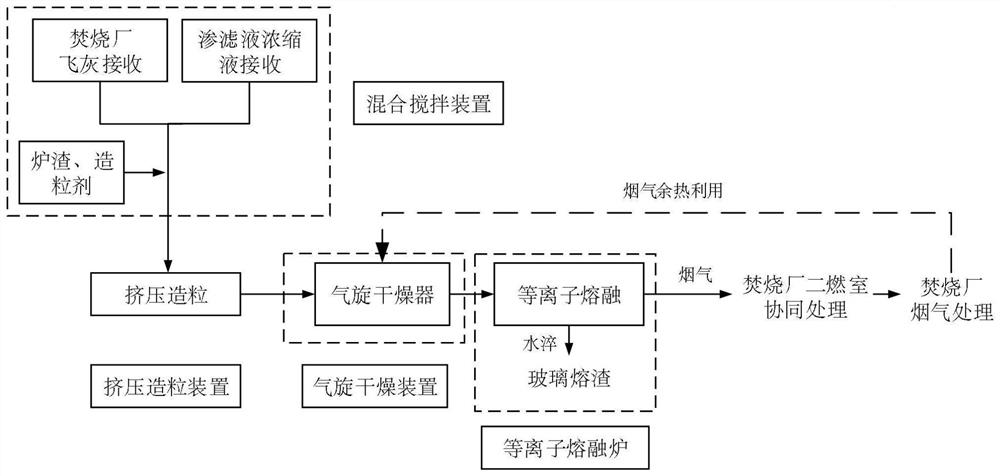

Melting method and system based on co-processing of fly ash and leachate in waste incineration plant

A co-processing and waste incineration technology, applied in the direction of combustion methods, incinerators, combustion types, etc., can solve the problems of shortened service life of equipment, low biodegradability, large overall investment, etc., to achieve optimized process and co-treatment of flue gas, Achieve double resource utilization and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

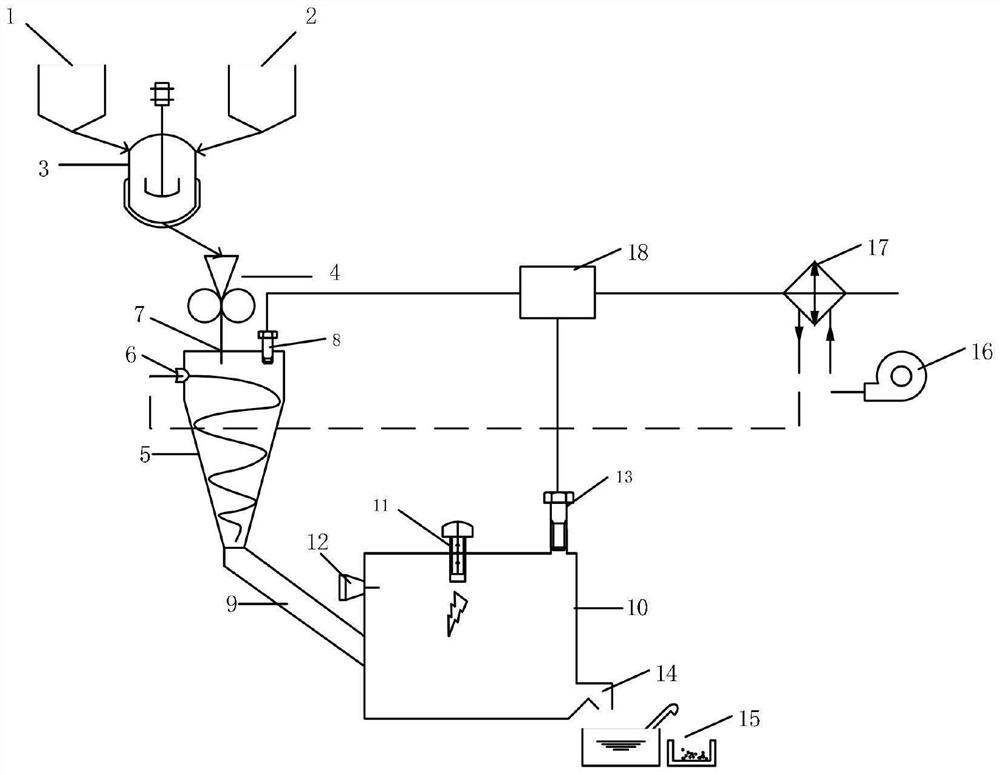

Embodiment 1

[0040] Add 500 kg of fly ash, slag and granulating agent into the storage bin (1), the content of silicon (Si) and aluminum (Al) in the fly ash is about 11%, the content of calcium (Ga) is about 25%, and the content of chlorine (Cl) 11%, insert 3500L of the leachate concentrate into the storage bin (2), the concentration of the concentrate is COD 7800mg / L, TDS 28600mg / L, ammonia nitrogen 80mg / L, then add the mixing and stirring device (3), after stirring for 15min, Import the extrusion granulation device (4) to carry out mixing and granulation, and the particle diameter of the extrusion granulation is about 5-7mm. After the granulation is completed, it is passed into the cyclone drying device (5) for cyclone drying, and the temperature of the hot air is 160°C. Through the blowing off of the hot air, the granulated matter is under the action of its own weight and air flow, and the granulated matter is in the state of rotation. The spiral descends to realize the drying of the gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com