Patents

Literature

56results about How to "Improve sulfur recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

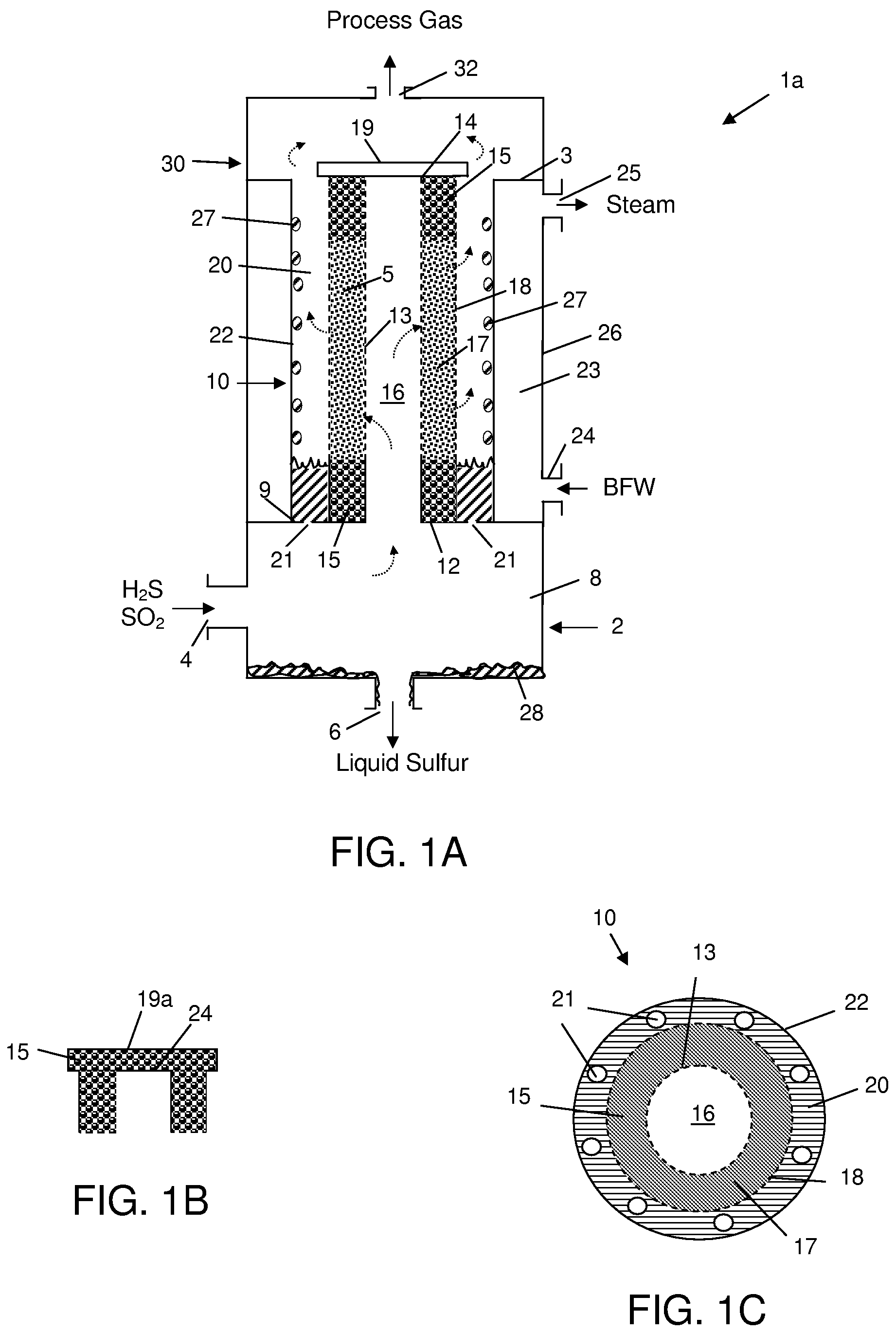

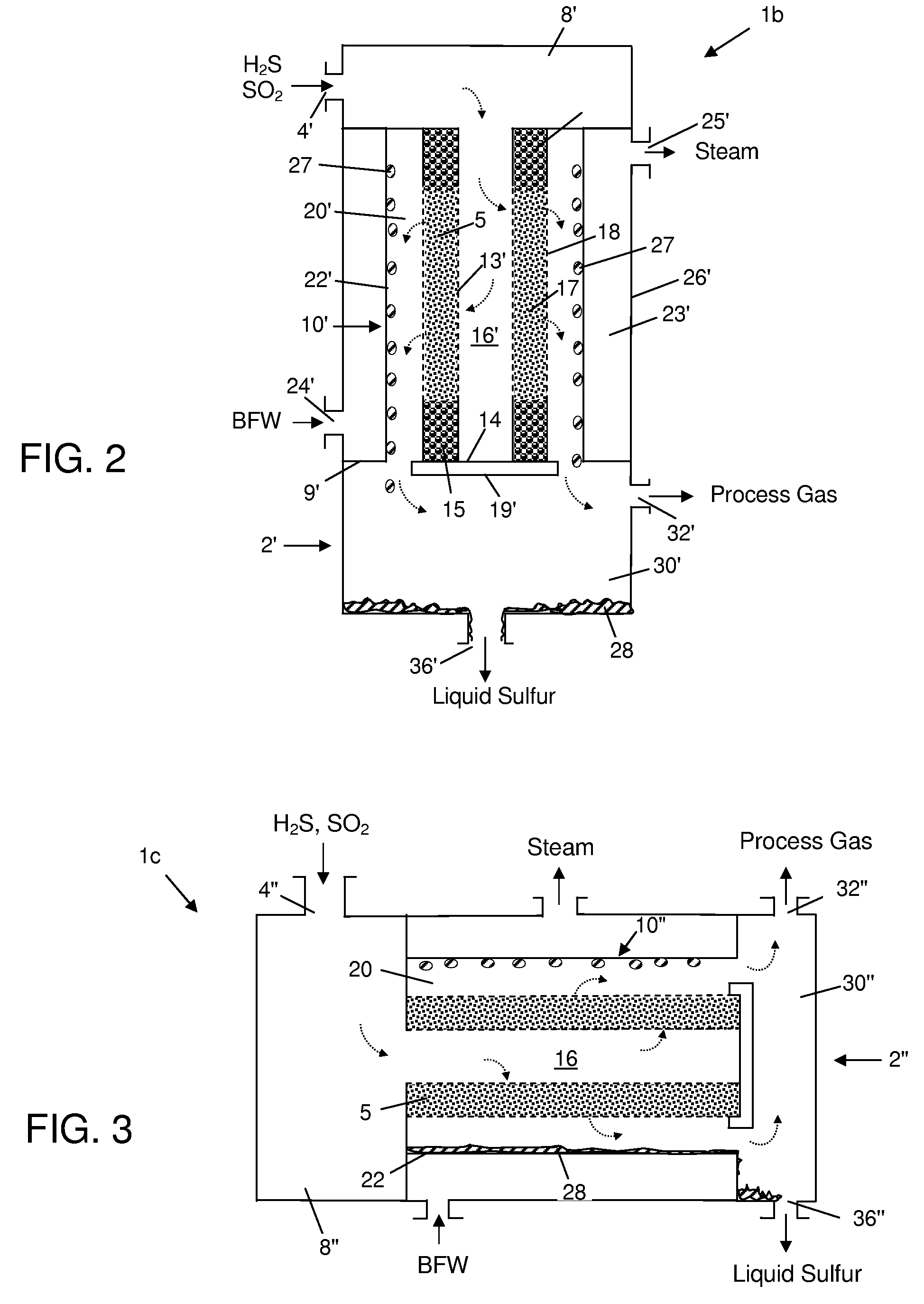

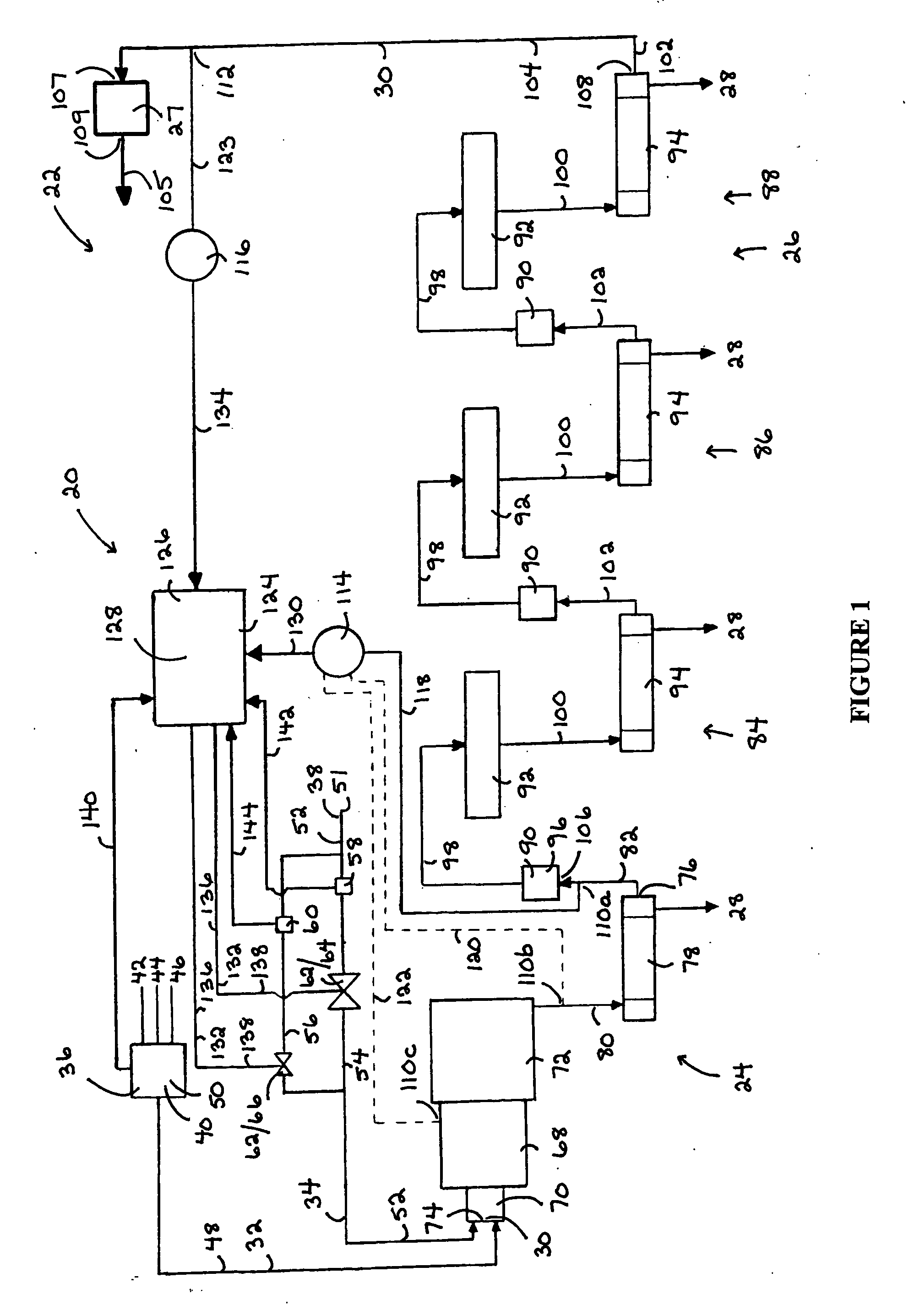

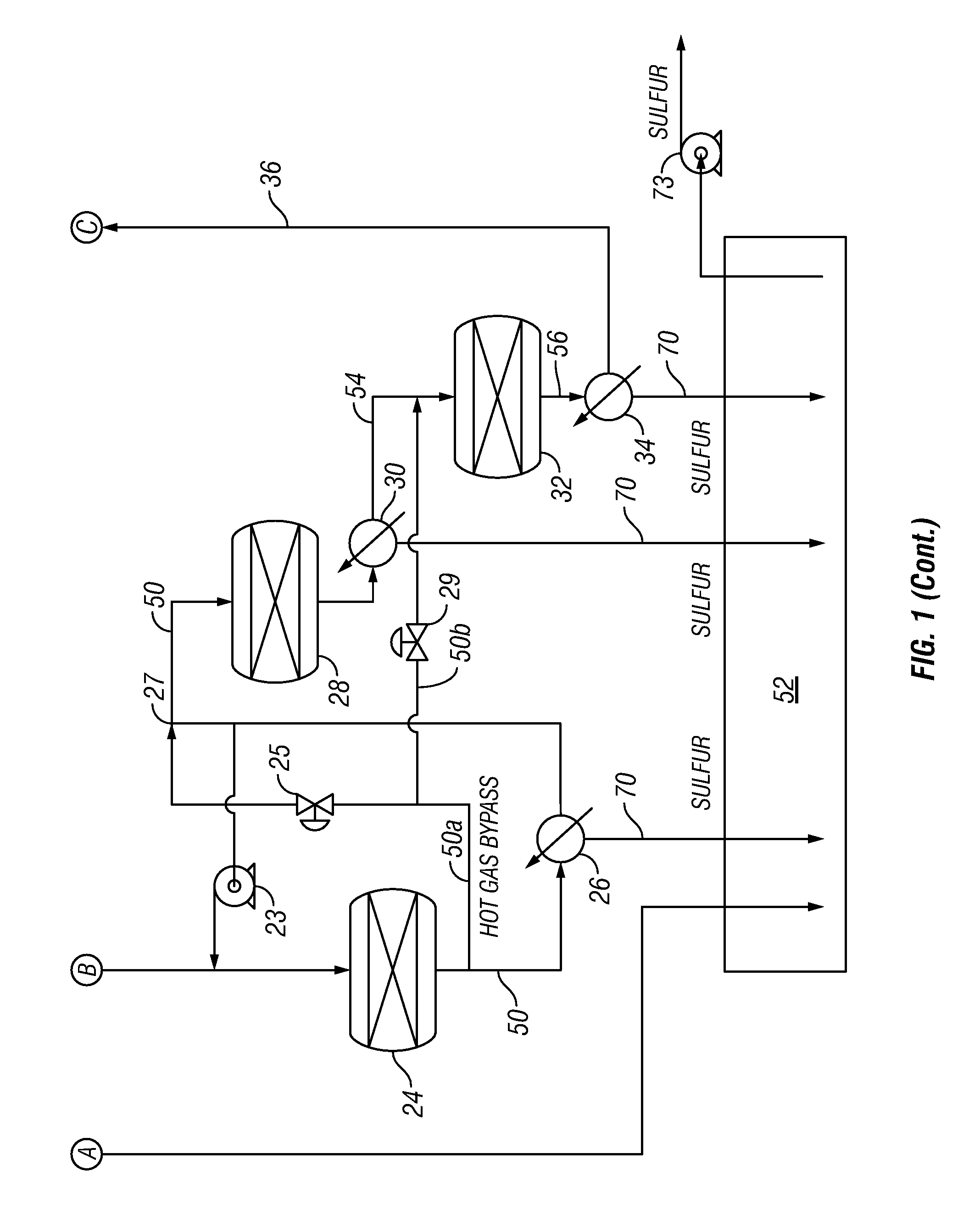

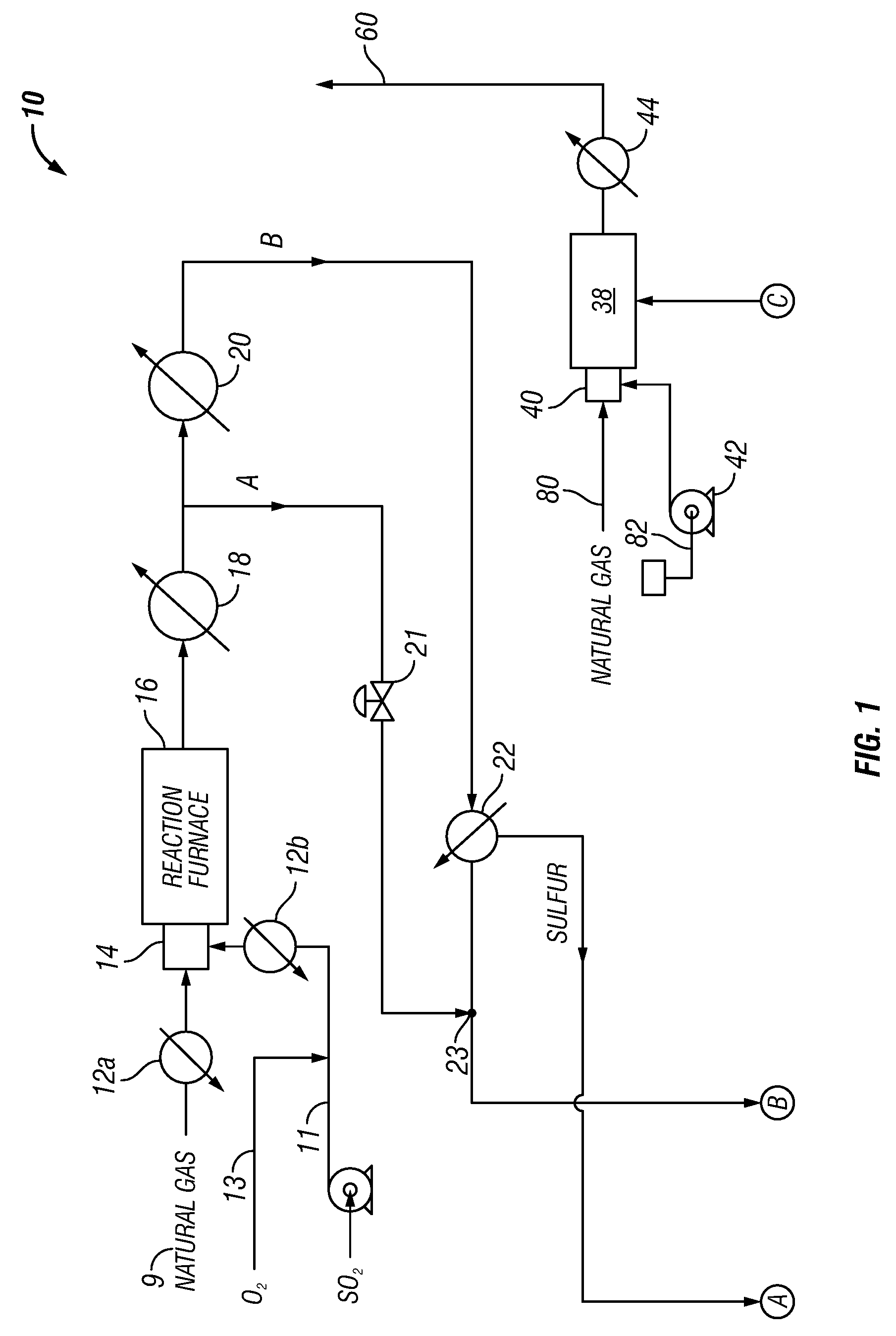

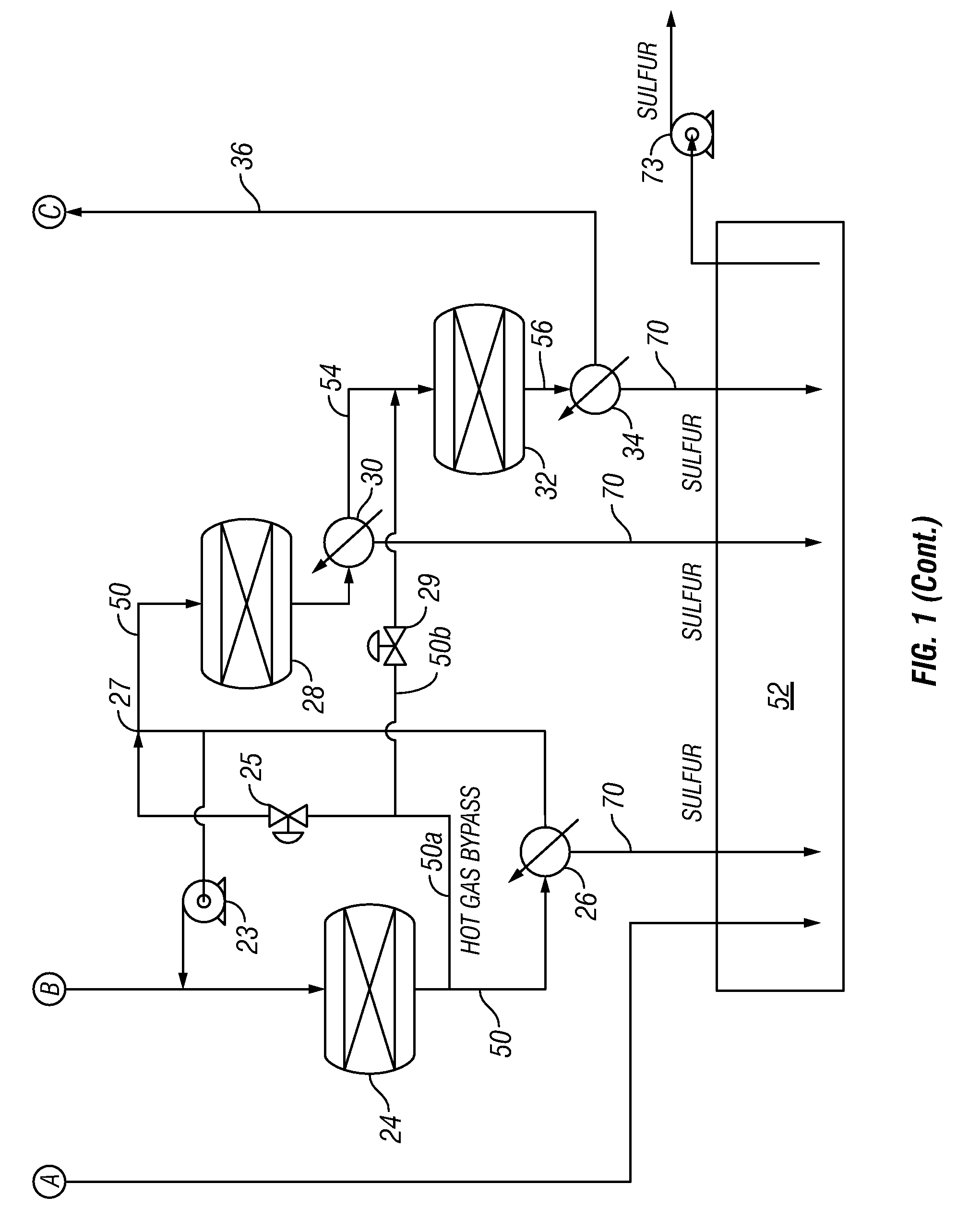

Increased Capacity Sulfur Recovery Plant and Process for Recovering Elemental Sulfur

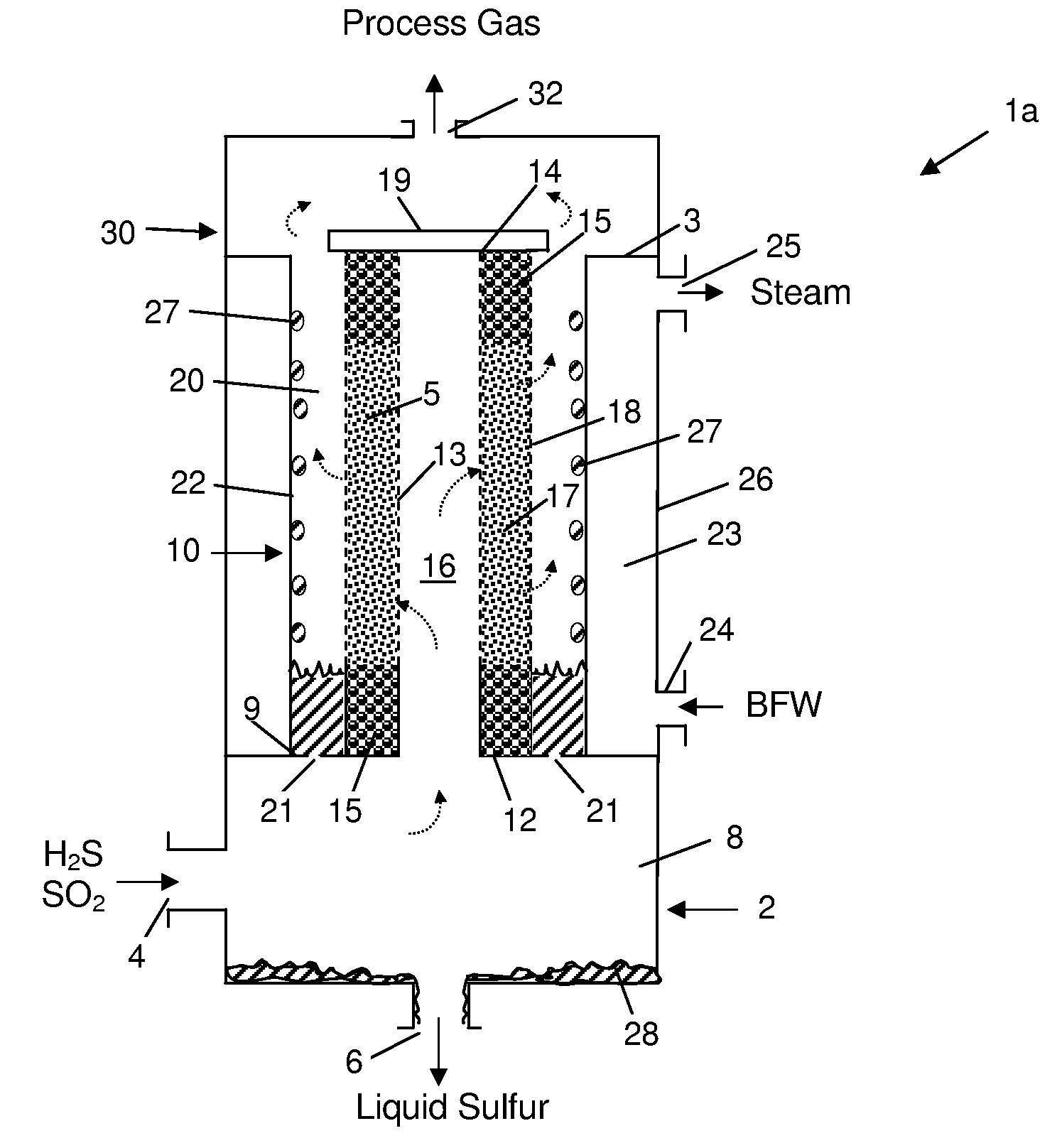

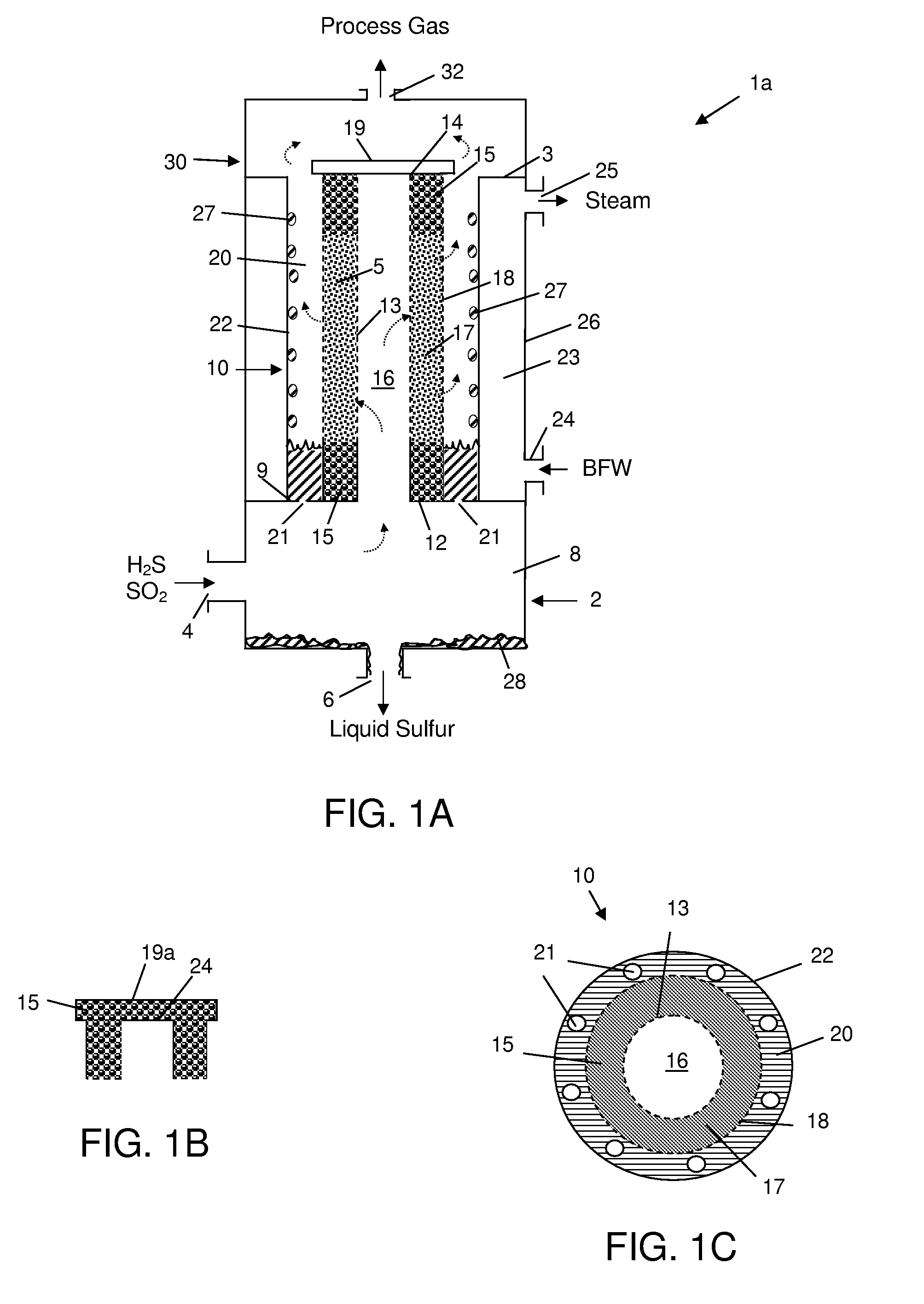

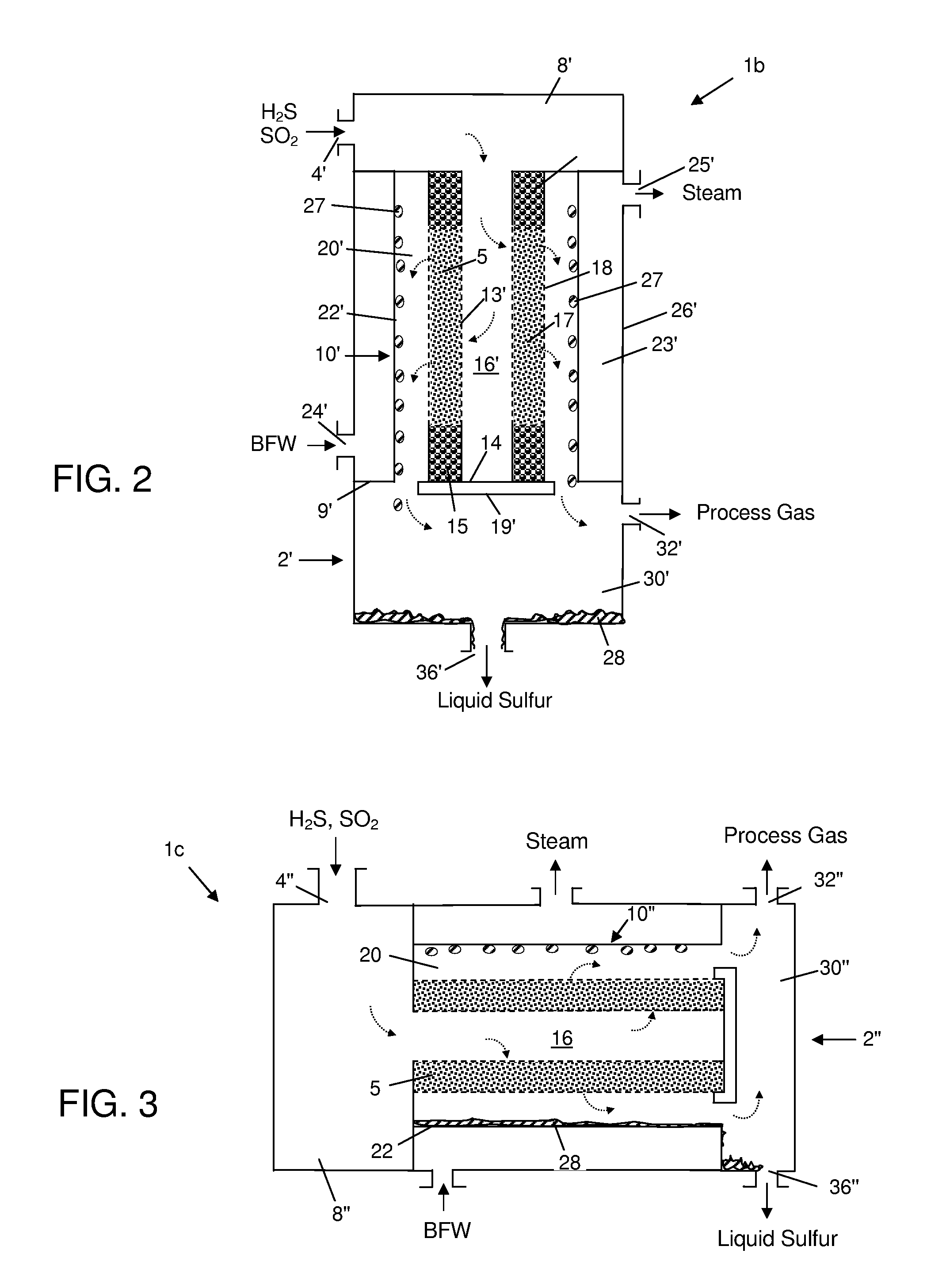

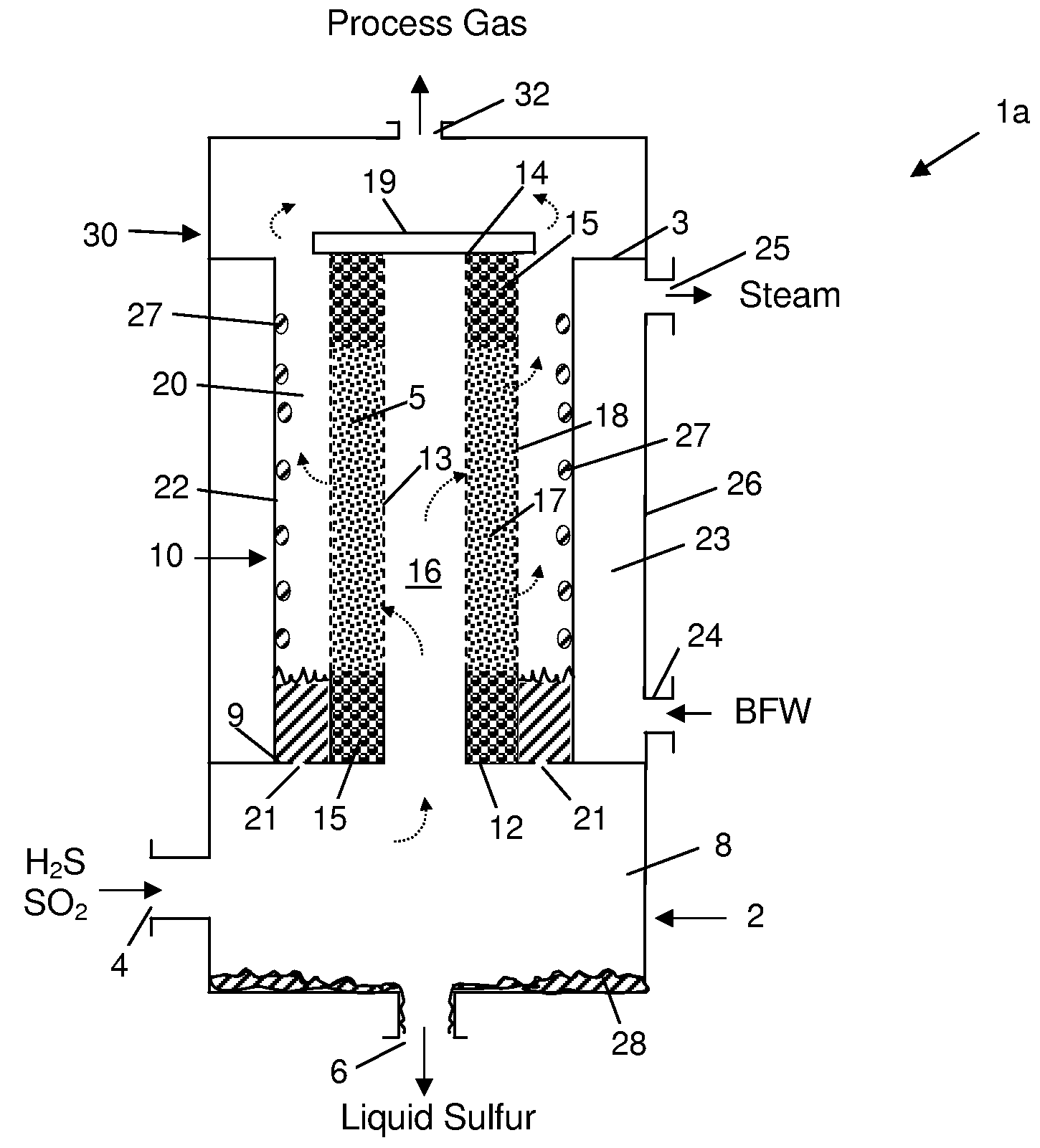

ActiveUS20080050306A1Eliminate needIncreasing sulfur recovery capacityCombination devicesTeeth fillingSingle stageMicro heat exchanger

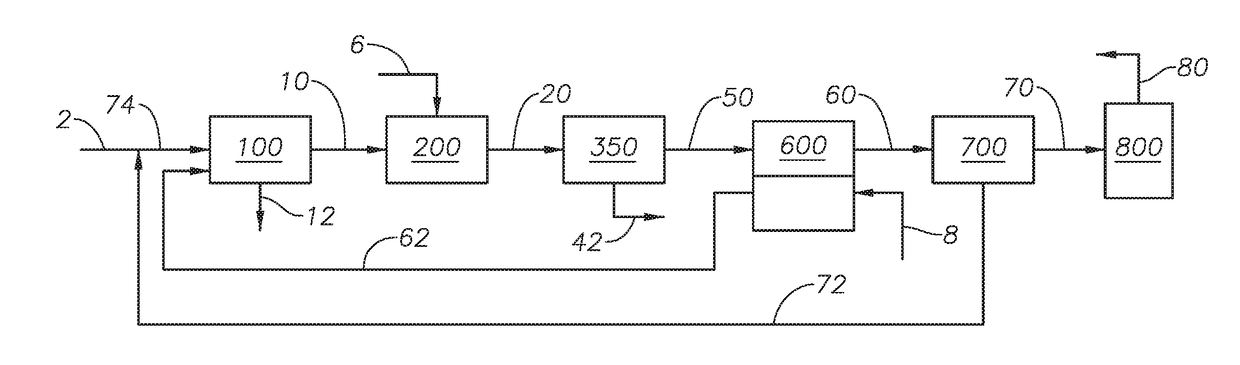

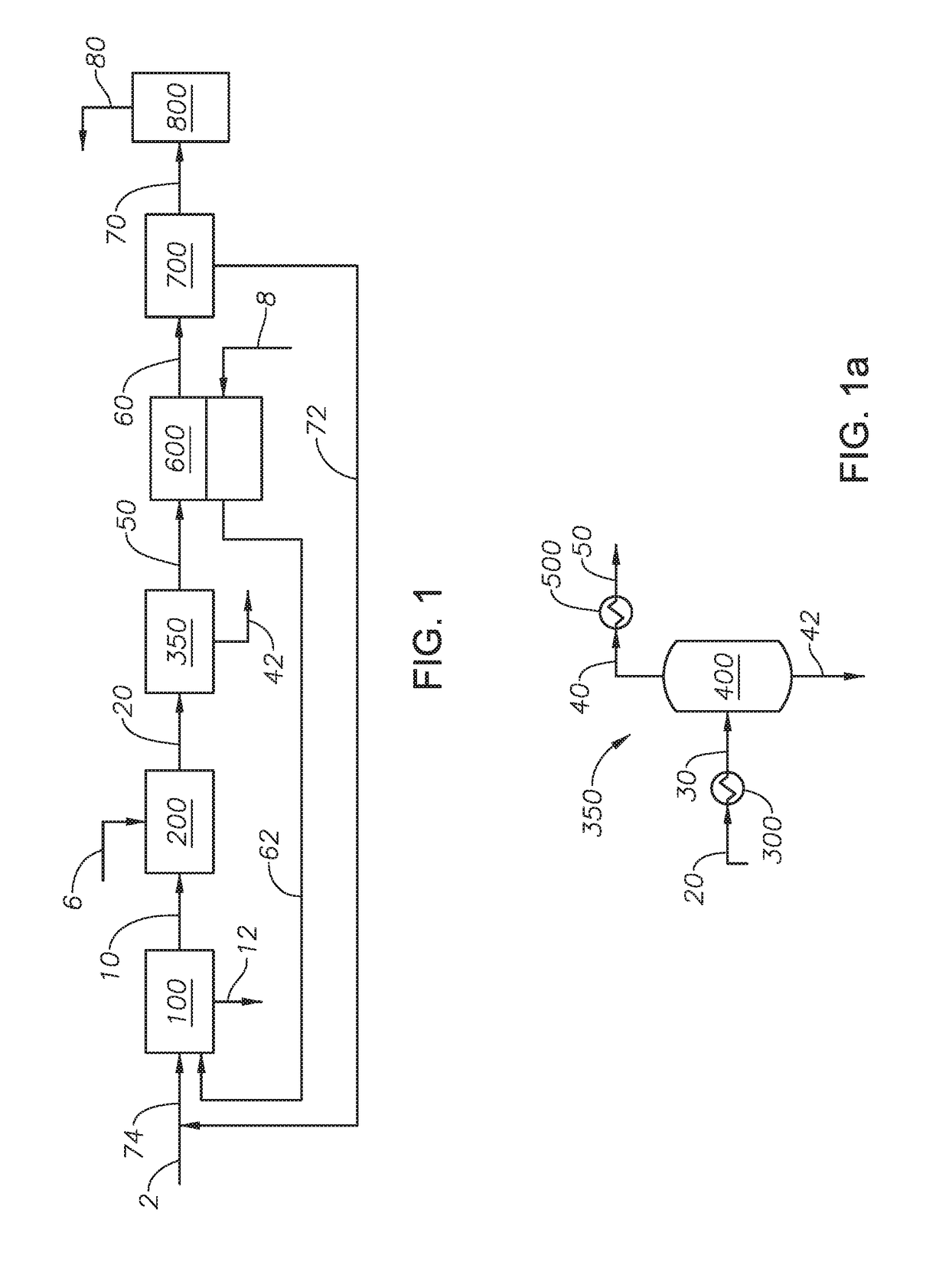

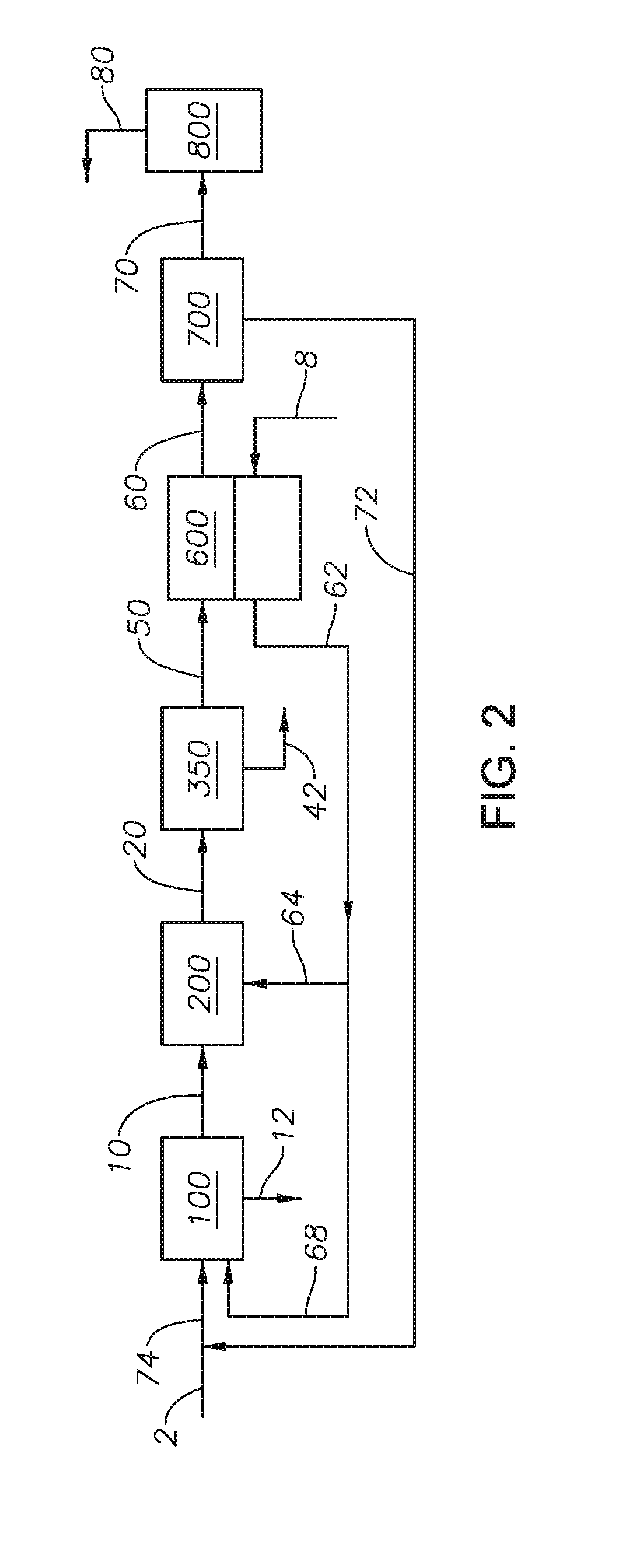

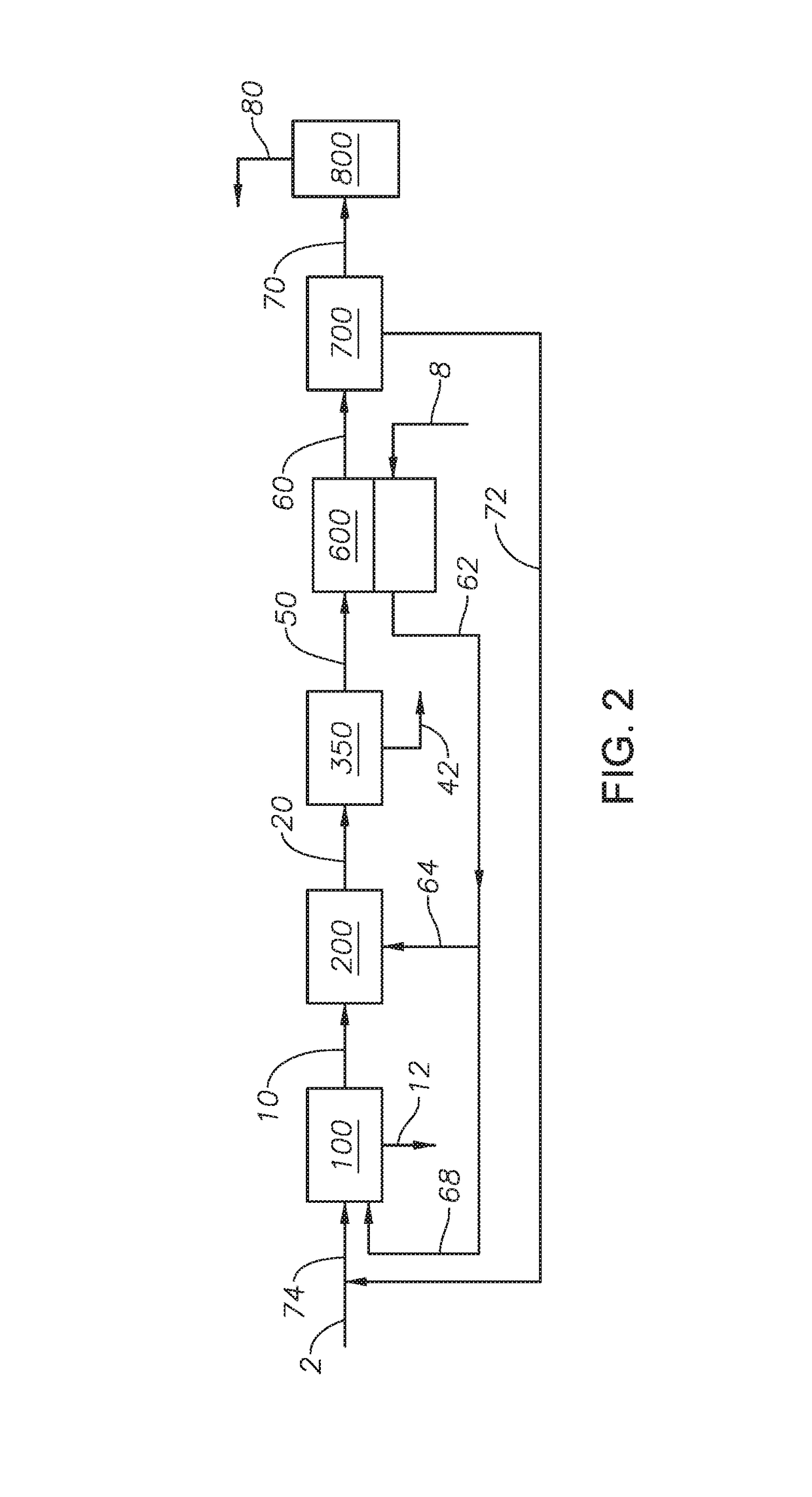

Claus sulfur recovery plants that include one or more single-stage or multi-stage compact tubular Claus catalytic reactor-heat exchanger units are disclosed. In some instances, these new or improved Claus plants additionally include one or more compact heat exchanger containing cooling tubes that are filled with a heat transfer enhancement medium. The new compact tubular Claus catalytic reactor-heat exchanger units and HTEM-containing heat exchangers are also disclosed. A process for recovering sulfur from a hydrogen sulfide-containing gas stream, employing the new tubular Claus catalytic reactor-heat exchanger unit, and in some instances a HTEM-containing heat exchanger, are also disclosed.

Owner:PHILLIPS 66 CO

Increased capacity sulfur recovery plant and process for recovering elemental sulfur

ActiveUS7501111B2Increasing sulfur recovery capacityLow costCombination devicesTeeth fillingPlate heat exchangerSingle stage

Owner:PHILLIPS 66 CO

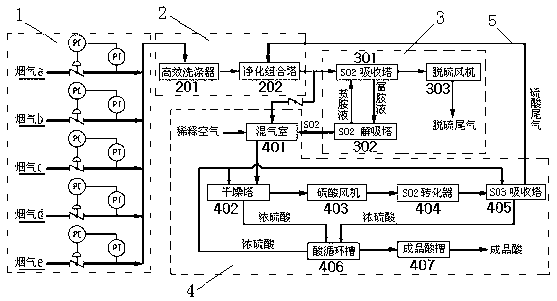

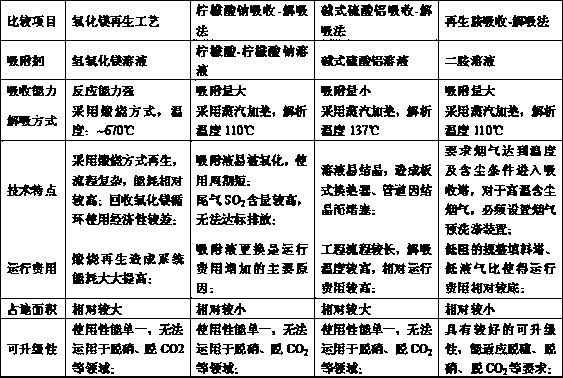

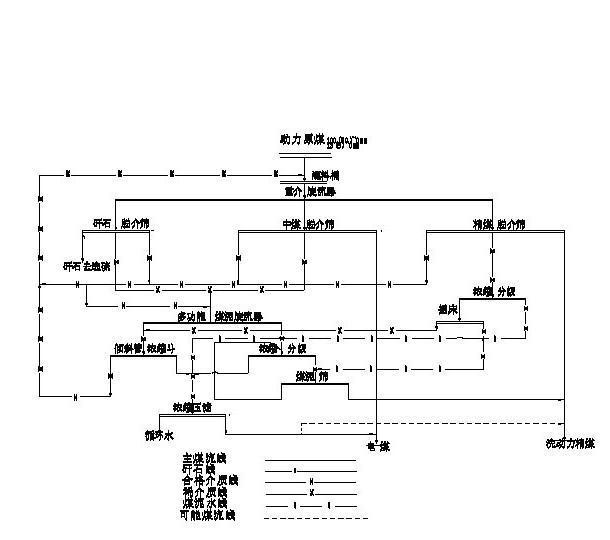

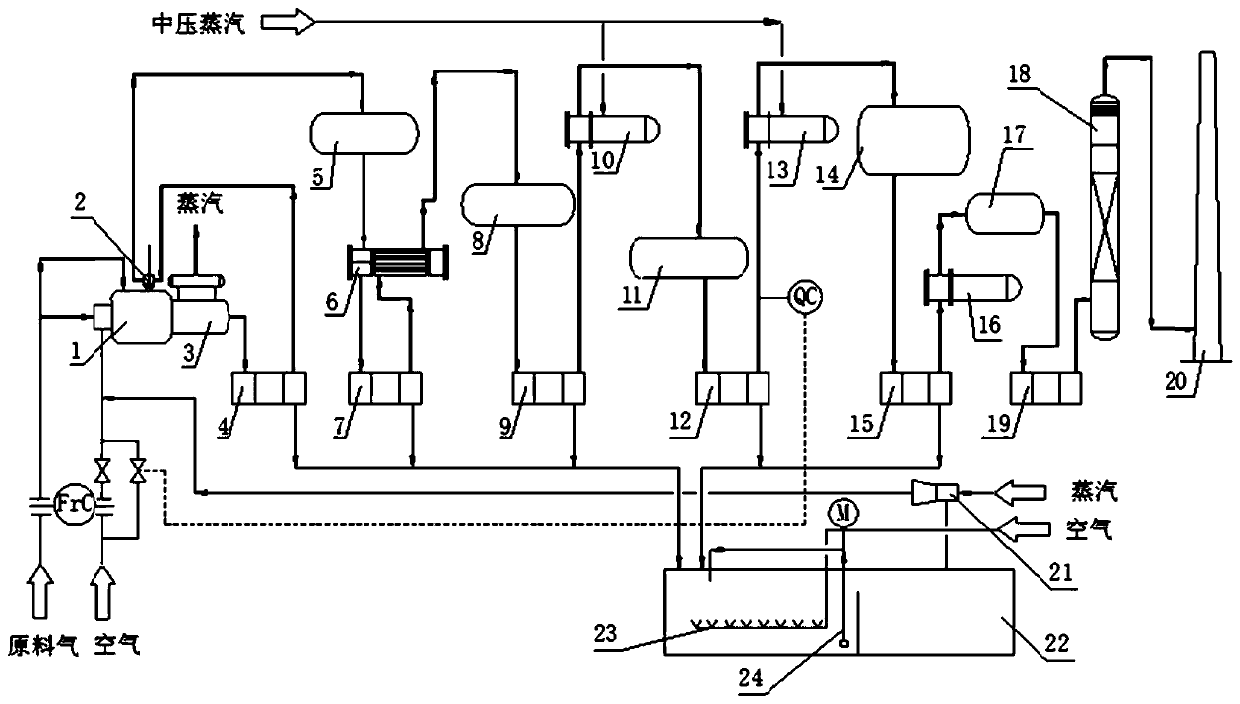

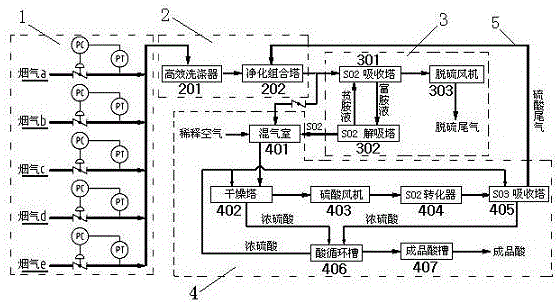

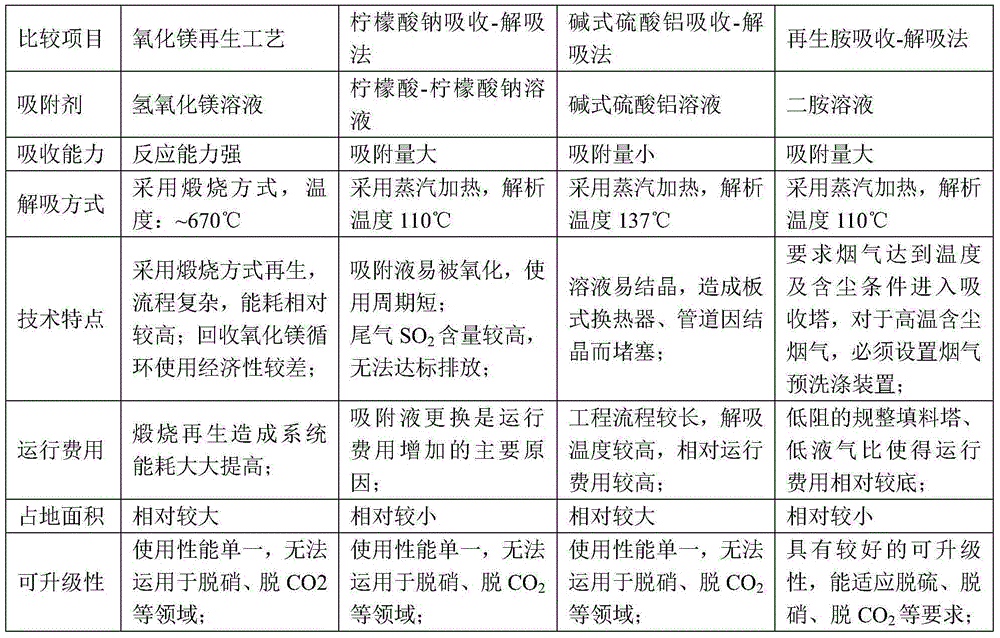

Comprehensive multi-gas source low-concentration SO2 fume recycling acid-making technological process

ActiveCN103303877AImprove sulfur recoveryOptimization of equipment and investmentDispersed particle separationSulfur compoundsScrubberCircular economy

The invention discloses a comprehensive multi-gas source low-concentration SO2 fume recycling acid-making technological process. The fume is mixed in a pressure adjusting gas distribution mode, is subjected to washing by using a high-efficiency washer and deep purification by using a combined purification tower, and is subsequently fed into a fume desulfurization system, and the tail gas is fed into a chimney to discharge out. The high-concentration SO2 which is produced from desulfuration and desorption is diluted by air or a part of pre-washed wet fume and is fed into an acid-making system, a finished product sulfuric acid is produced, the sulfuric acid tail gas is fed back to the combined purification tower and the fume desulfurization system, and the tail gas is discharged out when being subjected to up-to-standard desulfurization. The process is a comprehensive sulfur resource recycling technique that a multi-gas source mixed conveying technique, an SO2 recycling technique which employs an absorption-desorption method and a conversion-absorption acid-making technique are combined together, has the characteristics of high sulfur recycling rate, optimization in equipment and investment and low operation expense, can realize clean production and comprehensive recycling of SO2, prompts the development of circular economy of companies, and can be widely applied to comprehensive treatment on fume with low-concentration SO2 in industries of colored metal, steel and iron, thermal power, chemistry and the like.

Owner:CHINA NERIN ENG

Method for removing sulfur-dioxide in smoke by bamboo-carbon filler biological drip filtering tower

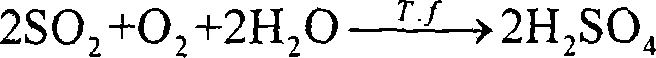

InactiveCN101073745AHigh removal rateImprove sulfur recoveryDispersed particle separationAir quality improvementSulfateSulfur

The invention is concerned with a method to remove sulfur dioxide of gas and smoke through bio-trickling filter tower with bamboo-carbon filler. The nutrient source spray on the filling inside the tower form the top of bio-trickling filter tower and run into the filling from up to down and enter the circulation gutter on the bottom of tower, then go back to the top of tower by circulation gutter. Meanwhile the gas and smoke with sulfur dioxide enter form the bottom of tower, during the rising process, it is cleaned by the bio-film with fixed desulfuration bacteria and discharged form the top of tower. The filling is the pretreatment bamboo-carbon and it is fit for getting Ferrous Sulfate desulfuration byproduct. The bamboo-carbon owns developed holes and strong adsorption ability to form steady and high active bio-film and to remove the sulfur dioxide. It has wide application future to callback sulfur with low cost.

Owner:NANJING UNIV

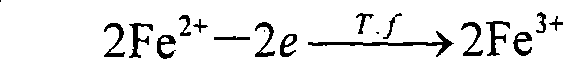

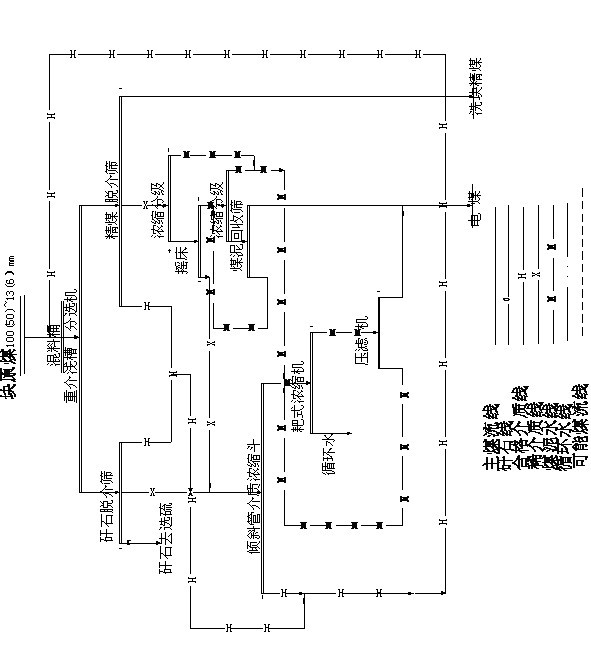

High-sulfur power raw coal sorting process

InactiveCN102489391AReduce manufacturing costSystem link simplificationSolid separationCoalProcess engineering

The invention relates to a high-sulfur power raw coal sorting process which comprises the following steps of: separating high-sulfur power raw coal into 100(50)-13(6) mm lump raw coal and 13(6)-0 mm power raw coal; leading the 100(50)-13(6) mm lump raw coal into a lump coal heavy medium shallow slot sorting system to discharge washed fine coal and gangue; leading the 13(6)-0 mm power raw coal into a heavy medium cyclone sorting system for sorting to discharge washed power fine coal and gangue; leading the gangue produced by both the lump coal heavy medium shallow slot sorting system and the heavy medium cyclone sorting system to enter an autogenous medium cyclone gangue sorting system for sorting to discharge ferric disulfide and electric coal, and simultaneously diverting fine ferric disulfide as a supplementary medium of the lump coal heavy medium shallow slot sorting system and the heavy medium cyclone sorting system; and finally processing the products of washed power fine coal, washed lump fine coal, ferric disulfide, electric coal and the like. The sorting system provided by the invention has simplified links, small floor space and low operating cost, the investment and operating cost of the whole factory is reduced by 15-20%; and meanwhile, the sorting system has good desulfurization property and obvious energy saving and emission reduction effects.

Owner:重庆南桐矿业有限责任公司选煤厂

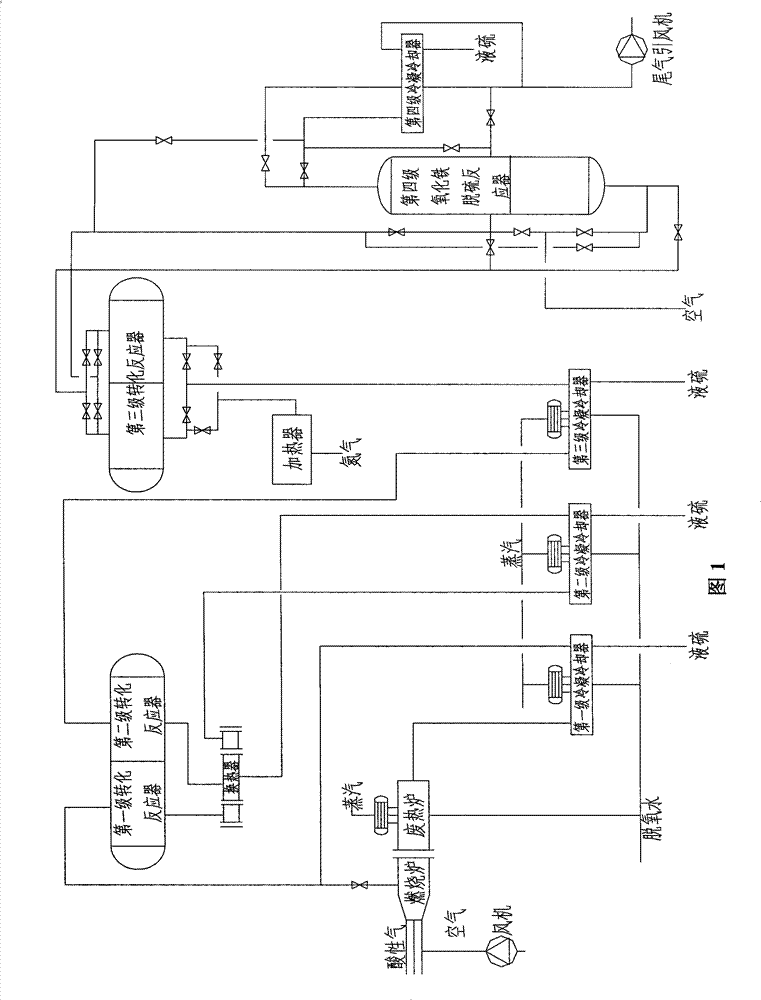

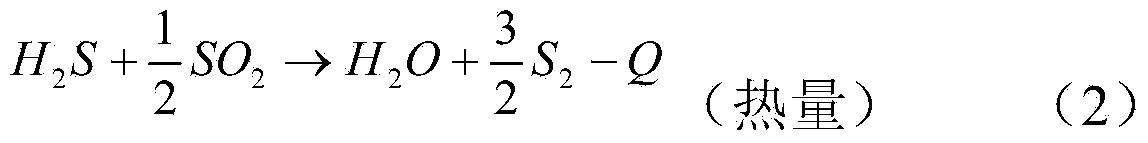

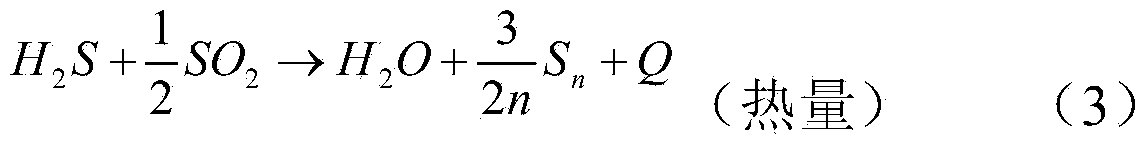

Desulfurization process containing H<2>S acidic gas

InactiveCN101530727BThe process idea is clear and simpleEasy to operate and manageDispersed particle separationCombustionSulfur

Owner:BEIJING HANGXINGSHIJI TECH DEV

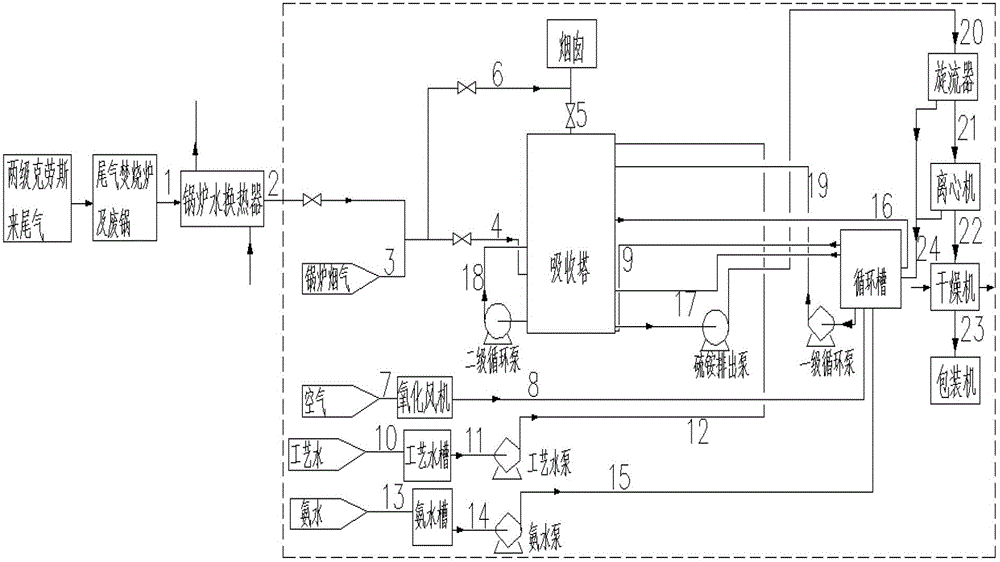

A method for treating sulfur recovery tail gas by using boiler flue gas ammonia desulfurization

ActiveCN103521060BImprove sulfur recoveryGuaranteed sulfur recoveryChemical industryDispersed particle separationTowerAqueous solution

The invention provides a method for desulfurization of a sulfur recovery tail gas by using a boiler flue gas ammonia method. The method comprises the following steps: (1) burning the sulfur recovery tail gas, wherein sulfide in the sulfur recovery tail gas is converted into sulfur dioxide; (2) converging the burnt sulfur recovery tail gas with the boiler flue gas to form merged flue gas, feeding the merged flue gas to an absorption tower, and discharging the merged flue gas after being absorbed by absorption liquid in a countercurrent manner in the absorption tower, wherein the absorption liquid is a water solution containing an ammonium salt, and the ammonium salt is a mixture of ammonium sulfate and ammonium sulfite. By adopting the method disclosed by the invention, not only can the sulfur recovery rate be better ensured, but also emission of the tail gas achieves the environmental protection requirements; meanwhile, investment and operative difficulty are reduced; the floor area is reduced; the comprehensive utilization efficiency of energy is improved; a good effect of treatment of waste by waste can also be achieved.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

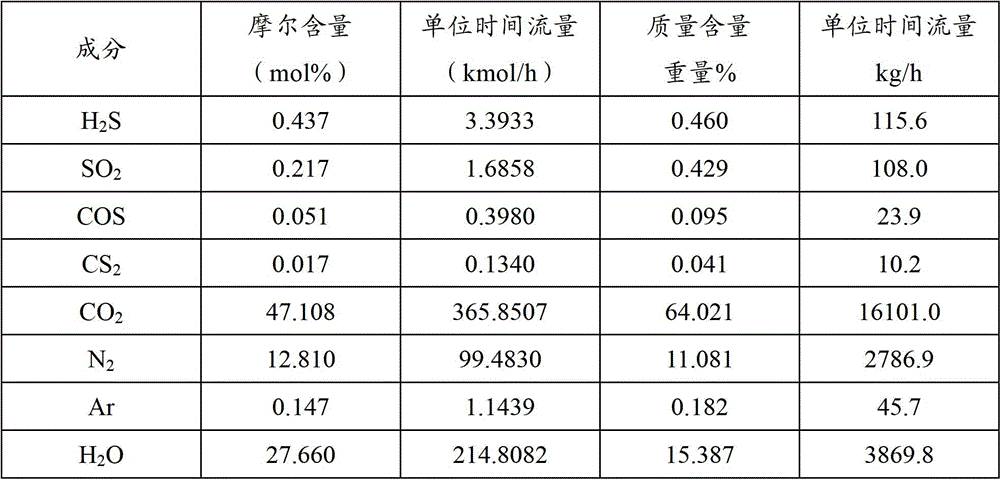

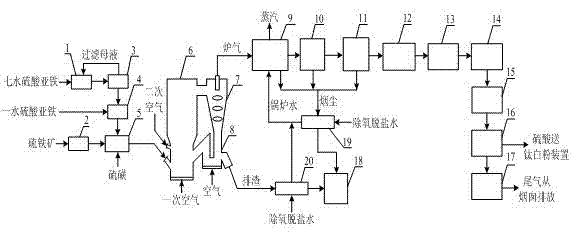

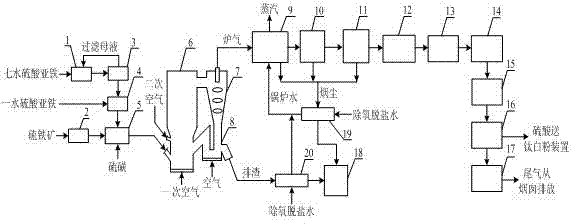

Method for joint production of sulfuric acid and refined iron powder by mixed burning of ferrous sulfate and pyrite

ActiveCN102502527AAchieve recyclingSolve the problem of difficult resource utilizationSulfur compoundsEnergy inputThermal stateFiltration

The invention discloses a method for joint production of sulfuric acid and refined iron powder by mixed burning of ferrous sulfate and pyrite and belongs to the technical field of environmental protection. The method comprises the following steps of: preparing ferrous sulfate monohydrate from ferrous sulfate heptahydrate by high-temperature crystal transformation, filtration and drying; drying and then feeding to drying equipment for free water removal together with ferrous sulfate monohydrate which is separated by concentrating waste acids from titanium dioxide production; drying and then feeding the mixture of ferrous sulfate monohydrate, pyrite and solid sulfur to a circulating fluid bed decomposition furnace; and introducing primary and secondary air for cyclic thermal decomposition. The high-temperature sulfur dioxide-containing flue gas discharged from the top of the circulating fluid bed decomposition furnace is subjected to cooling and dedusting treatment by a waste heat boiler, a cyclone dust collector and an electric dust collector and then fed into a dilute acid washing and purifying system and a double-transformation double-suction acid making system to produce sulfuric acid. The refined iron powder discharged from the circulating fluid bed decomposition furnace and the refined iron powder collected by the waste heat boiler, the cyclone dust collector and the electric dust collector, which have a thermal state w (Fe) of more than or equal to 60%, are cooled by a hot-material cooler and then fed into a refined iron powder bin. The method has good environmental and social benefits.

Owner:CHINA PETROCHEMICAL CORP +1

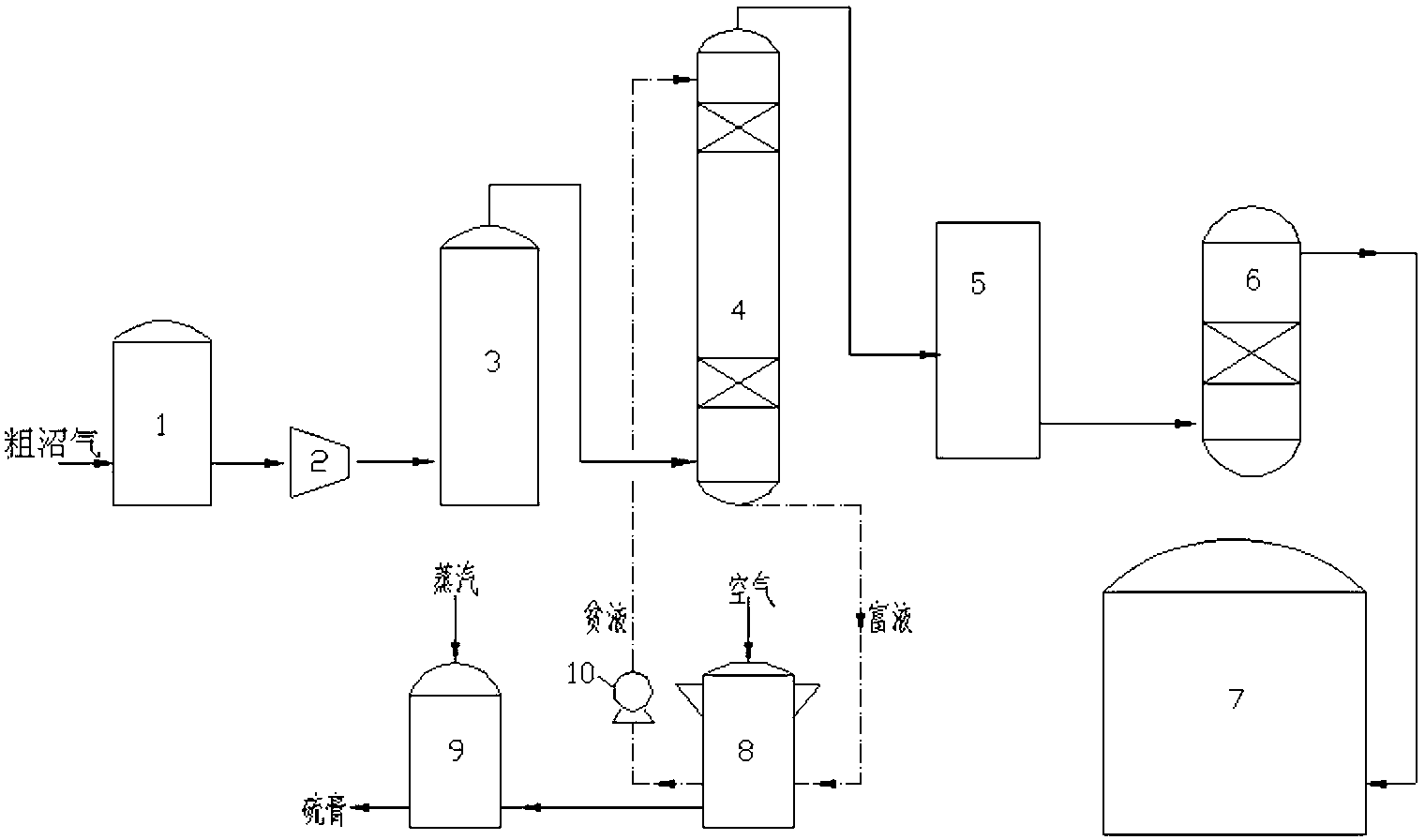

Biogas desulfurization method in series of wet method with dry method

InactiveCN103013600AHigh sulfur capacityMeet quality requirementsGaseous fuelsCooling towerTherapeutic effect

The invention discloses a biogas desulfurization method in series of a wet method with a dry method, which comprises the following steps: crude gas is boosted by a fan and enters a wet desulphurization tower after the temperature is lowered by a cooling tower; in the countercurrent contact process of crude gas and a desulfurization solution in the tower and a catalyst, most of impurities such as hydrogen sulfide are removed, and then the biogas is subjected to the dry desulfurization again after the moisture is separated through a dehydrating tower to further remove hydrogen sulfide so as to be lowered below 15 mg / Nm<3> to enter a biogas cabinet for use, and a rich fluid containing H2S is recycled in a regeneration tank. The method disclosed by the invention has the advantages of large treatment amount, stable treatment effect, high sulfur recovery rate, easily regenerated desulfurizer and long service life, and ensures that the hydrogen sulfide content of biogas meets the use requirements. The service life of the equipment pipeline in the biogas industrial application can be prolonged, the environmental problem of secondary pollution in use of biogas is eliminated, and a guarantee for further purifying and utilizing biogas is provided.

Owner:ZHONGJU TIANGUAN BIOLOGICAL ENERGY

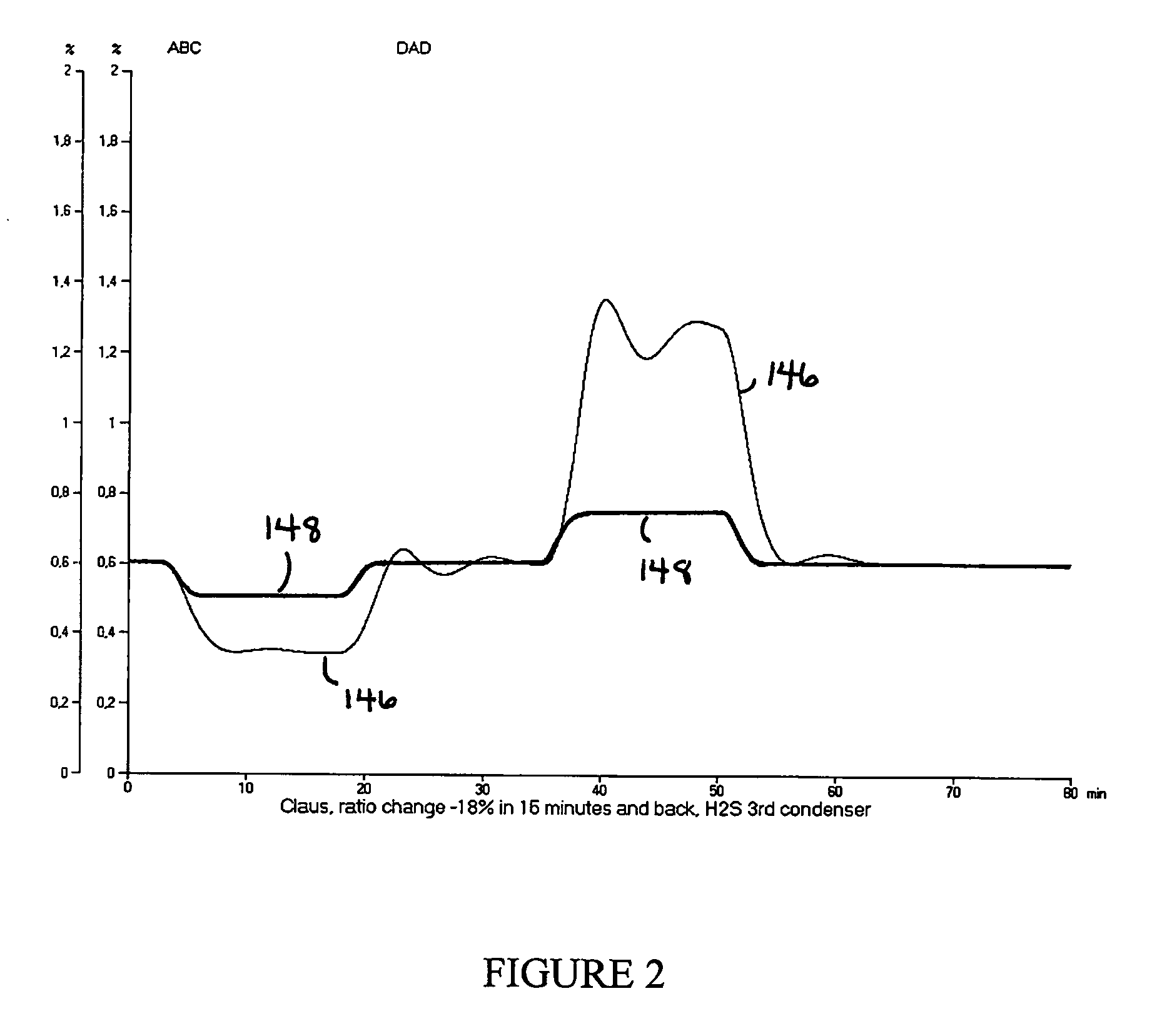

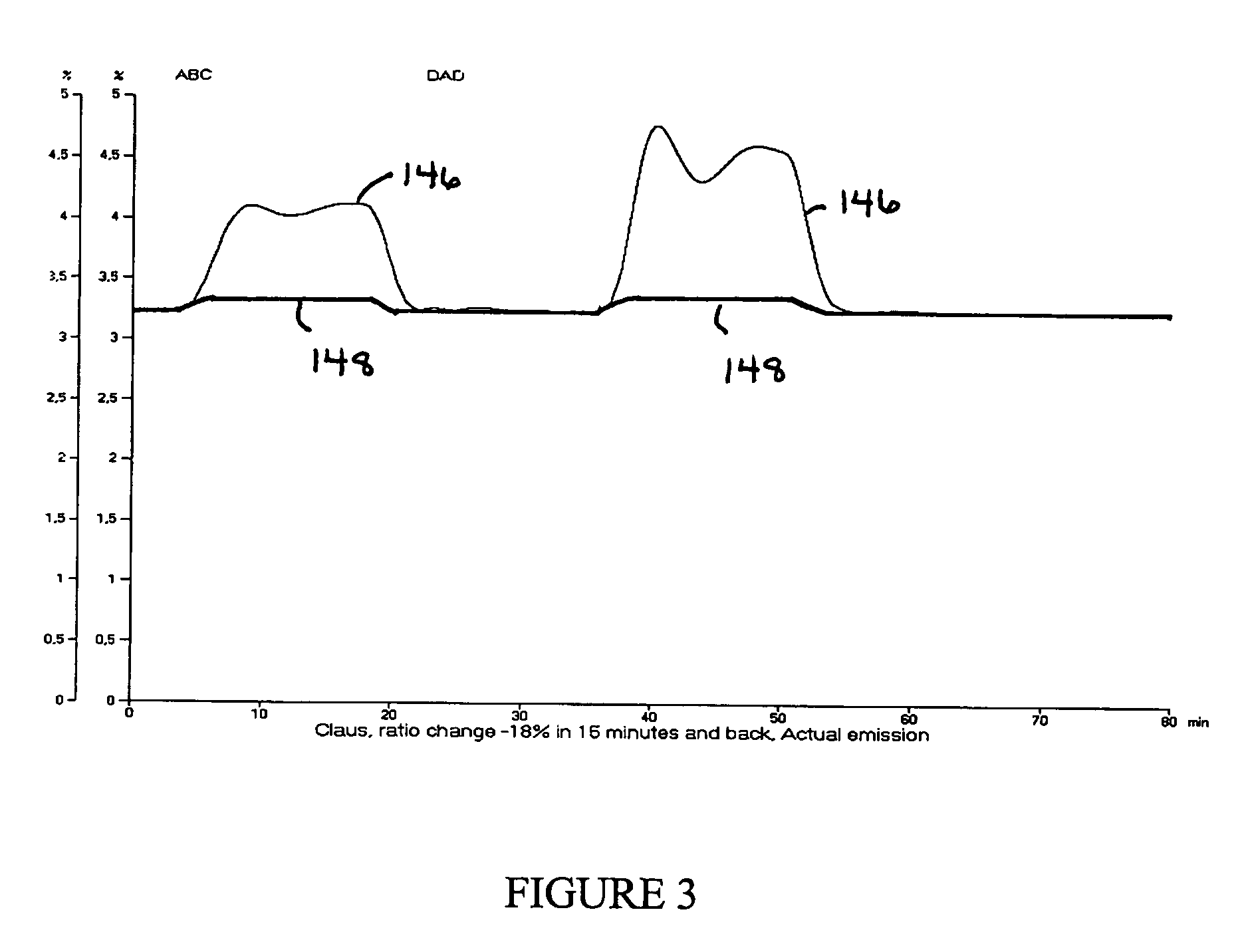

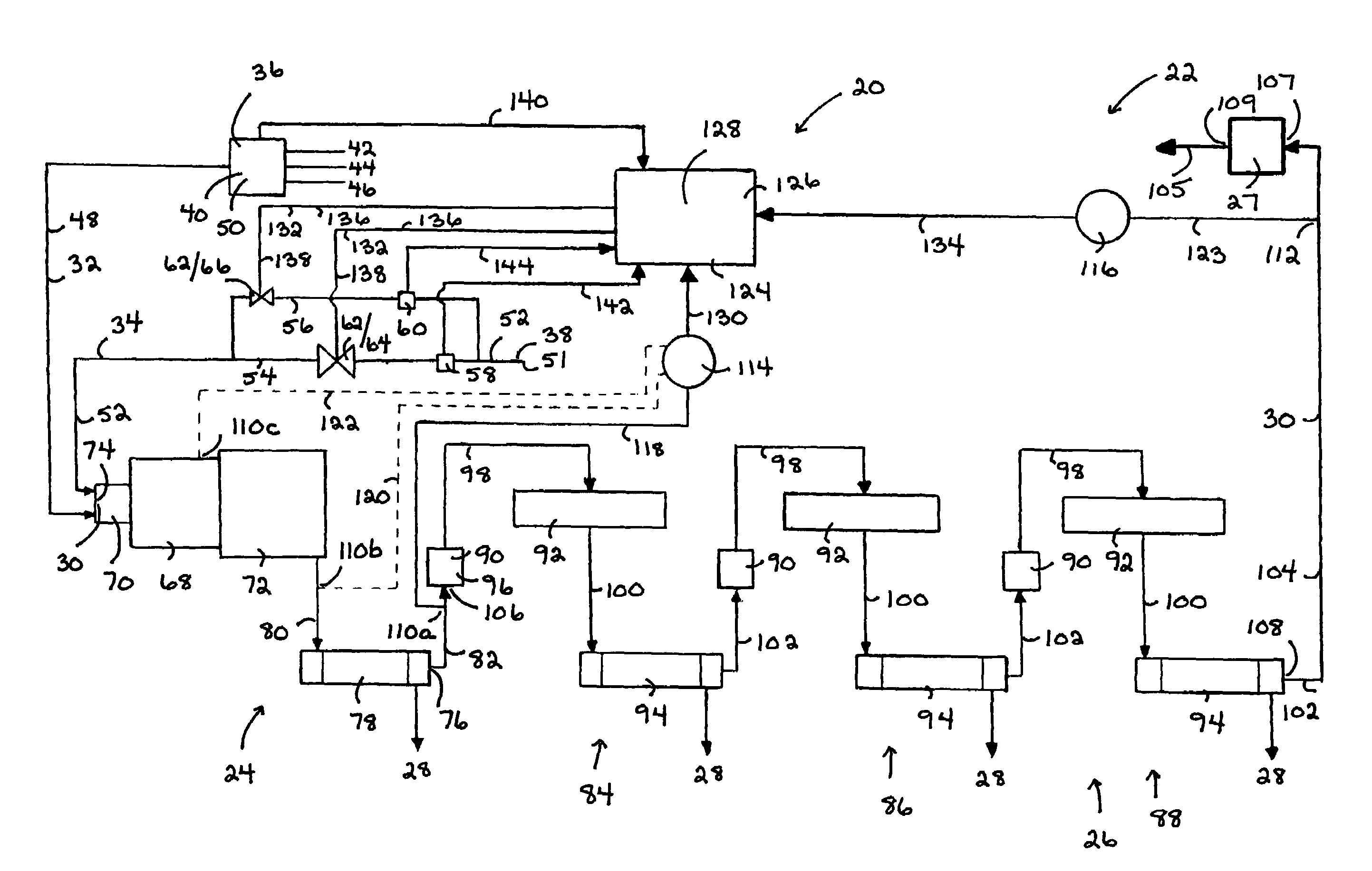

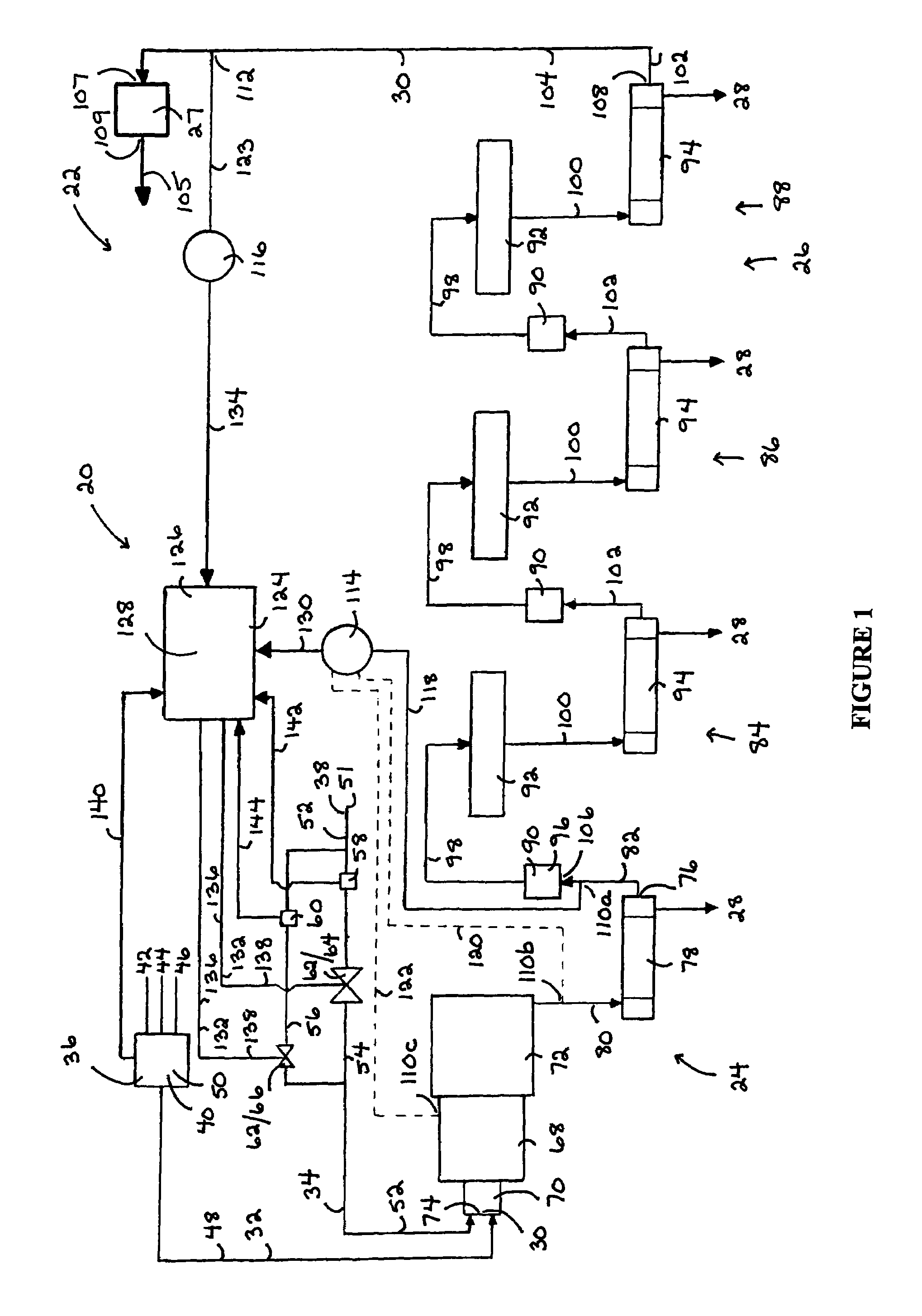

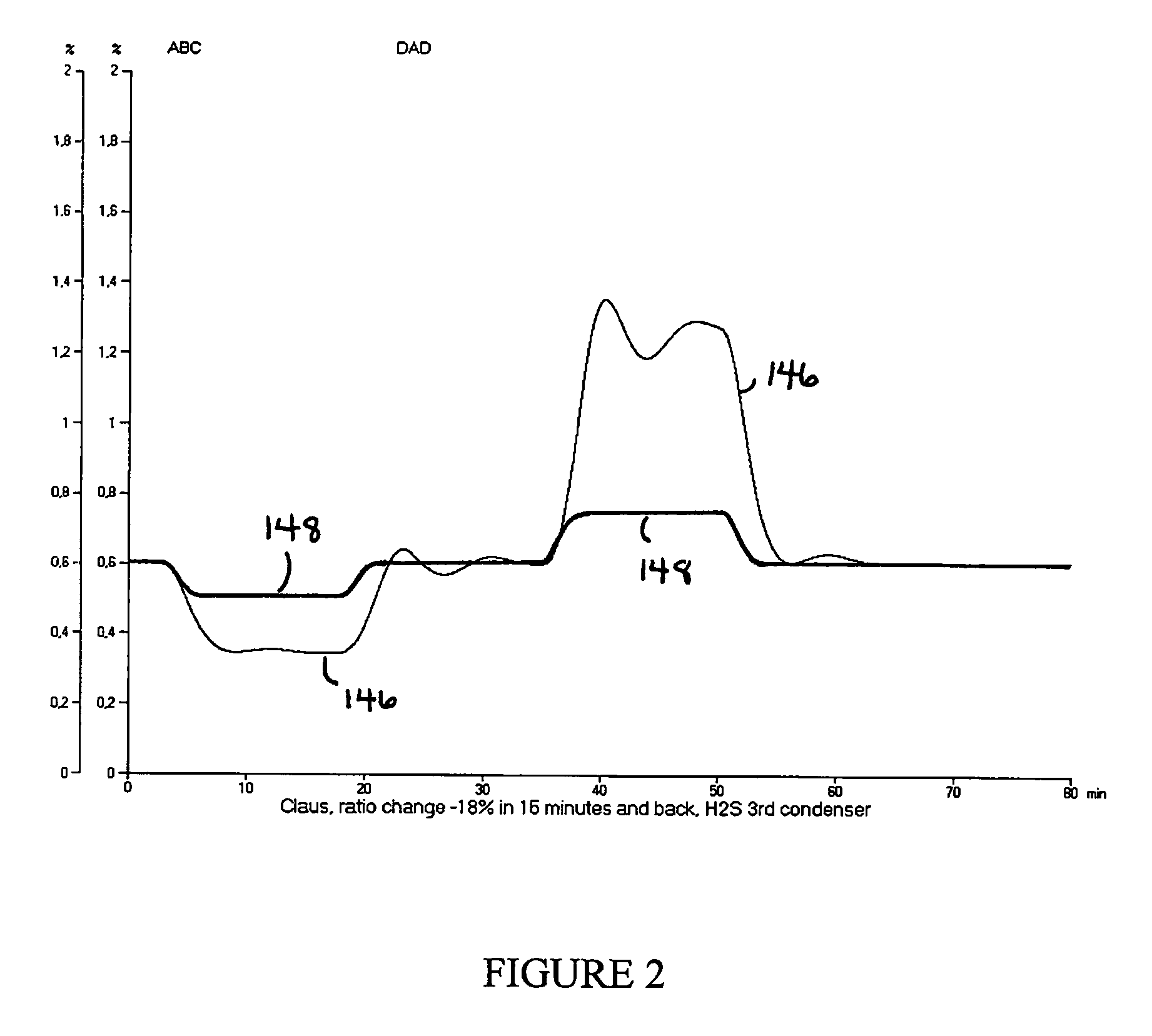

Process and system for controlling a process gas stream

ActiveUS20060014292A1Reduce the impactReduce the amplitudeExhaust apparatusTemperatue controlControl systemOxygen

In a process and system for recovering sulfur from a process gas stream initially comprising a hydrogen sulfide containing gas and an oxygen containing gas, a control process and system respectively are provided. The sulfur recovery process includes a thermal step having a beginning followed by a catalytic step having an end. The control process includes first analyzing a composition of the process gas stream at a first location between the beginning of the thermal step and the end of the catalytic step, first controlling the oxygen containing gas having regard to that first composition, second analyzing the composition of the process gas stream at a second location downstream of the end of the catalytic step, and second controlling the oxygen containing gas having regard to that second composition. The sulfur recovery system and control system therefor are provided for performing the steps of the sulfur recovery process and control process respectively.

Owner:DREWES VINCENT +1

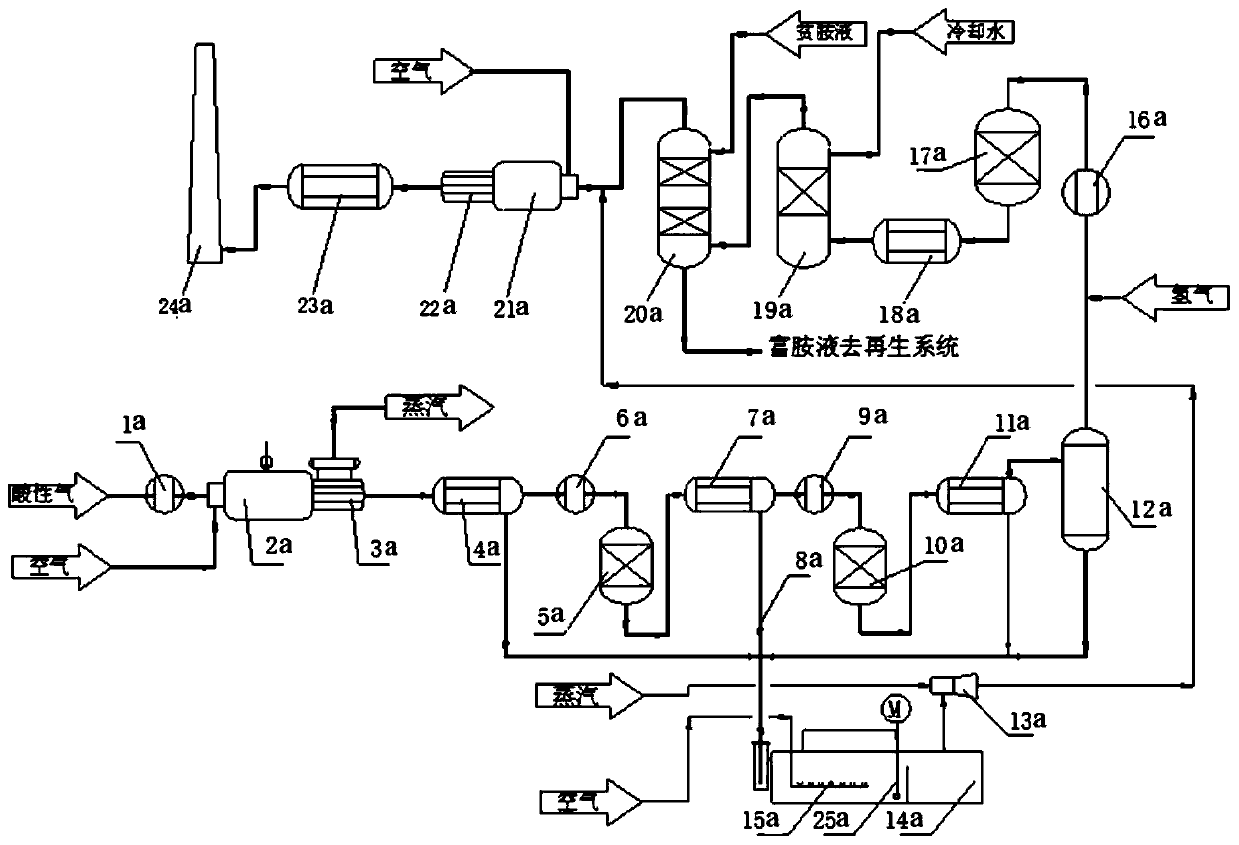

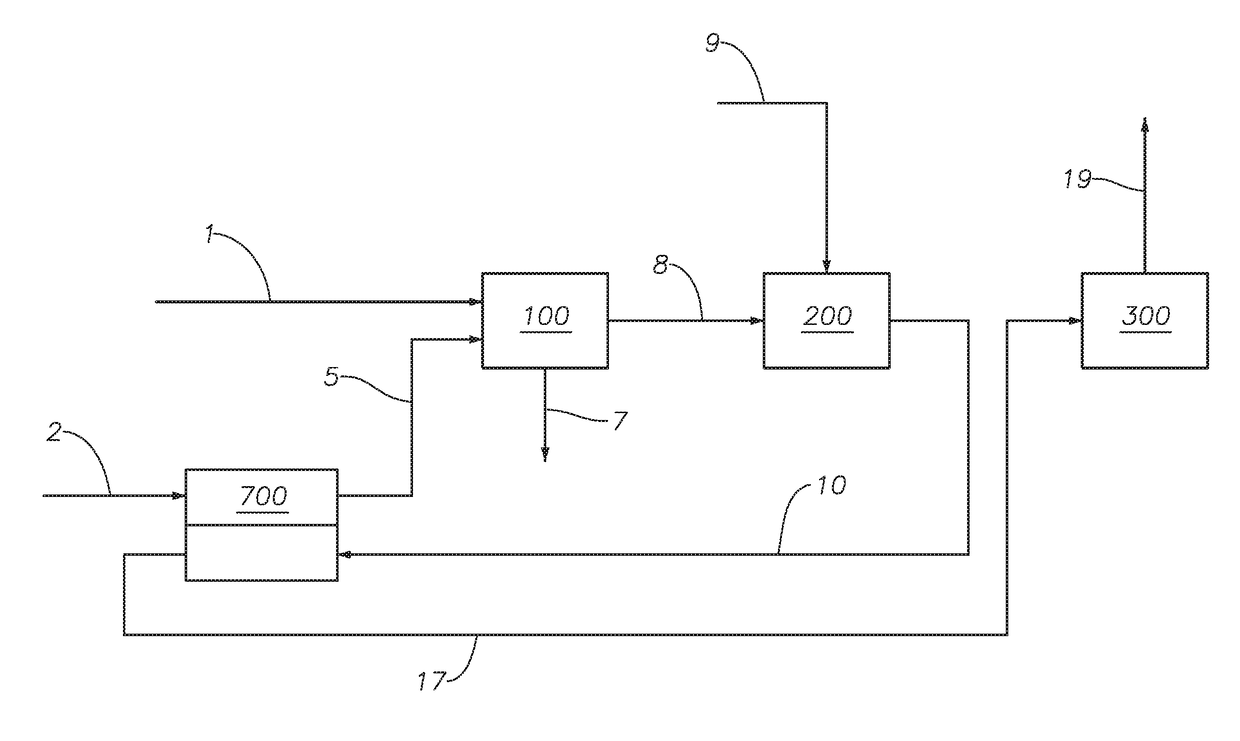

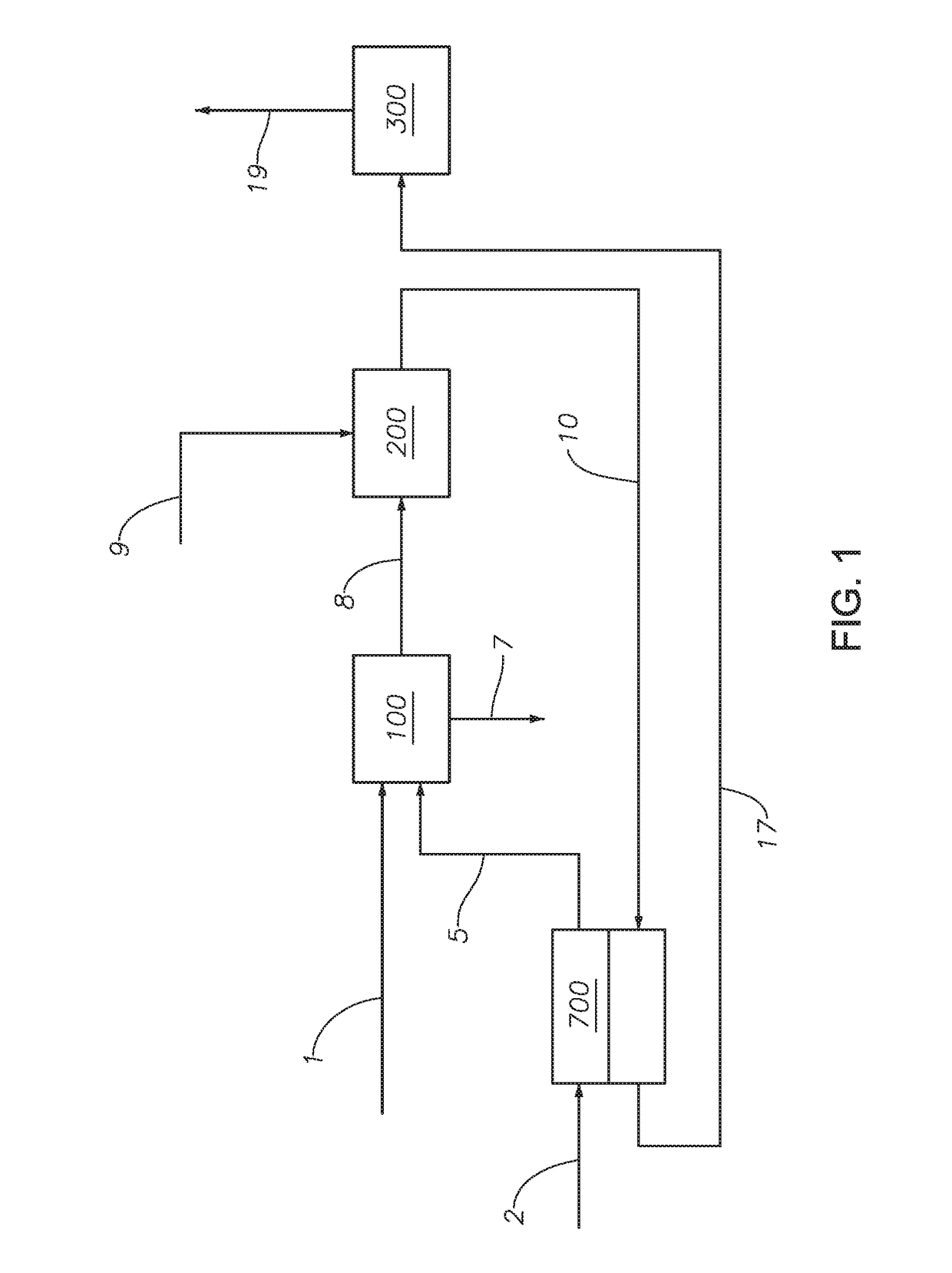

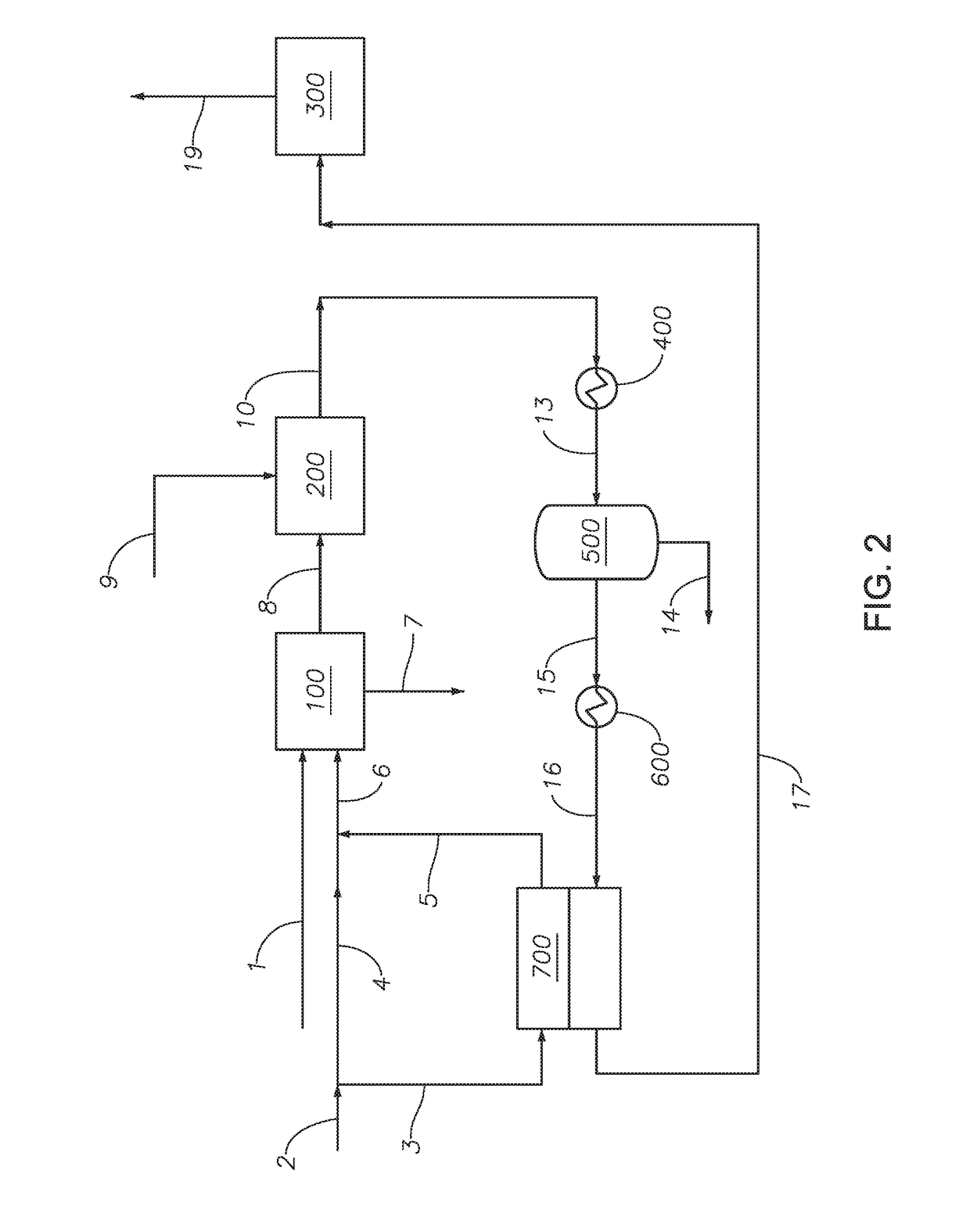

SWSR-8 pressurization sulfur recovery process

ActiveCN105947992AEmission reductionReduce sizeEnergy inputSulfur preparation/purificationSulfurFlue gas

The invention belongs to the field of sulfur recovery, and particularly relates to an SWSR-8 pressurization sulfur recovery process. The process comprises the steps that acid gas enters a sulfur making furnace, H2S is subjected to a high-temperature Claus reaction and converted into sulfur, and sulfur enters a two-stage converter to conduct two stage catalytic conversion for recovering sulfur; sulfur making tail gas enters a hydrogenation reactor, under the action of a hydrogenation catalyst, SO2 and COS are reduced to H2S through hydrogenation hydrolysis, reduced H2S gas is absorbed with an MDEA solution, and after purified tail gas recovers heat through incineration, flue gas is exhausted to the atmosphere through a chimney, wherein the pressure of acid gas entering the sulfur making furnace ranges from 90 kPa(g) to 120 kPa(g), and the pressure of the sulfur making furnace ranges from 90m kPa(g) to 120 kPa(g). The pressure of cooling and heat exchange equipment such as a sulfur making waste heat furnace, a first stage sulfur condenser, a second stage sulfur condenser, a third stage sulfur condenser, a steam generator and a tail gas waste heat boiler is higher than that in the prior art, the total heat transfer coefficient is increased, the occupied area is decreased, catalytic and absorption reactions can be conducted conveniently, the sulfur recovery rate is increased, and SO2 discharge is reduced.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

Device and process for recovering sulfur by treating low-concentration acid gases

ActiveCN110155953AImprove sulfur recoveryLess investmentSulfur preparation/purificationExhaust gasFlue gas

The invention belongs to the technical field of industrial sulfur recovery and specifically relates to a device for recovering sulfur by treating low-concentration acid gases and a process for recovering sulfur from low-concentration acid gases based on the device. The device for recovering sulfur by treating low-concentration acid gases is used for recovering and treating the acid gases through asulfur production unit, a tail gas treatment unit, a flue gas purification unit and a liquid sulfur degassing unit, and a catalyst in each stage of reactor is reasonably graded, so that the sulfur recovery rate of the overall recovery device is effectively increased; and by using the device for recovering sulfur, provided by the invention, the flue gas SO2 emission concentration can be stably lower than 20 mg / m<3> and even lower than 10 mg / m<3>, so that the flue gas SO2 emission concentration is greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

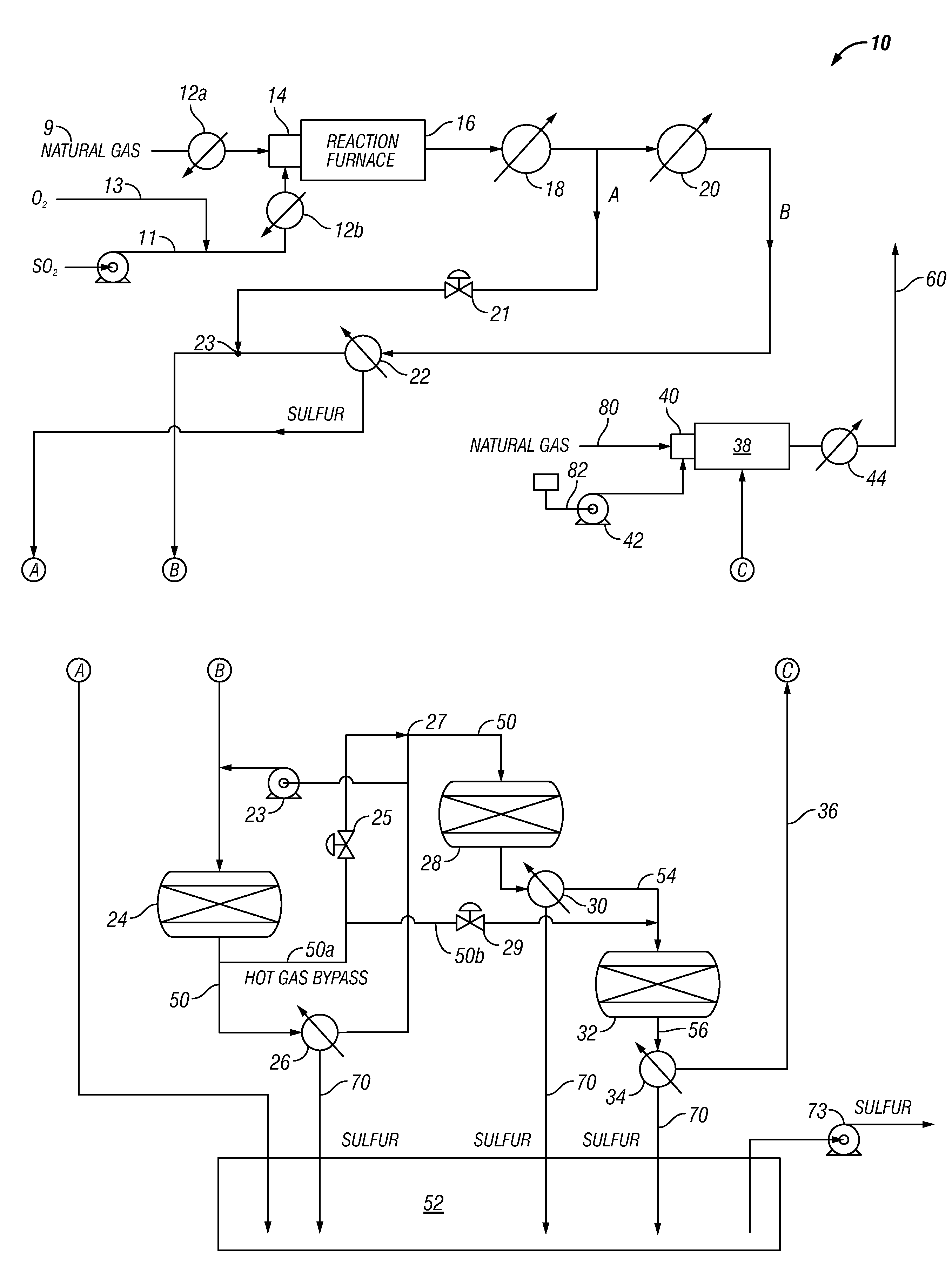

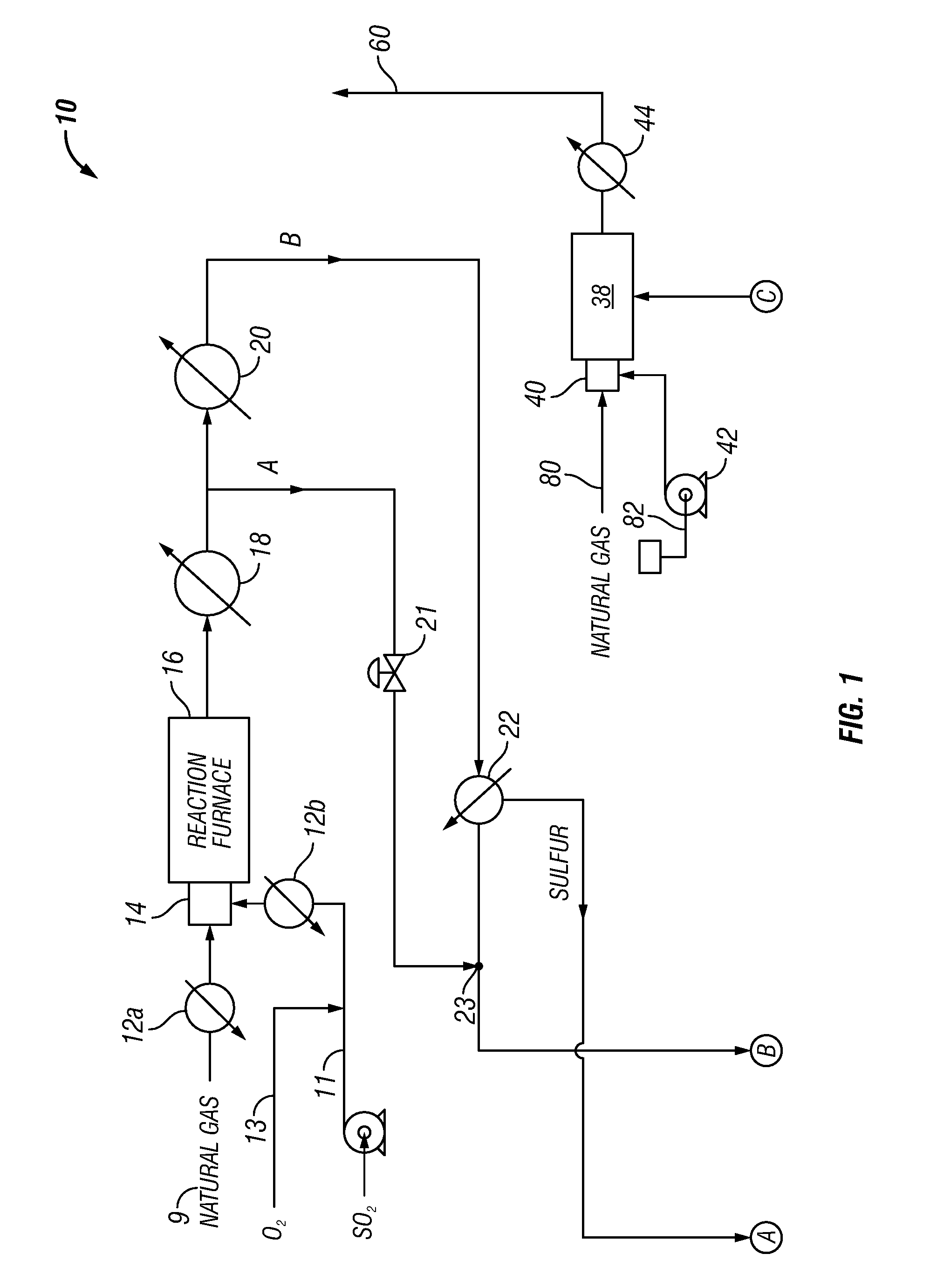

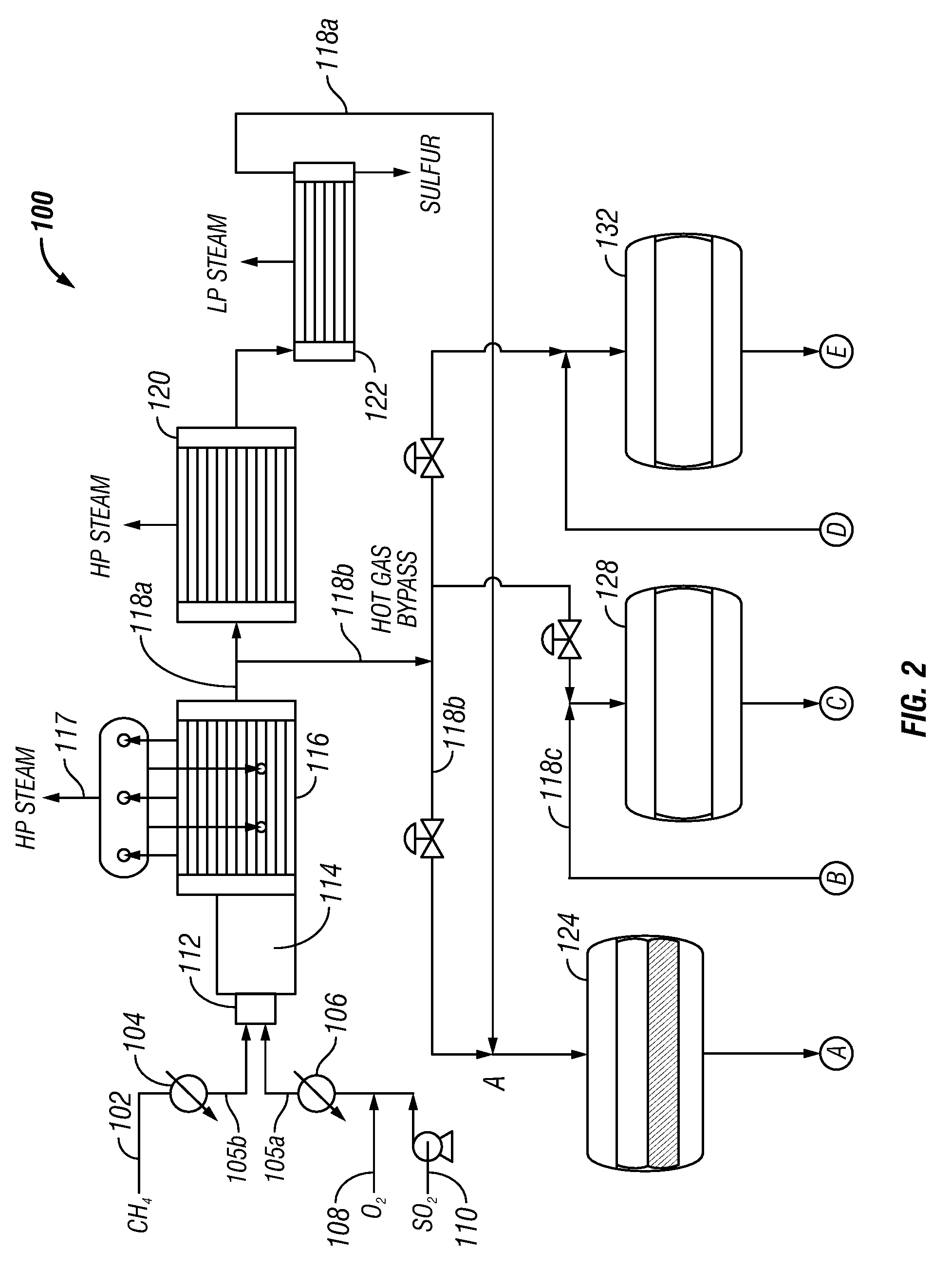

Process for the Thermal Reduction of Sulfur Dioxide to Sulfur

ActiveUS20090010834A1Reduce fuel consumptionFavorable operability parameterSulfur preparation/purificationSulfurSulfur dioxide

Processes for the thermal reduction of sulfur dioxide to elemental sulfur are described and disclosed. The processes described include three general reaction sections, including the reaction furnace portion where the SO2-containing stream is combusted, the hydrogenation portion wherein the effluent from the reaction furnace is hydrogenated over an appropriate catalyst, and a Claus conversion portion, wherein residual H2S and SO2 are further reacted to produce additional elemental sulfur.

Owner:WORLEYPARSONS GROUP

Process for the thermal reduction of sulfur dioxide to sulfur

ActiveUS7722852B2Reduce fuel consumptionEasy to operateSulfur preparation/purificationSulfurSulfur dioxide

Processes for the thermal reduction of sulfur dioxide to elemental sulfur are described and disclosed. The processes described include three general reaction sections, including the reaction furnace portion where the SO2-containing stream is combusted, the hydrogenation portion wherein the effluent from the reaction furnace is hydrogenated over an appropriate catalyst, and a Claus conversion portion, wherein residual H2S and SO2 are further reacted to produce additional elemental sulfur.

Owner:WORLEYPARSONS GROUP

Enhancement of claus tail gas treatment by sulfur dioxide-selective membrane technology and sulfur dioxide-selective absorption technology

ActiveUS20180257936A1Improve sulfur recoveryMinimizing sulfur dioxide emissionProductsGas treatmentMembrane technologySulfur

A method for recovering sulfur from an acid gas feed is provided. The method comprising the steps of mixing the acid gas feed and an absorption process outlet stream to form a combined Claus feed, introducing the combined Claus feed and a sulfur dioxide enriched air feed to a Claus process to produce a Claus outlet gas stream, introducing the Claus outlet gas stream to a thermal oxidizer, treating the thermal oxidizer outlet stream in a gas treatment unit to produce a dehydrated stream, introducing the dehydrated stream to a membrane sweeping unit to produce a sweep membrane residue stream and a sulfur dioxide enriched air feed, introducing a sweep air stream to a permeate side of the membrane sweeping unit, and introducing the sweep membrane residue stream to a sulfur dioxide absorption process to produce the absorption process outlet stream and a stack feed.

Owner:SAUDI ARABIAN OIL CO

Sulfur recovering heat utilization device and method

ActiveCN103964399AReduce loadReduce the impactChemical industrySteam/vapor condensersWater trapCondensed water

The invention discloses a sulfur recovering heat utilization device and method. The device comprises a steam air cooler, a condensed water recovery tank and a condensed water pump which are connected with one another in sequence, wherein the steam air cooler is connected with a steam pipeline of all stages of sulfur condensate coolers through a pipeline, and a height difference exists between a condensed water outlet of the steam air cooler and an inlet of the condensed water recovery tank; a pressure-regulating emptying pipeline is arranged at the tank top of the condensed water recovery tank, and the condensed water recovery tank is connected with various water traps of the sulfur recovery device through the pipeline and is also in water supply connection with a low-pressure boiler of a plant system through a water replenishing pipeline; the condensed water pump is connected with a water pipeline on all the stages of sulfur condensate coolers through the pipeline. The sulfur recovering heat utilization device and the method have the benefits that a part of heat in the sulfur recovery process is effectively taken away by utilizing a steam-condensed water self-circulating system, limitation on the specification of the plant steam system is avoided, and the outlet temperature of the sulfur condensate coolers is further reduced, so that the total sulfur recovery rate is further effectively improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

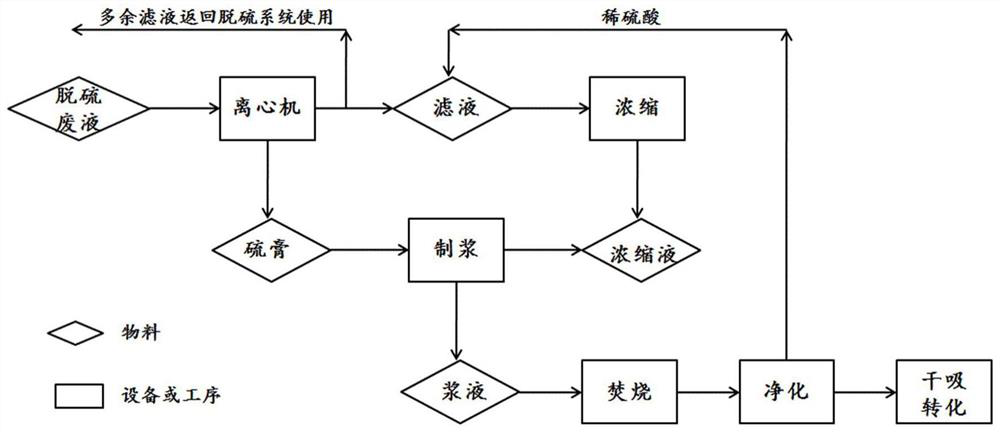

Desulfurization waste liquid acid making system and method

PendingCN112110423AImprove resource utilization efficiencyIncrease productionSulfur compoundsProcess engineeringSlurry

The invention provides a desulfurization waste liquid acid making system and method, which relate to the field of acid making. The system comprises a pretreatment unit, a concentration unit, a pulpingunit, an incineration unit, a purification unit and a dry absorption conversion unit, wherein a dilute sulfuric acid outlet in the purification unit is connected with a filtrate storage tank for storing filtrate in the pretreatment unit. The acid making method comprises a pretreatment step for separating the desulfurization waste liquid from the desulfurization unit into a sulfur paste and a filtrate, a concentration step for concentrating the filtrate to obtain a concentrated solution, a pulping step for mixing the sulfur paste and the concentrated solution into a slurry, an incineration step for incinerating the slurry to produce SO2 gas, a purification step for washing the SO2 gas, and a dry absorption conversion step for preparing concentrated sulfuric acid from the purified SO2 gas.Dilute sulfuric acid generated in the purification step is returned to the filtrate to be neutralized. According to the method, dilute sulfuric acid and ammonia contained in the filtrate are directlysubjected to a neutralization reaction, the raw material SO2 is further obtained through incineration, and the sulfur recovery rate and the concentrated sulfuric acid yield are increased.

Owner:NINGBO JINYUANDONG PETROCHEM ENG TECH

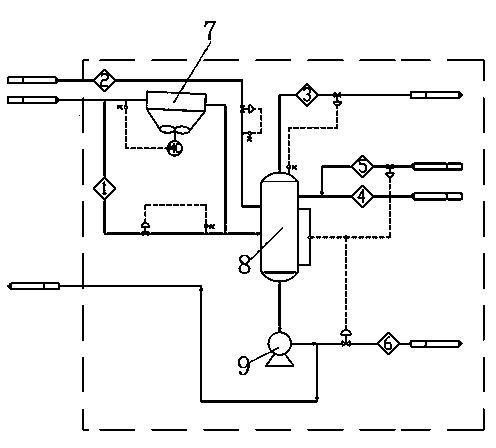

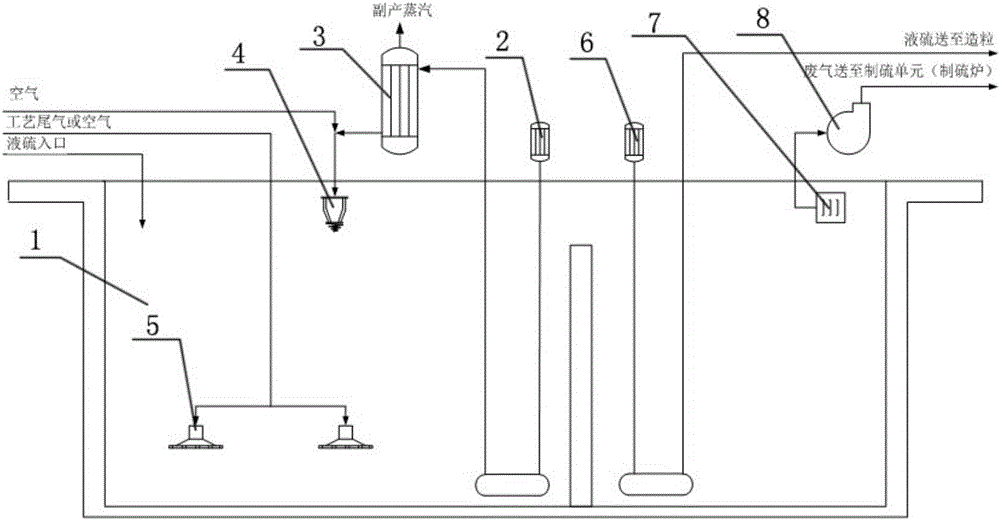

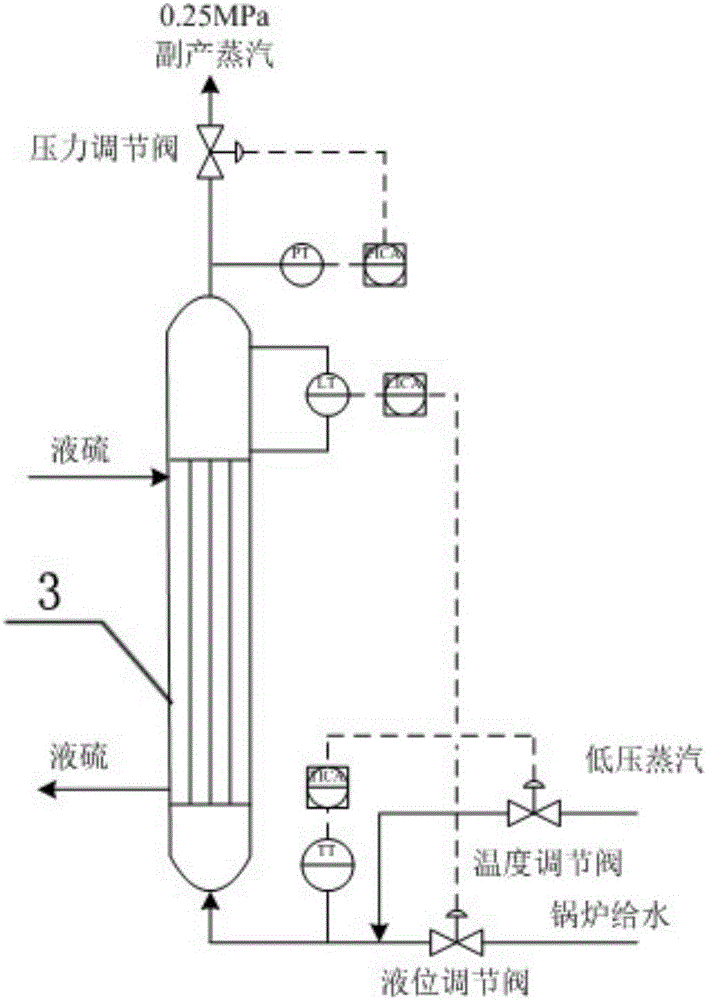

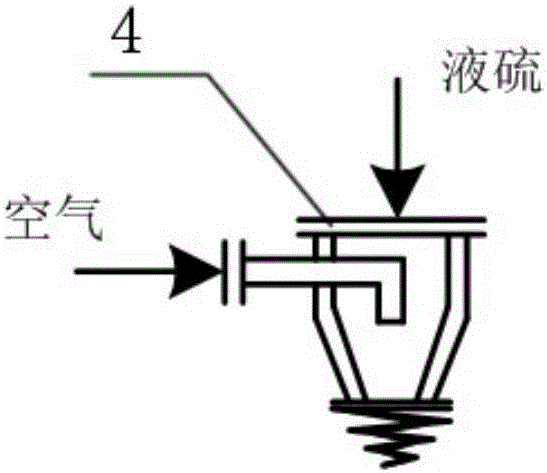

System and method for removing H2S in liquid sulfur

The invention discloses a system and method for removing H2S in liquid sulfur. The system for removing H2S in liquid sulfur comprises a liquid sulfur tank, a liquid sulfur pump, a liquid sulfur cooler, a liquid sulfur spray head, gas stirrers, a product liquid sulfur pump and a waste gas booster fan; liquid sulfur is stored in the liquid sulfur tank; the liquid sulfur pump is connected to the bottom of the liquid sulfur tank to pump liquid sulfur out of the liquid sulfur tank; the liquid sulfur cooler is connected with the liquid sulfur pump, and liquid sulfur pumped by the liquid sulfur pump is cooled in the liquid sulfur cooler; the liquid sulfur spray head is connected with the liquid sulfur cooler, and liquid sulfur cooled by the liquid sulfur cooler is sprayed back to the liquid sulfur tank through the liquid sulfur spray head; the gas stirrers are arranged in the liquid sulfur tank and used for stirring and conducting steam stripping on liquid sulfur in the liquid sulfur tank; the product liquid sulfur pump is connected to the bottom of the liquid sulfur tank, liquid sulfur in which H2S is removed is delivered to a granulation unit through the product liquid sulfur pump; the waste gas booster fan is arranged above the liquid sulfur tank and delivers waste gas to a sulfur production unit.

Owner:江苏晟宜环保科技有限公司

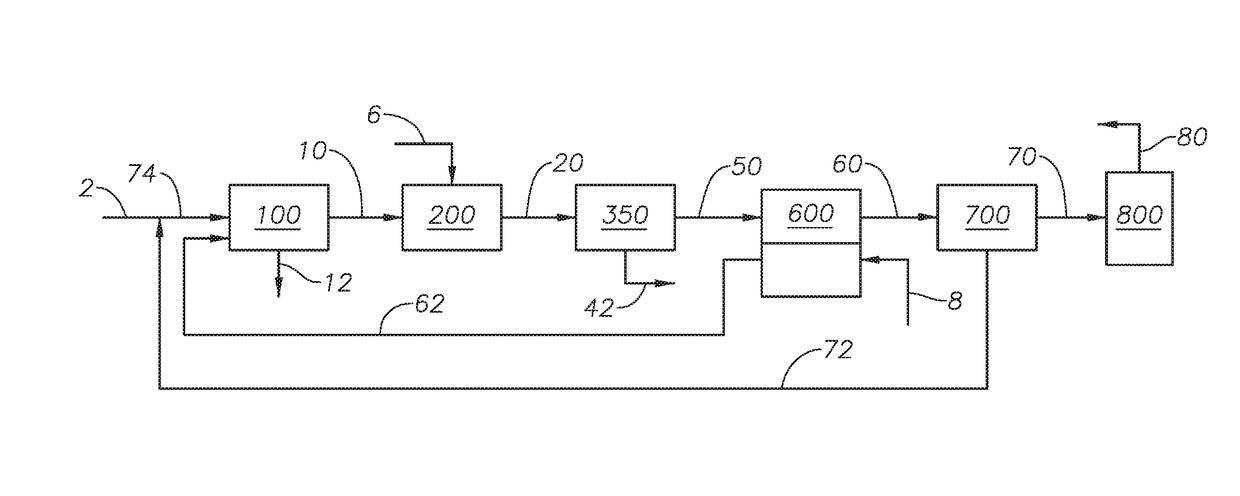

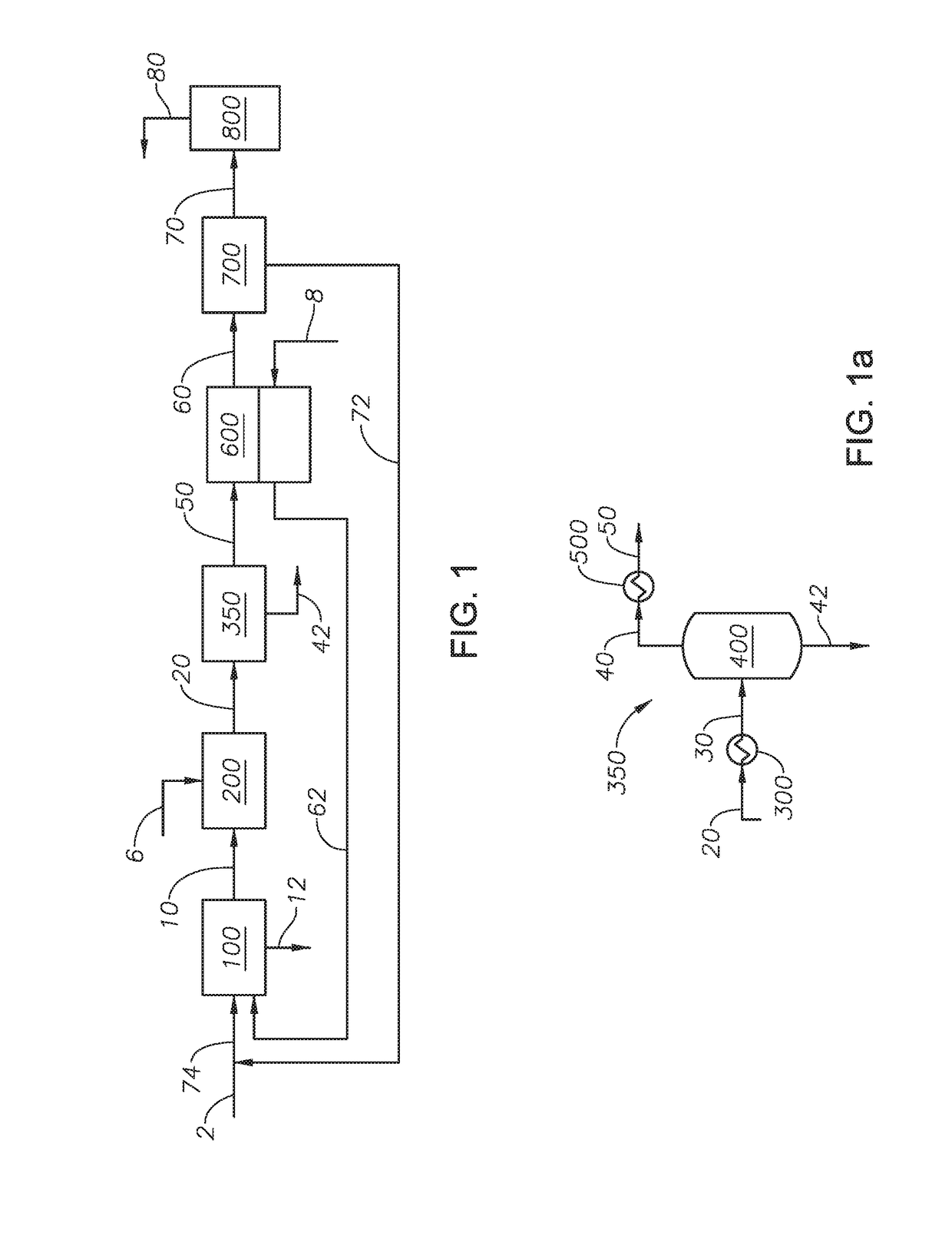

Enhancement of claus tail gas treatment by sulfur dioxide-selective membrane technology and sulfur dioxide-selective absorption technology

ActiveUS10106411B2Improve sulfur recoveryEmission reductionProductsGas treatmentMembrane technologySulfur

A method for recovering sulfur from an acid gas feed is provided. The method comprising the steps of mixing the acid gas feed and an absorption process outlet stream to form a combined Claus feed, introducing the combined Claus feed and a sulfur dioxide enriched air feed to a Claus process to produce a Claus outlet gas stream, introducing the Claus outlet gas stream to a thermal oxidizer, treating the thermal oxidizer outlet stream in a gas treatment unit to produce a dehydrated stream, introducing the dehydrated stream to a membrane sweeping unit to produce a sweep membrane residue stream and a sulfur dioxide enriched air feed, introducing a sweep air stream to a permeate side of the membrane sweeping unit, and introducing the sweep membrane residue stream to a sulfur dioxide absorption process to produce the absorption process outlet stream and a stack feed.

Owner:SAUDI ARABIAN OIL CO

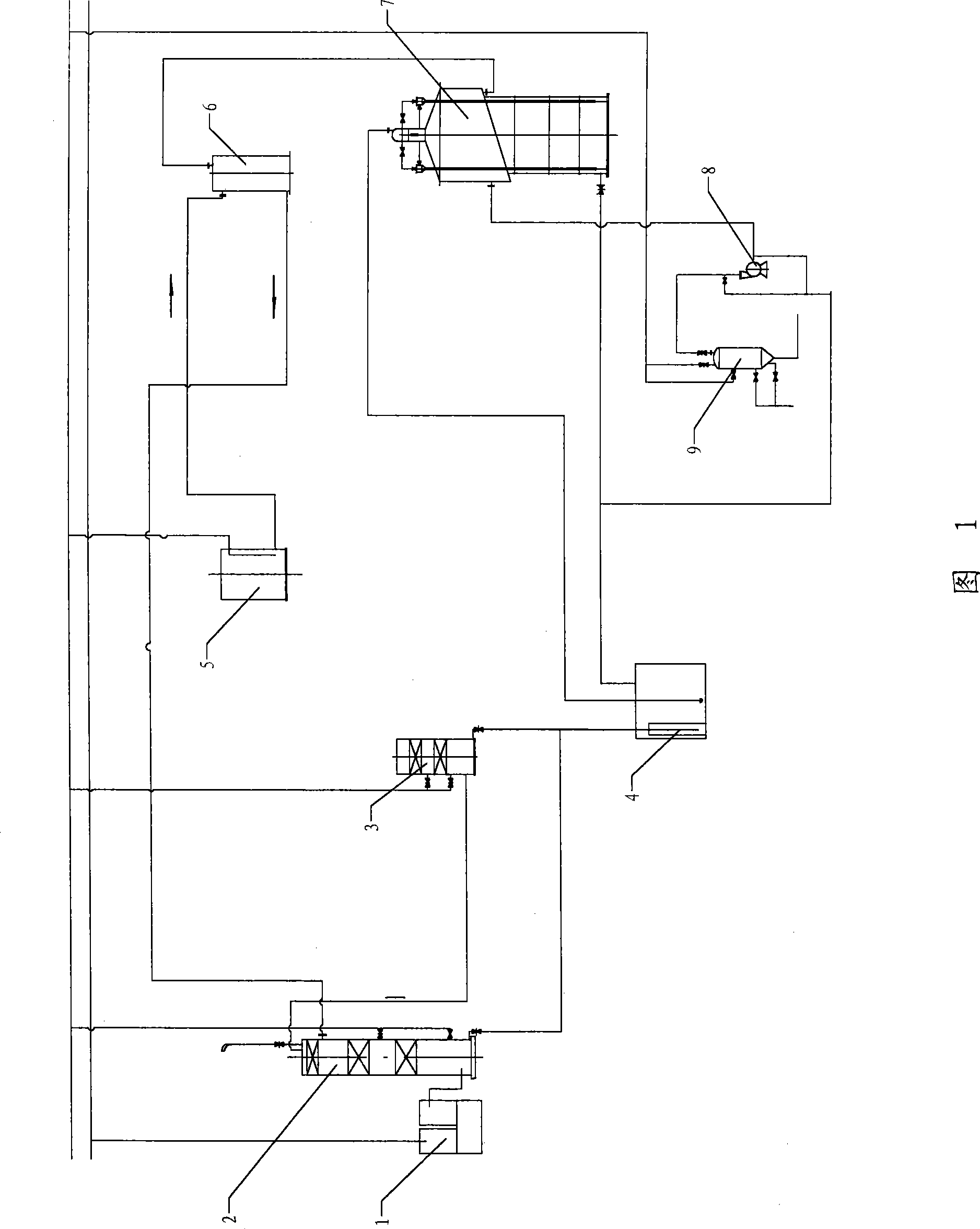

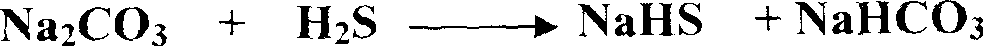

Producer gas desulphurization process

InactiveCN101434873AImprove sulfur recoveryNo sulfur pluggingCombustible gas purificationProducer gasChemistry

The invention provides a desulfurization process of generator gas, comprising the following step: the generator gas containing sulfur is absorbed by a desulfurization solution containing a mimosa extract in a desulfurization tower; the process is characterized in that the desulfurization solution also comprises vanadium pentoxide; and the sulfur content of the generator gas is 1500-2500mg / Nm<3>. The process is suitable for a situation that the content of H2S in the gas is high. The method has high desulfurization rate and the sulfur content of the gas coming out of the tower is not more than 150mg / Nm<3>.

Owner:山东万丰煤化工设备制造有限公司

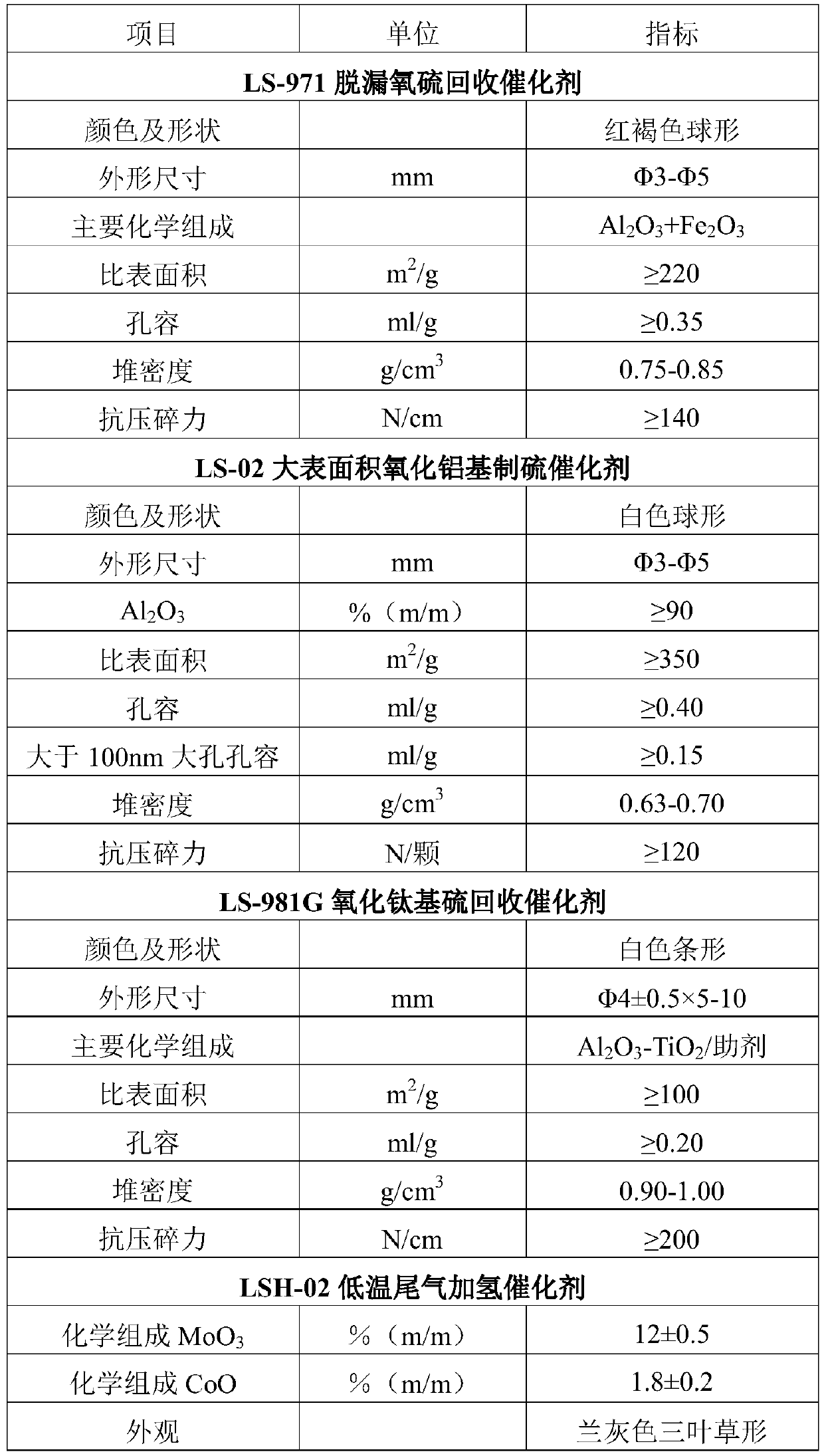

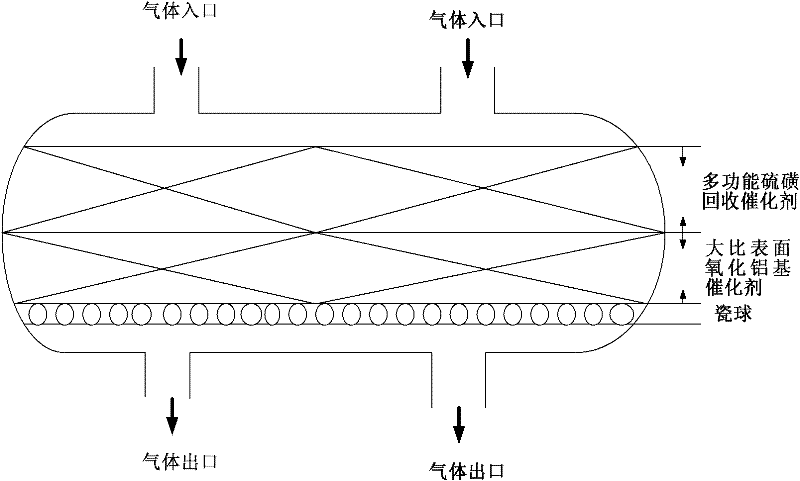

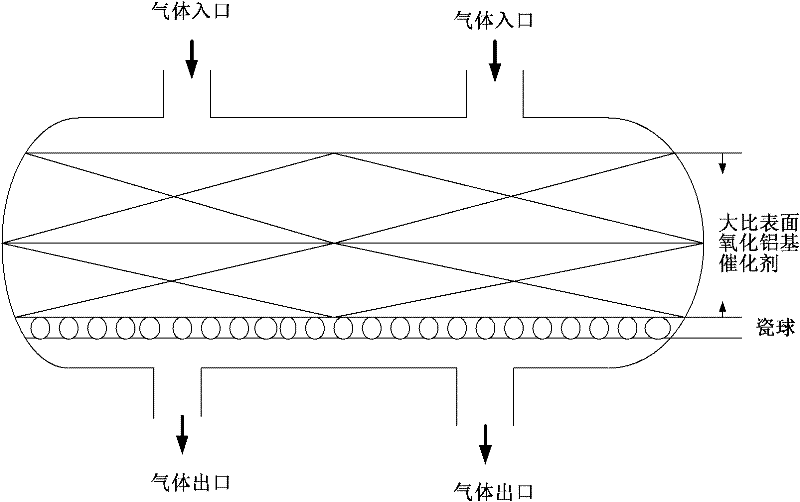

Filling method for sulfur recycled catalyst with high content of CO2 in raw material gas to be treated

InactiveCN102642816AMaintain high Claus activityExtended operating cycleSulfur preparation/purificationChemical recyclingChemistryCoal chemical industry

The invention relates to a filling method for sulfur recycled catalyst with a high content of CO2 in a raw material gas to be treated, which belongs to the method of preparing sulfur from a sulfur compound in a gaseous state of sulfides in the gaseous state. By the adoption of a two-stage sulfur preparation and conversion process, multi-functional sulfur recycled catalyst with high hydrolysis activity of organic sulfur is filled at the height from one thirds to a half in the upper part of the first-stage converter, and alumina base sulfur recycled catalyst with a large ratio surface is filled at the height from two thirds to a half in the lower part of the first-stage converter; the second-stage converter is totally filled with alumina base sulfur recycled catalyst with the large ratio surface. According to the filling method for sulfur recycled catalyst with the high content of CO2 in the raw material gas to be treated, the hydrolysis activity of sulfur is increased, and the Claus activity can be maintained high, the gas volume of CO2 in the raw material gas to be treated is as high as 50 percent, the total sulfur conversion rate of the sulfur recycle device can reach above 96 percent, and the service life of the catalyst can reach more than six years. The filling method provided by the invention is suitable for the sulfur recycling devices of facilities in petroleum refining and production, coal chemical industry and natural gas purifying.

Owner:CHINA PETROLEUM & CHEM CORP

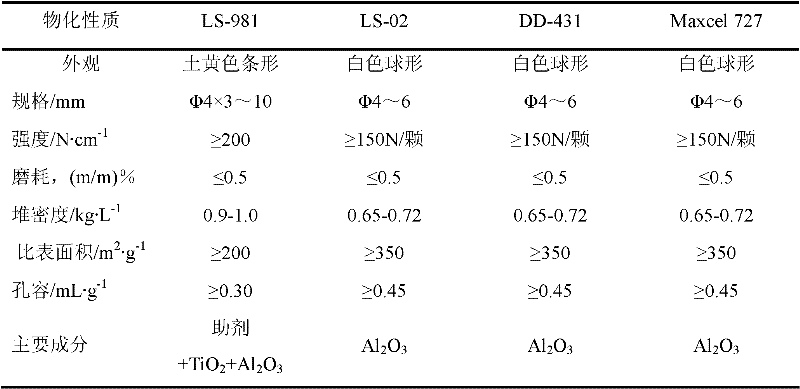

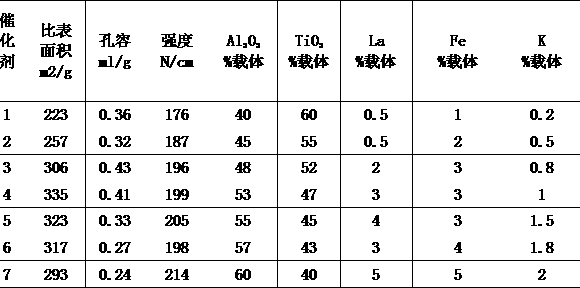

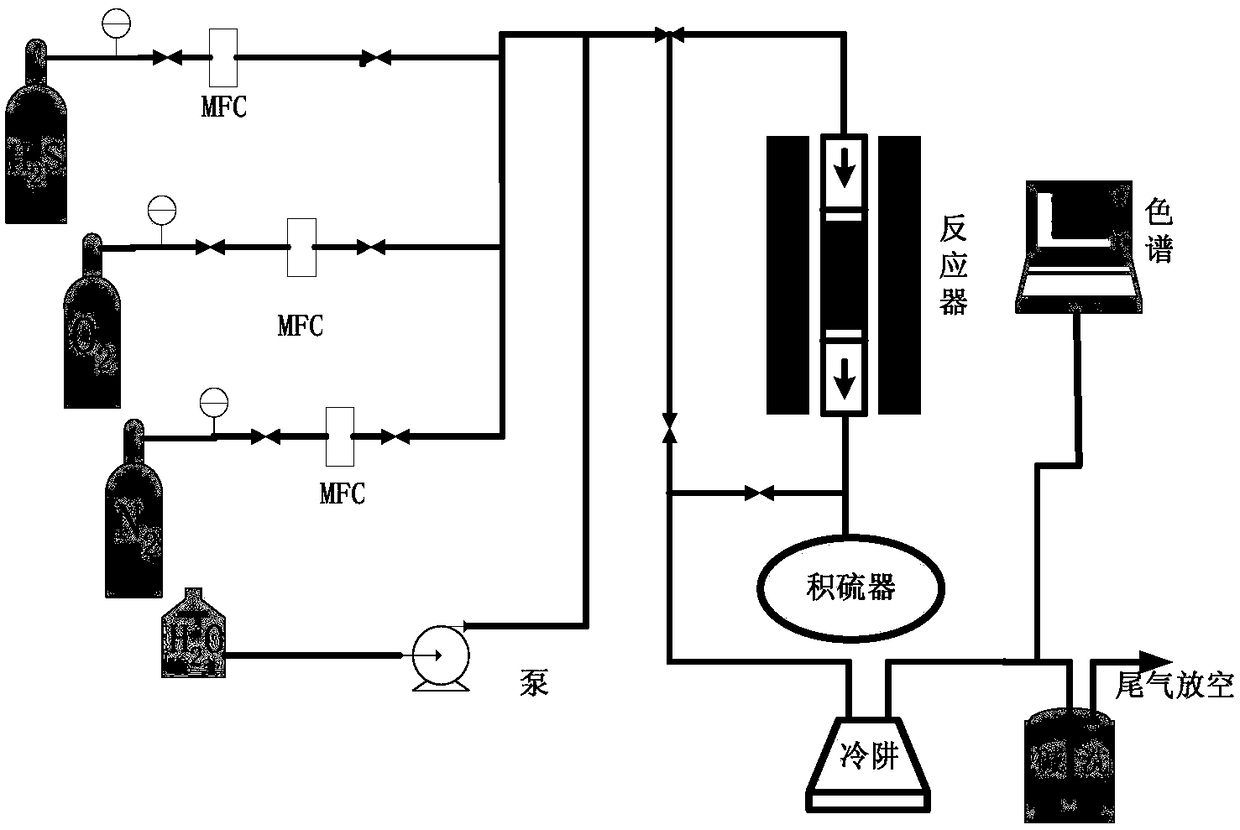

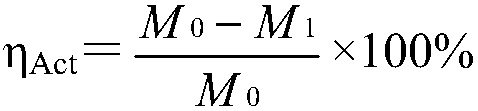

Preparation method of low-temperature multifunctional sulfur recycling catalyst

InactiveCN108097257AFunction increaseImprove low-temperature Claus reaction performanceHeterogenous catalyst chemical elementsSulfur preparation/purificationSulfurPotassium

The invention relates to a preparation method of a low-temperature multifunctional sulfur recycling catalyst. The preparation method comprises the following steps: i, mixing pseudo-boehmite and metatitanic acid; adding a pore-forming agent and a binding agent; blending and grinding at the same time; drying at 120 DEG C for 2h; finally, roasting at 400 DEG C for 4h to obtain a carrier; ii, loadinglanthanum on the carrier obtained by step i through an equal-volume immersion method; iii, loading iron on a solid in step ii through the equal-volume immersion method; iv, loading potassium on a solid in step iii through the equal-volume immersion method; v, roasting a solid in step iv at 400 to 600 DEG C for 3 to 5h, so as to obtain the catalyst. The multifunctional sulfur recycling catalyst prepared through the preparation method provided by the invention has the main technical characteristics that aluminum oxide and titanium dioxide are prepared into the composite carrier, iron oxide is loaded and advantages of a traditional catalyst are expressed; the sulfation resisting capability and the deoxygenation protection function of the catalyst are improved.

Owner:JIANGHAN UNIVERSITY

Enhancement of Claus tail gas treatment by sulfur dioxide-selective membrane technology

ActiveUS10106410B2Improve sulfur recoveryEmission reductionGas treatmentDispersed particle separationMembrane technologySulfur

Owner:SAUDI ARABIAN OIL CO

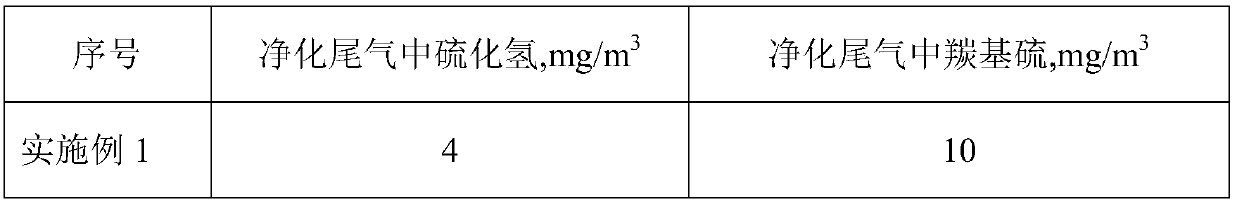

Complexing iron desulfurizing agent for Claus tail gas treatment

ActiveCN110876881AEmission reductionHigh activityGas treatmentDispersed particle separationIron saltsPhysical chemistry

The invention belongs to the technical field of gas purification, and particularly relates to a complexing iron desulfurizing agent for Claus tail gas treatment, wherein the complexing iron desulfurizing agent comprises the following components: a soluble iron salt, a soluble cerium salt, a chelating agent, an inorganic alkali, an organic additive and water, wherein the weight percentage of the iron ions is 0.5-5% wt, a molar ratio of Fe<3+> to Fe<2+> is 0.5-5.0, the weight percentage of the cerium ions is 0.1-0.5% wt, a molar ratio of the cations to the iron ions in the inorganic alkali is 0.5-1.0, a molar ratio of the chelating agent to the sum of the iron ions and the cerium ions is 1.0-3.5, and the weight percentage of the organic additive is 0.2-2 wt%. The desulfurizing agent can simultaneously remove hydrogen sulfide and carbonyl sulfide in Claus tail gas, wherein the content of the hydrogen sulfide in the purified tail gas after desulfurization is smaller than 10 mg / m<3>, and the content of the carbonyl sulfide in the purified tail gas after desulfurization is smaller than 20 mg / m<3>, so that the national environmental protection standard requirement is met, the cost is low,the desulfurizing agent activity is high, and the desulfurizing effect is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

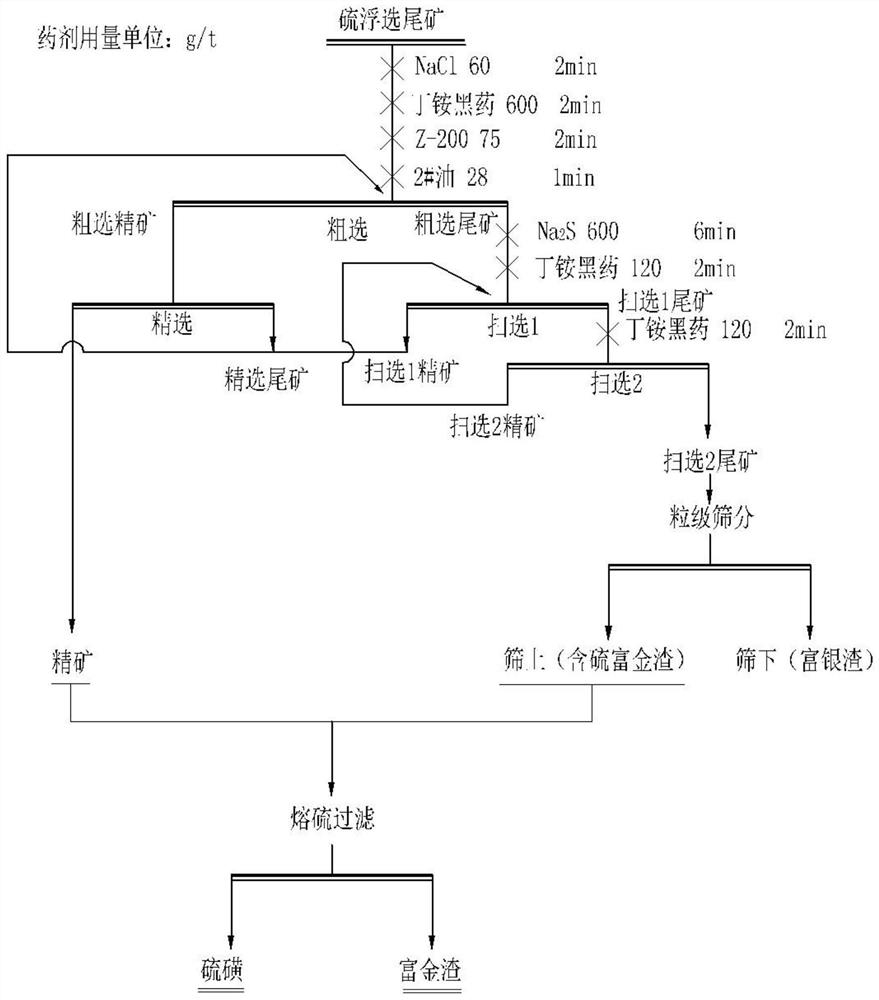

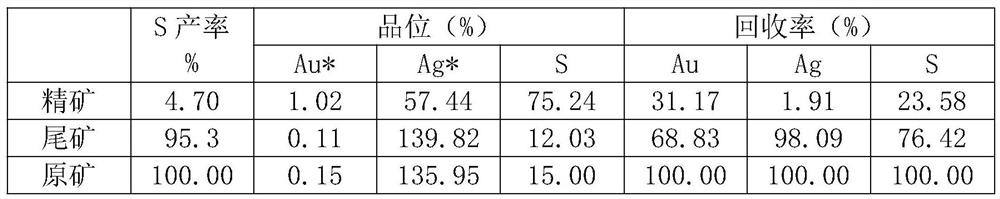

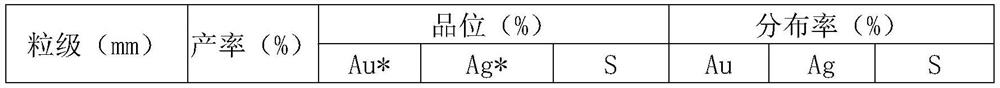

Method for recycling zinc-oxygen pressure leaching sulfur flotation tailings

The invention discloses a method for recycling zinc-oxygen pressure leaching sulfur flotation tailings. According to the method for recycling the zinc-oxygen pressure leaching sulfur flotation tailings, one-stage roughing, one-stage concentration and two-stage scavenging are carried out again on the flotation tailings to obtain sulfur-containing concentrate and tailings, then size fraction screening is carried out on the tailings to obtain oversize products and undersize products, the oversize products are mainly gold-enriched slag, and the undersize products are mainly silver-enriched slag. Effective separation of sulfur, gold and silver is achieved through combination of reagent flotation and size fraction screening; and the problems that the oxygen pressure leaching sulfur flotation tailings are high in sulfur content, low in gold and silver content and incapable of being recycled are solved, so that the oxygen pressure leaching sulfur flotation tailings are recycled, and the methodfor recycling the zinc-oxygen pressure leaching sulfur flotation tailings has the advantages that the sulfur content is reduced, and the gold, silver and sulfur separation is achieved.

Owner:WESTERN MINING CO LTD +2

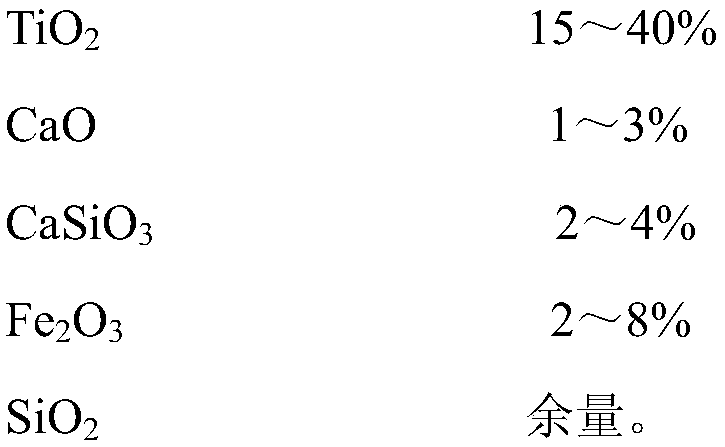

Hydrogen sulfide selective oxidation catalyst and preparation method thereof

ActiveCN109382105APore structure is suitableAvoid Claus Reverse ReactionHeterogenous catalyst chemical elementsSulfur preparation/purificationCalcium silicateWater vapor

The invention belongs to the technical field of sulfur recovery, and particularly relates to a hydrogen sulfide selective oxidation catalyst and a preparation method thereof, wherein the raw materialsof the carrier comprise metatitanic acid, silica powder and calcium silicate, iron oxide and calcium oxide are used as active components, and the silica powder is fumed silica powder having a specific surface area of 40-60 m<2> / g. According to the present invention, by using the carrier of the invention, the catalyst can have a suitable pore structure, the Claus reverse reaction of the catalyst at the selective oxidation stage can be avoided, and the sensitivity of the catalyst to water vapor and the oxygen content can be reduced; the catalyst has characteristics of high activity, insensitivity to water vapor and oxygen content in the process gas, high side pressure and high H2S conversion rate; and by using the catalyst, the hydrogen sulfide conversion rate can reach more than 95%, the sulfur yield can reach more than 90%, and the side pressure strength can reach more than 120 N / cm so as to improve the sulfur recovery rate of the sulfur recovery device and achieve the significant economic and social benefits.

Owner:CHINA PETROLEUM & CHEM CORP

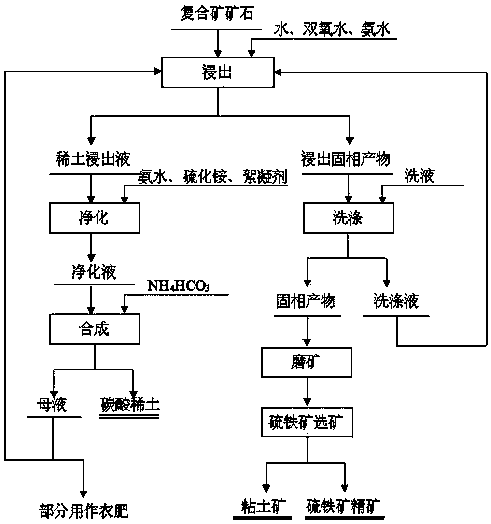

Method for separating each component ore in pyrite-ion adsorption type rare earth complex ore

InactiveCN104263925AAvoid the problem of excessive ammonia nitrogenCoarse granularityProcess efficiency improvementWet separationClay mineralsRare earth

The invention provides a method for separating each component ore in a pyrite-ion adsorption type rare earth complex ore. The method comprises the following steps: grinding a raw ore until an 80-mesh ore accounts for 30-60% of the weight of the raw ore, adding into water according to a liquid-solid mass ratio of 0.8-1.5, uniformly stirring, then adding hydrogen peroxide which accounts for 0.6-0.9% of the weight of the raw ore, uniformly stirring, then adjusting the pH value of slurry to be 4.0-4.6 by adding dilute ammonia water, and uniformly stirring to obtain ore pulp; and performing solid-liquid separation on the obtained ore pulp to obtain a rare earth leaching liquid and a solid phase containing pyrite and clay minerals, then purifying the rare earth leaching liquid to prepare a rare earth compound, and performing flotation on the solid phase to obtain pyrite and the clay minerals. The method provided by the invention successfully achieves the comprehensive recycling of rare earth, pyrite and the clay minerals by adopting water as an initial leaching agent, also is simple in process and easy to operate, does not need to use ammonium sulfate chemical products in a leaching process, also can be used for producing agricultural ammonium sulfate as a by-product, and is environment-friendly.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI +1

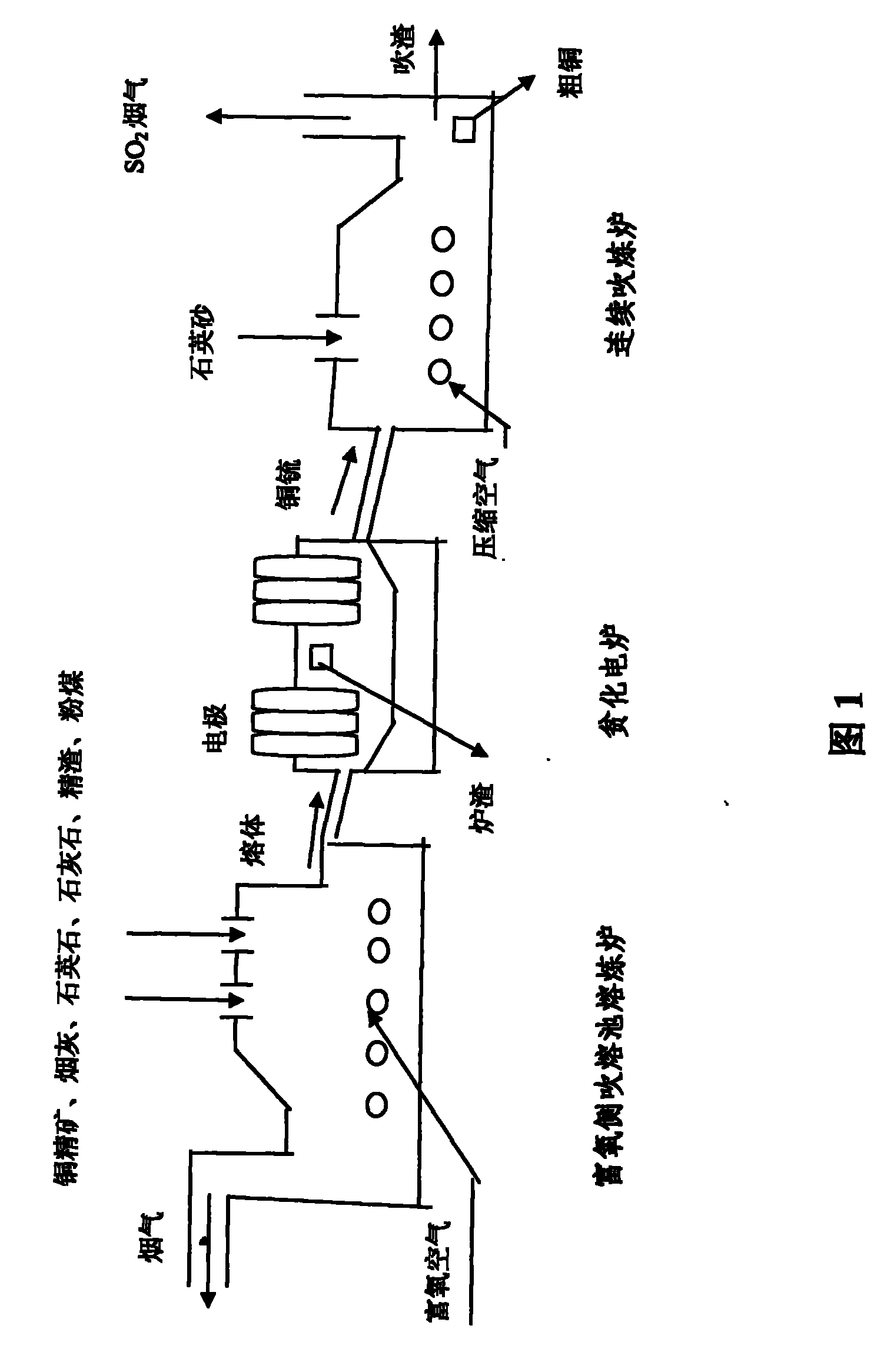

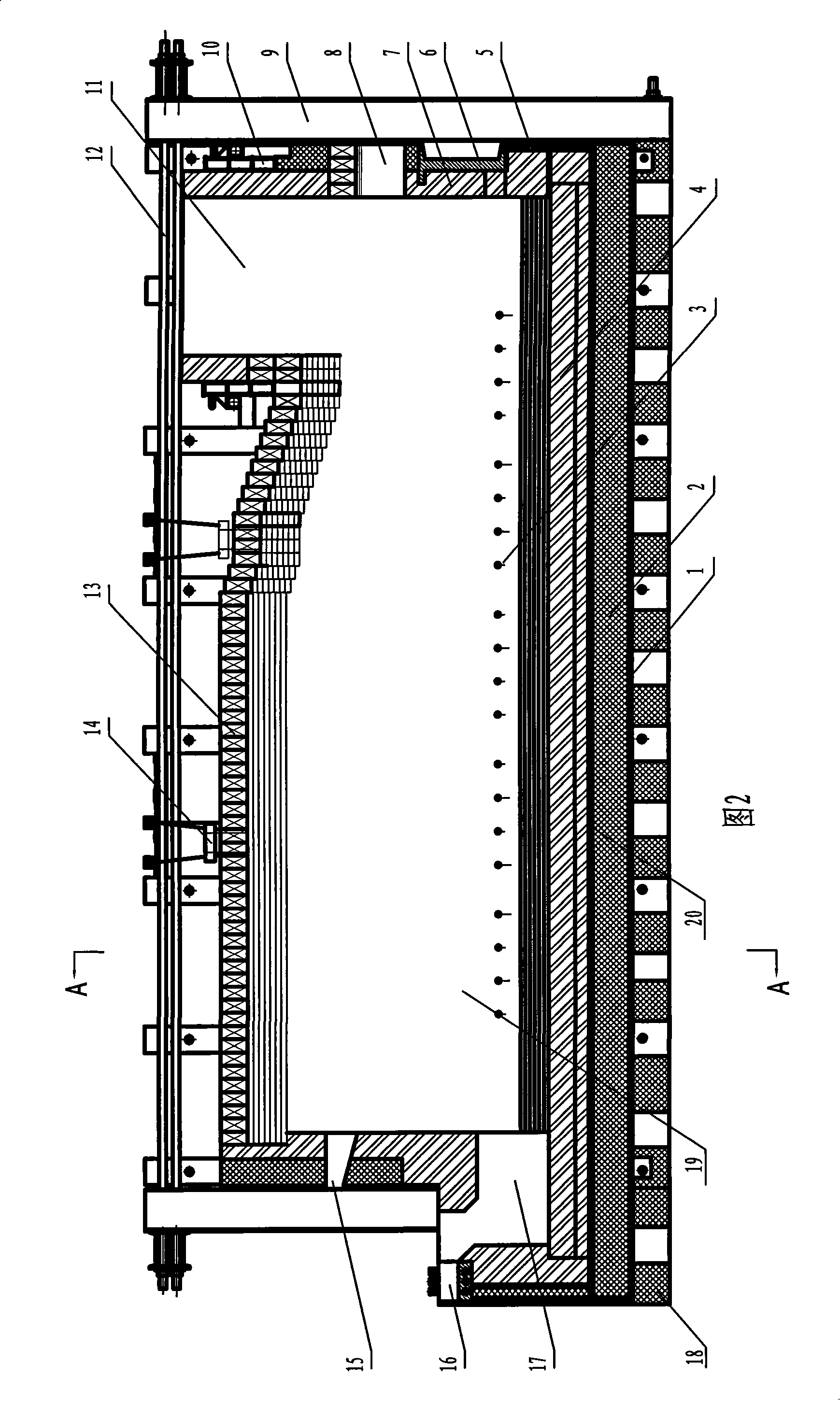

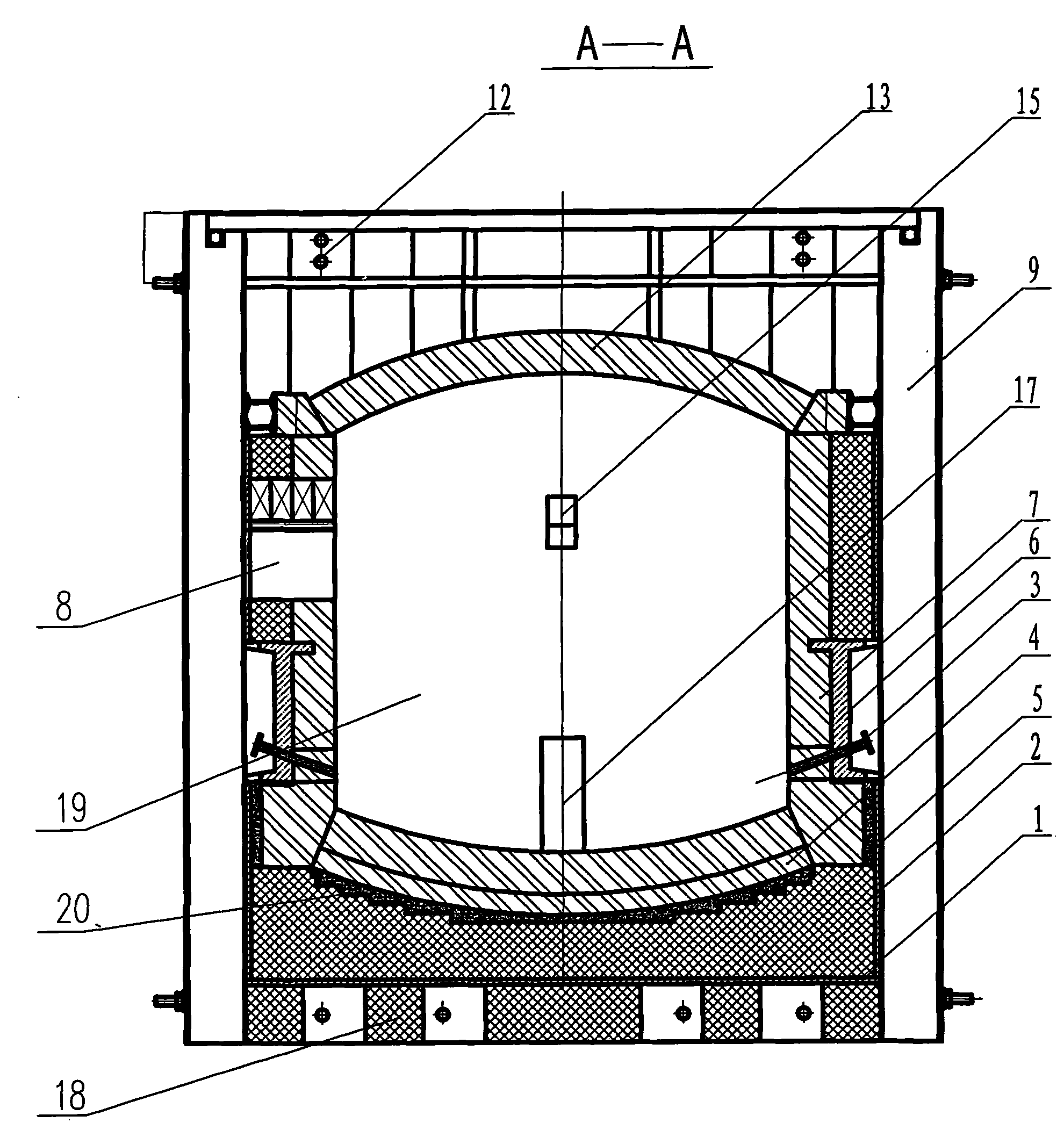

Manufacturing technique for oxygen-enriched side blowing molten pool raw copper smelting and special equipment thereof

InactiveCN101275185BLess investmentReduce energy consumptionRotary drum furnacesCrucible furnacesMelting tankHigh pressure

The invention disclose a production process for melting blister copper in a bath by side-blowing of oxygen enrichment and special apparatuses thereof, the process comprises the steps of melting concentrate of copper, diluting the slug and air refining copper matte, which is to say, adding the material comprising copper, quartz, limestone and fine coal into the furnace of bath and blowing the highpressure oxygen enrichment air into the furnace, the formed copper matte, slug are ceaselessly flowed into a diluting electric furnace, manufacturing acid after recycling waste heat by smoke gas at high temperature; overheating the slug through an electrode and separating the slug from copper matte to obtain the diluted slug and copper matte which is fed into the continuously-air-refining furnacethrough a chute slipway; reacting the copper matte with arenaceous quartz under the effect of compressed air to obtain the blister copper, performing mineral dressing to the air-refined slug, manufacturing the acid with SO<2>; the invention has less process investment, high heat utilization rate, low energy consumption, good effect of environmental protection, compact apparatus structure, small occupied area, great processing ability, light sticking in air flue, simple operations, diverse measures in adjusting the condition of furnace which is easy to control, high level of mechanization and low labor intensity.

Owner:YANTAI PENGHUI COPPER IND

Process and system for controlling a process gas stream

ActiveUS7531135B2Reduce impactReduce the amplitudeExhaust apparatusTemperatue controlControl systemProduct gas

In a process and system for recovering sulfur from a process gas stream initially comprising a hydrogen sulfide containing gas and an oxygen containing gas, a control process and system respectively are provided. The sulfur recovery process includes a thermal step having a beginning followed by a catalytic step having an end. The control process includes first analyzing a composition of the process gas stream at a first location between the beginning of the thermal step and the end of the catalytic step, first controlling the oxygen containing gas having regard to that first composition, second analyzing the composition of the process gas stream at a second location downstream of the end of the catalytic step, and second controlling the oxygen containing gas having regard to that second composition. The sulfur recovery system and control system therefor are provided for performing the steps of the sulfur recovery process and control process respectively.

Owner:DREWES VINCENT +1

Process flow of comprehensive recovery of low-concentration SO2 flue gas from multiple gas sources

ActiveCN103303877BImprove sulfur recoveryAchieve recyclingDispersed particle separationSulfur compoundsHigh concentrationDesorption

The invention discloses a comprehensive multi-gas source low-concentration SO2 fume recycling acid-making technological process. The fume is mixed in a pressure adjusting gas distribution mode, is subjected to washing by using a high-efficiency washer and deep purification by using a combined purification tower, and is subsequently fed into a fume desulfurization system, and the tail gas is fed into a chimney to discharge out. The high-concentration SO2 which is produced from desulfuration and desorption is diluted by air or a part of pre-washed wet fume and is fed into an acid-making system, a finished product sulfuric acid is produced, the sulfuric acid tail gas is fed back to the combined purification tower and the fume desulfurization system, and the tail gas is discharged out when being subjected to up-to-standard desulfurization. The process is a comprehensive sulfur resource recycling technique that a multi-gas source mixed conveying technique, an SO2 recycling technique which employs an absorption-desorption method and a conversion-absorption acid-making technique are combined together, has the characteristics of high sulfur recycling rate, optimization in equipment and investment and low operation expense, can realize clean production and comprehensive recycling of SO2, prompts the development of circular economy of companies, and can be widely applied to comprehensive treatment on fume with low-concentration SO2 in industries of colored metal, steel and iron, thermal power, chemistry and the like.

Owner:CHINA NERIN ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com