Dual-station low-pressure casting machine

A low-pressure casting machine and double-station technology, applied in the field of low-pressure casting equipment, can solve the problems of low casting efficiency and achieve the effects of high casting efficiency, cost reduction and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

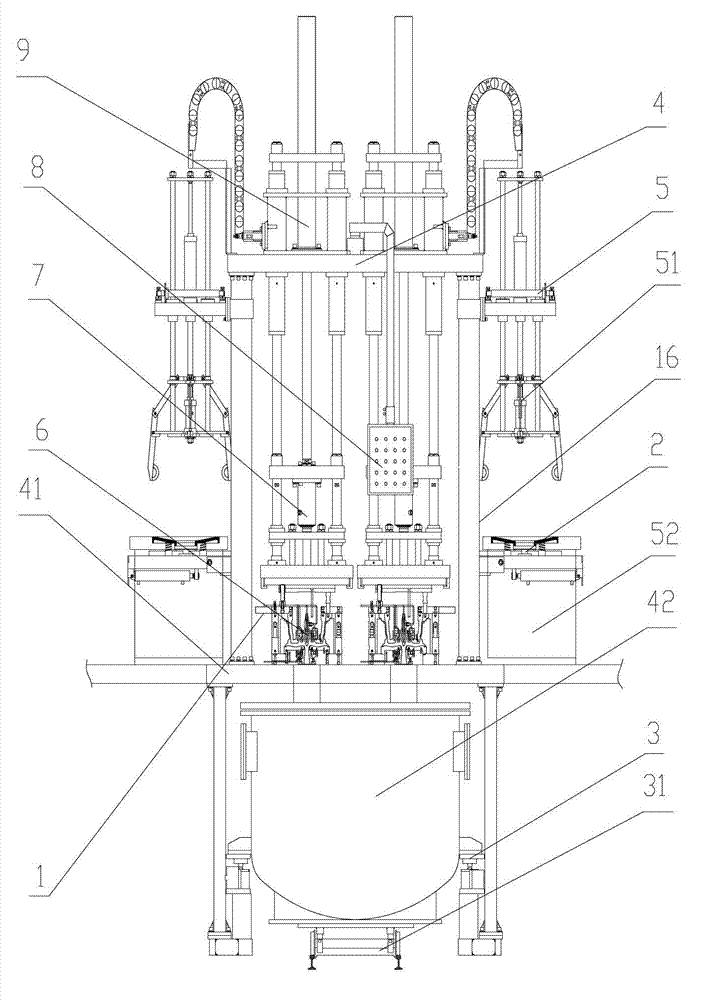

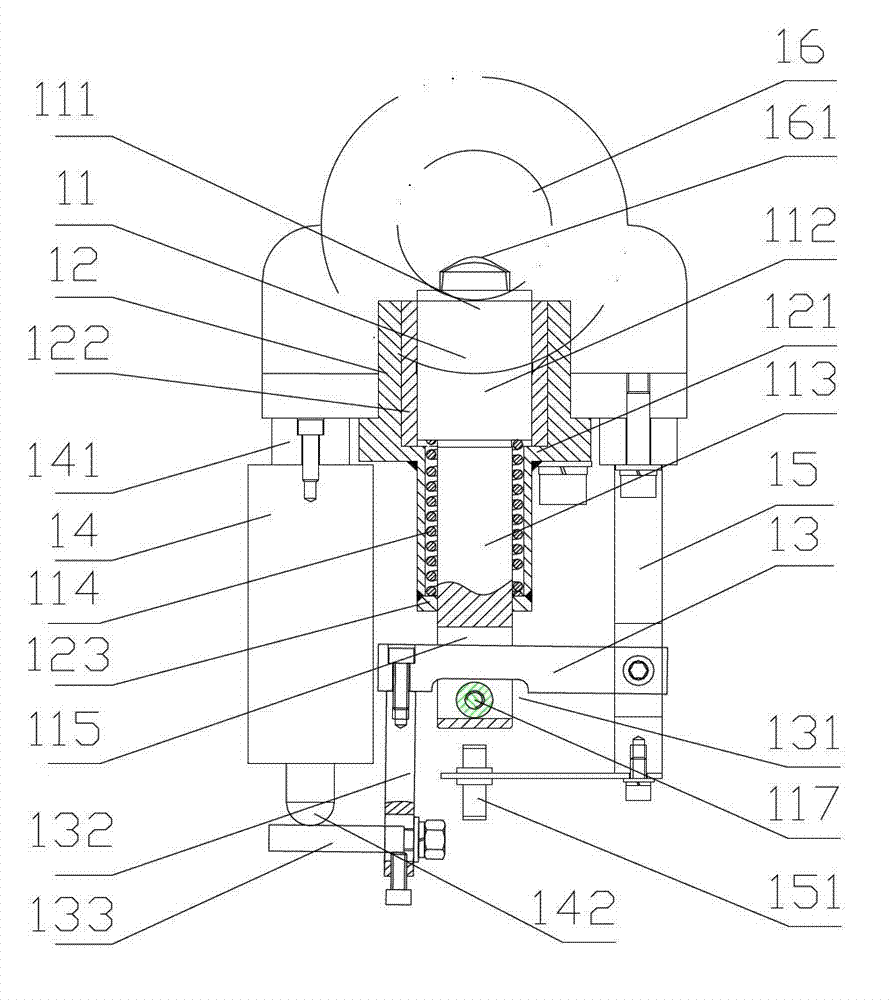

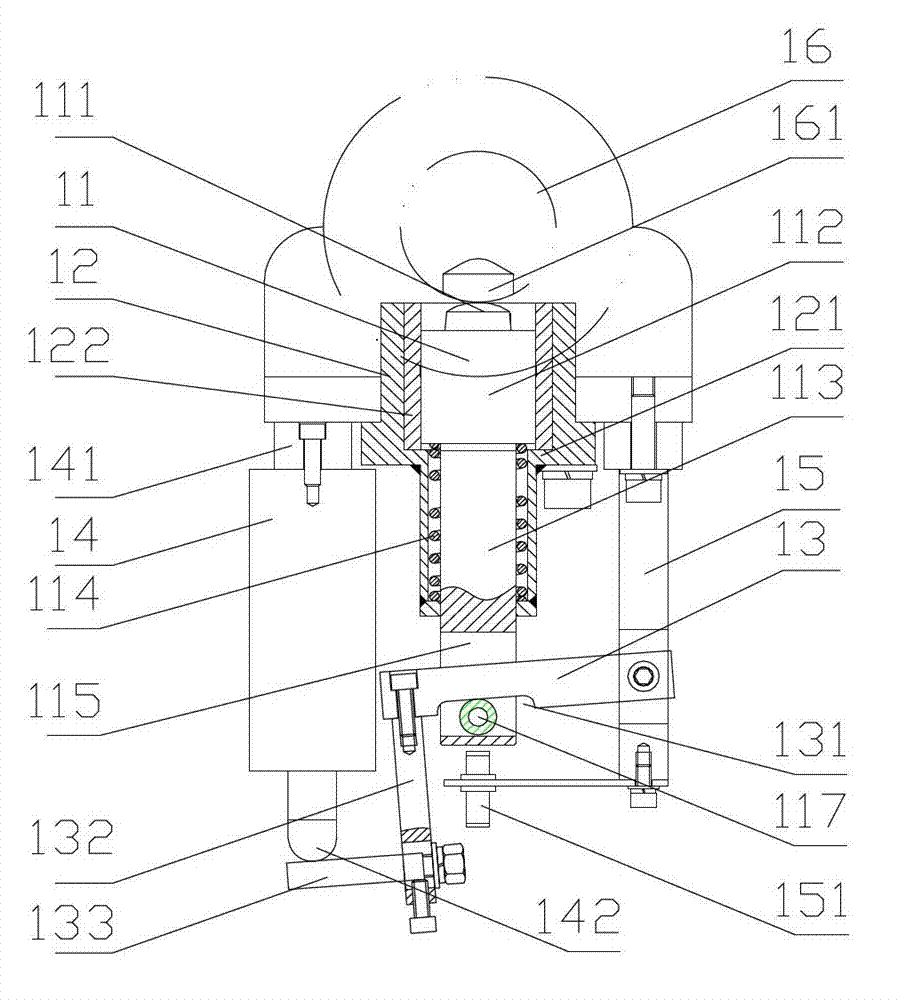

[0030] combine figure 1 Illustrate the embodiment of double-station low-pressure casting machine of the present invention, comprise frame 4, a machine plane 41 is arranged in the middle part of said machine plane, two sets of hub molds 6 are arranged in parallel on the left and right sides of said machine plane, said frame A holding furnace 42 is arranged below the machine plane, and the holding furnace communicates with two sets of wheel hub mold cavities respectively through two riser pipes and gates on two sets of wheel hub molds. There is an upper mold lifting mechanism 9 that drives the upper mold to rise and a demoulding mechanism 7 that separates the upper mold and the wheel hub that are tightly hugged together. The wheel hub after demoulding. The four corners of the machine plane plane are respectively provided with a column 16, and the upper end of the column is provided with a crossbeam. The wheel hub on the material mechanism and put into the soaking water tank 52...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com