Method and device for producing thiamine from sulfur dioxide in recorered smoke

A technology of sulfur dioxide and ammonium sulfate, applied in chemical instruments and methods, separation methods, ammonium sulfate and other directions, can solve problems such as consumption of natural resources, failure of ammonia method to develop well, pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

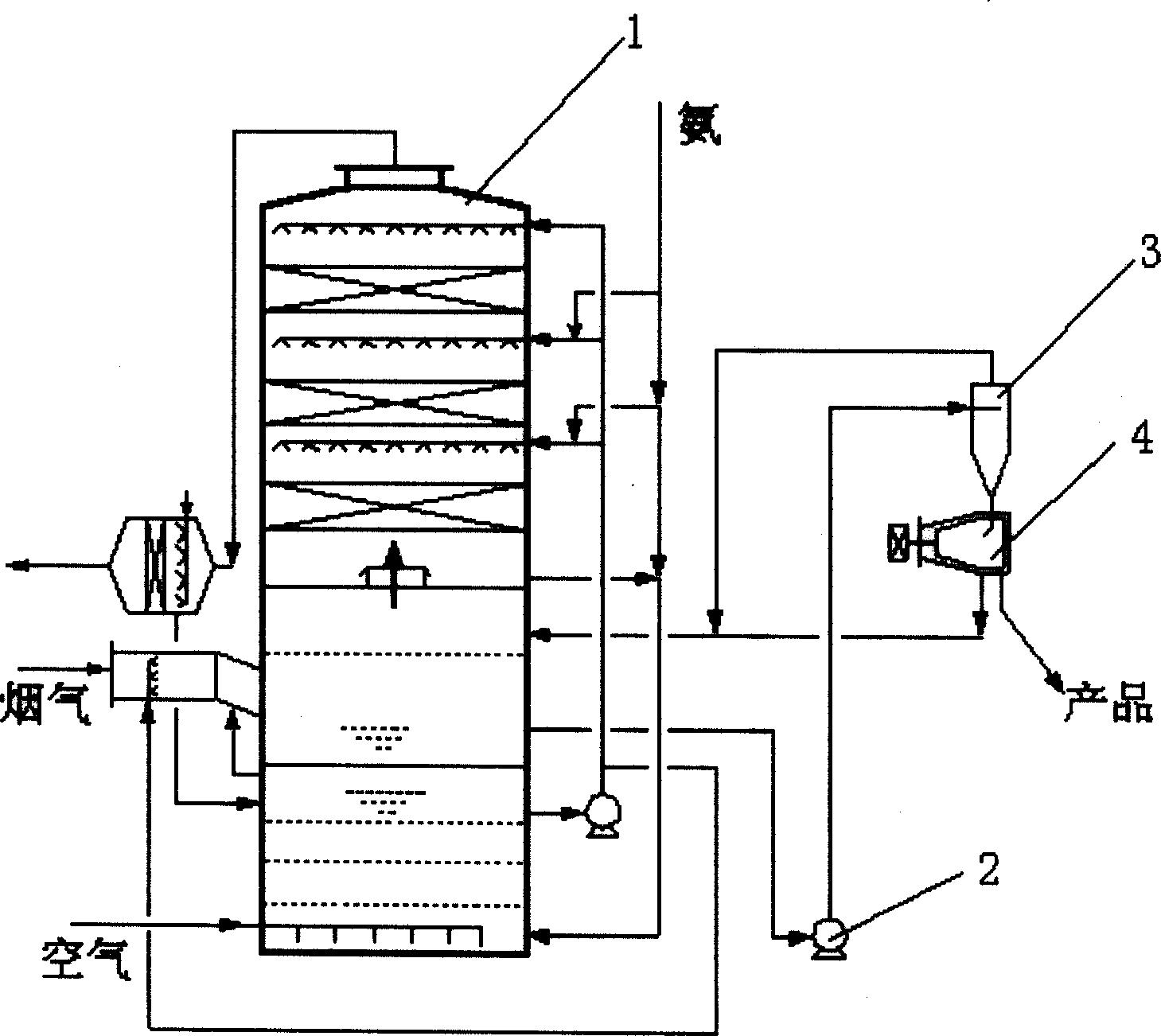

[0106] use figure 2 the process described.

[0107] A 260T / h thermoelectric boiler, burning coal with a sulfur content of 0.8%, and a flue gas flow rate of 340,000 Nm 3 / hr, SO 2 The content is 2000mg / Nm 3 , the electrostatic precipitator is 4 electric fields, and the dust content of the flue gas is 80mg / Nm 3 , the flue gas temperature is 140°C.

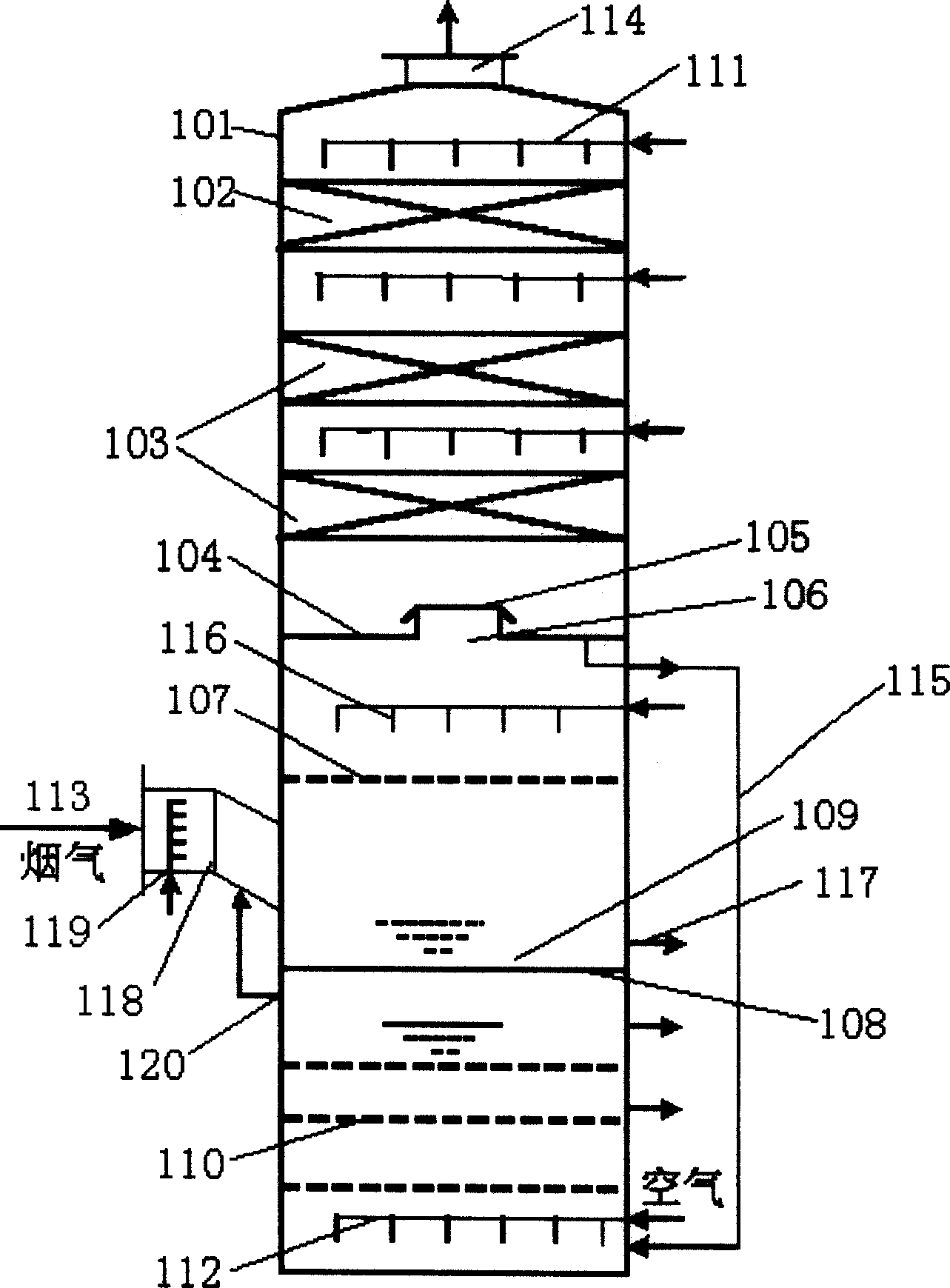

[0108] The diameter of the desulfurization tower is 7m, the height is 25, SO 2 The absorption section adopts a layer of padding.

[0109] After the flue gas passes through the pre-cooling on the flue inlet pipe, the temperature drops to 95°C, and then enters the flue gas humidification and cooling section of the desulfurization tower, where the temperature drops to 50.5°C, and then enters the SO 2 In the absorption section, the desulfurization efficiency is 95.6%, and then enters the ammonia recovery section, the desulfurization efficiency increases to 99.3%, and when leaving the desulfurization tower after the defoaming secti...

Embodiment 2

[0113] use figure 2 process.

[0114] A 300,000 kW thermal power generation unit burns coal with a sulfur content of 2.5%, and the flue gas flow rate is 1.1 million Nm 3 / hr, SO 2 The content is 6285mg / Nm 3 , the electrostatic precipitator is 4 electric fields, and the dust content of the flue gas is 100mg / Nm 3 , the flue gas temperature is 145°C.

[0115] The diameter of the desulfurization tower is 12m, the height is 28m, SO 2 The absorption section adopts two layers of packing.

[0116] After the flue gas passes through the pre-cooling on the flue inlet pipe, the temperature drops to 95°C, and then enters the flue gas humidification and cooling section of the desulfurization tower, where the temperature drops to 50.5°C, and then enters the SO 2 In the absorption section, the desulfurization efficiency is 96.6%, and then enters the ammonia recovery section, the desulfurization efficiency increases to 99.6%, and when leaving the desulfurization tower after the defoamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com