Treatment system for oxide skin of main valve rod and valve disc of thermal power plant and treatment method

A technology for thermal power generation and processing methods, which is applied in pipeline systems, metal material coating processes, gas/liquid distribution and storage, etc. , Reduce the risk of mechanical damage, the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

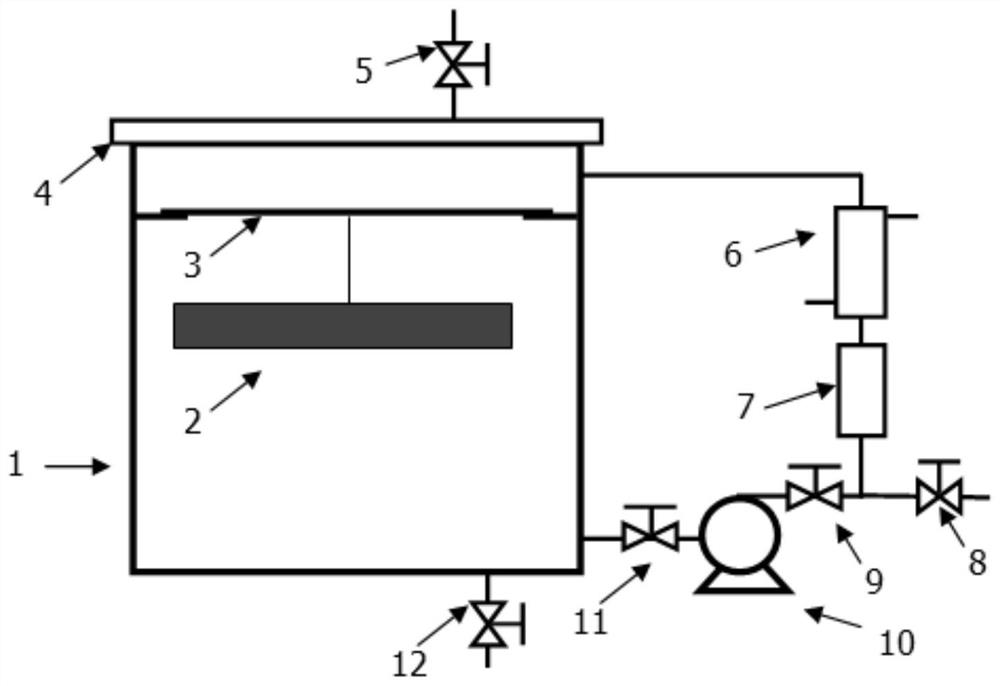

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] Before adding desalted water into the cleaning tank 1, close the circulation pump inlet valve 11 and the circulation pump outlet valve 9, close the sampling valve 8, and then prepare a cleaning agent with a citric acid concentration of 7% and a corrosion inhibitor concentration of 0.3 in the cleaning tank 1. %, reducing agent concentration 0.5%, the citric acid cleaning agent pH value is adjusted to 3.8 with ammonia water; Adopt strippable glue to coat the thread position on the workpiece 2 (main steam valve stem), after the strippable glue dries, put The workpiece 2 is bound with a hanger 3, immersed in the citric acid cleaning agent in the cleaning box 1, the cleaning box upper cover 4 is closed, and the exhaust valve 5 is opened; the inlet valve 11 and the outlet valve 9 of the circulation pump 10 are opened to start the cycle Pump 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com