Coal-containing wastewater treatment reconstruction device for coal transportation

A technology for wastewater treatment and coal transportation, which is applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the failure of fiber ball compaction and the black effluent quality that does not meet the standard of reused water. and other problems to achieve the effect of reducing operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

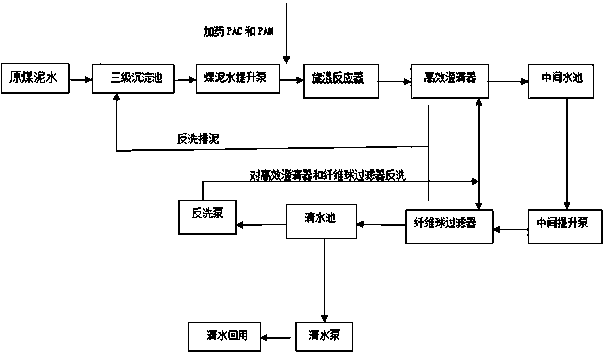

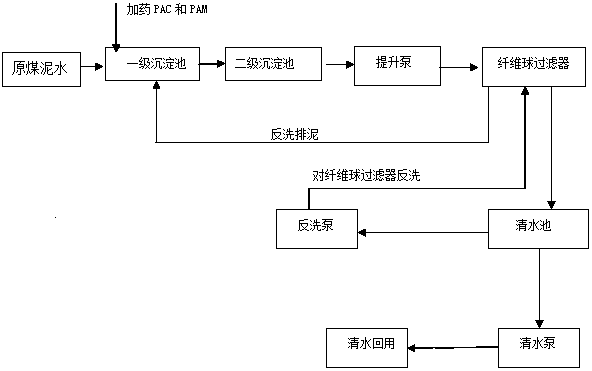

[0027] Such as figure 2 , Figure 4 As shown, the reforming device for treating coal-containing wastewater from coal transportation includes a primary sedimentation tank for feeding raw coal slime water. The primary sedimentation tank is connected to the dosing system, and a labyrinth barrier 1 is arranged in the primary sedimentation tank. The sewage in the primary sedimentation tank enters the secondary sedimentation tank after overflowing, and the outlet water of the secondary sedimentation tank enters the fiber ball filter through the lifting pump, and the water outlet of the fiber ball filter is connected with the water inlet of the clear water tank. Connected by a one-way valve, the outlet water of the clear water pool is reused after passing through the clear water pump; the clear water pool is also connected with the backwash pump, and the water outlet of the backwash pump is connected with the backwash water inlet of the fiber ball filter connected, and the backwash...

Embodiment 2

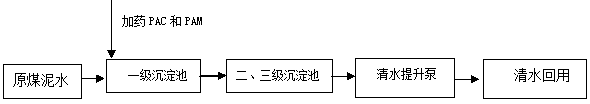

[0038] Such as image 3 , Figure 4 As shown, the reforming device for treating coal-containing wastewater from coal transportation includes a primary sedimentation tank for feeding raw coal slime water. The primary sedimentation tank is connected to the dosing system, and a labyrinth barrier 1 is arranged in the primary sedimentation tank. The sewage of the first-stage sedimentation tank enters the second-stage sedimentation tank after overflowing, and the water outlet of the second-stage sedimentation tank is connected with the water inlet of the third-stage sedimentation tank, and the outlet water of the third-stage sedimentation tank is returned to after passing through the clean water pump. use.

[0039] The dosing system is provided with a coagulant dosing port and / or a flocculant dosing port.

[0040] The coagulant includes PAC, and the flocculant includes PAM.

[0041] An automatic mixing unit is provided in the primary sedimentation tank.

[0042] The automatic mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com