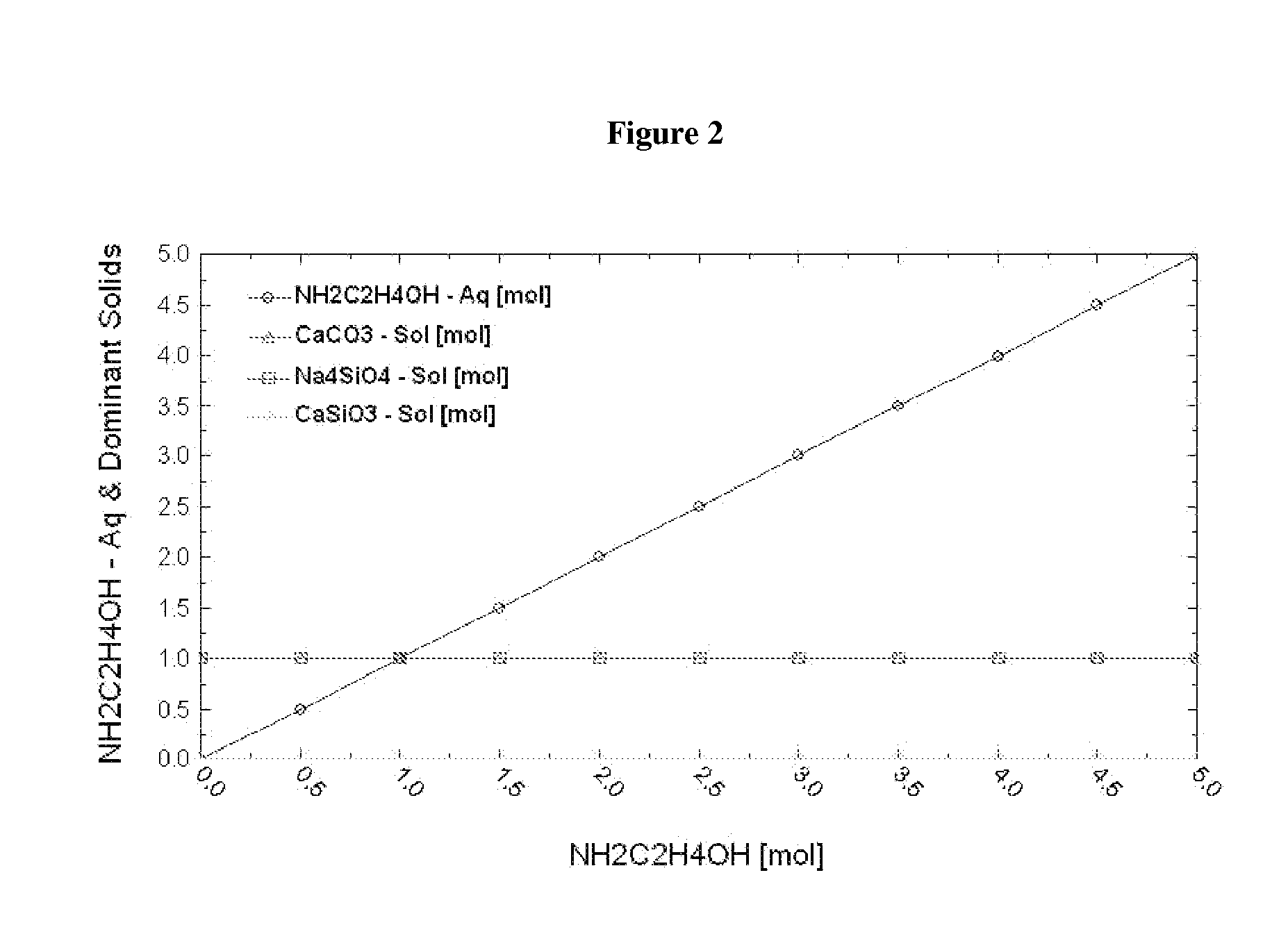

Sequestration of a gas emitted by an industrial plant

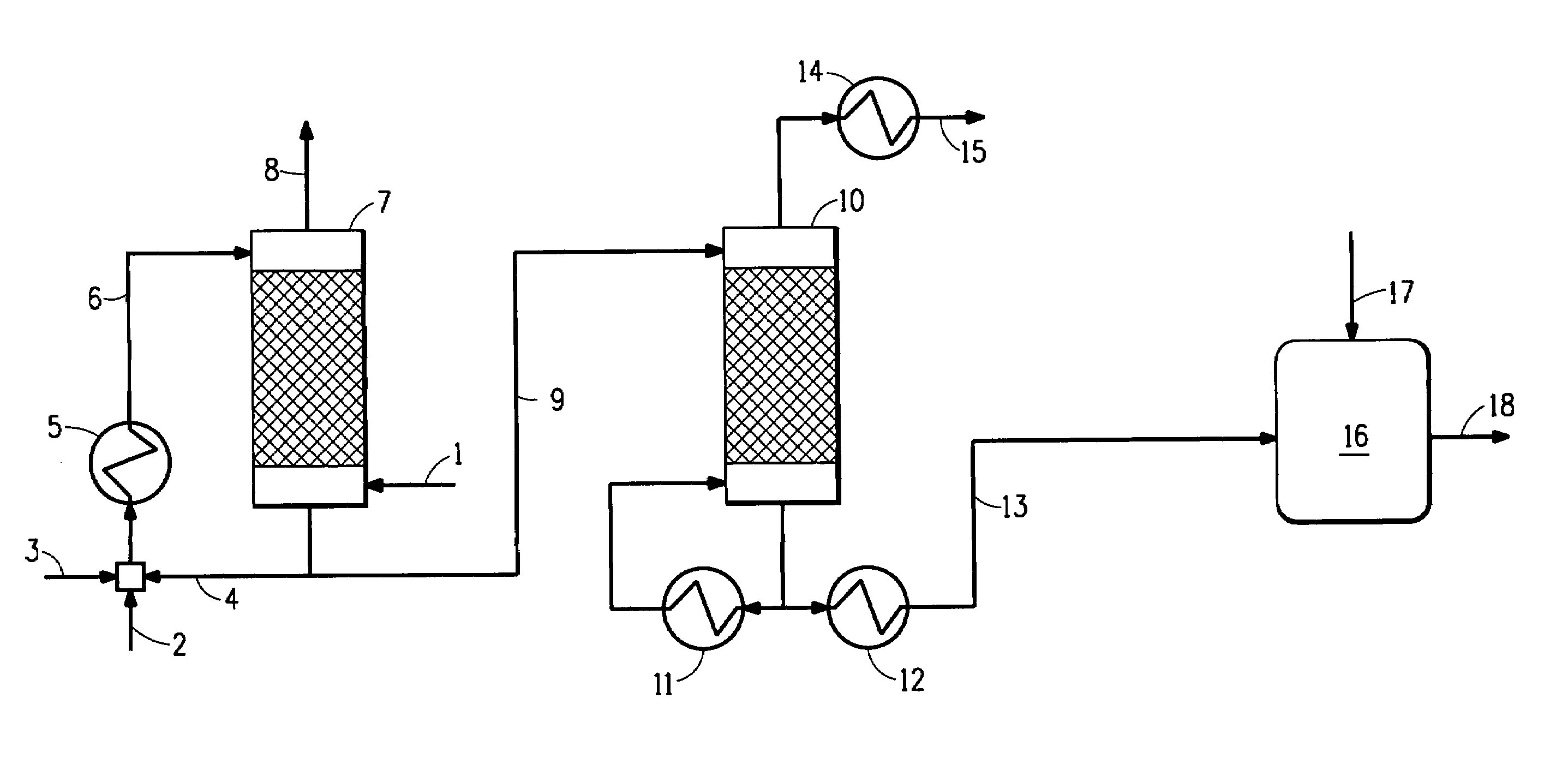

InactiveUS20110182799A1Eliminate needCalcium/strontium/barium carbonatesAmmonium nitratesNitrogenNitrogen gas

A method of sequestering a multi-element gas emitted by an industrial plant is described herein, the method comprising: contacting a solution, including a first reactant comprising a multi-element gas emitted by an industrial plant and at least one gas absorber comprising nitrogen, for example ammonia or an amine, with a solid, including a second reactant, under conditions that promote a reaction between the first reactant and the second reactant to provide a first product, which incorporates one or more elements of the multi-element gas, thereby sequestering the multi-element gas.

Owner:RUTGERS THE STATE UNIV

Controlled Release Fertilizer Composition

ActiveUS20100011825A1Reduce manufacturing costReduce the amount requiredBiocideOrganic phosphatic fertilisersControl releaseSulfur

A controlled release fertilizer composition and methods to produce the controlled release fertilizer composition are described. The controlled release fertilizer composition comprises a water soluble fertilizer core that is coated with a polymeric layer, intermediate layer, and a sulfur layer. If desired, the sulfur layer can be coated with an outer water-insoluble layer.

Owner:KOCH AGRONOMIC SERVICES LLC

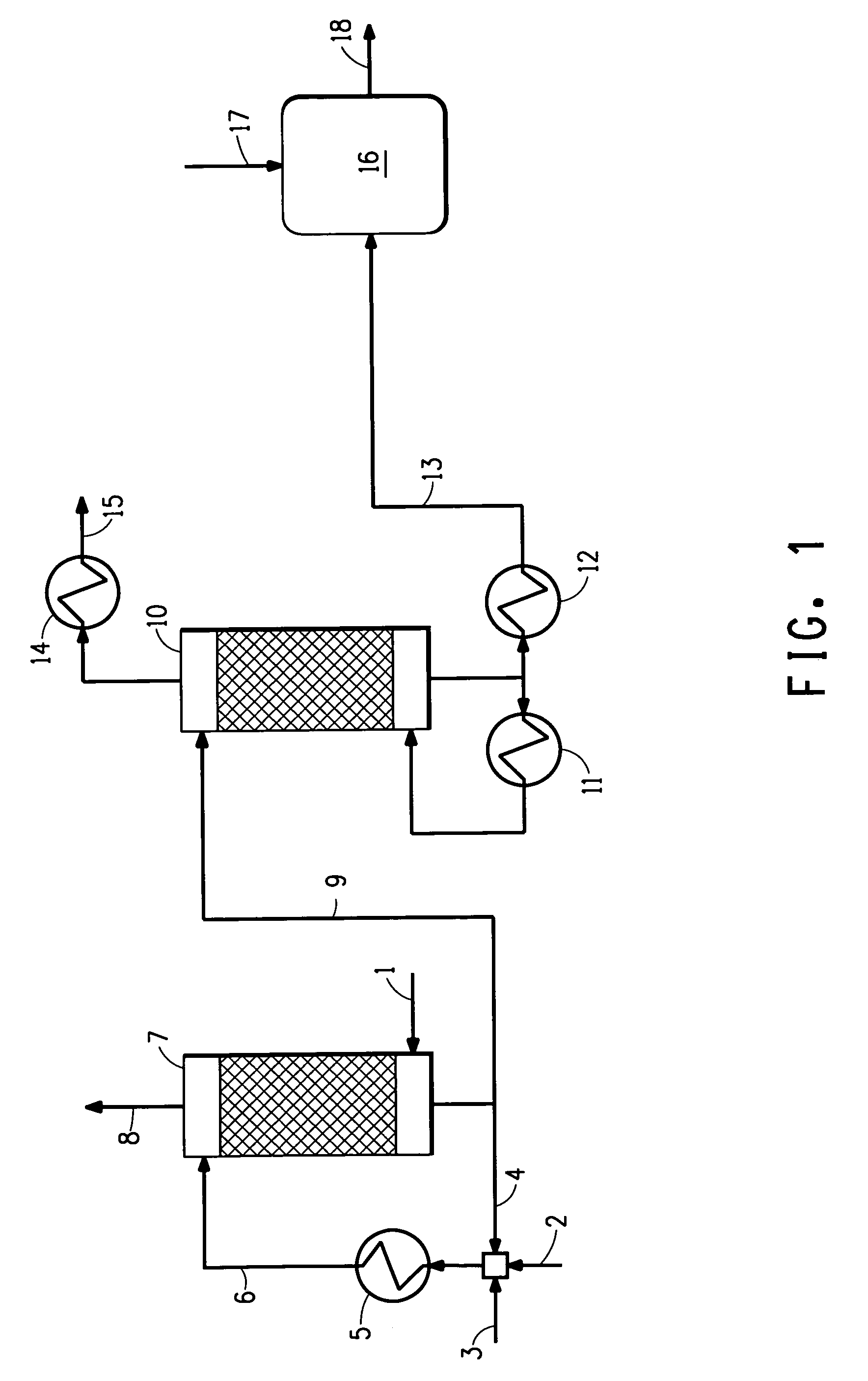

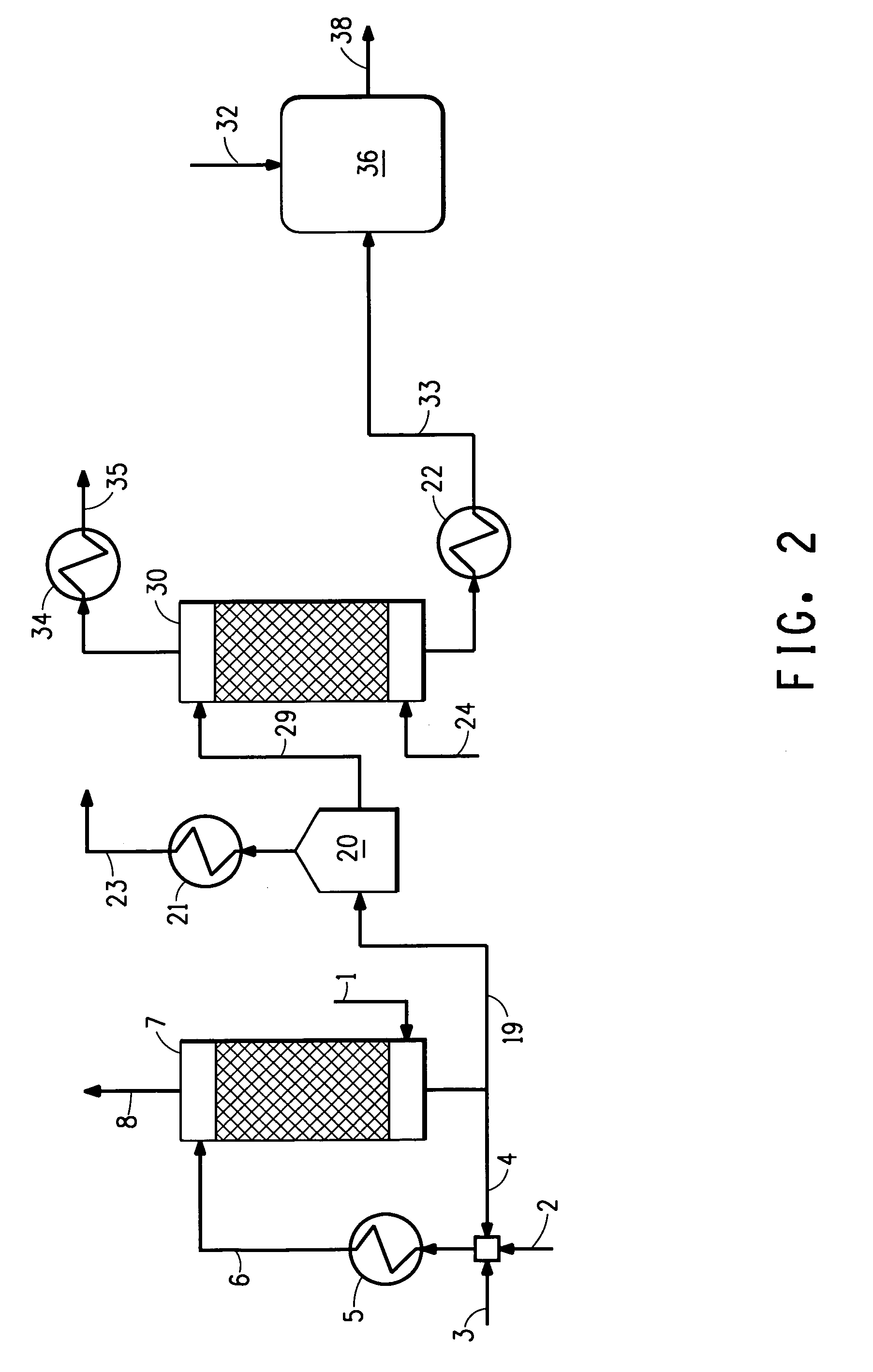

Process for scrubbing ammonia from acid gases comprising ammonia and hydrogen sulfide

The present invention provides a process for removing ammonia as an aqueous salt solution from an acid gas comprising ammonia and hydrogen sulfide. A strong acid, such as sulfuric acid, is used as a scrubbing agent to convert ammonia to an ammonium salt. Control of pH and stripping in combination with reboiler or evaporators reduces hydrogen sulfide concentration. The ammonium salt is produced as an aqueous solution, which may crystallized to form a solid product. The ammonium salt solution or solid may be used as a fertilizer.

Owner:EI DU PONT DE NEMOURS & CO

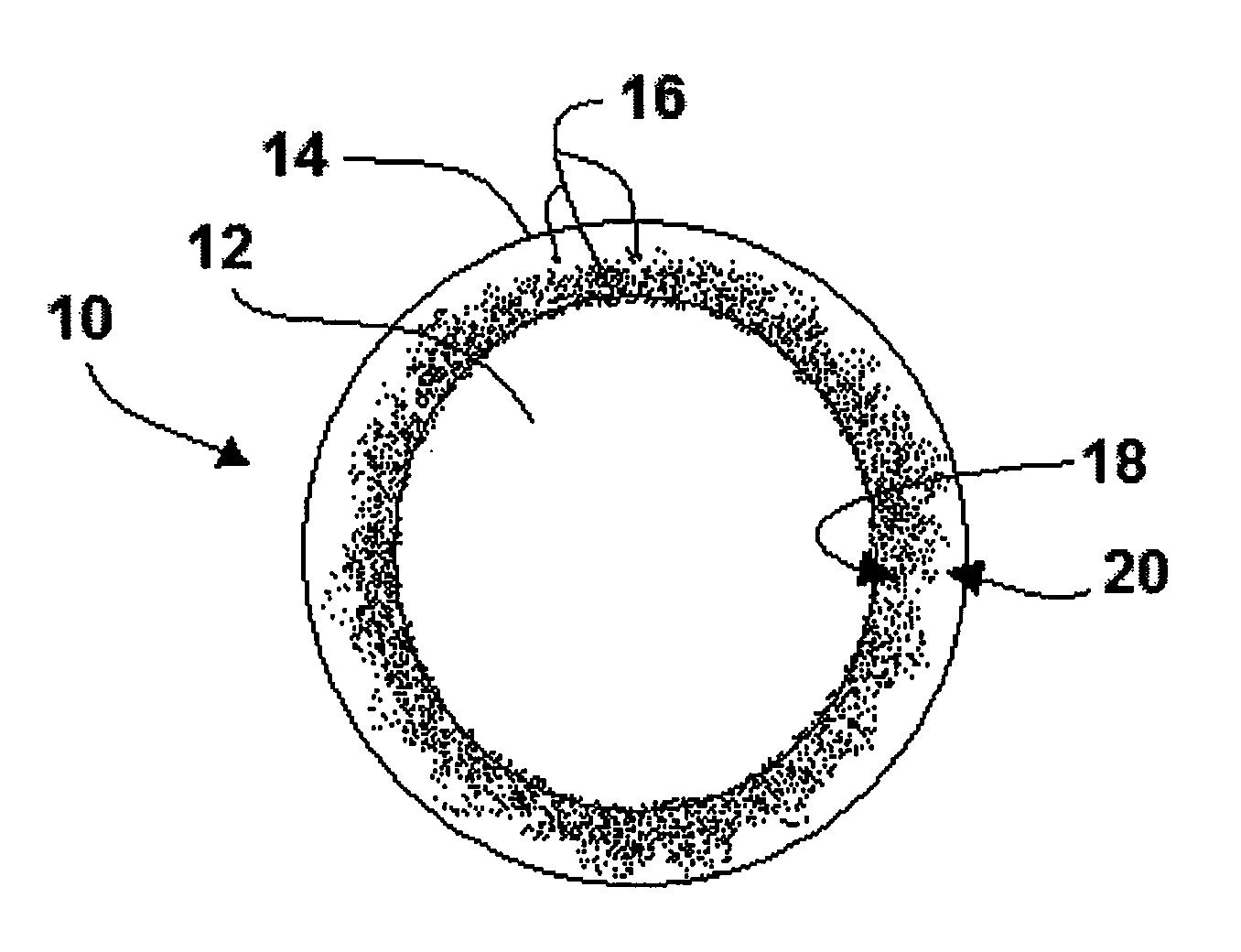

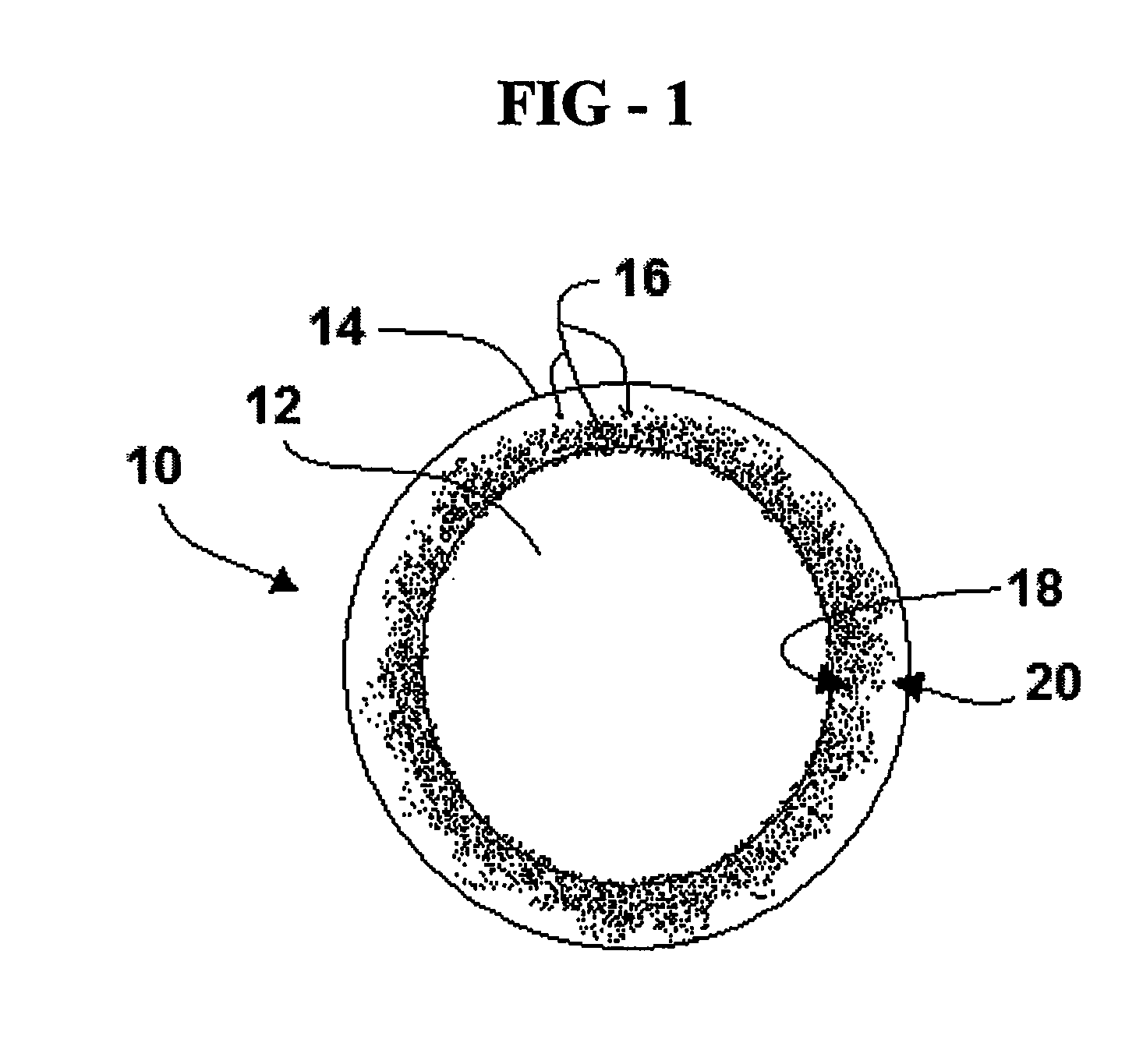

Encapsulated particle

ActiveUS20100326152A1Improve moisture resistanceImprove the immunityBiocideGlass/slag layered productsPolyolFire retardant

An encapsulated particle comprises a core particle and a polyurethane layer disposed about the core particle. The core particle can be various particles, such as fertilizer, biocides, flame retardants, seeds, etc. The polyurethane layer comprises the reaction product of an isocyanate component and an isocyanate-reactive component. The isocyanate-reactive component comprises a graft polyol having a continuous phase and polymeric particles. A method of forming the encapsulated particle comprises the steps of providing the core particle, applying the isocyanate and isocyanate-reactive components to the core particle, and reacting the isocyanate and isocyanate-reactive components to form the polyurethane layer. The encapsulated particle has excellent physical properties, such as increased water repellency, resiliency and shelf life.

Owner:BASF AG

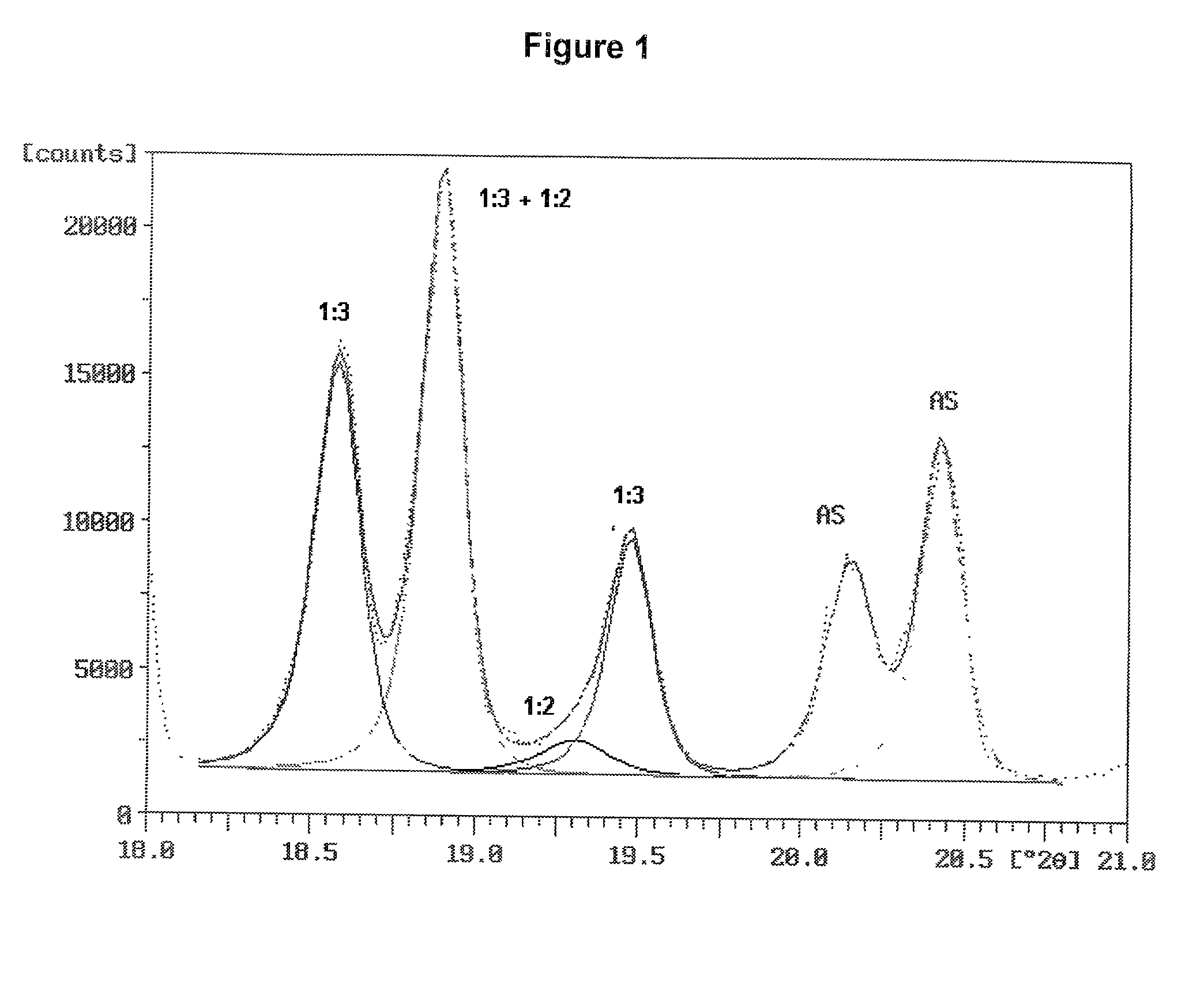

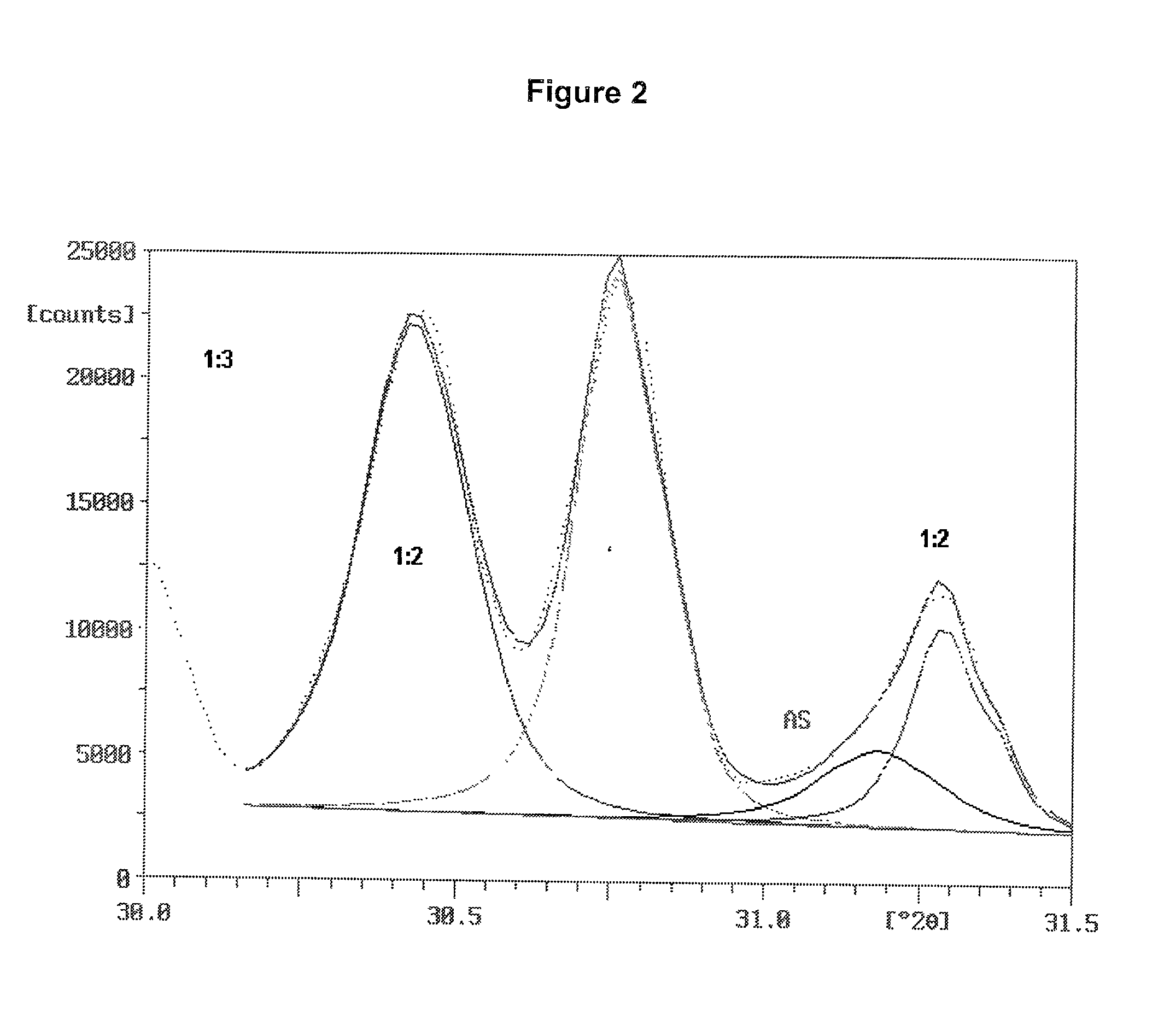

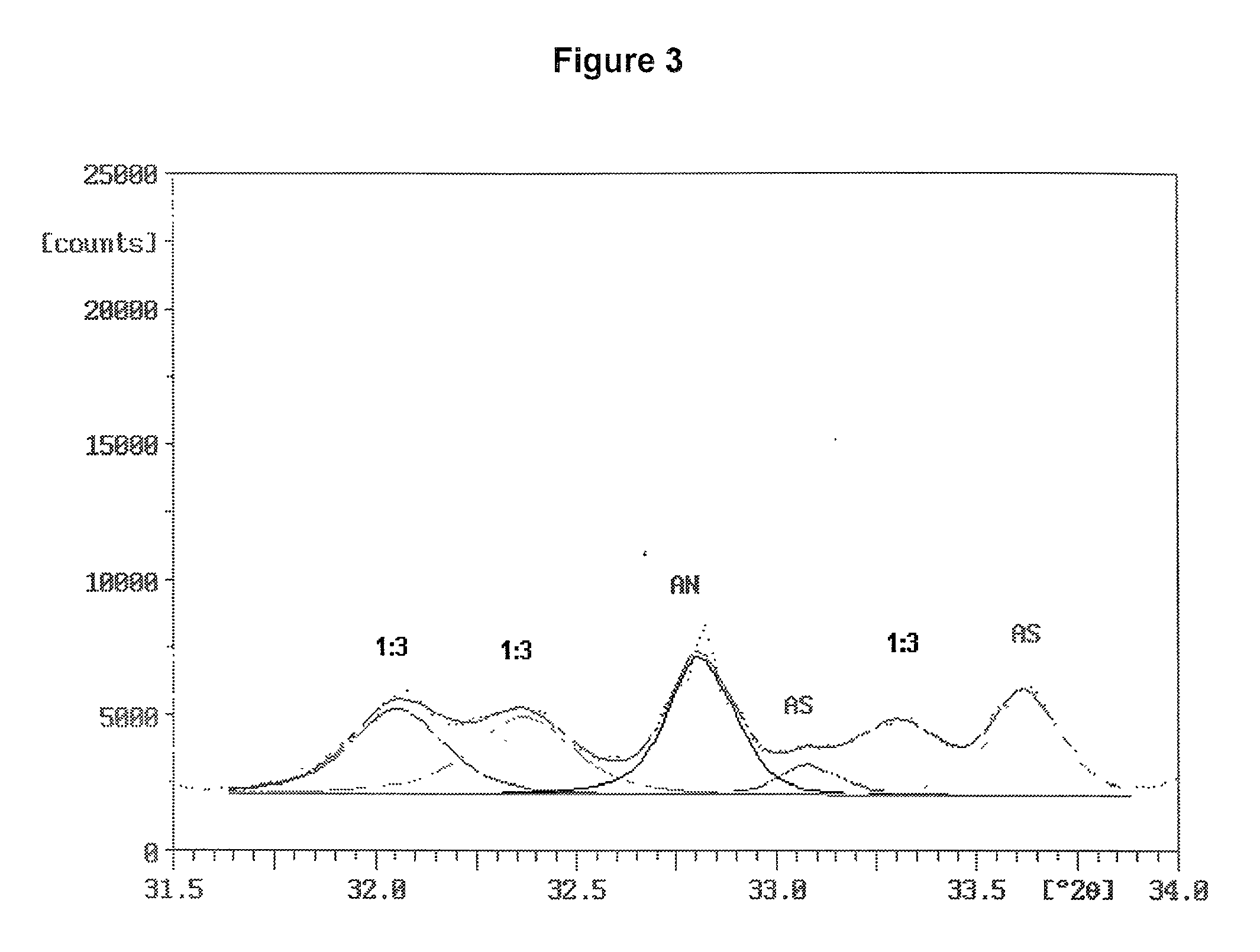

Ammonium sulfate nitrate

Ammonium sulfate nitrate composite materials useful as fertilizers having desirable levels of nitrate ions, superior stability against detonation, higher density, greater resistance to moisture, and a method for their manufacture. The ammonium sulfate nitrate composites have as essential constituents ammonium sulfate and the NH4SO4.2(NH4NO3) double salt with less than 5 wt. % in combined total of the more hazardous NH4SO4.3(NH4NO3) double salt and ammonium nitrate. The composites of the invention are formed by reacting ammonium sulfate with ammonium nitrate in a molar ratio of about 0.9:1 to about 1.1:1 in the presence of a small amount of water in a narrow range of temperatures and then cooling to solidification at a sufficiently rapid rate to prevent macroscopic segregation of the reaction products.

Owner:ADVANSIX RESINS & CHEM LLC

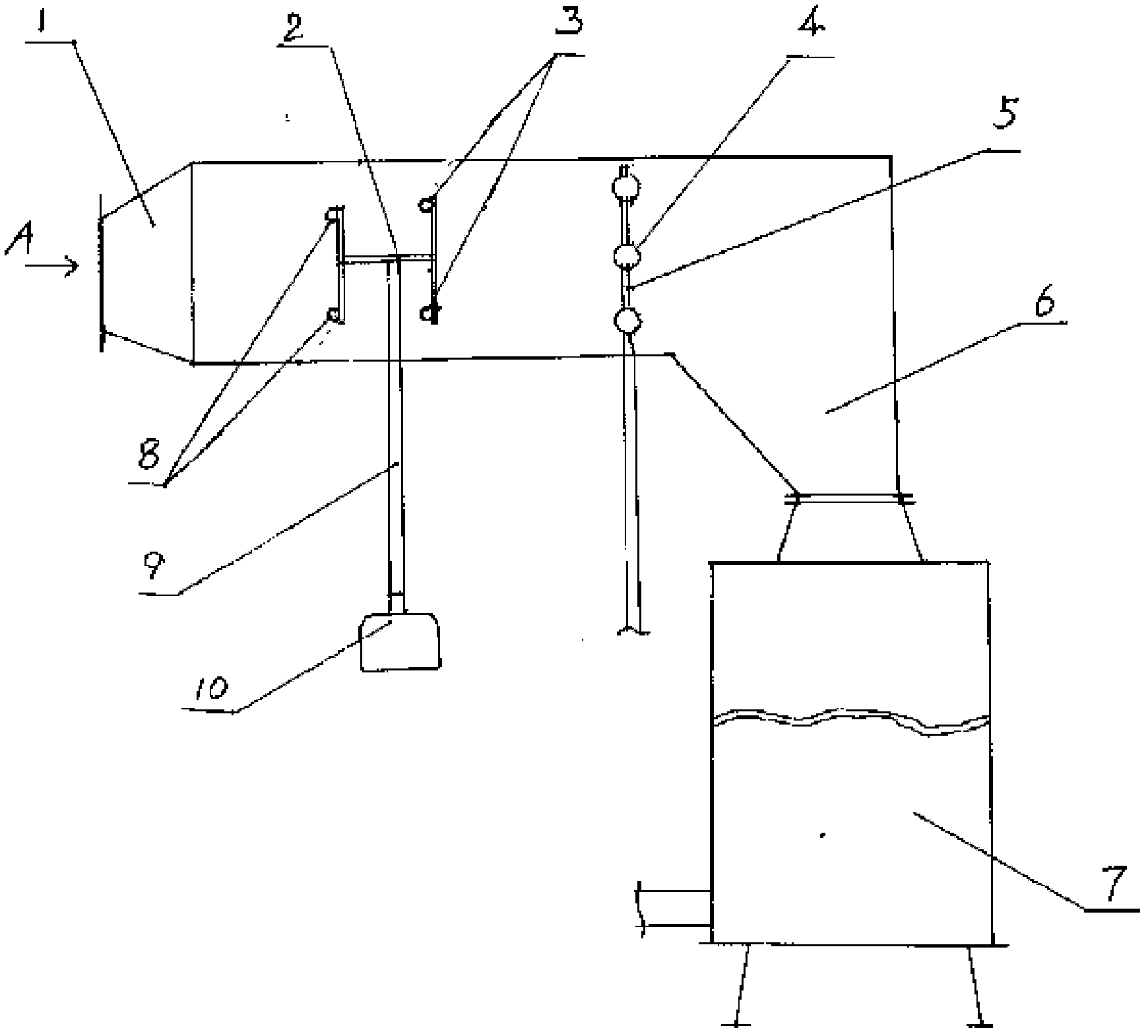

Industrial flue gas purification, desulfurization and denitrification integrated device and working method thereof

ActiveCN102489129AReduce usageEfficient removalAmmonium nitratesDispersed particle separationParticulatesSulfur dioxide

The invention discloses an industrial flue gas purification, desulfurization and denitrification integrated device and a working method thereof. A section of pretreatment flue is additionally arranged on a flue in front of an absorption tower, and the outlet of the pretreatment flue is connected to the inlet flue of the absorption tower in a downward gradient mode; an ozone spraying device and a pre-spraying device are arranged in the pretreatment flue from the inlet in turn; and the ozone spraying device is connected with an ozone generator through a gas transmission pipeline and converts SO2 into SO3 sulfide which is freely soluble in water, the pre-spraying device absorbs SO3 which is freely soluble in water and converts the SO3 into H2SO4, namely sulfuric acid, and flue gas is cooled simultaneously, so that the aim of removing nitrogen oxide and sulfur dioxide is fulfilled. The device can efficiently remove the nitrogen oxide, has an obvious effect of removing particulate matters such as the sulfur dioxide, dust and the like, and is desulfurization and denitrification equipment with a wide application prospect.

Owner:山东中玻节能环保发展有限公司

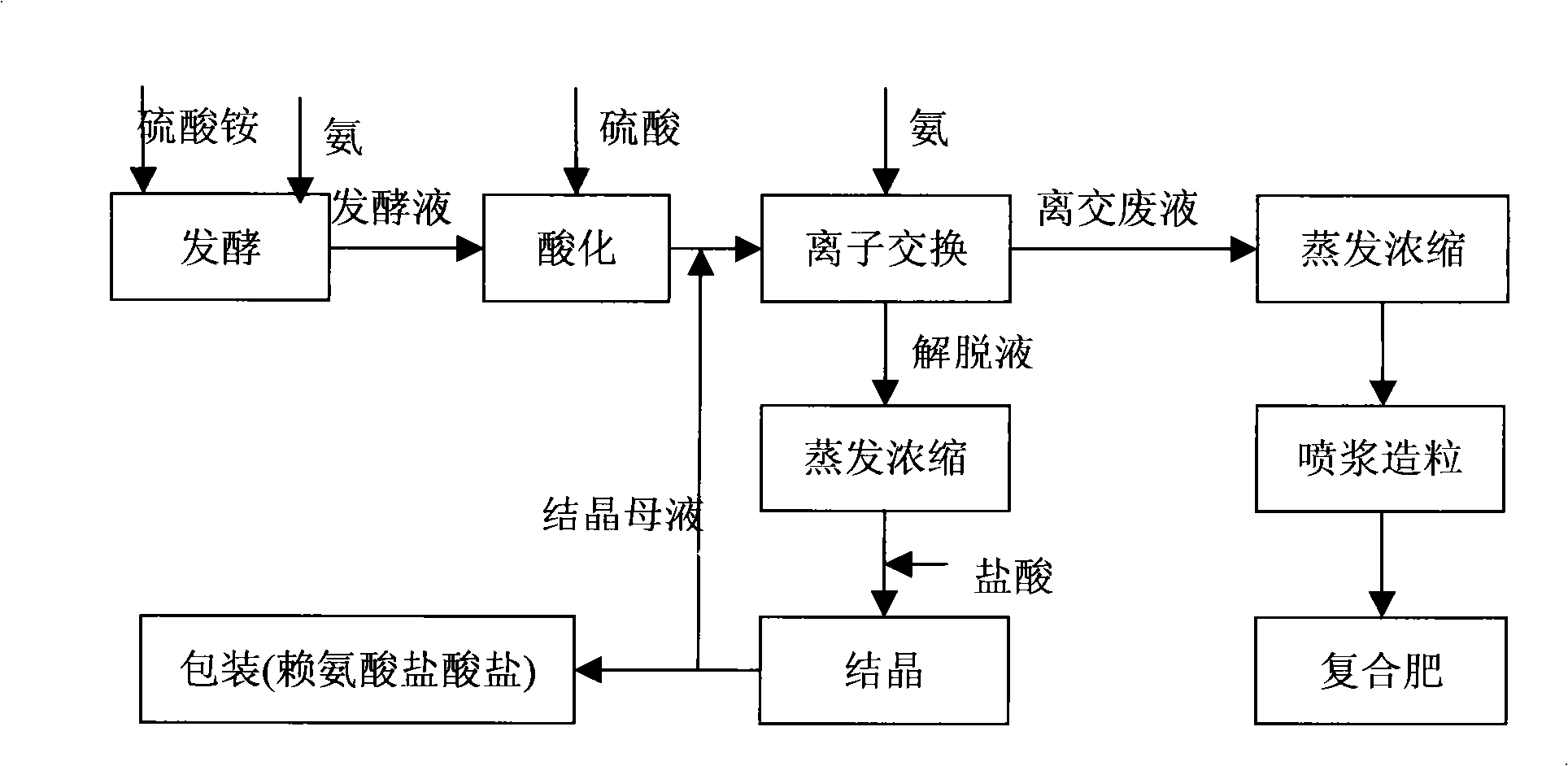

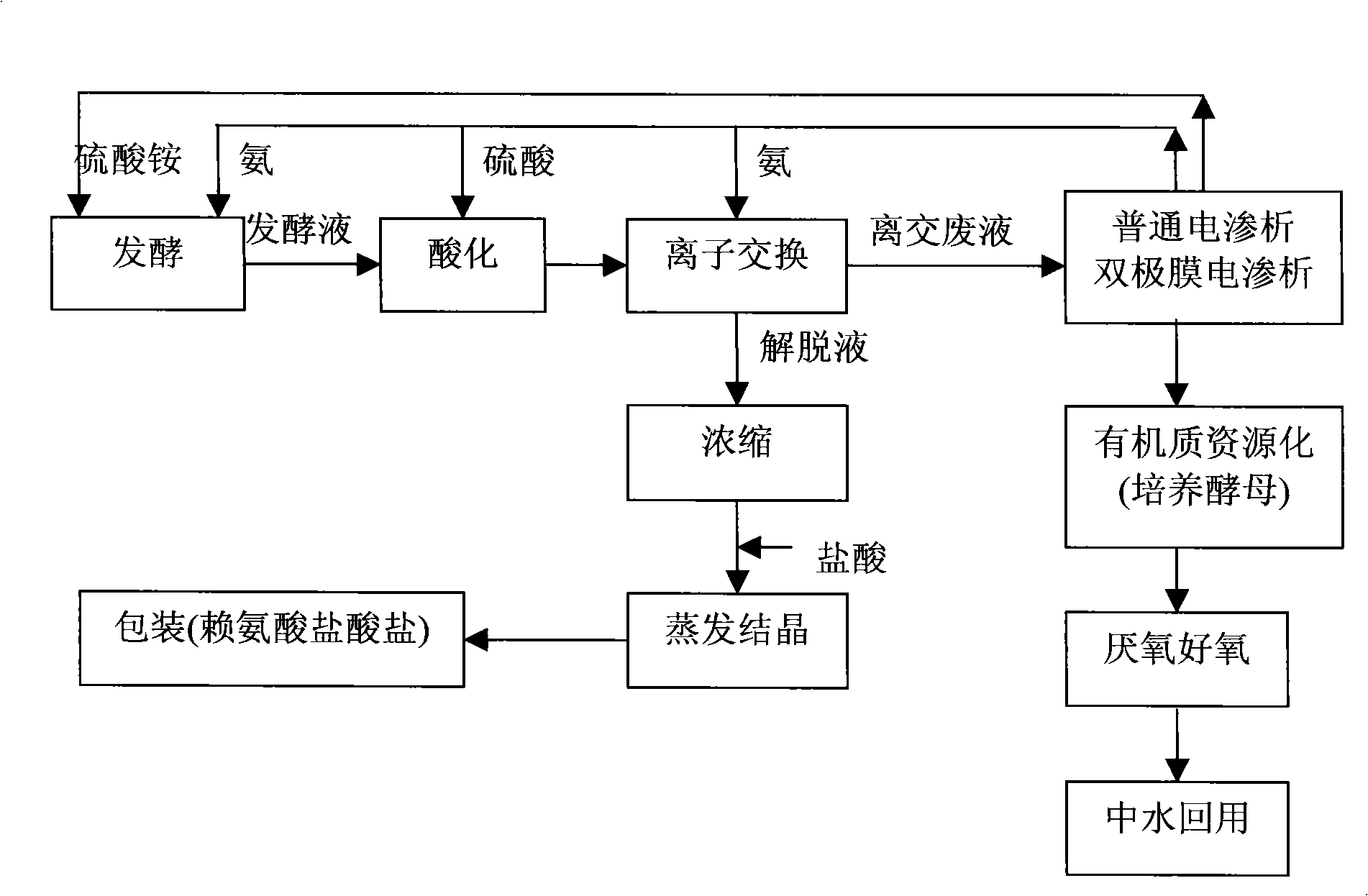

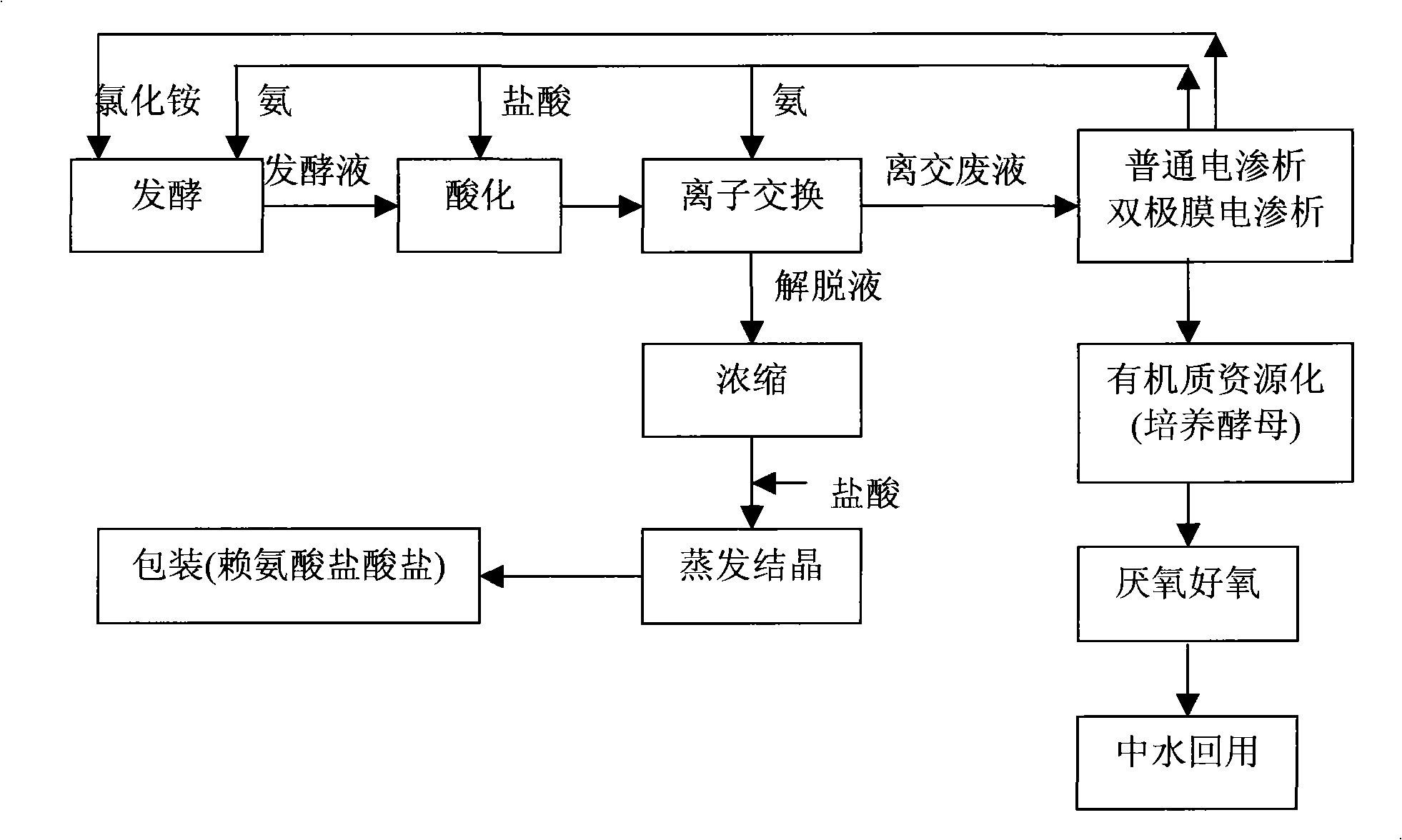

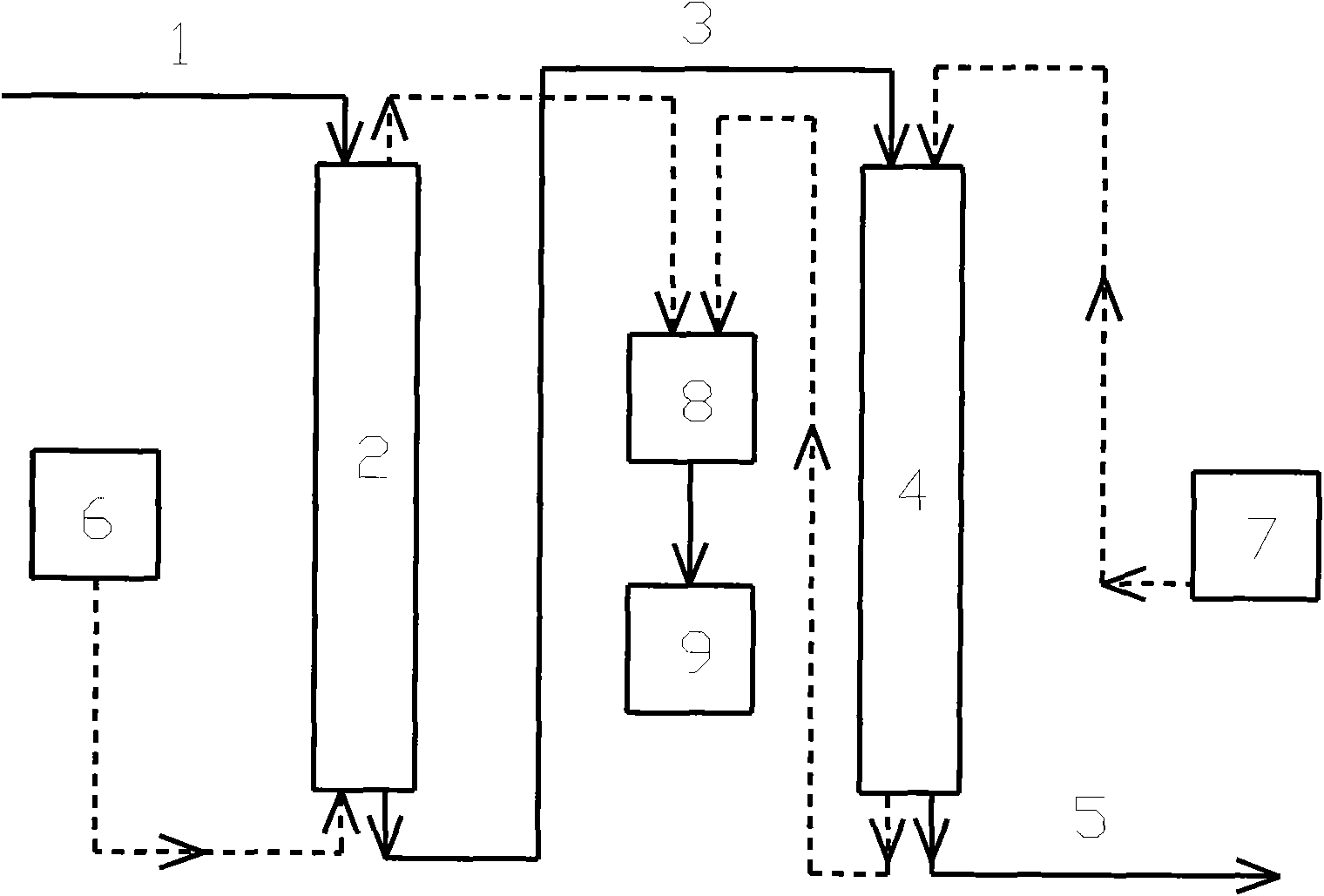

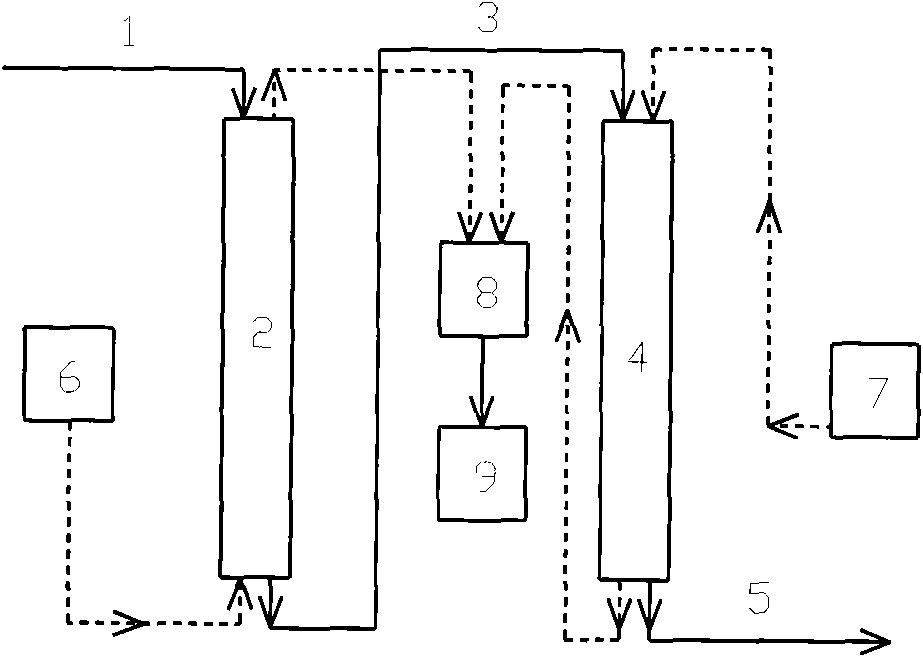

Method for processing ion exchange waste liquor of lysine production by fermentation method

InactiveCN101407350AFast growthLarge biomassAmmonium nitratesDispersed particle separationIon exchangeLysine fermentation

The invention belongs to the ferment industry, in particular relates to a treatment method of ion exchange waste liquor in lysine production by a fermentation method. The invention adopts a common electrodialysis technology to recycle ammonium sulfate, ammonium chloride or ammonium nitrate in the lysine ion exchange waste liquor produced by extracting the lysine from lysine fermentation production to water solution of ammonium sulfate, ammonium chloride or ammonium nitrate, or adopts a bipolar membrane electrodialysis technology to regenerate sulfuric acid, hydrochloric acid or nitric acid and NH3 by ammonium sulfate, ammonium chloride or ammonium nitrate in the lysine ion exchange waste liquor produced by extracting the lysine from the lysine fermentation production, or adopts the combination of the common electrodialysis technology and the bipolar membrane electrodialysis technology to recycle ammonium sulfate, ammonium chloride or ammonium nitrate in the lysine ion exchange waste liquor produced by extracting the lysine from the lysine fermentation production and regenerate sulfuric acid, hydrochloric acid or nitric acid and NH3. The invention realizes the resource recycling of the ion exchange waste liquor and clean production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Fertilizer Suspension and Method of Preparation

A concentrated, homogenous, stable, water-soluble fertilizer suspension comprising: water-soluble mineral nutrients of at least nitrogen, phosphorous, potassium, calcium, and magnesium; and an organic stabilizing additive; and wherein the pourable, aqueous suspension has water-soluble mineral nutrients amounting to at least about 80 percent by weight (wt. %) of the suspension.

Owner:HGCI INC

Production of silver sulfate grains using organo-sulfate or organo-sulfonate additives

ActiveUS7261867B1Uniform morphologyUniform sizePigmenting treatmentCosmetic preparationsOrganic sulfonic acidSulfonate

An aqueous precipitation process for the preparation of particles comprising primarily silver sulfate, comprising reacting an aqueous soluble silver salt and an aqueous soluble source of inorganic sulfate ion in an agitated precipitation reactor vessel and precipitating particles comprising primarily silver sulfate, wherein the reaction and precipitation are performed in the presence of an aqueous soluble organo-sulfate or organo-sulfonate additive compound, the amount of additive being a minor molar percentage, relative to the molar amount of silver sulfate precipitated, and effective to result in precipitation of particles comprising primarily silver sulfate having a mean grain size of less than 50 micrometers.

Owner:EASTMAN KODAK CO

Process for treating nitrogen-containing wastewater by ion exchange and reclaiming ammonium nitrate

InactiveCN101891316AAchieve reuseFlexible operation and managementAmmonium nitratesWater/sewage treatment by ion-exchangeHigh concentrationStrong acids

The invention discloses a process for treating nitrogen-containing wastewater by ion exchange and reclaiming ammonium nitrate, and belongs to the technical field of environmental protection and wastewater treatment. The process is characterized in that: a strong acid cation exchanger and a weak alkali anion exchanger are connected in series to realize denitrification of the nitrogen-containing wastewater of a nitrogen fertilizer plant; the process is used for treating the high-concentration ammonia nitrogen and median-concentration nitrate nitrogen containing wastewater of the nitrogen fertilizer plant; strong acid cation exchange resin and weak alkali anion exchange resin are regenerated by adopting nitric acid and aqueous ammonia respectively; and the regenerated waste liquid ammonium nitrate is evaporated and concentrated to reclaim the ammonium nitrate. Compared with the traditional wastewater denitrification method, the process can remove ammonia nitrogen and nitrate nitrogen from the wastewater at the same time, reclaim the ammonium nitrate and recycle production water, does not produce secondary pollution, reclaims products from the pollutants, has obvious environmental benefit and economic benefit, and is a new path for treating the high-concentration ammonia nitrogen and median-concentration nitrate nitrogen containing wastewater of the nitrogen fertilizer plant.

Owner:TAIYUAN UNIV OF TECH

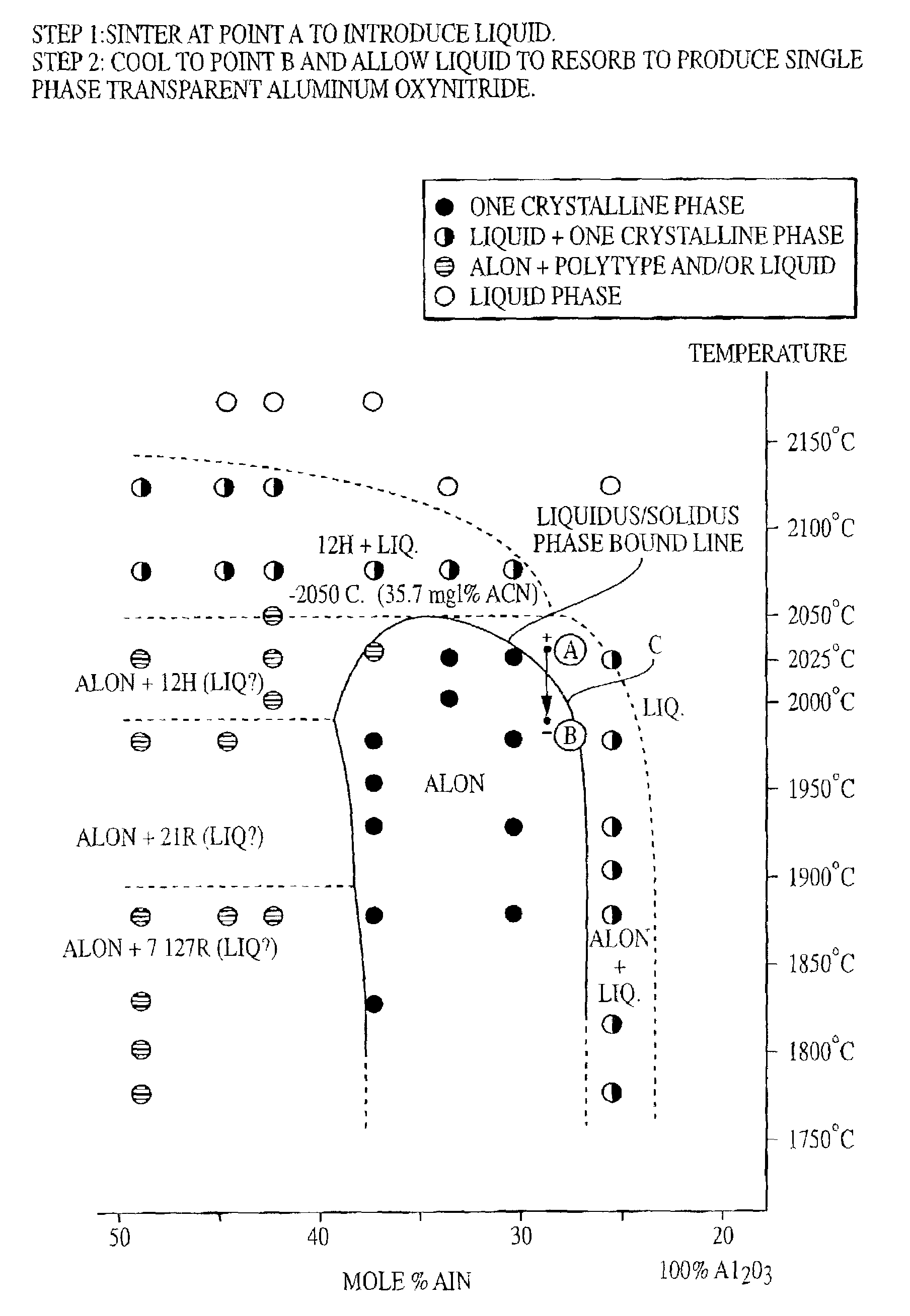

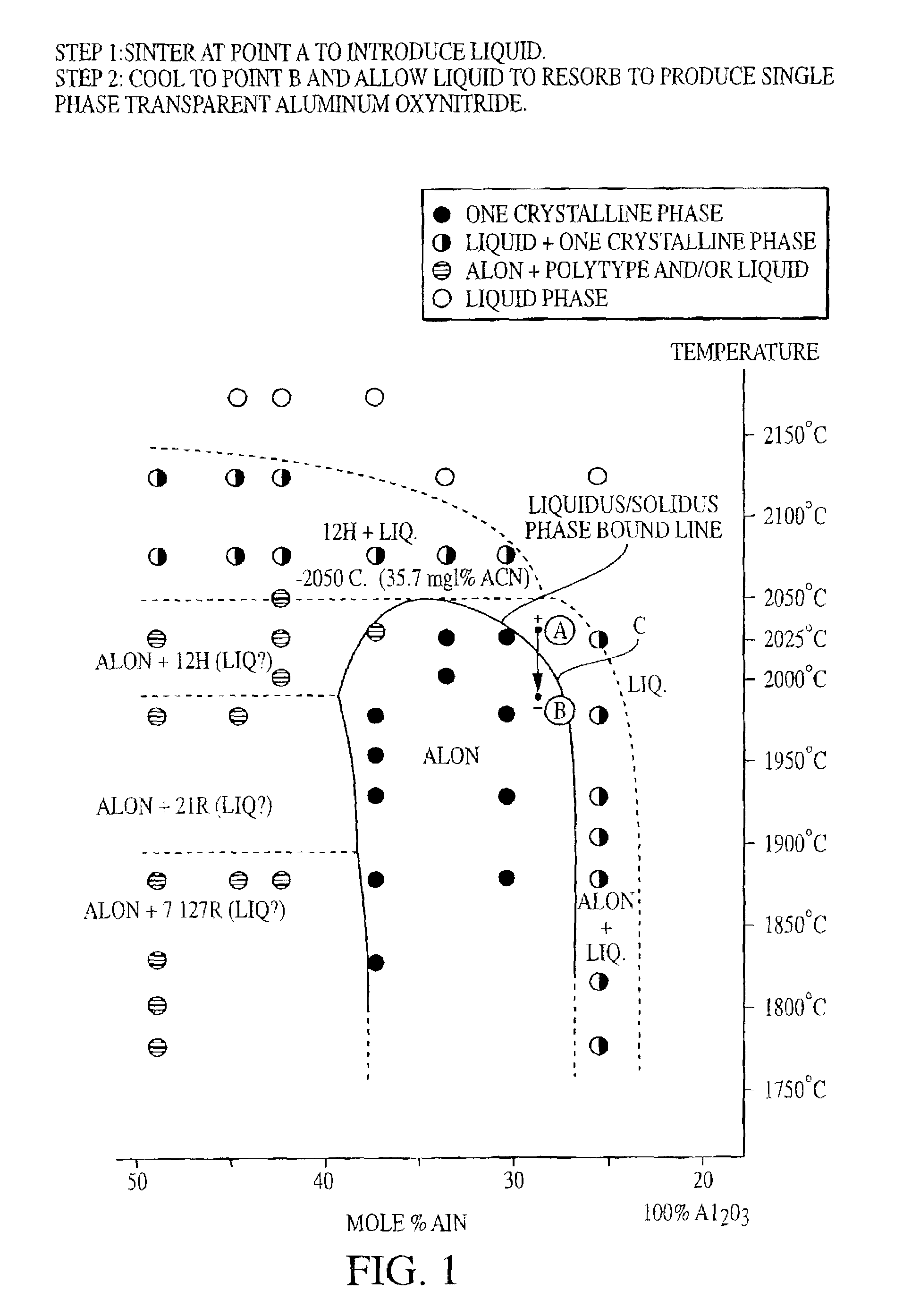

Transient liquid phase reactive sintering of aluminum oxynitride (AlON)

InactiveUS7045091B1Low production costShorten the sintering timeAmmonium nitratesNitrogen compoundsSolid regionAluminum oxynitride

A transparent aluminum oxynitride product is produced by a first heat treating step wherein a combination of Al2O3 and AlN at a temperature within the solid-liquid phase and a second step of sintering the heat treated combination at a temperature at least 50° C. less than the heat treating temperature. The method introduces a small fraction of liquid that aids in pore elimination and densification. In a single step, the material is shifted from the liquid / solid region into a solid AlON solution region, wherein the liquid is fully reacted with the solid AlON phase, with further sintering occurring. The procedure is sufficient to eliminate voids and other imperfections which often result in a reduction in optical clarity.

Owner:ARMY UNITED STATES OF THE AMERICAS AS REPRESENTED BY THE SEC OF THE

Method for increasing crop yield

InactiveUS20120096912A1Increase productionEliminating and reducing useBiocideAmmonium nitratesAmmonium sulfateNutrient

The method for increasing yield of crop plants uses foliar application to the plants during the plant growth stage of a granular fertilizer consisting essentially of urea, ammonium sulfate and a fertilizer stabilizing agent. The stabilizing agent regulates and slows down decomposition nitrogen in urea and / or ammonium sulfate to maximize use thereof. The granular fertilizer has a urea / ammonium sulfate weight ratio of about 4 / 1 and contains at least 40% nitrogen and at least 4% sulfur. The relatively high N—S fertilizer is applied at relatively high rates of about 100 to 150 pounds per acre to ensure that the fertilizer nutrients are always available to the plants at several stages of growth.

Owner:RIZZO JOHN M

Catalyst composition and method of controlling PFC and HFC emissions

The present invention relates to a catalytic process for the destruction of PFC's and HFC's using a catalyst which comprises aluminum oxide that has preferably been stabilized through the addition of a stabilizing agent (such as, titanium, zirconium, or cobalt, or mixtures of these elements). The addition of these elements to the aluminum oxide unexpectedly enhances the catalyst's stability without significantly altering its reactivity. The total amount of stabilizing agent added to the catalyst can be as low as 0.005 parts (by weight) stabilizing agent per part (by weight) aluminum oxide (Al2O3) or as great as 2 or more parts (by weight) stabilizing agent per part (by weight) aluminum oxide; so long as there is sufficient aluminum oxide available to effectively catalyze the destruction of the target PFC's and / or HFC's. An oxidizing agent, such as, for example, platinum, palladium, rhodium, iridium, silver, nickel, copper, iron, vanadium, and / or cerium, may be added to the catalyst to effectively convert any carbon monoxide to carbon dioxide.

Owner:GUILD ASSOCS

Fast dissolving water-soluble fertilizer formulations and methods and uses thereof

ActiveUS20100186471A1Fast preparationReadily and rapidly compoundBiocideAmmonium nitratesFree solutionWater soluble

Improved, solid water-soluble fertilizer (WSF) compositions are presented which comprise at least one acid (optionally nutritive) and at least one basic fertilizer component. In one or more embodiments of the present invention, the WSF compositions demonstrate improved solubility of one or more nutrients or additives in solution, do not require additional dissolution aids or anti-caking agents, demonstrate fast dissolution times, produce precipitate free solutions, are readily compounded without intermediate wetting or drying steps, do not generate gas, and demonstrate improved stability under typical usage conditions. Finally, the WSF compositions may be used in improved processes for the creation of stock solutions, optionally with cold water, and / or delivery of nutrients to plants.

Owner:EVERRIS INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com