Patents

Literature

352results about How to "Improve casting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for high-toughness nodular cast iron

The invention provides a preparation method for high-toughness nodular cast iron, which is a method for producing high-toughness nodular cast iron by utilizing a medium-frequency electric furnace and selecting materials such as cast iron which is low in sulfur, phosphor and manganese content, waste steel, and the like. The preparation method mainly comprises chemical component design, furnace burden selection, medium-frequency furnace smelting, a nodulizing agent selection and nodulizing treatment method, a nucleating agent selection and nucleating treatment method, and the like. The method disclosed by the invention does not need thermal treatment and desulfuration treatment, is less in processes, adopts a wet type sand production line to manufacture QT600-10 casting pieces, has casting efficiency higher than that of sand-lined iron type, and is low in cost. The produced nodular cast iron is high in strength, good in plasticity and toughness, can be used for components such as a transmission shaft, a rear axle shell, a differential mechanism shell, a bracket, and the like for a car and a tractor chassis.

Owner:HENAN POLYTECHNIC UNIV

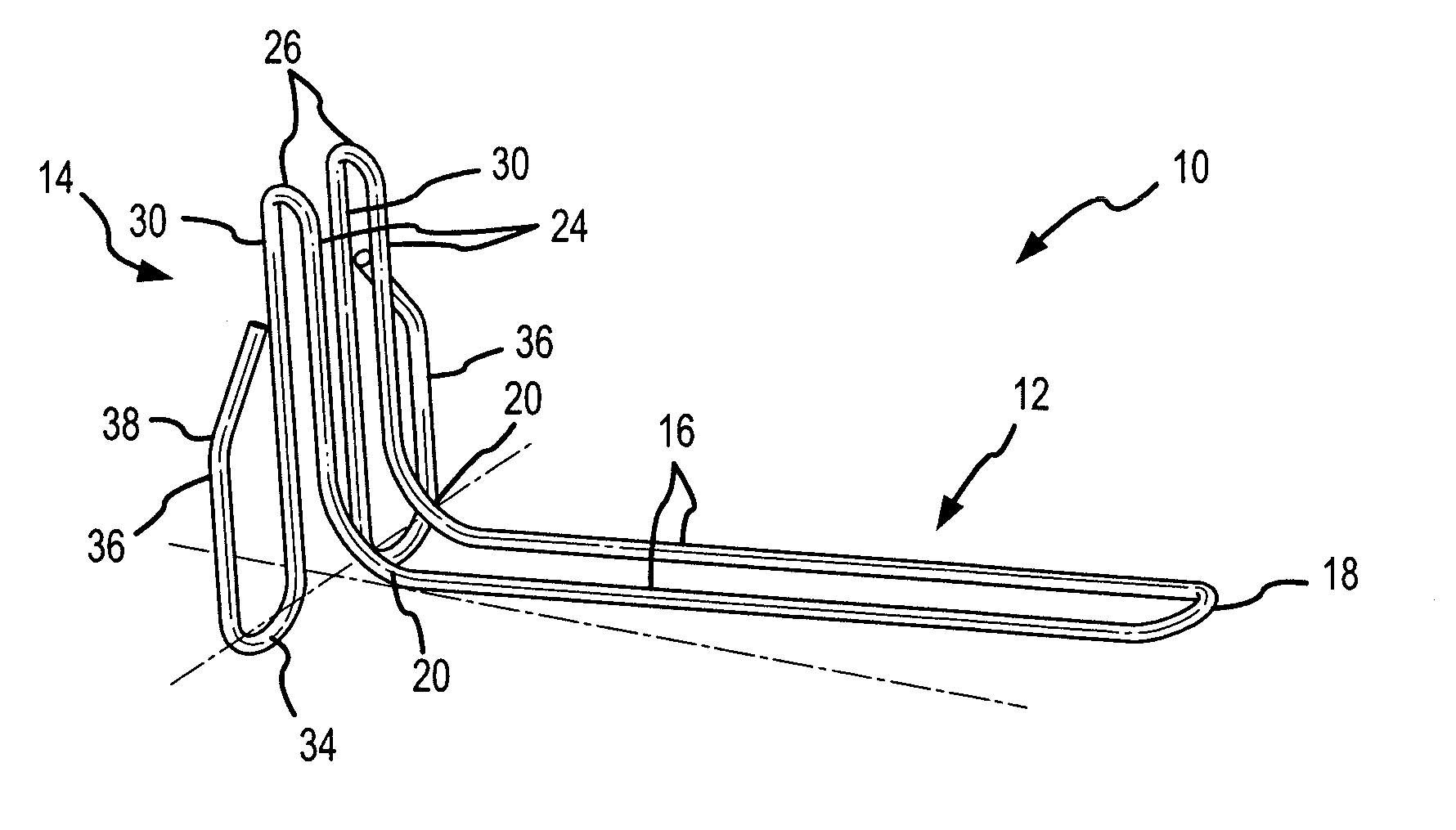

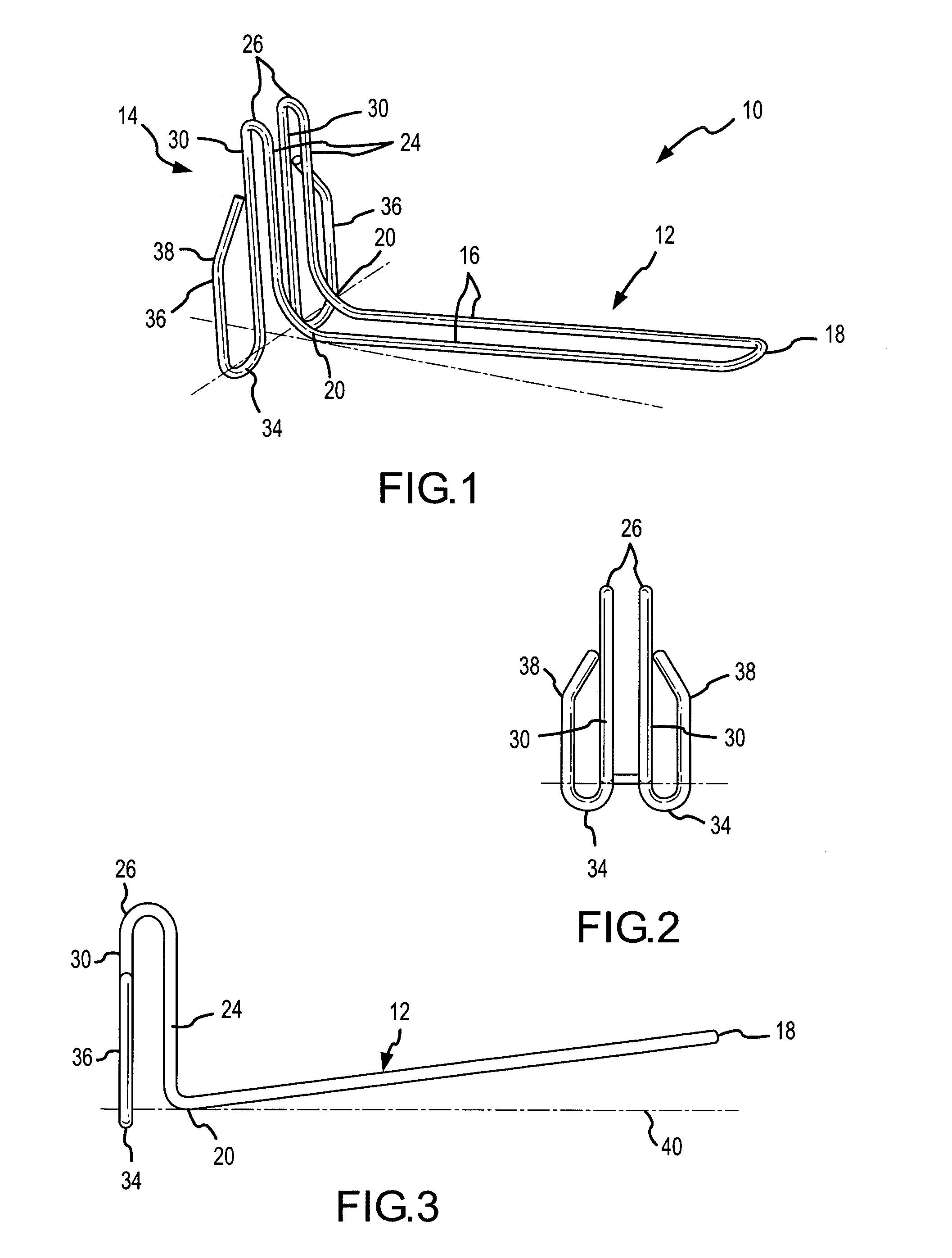

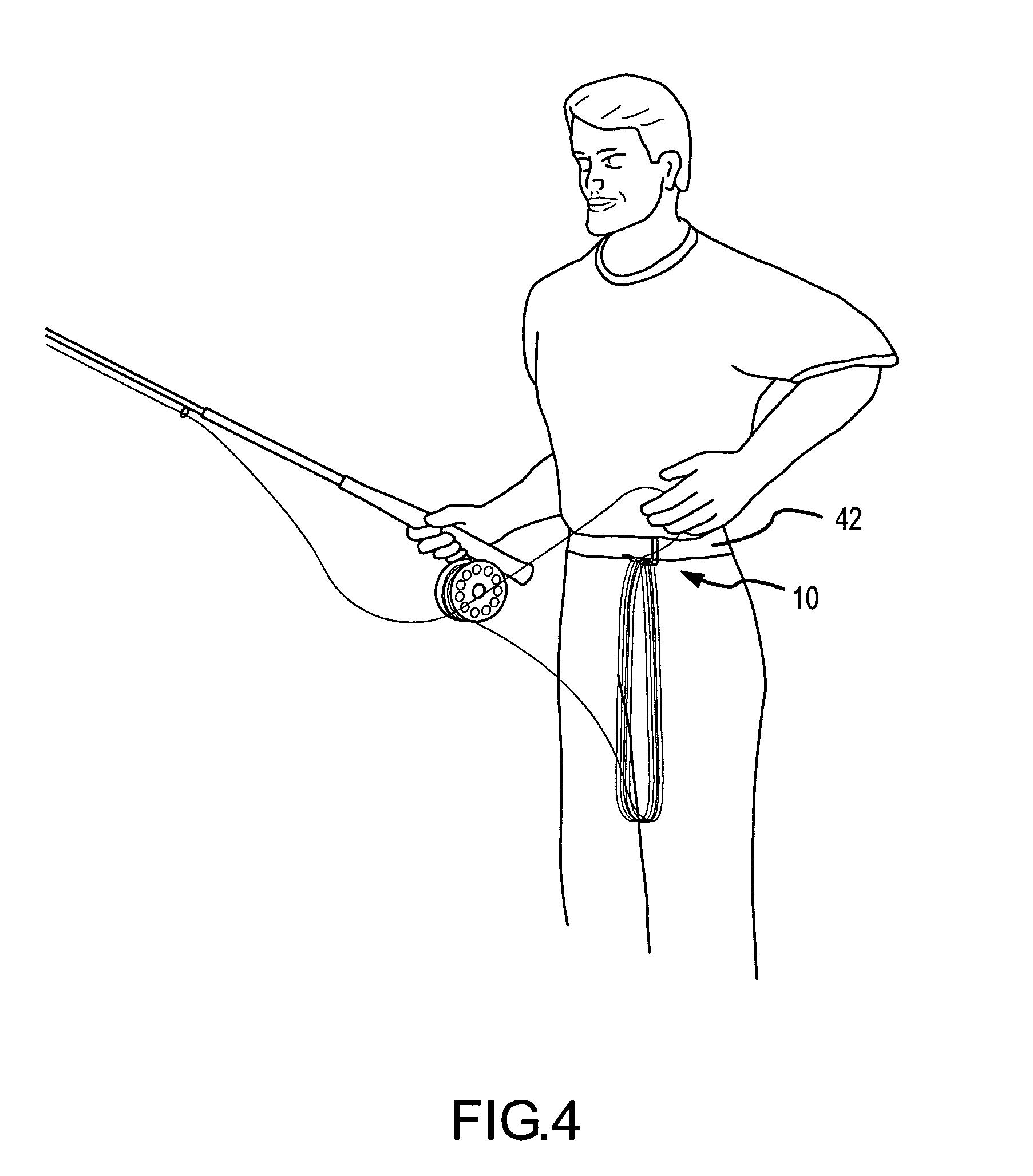

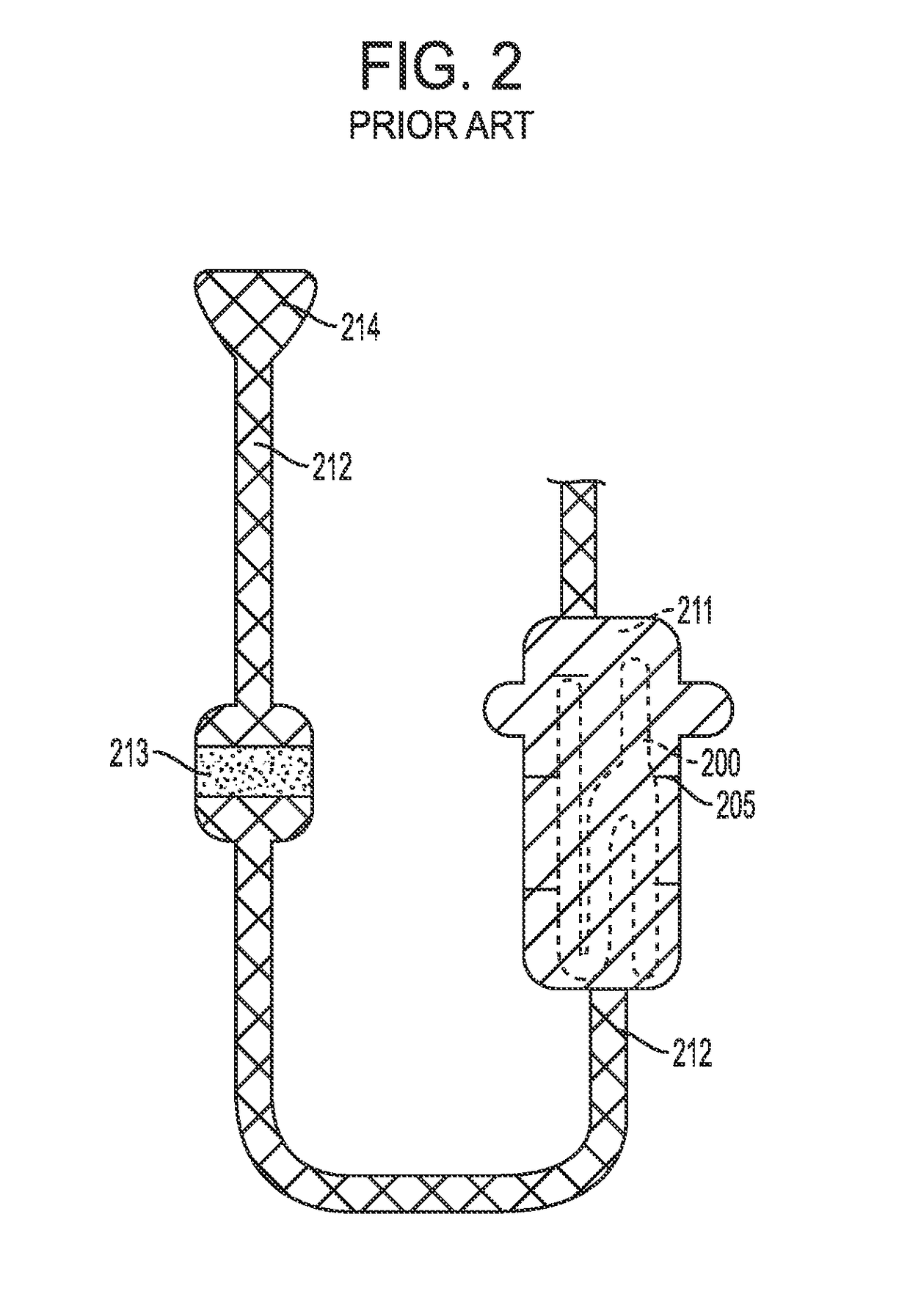

Fishing line retaining device

InactiveUS7140148B1Extended service lifeImprove casting efficiencyTravelling carriersHoldersEngineeringMechanical engineering

A one piece device for temporarily holding fly fishing line stripped from a reel and prior to being cast. The device is made from a single piece of continuous metal rod, bent at various locations along the rod to form a holding arm and a base clip. The fishing line is hung in coils from the holding arm. The clip may be attached to clothing, thereby securing the device on or about an angler, so that when a cast is made, the line uncoils from the arm.

Owner:WILLIAMS II WALLACE W

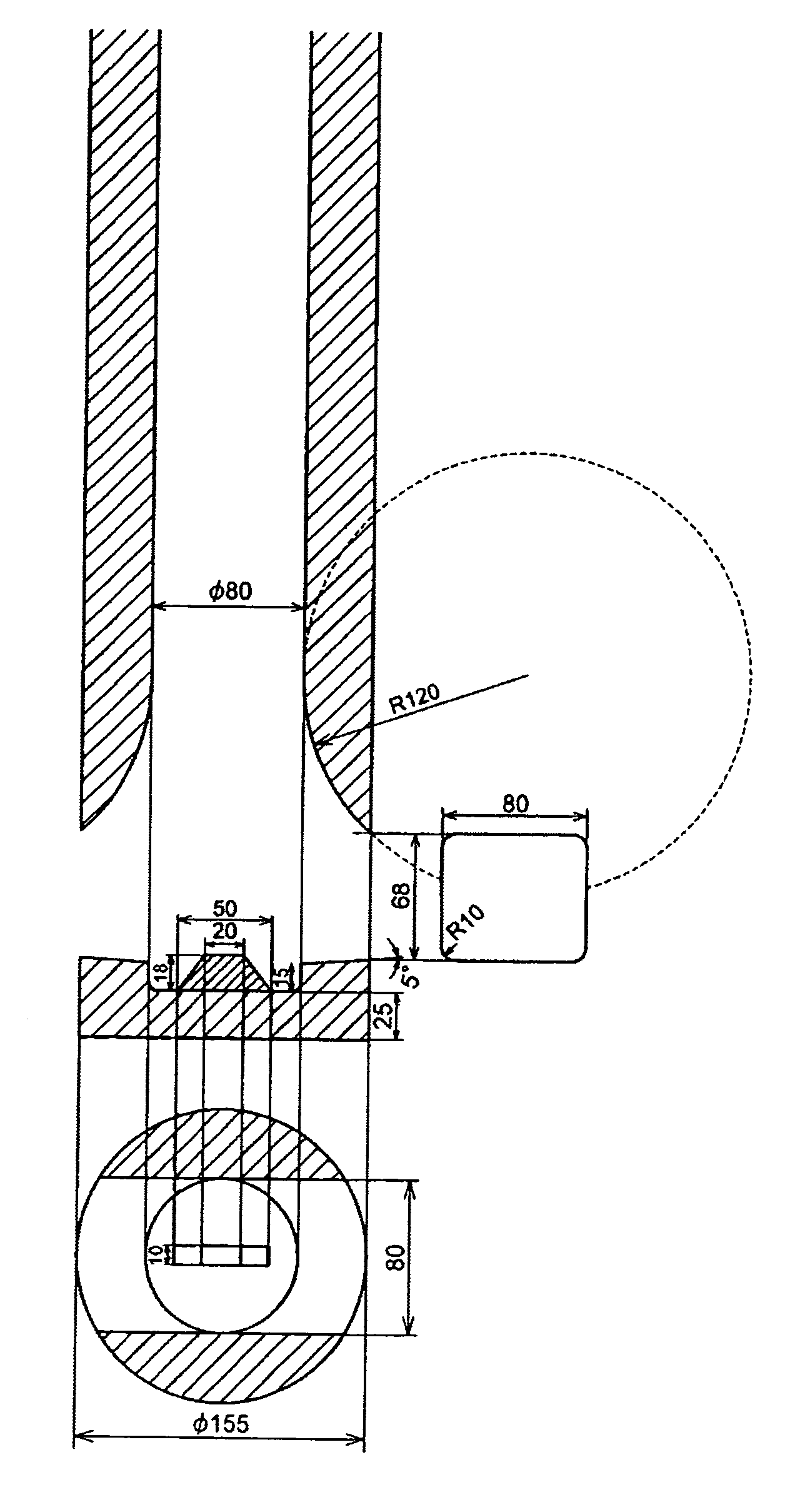

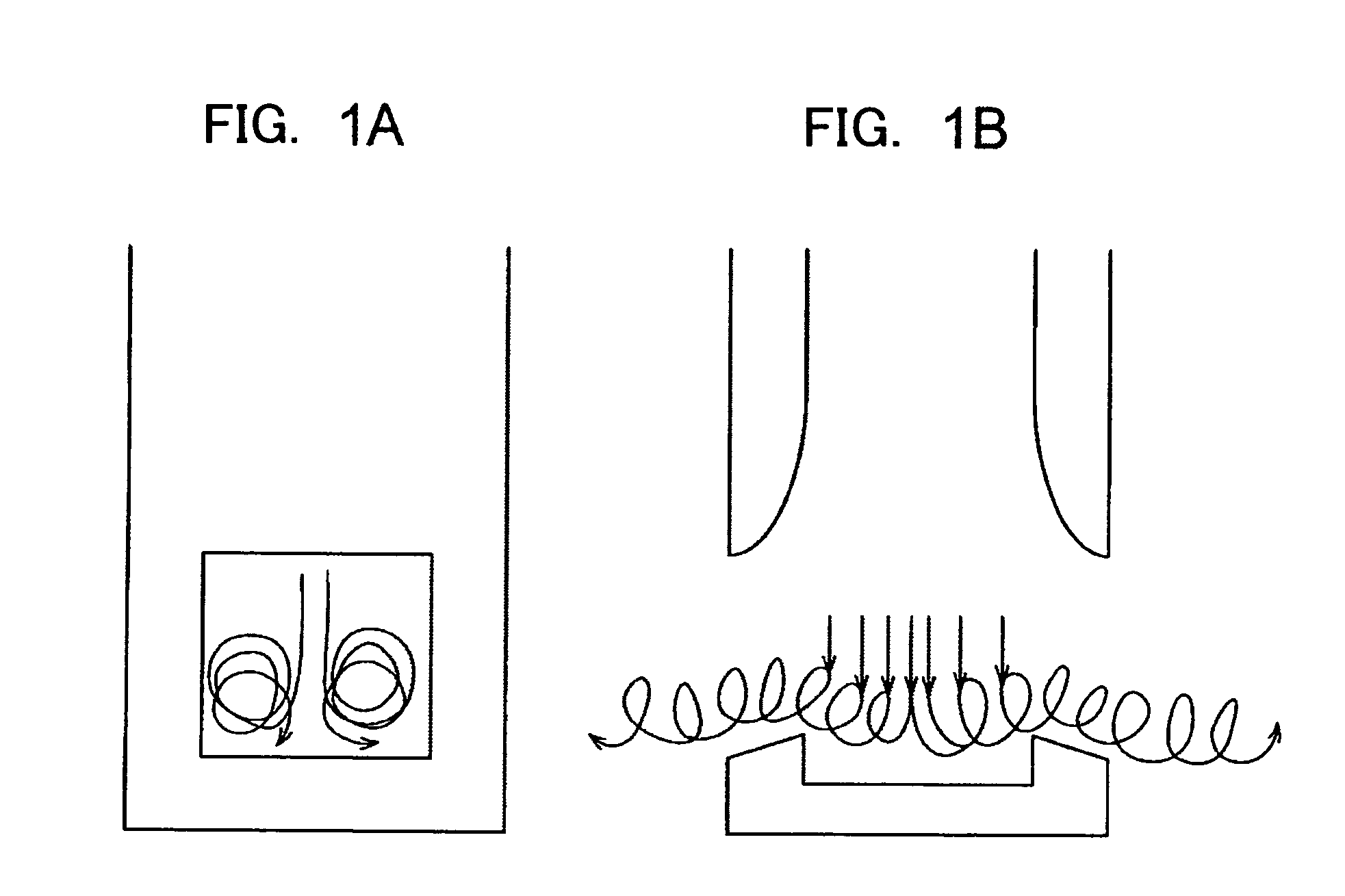

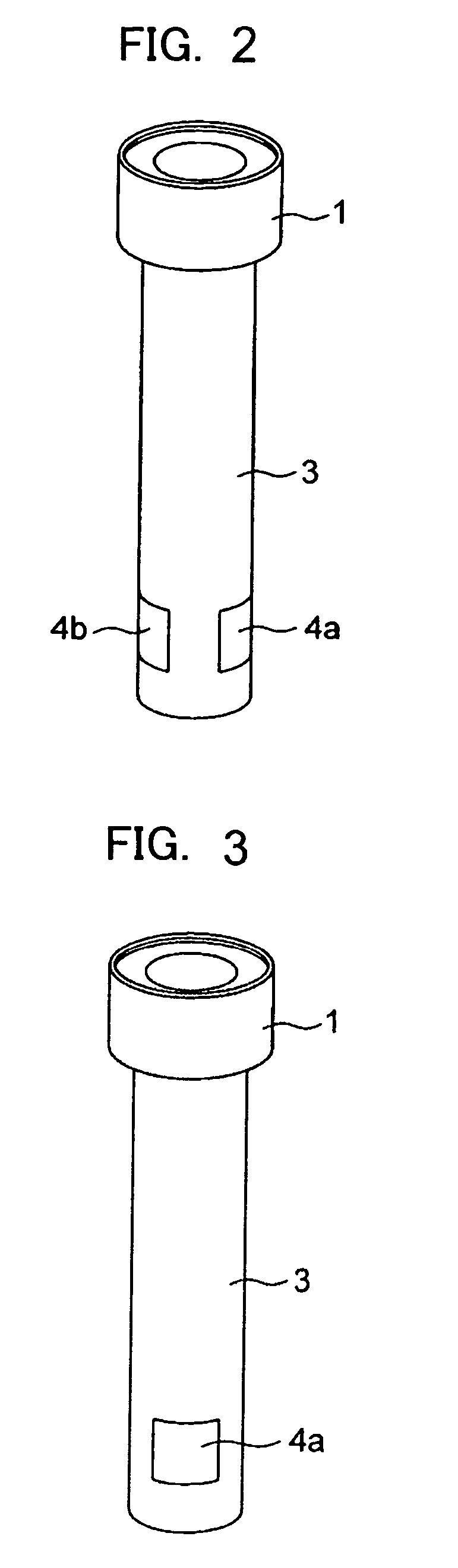

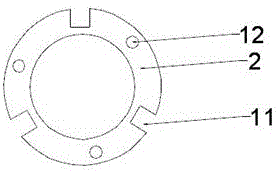

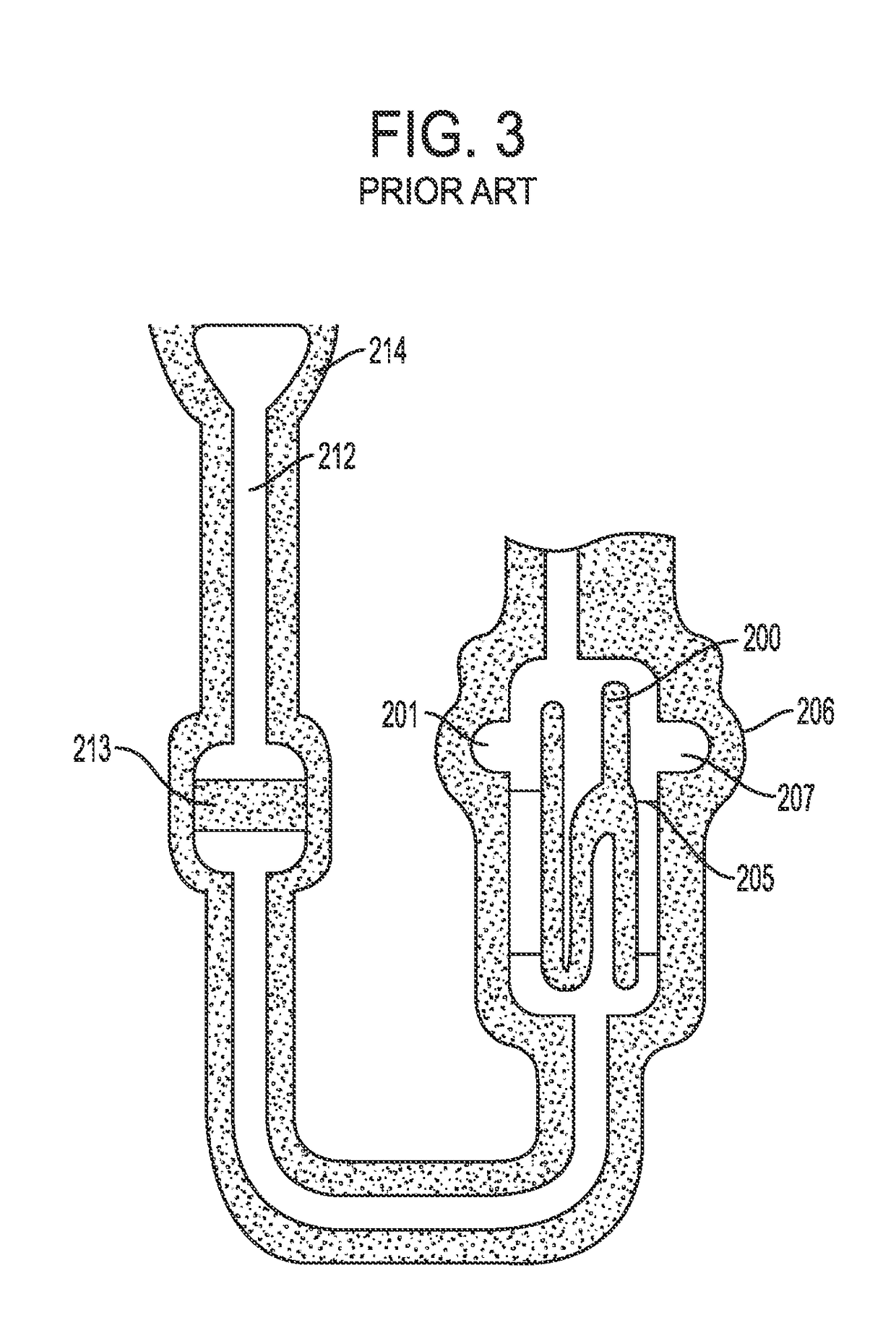

Immersion nozzle for continuous casting and continuous casting method using the immersion nozzle

InactiveUS20070158884A1Stable slab qualityImprove efficiencyMelt-holding vesselsManufacturing convertersMaximum depthSelf excited oscillation

An immersion nozzle for continuous casting which enables improvement in quality of a slab surface and increase in the efficiency of casting by suppressing the self-excited oscillation of a flow in a mold without using a complicated mechanism such as a swirl flow generating immersion nozzle is to be provided. A first immersion nozzle for continuous casting is a nozzle comprising a cylindrical body and a pair of outlet ports formed to face each other in a side wall in the vicinity of a bottom part of the cylindrical body, wherein a ridge-shaped projection extending parallel with the discharge direction projected on a cross section of the nozzle is formed on an inner surface of the bottom part, which is formed in a waterfall basin-like recessed shape having a maximum depth of 5 mm to 50 mm. A second immersion nozzle for continuous casting is a nozzle comprising a cylindrical body and a pair of outlet ports formed to face each other in a side wall in the vicinity of a bottom part of the cylindrical body, wherein each sectional area of the outlet ports vertical to a discharge direction projected on a cross section or longitudinal section of the nozzle is decreased toward an exit.

Owner:SUMITOMO METAL IND LTD

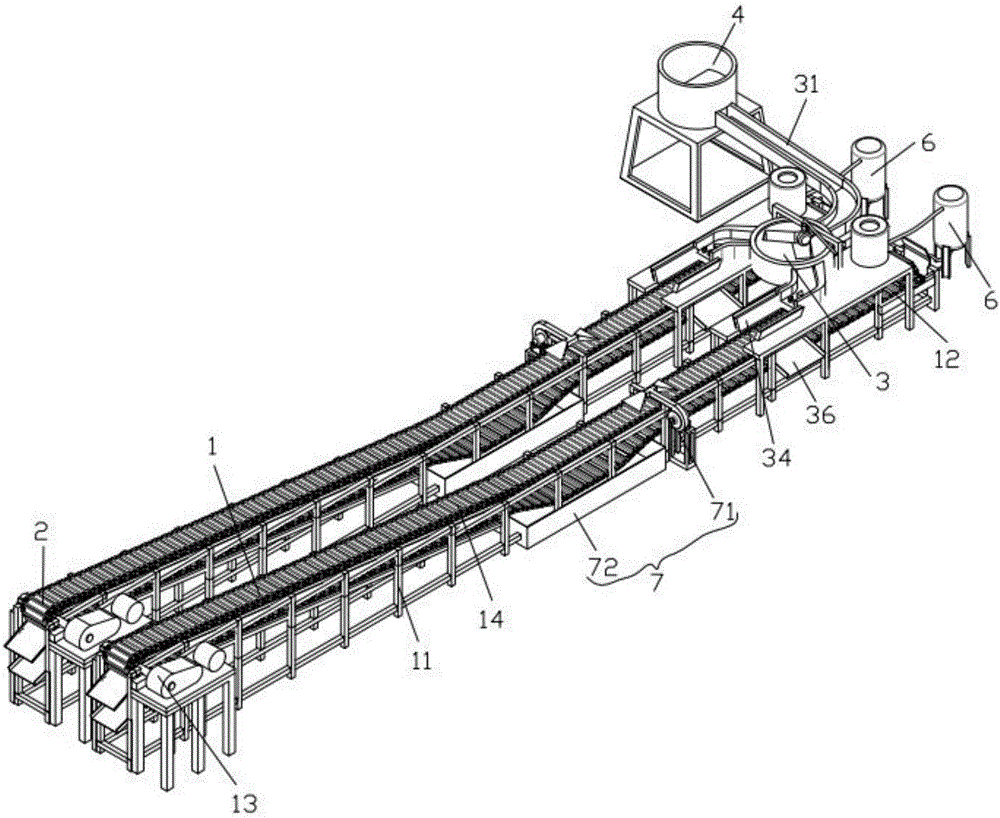

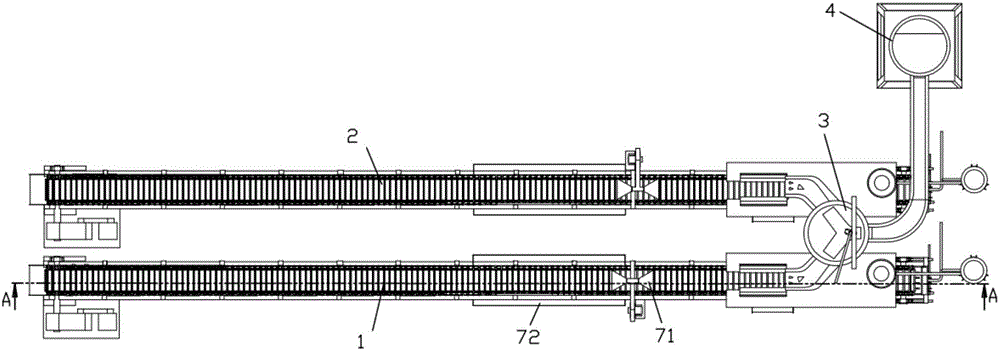

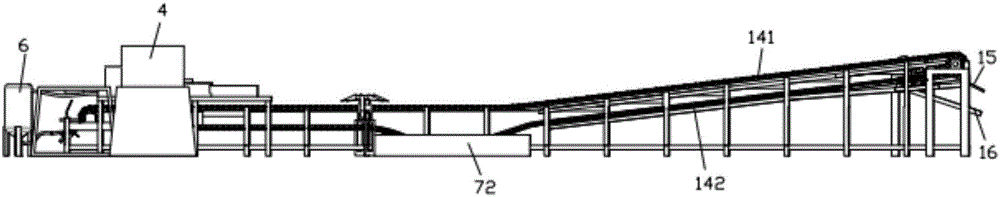

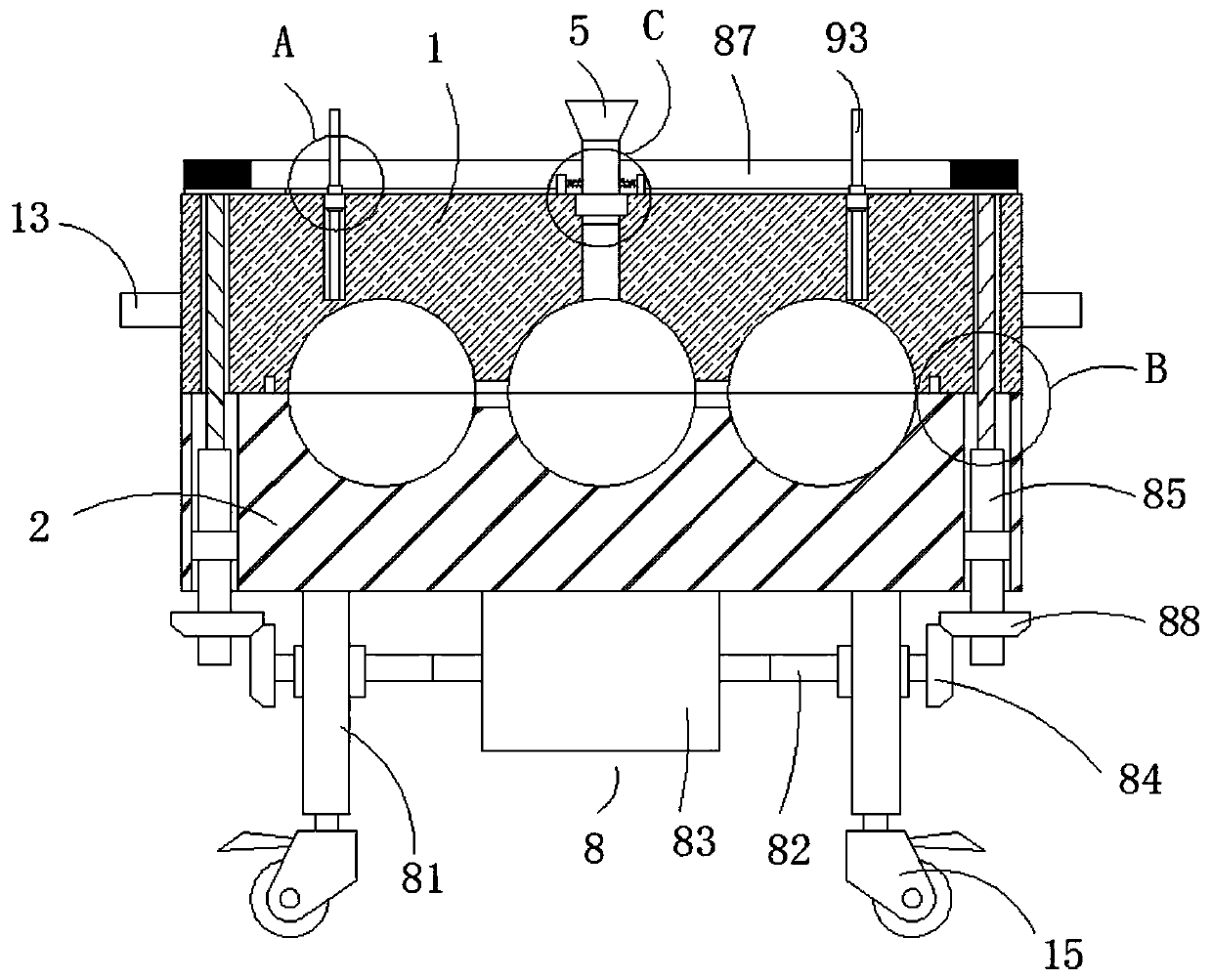

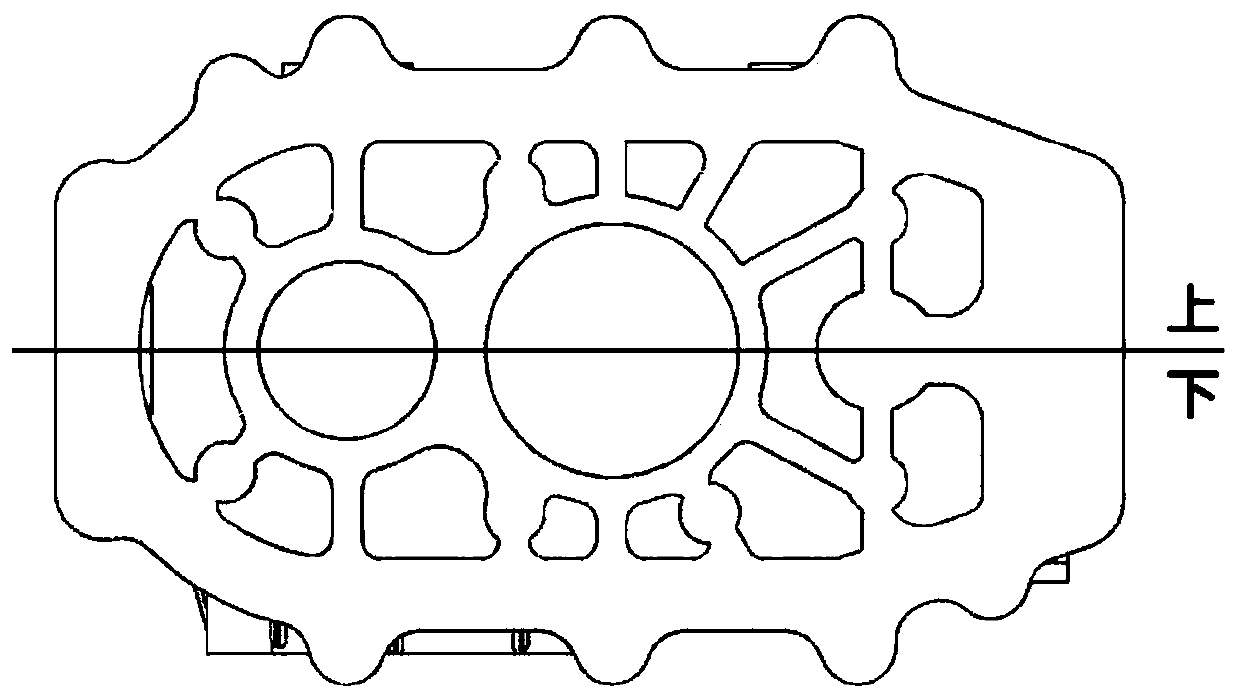

Double-row type continuous casting system

A double-row type continuous casting system comprises a first casting machine, a second casting machine, a flow division device, a molten pool and a self-vibration device. One end of the flow division device is connected with the molten poor, and the other end of the flow division device is connected with the first casting machine and the second casting machine. The first casting machine comprises a casting part. The second casting machine comprises a casting part. The flow division device comprises an upper liquid pipeline, a buffer flow divider, a first flow division pipeline and a second flow division pipeline. One end of the upper liquid pipeline is connected with the molten pool, and the other end of the upper liquid pipeline is connected with the buffer flow divider. The side wall of the buffer flow divider is provided with a confluence inlet, a first flow division opening and a second flow division opening. According to the double-row type continuous casting system, double-channel simultaneous casting is achieved through the first casting machine and the second casting machine, and the purpose of improving the casting efficiency is achieved accordingly; and the flow division device is arranged to reasonably distribute molten metal for the first casting machine and the second casting machine, and double-channel casting is completed accordingly.

Owner:宁夏铸源机械制造有限公司

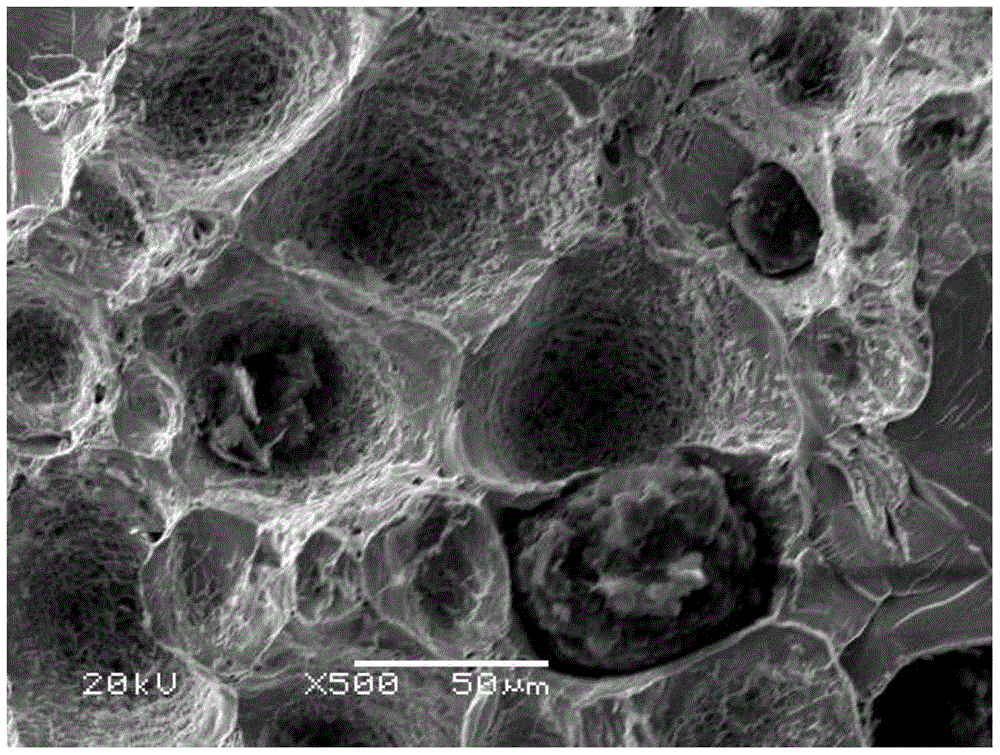

Continuously-cast crystallizer copper liner

The invention discloses a continuously-cast crystallizer copper liner, which is prepared by a method comprising: preparing copper-aluminum alloy powder with an aluminum content of 0.03 to 0.6 weight percent, wherein the grain size of the copper-aluminum alloy powder is less than 150mum and the grain size of over 50 weight percent of powder is less than 74mum; filling the copper-aluminum alloy powder in an oxygen supply furnace, supply oxygen in a molar ratio of the oxygen to the aluminum in the copper and aluminum alloy of 3:2 to 6:2, and heating the copper-aluminum alloy powder to 100 to 300 DEG C to perform reaction for 3 to 30 hours; preparing dispersion copper powder ingot blanks; extruding the ingot blanks at 700 to 1,000 DEG C to a nearly formed pipe; drawing the extruded pipe blank by required specifications; and plating the surface of the drawn pipe blank. The copper alloy liner of the invention has the advantages that: casting efficiency can be improved greatly; the casting drawing speed can be improved by 1.5 to 2 times compared with the original drawing speed; the service life of the crystallizer copper pipe is improved greatly; and the productivity of the crystallizer is 1.5 to 3 times that of the traditional crystallizer.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

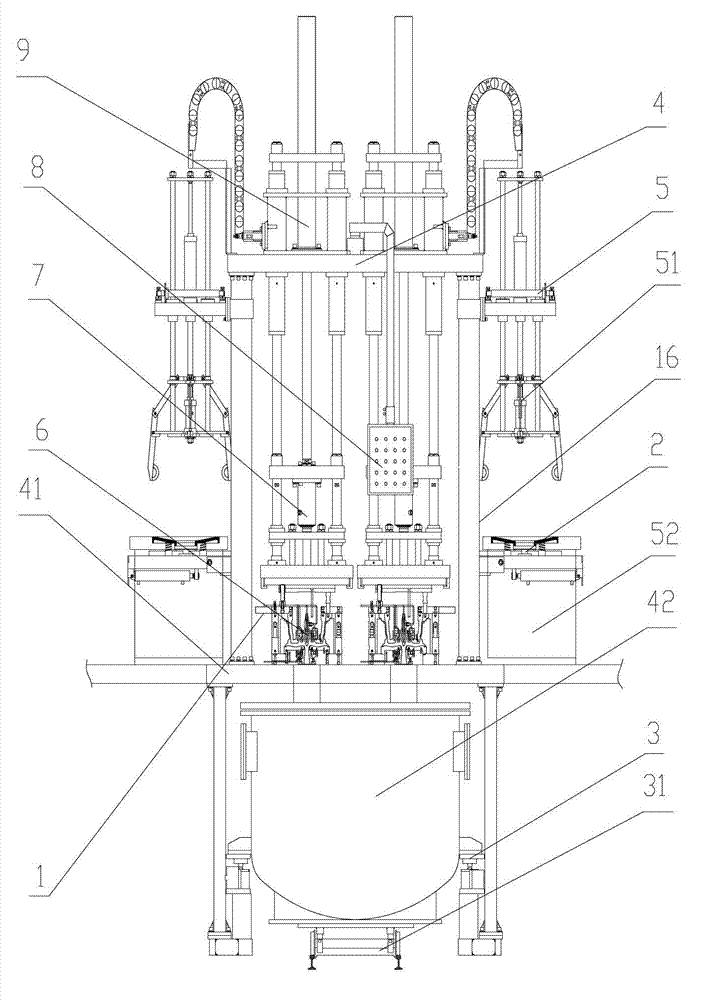

Dual-station low-pressure casting machine

The invention discloses a dual-station low-pressure casting machine, which comprises a rack, wherein the middle of the rack is provided with a table plane; the left and the right of the table plane are provided with two sets of hub modules in parallel; the rack is provided with a maintaining furnace below the table plane; the maintaining furnace is respectively communicated with cavities of the two sets of hub modules by two stalks and pouring gates on the two sets of hub modules; the rack is provided with an upper module lifting mechanism and a demoulding mechanism above the hub modules, wherein the upper module lifting mechanism drives an upper module to lift; the demoulding mechanism is used for separating the upper module and a hub which are tightly combined; and the rack is respectively provided with one set of material carrying mechanism on the left side and the right side of the two sets of hub modules to carry the demoulded hub. The dual-station low-pressure casting machine has the advantages of high casting efficiency and energy saving, and consumption and cost are lowered.

Owner:ZHEJIANG JINYUE MACHINERY TECH DEV

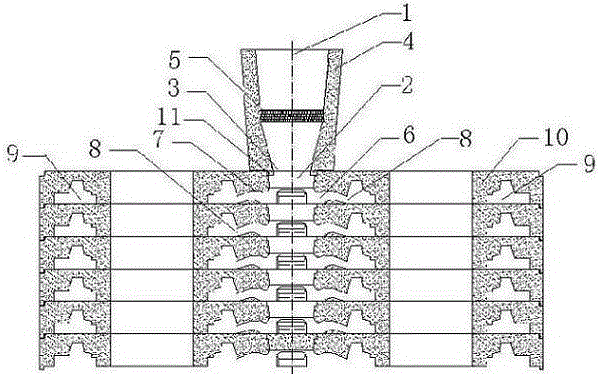

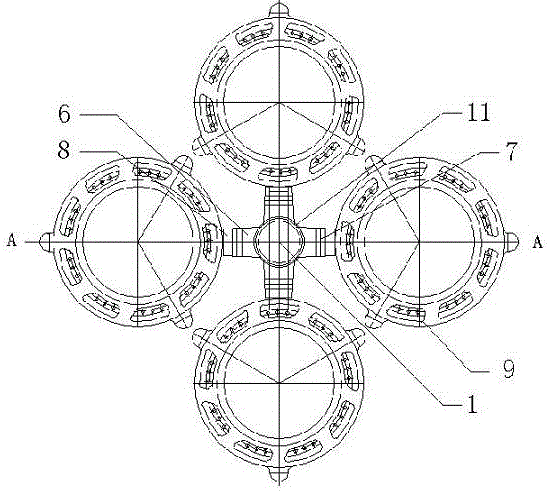

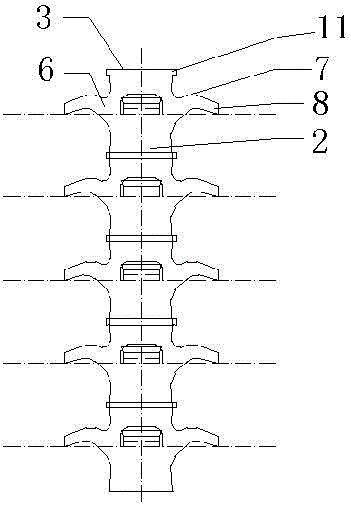

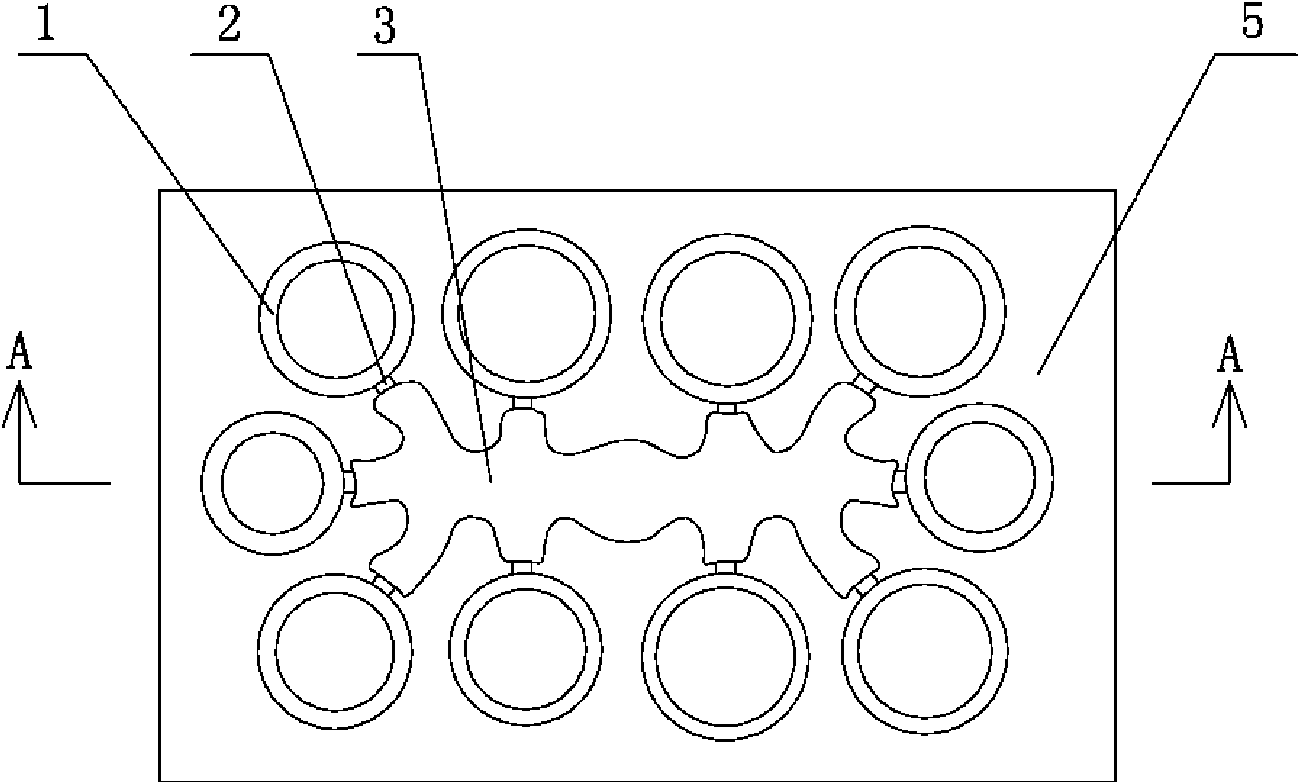

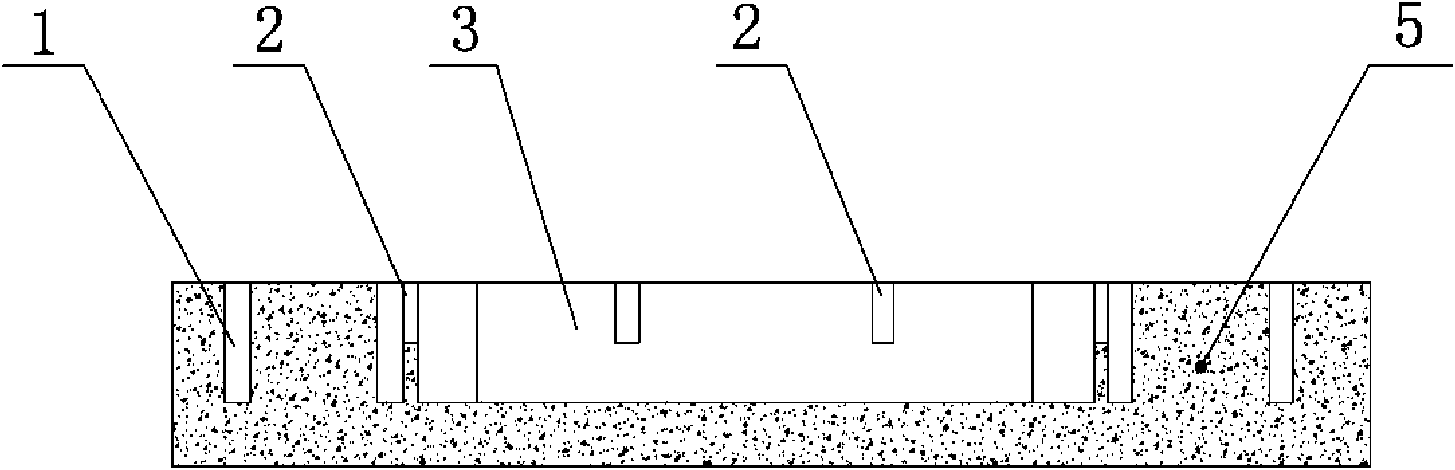

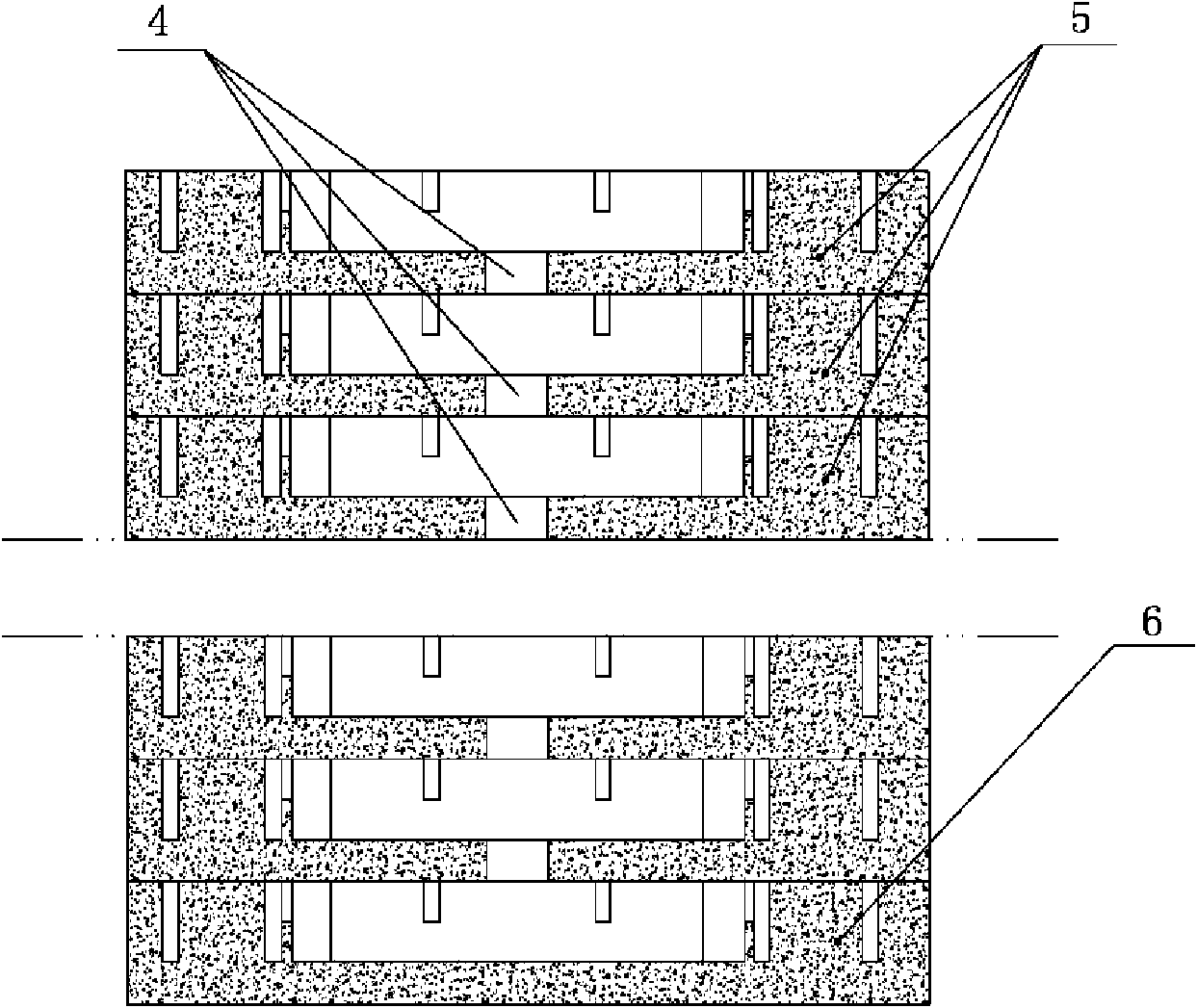

Efficient multipart multilayer stacked pouring system and technology

InactiveCN104985127AImprove casting efficiencyImprove utilizationFoundry mouldsFoundry coresSlagEngineering

The invention discloses an efficient multipart multilayer stacked pouring system and technology. The system is characterized in that the pouring system is divided into a plurality of layers which are stacked; a sprue is arranged in each layer, and the sprues are cavities with pouring gates at the upper ends and the lower ends; the pouring gate of the pouring system body on the top layer is sleeved with a pouring gate cup, and the pouring gate at the lower end of each layer of pouring system body is arranged on the pouring gate at the upper end of the next layer of pouring system body in a sleeving manner; and the pouring gate of the bottom layer of pouring system body is sealed. Two or more transverse sprues are evenly distributed on the inner sides of the sprues, and are led to the inner pouring gates; and the inner pouring gates are communicated with product sand mould cavities; and the transverse sprues are circular-arc cavities, and slag accumulating plates are arranged on the inner walls of the cavities at the circular-arc upper ends of the transverse sprues. According to the efficient multipart multilayer stacked pouring system, each of the multiple layers of stacked pouring system bodies is provided with a plurality of inner pouring gates to pour a plurality of multilayer stacked castings, and the casting production efficiency is improved; and the casting time is shortened, the composition and temperature balance of multilayer cast molten iron can be ensured, and the quality of cast products can be improved.

Owner:HUBEI YAGANG METAL MFR

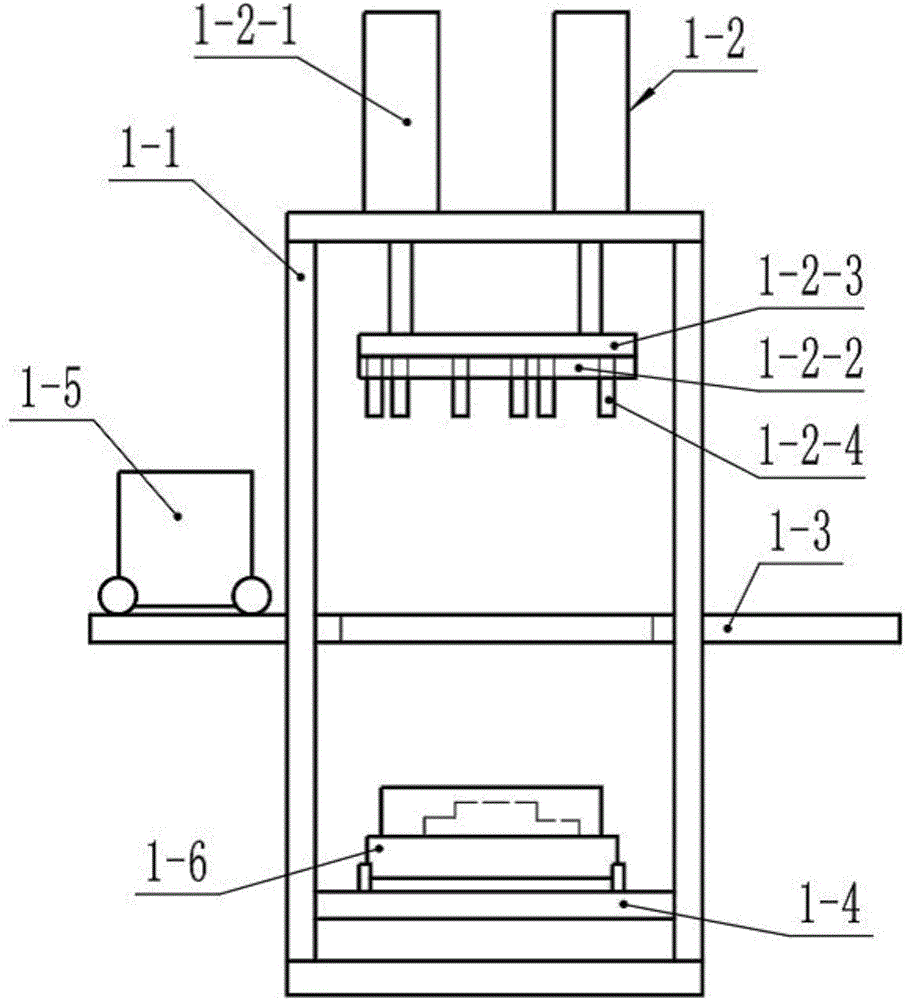

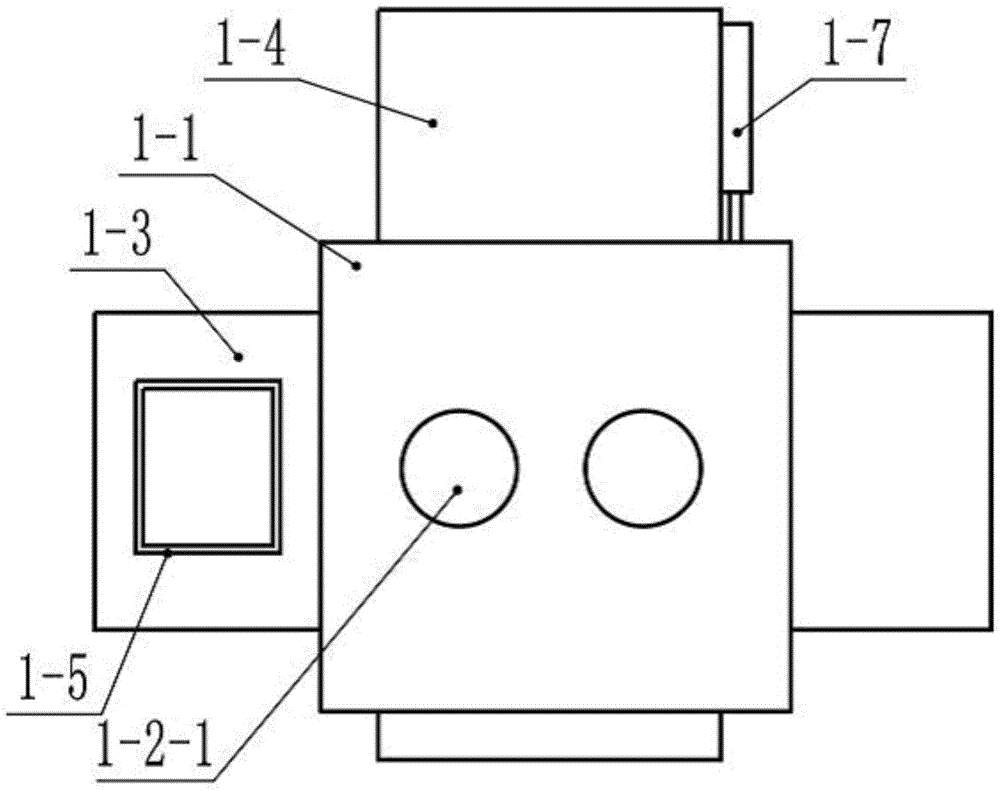

Casting production line

InactiveCN105798283AFully automatedCompact structureCasting plantsMoulding machinesManufacturing lineIndustrial engineering

The invention provides a casting production line. A full-automatic sand box molding device is provided with a frame (1-1) and a sand smashing device (1-2). A sand adding track (1-3) horizontally arranged is installed in the middle portion of the frame (1-1). A die track (1-4) horizontally arranged is installed at the bottom of the frame (1-1). The full-automatic sand box molding device further comprises a control box. The sand adding track (1-3) is provided with a sand frame (1-5) controlled by the control box to horizontally move along the sand adding track (1-3). The top and the bottom of the sand frame (1-5) are both provided with openings. A sand falling port is further formed in the sand adding track (1-3), located under the sand smashing device (1-2) and located over the die track (1-4). According to the casting production line, automatic casting production can be achieved, repeated utilization of casting sand is achieved, and the casting production line has the beneficial effects of being good in casting quality, high in efficiency, low in labor cost, capable of saving energy and environment-friendly.

Owner:徐明

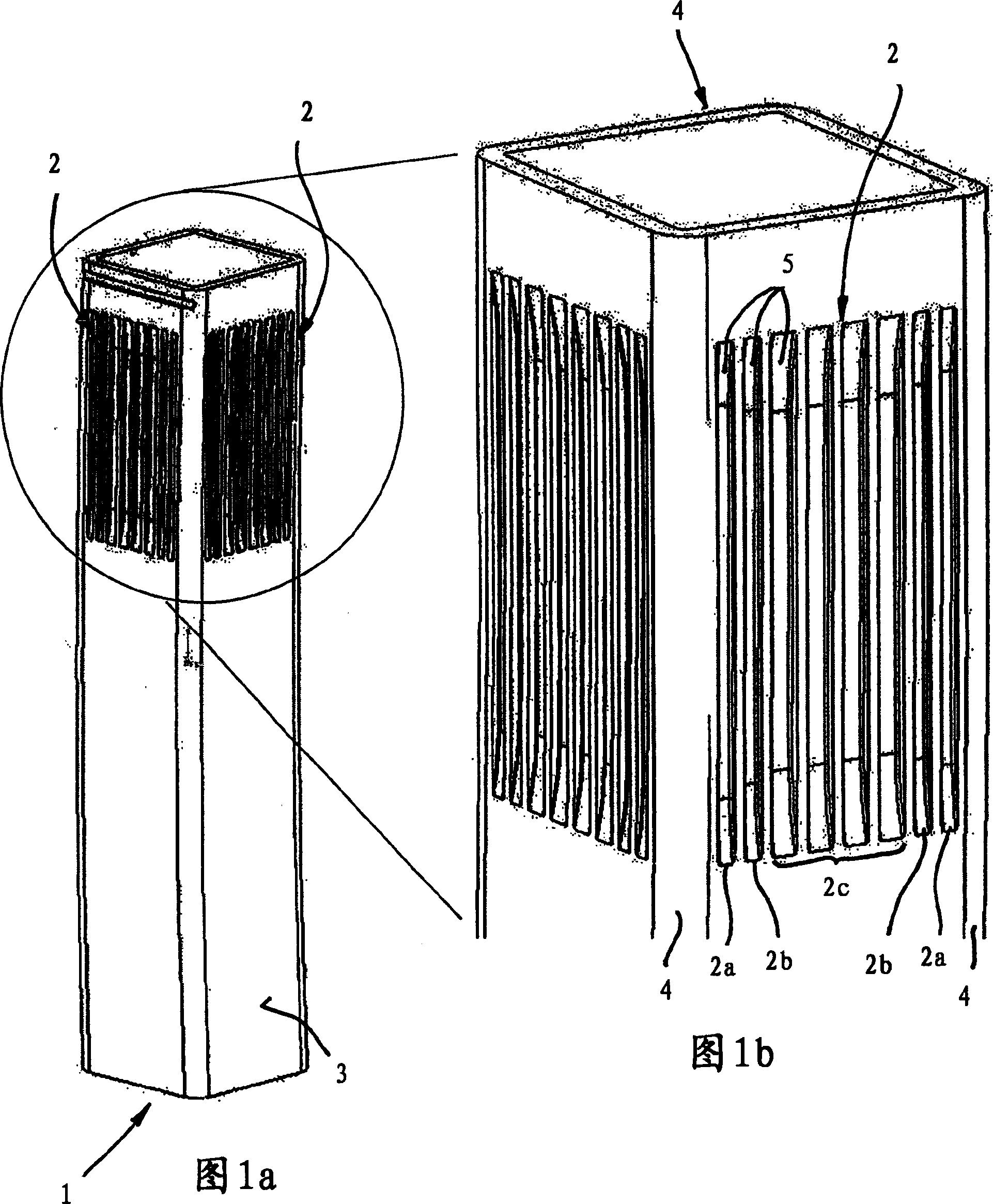

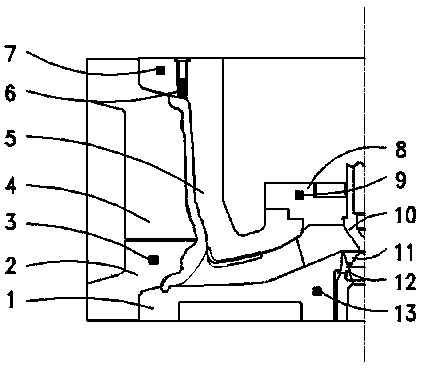

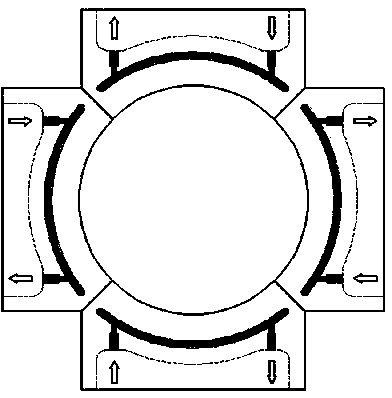

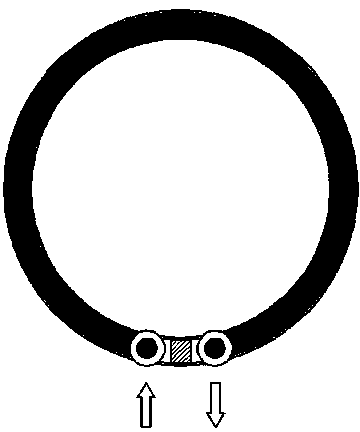

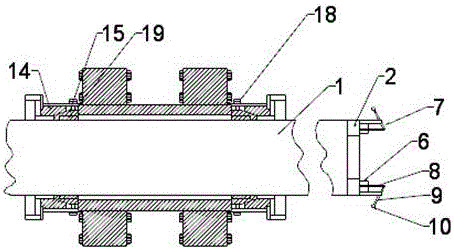

Mould for continuous casting metal

The invention relates to a crystallizer (1) for continuous casting metal, wherein cooling vats (2, 2a, 2b, 2c) are arranged at least one part region of the crystallizer outer surface. The depth and / or width of cooling vats (2, 2a, 2b, 2c) in centre of the crystallizer (1) parietal side is maximal, and minish in the direction of corner regions (4) of inner parietal side. Thereby, heat dispersed uniformly and higher casting speed is possible with said heat dispersing.

Owner:KME GERMANY GMBH & CO KG

Graphite paste spray material of anode steel claw and spraying method of graphite paste sprayer

InactiveCN103084315AReduce frequency of refillingImprove efficiencyLiquid surface applicatorsCoatingsKeroseneGraphite

The invention discloses a graphite paste spray material of an anode steel claw and a spraying method of the graphite paste spray material. The graphite paste spray material comprises, by mass, 5-24% of graphite and the balance kerosene. The spraying method includes: utilizing compressed air at 0.3-0.6 megapascal as a carrier to spray the kerosene on the surface of the anode steel claw via a spraying tool; and after 5-10 seconds, utilizing the compressed air at 0.3-0.6 megapascal as a carrier to spray graphite powder on the surface of the anode steel claw via the spraying tool. In the graphite paste spray material in the embodiment, graphite content is greatly reduced, cost is saved, particles are diminished, the graphite paste spray material are easy to attach on the surface of the anode steel claw, and stability is enhanced.

Owner:SNTO TECH GRP

Expendable casting process method for heat-resistant steel perforated grate plate

An expendable casting process method for a heat-resistant steel perforated grate plate comprise employing a copolymerization material for foaming for preparing an expendable-casting-process heat-resistant steel perforated grate plate foam model, singly preparing a pouring gate, binding the heat-resistant steel perforated grate plate model with the pouring gate for combination, so as to form a combined model; putting the combined model in a special coating pool for three-time sagging of a coating and three-time baking, and controlling the accumulated thickness of the coating subjected to three-time baking to be 0.8 mm-1.5 mm; again combining the baked combined model in a negative-pressure sandbox by taking 10 models as a pouring body, and forming two pouring bodies; adding sand into the sandbox and compacting through shaking; vacuumizing the sandbox and performing oxygen-enriched combustion on the model to form a hollow shell; and finally performing casting. The casting method is simple in steps, convenient to operate, high in casting efficiency and good in effect, is capable of effectively improving the surface quality of the casting and preventing disadvantages that the casting generates burnt-on sand, sand inclusions, pores and carburets, and helps to reduce labor intensity and save production cost.

Owner:渠县金城合金铸业有限公司

Aluminum wheel water cooling low-pressure casting die and technology

InactiveCN104353813AIncrease the speed of solidificationImprove mechanical propertiesPressure castingMold filling

The invention discloses an aluminum wheel low-pressure casting water cooling die. A center die insert 8 is provided with a water cooling channel 9 for cooling the wheel center; a water cooling channel 7 for cooling the inner rim is arranged at the upper part of a head die 5; a lower edge die 2 is provided with a water cooling passage 3 for cooling a wheel hot spot. The casting technology mainly includes a slow-to-quick mold filling technology and a water-to-air cooling technology. According to the invention, the performance quality of the aluminum alloy wheel casting is improved, and the performance quality of the casting is greatly improved in stability and consistency due to the adoption of the slow-to-quick mold filling technology and the water-to-air cooling technology; the high water cooling intensity increases the freezing rate of the casting, thereby increasing the casting production efficiency; cooling water flows in the water cooling channels relatively sealed, so that noise pollution caused by compressed air in the air cooling technology is eliminated, and the casting working condition is improved.

Owner:CITIC DICASTAL

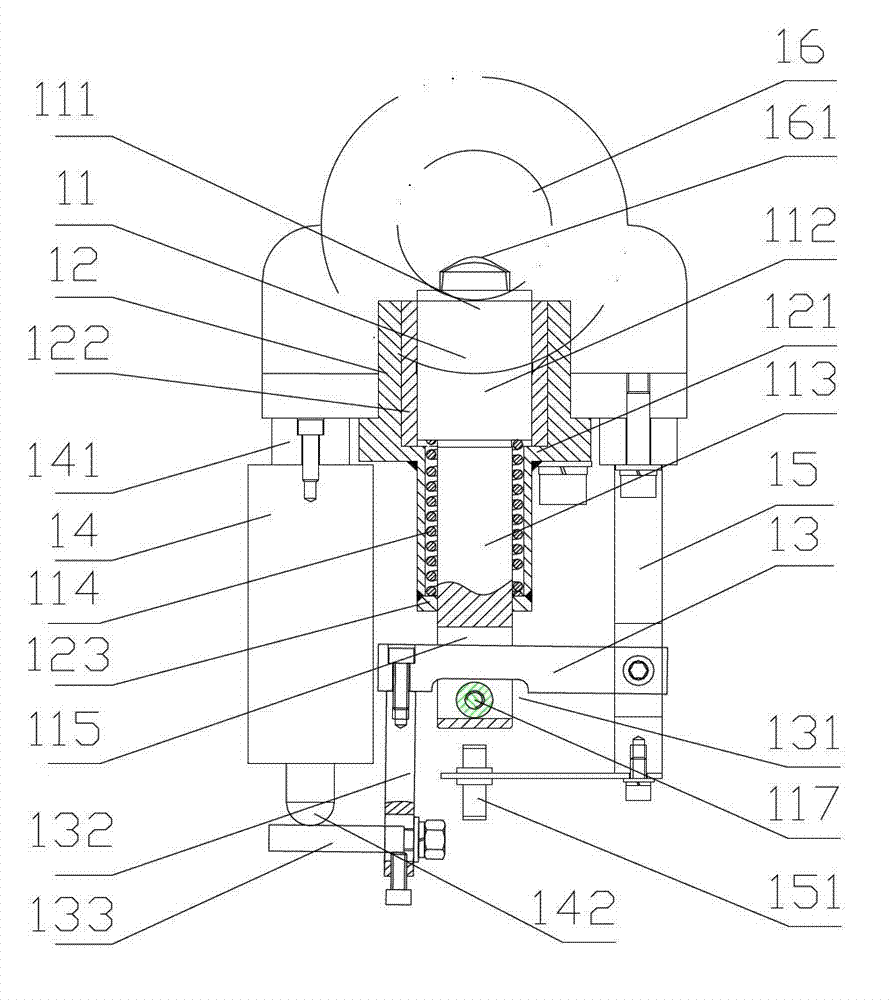

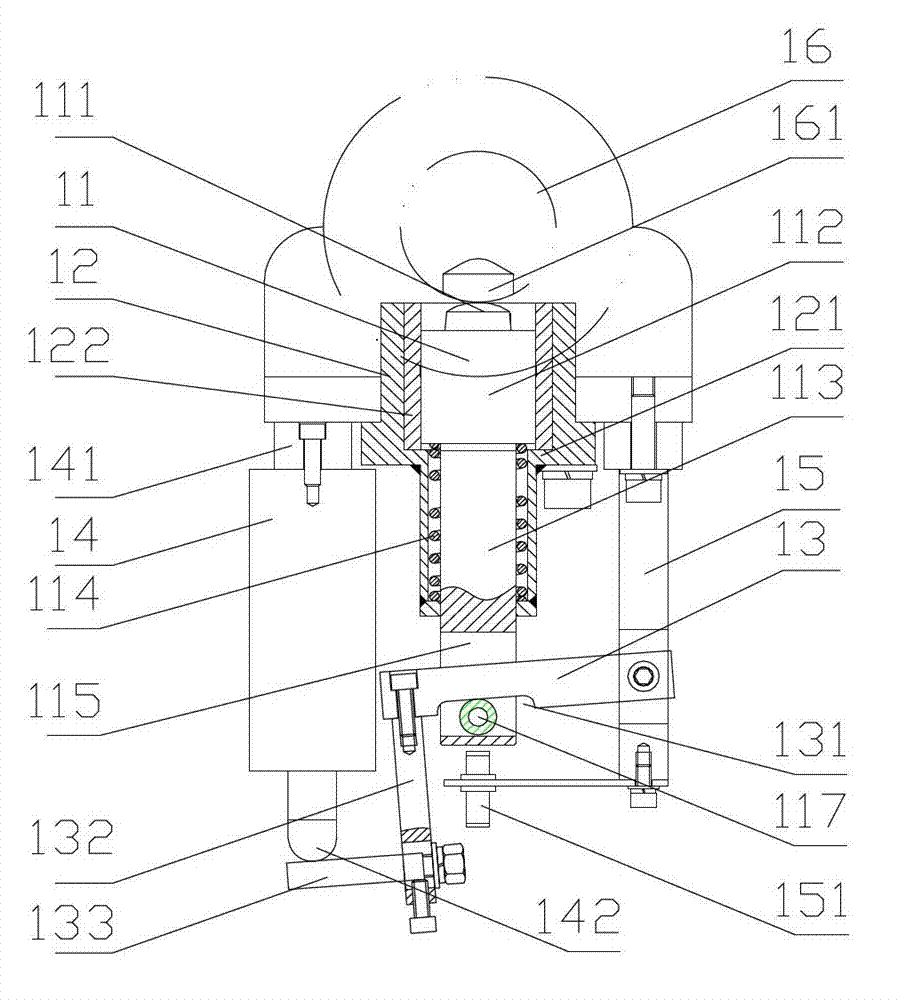

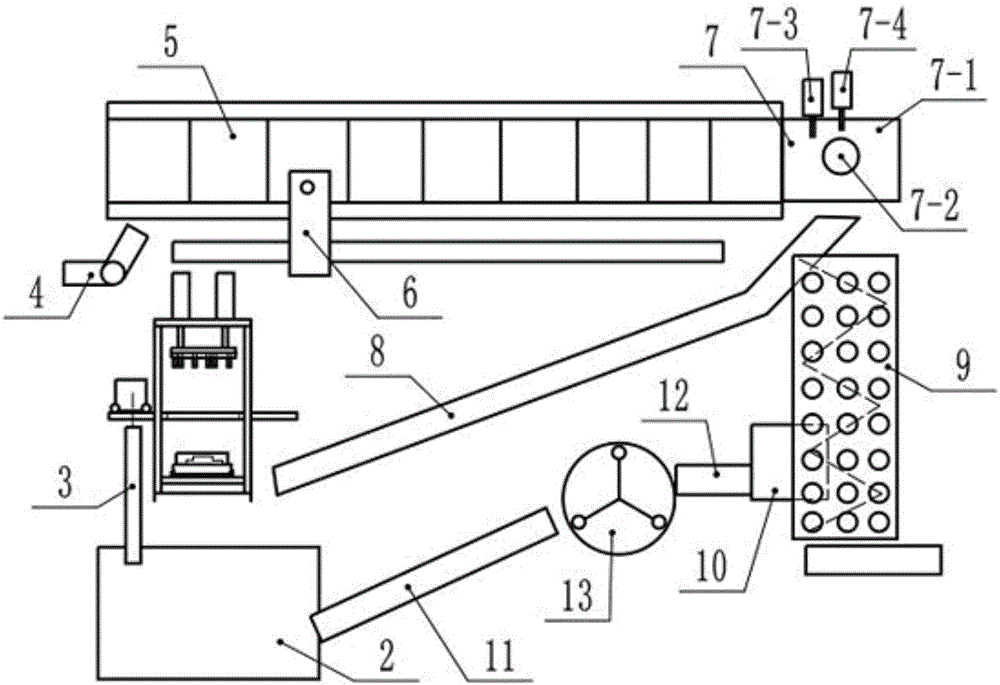

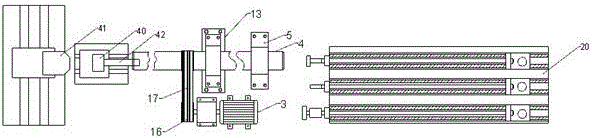

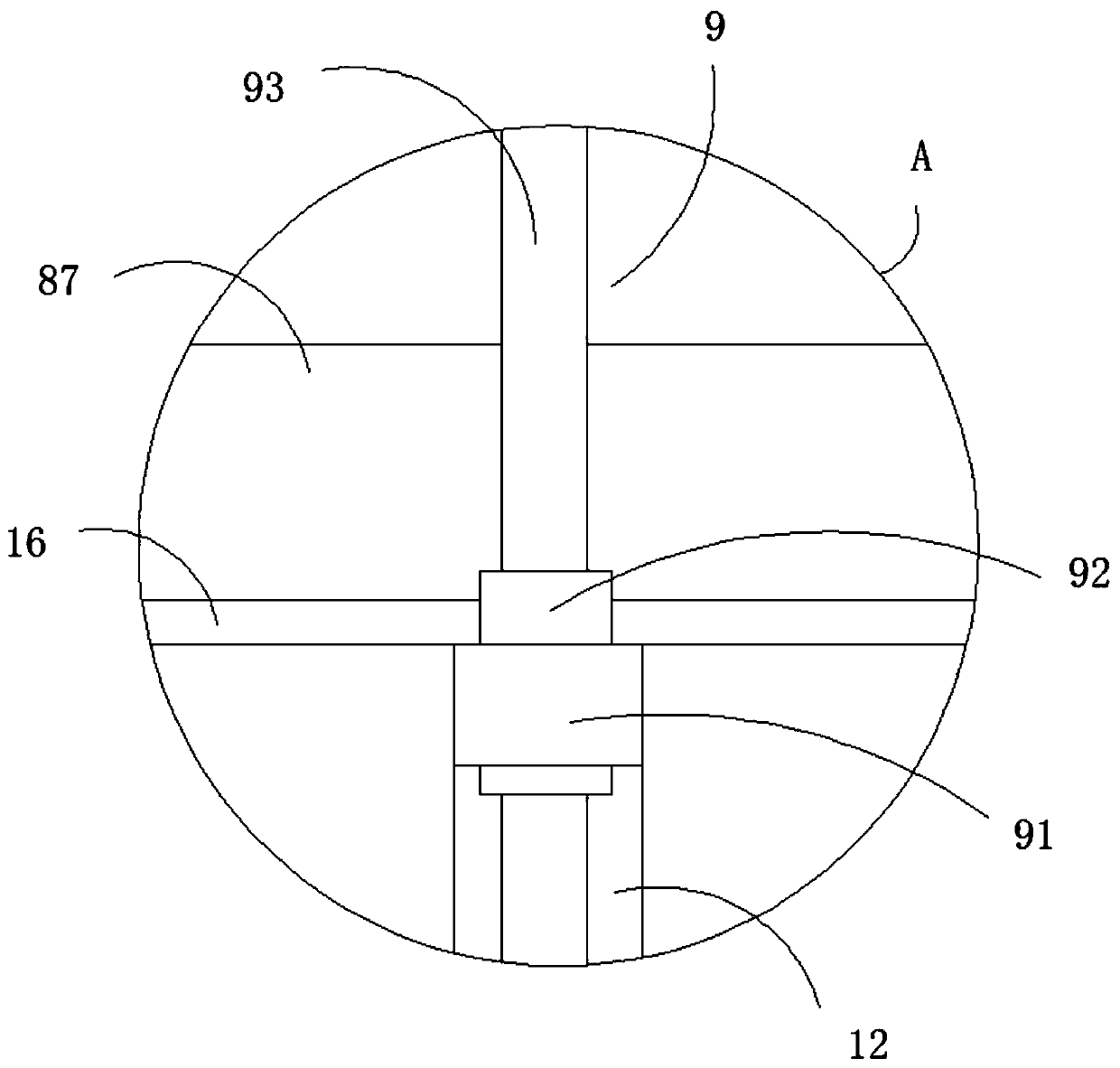

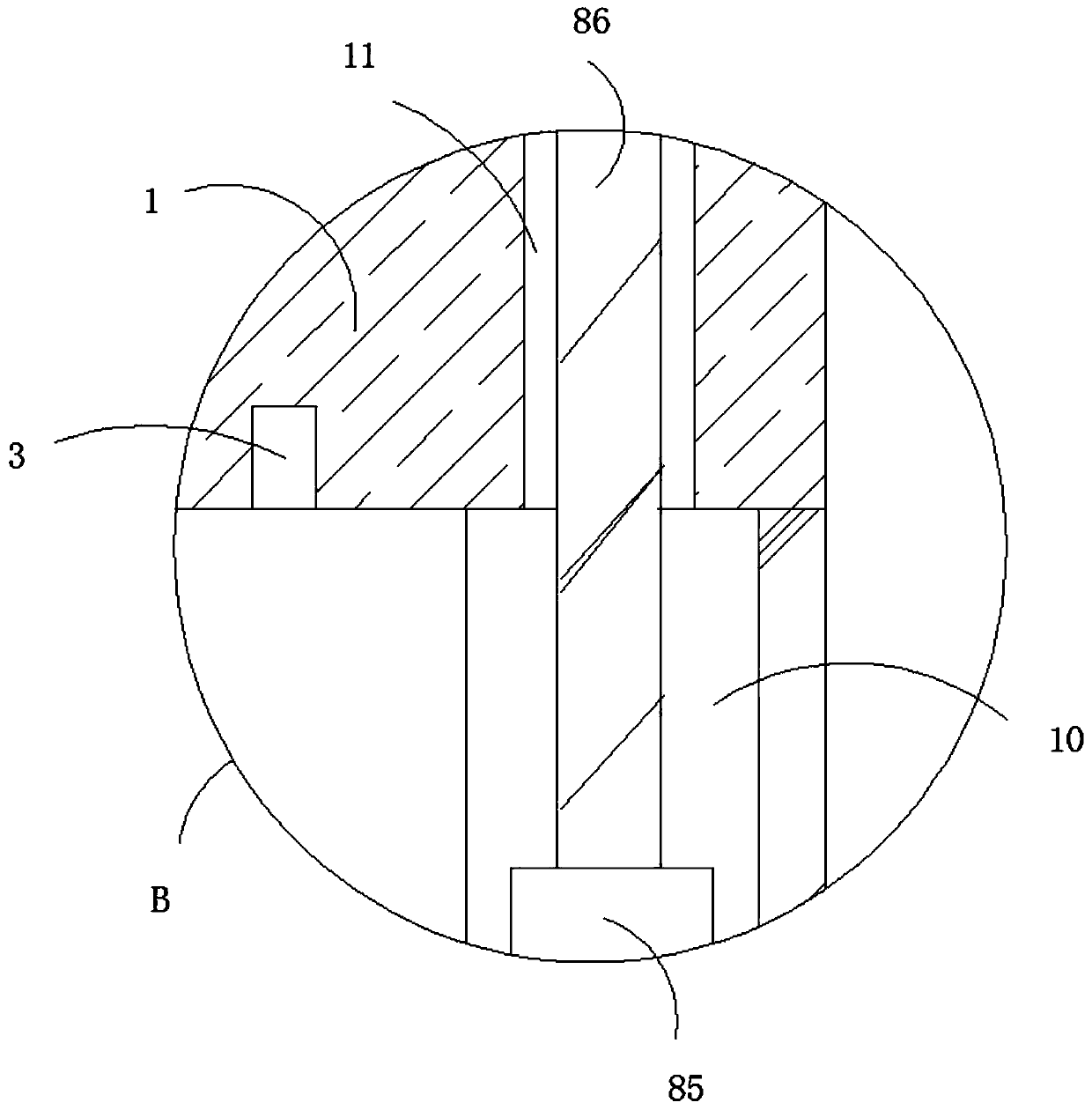

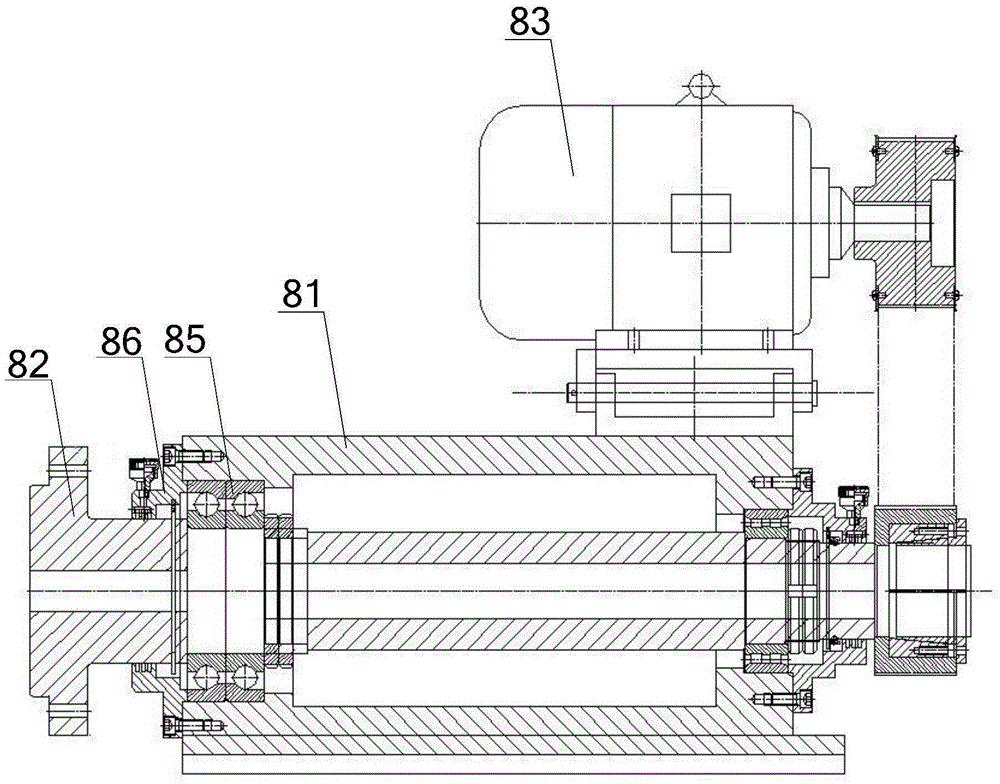

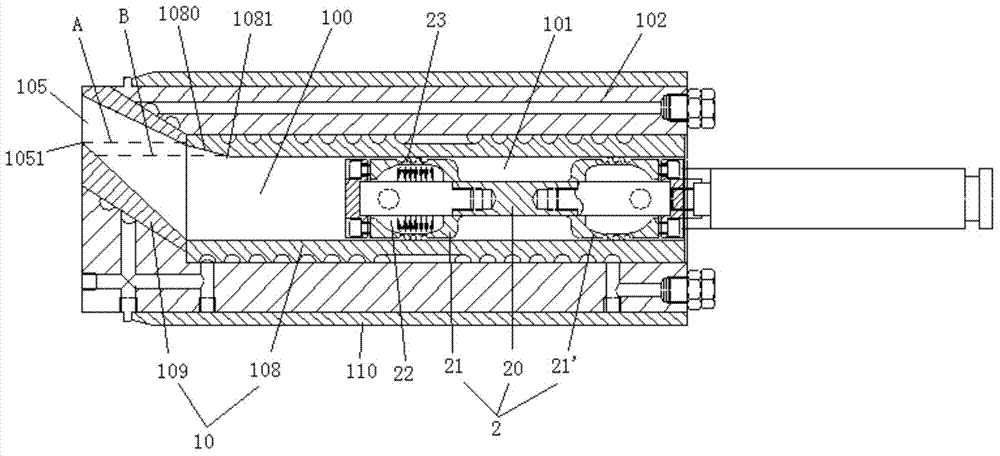

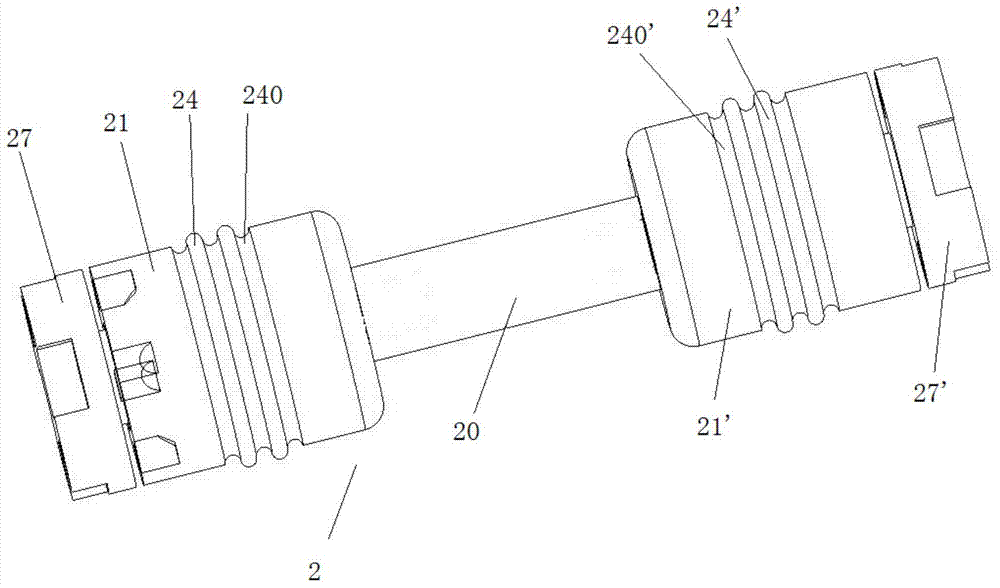

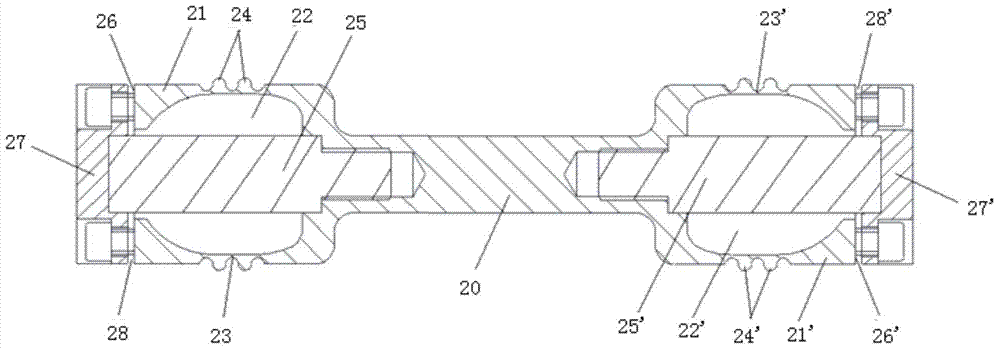

Centrifugal casting system for internal combustion engine air cylinder sleeve

The invention discloses a centrifugal casting system for an internal combustion engine air cylinder sleeve. The centrifugal casting system comprises a centrifugal machine, a pouring device, a spraying device, a pipe drawing device and a cleaning device. The centrifugal machine comprises a mould barrel for molding the air cylinder sleeve, end covers arranged at the two ends of the mould barrel, a power device and a transmission device connected with the power device. The transmission device comprises a hollow rotary shaft, the mould barrel is coaxially sleeved with the hollow rotary shaft, the hollow rotary shaft is supported on a bearing pedestal through a bearing, the power device drives the hollow rotary shaft to rotate, and therefore the mould barrel is driven to rotate. Compared with the prior art, the centrifugal casting system has the beneficial effects that the mould barrel is circumferentially restrained on the hollow rotary shaft, throbbing of centrifugal movement of the mould barrel is reduced, the rotating precision of the mould barrel is improved, and the quality and casting efficiency of a casting are improved; and when the mould barrel rotates at a high speed, weight blocks are subjected to the action of centrifugal force to move outwards, and therefore the end covers are locked through moving rods, and molten metal is prevented from being splashed.

Owner:ZYNP GRP ANHUI CO LTD

Precoated sand accelerating casting part forming and preparation method thereof

InactiveCN107096871ASpeed up moldingImprove molding qualityFoundry mouldsFoundry coresTetramineSand casting

The invention relates to the field relative to precoated sand casting technologies, in particular to precoated sand accelerating casting part forming. The precoated sand is prepared from the following components of a silica sand body, a ceramsite sand body, a magnetite sand body, thermoplastic phenolic resin, modified polyester resin, hexamethylene tetramine, ammonium acetate, calcium stearate, ceramic glaze powder, ammonium stearate and a forming agent. According to the precoated sand accelerating casting part forming, the problem that a majority of precoated sand is low in forming speed and poor in forming effect is solved, the forming agent is added into the precoated sand, and the specific precoated sand preparation technology is matched, so that through the preparation method of the precoated sand, the casting part forming speed can be increased, and the casting part forming quality can be improved, and casting efficiency is improved.

Owner:李吕军

Combined steel ball casting mold

InactiveCN110303118AImprove casting efficiencyFast connectionFoundry mouldsFoundry coresSteel ballCasting mold

The invention relates to the technical field of molds, and discloses a combined steel ball casting mold. The casting mold comprises an upper mold and a lower mold, wherein a connecting frame is fixedly connected to the upper surface of the lower mold, and a connecting groove matched with the connecting frame is formed in the upper surface of the upper mold; a T-shaped pouring channel is formed inthe upper surface of the upper mold, a pouring bucket is movably connected to the inner wall of the T-shaped pouring channel, and two connecting mechanisms which are symmetrically distributed are fixedly connected to the outer wall of the pouring bucket; and a fixing block is fixedly connected to the upper surface of the upper mold, a fixing mechanism is fixedly connected to the lower surface of the lower mold, two first circular through holes which are symmetrically distributed are formed in the lower surface of the lower mold, and two second circular through holes which are symmetrically distributed are formed in the upper surface of the upper mold. The combined steel ball casting mold has the advantages of time saving and labor saving, simple and quick in connection and fixation betweenthe upper mold and the lower mold, the labor intensity of workers is reduced, the mold cooling speed is increased, and the steel ball casting efficiency is improved.

Owner:徐州国隆电力配件铸造有限公司

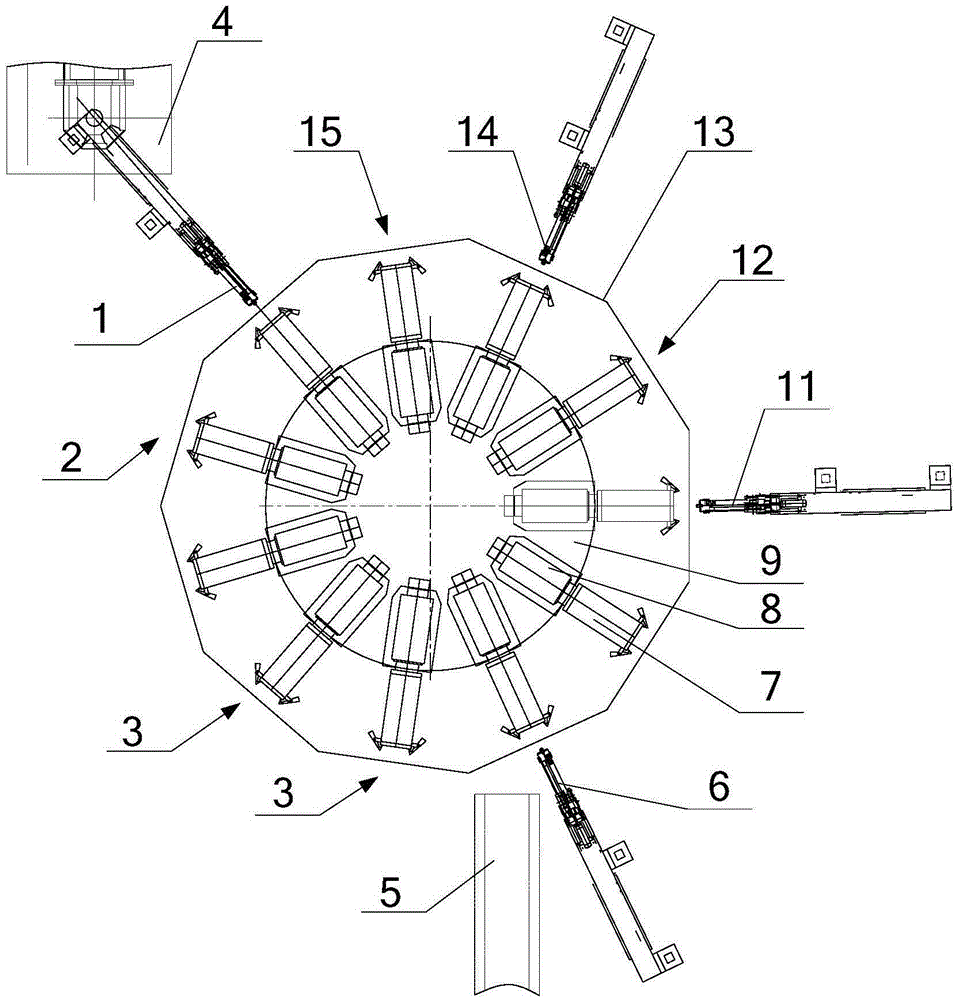

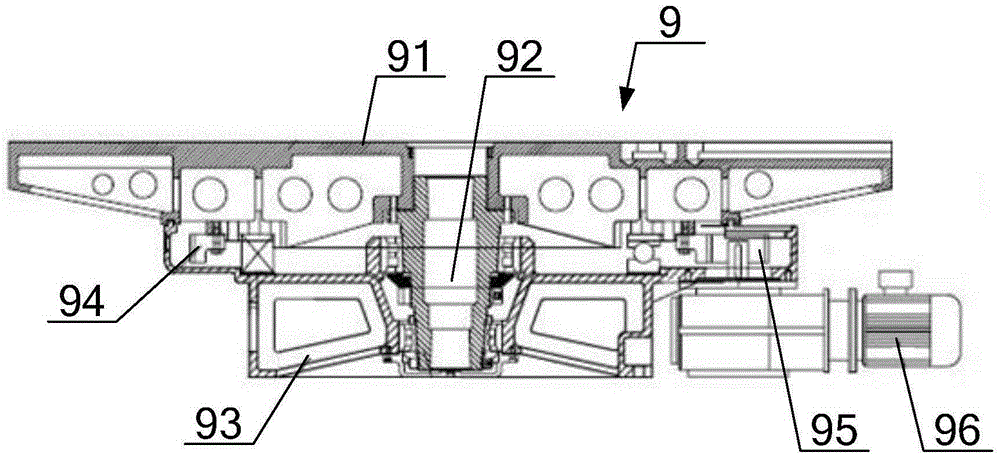

Cylindrical part casting equipment

InactiveCN105364044AImprove casting efficiencyReduce manual labor intensityControl systemEngineering

the application discloses cylindrical part casting equipment which comprises a rotary worktable, a plurality of casting power heads, a casting device, a drawing device, a cleaning device, a spraying device and a control system, wherein the plurality of casting power heads are arranged on the periphery of the rotary worktable; the axial lines of rotating shafts of the casting power heads are in the radial directions of the rotary worktable; the rotating shafts of the casting power heads are used for connecting centrifugal casting moulds; the casting device, the drawing device, the cleaning device and the spraying device are arranged on the periphery of the rotary worktable, and are arranged in the rotation direction of the rotary worktable in sequence; each of the casting device, the drawing device, the cleaning device and the spraying device respectively corresponds to one casting power head; the control system is used for controlling the rotary worktable, the casting power heads, the casting device, the drawing device, the cleaning device and the spraying device to operate. The cylindrical part casting equipment can cast a plurality of parts at the same time; compared with manual casting in the prior art, the cylindrical part casting equipment has the advantages that the casting efficiency is greatly improved, and the manual labor intensity is reduced.

Owner:ZYNP GRP

Material injection device of die casting machine

The invention discloses a material injection device of a die casting machine. The material injection device comprise a material cylinder and a plunger, wherein the material cylinder is used for containing molten metal liquid, the plunger is arranged in an inner cavity of the material cylinder, the material cylinder comprises a flat part and a gooseneck part which are in transition connection by an inclining part, the lowest point of the inclining part is lower than the lowest point of a material outlet of the gooseneck part, the plunger comprises a plunger head and a second plunger head which are connected by a plunger rod, a non-pressure chamber for containing the molten metal liquid is formed among the plunger head, the second plunger head, the plunger rod and the flat part, a pressure chamber for containing to-be-injected molten metal liquid is formed among the plunger head, the gooseneck part and the flat part, and a one-way flowing device is arranged between the non-pressure chamber and the pressure chamber, is sealed during material injection, and is opened in the plunger resetting process. The material injection device of the die casting machine has the advantages that the die casting cycle is short, the production efficiency is high, the qualified rate of products is higher, the heating temperature of the metal liquid is lowered, and the service life of a die and other parts is prolonged.

Owner:苏州圣美特压铸科技有限公司

Method and mould for manufacturing valve retainer

InactiveCN101590586AAvoid leaningAvoid deformationFoundry mouldsFurnace typesEnergy consumptionMaterials science

The invention discloses a method for manufacturing a valve retainer, which comprises the following steps: arranging a sprue on a mould; and carrying out smelting, casting, demoulding, heat treatment and ground finishing on metal, wherein the mould is a directly molded mould for the valve retainer. Compared with the prior manufacturing method, the method for manufacturing the valve retainer saves four steps of sliping a head, boring an inner hole, digging up an excircle and cutting off. Therefore, the method simplifies the production steps, saves a large amount of labors, reduces the equipment input and energy consumption, shortens the production cycle and reduces the production cost.

Owner:张永炤 +1

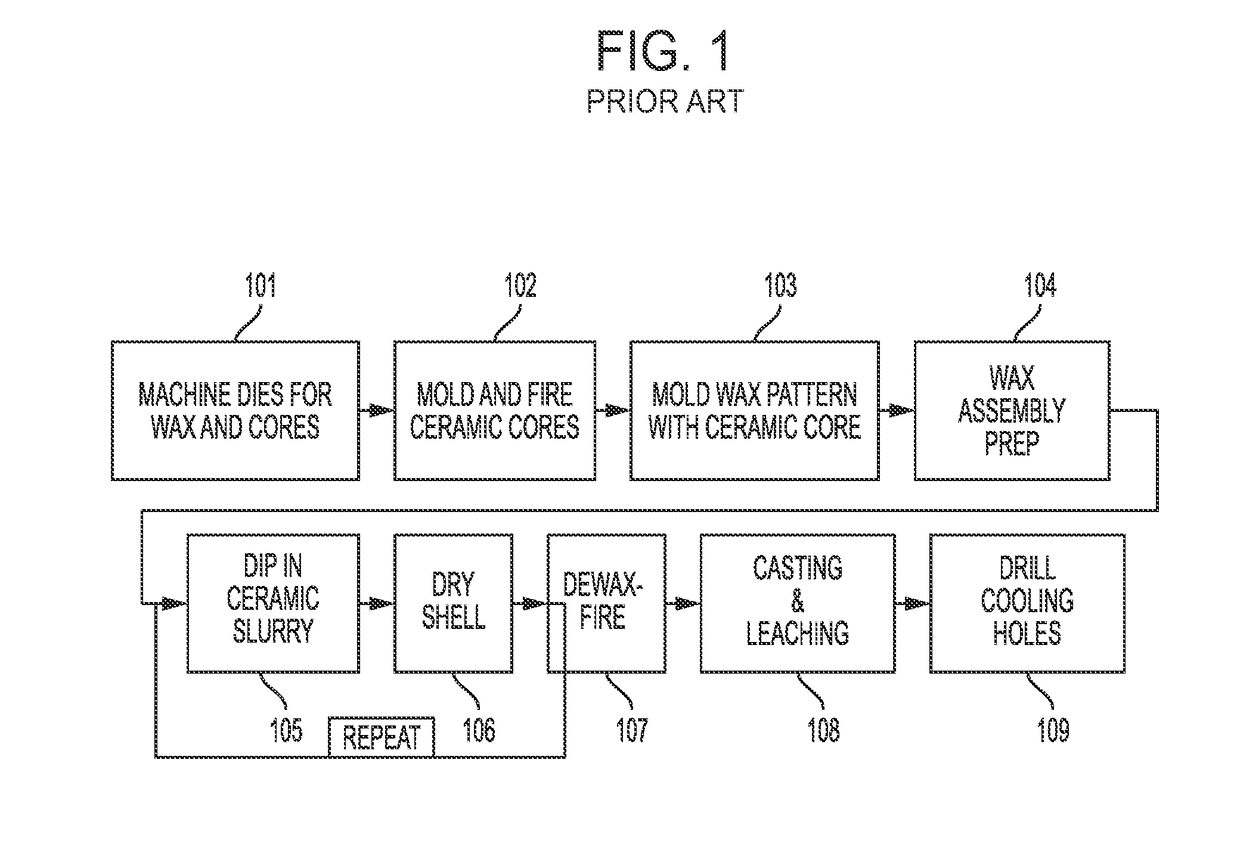

Additively manufactured casting core-shell hybrid mold and ceramic shell

ActiveUS20190001405A1Improves Structural IntegrityReduce build timeAdditive manufacturing apparatusFoundry mouldsMetallurgyCeramic coating

The present disclosure generally relates to integrated core-shell investment casting molds that provide a filament structure corresponding to a cooling hole pattern in the surface of the turbine blade, stator vane, or shroud. The disclosure also relates to the forming of a ceramic coating on at least a portion of the shell of the core-shell casting mold.

Owner:GENERAL ELECTRIC CO

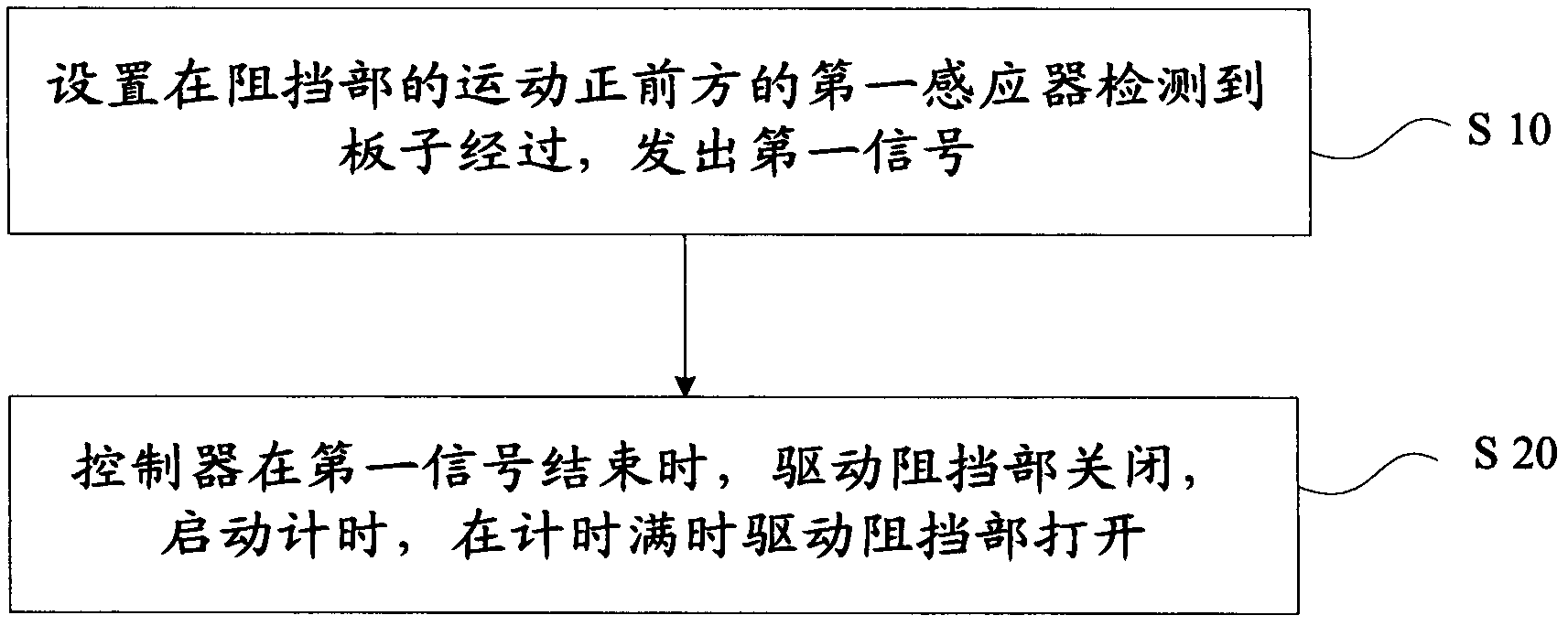

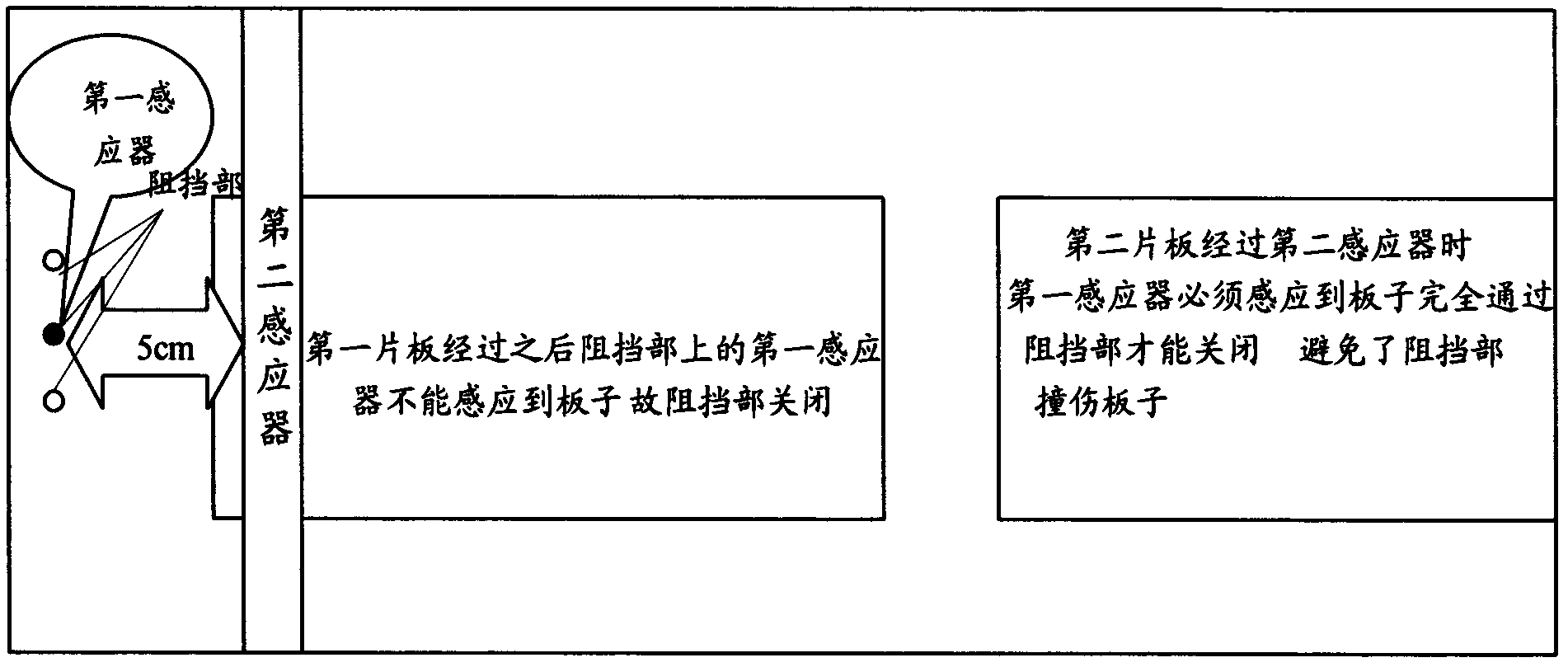

Board incoming control method and device for horizontal line and horizontal line

ActiveCN102083279AImprove casting efficiencyLow failure ratePrinted circuit manufactureEngineeringLevel line

The invention provides a board incoming control method for a horizontal line, the horizontal line is used for producing printed circuit boards, and the method comprises the following steps: a first sensor arranged right ahead the motion of a stop part is used for detecting passage of the printed circuit board and emitting a first signal, wherein the stop part is arranged at the board incoming endof the horizontal line; and a controller is used for driving the stop part to close when the first signal is finished, starting timing and driving the stop part to open when achieving full time. The invention further provides a board clamping detection device for the horizontal line and the horizontal line. According to the invention, a spacing interval between adjacent board materials which are artificially put into the horizontal line can be adjusted to the best distance.

Owner:NEW FOUNDER HLDG DEV LLC +1

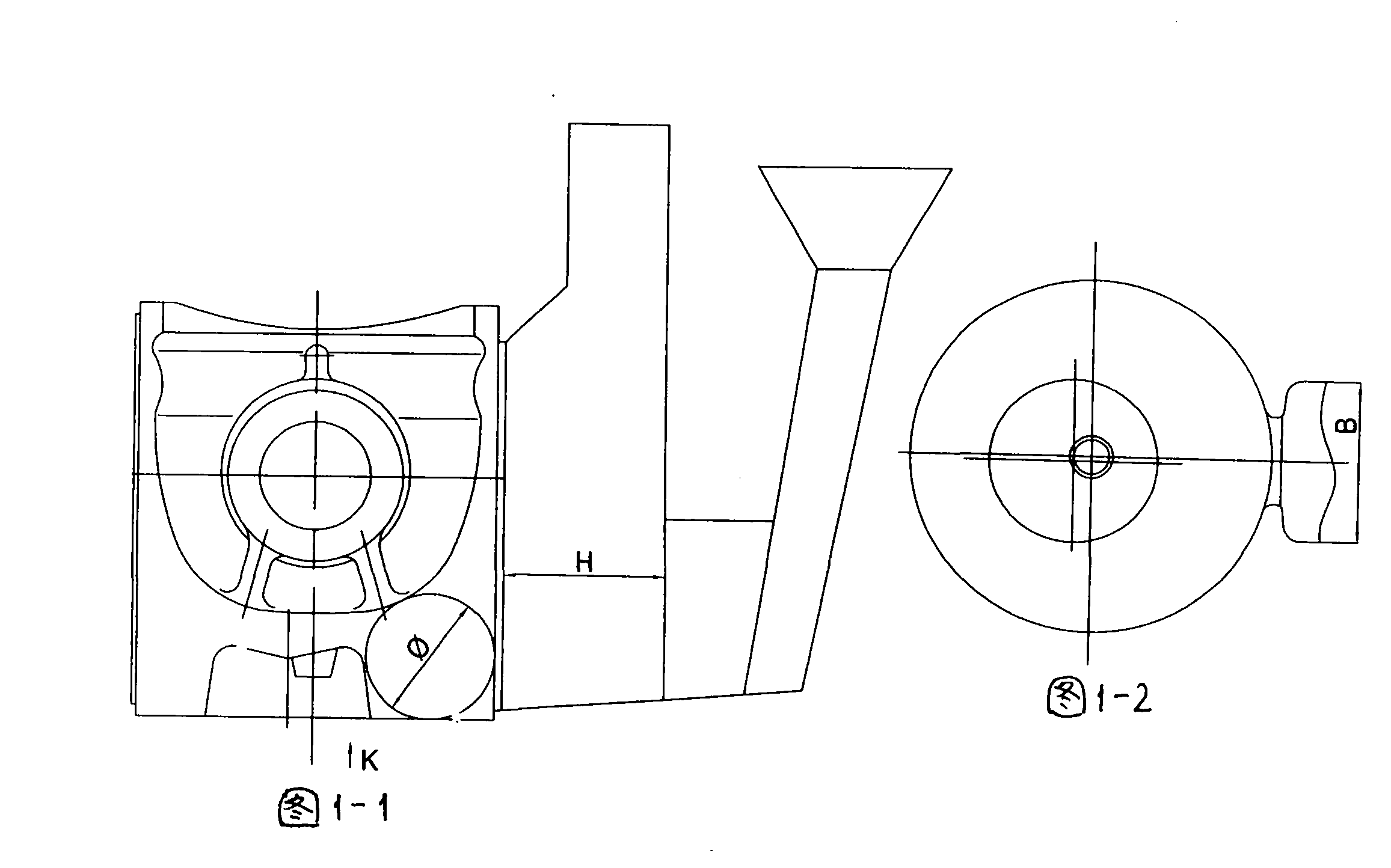

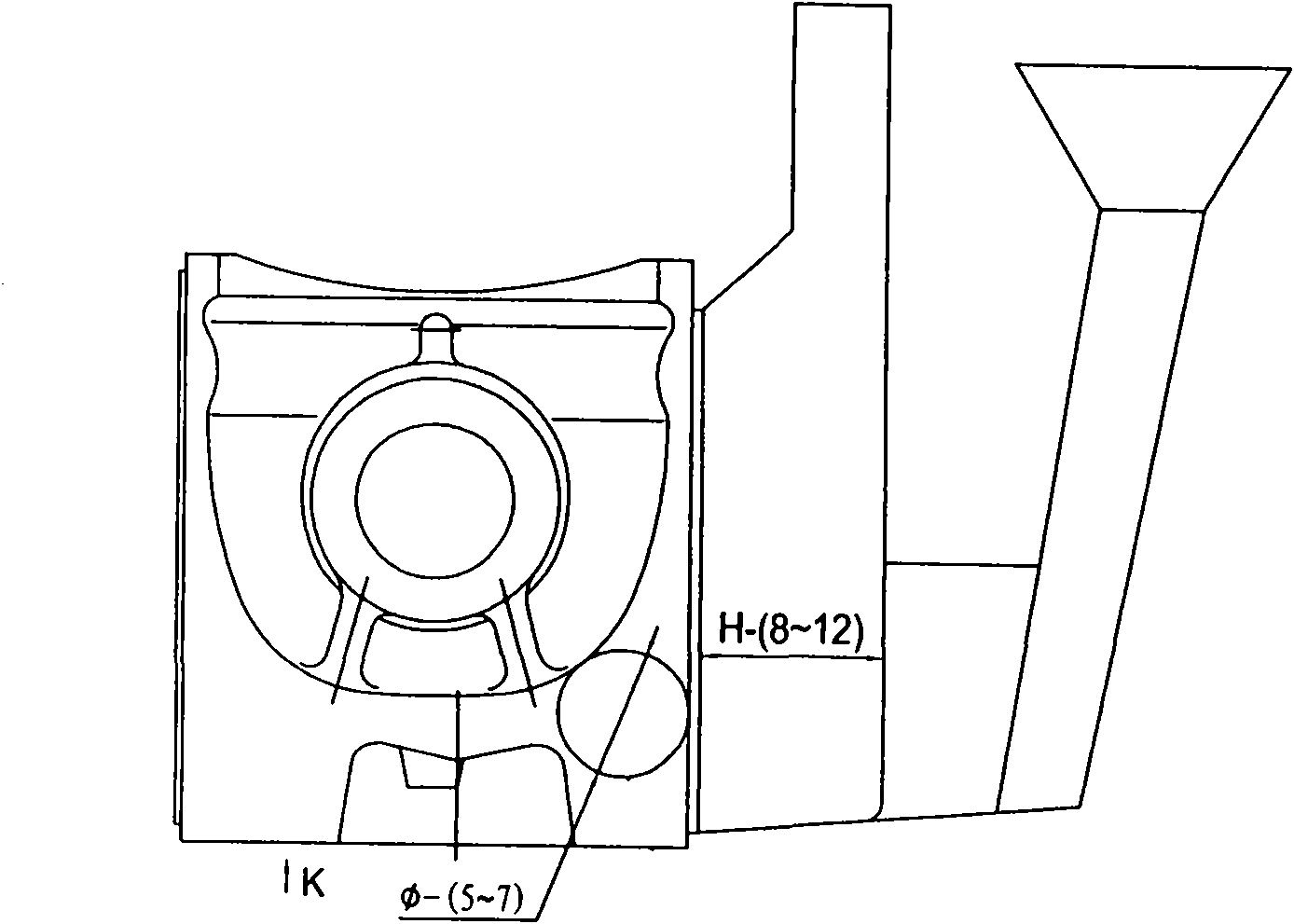

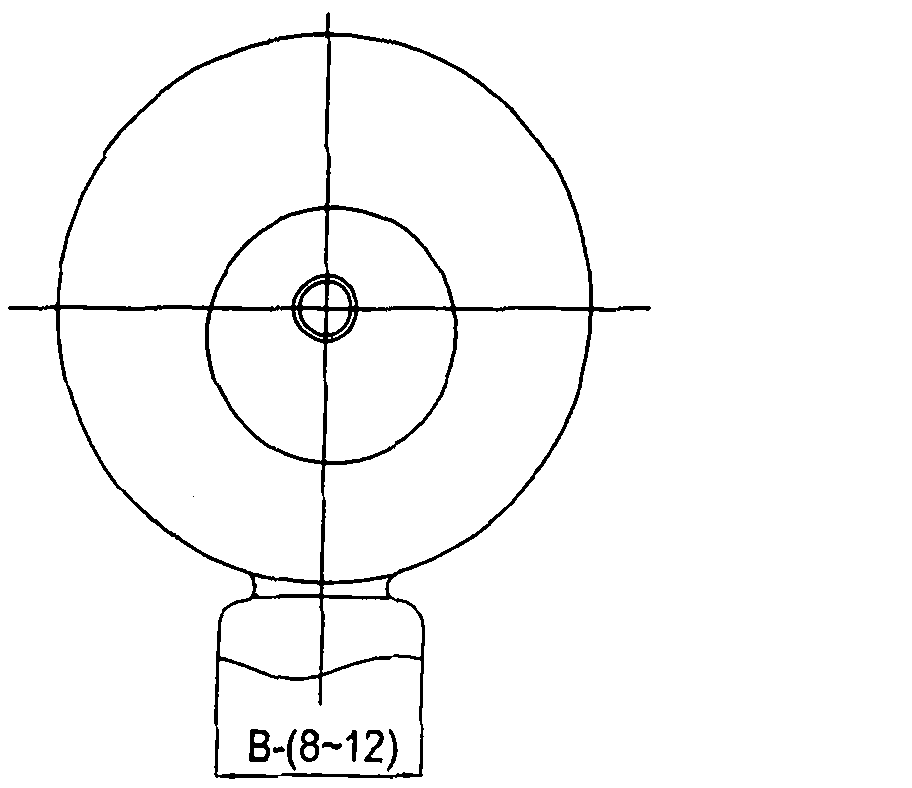

Process for improving metallographic structure of piston head and increasing casting production efficiency

ActiveCN101829763AReduced packing timeImprove cooling effectFoundry mouldsFoundry coresPistonMechanical engineering

The invention provides a process for improving the metallographic structure of a piston head and increasing casting production efficiency. The process comprises the steps of: (1) eliminating an exhaust hole and an exhaust nail on a bottom die, and meanwhile reducing the thickness of a wall between the bottom die and a cooling water cavity, respectively subtracting 10mm from the length and the width of a casting head on an outer die, wherein the specifications of the length and the width are respectively 48mm-55mm and 48mm-54mm; and meanwhile, adding 10mm-12mm to the length L2 of the rear part of the outer die, and adding 5mm-8mm to the width D of the rear part of the outer die, wherein the specifications of the length L2 and the width D are respectively 176-mm-195mm and 78mm-85mm; (2) processing a tooling die; (3) preparing for the smelting of an aluminum liquid; (4) assembling and debugging the tooling die; (5) casting in field production; (6) hot treating a piston blank; and (7) detecting the quality of the piston. The invention can refine the metallographic structure of the piston head by 1-2 levels and improve casting efficiency by more than 15%.

Owner:CHENGDU GALAXY POWER CO LTD

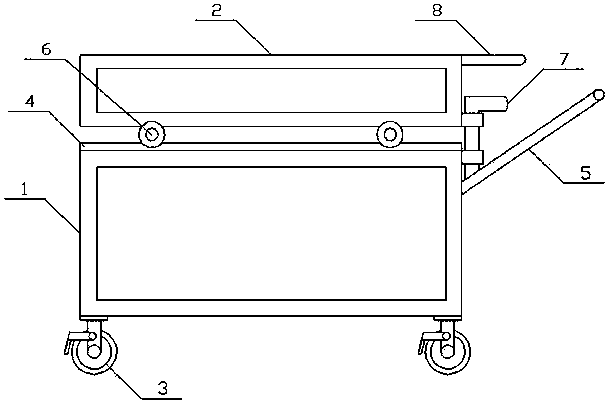

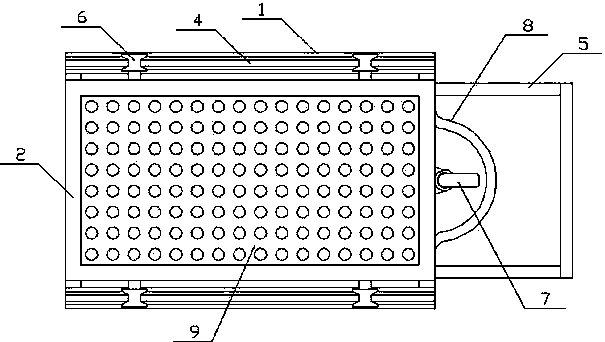

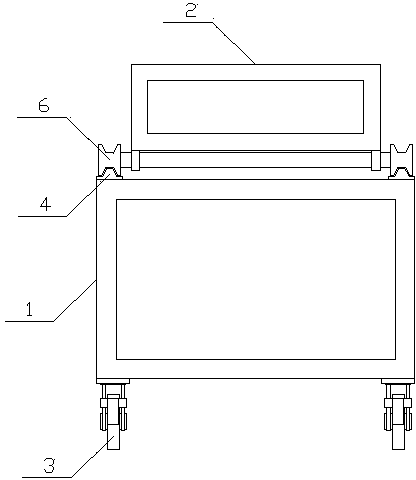

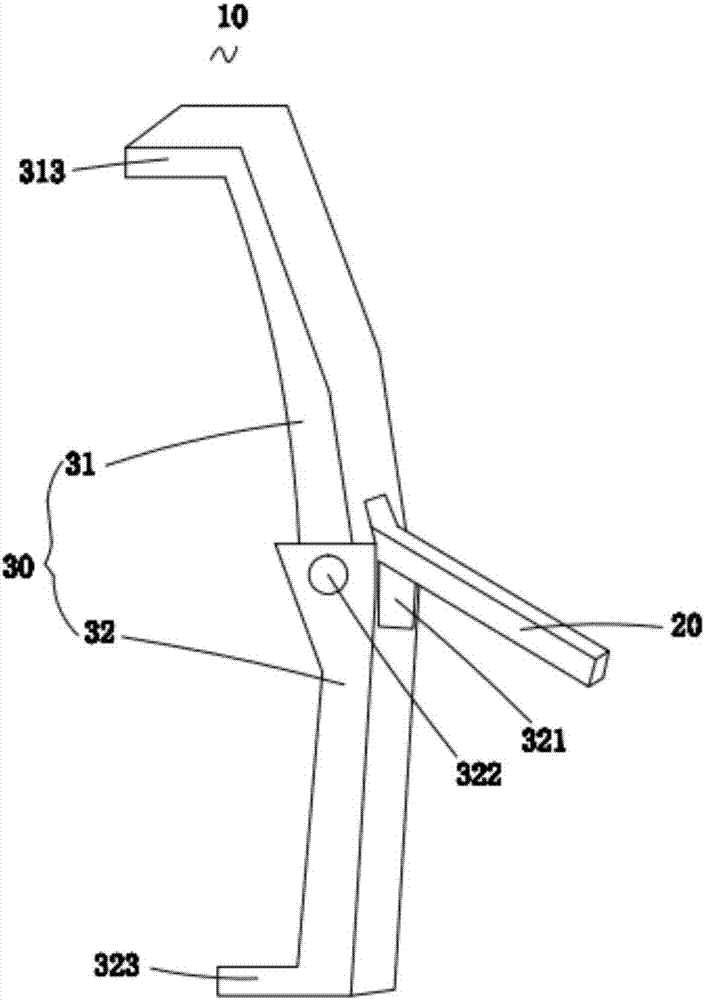

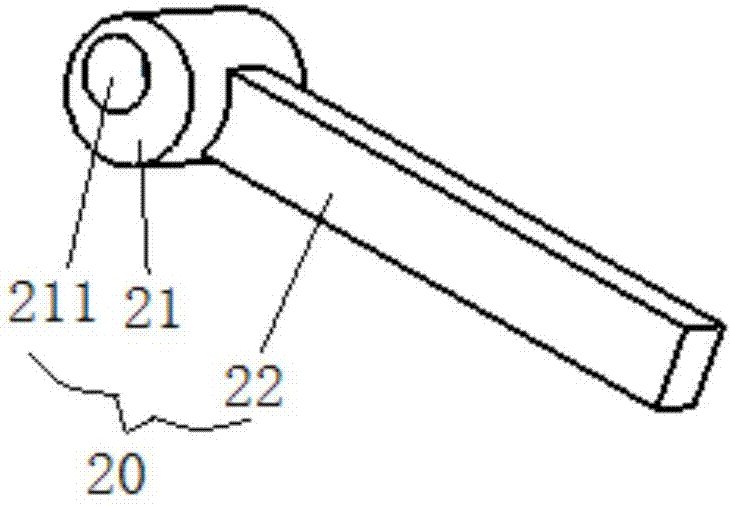

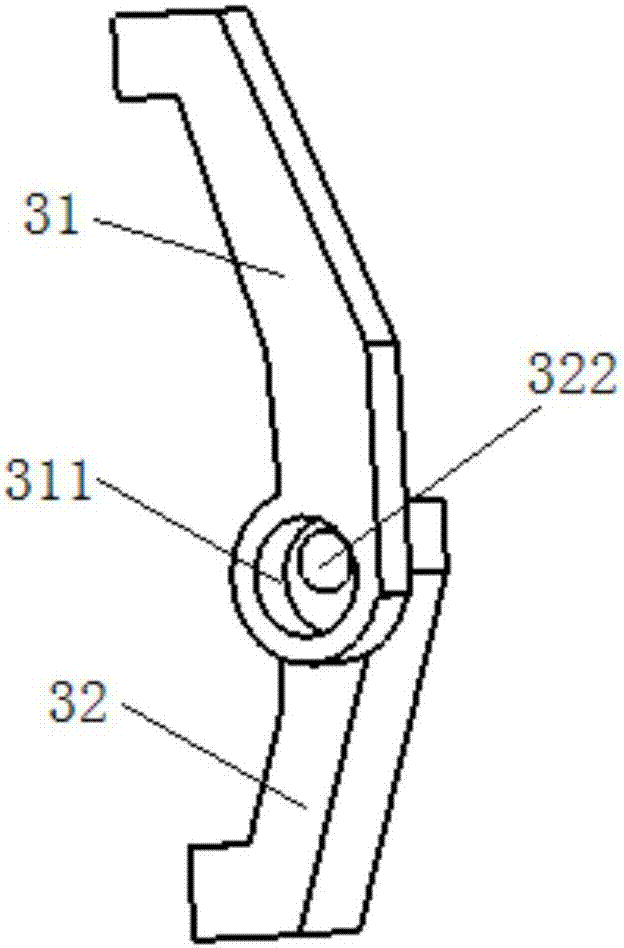

Melted wax trolley for conveying molds

InactiveCN103962538AEffective movementImprove casting efficiencyFoundry mouldsFoundry coresWaxEngineering

The invention discloses a melted wax trolley for conveying molds, and belongs to the field of mechanical conveying devices. The melted wax trolley for conveying molds comprises a fixed trolley body and a movable trolley body, the movable trolley body is arranged on the fixed trolley body and can slide along the fixed trolley body, four universal wheels with brakes are evenly arranged under the fixed trolley body, two guiding rails are horizontally arranged at the upper end of the fixed trolley body, a fixed handle is arranged on one side of the fixed trolley body, guiding wheels are connected to the lower end of the movable trolley body in a rotating mode, guiding grooves in the guiding wheels are matched with the guiding rails, the guiding wheels can slide along the guiding rails, and a screen plate is horizontally arranged on the lower side of the movable trolley body. The melted wax trolley is simple in structure and can be used for quickly and efficiently conveying molds of mechanical parts, the movable trolley body storing the molds can be pushed into a wax melting heating furnace, wax melting of the molds is facilitated, mechanical part manufacturing efficiency is improved, labor intensity of workers is lowered, and production requirements are met.

Owner:桐乡市红旗塑料包装袋厂

Expansion-resistant nano building material for preventing smog and preparation method of expansion-resistant nano building material

InactiveCN106084647AHigh temperature resistantImprove mechanical propertiesCrack resistanceHexamethylenetetramine

The invention discloses an expansion-resistant nano building material for preventing smog and a preparation method of the expansion-resistant nano building material. The expansion-resistant nano building material is prepared from the following raw materials in parts by weight: 50 to 70 parts of active carbon, 12 to 20 parts of montmorillonite, 5 to 12 parts of nano titanium dioxide, 3 to 7 parts of silicon dioxide, 1 to 10 parts of gamma-aminopropyltriethoxysilane, 6 to 12 parts of hydroxypropyl methyl cellulose and 5 to 10 parts of oligomerization 3-aminopropyltriethoxysilane. The added nitrile rubber modified phenolic resin is mixed with raw materials to be cured by heating, and the molten resin is converted rapidly from a linear structure to a non-molten mass structure under the effect of methylene separated from methenamine; and the mechanical performance is improved, so that the expansion-resistant nano building material has high temperature resistance and low expansion performance. The expansion-resistant nano building material has the characteristics of high adsorption capacity, relatively good thixotropy, heat stability, plasticity, viscosity, high dry pressure and the like. By adding reinforcing agents such as coal gangue, conductive mica powder and nano conductive graphite powder, the heat aging resistance and crack resistance can be improved, so that the casting efficiency can be improved, and the casting cost can be reduced.

Owner:SUZHOU RUI TE JIE CHEM PROD CO LTD

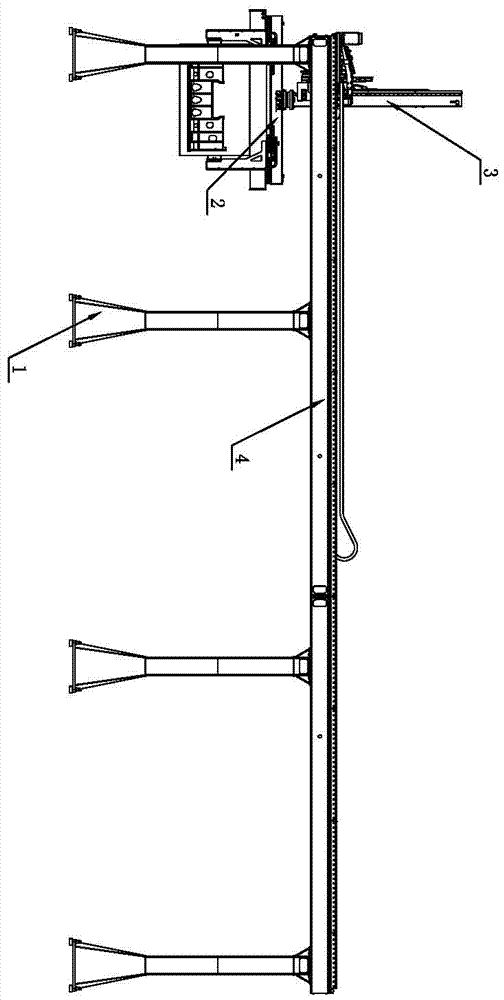

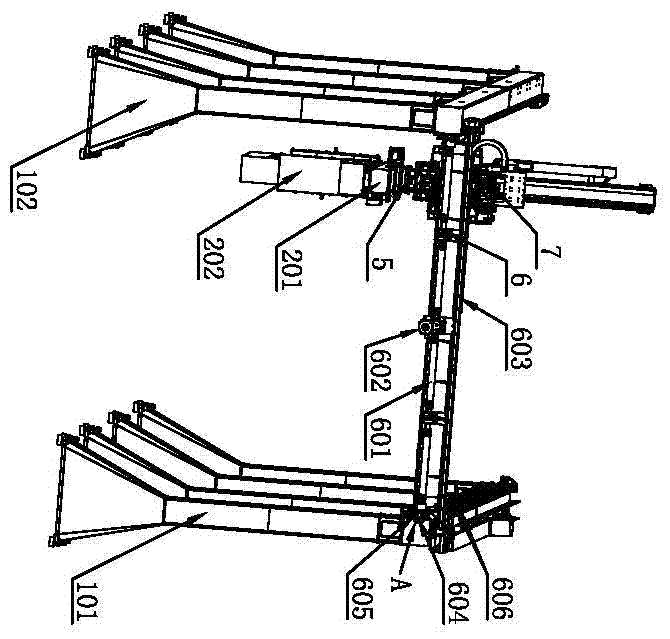

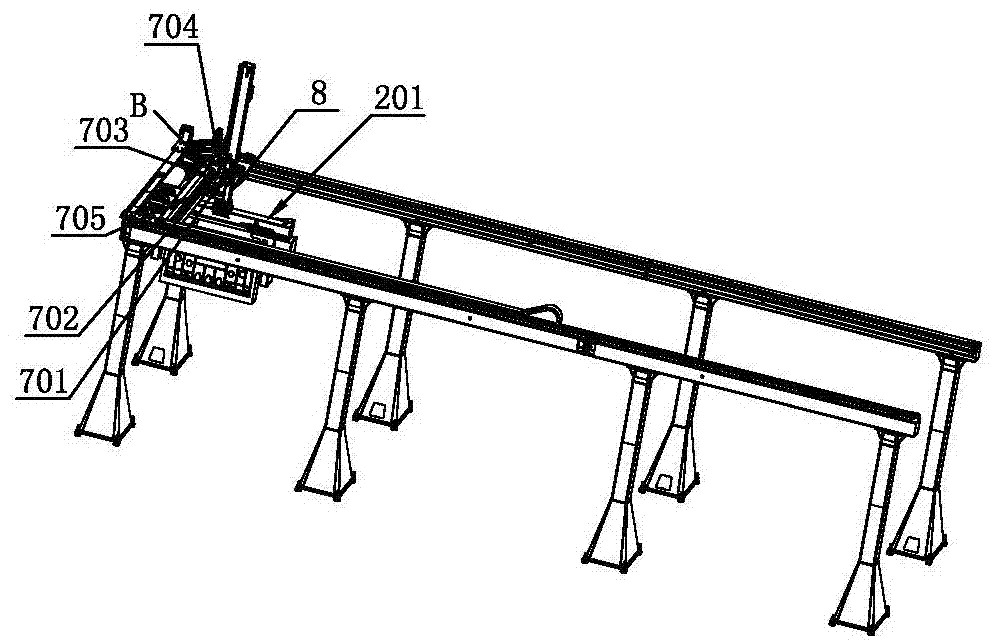

Truss robot

InactiveCN107498545ASolve technical problems with low level of intelligenceCompact structureProgramme-controlled manipulatorEngineeringStructural engineering

The invention discloses a truss robot in the field of casting transferring mechanisms. The truss robot comprises a transverse moving mechanism, and a plurality of supporting assemblies which are sequentially arranged from left to right, wherein each supporting assembly comprises a first vertical column and a second vertical column which are structured the same and oppositely arranged in front-back direction; the first vertical columns and the second vertical columns are fixed to a foundation; the transverse moving mechanism comprises a transverse supporting block; a fixing supporting seat is fixedly connected to the upper sides of the first vertical columns and the second vertical columns; the transverse supporting block can horizontally linearly move in the length direction of the fixing supporting seat; a horizontal moving mechanism is in sliding connection with the transverse supporting block; a vertical moving mechanism which linearly move in the vertical direction is arranged on the horizontal moving mechanism; a rotatable clamping mechanism for clamping a sand core is arranged at the lower side of the vertical moving mechanism. The truss robot is compact in structure, high in intelligence degree, and high in casting efficiency.

Owner:NINGXIA KOCEL MOLD

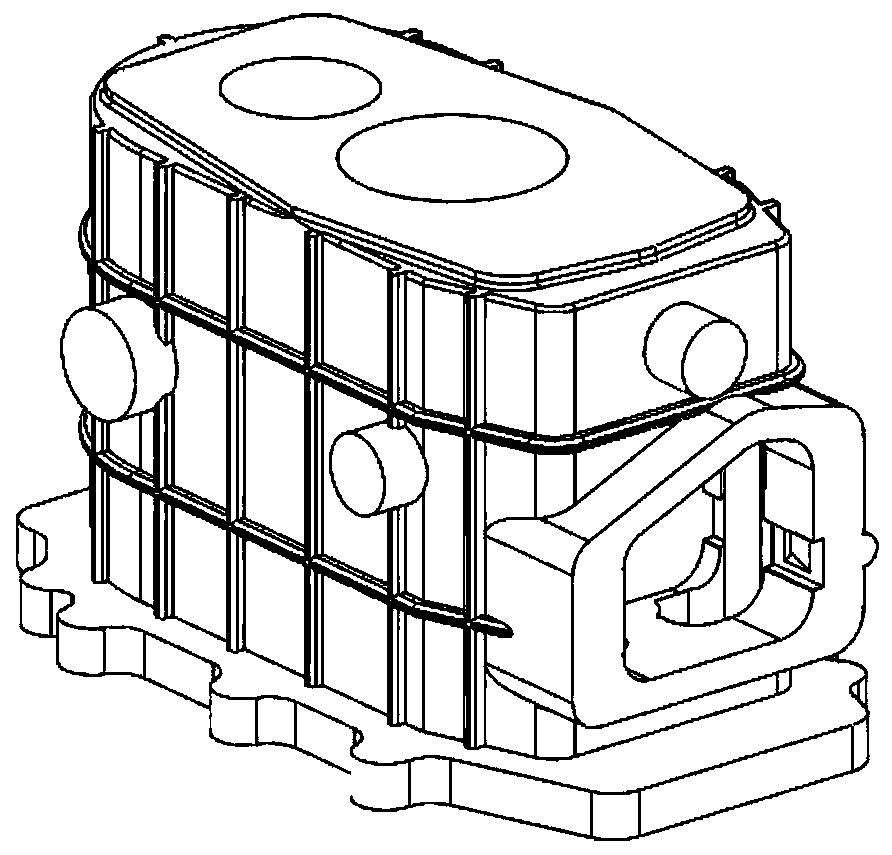

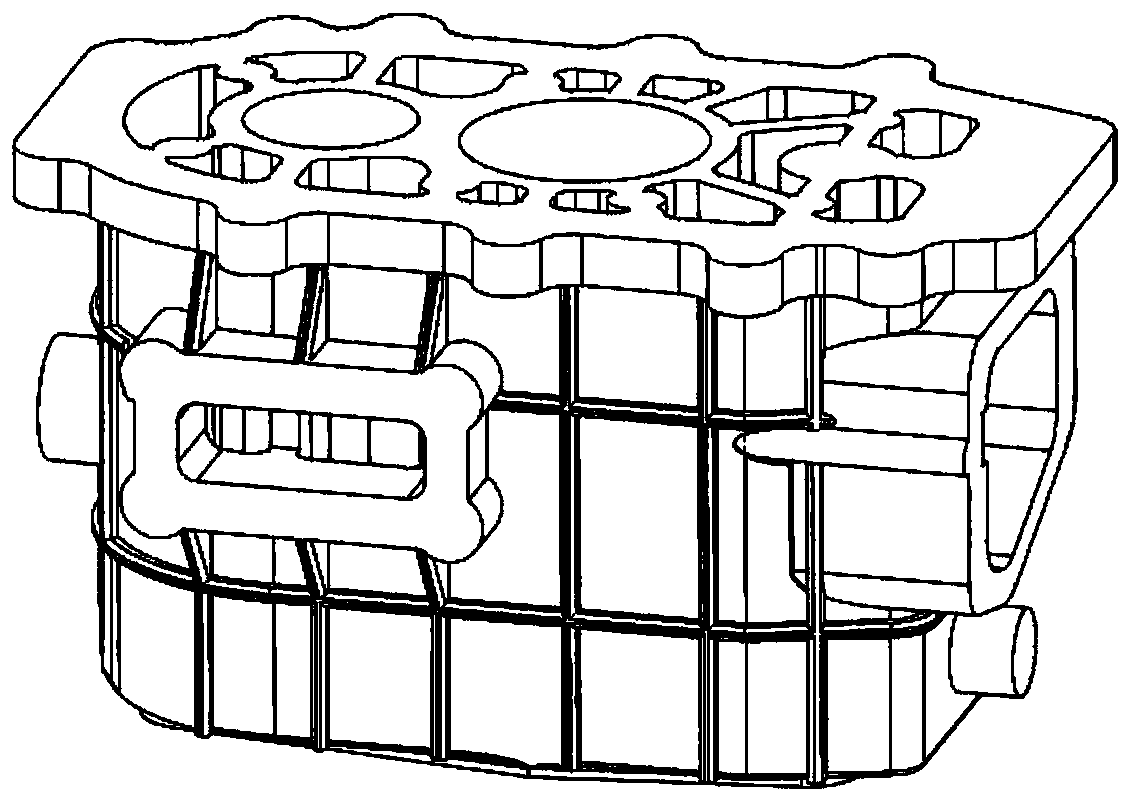

Gearbox rear shell casting method

InactiveCN110449556AReduce casting defectsImprove mechanical propertiesFoundry mouldsFoundry coresShrinkage rateMechanical property

The invention discloses a gearbox rear shell casting method. The method includes the steps that modeling material selection is conducted; parting face selection is conducted; casting position determining is conducted; one box is adopted for containing one part; the casting shrinkage rate is set; the pattern draft is set; a sand core is designed, wherein a positioning core head is arranged on the sand core, resin self-hardening sand is adopted for manufacturing the sand, and an exhaust channel is formed in the sand core; a casting manner is selected, wherein a sealed intermediate injection typecasting system is adopted, a semispherical sprue base is arranged, and a funnel-shaped sprue cup provided with a foam type ceramic filter net is arranged; a chilling block is arranged; the sizes of inner frames of an upper box and a lower box are the same; smelting is conducted; casting forming is conducted; and heat treatment is conducted. By means of the gearbox rear shell casting method, sequential solidification is achieved at the defect position of a casting, a compact structure is formed, in addition, grains at the position are refined, and the mechanical performance of the casting canbe improved; and during casting, large impurities can be intercepted on the outer surface of a filter, micro impurities are adsorbed on the wall face of a channel, a metal liquid flowing manner is changed into a laminar flow manner from a turbulent flow manner, and the probability that filtered metal is further oxidized is lowered.

Owner:GUIZHOU UNIV

Box clamping device of small sand box for casting

ActiveCN107414034AAvoid defects such as sand inclusions and poresAvoid the problem of cavity coating and loose sand fallingMoulding flasksEngineeringCam

The invention discloses a box clamping device of a small sand box for casting, and relates to the technical field of sand box clamping apparatuses. The device comprises a handle and fixing jaws; the handle comprises a cam and a columnar handle, the cam is fixedly connected with one end of the columnar handle, a rotating shaft is arranged in the cam, the fixing jaws comprise a first fixing jaw and a second fixing jaw, the first fixing jaw and the second fixing jaw are symmetrically arranged with the cam as the center, and are used for fixing and clamping the sand box, through the cam and the rotating shaft which are arranged at one end of the handle, the first fixing jaw, the second fixing jaw and the handle are relatively connected, meanwhile, the position of the cam is adjusted through the columnar handle, the first fixing jaw and the second fixing jaw are in the loosened and shrinkage states, and pouring work is finished. Through the device, in the casting process, the small sand box is fastened, the defects of sand inclusion, air holes and the like of castings are overcome, integrality and size stability of casted sand moulds can be effectively ensured, the structure is simple, use is convenient, and casting efficiency is improved.

Owner:KOCEL EQUIP

Graphene fiber modified nano adsorbing material and preparation method

InactiveCN106243652AGood thermal insulation performanceExcellent fire resistance and aging resistanceAdhesiveZinc sulfide

The invention discloses a graphene fiber modified nano adsorbing material and a preparation method. The nano adsorbing material comprises organic silicon resin, an organic solvent, glass beads, titanium dioxide, quartz sand, silicon carbide micro powder, nano cerium oxide, oxalic acid polyesters, light calcium carbonate, high-water-retention resin polyvinyl alcohol, a dispersing agent, a thickening agent, a brightening agent, zinc sulfide, foamed aluminum, hydroxypropyl methyl cellulose, nano silica, an adhesive, cobalt naphthenate, molybdenum, nickel, propylene glycol and chromium. Due to the fact that molecules of chitosan has positive charges, bacteria with negative charges can be adsorbed, and the material has a sterilization function; structurally, fibrous membrane layers with different diameters and pores are prepared, and in combination with nano graphene between the layers, the porosity and specific surface area of a composite adsorption membrane are improved, and effects are enhanced; by the adoption of pitch-based carbon fibers, the mechanical properties of the material are enhanced, and harmful gas and dust substances in tail gas can be greatly adsorbed and removed.

Owner:SUZHOU RUI TE JIE CHEM PROD CO LTD

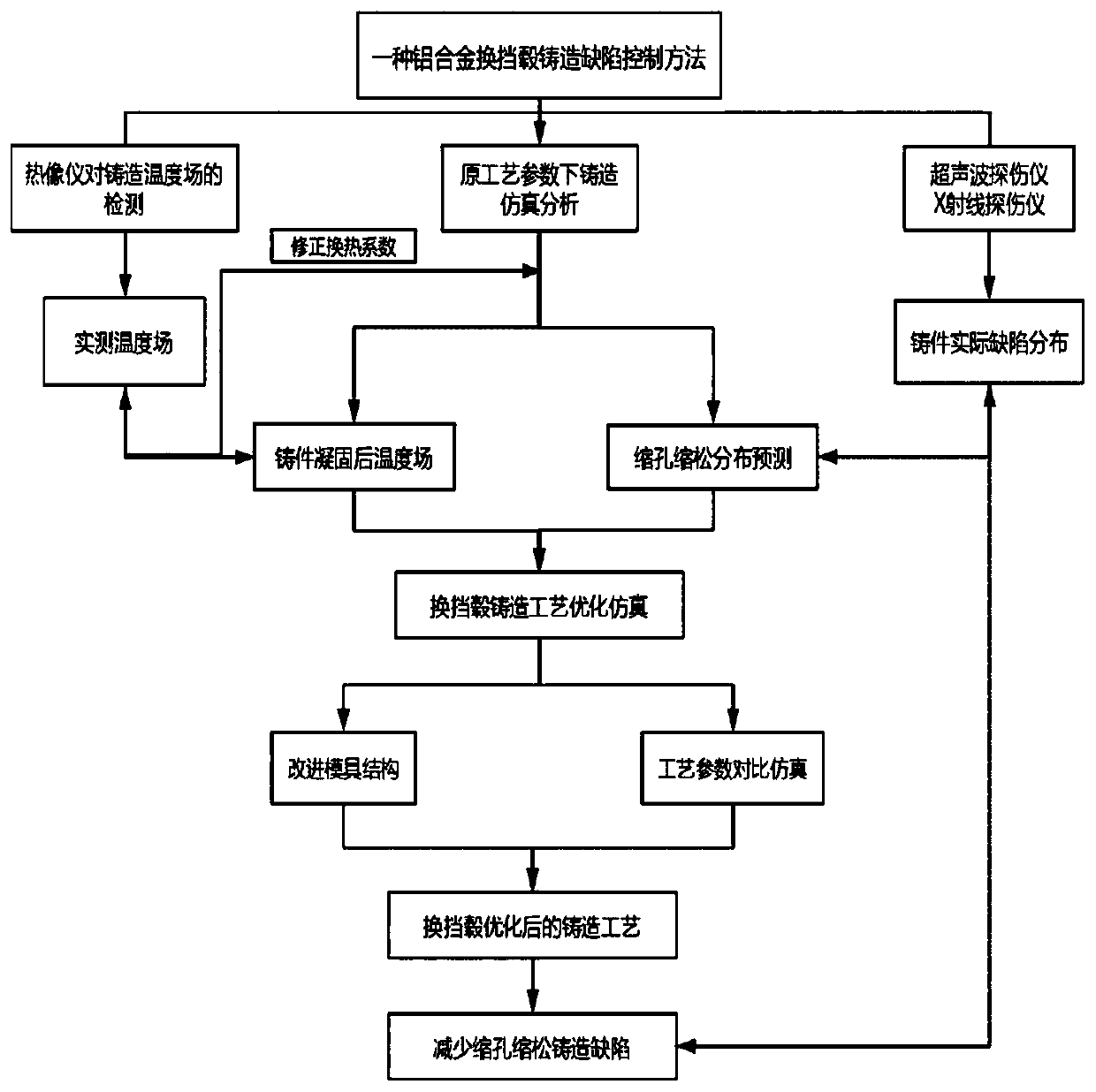

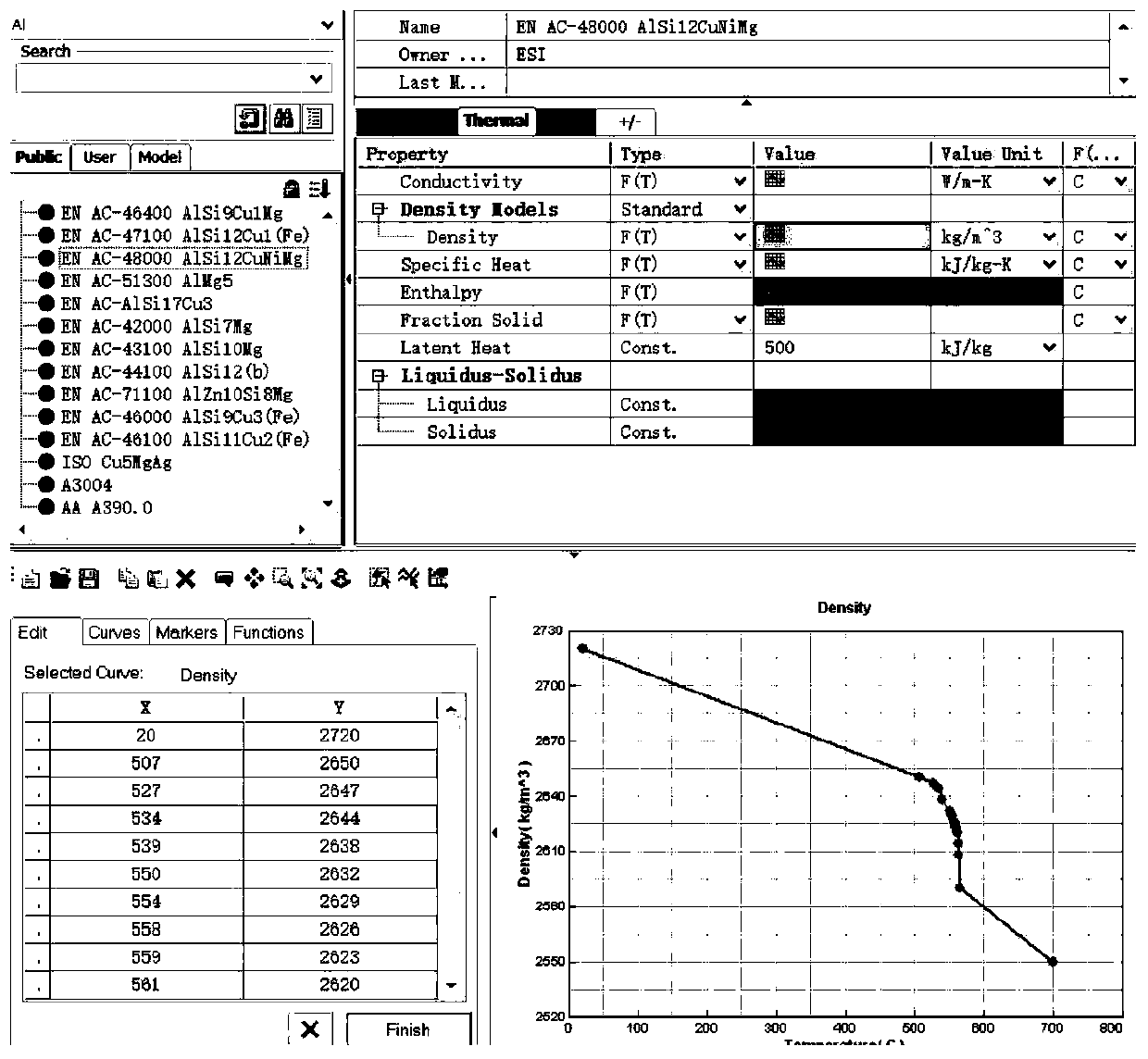

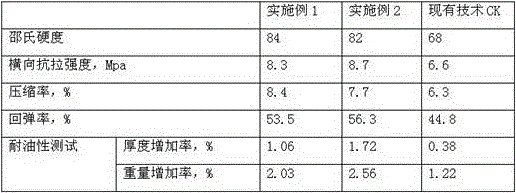

Aluminum alloy gear shifting hub casting defect control method

ActiveCN110976830AQuality improvementTo achieve the purpose of shrinkage cavity shrinkage defect controlMolten metal pouring equipmentsFoundry mouldsLiquid metalCasting defect

The invention provides an aluminum alloy gear shifting hub casting defect control method and belongs to the technical field of liquid metal forming. The aluminum alloy gear shifting hub casting defectcontrol method comprises the steps of detecting the casting temperature in the actual casting die opening process to obtain a casting temperature field; conducting defect detection on actually cast aluminum alloy gear shifting hub casting products to obtain shrinkage porosity casting defect forming areas in the actual casting process; establishing a casting process finite element simulation analysis model, simulating the gear shifting hub die filling and solidifying process through professional casting simulation software ProCAST, comparing the simulation result with an actual detection result and carrying out necessary correction on parameters; and conducting simulation analysis and optimization on technological parameters such as dies, casting temperatures, die preheating temperatures and casting speeds through the simulation model, and obtaining qualified castings with the aluminum alloy gear shifting hub casting shrinkage porosity casting defects improved effectively through trialcasting. Thus, the purposes of improving gear shifting hub casting defects and improving the casting quality are achieved.

Owner:UNIV OF SCI & TECH BEIJING +1

Expansion-resistant graphene fiber nano building material and preparation technology thereof

The invention discloses an expansion-resistant graphene fiber nano building material and a preparation technology thereof. The expansion-resistant graphene fiber nano building material comprises the following raw materials in parts by weight: 80-90 parts of an ethylene-vinyl acetate copolymer, 40-50 parts of high-density polyethylene, 20-30 parts of a nano active agent, 2-8 parts of a plasticizer and the like. According to the expansion-resistant graphene fiber nano building material and the preparation technology thereof, provided by the invention, added nitrile rubber modified phenolic resin is mixed with raw materials to form a mixture, the mixture is cured when heated, and under the action of methylene decomposed by urotropin, the molten resin quickly changes from a linear structure into a non-molten three-dimensional structure; by improving mechanical properties, the expansion-resistant graphene fiber nano building material has high temperature resistance and low expansion; structurally, fiber membrane layers with different diameters and porosities are prepared, nanographene among bonding layers improves the porosity and the specific surface area of a composite adsorption membrane and enhances the efficacy; through adoption of asphalt-based carbon fiber, mechanical properties of the expansion-resistant graphene fiber nano building material is enhanced, so that the expansion-resistant graphene fiber nano building material can greatly adsorb and remove harmful gas and dust substances in exhaust gas.

Owner:SUZHOU RUI TE JIE CHEM PROD CO LTD

Modified nano building functional material for magnetic oil-resistant fiber and preparation method of material

The invention discloses a modified nano building functional material for a magnetic oil-resistant fiber and a preparation method of the material. The material is prepared from 50-60 parts of butadiene-acrylonitrile rubber, 30-40 parts of polyurethane rubber, 10-15 parts of 12-methyl hydroxy stearate, 8-12 parts of magnesium methacrylate, 6-10 parts of tri(2-butaneneoxime)cinylsilane, 20-25 parts of nylon-66 short fibers, 5-10 parts of polypropylene glycol adipate and 10-16 parts of diethylene glycol dibenzoate. According to the material, added butadiene-acrylonitrile rubber-modified phenolic resin is mixed with the raw materials and cured during heating, and the molten resin is quickly converted into a non-molten haplotype structure from a linear structure under action of methylene decomposed from urotropine; the mechanical property is improved, and the high temperature resistance and the low expansion property are achieved; by combining nano-graphene among layers, the porosity and the specific surface area of a composite adsorption membrane are increased, and the effects are enhanced; asphalt-based carbon fibers are adopted, therefore, the mechanical property of the material is enhanced, and harmful gas and dust substances in tail gas can be greatly adsorbed and removed.

Owner:常熟市瑞思知识产权服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com