Patents

Literature

3541results about "Hulling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure sensitive adhesive for polarizing plates, polarizing plate with pressure sensitive adhesive and production process for polarizing plate

ActiveUS20060162857A1Increased durabilityLiquid crystal compositionsOrganic dyesLiquid-crystal displayOptical thin film

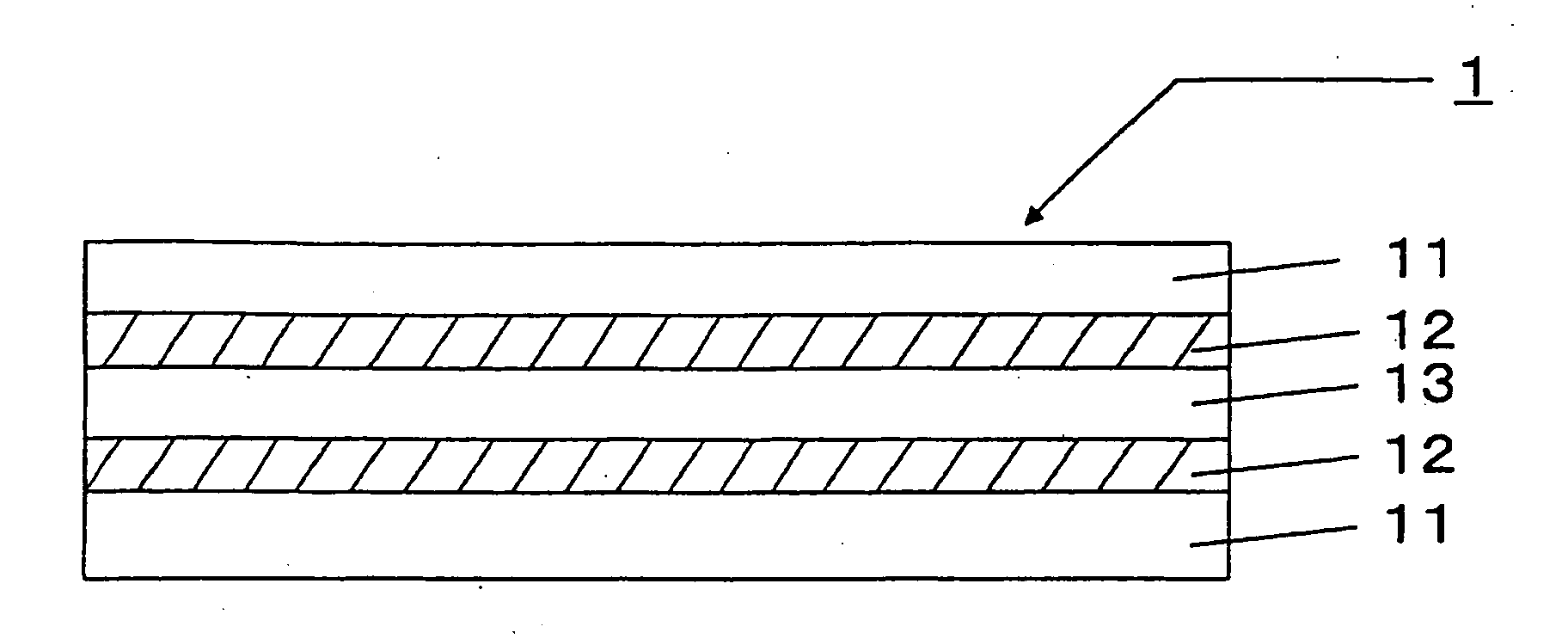

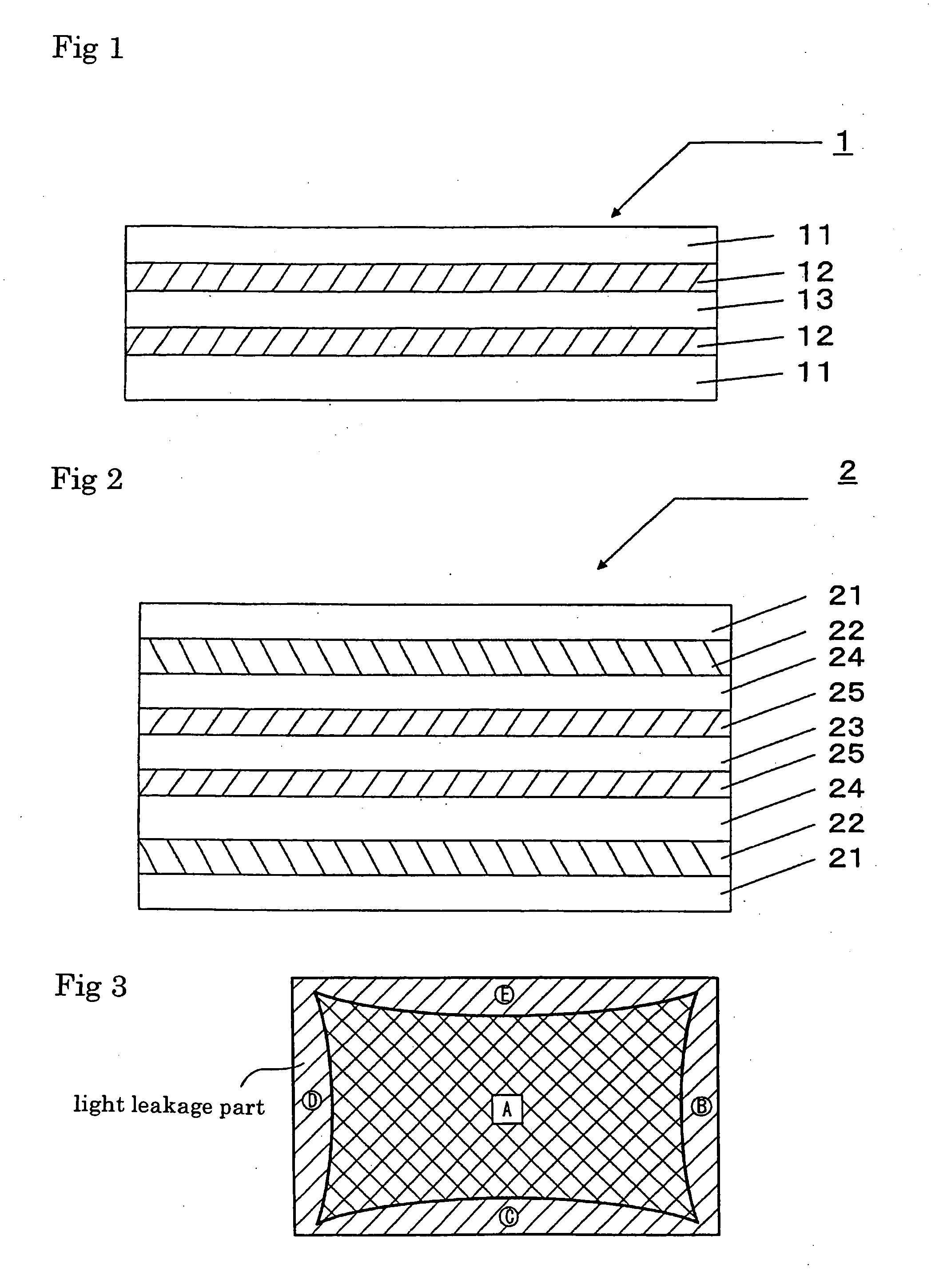

The disclosed a pressure sensitive adhesive for polarizing plates which has a storage elastic modulus (G′) at 23° C. of at least 0.3 MPa; a polarizing plate having a pressure sensitive adhesive; a process for producing the above polarizing plate which comprises sticking a polarizing plate on a tacky adhesive material layer formed on a releasing layer of a releasing sheet, and thereafter irradiating with an active energy beam from the releasing sheet side; an optical film which comprises a polarizing plate and a phase difference plate; and a process for producing the above optical film. The pressure sensitive adhesive and polarizing plate having the pressure sensitive adhesive are characterized in that they are capable of sticking with high durability, the polarizing plate to a and phase difference plate, and the resultant liquid crystal display unit is less liable to cause light leakage under the conditions of high temperature.

Owner:LINTEC CORP

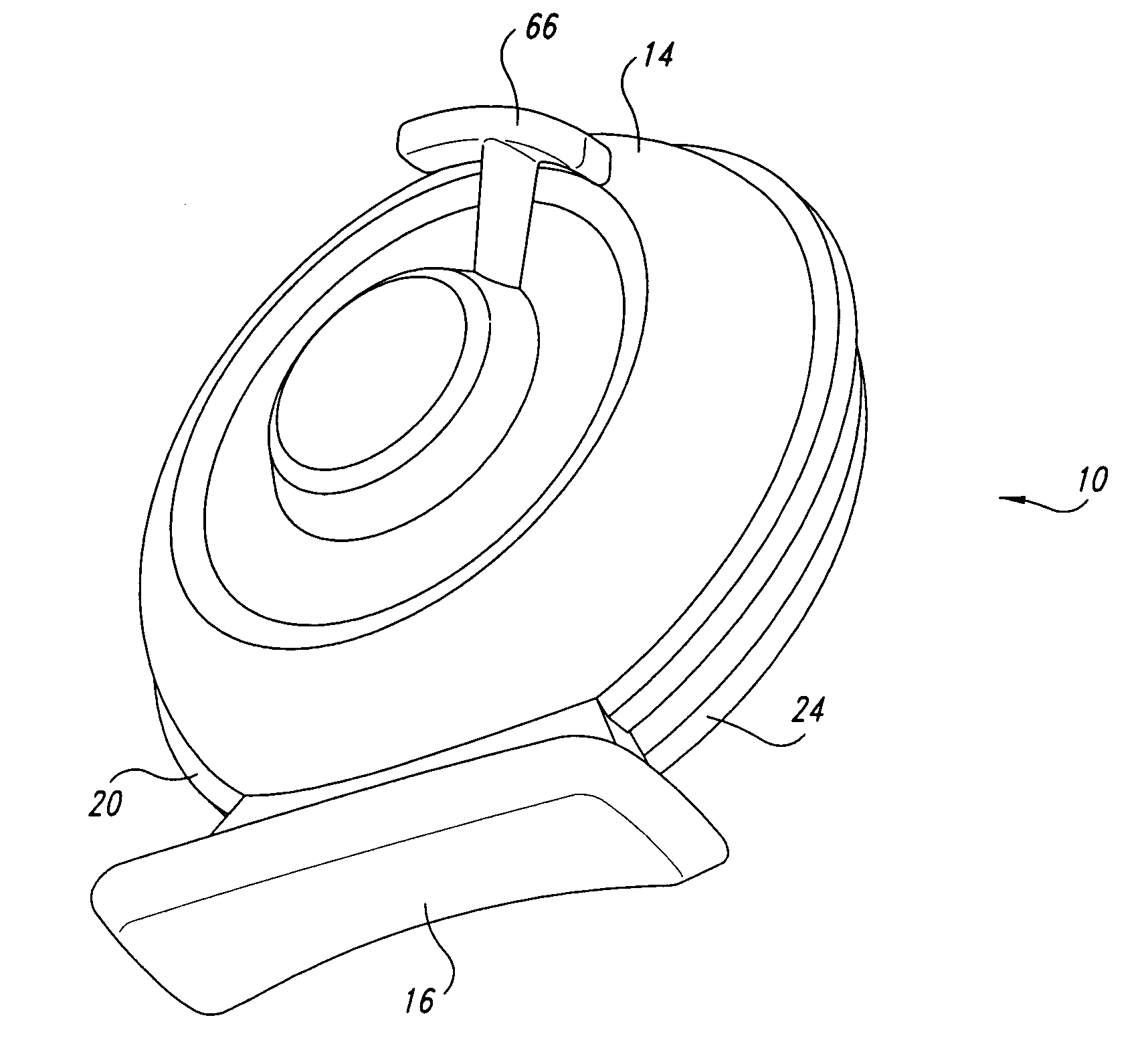

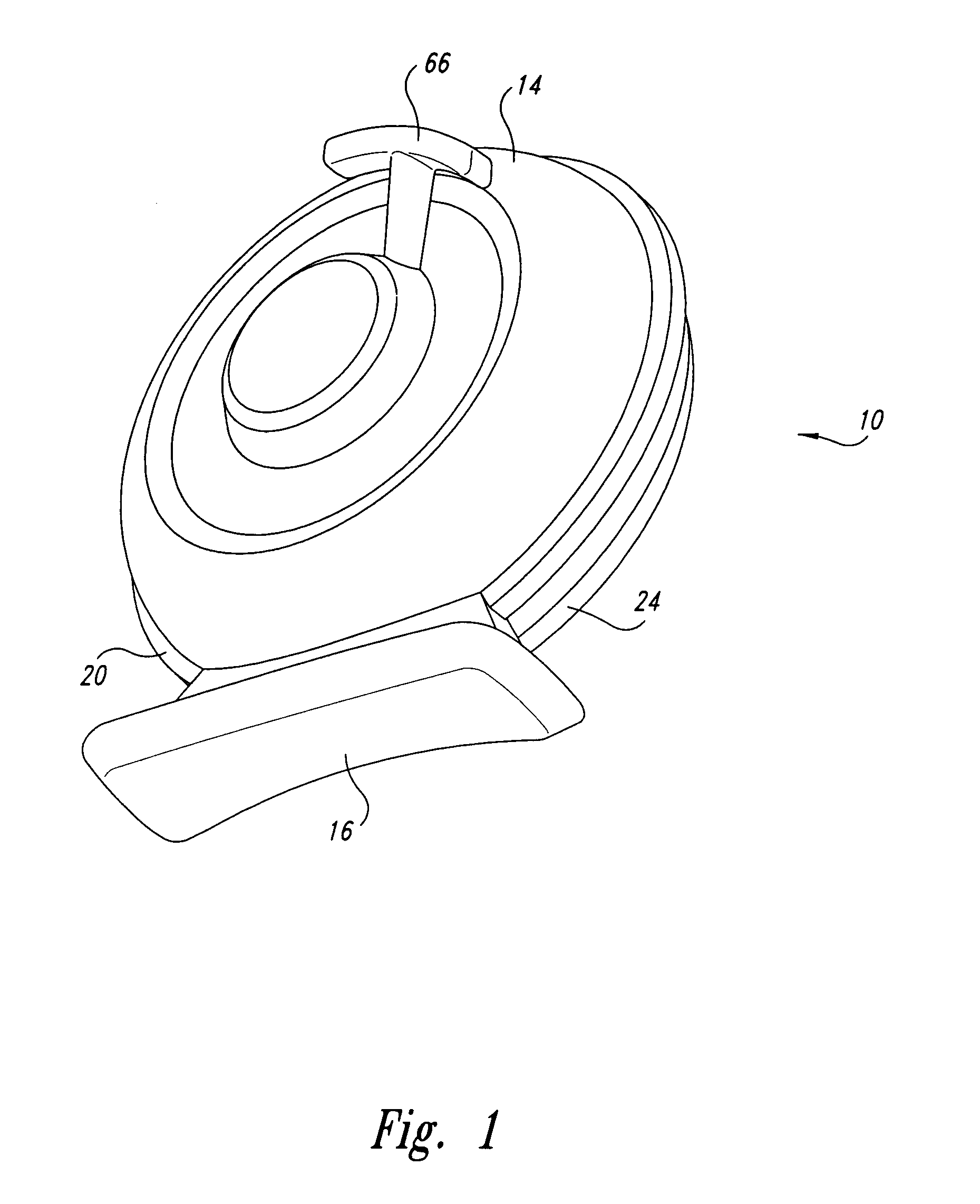

Hand-held food processor

InactiveUS7264189B2Increase torqueLong and high torque rotational forceMetal sawing devicesCoffee millsHand heldEngineering

A hand-held hand-powered food processor having a pull cord motor for rotating a spindle that carries an arm. The arm can be a cutter blade or an elastomeric flexible peeler arm having a durometer of preferable between Shore 80A and Shore 82A. A food processor having a spindle, an elastomeric arm driven by the spindle, a stop block on a sidewall near the end of the arm, and a drive for rotating the spindle to rub against the skin of food in the processor for peeling the food. The cover of the processor has a flat outer periphery so the cover can be used as a storage unit for the contents of the processor.

Owner:CHEFN

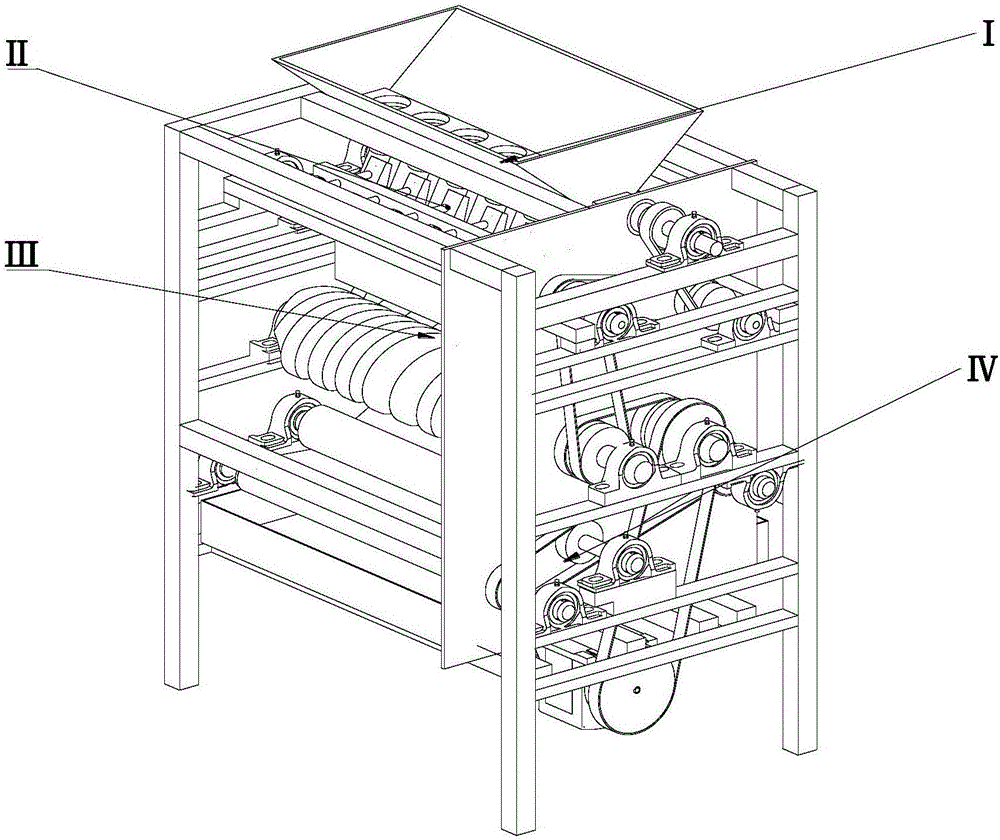

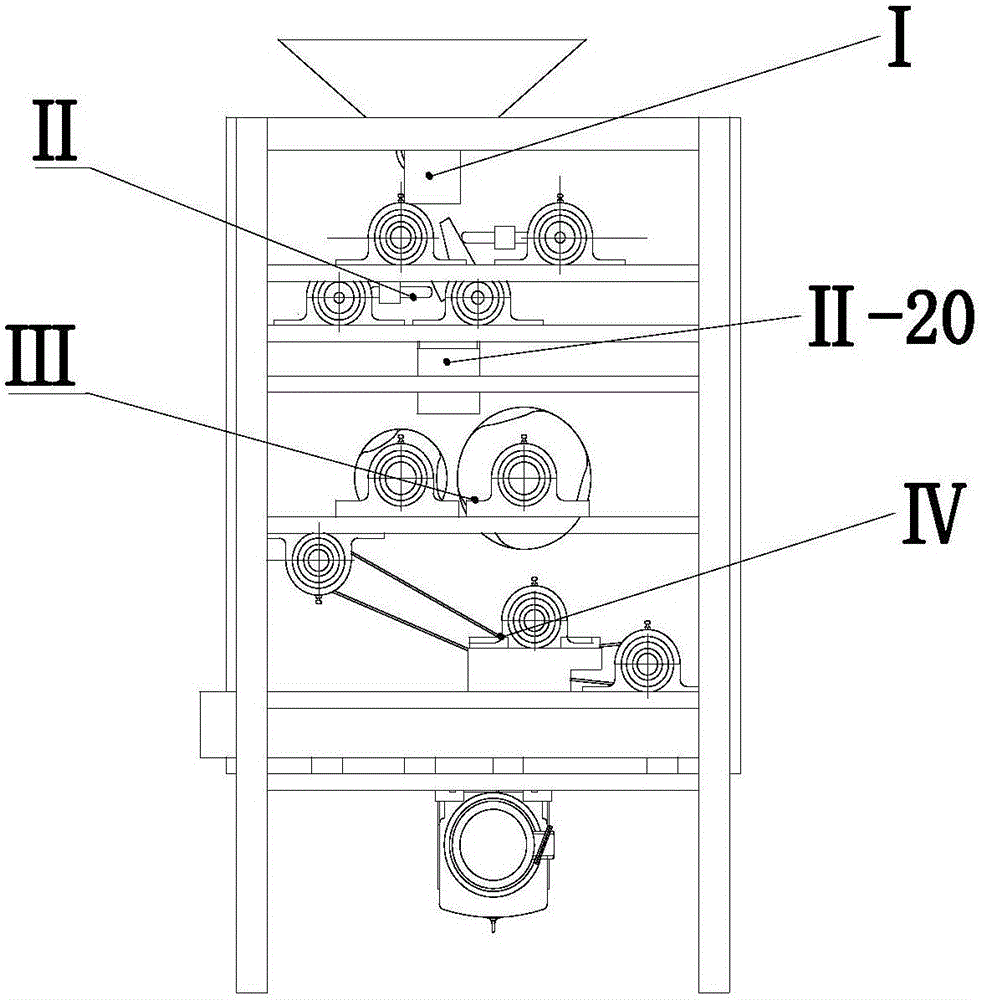

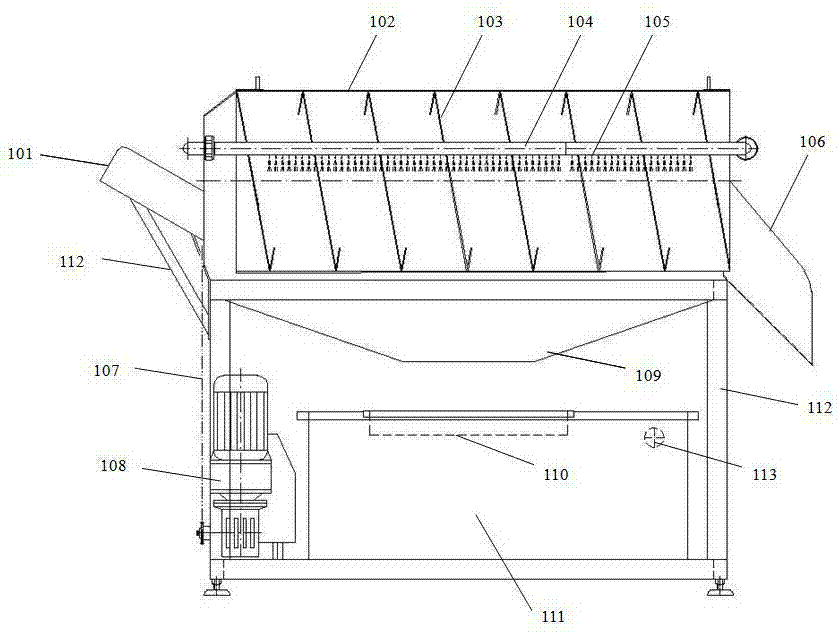

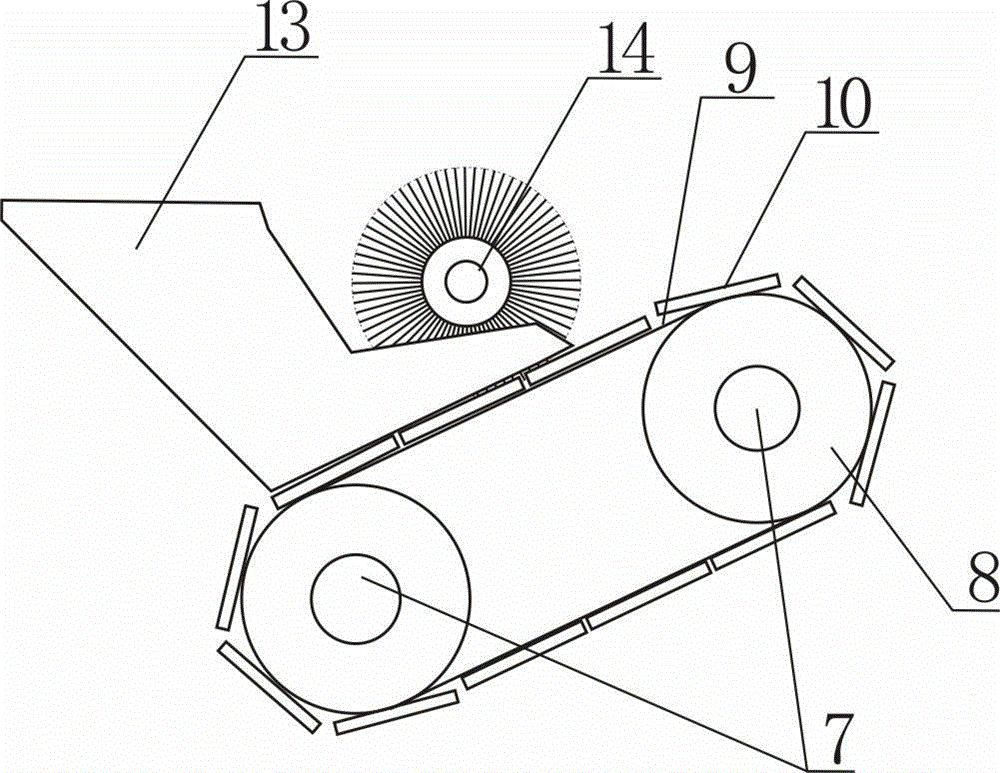

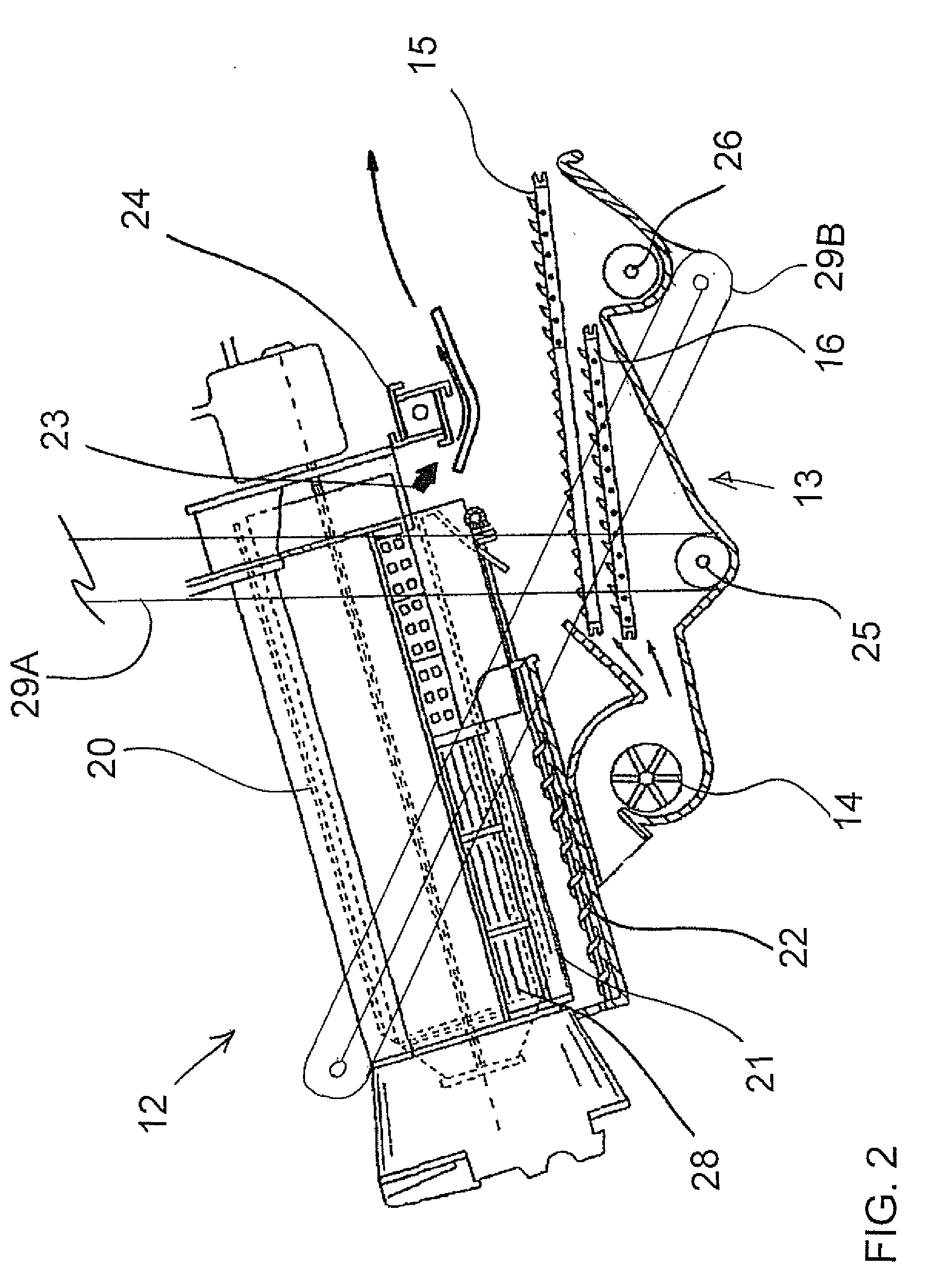

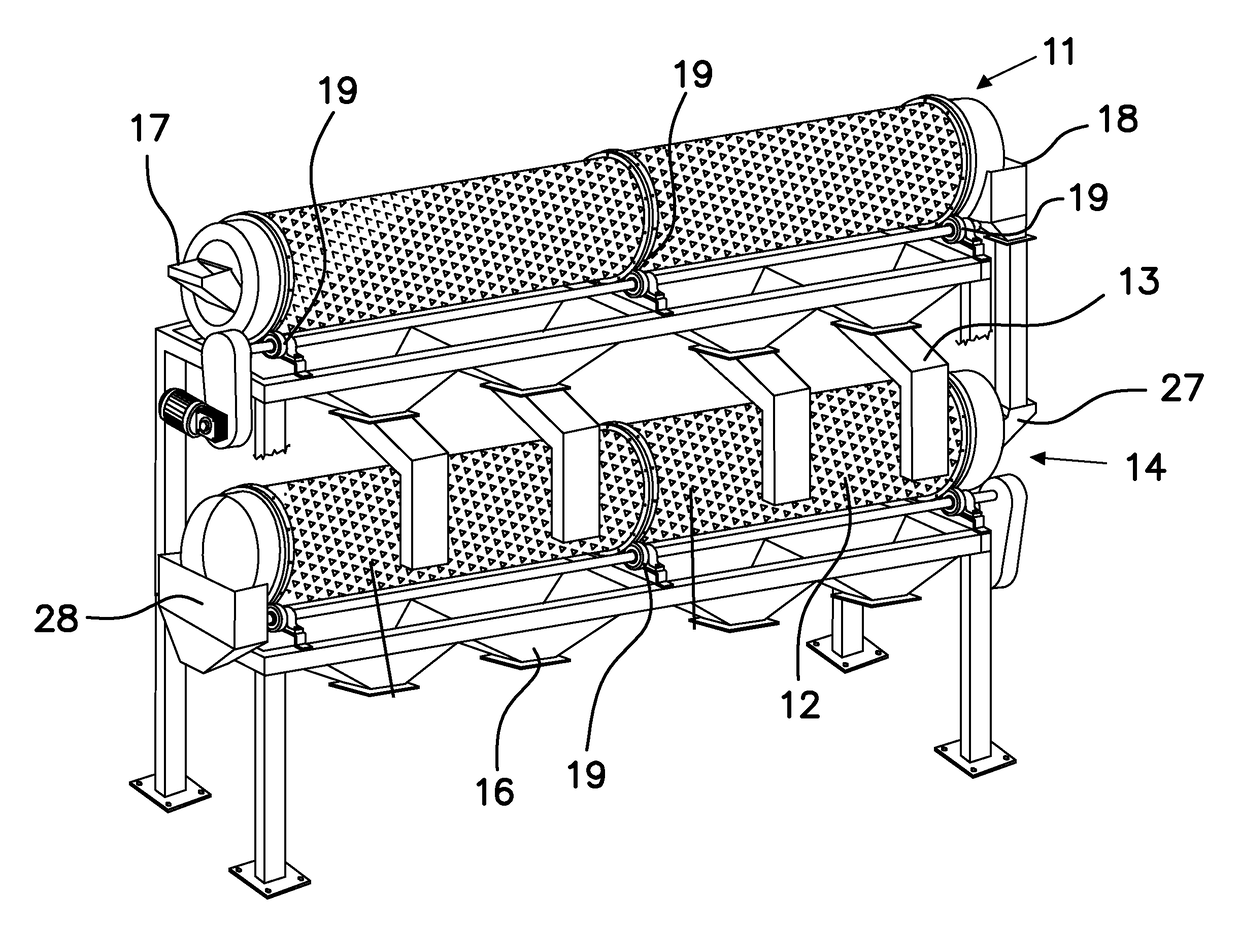

Rub type shelling and sorting machine for camellia fruits

ActiveCN103271415AEffective shelling and sortingEasy to processSievingScreeningEngineeringAgriculture

The invention belongs to the technical field of agriculture-forestry product processing machinery and particular relates to a rub type shelling and sorting machine for camellia fruits. The shelling and sorting machine is integrated with functions of camellia fruit shelling and shell and camellia seed sorting. The shelling and sorting machine mainly comprises a frame, a camellia fruit sorting roller screen device, a camellia fruit rub shelling device, a flexible bar stirring roll seed-shell separating device and a seed-shell sorting vibrating screen device, wherein the camellia fruit sorting roller screen device, the camellia fruit rub shelling device, the flexible bar stirring roll seed-shell separating device and the seed-shell sorting vibrating screen device are sequentially mounted on the frame according to a feed direction of the camellia fruits. By the shelling and sorting device, the camellia fruits can be shelled efficiently without damaging camellia seeds, and shells and the camellia seeds can be sorted simultaneously. The rub type shelling and sorting machine is high in shelling and sorting efficiency, compact in structure, convenient to use, and high in productivity.

Owner:HUNAN ACAD OF FORESTRY

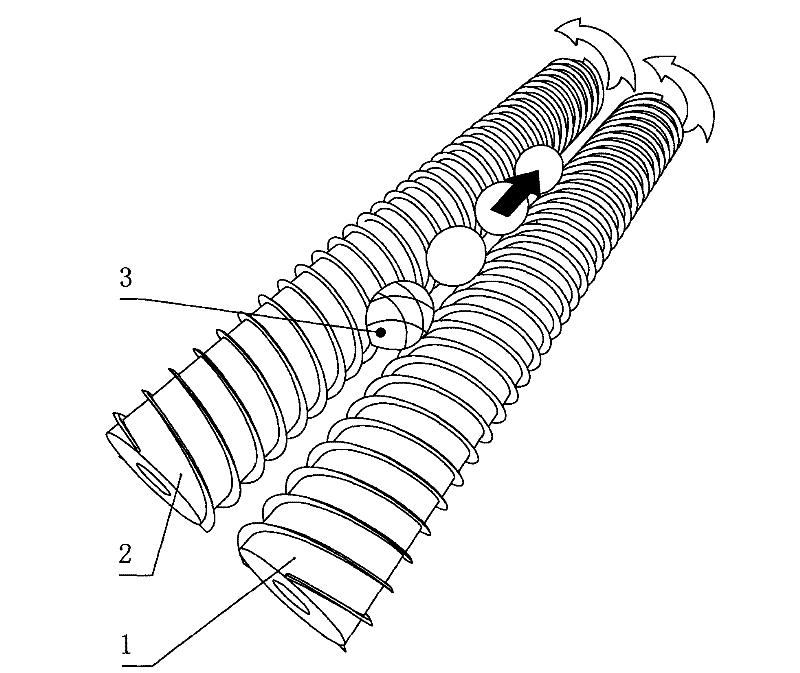

Method for stripping off green husk of nut through mechanized dry process

The invention discloses a method for stripping off green husks of nuts through a mechanized dry process and relates to a fruit processing technique, in particular to a processing technique for stripping off the green husks of the nuts. Crossed reticular knife marks are cut on the surfaces of fermented mature green nuts through two spiral knife rolls which have opposite spiral directions and rotate in the same direction at different speeds, and then the spiral knife rolls rotate to apply tangential force and axial force on the nuts to rotate and turn over the nuts so as to enable the green husks to be split and separated from the surfaces of the nuts. Since the spiral knife rolls have sharp edges, when the spiral knife rolls cut into the green husks, sap in the green husks is not squeezed out and is prevented from contaminating the exterior surfaces of the nuts during processing. Though the entire green husk stripping motions are equivalent to simulated manual stripping actions, the mechanized high-efficiency application of the green husk stripping action is realized. Therefore, the invention provides the effective method for stripping the green husks of the nuts through the dry process.

Owner:YUNNAN SARDE TECH +1

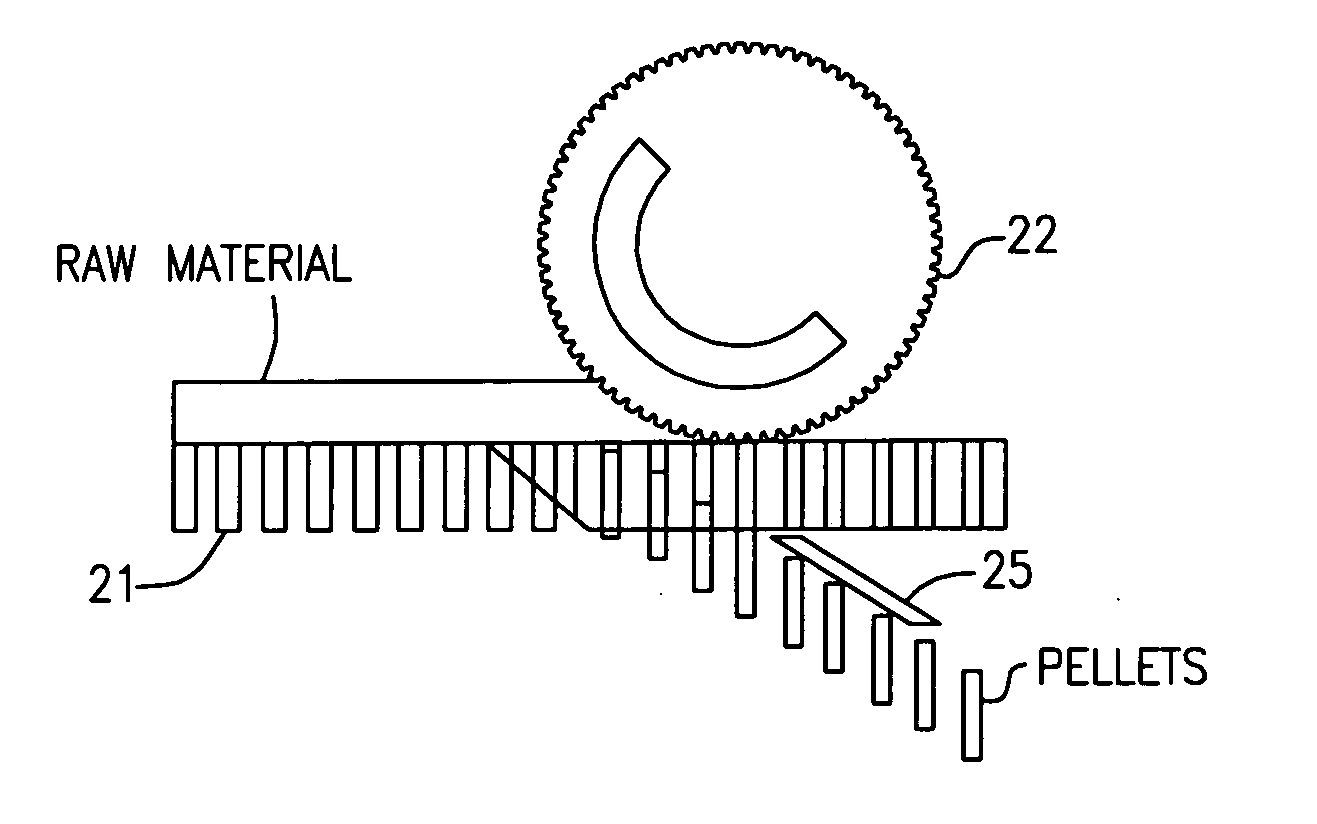

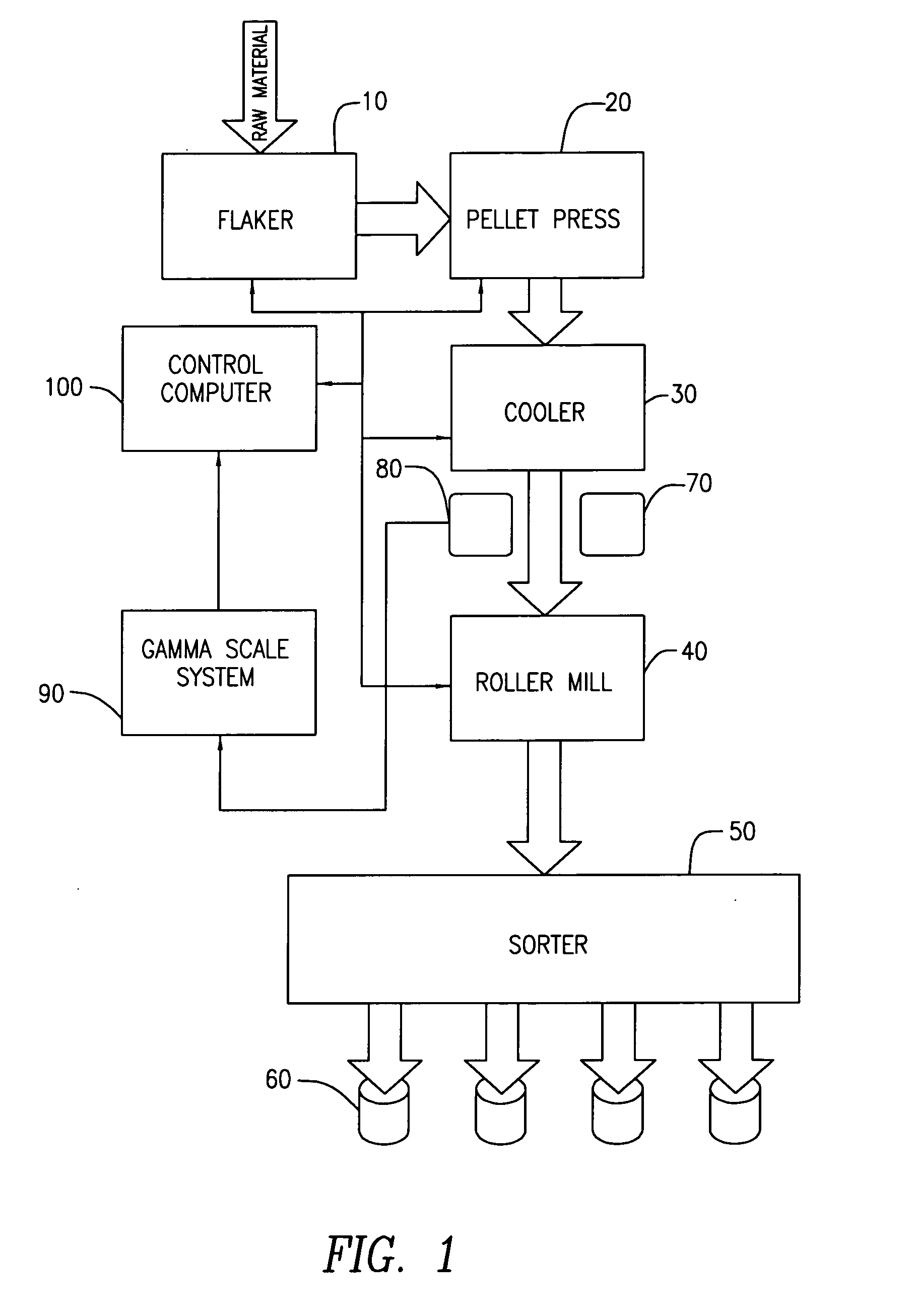

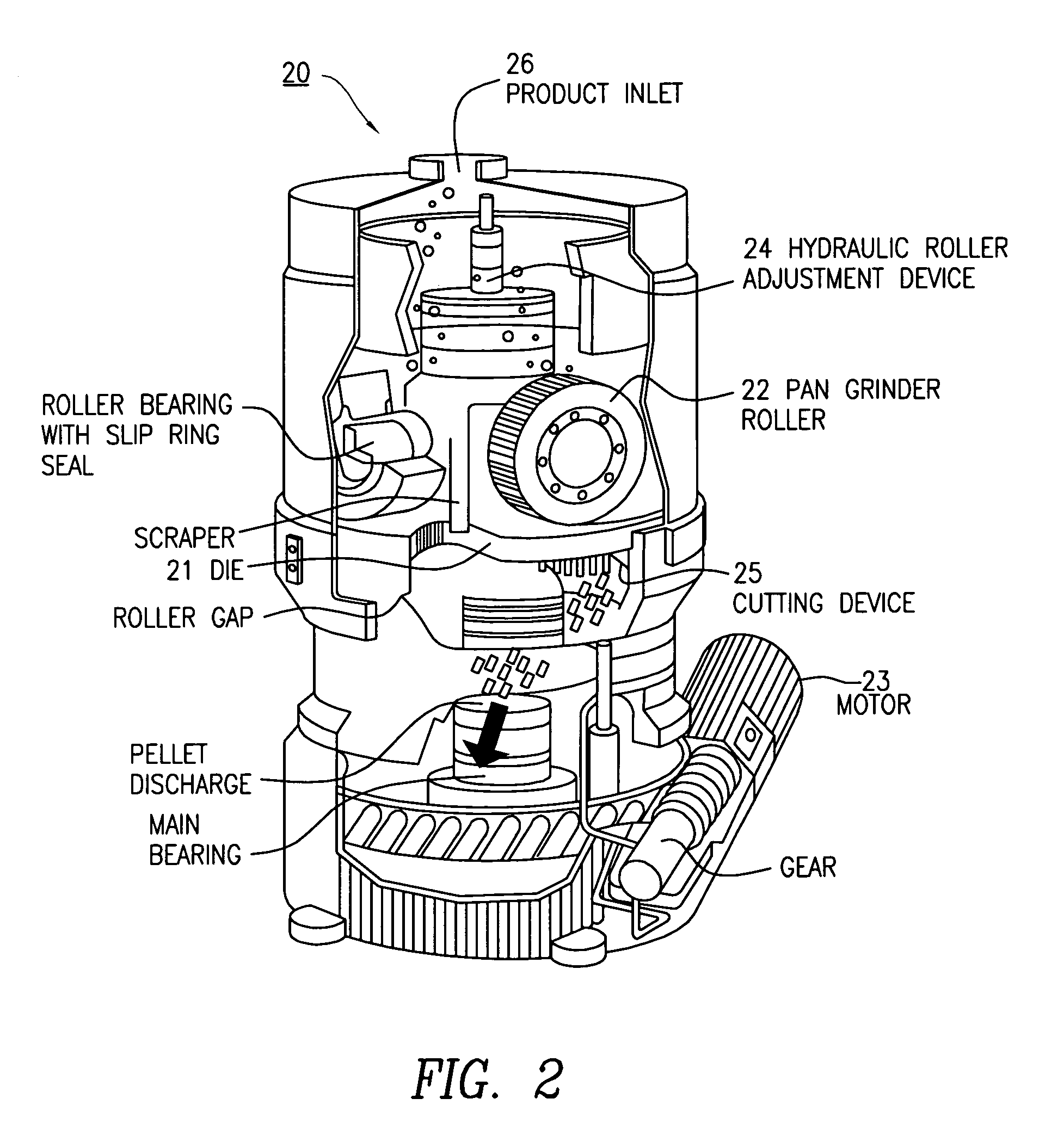

Pellet mill and method of making peanut hull granules

InactiveUS20050230872A1Minimizes of other wasteReduce energy costsConfectionerySweetmeatsEngineeringPeanut hull

To make peanut hull granules peanut shells are supplied to a flaker where the shells are flaked. The flaked shells are fed into a hydraulic pellet press where they are pressed into pellets using a horizontal die. The pellets are then cooled using cooler. The cooled pellets are processed by a roller mill that crumbles the pellets into granules.

Owner:AG FIBERS

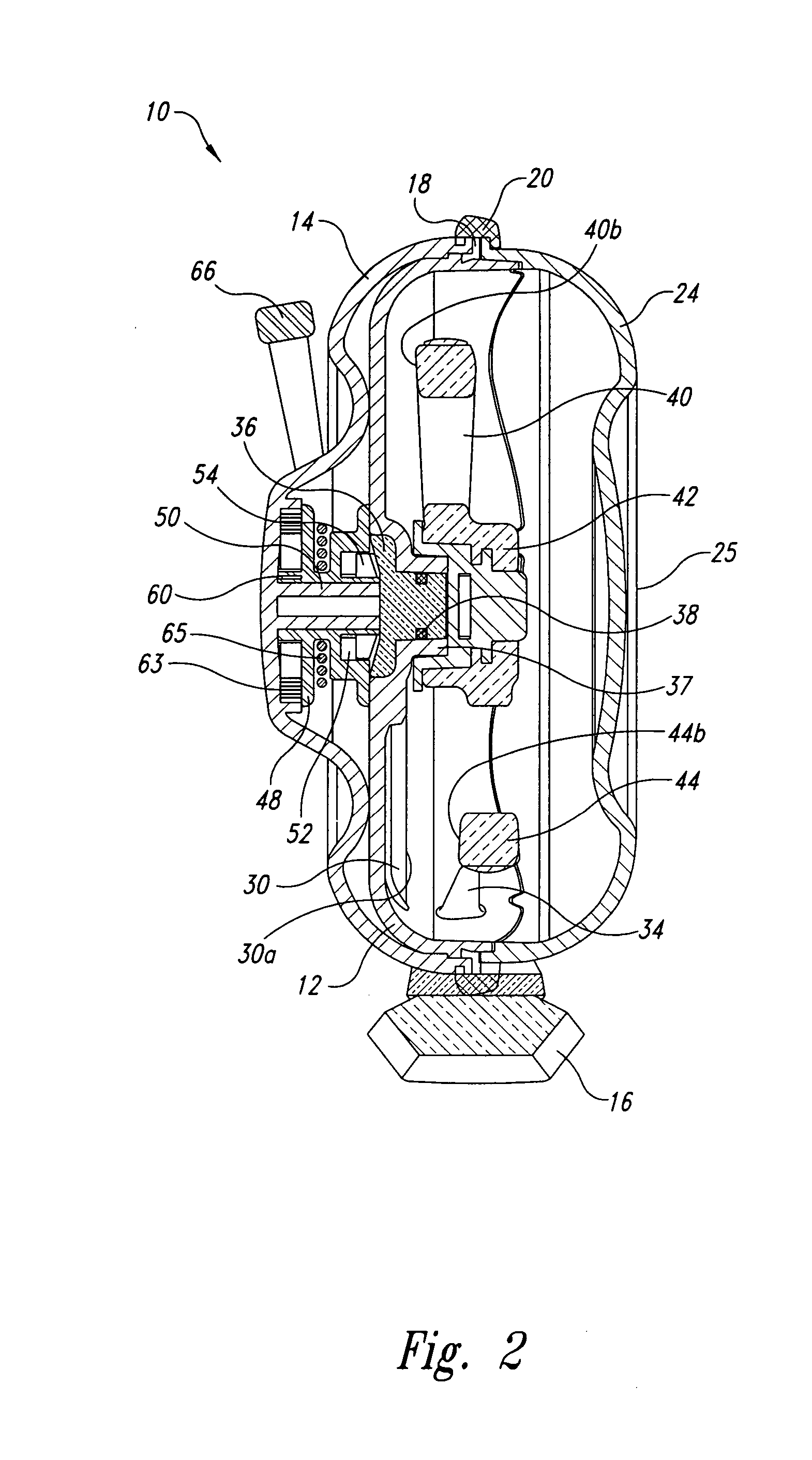

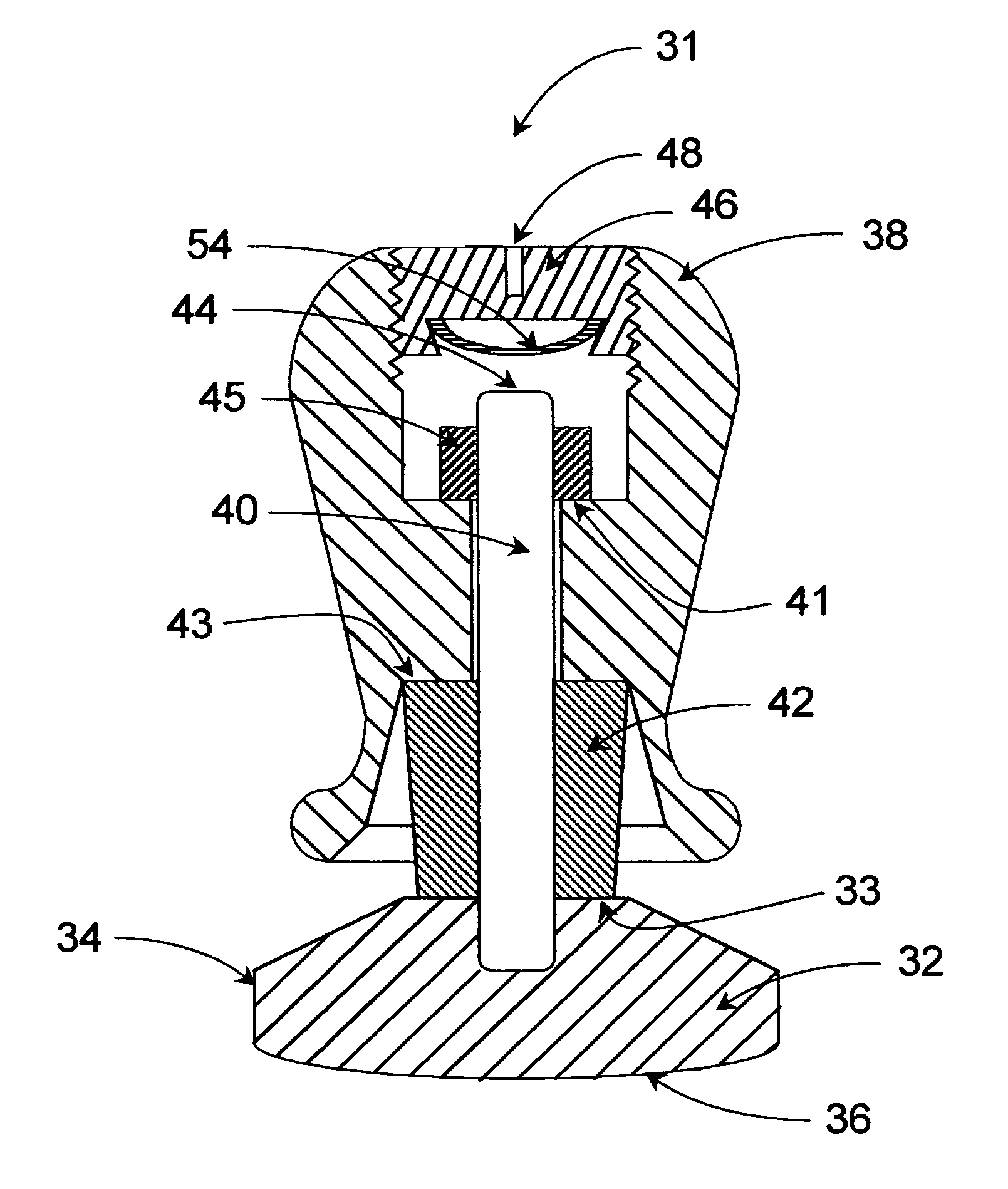

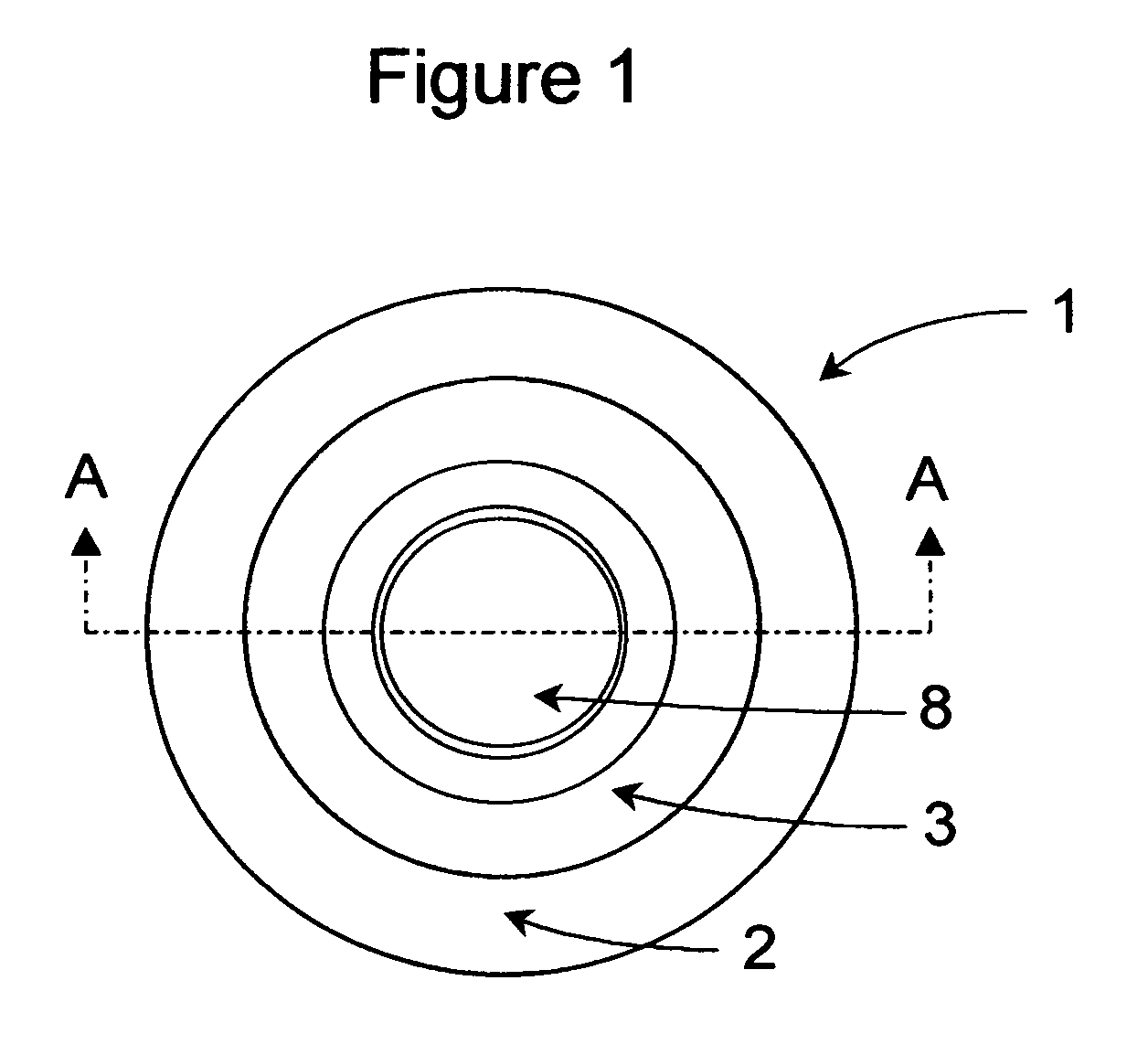

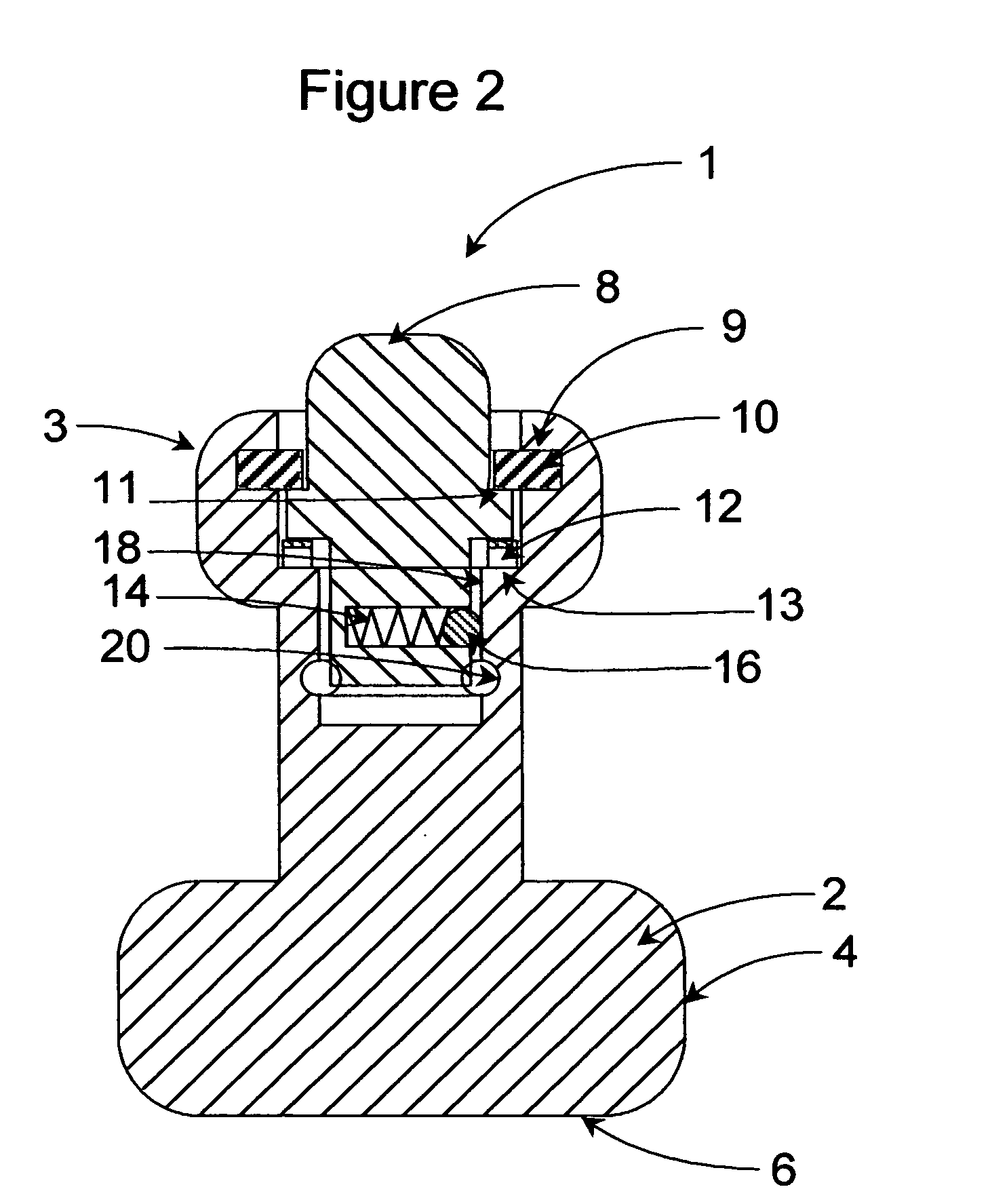

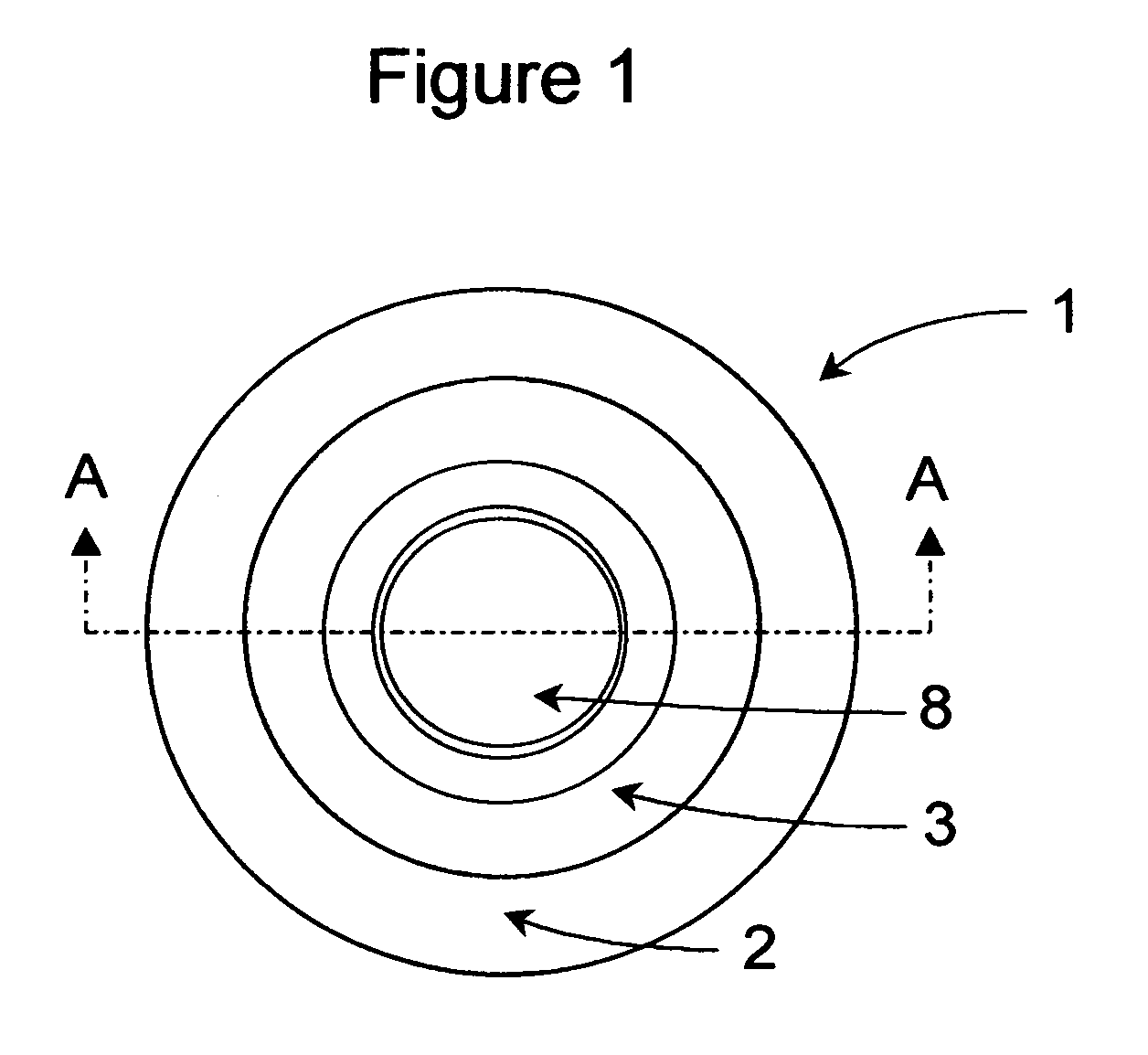

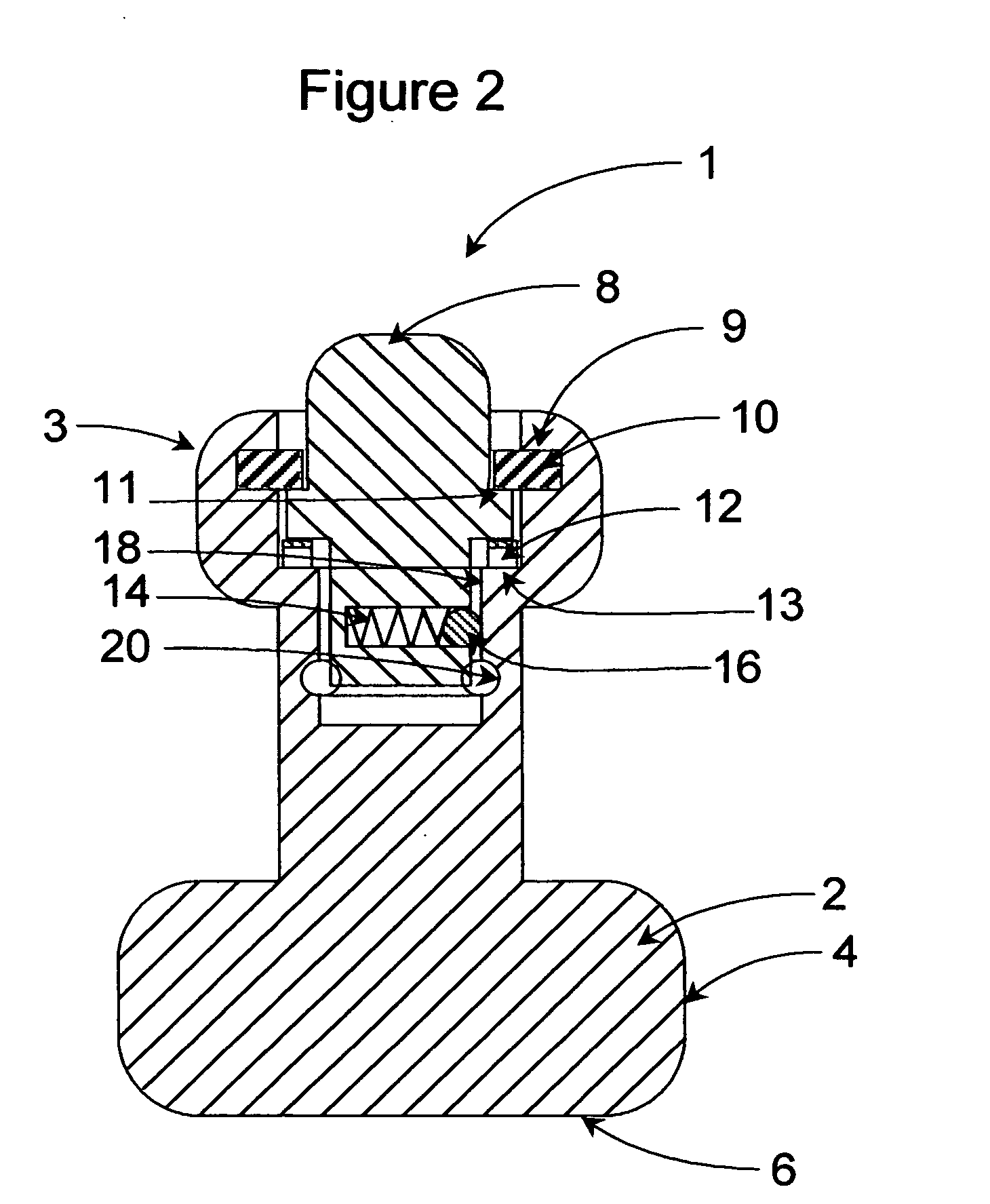

Calibrated handheld espresso tamper

An espresso tamper including a force calibration means is shown. The tamper is optimally handheld. Upon force of a desired magnitude being applied by a user, at least one discrete signal, such as an audible, visual, tactile or electrical signal is emitted. The tamper handle includes an anti-rotation feature. The handle is flared to avoid pinching the user's fingers during operation and to stop the user's fingers from sliding down the handle or in any way touching the base, thereby rendering the tamper more effective and safe. The tamper and force-calibration kit and method of use optimize espresso making.

Owner:ESPRO

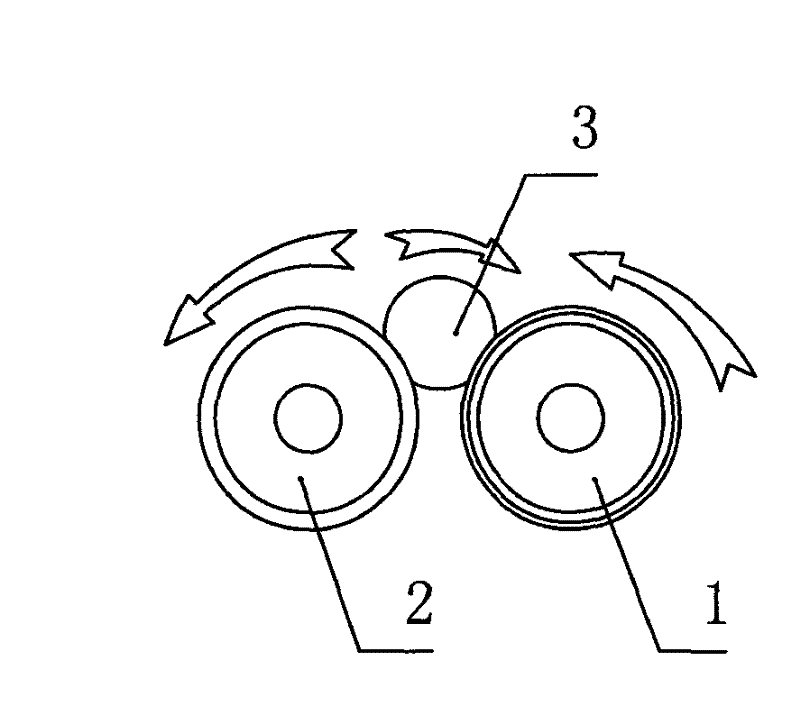

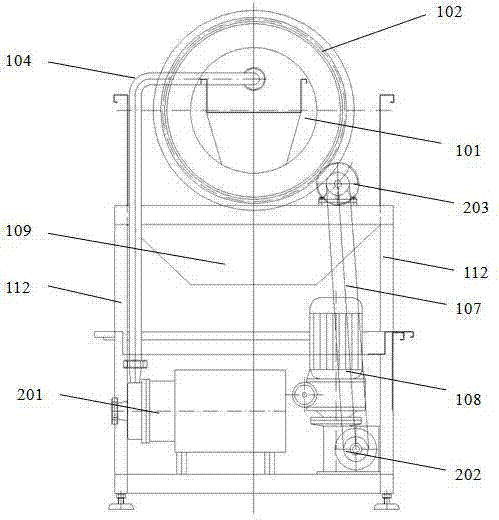

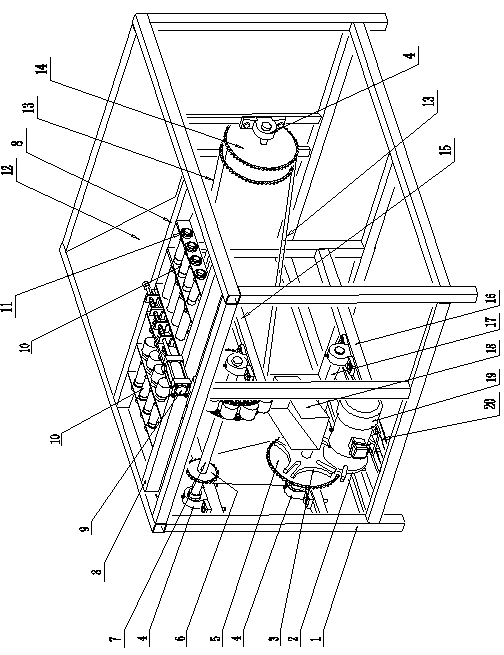

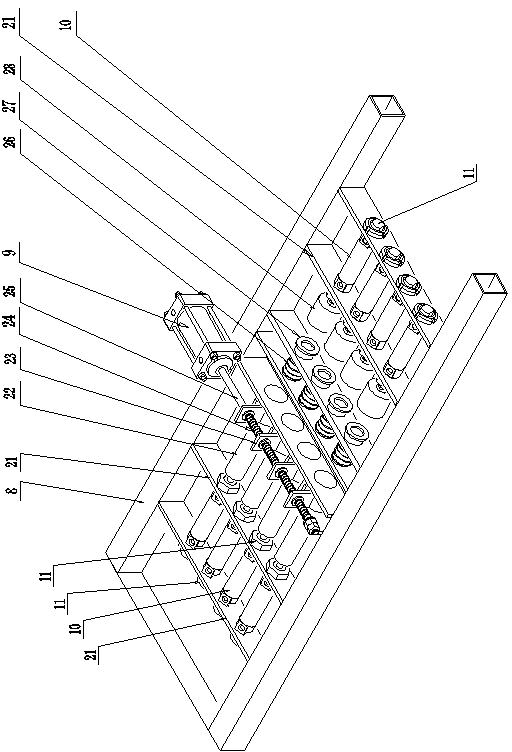

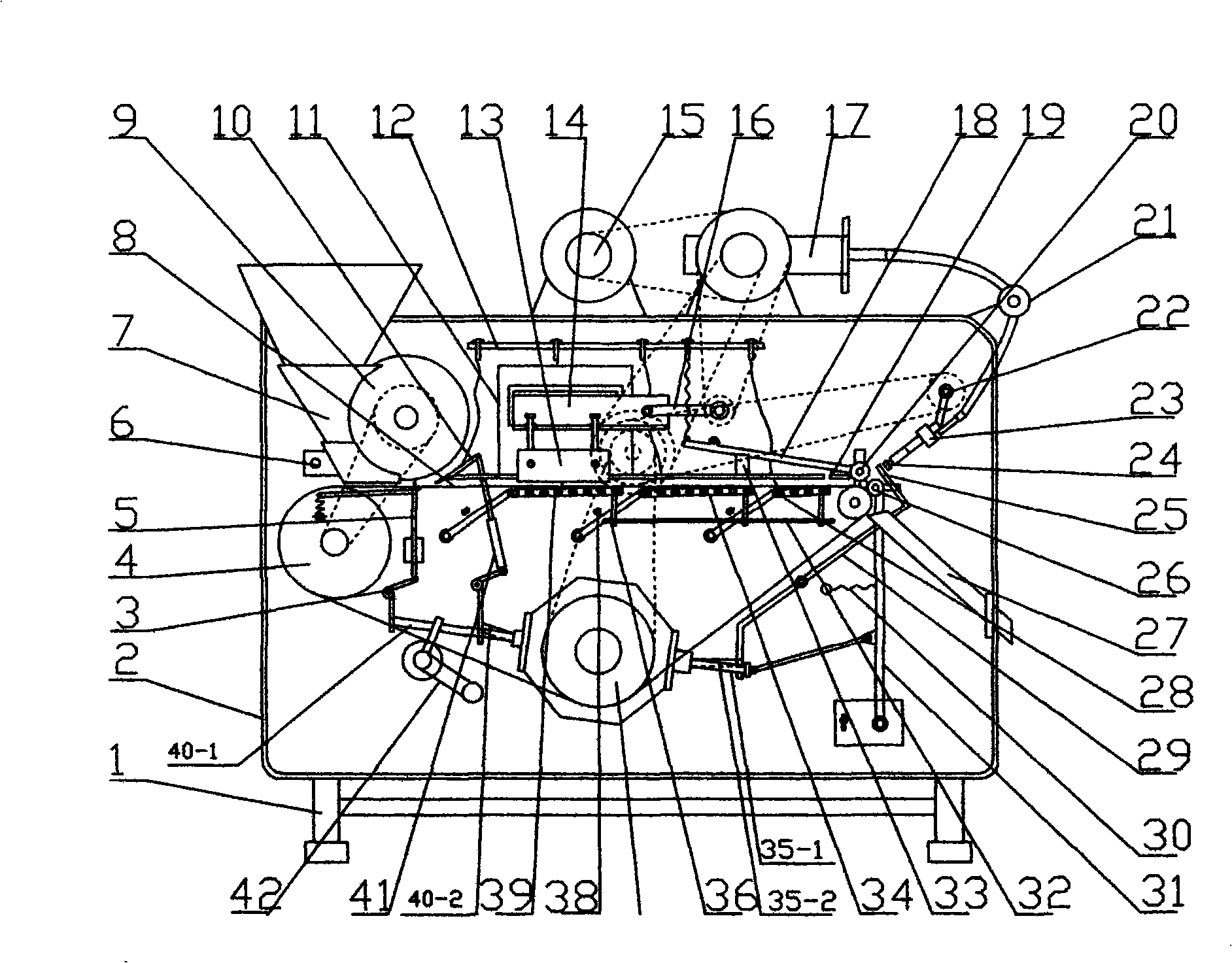

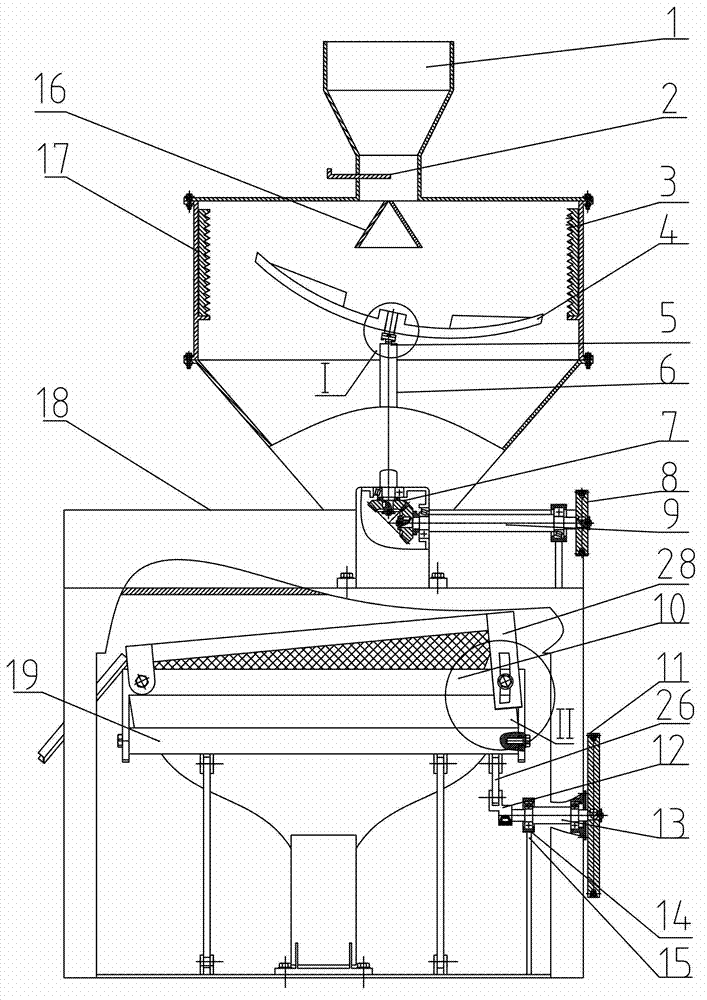

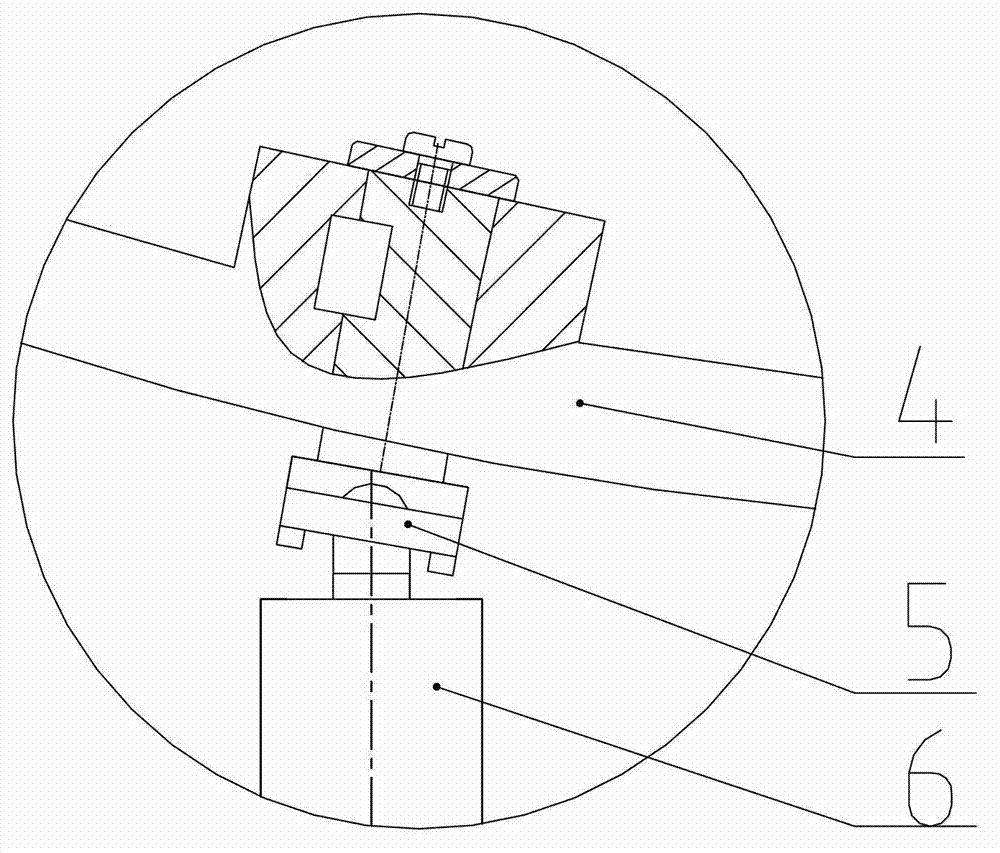

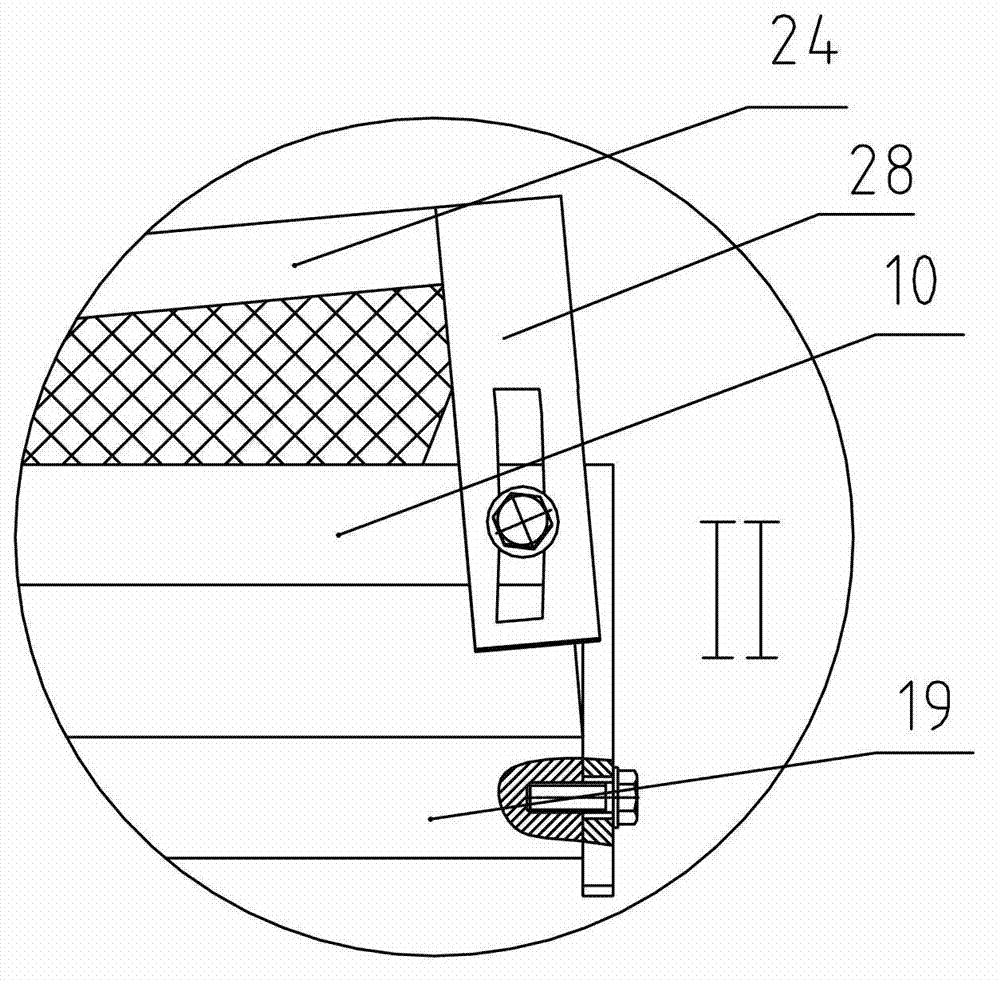

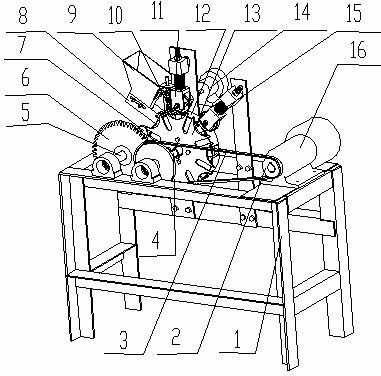

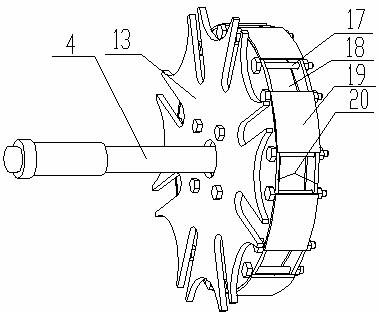

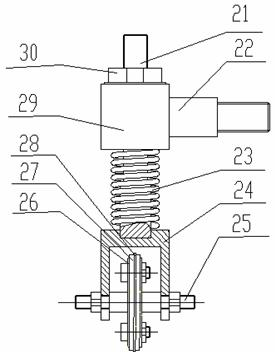

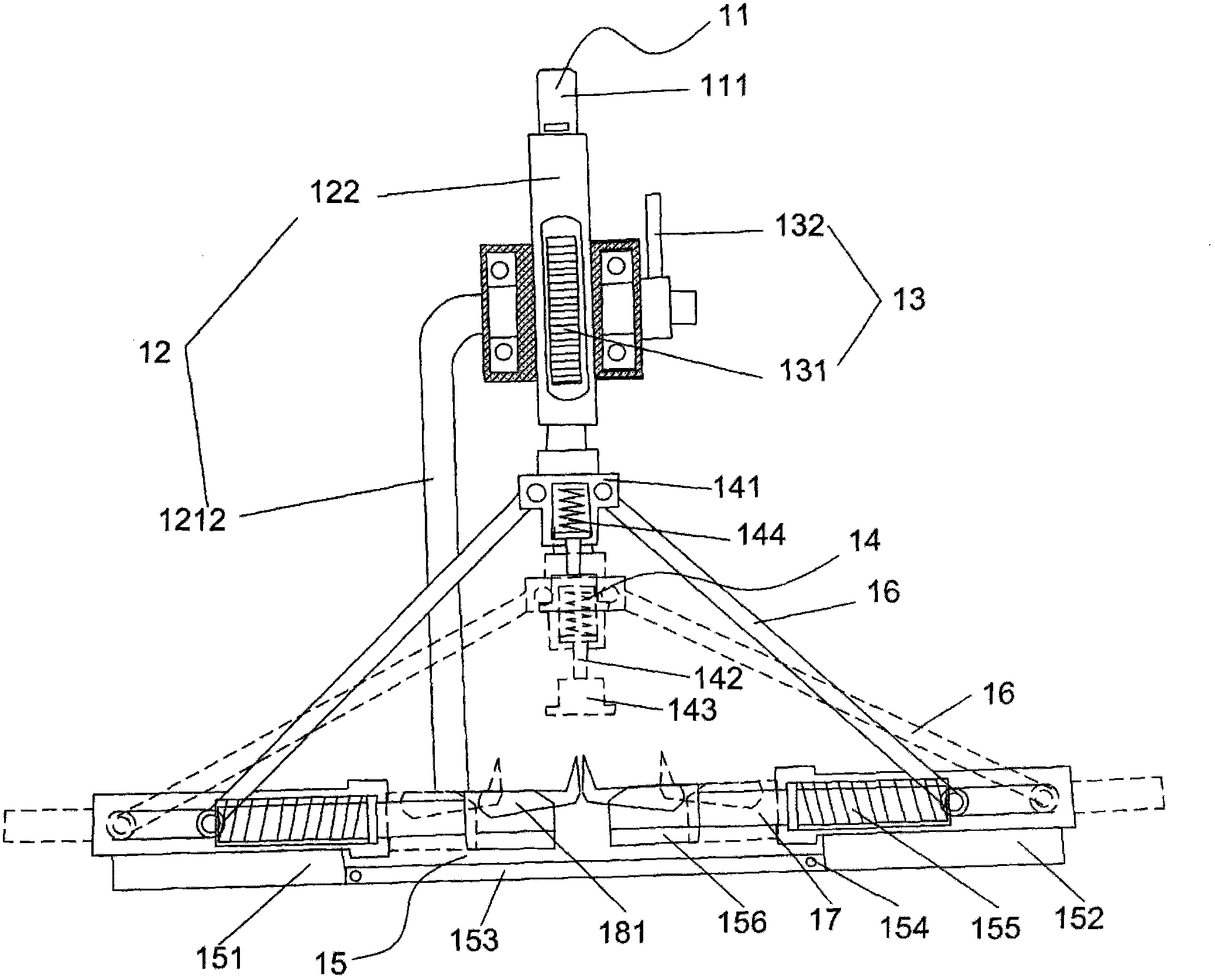

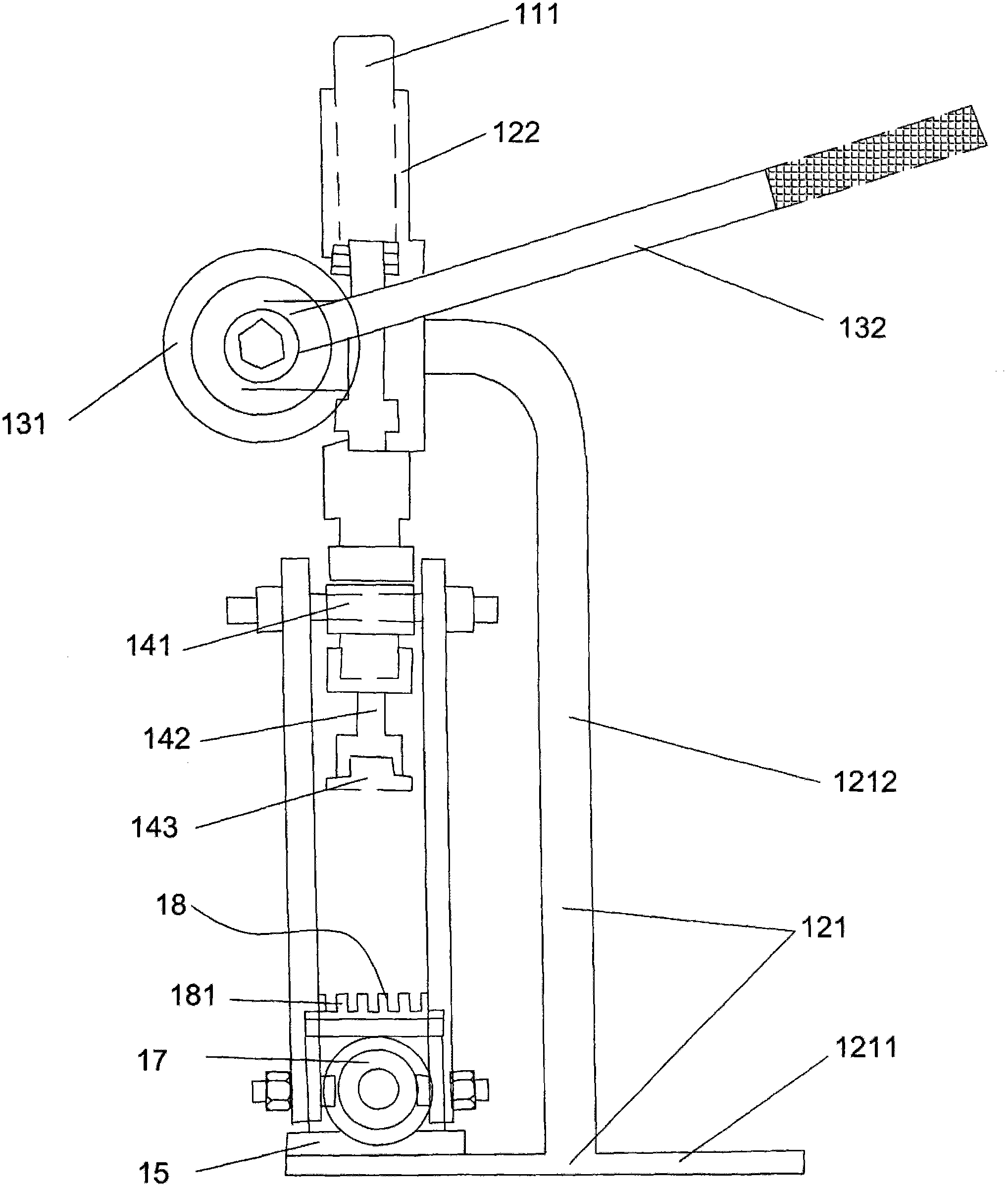

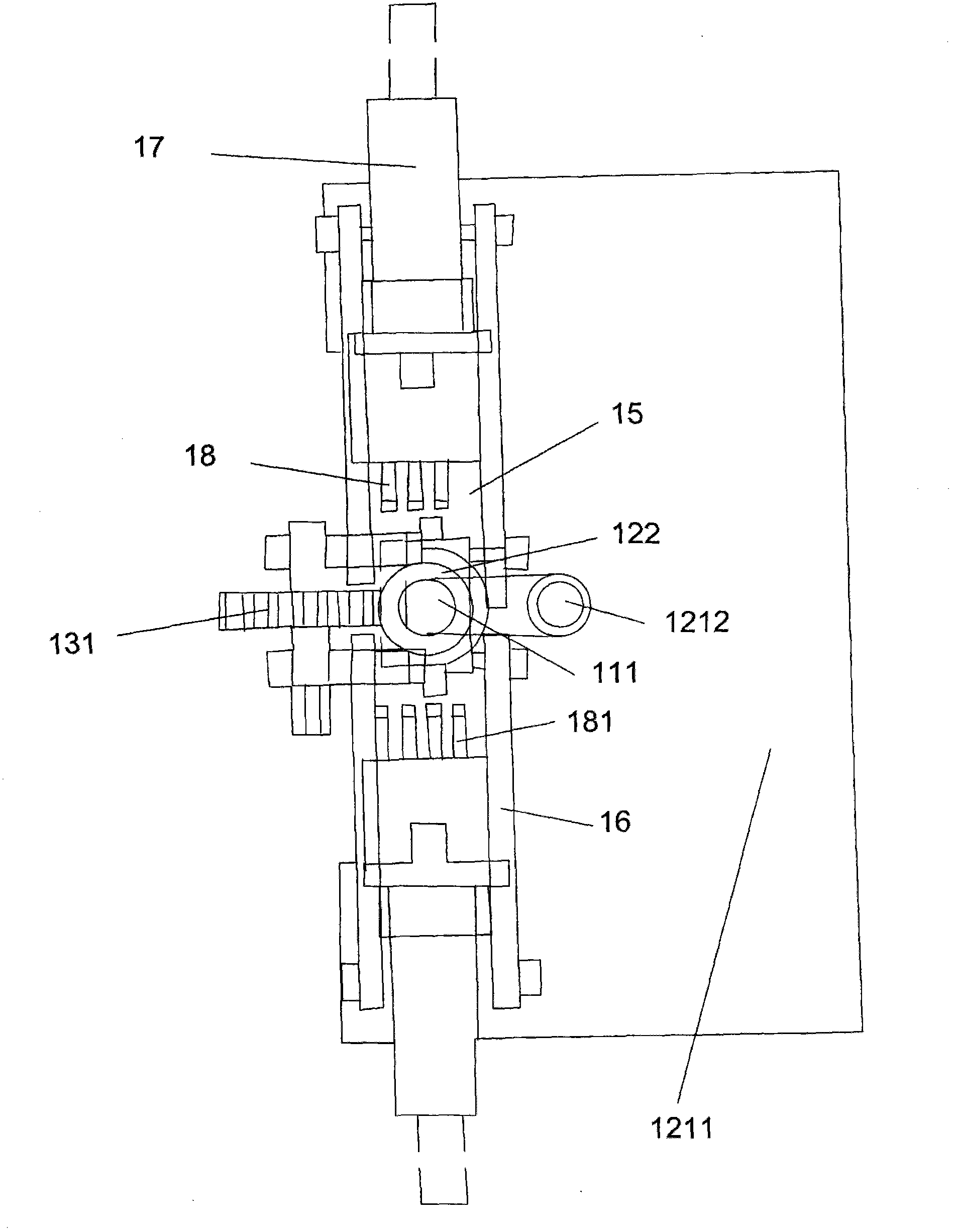

Device for breaking walnut shells and taking walnut kernels, having functions of self-positioning, pre-breaking shells, equidirectional spiral self-grading and flexible extrusion

ActiveCN106473167AReduce grading processPrecise pre-crackingHuskingHullingWalnut NutReciprocating motion

The invention discloses a device for breaking walnut shells and taking walnut kernels, having functions of self-positioning, pre-breaking shells, equidirectional spiral self-grading and flexible extrusion. The device comprises an intermittent feeding device, the a shell pre-breaking device, a flexible shell breaking device and a separating device, which are fixed on a machine frame, wherein the intermittent feeding device is used for performing intermittent batch feeding for the shell pre-breaking device; the shell pre-breaking device comprises an extruding part and a blanking part which are mutually matched; the extruding part is in reciprocating movement, and is matched with the blanking part for extruding walnuts, so that cracks are generated in the walnuts; the blanking part is in reciprocating movement, so that the extruded walnuts fall off to the flexible shell breaking device; the flexible shell breaking device is used for breaking walnut shells; and shells and kernels of the walnuts after shell breaking are separated for storage through the separating device. The device disclosed by the invention integrates a plurality of systems, and is compact in structure, the manufacturing cost of a machine is reduced, the occupied space for the operation of the machine is also reduced, and the miniaturization and the high efficiency of the machine are facilitated; in structure design, multiple connections including splicing, combining and the like for cooperating work can be realized; and the requirements of various production scales and the requirements of various production sites can be met, and the device is also suitable for families, and is widely applied.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +2

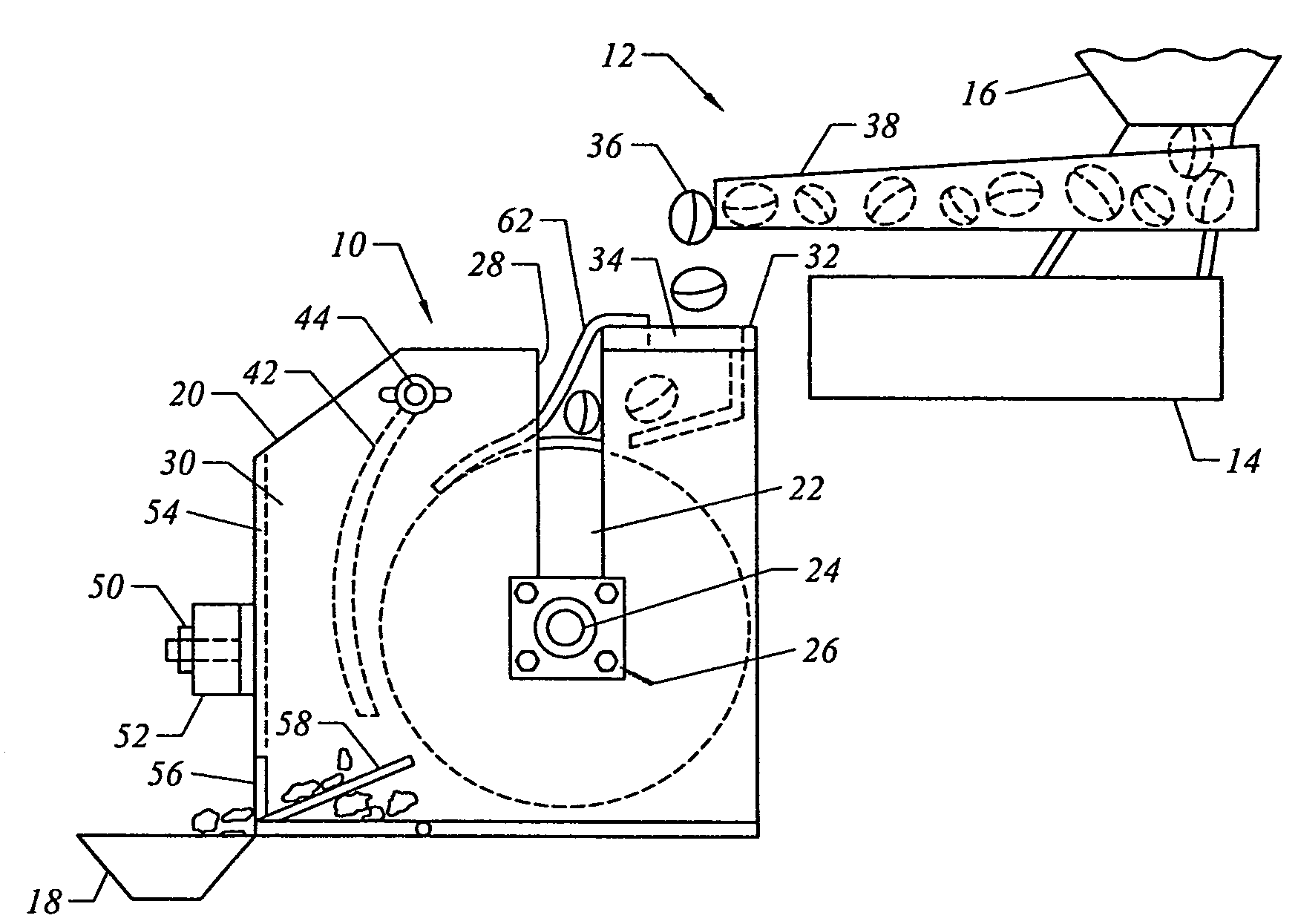

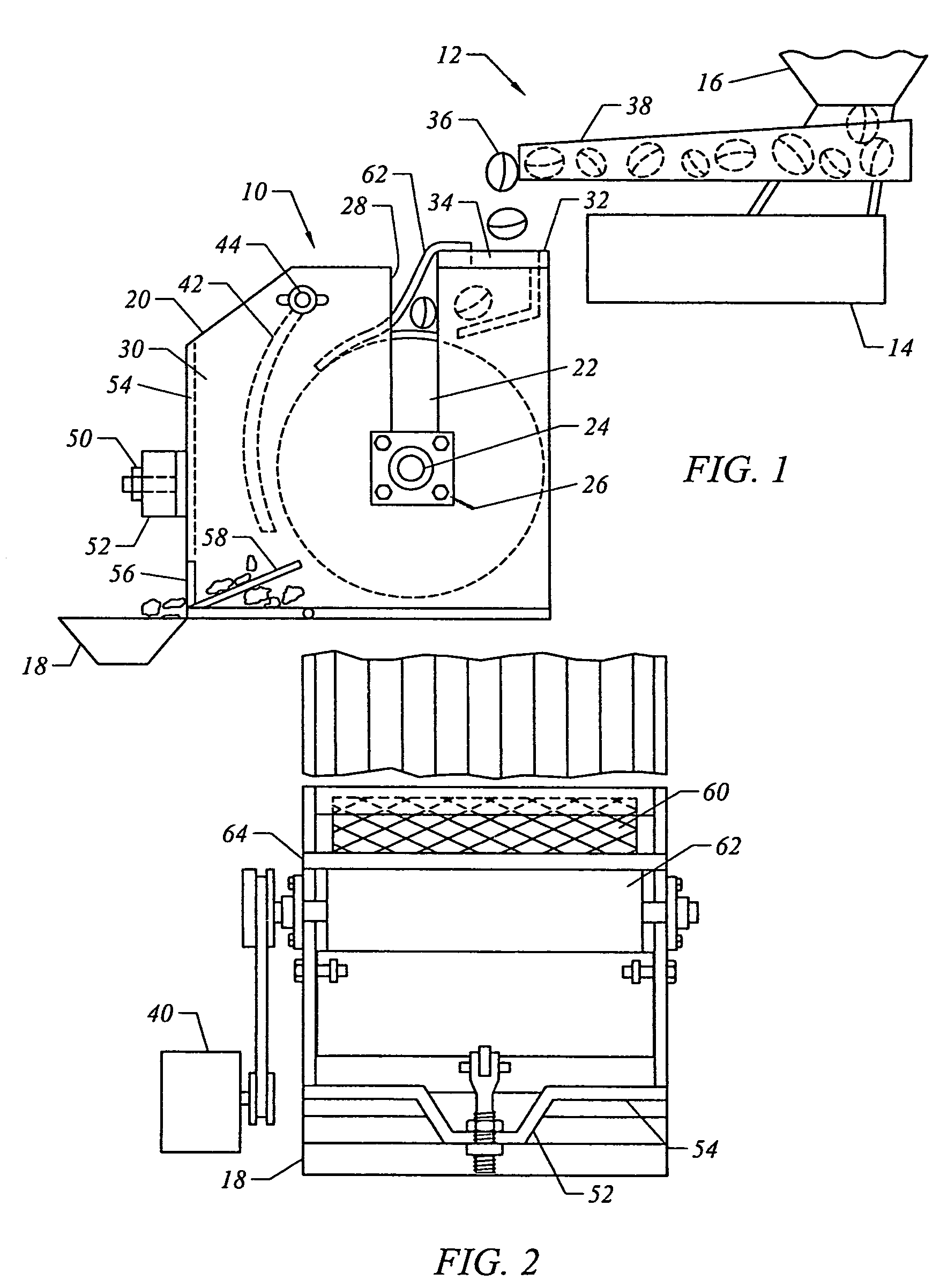

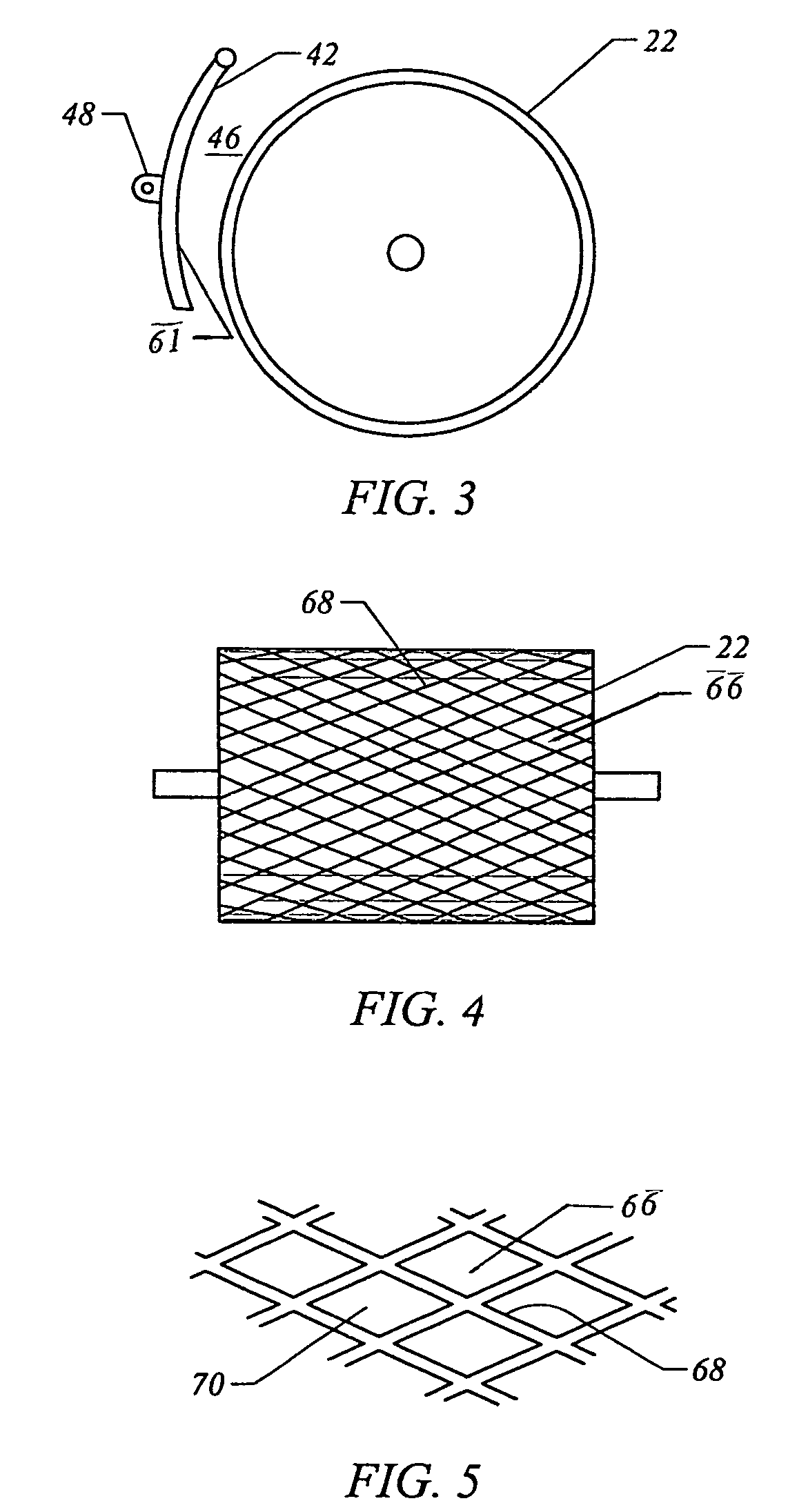

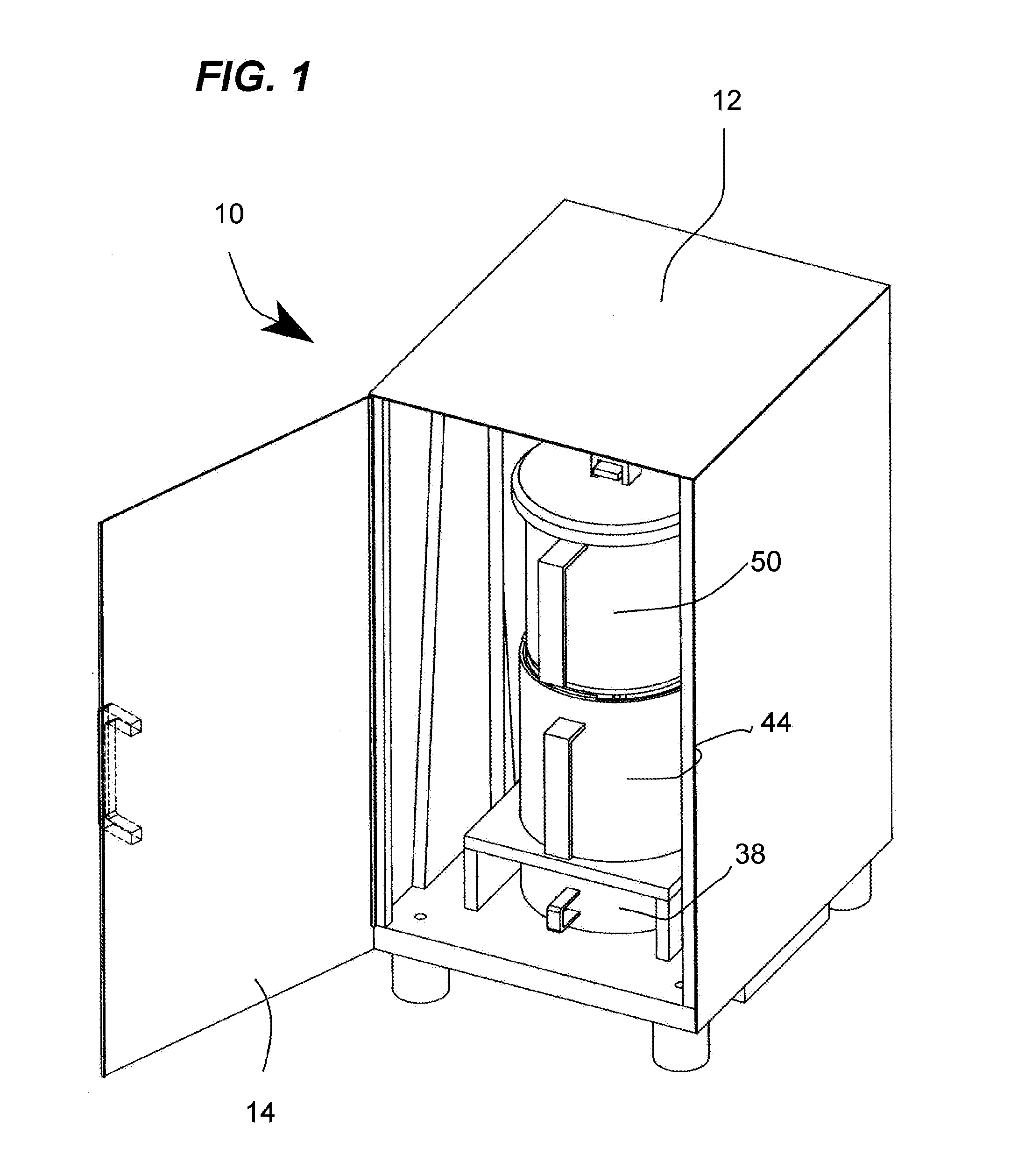

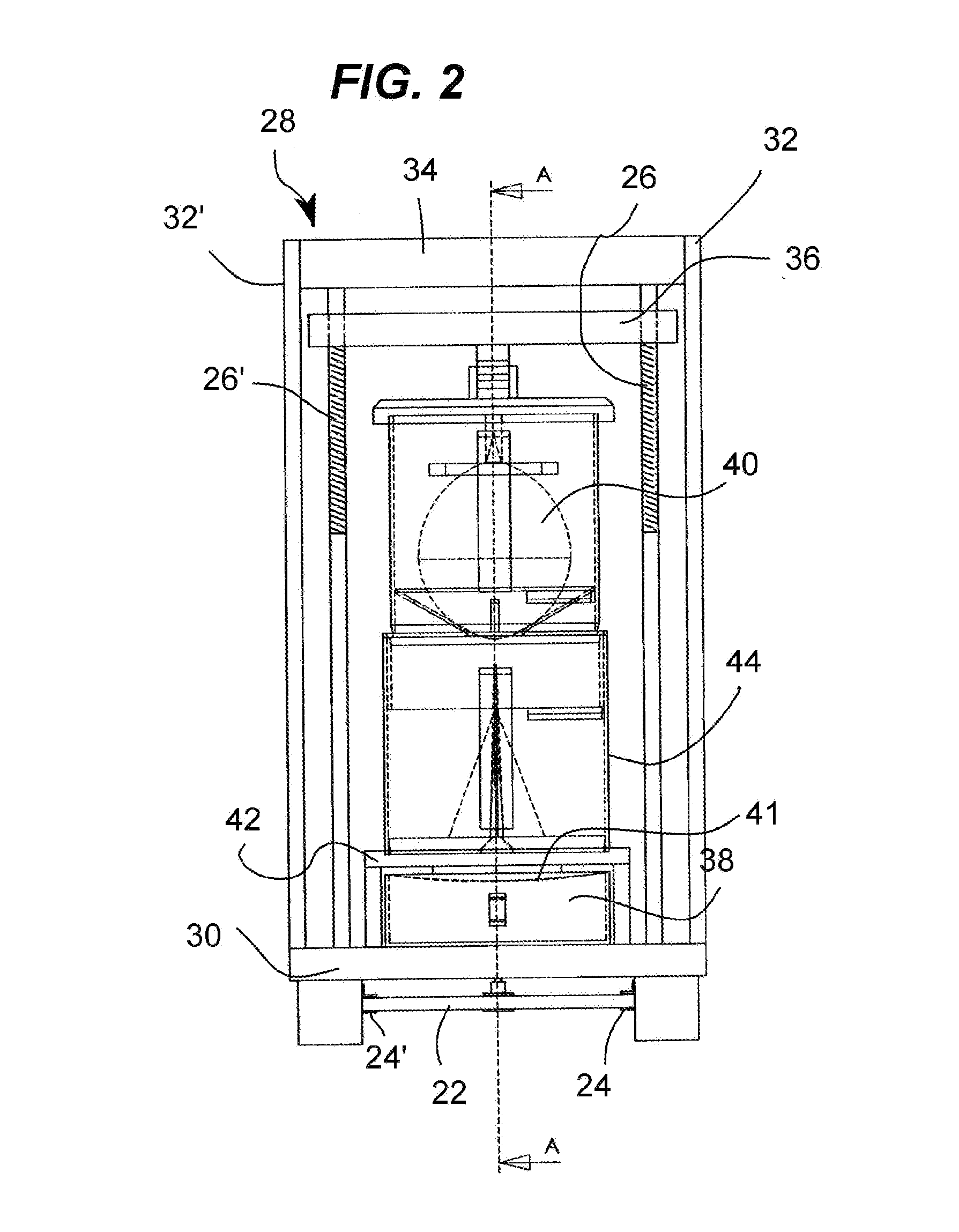

Nut cracking mechanism for variable-sized nuts

InactiveUS7717033B1Easily damagedAmenable to cracking under applied pressureKitchen equipmentHuskingPortion sizeMechanical engineering

A nut cracking mechanism for shelling variable-sized nuts having a brittle shell and fragile nut meat, the nut cracker mechanism having a housing with a horizontally positioned rotatable drum contained in the housing, and an adjustable, substantially vertical compression plate mounted in the housing with a cracking surface displaced from a cylindrical slip resistant cracking surface of the drum to form a narrowing gap between the drum and the compression plate, the gap having an upper portion sized to accommodate nuts of varying sizes and a lower portion sized to compress nuts between the cylindrical surface of the drum and the compression plate until the nut cracks and releases its meat, the mechanism having associated components to feed nuts to the top of the mechanism and receive shells and meat from the bottom of the mechanism.

Owner:KIM SUN Y

Walnut kernel peeling method

The present invention relates to a method for removing walnut kernel seed cover under the condition of normal temperature after the walnut kernel is frozen at low-temperature. It is characterized by that for dried walnut kernel the walnut kernel is soaked in the water with 0-10deg.C, after the walnut kernel is reconstituted, the walnut kernel is frozen; for fresh walnut kernel whose water content is greater than or equal to 45% it has no need of reconstitution, can be directly frozen; its freeze temperature is -5 - -25deg.C; after a lyer of ice cover is formed on the walnut kernel surface, the walnut kernel can be taken out and can be placed at normal temperature or into water with 30-60deg.C to melt the ice cover, then a manual method or mechanical method can be adopted to strip seed cover of walnut kernel. Its technological process includes the following steps: reconstitution, freezing, melting, stripping seed cover so as to obtain finished product.

Owner:SHANDONG INST OF POMOLOGY

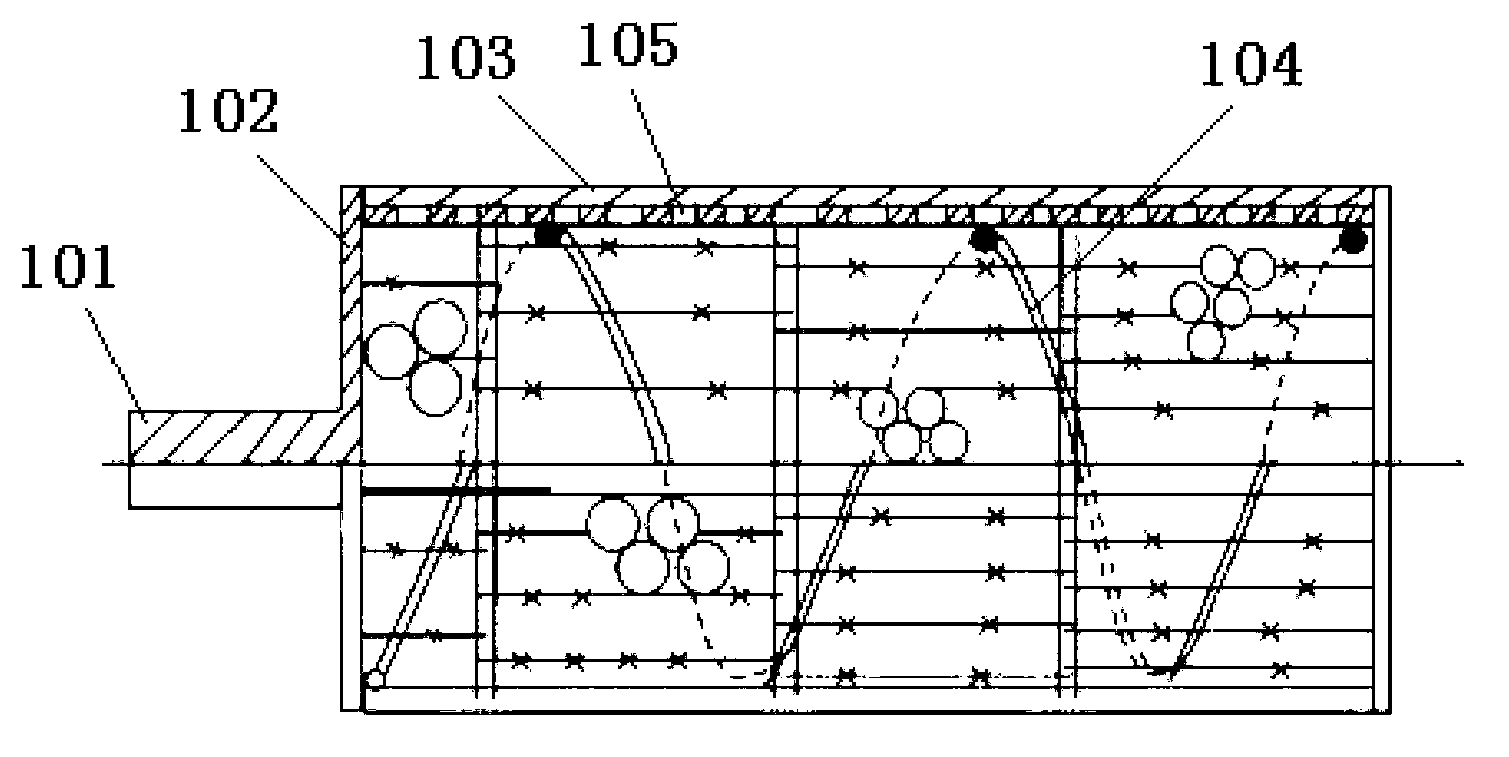

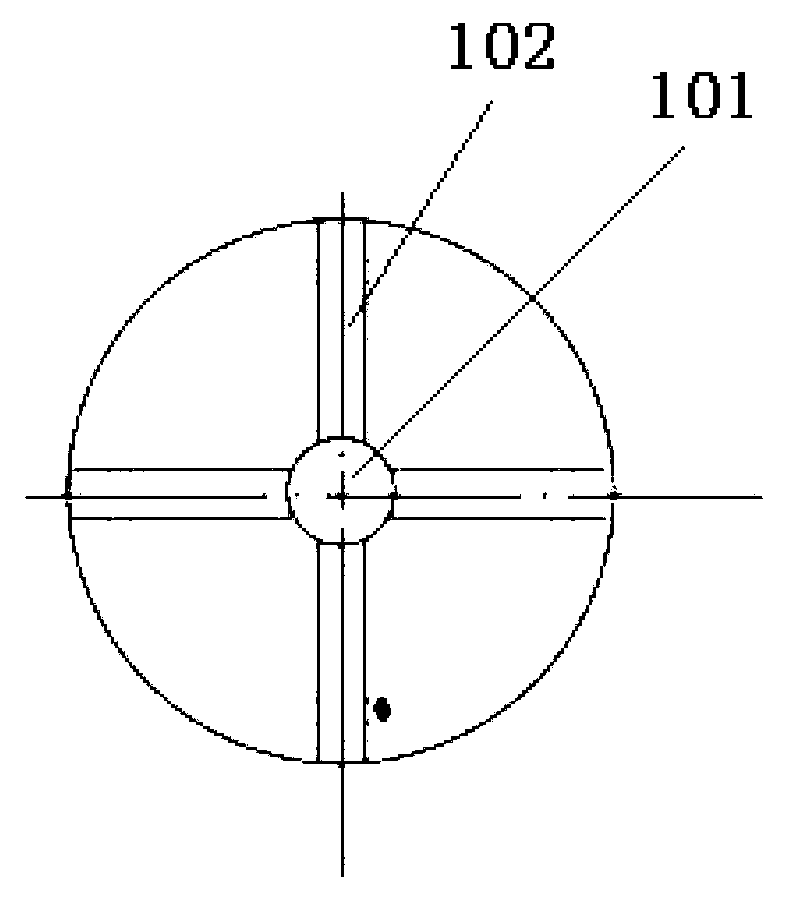

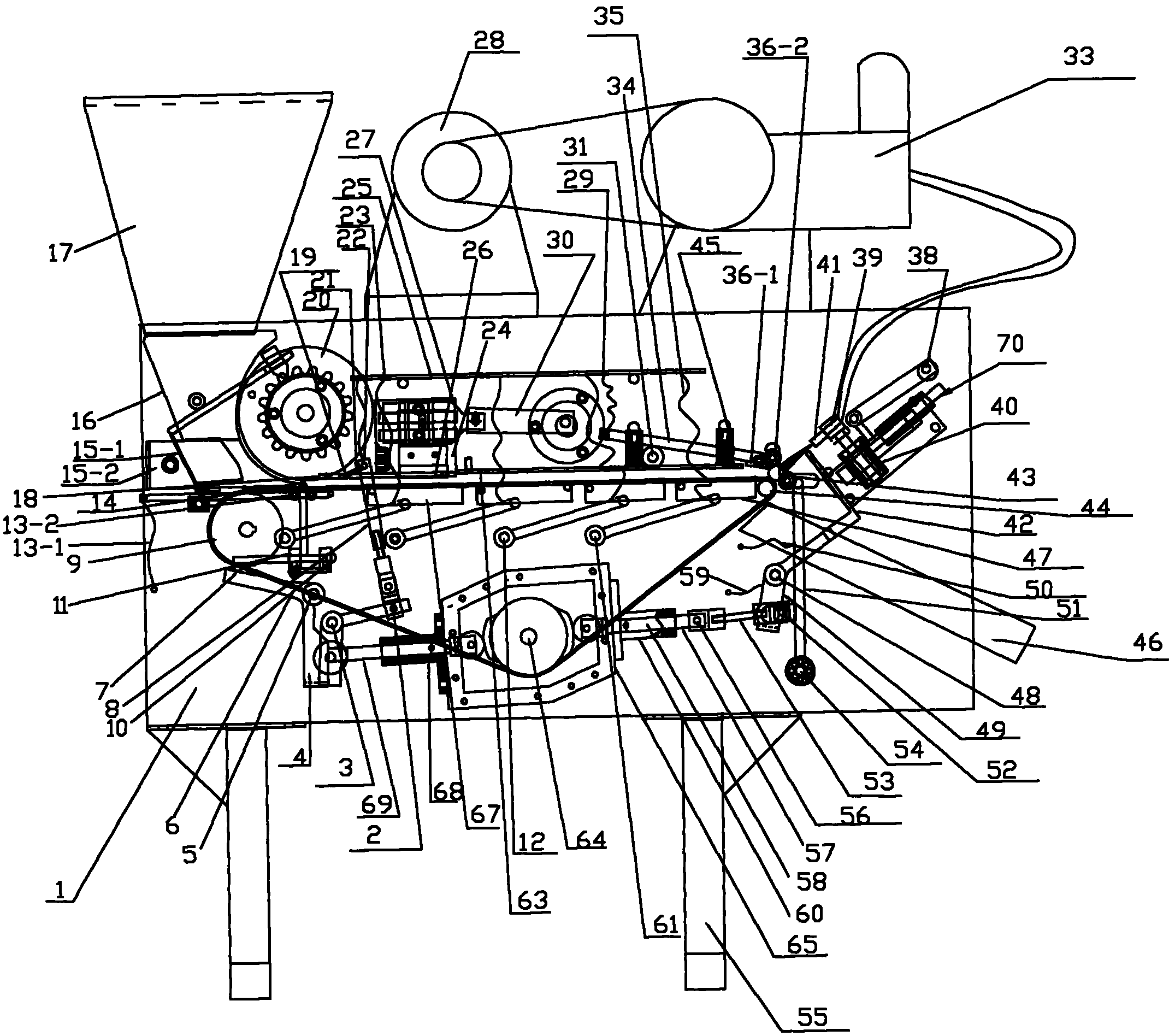

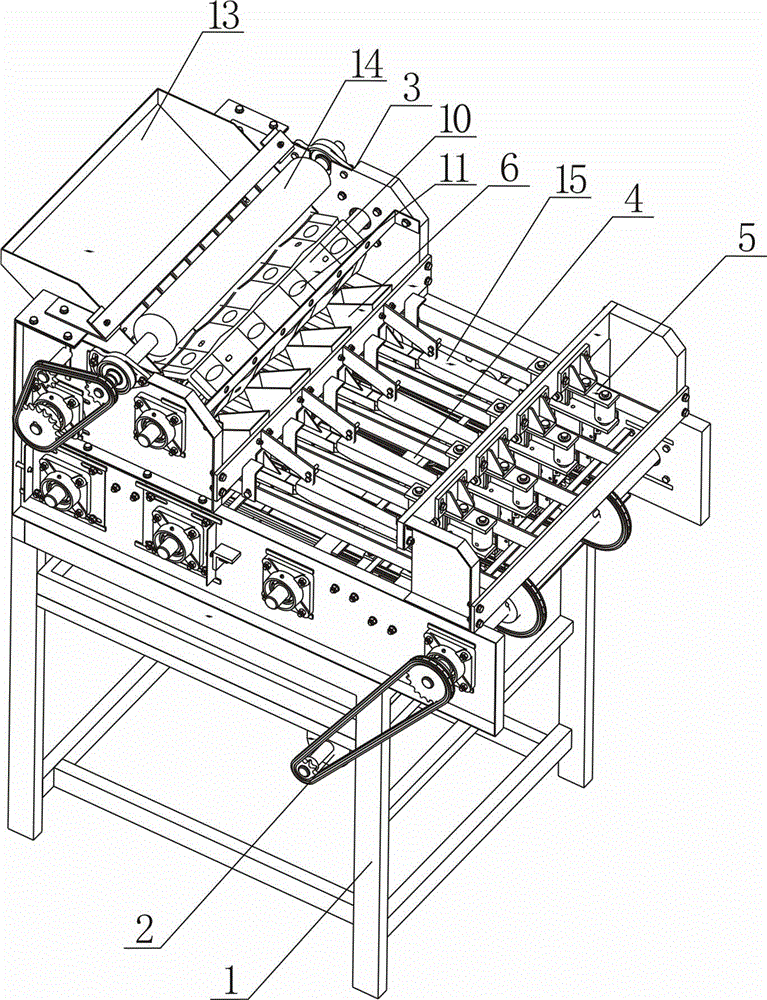

Husking and peeling integrated machine for lotus seeds

ActiveCN102349688ACompact structureSolve the trouble of producing white lotusHuskingHullingDrivetrainEngineering

The invention discloses a husking and peeling integrated machine for lotus seeds, relating to the field of peeling of crops. The husking and peeling integrated machine comprises a foot rest (55), a machine body (1), a conveyor belt (6), a secondary hopper (16), a high-pressure water pump (33), a power device and a power driving system and mainly comprises a lotus seed positioning device, a spacing device, a husk sawing device, a husking device, a peeling device and a conveying device; the lotus seed positioning device and the peeling device are respectively arranged at two ends of the conveying device; the spacing device, the husk sawing device and the husking device are sequentially arranged above the operation surface of the conveyor belt in the conveying device in parallel; a conveyingguide rail is correspondingly arranged above the conveyor belt (6) among the spacing device, the husk sawing device and the husking device; and the lotus seeds are positioned by the positioning device and are respectively rolled and conveyed to the spacing device, the husk sawing device and the husking device and then enter the husking device. According to the husking and peeling integrated machine, the lotus seeds can be quickly husked and peeled one by one.

Owner:广昌县兴莲机械制造有限公司

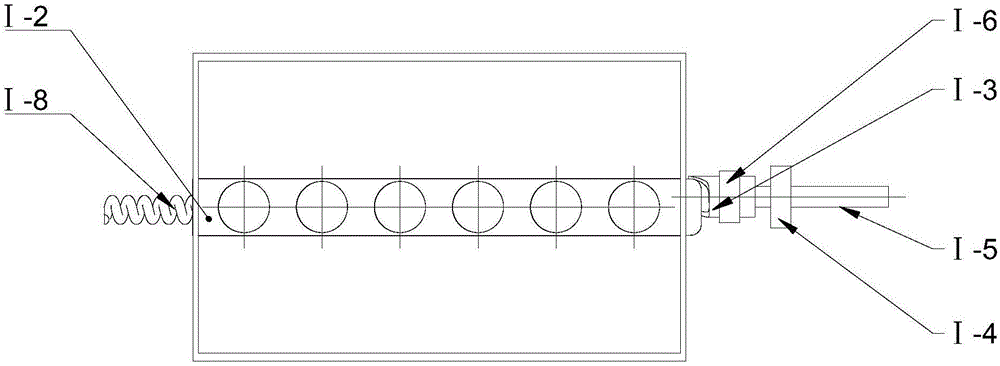

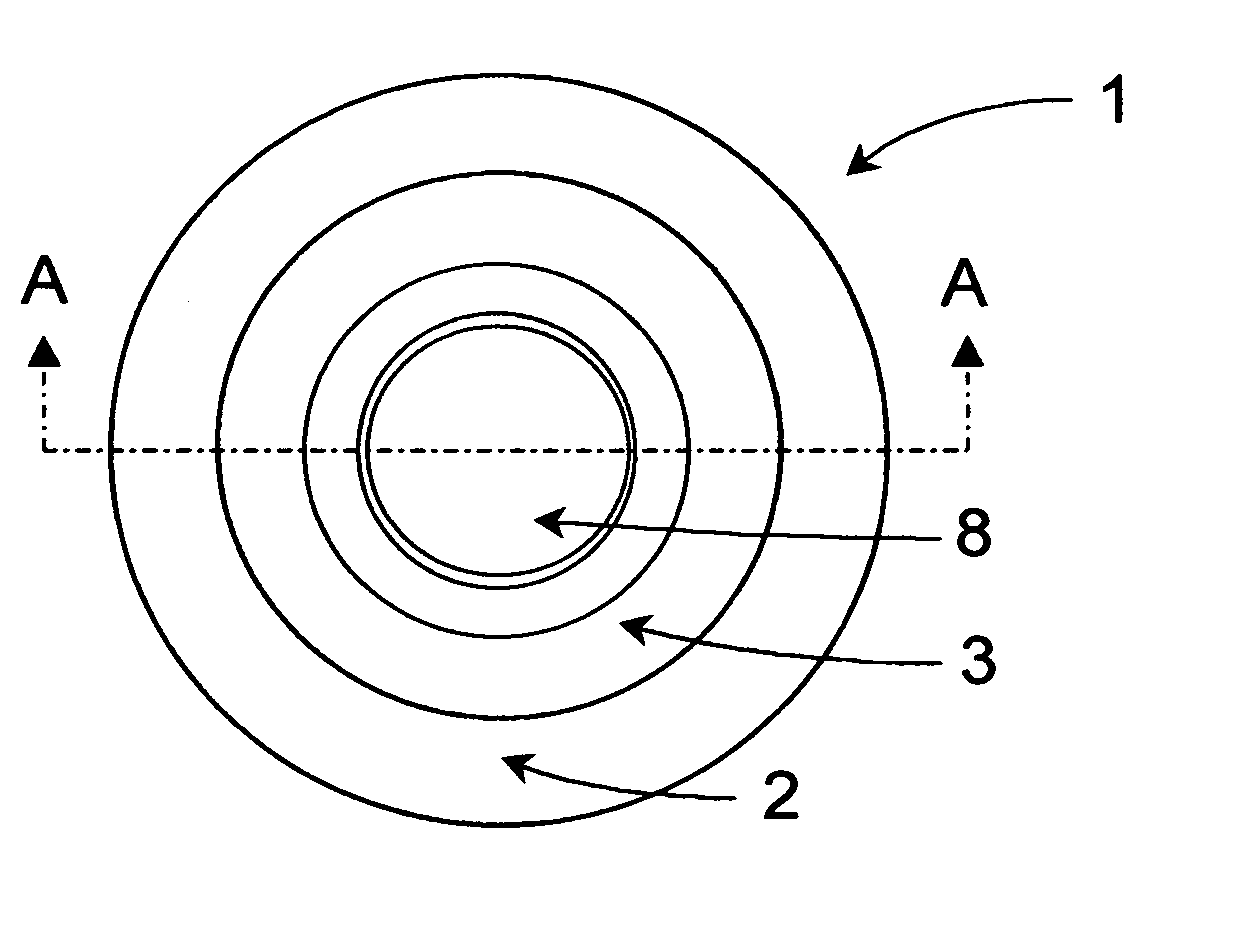

Continuous rolling tube high-pressure water spraying walnut kernel peeling device

InactiveCN102763887ASave resourcesImprove peeling efficiencyHuskingHullingWater resourcesHigh pressure water

The invention relates to a continuous rolling tube high-pressure water spraying walnut kernel peeling device, which comprises a material inlet hopper, a rolling tube, a high-pressure water pipe, a material outlet hopper, a motor, a water collecting hopper and a water collecting tank, wherein a spiral scraping plate is arranged in the rolling tube, walnut kernels are pushed from a material inlet to a material outlet, the high-pressure water pipe is arranged in the axial direction of the rolling tube and is positioned above the axial direction, a plurality of high-pressure water spray openings are symmetrically arranged under the water pipe, and the rolling tube is driven by a motive power system. The water collecting bank is positioned under the rolling tube, a filter net is arranged on the water collecting tank, the walnut kernel flushing and spraying is completed through high-pressure water, the water enters the water collecting tank through the water collecting hopper and the filter screen, the water in the water collecting tank enters the high-pressure water pipe arranged in the rolling tube after the pressure boosting via a centrifugal pump, and the water consumption circulation is formed. The continuous walnut kernel peeling can be realized, the peeling efficiency is high, the daily yield is high, the peeling is thorough and uniform, in addition, the peeling, the separation and the cleaning are combined, the production steps are saved, meanwhile, the circulation water is adopted, the water resource saving is realized, and the device is suitable for industrial mass walnut kernel peeling production.

Owner:食品行业生产力促进中心

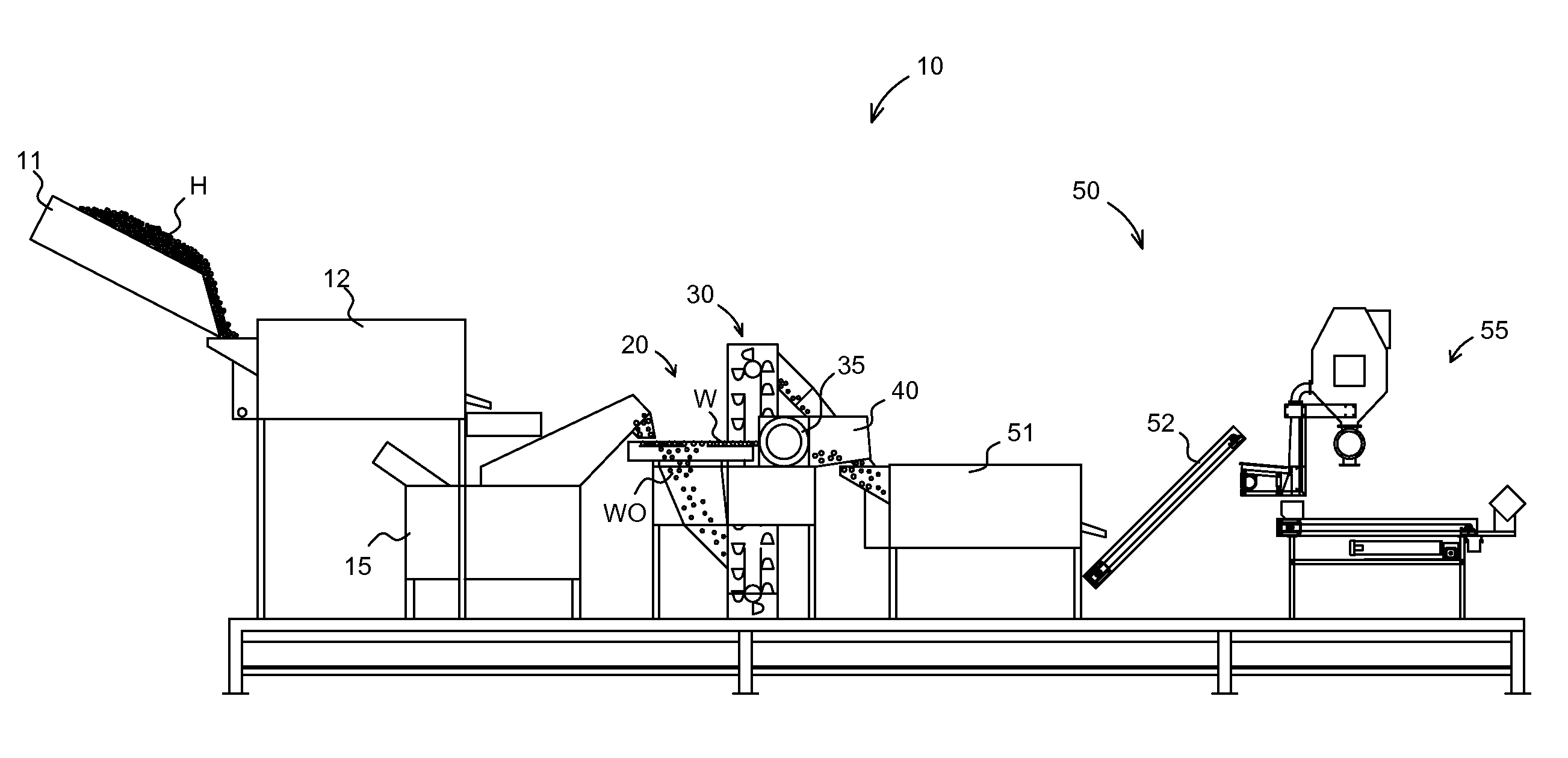

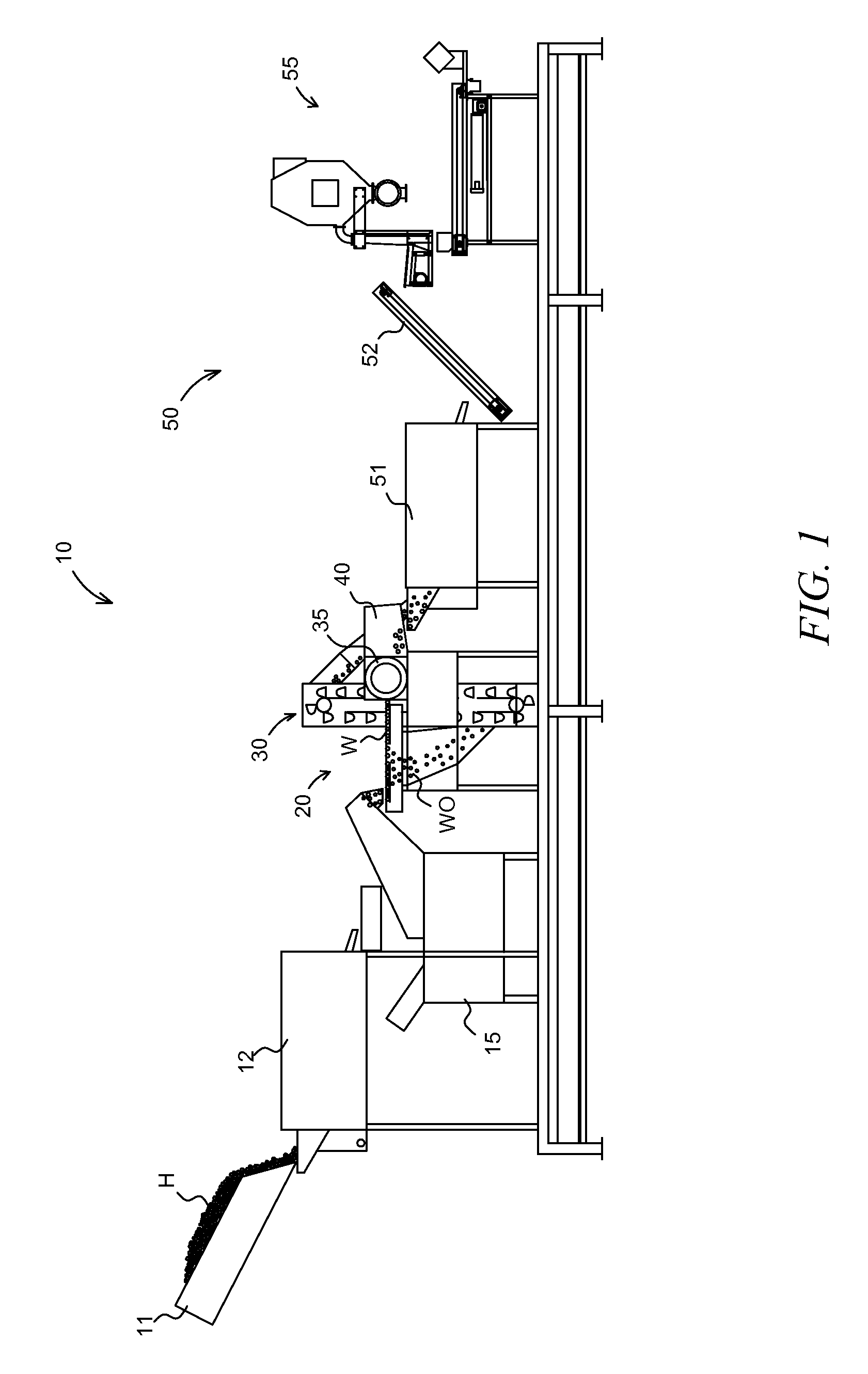

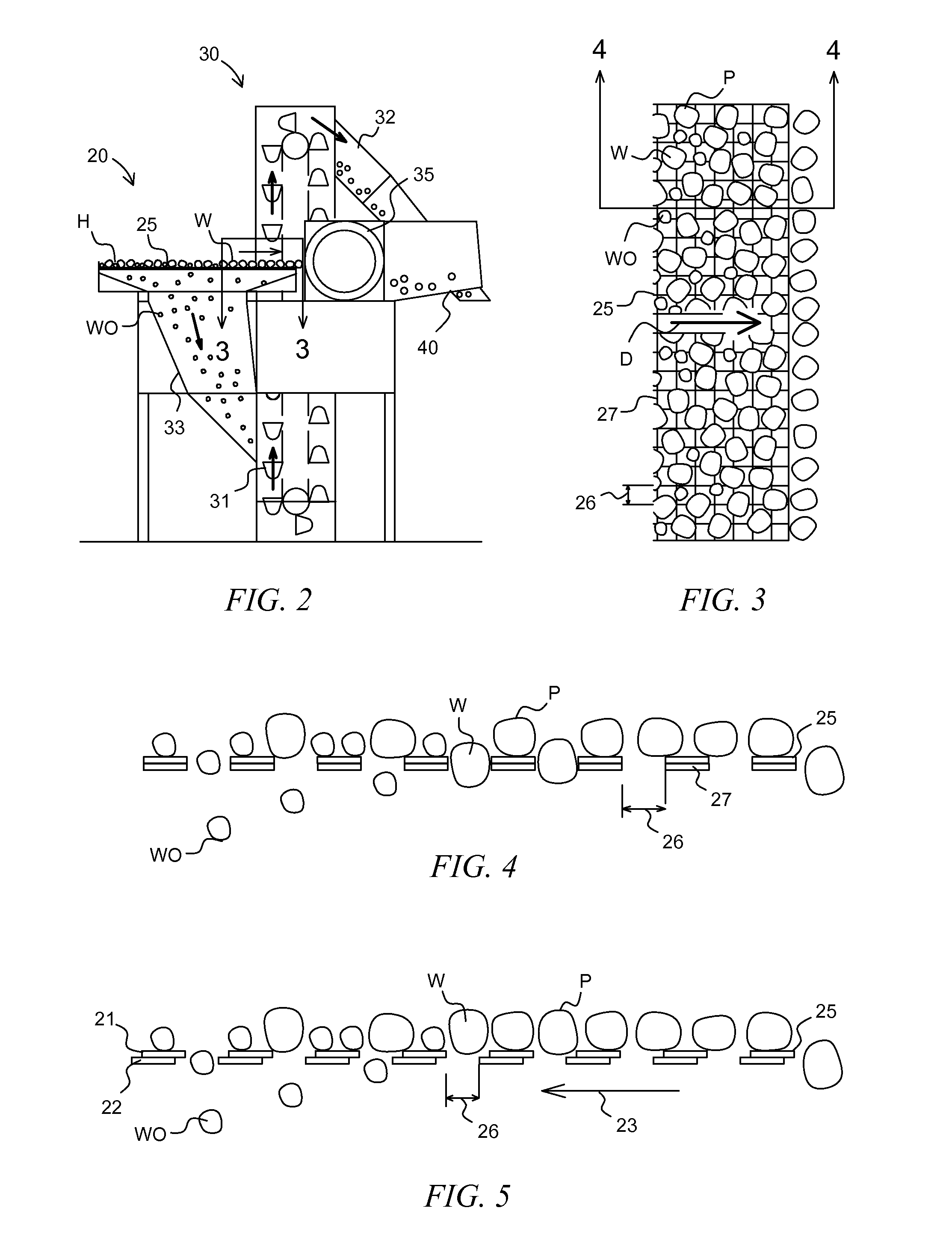

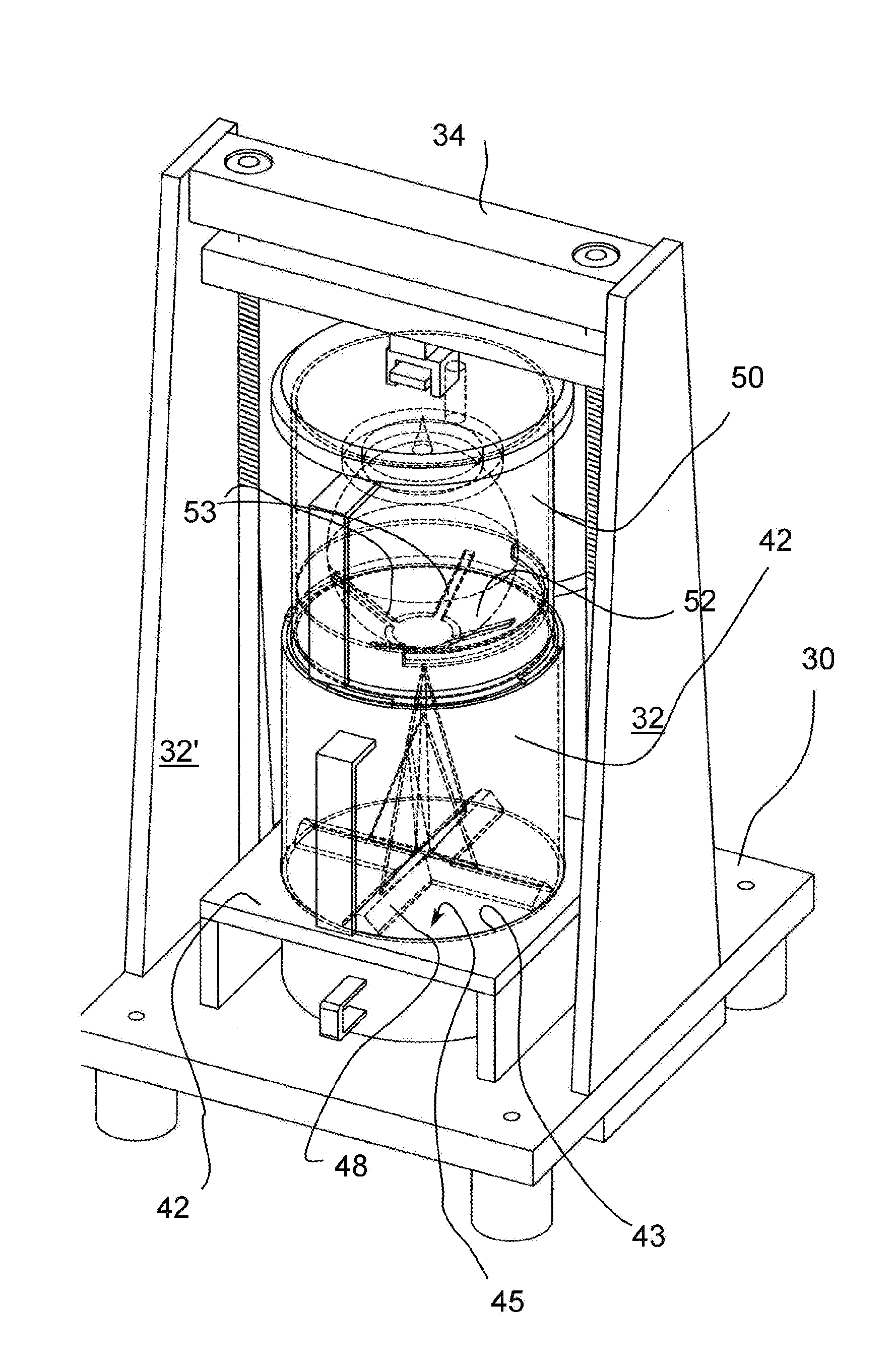

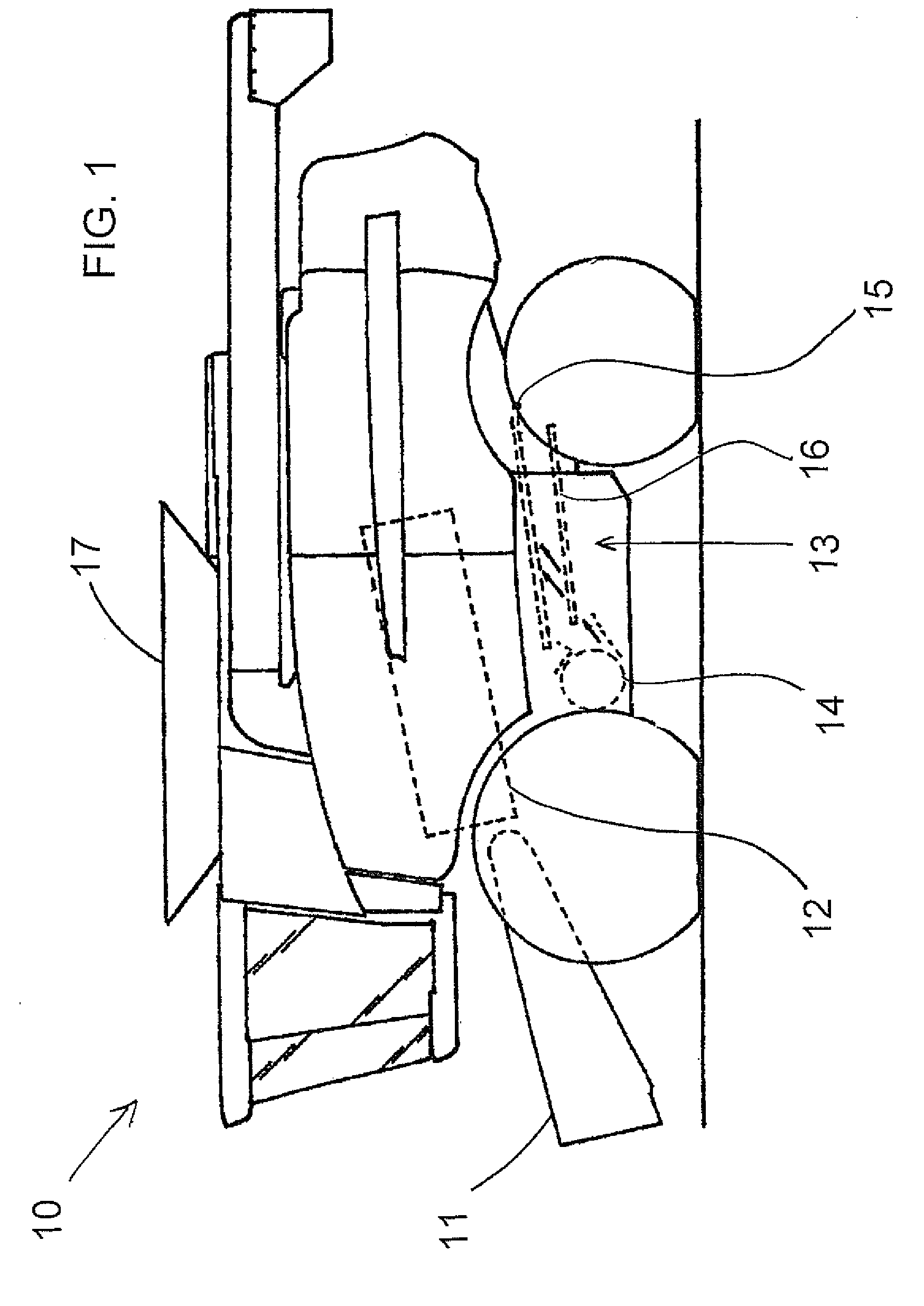

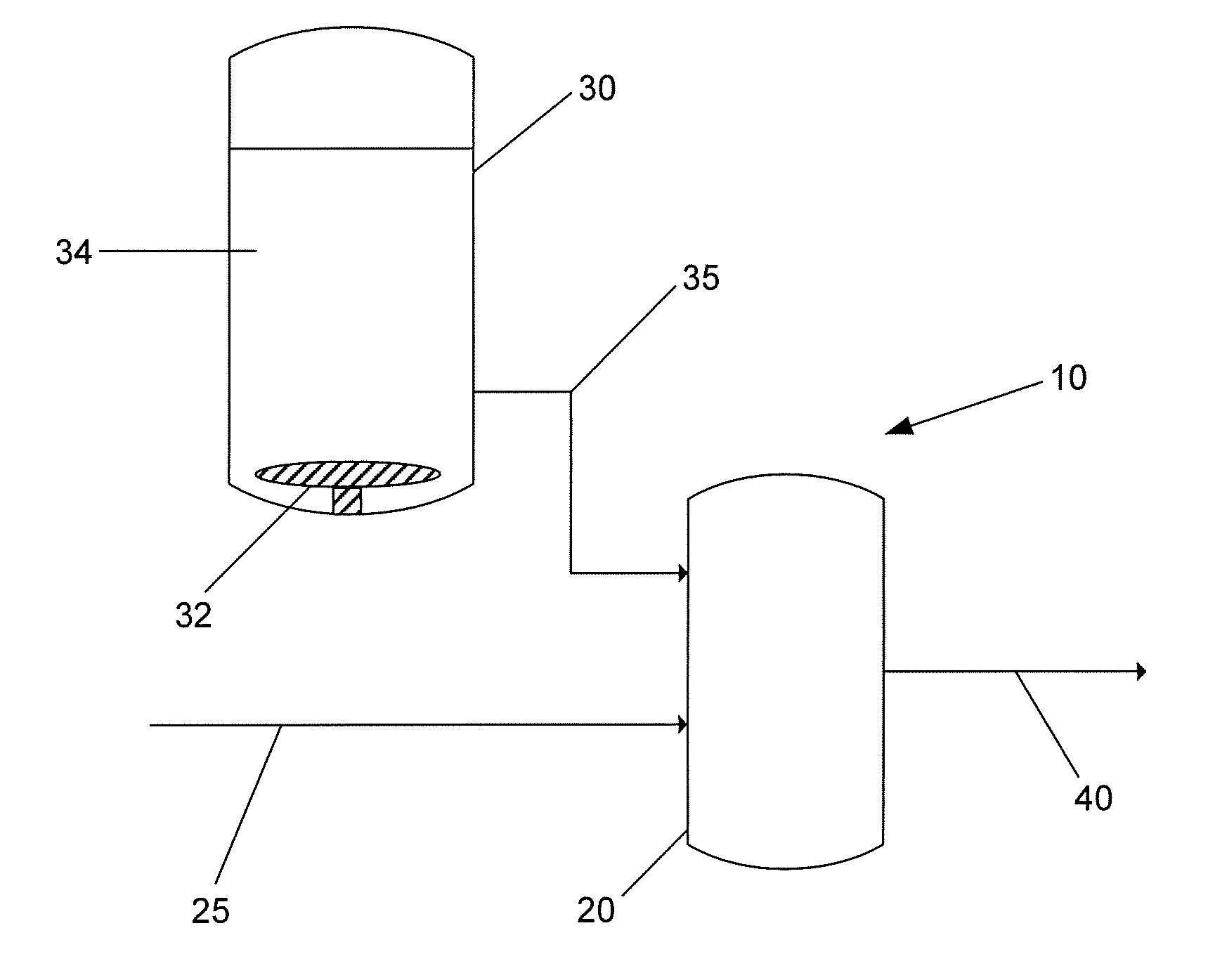

System, device and method for processing harvested walnuts

A system and method for processing harvested walnuts that includes a walnut separator for separating walnuts without hulls from walnuts with hulls prior to a hulling process in order to increase productivity of the huller. A huller by-pass system conveys walnuts without hulls to a post-hulling processing. A walnut separator may include a screen having a selected screen size that permit walnuts without hulls to pass through the screen and prohibit walnuts with hulls and therefore a larger diameter, to pass through the screen. Alternately the walnut separator may include an optical sensor positioned to scan harvested walnuts. A controller connected to the optical sensor processes input from the optical sensor and selectively actuates a walnut selection or ejection device causing a walnut to by-pass a process.

Owner:WIZARD MFG

Coconut Splitting Device

InactiveUS20090139094A1Easy to useQuick fixKitchen equipmentHuskingMechanical engineeringEngineering

Owner:BELOIN PIERRE

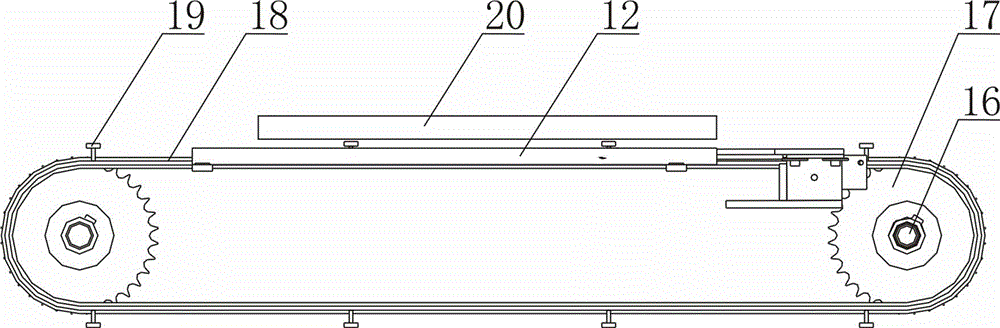

Pneumatic walnut hull breaking machine

The invention provides a pneumatic walnut hull breaking machine and belongs to the field of forest fruits. The pneumatic walnut hull breaking machine consists of a machine frame, a transmission control device, a feeding mechanism and a hull breaking device. The hull breaking device is installed on the machine frame and consists of impact cylinders and holding cylinders which are installed among partition plates of a working rack in a connecting mode. The transmission control device is installed under the front portion of the machine frame and consists of an electric motor, a poking wheel, a control cam, a driving chain wheel, a grooved wheel, side-by-side front end chain wheels, a driven chain wheel, side-by-side back end chain wheels, a clamping switch, a holding switch and a strike switch, wherein the poking wheel, the control cam and the electric motor are sleeved coaxially, the driving chain wheel and the grooved wheel are sleeved on a lower shaft, the side-by-side front end chain wheels and the driven chain wheel are sleeved on an upper shaft, the side-by-side back end chain wheels are installed at the back portion of the machine frame, and the clamping switch, the holding switch and the strike switch are installed at the lower portion of the machine frame at intervals. The driving wheel, the driven wheel, the front end chain wheels and the back end chain wheels are respectively linked through chains, a material box is installed at the back portion of the working rack, a slot is arranged on one wall of the box, and the feeding mechanism is arranged under the position tightly close to the slot and consists of the side-by-side chains, rotary rollers installed on the chains at intervals in a connecting mode, rolling plate supporting the rotary rollers and tensioning chain wheels. The pneumatic walnut hull breaking machine is strong in adaptability on walnut types, complete in walnut hull separation, few in broken walnut nuts and high in hull breaking efficiency.

Owner:XINJIANG AGRI UNIV

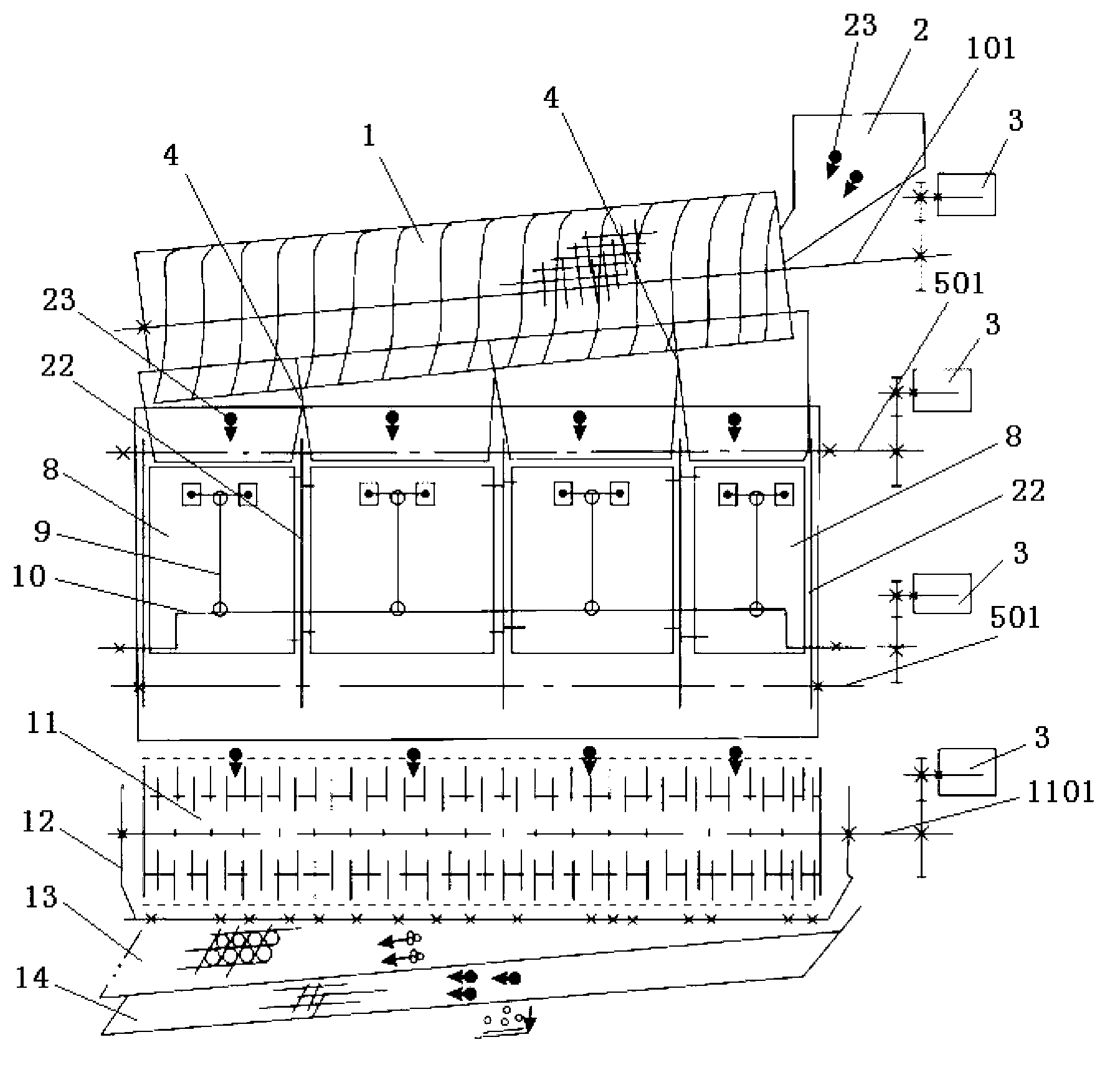

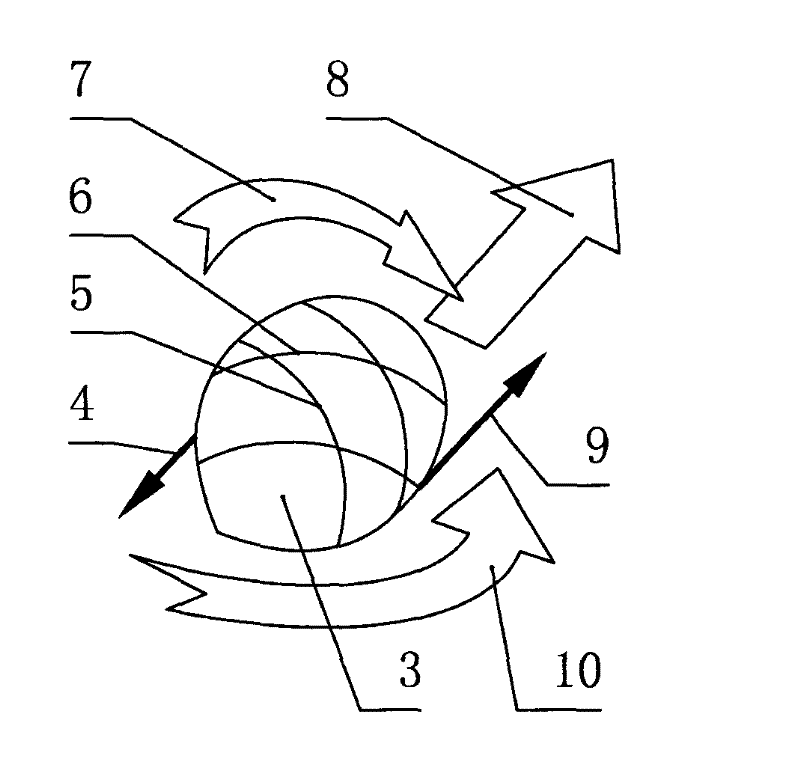

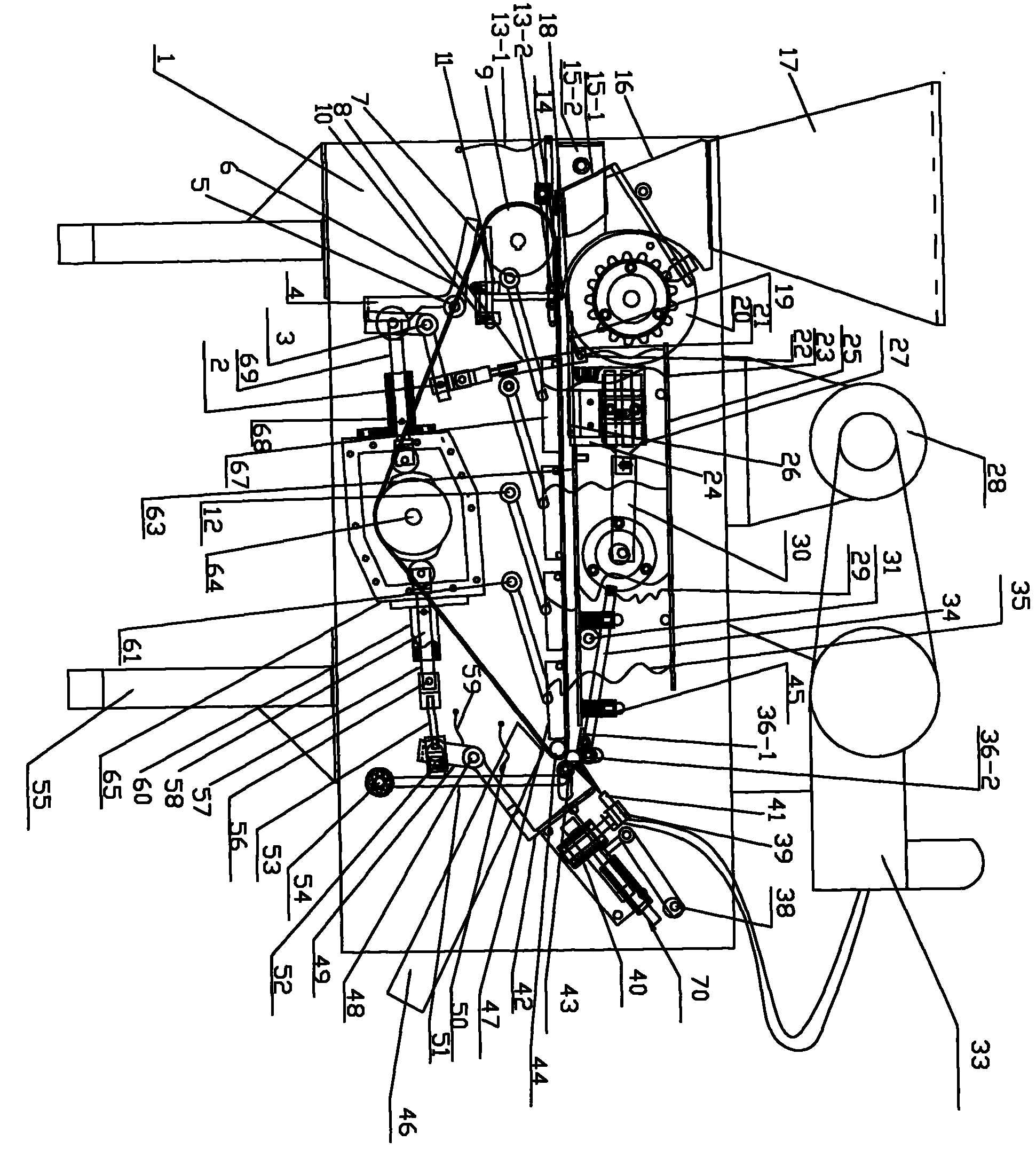

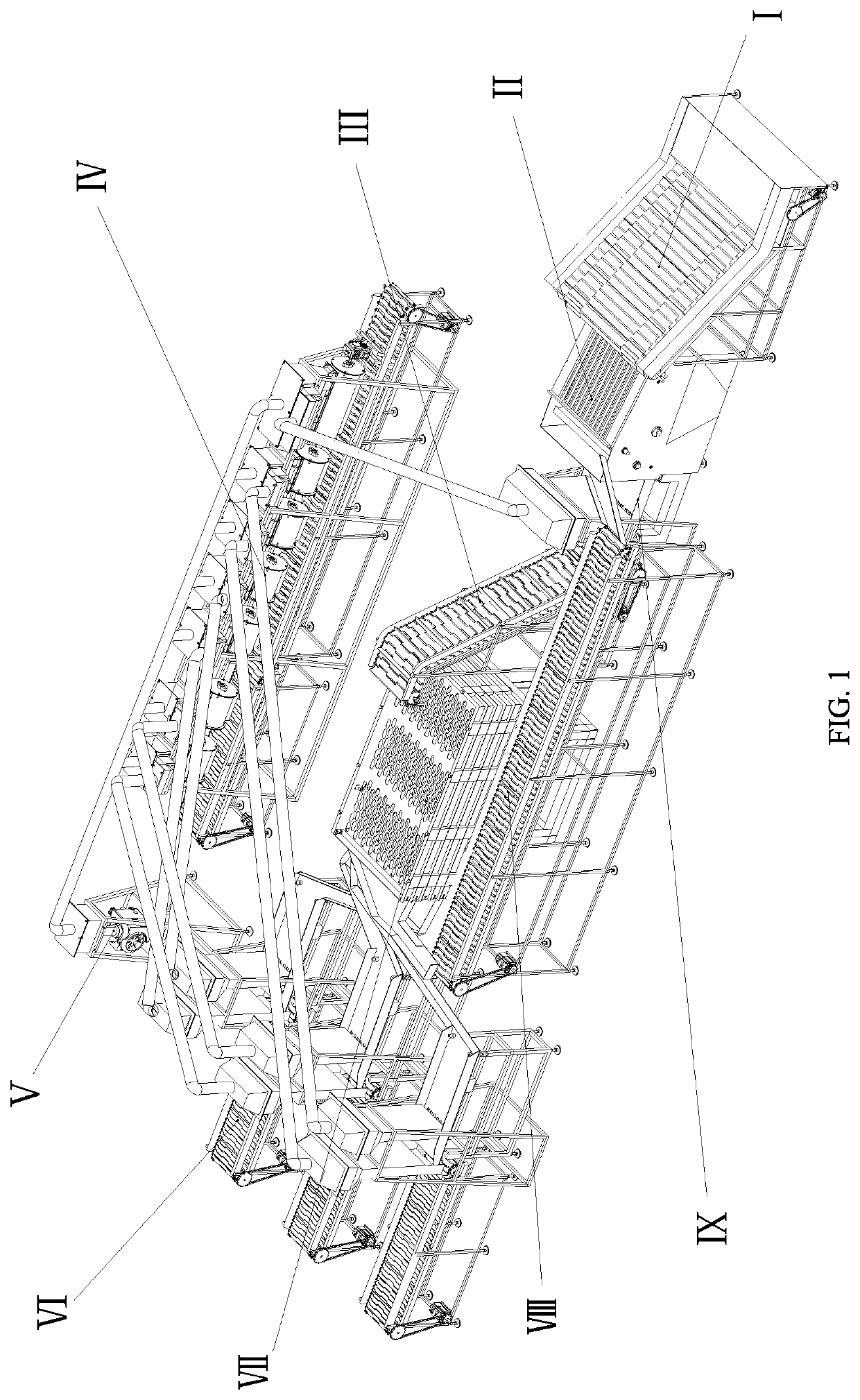

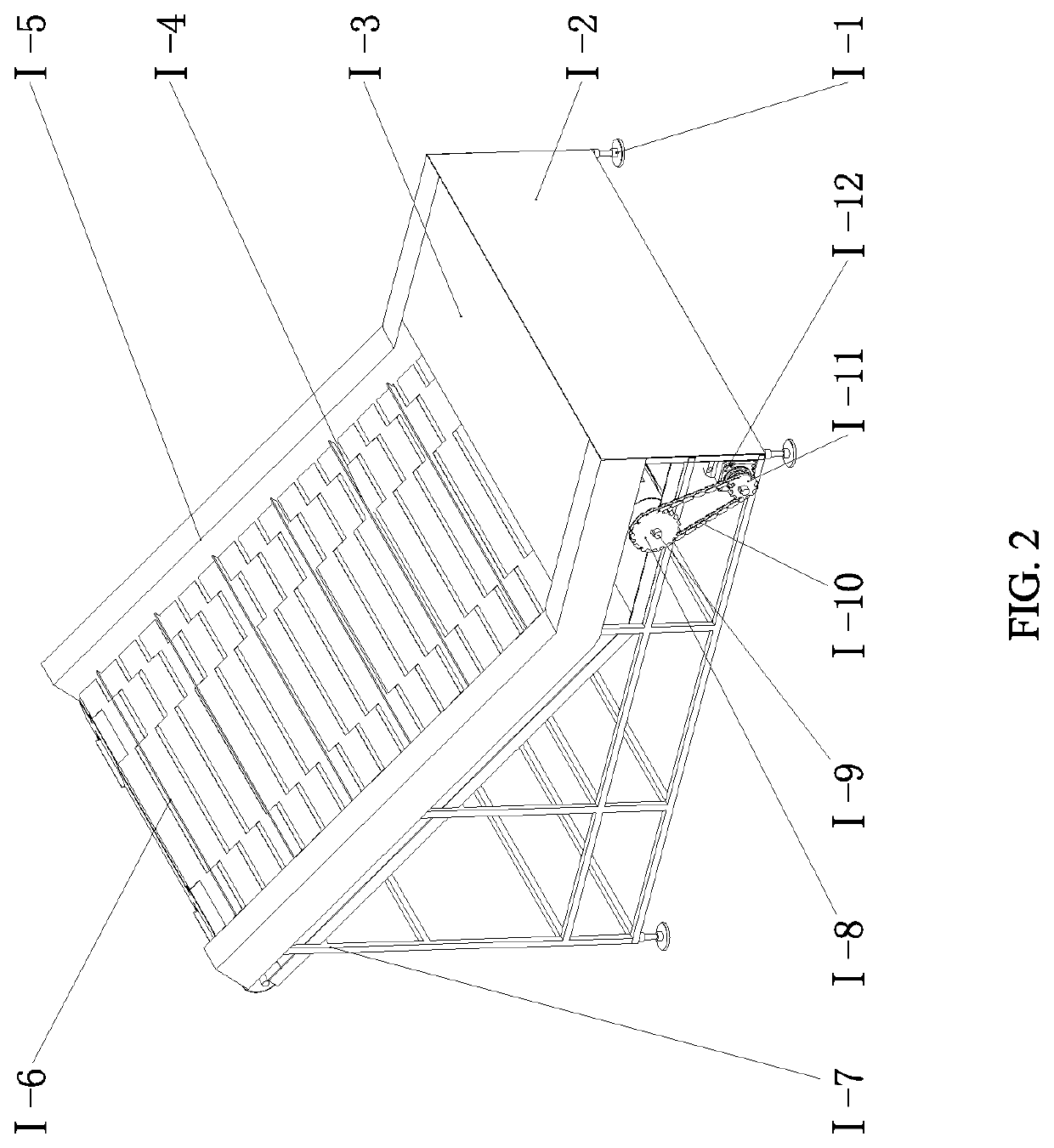

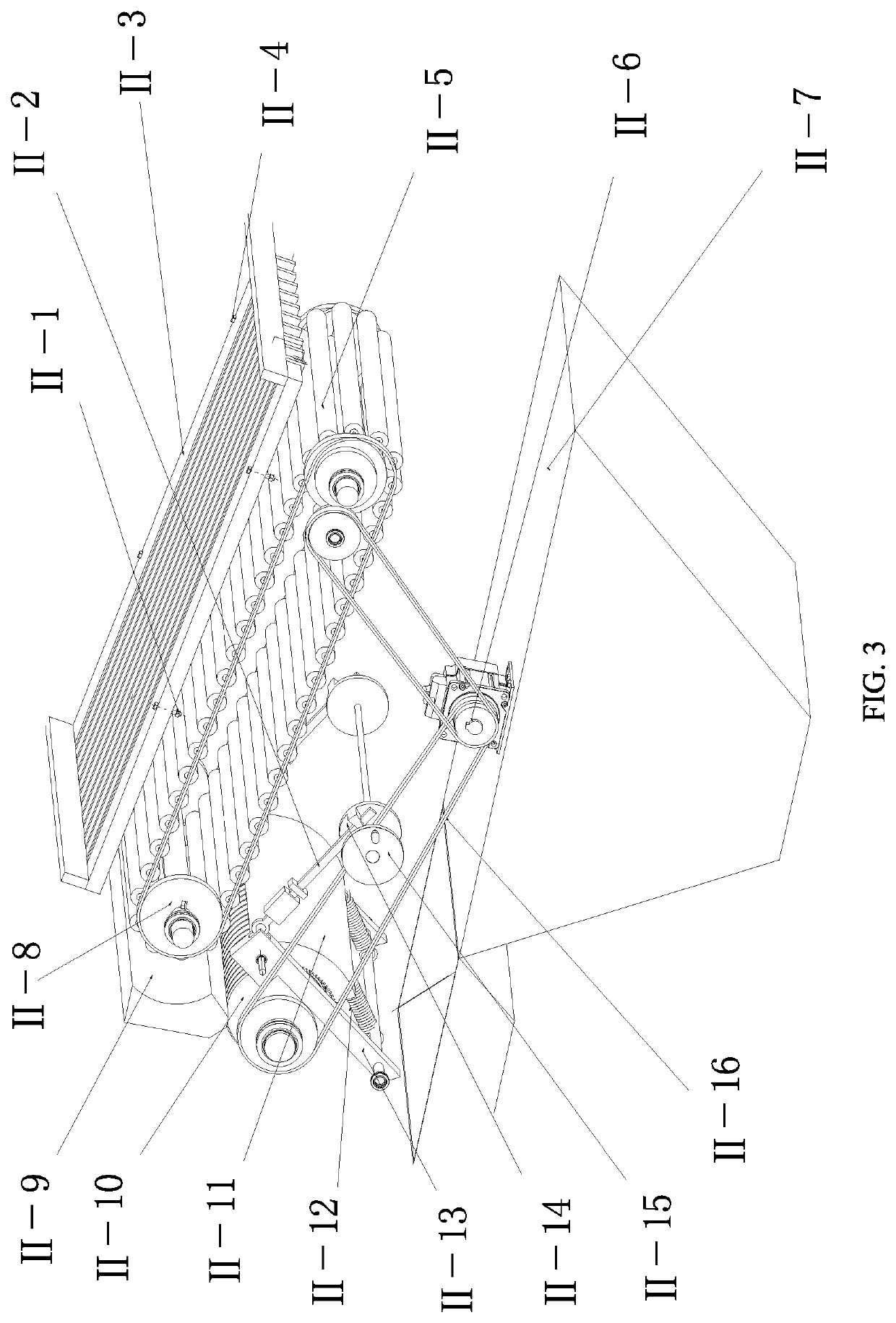

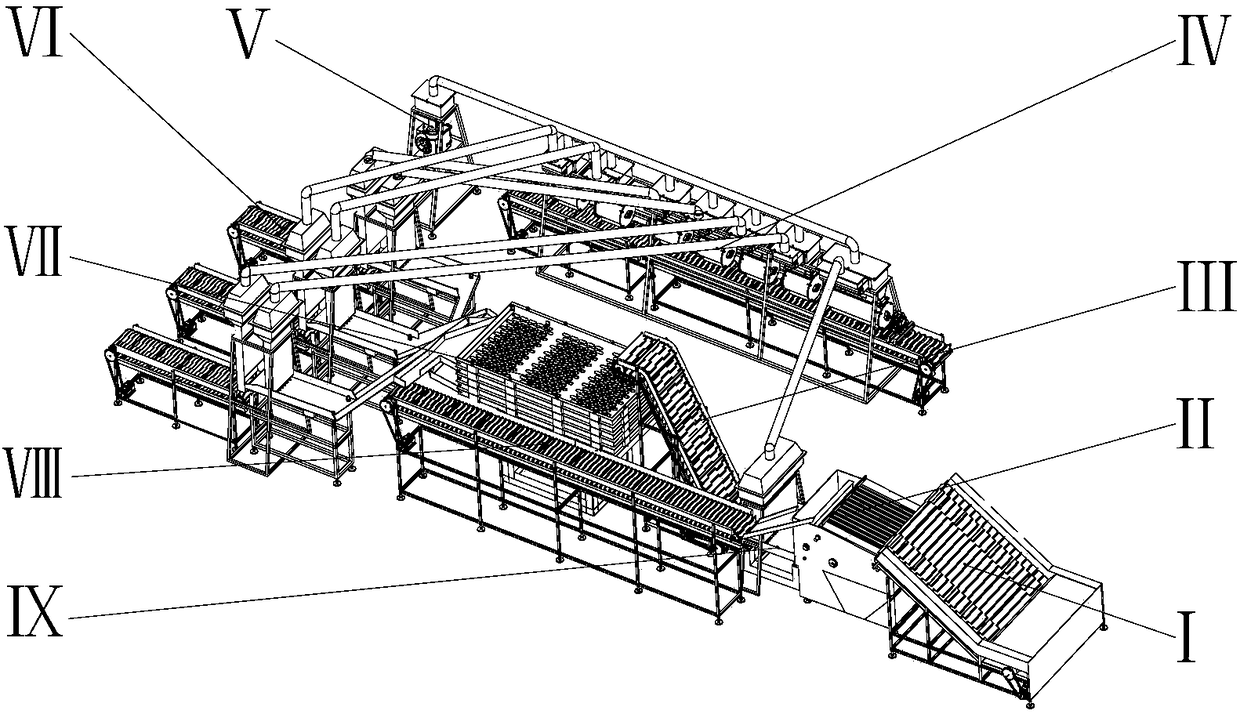

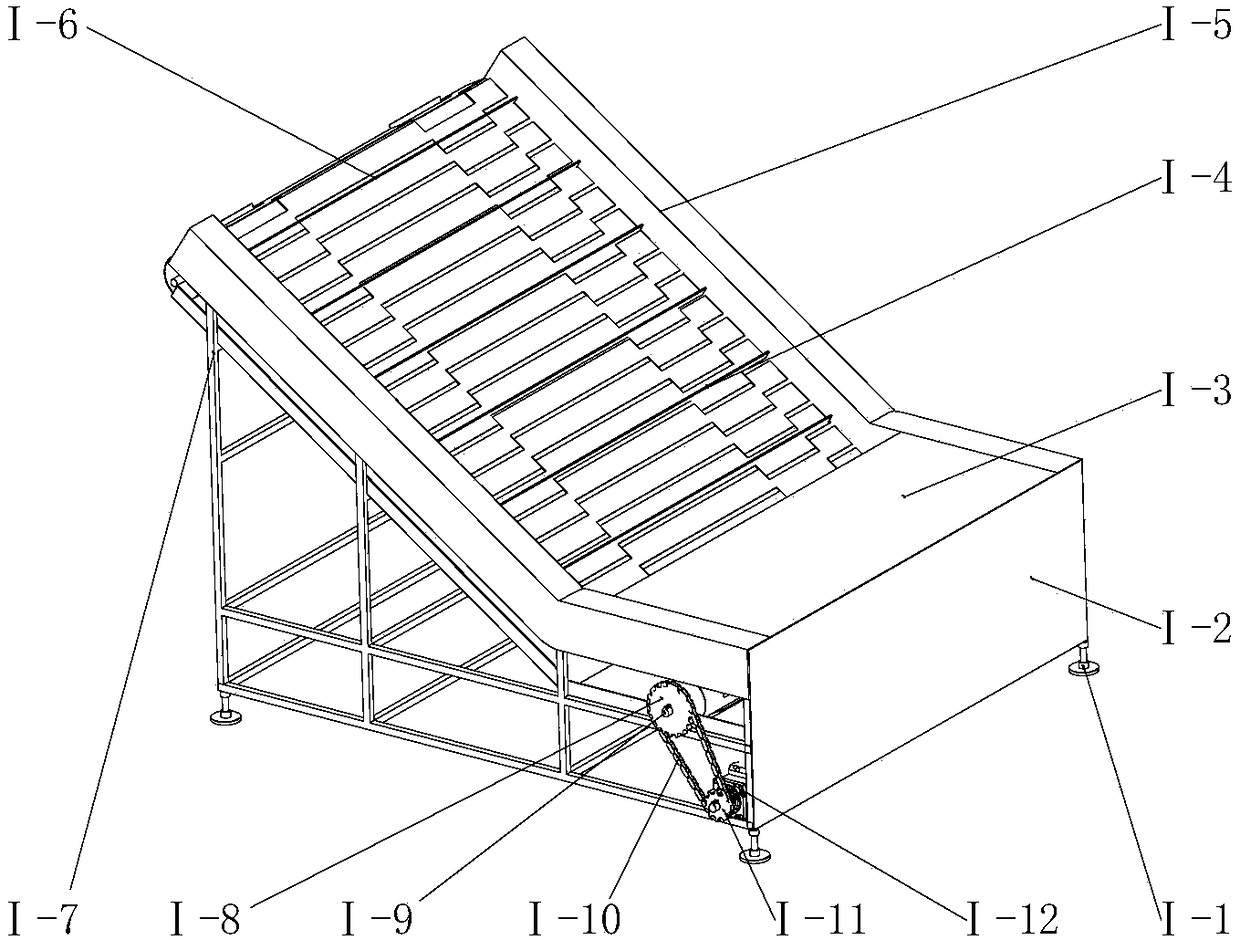

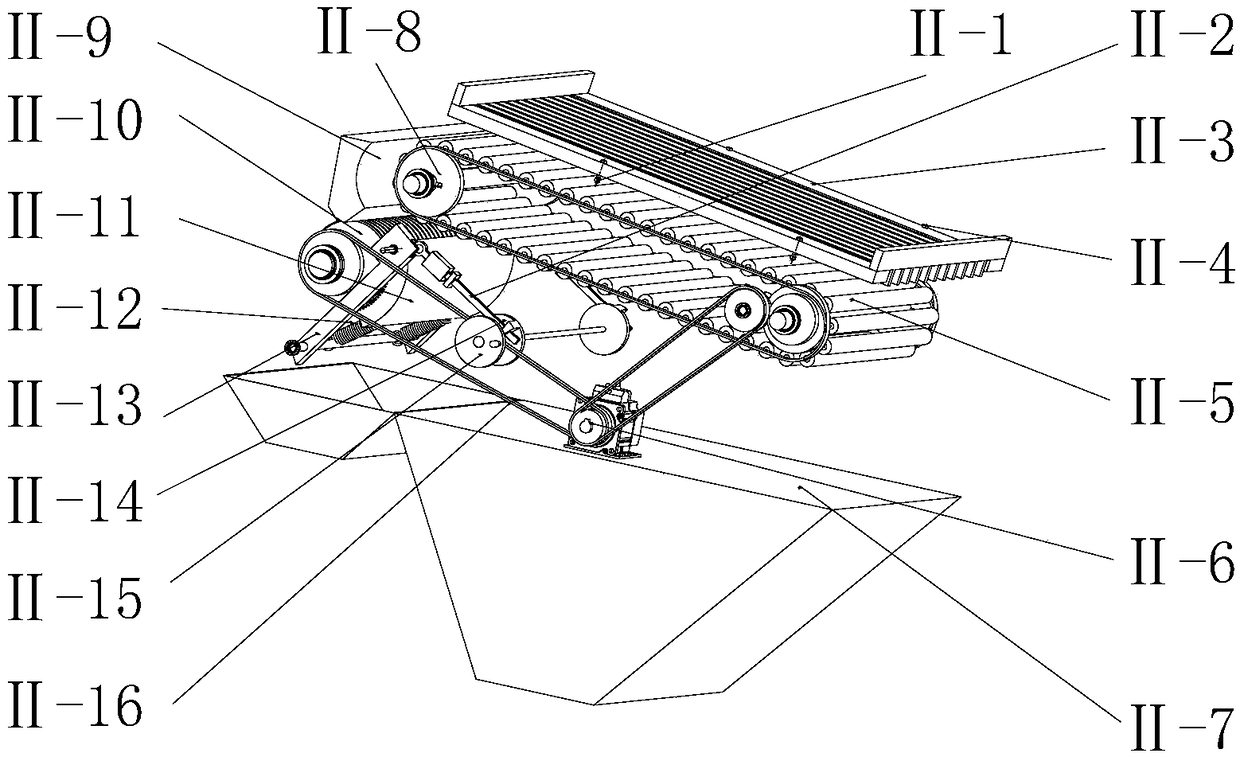

Automated production system for efficient walnut shell-breaking, kernel-taking and shell-kernel separation

PendingUS20200138083A1High speedHigh-efficiency walnut shell-breakingGas current separationHuskingWalnut NutProcess engineering

The disclosure discloses an automated production system for efficient walnut shell-breaking, kernel-taking and shell-kernel separation, solving the problem that the existing walnut shell breaking device cannot adapt to walnuts having different sizes and shell breaking rate and shell breaking efficiency cannot be ensured. The system can realize efficient shell-breaking, kernel-taking and shell-kernel separation on different varieties of walnuts, is quick in production speed and high in automation degree, and meanwhile is capable of improving entire kernel rate and kernel obtaining rate, reducing the damage rate of the walnut kernel and ensuring the high shell-breaking efficiency and thoroughness of shell and kernel separation.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

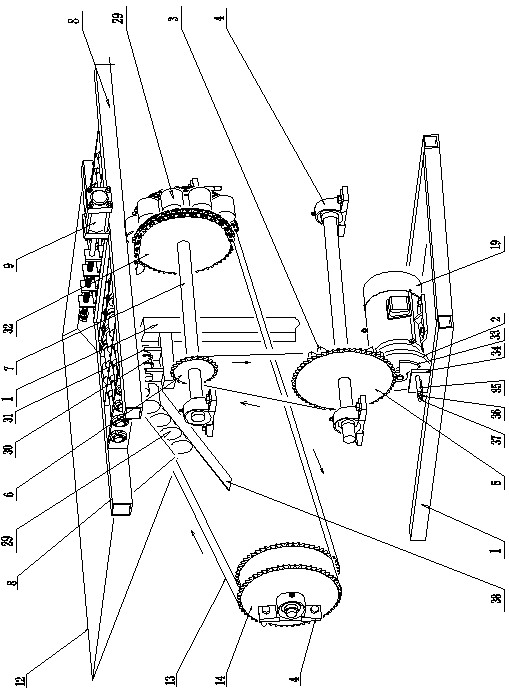

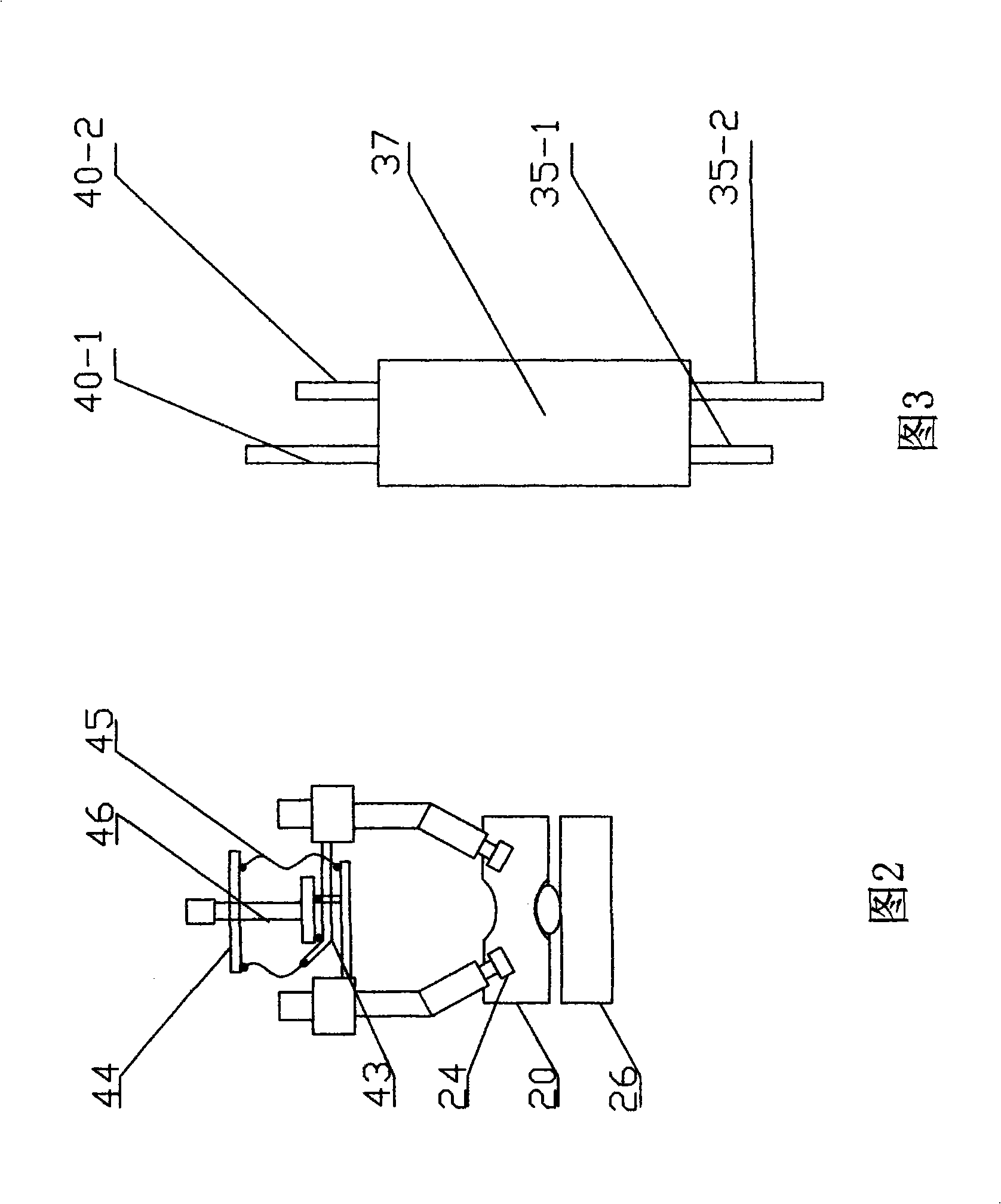

Automatic production system for highly-efficient walnut shell breaking and kernel obtaining and shell-kernel separation

PendingCN108576844AReduce manufacturing costSmall footprintGas current separationHuskingProduction rateSuction force

The invention discloses an automatic production system for highly-efficient walnut shell breaking and kernel obtaining and shell-kernel separation, and the automatic production system solves problemsthat the existing walnut shell breaking device can not adapt to walnuts in different sizes, and the shell breaking rate and the shell breaking efficiency can not be guaranteed. The automatic production system is capable of realizing highly-efficient shell breaking and kernel obtaining and shell-kernel separation for walnuts in different varieties, high in production rate and automation degree, improved in whole kernel rate and kernel obtaining rate, reduced in damage rate of walnut kernels and capable of ensuring high efficiency of shell breaking and thoroughness degree of shell-kernel separation. A technical scheme of the automatic production system is that: the automatic production system includes a shell breaking device: extruding components are arranged to extrude and break walnut shells; a walnut kernel vibrating and grading device: receiving shell-kernel mixture after shell breaking, subjecting the shell-kernel mixture to vibrating and grading, and conveying the graded shell-kernel mixture to each negative pressure shaking and sorting device, respectively; and the negative pressure shaking and sorting devices are connected to a negative pressure separation device, the negative pressure separation device sucks and stores the walnut shells through negative pressure suction force, and the walnut kernels are classified and stored through the negative pressure shaking and sorting devices.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

Integrated machine for shelling and peeling lotus seed

InactiveCN101406312ACompact structureSolve the trouble of producing white lotusHuskingHullingEngineeringConveyor belt

The invention belongs to the field of crop peeling, and in particular relates to a lotus seed shelling and peeling all-in-one machine which mainly comprises a lotus seed positioning device, a spacing device, a shell sawing device, a shelling device, a peeling device and transmission equipment, wherein the lotus seed positioning device and the peeling device are positioned on two ends of the transmission equipment respectively; the spacing device and the shell sawing device as well as the shelling device are positioned on the upper part of the working surface of a conveyor belt 8 in the transmission equipment in sequence and side by side; transmission guide rails are correspondingly arranged among the positioning device, the spacing device and the shell sawing device; and lotus seeds are positioned by the positioning device and are transmitted rotationally to the spacing determining device, the shell sawing device and the shelling device respectively by the conveyor belt 8, and then are sent to the peeling device. The lotus seed shelling and peeling machine is capable of rapidly shelling and peeling lotus seeds one by one. The machine greatly improves the lotus seed producing efficiency. With matching power 3KW as an example, the working efficiency can reach 30 to 35 kilograms per hour; the peeling efficiency can be more than 97 percent under the condition that lotus seeds have normal tenderness; the quality of the processed lotus seeds can approach the effect of handwork; meanwhile, the water consumption is only one third of that of the prior processing method.

Owner:曹志强

Camellia seed huller

The invention discloses a camellia seed huller. The camellia seed huller comprises a rack, a feeding device, a hulling device, a cleaning and separating device and a transmission device, wherein the feeding device is arranged at the upper part of the hulling device and consists of a feeding hopper, a feeding quantity adjustment plate and a cone-shaped shunt; the cone-shaped shunt is arranged at the connection position of the feeding device and the hulling device and is used for uniformly feeding materials into a hulling chamber; the hulling device consists of the hulling chamber and a hulling chamber lower housing; the hulling chamber comprises a toothed plate and a projecting disc, a main shaft, a universal joint and the toothed plate; the projecting disc is in a cone bowl shape; a plurality of blades are arranged on the projecting disc; the projecting disc is arranged at the outlet end of the universal joint through a key joint; the toothed plate is fixed in the hulling chamber housing; and the hulling chamber lower housing takes a cone shape and is connected with the cleaning and separating device. The camellia seed huller is high in production efficiency and hulling ratio, and can effectively separate camellia seeds from impurities, improve the purity degree of the camellia seeds and perform hulling and cleaning at one time, so that the manufacturing procedure is less and the manufacturing cost is low.

Owner:HUNAN AGRICULTURAL UNIV

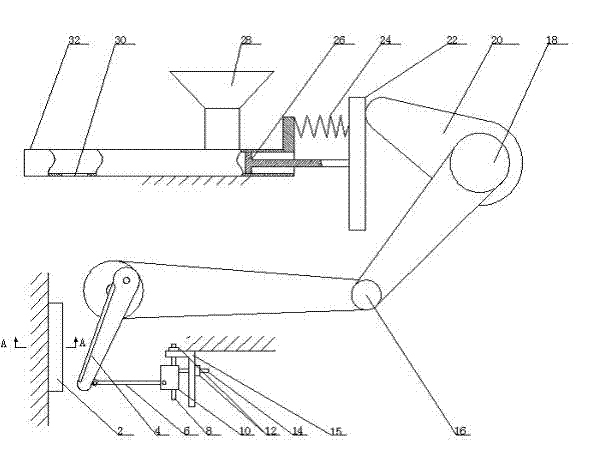

Hobbing type lotus seed shucker

The invention relates to a hobbing type lotus seed shucker, which is composed of a frame, a feeding mechanism, a conveying mechanism, a cutting mechanism, an uncoating mechanism, a motor and the like, wherein the conveying mechanism is driven by a grooved pulley, and step performing of lotus seed shucking and uncoating is realized by the intermittent movement of a grooved pulley mechanism, so that the shucking is more thorough and more effective; and spring adjustment systems are respectively installed on the shucking mechanism and the uncoating mechanism, and the springs can automatically adjust the distance between a cutting blade and an uncoating roller as well as a rubbing roller according to the lotus seed size, so that the shucking of lotus seeds with different sizes is adapted. The shucker has the characteristics of high shucking rate and low breakage rate in the shucking process, and has the characteristics of simple structure, small volume, low manufacturing cost, stability in operation and the like in the equipment performance.

Owner:NANCHANG UNIV

Full automatic cashew nut hull breaking machine

The invention discloses a full automatic cashew nut hull breaking machine which is mainly composed of a machine frame, a motor, a feeding mechanism, a conveying mechanism, a fruit picking mechanism and a cutting mechanism. The conveying mechanism is mainly formed by guide rails, a transmission shaft, a transmission chain wheel, a transmission chain and a fruit pushing plate. The guide rails are formed by an upper guide rail and a lower guide rail, the transmission chain drives the fruit pushing plate to penetrate a gap between the upper guide rail and the lower guide rail, the feeding mechanism is located at one end of the guide rail, and the cutting mechanism is located at the other end of the guide rail. The lower guide rail is formed by a left half portion and a right half portion. The fruit picking mechanism is mainly formed by two transmission shafts, a transmission chain wheel, two transmission chains and more than two fruit poking plates, and the transmission chains drive the fruit poking plates to enable poking pieces on the fruit poking plates to penetrate a gap between the left half portion and the right half portion. The full automatic cashew nut hull breaking machine is capable of achieving automatic feeding, conveying and centralizing, can improve the production efficiency, reduce labor intensity and reduce production cost, and is high in safety. The rate of perfect kernel can reach 50%-70%.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

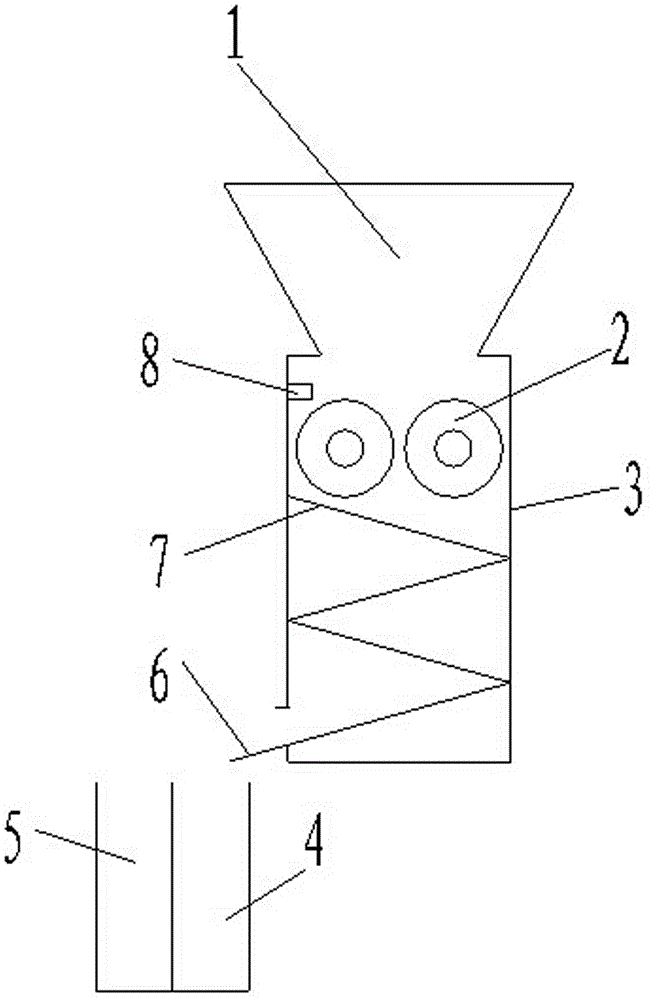

Dust-free peanut sheller

InactiveCN104397837AAvoid it happening againGood for healthHuskingHullingEngineeringMechanical engineering

The invention discloses a dust-free peanut sheller. The dust-free peanut sheller comprises a box body, a feed inlet is opened at one side of the top end of the box body, two shell smashing rollers are arranged below the feed inlet in a parallel mode, a sprinkler head is formed between the shell smashing roller and the feed inlet, a discharge plate inclining downward is arranged below the shell smashing rollers, a shell collecting bucket and a peanut collecting bucket are mounted below one end of the discharge plate extending out the box body, the shell collecting bucket is close to the end of the discharge plate extending out the box body. The dust-free peanut sheller can avoid the dust during the peanut production process, protect the environment and is beneficial to the good health for workers, the structure is simple and beneficial to produce and maintain and is not easy to break down.

Owner:GUANGXI GAONONG MACHINERY

Calibrated handheld espresso tamper

ActiveUS20050132890A1Application of tamping forceIncreasing tamping forceBeverage vesselsLiquid dispensingEngineeringCalibration set

An espresso tamper including a force calibration means is disclosed. The tamper is optimally handheld. Upon force of a desired magnitude being applied by a user, at least one discrete signal, such as an audible, visual, tactile or electrical signal is emitted. The tamper handle includes an anti-rotation feature. The handle is flared to avoid pinching the user's fingers during operation and to stop the user's fingers from sliding down the handle or in any way touching the base, thereby rendering the tamper more effective and safe. The tamper and force-calibration kit and method of use optimize espresso making.

Owner:ESPRO

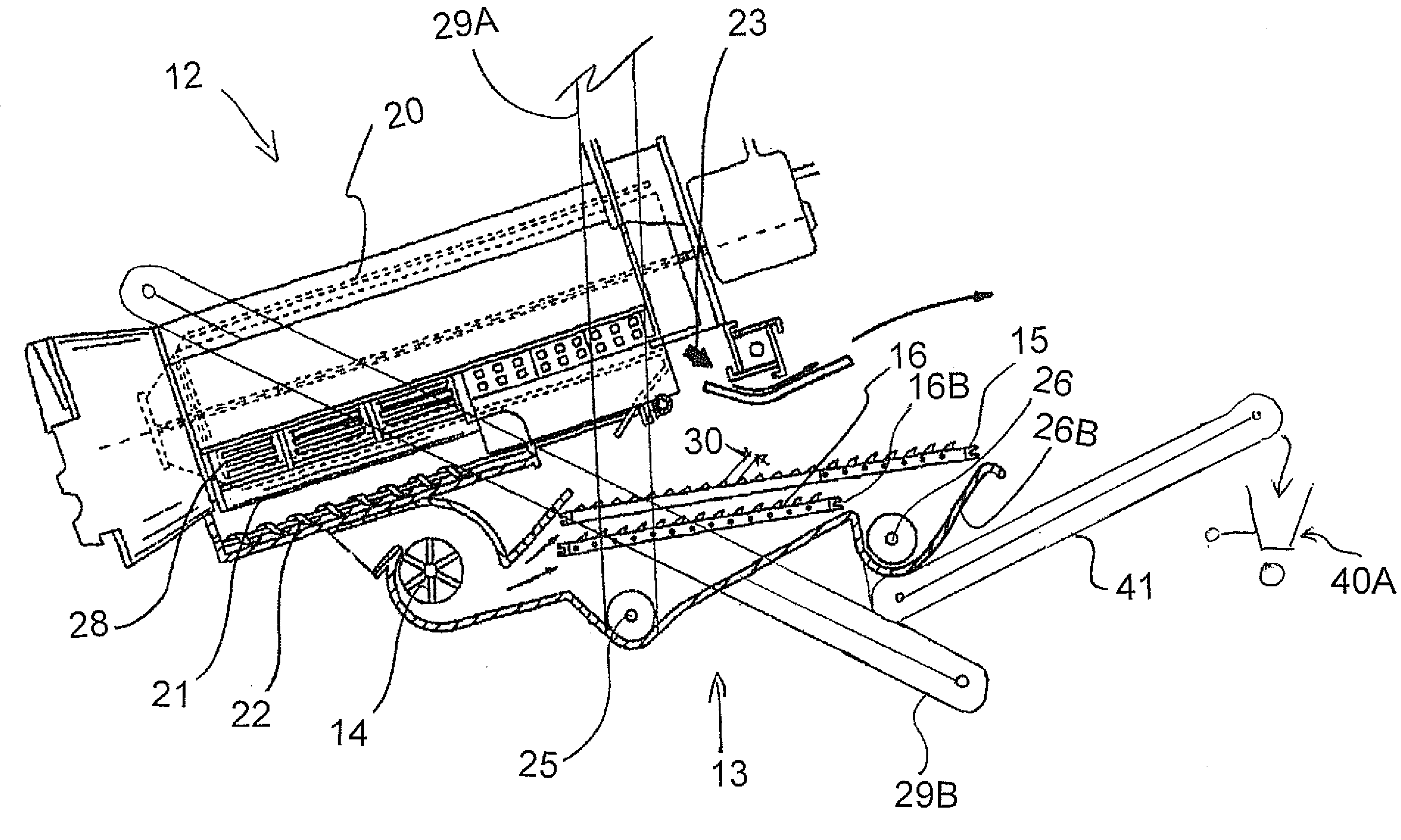

Separating cobs from grain in a corn harvester

InactiveUS20090137295A1Eliminate needReduce compactionGrain huskingSievingEngineeringCombine harvester

A combine harvester for corn is adjusted so that the threshing system maintains the grain and cobs together and there is provided a first sieve to separate the grain and cobs from residue material which is discharged from a rear of the first sieve and a second sieve to separate the grain which passes through the second sieve from the cobs which are discharged from a rear end of the second sieve. The grain is transferred to a clean grain tank and the cobs are conveyed to a tank on a towed cart.

Owner:REDEKOP ENTERPRISES

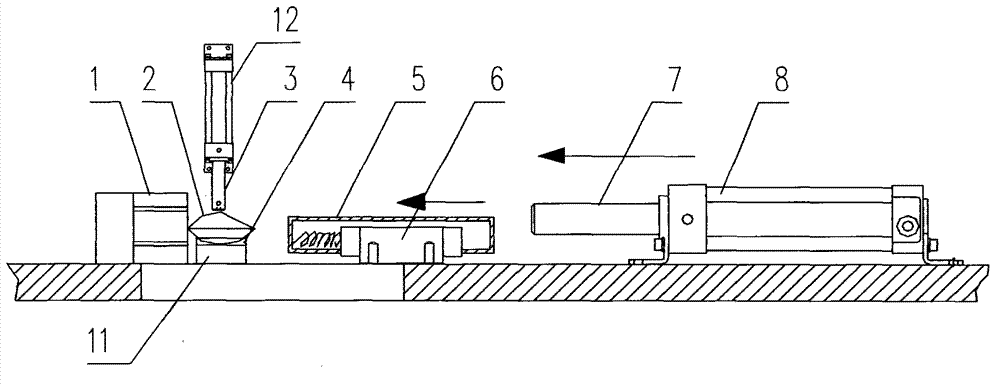

Apricot pit hull breaking machine

InactiveCN103169135AImprove efficiencyQuality improvementHuskingHullingProgrammable logic controllerControl switch

The invention discloses an apricot pit hull breaking machine which comprises an apricot pit supporting pad and an apricot pit conveying part, wherein a collision stopping seat and a collision rod are respectively arranged on two sides of the supporting pad; a sliding block is arranged between the collision stopping seat and the collision rod; a pressing rod for pressing and stabilizing apricot pits is arranged above the supporting pad; a photoelectric sensor for identifying whether an apricot pit is put on the supporting pad is arranged beside the supporting pad; and a programmable logic controller (PLC) is additionally arranged and is in signal and control connection with the photoelectric sensor, an apricot pit conveying part execution switch, an up-and-down moving control switch of the pressing rod, and a collision motion control switch of the collision rod. The apricot pit hull breaking machine is used for breaking hulls of the apricot pits or other fruit kernels or other nuts, and is complete in structure, high in automation degree, good in effect, high in efficiency and wide in application.

Owner:陈皓

Biophysical method for removing endopleura of walnut

InactiveCN102972850AEasy to operateMild treatment conditionsFood preservationHuskingPectinaseWalnut Nut

The invention provides a biophysical method for removing the endopleura of a walnut. The walnut with the shell is soaked by tap water for 12 to 24 hours, the shell is removed, the kernel is taken out, pectinase with the activity being 30000 IU is dissolved into disodium hydrogen phosphate-citric acid buffer liquid with the pH being 3.2 to 3.8, and 3 percent to 5 percent of pectic enzyme liquid is prepared and is heated to 50 DEG C. The soaked walnut kernel is soaked in the pectic enzyme liquid and is placed into an ultrasonic generator with the power being 250W and the work frequency being 40KHZ, the enzymolysis and the ultrasonic treatment are carried out for 2.5 to 5 hours at the constant temperature being 50 DEG C, the walnut kernel is fished out and is sprayed and flushed by flowing water with the pressure being 7 to 10 MPa until the endopleura is completely removed, the walnut kernel with the advantages that the color and the luster are opacified, the kernel fruit is complete, the texture is flexible, the mouth feeling and the flavor are pure and sweet as those of the fresh walnut kernel can be obtained, and when the walnut kernel is in vacuum package and freezing storage, a fresh walnut kernel storage method is obtained. The biophysical method adopts the advanced biological enzyme technology to be combined with the ultrasonic physical technology and has the obvious characteristics that the operation is simple, the processing condition is mild, no chemical pollution exists, the kernel and the nutrition are kept complete, and the sensory quality is good.

Owner:BEIJING UNION UNIVERSITY

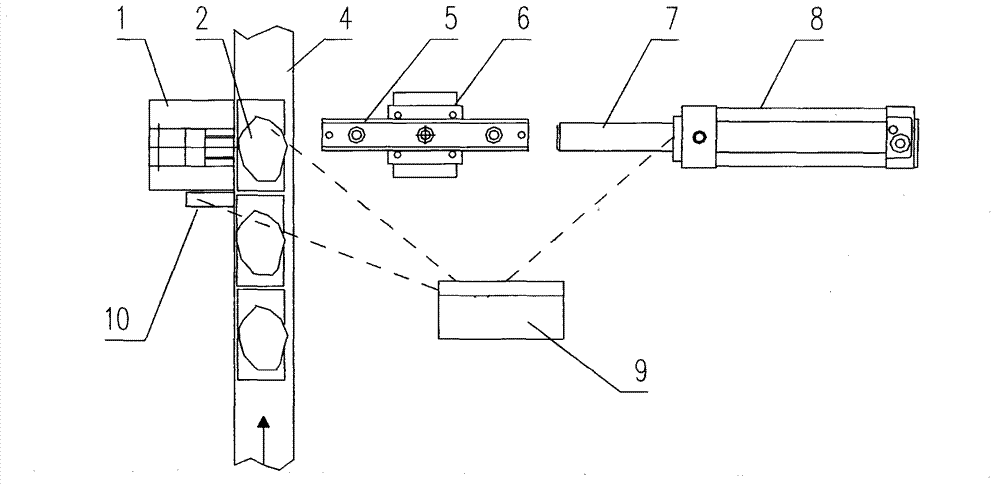

Hand-operated Chinese chestnut shucking machine

ActiveCN103230082AGood removal effectSimple structureHuskingHullingEngineeringMechanical engineering

The invention relates to a hand-operated Chinese chestnut shucking machine which comprises a compression bar assembly, a support assembly, a transmission assembly, a sliding chute, two slide bars and an inclined connecting bar, wherein the compression bar assembly reciprocates vertically; the support assembly is used for supporting the compression bar assembly to reciprocate vertically; the transmission assembly drives the compression bar assembly to reciprocate vertically; the sliding chute is horizontally placed and fixed with the support assembly; the two slide bars slide relatively and horizontally in the sliding chute; the inclined connecting bar drives the slide bars to move horizontally by the aid of the vertical reciprocation of the compression bar assembly; at least one hooked blade is connected to the opposite end parts of the two slide bares respectively; the shucking machine further comprises a material pressing assembly which is elastically pressed against Chinese chestnuts under the drive of the compression bar assembly; hook tips of the hooked blades are upward; and the hook tips of the hooked blades which are arranged at the end parts of the two slide bars encounter right below the material pressing assembly. The hand-operated Chinese chestnut shucking machine is simple in structure, low in cost and simple to operate and can very conveniently remove both Chinese chestnut hair bulbs and hulls.

Owner:启东市天汾电动工具技术创新中心

Nut cracking device

InactiveCN103110167AConvenient whereaboutsAchieve mass productionHuskingHullingEngineeringBatch production

The invention discloses a nut cracking device which comprises a cracking device and a feeding device. The cracking device comprises a side plate arranged vertically, one side of the side plate is fixed, a pressure plate is arranged on the other side of the side plate in a clearance manner, the upper end of the pressure plate is hinged on a rotating device which is driven by a driving device to rotate, a connecting rod is hinged at the lower end of the pressure plate, the other end of the connecting rod is hinged on a fixed plate arranged fixedly, the feeding device comprises a charging opening and a container, the charging opening is arranged above the side plate and the pressure plate, and the container is used for accommodating nuts. A nut falls into space between the pressure plate and the side plate via the charging opening, and the rotating device rotates to drive the pressure plate to ascend and descend; when the pressure plate ascends, an included angle between the connecting rod and the pressure plate is enlarged, the pressure plate is pushed to approach the side plate, and accordingly a shell of the nut is crushed under pressure; when the pressure plate descends, the included angle between the connecting rod and the pressure plate is diminished, the pressure plate leaves the side plate, and sufficient clearance is formed, so that the nut with the crushed shell falls down; and the cycle continues, the pressure plate performs cyclic crushing and discharging relative to the side plate, and batch production is realized.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

Brain-invigorating walnut beverage and production technology thereof

The invention discloses a brain-invigorating walnut beverage and a production technology thereof. The brain-invigorating walnut beverage is prepared by the following steps: selecting semen juglandis; soaking in clean water; quickly freezing at low temperature, drying by forced air, and blanching; performing vacuum drying; crushing; squeezing at low temperature and degreasing partially; grinding into thick liquid; blending; homogenizing; performing vacuum degassing; and sterilizing and filling. The invention conducts an improvement on the production technology of the walnut beverage, overcomesthe technical defect of an alkaline method by using the mode of quickly freezing at low temperature firstly and melting under rising temperature secondarily to blanch, avoids the problems of protein denaturation and nutrition loss, prevents the phenomenon of layered beverage by adopting the method of squeezing at low temperature and degreasing partially, ensures low fat and health of the walnut beverage, has no influence on aromatic and smooth taste of the walnut beverage, is added with nutrition components such as DHA, AA, taurine and the like, has reasonable formula, and has the advantages of invigorating and nursing brain, improving nutrition of brain, increasing brain activity, promoting intelligence development, ameliorating memory and alleviating mental fatigue.

Owner:YUNNAN DALI ERBAO IND

Method of washing cocoa beans to improve the quality of the cocoa products obtained from such beans

ActiveUS20110229616A1Reduce the amount of metalReducing free fatty acidsFruit stoningCocoaButter cocoaPre washing

Owner:OLAM INT

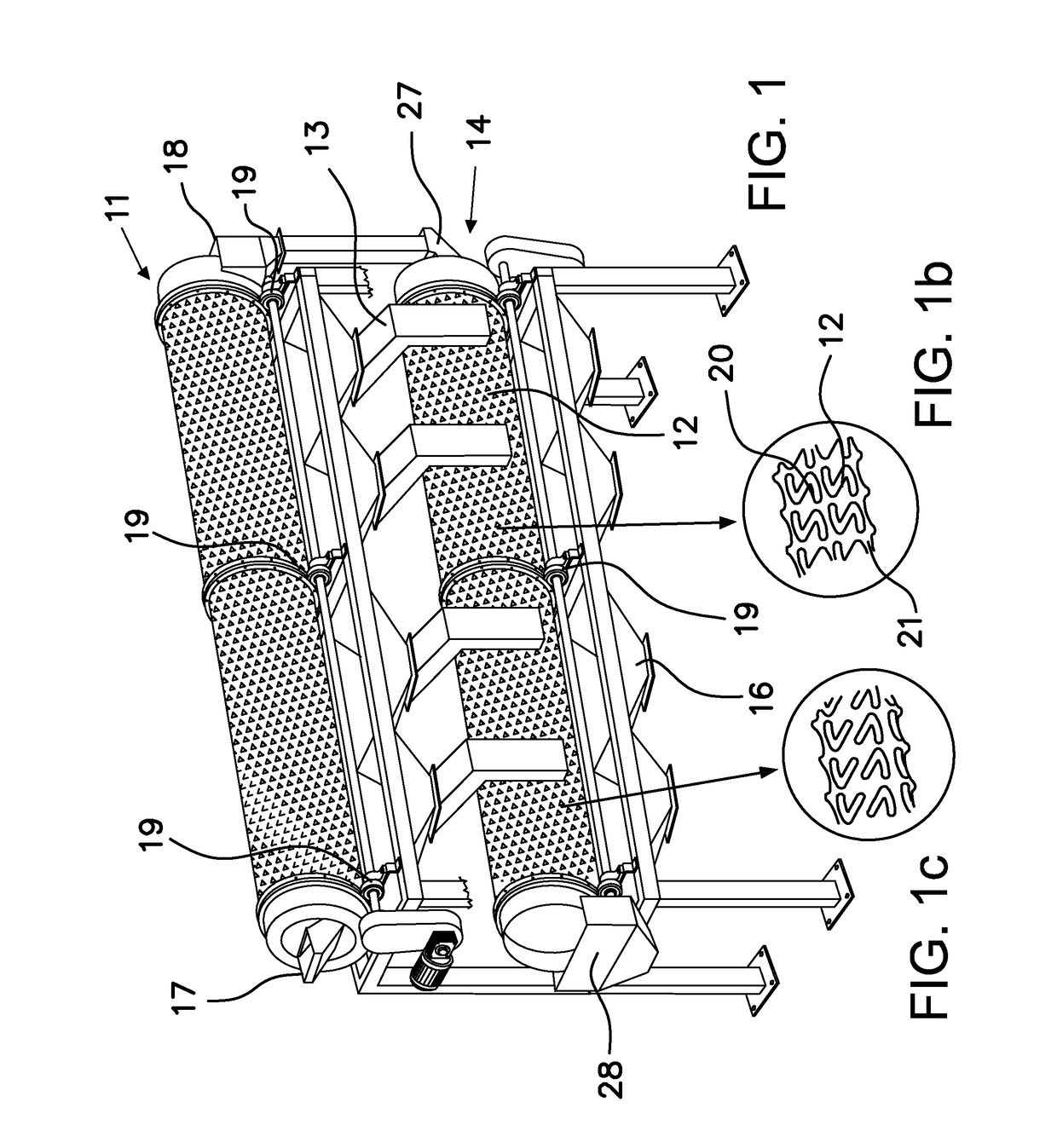

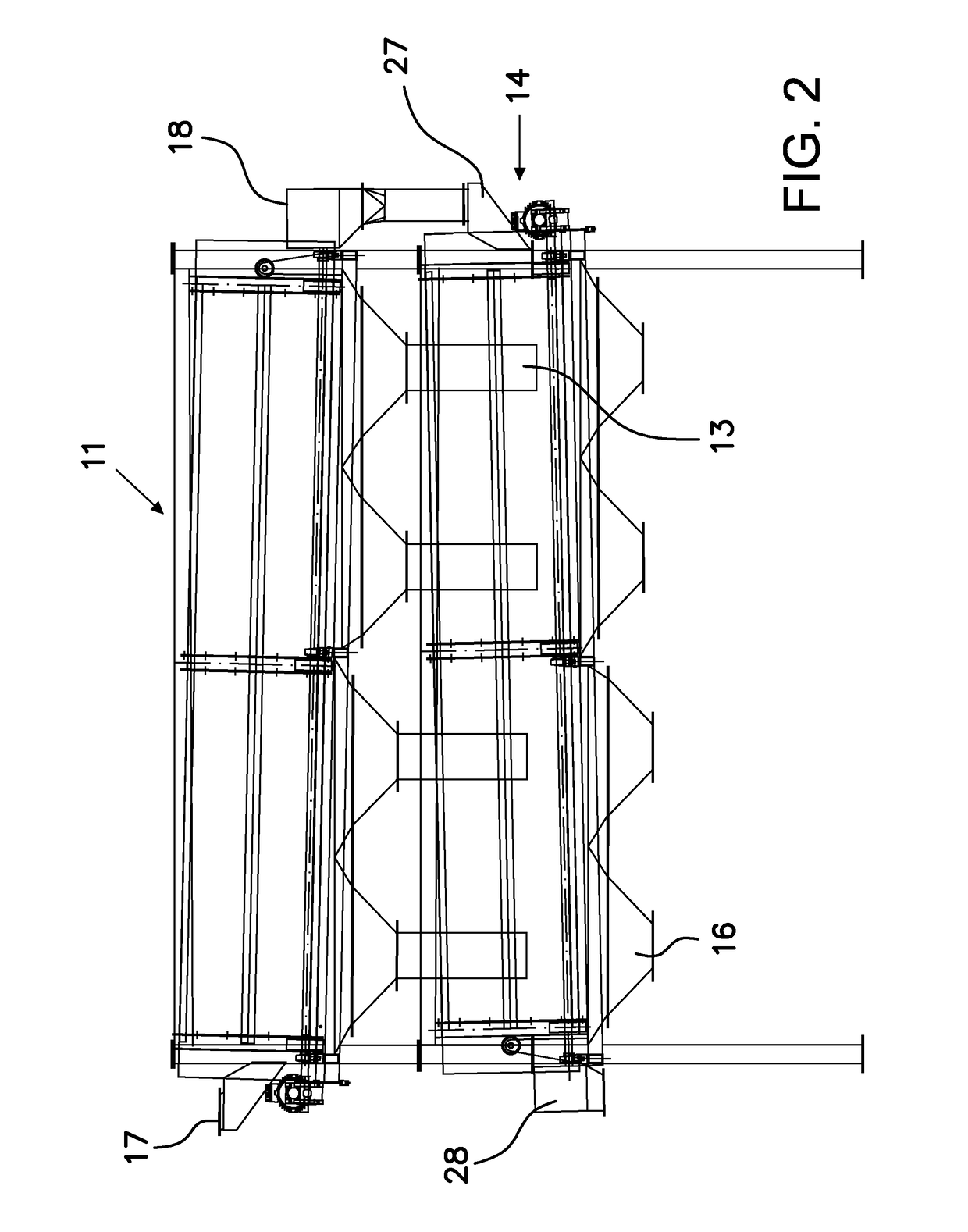

Method for separating the shell from seeds or fruit, sifting device, and selection device

InactiveUS20170164649A1Improve productivityLow costGrain huskingGrain polishingHuskDevices procedures

Owner:INNO ALMOND FLY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com