Industrial flue gas purification, desulfurization and denitrification integrated device and working method thereof

A technology for desulfurization and denitrification, industrial flue gas, applied in chemical instruments and methods, fertilization devices, separation methods, etc., can solve the problems of difficult to use by-products, high operating costs, large equipment, etc. The effect of low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

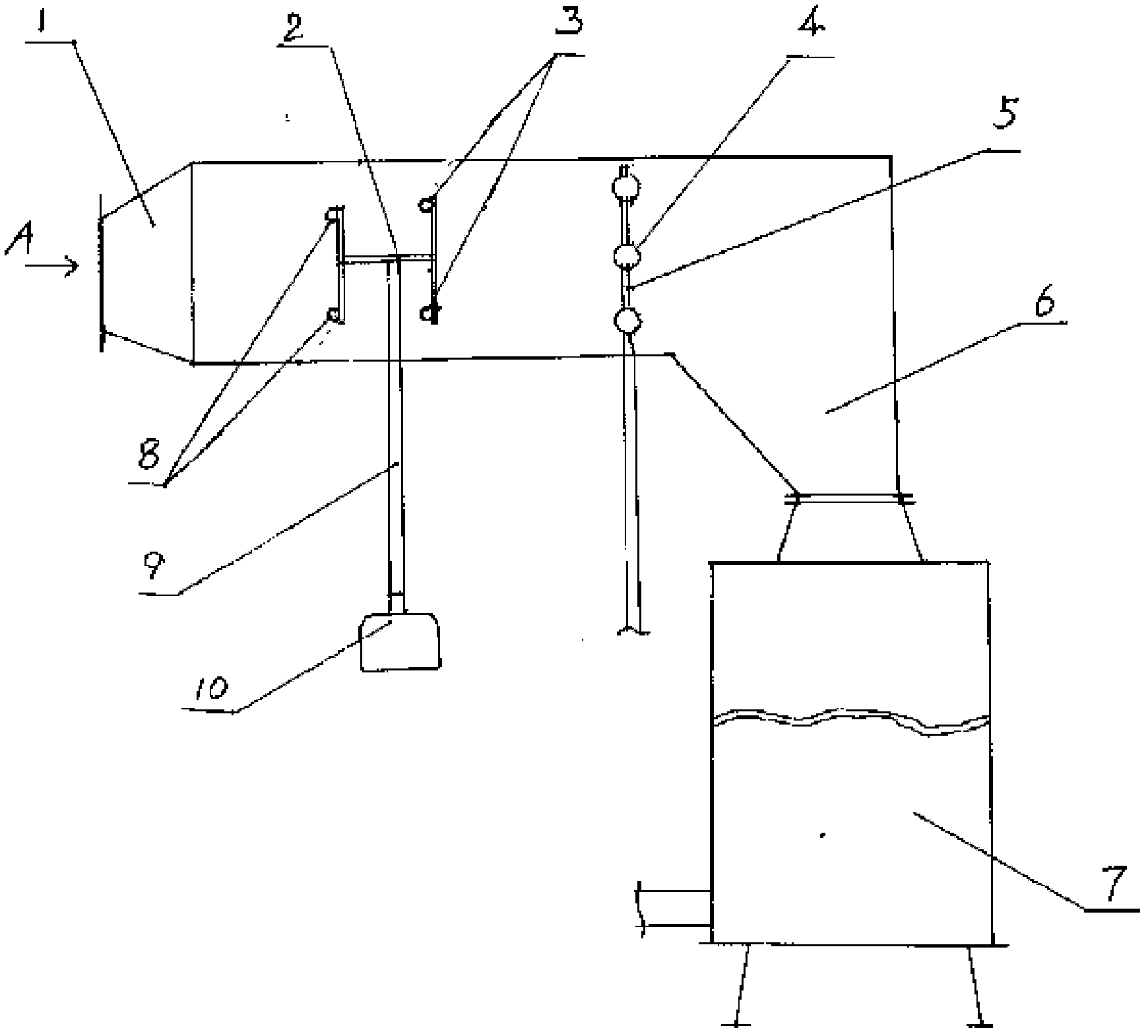

[0036] Such as figure 1 As shown, an industrial flue gas purification desulfurization and denitrification device: it includes an absorption tower 7, on the flue before entering the absorption tower 7, a section of pretreatment flue 1 is added, and the outlet 6 of the pretreatment flue 1 is connected with a downward slope On the inlet flue of the absorption tower 7; from the entrance in the pretreatment flue 1, an ozone injection device 2 and a pre-spray device are arranged successively; on the ozone injection device 2, an ozone machine 10 is connected with a gas pipeline 9.

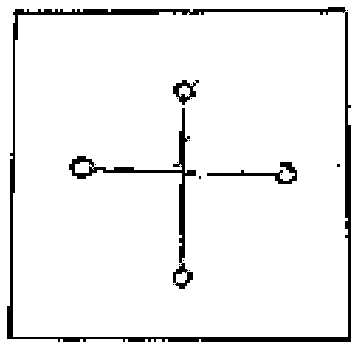

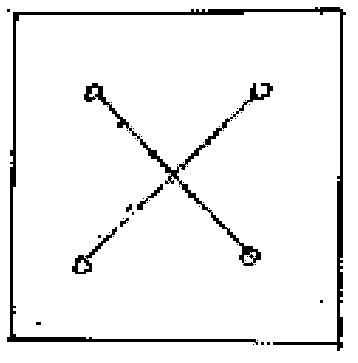

[0037] Described ozone spraying device 2 is to be made up of gas nozzle 8 of the first layer, gas nozzle 3 of the second layer with gas pipeline 9, and four gas nozzles are evenly arranged on every layer; And the gas nozzle 8 of the first layer and the gas nozzle of the second layer Two layers of gas nozzles 3 are staggered mutually, as figure 2 The first layer of gas nozzles 8 are arranged in a cross f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com