Percolate lifting device

A leachate and support frame technology, applied to water supply devices, waterway systems, drainage structures, etc., can solve problems such as insufficient suction, increased treatment costs, and timely heat dissipation, so as to simplify the leachate treatment system, reduce maintenance and Use cost, effect of reducing load variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

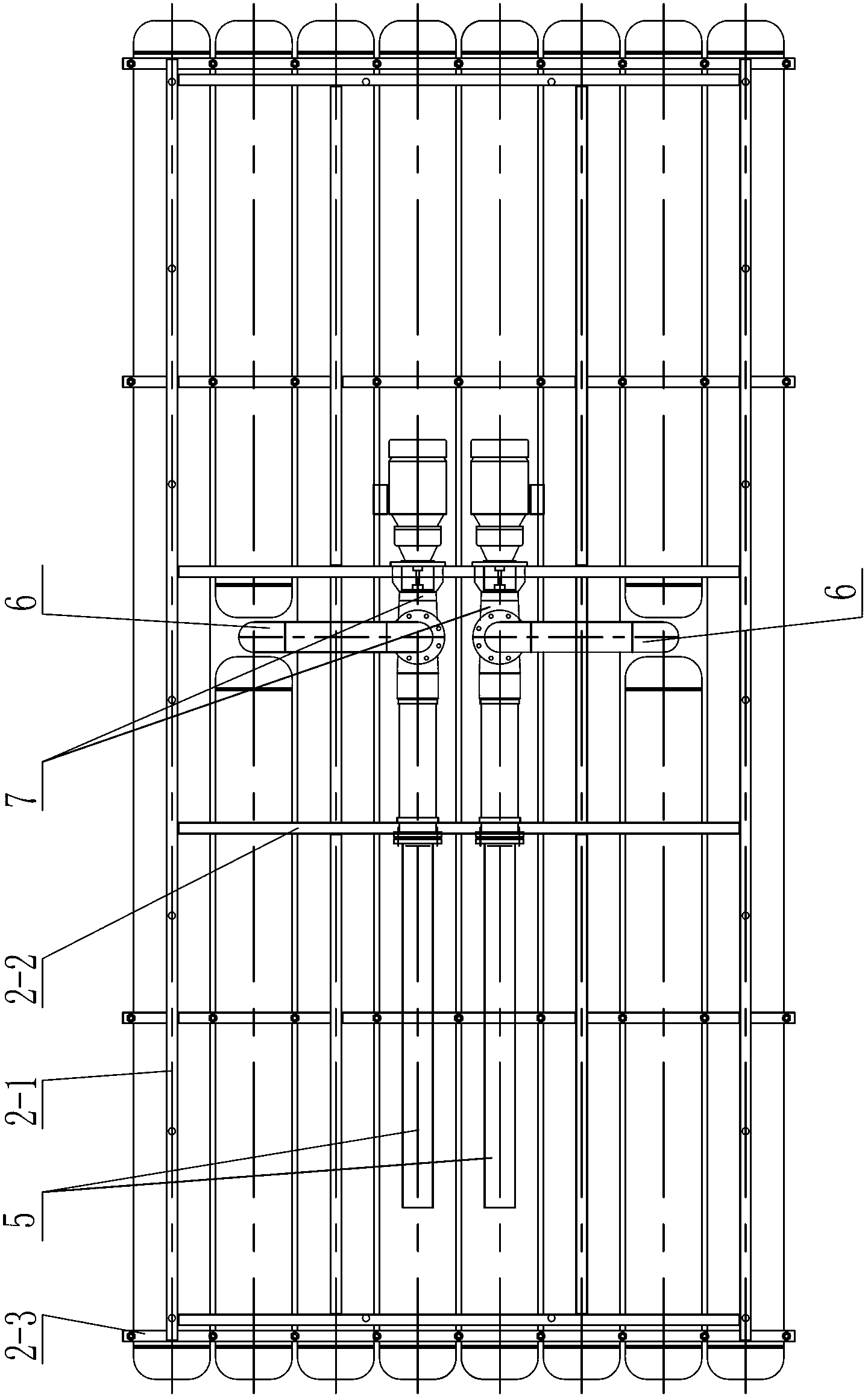

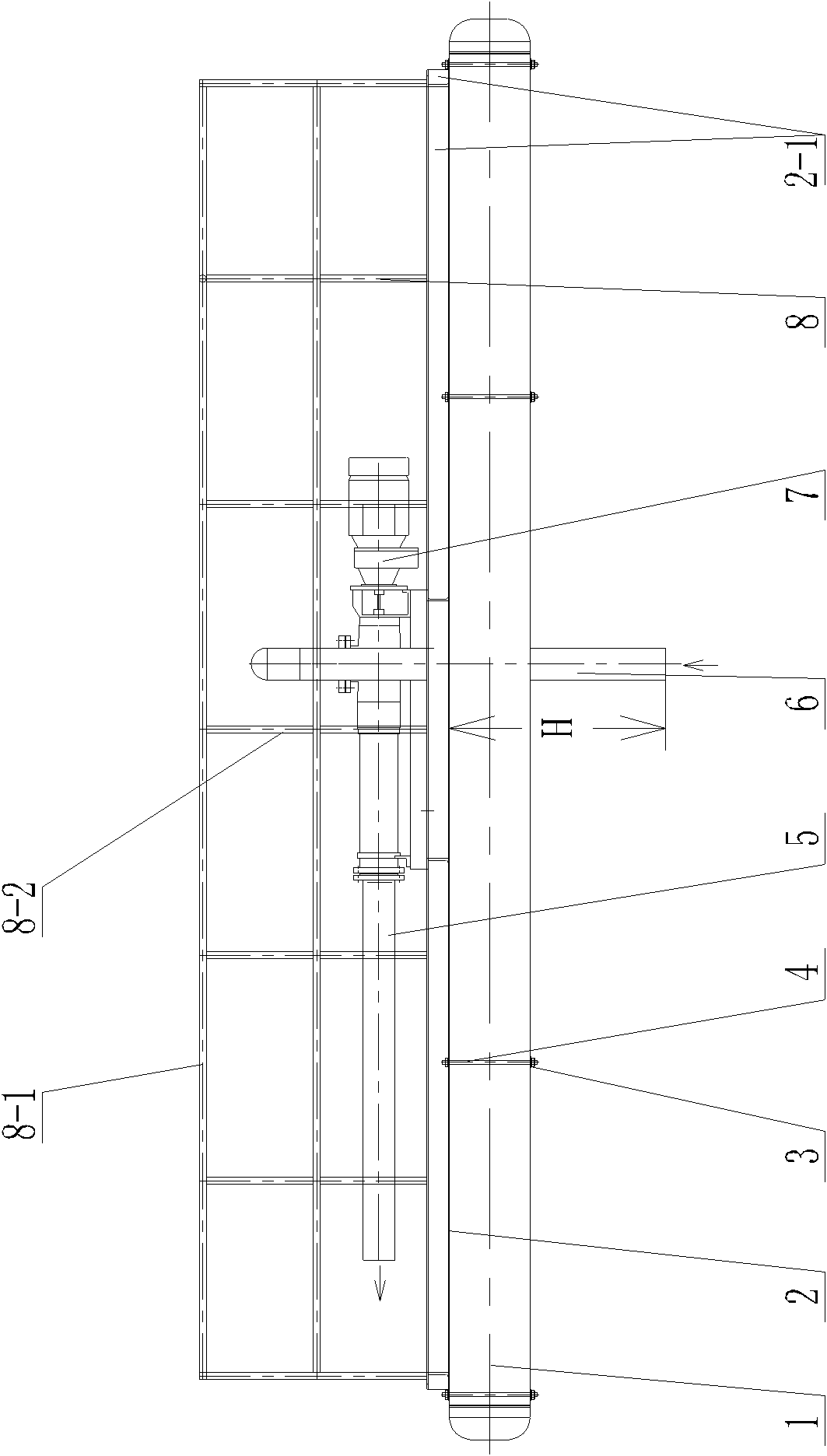

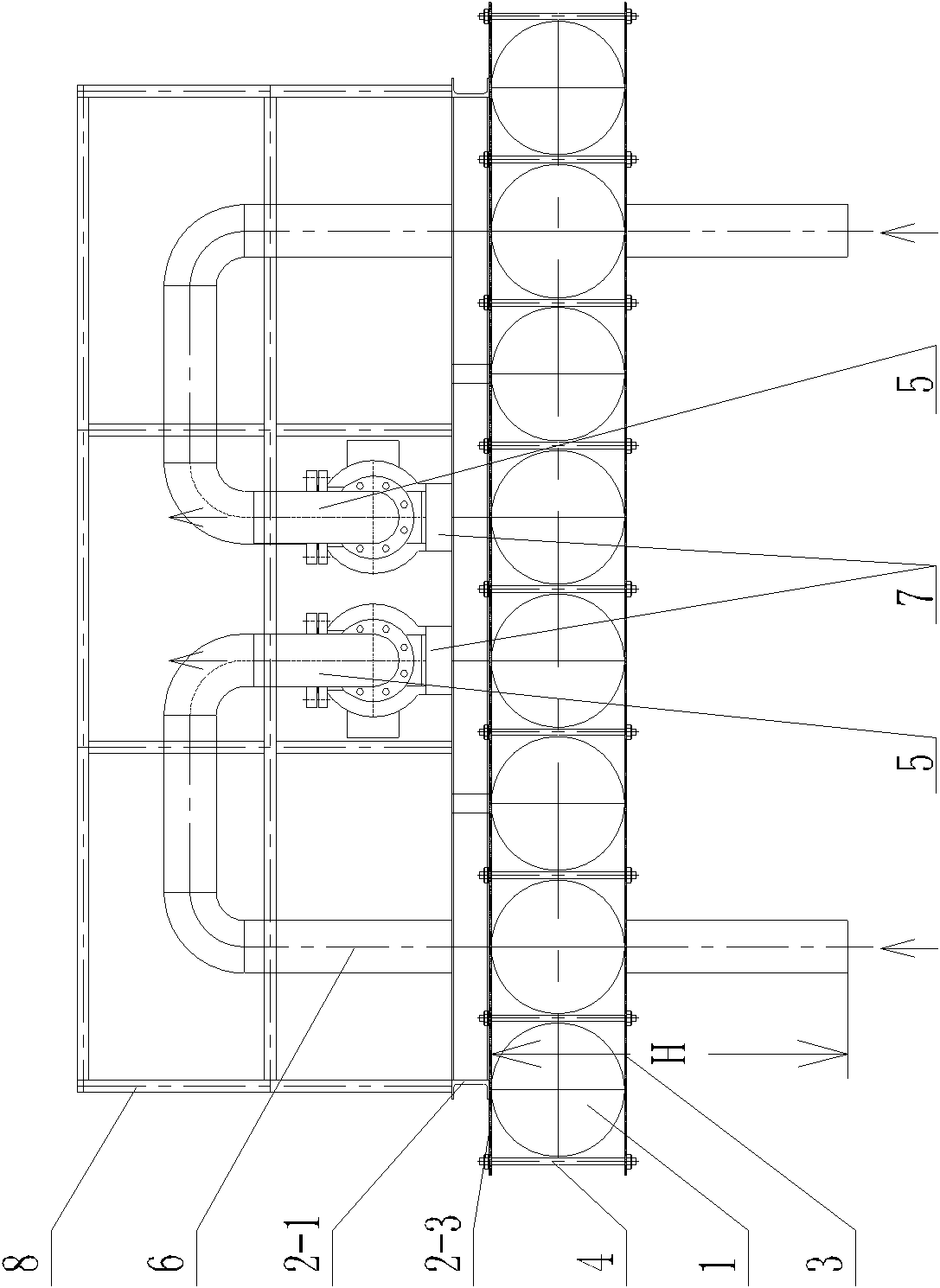

[0016] See Figure 1~3 As shown, the leachate lifting device of the present invention includes a floating support mechanism, a water pump pipeline mechanism and a guardrail 8 . The floating support mechanism of the present invention includes more than four buoys 1 and a support frame 2, and the support frame 2 includes side beams 2-1 around and beams or / and longitudinal beams 2-2 fixed between the side beams 2-1 , each buoy 1 is installed on the bottom of the support frame 2 through a fastener 4, the fastener 4 can be a U-shaped bolt, the closed end of the U-shaped bolt is wrapped on the buoy 1, and the upper part is connected with the support frame 2 by a nut The beams or longitudinal beams 2-2 are connected, the buoyant bucket 1 is installed on the bottom of the support frame 2, and the buoyancy of the buoyant bucket 1 makes the support frame 2 be located on the liquid surface of the regulating pool. The floating support mechanism of the present invention also has lower con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com