Electromagnetic semicontinuous casting device and casting method thereof

A semi-continuous, electromagnetic technology, applied in the field of metal material preparation, can solve the problems of difficult industrial application, bulky, unfavorable crystallizer layout, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

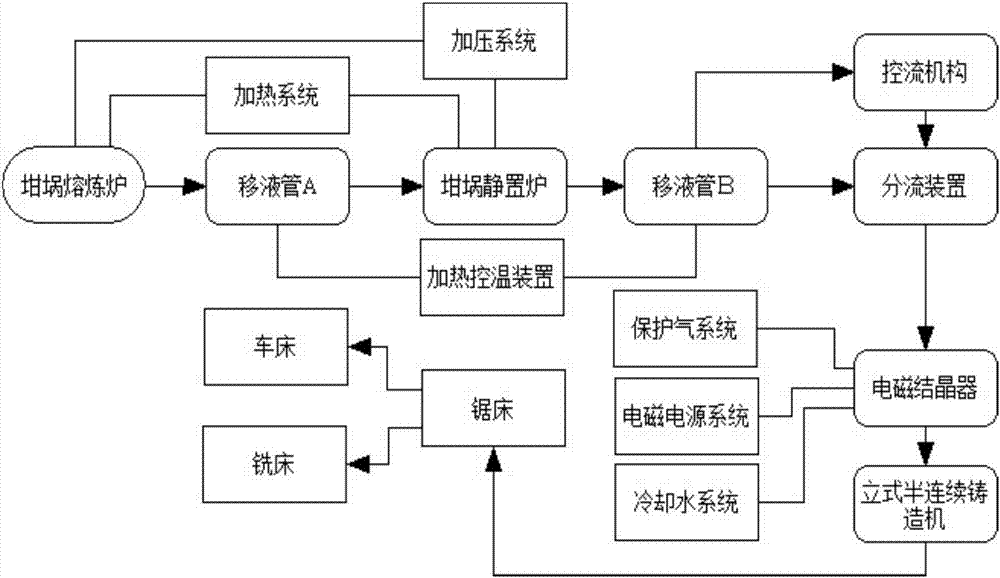

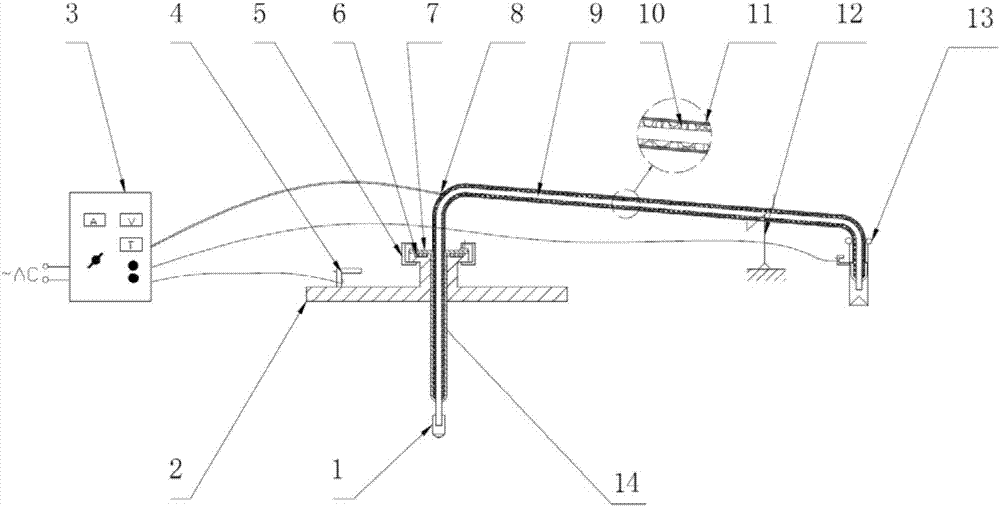

[0109] Such as figure 1 As shown, add magnesium ingots and aluminum ingots to the crucible melting furnace according to the requirements of AZ31B components, set the melting temperature to 700°C, add zinc ingots after complete melting, raise the temperature to 720°C, and add MnCl 2 , stirring and refining with RJ2 flux and argon gas at 730°C, the refining time is 20 minutes, and the bottom slag is removed and left to stand for 15 minutes; the liquid is transferred to the crucible resting furnace by pressurized method, and the second refining process is carried out at 740°C , the refining time is 10 minutes, and then the temperature is lowered to 640°C for 40 minutes, and then the temperature is raised to 700°C for 25 minutes; 2 +1% SF 6 Under the mixed gas, the melt is introduced into the diversion device through the flow control mechanism, and then enters the 330mm electromagnetic crystallizer system. The casting speed is controlled at 60mm / min, the water volume is 300L / min,...

Embodiment 2

[0113] Method is with embodiment 1, and difference is:

[0114] (1) Carry out the second refining treatment at 720° C., and the refining time is 15 minutes; carry out the third refining treatment at 730° C., and the refining time is 10 minutes;

[0115] (2) The iron removal process is: after cooling down to 630°C in 35 minutes, the temperature is raised to 705°C in 30 minutes;

[0116] (3) Electromagnetic field is applied during the casting process, the conditions are: frequency f=4Hz, average current I=20A, duty cycle d=10%.

[0117] Its macroscopic organization is as Figure 23 As shown, the grain size fraction of different parts such as Figure 24 shown. It can be seen that compared with Example 1, the ingot is clearly divided from the outside and the inside into a sharply cooled fine-grained region with a very thin surface, a columnar crystal region and an equiaxed fine-grained region. Although the columnar crystal region is all widened, it is equiaxed The coarse grain...

Embodiment 3

[0119] Method is with embodiment 1, and difference is:

[0120] (1) Carry out the second refining treatment at 730°C, and the refining time is 20 minutes;

[0121] (2) The iron removal process is: after cooling down to 630°C in 40 minutes, the temperature is raised to 700°C in 25 minutes;

[0122] (3) A rectangular groove with a concave bottom with a cross section of 180mm×120mm;

[0123] (4) In a rectangular mold with a casting mold size of 322mm×218mm, the casting speed is controlled to be 52mm / min, the water volume is 400L / min, and the casting temperature is 700C;

[0124] (5) Electromagnetic field is applied during the casting process, the conditions are: frequency f=4Hz, average current I=40A, duty cycle d=20%.

[0125] Its macroscopic organization is as Figure 25 As shown, the grain size fraction of different parts such as Figure 26 shown. It can be seen that compared with Example 1, the ingot is clearly divided into a sharply chilled fine-grained region, a columnar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com