Patents

Literature

1030results about "Ammonium sulfates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zero emission gasification, power generation, carbon oxides management and metallurgical reduction processes, apparatus, systems, and integration thereof

ActiveUS7674443B1Improvement in individual technology componentEnhances economic performanceUsing liquid separation agentBiofuelsCyclonic separationOxygen

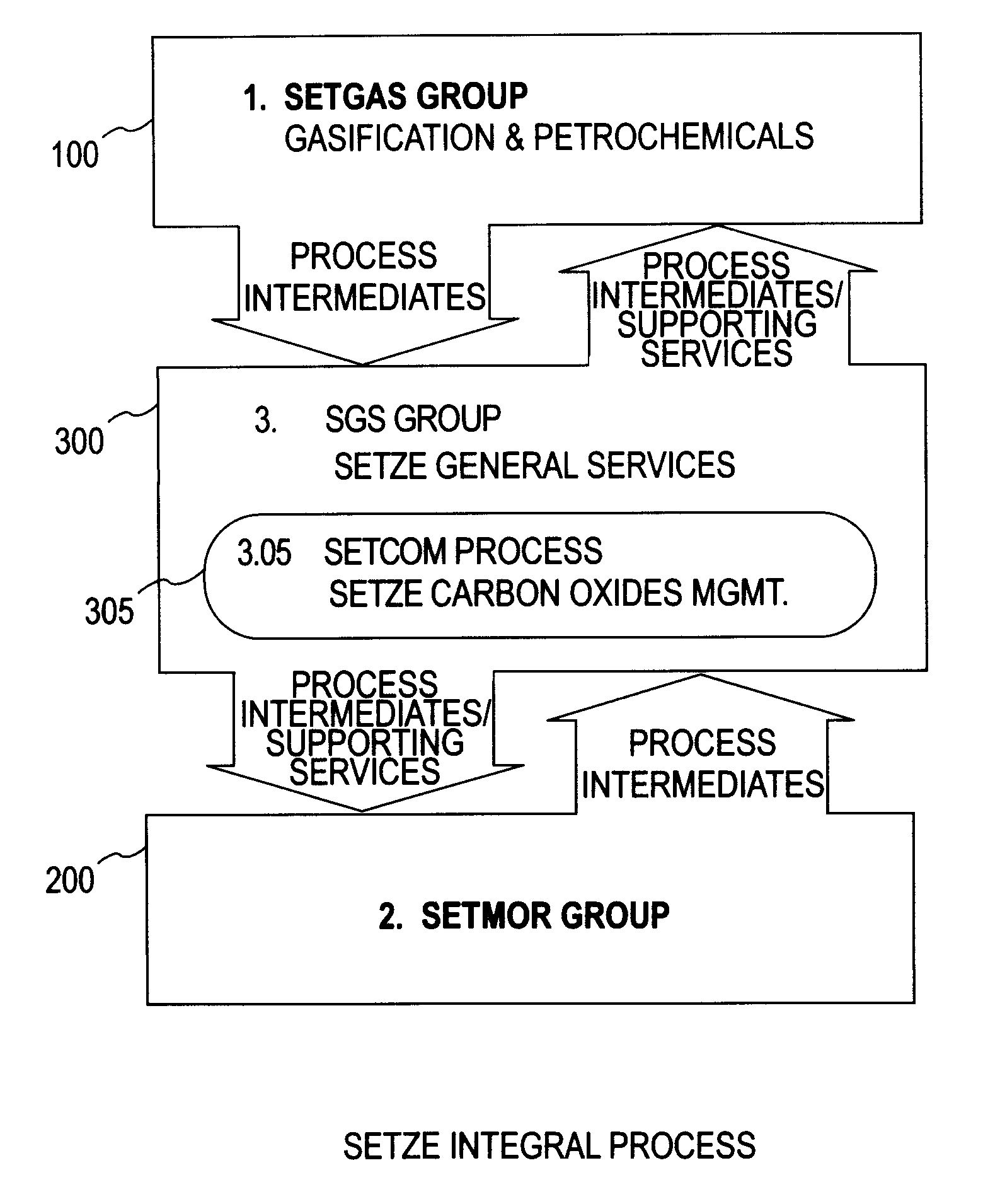

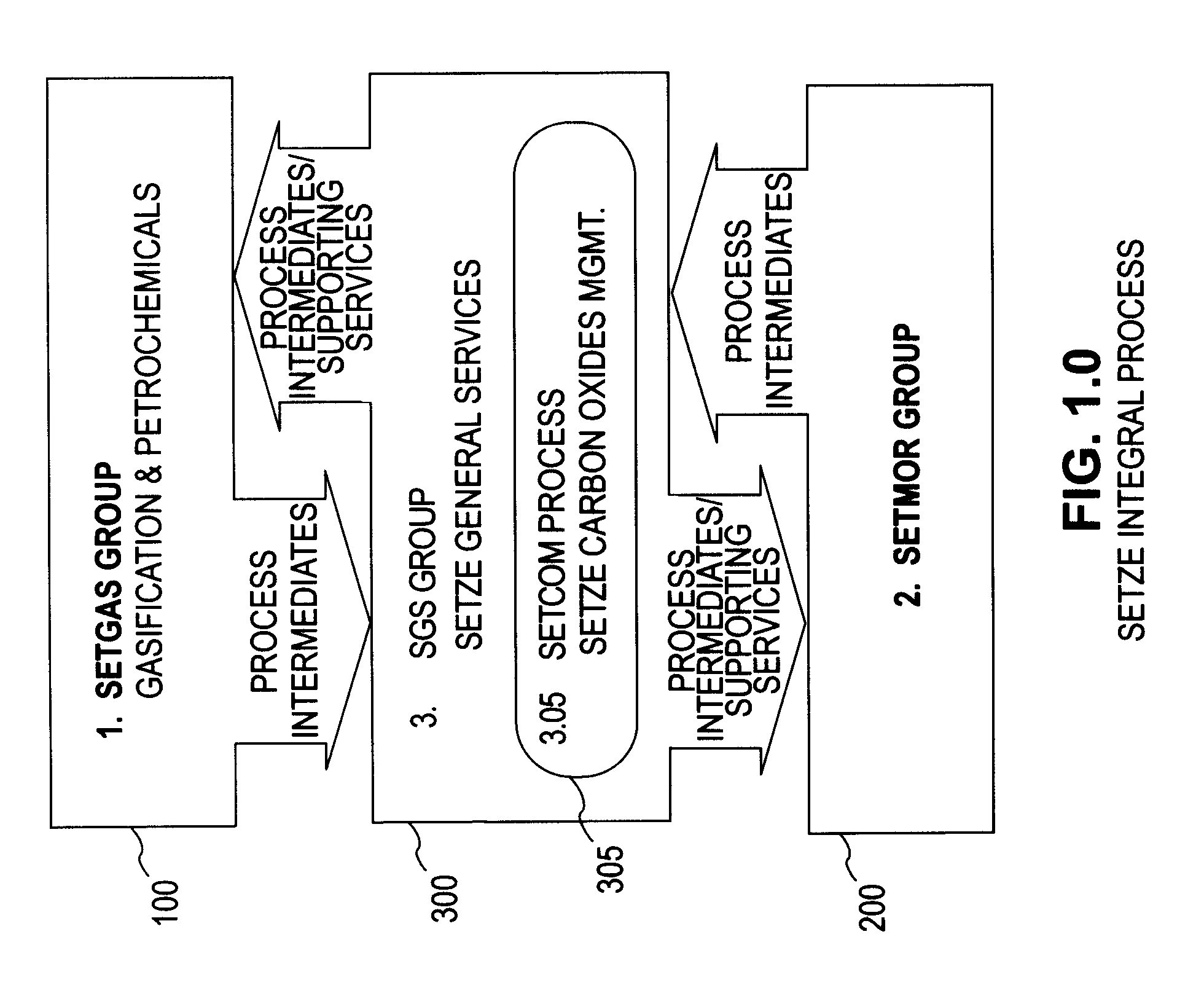

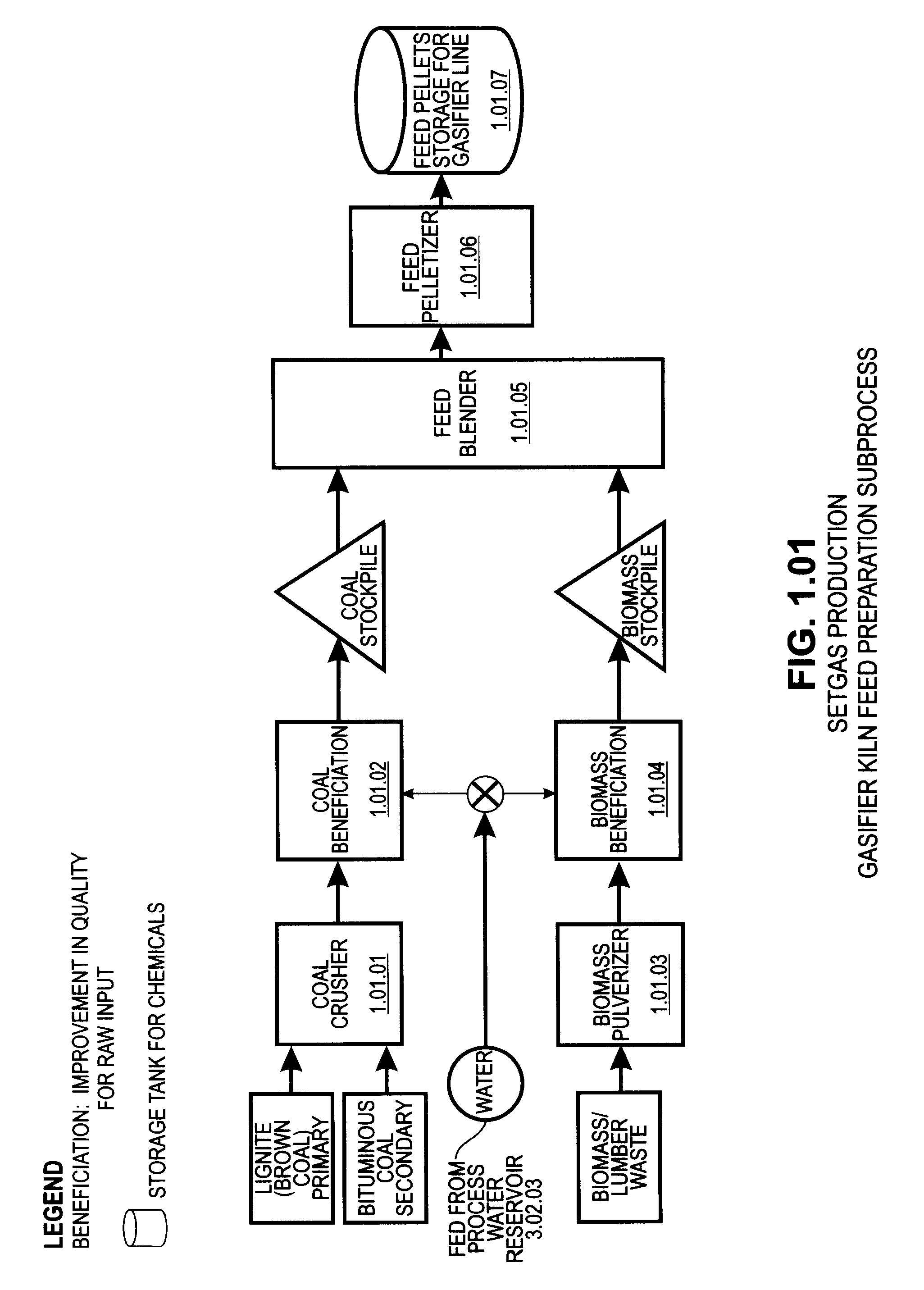

A system involving a two-step gasification of a carbonaceous source to produce bulk hydrogen that avoids the early formation of CO2 and obviates the traditional water gas shift (WGSR) step, carbochlorination of a metallic ore the production of metals found in the ore that utilizes carbon monoxide as an oxygen sink, rather than the traditional coke, and carbon oxides management that eliminates major impediments to emission-neutral power generation and the reduction of major metals. The gasification uses a rotary kiln reactor and gas-gas cyclonic separation process to separate synthesis gas into purified hydrogen and purified carbon monoxide. Purified bulk carbon monoxide issued in metallurgical reduction, and purified bulk hydrogen as fuel for an emission-neutral hydrogen combined cycle (HCC) turbine power generation station. The carbochlorination is integrated with: a) the concurrent separation and purification of all metal-chlorides (metchlors) and capture of CO2 for passage to the carbon oxides management system; b) the direct reduction of metchlors to nanoscale metallurgical powders and / or to dendritically-shaped particles, including metchlor reduction for the ultrahigh-performance semiconductor metals of the III-V group; and, c) the reforming of metal-oxides with improved crystalline structure from metchlors. The carbon oxides management collects, stores and directs to points of usage, carbon oxides that arise in various processes of the integrated system, and captures carbon monoxide for process enhancement and economic uses and captures carbon dioxide as a process intermediate and for economic uses.

Owner:DAVIS OLUMIJI B +1

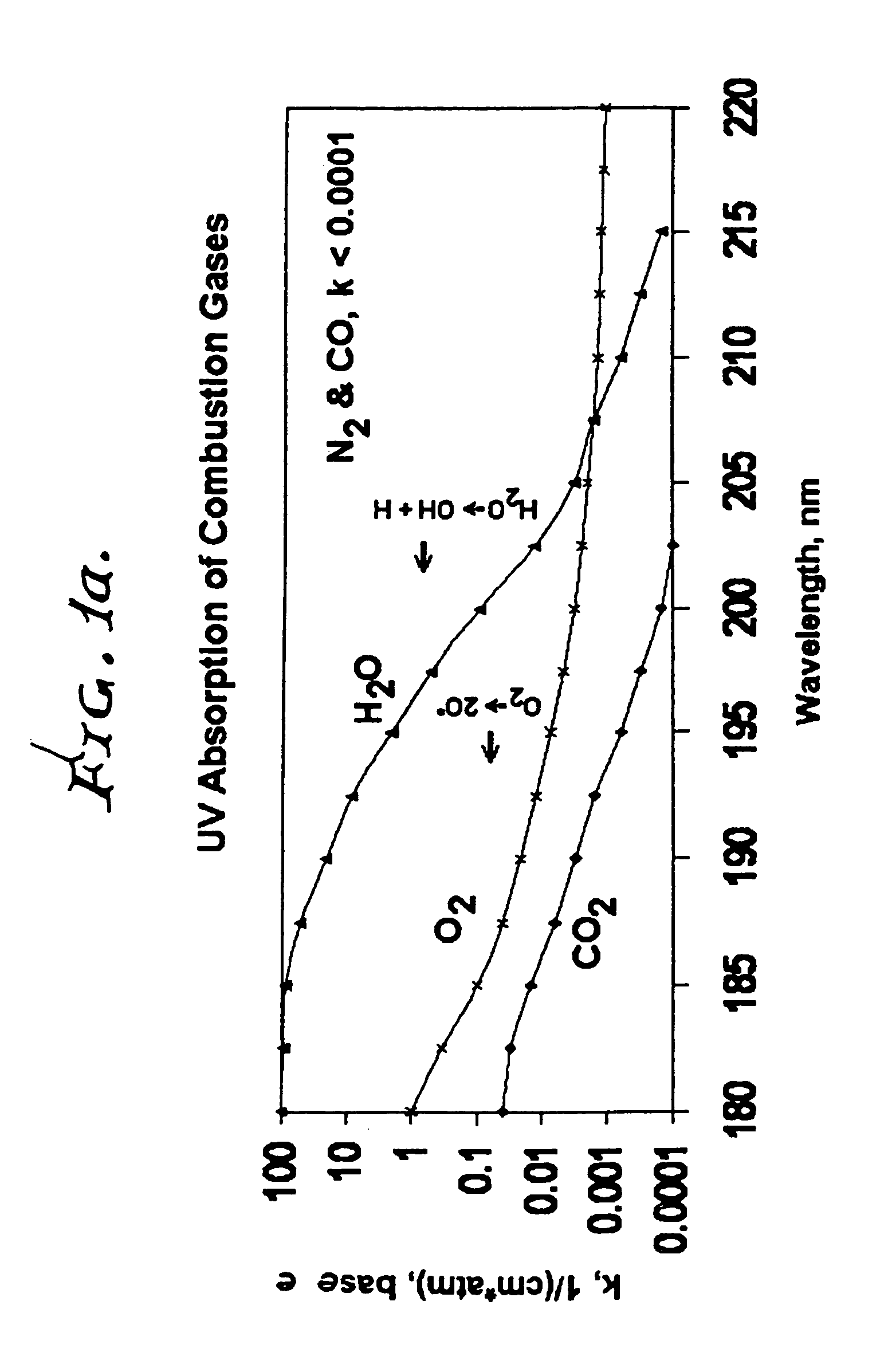

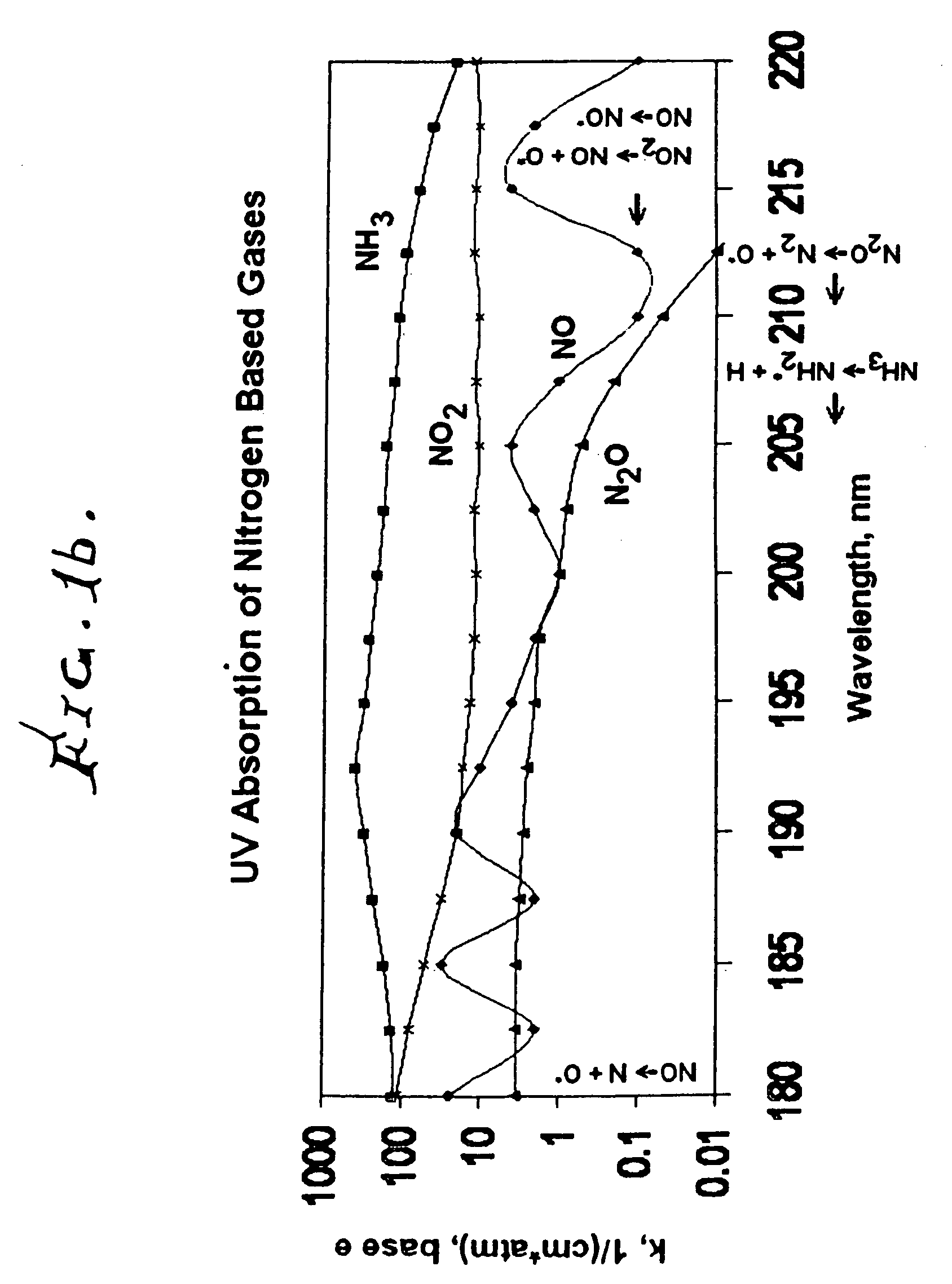

Controlled spectrum ultraviolet radiation pollution control process

InactiveUS7498009B2Cost effectiveEasy to adaptCombination devicesOrganic chemistryEnvironmental engineeringNitrogen oxide

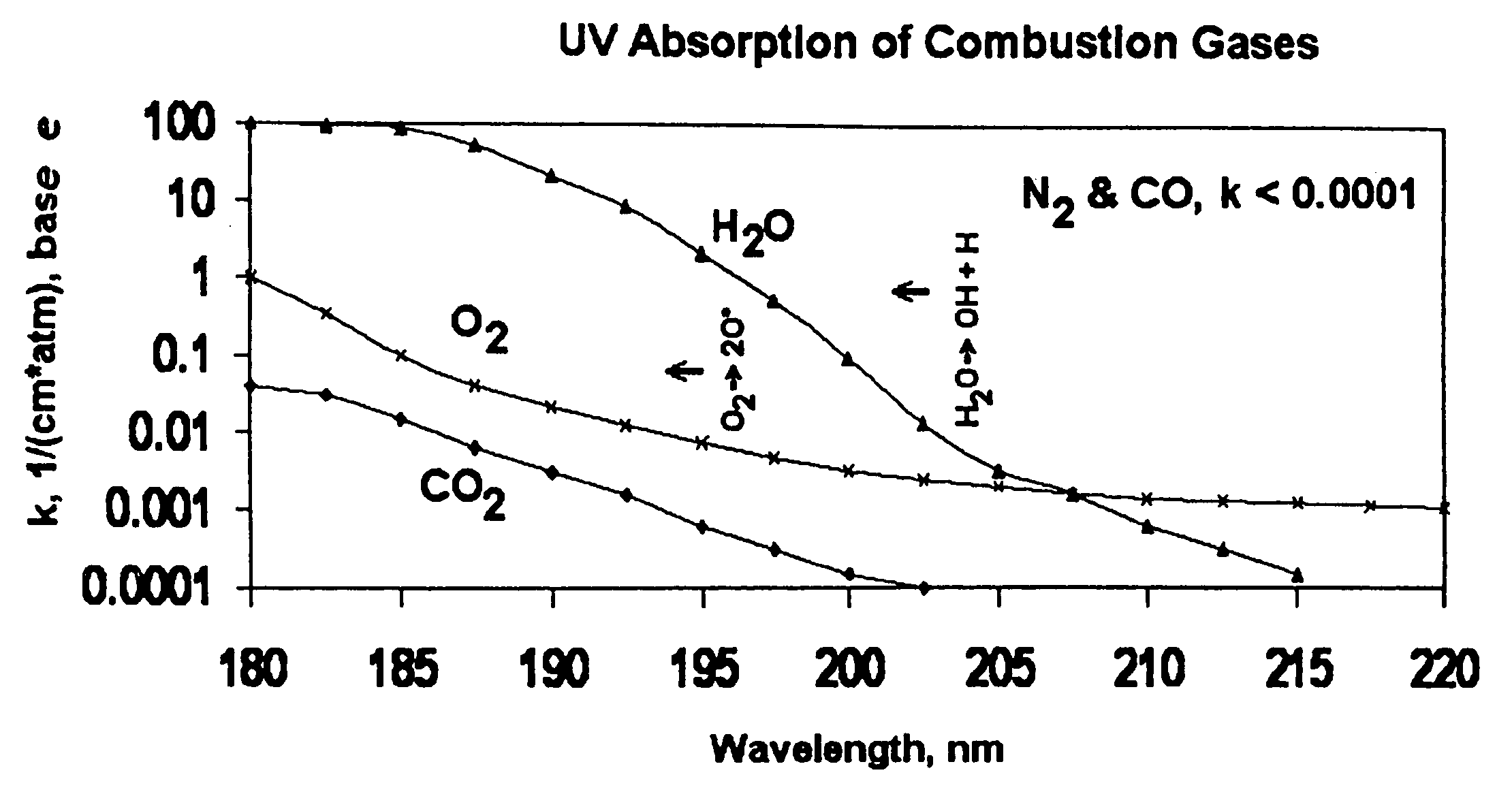

A method for reducing or substantially eliminating oxides of nitrogen from an effluent gas stream, that includes providing a source of ultraviolet radiation with a precise wavelength, adding ammonia or an ammonia based reagent to the effluent stream, upstream of the ultraviolet radiation source, controllably operating the ultraviolet radiation source to irradiate the effluent stream flowing in the duct and substantially reducing or eliminating oxides of nitrogen by promotion a reaction of ammonia with the oxides of nitrogen to produce N2 and H2O, and also thereby destroying any surplus ammonia. This process can also be modified to oxidize carbon monoxide and VOC's to CO2 and H2O.

Owner:DANA UV

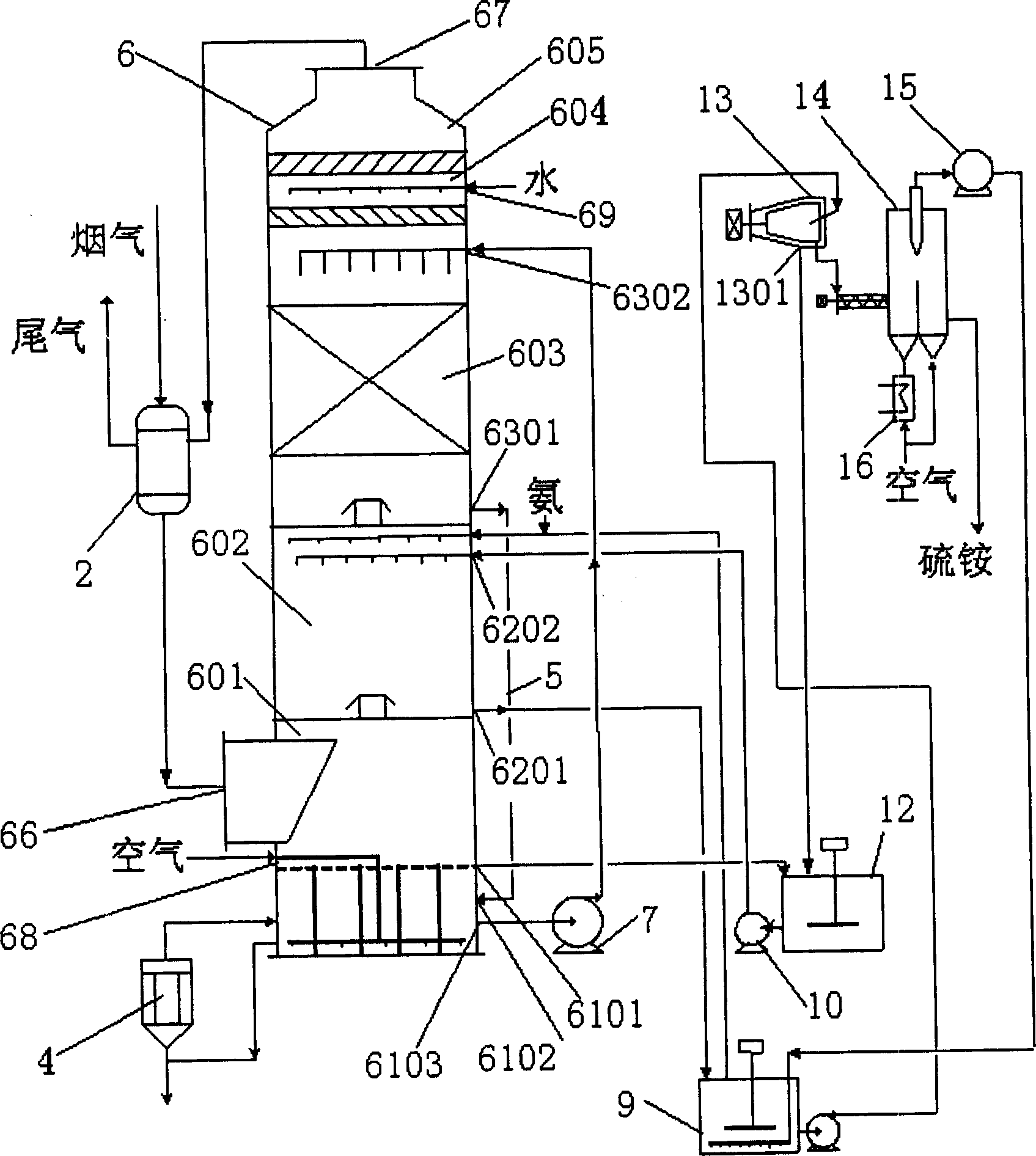

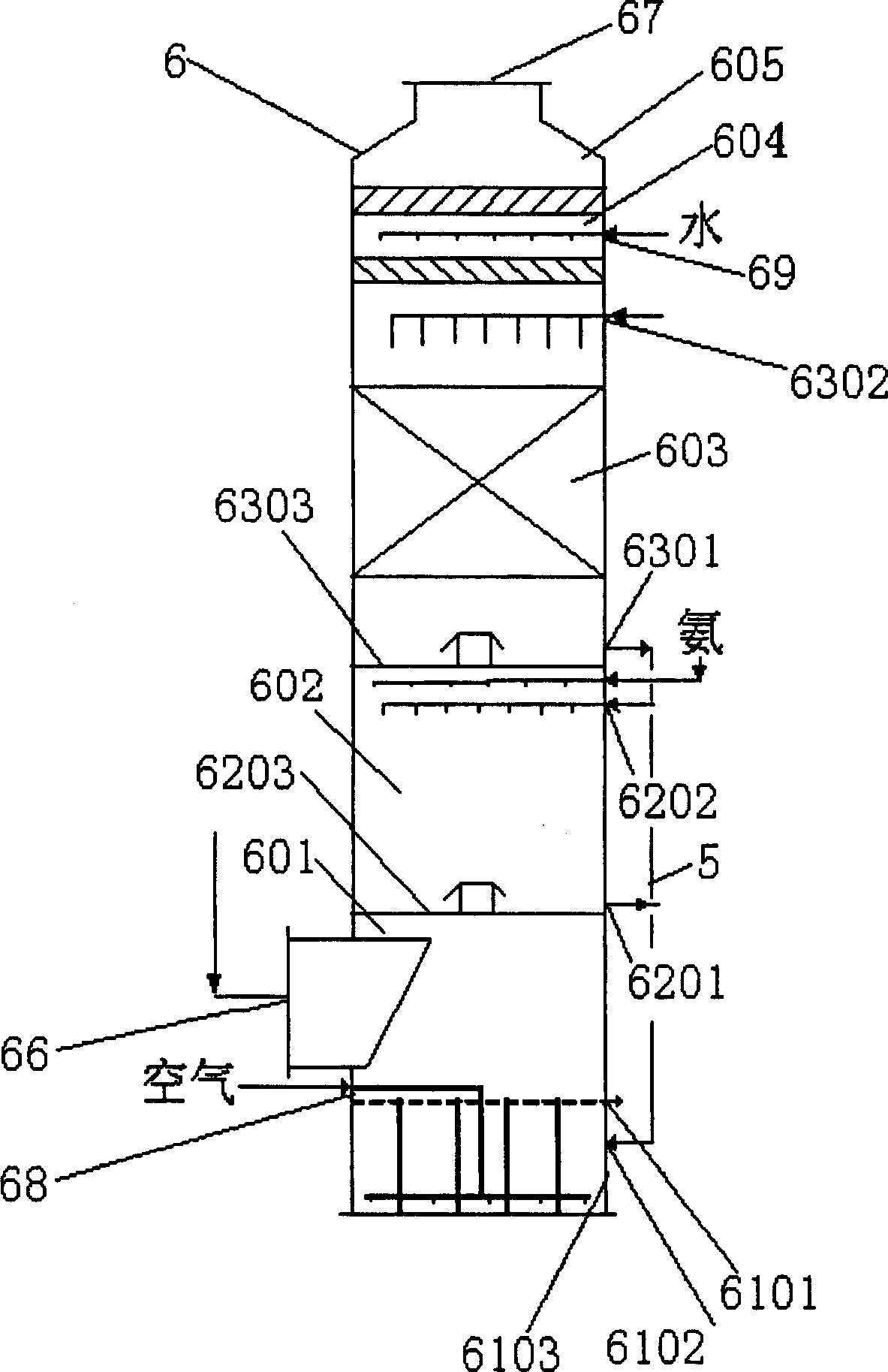

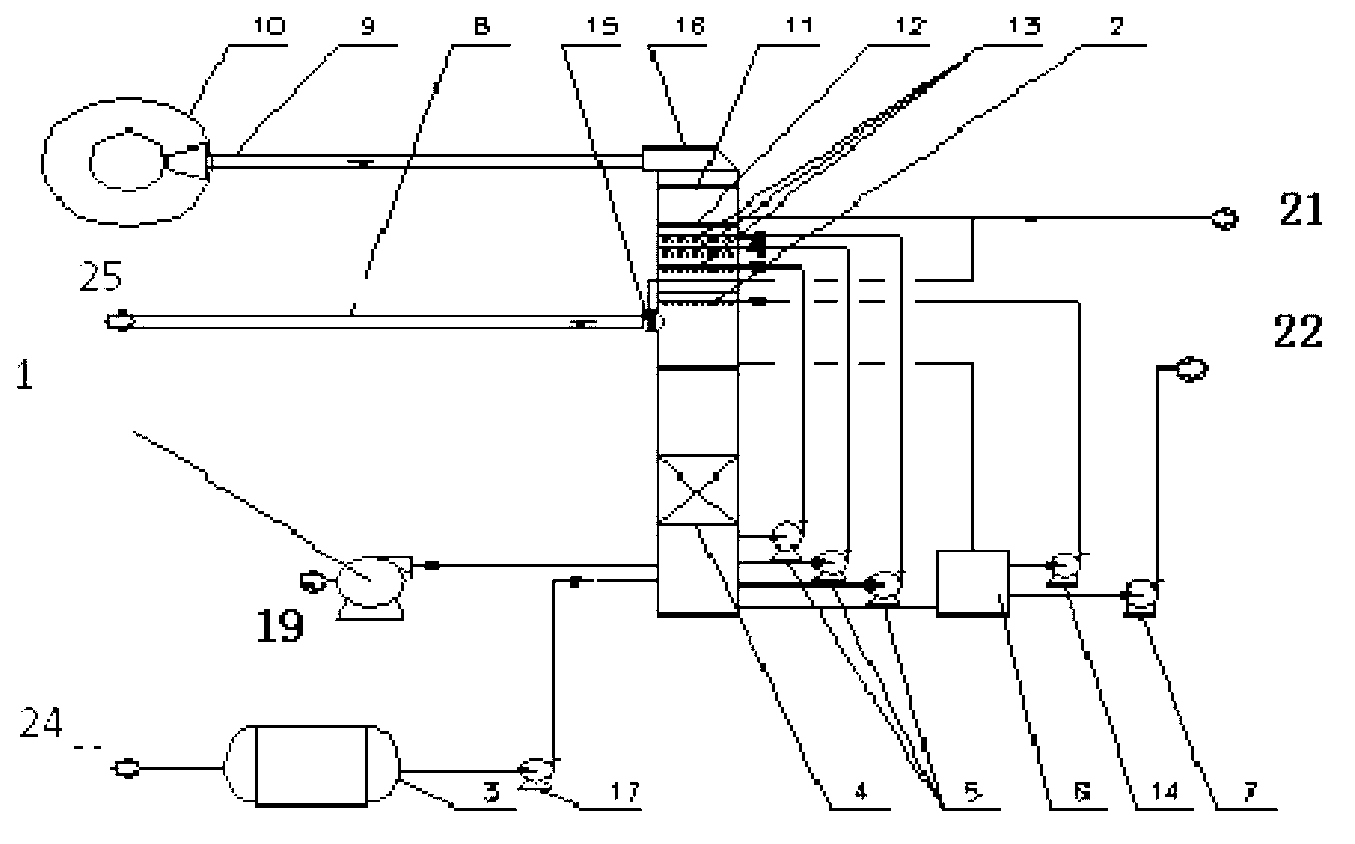

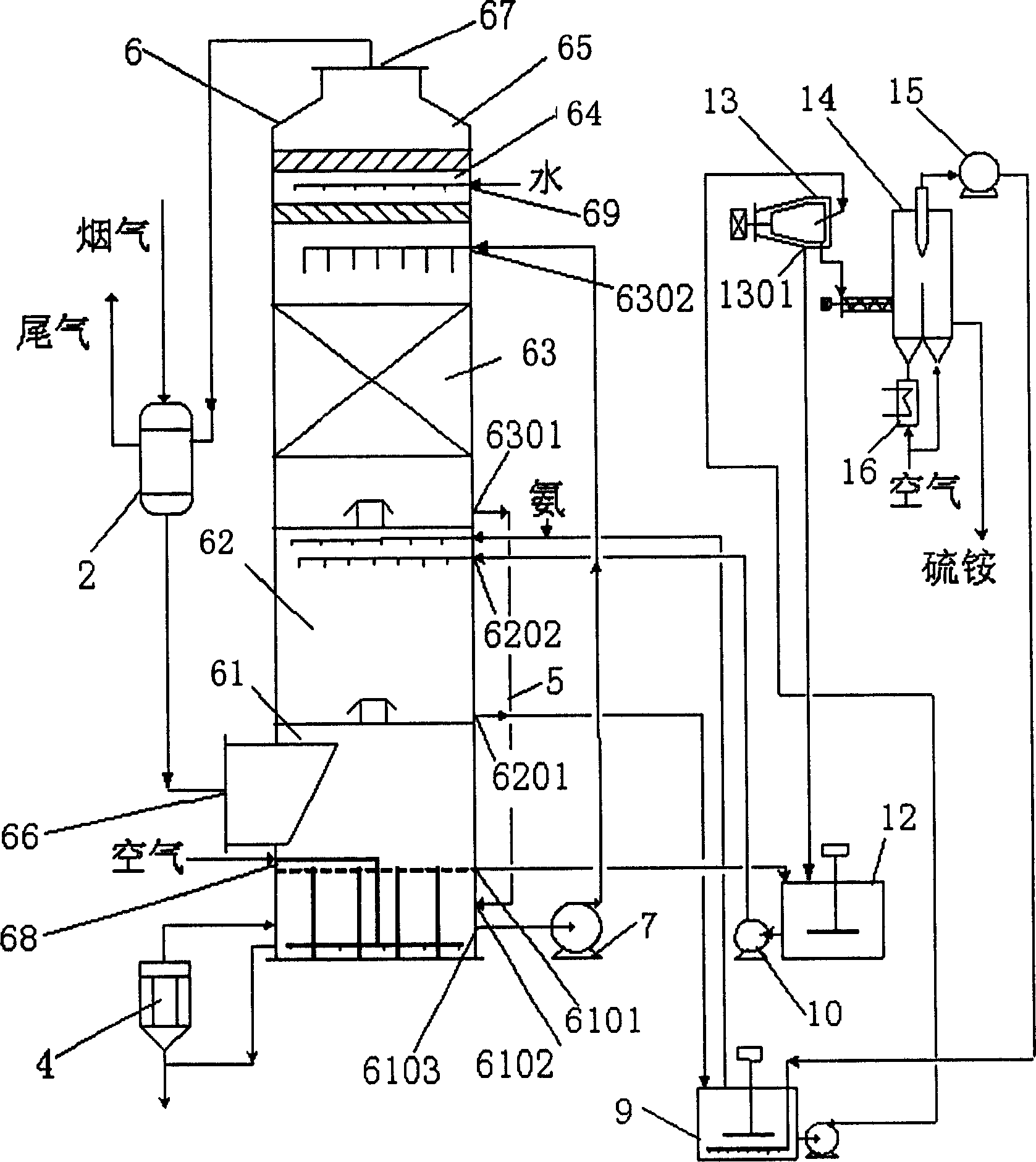

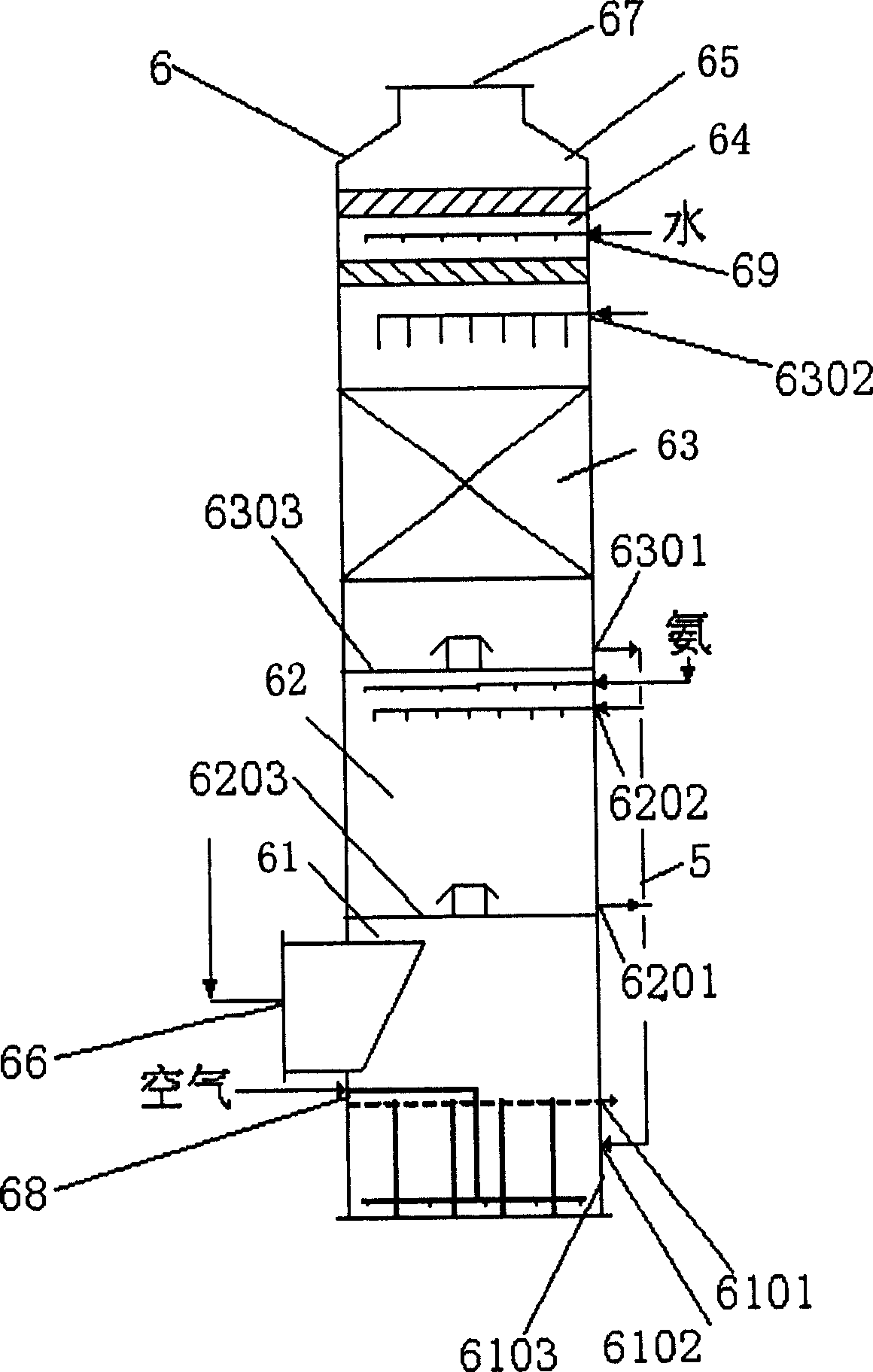

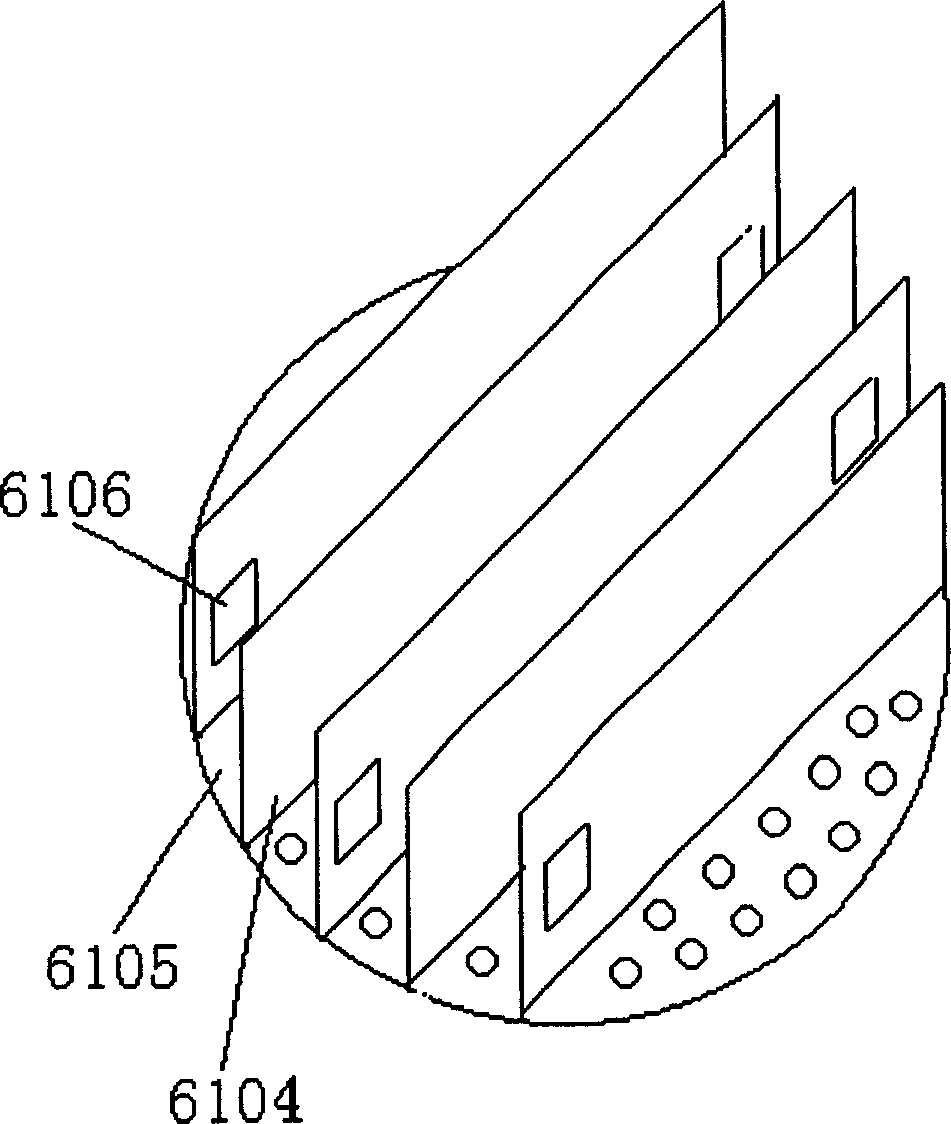

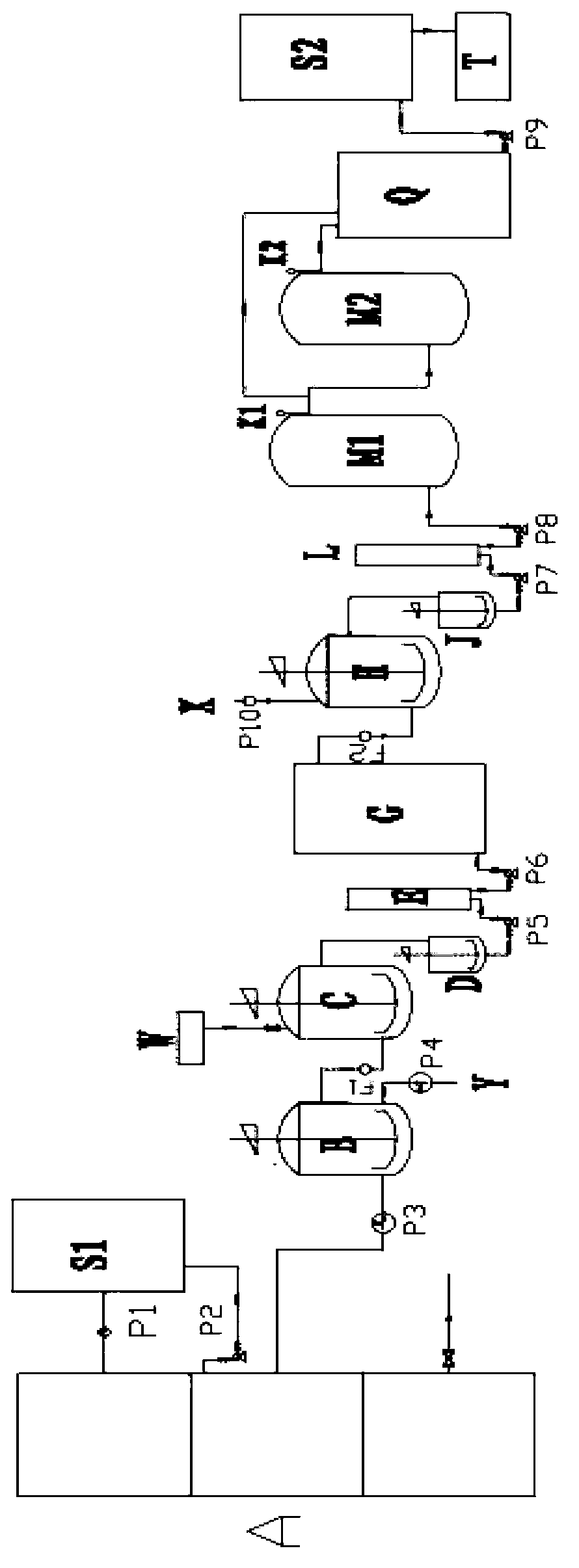

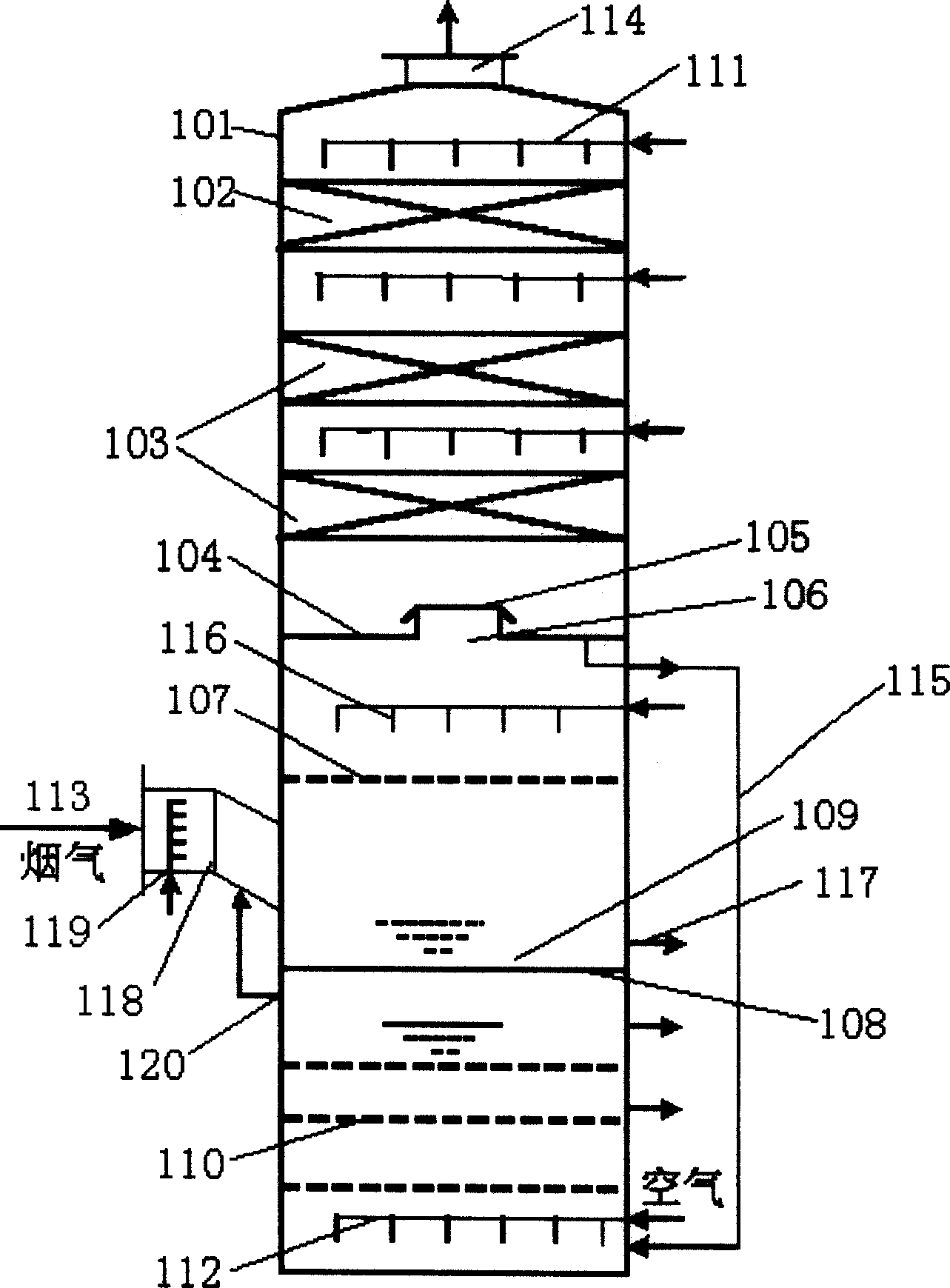

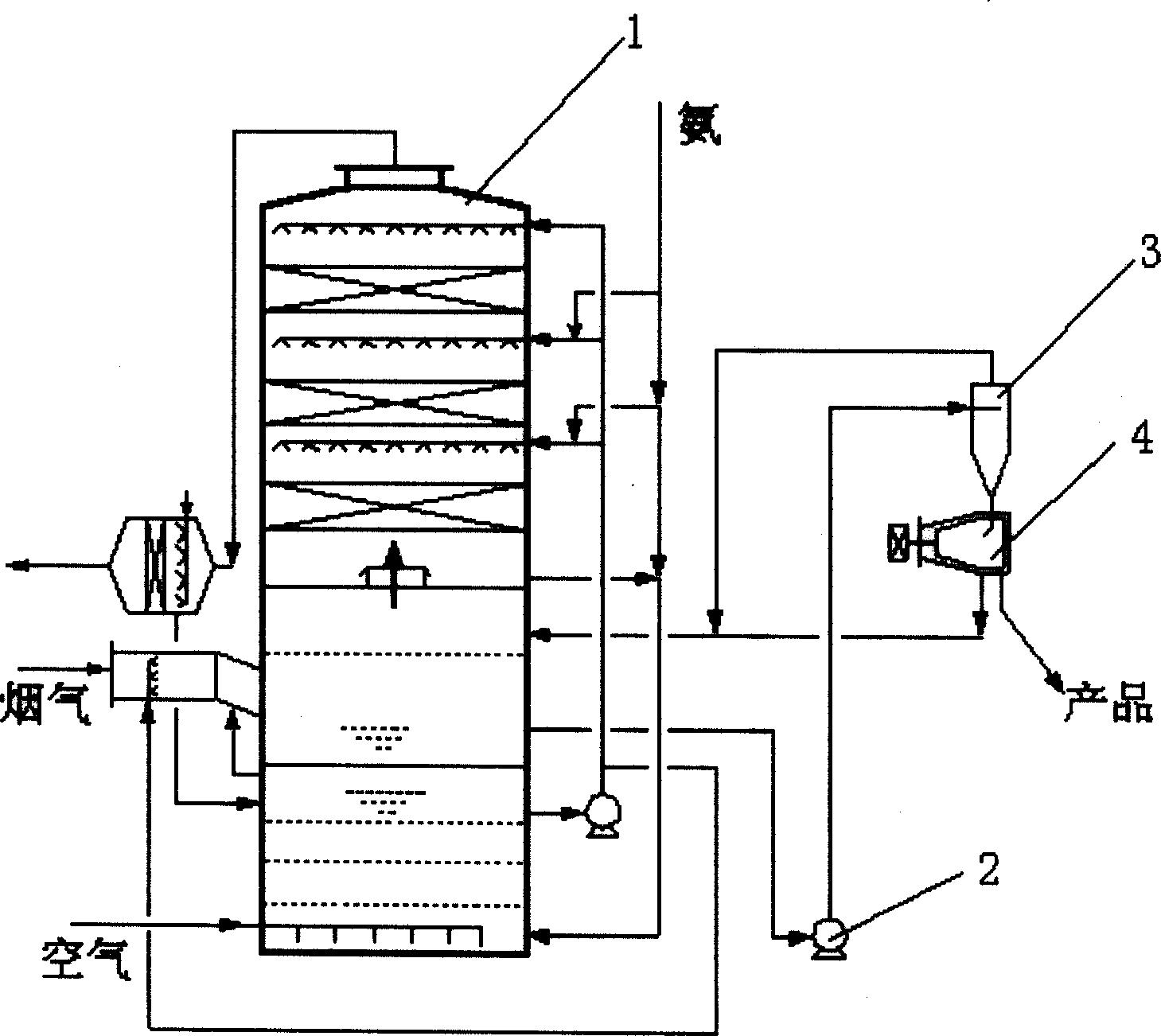

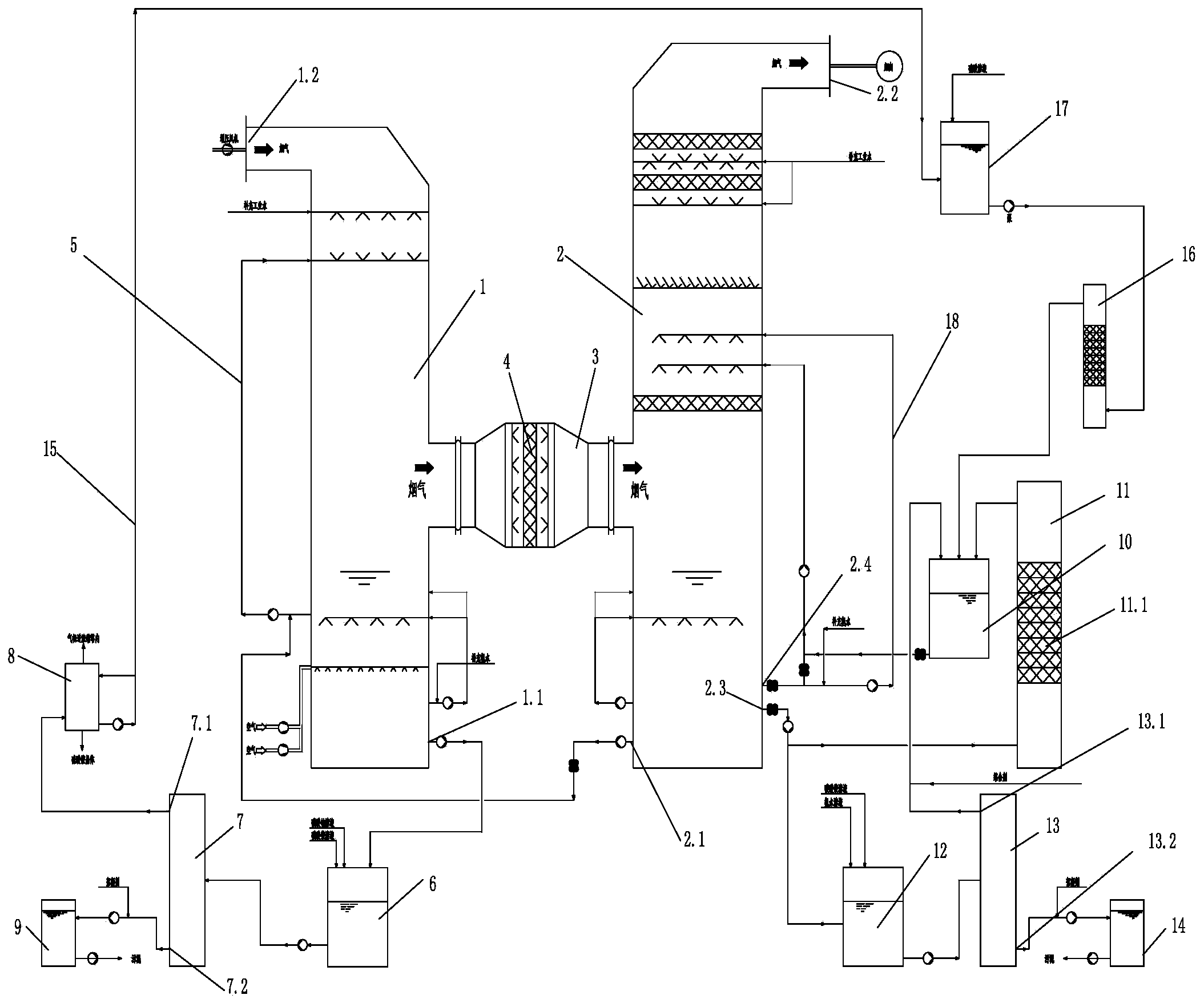

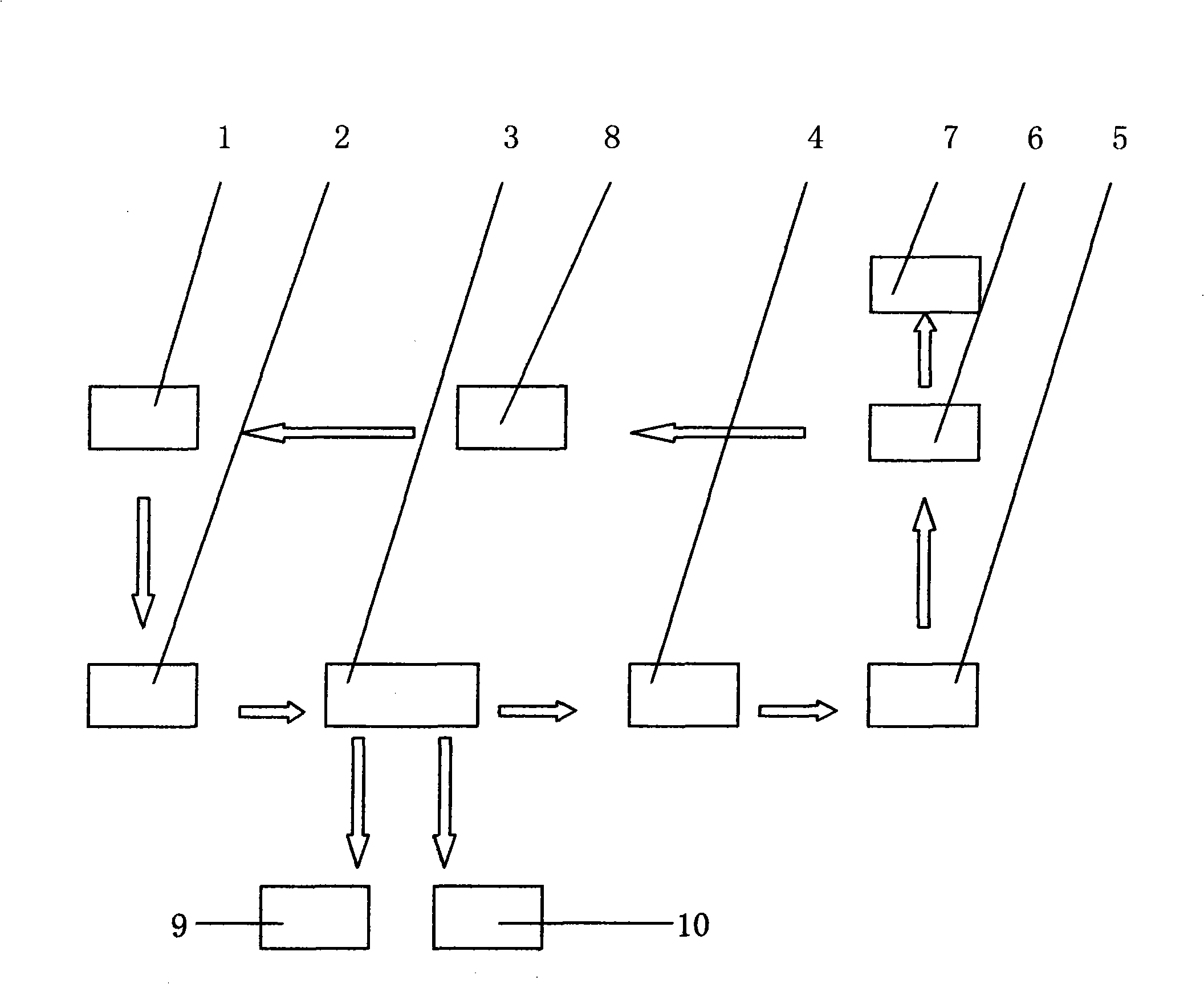

Removing and recovering process and device for SO2 in flue gas

InactiveCN1408464AReduce consumptionEasy to operateDispersed particle separationAmmonium sulfatesRecovery methodGas to liquids

The recovering process includes the steps of: the reaction of the S containing fume with water solution of ammonia, with ammonia-to-sulphur molar ratio of 1.3-1.8 and gas-to-liquid ratio of 2000-5000, to produce ammonium sulfite solution; the oxidation of ammonium sulfite solution with air to obtain ammonium sulfate solution; the contact of the ammonium sulfate solution with hot fume to evaporatewater and the crystallization of ammonium sulfate in a crystallizer to produce commercial ammonium sulfate fertilizer. The equipment includes one desulfurizing tower with SO2 absorbing section, one ammonium sulfite oxidizing section, ammonium sulfate solution concentration section, one water washing section and mist elimianting section. The present invention can lower cost and steam consumption, reduce fume density and produce ammonium sulfate fertilizer.

Owner:EAST CHINA UNIV OF SCI & TECH

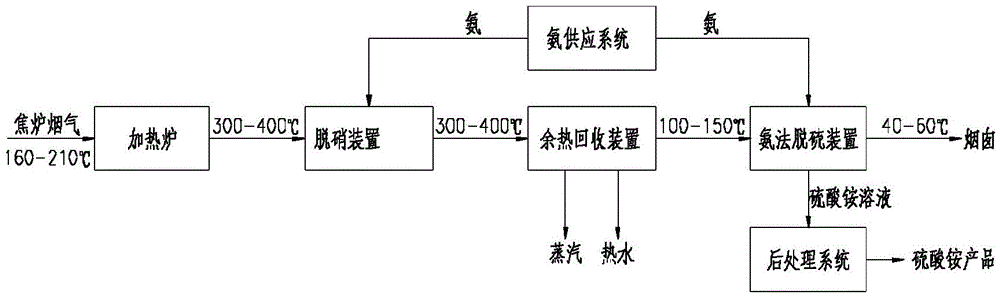

Coke oven flue gas desulfurization, denitration and waste heat recovery integrated method

InactiveCN104923046ASimple processWork lessDispersed particle separationEnergy inputFlue gasReaction temperature

The invention relates to a coke oven flue gas desulfurization, denitration and waste heat recovery integrated method. Flue gas from a coke oven firstly enters a heating furnace to be heated to 300 to 400 DEG C, and then the flue gas enters a denitration device for removing nitrogen oxide in the flue gas through a denitration reducer and a denitration catalyst, wherein the denitration reducer is ammonia; and the flue gas discharged from the denitration device is subjected to heat recovery through a waste heat recovery device and cooled to 100 to 150 DEG C, and then the flue gas enters an ammonia desulfurization device for removing sulfur dioxide in the flue gas. Both a desulfurization absorbent and the denitration reducer in the method are ammonia, and public ammonia is supplied to a system, so that operation and maintenance work is reduced. The heating furnace for heating and the waste heat recovery device are arranged, so that the flue gas temperature reaches the optimal denitration and desulfurization reaction temperatures respectively, relatively high denitration and desulfurization efficiency can be achieved, and flue gas waste heat can be recycled for greatly reducing the operation cost of coke oven flue gas treatment.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

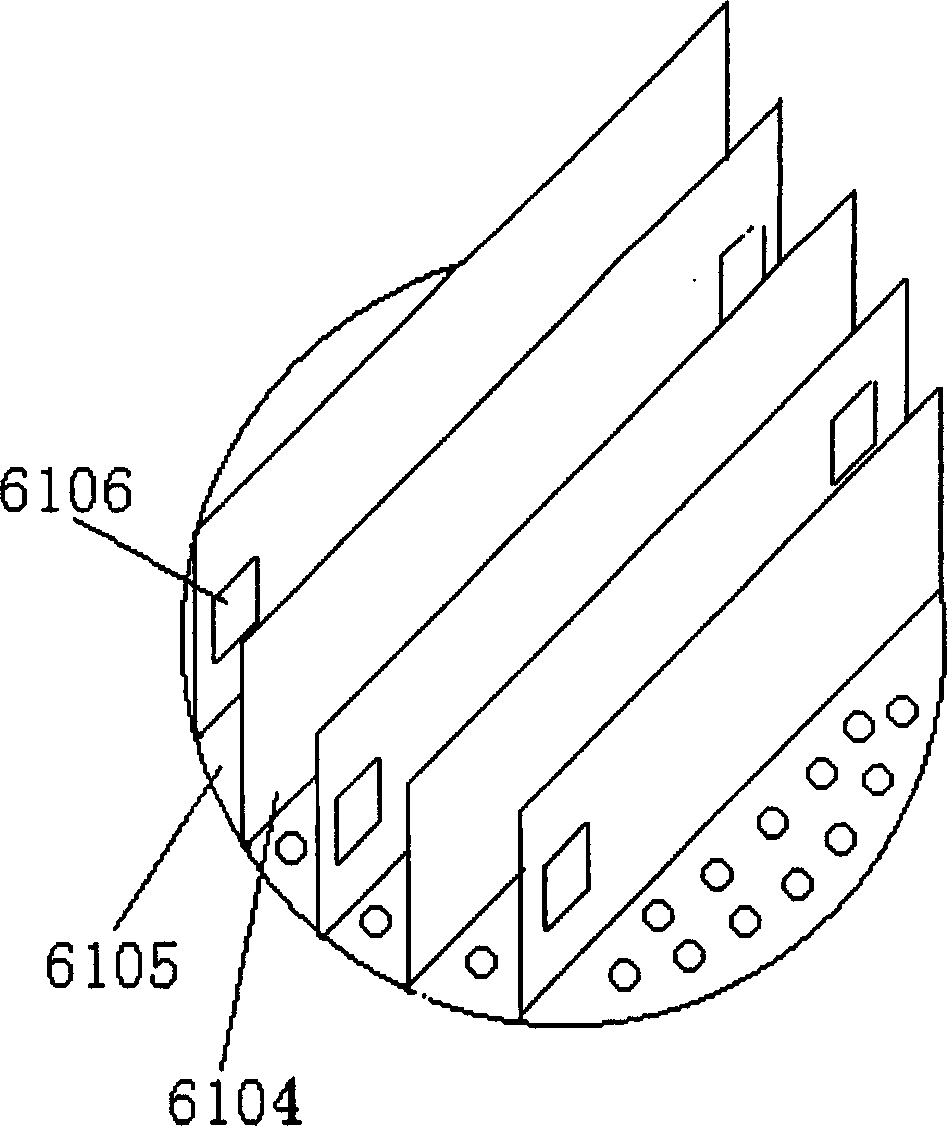

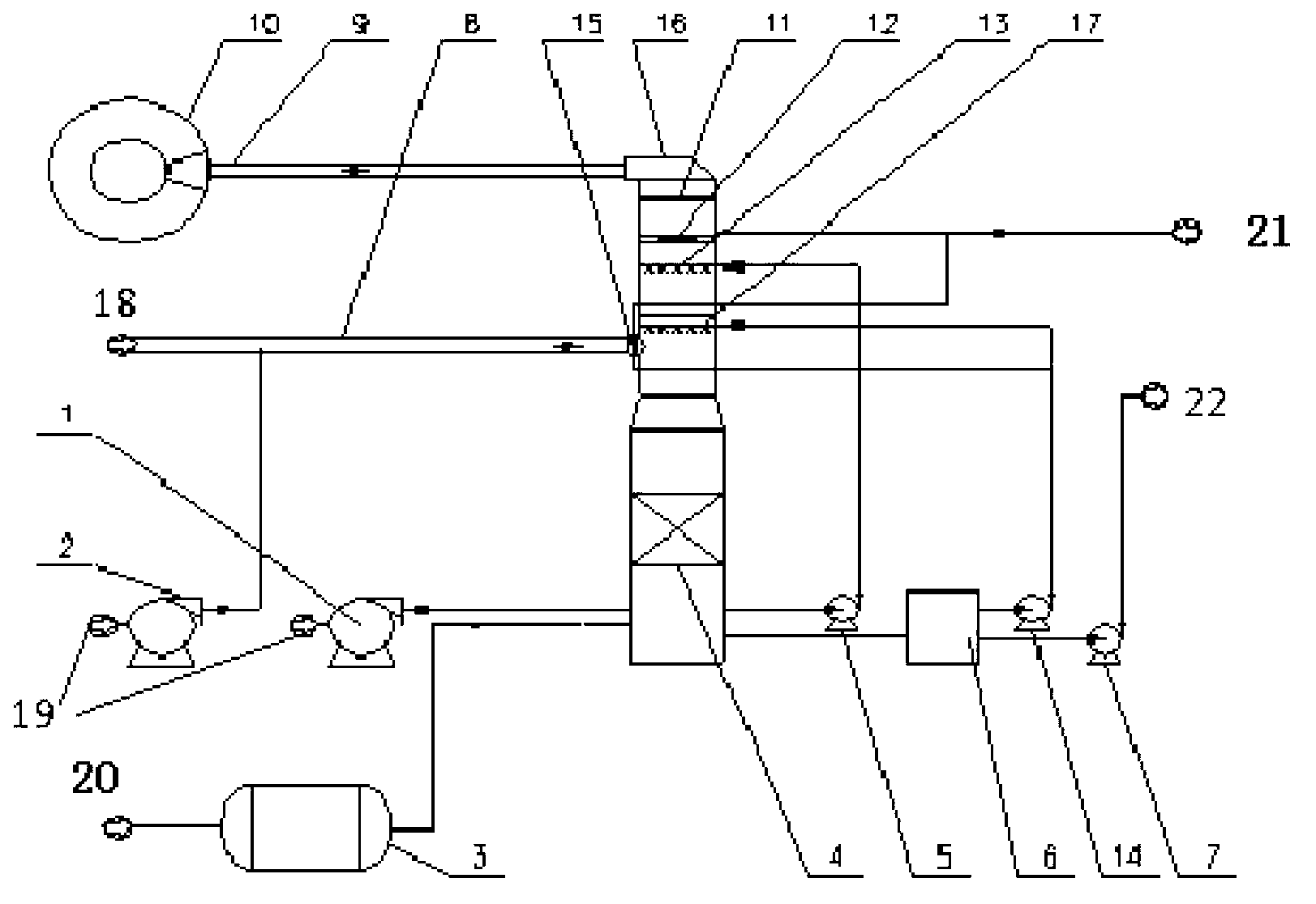

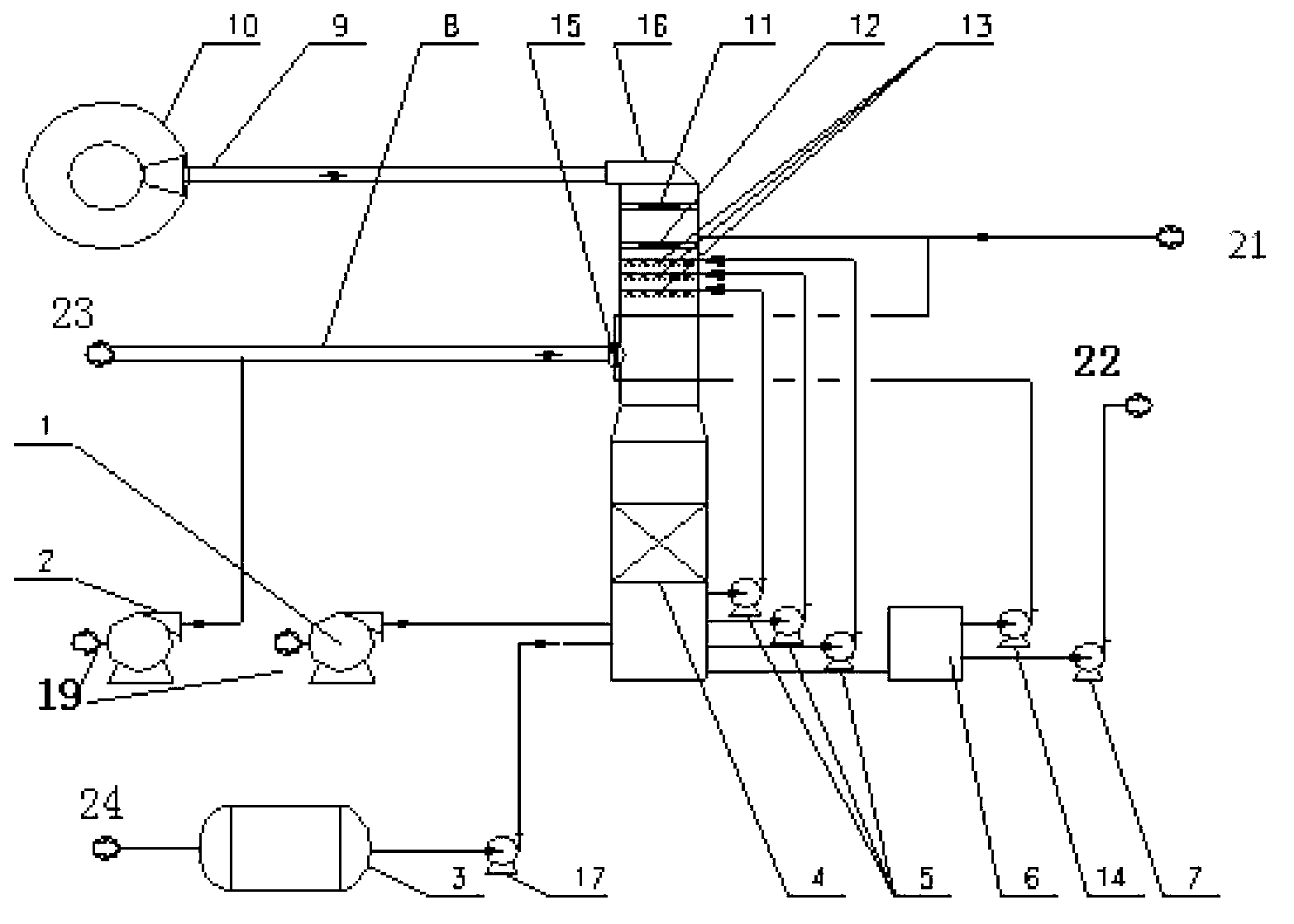

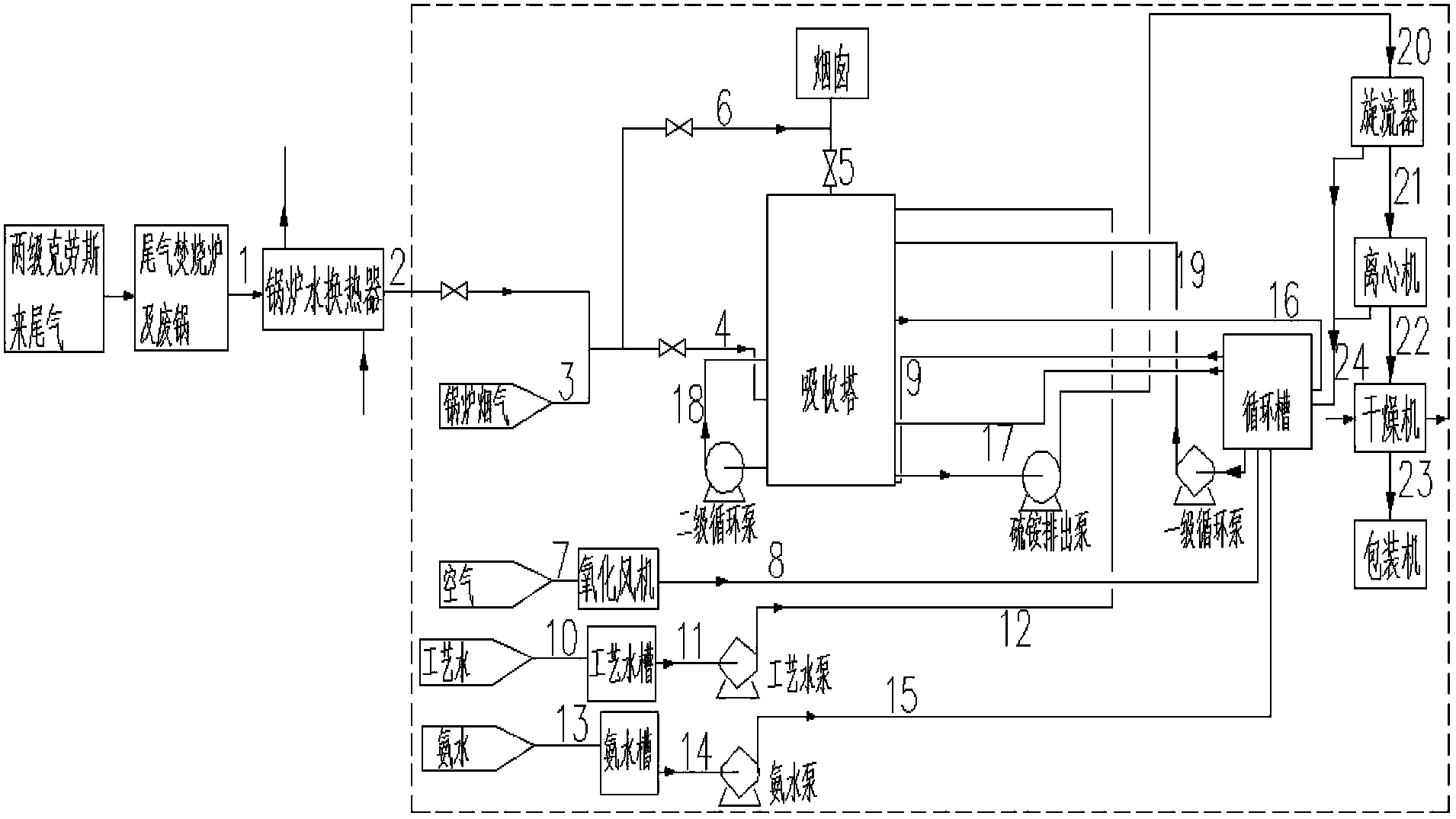

Ammonia process flue gas treatment method for acidic tail gas and device

ActiveCN103223292AIncreased self-concentrationGood desulfurization absorptionDispersed particle separationAmmonium sulfatesEnvironmental resistanceAmmonia storage

The invention relates to an ammonia process flue gas treatment method for acidic tail gas. The method includes the steps of: 1) controlling the sulfur dioxide concentration of tail gas entering an absorption tower at a level of less than or equal to 30000mg / Nm<3>; 2) arranging process water in an absorption tower entrance flue or in the absorption tower or cooperating with a ammonium sulphate solution to perform spray cooling; 3) disposing an oxidation section in the absorption tower, setting an oxidation distributor at the oxidation section to achieve oxidation of a desulfurized absorption liquid; 4) arranging an absorption section in the absorption tower, utilizing an absorption liquid distributor in the absorption section to realize desulfurization spray absorption by an ammonia-containing absorption liquid, which is fed through an ammonia storage groove; 5) arranging a water washing layer at an absorption section upper part in the absorption tower, washing the absorption liquid in the tail gas by the water washing layer and reducing the absorption liquid escape; and 6) setting a demister at the upper part of the water washing layer in the absorption tower to control the mist drop content in the purified tail gas. Employment of the Claus sulfur recovery and ammonia process desulfurization integrated desulfurization technology in the coal chemical industry can reduce the investment cost of after-treatment, the process can be simpler, and factory environmental protection treatment can form an intensive advantage.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

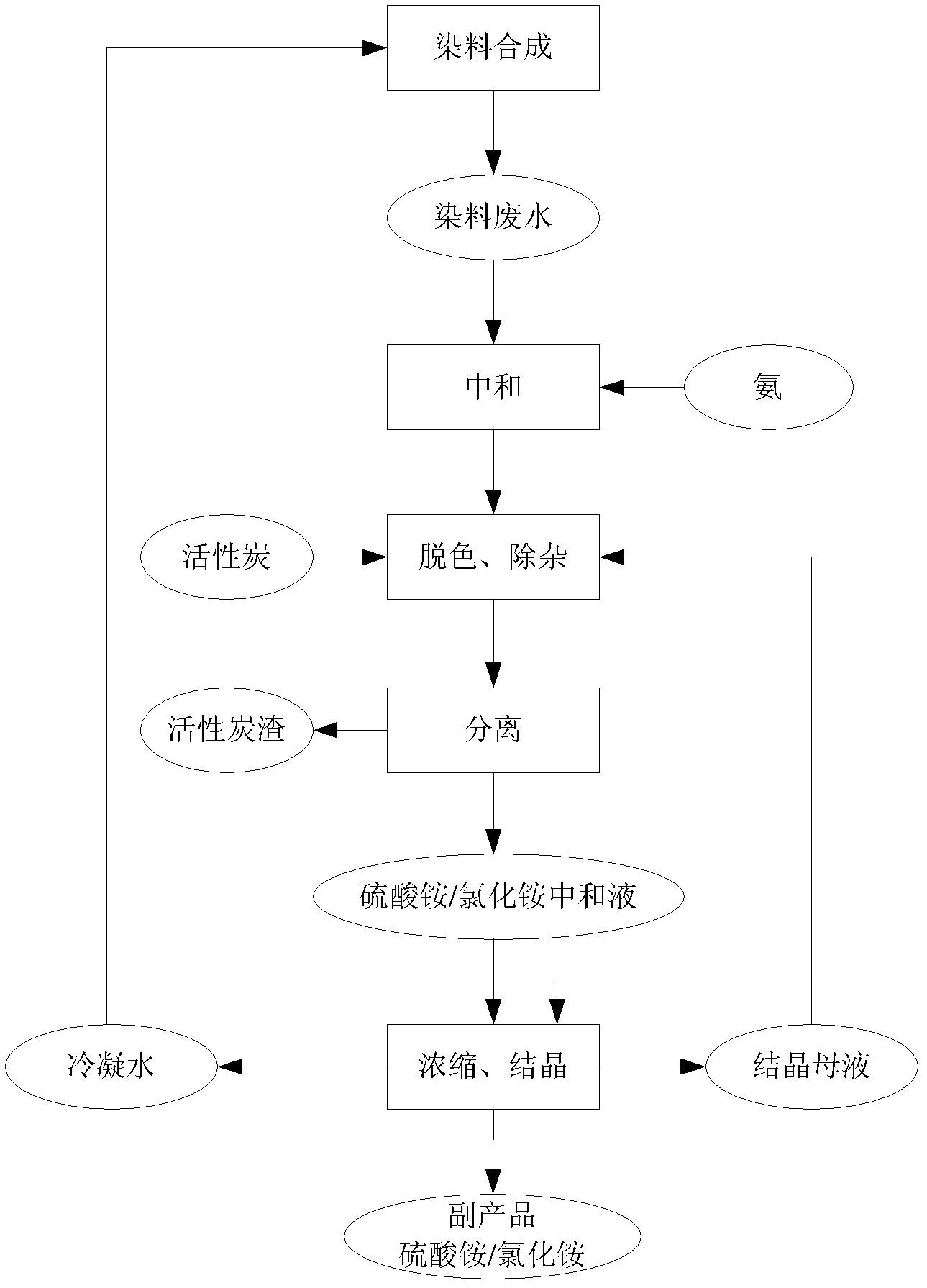

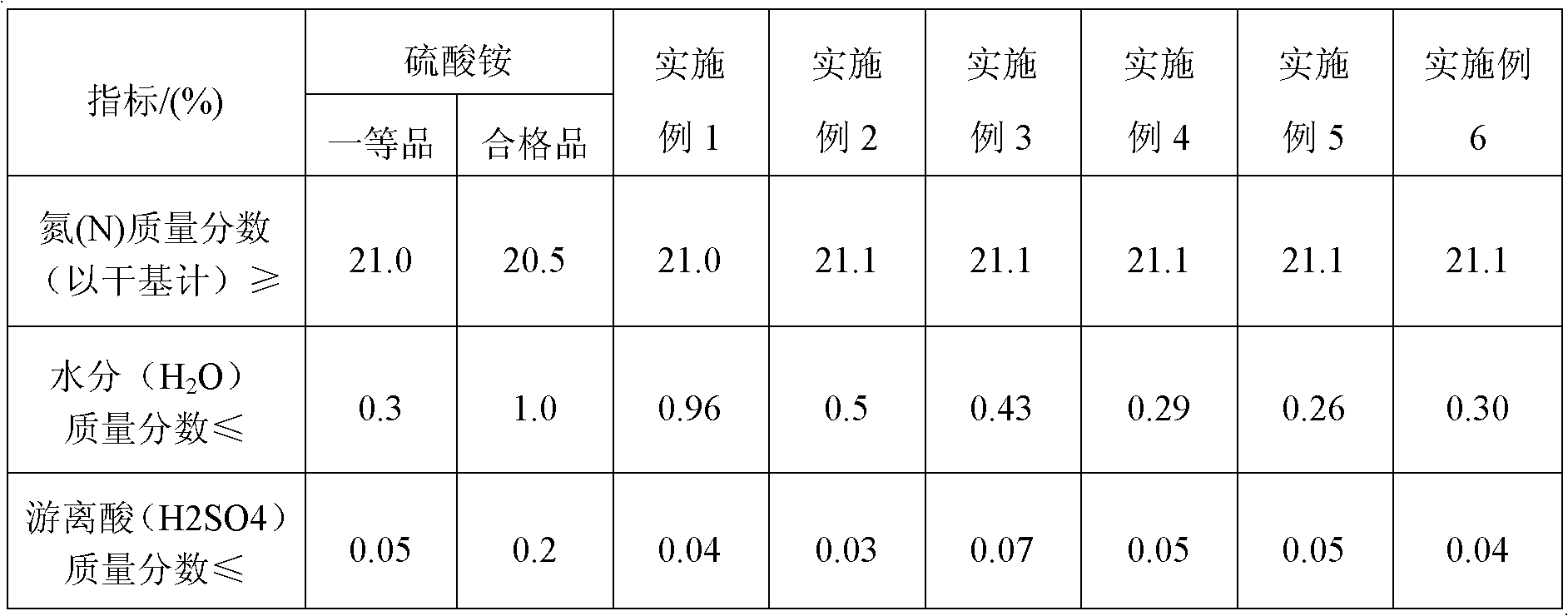

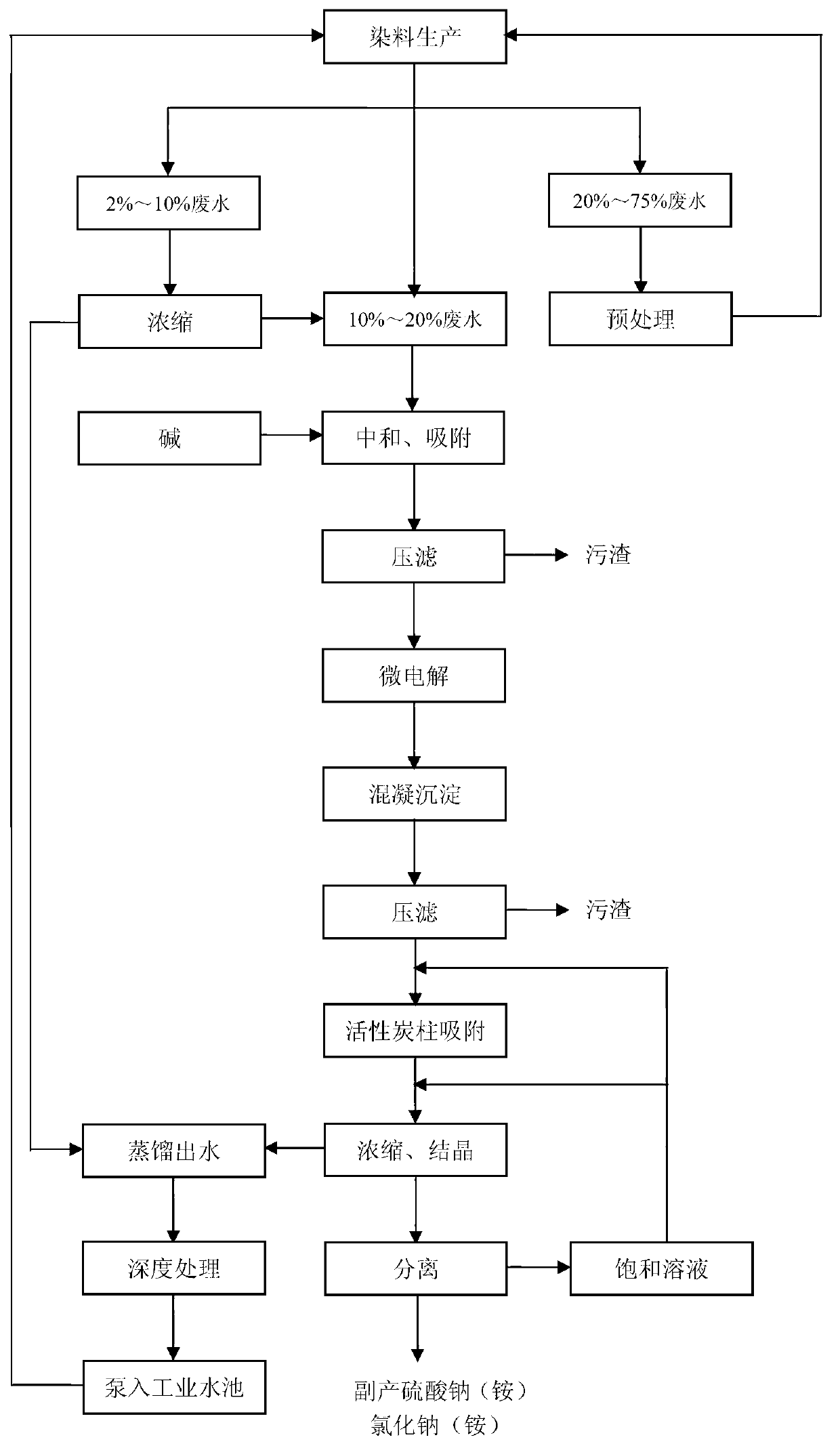

Cleaning treatment method of dying industrial acidic wastewater

ActiveCN102826673AAchieve recyclingAvoid it happening againAmmonium sulfatesMultistage water/sewage treatmentSulfateWastewater

The invention provides a cleaning treatment method of dying industrial acidic wastewater. After purified by measurements of neutralization, decolouring, oxidation, condensation, separation and the like, wastewater is reused as synthetic bottom water and dye filter cake washing water for dye production, thus avoiding discharge of a lot of colored wastewater with high COD value during a traditional dye production process. By a method of using a by-product ammonium sulfate or ammonium chloride, generation of calcium sulfate is avoided during neutralization of wastewater by the use of lime. Therefore, the dangerous solid waste calcium sulfate slug treatment problem is solved, and the cleaning production purposes of water saving, emission reduction and synergy are reflected.

Owner:ZHEJIANG LONGSHENG GROUP +1

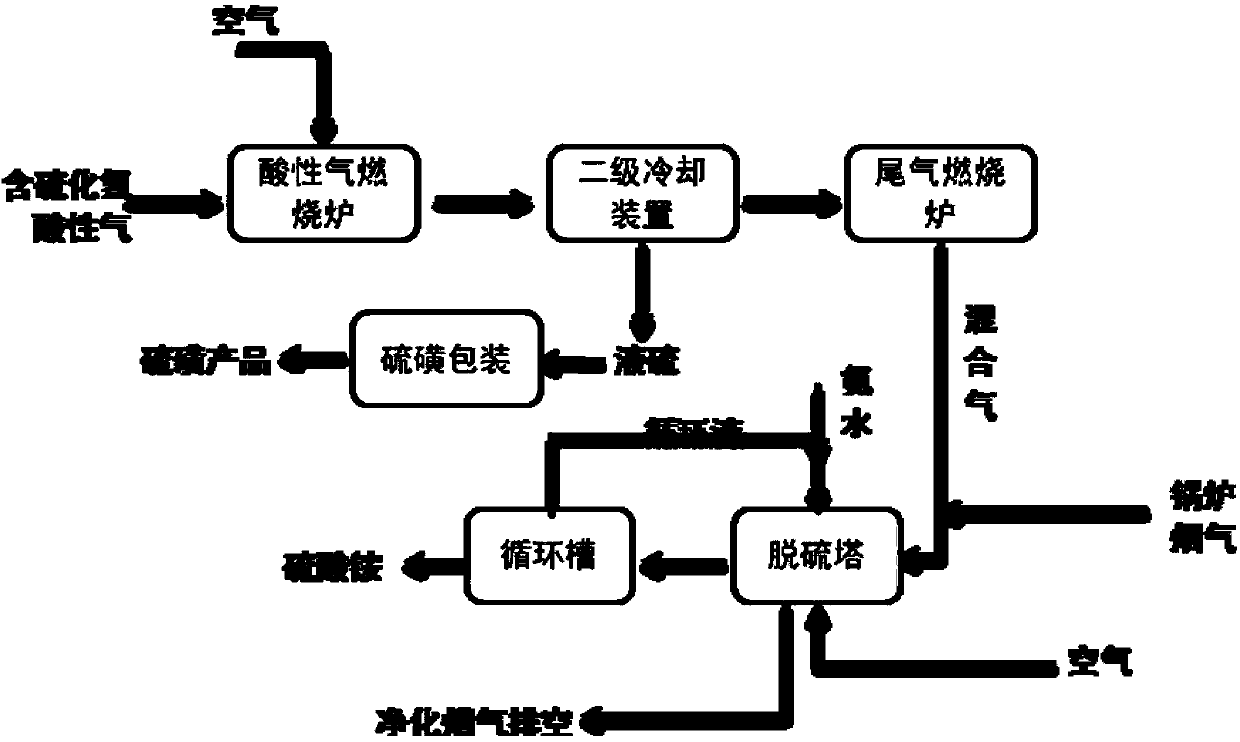

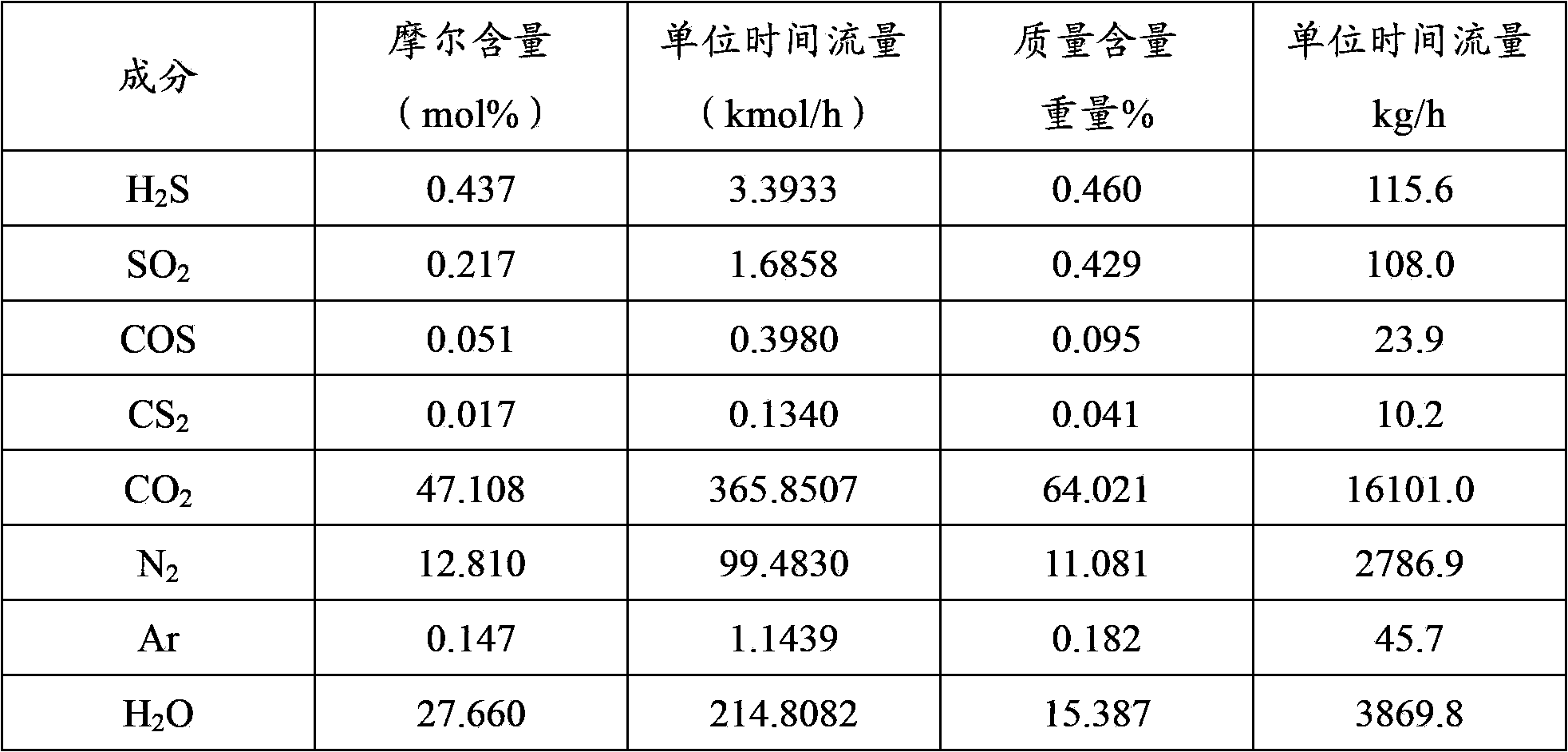

Comprehensive desulphurization technology in coal chemical industry

InactiveCN103418223AHigh recovery rateEmission reductionDispersed particle separationAmmonium sulfatesCombustionTower

The invention discloses a comprehensive desulphurization technology in the coal chemical industry. The comprehensive desulphurization technology comprises the following steps: acidic gas containing hydrogen sulfide and coming from a low-temperature methanol washing device burns to generate mixed gas, and the mixed gas is subjected to two stages of cooling to separate out liquid sulfur for producing solid sulfur; sulphuric mixed gas separated out after cooling is subjected to secondary combustion so that all sulphureous components in the mixed gas are changed into SO2, tail gas generated after combustion and boiler flue gas of a heating power station are fully mixed and enter a desulphurization tower, circulating liquid containing aqua ammonia is used as an absorbent to absorb SO2 in a countercurrent contact way and react to generate ammonium sulfite, and ammonium sulfite is further oxidized to change into ammonium sulfate; desulphurized and purified flue gas is discharged into air through a chimney; ammonium sulfate solution at the bottom of the desulphurization tower enters a circulation tank and is crystallized to form the ammonium sulfate product. The comprehensive desulphurization technology adopts a novel combined desulphurization technology to replace the traditional Klaus Scott or Super Claus technology, and can effectively lower investment, improve recovery rate of sulfur and reduce discharge of sulfur.

Owner:XINWEN MINING GROUP

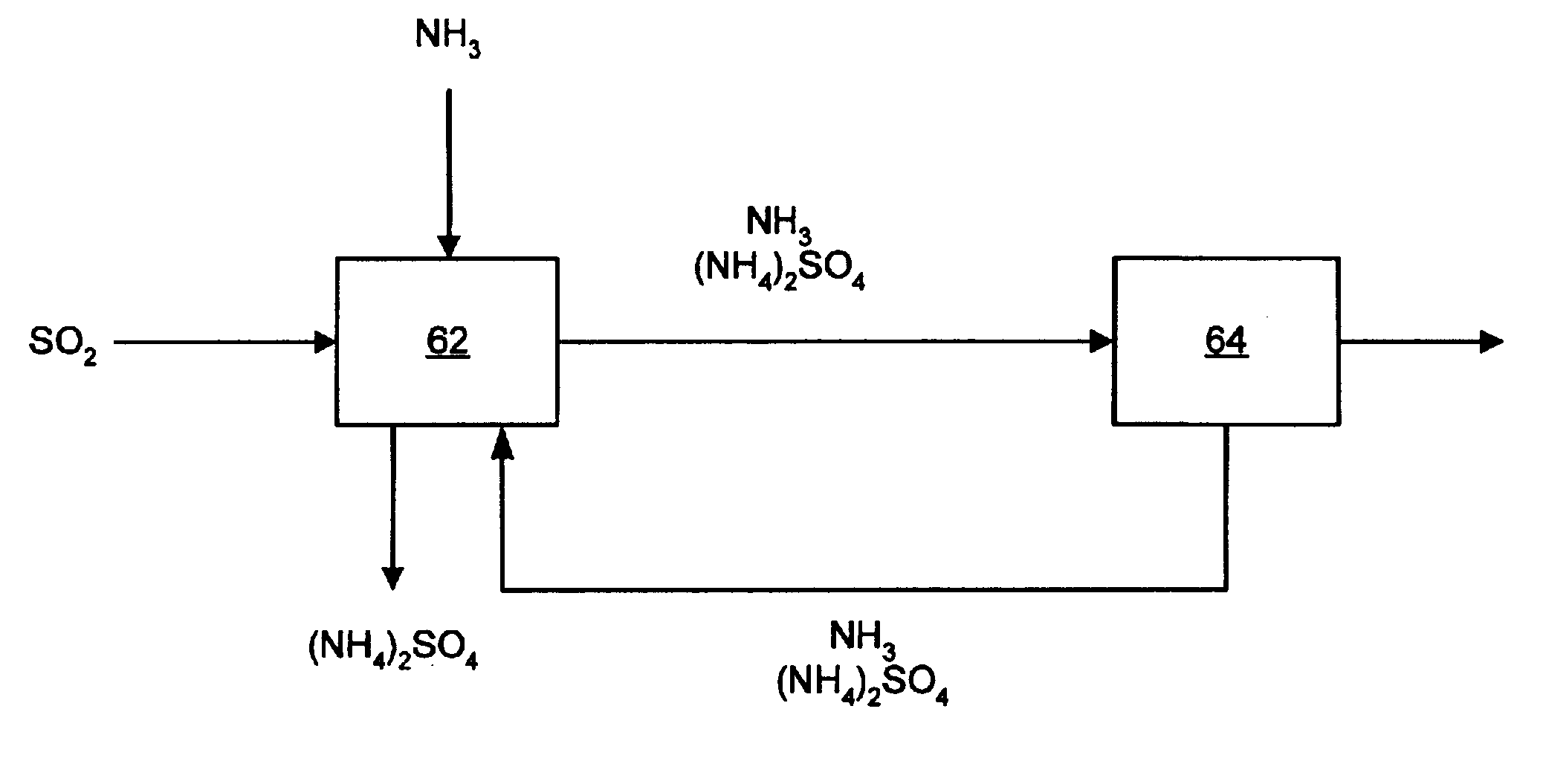

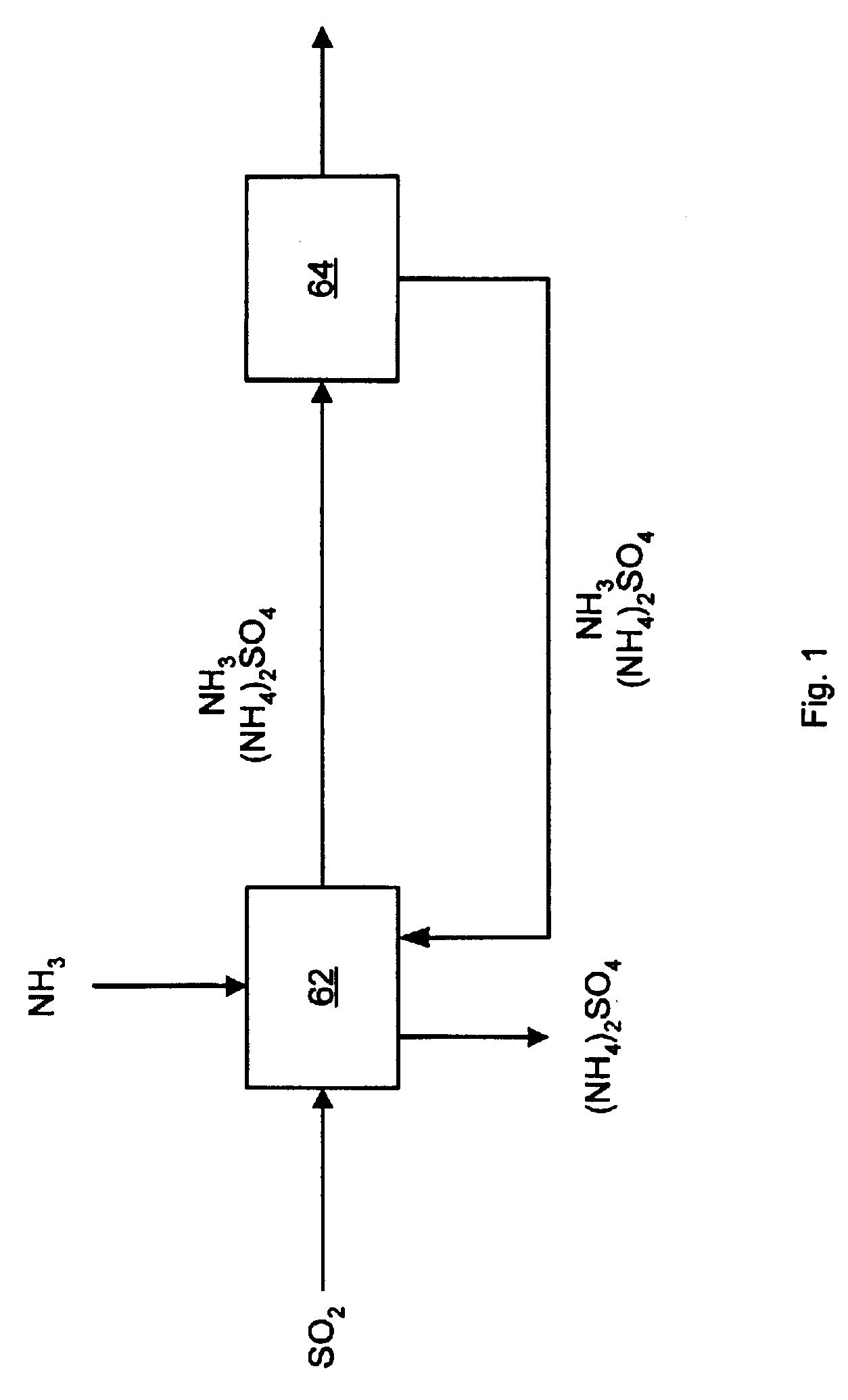

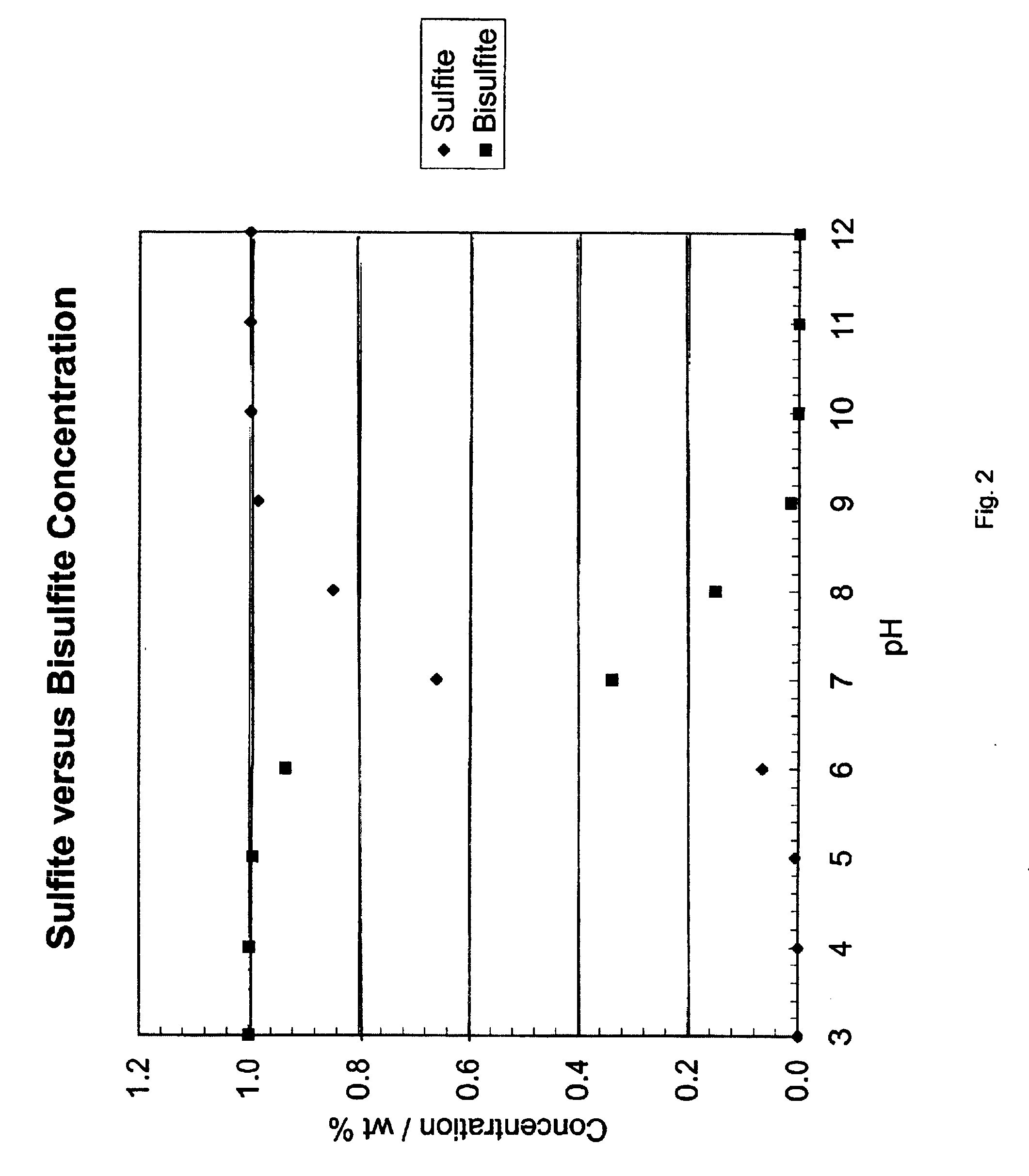

Sulfur dioxide removal using ammonia

InactiveUS6605263B2Small sizeImprove efficiencyCombination devicesAmmonium sulfatesCorrosion resistant alloySulfite

Owner:POWERSPAN CORP

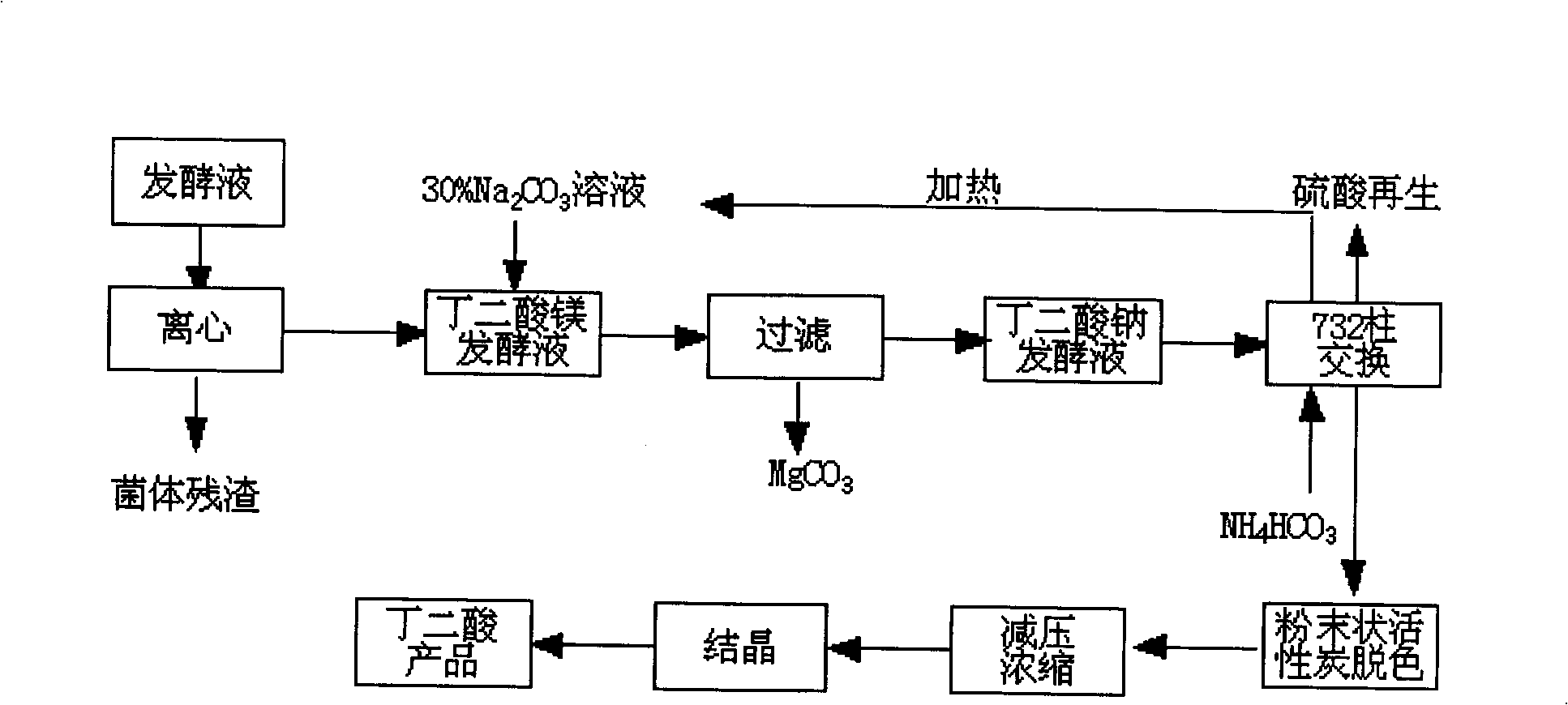

Method for extracting amber acid in fermentation liquor by cationic resin exchange

InactiveCN101348429AAchieving a circular economyShort process routeAmmonium sulfatesFermentationSodium bicarbonateSuccinic acid

A method for extracting succinic acid from fermentation broth through cation resin exchange belongs to the biochemical technical field. The method comprises the following steps that fermentation broth undergoes heated centrifugal filtration or membrane filtration so as to eliminate thalli; sodium carbonate is added in the clear solution to generate magnesium carbonate precipitation; a filter cake is reclaimed after filtration; then, the filtrate flows through a cation resin column, and the effluent is succinic acid solution; a succinic acid product is obtained after decoloring, concentration and crystallization; the cation resin column is eluted by ammonium carbonate after exchange so as to obtain sodium bicarbonate effluent; sodium salt is reclaimed and reused in fermentation broth treatment after ammonia is eliminated by heating; furthermore, resin regeneration can be realized by sulphuric acid through a conventional method, and the generated (NH4)2 SO4 can be used as a fertilizer. The method does not need to carry out acidification for the filtrate, and has the advantages of short technological line and high yield, thereby realizing element cycle economy. The invention provides a method for extracting succinic acid from microorganism fermentation broth with simple operation and economical efficiency.

Owner:JIANGNAN UNIV

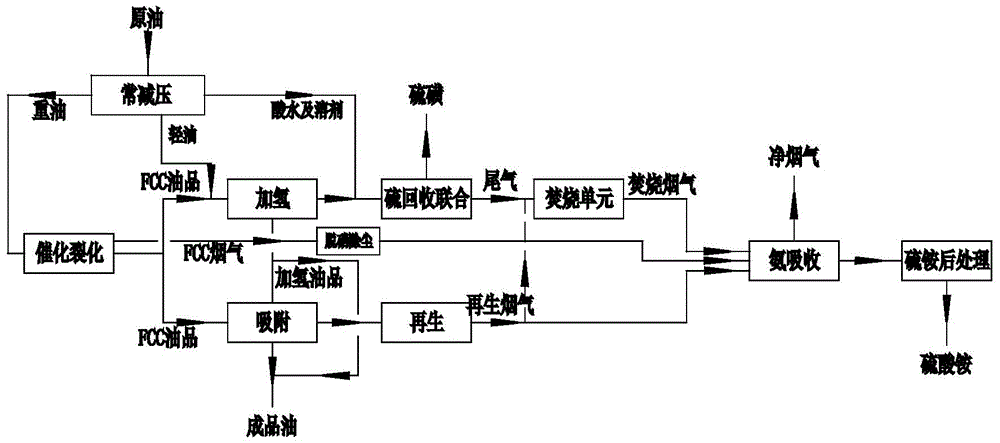

Integrated ammonia-process desulfurization method of various acidic gases in oil refining device

ActiveCN105126573ASimple processLess investmentDispersed particle separationSulfur preparation/purificationPtru catalystFlue gas

An integrated ammonia-process desulfurization method of various acidic gases in an oil refining device includes the following steps: (1) preparing heavy oil, light oil, acidic liquid and solvents through an atmospheric and vacuum distillation unit from crude oil, and feeding the heavy oil into a catalytic cracking device, the light oil into a hydrogenation device, and the acidic liquid and the solvents into a sulfur recovery combined device; (2) mixing a part of FCC oil, which is produced through the catalytic cracking device, with the light oil and feeding the mixed oil into the hydrogenation device to produce hydrogenated oil, the acidic liquid and solvents, wherein a part of the hydrogenated oil is fed into an adsorption device while the other part of the hydrogenated oil is stored and marketed as product oil; (3) feeding the acidic liquid and solvents and the acidic liquid and solvents prepared from the atmospheric and vacuum distillation unit into the sulfur recovery combined device to produce sulfur, and feeding the tail gas into an incineration unit for incineration to obtain incinerated flue gas; (4) feeding a part of the FCC oil which is produced in the catalytic cracking device into the adsorption device, performing adsorption desulfurization, and feeding an adsorption catalyst into a regenerative device to regenerate the adsorption catalyst in an oxidizing manner to obtain regenerated flue gas; and (5) feeding the FCC flue gas, the incinerated flue gas and the regenerated flue gas into an ammonia absorption device to perform absorption desulfurization and discharging cleaned flue gas after the flue gas meets standard.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

Removing and recovering process and device for SO2 in flue gas

InactiveCN1178735CReduce consumptionEasy to operateDispersed particle separationAmmonium sulfatesSulfateEnvironmental engineering

The present invention provides a method and apparatus for eliminating and recovering S02 from fume, including the following steps: l ) firstly, the fume containing low sulphur reacts with aqueous solution of ammonia, producing ammonia sulfite solution, ammonia / sulphur=1.3-1.8 (molar ratio), gas / liquid=2000-5000 (volume ratio); 2) the oxidizing reaction between the ammonium sulfite and air produces ammonia sulfate solution; 3) the ammonia sulfate solution is contacted heat fume, then the water-vaporized ammonia sulfate solution is delivered to crystallizer to be processed into ammonia sulfate fertilizer. The apparatus includes a desulphurizing tower, the desulphurizing tower includes S02 adsorption section, ammonia sulfite oxidizing section, ammonia sulfate solution condensing section, scrubbing section and demisting section. The apparatus can be operated easily. The cost can be reduced 10-30%.The vapor consumption can be reduced 90%. The concentration of S02 of fume can be reduced less than 10-100ppm. The quality of ammonia sulfate meets national standard.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing light calcium carbonate and co-producing ammonium sulfate from phosphogypsum

ActiveCN101993105AAchieve separationAvoid secondary pollutionCalcium/strontium/barium carbonatesSolid waste disposalAtherion elymusCarbonization

The invention discloses a method for preparing light calcium carbonate and co-producing ammonium sulfate from phosphogypsum, which comprises the steps of: firstly, converting phosphogypsum into a soluble calcium ion solution through phase transfer reaction; secondly, adding a carburizer in the soluble calcium ion solution, settling and separating to obtain calcium carbonate and filtrate; and thirdly, cooling and crystallizing or evaporating the filtrate to obtain the ammonium sulfate. The invention has the advantages of short process procedure and no need of strong acid leaching and twice carbonization, and avoids the secondary pollution of CO2 to the environment; and the prepared light calcium carbonate accords with the requirement on national corresponding product standards and lays the research foundation for the industrialized massive production.

Owner:HEFEI UNIV OF TECH

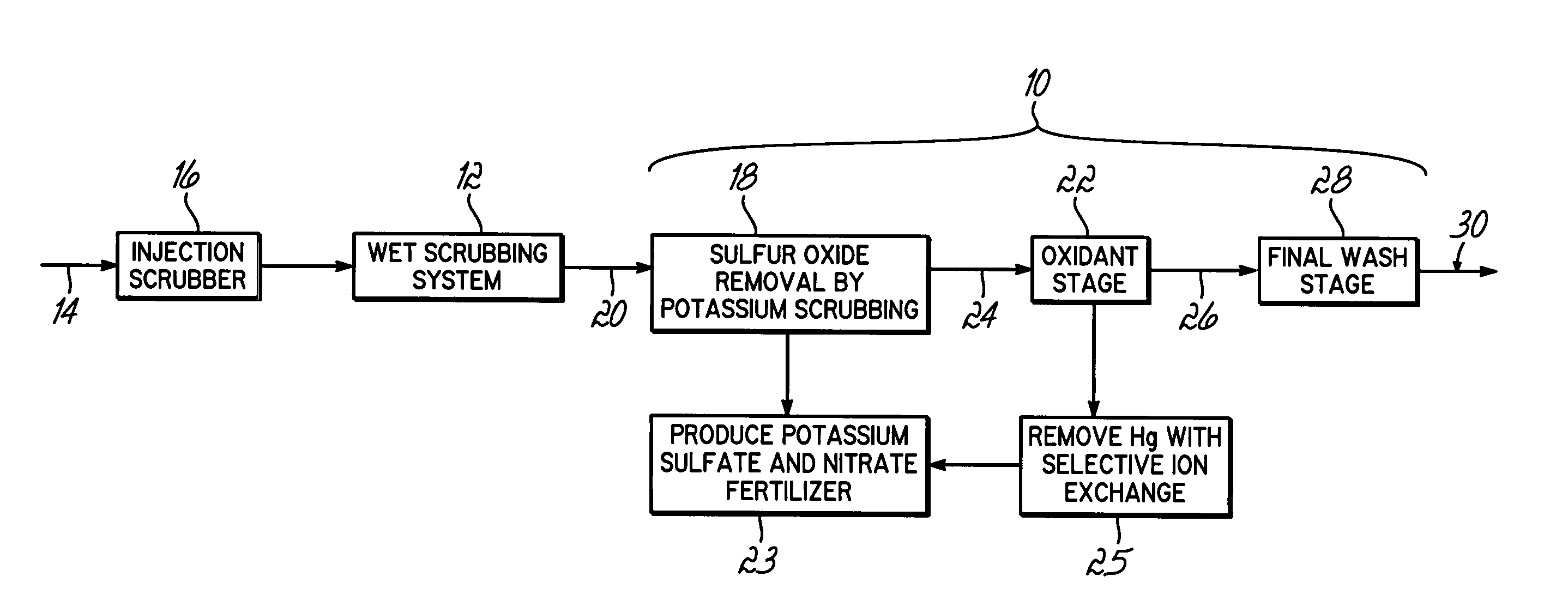

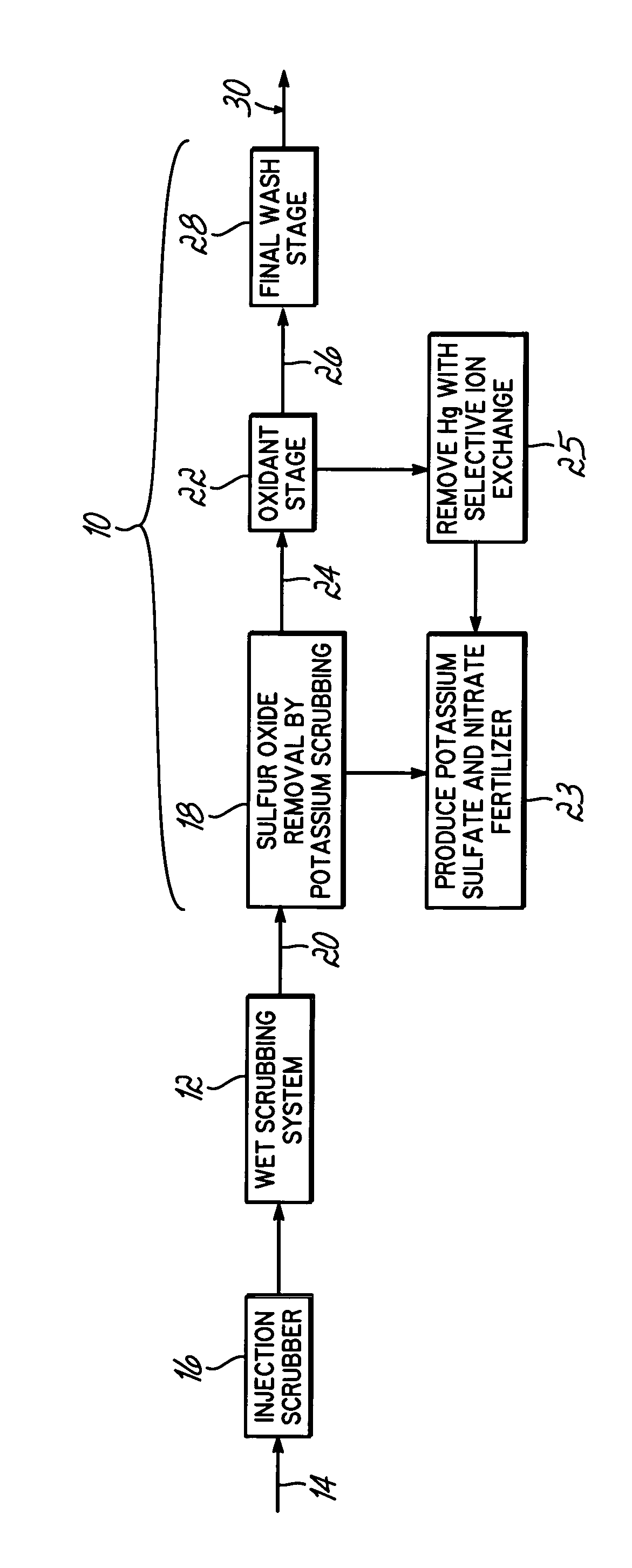

Method for removing sulfur dioxide, mercury, and nitrogen oxides from a gas stream

InactiveUS7514053B2Improve performanceAvoid pollutionAmmonium nitratesNitrogen compoundsNitrogen oxidesSorbent

Methods for scrubbing gas streams to remove acid gases including sulfur dioxide, mercury-containing substances, and / or nitrogen oxides from the gas stream. The gas stream is contacted with a potassium-based sorbent effective for removing at least a portion of the acid gases. The partially cleaned gas stream is then contacted with an oxidant effective to remove at least a portion of the nitrogen oxides and / or mercury-containing substances after partially removing the acid gas substance.

Owner:ENVIROSOLV ENERGY

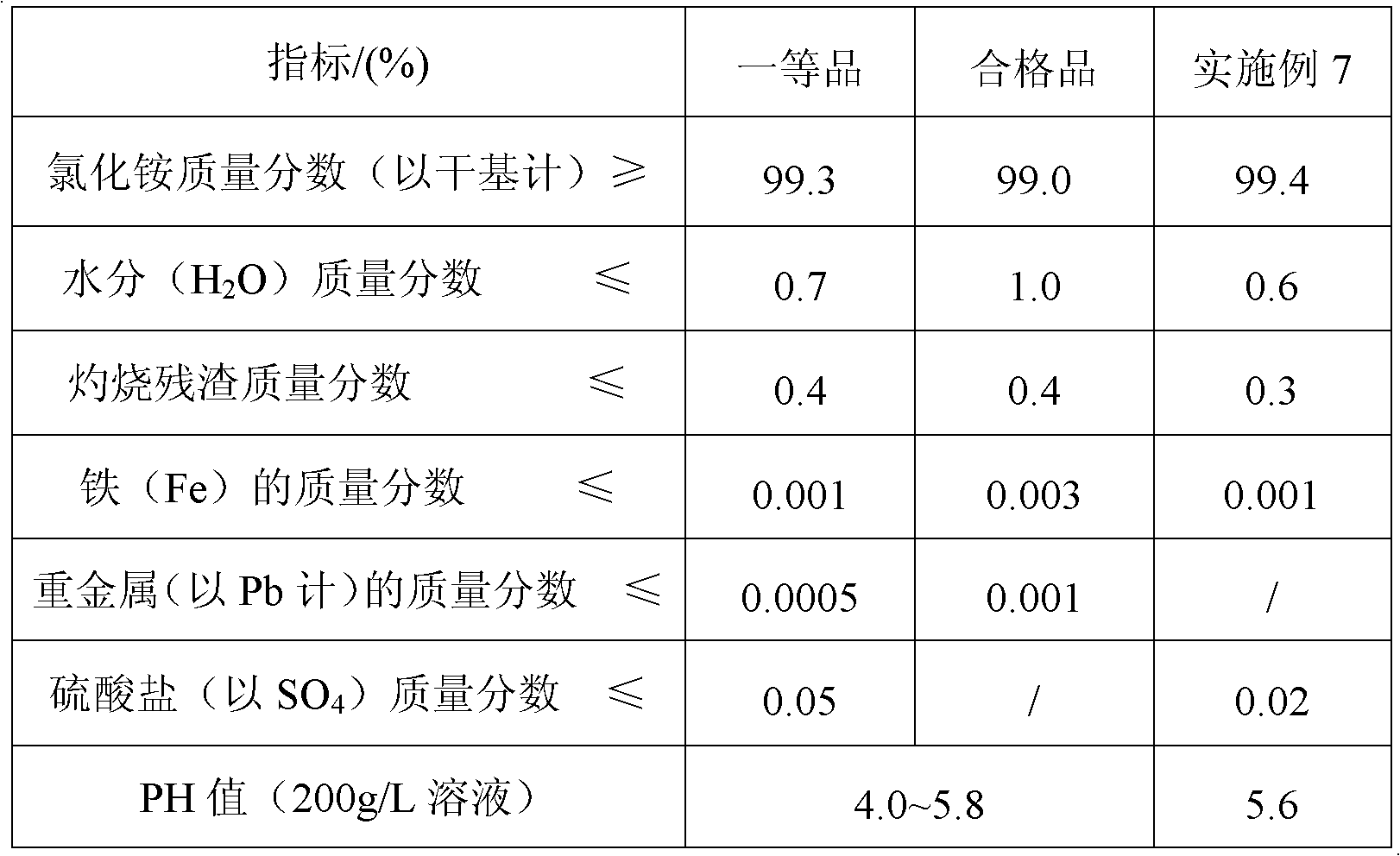

Dye acidic waste water treatment method and device

ActiveCN103130370AWide pH rangeLow costAmmonium sulfatesMultistage water/sewage treatmentAutomatic controlWater discharge

The invention relates to a dye acidic waste water treatment method and device. The method comprises steps as follows: separately collected dye waste acid is subjected to distilling concentration, neutralization, adsorption, micro-electrolysis, coagulative precipitation, activated carbon column adsorption, concentrating crystallization and separation through an automatic control system to prepare sodium (ammonium) sulfate or sodium (ammonium) chloride; and the distilled water is subjected to advanced treatment to reach the industrial reuse water standard, enters an industrial water storage tank, and is circulated to the dye production procedure. The method and device are especially suitable for industries generating abundant waste sulfuric acid and waste hydrochloric acid, such as production of dyes, titanium white and the like. The abundant waste sulfuric acid and waste hydrochloric acid generated in the production process can be utilized to prepare sodium (ammonium) sulfate or sodium (ammonium) chloride, thereby recycling acidic waste water, and changing wastes into valuable substances; and meanwhile, the distilled water can be circulated into industrial production after advanced treatment, thereby reducing the waste water discharge.

Owner:ZHEJIANG DIBANG CHEM

Method and device for producing thiamine from sulfur dioxide in recorered smoke

InactiveCN1648049ANo secondary pollutionDispersed particle separationAmmonium sulfatesPollutionAmmonium sulfate

The present invention discloses method and apparatus for recovering SO2 from fume to produce ammonium sulfate. The present invention has ammonia recovering section over the absorbing section to avoid loss of ammonia and independent fume cooling and humidifying section to produce ammonium sulfate crystal in a saturation and crystallization process in lowered steam energy consumption. Hydraulic staged cyclonic unit is used as effective liquid-solid separator to raise the crystallization degree of the ammonium sulfate product. The whole desulfurizing system produces no waste and has no secondary pollution. The desulfurizing tower has high eliminating efficiency of harmful SO2, SO3, NOx, HCl, HF and dust.

Owner:EAST CHINA UNIV OF SCI & TECH

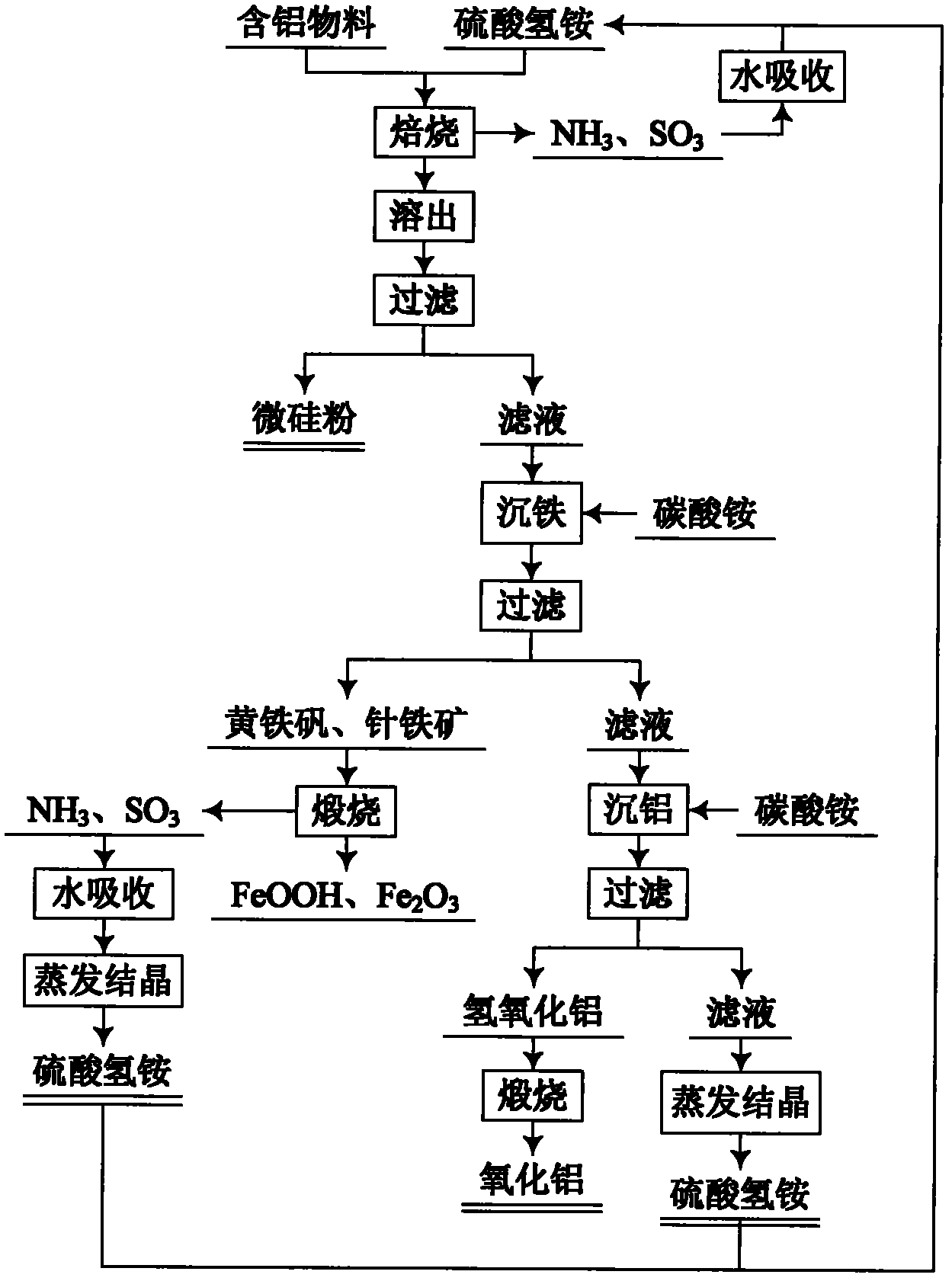

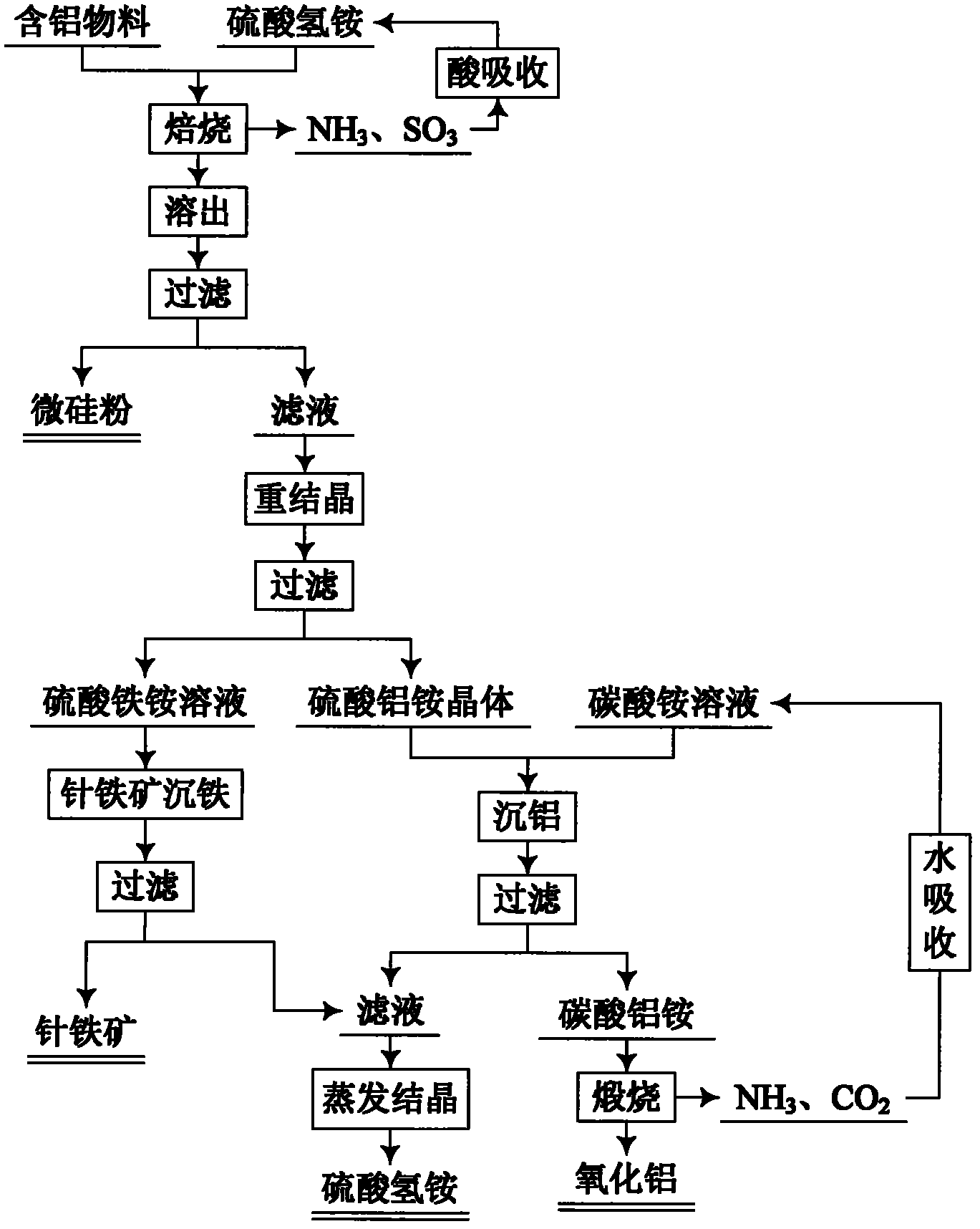

Method for comprehensive utilization of aluminum-containing material

The invention relates to a method for preparing aluminum oxide and other products by aluminum-containing materials of bauxite, alunite, nepheline, fly ash, kaolin, coal gangue and clay. The method comprises the following steps: (1) crushing and grinding an aluminum-containing material, carrying out mixing and baking for the treated aluminum-containing material and ammonium bisulfate; (2) carryingout dissolution and filtering for the baked clinker to obtain a crude ammonium aluminum sulfate solution and aluminum extracting residue; (3) carrying out an iron precipitating treatment for the ammonium aluminum sulfate solution with the concentration more than 1 g / L by adopting a jarosite method, then carrying out an iron precipitating treatment by a goethite method, carrying out an aluminum precipitating treatment for the resulting solution, carrying out calcination for the resulting aluminium hydroxide to prepare aluminum oxide; (4) carrying out an iron precipitating treatment for the ammonium aluminum sulfate solution with the concentration less than 1 g / L by adopting the goethite method, and carrying out an aluminum precipitating treatment to prepare aluminum oxide, or adopting a recrystallization method to carry out purification, adopting a reaction of the ammonium aluminum sulfate crystal and a ammonium carbonate solution to precipitate the aluminum to obtain ammonium aluminumcarbonate, carrying out calcination for the ammonium aluminum carbonate, and adopting a Bayer method to treat the calcined ammonium aluminum carbonate to prepare sandy aluminum oxide; (5) washing anddrying the aluminum extracting residue, wherein the dried aluminum extracting residue is adopted as the silicon dioxide product.

Owner:NORTHEASTERN UNIV

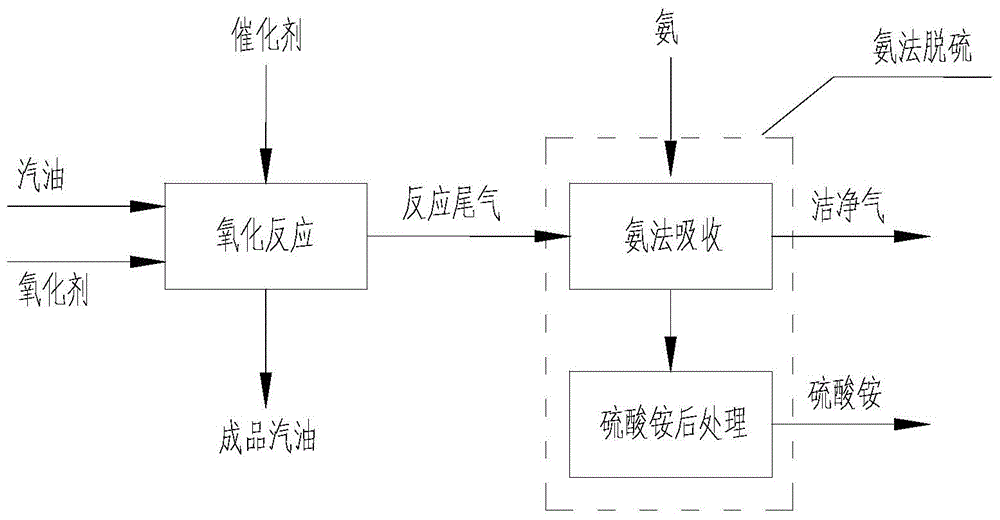

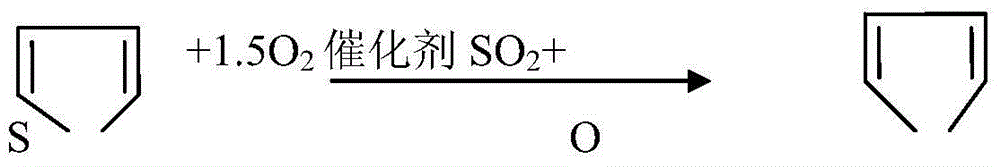

Gasoline-oxidation ammonia-process desulfurization method

InactiveCN104946296ARealize recycling of resourcesImprove desulfurization efficiencyRefining with oxygen compoundsDispersed particle separationGasolineComponents of crude oil

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

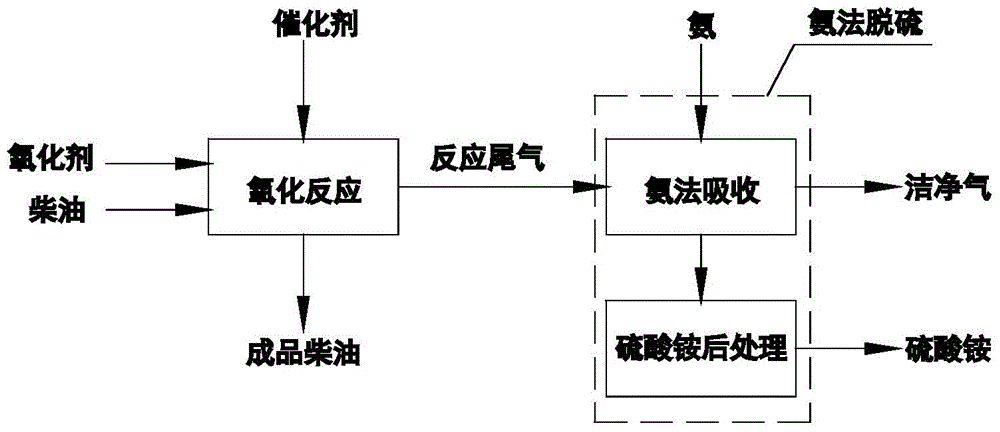

Diesel oxidation ammonia desulfurization method

InactiveCN104927894ASimple processSuitable for mass productionRefining with oxygen compoundsDispersed particle separationSulfur containingPetroleum

The present invention discloses a diesel oxidation ammonia desulfurization method (DOA), comprising steps of:1) oxidation reaction. In the presence of a catalyst, using an oxidant and selectively oxidizing sulfur-containing compounds of diesel to obtain a finished diesel with the sulfur dioxide reaction exhaust and sulfur content amount is not more than 10ppm; 2) ammonia desulfurization. Using an ammonia desulfurization method to process the sulfur dioxide reaction exhaust, converting the sulfur dioxide into an ammonia sulfate fertilizer and emitting clean gas under required standards; and in the presence of the catalyst, using the oxidant and selectively oxidizing sulfur-containing compounds of diesel (mainly mercaptans, sulphides, and thiophenes sulfur-containing compounds). The method is simple in process with no secondary pollution and can be widely used in petroleum refining industry.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

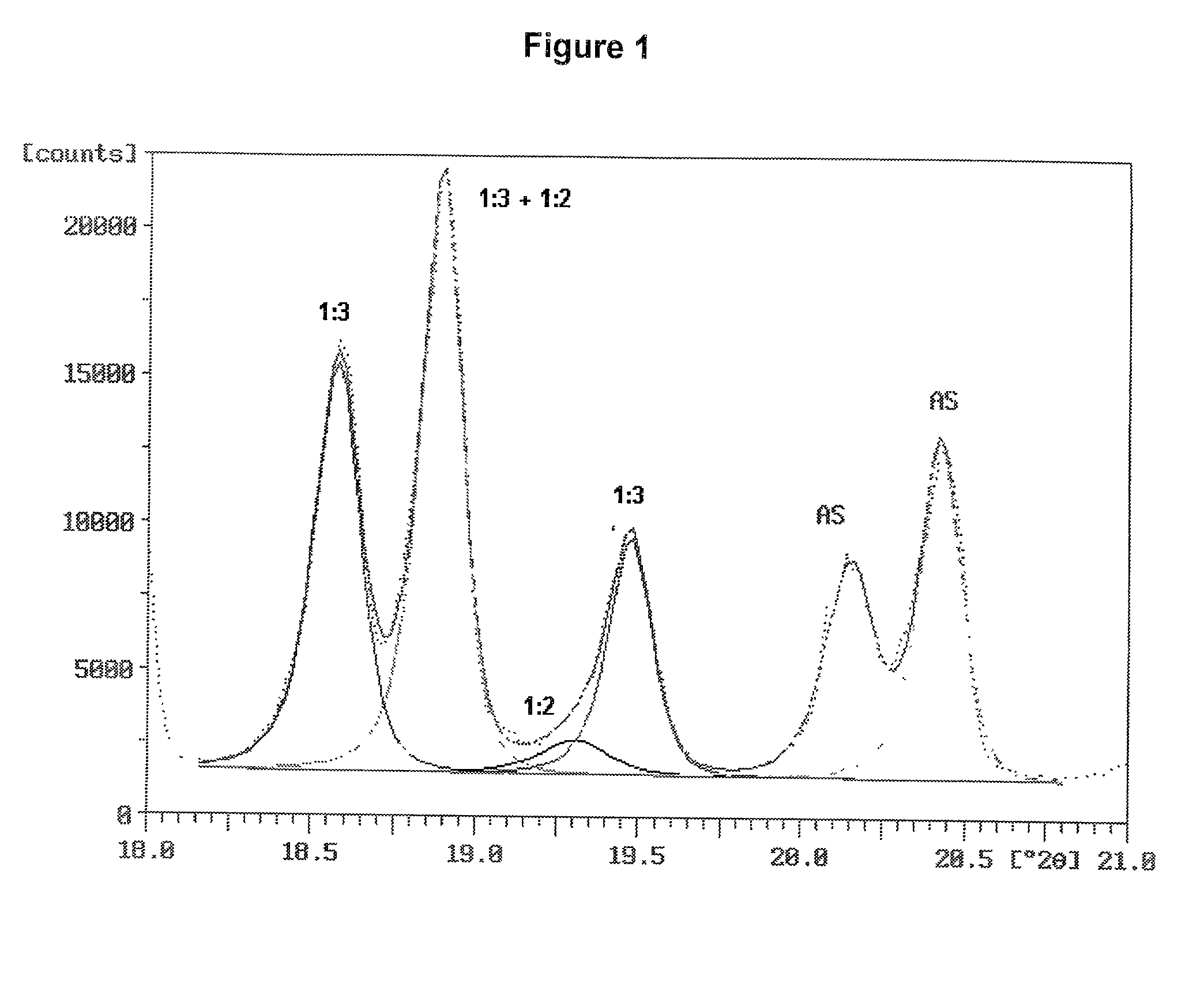

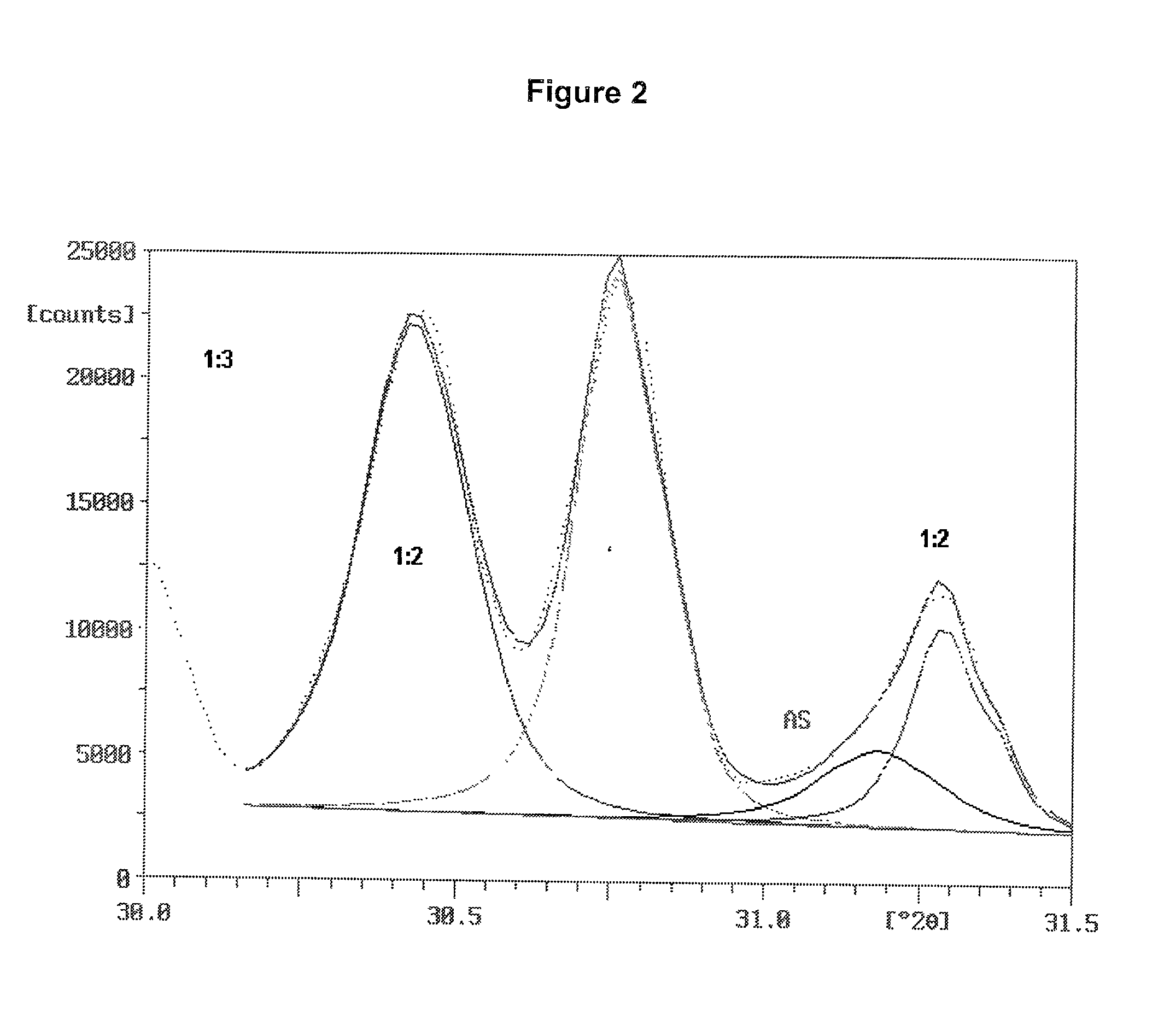

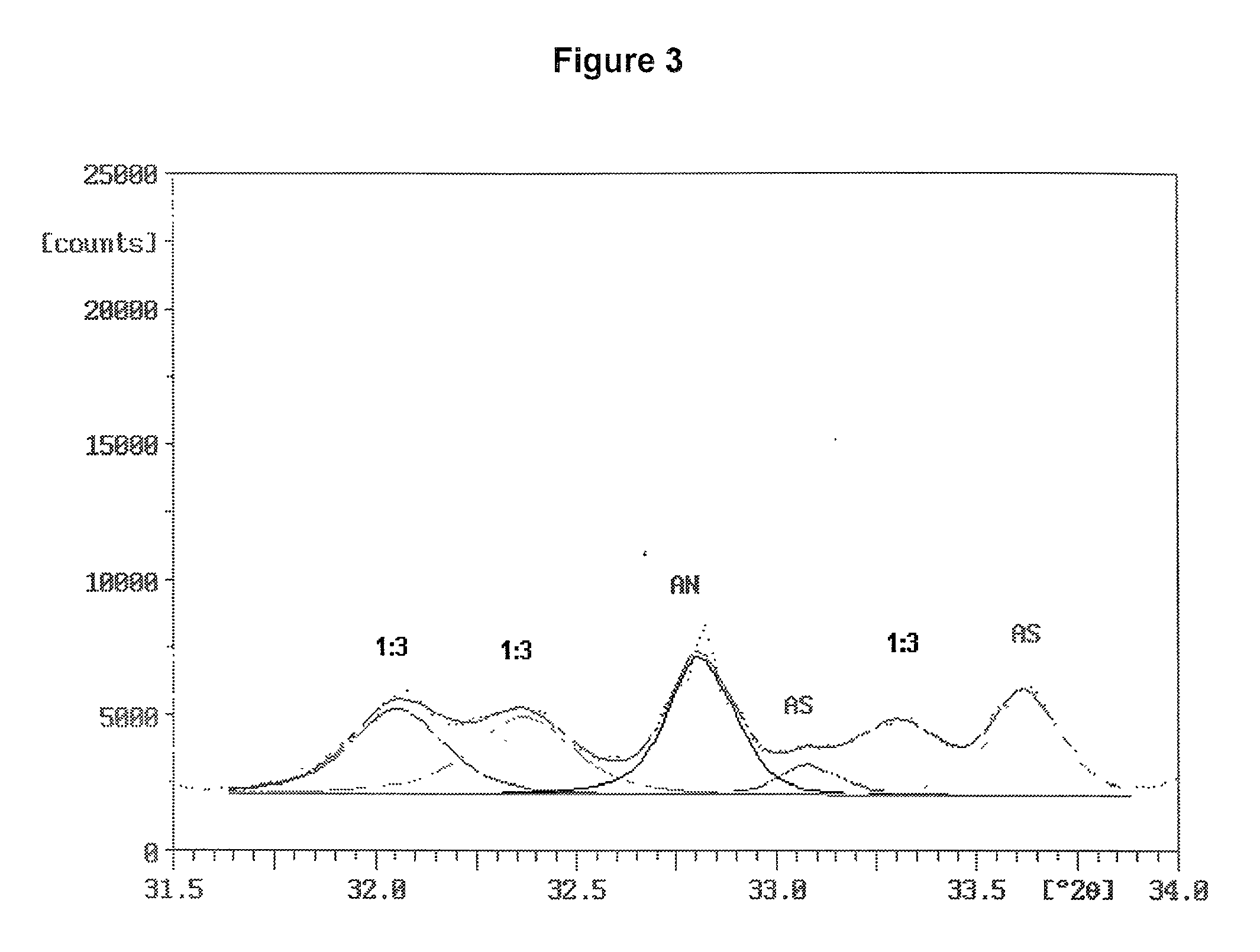

Ammonium sulfate nitrate

Ammonium sulfate nitrate composite materials useful as fertilizers having desirable levels of nitrate ions, superior stability against detonation, higher density, greater resistance to moisture, and a method for their manufacture. The ammonium sulfate nitrate composites have as essential constituents ammonium sulfate and the NH4SO4.2(NH4NO3) double salt with less than 5 wt. % in combined total of the more hazardous NH4SO4.3(NH4NO3) double salt and ammonium nitrate. The composites of the invention are formed by reacting ammonium sulfate with ammonium nitrate in a molar ratio of about 0.9:1 to about 1.1:1 in the presence of a small amount of water in a narrow range of temperatures and then cooling to solidification at a sufficiently rapid rate to prevent macroscopic segregation of the reaction products.

Owner:ADVANSIX RESINS & CHEM LLC

Method for desulfurization of sulfur recovery tail gas by using boiler flue gas ammonia method

ActiveCN103521060AImprove sulfur recoveryGuaranteed sulfur recoveryChemical industryDispersed particle separationTowerAqueous solution

The invention provides a method for desulfurization of a sulfur recovery tail gas by using a boiler flue gas ammonia method. The method comprises the following steps: (1) burning the sulfur recovery tail gas, wherein sulfide in the sulfur recovery tail gas is converted into sulfur dioxide; (2) converging the burnt sulfur recovery tail gas with the boiler flue gas to form merged flue gas, feeding the merged flue gas to an absorption tower, and discharging the merged flue gas after being absorbed by absorption liquid in a countercurrent manner in the absorption tower, wherein the absorption liquid is a water solution containing an ammonium salt, and the ammonium salt is a mixture of ammonium sulfate and ammonium sulfite. By adopting the method disclosed by the invention, not only can the sulfur recovery rate be better ensured, but also emission of the tail gas achieves the environmental protection requirements; meanwhile, investment and operative difficulty are reduced; the floor area is reduced; the comprehensive utilization efficiency of energy is improved; a good effect of treatment of waste by waste can also be achieved.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

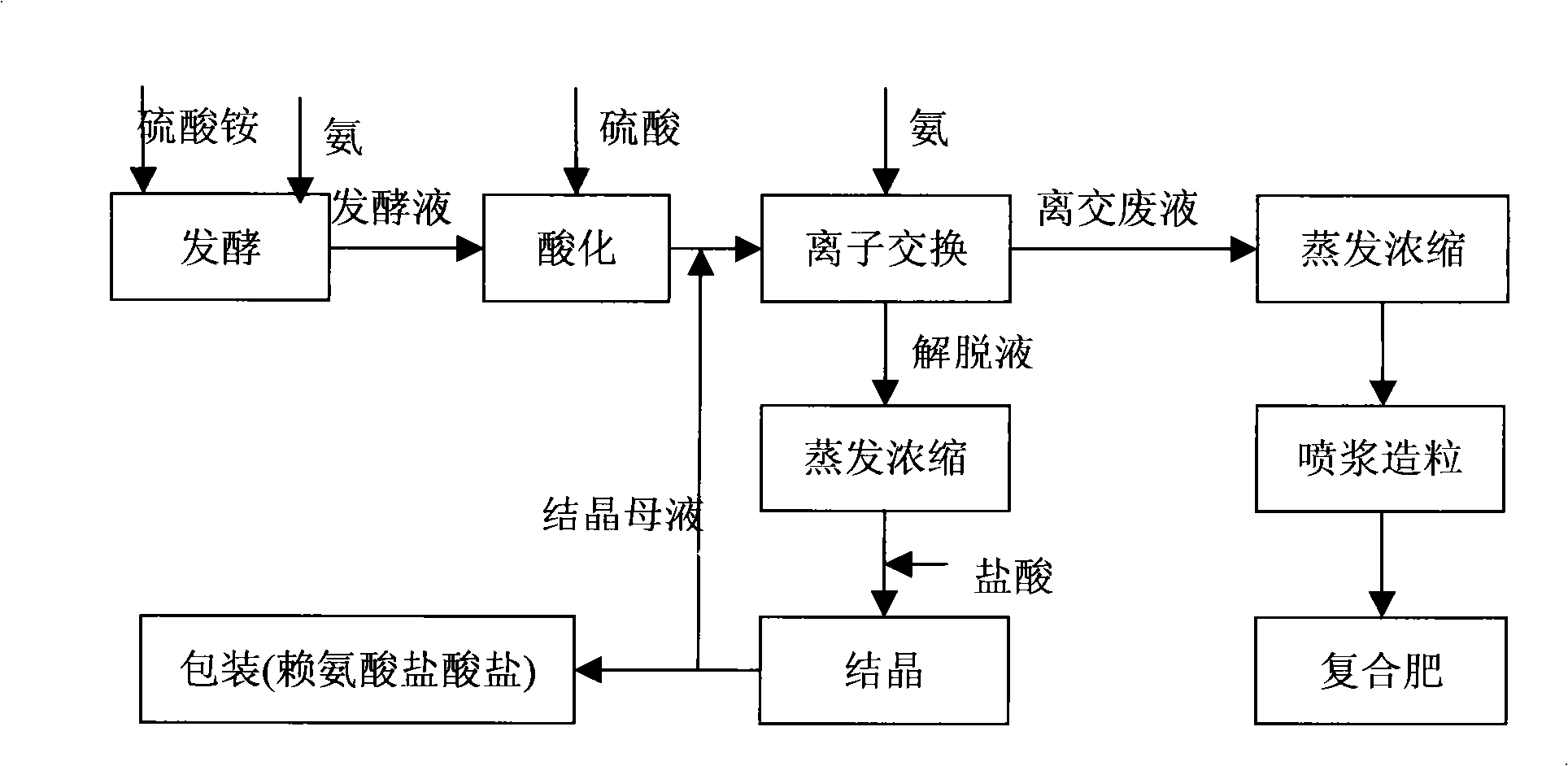

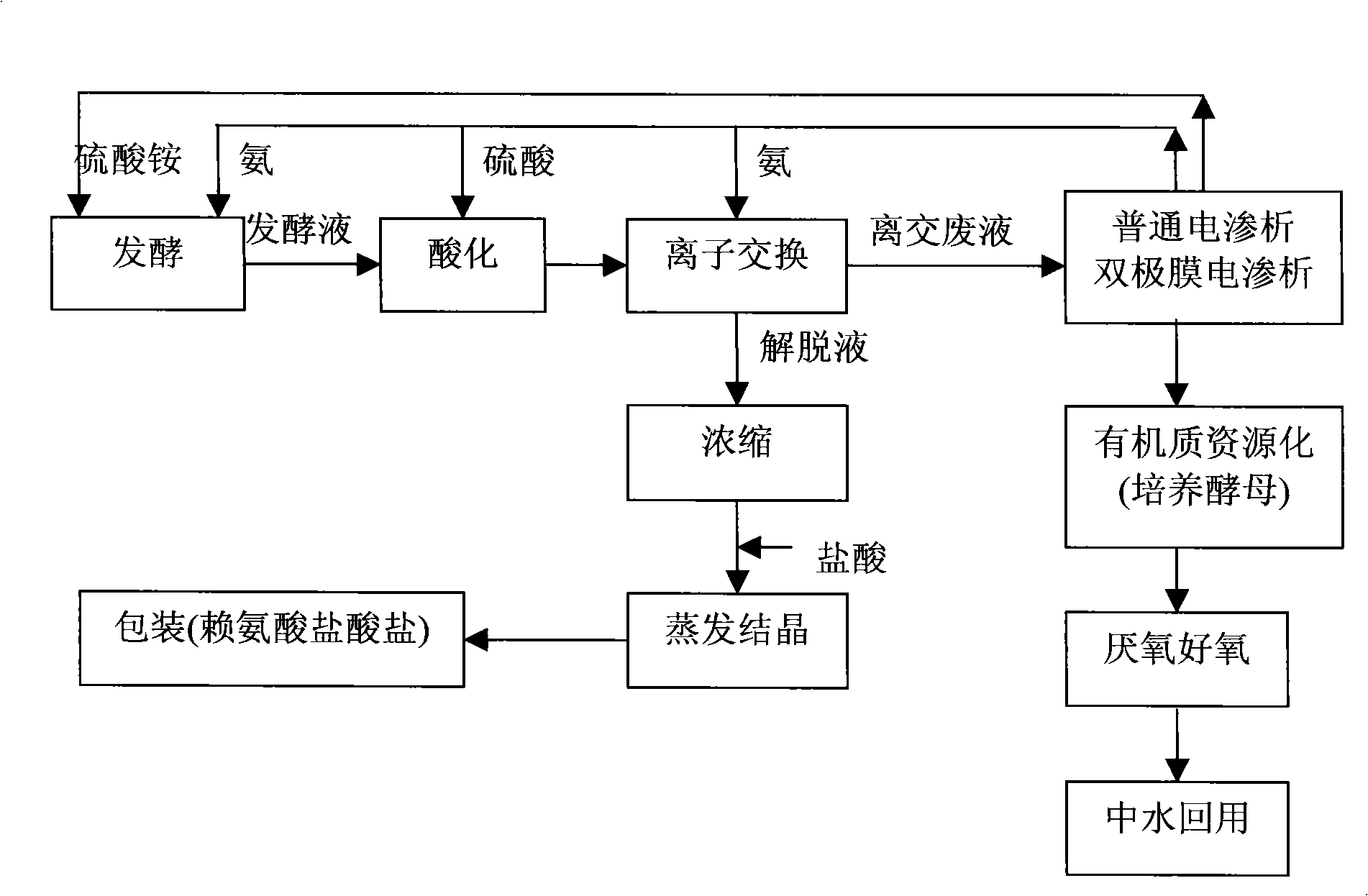

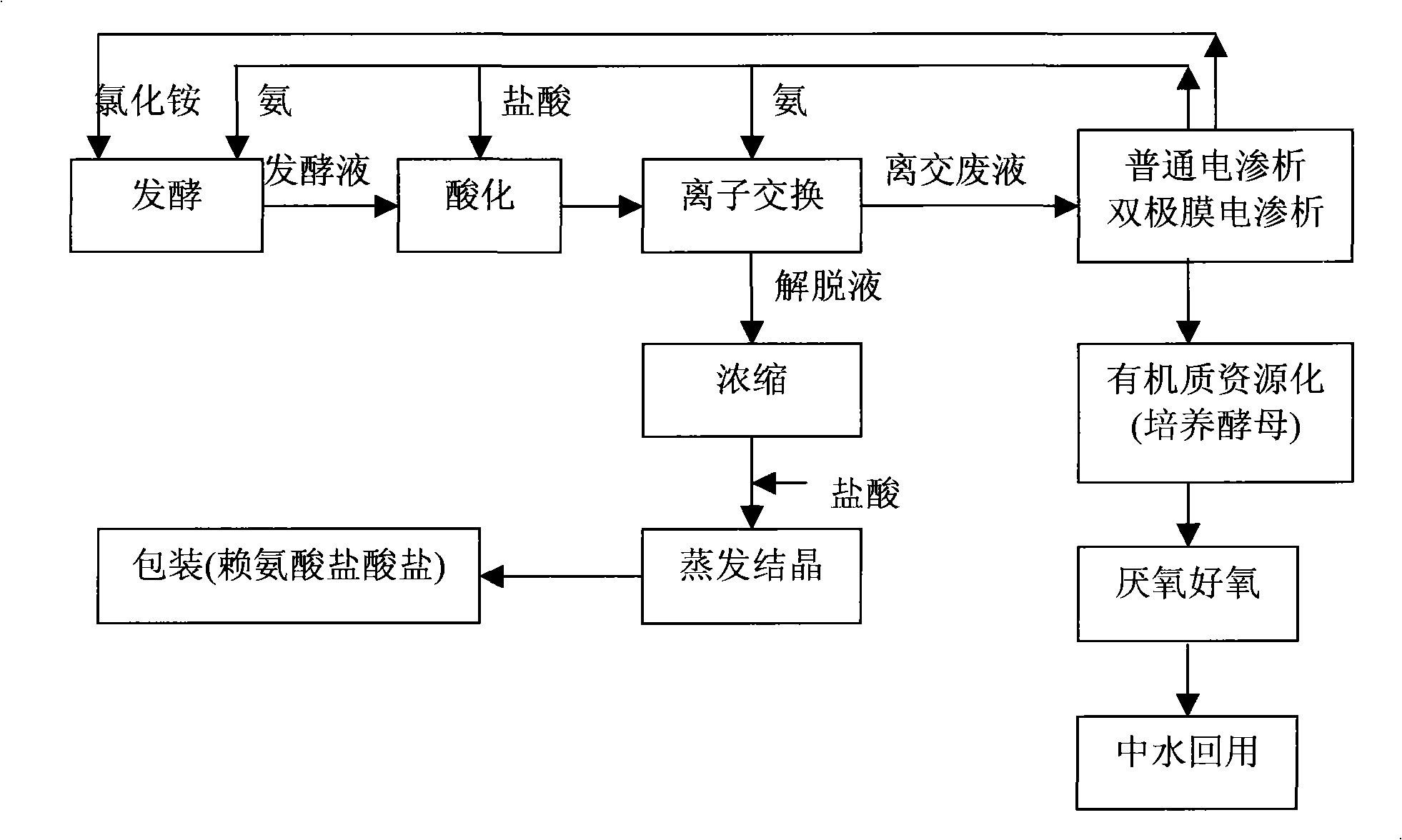

Method for processing ion exchange waste liquor of lysine production by fermentation method

InactiveCN101407350AFast growthLarge biomassAmmonium nitratesDispersed particle separationIon exchangeLysine fermentation

The invention belongs to the ferment industry, in particular relates to a treatment method of ion exchange waste liquor in lysine production by a fermentation method. The invention adopts a common electrodialysis technology to recycle ammonium sulfate, ammonium chloride or ammonium nitrate in the lysine ion exchange waste liquor produced by extracting the lysine from lysine fermentation production to water solution of ammonium sulfate, ammonium chloride or ammonium nitrate, or adopts a bipolar membrane electrodialysis technology to regenerate sulfuric acid, hydrochloric acid or nitric acid and NH3 by ammonium sulfate, ammonium chloride or ammonium nitrate in the lysine ion exchange waste liquor produced by extracting the lysine from the lysine fermentation production, or adopts the combination of the common electrodialysis technology and the bipolar membrane electrodialysis technology to recycle ammonium sulfate, ammonium chloride or ammonium nitrate in the lysine ion exchange waste liquor produced by extracting the lysine from the lysine fermentation production and regenerate sulfuric acid, hydrochloric acid or nitric acid and NH3. The invention realizes the resource recycling of the ion exchange waste liquor and clean production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Scavenger for aldehyde(s) and a manufacturing method of a woody panel using the same

InactiveUS20090130474A1Ease of evaluationImprove trapping efficiencyOrganic chemistrySulfate/bisulfate preparationScavengerRoom temperature

Regarding the scavenger for aldehyde(s) used at the time of manufacturing a woody panel using woody materials and formaldehyde-based binders, the scavenger for aldehyde(s) without lowering of trapping properly even when a surface of said woody panel is sanded and having an excellent trapping property of trapping formaldehyde is provided. Further, the method of manufacturing a woody panel using a scavenger for aldehyde(s) and a woody panel are provided.At least one kind of compound for trapping aldehyde(s) being solid at a room temperature is included and said compound for trapping aldehyde(s) is defined to be a powdery scavenger for aldehyde(s) having a property of generating acidic gas, in particular, sulfurous acid gas by heating and said compound for trapping aldehyde(s) is added to a binder or woody materials followed by a hot press, thereby manufacturing a woody panel.

Owner:IPPOSHA OIL INDS

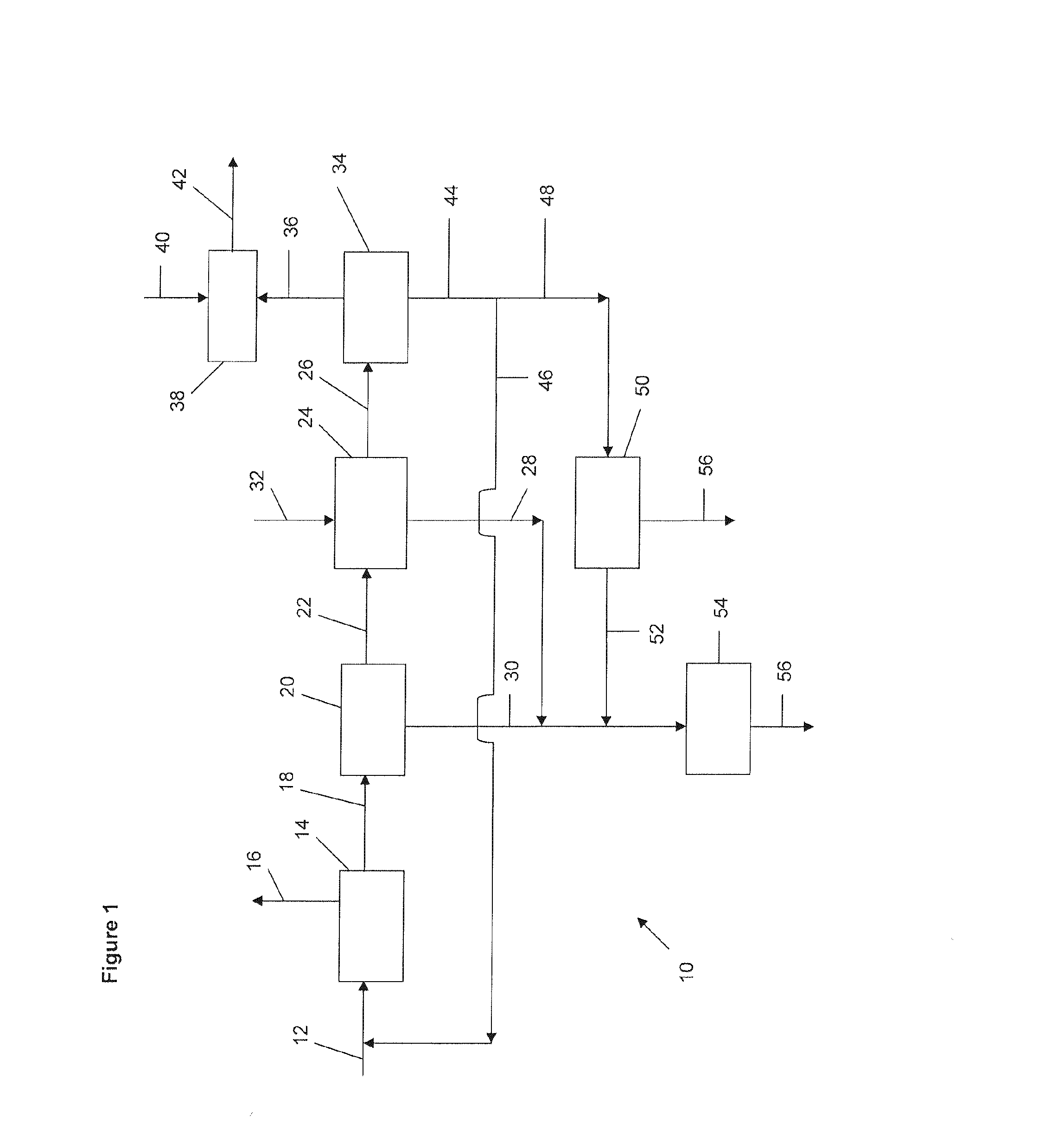

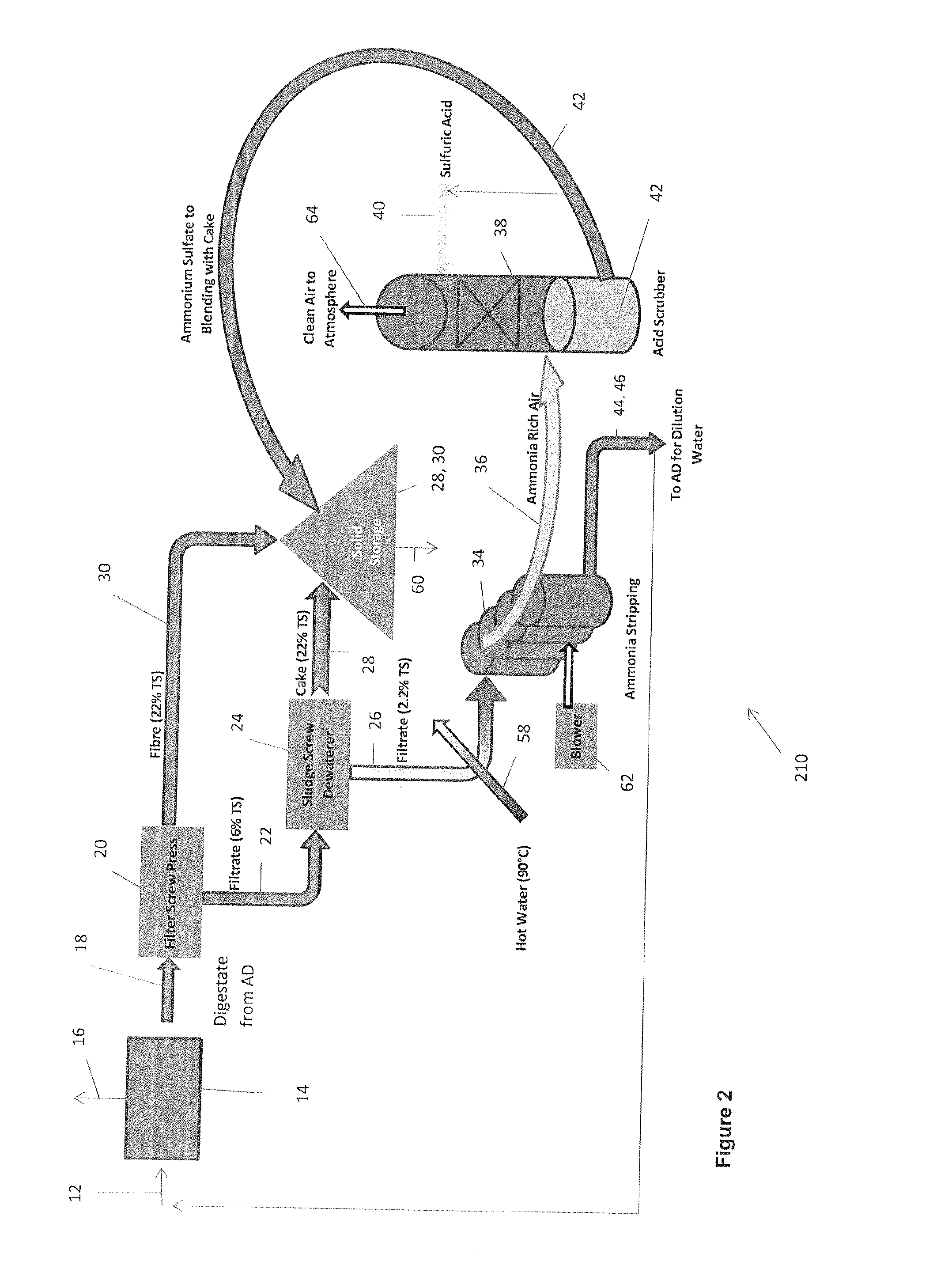

Nutrient recovery process

ActiveUS20150329399A1Reduce concentrationHigh pHBio-organic fraction processingSludge processingAmmoniaSalt solution

An apparatus for recovering nutrients or water from digestate comprises one or more solid-liquid separation units, an ammonia stripping device, and a gas scrubbing unit. In a process, digestate is separated into a solids portion and a liquid portion. Ammonia is stripped from the liquid portion and converted into an ammonium salt solution which may be sold or used as, or blended with, a fertilizer product. Optionally, at least part of the remaining liquid portion may be concentrated to produce brine. The brine is mixed with the solids portion. The mixture may be dried and used as, or blended with, a fertilizer product. Optionally, a least part of the remaining liquid portion may be re-used as dilution water in a digester. A solids portion of the digestate, and one or both of an ammonium salt solution and a brine, may be used as fertilizer without thermal drying.

Owner:ANAERGIA

Synchronous denitration process based on wet ammonia process flue gas desulfurization

InactiveCN104226095ALow investment costLow running costDispersed particle separationAmmonium sulfatesSulfateFlue gas

The invention discloses a synchronous denitration process based on wet ammonia process flue gas desulfurization. The problems such as high operating cost and equipment investment cost, complex process and high energy consumption existing in an existing process are solved. According to the technical scheme, the process comprises the following steps: pressurizing flue gas, feeding the flue gas into a concentrating tower, allowing the flue gas to contact and react with a concentrated solution in the tower, feeding the flue gas out of the concentrating tower into an absorption tower to contact and react with absorption liquid in the tower, feeding a small amount of reacted concentrated solution at the bottom of the concentrating tower into an ammonium sulfate crystallization system, and adding a complexing agent EDTA-Fe (II) or adding EDTA-Na salt and ferrous sulfate according to a molar ratio of 1:1 into the absorption liquid in the absorption tower, so that the concentration of the EDTA-Fe (II &III) in the absorption liquid is 0.015-0.05mol / L; and feeding a small amount of absorption liquid in the absorption tower into the concentrating tower to be mixed with the concentrated solution. The synchronous denitration process disclosed by the invention has the advantages of simplicity, low operating cost and equipment investment, capacity of performing high-efficiency synchronous desulfurization and denitration and low energy consumption.

Owner:WUHAN WUTUO TECH +2

Electrolytic manganese slag comprehensive utilization technique

InactiveCN101306425AAvoid pollutionEliminate sources of pollutionSolid waste managementSolid waste disposalBuilding productElectrolysis

The invention relates to an electrolytic manganese slag processing method, in particular to an electrolytic manganese slag comprehensive utilization process. The method recovers the recyclable materials in electrolytic manganese slag through repeated water washing and filtering. The method can solve the air pollution source, particularly eliminate the water pollution source, and protect people health from being damaged. The method can extract higher-value chemical products through the scientific flow, and make the residuary filter residue into building products, thereby effectively utilizing the resource. Zero discharge is realized during the overall process of the technical proposal of the method, and because no additional chemical substances are added, additional environmental pollution can not be caused.

Owner:卿富安

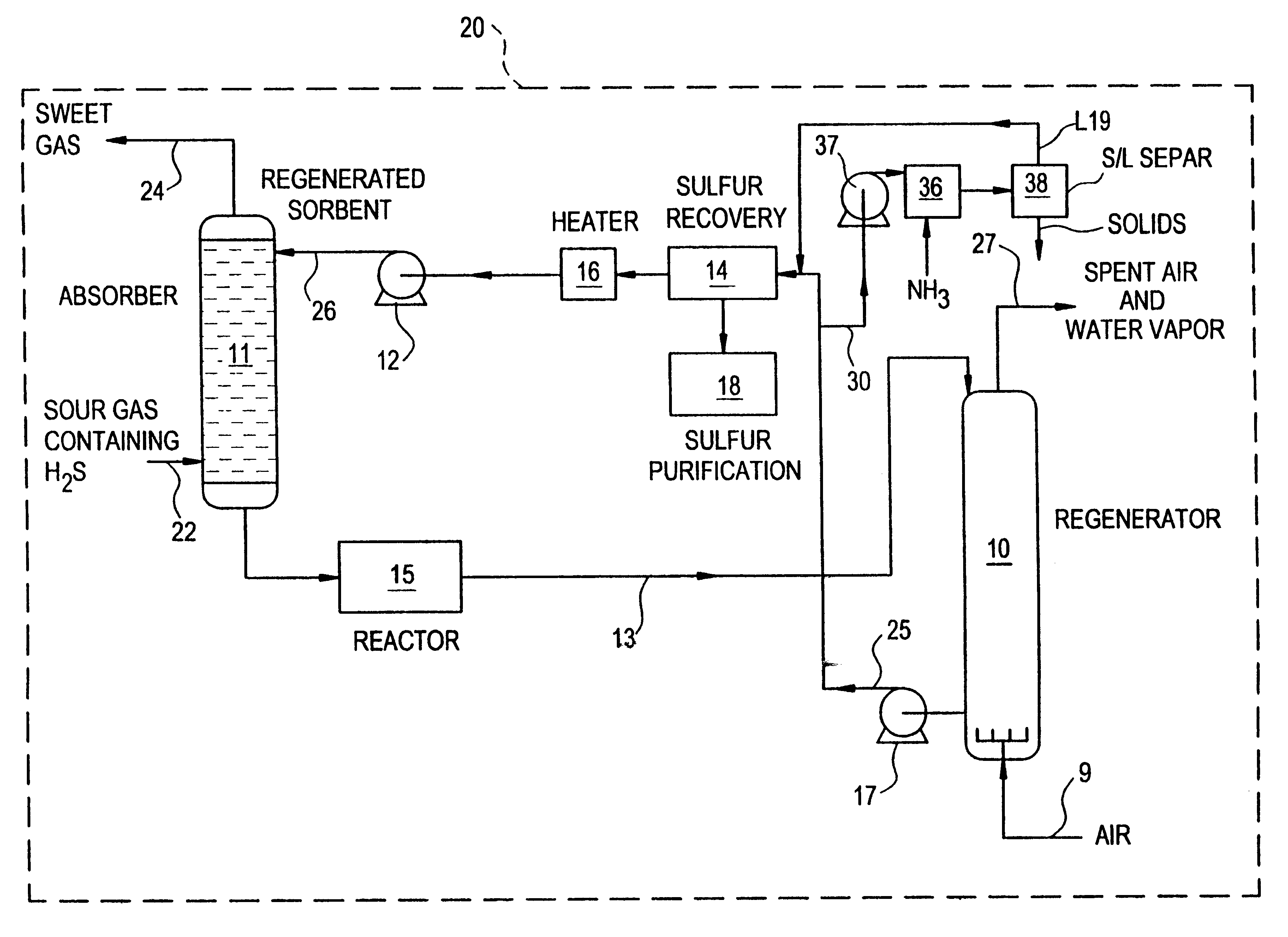

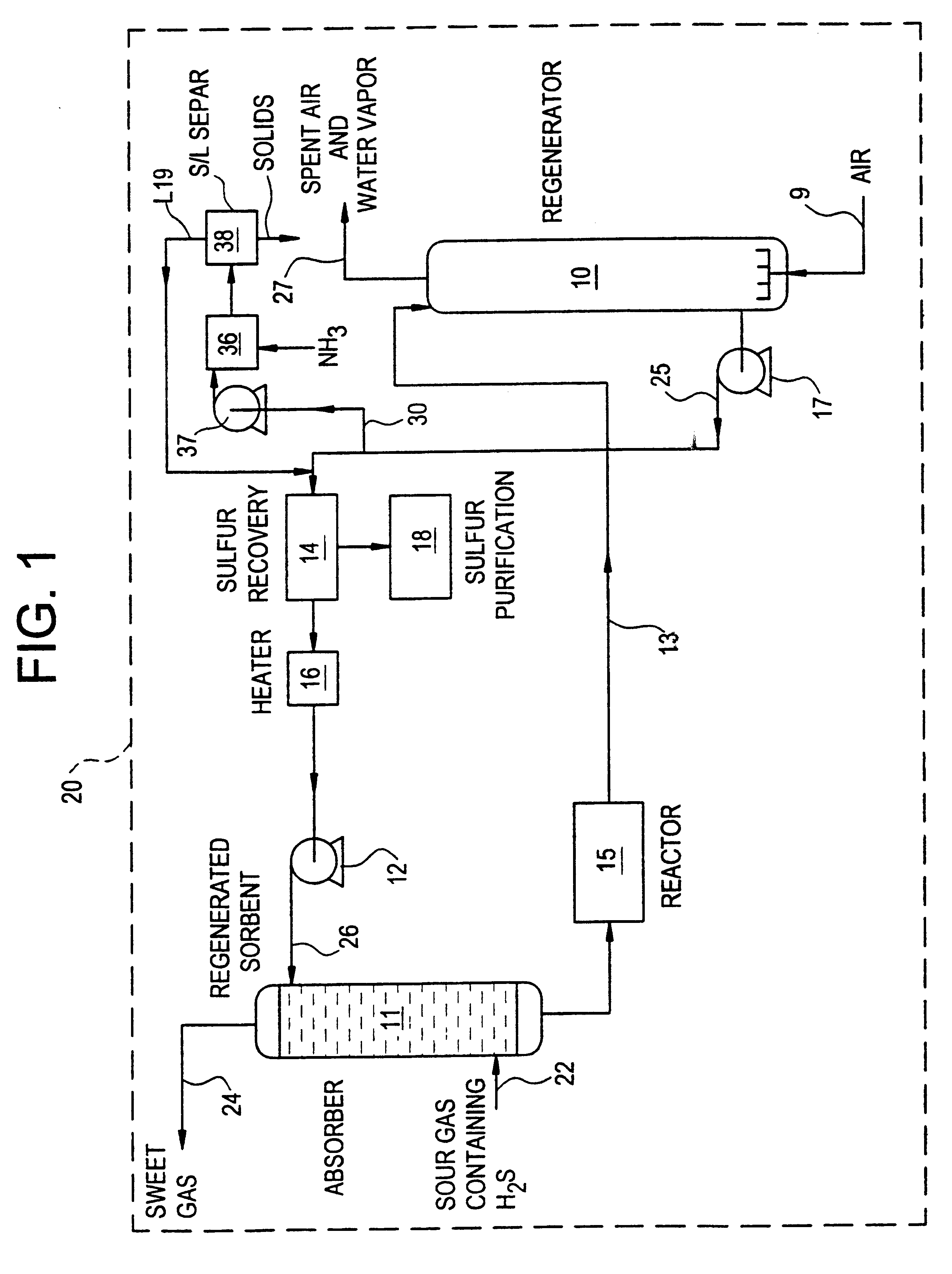

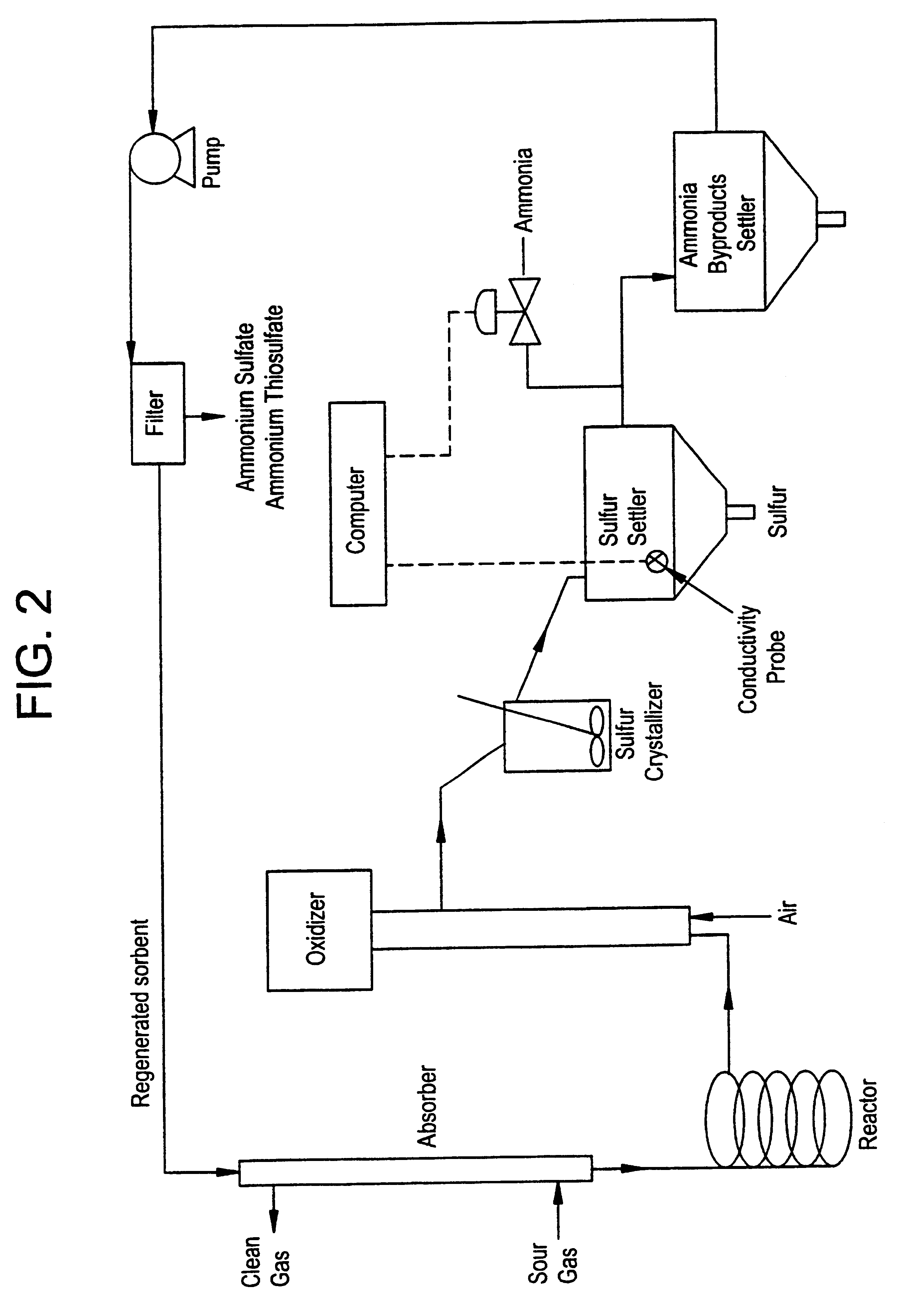

Regeneration method for process which removes hydrogen sulfide from gas streams

InactiveUS6544492B1Removal process is favorableAvoid problemsThiosulfates/dithionites/polythionitesHydrogen sulfidesThio-Sulfide

A process is provided for the removal of hydrogen sulfide out of a gaseous stream (22), such as a natural gas, by contacting the hydrogen sulfide containing gas with a sorbing liquid (26) containing a tertiary amine so that the hydrogen sulfide is sorbed into the liquid in absorber (11) and transferring the sorbing liquid / hydrogen sulfide mixture to a reactor (15) where the tertiary amine promotes the conversion of the hydrogen sulfide into polysulfide via reaction with sulfur; transferring the polysulfide solution from the reactor (15) to a regenerator (10) where polysulfide is converted into elemental sulfur via reaction with air (9); transferring at least a portion of the solution (25) containing elemental sulfur, as well as sulfate and thiosulfate species, into a mixture (36) where it is contacted with gaseous ammonia which reacts with the sulfate and thiosulfate species to produce ammonium sulfate and ammonium thiosulfate which are removed from the solution while the remaining portion of solution (25) is transferred to a sulfur recovery unit (14). That portion of the solution which has been subjected to ammonium sulfate and ammonium thiosulfate removal is rejoined with that portion of the solution (25) being forwarded to sulfur recovery unit (14). The solution from the sulfur recovery unit (14) is recycled back to the absorber (11).

Owner:URS

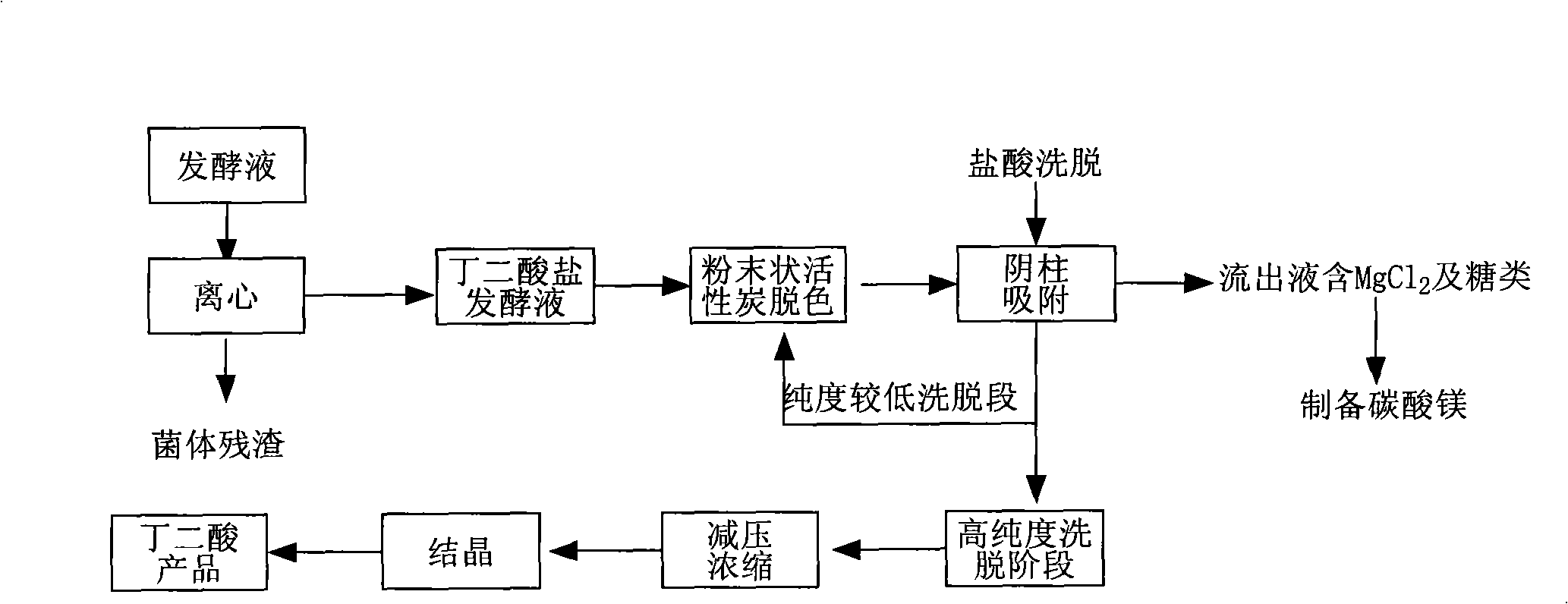

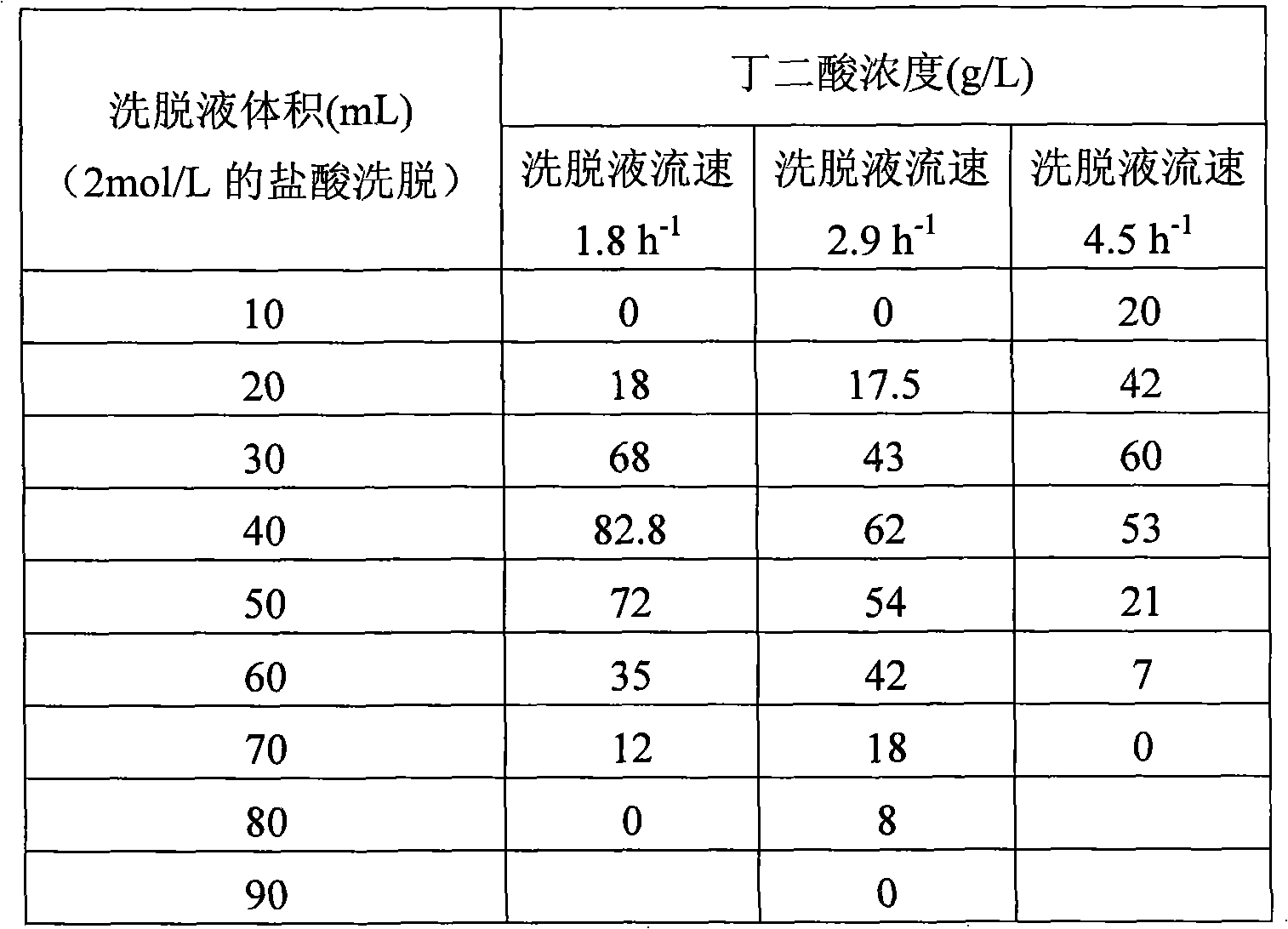

Method for extracting amber acid in fermentation liquor by anion resin adsorption

InactiveCN101348428AEnable recyclingReduce consumptionAmmonium sulfatesFermentationSuccinic acidImpurity

A method for sorption extraction of succinic acid in fermentation broth by an anion resin belongs to the biochemical technical field. The method comprises the following steps that succinic acid fermentation broth undergoes decoloring treatment by heated active carbon; fungus residue is eliminated through centrifugal filtration or microfiltration membrane filtration; the obtained fermentation clear solution is adsorbed by an alkaline anion resin column, and impurity is flushed away by water after adsorption saturation and then is eluted by hydrochloric acid solution or sulfuric acid solution, thereby obtaining succinic acid solution; the succinic acid solution undergoes depressurized concentration and crystallization so as to obtain a succinic acid product; moreover, MgCl2 and residual sugar in effluent after anion resin column adsorption of the fermentation broth is reclaimed; the MgCl2 in the effluent generated during anion resin adsorption is passed through CO2 or (Na)2CO3 so as to prepare magnesium carbonate which is reclaimed and used in buffering and adjusting pH during fermentation; and sugar in filtrate is reclaimed and used in fermentation ingredients for further fermentation. The method can realize recovery and reuse of materials during operation, and substantially reduces material consumption during extraction; moreover, the method reduces the treatment cost of waste water for environmental protection, and increases the economic benefit of products.

Owner:JIANGNAN UNIV

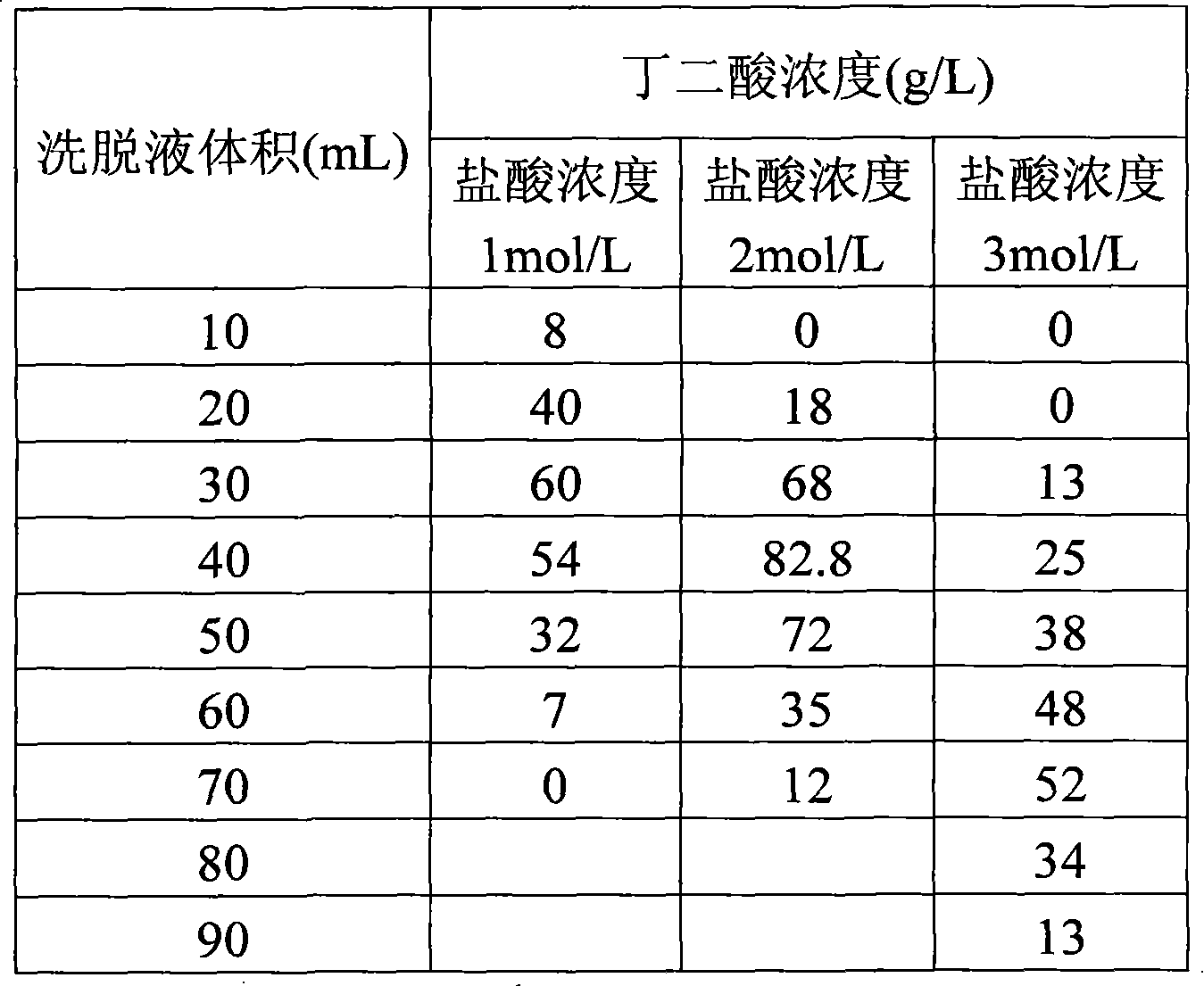

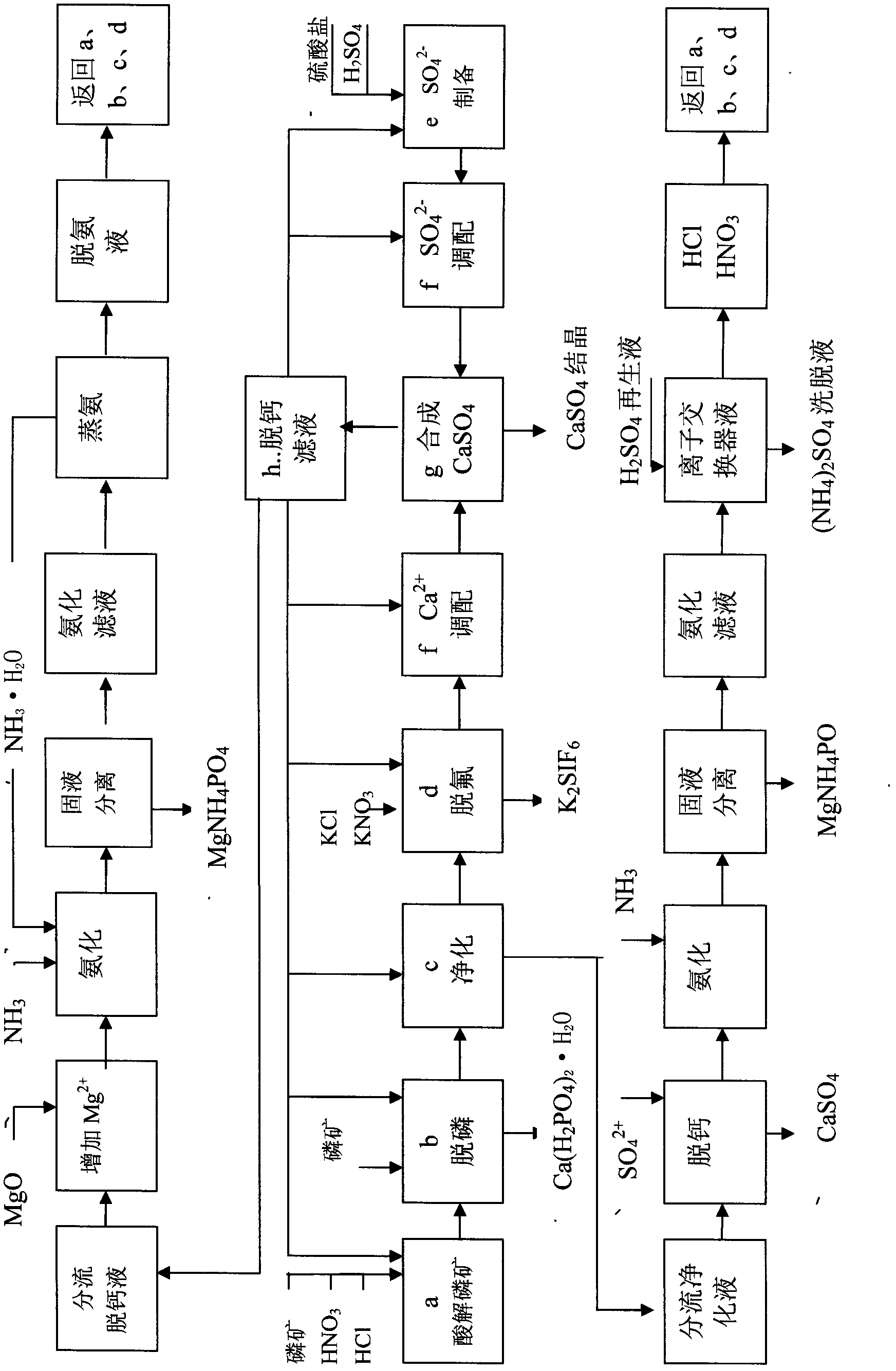

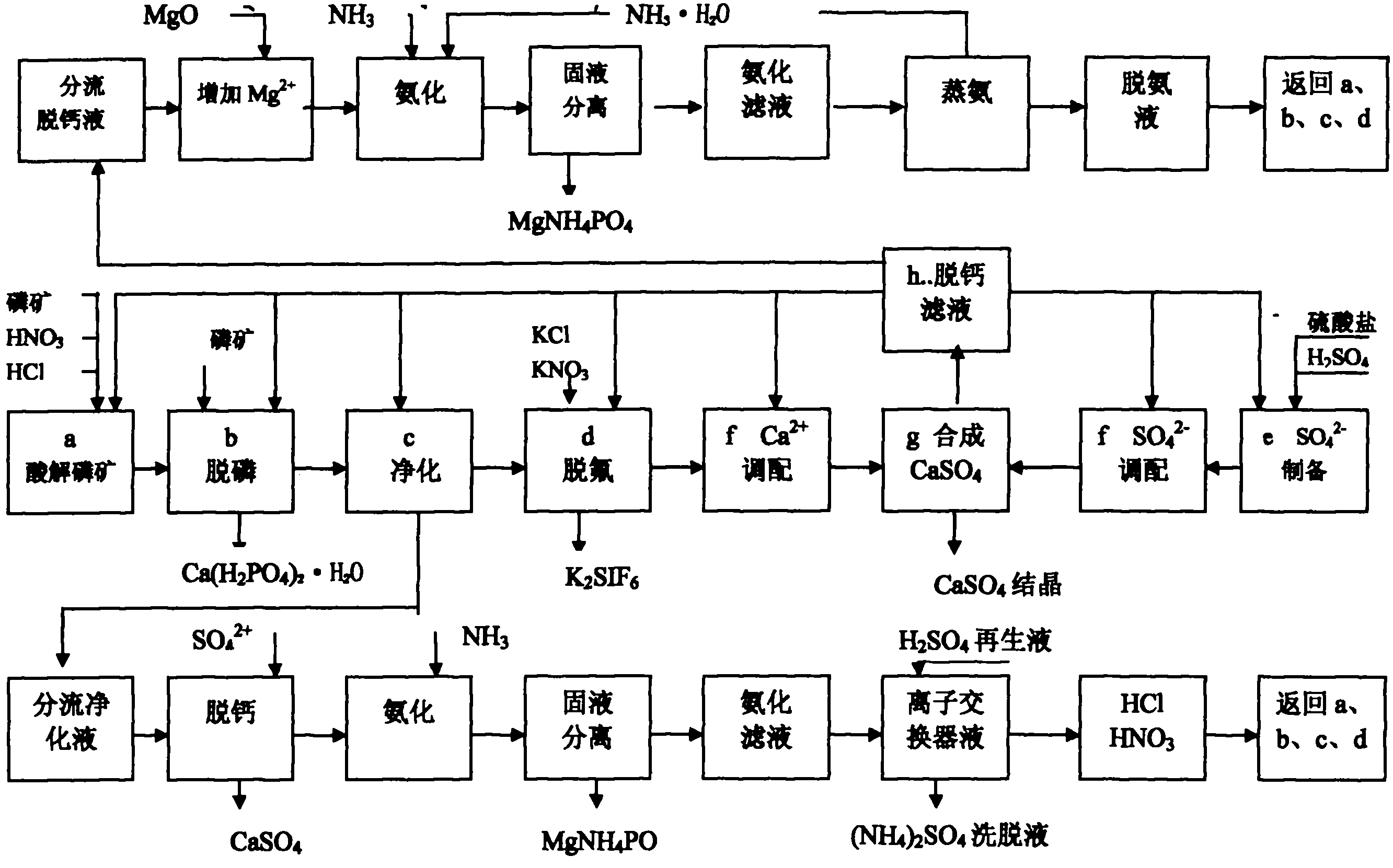

Acidolysis method of magnesium-containing phosphate rock

ActiveCN102417169AAchieving Theoretical UtilizationEasy to processCalcium/strontium/barium sulfatesAmmonium sulfatesHigh magnesiumPhosphor

The invention discloses an acidolysis method of magnesium-containing phosphate rock. The method provided by the invention is characterized by comprising the following steps of: carrying out acidolysis on the magnesium-containing phosphate rock to obtain a water-soluble calcium, magnesium and phosphoric acid containing acidolysis solution, carrying out acidolysis on the phosphate rock by using the generated phosphoric acid to generate Ca(H2PO4)2.H2O solid, performing a reaction between H2SO4 and water-soluble calcium to generate high-pureness calcium sulfate whisker, and performing a reaction between water-soluble magnesium and phosphor in the acidolysis solution and NH3 to generate character separation magnesium ions of a MgNH4PO4 solid so as to realize complete high-efficiency comprehensive utilization of the acidolyzed magnesium-containing phosphate rock. The focus of the invention is to change magnesium ions into controllable parameters which are beneficial to circulation of the acidolysis solution. The magnesium-containing phosphate rock can be efficiently utilized, and also the compound magnesium ammonium phosphate can be used to realize the separation of phosphor magnesium from a circulation medium HCl or HNO3 or CaCL, Ca(NO3)2, thus realizing the combination and combined production with a present ammonium phosphate and phosphor product processing technology. The method provided by the invention has advantages of concise technology, less investment, low energy consumption, low cost, high benefit and no discharge of ''three wastes (waste gas, wastewater and industrial residue)'', and fully presents great business value and great resource value of the high magnesium-containing phosphate rock.

Owner:武善东 +1

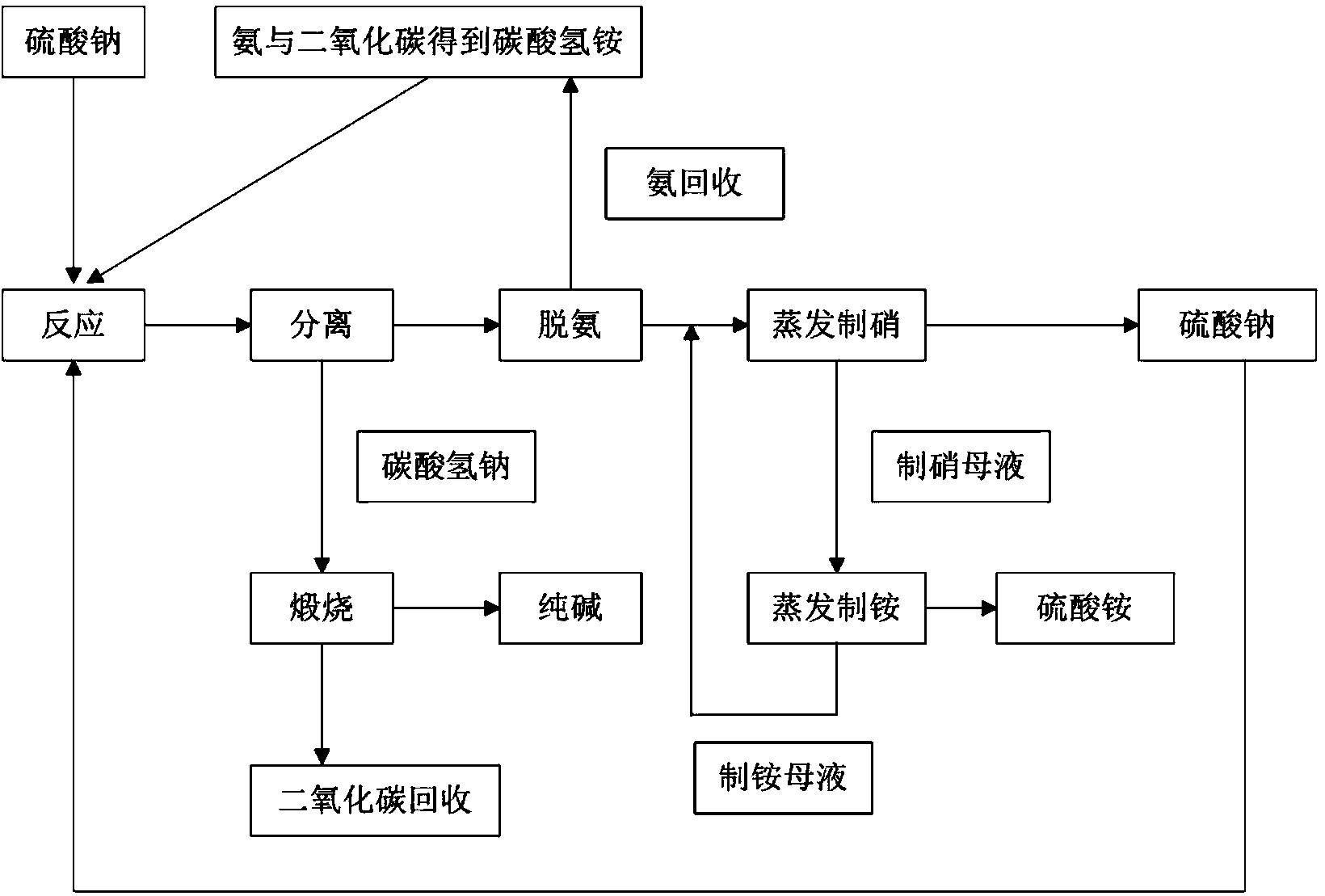

Thermal circulation technology of utilizing sodium sulfate solution or carrier to cogenerate sodium carbonate and ammonium sulfate

ActiveCN104355326AIncrease added valueReduce energy consumptionAmmonium sulfatesCarbonate preparationAmmonium Hydrogen CarbonateSodium sulfate

The invention provides a thermal circulation technology of utilizing sodium sulfate solution or a carrier to cogenerate sodium carbonate and ammonium sulfate. The thermal circulation technology comprises the following steps: regarding an ammonium hydrogen carbonate solution prepared from sodium sulfate, ammonia and carbon dioxide as a raw material to be conducted with a replacement reaction, then carrying out separation to obtain sodium hydrogen carbonate (which can be calcined to obtain a pure alkali product) and an alkali preparing mother solution containing ammonium sulfate, sodium sulfate, ammonium hydrogen carbonate and ammonium carbonate; preheating the alkali preparing mother solution to a high temperature to remove ammonium hydrogen carbonate and ammonium carbonate, and then obtaining the deaminized mother solution containing ammonium sulfate and sodium sulfate; evaporating the deaminized mother solution at a high temperature to obtain sodium sulfate and a niter preparing mother solution; evaporating the niter preparing mother solution at a low temperature to obtain ammonium sulfate and an ammonium preparing mother solution; circulating the sodium sulfate to the replacement reaction working procedure; circulating the ammonium preparing mother solution to the deaminized mother solution high-temperature evaporation working procedure. The main products and byproducts prepared by thermal circulation technology disclosed by the invention are high in quality and added value; the thermal circulation technology is well-adapted in raw materials, low in sodium sulfate theoretical use ratio, production cost and energy consumption, closed circulating, free of three-waste discharge, and capable of saving energy and reducing emission.

Owner:CHINA LIGHT IND INT ENG CO LTD

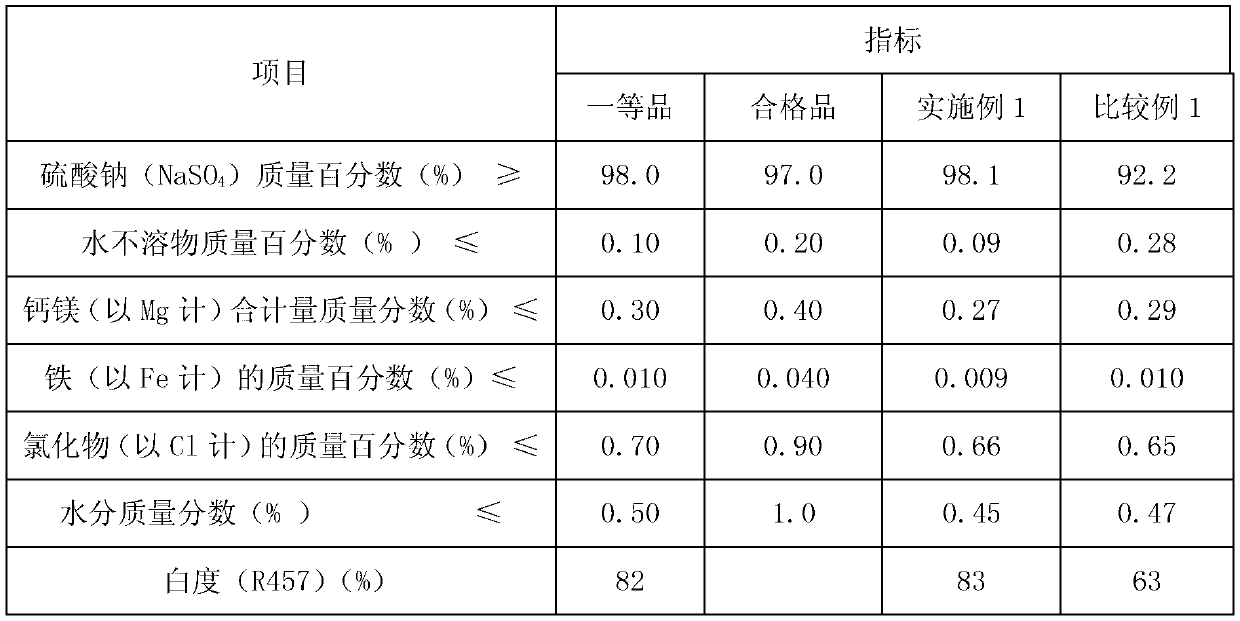

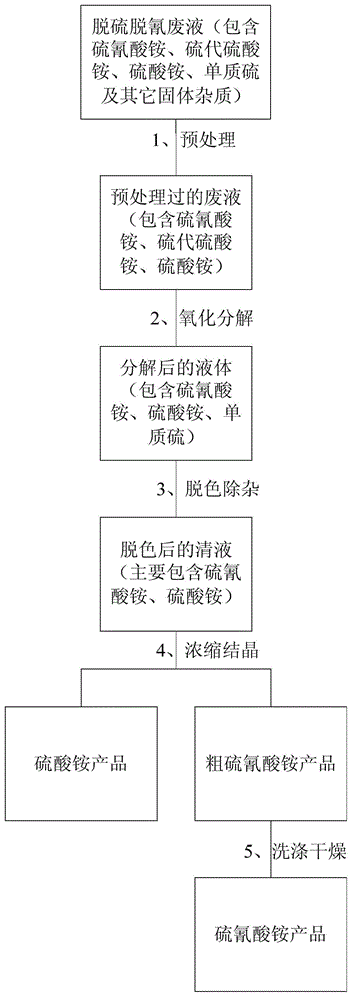

Method for extracting high-purity ammonium thiocyanate and ammonium sulphate from coking desulfurization/decyanation waste liquor

InactiveCN102976361AEfficient decompositionHigh purityThiocyanic acidAmmonium sulfatesPollutionAmmonium sulfate

The invention provides a method for recycling ammonium salt from chemical waste liquor generated in the desulfurization / decyanation process of coke oven gas, and particularly, the invention provides a method for extracting high-purity ammonium thiocyanate and ammonium sulphate from coking desulfurization / decyanation waste liquor. The purities of ammonium thiocyanate and ammonium sulphate produced by using the method disclosed by the invention are greatly improved in comparison with those of products produced by contrasted embodiments. According to the method disclosed by the invention, high-purity products can be prepared under the condition of only carrying out one-time step-by-step concentration, so that the wastewater discharge amount is reduced and the environment pollution of coking plants is alleviated; and high-purity and high-added-value chemical raw materials are recycled, thereby increasing the economic benefits of enterprises.

Owner:BEIJING RISUN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com