A kind of mosfet device nitriding method

A device and nitriding treatment technology, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem that the interface state density cannot be sufficiently reduced, the reliability of SiO gate dielectric is reduced, and the nitriding passivation effect is reduced, etc. problems, avoiding the reduction of reliability and breakdown electric field strength, avoiding the risk of potential toxicity and poisonous gas leakage, and simplifying the effect of nitriding passivation gas system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0063] According to a preferred embodiment of the present invention, the method further includes: after the oxidation treatment and nitriding treatment, annealing the MOSFET device in an inert gas atmosphere, and then lowering the temperature in an inert gas atmosphere; the preferred annealing temperature is 1200-1500 ℃, the annealing time is 30-120 minutes. The annealing treatment of this step does not contain N 2 Inert atmosphere, such as Ar atmosphere. Further inert gas treatment favors the release of SiO 2 Impurities in the medium improve the compactness of the oxide film.

[0064] Then, the temperature was naturally lowered to room temperature in an inert gas atmosphere without N2, and finally the SiO 2 dielectric SiC epitaxial wafers. Natural cooling in an inert gas atmosphere that does not contain N2 avoids N during the cooling process 2 with SiO 2 Unstable reactions at the / SiC interface, thereby affecting the SiO 2 / SiC interface quality.

[0065] According to...

specific Embodiment 1

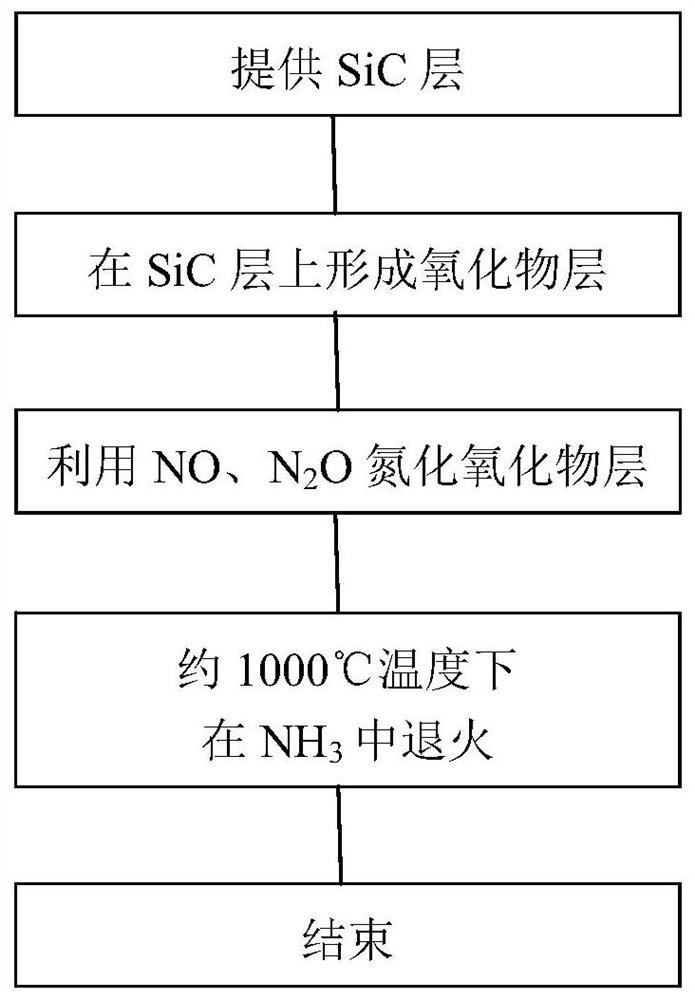

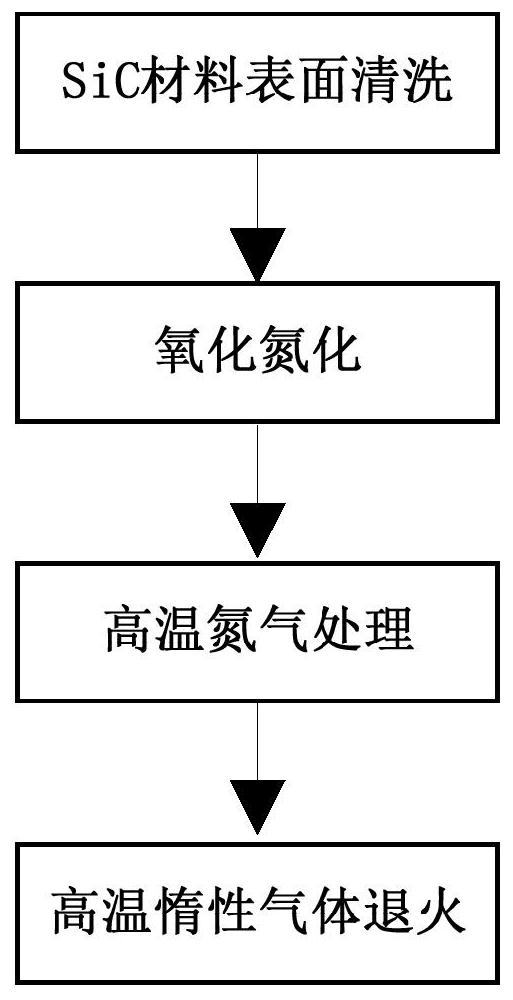

[0074] use as image 3 The operation process shown is to clean the SiC epitaxial wafer of the SiC MOSFET device, perform high-temperature oxidative nitriding treatment, high-temperature nitriding treatment, annealing, and cooling treatment.

[0075] 1) SiC epitaxial wafer cleaning

[0076] The SiC epitaxial wafer of the SiC MOSFET device is cleaned by the RCA cleaning process using SPM solution, APM solution, HPM solution and HF solution (the specific conditions are as above, and the details of the cleaning operation are not described here), and the surface of the SiC epitaxial wafer is removed. Contaminants such as organic matter, particles and metal impurities that may be present.

[0077] 2) SiC epitaxial wafer oxidation and nitriding treatment

[0078] The SiC epitaxial wafer cleaned by RCA was placed in a vertical oxidation furnace, and the temperature was raised to 1350°C, the heating rate was 10°C / min, the gas atmosphere was Ar, and the pressure in the furnace tube wa...

specific Embodiment 2

[0089] 1) SiC epitaxial wafer cleaning

[0090] The SiC epitaxial wafer of the SiC MOSFET device is cleaned by the RCA cleaning process, using SPM solution, HF solution, APM solution and HPM solution to remove the organic matter, particles and metal impurities that may exist on the surface of the SiC epitaxial wafer.

[0091] 2) SiC epitaxial wafer oxidation treatment

[0092] The SiC epitaxial wafer cleaned by RCA was placed in a vertical oxidation furnace, and the temperature was raised to 1350°C, the heating rate was 10°C / min, the gas atmosphere was Ar, and the pressure in the furnace tube was 800mbar.

[0093] After the temperature of the furnace tube of the oxidation furnace is stabilized at the set oxidation temperature, the oxidizing gas (O 2 and H 2 ).

[0094] 3) High temperature nitrogen treatment

[0095]After the oxidation process is completed, the oxidizing gas is turned off, and N is introduced into the furnace tube at a rate of 2.0 slm. 2 , in pure N 2 Ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com