Apricot pit hull breaking machine

An apricot core shell breaking machine and apricot core technology are applied in the field of apricot core shell breaking machines, which can solve the problems of unsatisfactory quality and effect of opening shell breaking, low efficiency and quality, and difficulty in guaranteeing quality, etc. Perfect structure, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

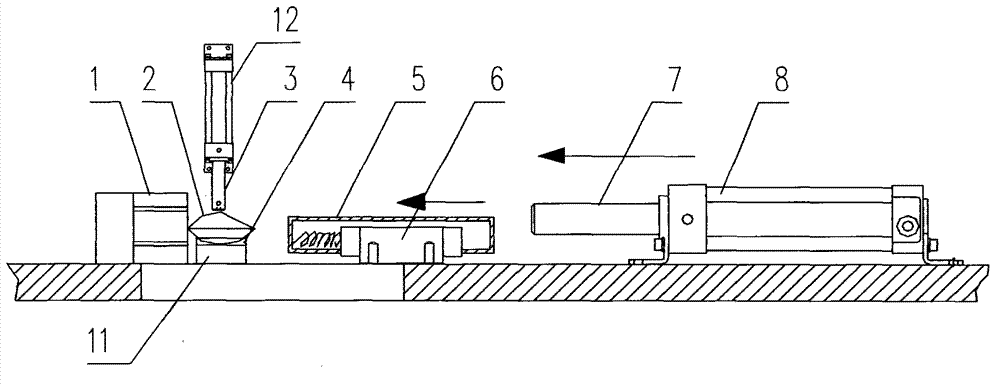

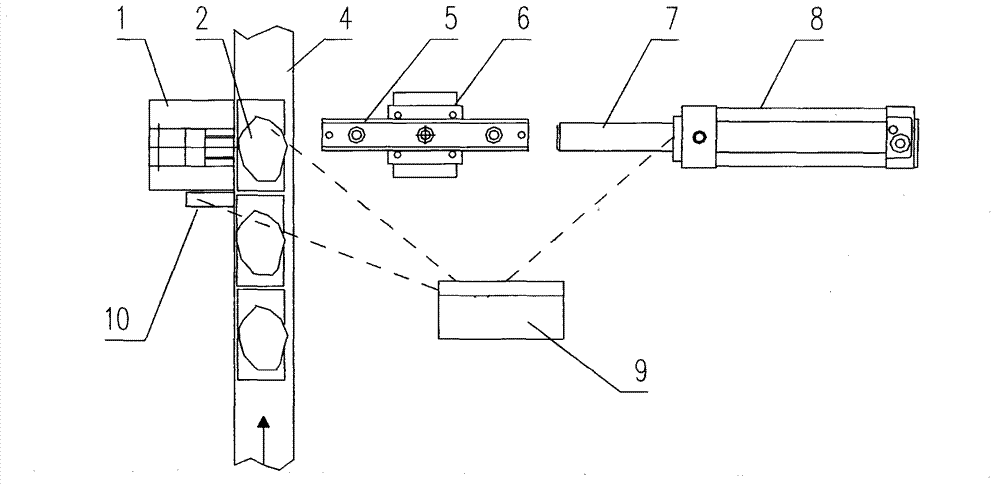

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is described, embodiment: referring to accompanying drawing, apricot core shell breaking machine is provided with apricot core support pad 11 and the apricot core transmission part 4 that apricot core 2 is put on the support pad successively, in One side of the support pad is provided with the impact stop seat 1 that withstands the apricot nucleus when the apricot nucleus is hit, and the other side of the support pad opposite to the impact stop seat is provided with a strike bar 7, between the impact stop seat and the impact A slider that can slide in parallel and is provided with a return spring is provided between the rods. The impact block, the support pad, the slider and the impact rod are arranged on a straight line. Adjustable intervals; above the support pad, there is a pressing rod 3 for pressing and stabilizing the almond stone. Next to the support pad is provided with a photoel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com