Automatic sludge discharging system for mine sump

A technology of automatic drainage and water tank, applied in chemical instruments and methods, separation methods, sedimentation separation, etc., can solve the problems of harsh working environment, incomplete solid-liquid separation, low cleaning efficiency, etc., and achieve simplified mine water treatment system , The roadway excavation technology is mature, and the effect of saving infrastructure time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

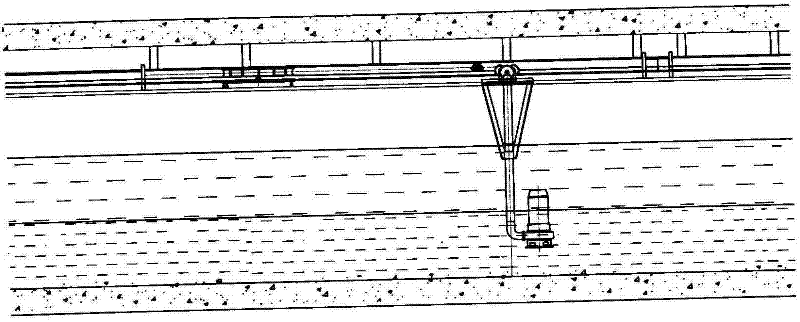

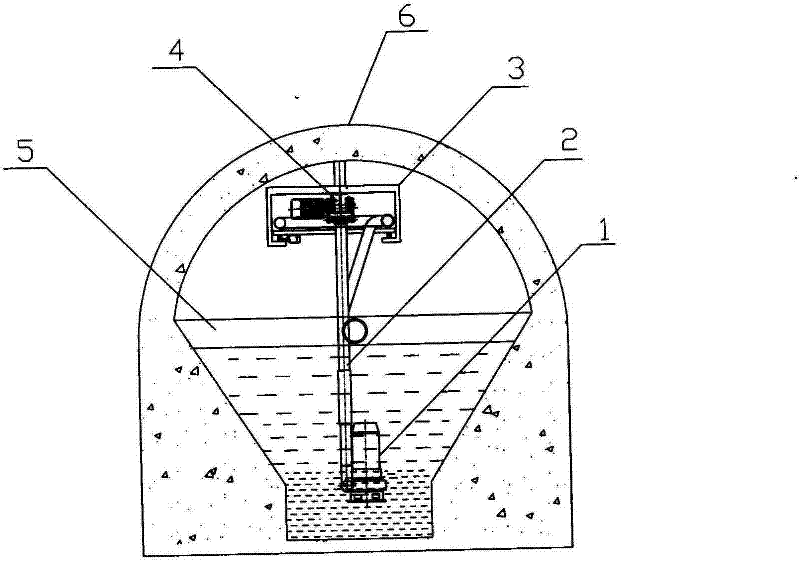

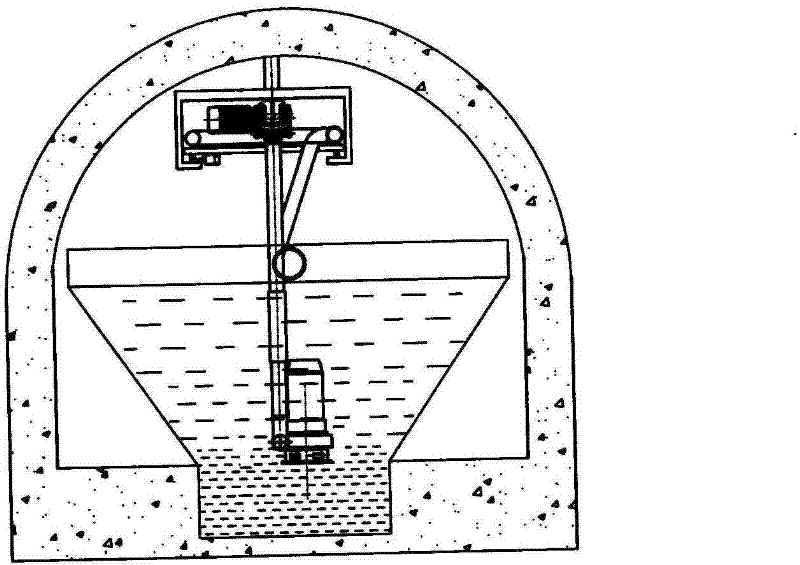

[0036] Such as figure 1 , figure 2 , Figure 4 As shown, the system of the present invention includes the concentrated sedimentation tank 5 arranged in the underground roadway, the guide rail device whose length at the top of the concentrated sedimentation tank in the erected roadway is greater than the length of the concentrated sedimentation tank, installed on the guide rail device fixed frame 3 both sides in parallel The mobile coil mechanism 10 on the mobile coil mechanism slideway 11 (see Figure 5 ), the monorail trolley 8 formed by the guide wheel and the driving mechanism is installed in a suspended manner on the monorail 7 arranged along the longitudinal central axis of the guide rail device fixture 3, and the monorail crane 4 is hoisted on the monorail through the connecting rod 2 The slurry pump 1 at the bottom of the crane 4; the moving coil mechanism (see Figure 6 ) includes a vehicle 16, a turntable 12, and a slag discharge pipe 9 coiled on the turntable. Th...

Embodiment 2

[0040] Such as Figure 9 , Figure 10 , Figure 11 As shown, the slag discharge pipeline section located between the turntable and the slurry pump in the present invention can also be suspended under the single guide rail through a plurality of pulley hoisting frames 19 . Specifically: arrange some pulley hoisting frames 19 on the single guide rail 7, and select a node to be fixed on the pulley hoisting frame 19 every other suitable length on the slag discharge pipeline; the length of the single guide rail 7 will be slightly longer than the length of the sedimentation tank, So that when the slag discharge pipeline is fully compressed, the slurry pump can be located at the endpoint of one end of the sedimentation tank, and when the slag discharge pipeline is fully extended, the slurry pump can reach the endpoint of the other end; when the monorail crane drives the slurry When the pump moves away from the outlet end, due to the effect of traction, the pulley hoisting frame 19 ...

Embodiment 3

[0042] The device of the present invention can also be used as Figure 12-13 In the embodiment shown, specifically, a moving coil mechanism is used to suspend the slurry pump on the top of the thickening roadway. The moving coil mechanism is connected with a transmission device and can reciprocate along a track erected on the top of the roadway. Back and forth between the two ends of the concentrated sedimentation tank. The inlet pipe of the slurry pump is connected to the concentrated underflow, and the slurry is pumped while moving with the moving coil mechanism. The slag discharge pipe of the slurry pump is wound on the moving coil mechanism, and can expand or contract with the movement of the moving coil mechanism: when the moving coil mechanism moves towards one end of the thickening roadway, the slag discharge pipe is gradually moved Rolled into the moving coil mechanism until it moves to the end point; when the moving coil mechanism moves towards the other end of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com