Method for recycling zinc-oxygen pressure leaching sulfur flotation tailings

A technology of sulfur flotation and resource utilization, applied in chemical instruments and methods, flotation, wet separation, etc., can solve problems such as difficulty in sales of sulfuric acid products, volatile flue, flue sticking, etc., to increase hydrophobicity and Floatability, high sulfur recovery, and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

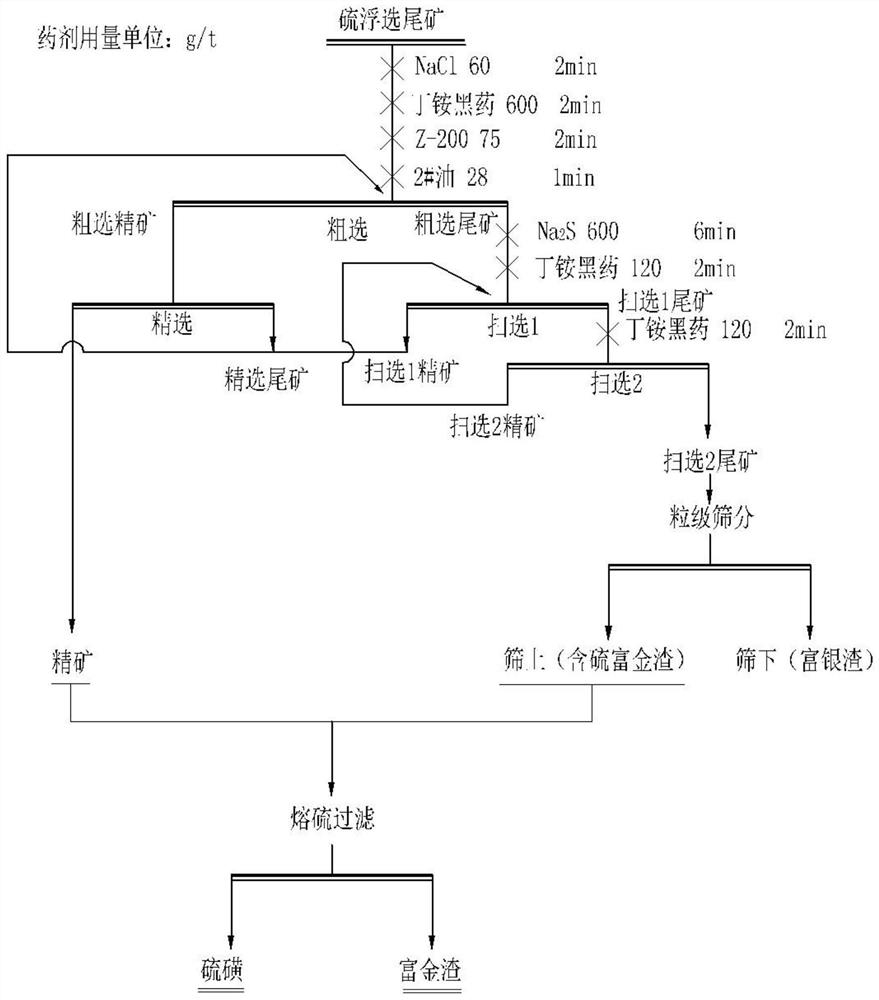

[0020] Attached below figure 1 The present invention is further described by specific embodiment:

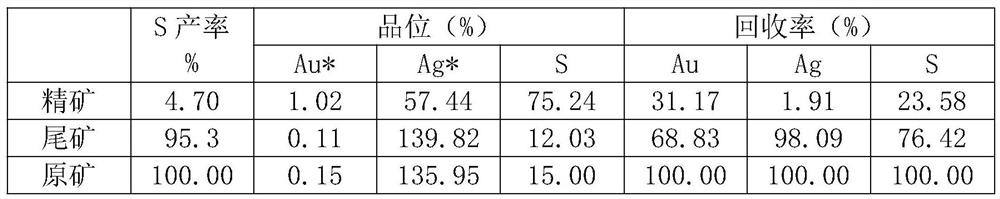

[0021] In this embodiment, 1L of zinc oxygen pressure leaching sulfur flotation tailings is taken, with a solid content of about 30%, and the test results are shown in Table 1:

[0022] Table 1 The test results of main elements in the floating sulfur tailings of zinc smelting by oxygen pressure leaching (%, * means g / t)

[0023] element Au* Ag* Zn Pb Fe S content 0.15 135.95 1.21 3.31 34.88 15.00

[0024] The process steps are:

[0025] 1) Add NaCl to the oxygen pressure leaching sulfur flotation tailings at 60g / t, add butyl ammonium black drug at 600g / t after 2 minutes, add Z-20075g / t after 2 minutes, and then add 2# oil after 2 minutes It is 28g / t, and after 1min, it is transported to the roughing tank to obtain roughing concentrate and roughing tailings.

[0026] 2) overflow the roughing concentrate obtained in step 1) to the concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com