Camellia seed huller

A technology of shelling machine and camellia oleifera seed, which is applied in the direction of shelling, pod removal, food science, etc., can solve the problems of not being able to meet the actual needs, increase the production process, and not much batch production, so as to improve production efficiency and remove Shell rate, simple and compact structure, less processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the specific implementation manner of this patent is described in further detail.

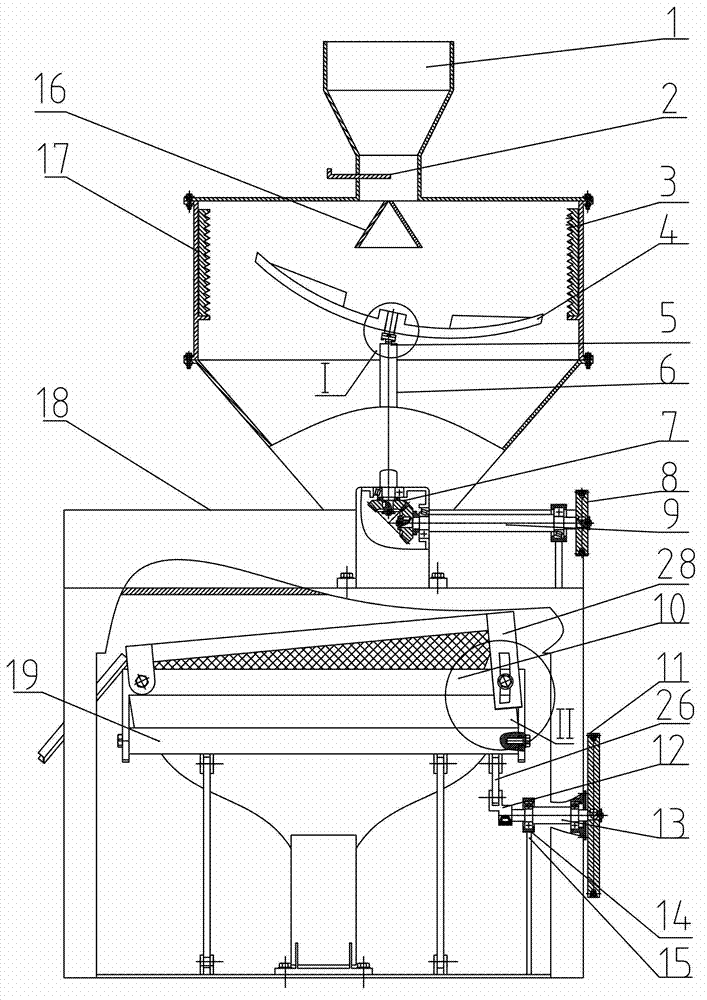

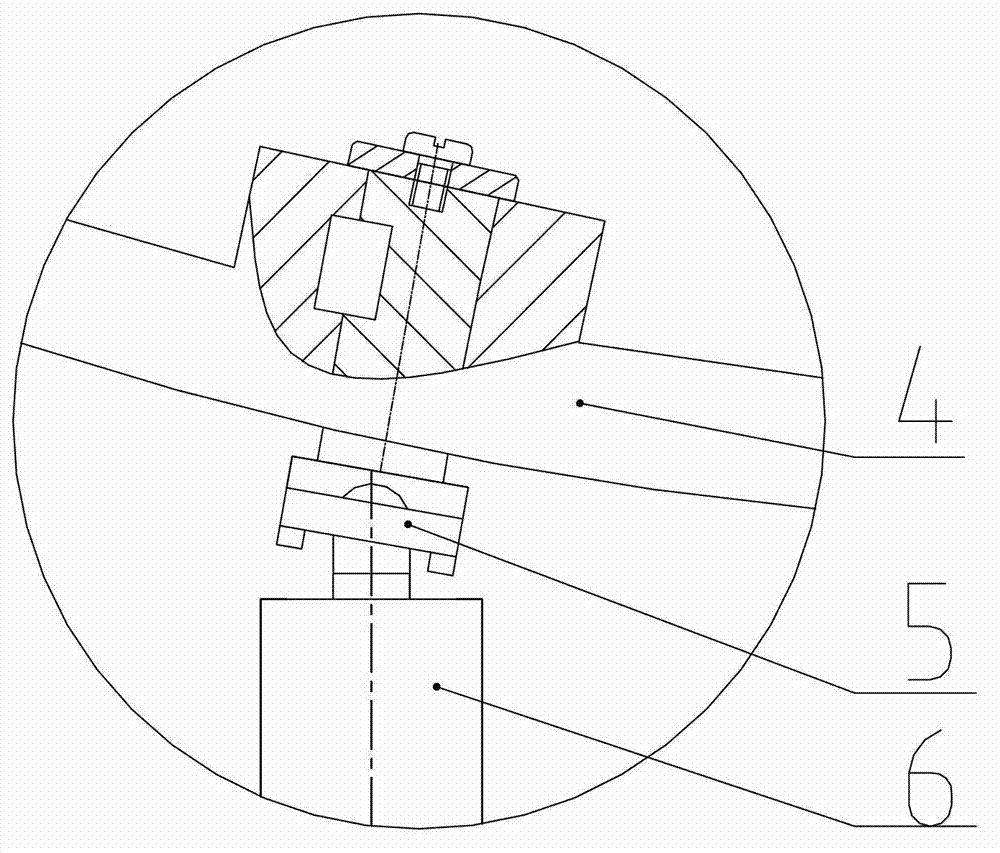

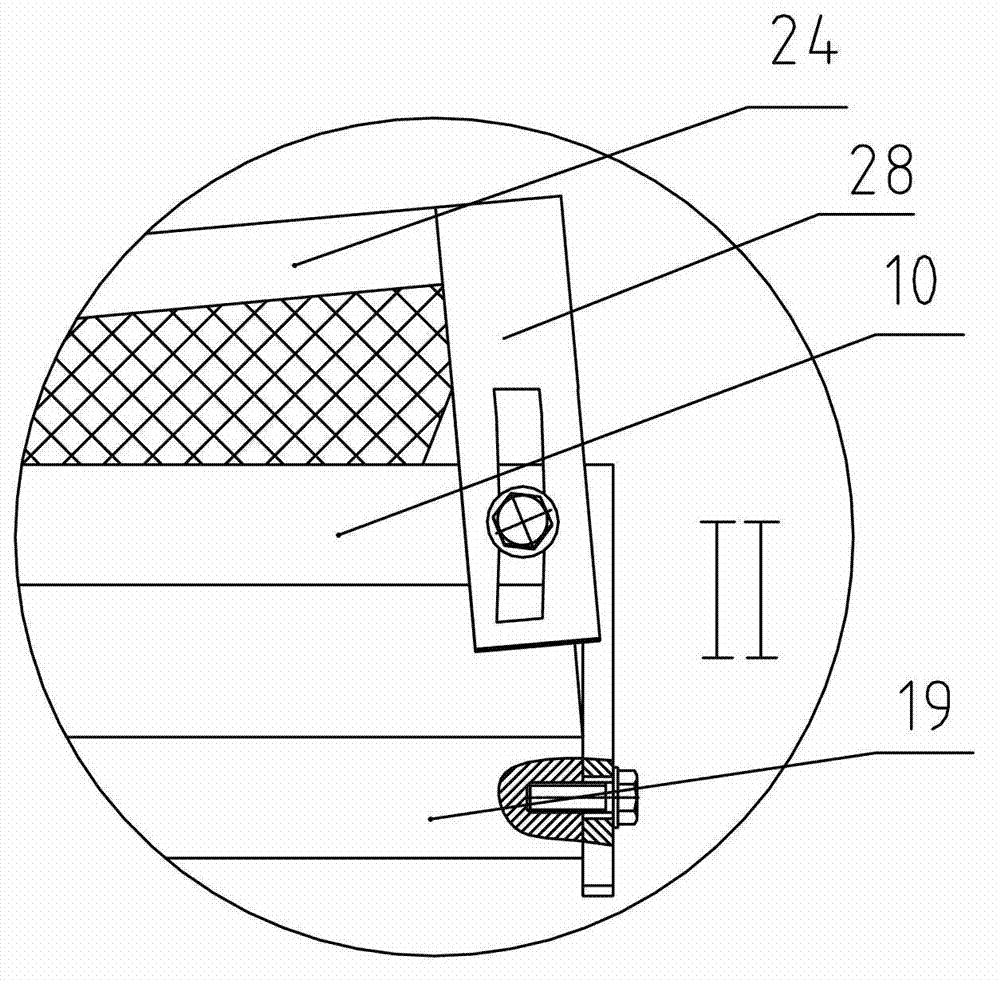

[0020] Referring to Figure 1, figure 2 , this device adopts the principle of shelling combined with centrifugal impact method and rubbing and the cleaning principle of gravity separation. The structure includes: feeding hopper 1, feeding amount adjustment plate 2, conical diverter 16, shelling chamber 17, Tooth plate 3, spinning disc 4, universal joint 5, main shaft 6, gear box 7, transmission shaft 9, pulley 8, frame 18, vibrating screen 24, vibrating screen support plate 19, vibrating screen adjusting plate 10, pulley 11, Eccentric wheel 12, auxiliary shaft 13, bearing 14, support seat 15, vibrating bar 26, support bar 27, seed hopper 21, shell hopper 25, blower fan 23, air duct 22, motor 20. Wherein, the feeding regulating plate 2 is arranged between the feeding hopper 1 and the shelling chamber 17; the conical flow divider 16 is welded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com