A universal joint transmission lubricating device for easy maintenance

A lubricating device and a maintenance-friendly technology, applied in the direction of gear lubrication/cooling, elastic coupling, mechanical equipment, etc., can solve the problems of damage to the cross shaft and shaft fork related objects, unable to clean the blocked parts, time-consuming and labor-intensive, etc. The effect of increasing stability, simple structure, and increasing the length of the threaded portion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

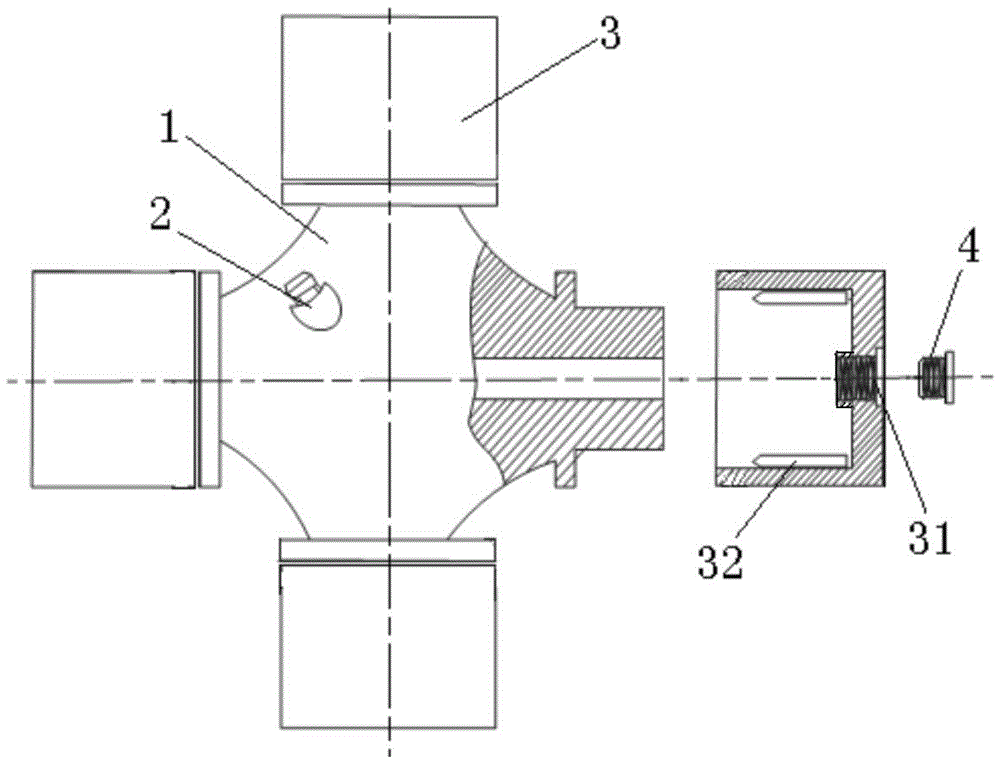

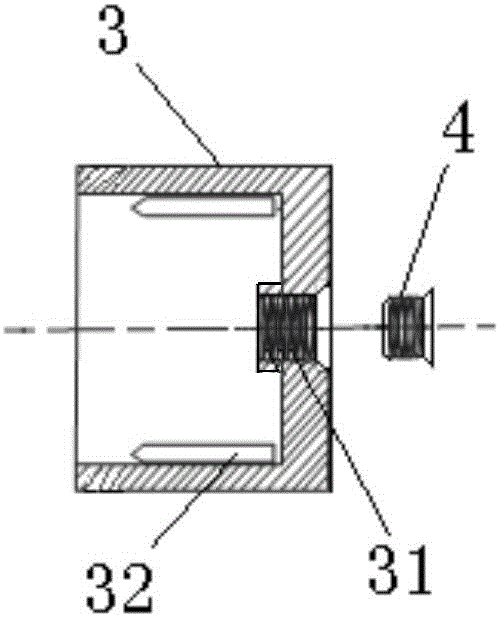

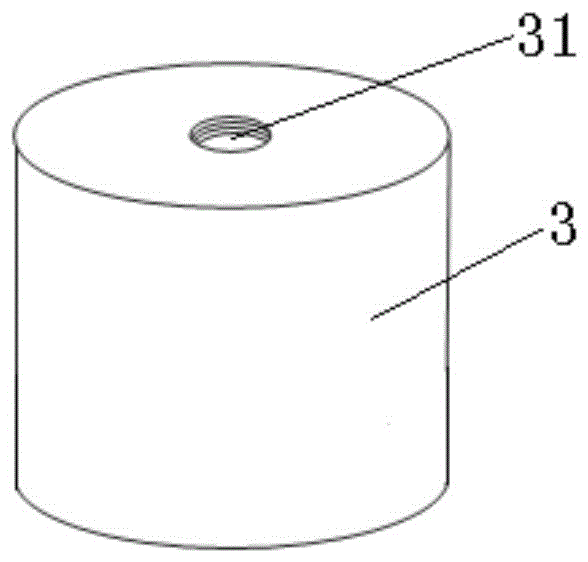

[0035] As shown in the accompanying drawings, a convenient maintenance universal joint transmission lubricating device of this patent includes a shaft fork 5, a cross shaft 1, a grease nozzle 2, a bearing frame 3, a retaining spring 6, and a countersunk screw 4; The oil nozzle 2 is arranged on the cross shaft 1, and the oil channel of the oil injection nozzle 2 communicates with the center of the cross oil channel of the cross shaft; There is a boss, and the center of the outer end surface of the bearing frame 3 is provided with a threaded hole 31 with a groove, the threaded hole 31 runs through the boss, and the center of the threaded hole 31 corresponds to the center of the cross oil channel of the cross shaft 1; In the threaded hole 31, the thickness of the screw head of the countersunk screw 4 is not greater than the depth of the groove on the end surface of the bearing frame 3, and the length of the threaded section of the countersunk screw 4 is not greater than the length...

Embodiment 2

[0043] Embodiment 2 is basically the same as Embodiment 1, only the shape of the groove of the threaded hole on the outer end surface of the retaining spring 6, the countersunk head screw 4 and the bearing frame 3 is different, and the retaining spring 6 is provided with a protrusion formed by indenting toward the center at the position opposite to the opening. The top of the protrusion is located at the center of the circlip, the bottom end is an open structure, and the length of the protrusion is greater than the radius of the circlip; the screw head of the countersunk screw 4 is a cone, and the grooved thread on the outer end surface of the bearing frame 3 The groove of the hole is set as a conical groove according to the shape of the screw head, and the groove on the end face of the screw head is a "one" shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com