A kind of cu-fe composite material double-melt mixed casting equipment and technology

A composite material and melt mixing technology, which is applied in the field of composite material preparation, can solve problems such as uneven composition and structure, and achieve the effects of suppressing fine structure, strong cooling capacity, and increasing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

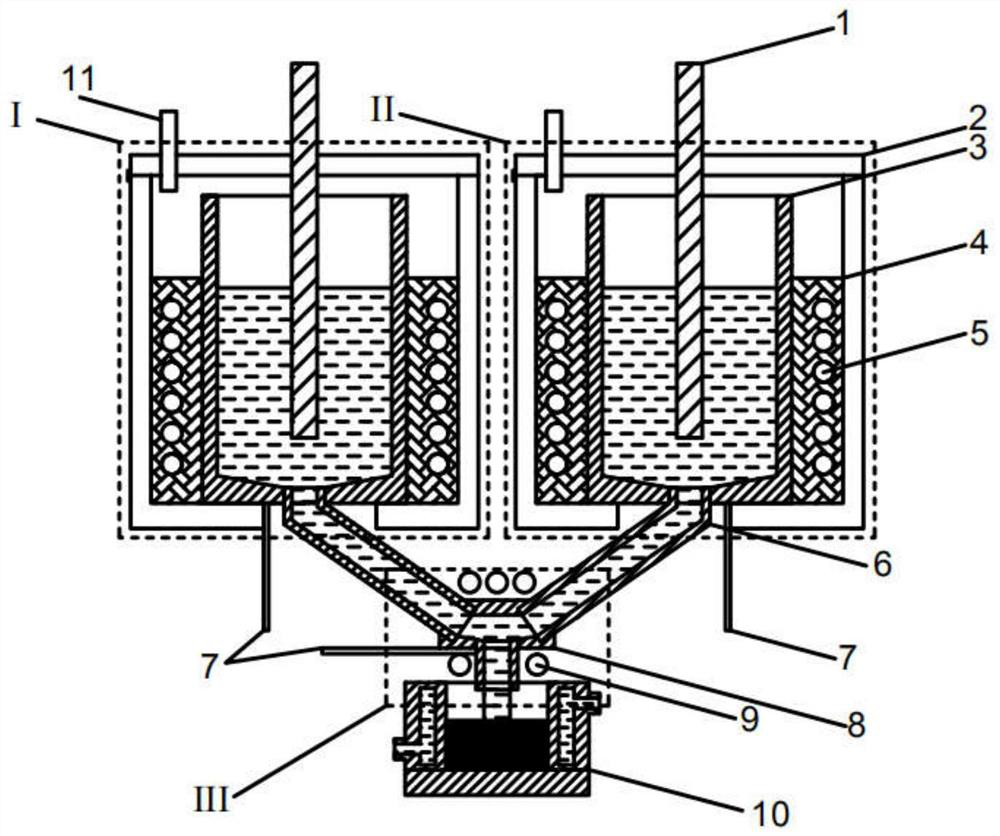

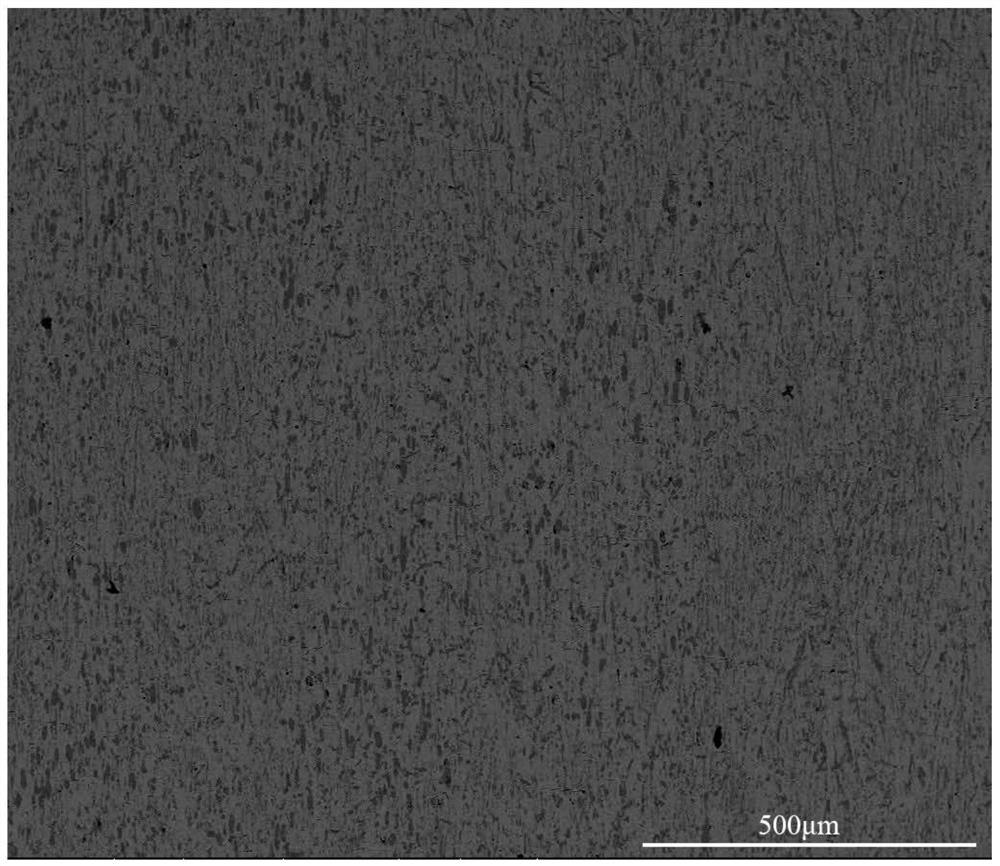

[0056] Embodiment 1: Casting of Cu-10wt.% Fe composite material

[0057] Put the electrolytic pure copper into the graphite crucible of the first melting furnace 1, heat, melt and keep warm through the induction heating coil, measure the melting temperature by the first temperature measuring element 7 (thermometer) to be 1180°C, and the holding temperature is 1180°C . Put pure iron and electrolytic copper with a mass ratio of Fe: Cu=1:4 into the graphite crucible of the second melting furnace II, heat, melt and keep warm through the induction coil, and measure the melting temperature through the second temperature measuring element 7 as 1450°C, holding temperature is 1450°C.

[0058] When the pure Cu liquid and the Fe-Cu alloy liquid reach the target temperature, start the graphite stopper mechanism 1, let the pure Cu liquid and the Fe-Cu alloy liquid enter the mixing chamber 8 through the guide tube 6 for mixing, and start the air pressure adjustment at the same time Mechan...

Embodiment 2

[0061] Embodiment 2: Casting of Cu-20wt.% Fe composite material

[0062] The electrolytic copper is put into the graphite mold 3 of the first melting furnace 1, heated and melted and kept warm by the induction coil, the melting temperature measured by the first temperature measuring element 7 is 1180°C, and the holding temperature is 1180°C. Put pure iron and electrolytic copper with a mass ratio of Fe:Cu=2:3 into the graphite crucible of the second melting furnace II, heat, melt and keep warm through the induction coil, and measure the melting temperature by a thermometer to be 1480°C. The holding temperature is 1480°C.

[0063] When the pure Cu liquid and the Fe-Cu alloy liquid reach the target temperature, start the graphite stopper mechanism 1, let the pure Cu liquid and the Fe-Cu alloy liquid enter the mixing chamber 8 through the guide tube 6 for mixing, and start the air pressure adjustment at the same time Mechanism 11 is used to regulate the flow rate of pure Cu liqu...

Embodiment 3

[0066] Embodiment 3: Casting of Cu-40wt.% Fe composite material

[0067] The electrolytic copper is put into the graphite mold 3 of the first melting furnace 1, heated and melted and kept warm by the induction coil, the melting temperature measured by the first temperature measuring element 7 is 1180°C, and the holding temperature is 1180°C. Put pure iron and electrolytic copper with a mass ratio of Fe:Cu=3:2 into the graphite crucible of the second melting furnace II, heat, melt and keep warm through the induction coil, and measure the melting temperature by the thermometer 7 to be 1500°C , holding temperature is 1500 ℃.

[0068] When the pure Cu liquid and the Fe-Cu alloy liquid reach the target temperature, start the graphite stopper mechanism 1, let the pure Cu liquid and the Fe-Cu alloy liquid enter the mixing chamber 8 through the guide tube 6 for mixing, and start the air pressure adjustment at the same time Mechanism 11 is used to regulate the flow rate of pure Cu liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com