Concentrating and precipitating device under mine and water well

A sedimentation device and well technology, applied in the direction of settlement tanks, etc., can solve the problems of harsh working environment, low cleaning efficiency, long cleaning time, etc., and achieve the effects of simplifying the mine water treatment system, saving infrastructure time, and mature technology

Inactive Publication Date: 2010-12-01

HENAN POLYTECHNIC UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This traditional method not only has a large workload, but also takes a long time to clear and excavate, and the working environment is harsh, and it is difficult to clean and excavate

Mechanized cleaning of mine water tanks is a difficult problem that coal mining enterprises have been eager to solve for many years. However, for decades, dozens of cleaning machines have been developed in my country, but they have not been popularized and used. The main reason is that the situation in the mine is complex and changeable. The water tank dredging equipment and its supporting system have disadvantages such as single performance, low dredging efficiency, and incomplete solid-liquid separation, which cannot adapt to the complex and changeable working environment of the underground tank

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

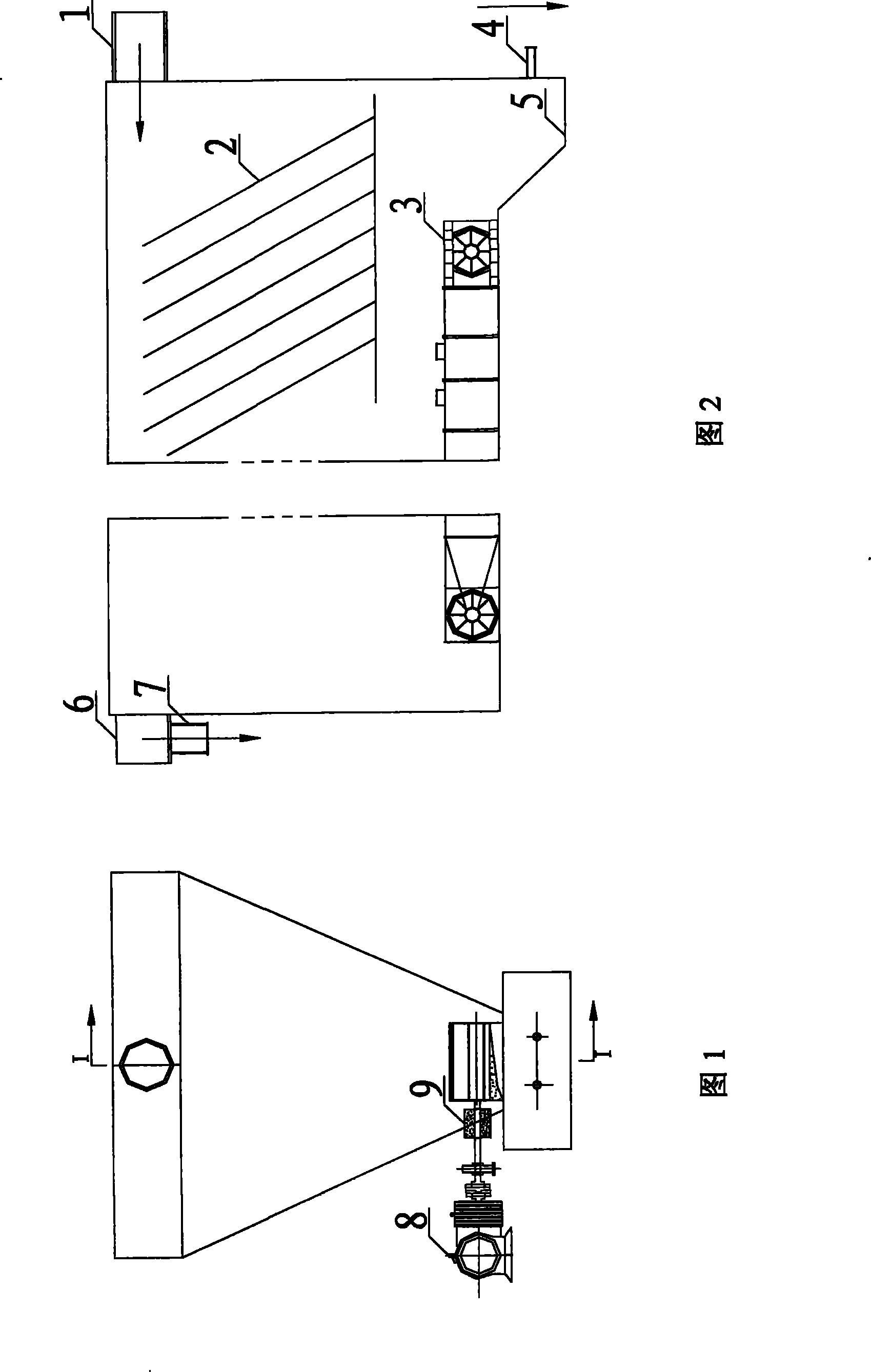

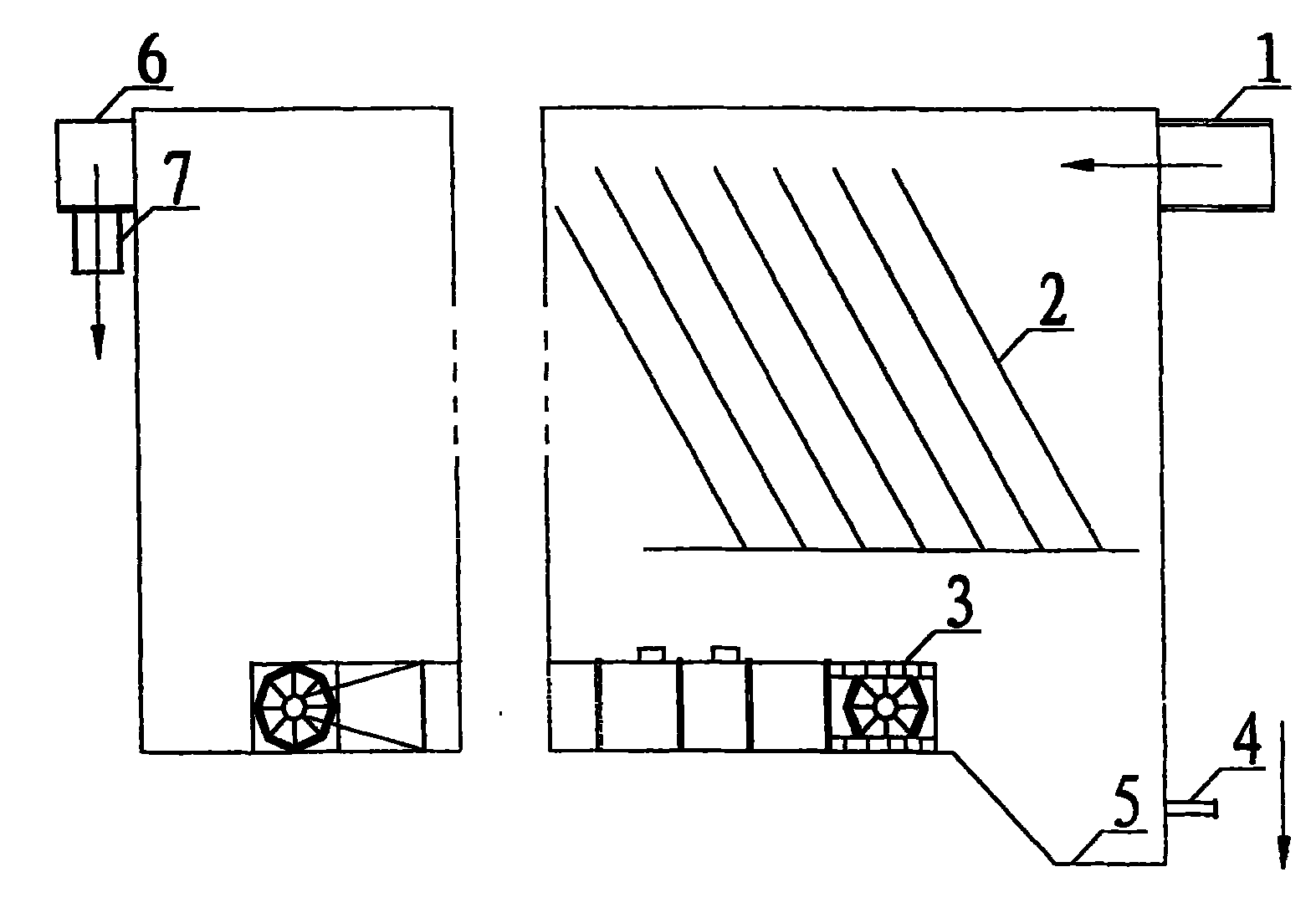

The invention relates to a concentration and settlement device for use in coal and water wells, which is characterized by comprising a settling pond, a plurality of sloping plates (2), a scraping plate conveyor (3) and a pipe orifice, wherein the settling pond is arranged in an underground roadway and has an integral trapezoidal structure narrowing from top down, the bottom of the pond is provided with an equipment mounting platform and a bottom current pond (6) with a downward concave structure, the edge of the pond is provided with a mine water inlet and an overflow groove and the inclined angle of the side wall of the settling pond is more than 65 degrees; the plurality of sloping plates (2) are arranged on the middle upper part of an inner cavity of the settling pond in a mode of inclining 55 to 65 degrees, and the distance between the sloping plates is 110 to 130 millimeters; the scraping plate conveyor (3) is arranged on the equipment mounting platform arranged on the bottom of the pond and under the sloping plates; and the pipe orifice is used for connecting a slurry pump and is arranged on the side wall of the bottom current pond.

Description

Mine water underground concentration and sedimentation device Technical field: The invention relates to an underground concentration and sedimentation device for mine water, which is used for the treatment of underground mine water, and can simultaneously obtain high-concentration underflow and clear overflow water, thus solving the difficult problem of dredging underground water tanks. Background technique: Coal mine water refers to all the water that seeps into the underground mining space during the coal mining process. Mine mines are generally equipped with special water tanks. Mine water is collected in the mine water tank and then pumped out of the well by the drainage system. The mine water tank is an important facility for safe production in coal mines and prevention of mine floods. Since the mine water contains a large amount of impurities mainly including coal slime and sand, these solid particles will be carried into the water tank by the mine water and will be ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01D21/02

Inventor 焦红光惠兵黄定国张传祥高艳阳

Owner HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com