Box clamping device of small sand box for casting

A sand box and card box technology, applied in the field of sand box fixtures, can solve the problems of short service life, cumbersome manufacturing of wedge box clips, time-consuming and laborious operation of bolt fixtures, etc., so as to improve casting efficiency, ensure integrity and dimensional stability. The effect of sex, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

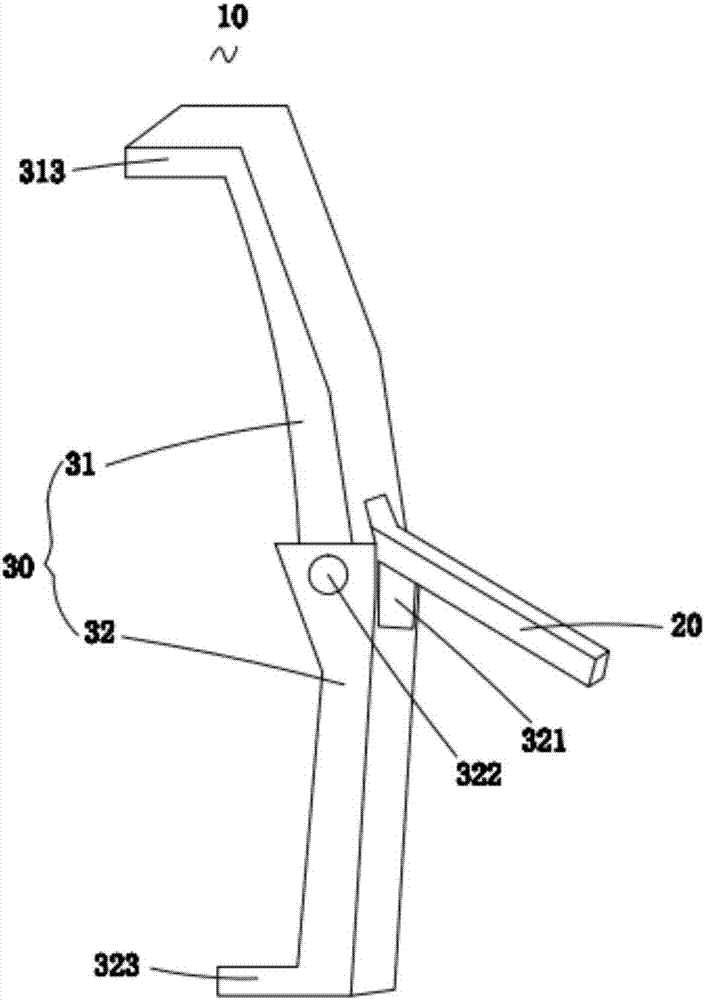

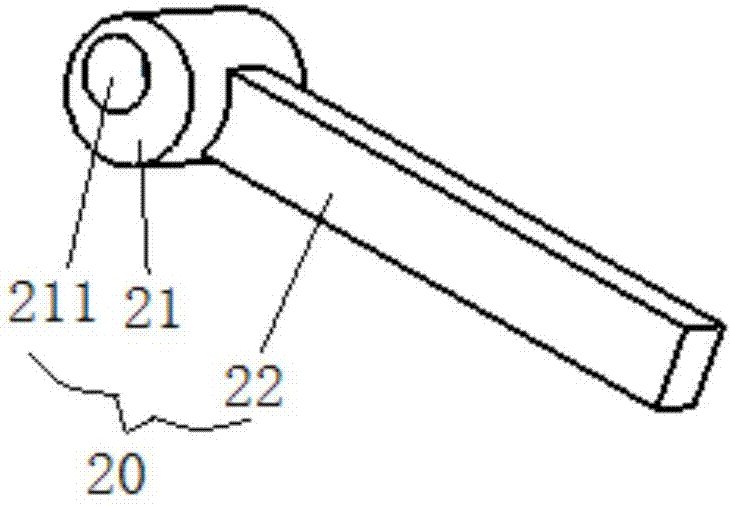

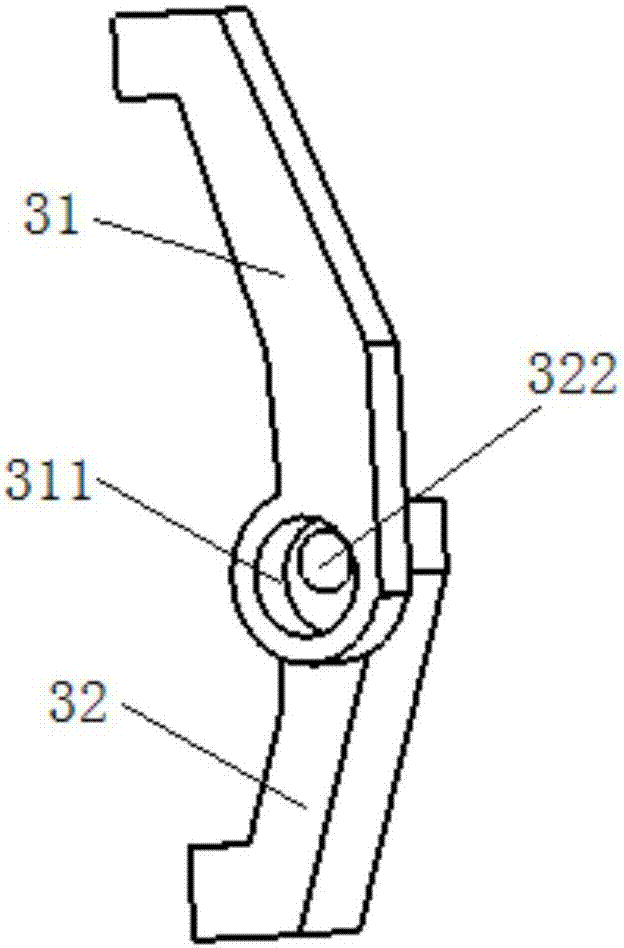

[0019] Please see Figure 1 to Figure 6 , the embodiment of the present invention provides a clamping box device 10 for a small sand box for casting, including a handle 20 and a fixed claw, the handle 20 includes a cam 21 and a cylindrical handle 22, and the cam 21 and the cylindrical handle One end of 22 is fixedly connected, and the cam 21 is provided with a rotating shaft 211. The fixed claw 30 includes a first fixed claw 31 and a second fixed claw 32. The first fixed claw 31 is an arc-shaped plate. The upper end of the first fixed claw 31 is horizontally fixed with a clamping plate 313 to clamp the sand box. A cam hole 311 is provided at the lower end of the first fixed claw 31, and the cam 21 is installed in the cam hole 311. The side center of the lower end of the first fixed claw 31 is provided with a rotating groove 312, and the cylindrical handle 22 can rotate up and down in the rotating groove 312. The second fixed claw 32 is an arc-shaped plate. The lower ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com