Patents

Literature

36results about How to "Simple handling system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

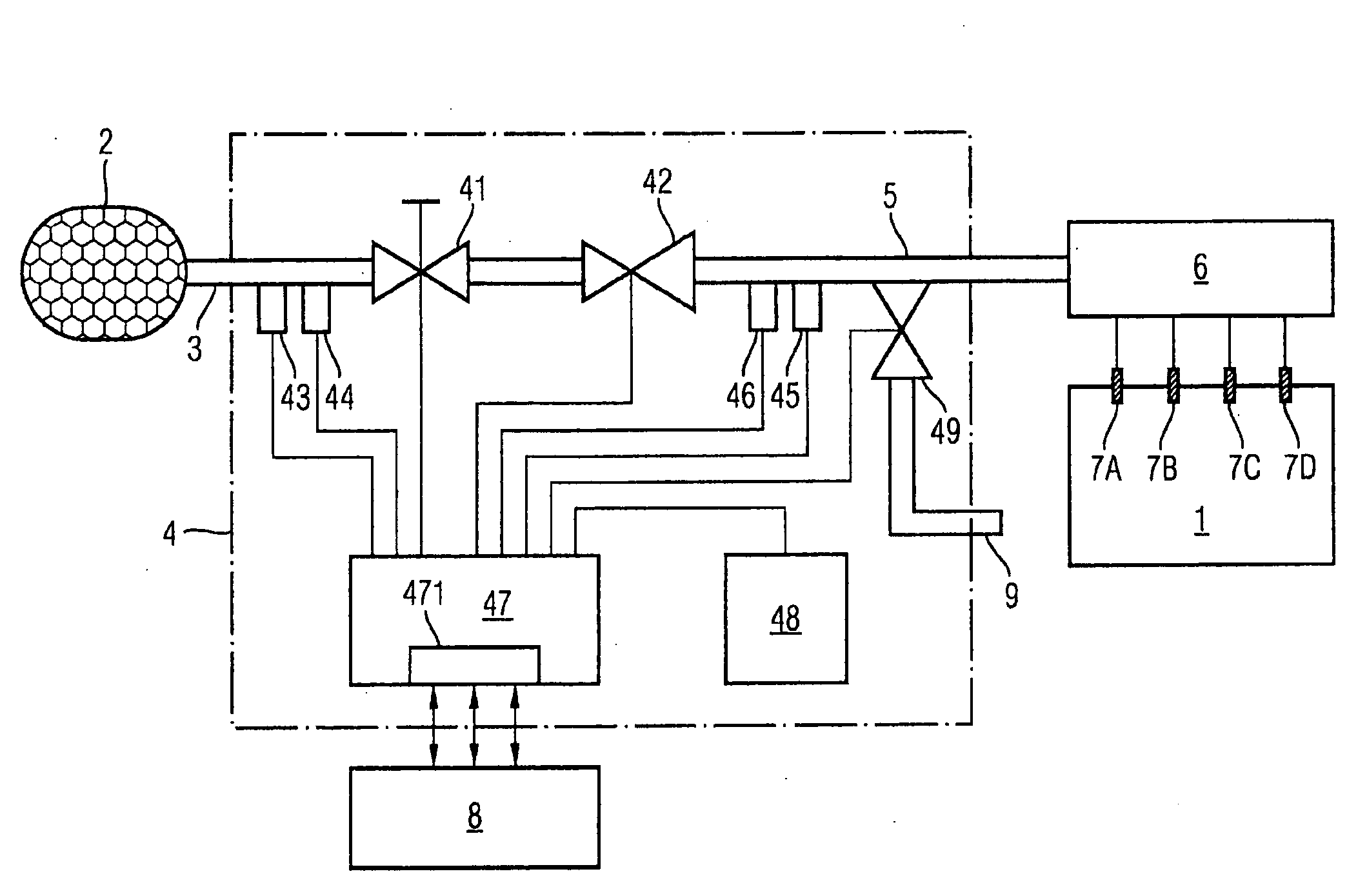

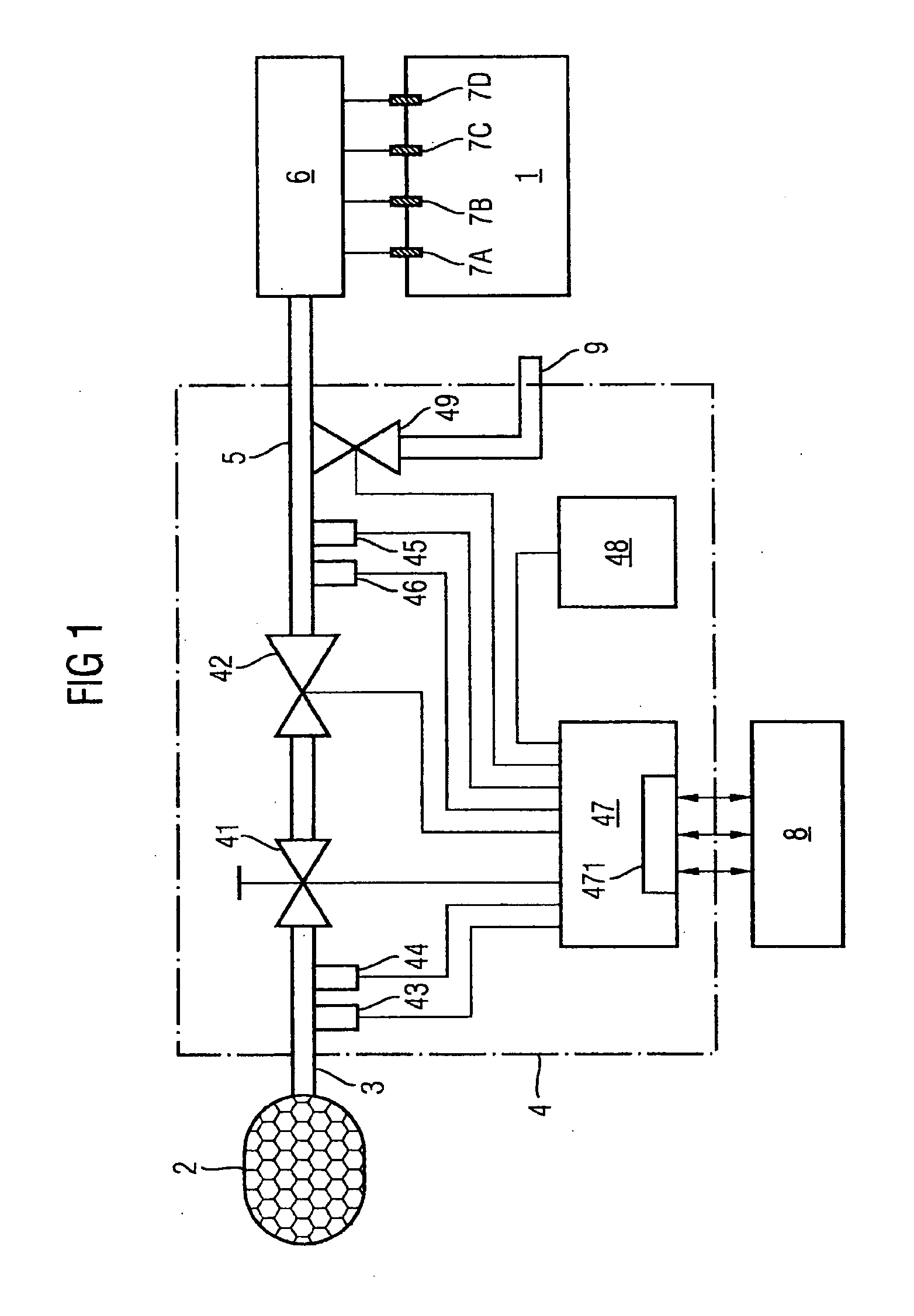

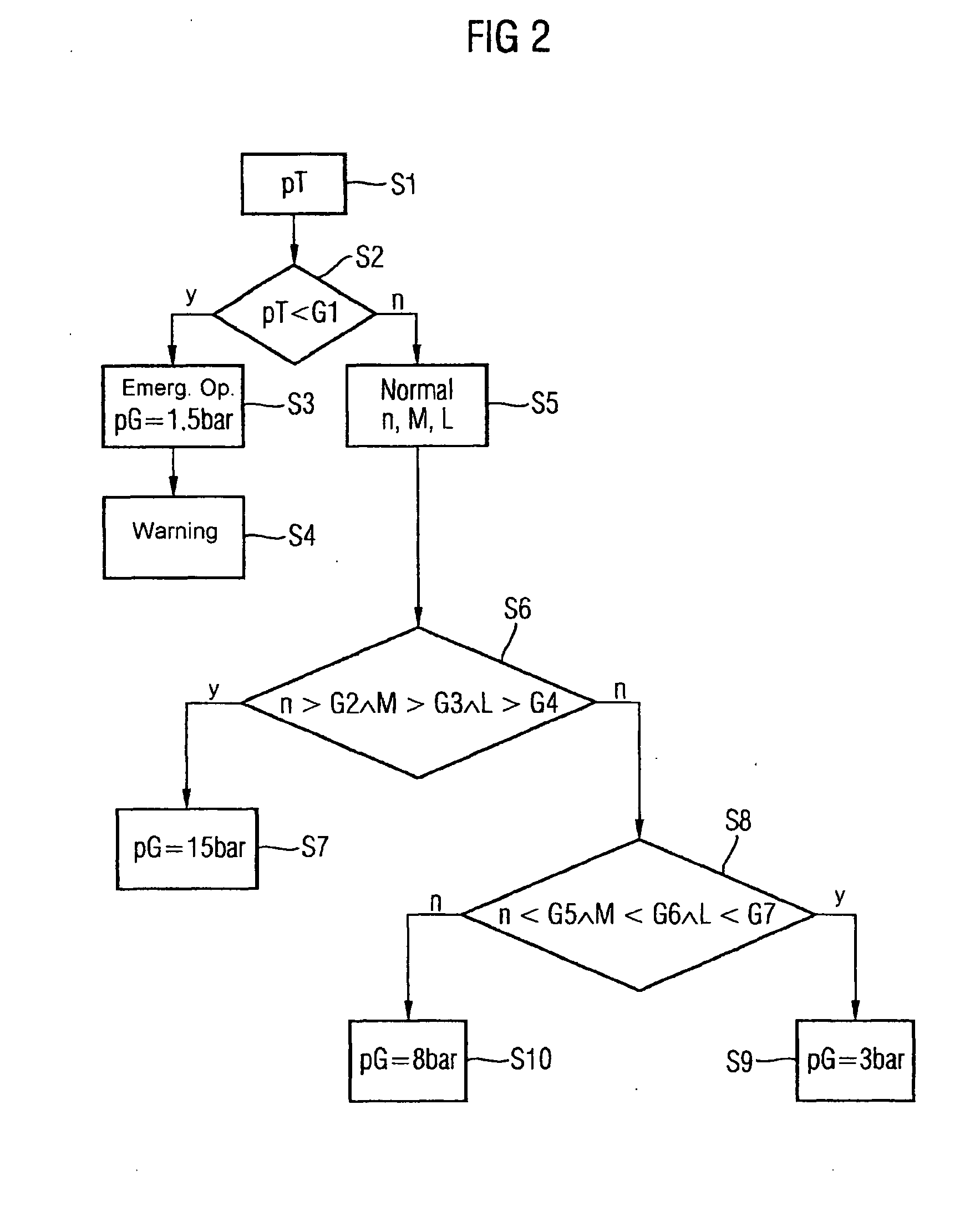

Operating Method and Device for a Gas-Operated Internal Combustion Engine

InactiveUS20090055077A1Low costSimple handling systemElectrical controlInternal combustion piston enginesExternal combustion enginePollutant emissions

The invention relates to an operating method and to a device for a gas-driven internal combustion engine. According to the invention, the pressure in a gas injection system is adapted to the operational state of the internal combustion engine. A higher pressure is adjusted in the gas injection system during a higher charge of the internal combustion engine. Said higher pressure enables a higher volume flow through the gas injection valves associated with the gas injection system. The power produced by the internal combustion engine can be optimized. A lower pressure in the gas injection system is adjusted in the event of a lower charge or if the internal combustion engine is switched off. The lower pressure emits lower pollutant emissions which are produced by the internal combustion engine. The invention is characterized by a bi-directional interface between a control device and a pressure reducer or pressure controller.

Owner:VITESCO TECH GERMANY GMBH

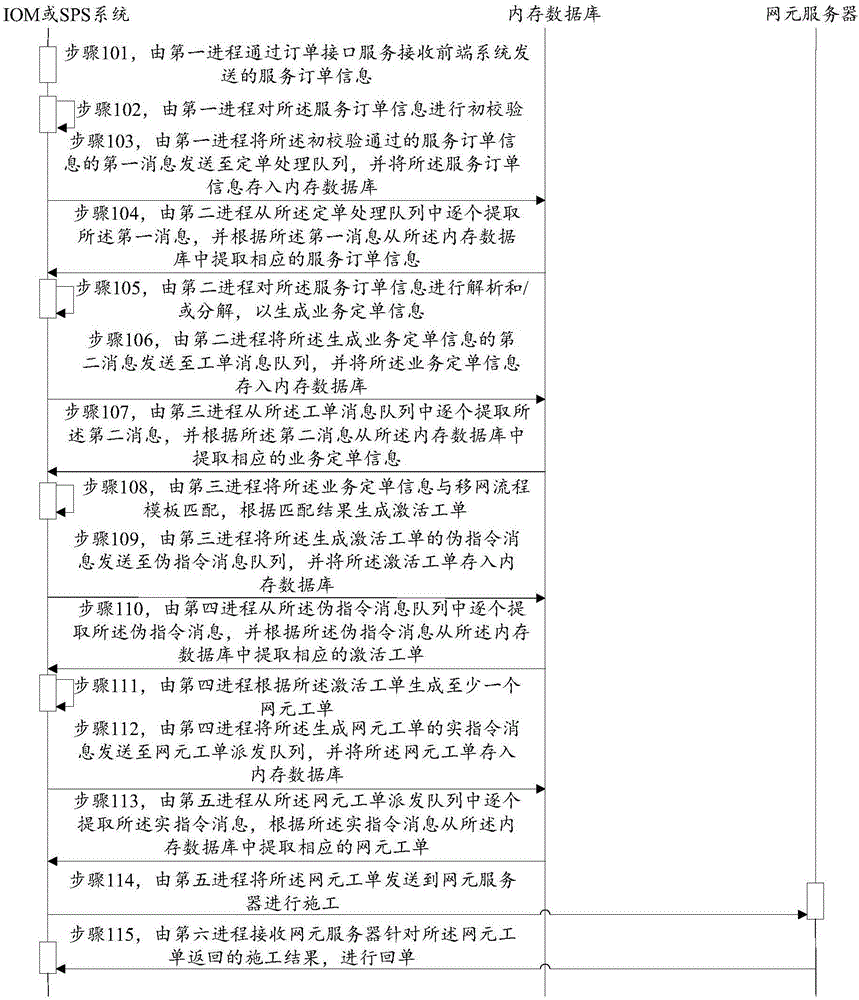

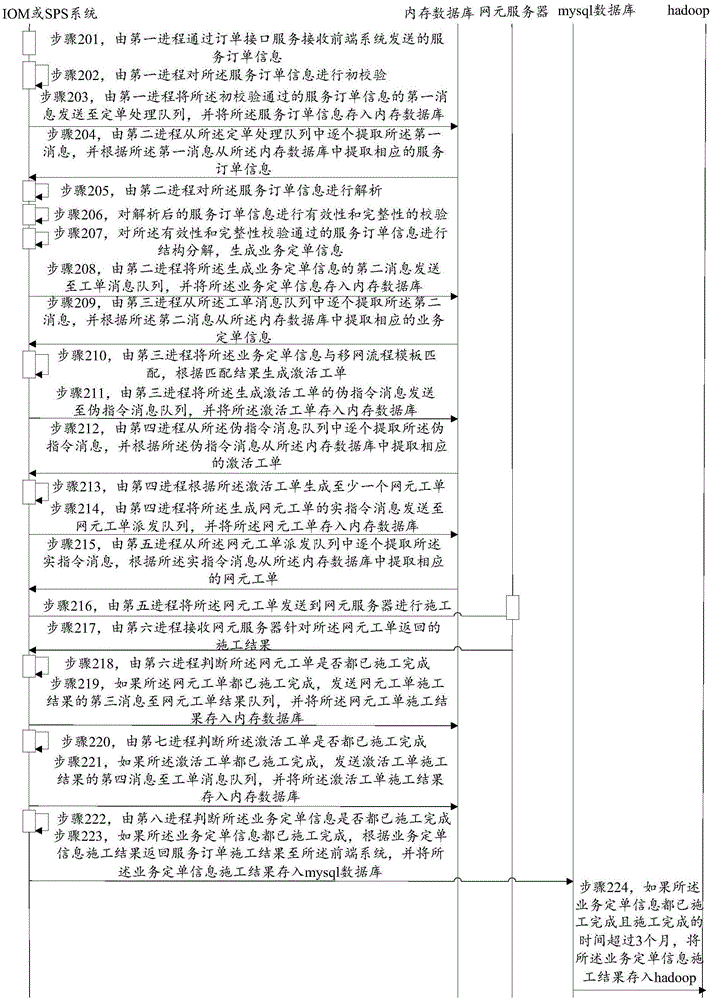

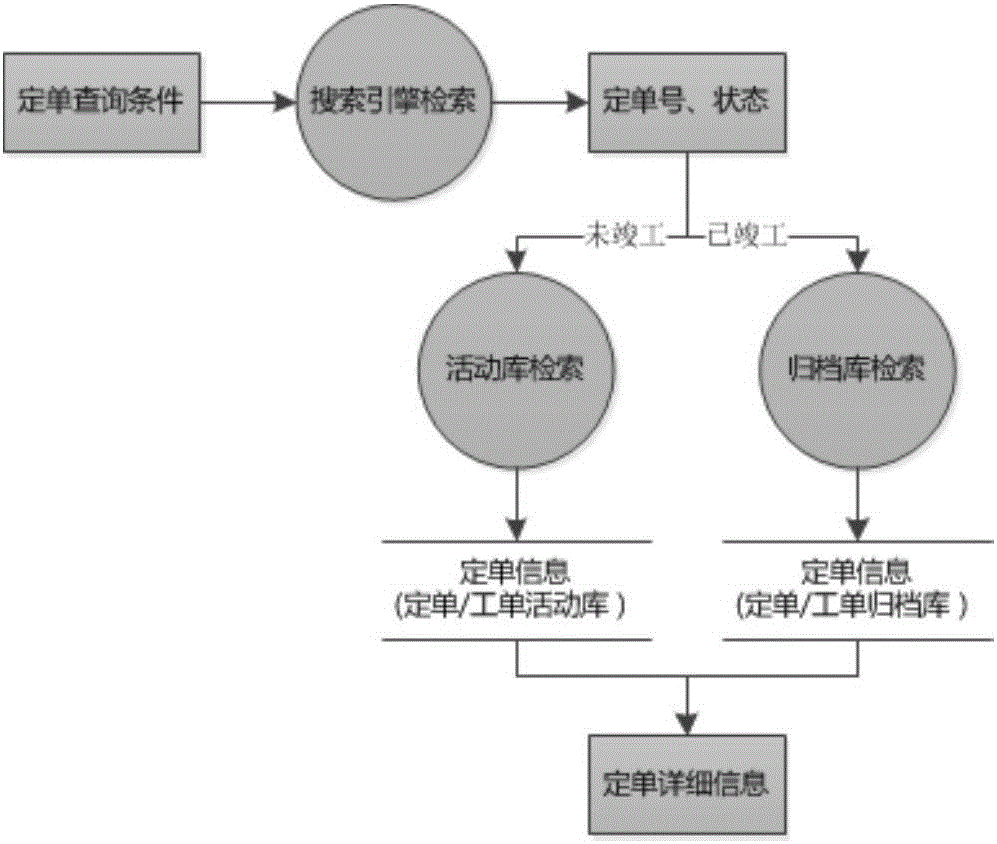

Method and system for achieving mobile network service fulfillment

ActiveCN106792630AImprove processing efficiencyReduce redundancyNetwork data managementEnd systemNetwork service

Embodiments of the invention provide a method and a system for achieving mobile network service fulfillment and relate to the technical field of communication. The invention receives the service order information sent by the front end system, performs initial verification on the service order information, analyzes and / or decomposes the service order information passed through the initial verification, generates the service order information, and matches the service order information with the mobile network template, according to the matching results, activation work orders are generated, according to the activation work orders, network element work orders are generated, the network element work orders are sent to the network element server to the construction, and finally according to the construction results, acknowledgement of orders is carried out. In the process of mobile network service fulfillment, the IOM or SPS system carry out the service fulfillment process scheduling and activation, no longer through the NAS system, which solves the problems that complexity of the fulfillment process leads to the low processing efficiency, the large interface abnormal probability, and the data redundancy, streamlines the system, reduces duplication of work, improves the processing efficiency, and reduces the abnormal interface probability and the data redundancy.

Owner:DATANG SOFTWARE TECH

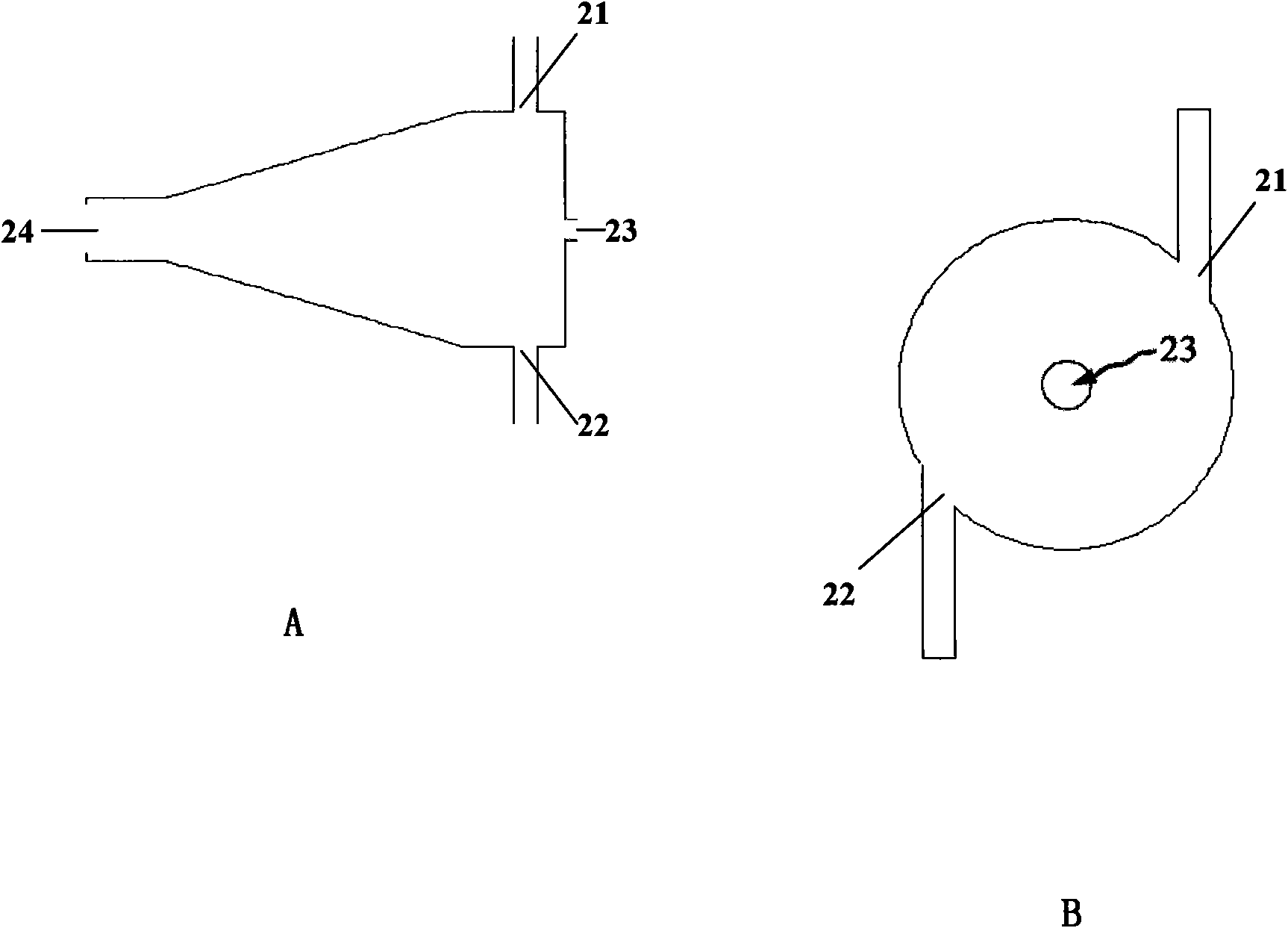

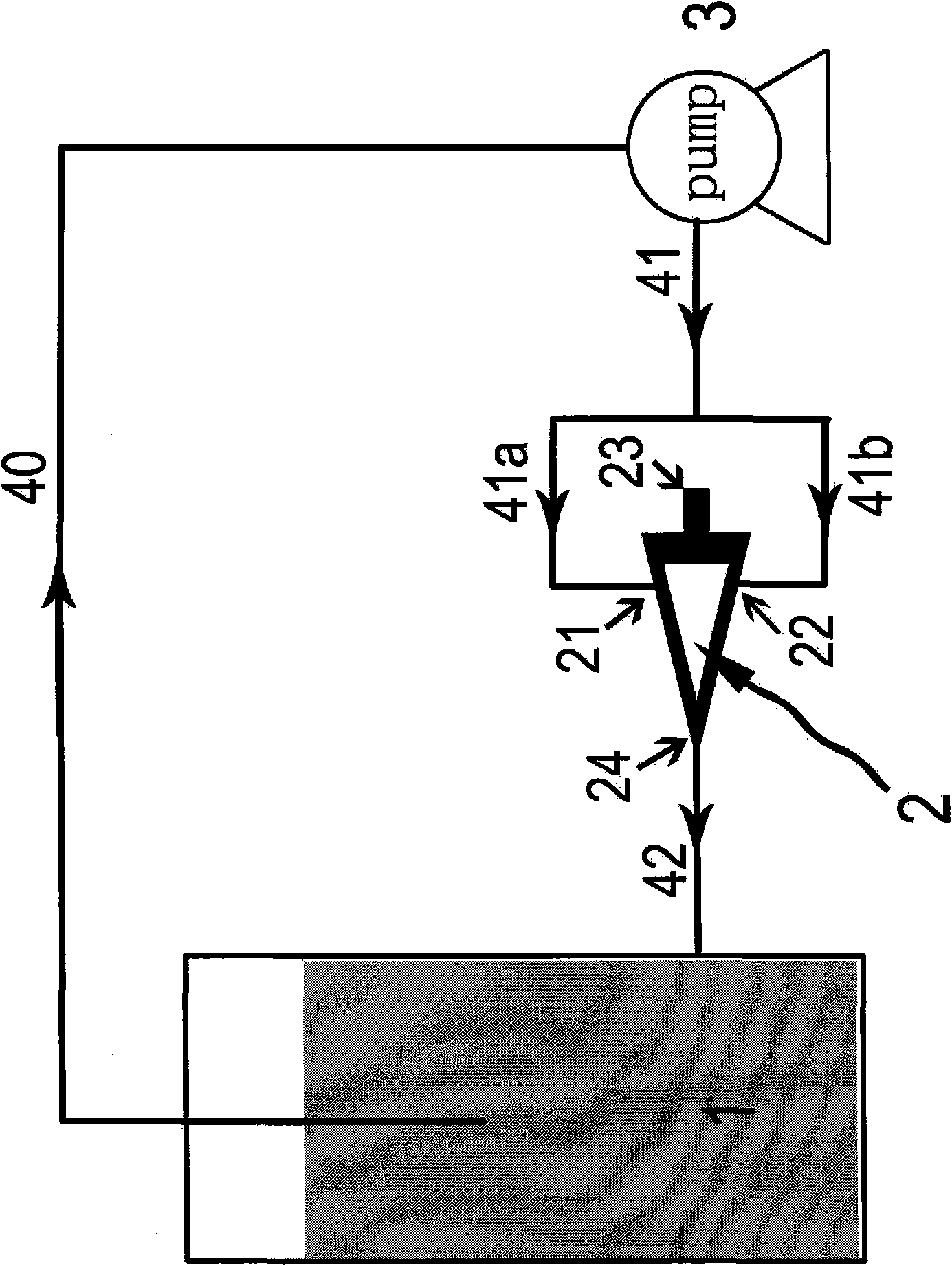

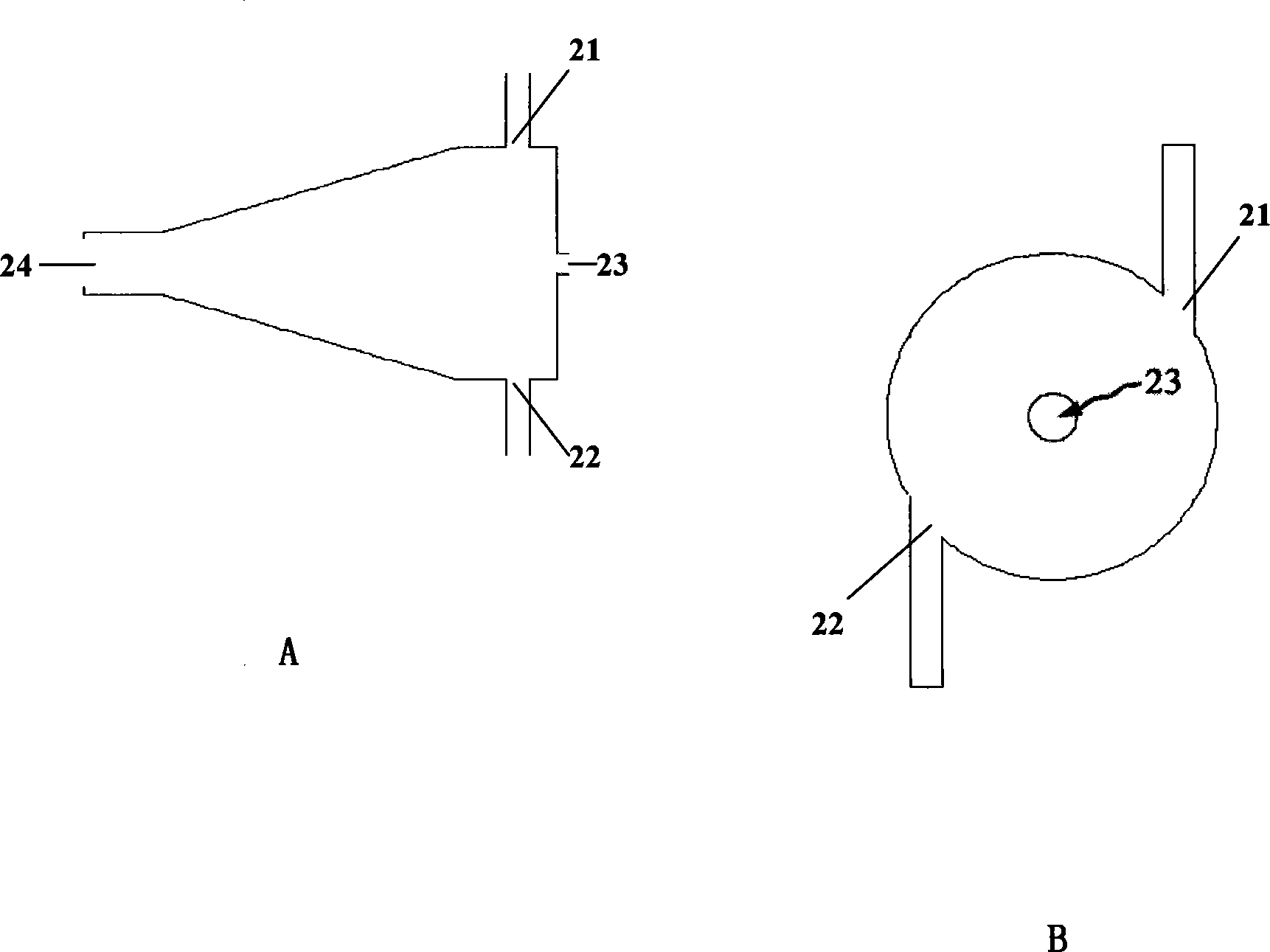

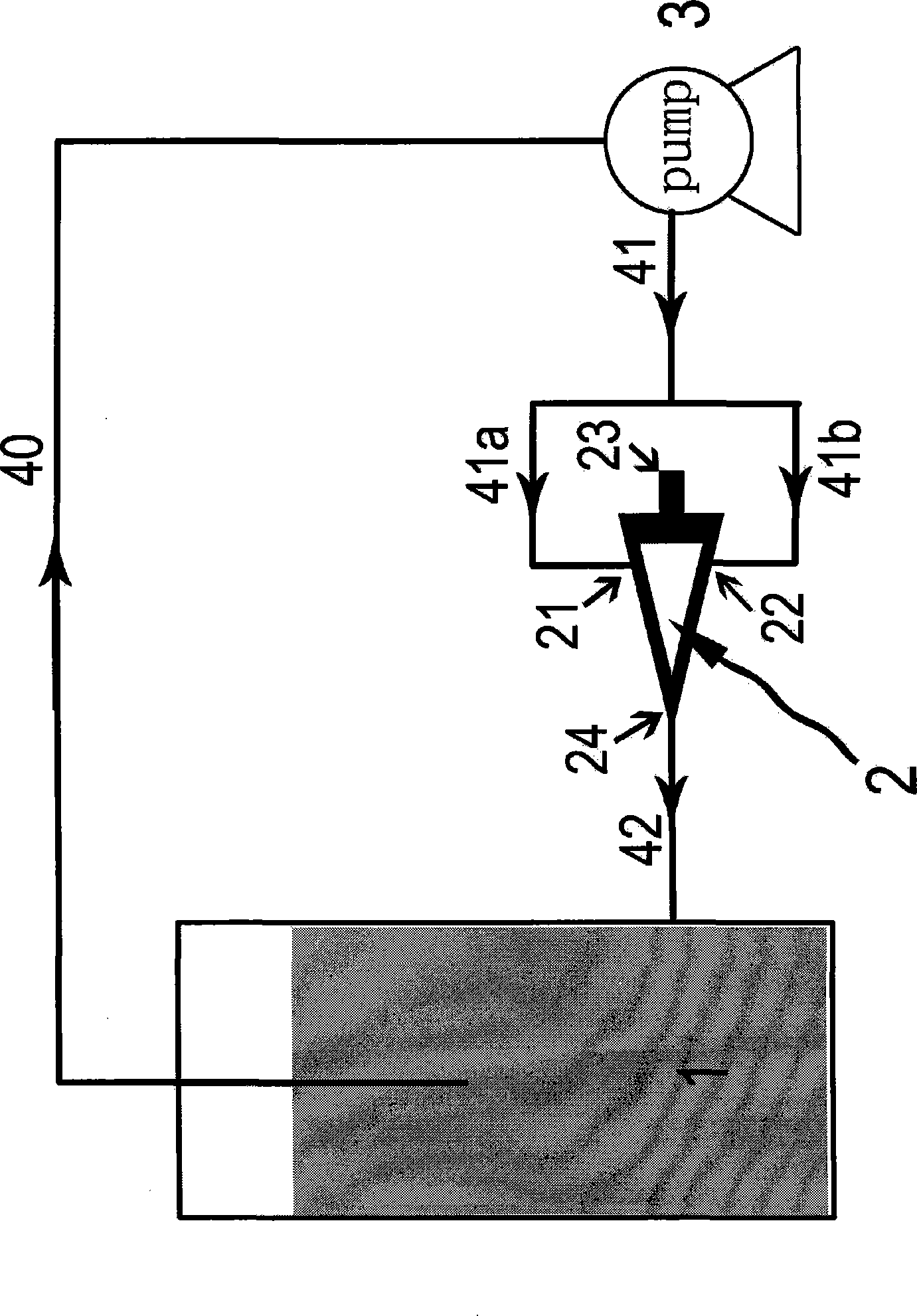

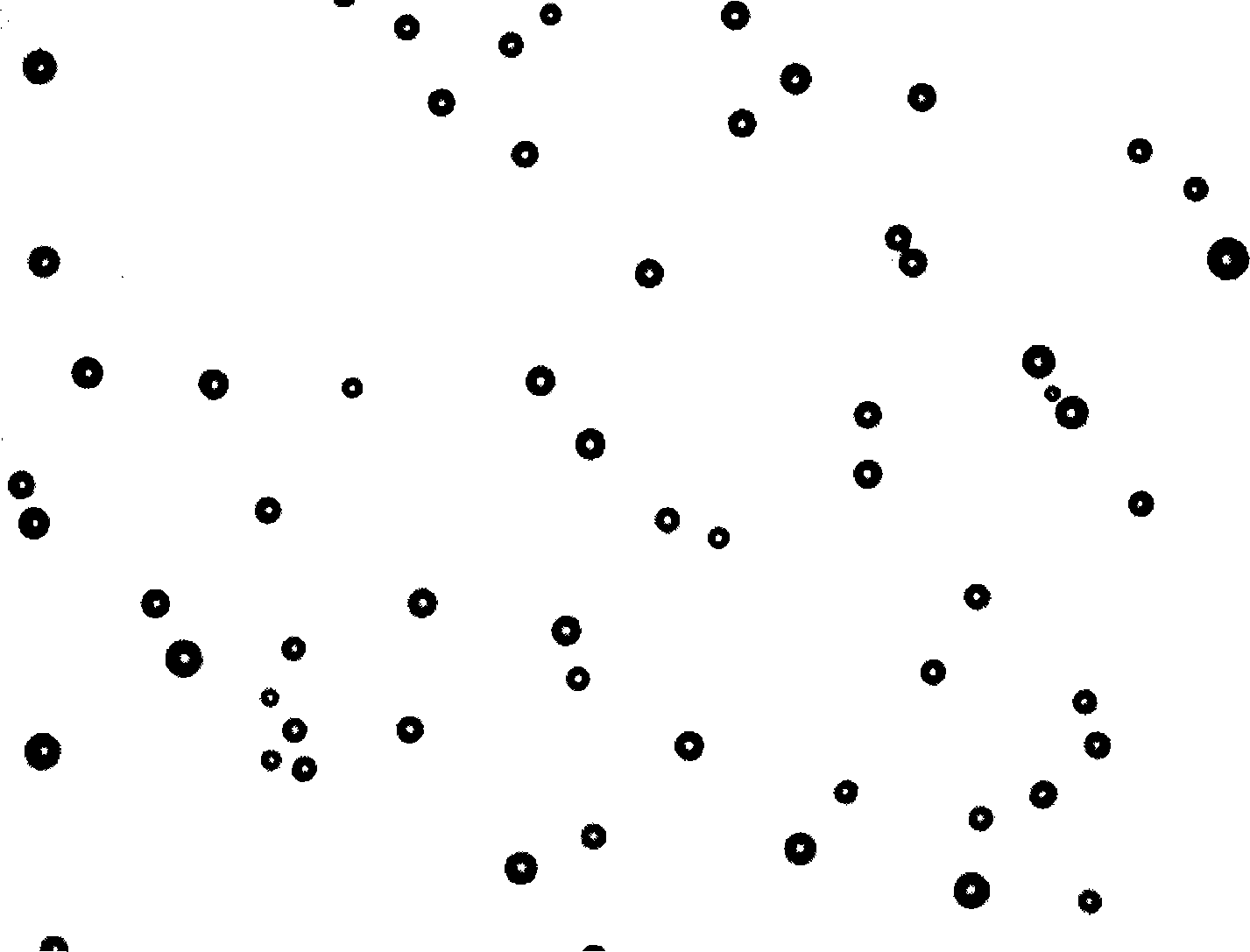

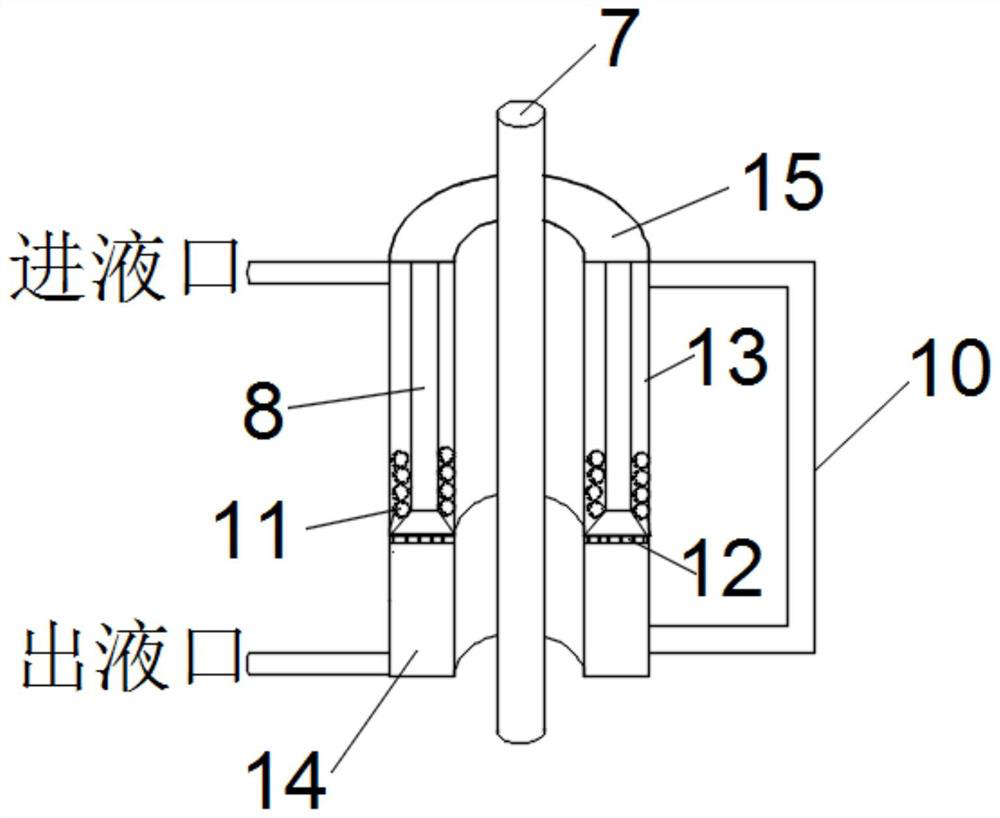

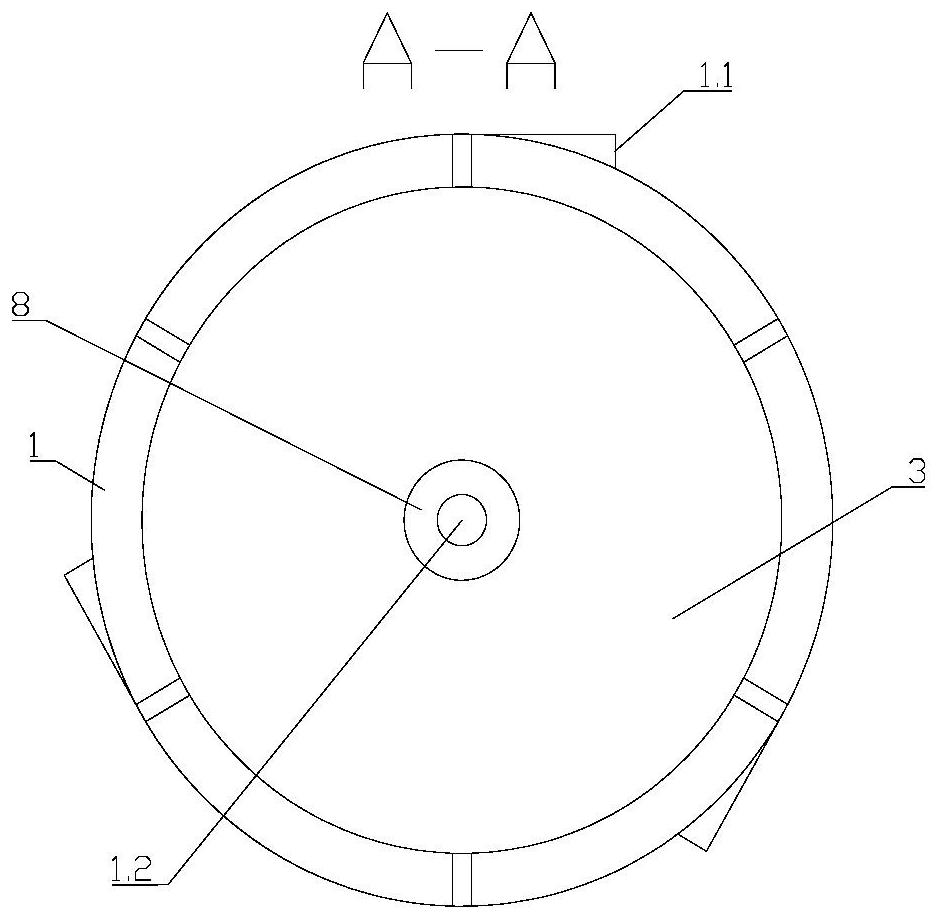

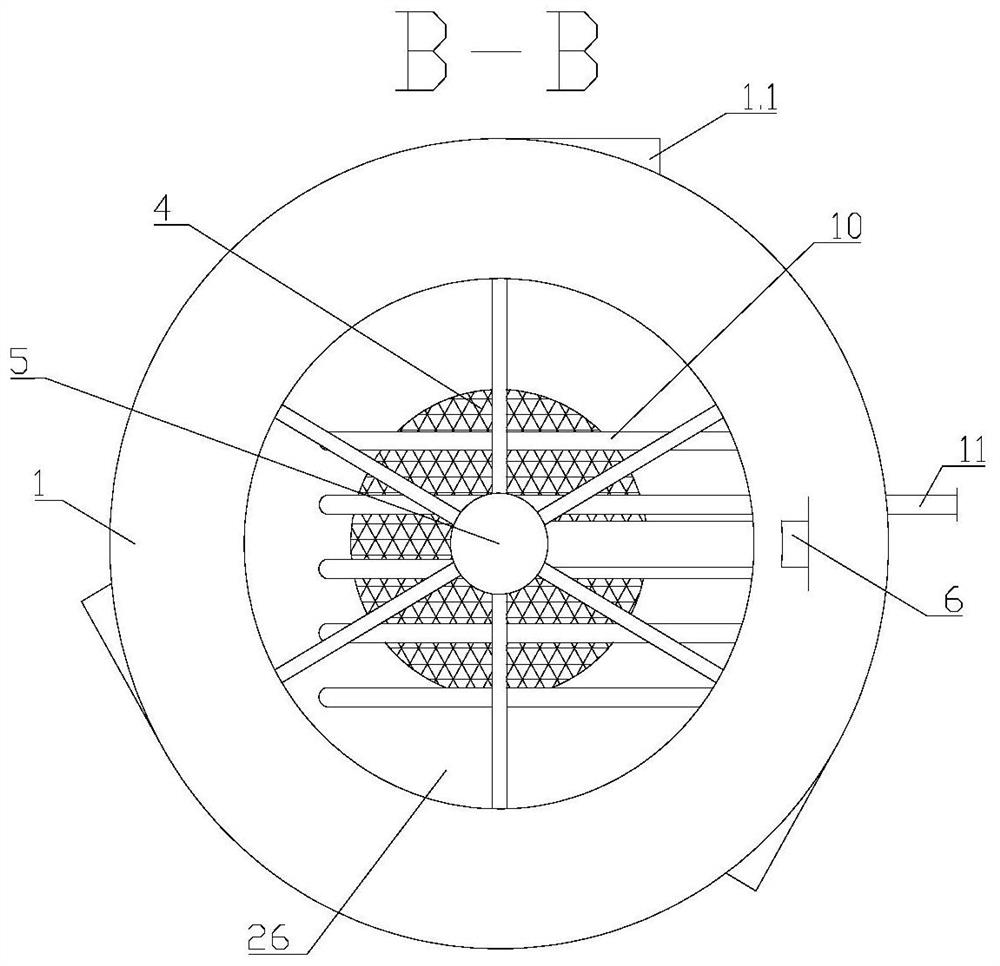

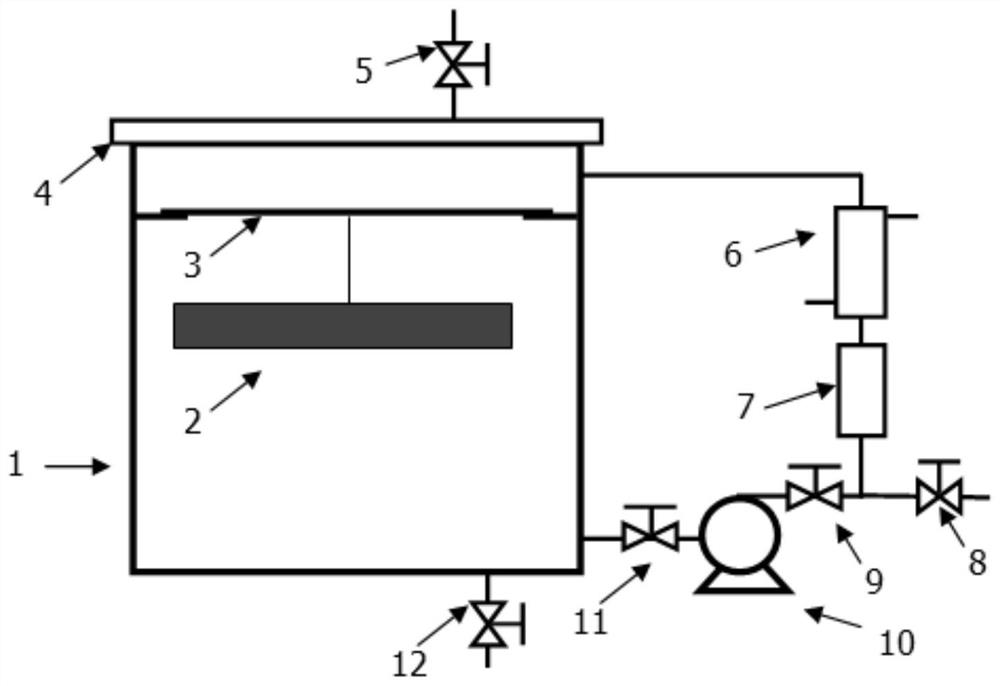

Micron bubble-generating device and special cyclone thereof

InactiveCN101565230ALow costReduce energy consumptionSustainable biological treatmentBiological water/sewage treatmentCycloneEngineering

The invention provides a micron bubble-generating device and a special cyclone thereof. The cyclone comprises a hollow through cavity consisting of a cylindrical cavity and a truncated-cone shape cavity, wherein the height of the truncated-cone shape cavity, the inner diameter of the upper bottom surface of the truncated-cone shape cavity, the inner diameter of the lower bottom surface of the truncated-cone shape cavity and the height of the cylindrical cavity are in a proportion of 1:(0.2-0.4):(0.8-1.1):(0.28-2.2); the side of the cylindrical cavity is provided with at least one pair of through holes; the lower bottom surface of the cylindrical cavity is provided with a through hole (23); and the upper bottom surface of the truncated-cone shape cavity is provided with a through hole (24). The micron bubble-generating device provided by the invention is formed by connecting the cyclone (2) with a water pump (3) through a pipeline. The particle size of micron bubbles generated by the device is less than 50 microns, and the dissolved oxygen concentration of the micron bubbles can reach a super-saturated state, so that the micron bubbles significantly improve oxygenation capacity and oxygen transfer efficiency, and have good application prospects in sewage treatment, pollution control over rivers and lakes, as well as aquaculture.

Owner:TSINGHUA UNIV

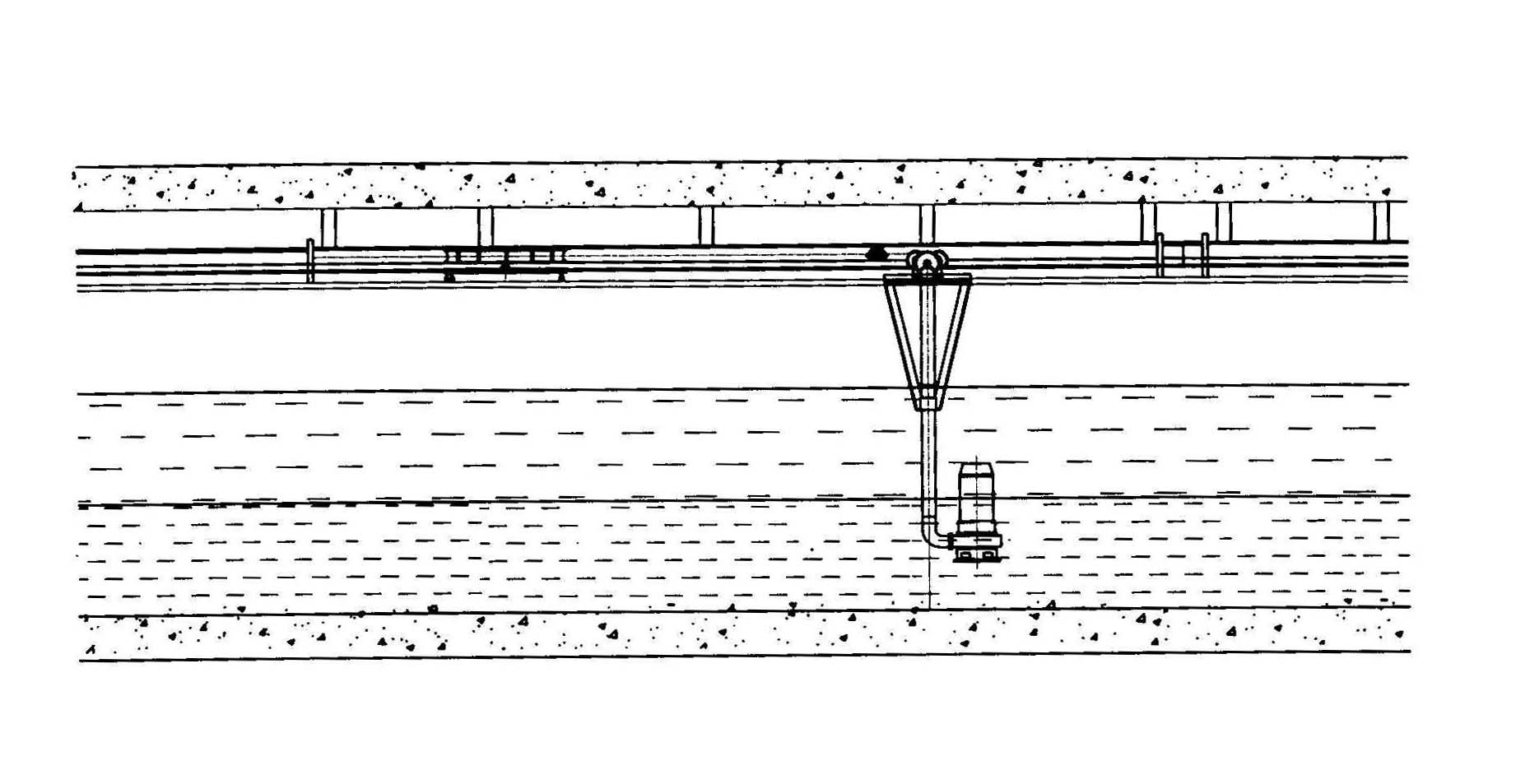

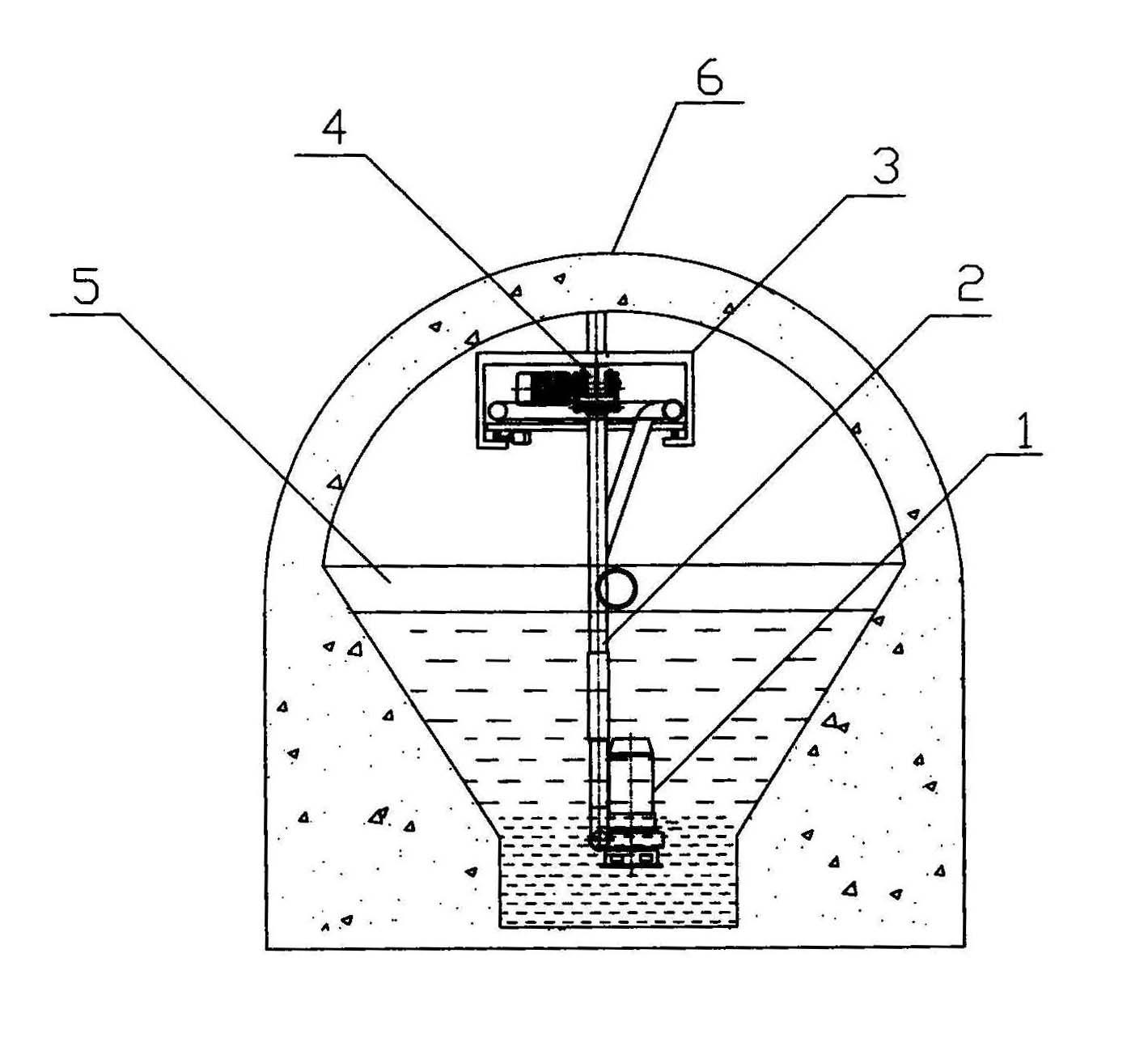

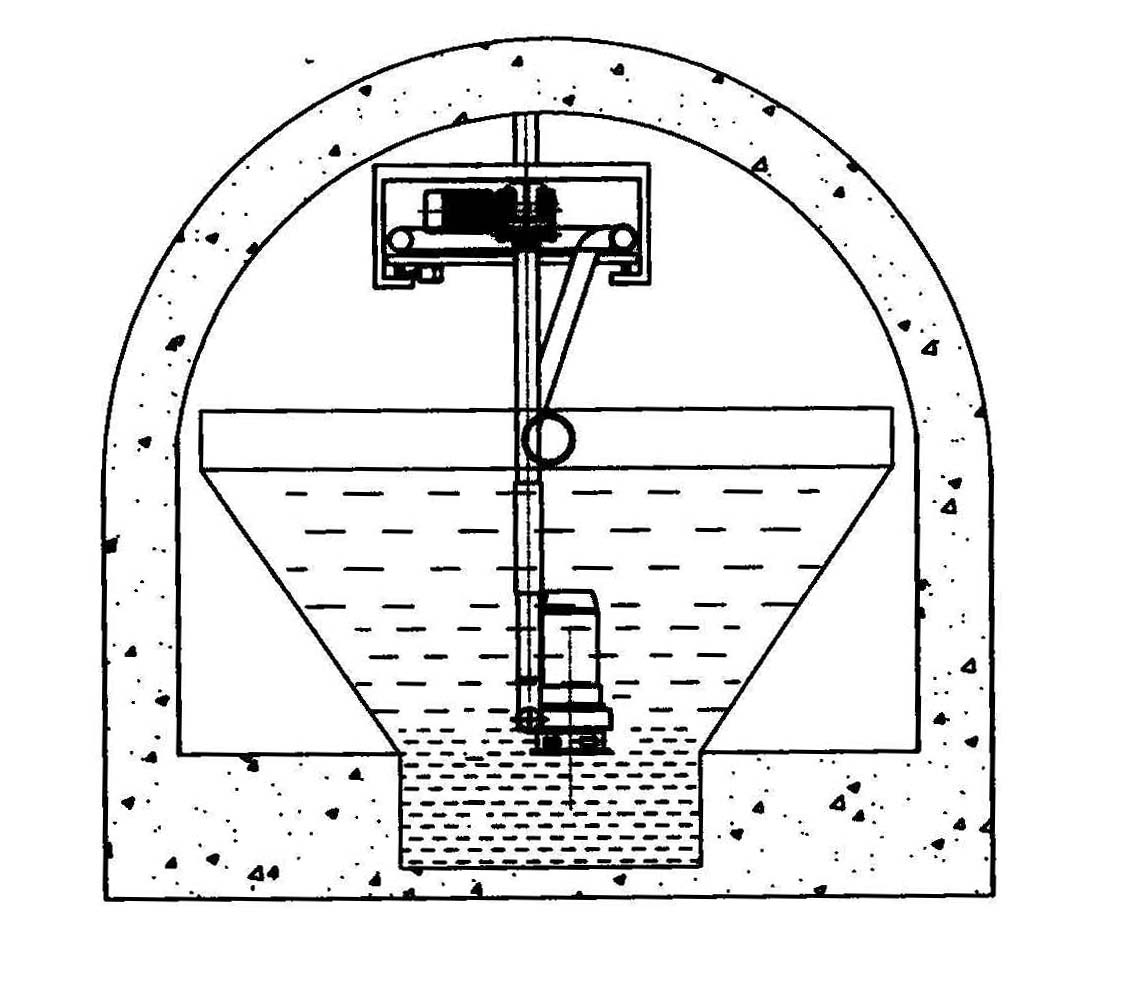

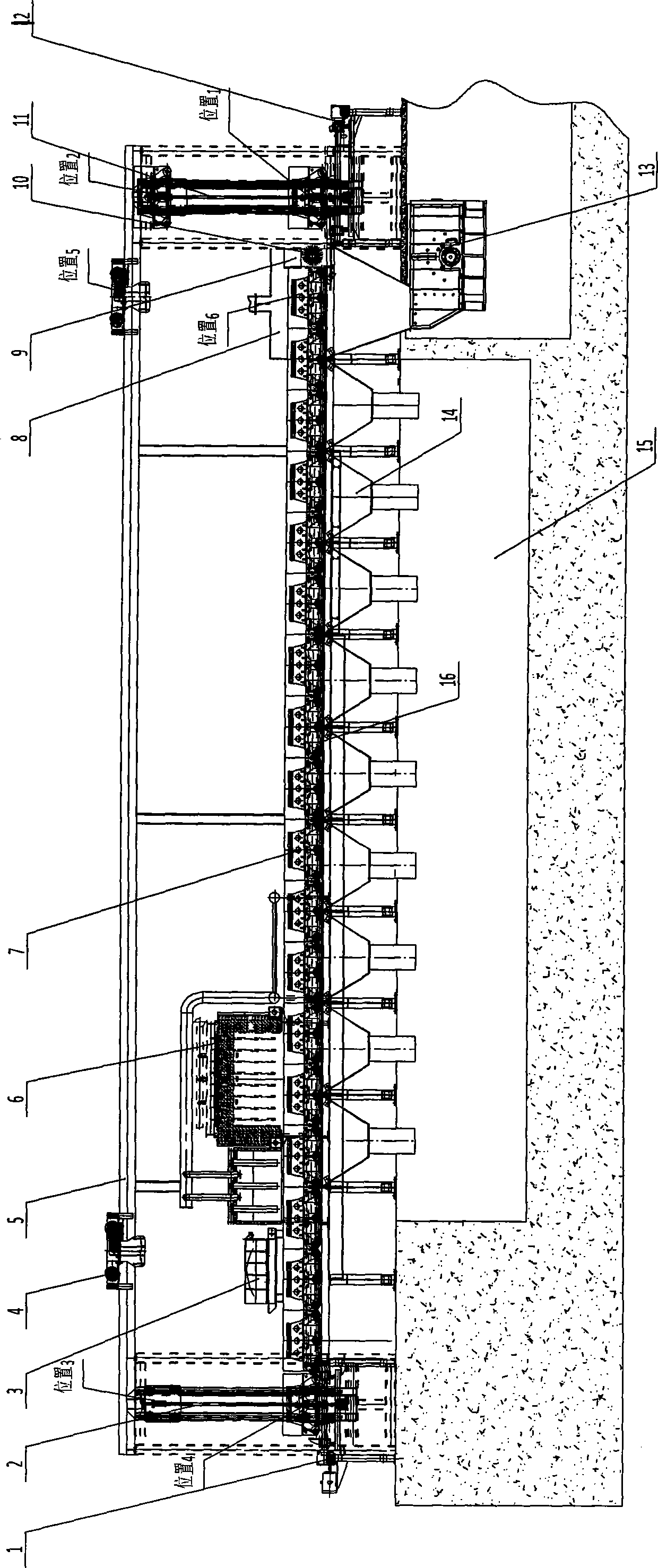

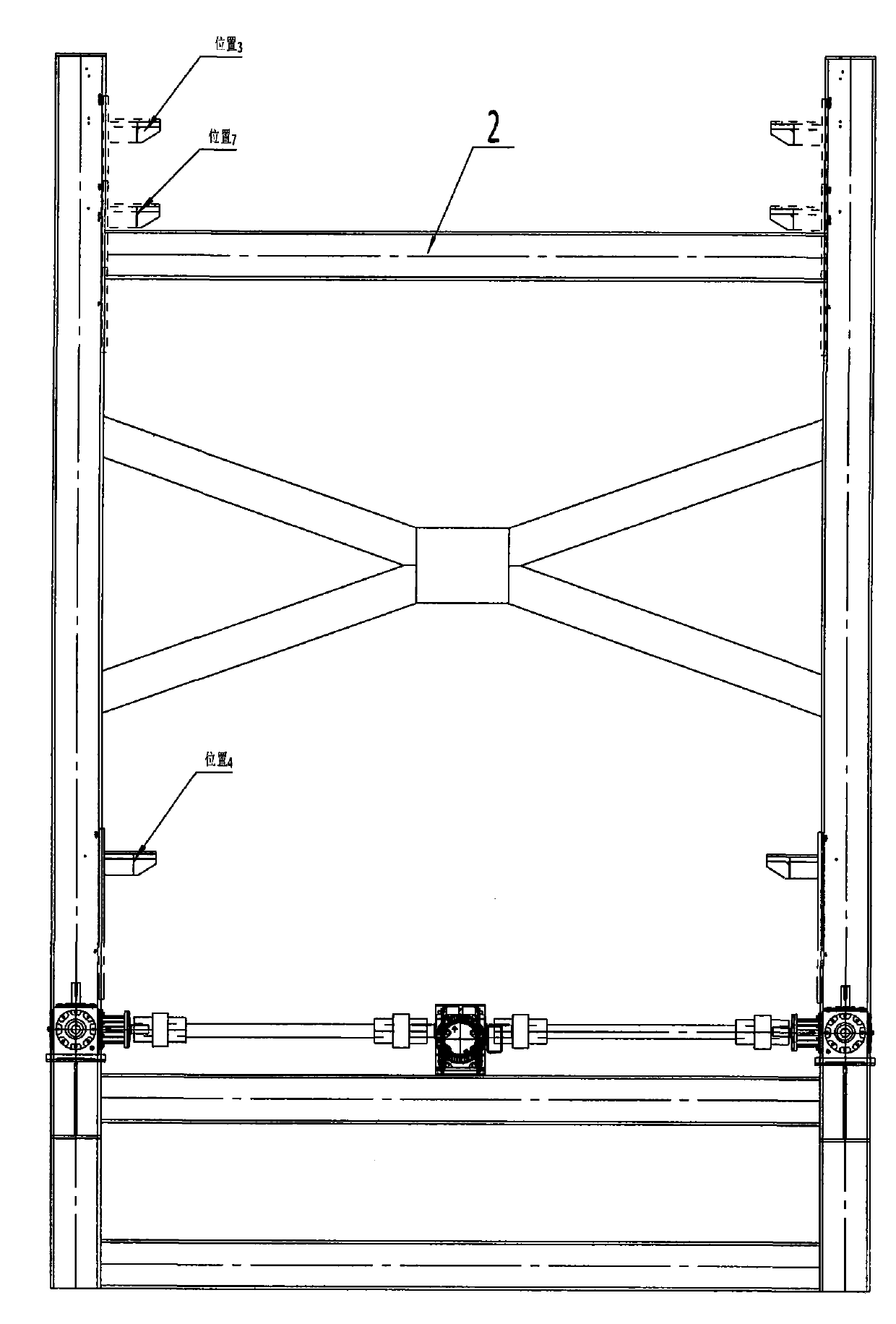

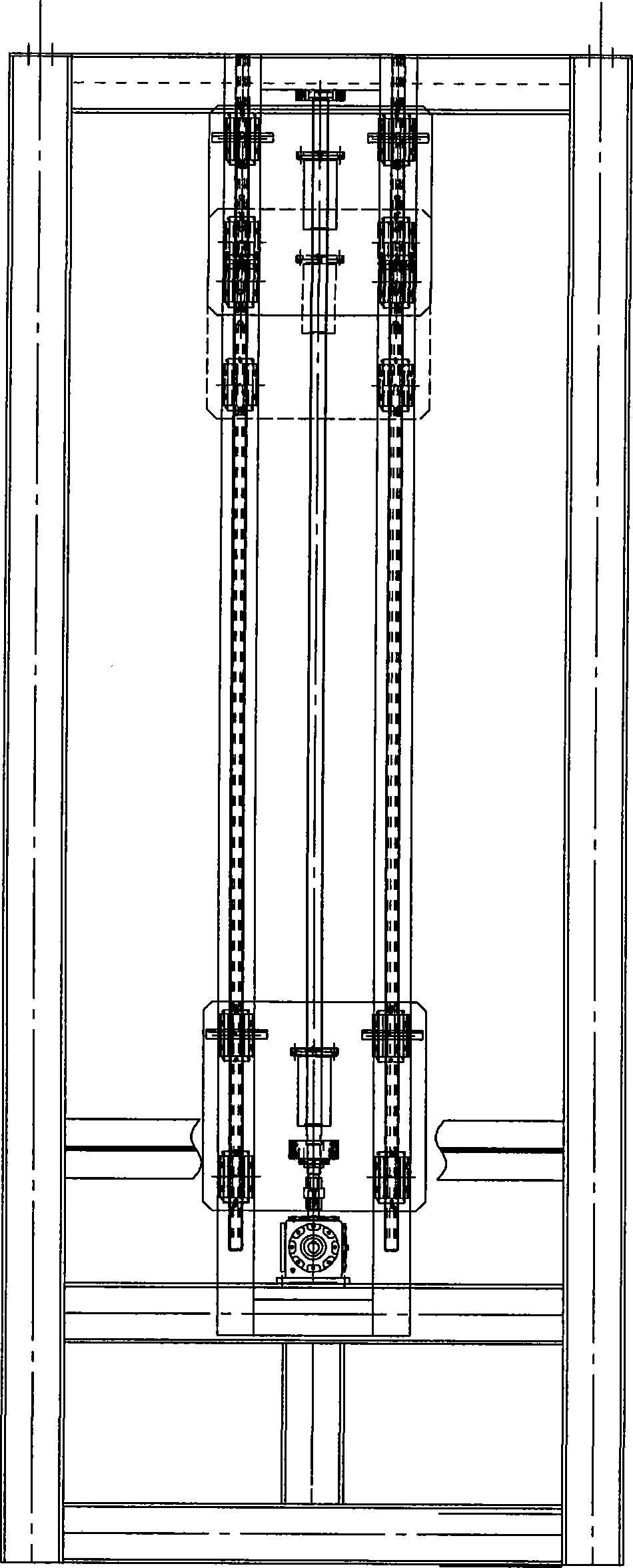

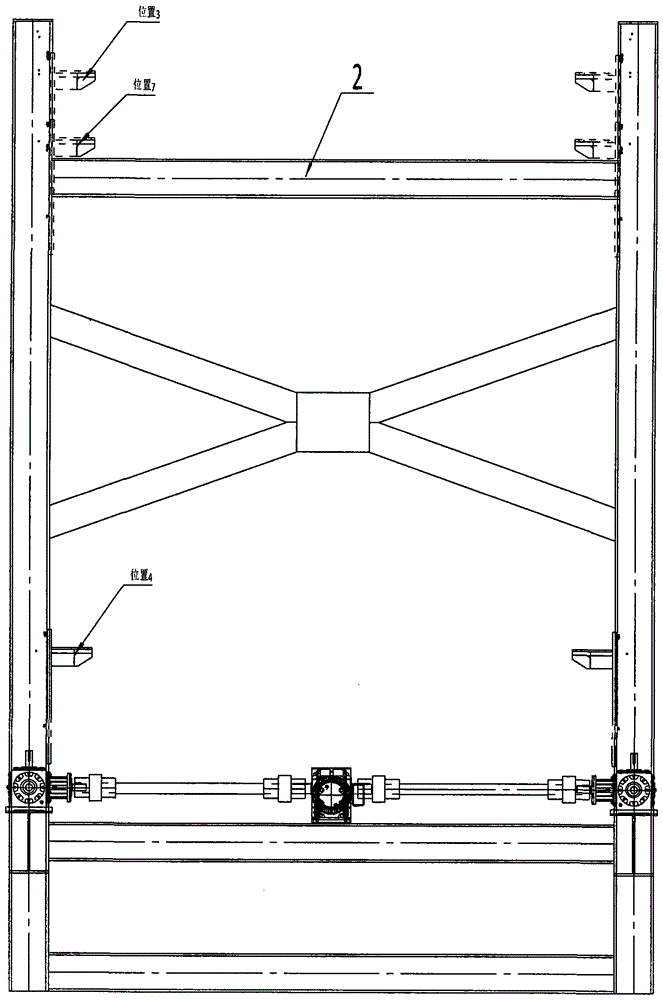

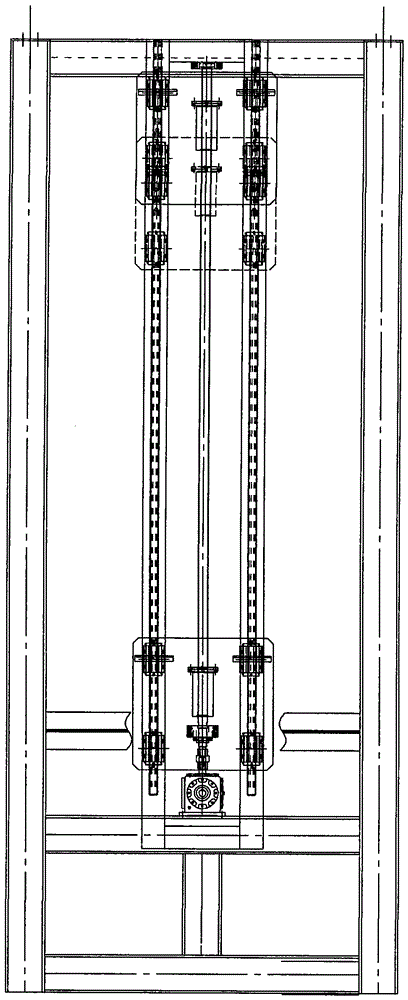

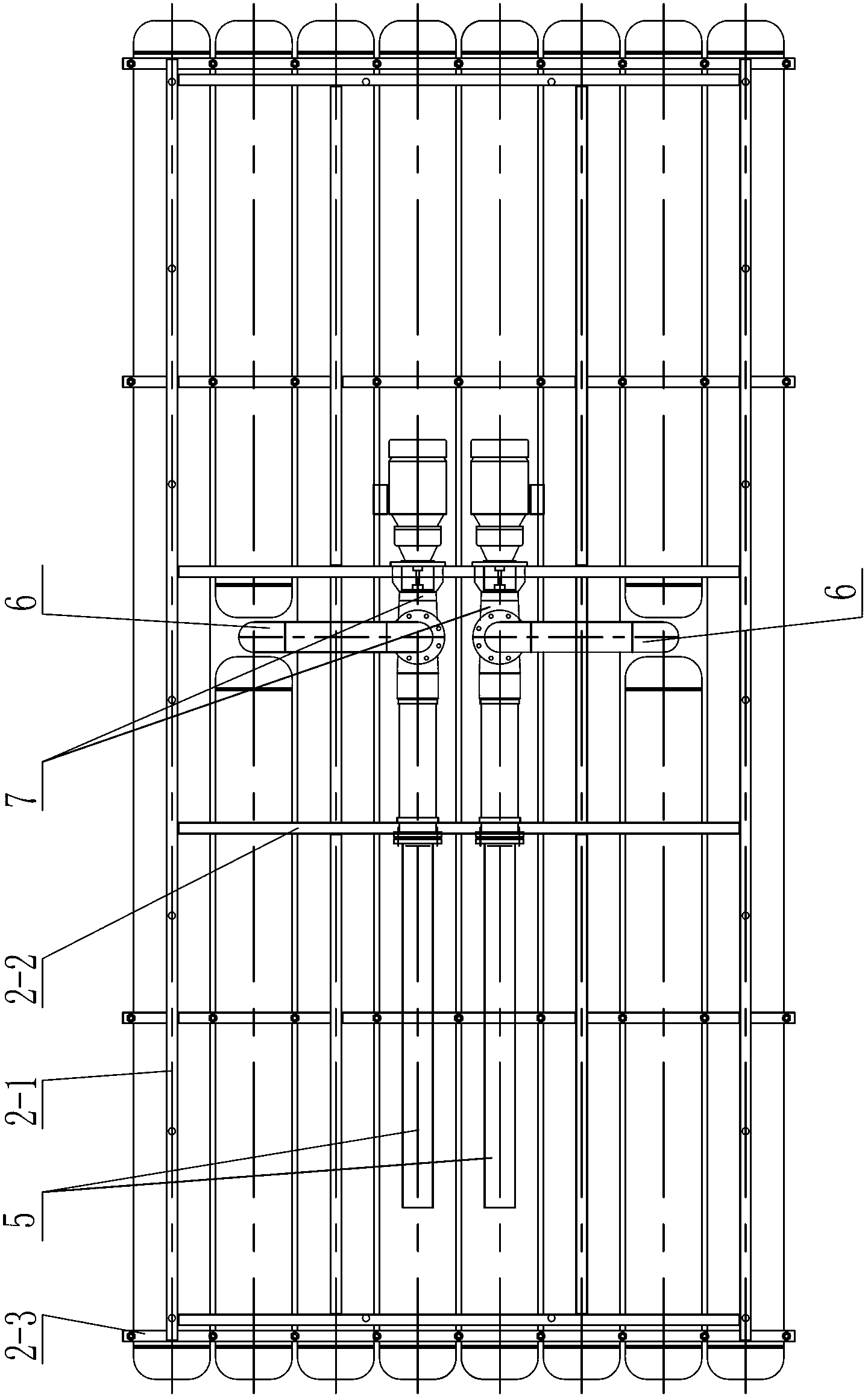

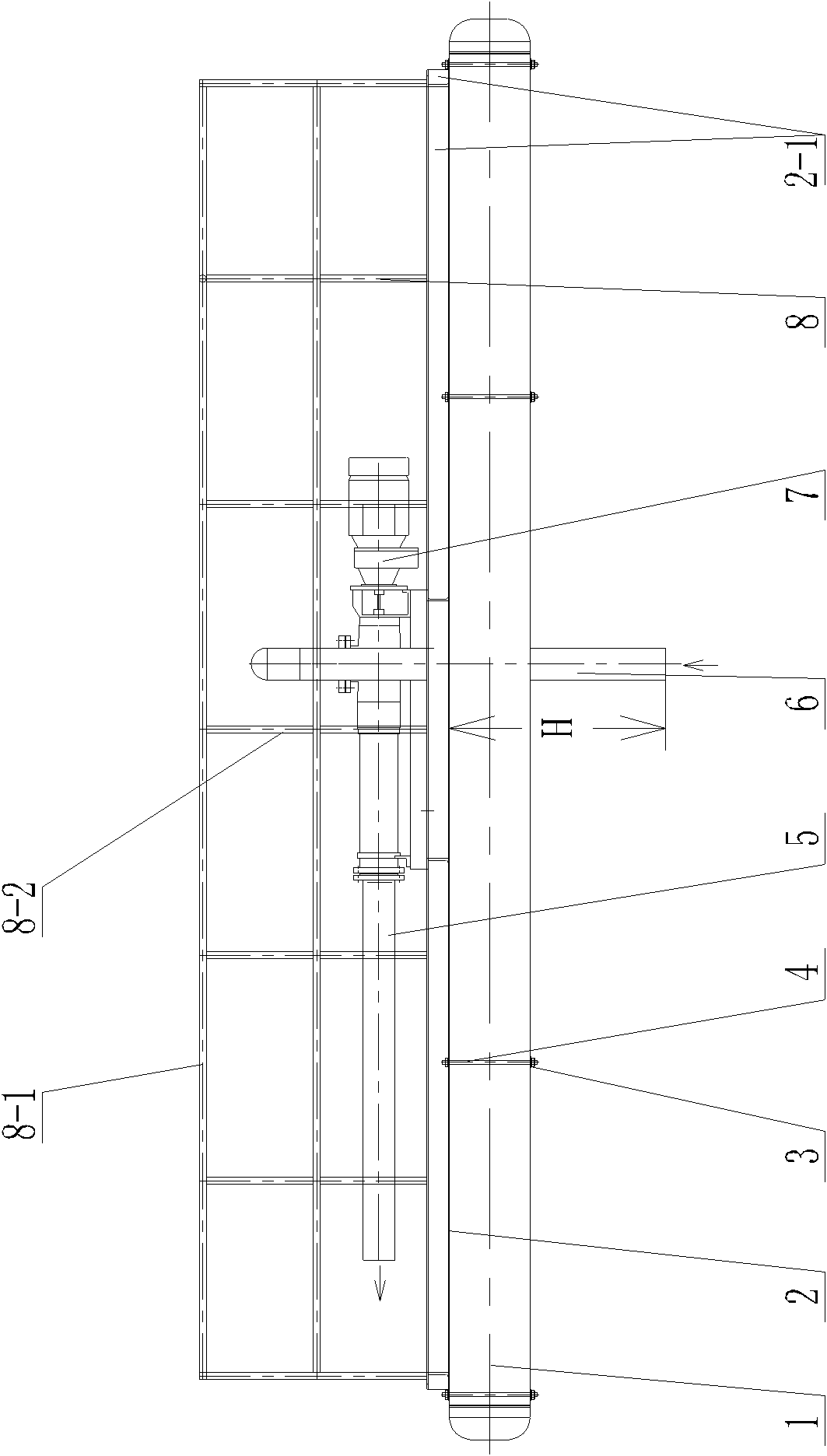

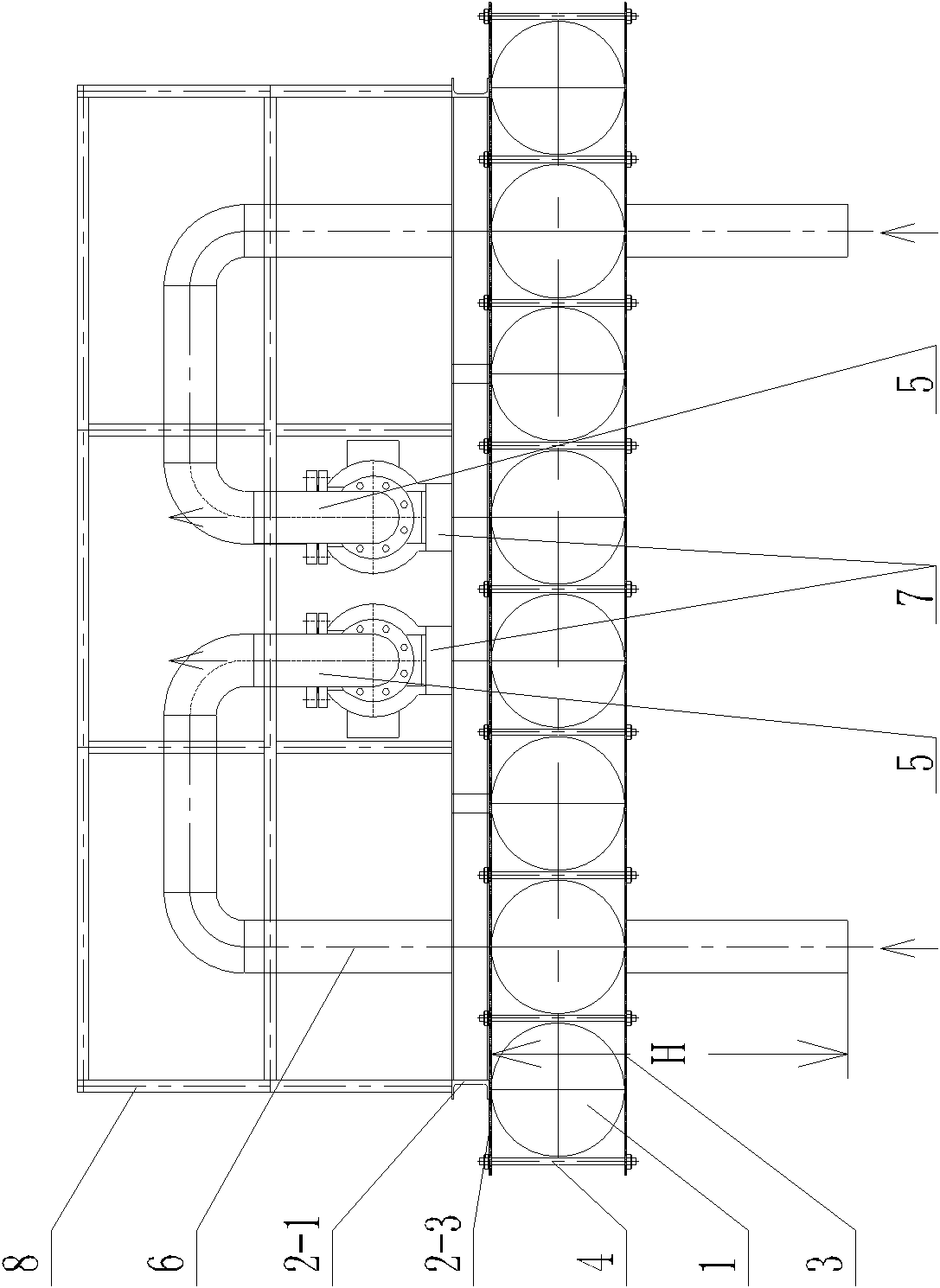

Automatic sludge discharging system for mine sump

The invention relates to an automatic sludge discharging system for a mine sump. The system comprises a concentration and sedimentation basin, a guide rail device, a moving coil mechanism, a monorail crane and a slurry pump, wherein the concentration and sedimentation basin is arranged in underworkings; the guide rail device is arranged at the top of the concentration and sedimentation basin in the underworkings; the moving coil mechanism is arranged on moving coil mechanism slide rails arranged on both sides of a guide rail device fixing bracket in parallel; the monorail crane is installed on a monorail arranged along the longitudinal central axis of the guide rail device fixing bracket through a guide wheel and a driving mechanism in a suspension mode; and the slurry pump is suspended to the lower part of the monorail crane. The moving coil mechanism comprises a carrier vehicle, a rotary disc and a slag discharging pipe wound around the rotary disc, wherein the carrier vehicle is placed on the moving coil mechanism slide rails through roller wheels arranged on both sides of the bottom surface and driven by a power source, and a vertical shaft for installing the rotary disc is arranged in the central part of the plane of the carrier vehicle; the rotary disc is combined with the vertical shaft arranged in the central part of the plane of the carrier vehicle through an axle hole arranged in the central part in a movable fit mode.

Owner:HENAN POLYTECHNIC UNIV

Micron bubble-generating device and special cyclone thereof

InactiveCN101565230BLow costReduce energy consumptionSustainable biological treatmentBiological water/sewage treatmentEngineeringSewage treatment

The invention provides a micron bubble-generating device and a special cyclone thereof. The cyclone comprises a hollow through cavity consisting of a cylindrical cavity and a truncated-cone shape cavity, wherein the height of the truncated-cone shape cavity, the inner diameter of the upper bottom surface of the truncated-cone shape cavity, the inner diameter of the lower bottom surface of the truncated-cone shape cavity and the height of the cylindrical cavity are in a proportion of 1:(0.2-0.4):(0.8-1.1):(0.28-2.2); the side of the cylindrical cavity is provided with at least one pair of through holes; the lower bottom surface of the cylindrical cavity is provided with a through hole (23); and the upper bottom surface of the truncated-cone shape cavity is provided with a through hole (24).The micron bubble-generating device provided by the invention is formed by connecting the cyclone (2) with a water pump (3) through a pipeline. The particle size of micron bubbles generated by the device is less than 50 microns, and the dissolved oxygen concentration of the micron bubbles can reach a super-saturated state, so that the micron bubbles significantly improve oxygenation capacity andoxygen transfer efficiency, and have good application prospects in sewage treatment, pollution control over rivers and lakes, as well as aquaculture.

Owner:TSINGHUA UNIV

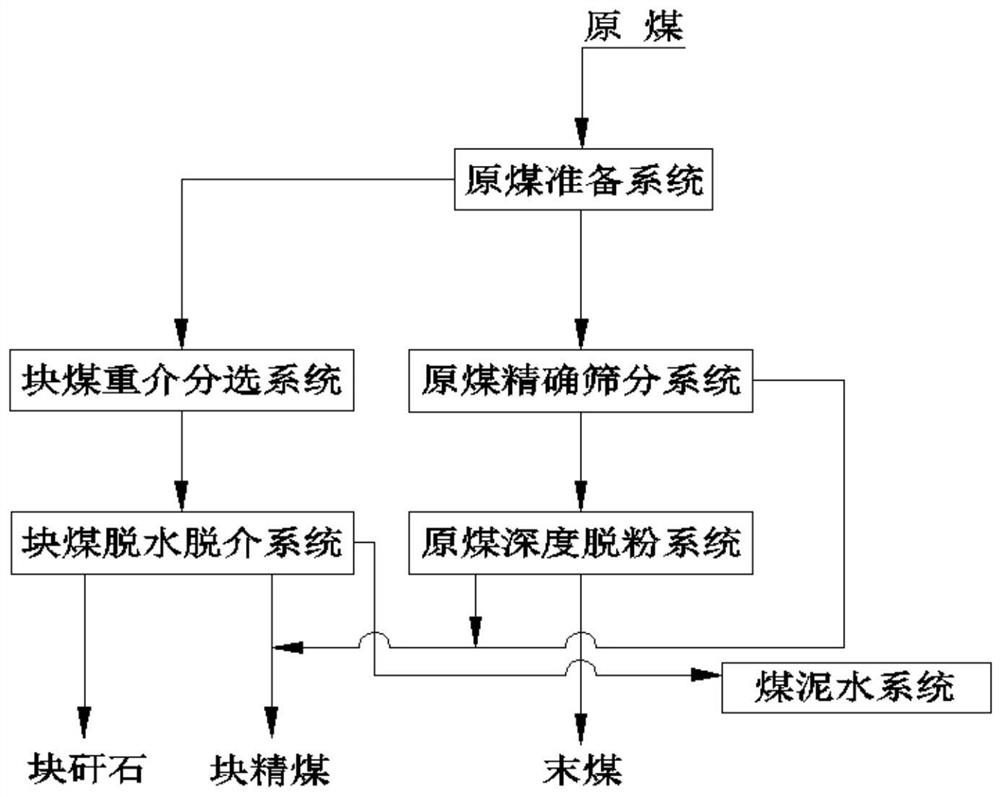

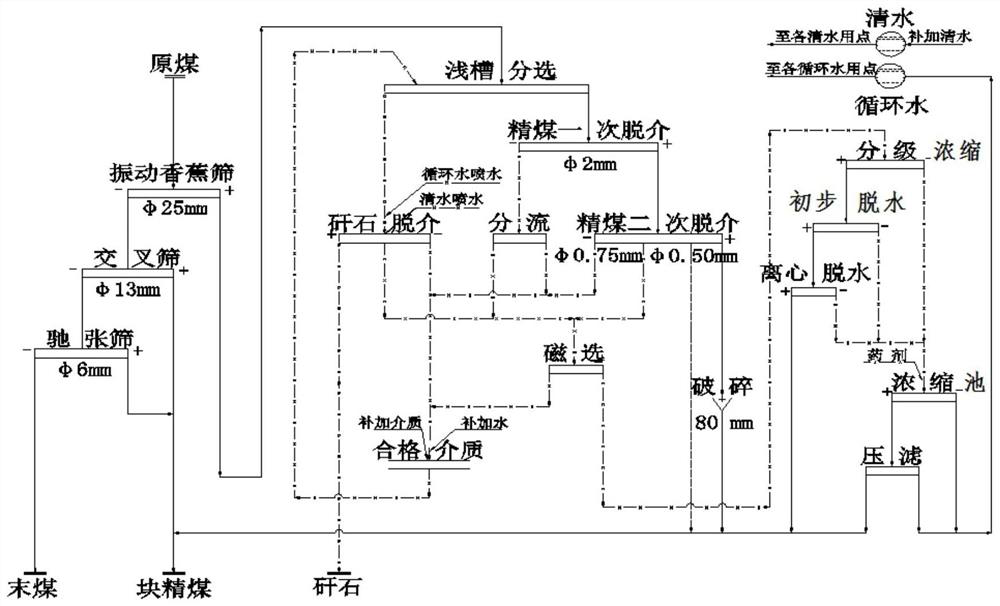

Classified washing process for thermal coal

InactiveCN112371325AQuality improvementSmall particle sizeSievingScreeningThermodynamicsWater treatment system

The invention discloses a classified washing process for thermal coal. The classified washing process comprises the following steps that raw coal is screened to raw coal with three particle sizes of being more than 25mm, between 25mm and 13mm and less than 13mm, all raw coal with the particle sizes of being more than 25mm enters into a lump coal dense medium separation system, the separated lump clean coal and lump gangue enter into a lump coal dehydration and medium removal system for treatment and then output separately, and screened water enters into a slime water treatment system; and allraw coal with the particle sizes between 25mm and 13mm is directly transferred to a lump clean coal belt, the raw coal with the particle sizes of being less than 13mm is subjected to deep screening and pulverized coal removal, the raw coal with the particle sizes of being more than 6mm is transferred to the lump clean coal belt to be output, and slack coal with the particle sizes of being less than 6mm enters a slack coal bunker to be output. The raw coal is classified and then enters different separation processes for separation, the characteristics of low separation lower limit and high separation precision of a dense-medium shallow-groove separator are combined, and the classified washing process is particularly suitable for thermal coal preparation plants with fragile coal quality andstrict requirements for product granularity, has the advantages of simple process arrangement and low production cost, improves the quality of clean coal, and also guarantees the yield of lump coal.

Owner:XINWEN MINING GROUP

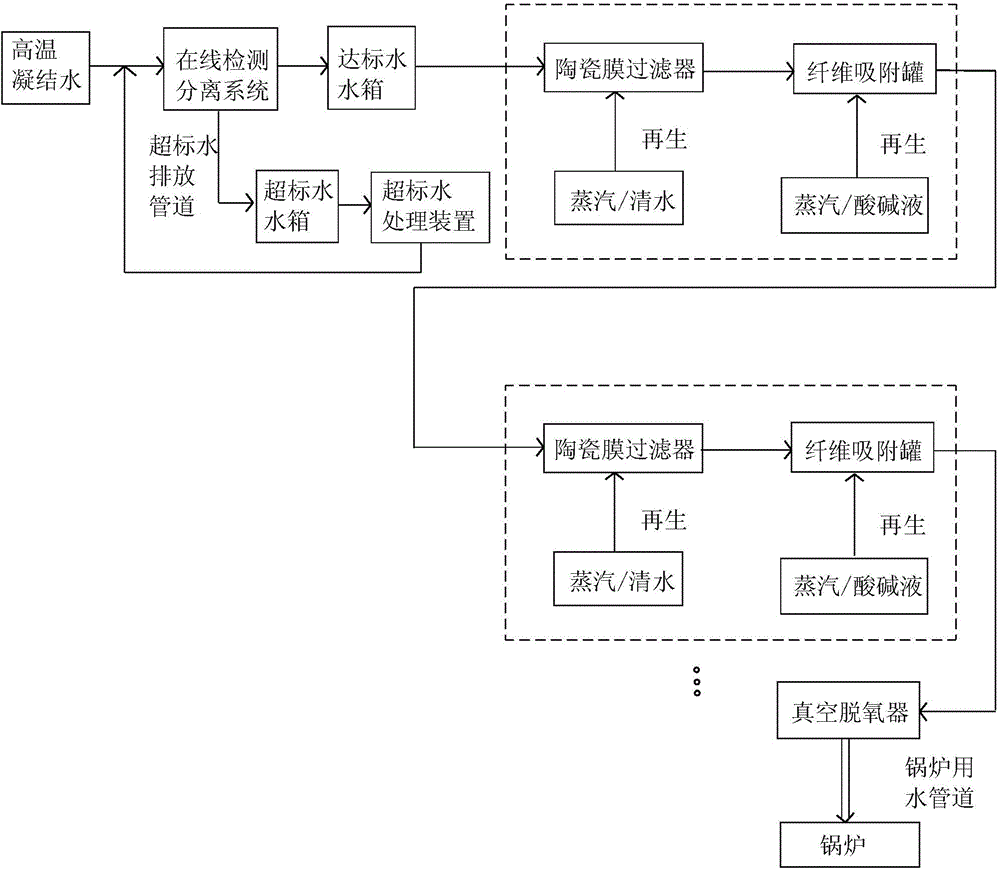

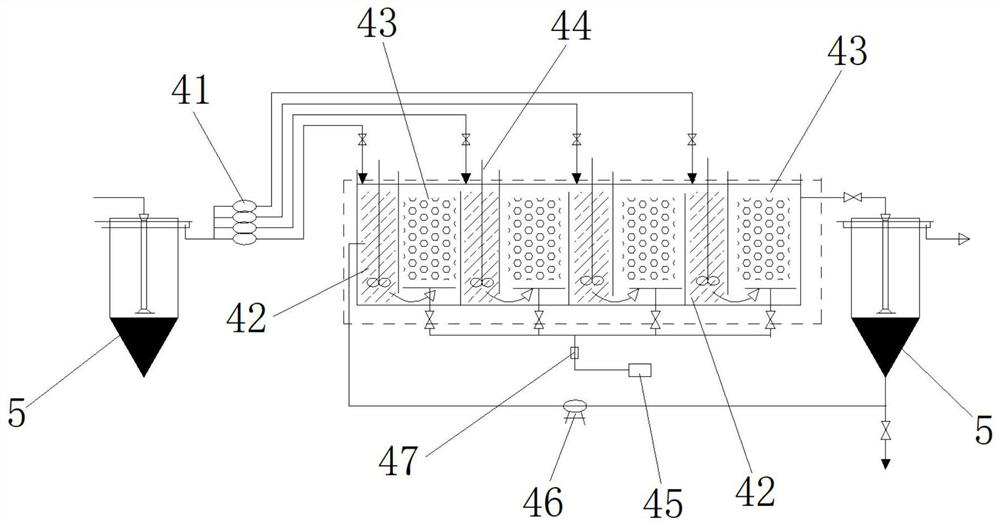

High-temperature condensation water fine treatment system and high-temperature condensation water fine treatment method

InactiveCN105271539ATo achieve the water effectReduce replacement costsMultistage water/sewage treatmentFiberOxygen

The present invention relates to a high-temperature condensation water fine treatment system and a high-temperature condensation water fine treatment method. According to the present invention, through online detection, condensation water meeting the treatment standard is introduced into the treatment system, and the condensation water is subjected to deoiling, desalination and degassing through a ceramic membrane filter, a fiber pot and a vacuum oxygen removing device; in the case of no requirement of cooling, trace grease, iron ions, copper ions, SiO2 sol and other impurities in the high-temperature condensation water are removed; the repeatable unit can be according to the water inlet of the boiler water, and the repeating units are connected in series in the treatment system; the degassed purified water can be directly reused in the boiler water; and the high-temperature condensation water treatment does not require the heat exchange equipment and the ion exchange resin, and the water outlet effect of the boiler water can be achieved by using the ceramic membrane filter and the active carbon fibers as the purification main body unit so as to save the equipment investment cost and the material replacement cost during the operation.

Owner:SHANGHAI ANHORN ENVIRONMENTAL TECH CO LTD

Three-in-one burning method for garbage

A garbage triad incineration method, of the garbage power generation boiler burning system technical field, includes the following technical technological process: a. mix the garbage with powder coal, the quantity added is 1-5% of garbage; b. add emulsifying agent and oil into water to create emulsified oil, with the quantity added of emulsifying agent and oil whose weight are 1-5% and 30-70% of water; c, the garbage mixed with powder coal is transferred into a boiler furnace cavity, burning, meanwhile, the emulsified oil prepared is injected to the boiler furnace cavity, burning. The invention uses garbage as base stock,and garbage, oil, powder coal combustion method, combines the advantages of oil and coal oxidizer, does good to making use of garbage, reducing coal quantity, cost and second pollution, saving energy, compared to the present technology.

Owner:ZHEJIANG LANTING HI TECH

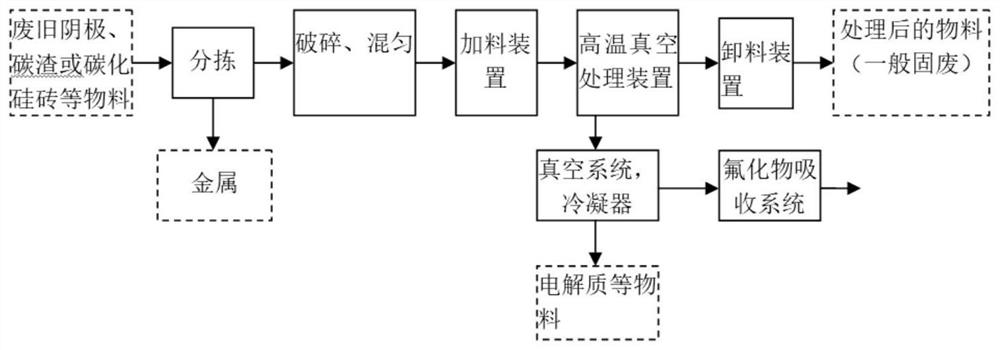

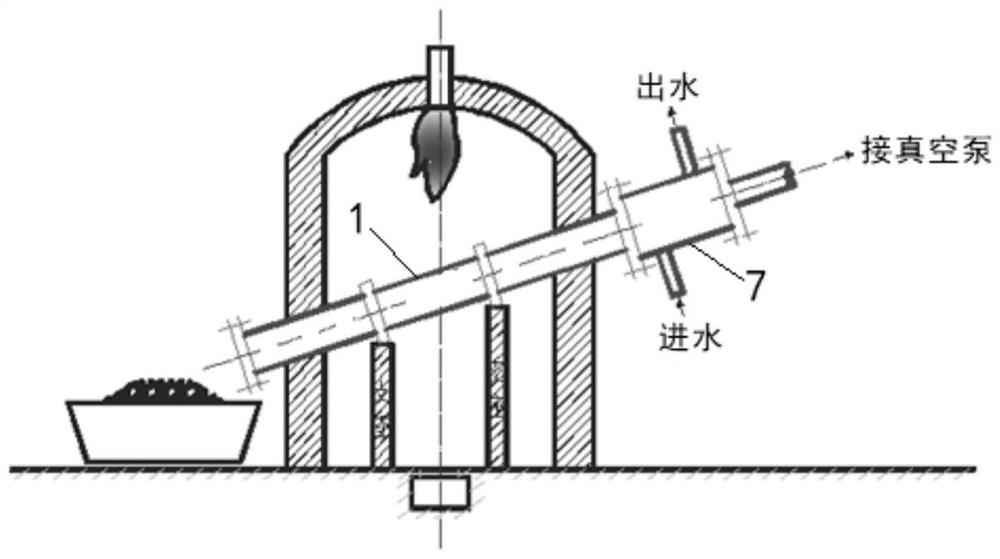

High-temperature vacuum treatment method and device for aluminum electrolysis waste cathodes, carbon residues or silicon carbide bricks and operation method of high-temperature vacuum treatment device for aluminum electrolysis waste cathodes, carbon residues or silicon carbide bricks

InactiveCN112108489AFast loading and unloadingGuaranteed treatment effectSolid waste disposalTransportation and packagingCarbide siliconExhaust fumes

The invention discloses a high-temperature vacuum treatment method and device for aluminum electrolysis waste cathodes, carbon residues or silicon carbide bricks and an operation method of the high-temperature vacuum treatment device for the aluminum electrolysis waste cathodes, the carbon residues or the silicon carbide bricks. The method comprises the following steps that 1, a to-be-treated material is subjected to crushing and blending treatment, and a treated material is obtained; 2, the treated material obtained in the step 1 is heated to a preset temperature, a preset duration is maintained in a vacuum environment, so that volatile matters in the material are fully volatilized, and harmful substances are decomposed and converted; and 3, a product converted into general solid waste isdischarged, and the volatile matters are condensed and collected. The method can be used for realizing harmless treatment and utilization of the waste cathodes, the carbon residues and the silicon carbide bricks, and no wastewater, harmful waste gas or new waste is generated in the treatment process.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

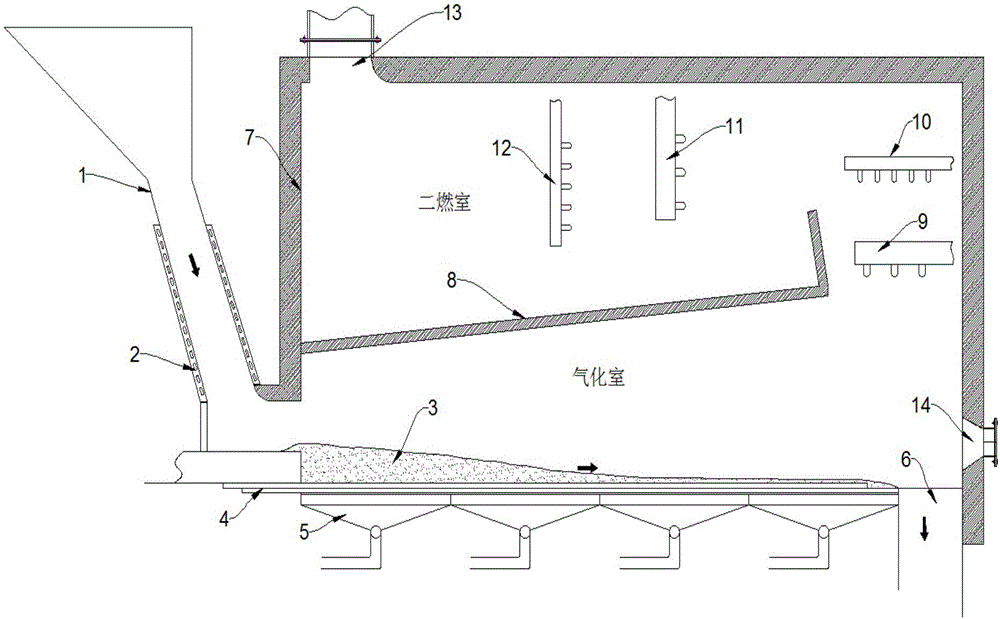

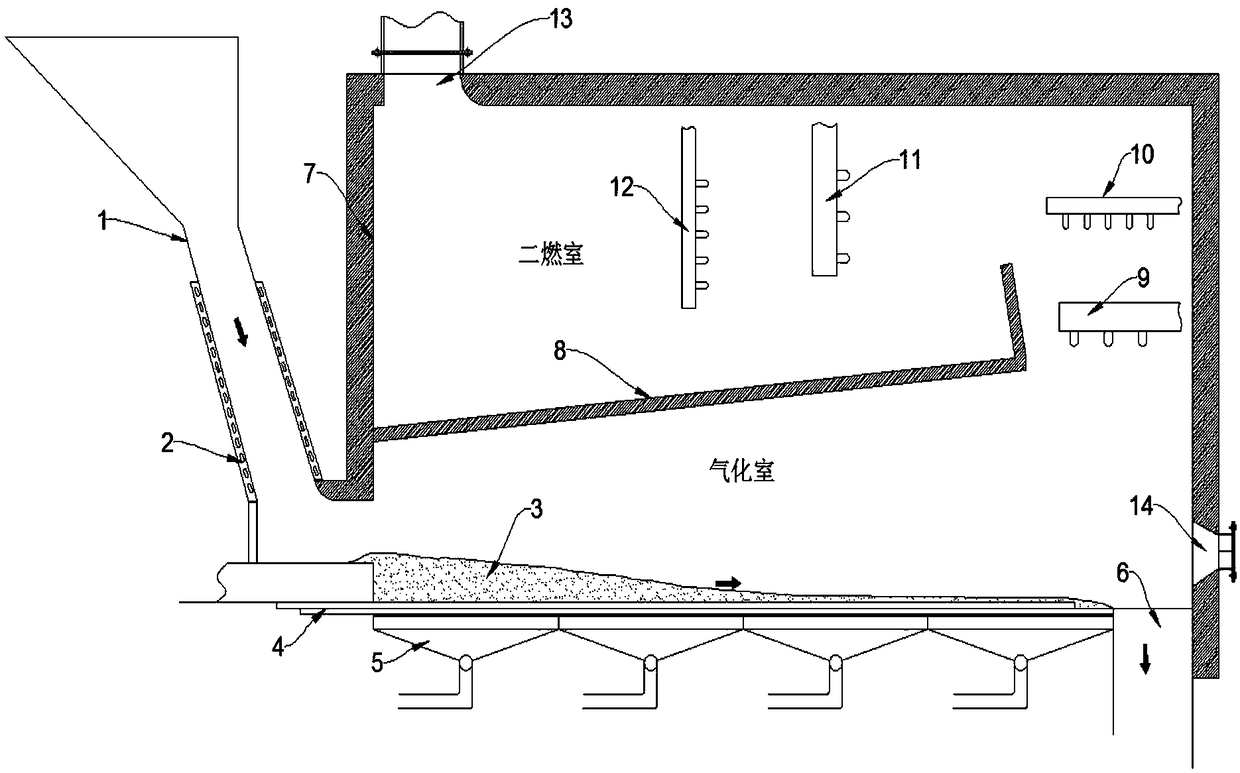

Gasifying incinerator applicable to household garbage with high heat value

ActiveCN106352343ASolve various disadvantages caused by incinerationEmission reductionDamper arrangementBlast-producing apparatusFlue gasCombustible gas

The invention provides a gasifying incinerator applicable to household garbage with high heat value. The gasifying incinerator is divided into a gasifying chamber and a secondary combusting chamber, wherein a horizontal grate is arranged at the bottom of the gasifying chamber, and a primary air bin is arranged at the bottom of the grate; the secondary combusting chamber is formed above the gasifying chamber, and secondary air and circulatory flue gas enter a hearth from the side surface of the secondary combusting chamber respectively to promote burn-out of combustible gas in the secondary combusting chamber and reduce the overall temperature of the secondary combusting chamber. The gasifying incinerator can effectively overcome various defects caused by a traditional household garbage incineration way and has the advantages that bottom ash has low carbon content, NOx emission is ultralow, concentration of fly ash is ultralow and the like, a flue gas treatment system is simplified, and investment cost and operation cost are reduced greatly.

Owner:EVERBRIGHT ENVIRONMENTAL TECH CHINA CO LTD

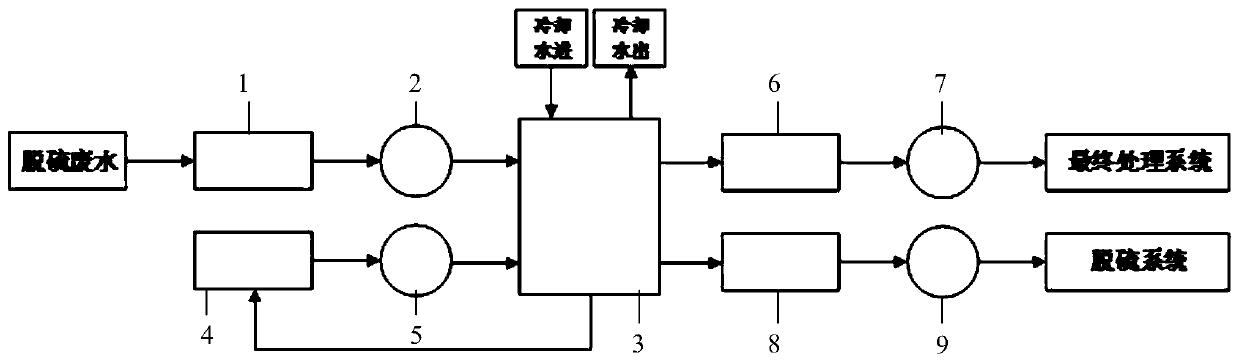

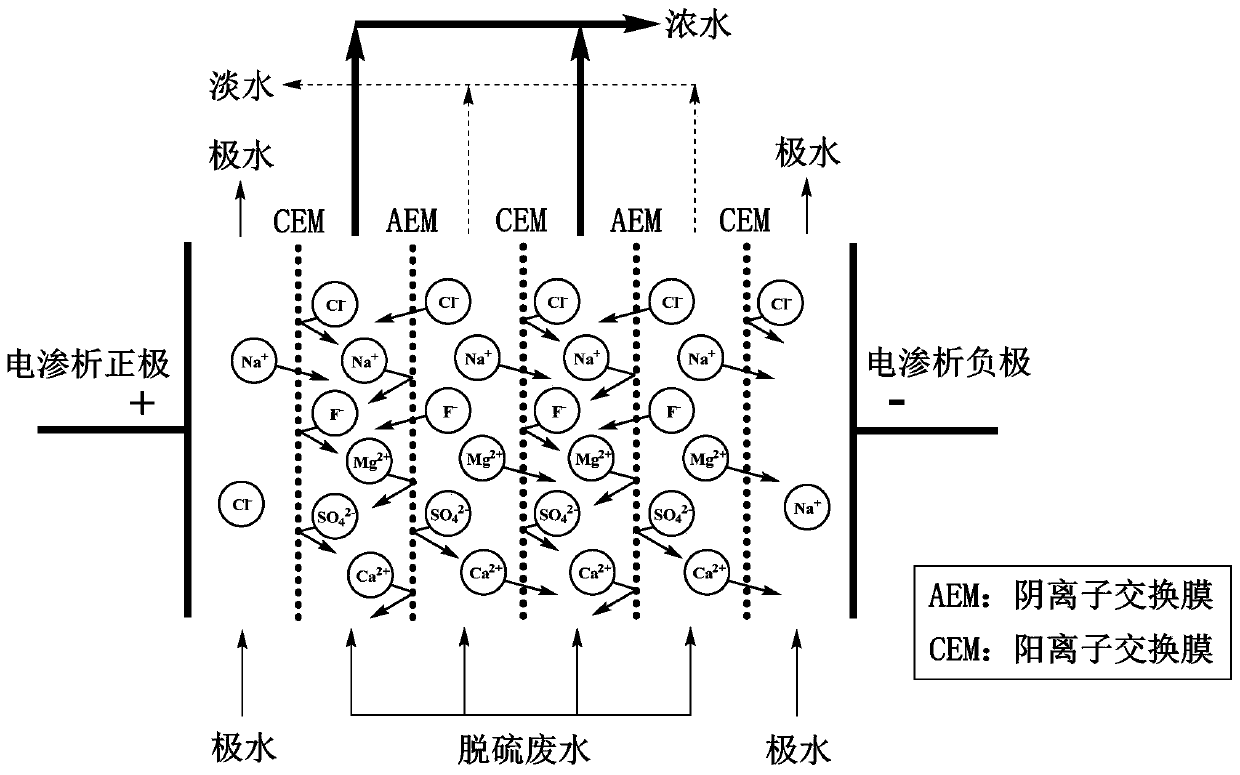

Desulfurization wastewater concentration reduction treating system and method based on nonsoftening and directional driving electrodialysis technology

PendingCN111439814AEffective concentration reductionImprove economyDispersed particle separationWater/sewage treatmentWastewaterFresh water

The invention relates to a desulfurization wastewater concentration reduction treating system based on a nonsoftening and directional driving electrodialysis technology. The system comprises a wastewater raw water tank, a wastewater raw water pump, a directional driving electrodialysis device, an electrode water tank, an electrode water pump, a wastewater concentrated water tank, a wastewater concentrated water pump, a wastewater fresh water tank and a wastewater fresh water pump. Desulphurization wastewater is connected to an inlet of the wastewater raw water tank, an outlet of the wastewaterraw water tank is connected with a wastewater inlet of the directional driving electrodialysis device through the wastewater raw water pump; a concentrated water outlet of the directional driving electrodialysis device is connected with an inlet of the wastewater concentrated water tank; an outlet of the wastewater concentrated water tank is connected to a final treating system through the wastewater concentrated water pump; a fresh water outlet of the directional driving electrodialysis device is connected with the wastewater fresh water tank which is connected to a desulfurization system through the wastewater fresh water pump. The desulfurization wastewater concentration reduction treating system has the beneficial effects that the directional driving electrodialysis device is arranged, so that the desulfurization wastewater can be effectively concentrated and reduced on the premise of not removing the hardness of calcium and magnesium in the wastewater, namely nonsoftening.

Owner:ZHEJIANG ZHENENG TECHN RES INST

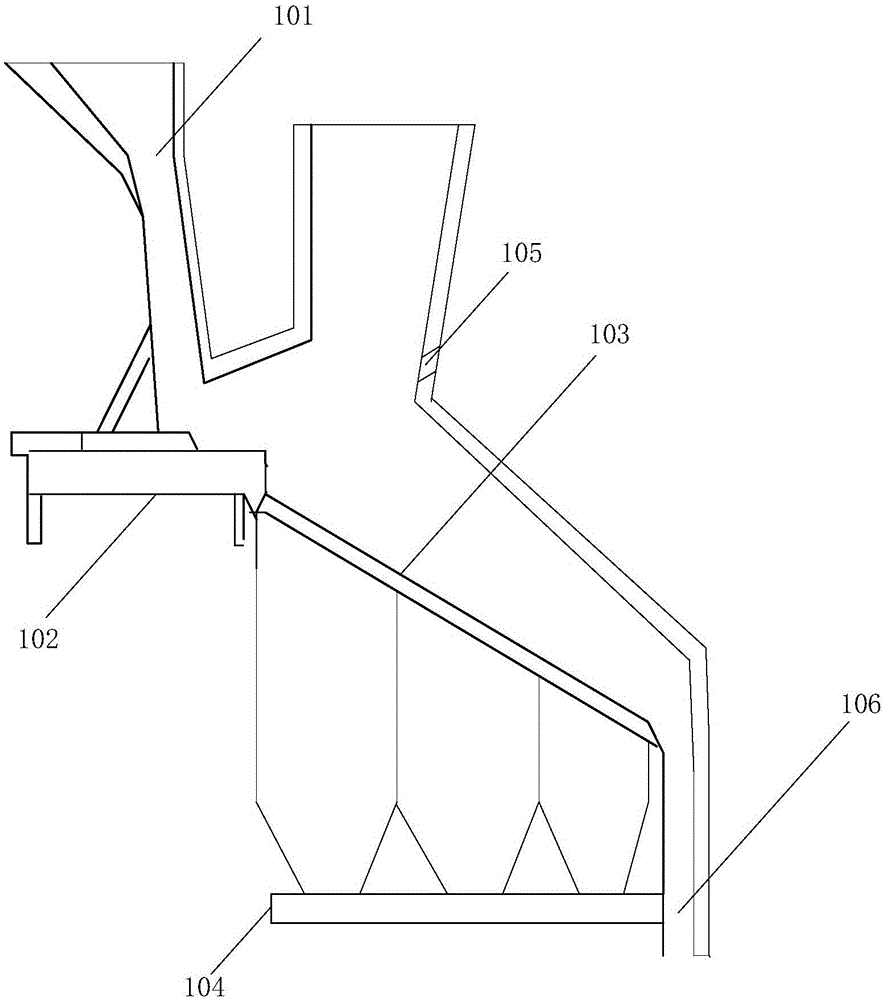

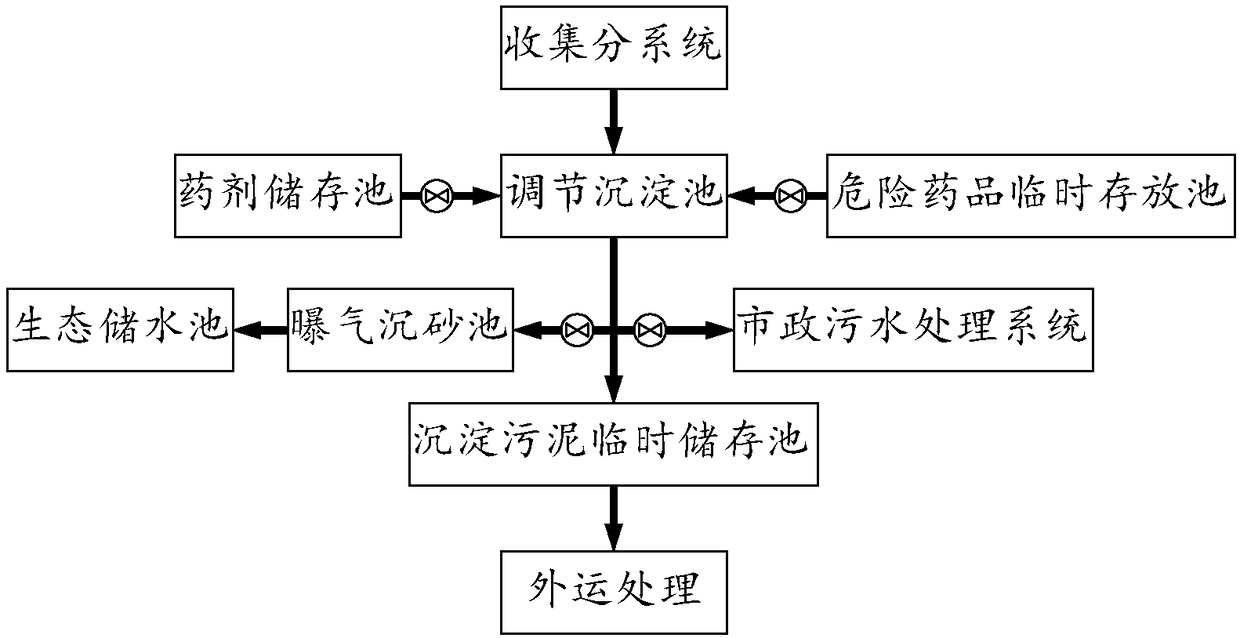

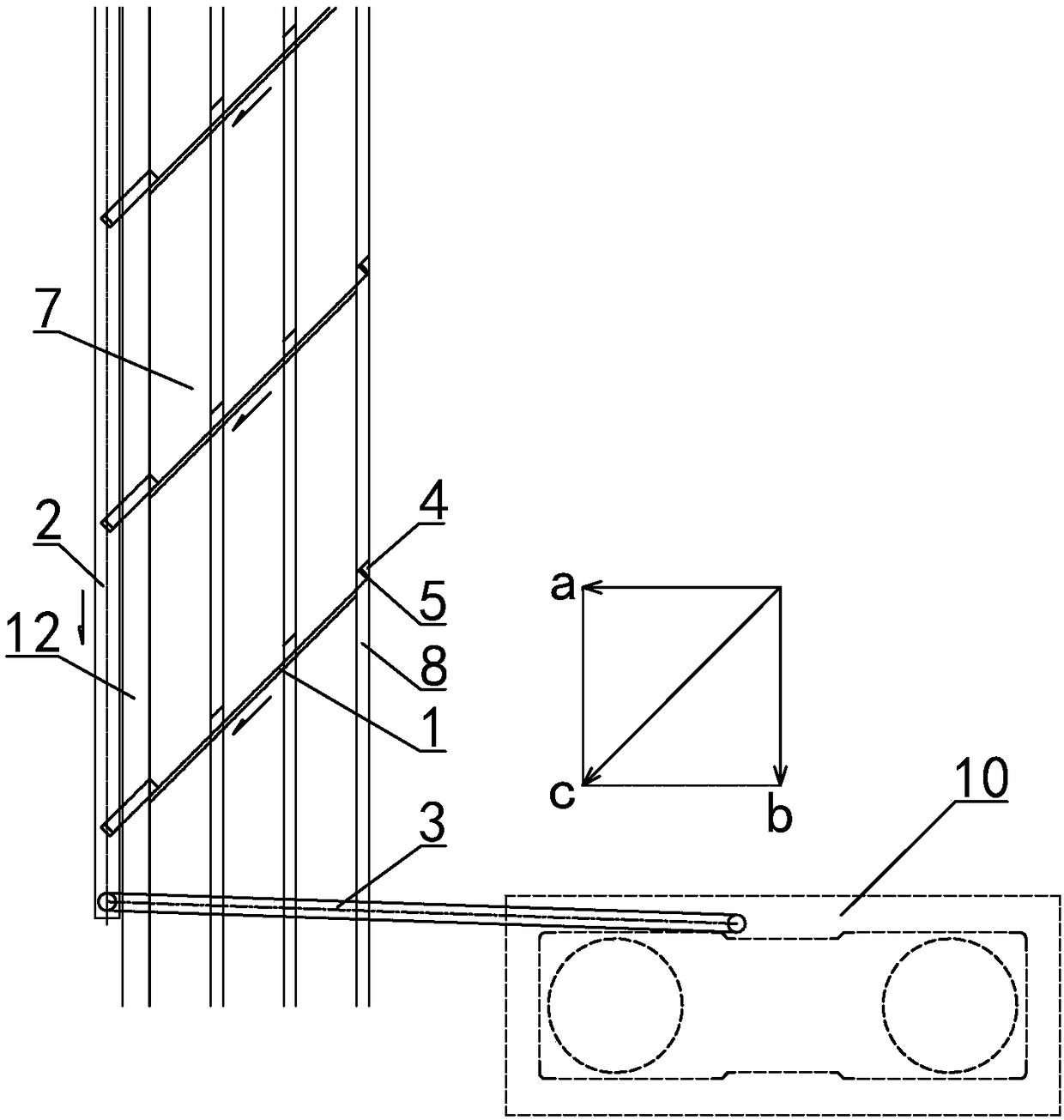

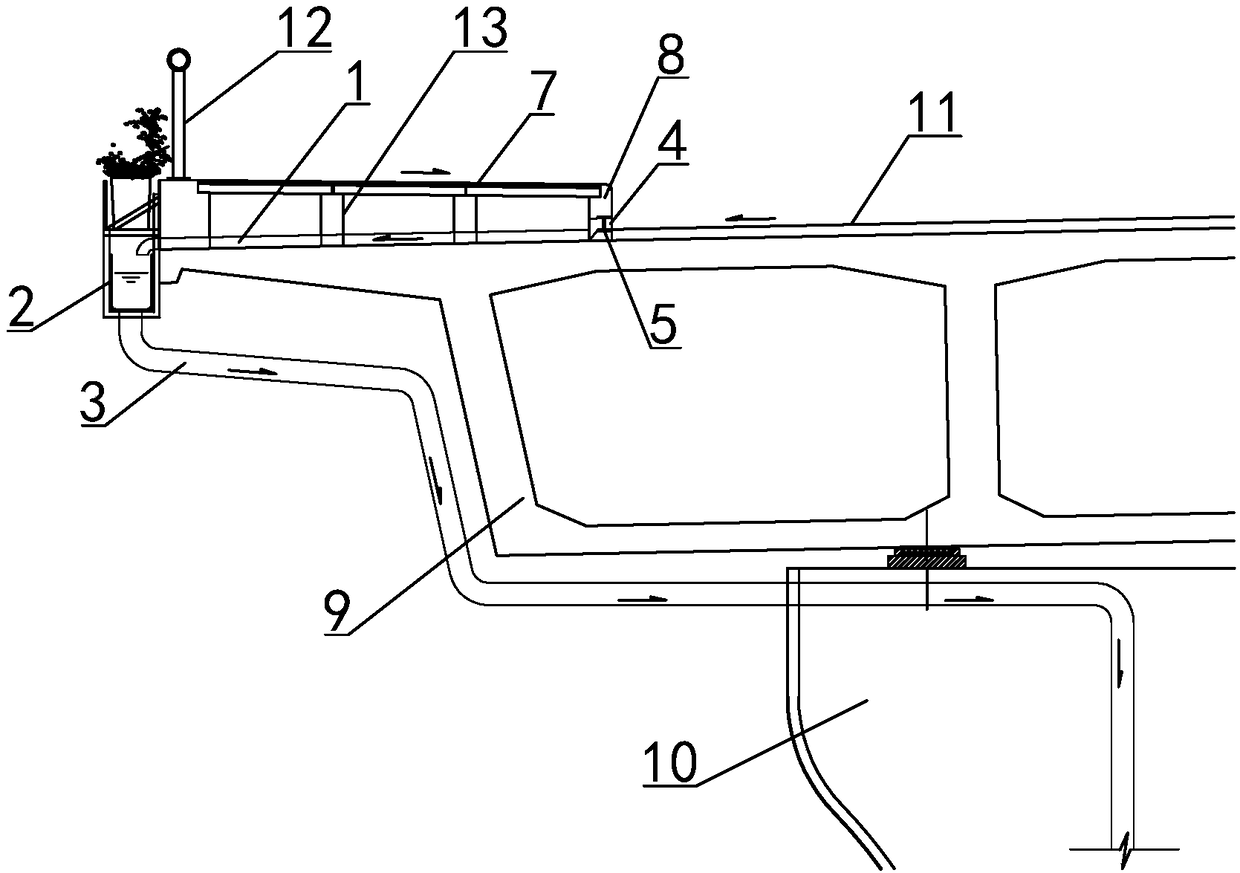

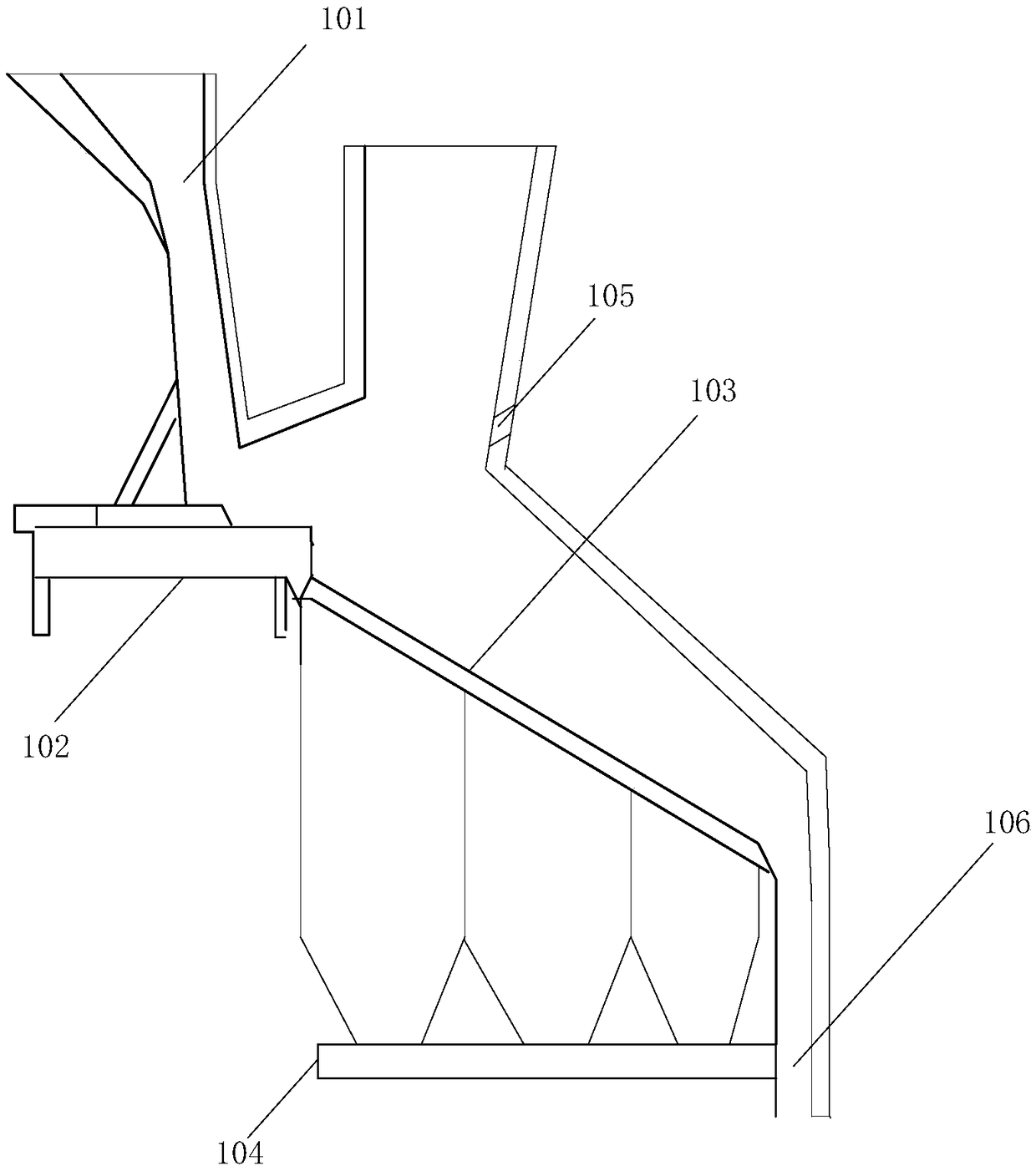

Environment-friendly collection purification system for sewage/wastewater on bridge surface of river-crossing bridge

PendingCN108457178AReduce runoffIncrease collection rateMultistage water/sewage treatmentBridge structural detailsWater dischargeDangerous goods

The invention discloses an environment-friendly collection purification system for sewage / wastewater on the bridge surface of a river-crossing bridge. The system includes a collection subsystem and apurification subsystem, and the collection subsystem includes an obliquely intersected open-type flow guiding groove, a U-shaped drainage groove and a water discharge pipe; the obliquely intersected open-type flow guiding groove is formed in the bridge surface of the bridge, the arrangement direction of the flow guiding groove is obliquely intersected with the longitudinal direction of the bridge,the U-shaped drainage groove is formed below a water outlet of the obliquely intersected open-type flow guiding groove, and the upper end of the water discharge pipe is communicated with the end of the U-shaped drainage groove. The purification subsystem includes an adjustment settling pond, an aeration grit chamber, a medicament storage pond, a dangerous medicine temporary storage pond, a settling silt temporary storage pond and an ecological water reservoir; the adjustment settling pond is connected with the lower end of the water discharge pipe, a water inlet control valve is arranged between the adjustment settling pond and the aeration grit chamber, the adjustment settling pond is connected with a municipal sewage disposal system through a pipeline, and the aeration grit chamber is connected to the ecological water reservoir through a pipeline. By means of the system, purification and emergency treatment can be conducted on rainwater, wastewater and liquid dangerous goods on thebridge surface; the guarantee degree is high, the efficiency is high, and the effect is great.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

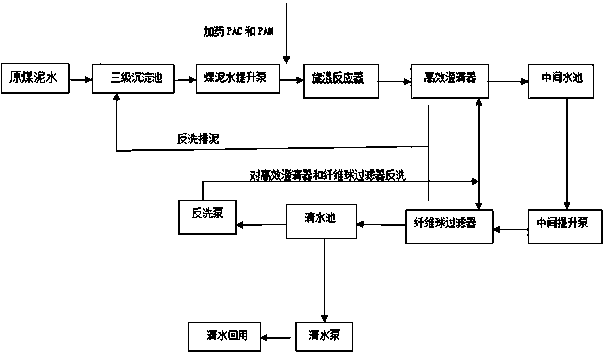

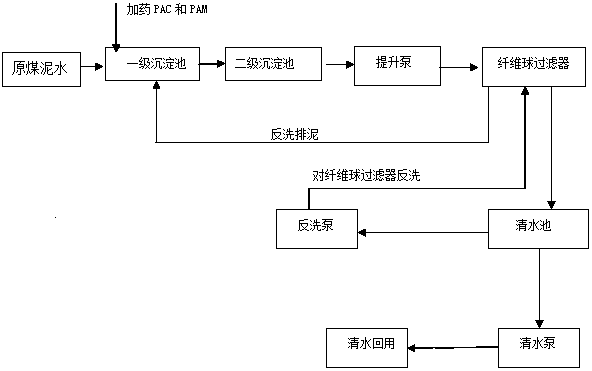

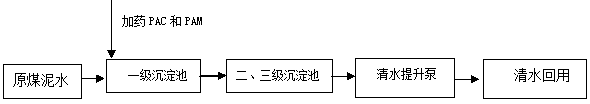

Coal-containing wastewater treatment reconstruction device for coal transportation

PendingCN109293044AReduce dosageLow operation and maintenance costsTreatment involving filtrationMultistage water/sewage treatmentFiberExisting Treatment

The invention discloses a coal-containing wastewater treatment reconstruction device for coal transportation, and belongs to the technical field of wastewater treatment. The device comprises a primarysedimentation tank for introducing raw coal mud water, the primary sedimentation tank is connected with a dosing system, a labyrinth parry is arranged in the primary sedimentation tank, overflowing sewage of the primary sedimentation tank enters a secondary sedimentation tank, effluent water of the secondary sedimentation tank enters a fiber ball filter through an elevator pump, the water outletof the fiber ball filter is connected with the water inlet of a clear water tank through a non-return valve, and effluent water of the clear water tank goes through a clear water pump and then is reused; and the clear water tank is also connected with a backwashing pump, the water outlet of the backwashing pup is connected with the backwashing water inlet of the fiber ball filter, and the backwashing water outlet of the fiber ball filter is connected with the primary sedimentation tank. The coal-containing wastewater treatment reconstruction device has the advantages of simplification of an existing treatment device, reduction of the investment cost, and stability and high efficiency in running.

Owner:国能常州发电有限公司

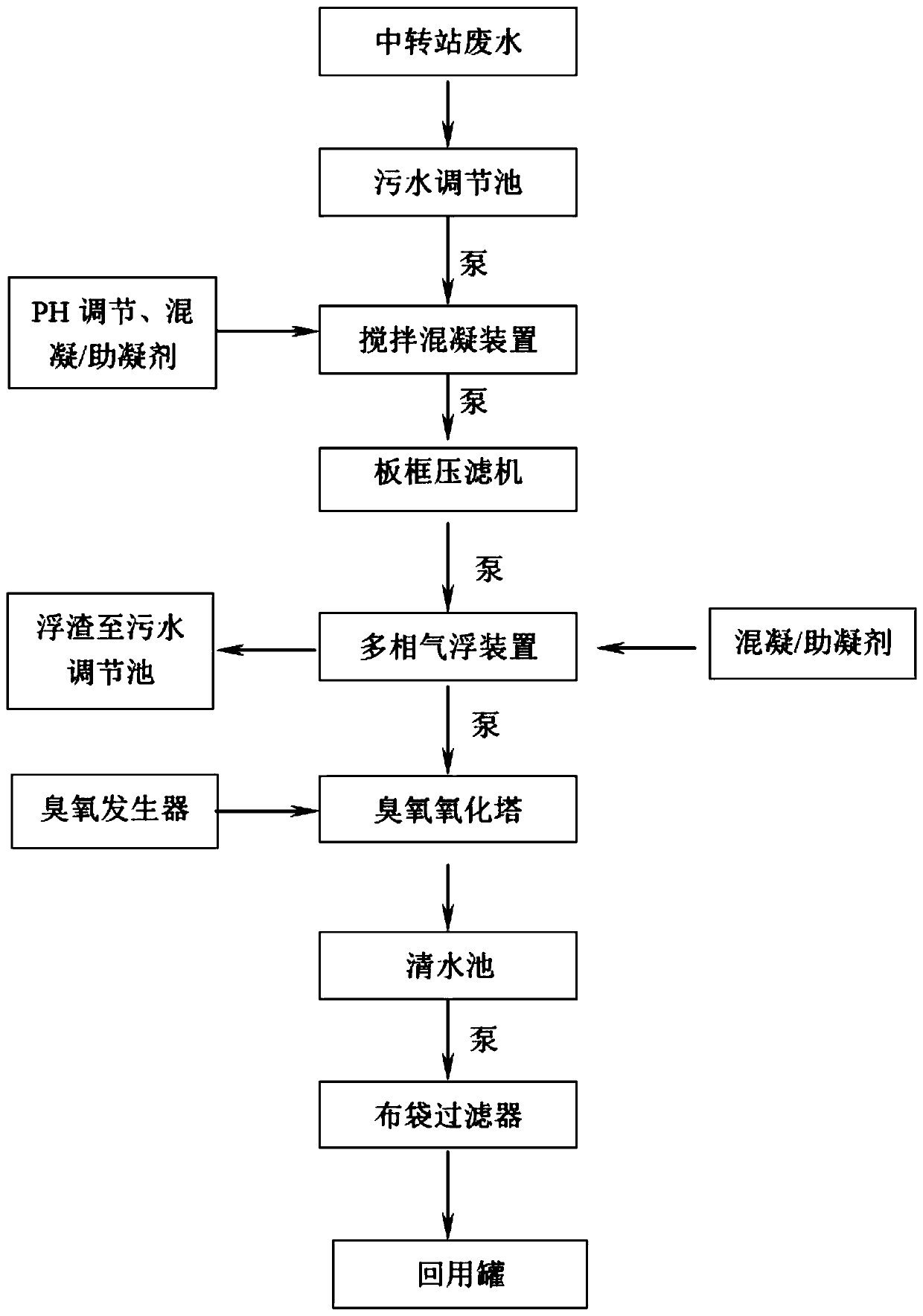

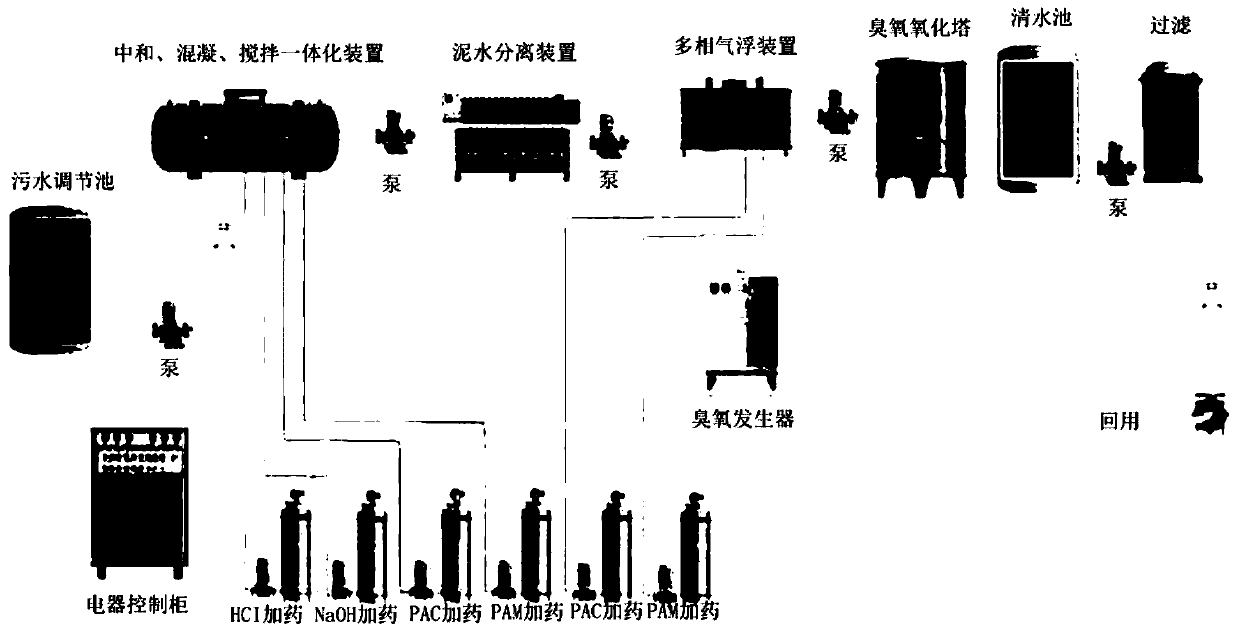

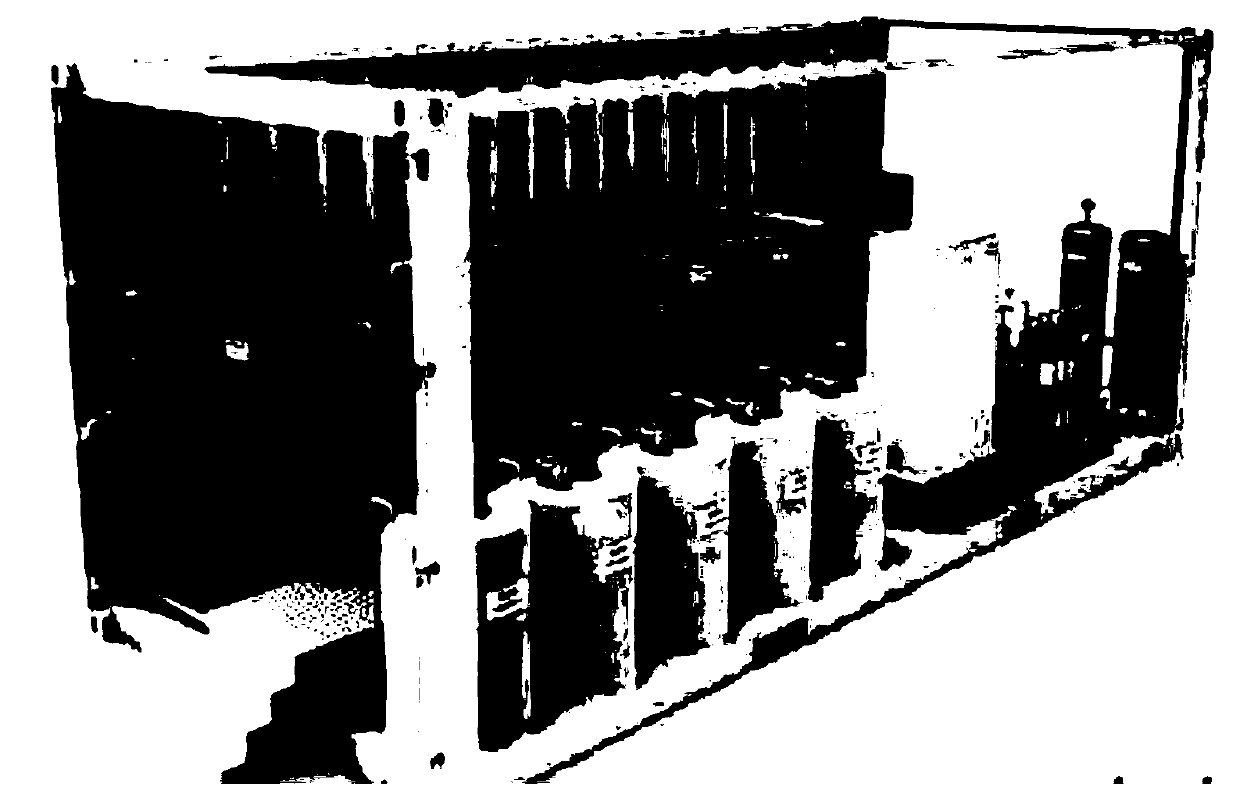

System and method for treating and recycling sewage of portable garbage transfer station

PendingCN110835184ASimple handling systemEasy to expandSludge treatmentPaint waste treatmentWater useOzone generators

The invention discloses a system and a method for treating and recycling sewage of a portable garbage transfer station. Sewage is sequentially treated through the following devices: a sewage adjustingtank for storing sewage and stabilizing the water quality; a neutralization, coagulation and stirring integrated device connected with a dosing device; a mud-water separation device adopting a plate-and-frame filter press; a multiphase air flotation device connected to the dosing device and comprising a pressure air dissolving system, a dissolved air release system and an air flotation separationsystem, wherein the pressure air dissolving system comprises a multiphase flow dissolved air water pump and an air-water buffer tank, and the dissolved air release system comprises a pressure regulating valve and a dissolved air water pipeline; an ozone oxidation tower is connected with an ozone generator; and a cloth bag filter. The system and the method are used for meeting the actual water consumption condition of the garbage transfer station.

Owner:南通汇佰川工程技术有限公司

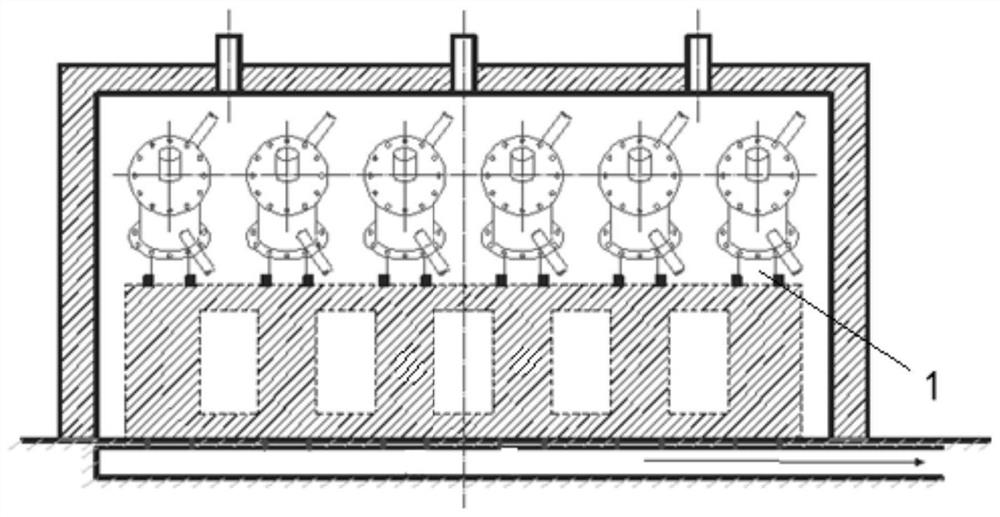

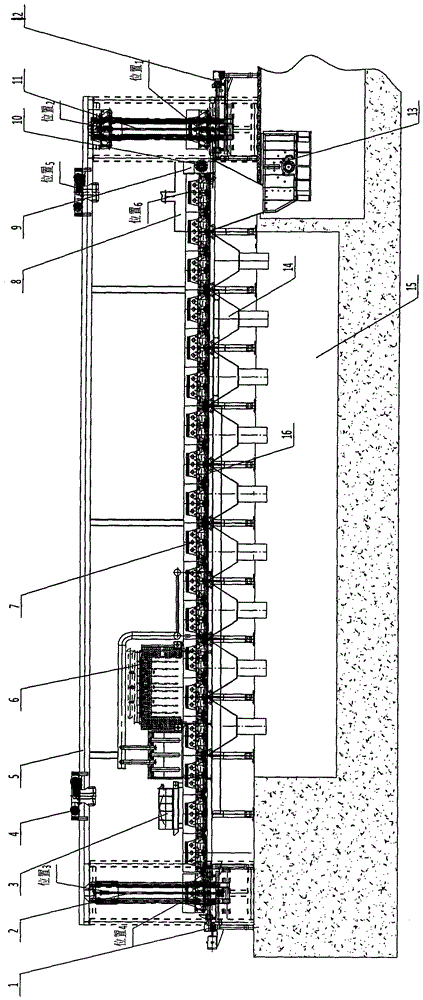

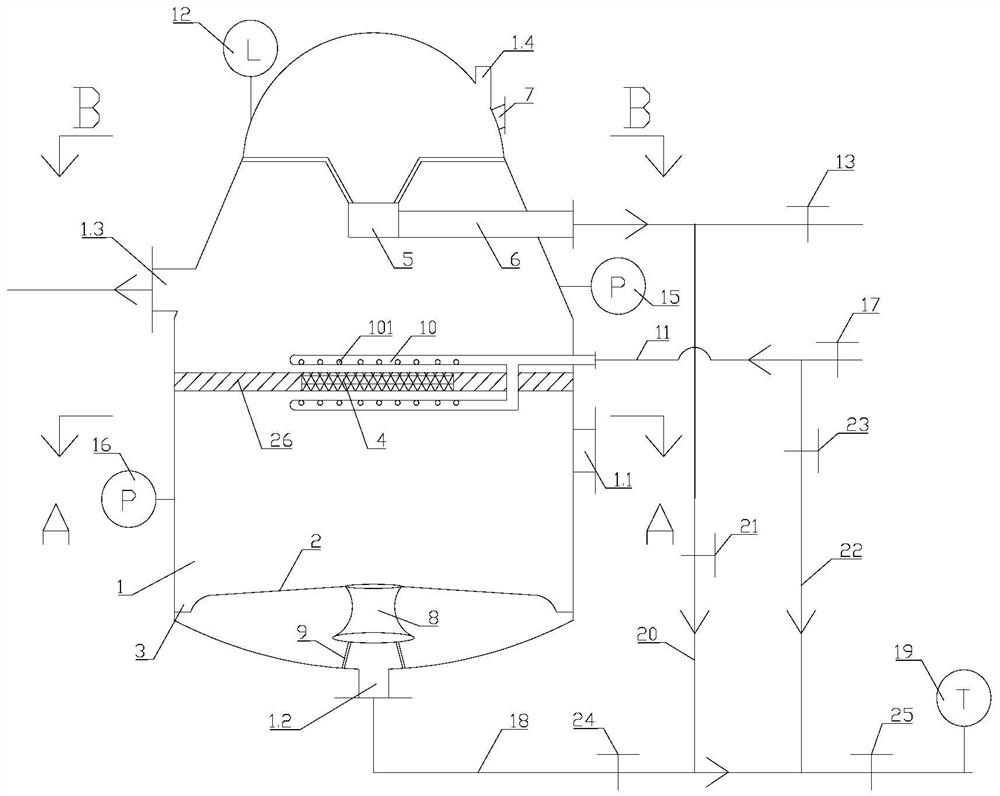

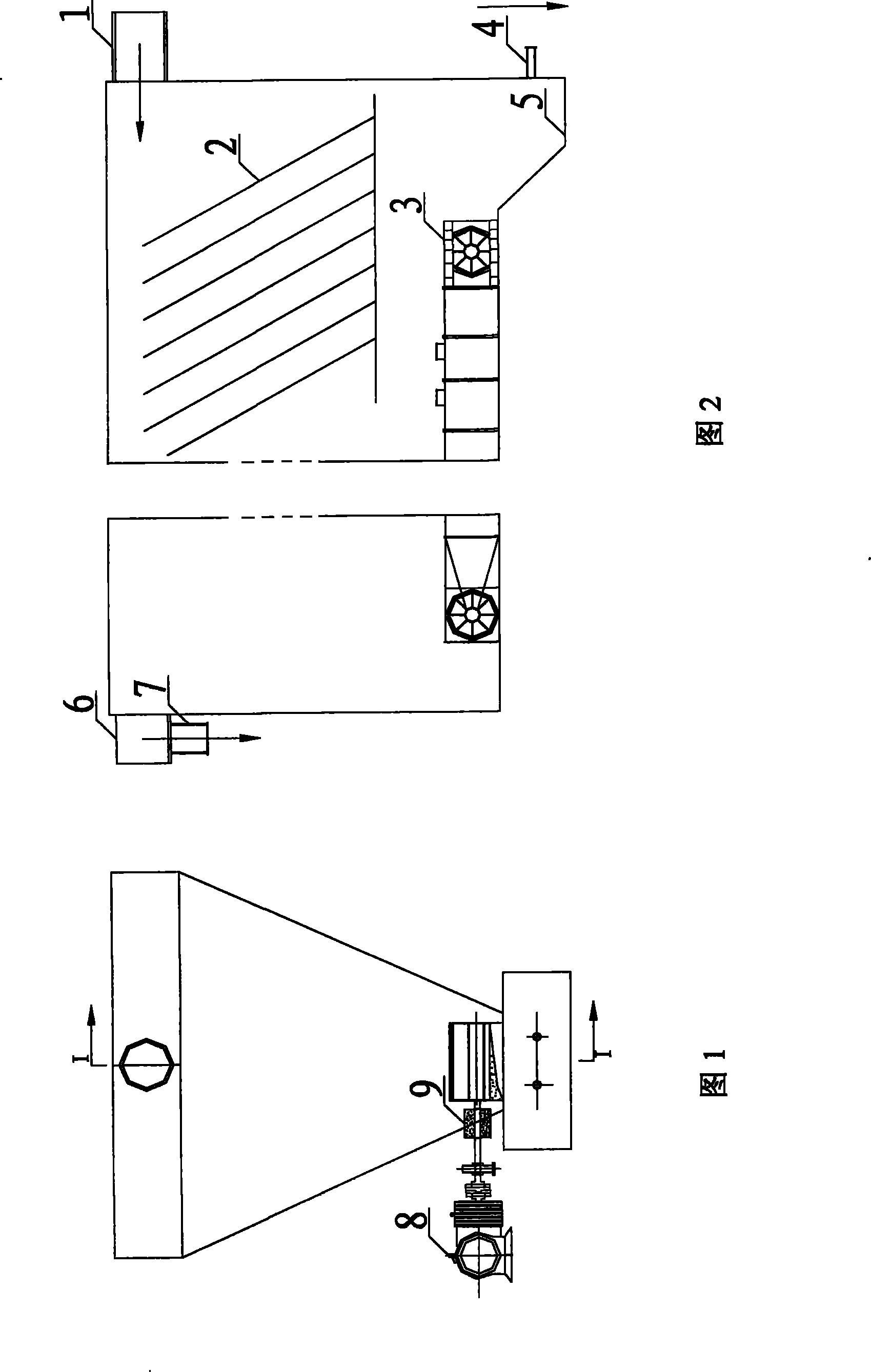

Circulation method and device of bridge type sintering machine

InactiveCN103994660ASimple handling systemSimple and reliable handling systemFurnace typesBridge typePropeller

The invention relates to a circulation method and device of a bridge type sintering machine. The circulation method and device of the bridge type sintering machine are particularly applicable to sintering of iron ore powder in the metallurgical industry and sintering for production of fly ash or industrial tailing ceramsite in the architectural material industry. The circulation device comprises a furnace trolley propeller, an igniter, an unloading machine, a furnace trolley lifter, a furnace trolley carrying power trolley and a crusher. Four to one hundred furnace trolleys are arranged on a sintering line linearly and share one dust collection chamber. A carrying trolley track is arranged above the furnace trolleys. The furnace trolley carrying power trolley walks on the track. An induction chamber is arranged below each sintering furnace trolley. The lower portion of each induction chamber is provided with an induction chamber pipeline communicated with the duct collection chamber. The brand new circulation method and device of the sintering machine are provided, the problem that all sintering machines always have the defects of equipment waste and low efficiency due to returning of empty furnaces after unloading is solved, and the purposes of improving yield, reducing equipment and investment and largely improving system operation reliability are achieved.

Owner:BEIJING SIDIQI SCI & TECH

Three-in-one garbage incineration method

The invention discloses a three-in-one garbage incineration method. The three-in-one garbage incineration method is characterized by being performed according to the following technological process: (a) pulverized coals are doped in garbage to be mixed for future use; and the doping quantity is 1-5% of the garbage by weight; (b) an emulsifying agent and oil are added in water to prepare emulsifying oil; and the adding quantities of the emulsifying agent and the oil are respectively 1-5% and 30-70% of the water by weight; and (c) the garbage containing the pulverized coals is fed into a boiler hearth for burning; and the prepared emulsifying oil is sprayed into the boiler hearth for burning.

Owner:徐小芹

Circulation method and device of bridge type sintering machine

InactiveCN103994660BSimple handling systemSimple and reliable handling systemFurnace typesBridge typePropeller

The invention relates to a circulation method and device of a bridge type sintering machine. The circulation method and device of the bridge type sintering machine are particularly applicable to sintering of iron ore powder in the metallurgical industry and sintering for production of fly ash or industrial tailing ceramsite in the architectural material industry. The circulation device comprises a furnace trolley propeller, an igniter, an unloading machine, a furnace trolley lifter, a furnace trolley carrying power trolley and a crusher. Four to one hundred furnace trolleys are arranged on a sintering line linearly and share one dust collection chamber. A carrying trolley track is arranged above the furnace trolleys. The furnace trolley carrying power trolley walks on the track. An induction chamber is arranged below each sintering furnace trolley. The lower portion of each induction chamber is provided with an induction chamber pipeline communicated with the duct collection chamber. The brand new circulation method and device of the sintering machine are provided, the problem that all sintering machines always have the defects of equipment waste and low efficiency due to returning of empty furnaces after unloading is solved, and the purposes of improving yield, reducing equipment and investment and largely improving system operation reliability are achieved.

Owner:BEIJING SIDIQI SCI & TECH

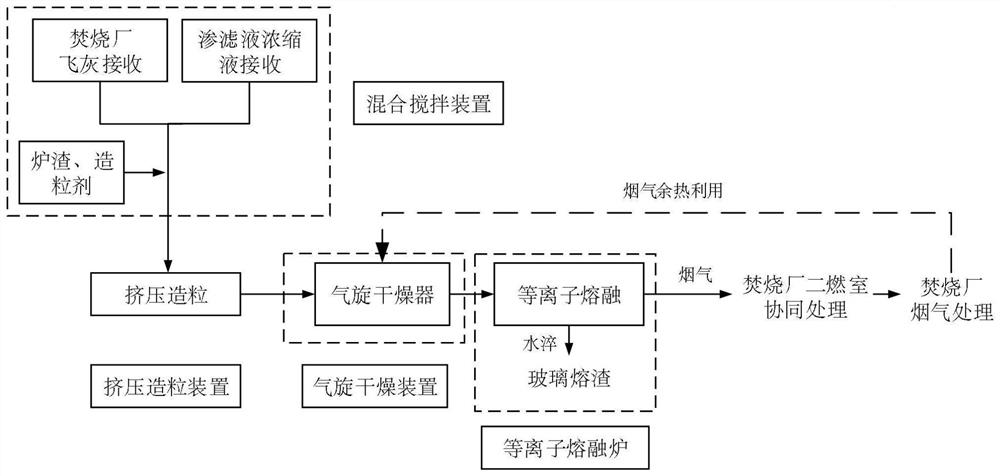

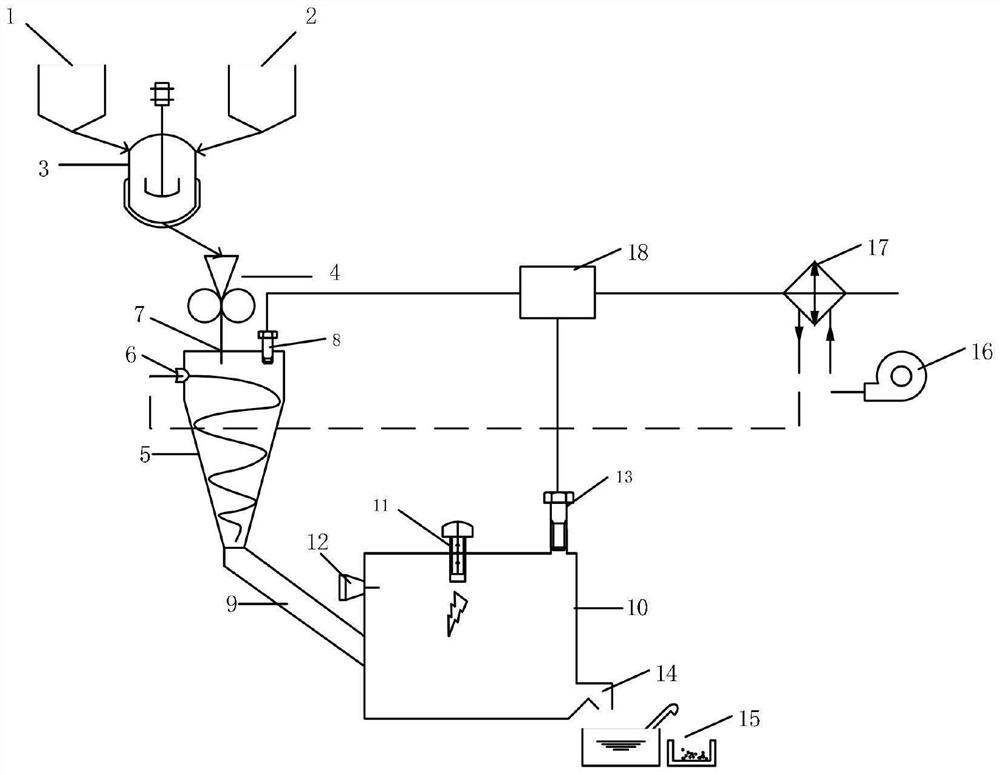

Melting method and system based on co-processing of fly ash and leachate in waste incineration plant

PendingCN114383142ASimple handling systemOptimized process and co-treatment of flue gasGranulation by pressingIncinerator apparatusCombustion chamberFlue gas

The invention discloses a method for co-processing and melting fly ash and percolate in a waste incineration plant. The method comprises the following steps: 1) mixing fly ash and slag generated by the incineration plant or a slag former with the percolate or a concentrated solution of the percolate, and granulating; 2) carrying out hot air cyclone drying on the mixed granulation material; (3) carrying out plasma melting treatment on the granulated material subjected to cyclone drying; (4) the hot flue gas obtained after cyclone drying and the flue gas of the plasma melting furnace are merged into a secondary combustion chamber of an incineration plant for secondary combustion; (5) flue gas waste heat is utilized for heating air circulation cyclone drying; fly ash generated by an incineration plant and a leachate concentrated solution are mixed and granulated, plasma melting treatment is performed after cyclone drying, generated flue gas enters a secondary combustion chamber of the incineration plant for collaborative incineration treatment, and slag is subjected to water quenching to obtain a glassy product for resource utilization. The removal of dioxin and organic matters in the fly ash and the leachate and the effective fixation of heavy metals are realized, the treatment system is simple, and the dual effects of harmless recycling of the fly ash and the leachate concentrated solution are realized.

Owner:NANJING WONDUX ENVIRONMENTAL PROTECTION TECH CO LTD

Waste incineration method

The invention discloses a waste incineration method. The method is characterized by the following process flow: a, mixing pulverized coal into waste and keeping the mixture for later use, the mixing amount of the pulverized coal is 5-10% by weight of the waste; b, adding an emulsifier and oil into water to prepare emulsified oil, the adding amounts of the emulsifier and the oil are respectively 5-8% and 35-70% by weight of the water; and c, sending the waste with the pulverized coal into a boiler furnace for combustion, and spraying the prepared emulsified oil into the boiler furnace for combustion. The purpose of the invention is to provide the waste incineration method which takes the waste as a base material, collects the advantages of the oil and the pulverized coal combustion-supporting material, turns the water into treasure, reduces the total amount of coal combustion, saves energy and reduces cost.

Owner:陈留成

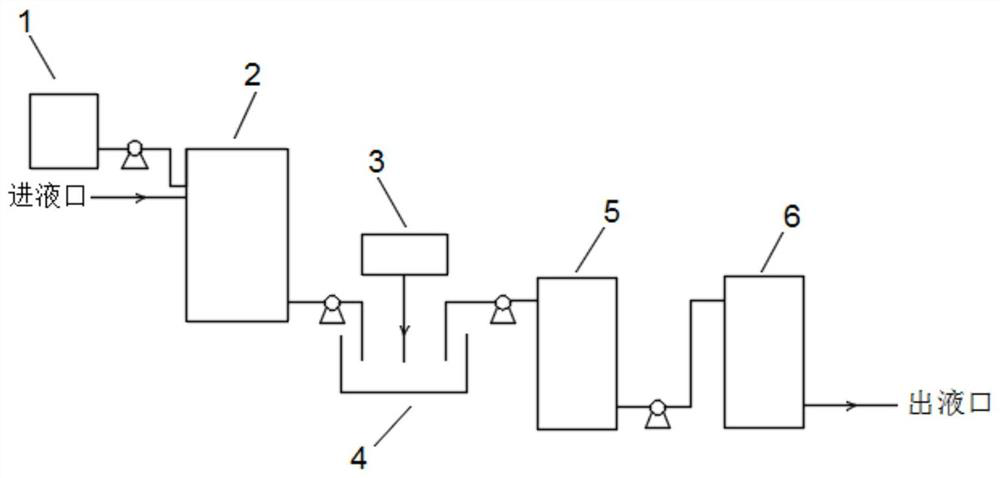

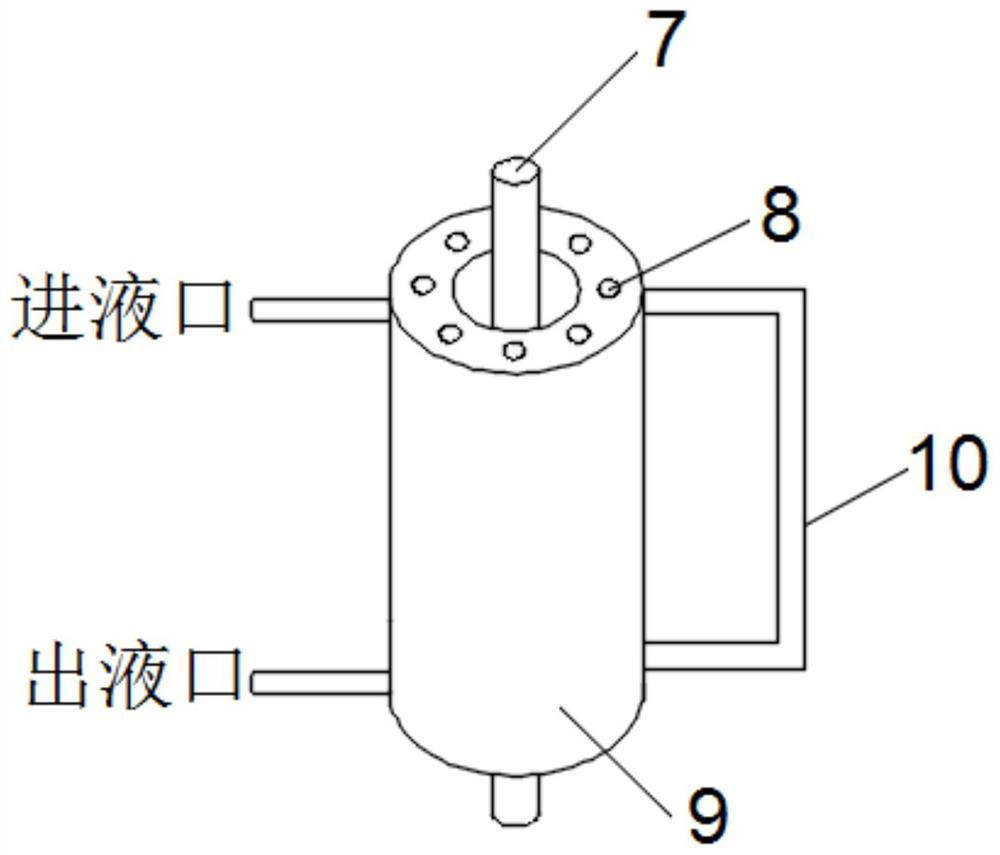

UV photolysis-Me microelectrolysis-Ee electrolysis combined catalytic oxidation wastewater and waste liquid treatment system

PendingCN111875131AAvoid compaction and passivationAvoid plate passivationWater/sewage treatment by irradiationMultistage water/sewage treatmentChemistryLiquid storage tank

The invention discloses a UV photolysis-Me microelectrolysis-Ee electrolysis combined catalytic oxidation wastewater and waste liquid treatment system. The system comprises an acid liquid tank, a photolysis micro-electrolysis coupling treatment device, a liquid storage tank, an electrochemical catalytic oxidation treatment device, a filter and an alkaline liquid tank. In the system, photolysis andmicro-electrolysis treatment are coupled in one treatment device, the synergistic effect of photolysis and micro-electrolysis treatment is brought into full play, the treatment device can be simplified and the wastewater treatment effect can be improved while hardening of micro-electrolysis filler is avoided, and the photolysis and micro-electrolysis coupling device is combined with electrolyticcatalytic oxidation, so that various wastewater with complex components can be treated; therefore, the system has wide applicability and can achieve a good treatment effect without being combined withbiochemical reaction.

Owner:四川春语环保科技有限公司

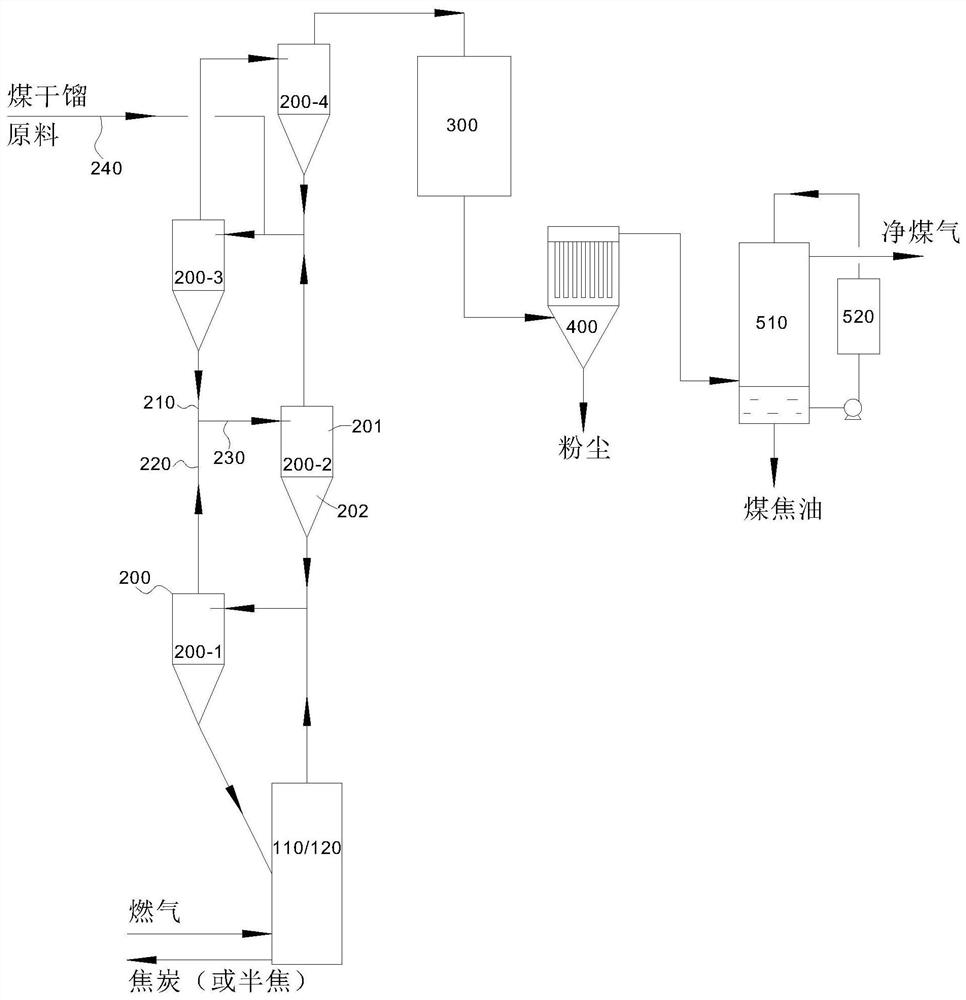

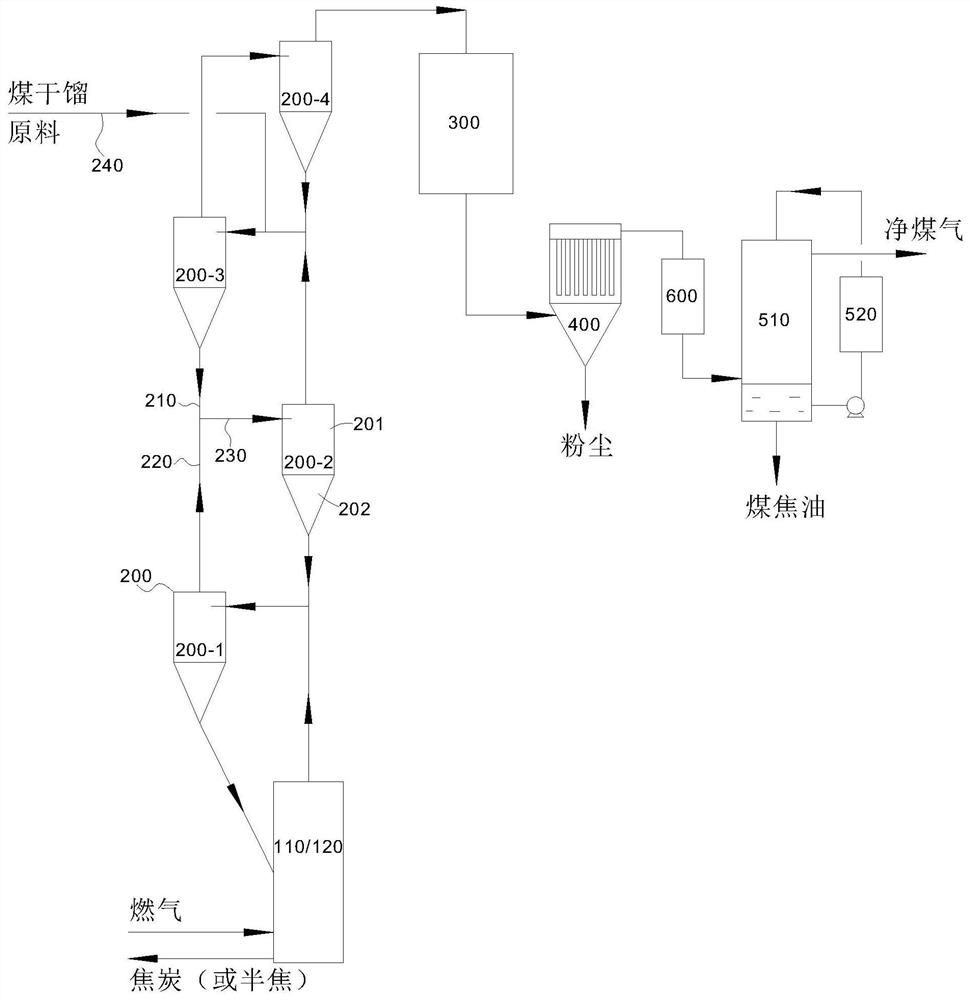

Treatment method of high-temperature dry distillation raw gas

ActiveCN114106890AAchieving High Value RecyclingRealize deep utilizationGas purification by non-gaseous materials condensationGas contaminants removalGas solidThermodynamics

The invention discloses a treatment method of high-temperature dry distillation raw gas, and solves the technical problem that the high-temperature dry distillation raw gas is not fully and efficiently treated in the prior art. The treatment method of the high-temperature dry distillation raw gas comprises the following steps: (1) carrying out pre-decomposition reaction and pre-dedusting on the raw gas from a coal dry distillation rotary kiln or a coal dry distillation furnace and a coal dry distillation raw material, and outputting first gas and solid; (2) drying the first gas, and outputting second gas; (3) carrying out gas-solid separation treatment on the second gas, and outputting third gas; and (4) condensing the third gas, and outputting coal tar and clean gas.

Owner:CHENGDU INTERMENT TECH

X-ray inspecting probe for large container and its preparing process

InactiveCN1129789CReduce volumeReduce weightMaterial analysis using wave/particle radiationElectromagnetic interferenceX-ray

An X-ray probe for inspecting large container is prepared from optical plastics through low-temp polymerizing to make X-ray conversion screen material, high-temp softening, drawing to obtain cone, connecting it with optical fibre by mechanical clamp or fusing, and making inspecting system. Its advantages include small size, light weight, high power to resist electromagnetic interference and simple system.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Solid-containing wastewater separation device and solid-containing wastewater separation control method

PendingCN113683211ASimple structureEasy to implementWater/sewage treatment by centrifugal separationWater treatment parameter controlWastewaterSewage

The invention discloses a solid-containing wastewater separation device and a solid-containing wastewater separation control method. The device comprises a shell, wherein a sewage inlet is arranged along the tangential direction of the shell; a separation plate is horizontally and fixedly arranged in the shell below the sewage inlet; a filter plate is horizontally fixed in the shell above the sewage inlet; a water outlet is formed in the side wall of the shell above the filter plate; and a collecting tank with an opening in the top is fixedly arranged in the shell above the water outlet. The method comprises the steps of (1) conducting primary separation; (2) conducting secondary separation; and (3) conducting third separation. The beneficial effects are that the solid-containing wastewater separation device is simple in structure and easy to implement; the treatment system of the solid-containing wastewater is simplified, the investment of equipment and civil engineering is reduced, and the treatment cost of the wastewater is reduced; the waste of pressure energy is avoided; and the method disclosed by the invention is simple in process, the quality of the wastewater discharged from the water outlet is ensured, and liquid-solid separation in the solid-containing wastewater is effectively realized.

Owner:XINNENG ENERGY CO LTD

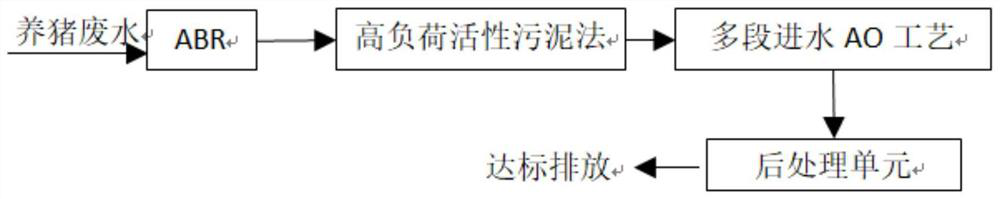

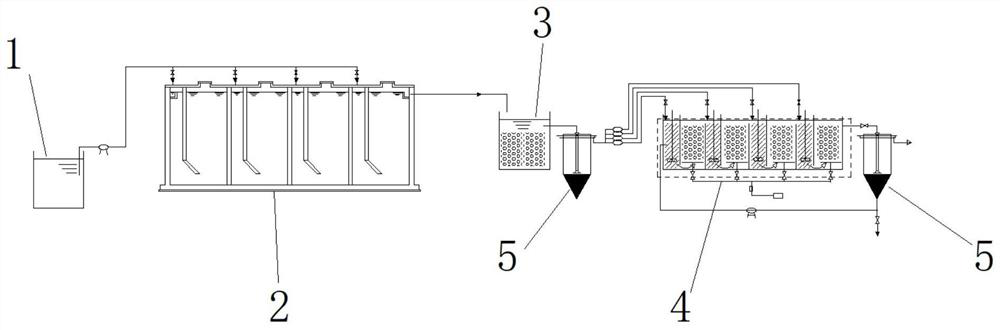

Pig raising wastewater treatment process and system

PendingCN112174451AReduce CODImprove processing efficiencyWater contaminantsWaste water treatment from animal husbandryActivated sludgeTreatment pond

The invention relates to a pig raising wastewater treatment process and system, and belongs to the technical field of livestock and poultry breeding wastewater treatment. The treatment process comprises the following steps: sequentially treating the wastewater by adopting an anaerobic baffled reactor and a sectional water inlet anoxic and aerobic process; the treatment system comprises the anaerobic baffled reactor and a sectional water inlet anoxic and aerobic treatment tank, wherein the anaerobic baffled reactor is communicated with the sectional water inlet anoxic and aerobic treatment tank, and the wastewater sequentially flows through the anaerobic baffled reactor and the sectional water inlet anoxic and aerobic treatment tank to be treated. The anaerobic baffled reactor, the high-load activated sludge process and the sectional water inlet anoxic-aerobic synergistic arrangement form the unification of the functions and the pool body structure, thereby being beneficial to reducingthe occupied area, optimizing the basic investment, enhancing the operation stability and lowering the operation cost.

Owner:CISDI ENG CO LTD

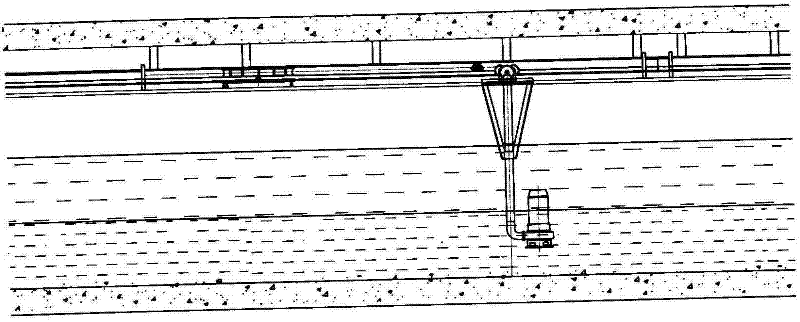

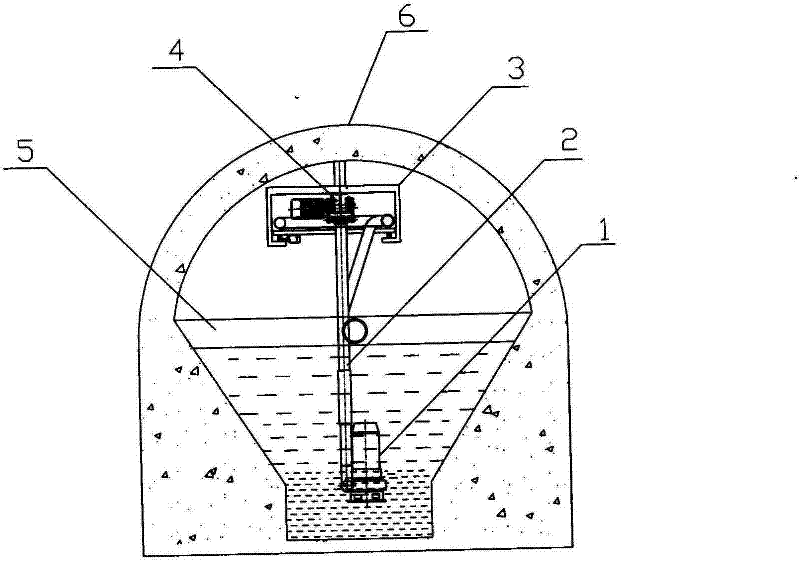

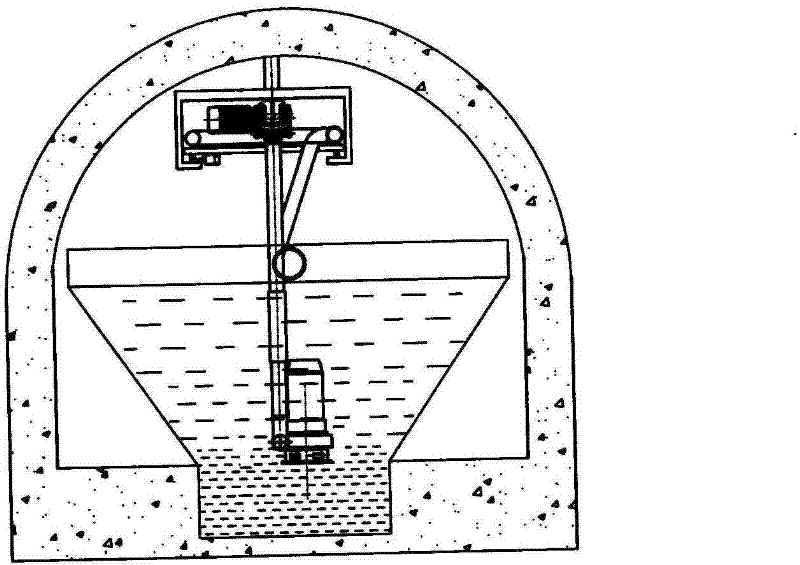

Automatic sludge discharging system for mine sump

InactiveCN101936181BSolve dredging problemsSolve the delivery problemSedimentation separationSludgeSlag

The invention relates to an automatic sludge discharging system for a mine sump. The system comprises a concentration and sedimentation basin, a guide rail device, a moving coil mechanism, a monorail crane and a slurry pump, wherein the concentration and sedimentation basin is arranged in underworkings; the guide rail device is arranged at the top of the concentration and sedimentation basin in the underworkings; the moving coil mechanism is arranged on moving coil mechanism slide rails arranged on both sides of a guide rail device fixing bracket in parallel; the monorail crane is installed on a monorail arranged along the longitudinal central axis of the guide rail device fixing bracket through a guide wheel and a driving mechanism in a suspension mode; and the slurry pump is suspended to the lower part of the monorail crane. The moving coil mechanism comprises a carrier vehicle, a rotary disc and a slag discharging pipe wound around the rotary disc, wherein the carrier vehicle is placed on the moving coil mechanism slide rails through roller wheels arranged on both sides of the bottom surface and driven by a power source, and a vertical shaft for installing the rotary disc is arranged in the central part of the plane of the carrier vehicle; the rotary disc is combined with the vertical shaft arranged in the central part of the plane of the carrier vehicle through an axle hole arranged in the central part in a movable fit mode.

Owner:HENAN POLYTECHNIC UNIV

Treatment system for oxide skin of main valve rod and valve disc of thermal power plant and treatment method

PendingCN113005464ASimple handling systemEasy to operatePipeline systemsMetallic material coating processesEngineeringCitric acid

The invention discloses a treatment system for oxide skin of a main valve rod and a valve disc of a thermal power plant and a treatment method. After the main valve rod and the valve disc with an oxide skin jamming problem are disassembled, high-temperature-resistant and acid-resistant peelable glue is used for coating threads, bare holes and other parts on parts of the valve rod and the valve disc; then the valve rod and the valve disc are put into citric acid cleaning liquid with the concentration being 6%-8% and the pH value being 3.5-4.0, oxide skin on the surfaces of the valve rod and the valve disc is dissolved under the condition of 85-95 DEG C, and after most of the oxide skin is removed and the oxide skin remaining on the surfaces of the parts is loose and soft, dissolving of the oxide skin is completed; the residual cleaning agent on the parts is washed away with alkaline water, and the parts are blow-dried with cold air; and then the valve rod and the valve disc are polished through a mechanical method, and the oxide skin on the surfaces of the parts is cleaned. The treatment system is simple, the treatment method is easy to operate and implement, the removal effect of the oxide skin on the surfaces of the parts such as the valve rod and the valve disc is improved, and the mechanical damage risk of the parts is reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

Percolate lifting device

ActiveCN102251578BInstallation will not affectExtended service lifeSewerage structuresMarine engineeringScrew pump

Owner:WELLE ENVIRONMENTAL GRP CO LTD

Gasification incinerator suitable for high calorific value domestic waste

ActiveCN106352343BSolve various disadvantages caused by incinerationEmission reductionDamper arrangementBlast-producing apparatusFlue gasCombustible gas

The invention provides a gasifying incinerator applicable to household garbage with high heat value. The gasifying incinerator is divided into a gasifying chamber and a secondary combusting chamber, wherein a horizontal grate is arranged at the bottom of the gasifying chamber, and a primary air bin is arranged at the bottom of the grate; the secondary combusting chamber is formed above the gasifying chamber, and secondary air and circulatory flue gas enter a hearth from the side surface of the secondary combusting chamber respectively to promote burn-out of combustible gas in the secondary combusting chamber and reduce the overall temperature of the secondary combusting chamber. The gasifying incinerator can effectively overcome various defects caused by a traditional household garbage incineration way and has the advantages that bottom ash has low carbon content, NOx emission is ultralow, concentration of fly ash is ultralow and the like, a flue gas treatment system is simplified, and investment cost and operation cost are reduced greatly.

Owner:EVERBRIGHT ENVIRONMENTAL TECH CHINA CO LTD

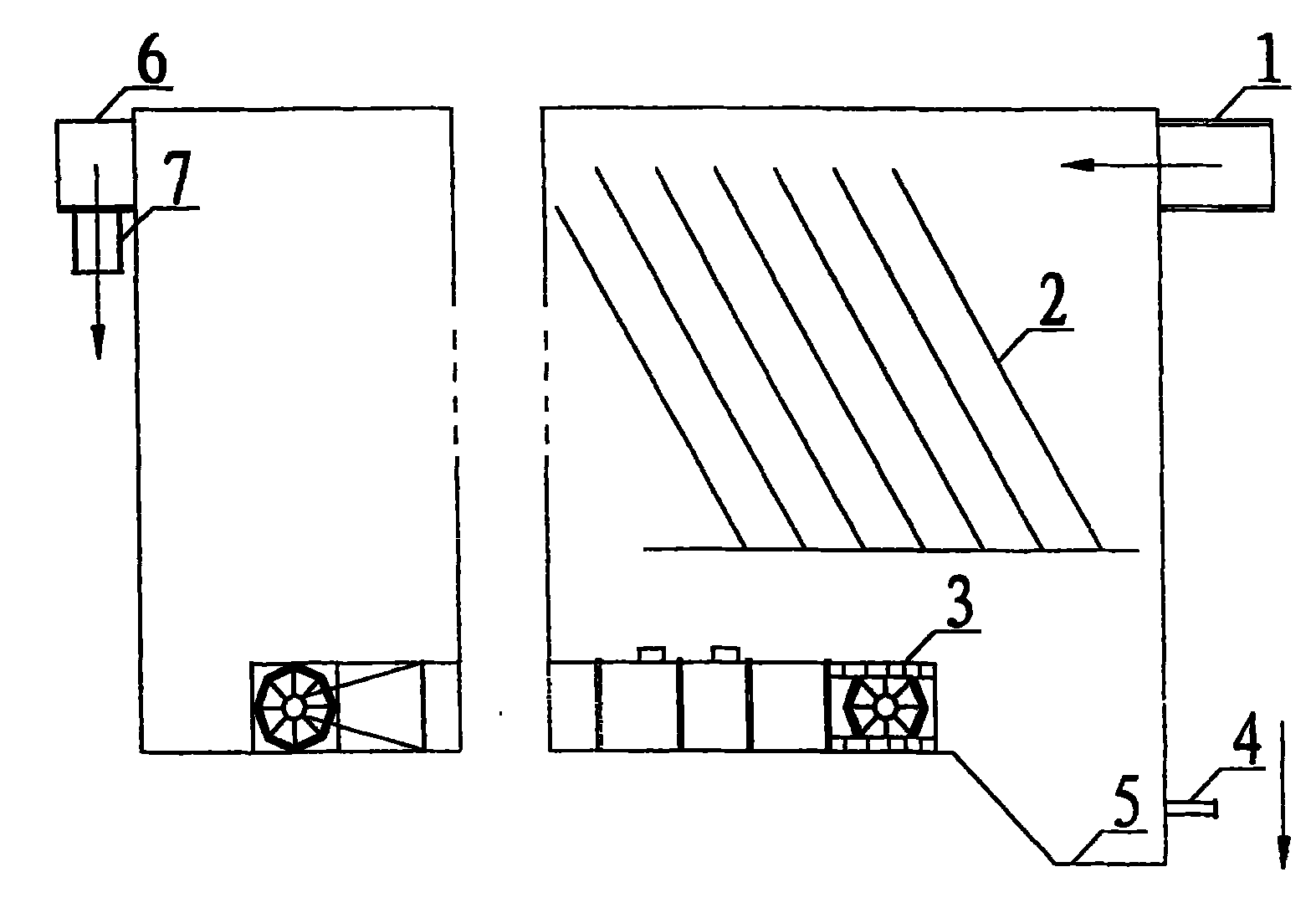

Concentrating and precipitating device under mine and water well

InactiveCN101496964BSolve dredging problemsFull recoverySedimentation settling tanksEngineeringWater well

The invention relates to a concentration and settlement device for use in coal and water wells, which is characterized by comprising a settling pond, a plurality of sloping plates (2), a scraping plate conveyor (3) and a pipe orifice, wherein the settling pond is arranged in an underground roadway and has an integral trapezoidal structure narrowing from top down, the bottom of the pond is provided with an equipment mounting platform and a bottom current pond (6) with a downward concave structure, the edge of the pond is provided with a mine water inlet and an overflow groove and the inclined angle of the side wall of the settling pond is more than 65 degrees; the plurality of sloping plates (2) are arranged on the middle upper part of an inner cavity of the settling pond in a mode of inclining 55 to 65 degrees, and the distance between the sloping plates is 110 to 130 millimeters; the scraping plate conveyor (3) is arranged on the equipment mounting platform arranged on the bottom of the pond and under the sloping plates; and the pipe orifice is used for connecting a slurry pump and is arranged on the side wall of the bottom current pond.

Owner:HENAN POLYTECHNIC UNIV

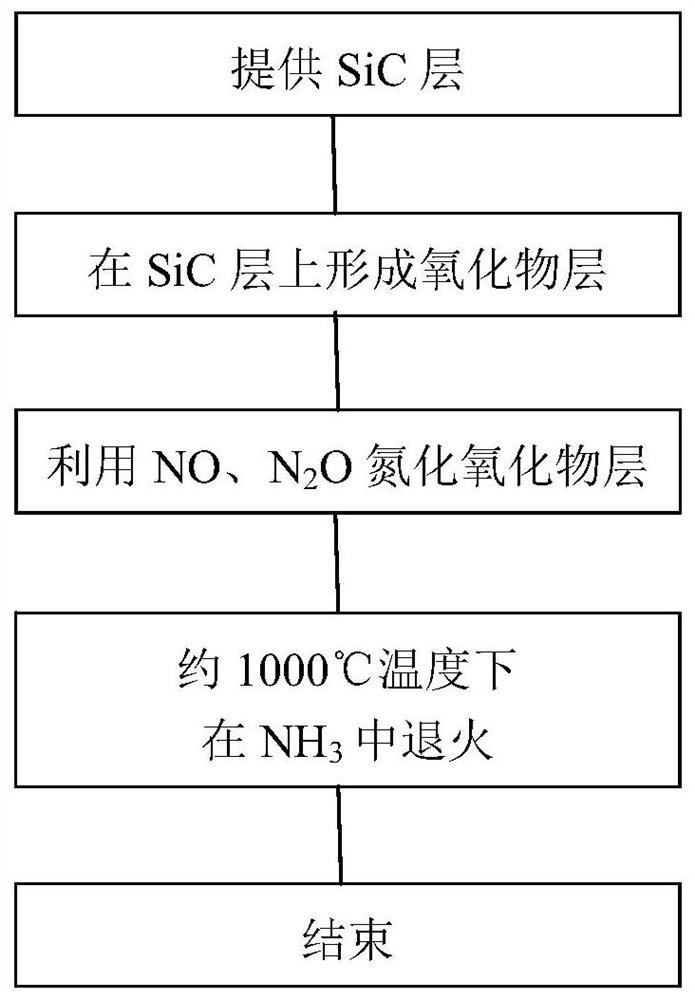

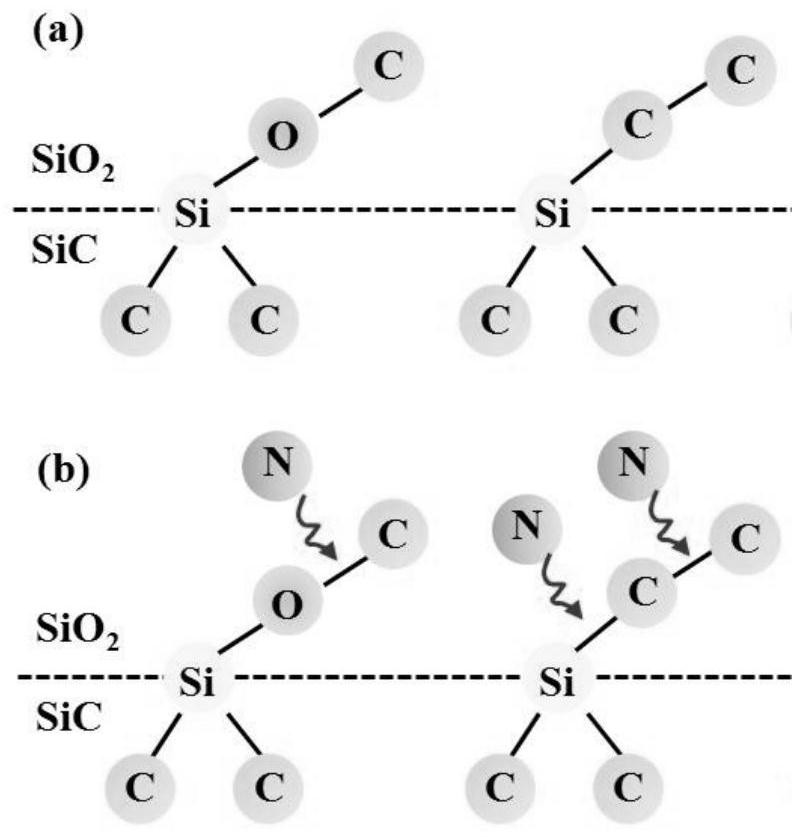

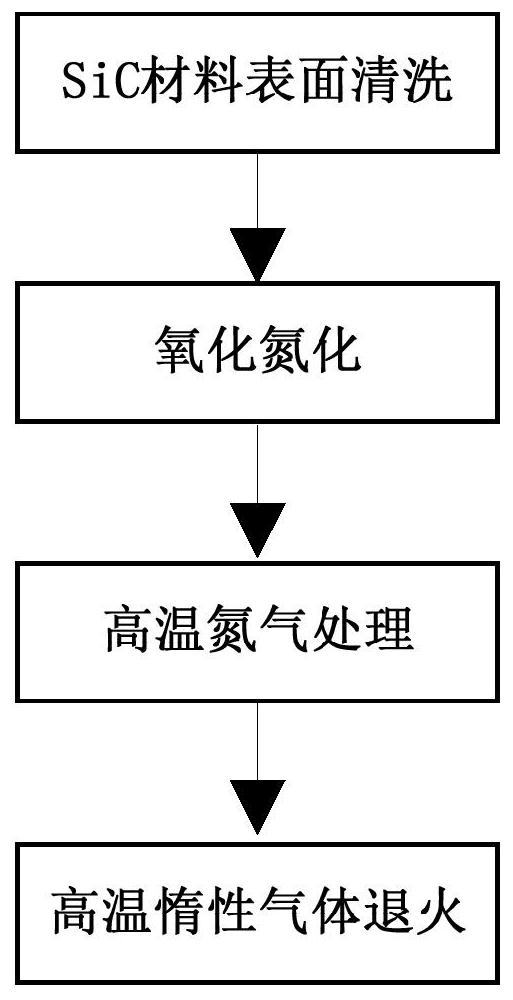

A kind of mosfet device nitriding method

ActiveCN107785270BImprove efficiencyImprove passivation effectSemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETToxic gas

The present invention provides a method for nitriding a MOSFET device, comprising nitriding the MOSFET device with nitrogen-containing gas, preferably the nitriding treatment is performed at a temperature of 1200-1500°C, preferably 1250-1450°C. According to the nitriding method of the power device provided by the present invention, nitrogen is used for nitriding at a high temperature during the oxidation process and / or after oxidation of the device, which simplifies the nitriding passivation gas system, avoids gate dielectric reliability and breakdown electric field strength The reduction of potential toxicity and poisonous gas leakage risk caused by nitriding gas is avoided, and the exhaust gas treatment system is simplified.

Owner:ZHUZHOU CRRC TIMES SEMICON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com