Patents

Literature

55results about How to "Reduce pollution emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

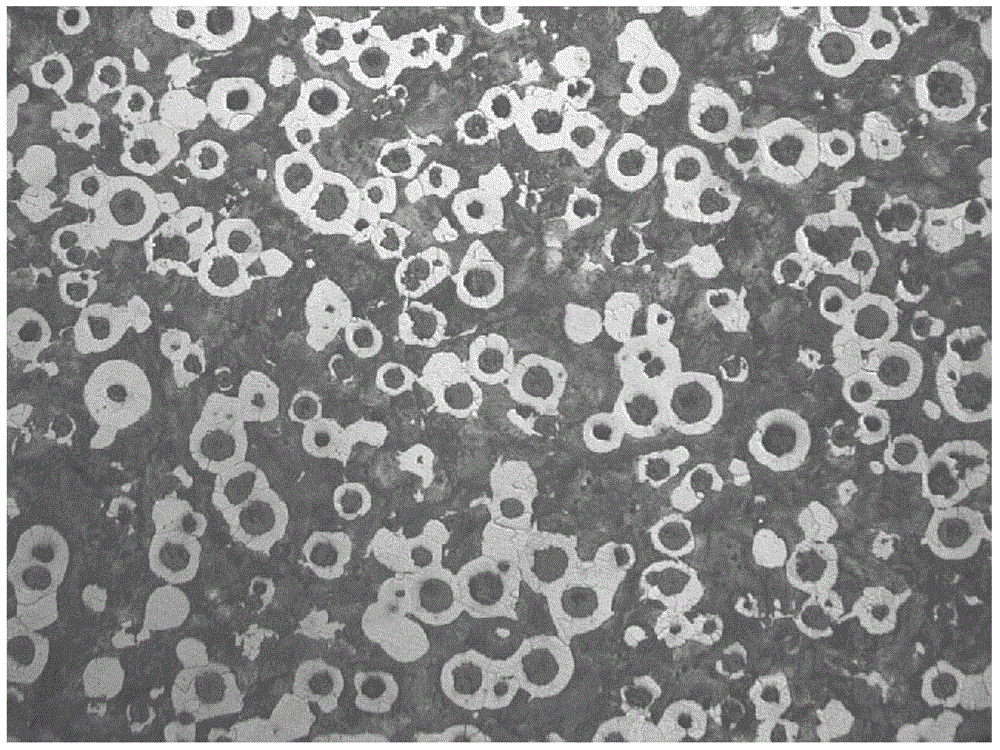

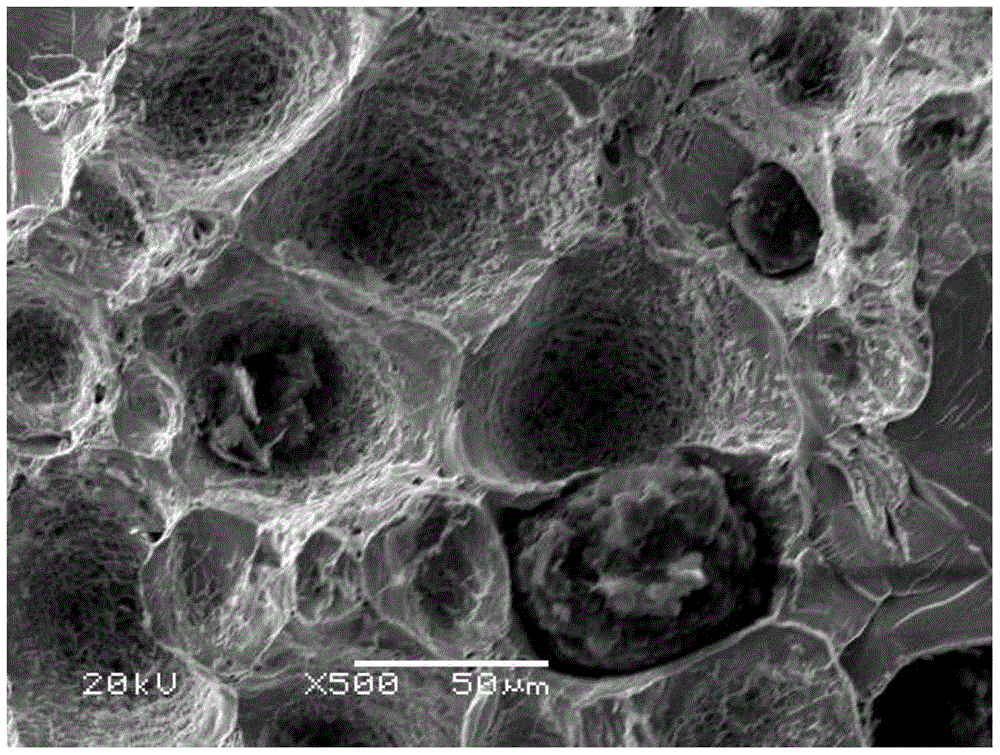

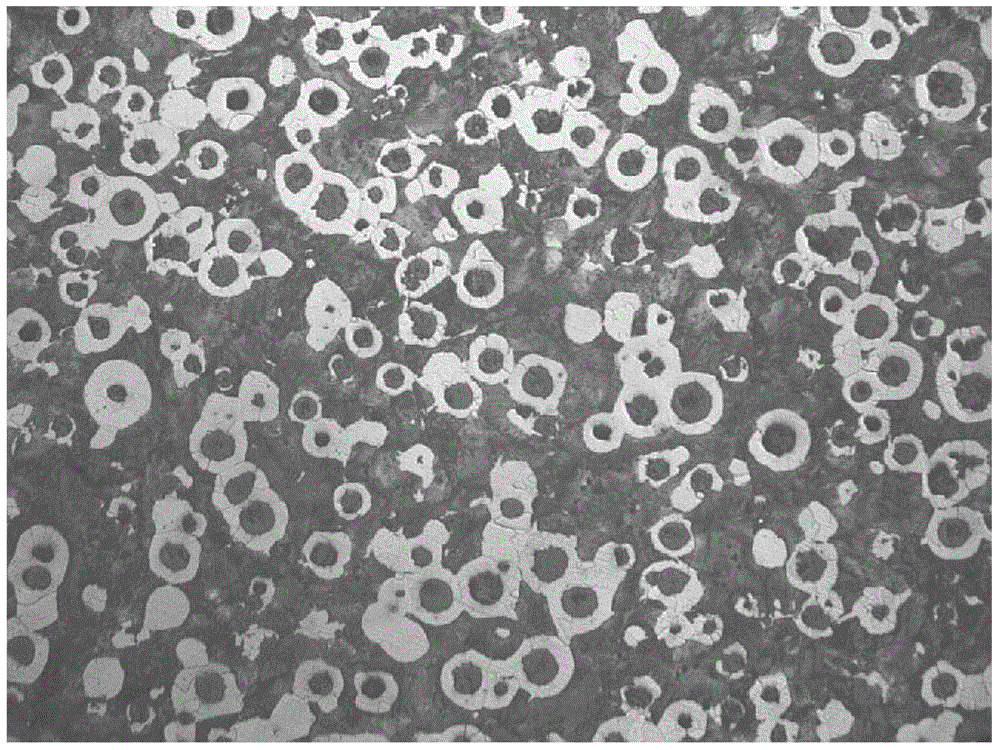

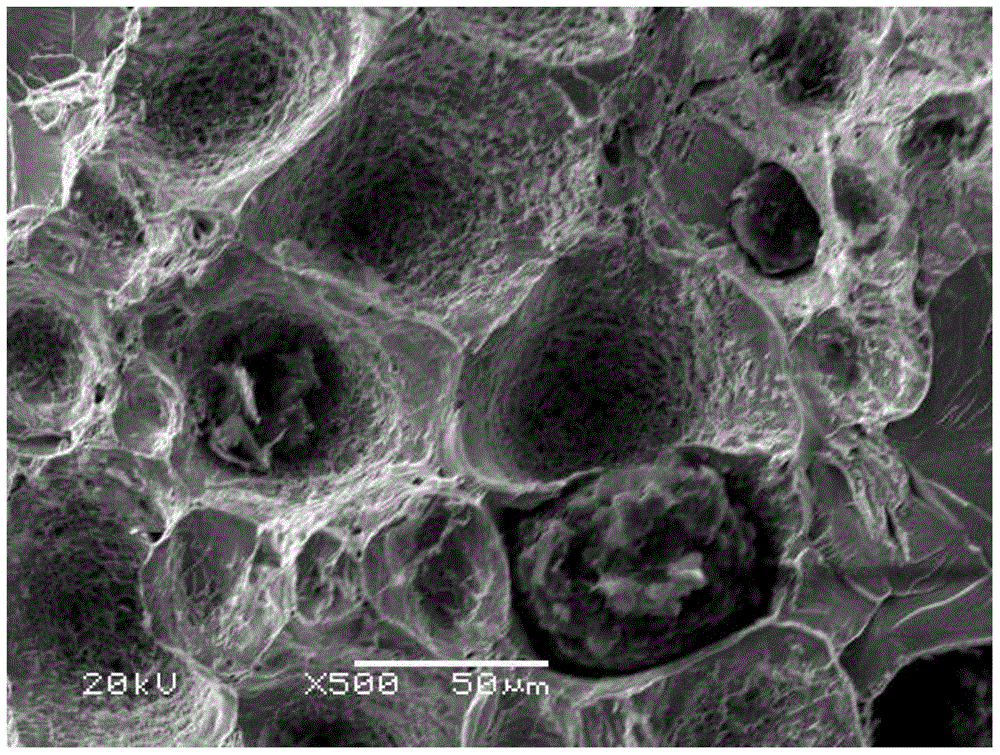

Preparation method for high-toughness nodular cast iron

The invention provides a preparation method for high-toughness nodular cast iron, which is a method for producing high-toughness nodular cast iron by utilizing a medium-frequency electric furnace and selecting materials such as cast iron which is low in sulfur, phosphor and manganese content, waste steel, and the like. The preparation method mainly comprises chemical component design, furnace burden selection, medium-frequency furnace smelting, a nodulizing agent selection and nodulizing treatment method, a nucleating agent selection and nucleating treatment method, and the like. The method disclosed by the invention does not need thermal treatment and desulfuration treatment, is less in processes, adopts a wet type sand production line to manufacture QT600-10 casting pieces, has casting efficiency higher than that of sand-lined iron type, and is low in cost. The produced nodular cast iron is high in strength, good in plasticity and toughness, can be used for components such as a transmission shaft, a rear axle shell, a differential mechanism shell, a bracket, and the like for a car and a tractor chassis.

Owner:HENAN POLYTECHNIC UNIV

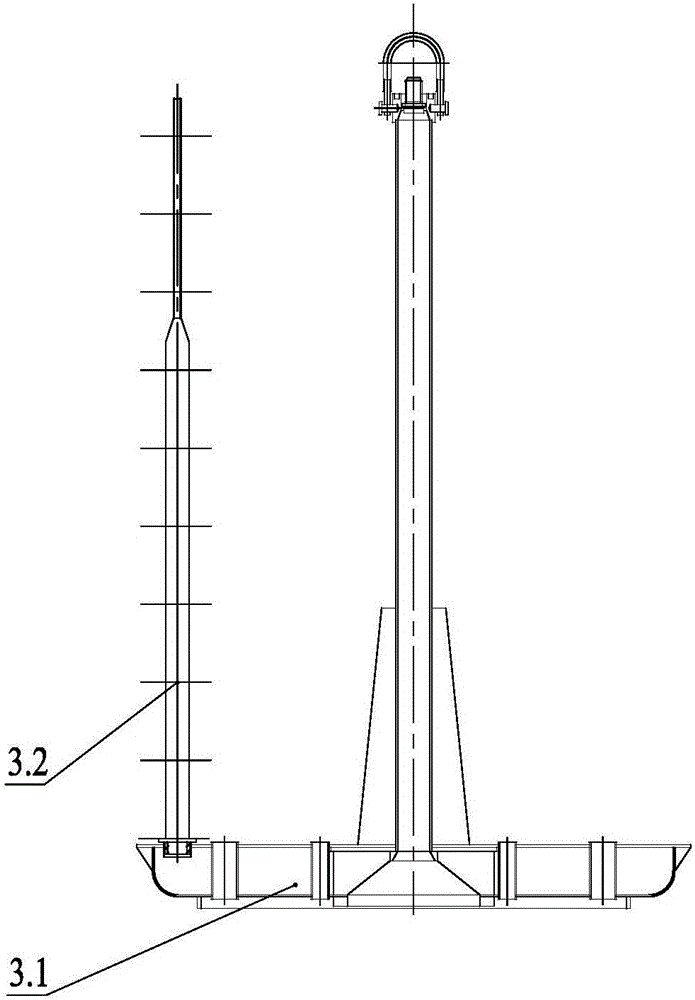

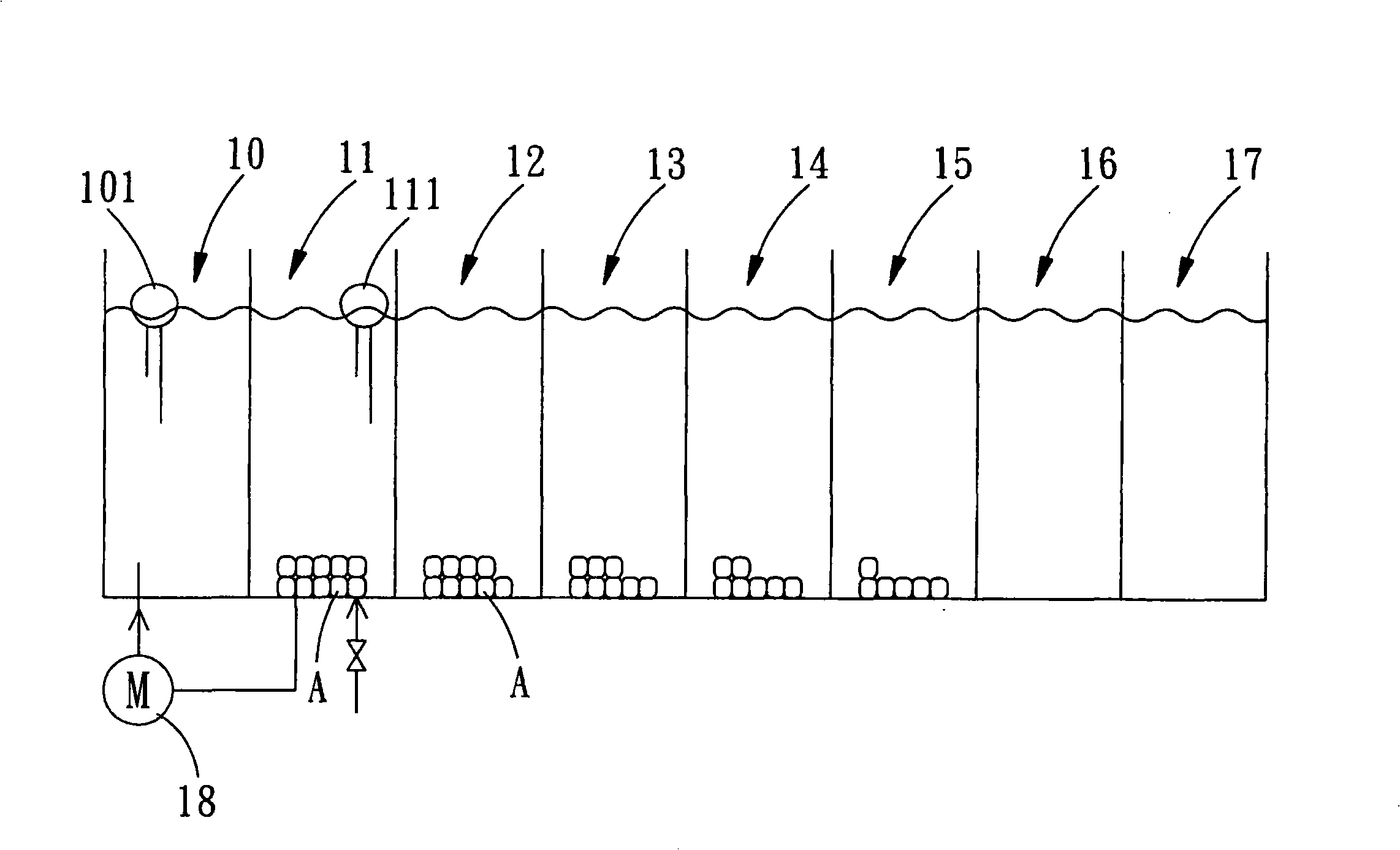

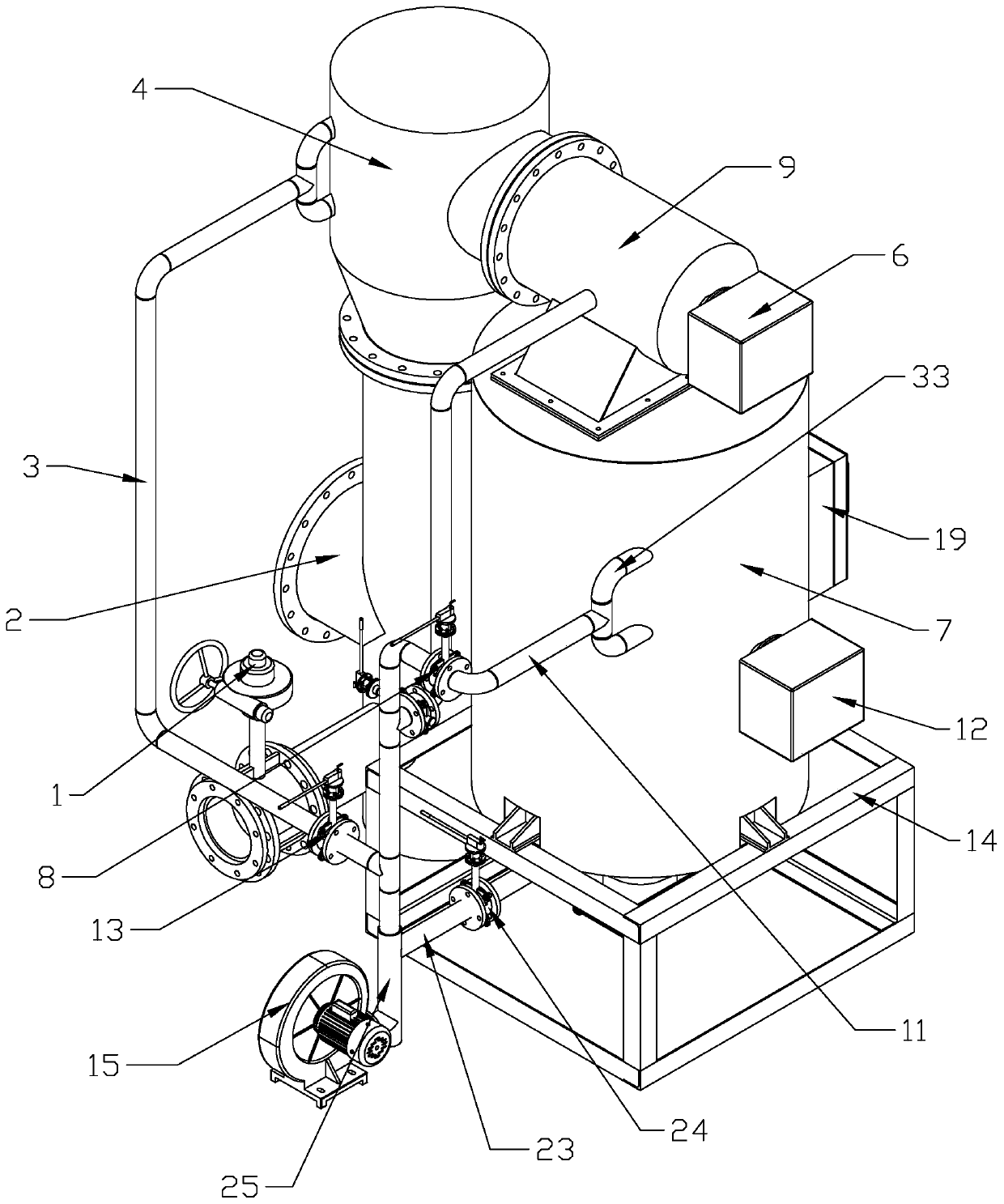

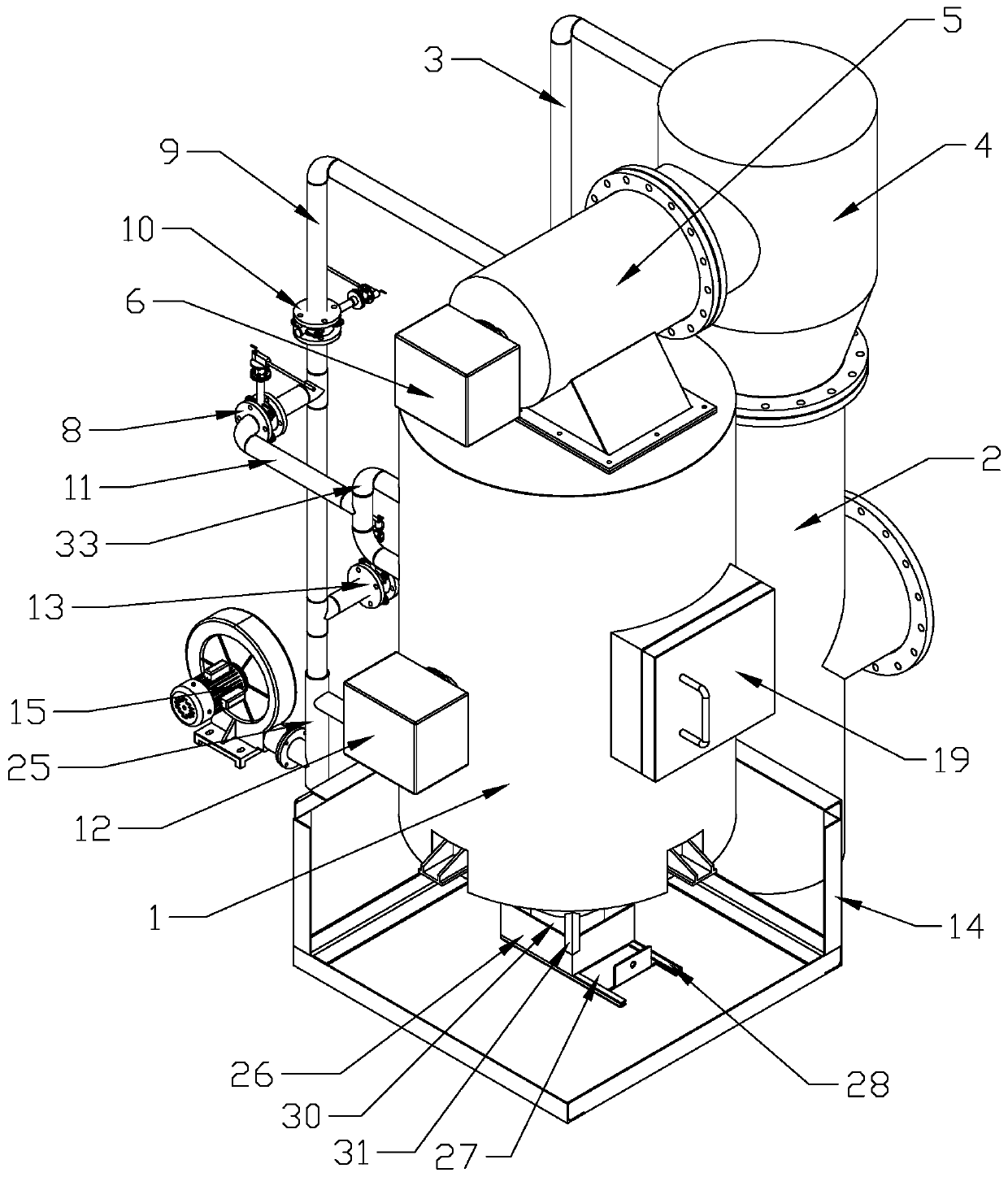

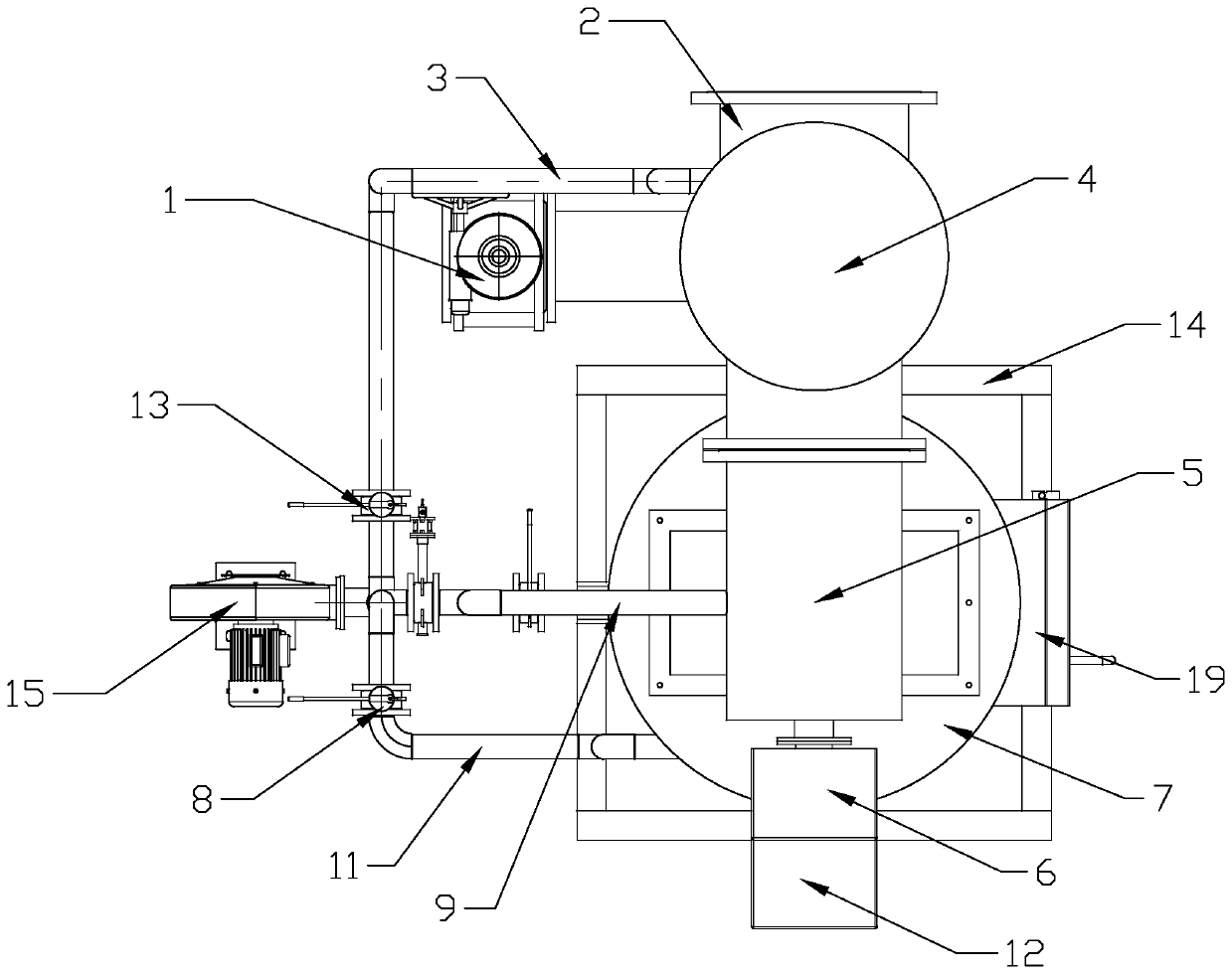

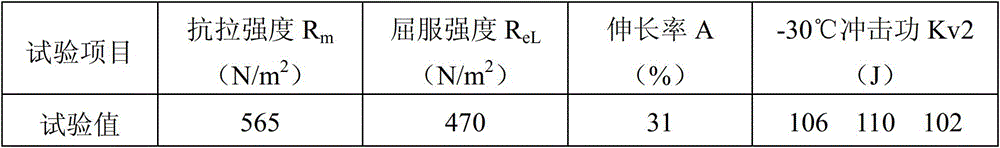

Desalination plant by using engine end gas

InactiveCN101306846ATake advantage ofFast heat transfer and heat exchangeGeneral water supply conservationSeawater treatmentThermal energyEngineering

The invention discloses a seawater desalting device for tail gas of an engine. The device comprises a superconductive pipe heat exchanger(4), a vacuum evaporating pot(6) and a condenser(5) which are orderly connected as a whole, wherein the superconductive pipe heat exchanger(4) is communicated with an exhaust pipe(2) of the engine through a flue gas diversion valve(3), and the condenser(5) has a seawater inlet provided with a sea water replenishing pump(10) and a condensed water outlet provided with a vacuum pump(9) and a fresh water collection pot(8). The invention utilizes the tail gas of the engine which is the waste energy to produce fresh water by the distillation method, which fully utilizes the energy, reduces the emission of pollutants and fully utilizes the heat energy of the tail gas; the seawater desalting device has the advantages of simple running, easy operation and maintenance, low cost, small volume and few requirements of the power section, and can effectively resolve the water supply problem for sailing warships, civilian ships and oil drilling platforms which use engines as power sources or use other devices the temperature of the tail gases of which is more than 80 DEG C, as power sources.

Owner:普瑞特机械制造股份有限公司

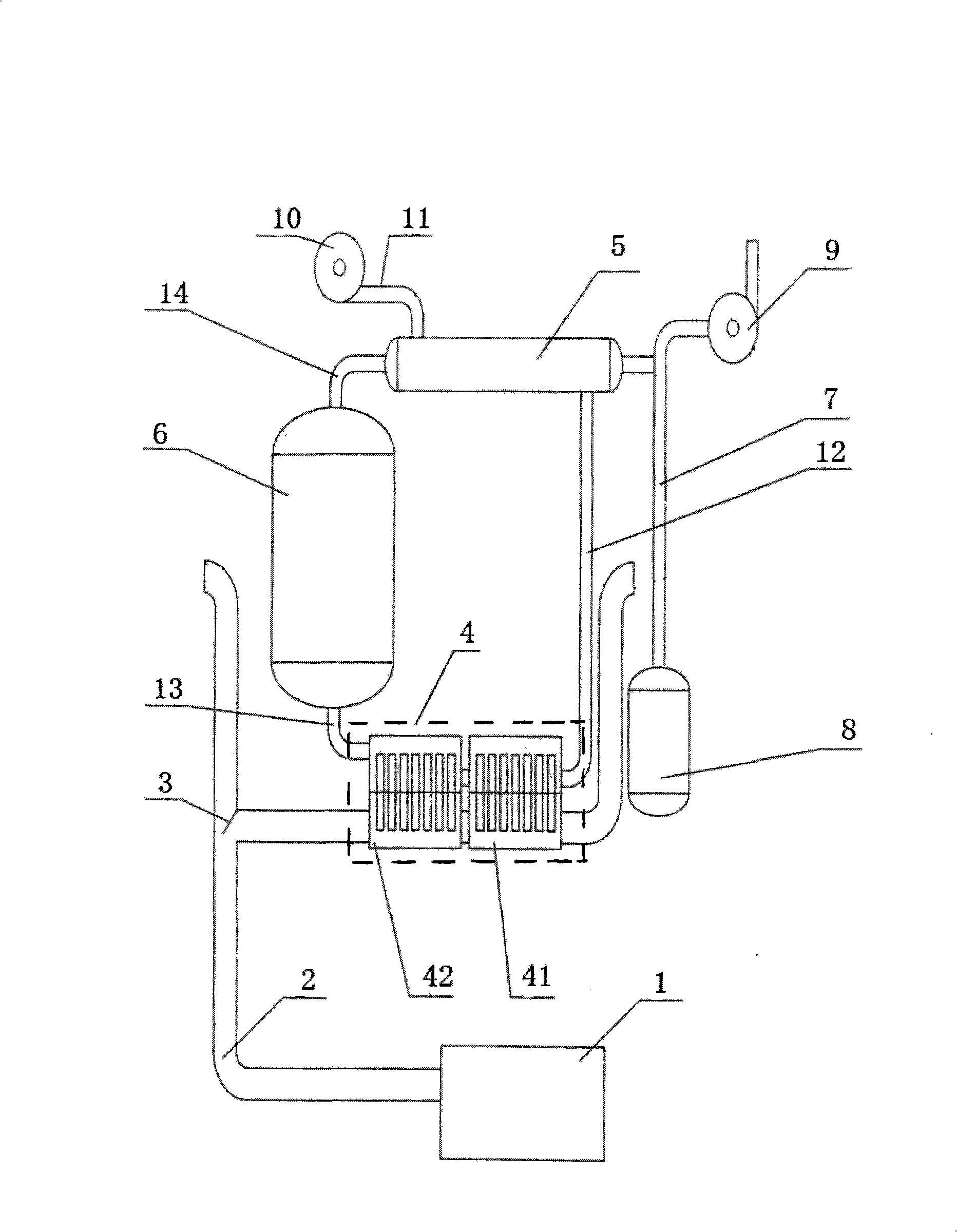

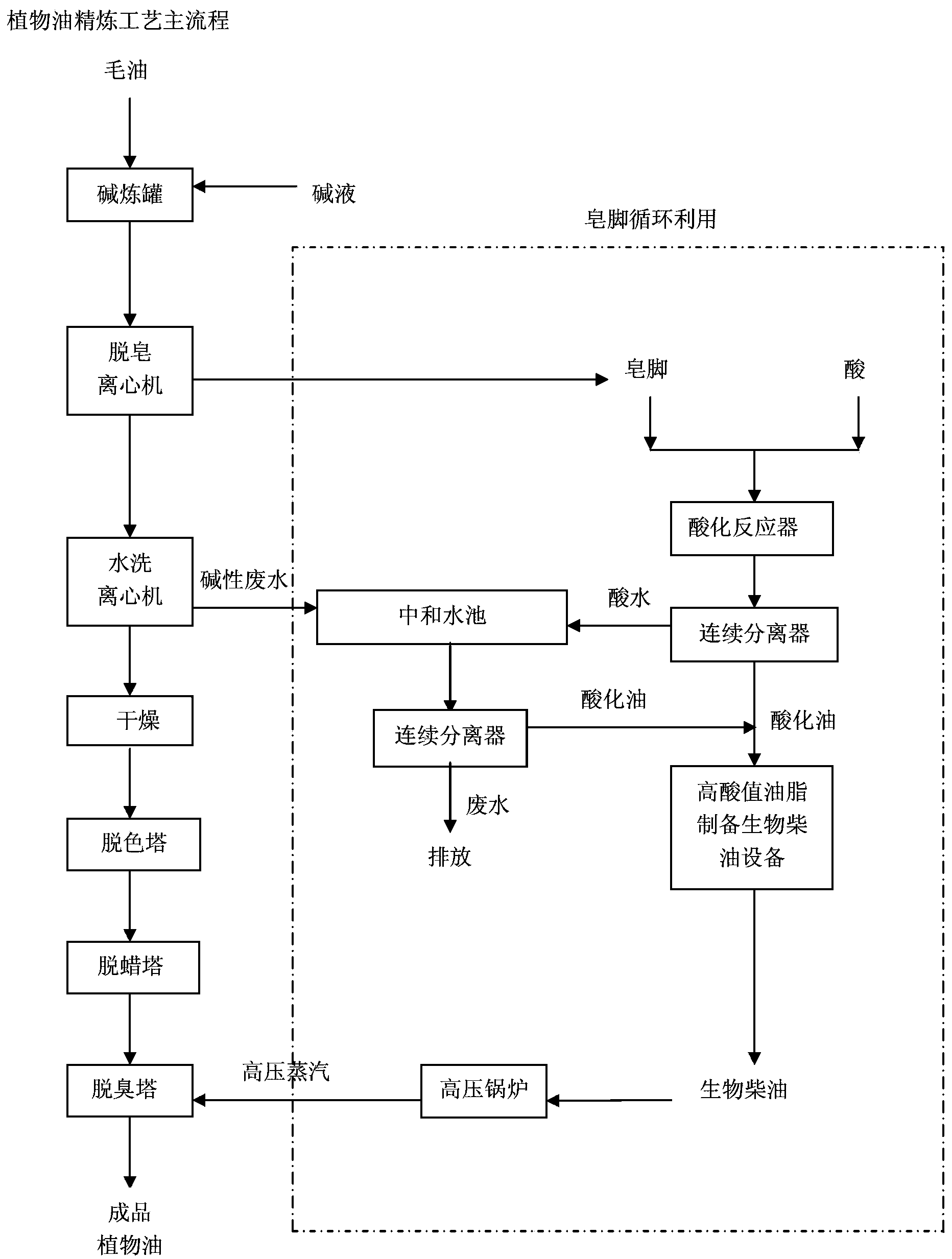

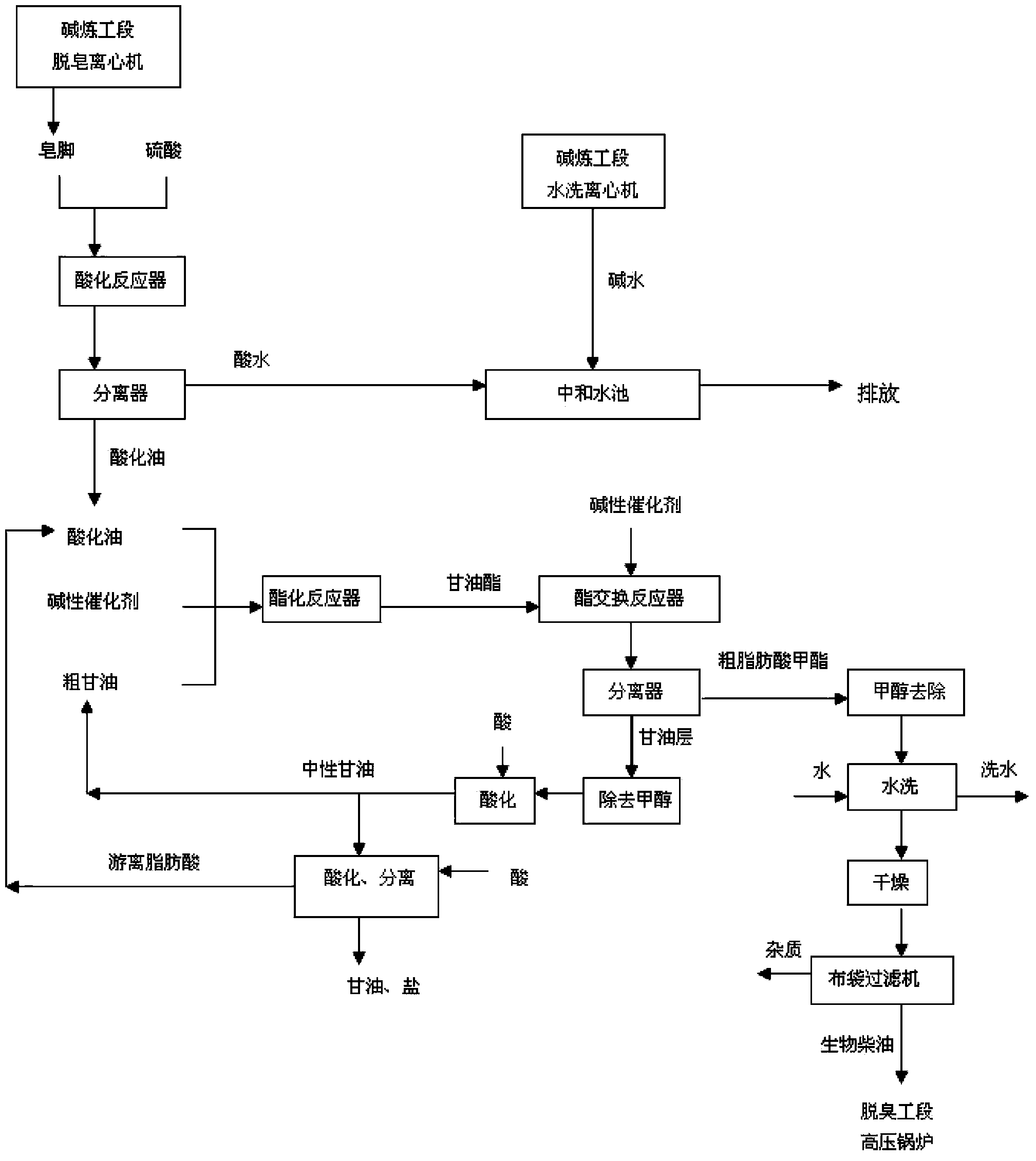

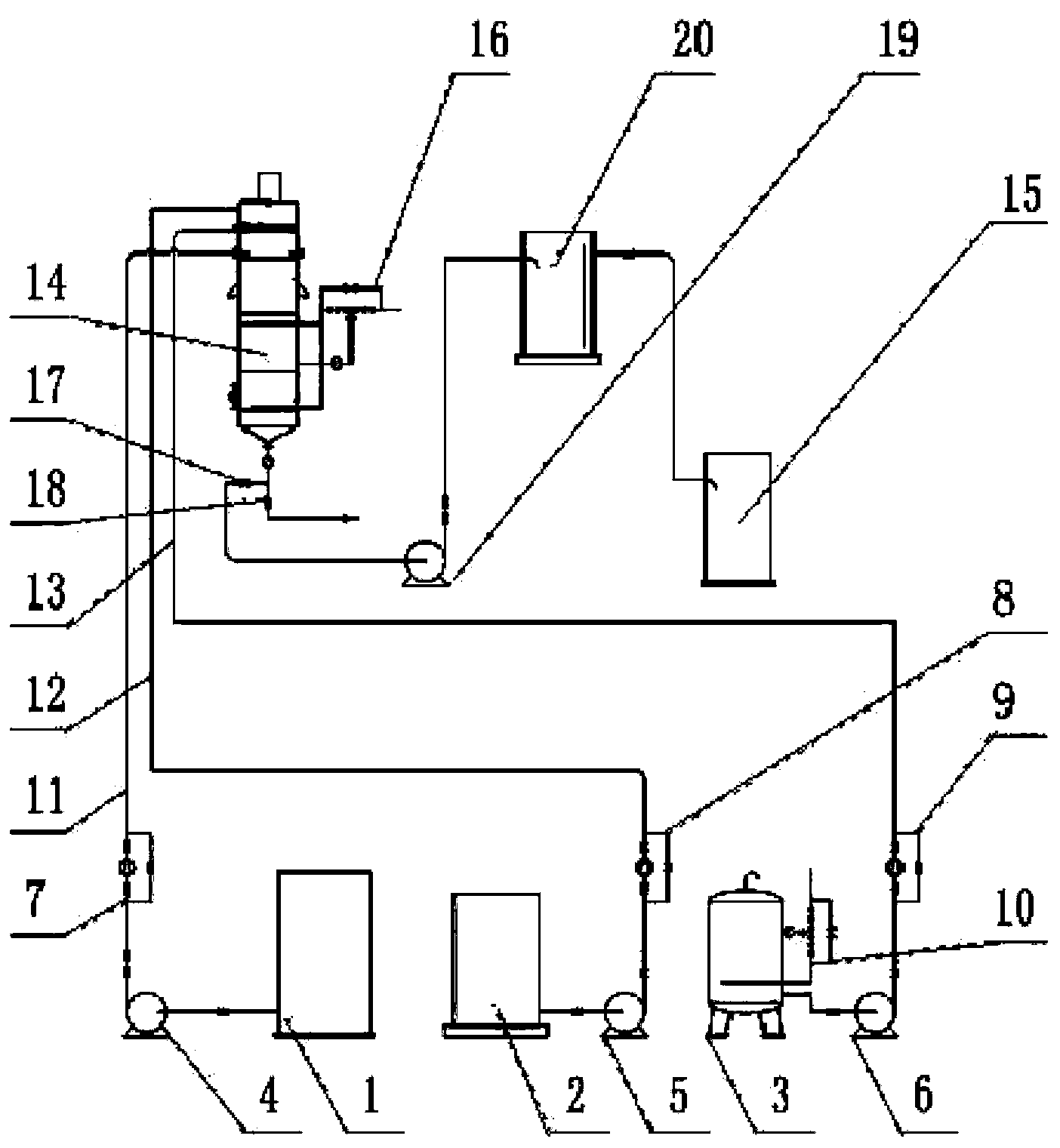

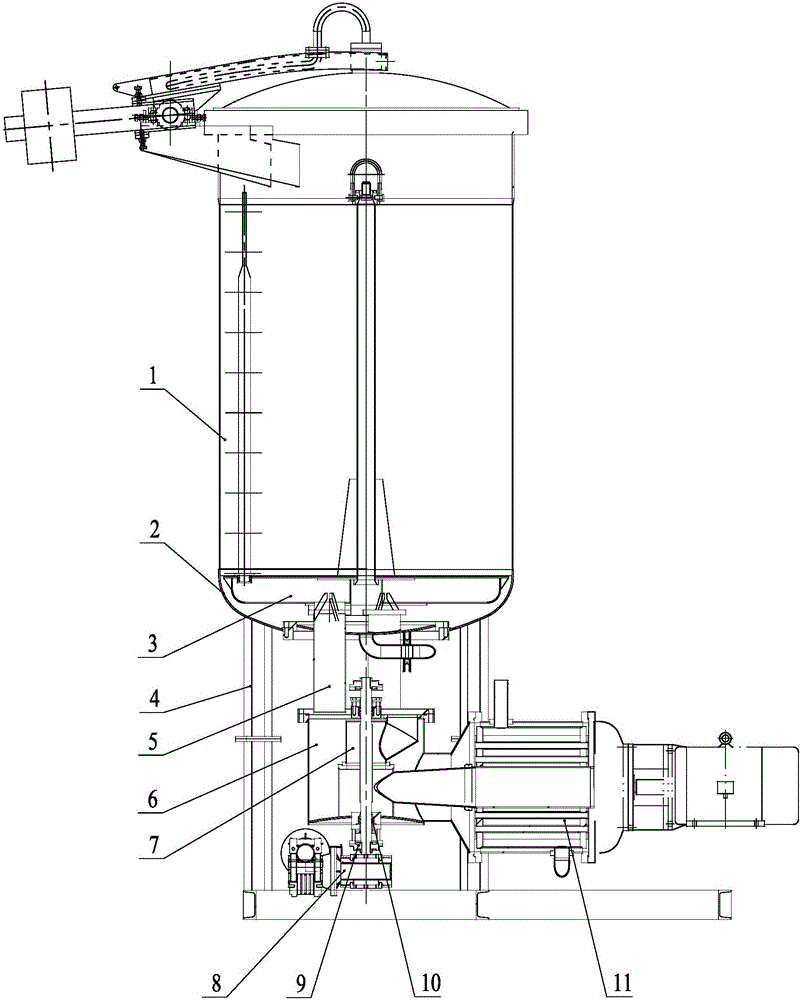

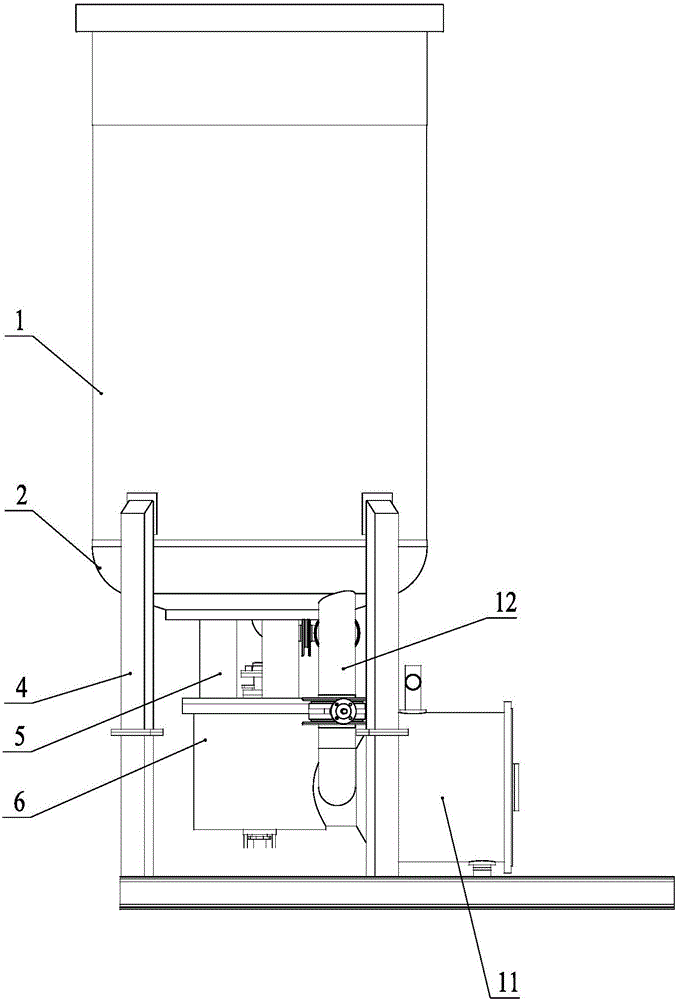

Recycling process for alkali refining by-product, namely soapstock in refining vegetable oil and reactor

InactiveCN103409242AImprove utilization efficiencyAchieve recyclingFatty oils/acids recovery from wasteFatty acid esterificationBiodieselVegetable oil

The invention discloses a recycling process for an alkali refining by-product, namely soapstock in refining vegetable oil and a reactor. The recycling process comprises the following steps: (1) acidizing the soapstock; (2), preparing a biodiesel through the acid oil; (3) neutralizing wastewater. According to the invention, a renewable energy source, namely the biodiesel is produced by directly acidizing the by-product, namely the soapstock produced in the vegetable oil refining process. Compared with the method of directly selling the soapstock, the recycling process has the advantages as follow: the problem that light diesel is needed to be purchased from the outside to be used as a fuel for the burning of a high-pressure steam generator in the deodorization working section of the same process is solved; secondary pollution after waste soapstock is sold is prevented; meanwhile, duo to acidified water after the soapstock is acidized, the discharge of high-alkalinity final washing water in the alkali refining working section is avoided; raw materials and water treatment cost are reduced. Therefore, the recycling process is an environment-friendly technology, and can bring more social and economic benefits.

Owner:广州市南洋国际工程技术服务公司 +2

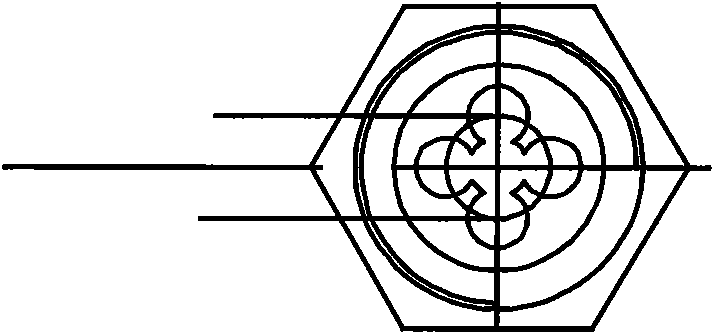

Dyeing equipment and method allowing dye liquor to flow inwards and outwards at the same time

ActiveCN106048931AFully combinedEvenly combinedTextile treatment machine partsLiquid/gas/vapor yarns/filaments treatmentYarnWater flow

The invention relates to dyeing equipment and method allowing dye liquor to flow inwards and outwards at the same time. In the dyeing equipment, an end socket is welded to the lower end of a cylinder body to form an airtight container, and the air container is supported and fixed through a supporting frame; a cheese creel is placed in the cylinder body and comprises a disc body and yarn rods, the disc body is hollow inside, and a plurality of yarn rods are evenly installed on the disc body; the yarn rods are hollow inside, an opening in the lower end of each yarn rod is communicated with an inner cavity of the disc body, and a plurality of small holes are formed in the wall of each yarn rod. The dyeing equipment is characterized in that the inner cavity of the disc body is divided into at least three mutually independent creel chambers through partition boards, a water access port is formed in the bottom of each creel chamber, the water access port of at least one creel chamber is connected with a water drainage port of a water pump through a periodical water flow reversing mechanism, and the water access ports of other creel chambers are connected with a water return port of the water pump through periodical water flow reversing mechanisms. According to the dyeing equipment, dye liquor conversion frequency is improved, effective circulation time is prolonged, and cost is saved.

Owner:普伟恩

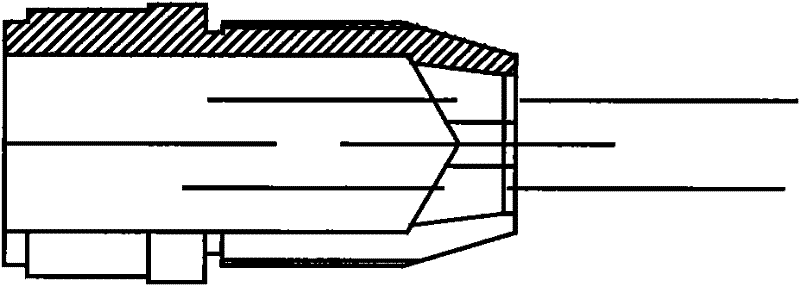

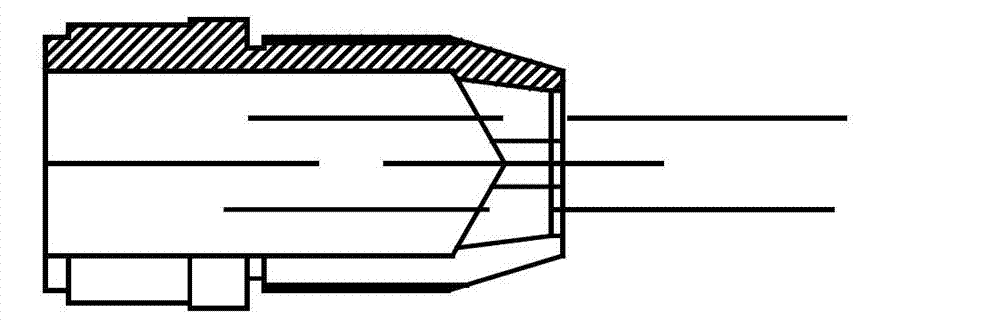

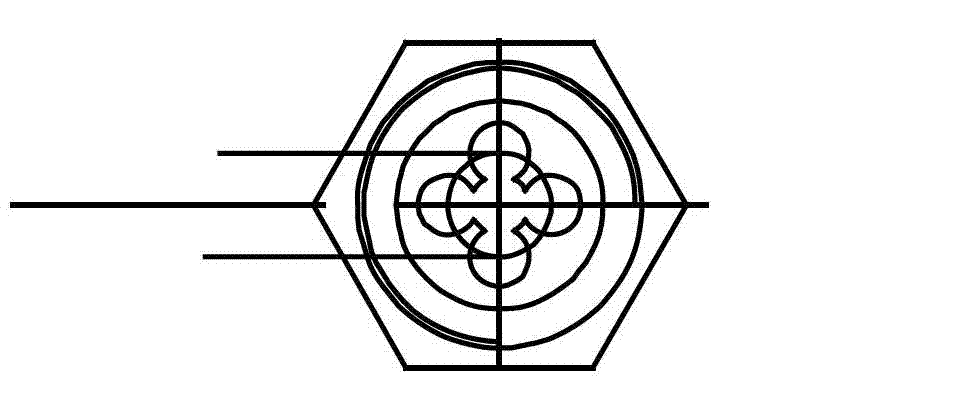

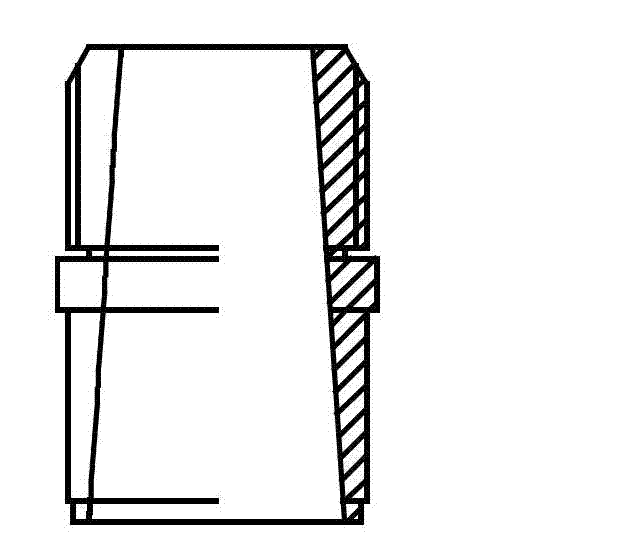

Biogas burner

ActiveCN101749707AImprove stable working rangeReduce pollution emissionsGaseous fuel burnerCombustorFlow sheet

The invention relates to a biogas burner, which includes an ejector and a nozzle. The biogas burner is characterized in that the ejector includes a lead-in section and mixing section which are coaxially arranged; the caliber of the mixing section is more than that of the lead-in section so as to form a clearance and lead in air for mixing; the mouth part of the nozzle is provided with a pluralityof channels with small calibers which are arranged in a plum blossom shape and are communicated; or a plurality of channels with small calibers are arranged in a circular shape separately; the circular-shaped channels with small calibers are arranged in multi-layers; the calibers of the inner layer are small and the calibers of the outer layer are big. The inlet end of the lead-in section is uniformly provided with a circle of small holes along a side wall; the upper port of the mixing section is uniformly provided with a circle of small holes along the side wall. The mixing section or the lead-in section is provided with swirling flow sheets; and the upper port of the mixing section is provided with a gridded flame holder. The biogas burner solves a plurality of problems like safely and effectively burning biogas in current fermentation biogas processing and utilizing system with none pollution, etc.

Owner:北京时代桃源环境科技股份有限公司

Biogas burner

ActiveCN102853427AImprove stable working rangeReduce pollution emissionsGaseous fuel burnerCombustorEngineering

Owner:无锡时代桃源环保设备有限公司

Pollution discharge prediction method based on industrial user electricity consumption data

InactiveCN105095996AAccurate power consumption forecastUser State ControlForecastingElectricityPredictive methods

The invention relates to a pollution discharge prediction method based on industrial user electricity consumption data. The method has the following steps: 1), obtaining industrial user electricity consumption sample data; 2), performing preprocessing on the sample data; 3), establishing a complex network representing relations between industrial users in industries according to the pre-processed data; 4), predicating the electricity quantities of the industrial users according to the complex network; 5), according to the industrial user electricity consumption sample data, establishing a quantity relation between the electricity quantities of industrial enterprises and direct pollutant discharge amounts; and 6), according to the prediction result in the step 4) and the quantity relation in the step 5), predicting the direct pollutant discharge amounts of the industrial users. Compared to the prior art, the method provided by the invention has the advantages of high accuracy, high reliability and the like.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Environment friendly process for biodiesel

InactiveCN101486923AReduce consumptionReduce investmentBiofuelsLiquid hydrocarbon mixture productionLiquid wasteWax

The invention discloses environmental protection technology for bio-diesel production, which comprises the following units: 1) raw material preparation; 2) pre-esterification; 3) fine esterification; 4) washing desulphurization esterification; 5) refined methyl ester separation; 6) low-temperature dewaxing; 7) emission recovery; and 8) wastewater treatment. The environmental protection technology has the advantages that: 1. energy saving and emission reduction: the low temperature is served as technology heat and reduces the consumption of the energy; after the unit separation and purification, the produced exhaust gas and waste liquid can be reused in the technology, thus reducing the pollution emissions; 2. rapid esterification speed: high esterification rate; the hydrous grease is separated promptly by a liquid separating tank, thus avoiding a reverse reaction and reducing the esterification time to 1 hour; the acid value recovery problem is solved, so that the esterification is more thorough; the esterification rate can reach more than 98%; 3.output improving: the environmental protection technology has compact technology and reasonable procedure and can realize continuous and large-scale flowing production; and 4. low bio-diesel solidifying point: the wax in the bio-diesel is removed effectively by using a jacketed crystallizer and a full-automatic pressing filter, and the solidifying point is reduced.

Owner:迟洪军

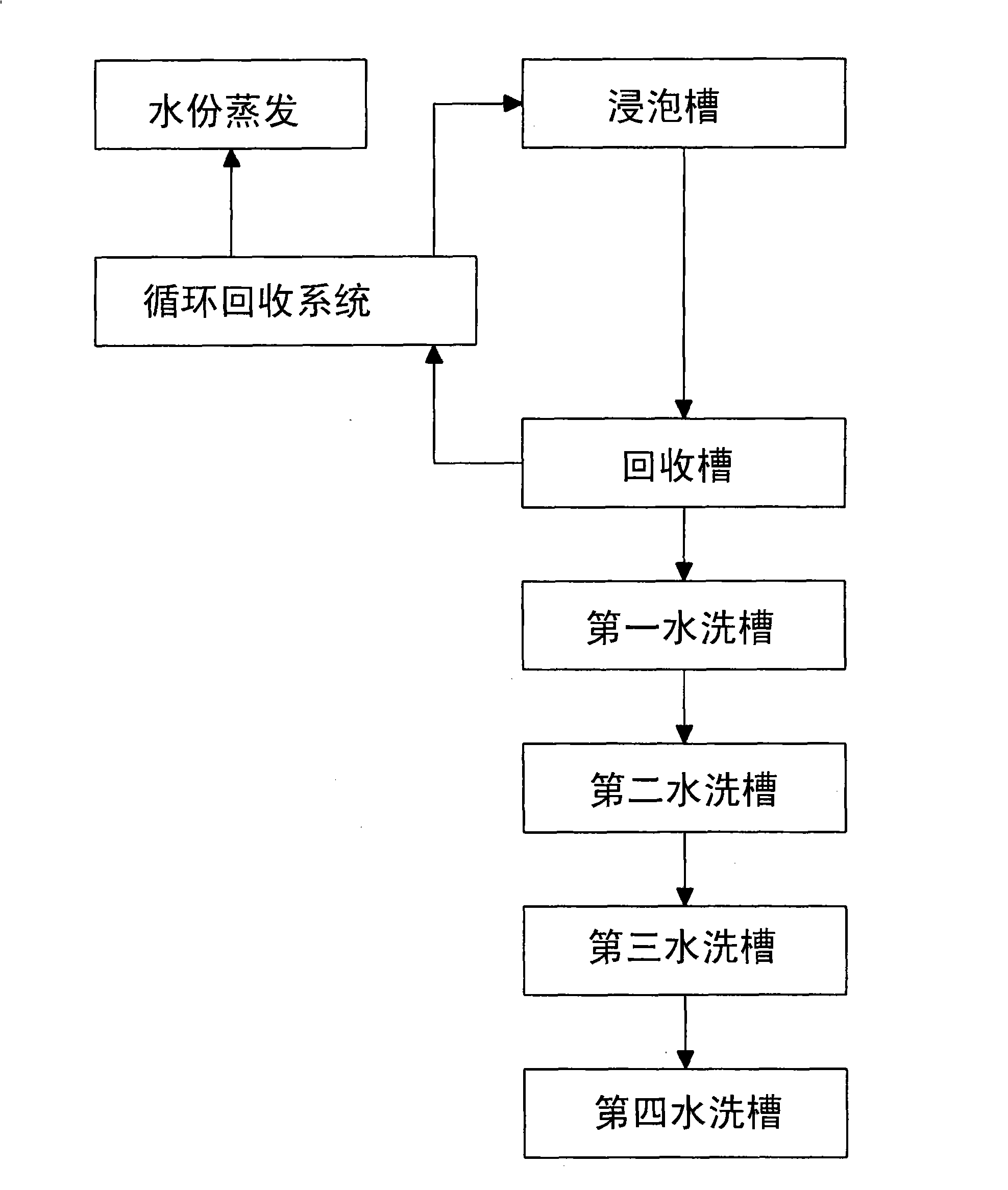

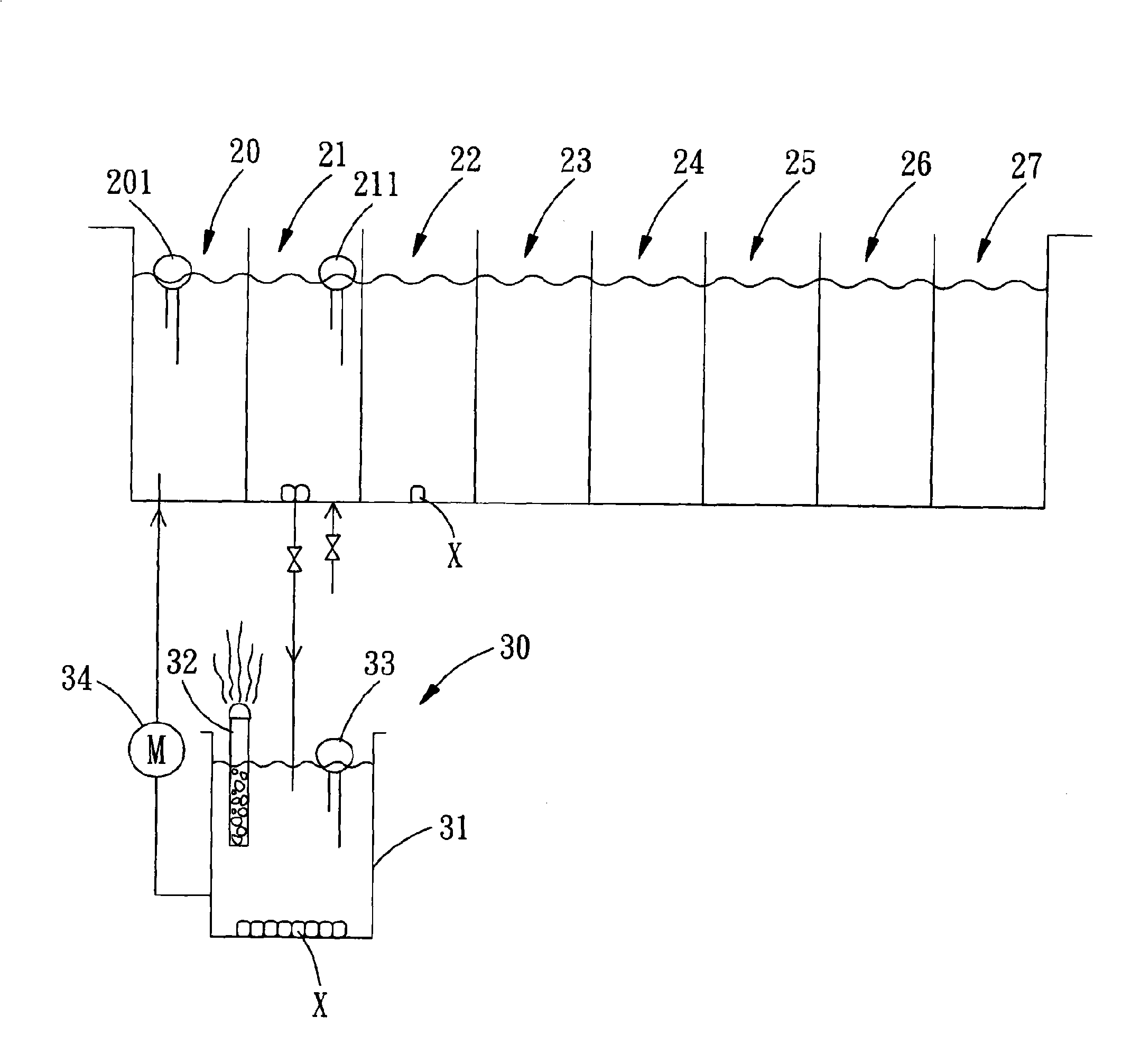

Recovery method for galvanization process and equipment thereof

InactiveCN101319346AGuaranteed recycling efficiencyAvoid takingCellsHigh concentrationRecovery method

The invention relates to an electroplating recovery method and an electroplating recovery device. The method comprises the following steps that: a recycling system is arranged between a soaking tank and a recovery tank for water-soluble electroplating metals and comprises a tank body, an evaporation heater, a water gauge and at least one pressure pump, wherein, the tank body applies the pressure pump to recover water-soluble electroplating molten metals at the bottom of the recovery tank; the water in the tank body is evaporated through the evaporation heater; and water-soluble electroplating molten metals with high concentration are recycled and sent back to the soaking tank. Therefore, the method can guarantee the high concentration of the soaking tank and the recovery efficiency of the recovery tank, can reduce the rinsing in the subsequent rinsing step, and not only reduces the pollution emission of a rinsing bowl but also avoids the electroplating molten metals from being brought into the metal electroplating operation in the next stage.

Owner:MAX ECHO TECH

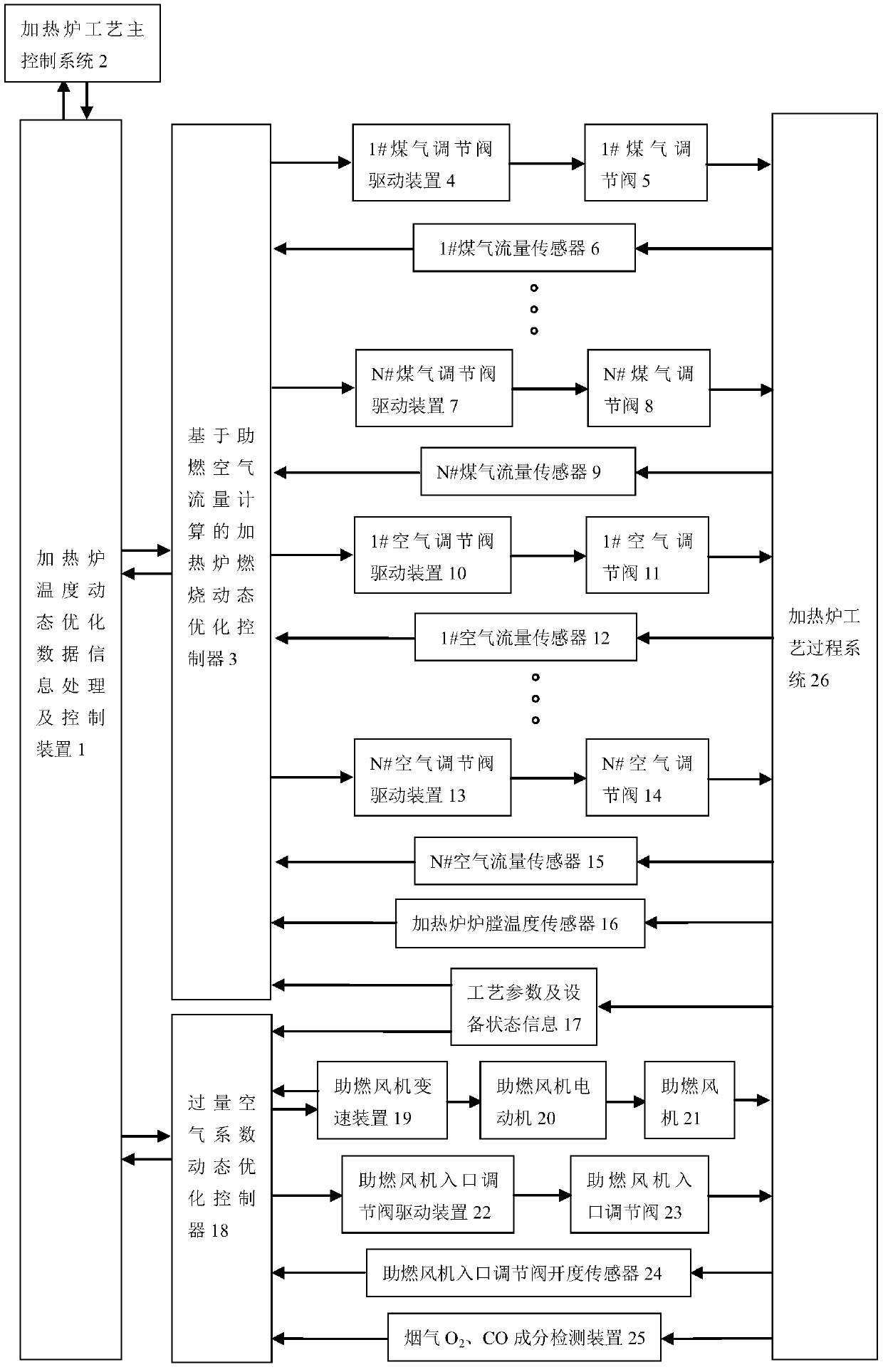

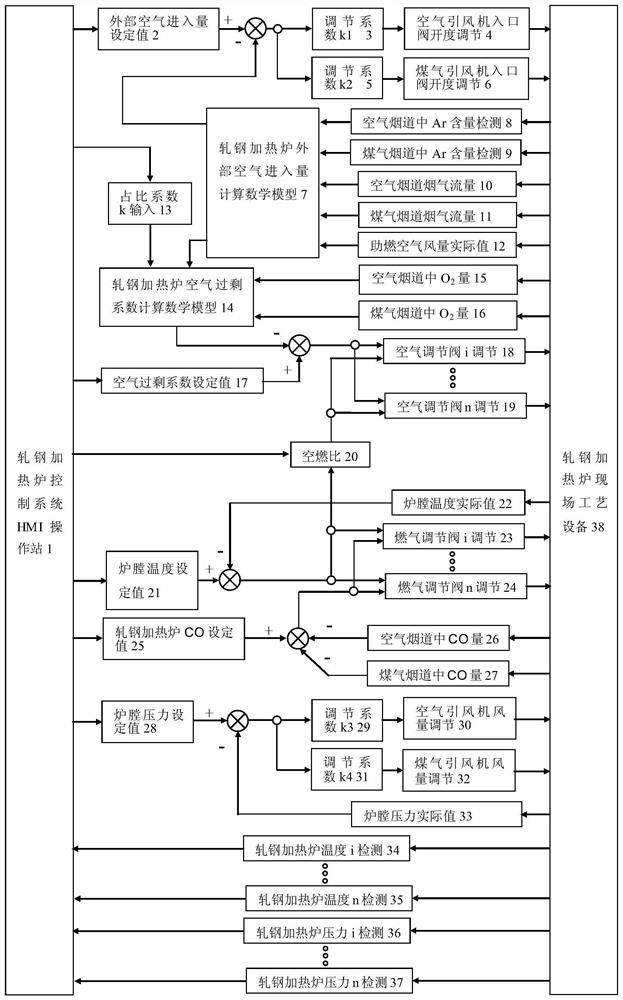

Dynamic optimization control method for temperature of heating furnace based on combustion-supporting air flow calculation

PendingCN111141153AImprove combustion efficiencyRealize fully automatic controlFurnace typesControl devices for furnacesThermodynamicsDynamical optimization

The invention discloses a dynamic optimization control method for temperature of a heating furnace based on combustion-supporting air flow calculation and belongs to a heating furnace control technology. The opening degree and the air flow of an air regulating valve are accurately controlled according to a set air-fuel ratio and the combustion-supporting air flow calculation of the heating furnace, so that the air flow is matched with the gas flow to obtain an optimal combustion effect; and according to O2 and CO components in detected smoke gas, a combustion-supporting fan speed adjusting method is adopted to dynamically control the excessive air coefficient, and the excessive air coefficient of the heating furnace is effectively controlled. The good combustion effect and the effective excessive air coefficient control achieve the multiple effects of improving the combustion efficiency of the heating furnace, reducing the total amount of generated smoke gas, improving the energy saving amount of a fan, reducing the pollution discharge amount, reducing the oxidation burning loss of a casting blank, realizing the full-automatic control of the heating furnace, reducing the labor intensity of an operator and improving the production operation rate, and the method can be used for new, expanded or renovated steel rolling furnaces and refining-chemical heating furnaces and heating furnace systems in other industries.

Owner:北京亿希欧科技有限公司

Preparation method of moss-proof baking-free brick

The invention discloses a preparation method of a moss-proof baking-free brick. The preparation method comprises the following operation steps: (1) uniformly mixing stainless steel slag, alunite and sal ammoniac, adding the mixture into a crusher for crushing, adding treating fluid into the mixture, and uniformly mixing and stirring the mixture to obtain a base material for later use; (2) uniformly mixing the base material, cement and fly ash, adding the mixture into a cement mortar mixer, carrying out stirring, adding water, a water reducing agent and an early strength agent into the mixer, continuing stirring the materials to obtain a mixture, adding the mixture into a mold, and carrying out compression molding to obtain bricks; and (3) taking out the bricks, and curing the bricks at room temperature for 15-20 days to obtain baking-free bricks. The moss-proof baking-free brick provided by the invention has excellent mechanical properties and high strength, is not easy to break duringcarrying and transportation, especially has excellent moss-proof properties, and can effectively prevent mosses and other bryophytes from growing and propagating on the surface of the brick.

Owner:安徽力峰建材科技有限公司

A kind of preparation method of high strength and toughness ductile iron

The invention provides a preparation method for high-toughness nodular cast iron, which is a method for producing high-toughness nodular cast iron by utilizing a medium-frequency electric furnace and selecting materials such as cast iron which is low in sulfur, phosphor and manganese content, waste steel, and the like. The preparation method mainly comprises chemical component design, furnace burden selection, medium-frequency furnace smelting, a nodulizing agent selection and nodulizing treatment method, a nucleating agent selection and nucleating treatment method, and the like. The method disclosed by the invention does not need thermal treatment and desulfuration treatment, is less in processes, adopts a wet type sand production line to manufacture QT600-10 casting pieces, has casting efficiency higher than that of sand-lined iron type, and is low in cost. The produced nodular cast iron is high in strength, good in plasticity and toughness, can be used for components such as a transmission shaft, a rear axle shell, a differential mechanism shell, a bracket, and the like for a car and a tractor chassis.

Owner:HENAN POLYTECHNIC UNIV

Method for improving ammonia-nitrogen content of H acid wastewater

InactiveCN106587494AEasy to handleReduce pollution emissionsOrganic compound preparationWater contaminantsAmmonia nitrogenSodium sulfate

The invention relates to an improvement on the ammonia-nitrogen content of H acid wastewater, in particular to a method for improving the ammonia-nitrogen content of the H acid wastewater. The method comprises steps of denitration, separation of sodium sulfate hydrate serving as a byproduct, reduction and T acid dissociation. According to the method, the treatment of the wastewater in a product preparation process can be improved to protect the environment and reduce pollutant discharge.

Owner:ZHEJIANG RIWA GRP

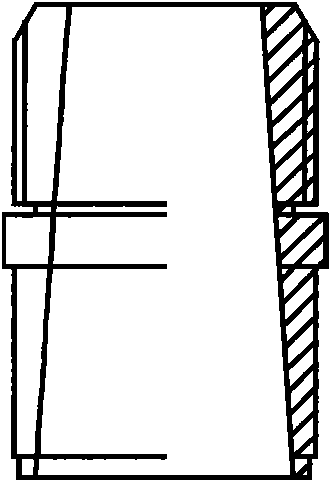

Domestic garbage smokeless oil-free vertical pyrolysis gasification furnace

PendingCN110260328AAchieve reductionHarmlessIncinerator apparatusIndirect carbon-dioxide mitigationCombustionEngineering

The invention discloses a domestic garbage smokeless oil-free vertical pyrolysis gasification furnace which comprises a furnace body and air pipelines. The air pipelines comprise a second combustion air pipeline and a first combustion air pipeline which are arranged up and down and communicate with the furnace body. The first combustion air pipeline extends into the bottom of the furnace body and communicates with the bottom of the furnace body through an air distributor, and the second combustion air pipeline communicates with the upper half part of the furnace body; and the air blown by an air blower is separately sent to the first combustion air pipeline and the second combustion air pipeline. The domestic garbage smokeless oil-free vertical pyrolysis gasification furnace is simple in structure and reasonable in design; and toxic and harmful gas is completely eliminated, and the heat of garbage is truly utilized for realizing reduction and harmlessness of the garbage.

Owner:诸城市宏利圣得环境科技有限公司

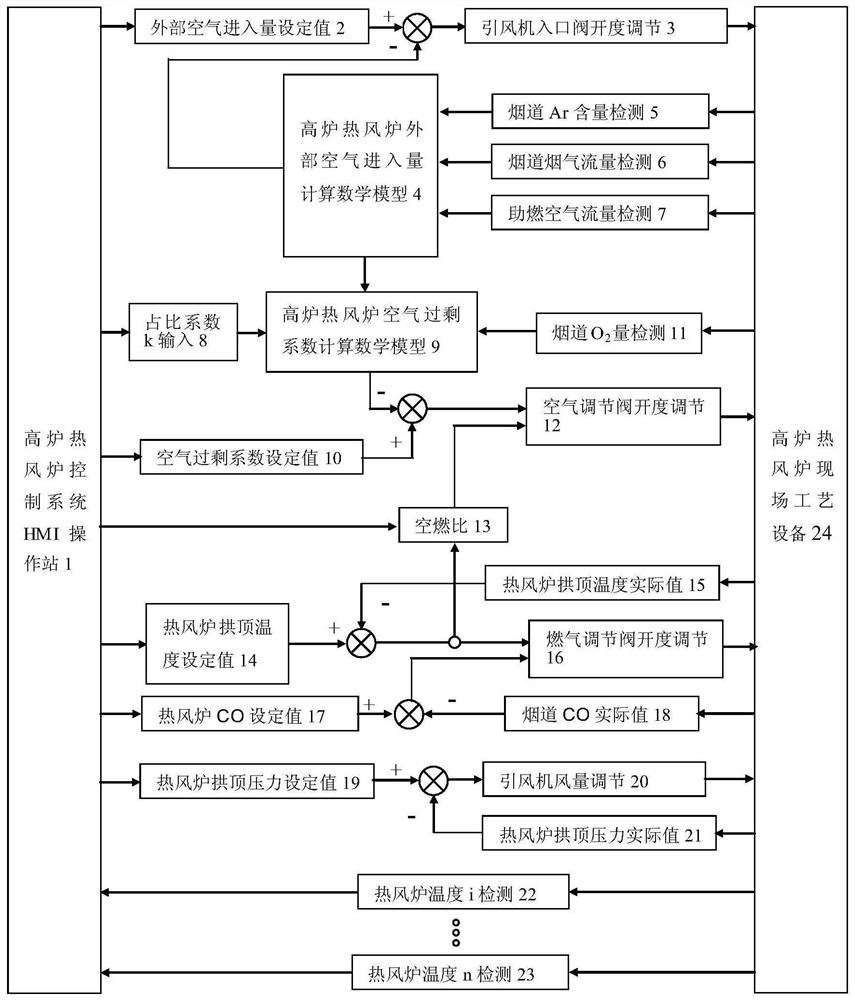

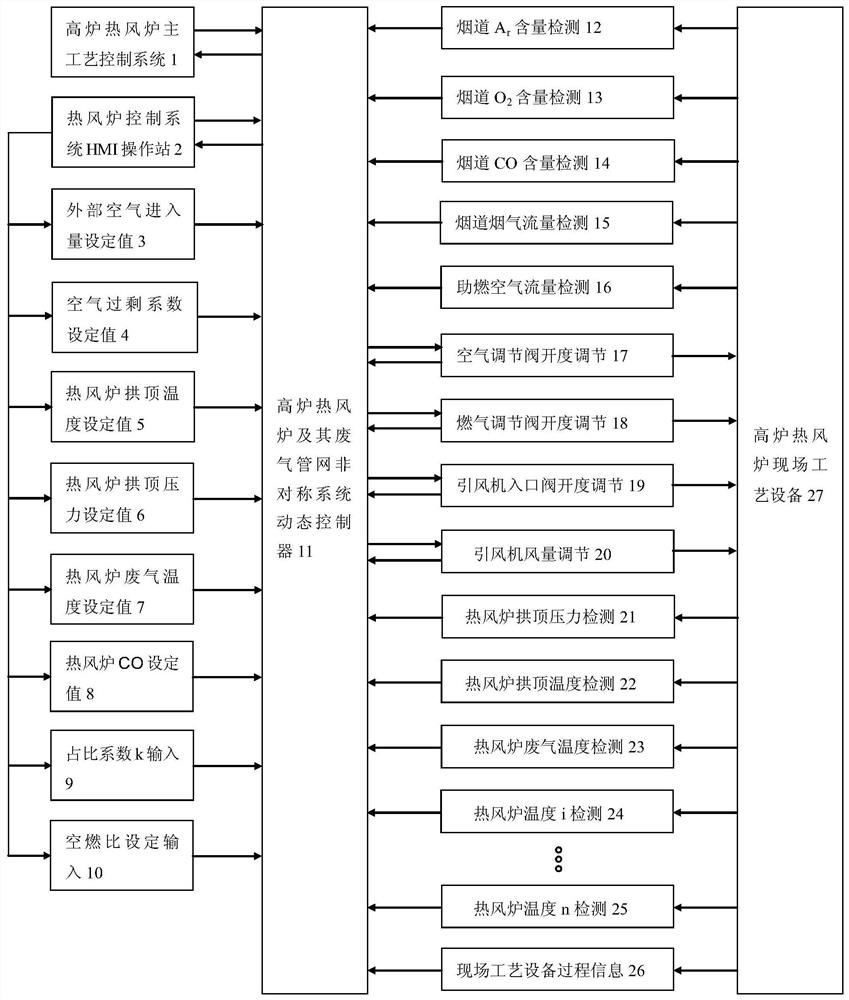

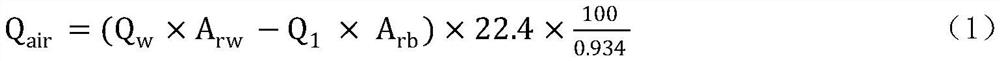

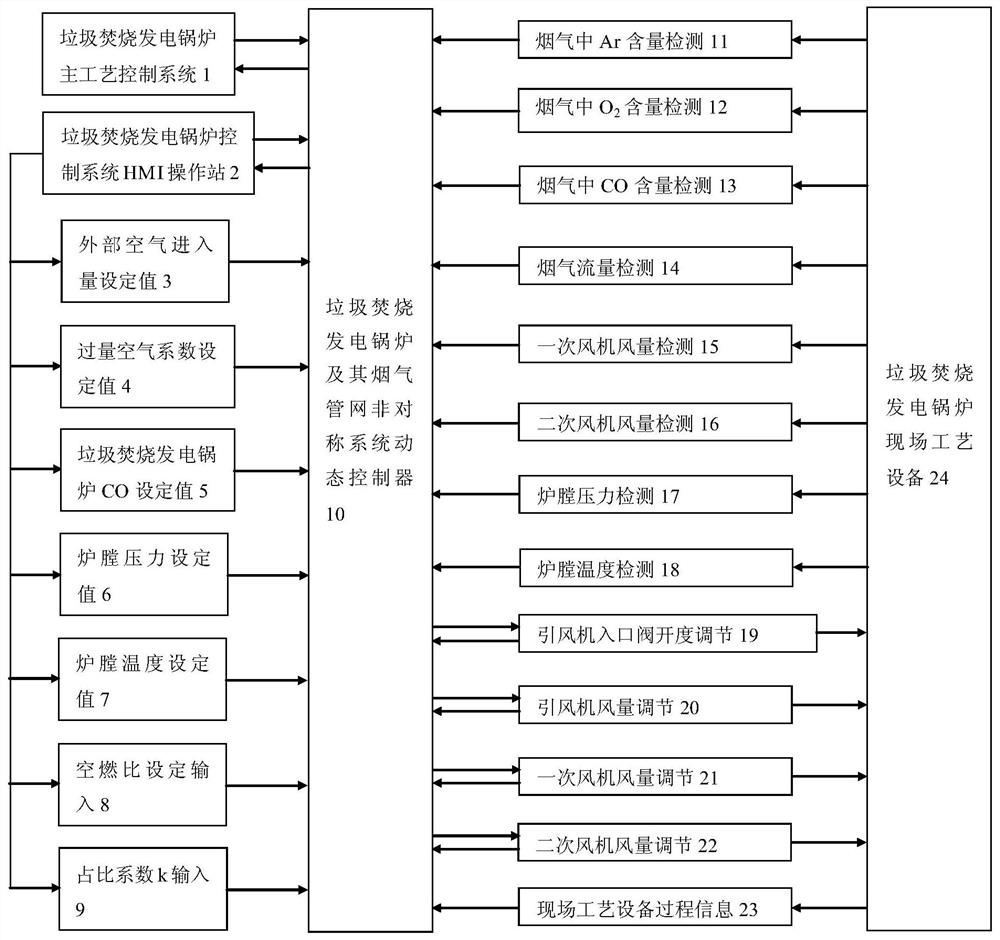

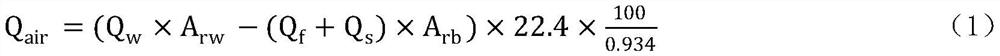

Asymmetric characteristic dynamic control method of blast furnace hot blast stove and waste gas pipe network of blast furnace hot blast stove

PendingCN112522464AImprove combustion efficiencyImprove energy savingSteel manufacturing process aspectsBlast furnace detailsAutomatic controlInlet valve

The invention discloses an asymmetric characteristic dynamic control method of a blast furnace hot blast stove and a waste gas pipe network of the blast furnace hot blast stove, and belongs to the blast furnace hot blast stove control technology. According to the operating conditions and physical characteristics of the blast furnace hot blast stove and the waste gas pipe network of the blast furnace hot blast stove, an asymmetric system theory of the blast furnace hot blast stove and the waste gas pipe network of the blast furnace hot blast stove is established, the dynamic control method based on the asymmetric system theory of the blast furnace hot blast stove and the waste gas pipe network of the blast furnace hot blast stove is developed, the argon content, the oxygen content and the CO content in flue waste gas are detected through flue gas analysis, a mathematical model is calculated according to the external air inlet amount, the external air inlet amount of the hot blast stoveis calculated, the opening degree of an inlet valve of an induced draft fan is adjusted, and the external air inlet amount is controlled within a set value range; an excess air coefficient is calculated according to an excess air coefficient calculation mathematical model, the opening degree of an air adjusting valve is adjusted by using a difference value between the calculated value and a set value, so that the excess air coefficient is kept in a set value range; and the multiple energy-saving and emission-reducing effects of improving the combustion efficiency, reducing the NOx pollution emission and achieving full-automatic control are achieved.

Owner:北京亿希欧科技有限公司

Method for granulating amorphous boron powder

InactiveCN101531556BHarm reductionReduce pollution emissionsMaterial granulationExplosivesPolyurethane adhesivePrill

The invention discloses a method for granulating amorphous boron powder, and in particular relates to a method for kneading and granulating amorphous boron powder for fuel-rich propellant. The method for granulating amorphous boron powder comprises the following steps: (1) premixing ethyl acetate, liquid polyurethane adhesive prepolymer, isocyanate curing agents and curing catalyst well accordingto a mass ratio which is 40-50:8-9:1-2:0.1-0.05 and controlling material temperature to between 35 and 40 DEG C; (2) mixing the amorphous boron powder with the premixed material; and (3) passing the obtained granular material through a 30-mesh standard sieve and drying the obtained granular material. In the process of granulating the amorphous boron powder, the method adopts the ethyl acetate which has little harm to environment and low dosage as a solvent for dispersing adhesive, and adopts a star-type stirring paddle to ensure that agglomerate mixtures can be denser under the cutting and extruding action of the stirring paddle. Granules obtained by the method are high in strength, are not easy to break when the granules are applied in formulations of fuel-rich propellant, and enable medicine pulp to be low in yield value and apparent viscosity.

Owner:XIAN MODERN CHEM RES INST

Asphalt mixture MLC modifier

PendingCN111534061AImproves rutting resistanceIncreased durabilityBuilding insulationsPolymer sciencePolyethylene terephthalate glycol

The invention discloses an asphalt mixture MLC modifier. The asphalt mixture MLC modifier comprises a powdery component A and a granular component B, wherein the component A comprises polyethylene glycol terephthalate, polyamide, polyolefin, 10-30 parts by mass of aromatic hydrocarbon oil, acrylamide and hydrazine hydrate. The component B comprises a hyperbranched polymer, rubber, natural latex, avulcanizing agent, a surfactant, tackifying resin, zinc oxide and carbon black. According to the MLC modifier disclosed by the invention, the anti-rutting capability of a pavement is improved; the anti-stripping performance of aggregate is improved, and water damage resistance is improved; the anti-fatigue life of the pavement is prolonged, so that the durability of the pavement is improved. Theconstruction temperature is reduced; an asphalt mixture can be mixed and paved at a lower temperature; the compaction effect is improved; the PG grade of the modified asphalt is improved, and the original low-viscosity characteristic of the matrix asphalt is maintained; energy consumption is reduced, and the pollution discharge is reduced.

Owner:浙江致欣检测技术有限公司

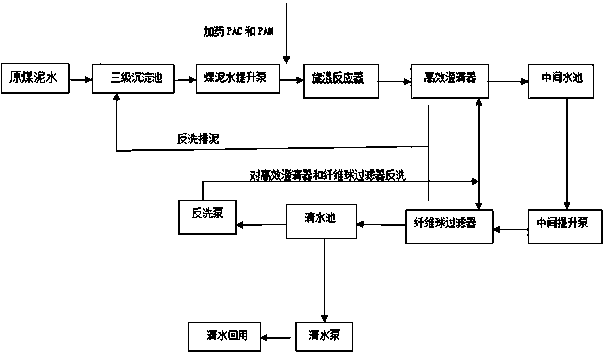

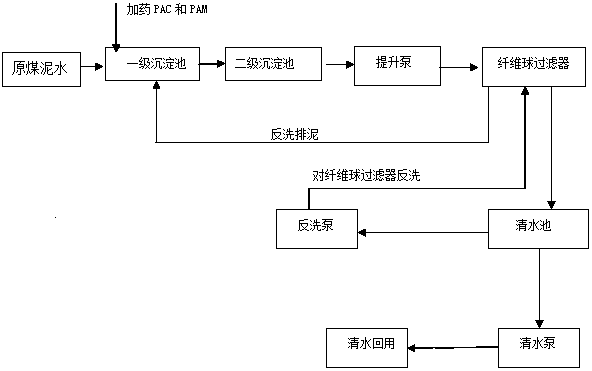

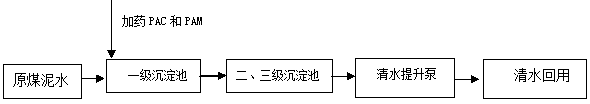

Coal-containing wastewater treatment reconstruction device for coal transportation

PendingCN109293044AReduce dosageLow operation and maintenance costsTreatment involving filtrationMultistage water/sewage treatmentFiberExisting Treatment

The invention discloses a coal-containing wastewater treatment reconstruction device for coal transportation, and belongs to the technical field of wastewater treatment. The device comprises a primarysedimentation tank for introducing raw coal mud water, the primary sedimentation tank is connected with a dosing system, a labyrinth parry is arranged in the primary sedimentation tank, overflowing sewage of the primary sedimentation tank enters a secondary sedimentation tank, effluent water of the secondary sedimentation tank enters a fiber ball filter through an elevator pump, the water outletof the fiber ball filter is connected with the water inlet of a clear water tank through a non-return valve, and effluent water of the clear water tank goes through a clear water pump and then is reused; and the clear water tank is also connected with a backwashing pump, the water outlet of the backwashing pup is connected with the backwashing water inlet of the fiber ball filter, and the backwashing water outlet of the fiber ball filter is connected with the primary sedimentation tank. The coal-containing wastewater treatment reconstruction device has the advantages of simplification of an existing treatment device, reduction of the investment cost, and stability and high efficiency in running.

Owner:国能常州发电有限公司

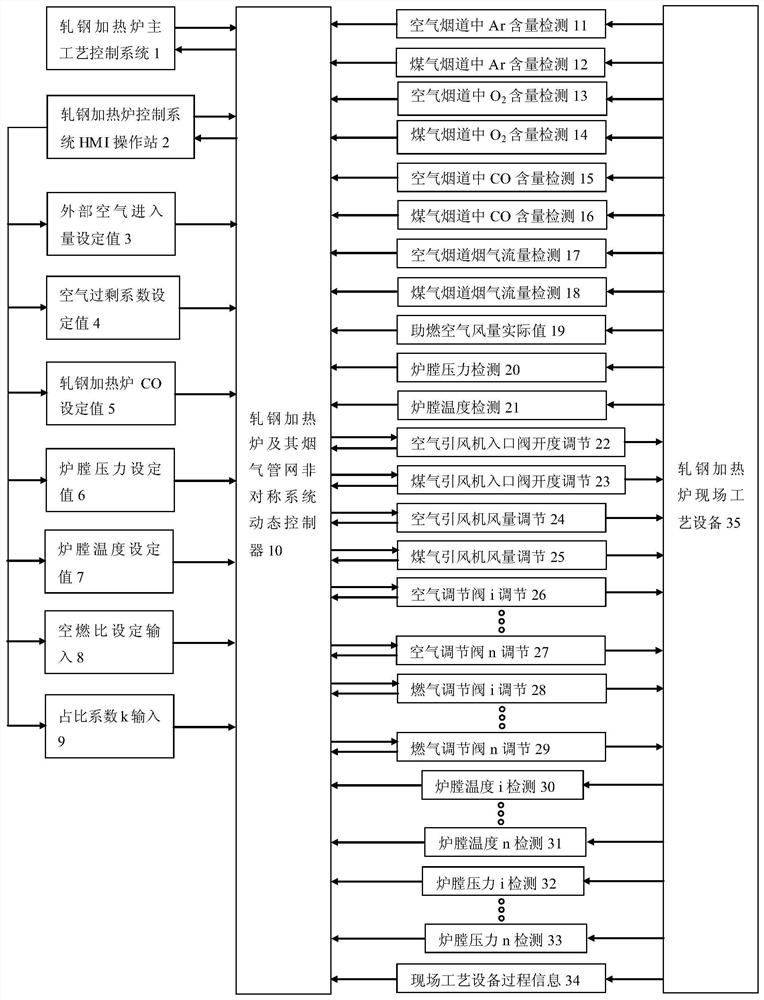

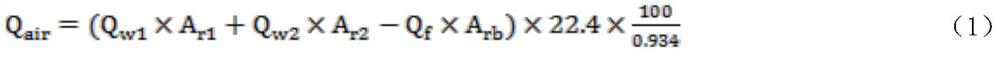

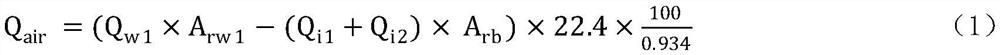

Steel rolling heating furnace and dynamic control method for asymmetric characteristics of flue gas pipe network thereof

PendingCN112556441AImprove combustion efficiencyRealize fully automatic controlControl devices for furnacesAutomatic controlMathematical model

The invention discloses a steel rolling heating furnace and a dynamic control method for asymmetric characteristics of a flue gas pipe network thereof, and belongs to a steel rolling heating furnace control technology. An asymmetric system theory of the steel rolling heating furnace is determined according to the operating condition characteristics of the steel rolling heating furnace and the physical characteristics of the flue gas pipe network; an external air inlet amount calculation mathematical model and an air excess coefficient calculation mathematical model of the steel rolling heatingfurnace are researched and developed; the external air inlet amount of the steel rolling heating furnace is calculated through the argon content detected by flue gas analysis; then the opening of aninlet valve of an induced draft fan is adjusted according to the difference between a set value and a calculated value of the external air inlet amount of the steel rolling heating furnace, so that the external air inlet amount is always controlled within a set value range; the air flow and the gas flow are adjusted according to the oxygen content and the carbon monoxide content detected by the flue gas analysis, so that the air excess coefficient is always controlled within the set value range; and multiple energy-saving and emission-reducing effects of improving the combustion efficiency ofthe heating furnace, reducing the NOx pollution emission and realizing full-automatic control are achieved.

Owner:BEIJING KDHY SCI & TECH DEV LTD

Mixed rare earth catalytic natural gas combustion catalyst and preparation method thereof,

PendingCN110898843ASimple preparation processExtensive sources of raw materialsHeterogenous catalyst chemical elementsGaseous fuelsPtru catalystPhysical chemistry

The invention provides a mixed rare earth catalytic natural gas combustion catalyst and a preparation method thereof, wherein the catalyst is prepared from the following components in percentage by weight: 5-15% of mixed rare earth, 1-3% of Fe2O3 and the balance of gamma-Al2O3 or a cordierite honeycomb ceramic carrier. According to the invention, the mixed rare earth catalytic combustion catalystprepared by an impregnation method and comprising double active ingredients of the mixed rare earth oxide and the transition metal oxide can be used for catalytic combustion of medium and low temperature natural gas stoves of resident users, can further be used for catalytic combustion of natural gas combustors of industrial sources, and solves the problems of low energy utilization rate, easy pollution generation and the like in flame combustion.

Owner:内蒙古智萃科技信息咨询有限公司

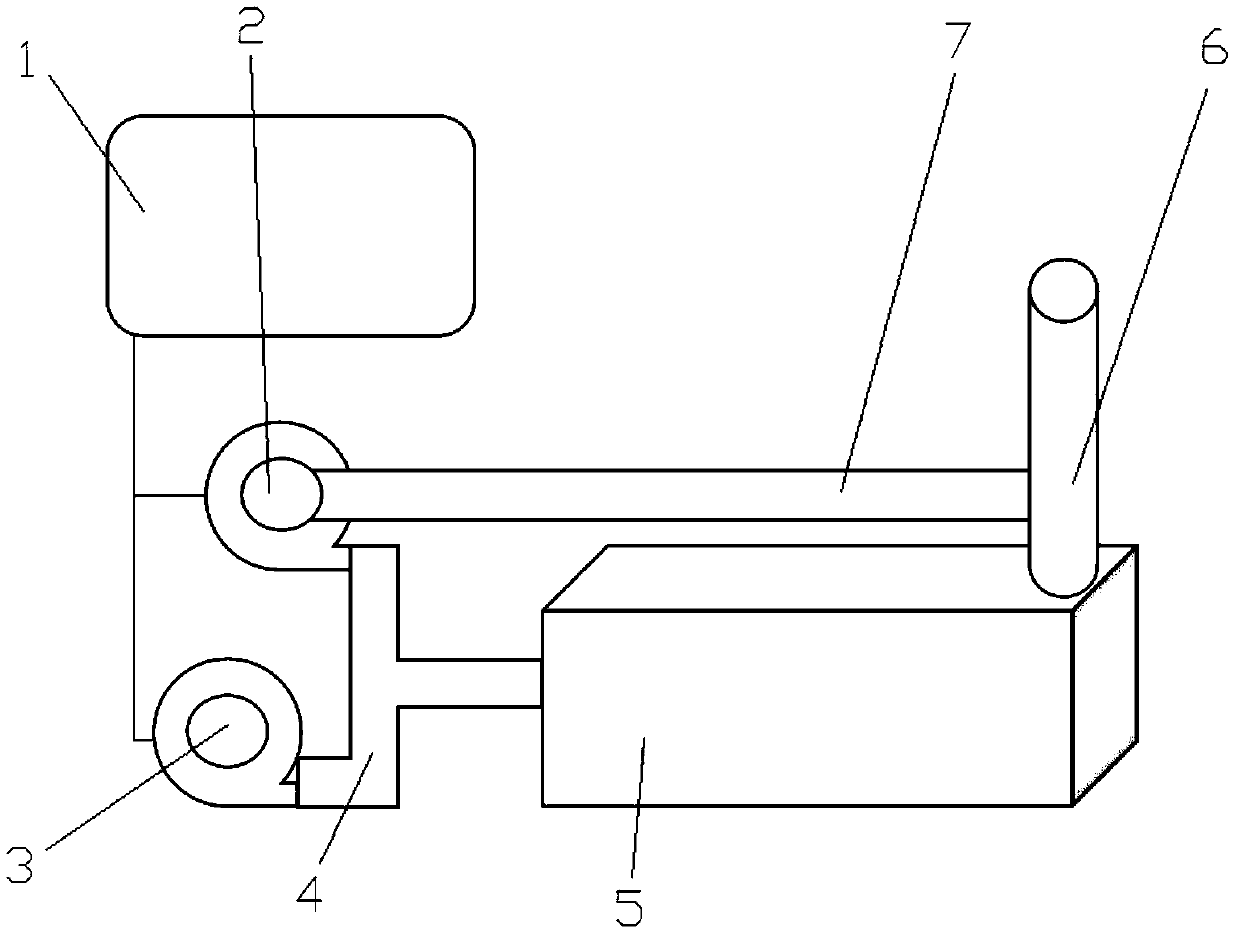

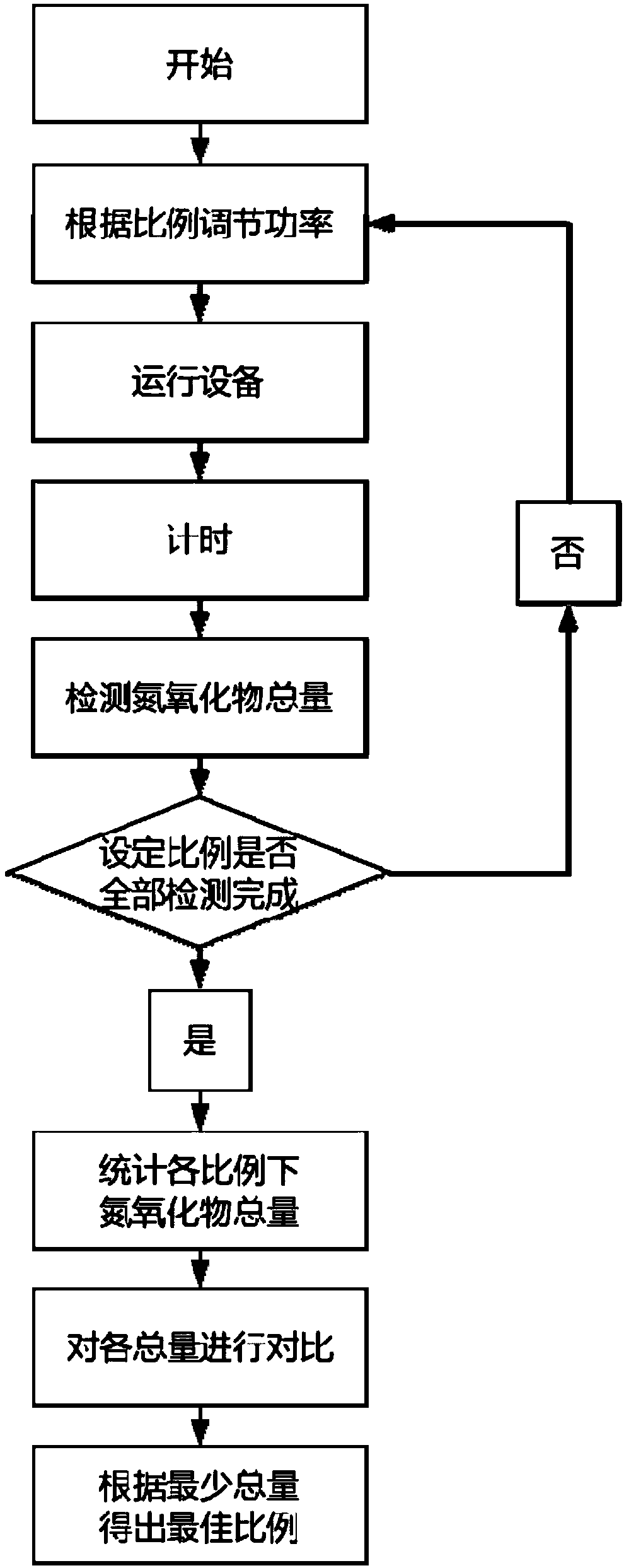

Low-nitrogen combustion fresh air and flue gas proportion regulation equipment

PendingCN109519958AReduce outputHigh efficiency of low nitrogen combustionFuel supply regulationIncinerator apparatusFlue gasLow nitrogen

The invention relates to low-nitrogen combustion fresh air and flue gas proportion regulation equipment. The equipment comprises a control unit used for a regulating the proportion of air and nitrogen, a flue gas fan used for extracting flue gas, a fresh air fan used for extracting air, a mixing pipeline connected with the flue gas fan and the fresh air fan and used for mixing the flue gas and theair, a boiler arranged at and connected with an outlet of the mixing pipeline and used for combusting fuel, and a stack connected with a boiler exhaust outlet and used for exhausting post-combustionflue gas. According to the equipment provided by the invention, by arranging the control unit in the equipment and arranging the fans for extracting the flue gas and air correspondingly, the power ofthe fans is set through the control unit so as to regulate the proportion of the glue gas and the air, meanwhile, the total amounts of oxynitrides produced under various proportion conditions can be detected and compared, accordingly, the proportion with the minimum produced oxynitride is selected, and low-nitrogen combustion efficiency can reach the maximum while the oxynitride output is lowered.

Owner:启明星宇节能科技股份有限公司

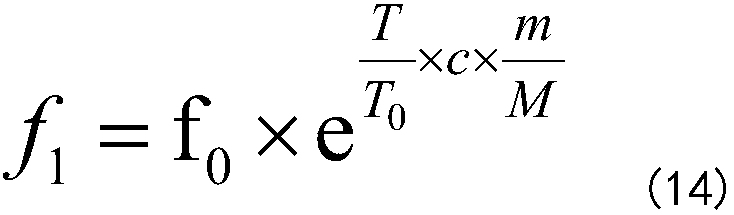

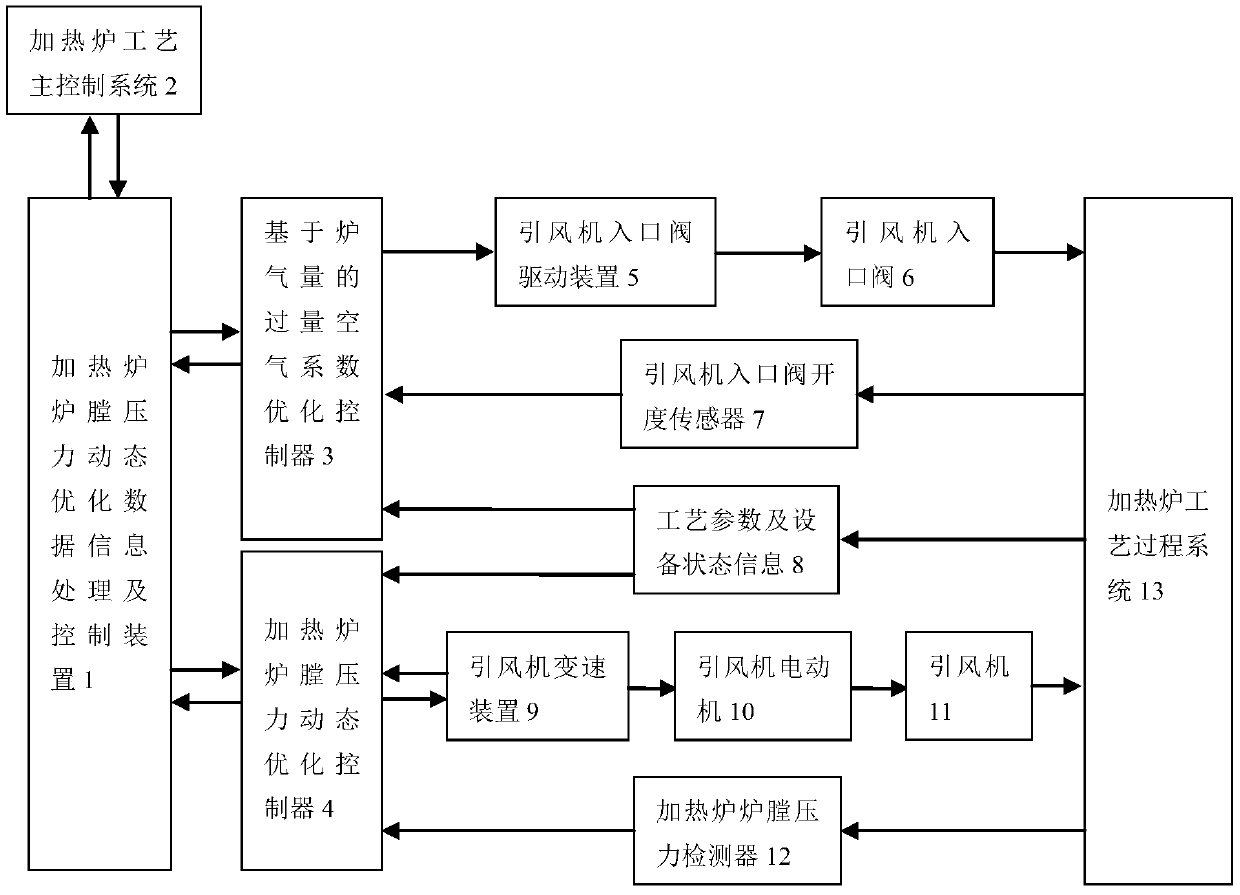

Heating furnace hearth pressure dynamic optimization control method based on furnace gas amount

PendingCN111088424AImprove combustion efficiencyImprove energy savingFurnace typesHeat treatment process controlThermodynamicsCombustion

The invention provides a heating furnace hearth pressure dynamic optimization control method based on the furnace gas amount and belongs to heating furnace control technologies. According to the furnace gas amount of a heating furnace, the opening degree of an inlet valve of an induced draft fan is adjusted to be matched with the furnace gas amount, so that the excess air coefficient of the heating furnace is controlled, on this basis, the speed of the induced draft fan is detected and adjusted according to the hearth pressure, and then the hearth pressure is stably kept within a set range; bythe adoption of the control strategy, a good hearth pressure control effect and an appropriate excess air coefficient are obtained; namely, the multiple effects of improving combustion efficiency ofthe heating furnace, reducing the total amount of smoke, improving the energy saving amount of the induced draft fan, reducing the emission of pollutants, lowering iron scale loss of casting blanks, achieving full automatic control over the heating furnace, lightening the labor intensity of an operator and improving the production operation efficiency are achieved, and the multiple benefits of saving energy, reducing emission, increasing yield and guaranteeing quality are achieved. The heating furnace hearth pressure dynamic optimization control method based on the furnace gas amount can be applied to newly-constructed or expanded or transformed various steel rolling heating furnace systems and refining-chemical heating furnaces and heating furnace systems under similar working conditionsin other industries.

Owner:北京亿希欧科技有限公司

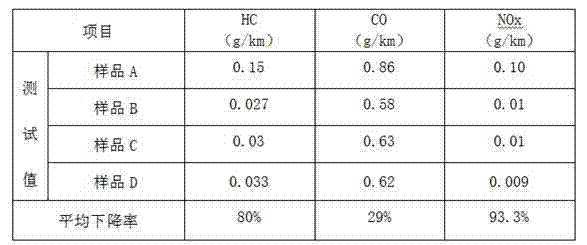

Gasoline quality improver applicable to national IV-level gasoline

ActiveCN104004553BImprove anti-corrosion performanceImprove ignition performanceLiquid carbonaceous fuelsGasolineAlkylphenol

Owner:SHANDONG JILIDA ENERGY SCI & TECH CO LTD

Treatment process for recycling chromate waste water in producing electrolytic manganese metal

ActiveCN102424490BSolve the emission problemReduce pollution emissionsPhotography auxillary processesMultistage water/sewage treatmentElectrolysisManganese

The invention discloses a treatment process for recycling chromate waste water in producing electrolytic manganese metal, comprising the following steps: adding a potassium dichromate solution in chromate waste water from a passivation tank to obtain a mixed solution A after mixing, and reputting the mixed solution A into the passivation tank for recycling; when impurity content in the chromate waste water is high, filtering the chromate waste water through a filter press for removing impurities, then adding an electrolytic catholyte and reducing Cr<6+> to Cr<3+> to obtain a mixed solution B after the reaction, and sending the mixed solution B into a manganese sulfate lixiviating tank through a pump for recycling. The concentration of the chromate waste water from the passivation tank is 5-9 g / L, the concentration of the potassium dichromate solution is 30-35 g / L, and the concentration of chromium in the mixed solution A is 13-17 g / L. According to the invention, the chromate waste water is recycled, the discharge problem of the chromate waste water is solved, the construction fund and processing cost are saved, and the pollution discharge capacity to the environment is reduced.

Owner:CHINA TIANCHEN ENG +1

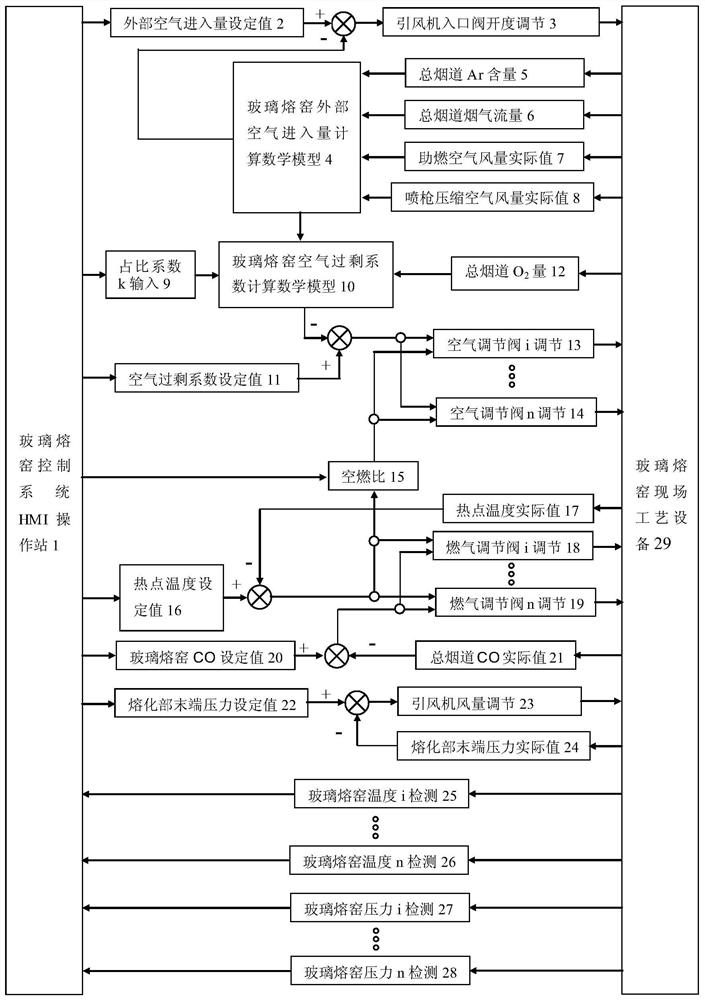

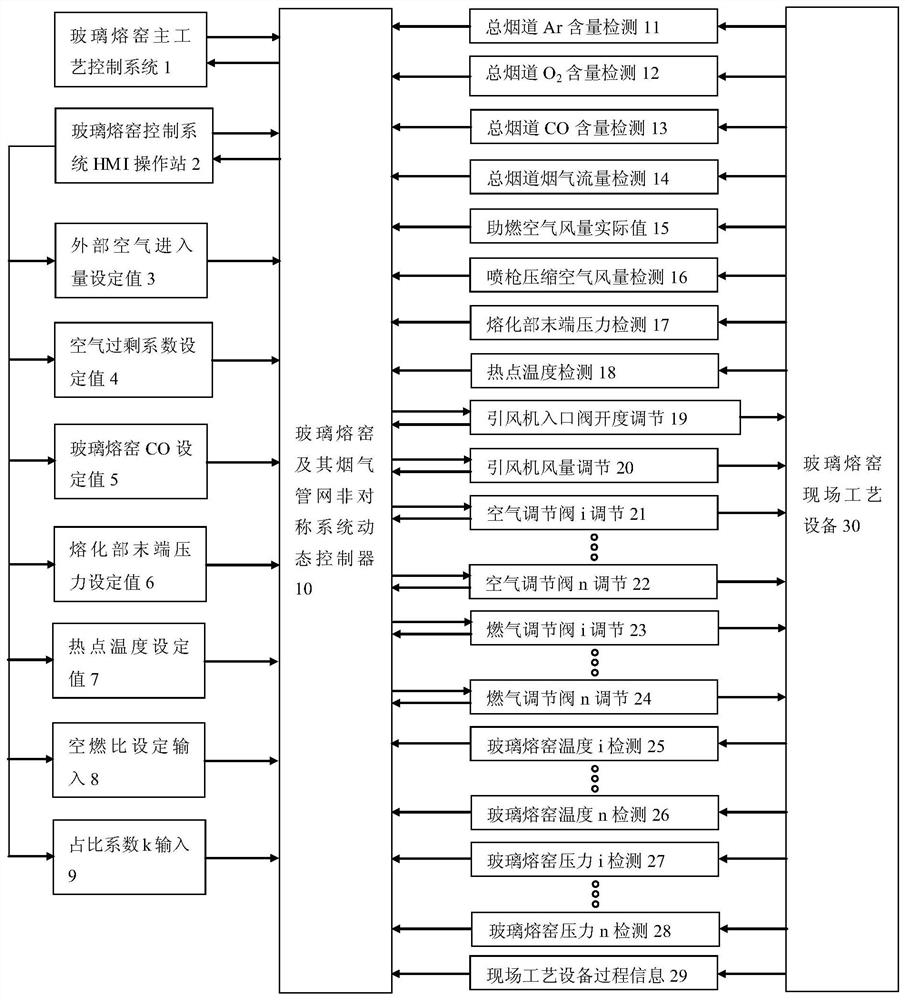

Glass melting furnace and asymmetric characteristic dynamic control method for flue gas pipe network of glass melting furnace

PendingCN112684835AImprove combustion efficiencyRealize fully automatic controlChemical property predictionGlass furnace apparatusAutomatic controlMathematical model

The invention discloses a glass melting furnace and an asymmetric characteristic dynamic control method for a flue gas pipe network of the glass melting furnace, belongs to a glass melting furnace control technology, and develops an external air inlet amount calculation mathematical model and an air excess coefficient calculation mathematical model to dynamically control the external air inlet amount and an air excess coefficient. The inlet amount of external air is calculated according to the argon content detected through flue gas analysis, and then the opening degree of an inlet valve of an induced draft fan is adjusted according to the difference between a set value and a calculated value, so that the inlet amount of the external air is always controlled within a set value range. The air flow and the fuel gas flow are adjusted according to the oxygen content and the carbon monoxide content of flue gas analyzing and detection to control the air excess coefficient, so that the air excess coefficient is always controlled within a set value range. According to the invention, multiple energy-saving and emission-reducing effects of improving the combustion efficiency, reducing the total amount of generated flue gas, improving the energy-saving amount of the induced draft fan, reducing the NOx pollution emission and realizing full-automatic control are achieved, and the method can be widely applied to newly-built, expanded and transformed glass melting furnace systems.

Owner:北京亿希欧科技有限公司

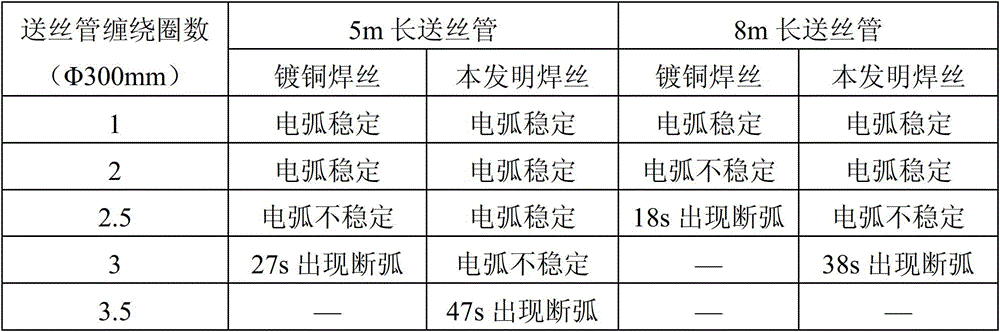

A kind of non-copper-plated solid wire for gas shielded welding and preparation method thereof

InactiveCN103537819BUniform treatmentStable wire feedingArc welding apparatusWelding/cutting media/materialsLiquid wasteCopper plating

The invention discloses a non-copper-plated solid welding wire for gas shielded welding. The non-copper-plated solid welding wire for gas shielded welding comprises a welding wire base body and a surface treatment layer, wherein the welding wire base body is formed by drawing of a wire rod, the surface treatment layer comprises a potassium base solid wire drawing lubricant agent left during drawing of the welding wire and high-voltage static coating oil, the amount of the remaining potassium base solid wire drawing lubricant agent is 5-10mg / m<2>, and the amount of the high-voltage static coating oil is 5-15mg / m<2>. The manufacturing method of the non-copper-plated solid welding wire for gas shielded welding comprises the steps that (1) husking, derusting, cleaning, lime coating and drying are carried out on the wire rod in sequence, (2) wire drawing reducing is carried out on the wire rod by means of a rough drawing reducing method and a finish drawing reducing method so that size requirements of a finished welding wire are met, (3) the lubricant agent on the surface of the welding wire is removed, (4) high-voltage static oil coating is carried out on the welding wire, (5) the welding wire is wound precisely and is packaged. The non-copper-plated solid welding wire has the advantages that surface treatment is even, wire feeding is stable, the electrical conductivity and rust resistance are high, and the success rate of arcing and the success rate of reignition of arc are high. The manufacturing method of the non-copper-plated solid welding wire for gas shielded welding has the advantages that discharging of waste acid, waste alkali, copper plating liquid waste and boron waste is avoided, water consumption is small, and environmental pollution is greatly reduced.

Owner:CHINA JINGYE ENG TECH CO LTD +1

Method and system capable of using waste heat for supplying hydrogen to HCNG engine power system

ActiveCN110836153AAchieve clean and efficient useImprove thermal efficiencyNon-fuel substance addition to fuelInternal combustion piston enginesMetallic hydrogenEngineering

The invention belongs to the field of HCNG engine application, and particularly relates to a method and system capable of using waste heat for efficiently and precisely supplying hydrogen to an HCNG engine power system. The system comprises a medium-high temperature solid metal hydride hydrogen storage reactor, a low-temperature solid metal hydride hydrogen storage reactor, a fuel mixing cavity, and an SI engine. The medium-high temperature solid metal hydride hydrogen storage reactor and the low-temperature solid metal hydride hydrogen storage reactor can achieve efficient releasing of hydrogen through waste heat of the HCNG engine, meanwhile, a dual-hydrogen source can be precisely regulated to provide needed mixed hydrogen for a natural gas internal combustion engine, and stable hydrogen supply and mixed hydrogen combustion are achieved. According to the system, the waste heat of the HCNG engine is used for driving the solid-state dual-hydrogen source system to achieve efficient, precise and stable hydrogen supply, the comprehensive heat efficiency of the natural gas engine can be improved, the pollutant emission amount of the natural gas engine can be effectively reduced, and the clean and efficient use of the natural gas can be achieved.

Owner:XI AN JIAOTONG UNIV

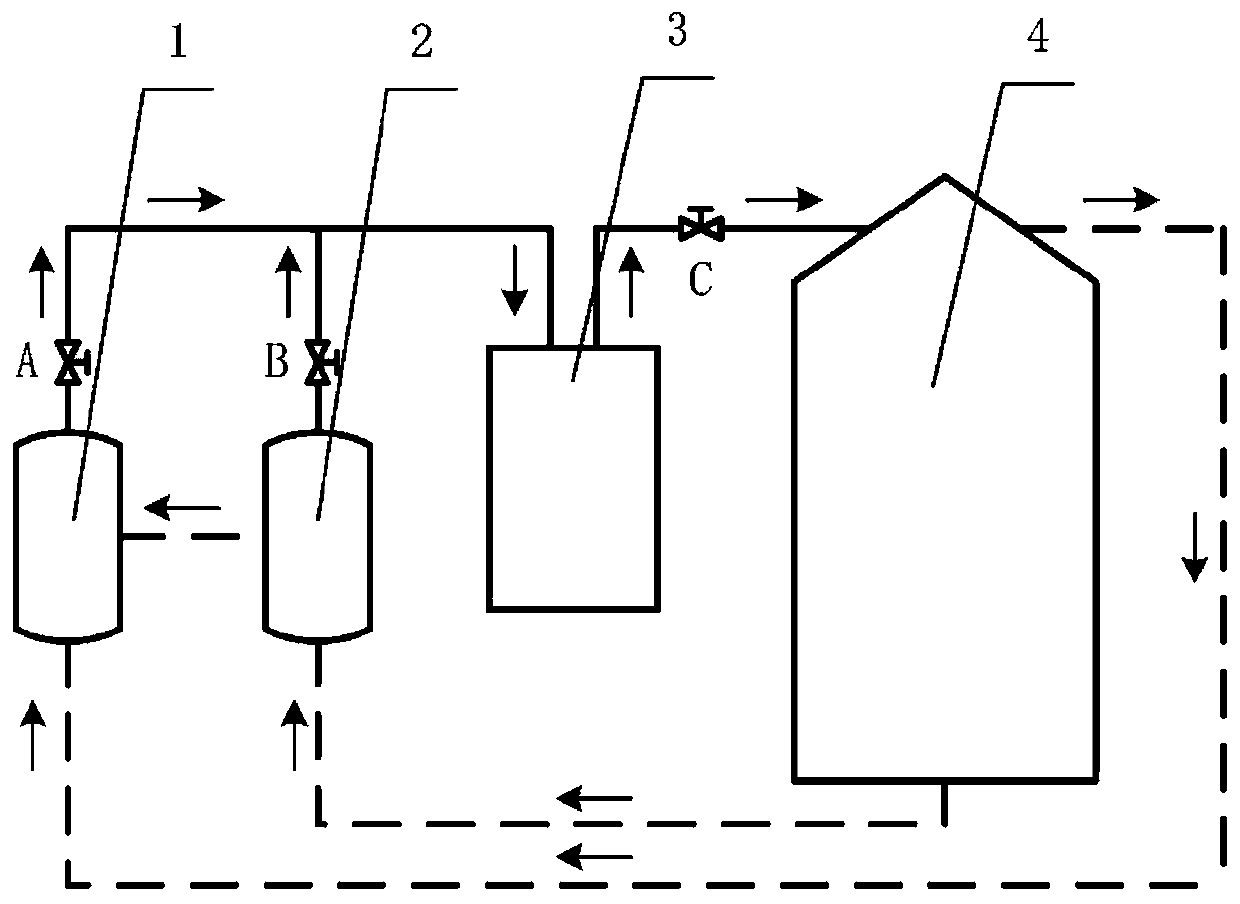

Waste incineration power generation boiler and flue gas pipe network asymmetric characteristic dynamic control method thereof

PendingCN112555859AHigh thermal efficiencyImprove energy savingIncinerator apparatusCombined combustion mitigationAutomatic controlAir volume

The invention discloses a waste incineration power generation boiler and a flue gas pipe network asymmetric characteristic dynamic control method thereof, belongs to a waste incineration power generation boiler control technology, and relates to a dynamic control method of an external air inlet amount calculation mathematical model, an air excess coefficient calculation mathematical model, an external air inlet amount and an air excess coefficient of the waste incineration power generation boiler. The external air inlet amount of the waste incineration power generation boiler is calculated through the argon content detected through flue gas analysis, and then the opening degree of an inlet valve of an induced draft fan is adjusted according to the difference between a set value and a calculated value of the external air inlet amount, so that the external air inlet amount is always controlled within a set value range. The secondary fan air volume and the primary fan air volume are adjusted according to the oxygen content and the carbon monoxide content which are analyzed and detected through the flue gas, so that the air excess coefficient is always controlled within a set value range. The multiple energy-saving and emission-reducing effects of improving the heat efficiency of the boiler, reducing NOx and VOC pollution emission and achieving full-automatic control are achieved.

Owner:BEIJING KDHY SCI & TECH DEV LTD

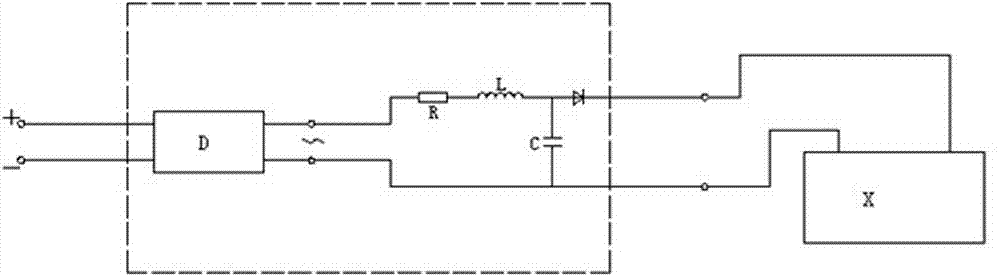

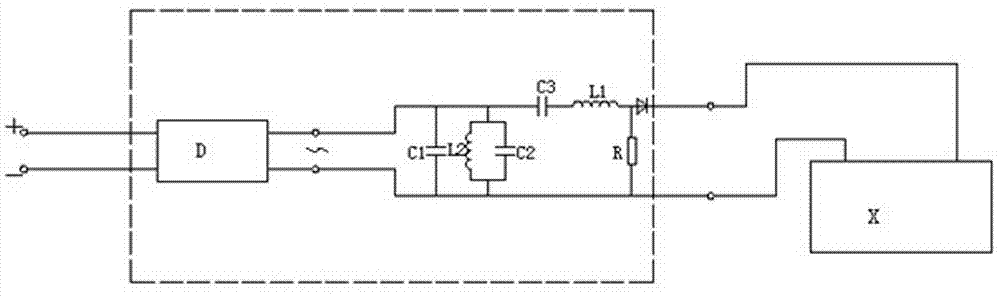

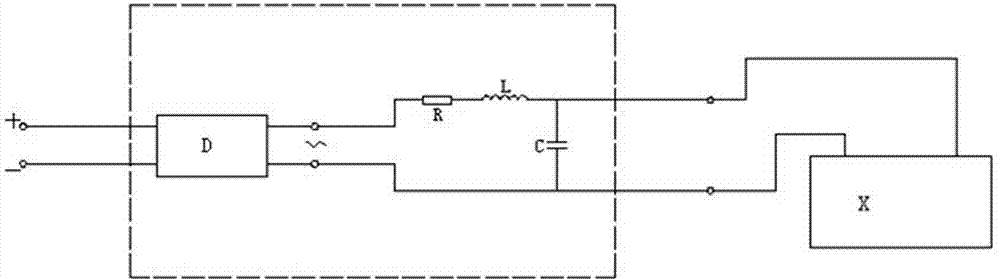

Energy-saving and emission-reducing device for changing electric energy property of automobile

ActiveCN102904476BSufficient batteryExtend your lifeElectric vehicle charging technologyVehicular energy storageAlternating currentRadio frequency

The invention provides a method and device with better energy saving and emission reducing effect of an automobile, which solve the problems of poor oil saving effect and poor energy saving effect of the traditional energy saving and emission reducing technology of the automobile. The device comprises a radio frequency alternating current pulse electric energy generator, wherein the radio frequency alternating current pulse electric energy generator is connected in parallel to a storage battery, the radio frequency alternating current pulse electric energy generator is used for inverting and processing direct current electric energy with voltage grade ranges of 12 V, 24V and 48V into alternating current pulse electric energy with a radio frequency range of 300Khz-5000Khz and overlapping the radio frequency alternating current pulse electric energy on original direct current electric energy of the storage battery to form composite electric energy comprising the direct current electric energy and the radio frequency pulse alternating current electric energy. The technology provided by the invention has a batter function on the aspect of appliances of the whole automobile, and the service life of the storage battery can be greatly prolonged; and because the composite electric energy contains the radio frequency pulse alternating current electric energy, vulcanization and crystallization of a polar plate of the storage battery are greatly lightened.

Owner:郑尔历

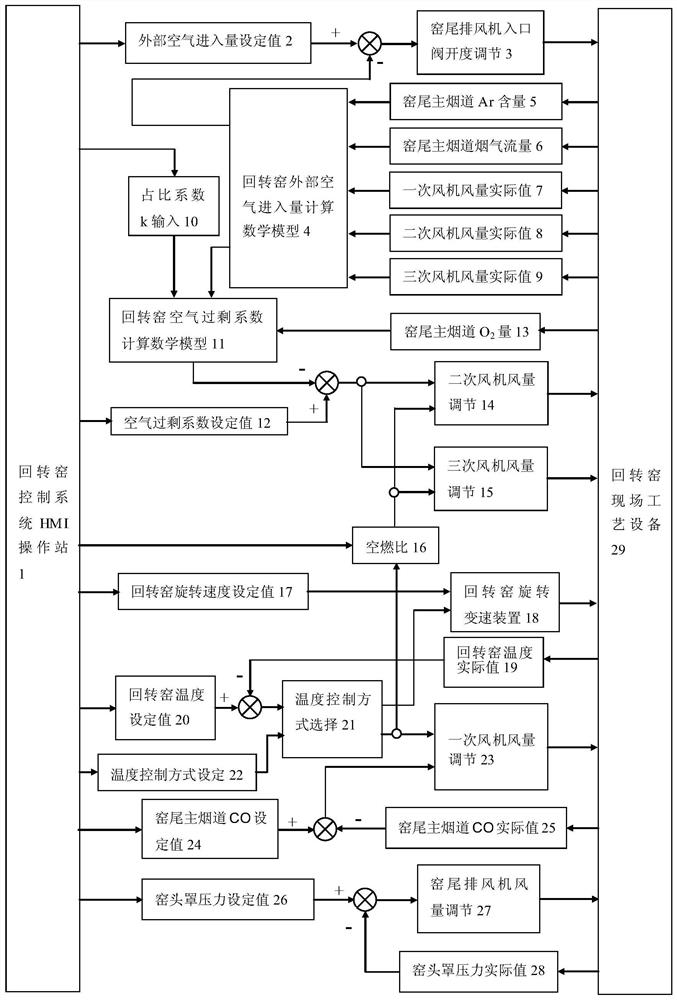

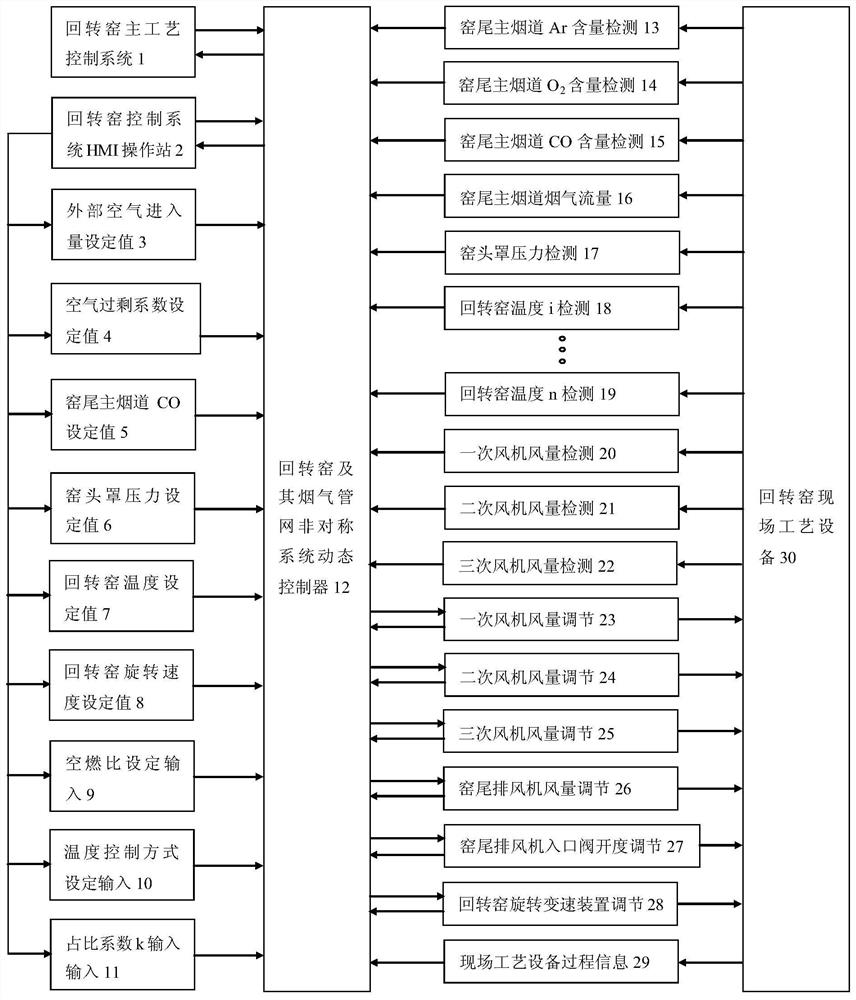

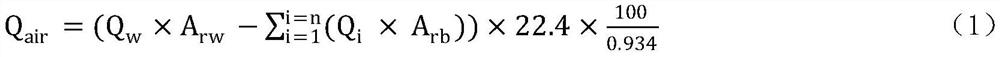

Rotary kiln and flue gas pipe network asymmetric characteristic dynamic control method thereof

PendingCN112524940AImprove combustion efficiencyRealize fully automatic controlRotary drum furnacesAir volumeRotary kiln

The invention discloses a rotary kiln and a flue gas pipe network asymmetric characteristic dynamic control method thereof, belongs to a rotary kiln control technology, and develops a rotary kiln external air inlet amount calculation mathematical model and an air excess coefficient calculation mathematical model. The inlet amount of rotary kiln external air is calculated through the argon contentdetected by flue gas analysis. The opening degree of an inlet valve of a kiln tail exhaust fan is adjusted according to the difference between an external air inlet amount set value and an external air inlet amount calculated value, so that the external air inlet amount of the rotary kiln is always controlled within a set value range; the air volume of a secondary fan, the air volume of a tertiaryfan and the air volume of a primary fan are adjusted according to the oxygen content and the carbon monoxide content which are analyzed and detected by the flue gas to control the air excess coefficient of the rotary kiln, so that the air excess coefficient of the rotary kiln is always controlled within a set value range; the energy conservation and emission reduction effects of improving the combustion efficiency, increasing the energy-saving amount of the exhaust fan, reducing the NOx pollution discharge amount and improving the production operation rate are achieved.

Owner:BEIJING KDHY SCI & TECH DEV LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com