Aluminum alloy gear shifting hub casting defect control method

A technology for casting defects and control methods, which is applied to the control of pouring molten metal from a casting ladle, casting equipment, casting molding equipment, etc., can solve the problems of not considering the improvement of casting molds and the accuracy of the model without further verification, etc. Achieve the effect of improving casting quality and improving casting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0046] The invention provides a method for controlling casting defects of an aluminum alloy shift hub.

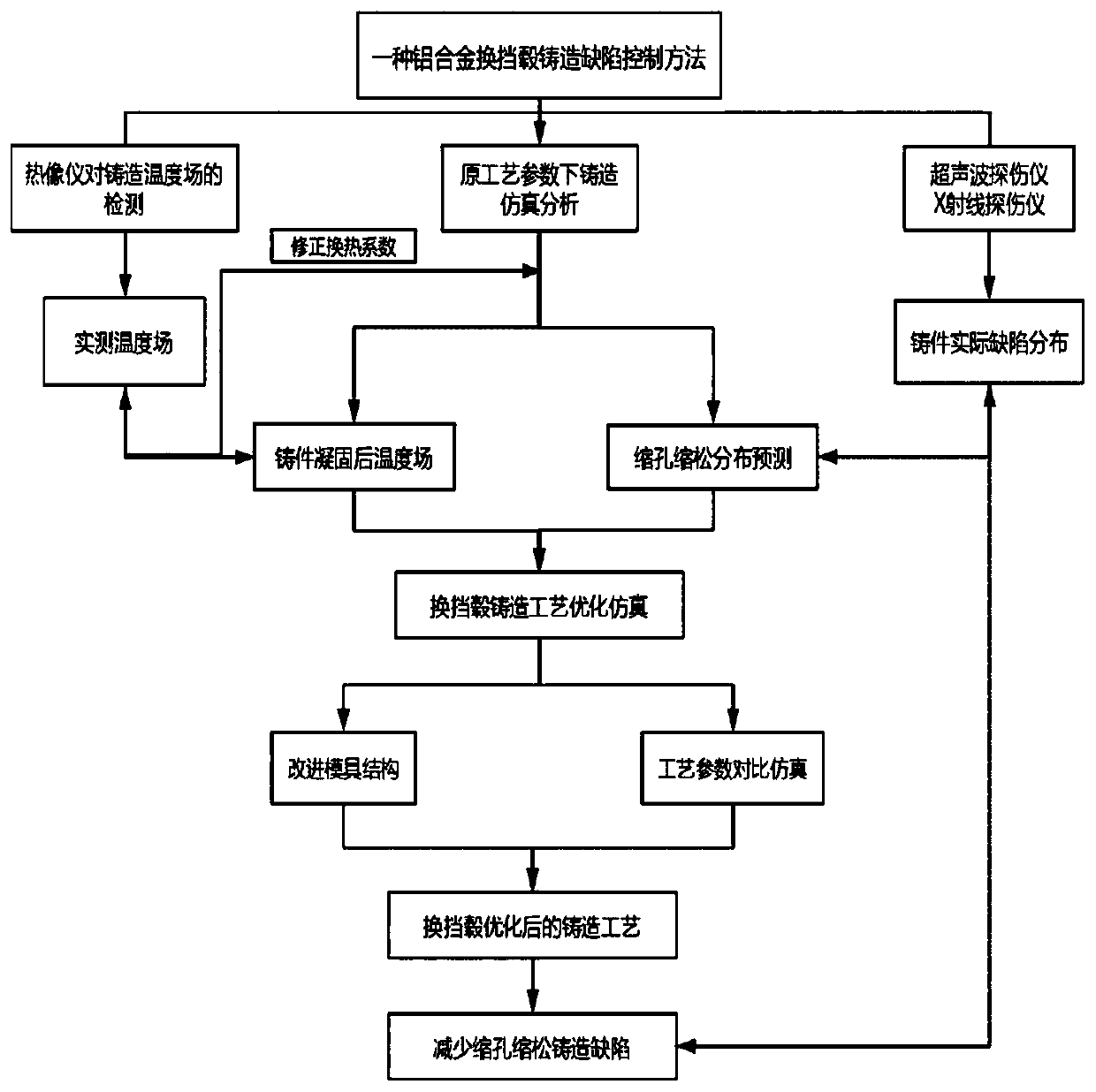

[0047] Such as figure 1 As shown, the method includes the following steps:

[0048] S1: Use a thermal imager to detect the casting temperature during the actual casting mold opening process to obtain the casting temperature field;

[0049] S2: Defect detection is carried out on the actually cast aluminum alloy shift hub casting products, and the shrinkage cavity shrinkage casting defect formation area in the actual casting process is obtained;

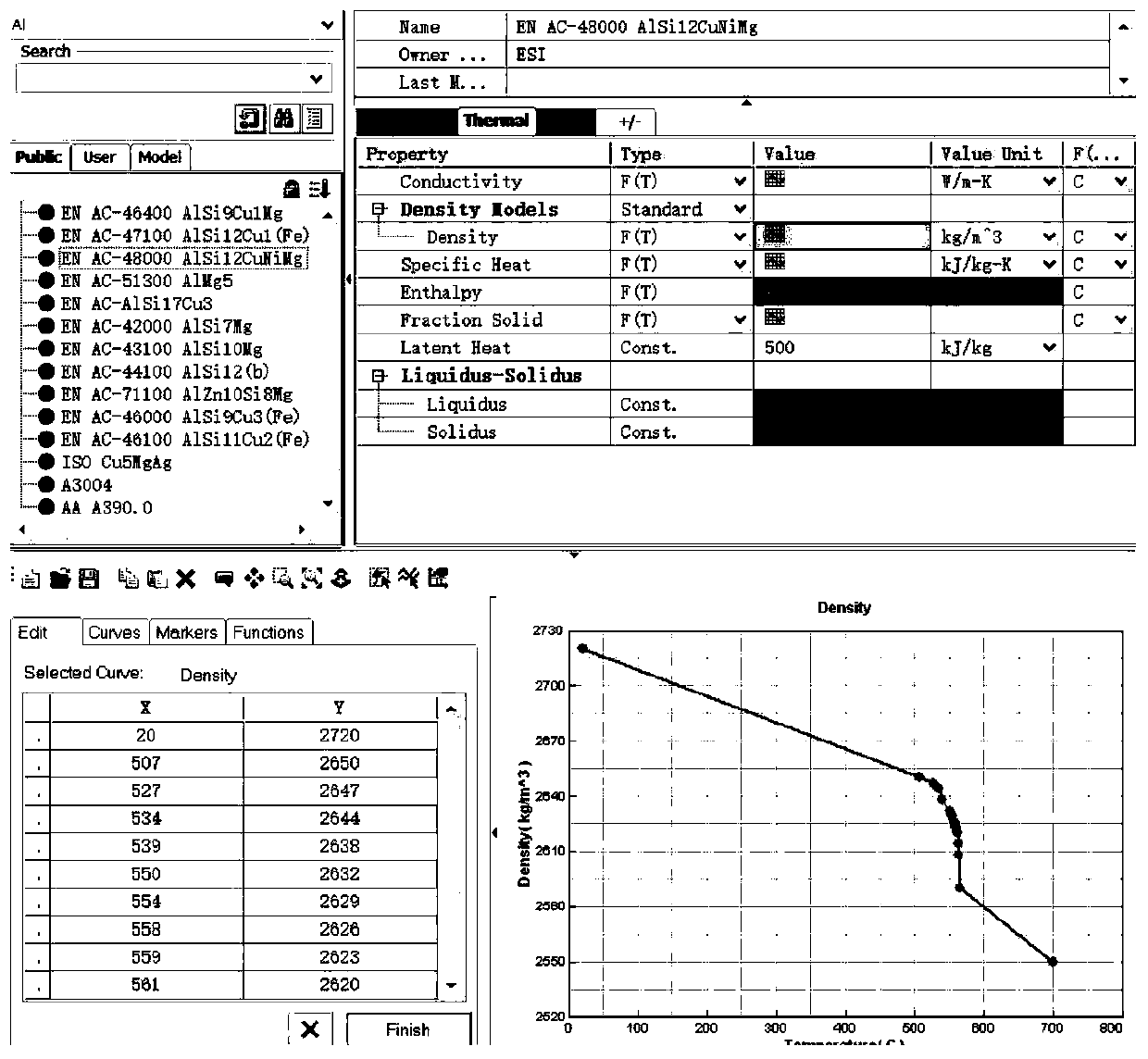

[0050]S3: Carry out computer simulation analysis on the casting process, obtain the temperature field of the casting from the simulation, compare it with the actual test results of S1, and correct the heat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com