Patents

Literature

481results about How to "Restricted degrees of freedom" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

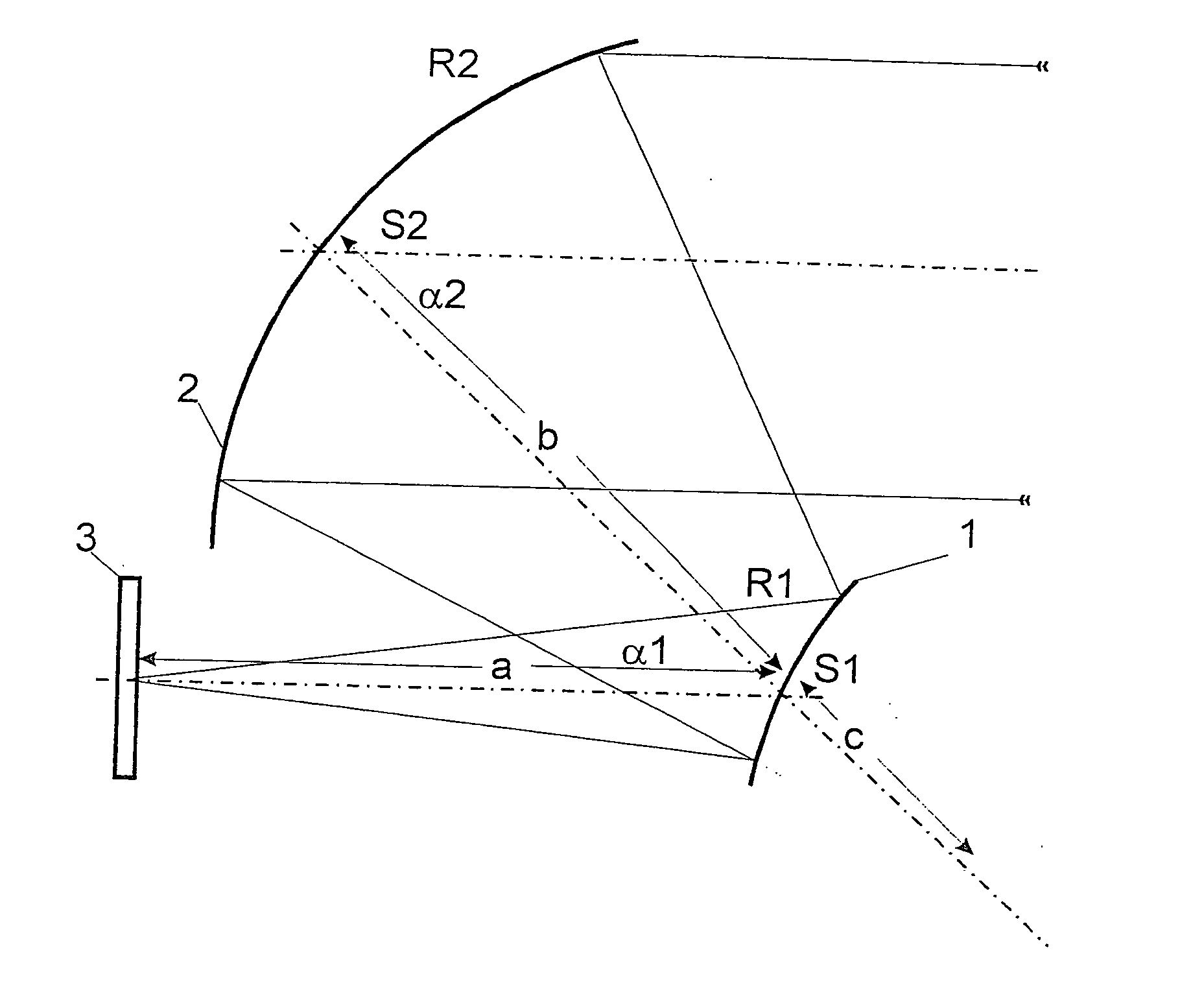

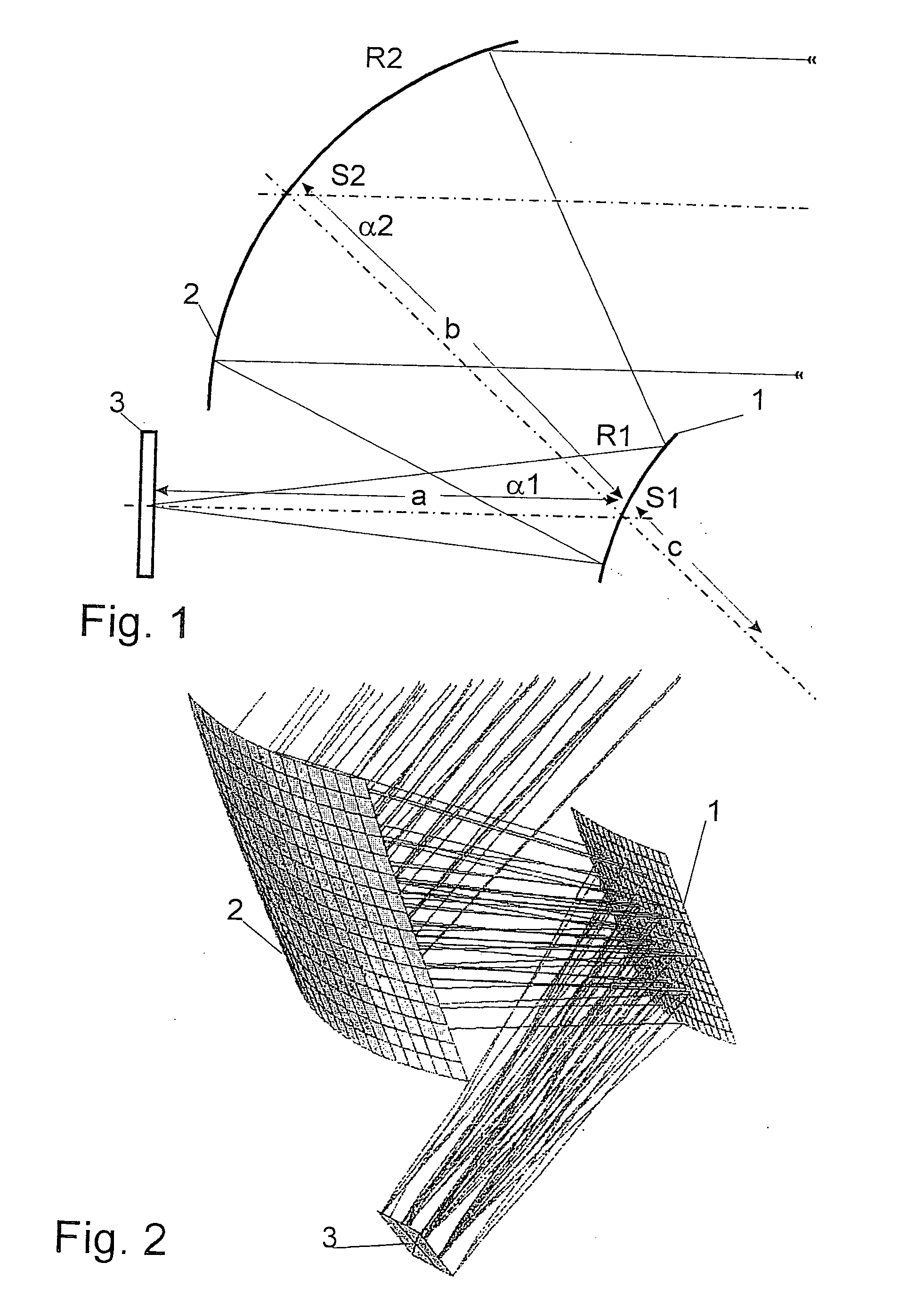

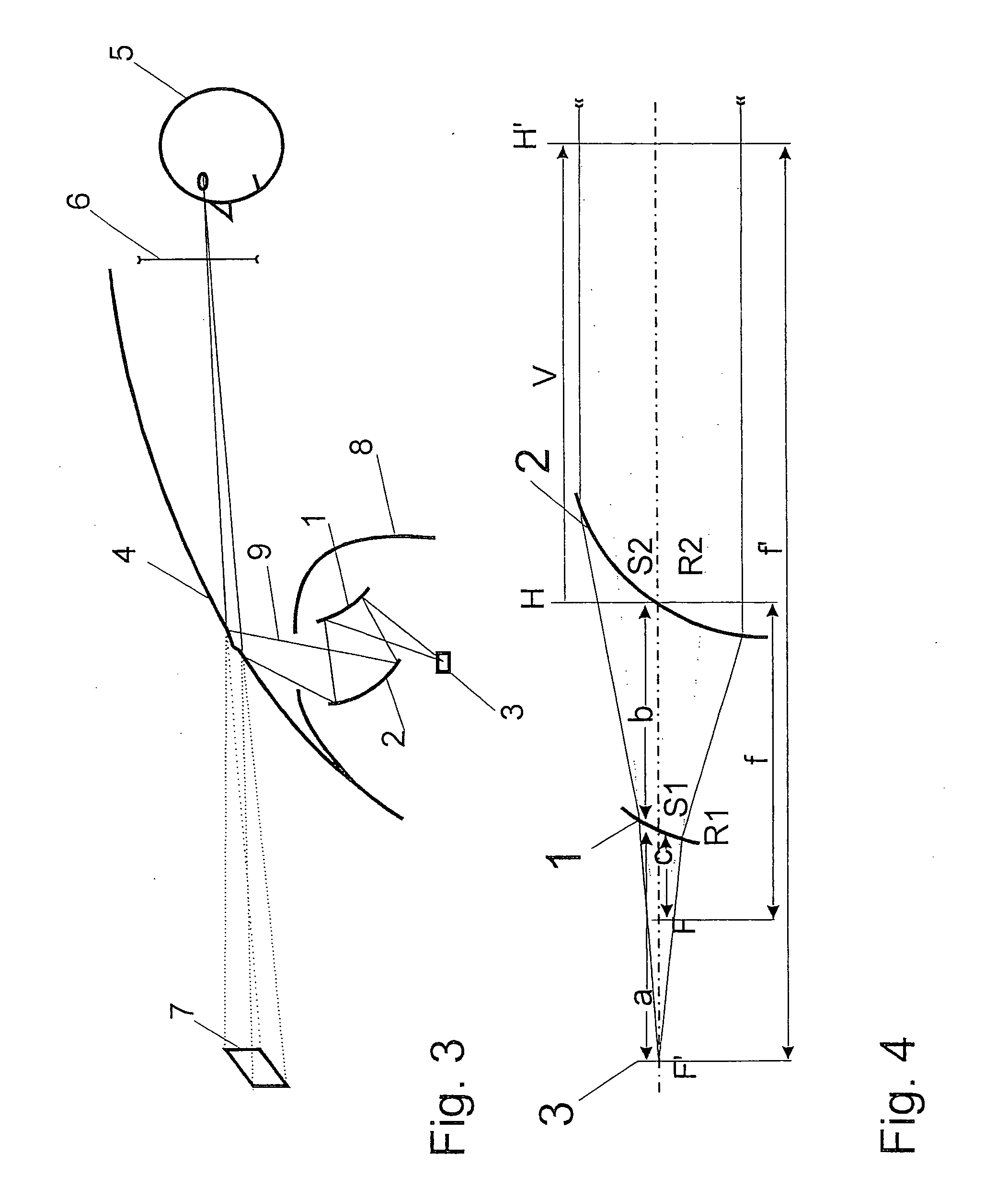

Projection unit for a head-up display

InactiveUS20060232853A1Minimizing optical transmission lengthExtended transmission lengthMicroscopesTelescopesHead-up displayLight beam

The invention is directed to a projection unit for a head-up display comprising an image generator and a first mirror and second mirror for optical imaging which are arranged in a housing one after the other in the light propagation direction in such a way that the beam path is folded twice. It is wherein one of the mirrors has a light-scattering surface shape, the other mirror h / as a light-collecting surface shape, and the two mirrors combined have a common focal point on the image generator.

Owner:CARL ZEISS JENA GMBH

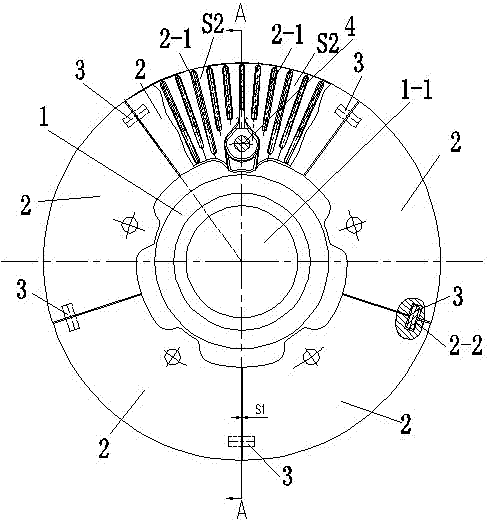

Side-pumped optical fiber structure and manufacturing method thereof

ActiveCN102298173ALarge optical contact areaEasy to operateGlass making apparatusOptical fibre with multilayer core/claddingManufacturing technologyCoupling

A lateral pumped fiber structure comprises: at least one active optical fiber, which is used to generate laser or amplify the laser; at least one passive optical fiber, which is used to connect a pumping source. The active optical fiber and the passive optical fiber form an optical contact in a radial direction. The manufacturing method of the lateral pumped fiber structure comprises the following steps: 1) respectively preparing an active optical fiber performing rod and a passive optical fiber performing rod; 2) respectively performing wire drawing to the prepared active optical fiber performing rod and the passive optical fiber performing rod and making the active optical fiber and the passive optical fiber; 3) coupling at least one active optical fiber to at least one passive optical fiber so that the optical contact in a radial direction between the active optical fiber and the passive optical fiber can be formed. By using the fiber structure of the invention, pumping efficiency is high; a manufacturing technology and coupling equipment are simple; costs are low. The fiber structure of the invention is especially suitable for a high power optical fiber laser and an optical fiber amplifier.

Owner:WUHAN YANGTZE SOTON LASER CO LTD

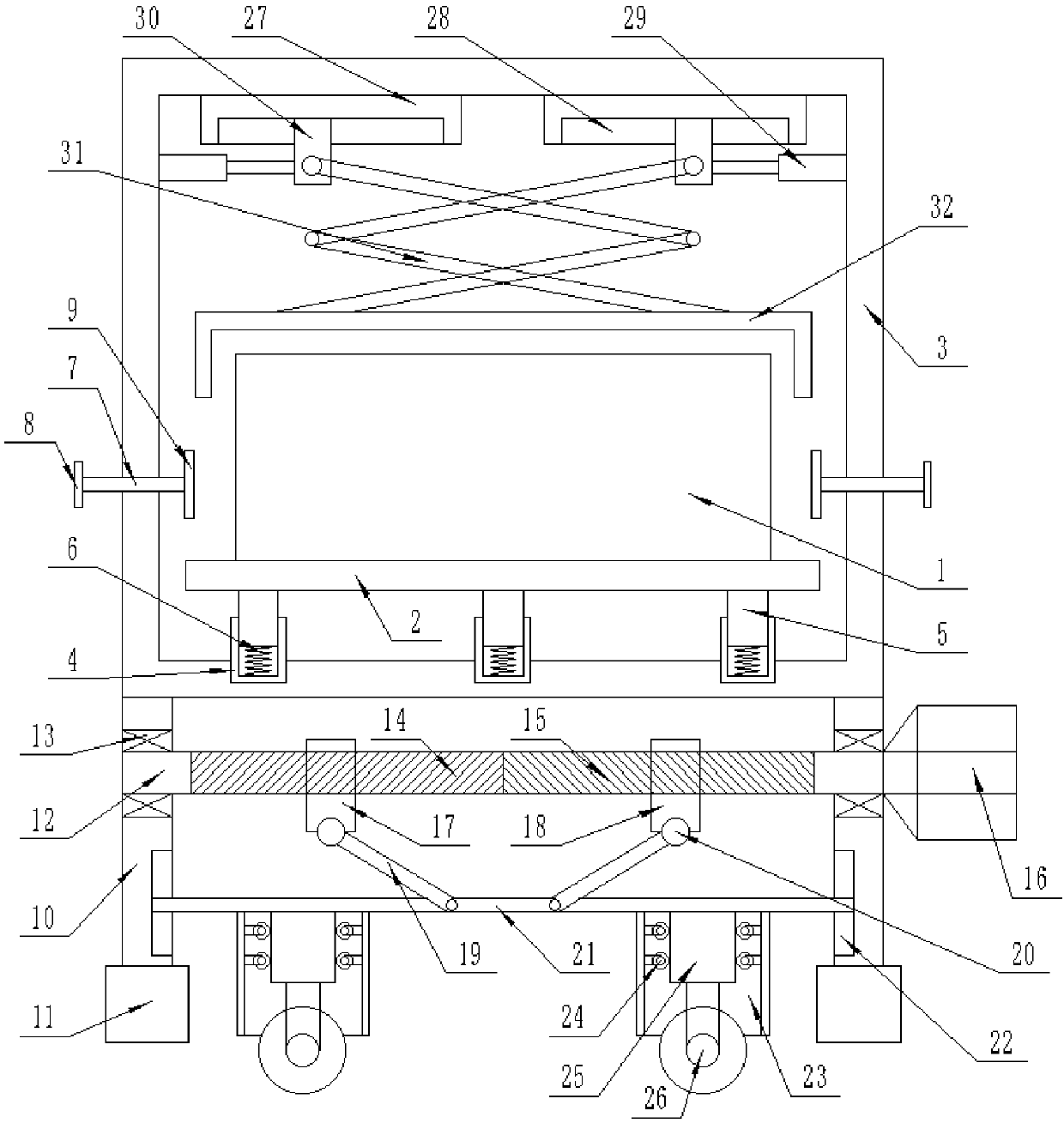

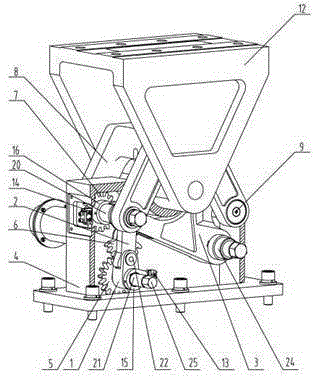

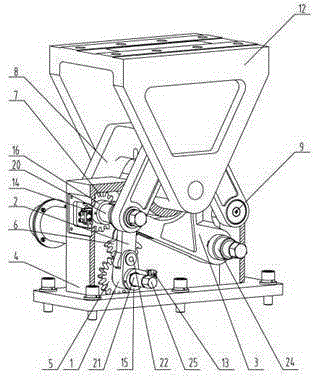

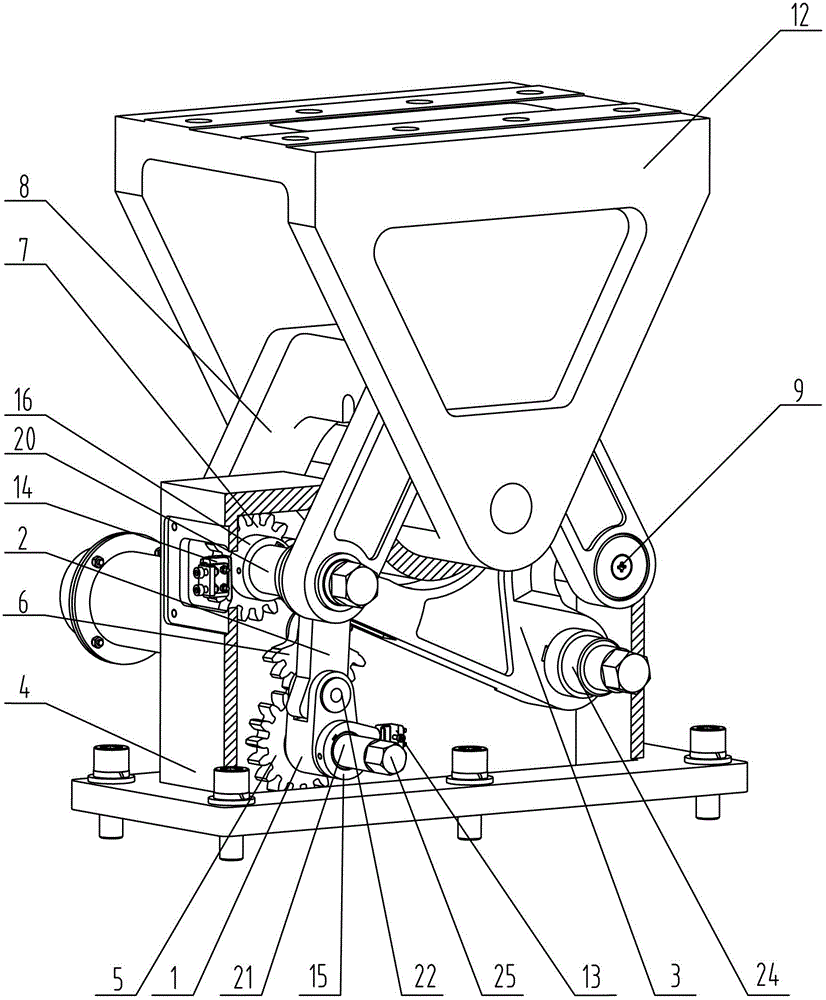

High-voltage inverter convenient to move

PendingCN108017009AWith shock absorption functionNot easy to damageNon-rotating vibration suppressionLifting framesFrequency changerMotor drive

The invention discloses a high-voltage inverter convenient to move. The high-voltage inverter convenient to move is simple and reasonable in structure, low in production cost, convenient to mount andcomplete in function. A moving device, with the damping function, special for the inverter is provided, the damping function is achieved, when the inverter is transported, the inverter is protected, the inverter is not prone to damage, and economic losses are reduced; a spring is arranged between a groove and a support, vibration can be effectively resisted, a handle is rotated, a clamping block clamps the inverter, shaking is prevented, damage in the transporting process is avoided, a hydraulic rod works, a lifting frame descends, a concave frame covers the inverter, the freedom degree of theinverter can be limited to a great degree, a rotating motor drives a rotating shaft to rotate, a first shaft sleeve and a second shaft sleeve move to achieve ascending and descending of the sliding rod, the height of the whole device is greatly adjusted, through motor ascending and descending, the inverter is stable and efficient, the inverter cannot be damaged, an air pressure rod extends out ofa universal wheel and is moved through the universal wheel, and after the air pressure rod is moved to the designated place, the air pressure rod retreats from the universal wheel.

Owner:SHISHI KURUI ELECTRICAL

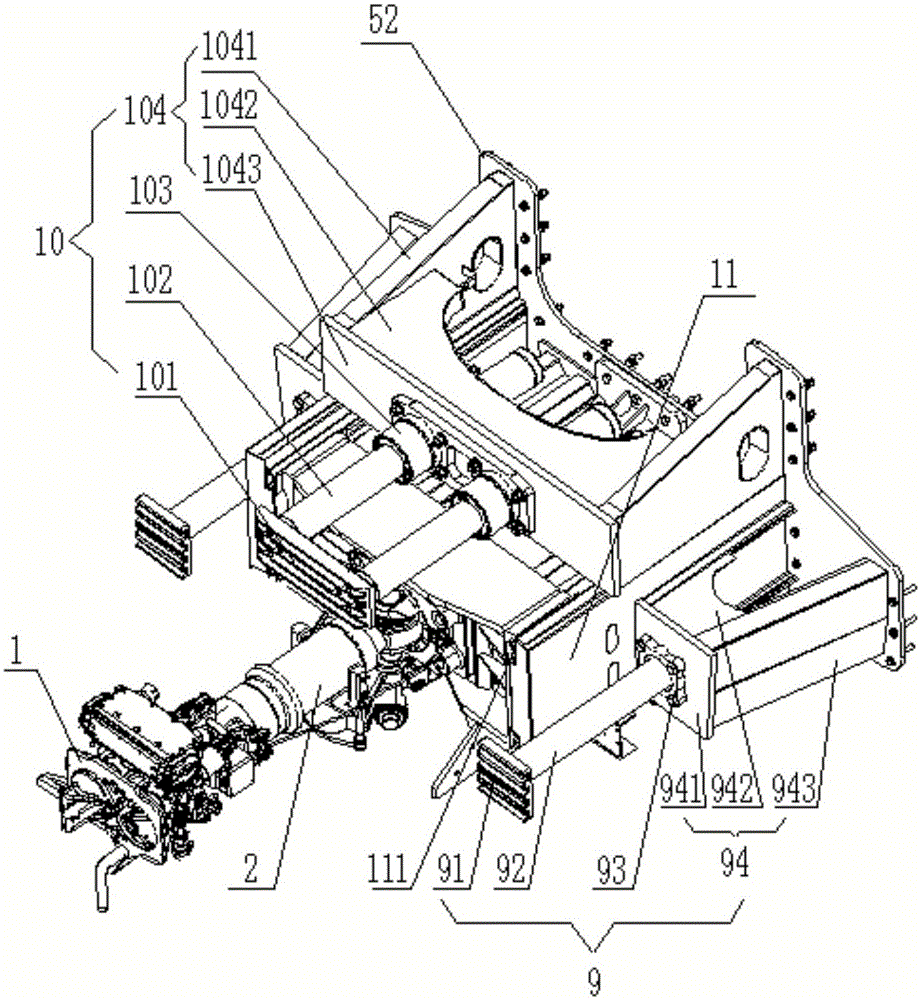

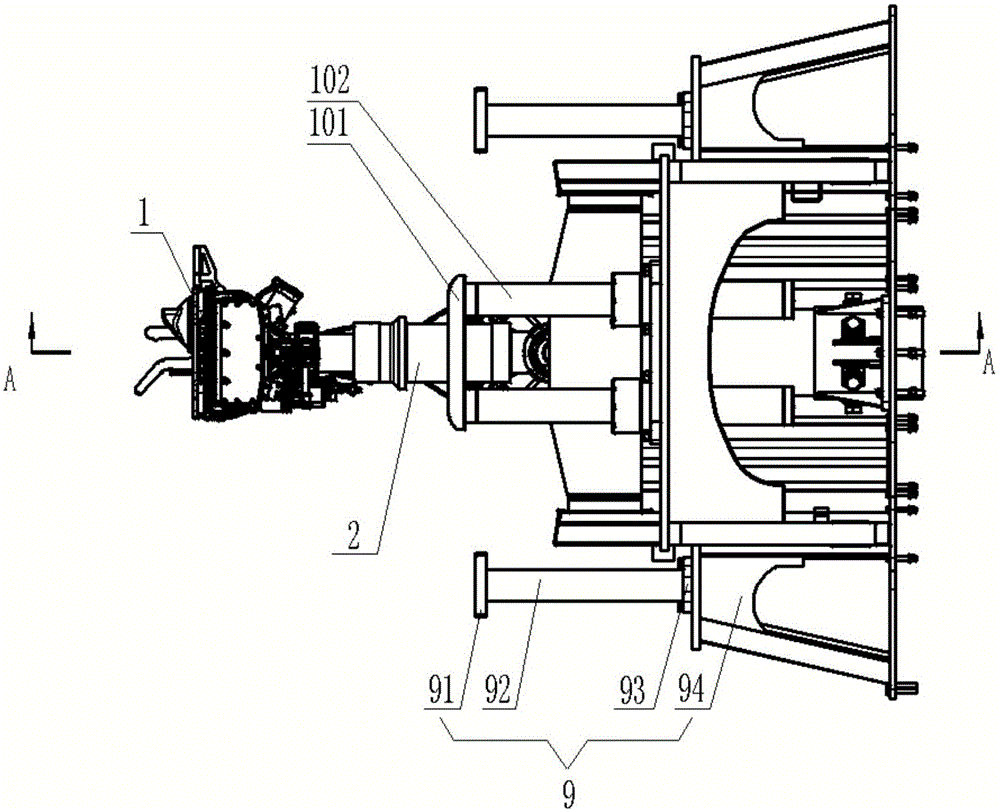

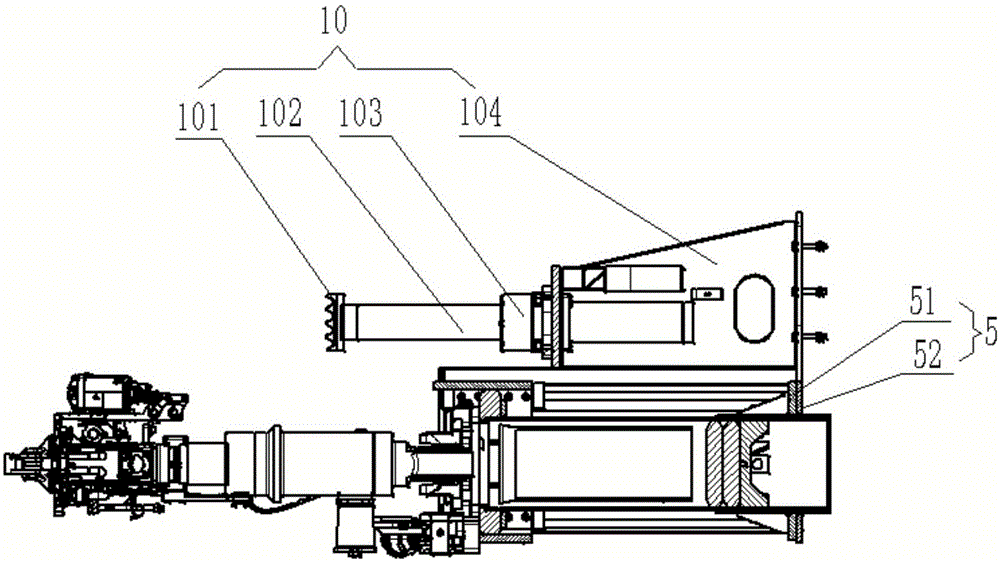

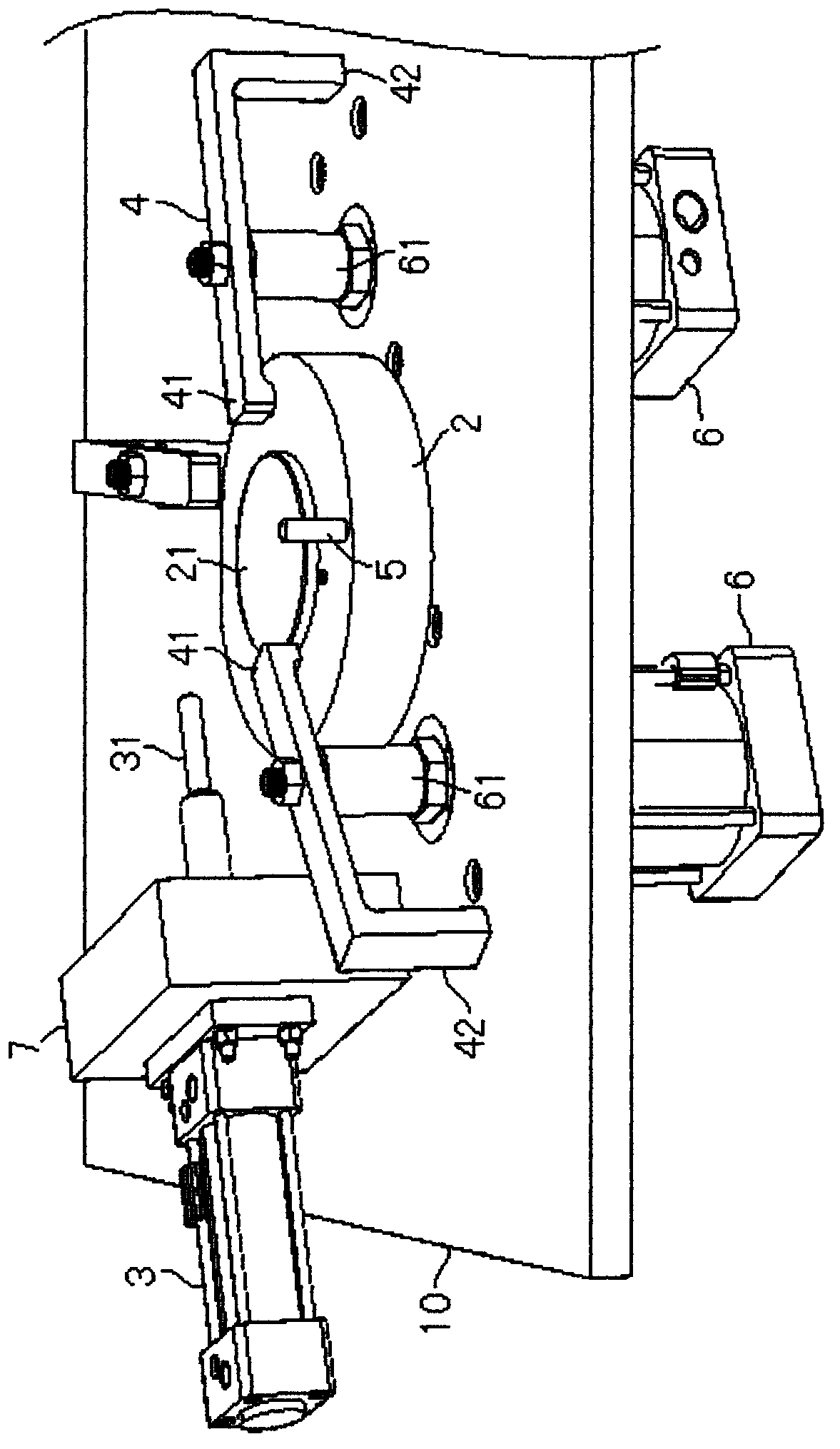

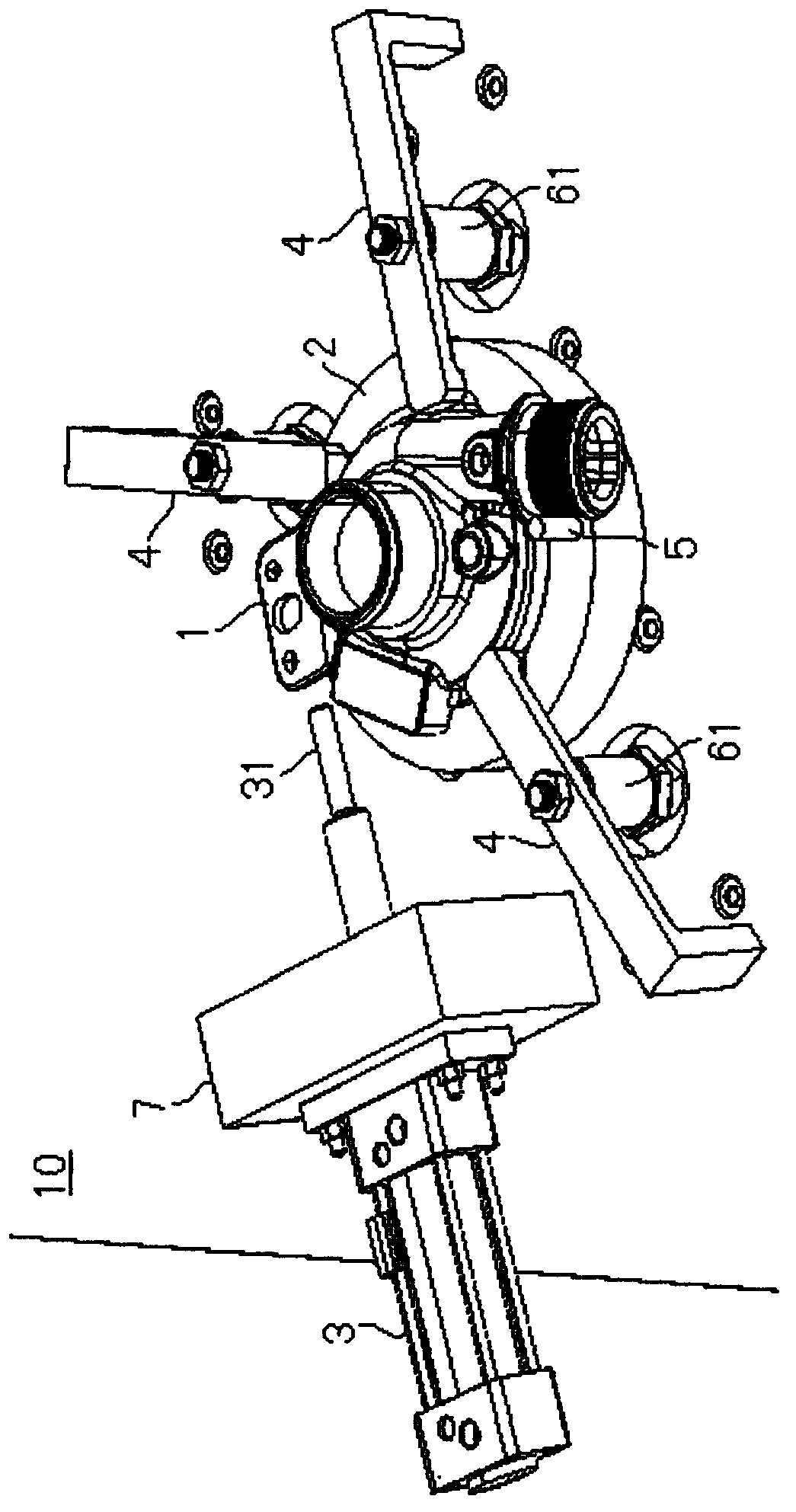

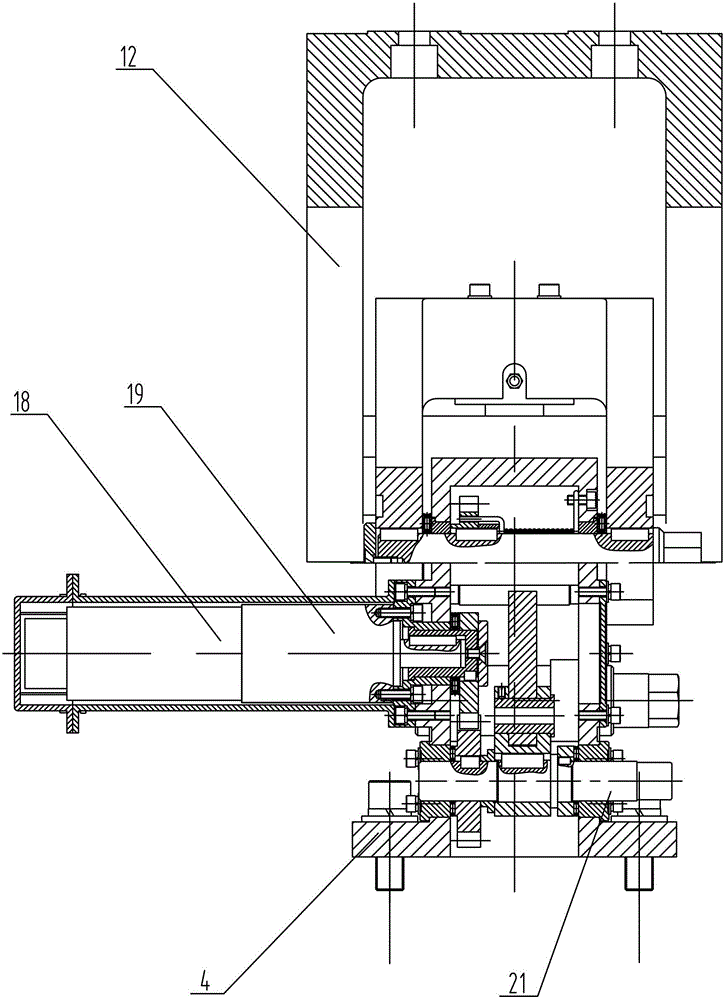

Energy absorption device and rail vehicle with energy absorption device

The invention provides an energy absorption device arranged at the front end of a train. The energy absorption device comprises a train coupler seat, a support, a pressure feeding tube, a train coupler, a guiding component, energy absorption elements and an anti-climbing assembly, wherein the support is fixedly arranged at the front end of the train; the pressure feeding tube is fixed at the train coupler seat; a train coupler connecting end is mounted in the pressure feeding tube in an inserted manner, and can slide relative to the pressure feeding tube; one end of the guiding component is fixed with the train coupler seat; the other end of the guiding component is mounted at the support in an inserted manner, and can slide relative to the support; the guiding component can limit the swing of the pressure feeding tube; the energy absorption elements are arranged between the train coupler seat and the support; the anti-climbing assembly is fixedly arranged on the support, and can be compressed. According to the energy absorption device disclosed by the invention, the energy generated by collision is absorbed by a manner that various energy absorption assemblies are arranged in a limited space; besides, the displacement perpendicular to the self direction, of the train, is limited by the guiding component and the anti-climbing assembly, so that train climbing and derailing are avoided.

Owner:CRRC QINGDAO SIFANG CO LTD

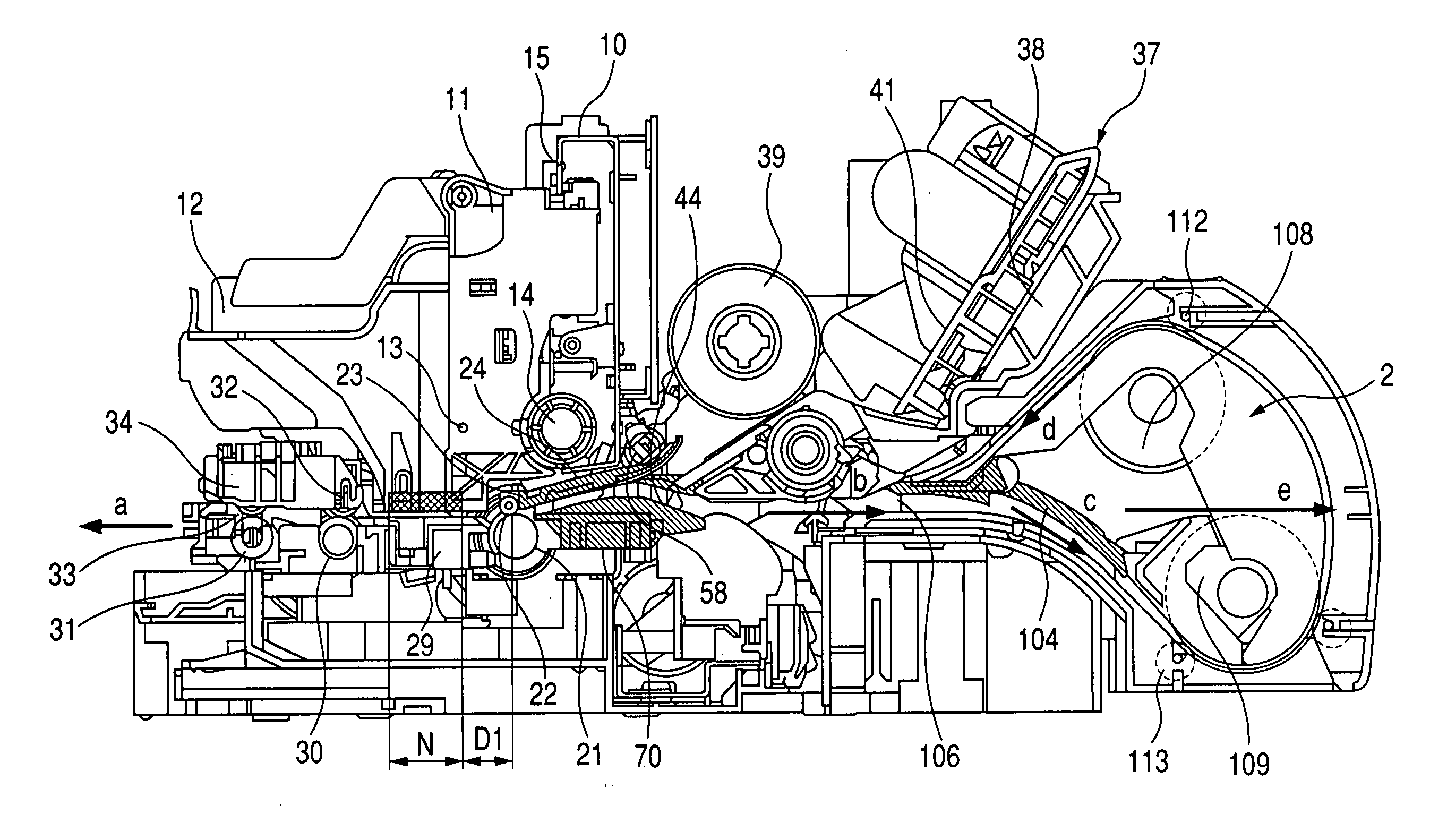

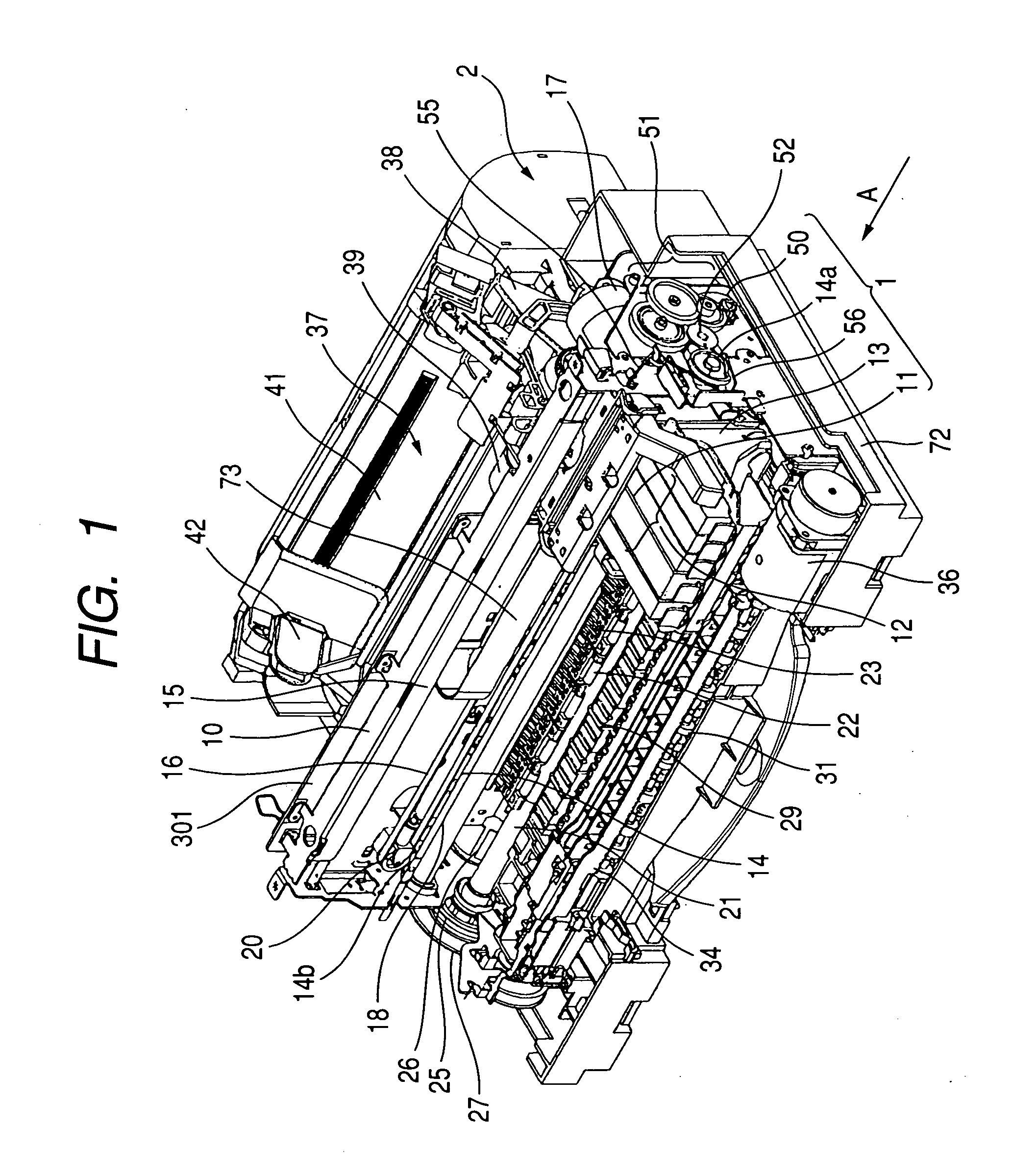

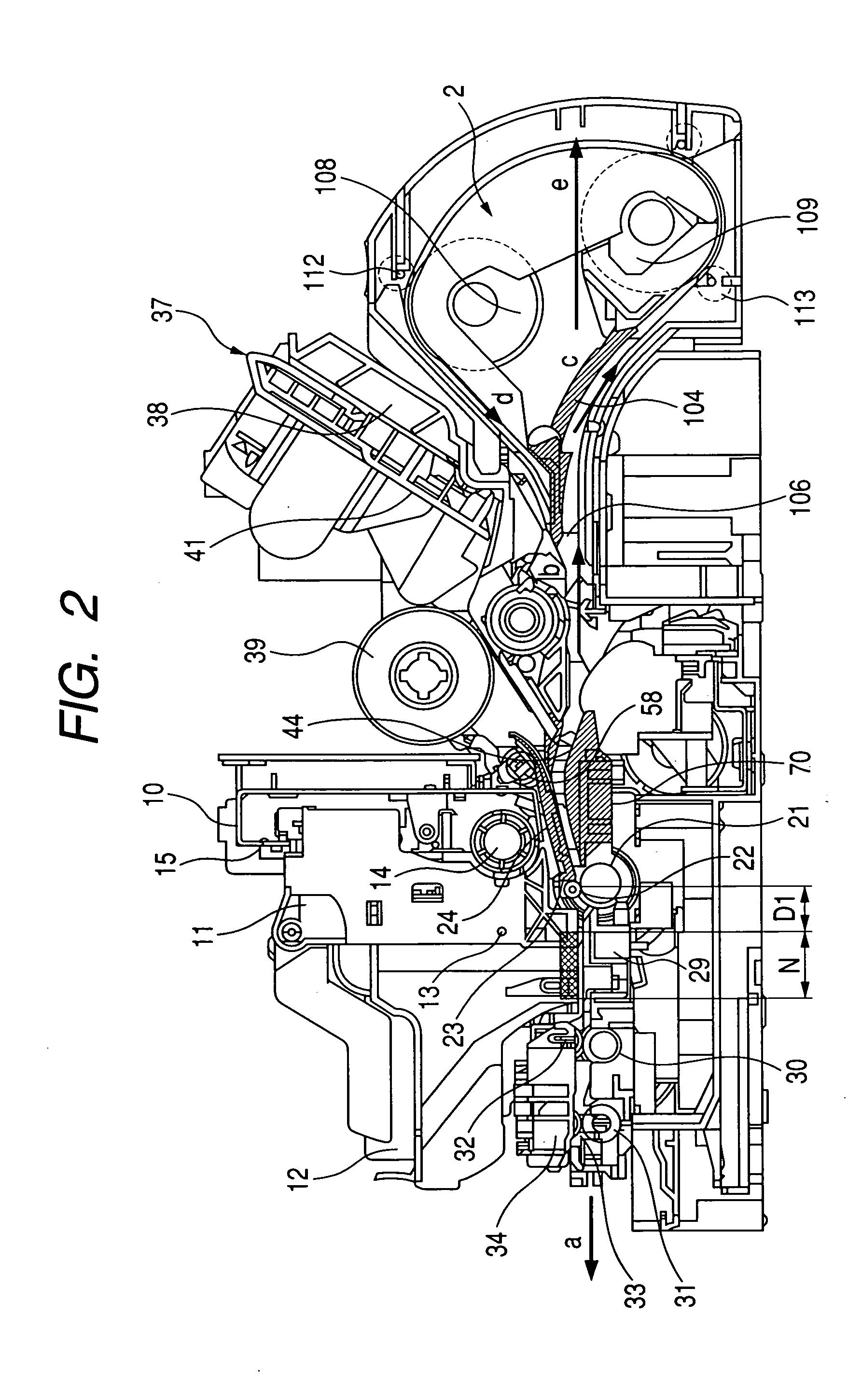

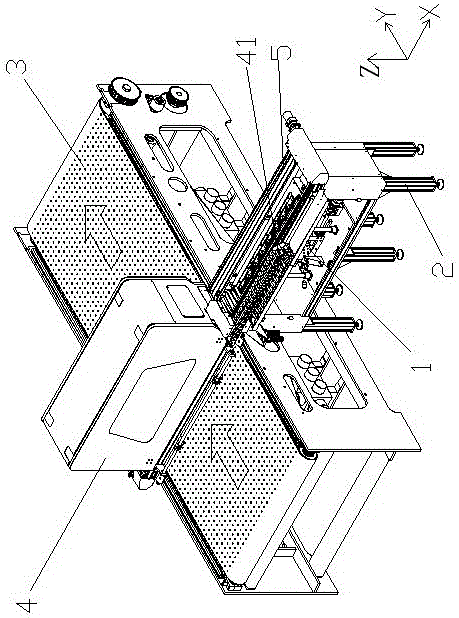

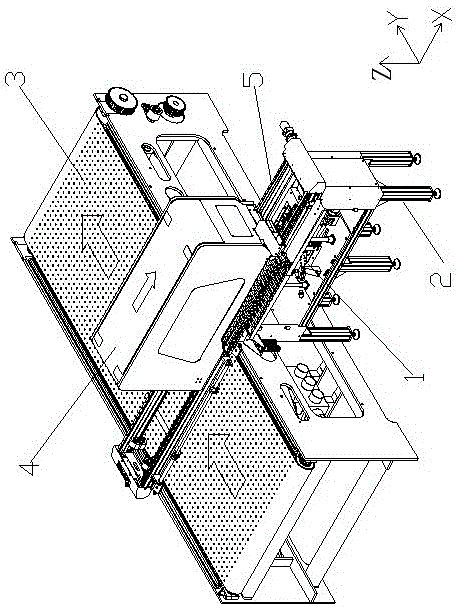

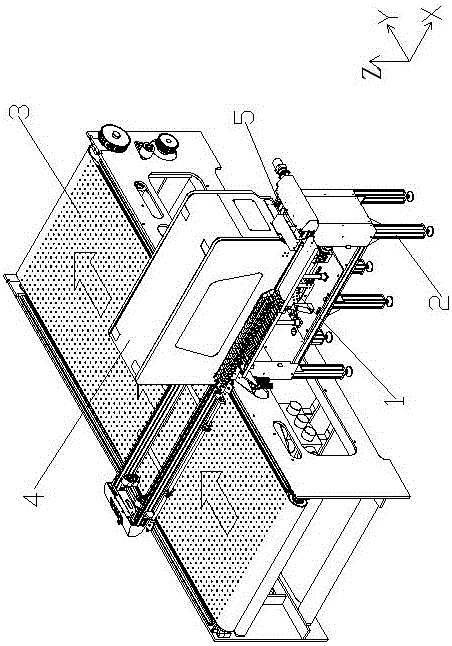

Both-side recording apparatus

InactiveUS20050012800A1Restricted degrees of freedomReduction in apparatus sizeTypewritersOther printing apparatusEngineeringPaper sheet

Driving sources of a reversing section roller and a sheet feeding roller are made common, a drive transmission mechanism to the reversing section roller is provided with clutch means for starting and stopping synchronous rotation after a predetermined rotation, and a degree of freedom in control is enhanced by properly bringing the reversing section roller into a halted state as necessary, thereby realizing reduction in load on the driving source, reduction in noises, and reduction in the size of the apparatus and cost. The apparatus is provided with clutch means, which starts synchronous rotation of the reversing section roller with the sheet feeding roller is started in a period of time from a start of a drive of the sheet feeding roller until nipping of a recording medium by the reversing section roller, after recording is performed onto a front surface, and stops the synchronous rotation of the reversing section roller with the sheet feeding roller in a period of time from release from the reversing section roller until finishing of a sheet discharge operation, after the recording medium from a sheet reversing section is nipped by the sheet feeding roller again.

Owner:CANON KK

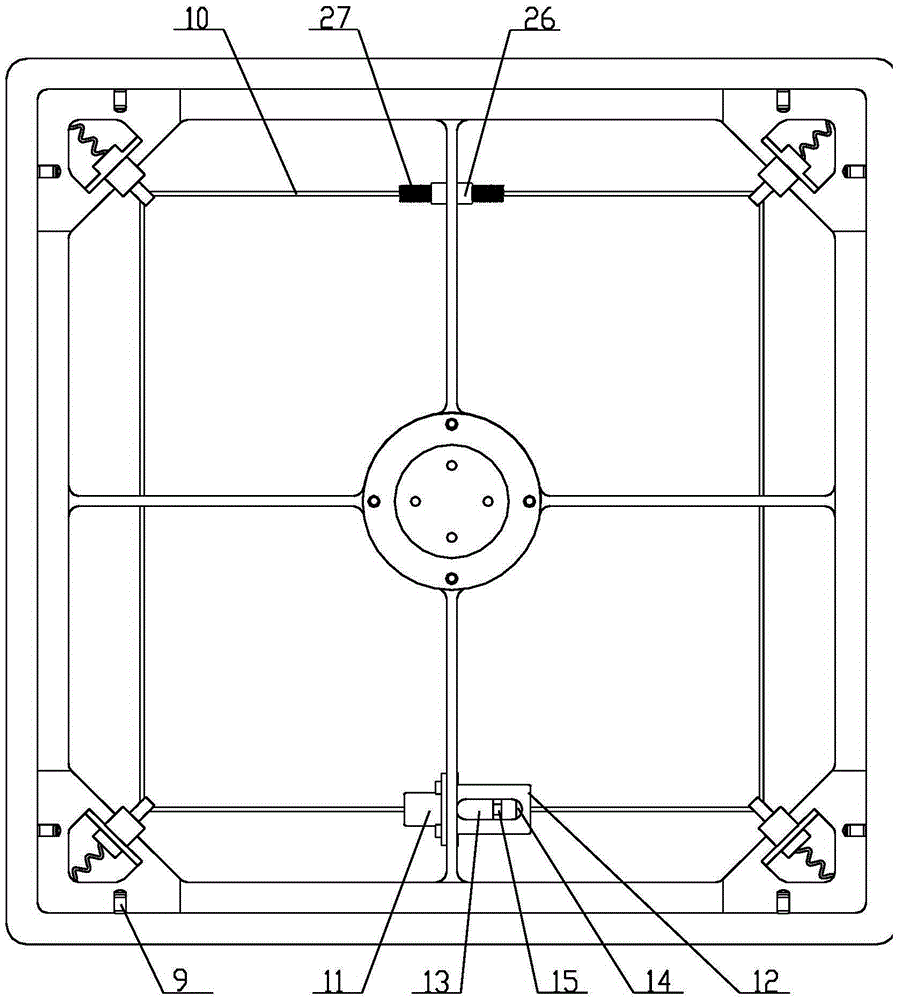

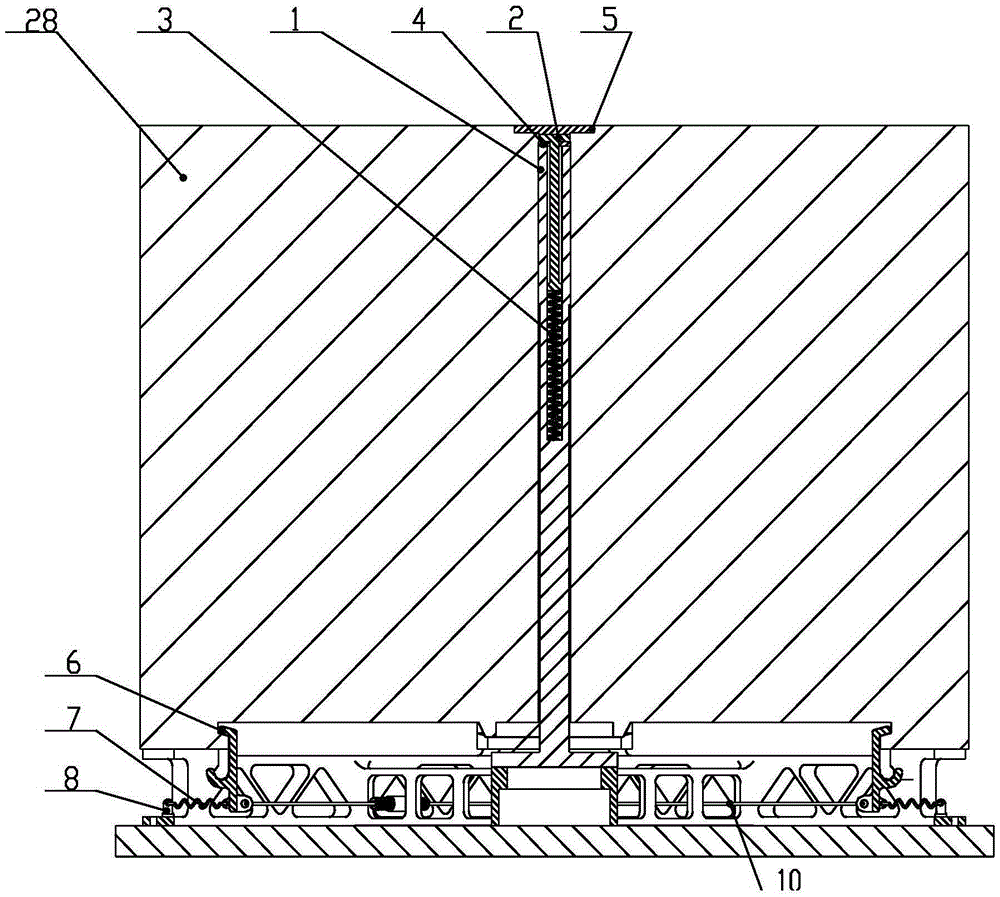

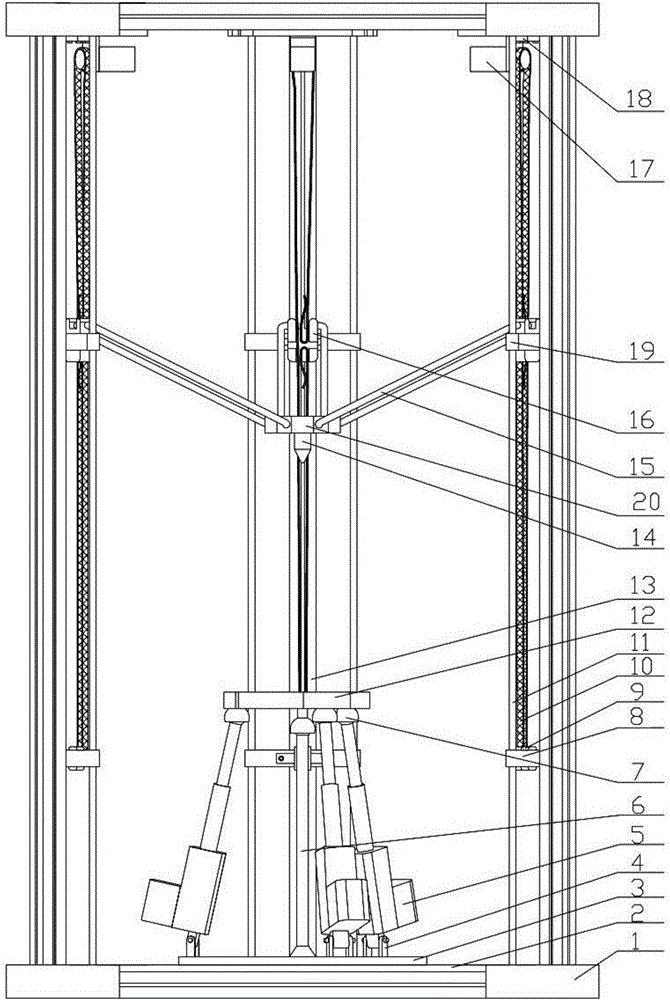

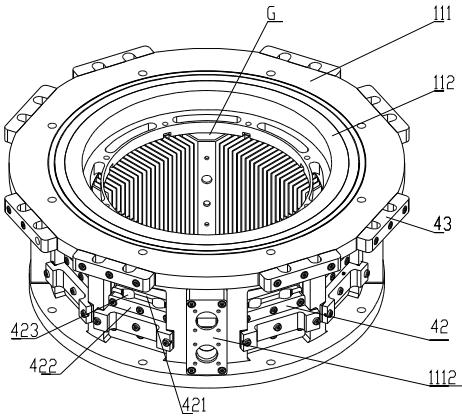

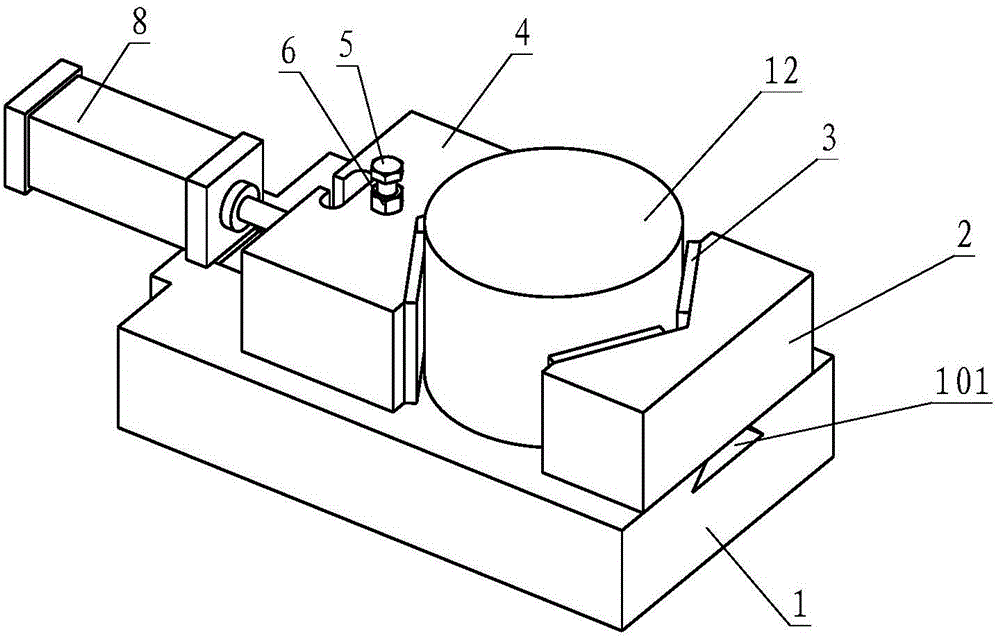

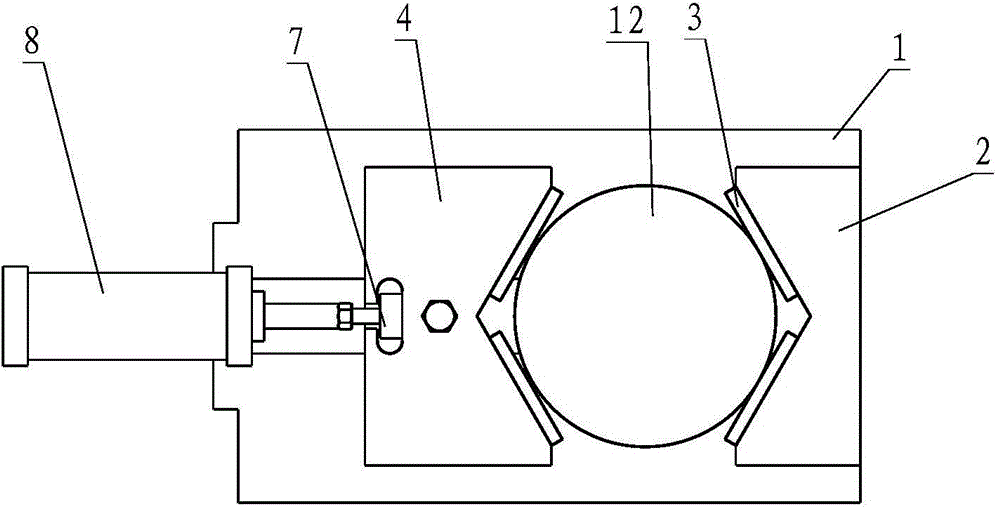

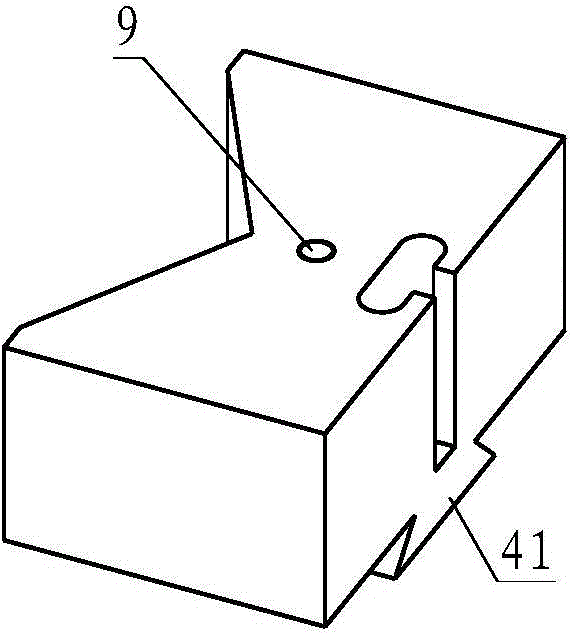

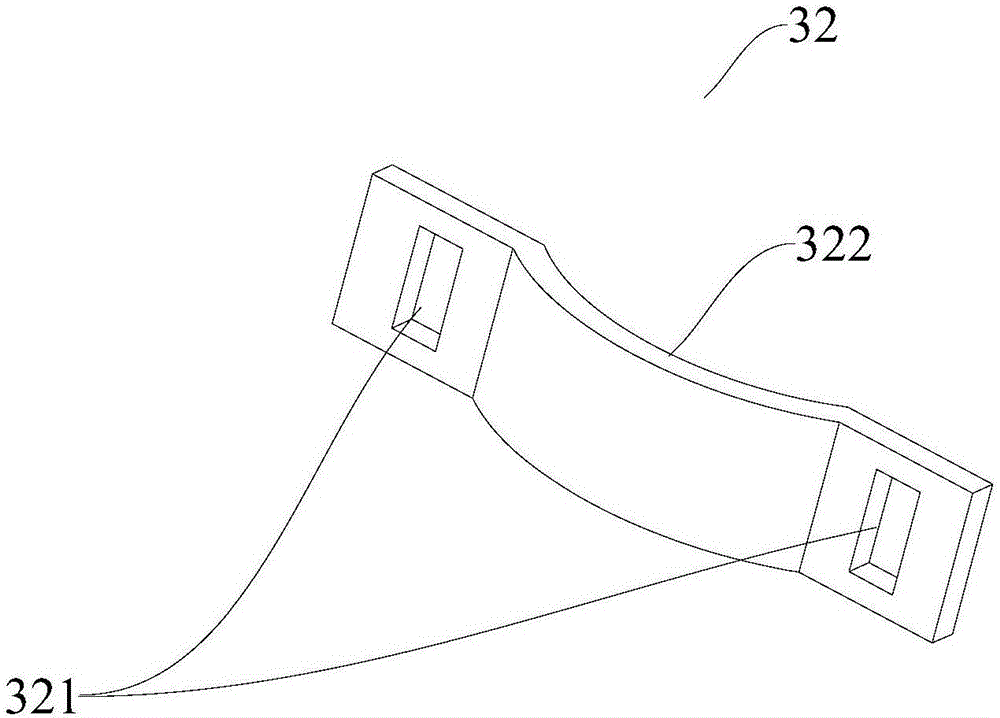

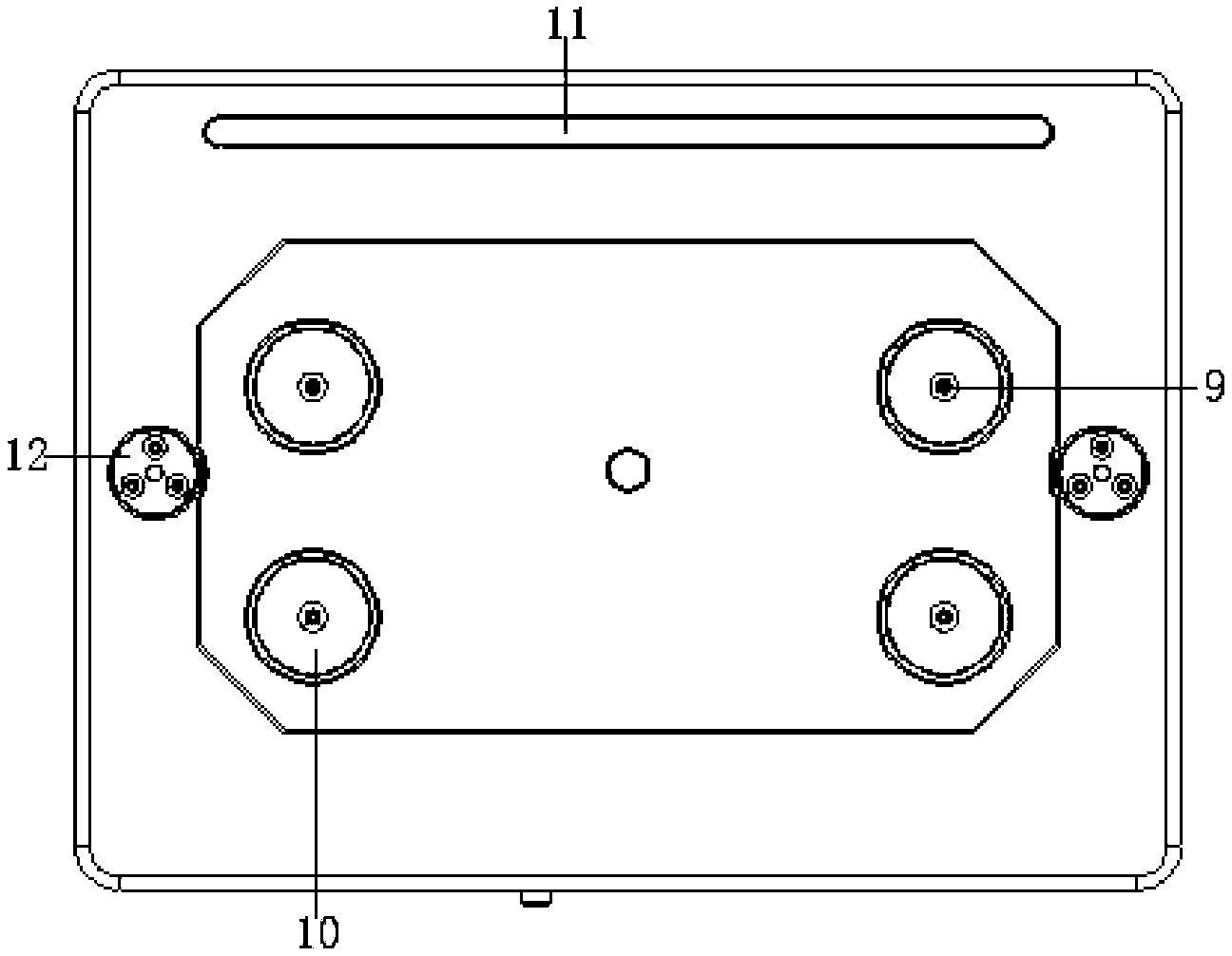

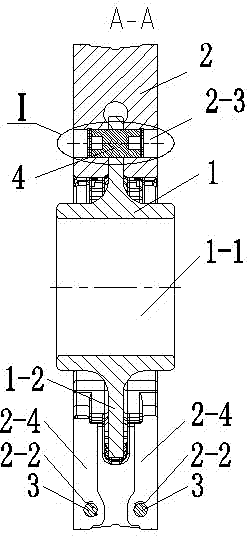

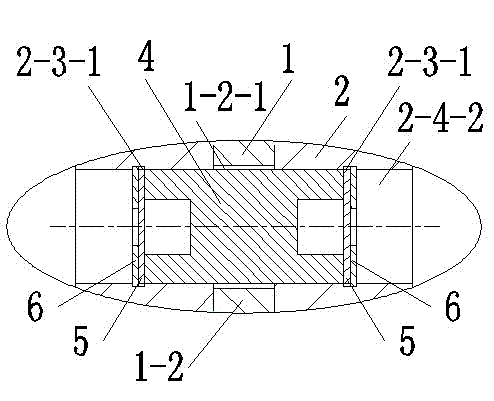

Microsatellite separating device

ActiveCN105416615ASimple structureCompact structureCosmonautic vehiclesCosmonautic component separationFixed frameLocking mechanism

The invention discloses a microsatellite separating device. The microsatellite separating device is arranged on a fixed frame, and the fixed frame is installed on a base. The microsatellite separating device comprises a guide mechanism, a locking mechanism, a pre-tightening mechanism and a releasing mechanism. The guide mechanism is arranged on the fixed frame, matched with a satellite, and used for constraining the satellite directionally and promoting the satellite to be separated. The satellite is fixed to the fixed frame through the locking mechanism. The releasing mechanism is matched with the pre-tightening mechanism and used for controlling the pre-tightening mechanism and the locking mechanism to relieve the fixation of the satellite. The microsatellite separating device has the characteristics of linkage type, modularization, light mass and low impact.

Owner:HARBIN INST OF TECH

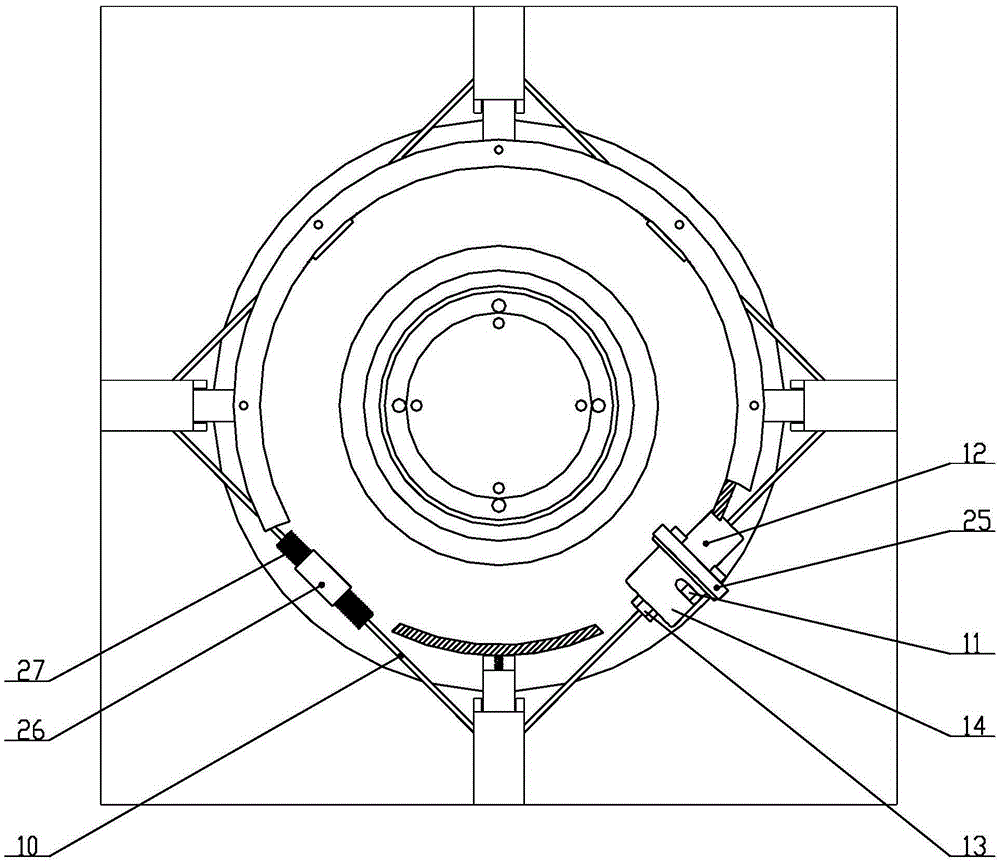

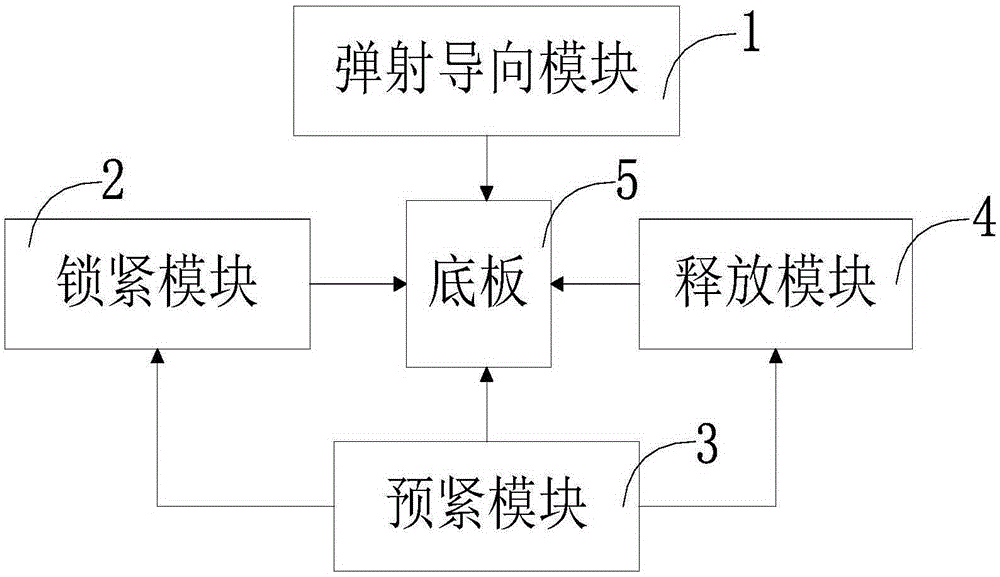

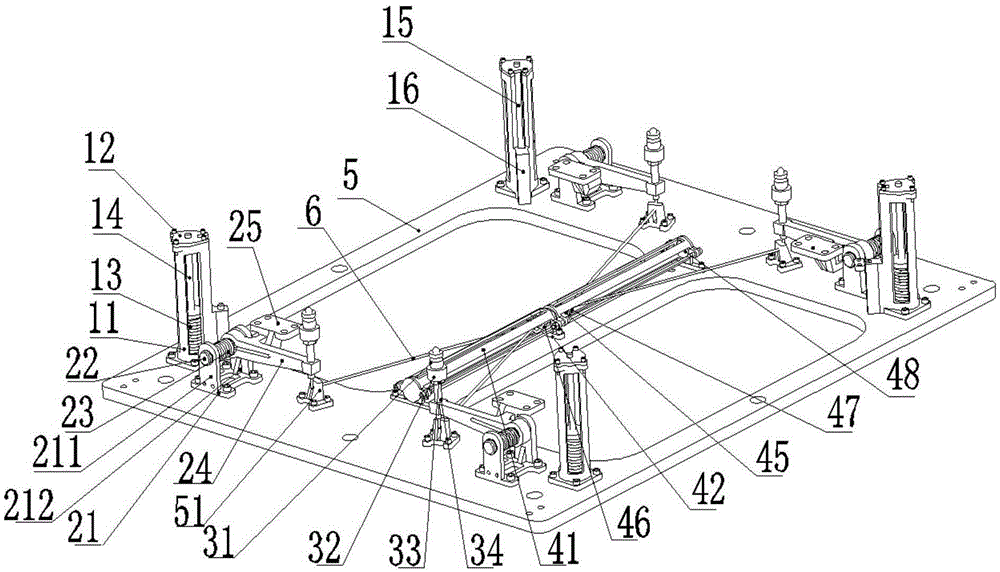

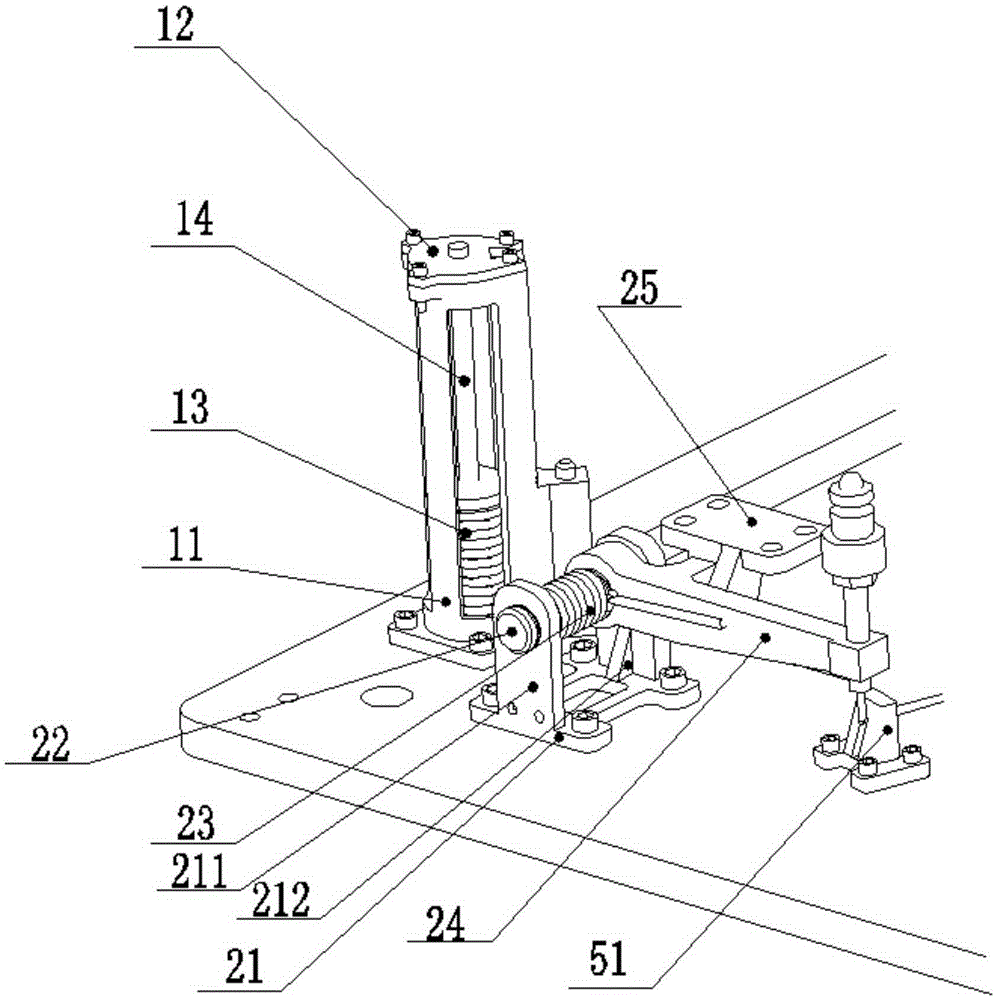

Modular low-impact linkage type microsatellite separating unit

ActiveCN105346736AReduce shockNon-affecting gestureCosmonautic vehiclesCosmonautic component separationModular unitMicrosatellite

The invention provides a modular low-impact linkage type microsatellite separating unit which comprises a launching guide module, a locking module, a pre-tightening module and a release module which are installed on a bottom plate. One end of the pre-tightening module is connected with the locking module through a pressing rod, the other end of the pre-tightening module is connected with the release module through a pull rope, and a linkage mechanism is formed. The separating unit is composed of a plurality of modular units and is simple and compact in structure, and all degrees of freedom of a fixed object are completely limited. In addition, the linkage mechanism is formed by the locking module, the pre-tightening module and the release module, and motion transfer is smooth and convenient. A grooving bolt is expanded to be broken through the release module based on shape memory alloy, so that impacts on microsatellites in the release process are extremely small, and no influence is generated on the posture and stability control over a spacecraft body and separated objects.

Owner:HARBIN INST OF TECH

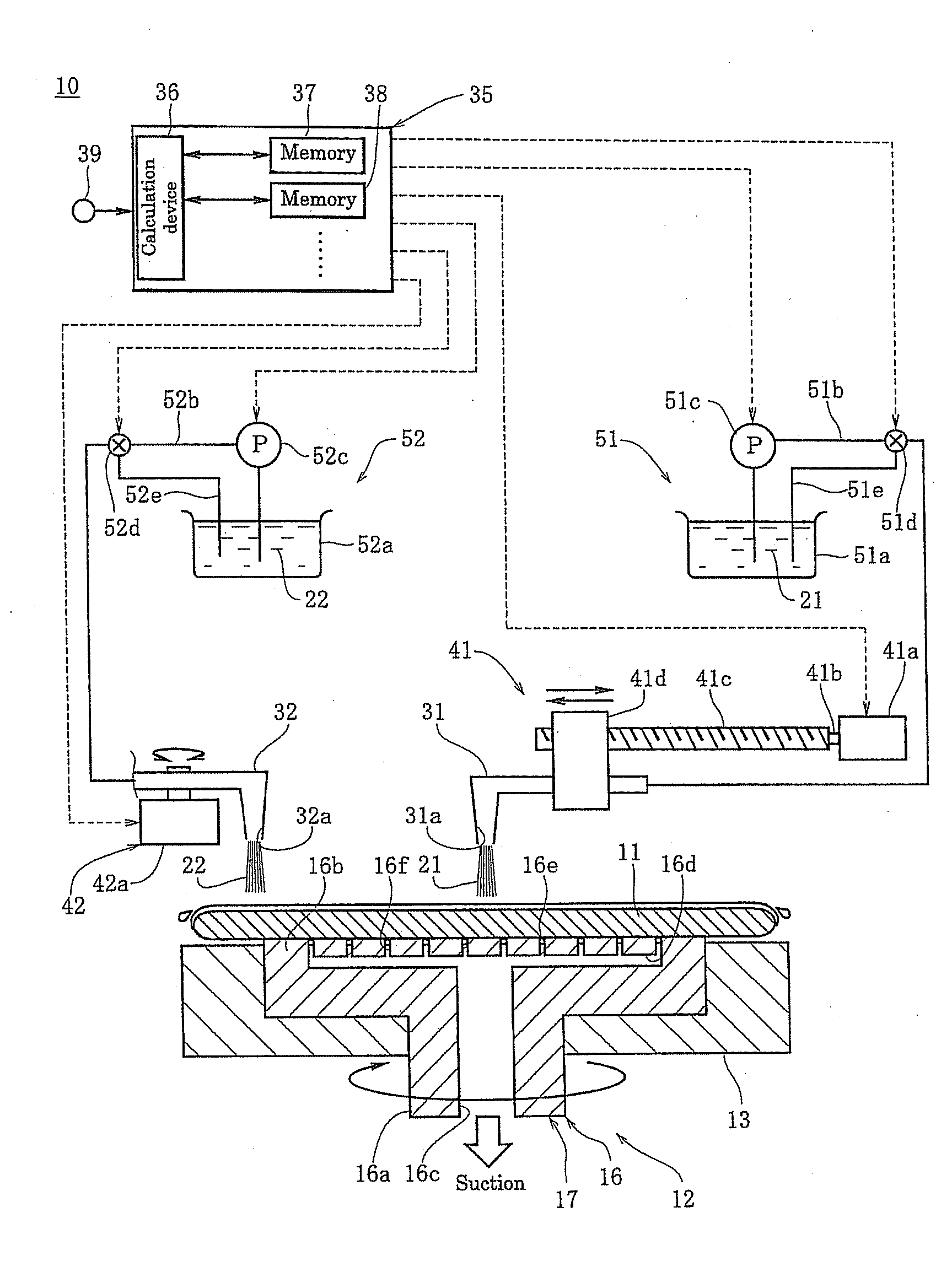

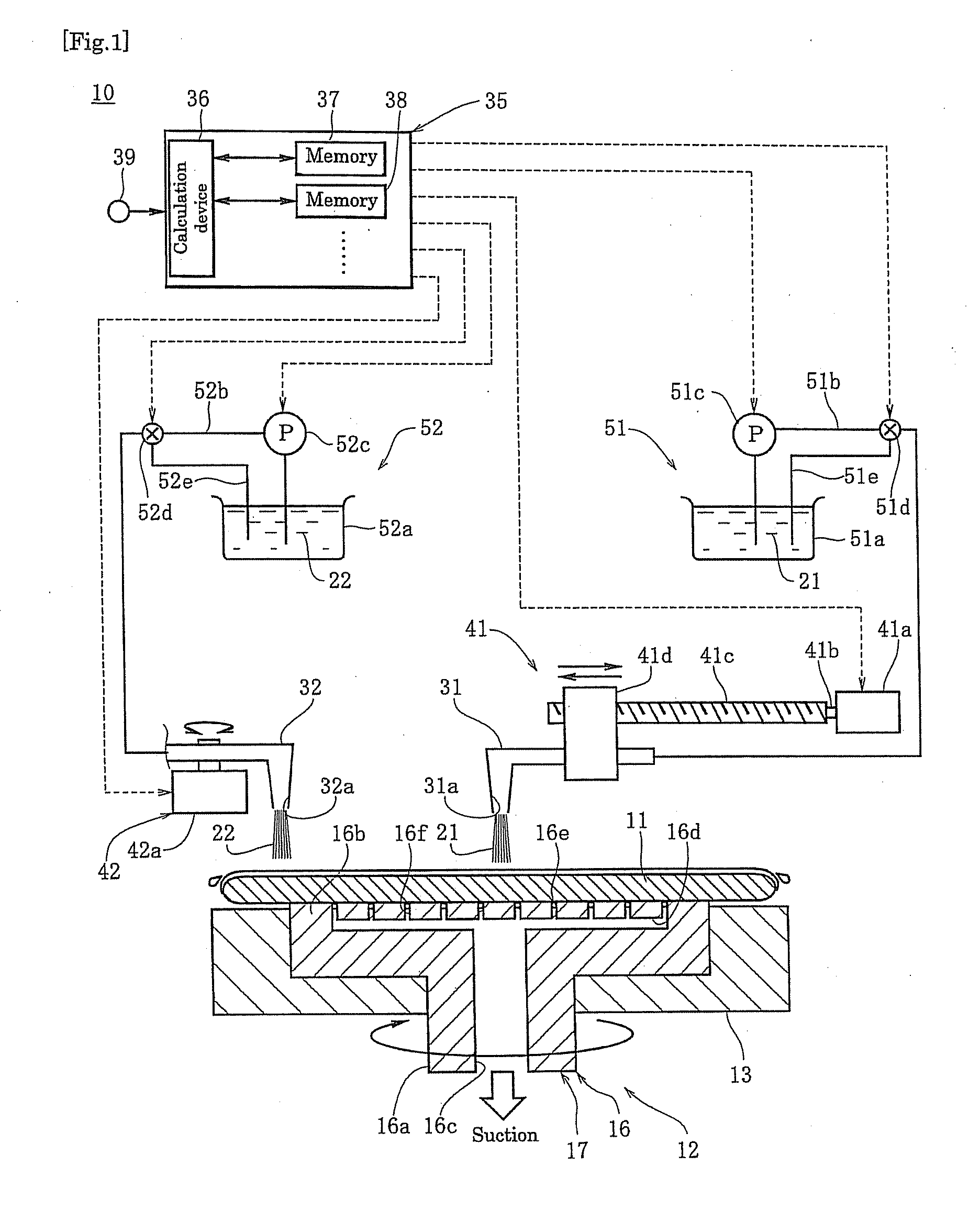

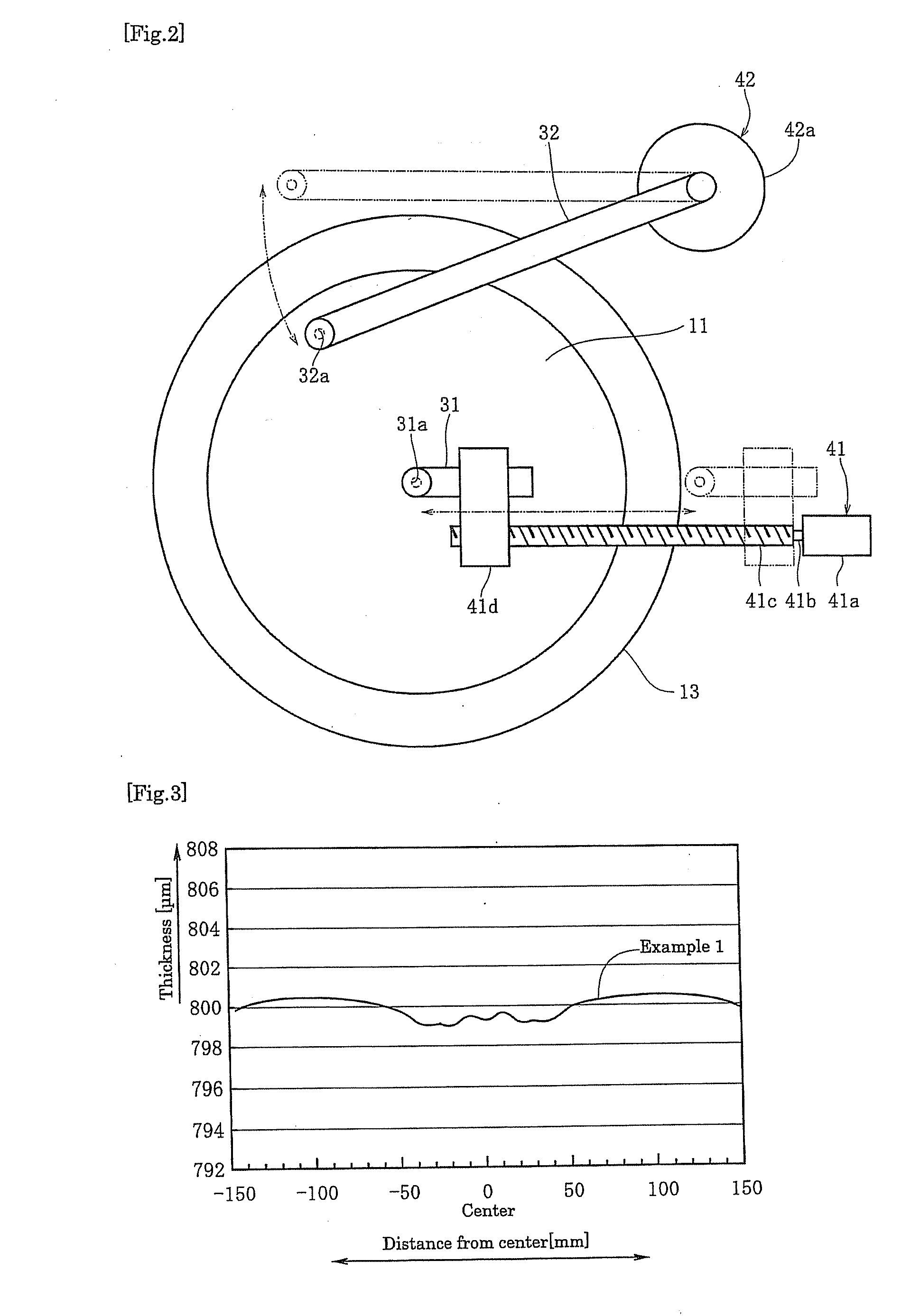

Method for Etching Single Wafer

ActiveUS20090004876A1Improve flatnessRestricted degrees of freedomDecorative surface effectsSemiconductor/solid-state device manufacturingProduction rateWafering

An object of the present invention is to provide a method for etching a single wafer, which effectively realizes a high flatness of wafer and an increase in productivity thereof. In a method for etching a single wafer, a single thin disk-like wafer sliced from a silicon single crystal ingot is spun, and a front surface of the wafer is etched with an etching solution supplied thereto. In the method, a plurality of supply nozzles are disposed above and opposite to the front surface of the wafer at different portions in the radial direction of the wafer, respectively; and then one or more conditions selected from the group consisting of temperatures, kinds, and supply flow rates of etching solutions from the plurality of supply nozzles are changed.

Owner:SUMCO CORP

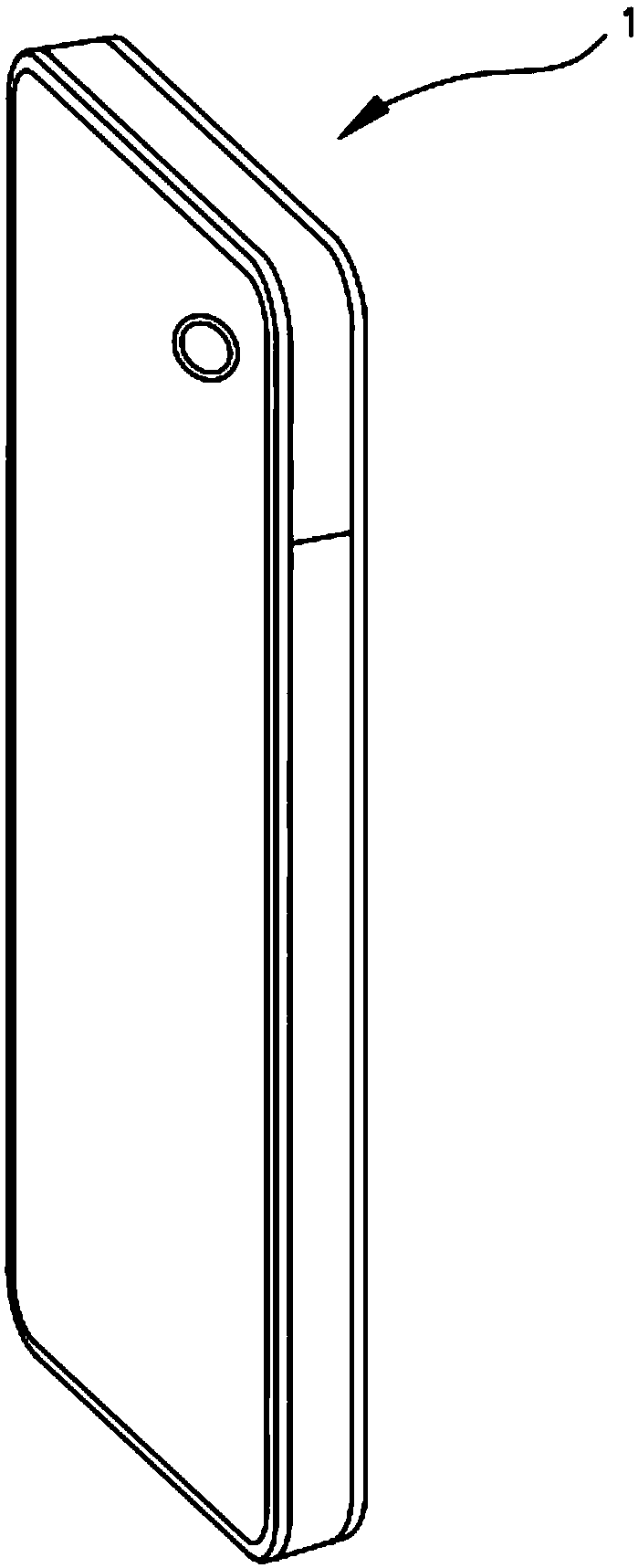

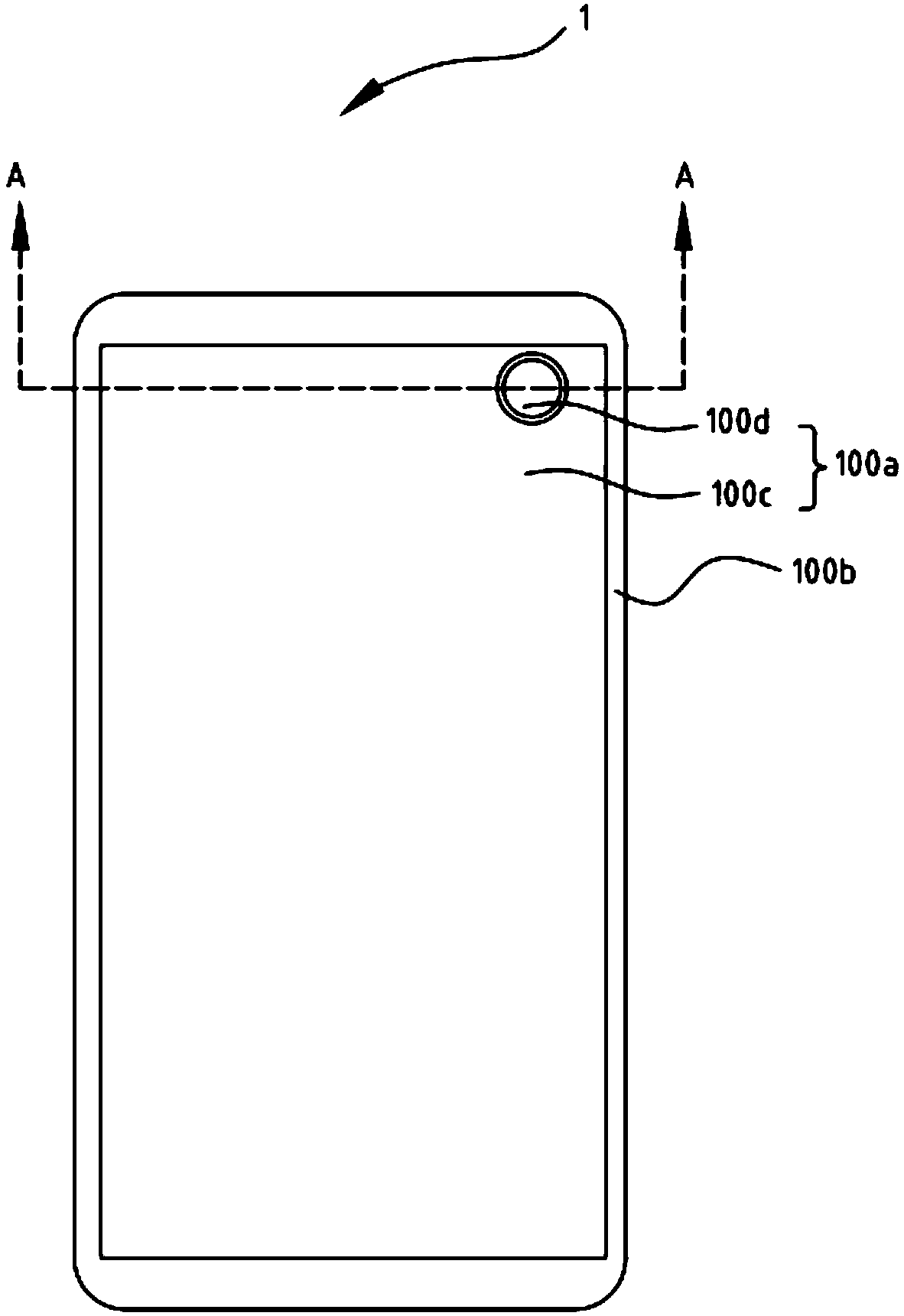

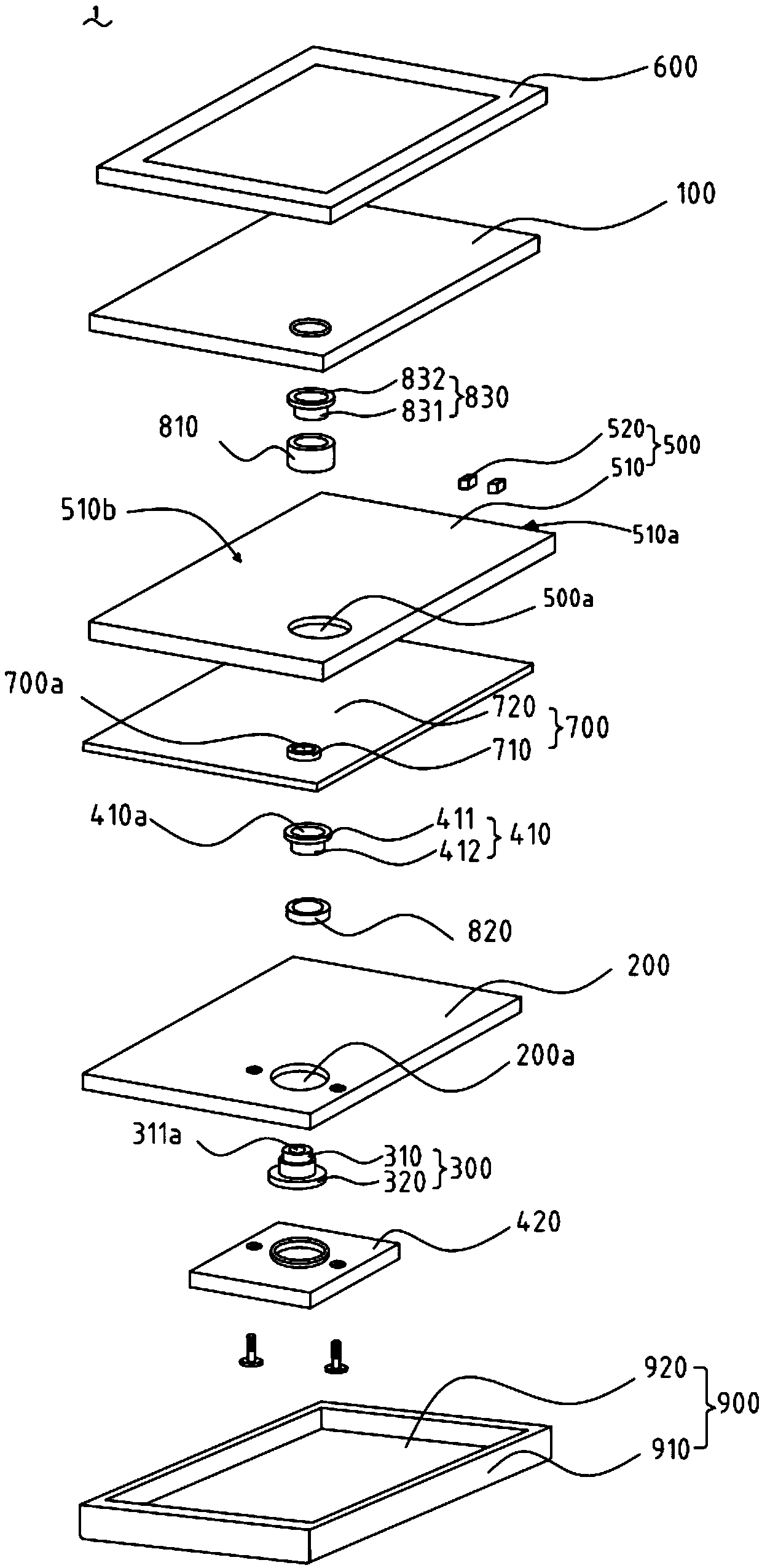

Electronic device

PendingCN108957819ARestricted degrees of freedomIncrease the screen ratioPrintersProjectorsLiquid-crystal displayComputer science

The invention provides an electronic device. The electronic device comprises a liquid crystal display screen, a backlight module, a supporting plate, a first positioning support and a camera, whereinthe liquid crystal display screen comprises a display area, the backlight module and the liquid crystal display screen are stacked, and a first through hole corresponding to the display area is formedin the backlight module. The supporting plate is arranged on the side, away from the liquid crystal display screen, of the backlight module, the supporting plate is used for supporting the backlightmodule, and the first positioning support is fixedly arranged on the surface, away from the backlight module, of the supporting plate. The camera at least partly penetrates through the first positioning support and the supporting plate and is contained in the first through hole, and the first positioning support is used for fixing the camera so as to limit the freedom degree, in the radial direction of the first through hole, of the camera.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

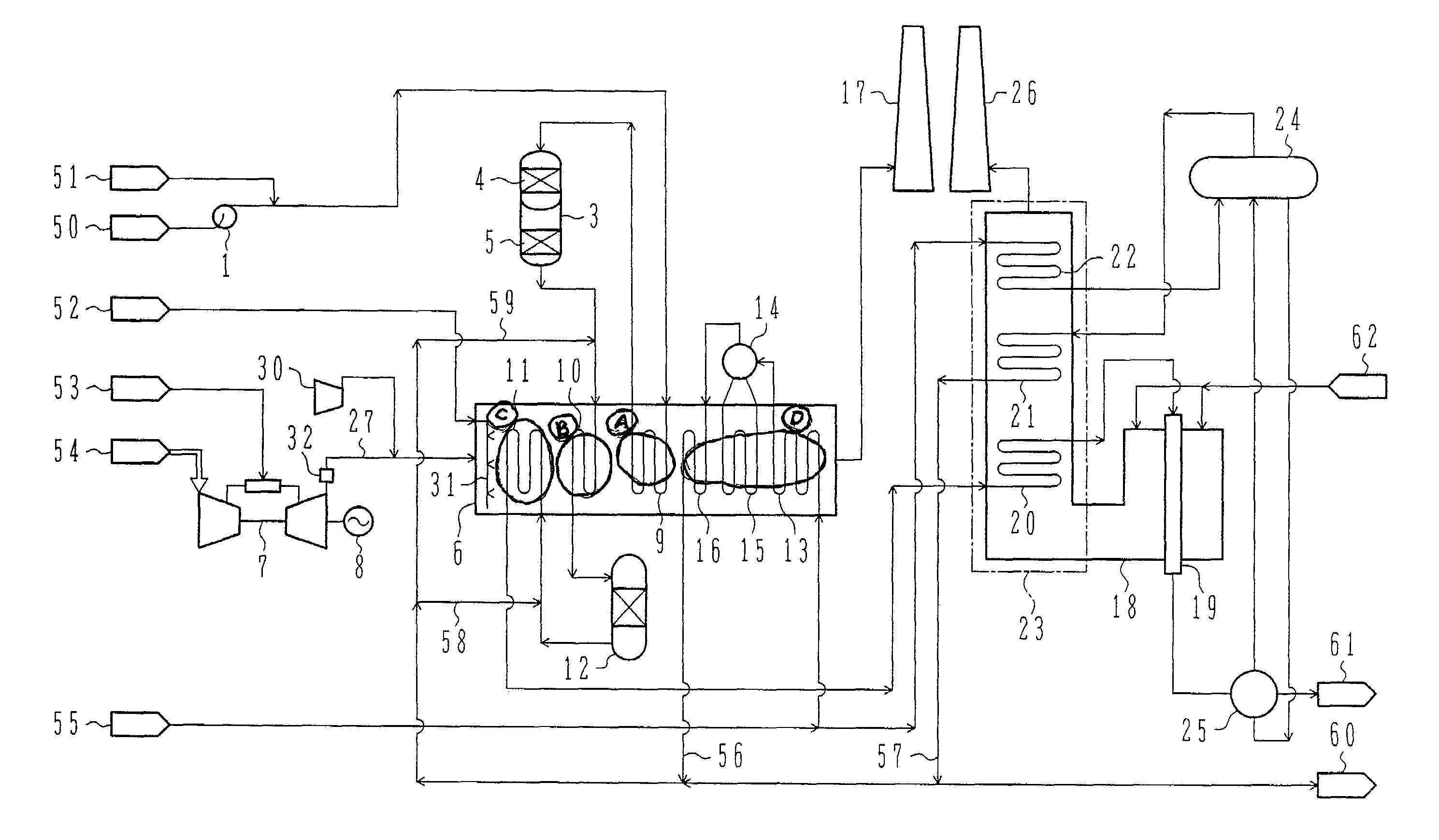

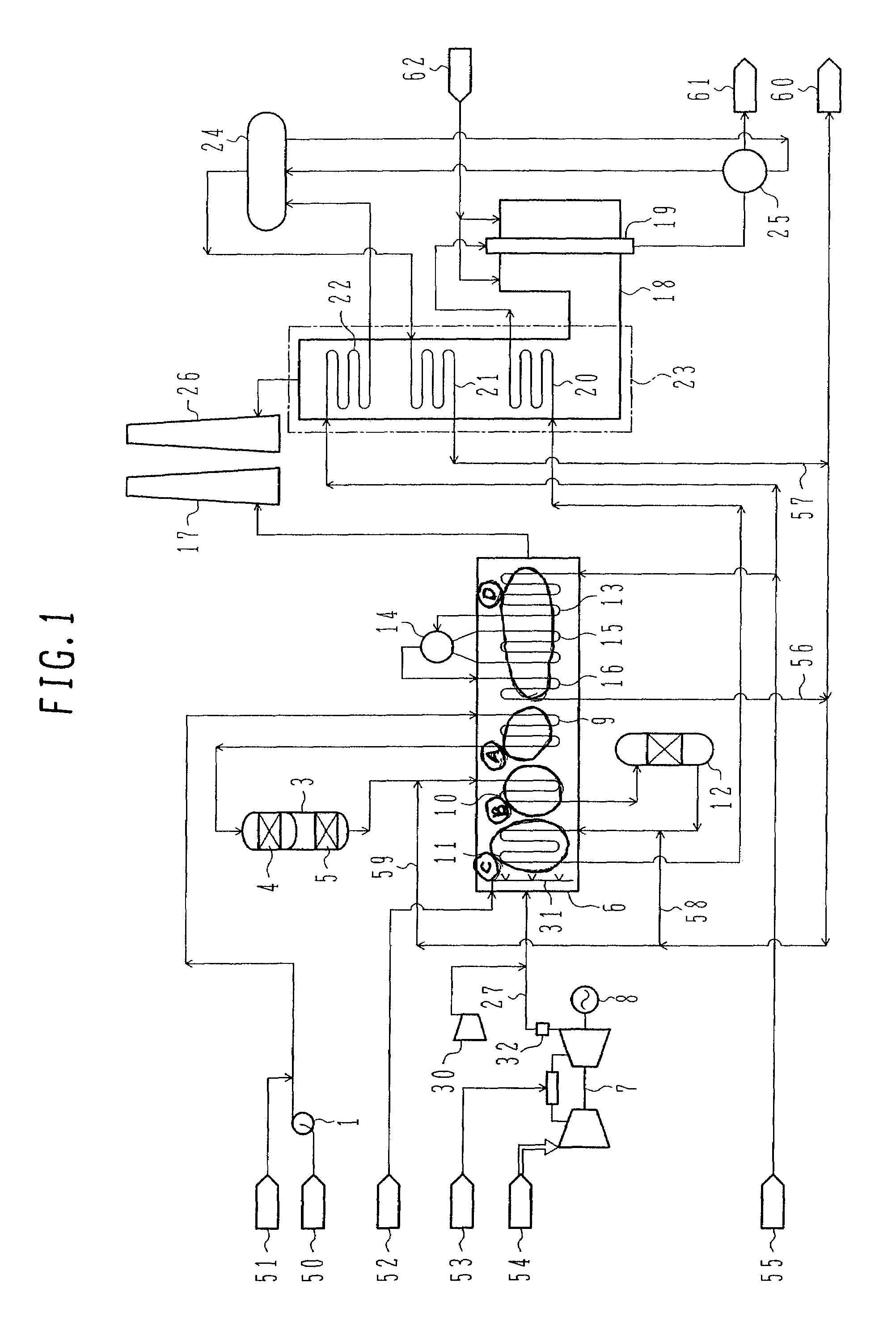

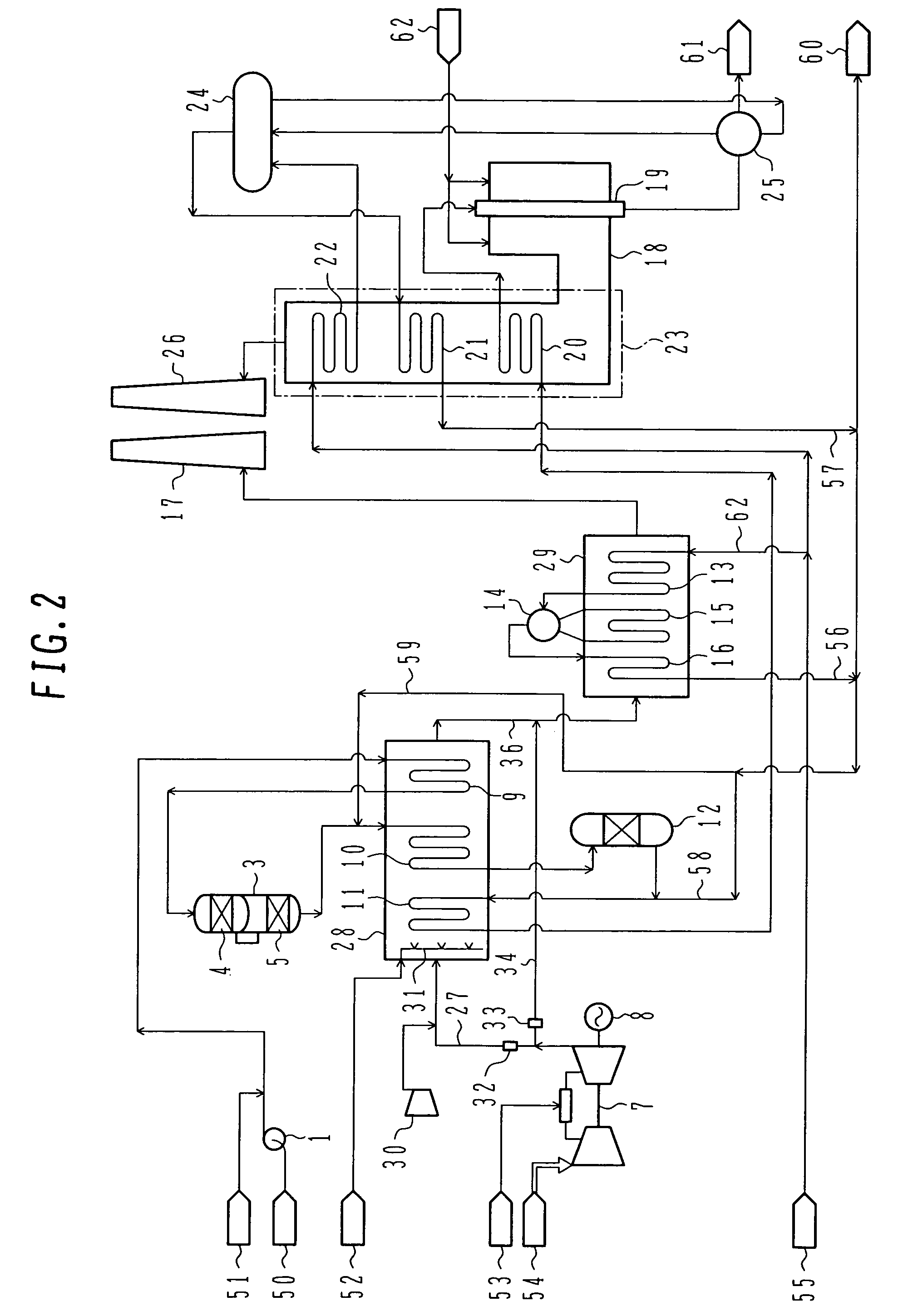

Steam reforming system

InactiveUS7707837B2Save consumptionLow calorific valueHydrogenOrganic compound preparationSteam reformingFlue gas

A steam reforming system with high thermal efficiency, which can compensate for a reduction in the amount of steam generated in a reformer without increasing the reformer size and without limiting the degree of freedom in layout of the reformer and a gas turbine. A gas turbine and a heat recovery exchanger are additionally installed such that the gas turbine generates electric power, and flue gases of the gas turbine are employed to preheat feedstocks supplied to the reformer and to generate steam used for the pre-reforming stage. The heat recovery exchanger is disposed in a downstream channel for the flue gases (at 500-600° C.) of the gas turbine to perform heat exchange between the high-temperature flue gases of the gas turbine and the feedstocks supplied to the reformer, thereby increasing the temperature of the feedstocks to a level suitable for vaporization and desulfurization, and to a level suitable for the pre-reforming stage in a pre-reformer. Generation and superheating of steam required for the pre-reforming stage are performed by the remaining heat of the flue gases of the gas turbine.

Owner:MITSUBISHI POWER LTD

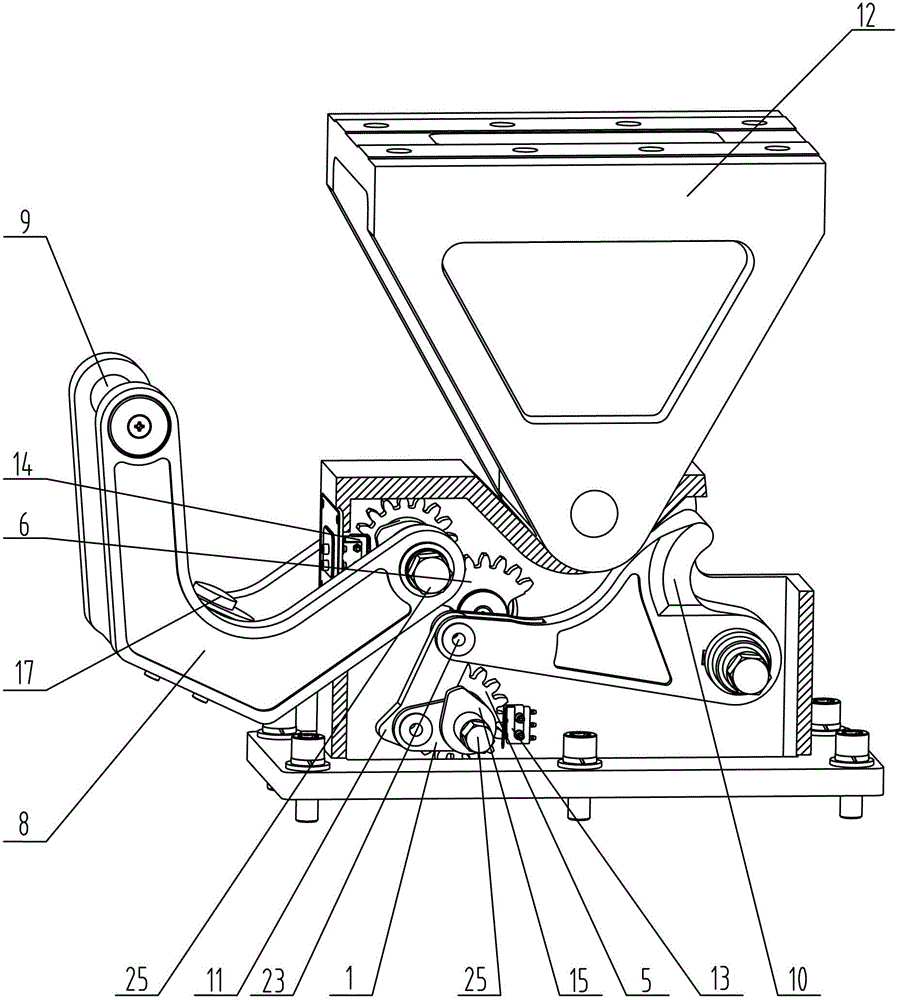

On-orbit repeated locking and releasing mechanism for space

InactiveCN106608373ARestricted degrees of freedomNon-affecting gestureCosmonautic component separationLocking mechanismEngineering

The invention relates to a repeated locking and releasing mechanism, in particular to an on-orbit repeated locking and releasing mechanism for space, and aims to solve the problem of repeated on-orbit locking and releasing of a large-scale actual load in a spacecraft. The on-orbit repeated locking and releasing mechanism comprises a trunnion locking mechanism, a lock hook compacting mechanism, a base locking mechanism, a crank and rocker mechanism and a driving gear mechanism, wherein the trunnion locking mechanism is arranged at the upper end of the base locking mechanism; and the driving gear mechanism is connected with the lock hook compacting mechanism and the crank and rocker mechanism. According to the on-orbit repeated locking and releasing mechanism disclosed by the invention, the trunnion locking mechanism, the lock hook compacting mechanism, the base locking mechanism, the crank and rocker mechanism and the driving gear mechanism are arranged in a crossed manner, so that the on-orbit repeated locking and releasing mechanism is simple and compact in structure; all the freedom degrees of a fixed object can be completely limited, and repeated locking can be realized; the maneuverability is good, so that the using requirement of on-orbit locking-releasing-relocking can be met. The on-orbit repeated locking and releasing mechanism disclosed by the invention is suitable for the technical field of aerospace and the technical field of electromechanical integration.

Owner:赵士野

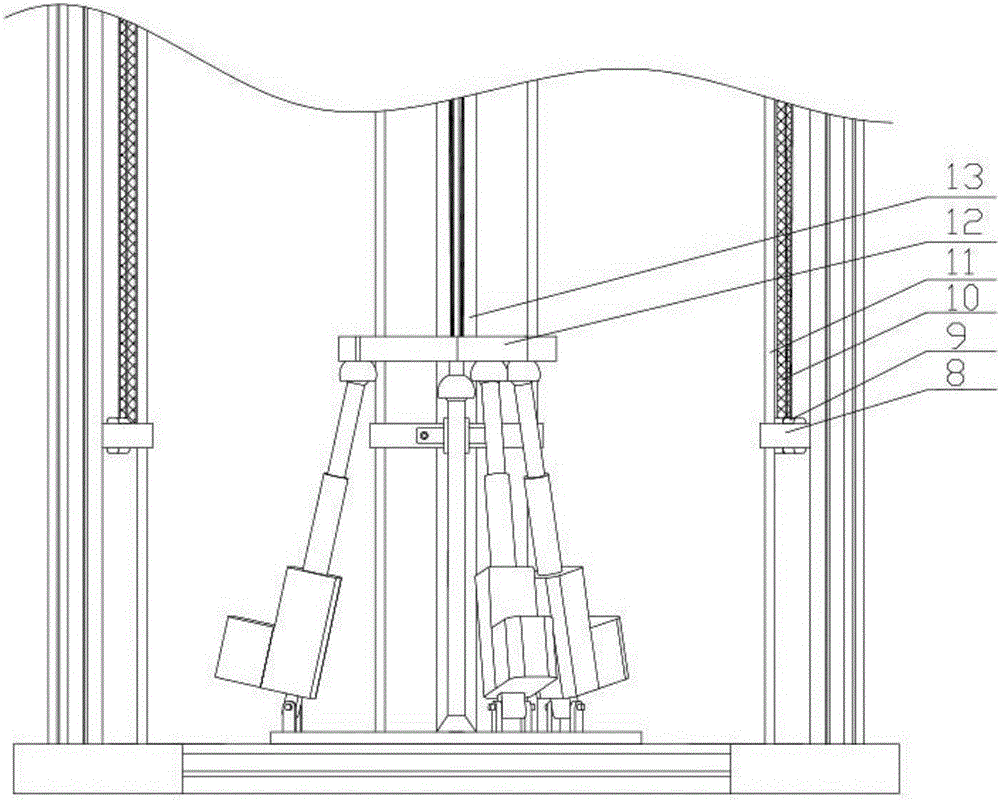

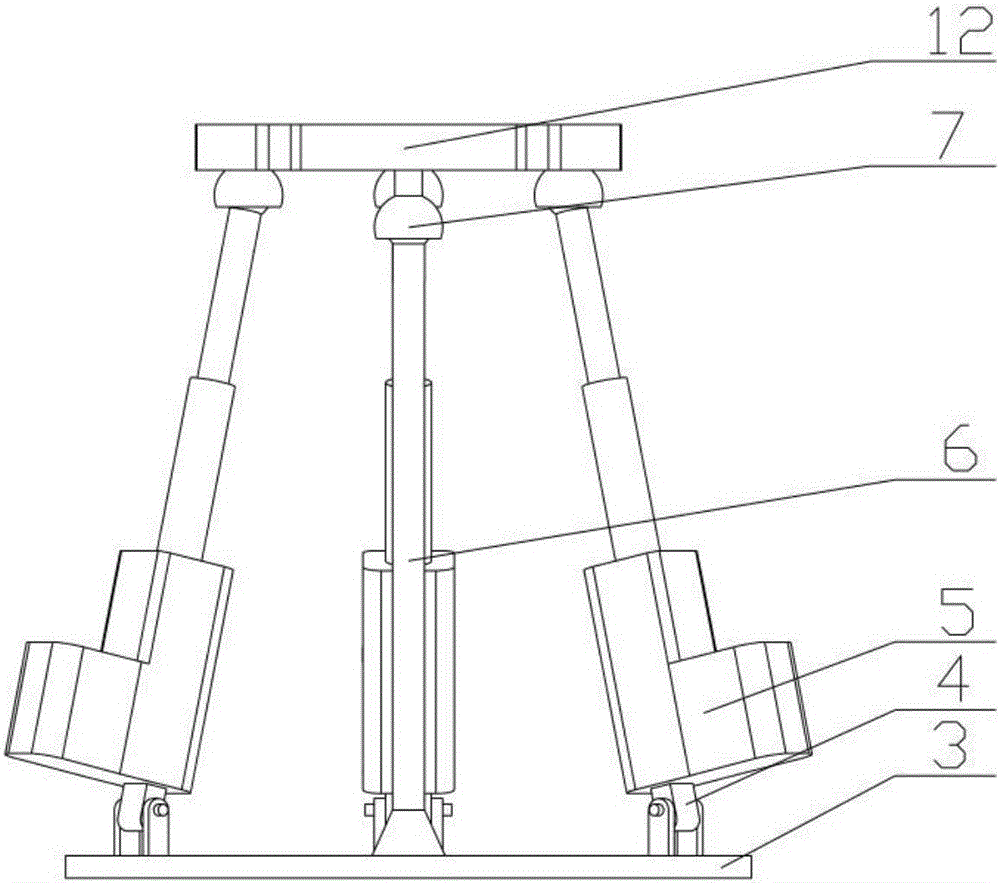

3D printing machine with inclinable working platform

InactiveCN105818393AImprove printing accuracyImprove printing efficiencyAdditive manufacturing apparatusEngineering3d printer

The invention discloses a 3D printing machine with an inclinable working platform, and belongs to the technical field of digital machining. The 3D printing machine is a five-shaft linkage 3D printing device based on a parallel mechanism. The working platform is inclined through electric push rods and spherical hinge structures; and the electric push rods are hinged to a lower platform adopted as a static platform of the parallel mechanism through hooke joints to form a 3-PRS parallel mechanism. According to the 3D printing machine with the inclinable working platform, the defects of a traditional two-shaft or three-shaft linkage 3D printing machine are overcome, the printing efficiency is greatly improved through five-shaft linkage, the gravity limit problem caused by a cantilever and a hollow structure during workpiece design engineering is solved, hollow polyhedrons, multi-layer honeycomb structure workpieces and curved surface workpieces can be directly printed through the 3D printing machine, and the 3D printing efficiency is improved.

Owner:JILIN UNIV

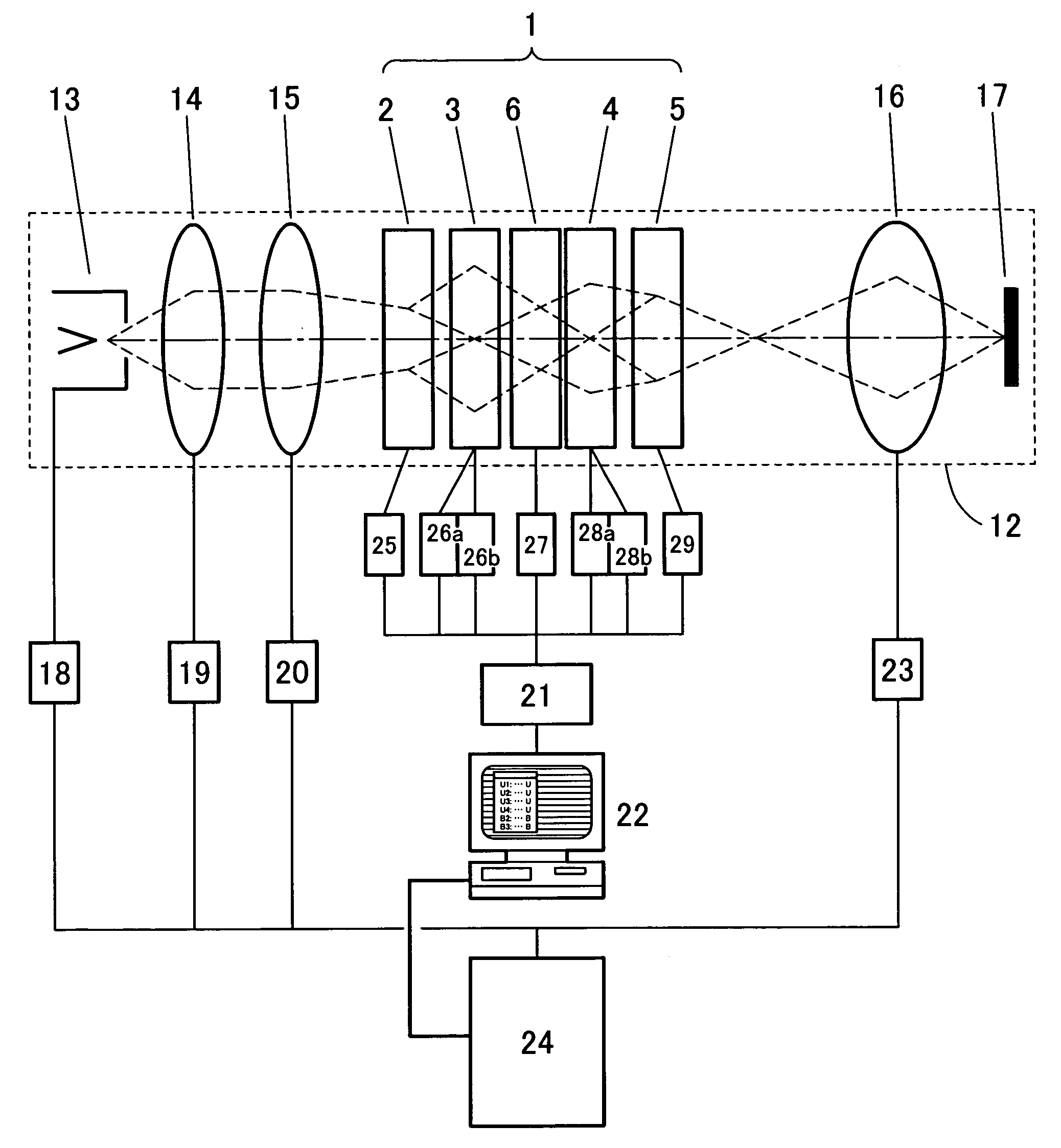

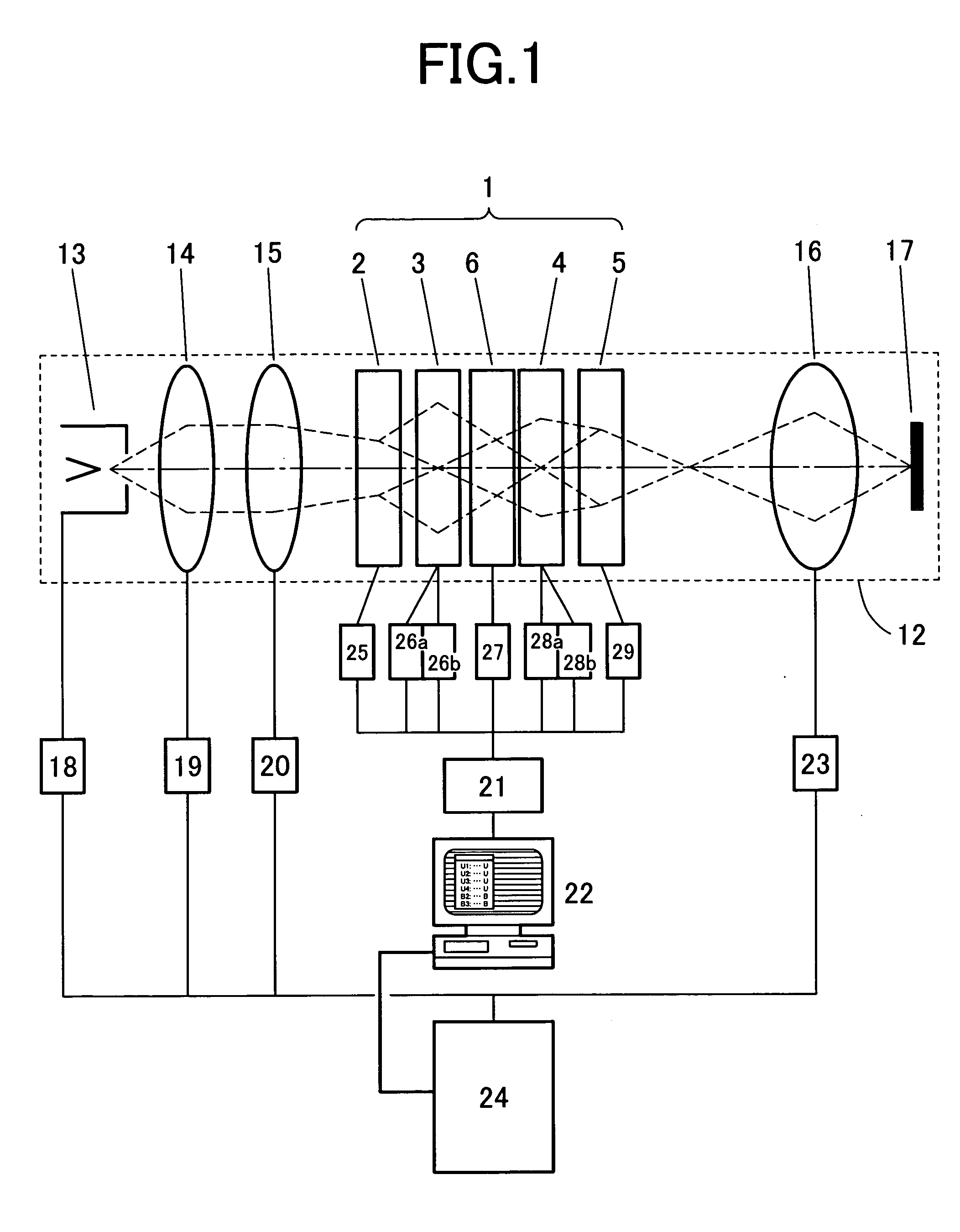

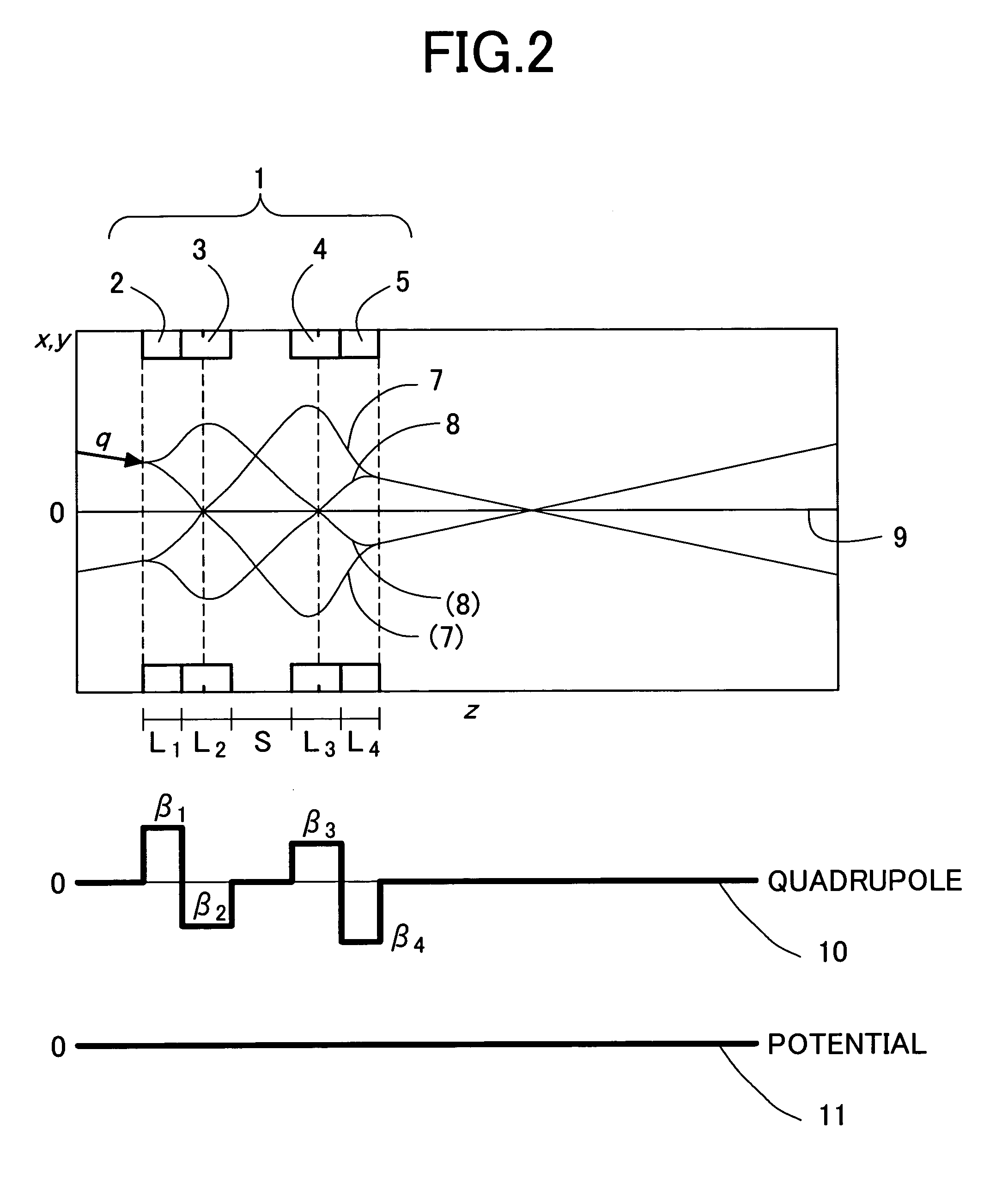

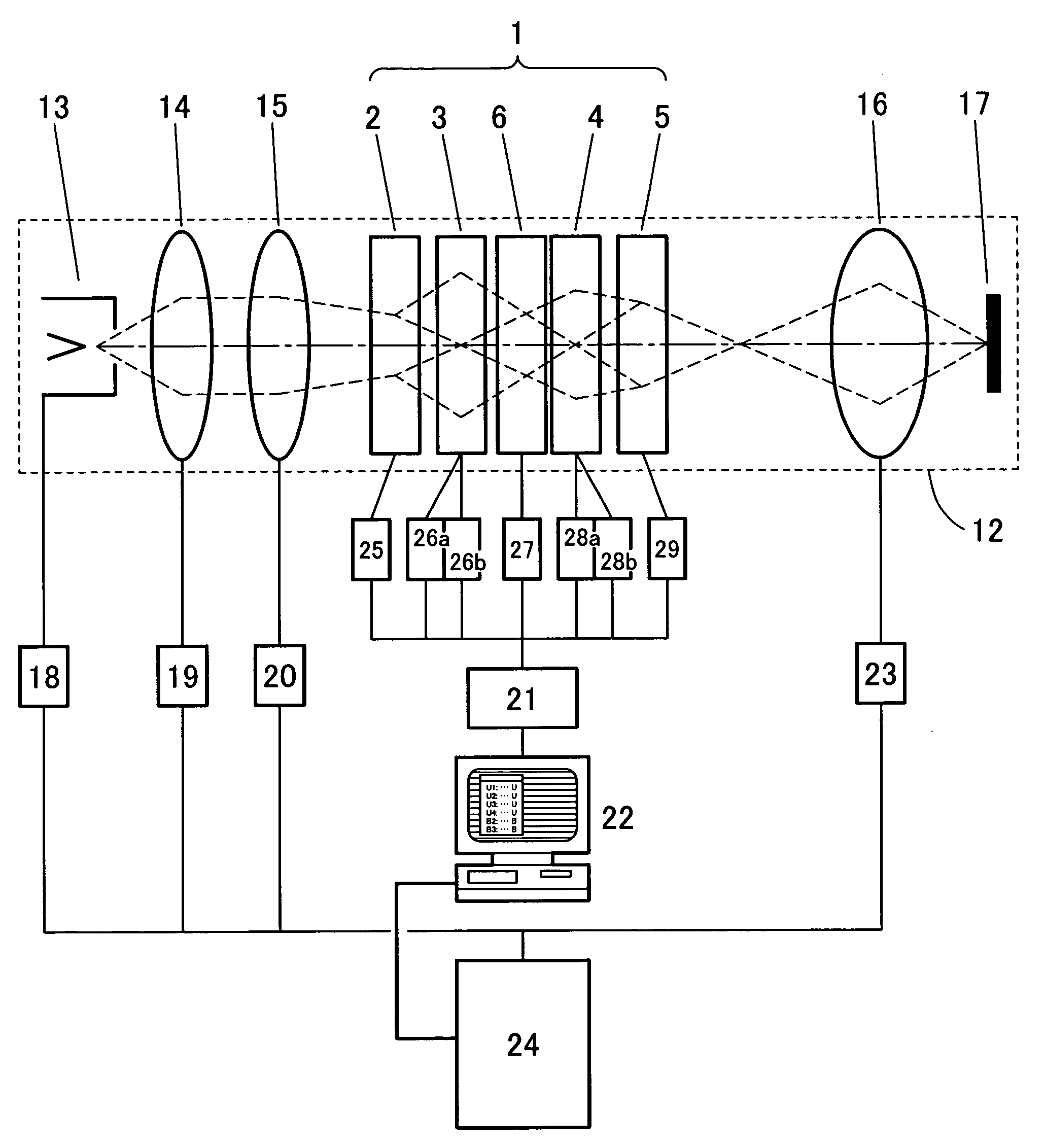

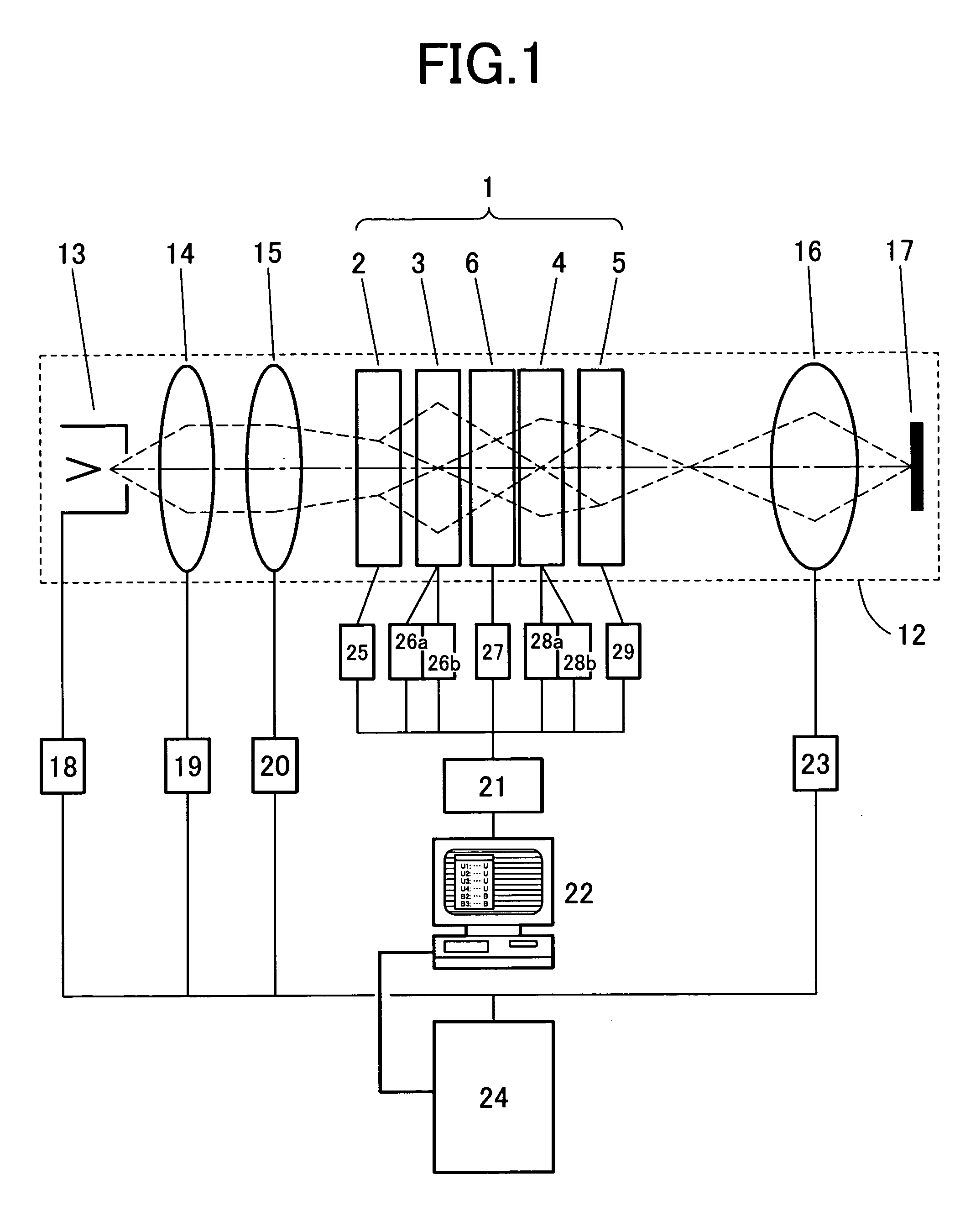

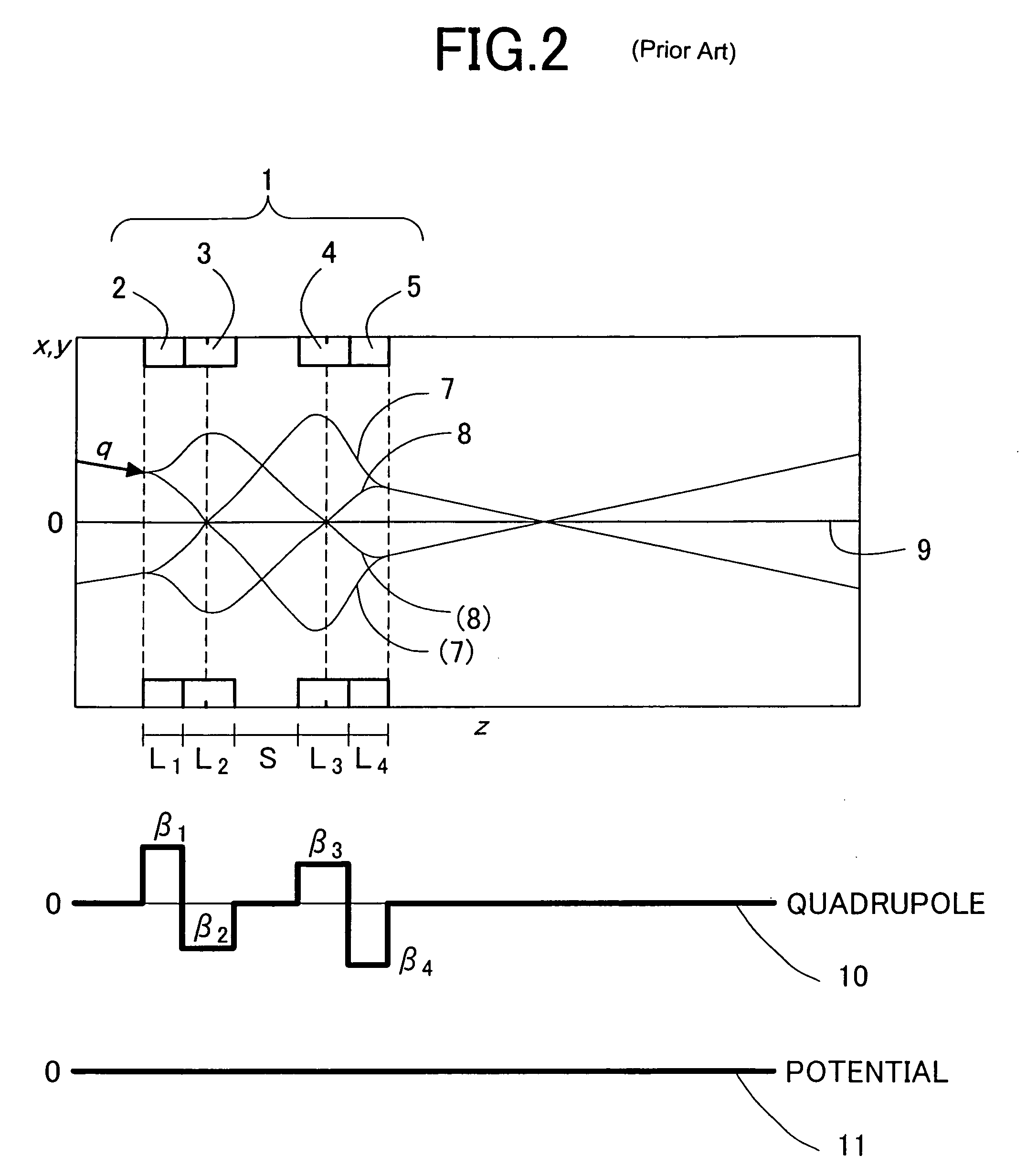

Chromatic aberration corrector for charged particles and charged-particle optical apparatus using the corrector

ActiveUS20050104006A1Optimal aberration correctionChromatic Aberration StabilizationStability-of-path spectrometersMaterial analysis using wave/particle radiationMolecular physicsCharged particle beam

The present invention provides an aberration corrector functioning under a condition outside the setting optical condition of an incorporated charged particle beam apparatus. An intermediate potential region different from the ground potential of an aberration corrector is provided in the space between the stages of multipole lenses constructing the aberration corrector to adjust a potential. Using this, when selecting an incident (outgoing) condition, an outgoing (incident) condition can be adjusted.

Owner:HITACHI HIGH-TECH CORP

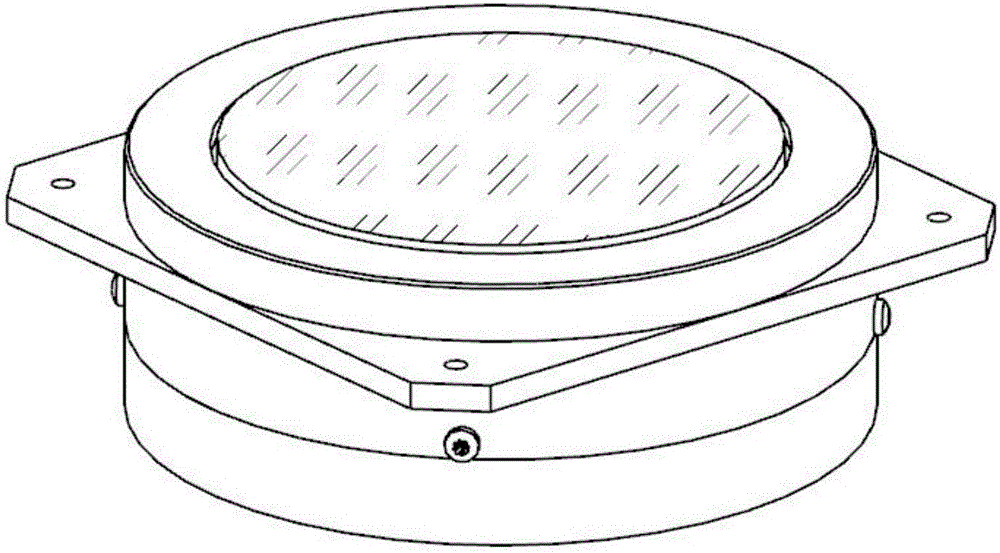

Universal large-aperture rigid bearing-type quick reflecting mirror

InactiveCN106324789AAchieve decouplingRestricted degrees of freedomMountingsPush and pullBall bearing

The invention discloses a universal large-aperture rigid bearing-type quick reflecting mirror, and relates to the technical field of precise optical mechanical structure design. The problems that an existing rigid bearing-type quick reflecting mirror cannot limit the Z-direction rotation freedom degree, miniaturization is difficult to achieve, and the universality is poor are solved. By means of the structural design that a universal ball bearing is combined with a flexible ring, rigid supporting can be provided for the large-aperture reflecting mirror, the two-dimensional rotation freedom degrees around the X axis and the Y axis can be provided, and the freedom degrees in the other directions are limited; a planar reflecting mirror is bonded with a reflecting mirror base through an optical epoxy adhesive, and therefore influences of the temperature, vibration and the like on the shape and the position of the reflecting mirror can be reduced; the reflecting mirror is driven in the mode that four linear voice coil motors conduct pushing and pulling two by two, the rotation moment is increased, and angle calculation is convenient; differential measuring is conducted by adopting four electric vortex sensors, the angle adjusting precision of a control system is improved; a driving assembly and a sensor assembly are symmetrically arranged in a staggered mode, and therefore the structural size of the system is decreased; an upper cover is universally installed, and therefore the quick reflecting mirror can be conveniently installed and used in various fields.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

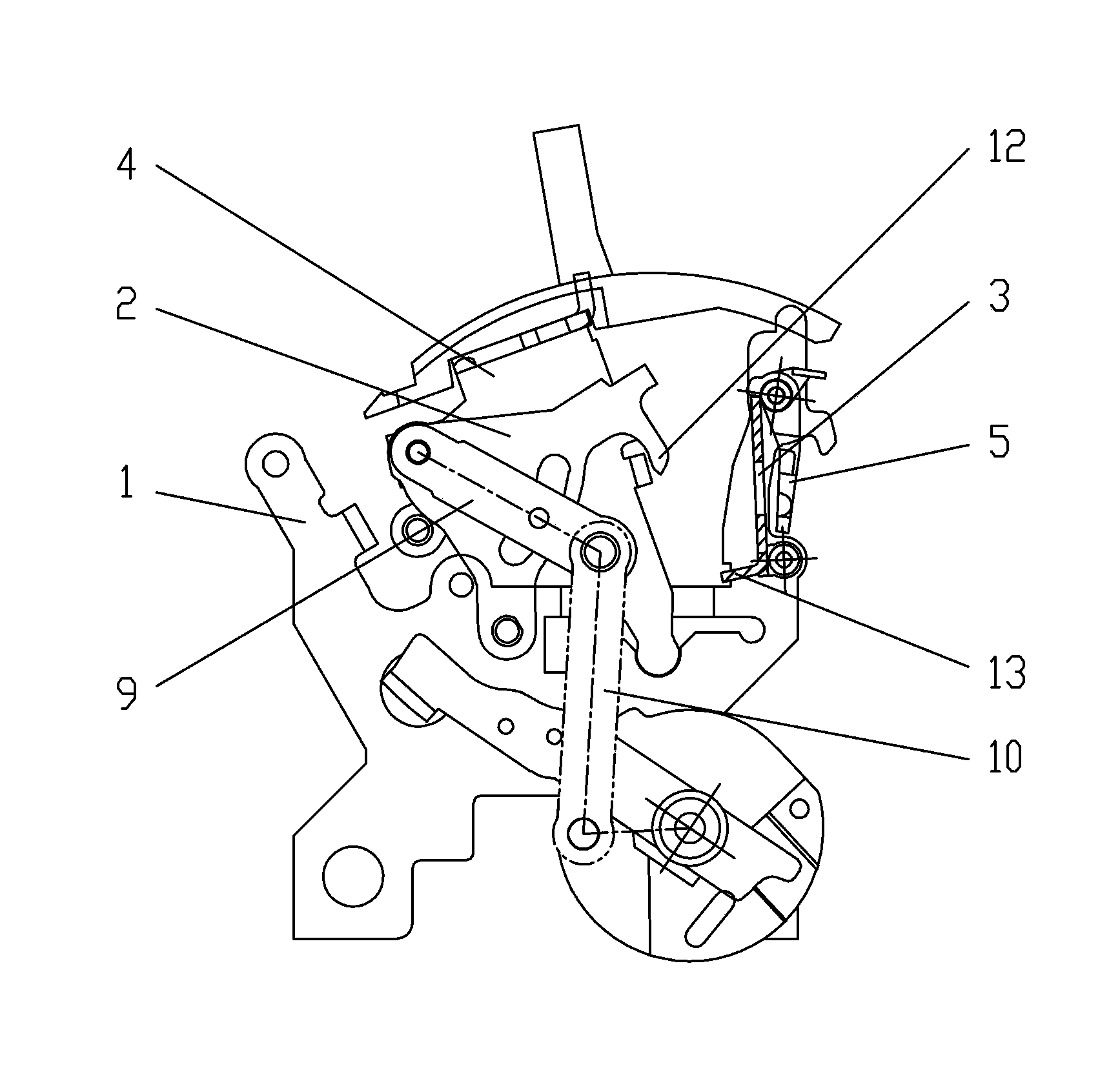

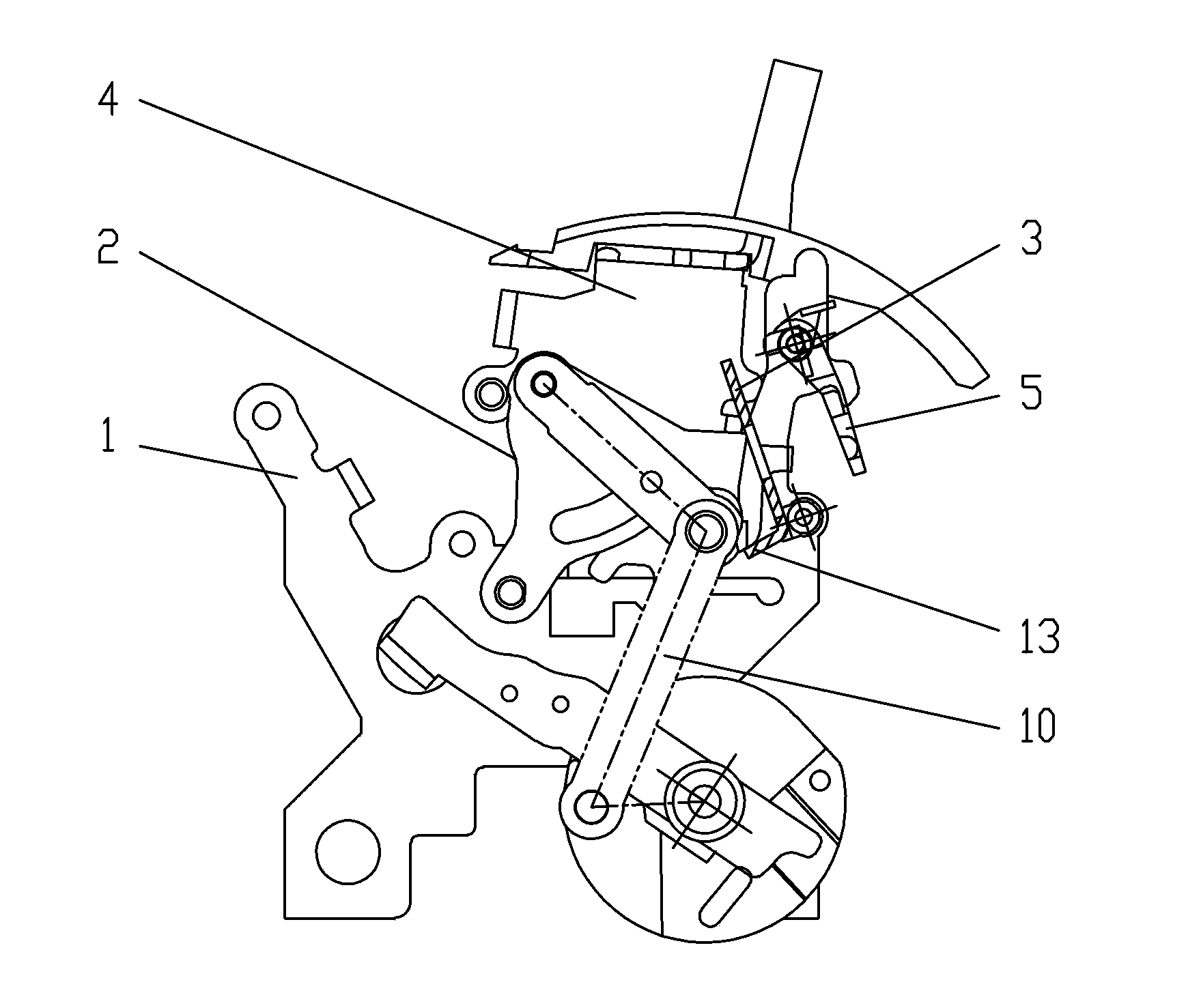

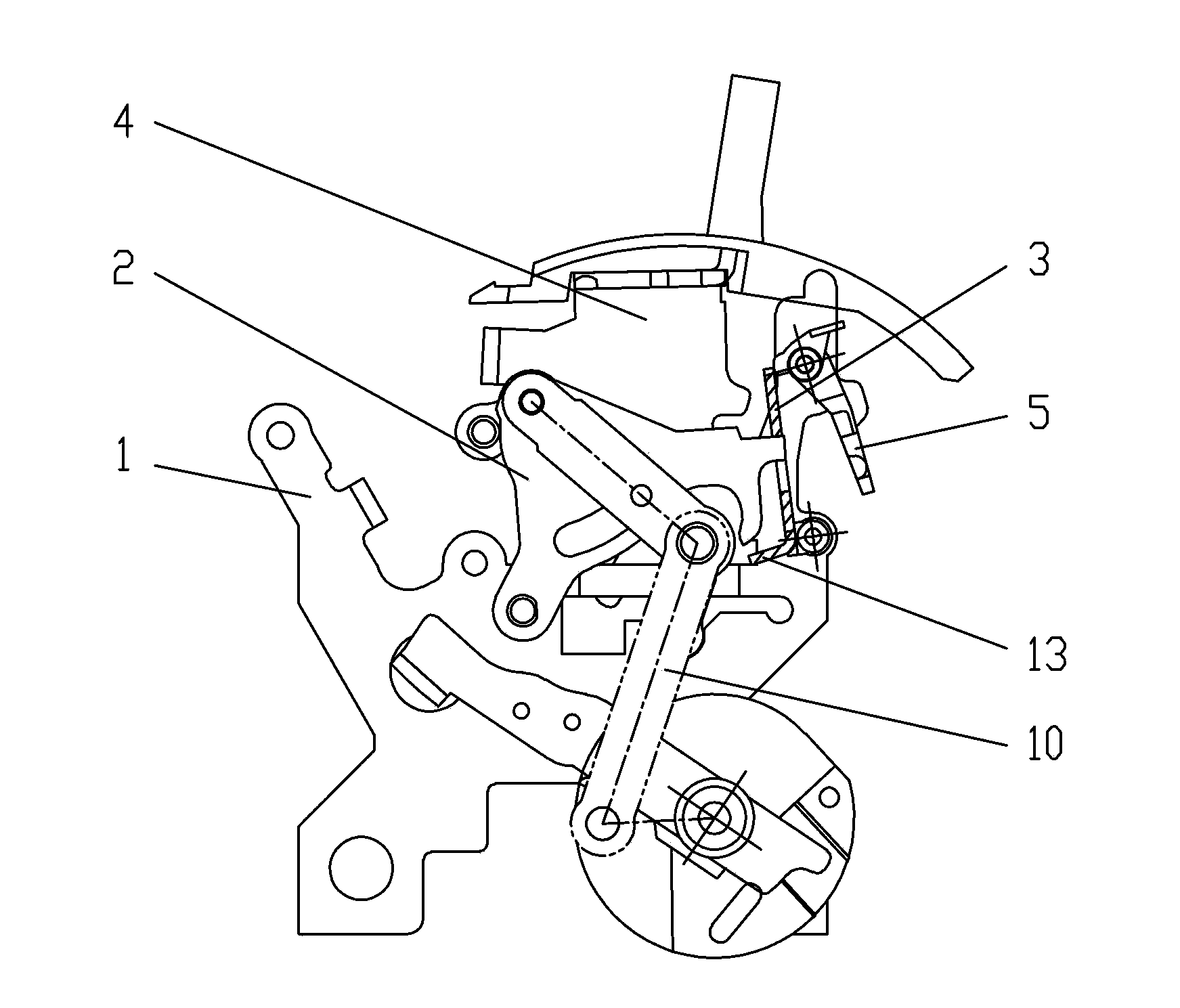

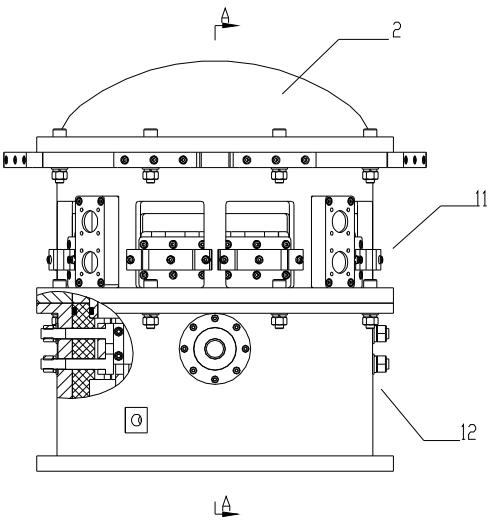

Molded case circuit breaker operating mechanism buckle carrying device

InactiveCN103441041ARestricted degrees of freedomChange direction of rotationElectric switchesProtective switch operating/release mechanismsPull forceContact method

The invention relates to a molded case circuit breaker operating mechanism buckle carrying device. A stroke of the reset process of a jumping buckle is utilized for pressing a locking buckle to move, the locking buckle is driven to rotate towards the direction of the jumping buckle, and the locking buckle is separated from a draw bar; after the process of buckling carrying is finished, the jumping buckle resets upwards through pulling force of a main tension spring, the locking buckle and the jumping buckle are tightly locked together, the locking buckle is resisted by the draw bar and cannot rotate, therefore, the jumping buckle is locked and cannot continue to turn over upwards, the freedom degree of the jumping buckle is locked, a five-connecting-rod mechanism is changed into a four-connecting-rod mechanism, and the divide-shut brake function of the mechanism is restored. A design method of a traditional mechanism is overturned by ingeniously utilizing the change of rotation direction of the locking buckle and the draw bar, and an original opening contact method at a position where buckle sliding happens easily is changed into a tightly attaching method. The buckle carrying function of the mechanism is optimized, the technical processes are simplified, and reliable assembling is achieved through simple parts.

Owner:江苏西门控电器有限公司

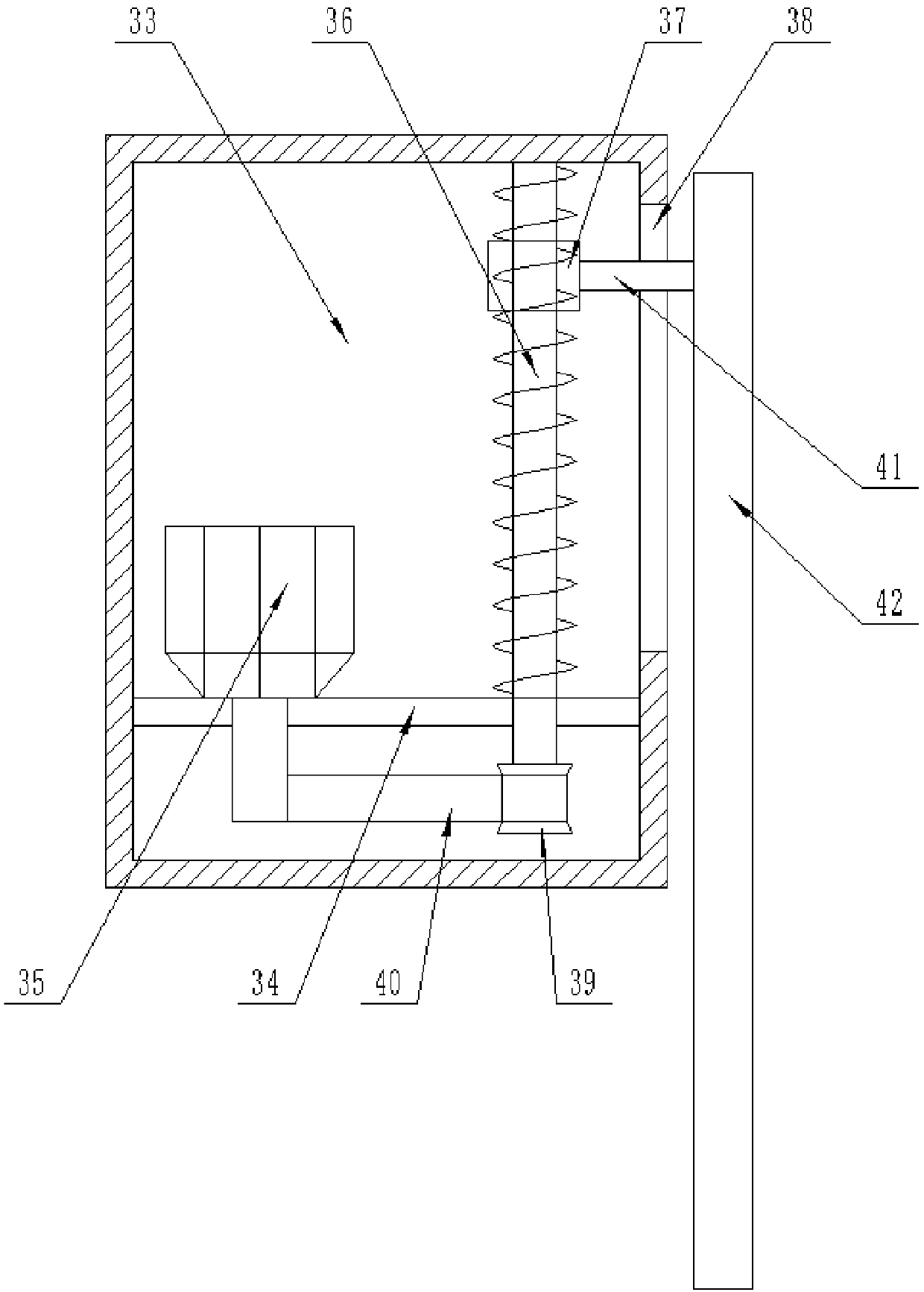

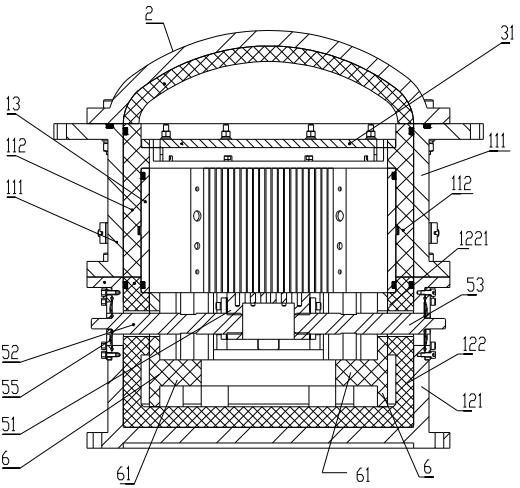

Environmental chamber for multi-parameter composite test

InactiveCN101920792AUniform temperatureSmall temperature differenceCosmonautic condition simulationsWeather/light/corrosion resistanceTemperature controlNoise generation

The invention discloses an environmental chamber for a multi-parameter composite test, comprising an airtight case which is connected with a case cover in a sealing mode, wherein the case and the case cover both comprise an outer layer made of metal to ensure the rigidity of the case and an insulation layer made of metal to maintain the internal temperature of a composite cavity, the inner cavity of the case forms an environmental composite cavity independent to the external; the composite cavity is successively provided with a noise generation mechanism fixed on the upper part of the composite cavity, a temperature control mechanism fixed on the wall of the composite cavity, a vibration generation mechanism, an air intake and an exhaust port from top to down, wherein the vibration generation mechanism is arranged in the composite cavity and is in linkage with an external vibration source, the air intake is connected with an air pump and used for introducing air into the composite cavity to form a pressure filed, and the exhaust port is connected with a vacuum generator in a sealing mode. The invention has the advantages of being capable of fully stimulating the working environment of parts and having good test result and high accuracy.

Owner:ZHEJIANG UNIV

Positioning method for machining workpiece and automatic clamp thereof

ActiveCN102039532AReliable positioningAvoid processing errorsPositioning apparatusMetal-working holdersMechanical engineeringReference surface

The invention relates to a positioning method for machining a workpiece and an automatic clamp thereof, wherein the positioning method comprises the following steps: A) selecting a reference surface of the workpiece; B) setting a reference plate, wherein the shape of the surface of the reference plate, which corresponds to the workpiece is in fit with the shape of the reference surface of the workpiece; C) setting a limiting block which is used for limiting the degree of freedom of the workpiece in the corresponding direction; and D) using a movable positioning block to push and press the workpiece to enable the workpiece to abut against the reference plate and form the surface contact. The automatic clamp mainly comprises the reference plate, a limiting part, a supporting part, the movable positioning block and a power system thereof. The automatic clamp for the positioning method can be used for positioning the workpieces in complex shapes or multi-position machining, the clamping is firm and reliable, and the problems of machining errors and the like caused by the deformation of the workpieces can be further avoided.

Owner:SHENZHEN SHANYUAN ELECTRONICS

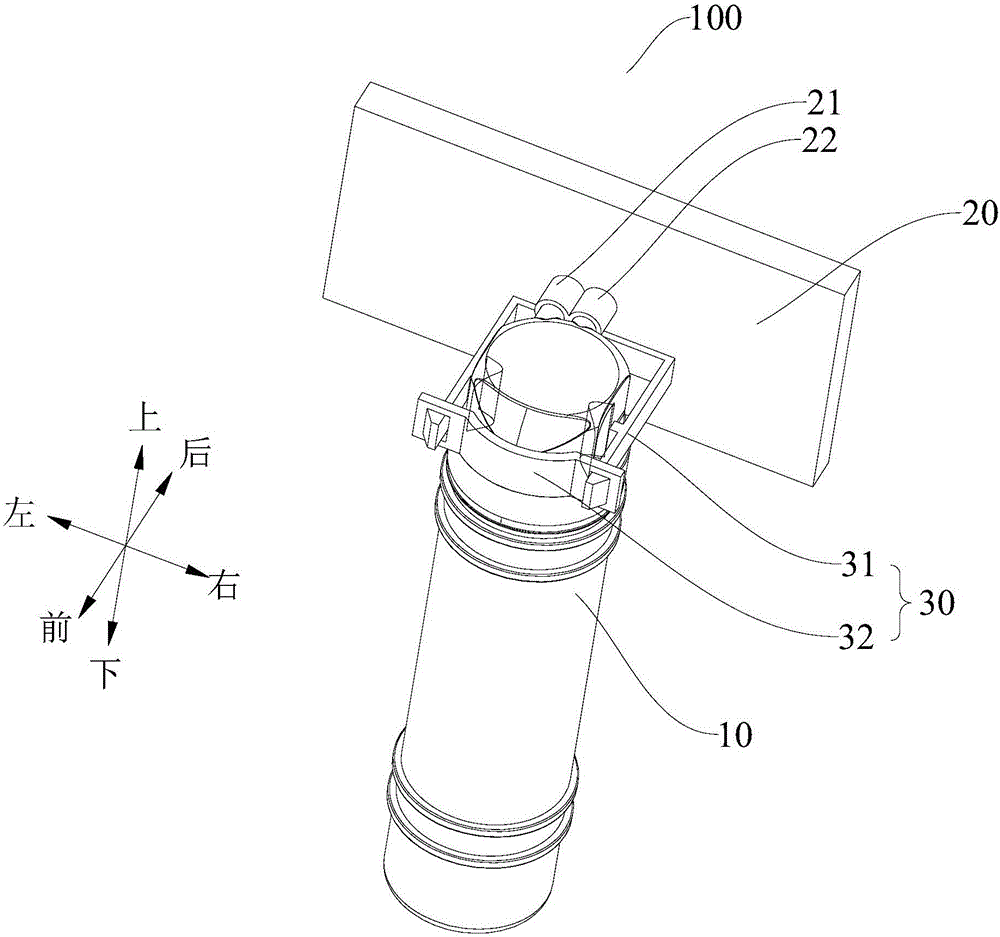

Roller brush fast dismounting and mounting device and cleaning instrument thereof

The invention discloses a roller brush fast dismounting and mounting device and a cleaning instrument thereof. The roller brush fast dismounting and mounting device comprises an ejection device and a position limiting device, wherein the ejection device exerts axial ejection elastic force on a roller brush; the position limiting device converts the elastic force into elastic potential energy and limits the axial displacement of the roller brush; the ejection device comprises an ejector pin and a pressure spring; the ejector pin is arranged inside an axial blind hole formed in one end of the roller brush; the ejector pin is provided with a flange; the pressure spring exerts axial elastic force on the ejector pin through abutting the flange; an ejector pin press plate for limiting the ejector pin to be disengaged from the blind hole is arranged in the opening position of the blind hole; one end of the roller brush is connected with a bearing seat; the roller brush has the rotating degree of freedom for rotating around the self axial line relative to the bearing seat; the position limiting device is provided with a release key with a projected part and a bearing seat with a position clamping groove; the projected part is matched with the position clamping groove. By using the device, the dismounting or the mounting of the roller brush can be realized only through one step; the cleaning of the roller brush is convenient; the roller brush mounting and dismounting efficiency is further improved; the operation environment is improved.

Owner:SUZHOU CHUNJU ELECTRIC CO LTD

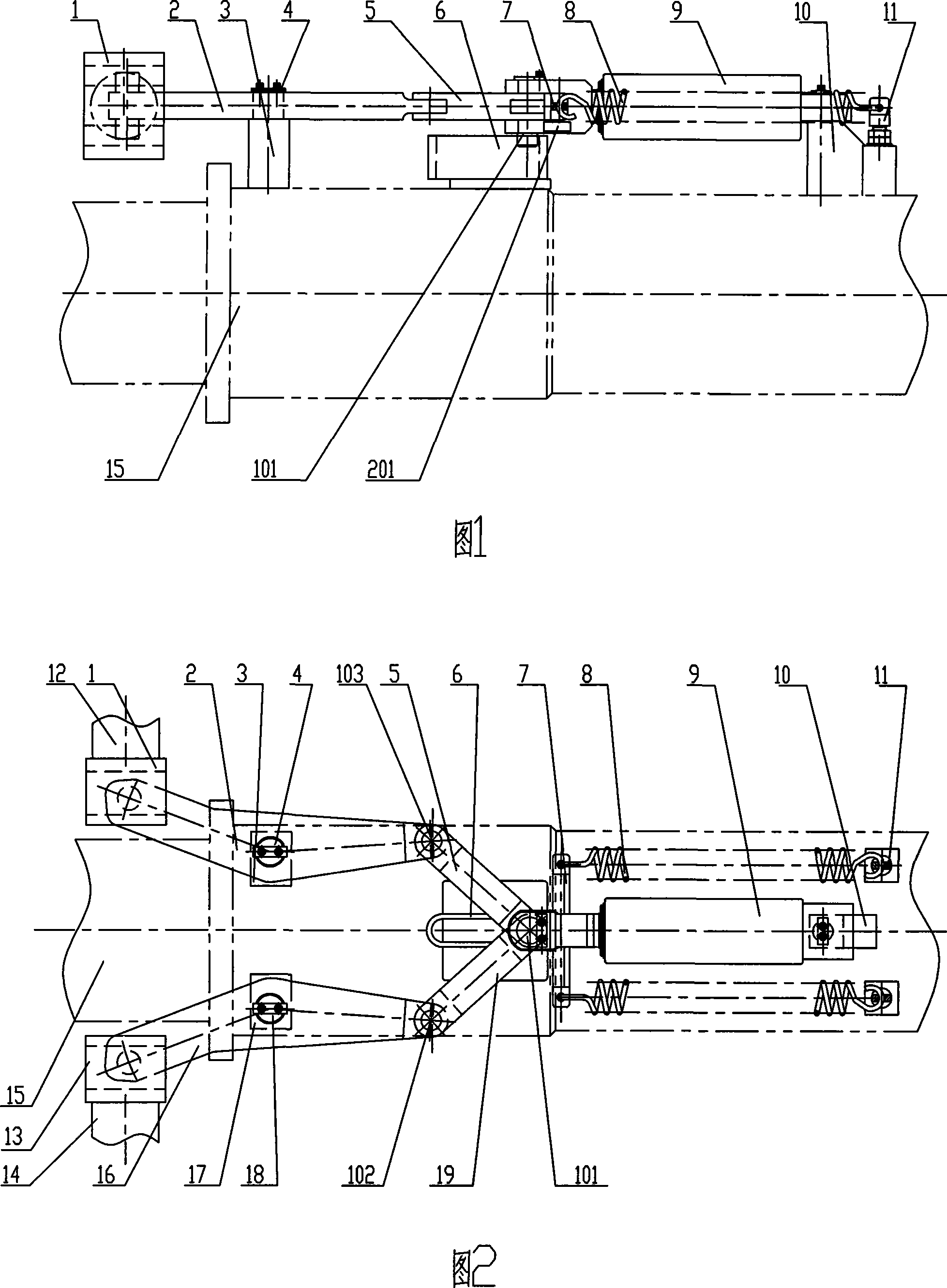

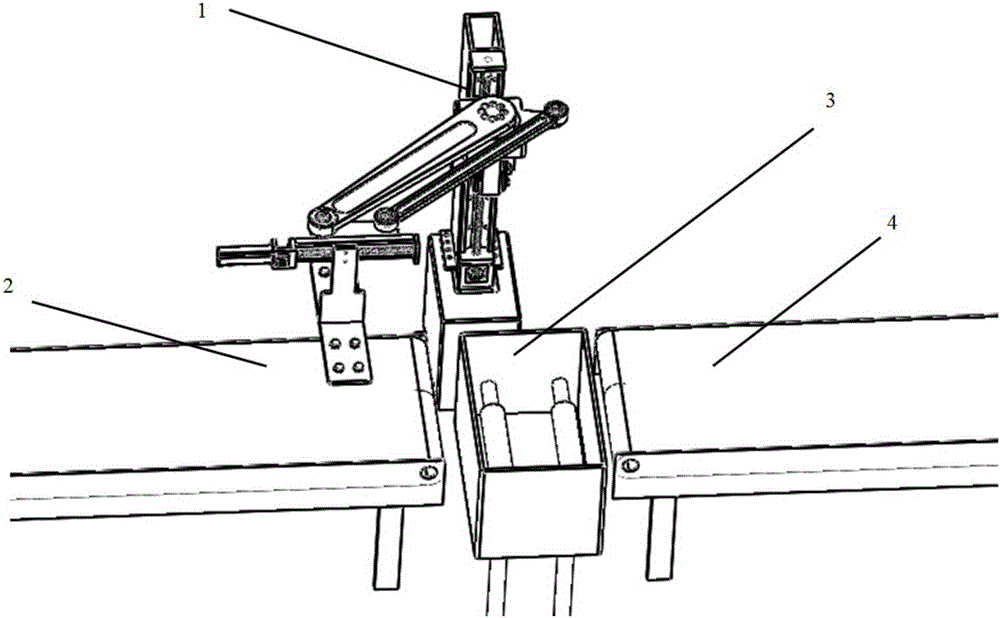

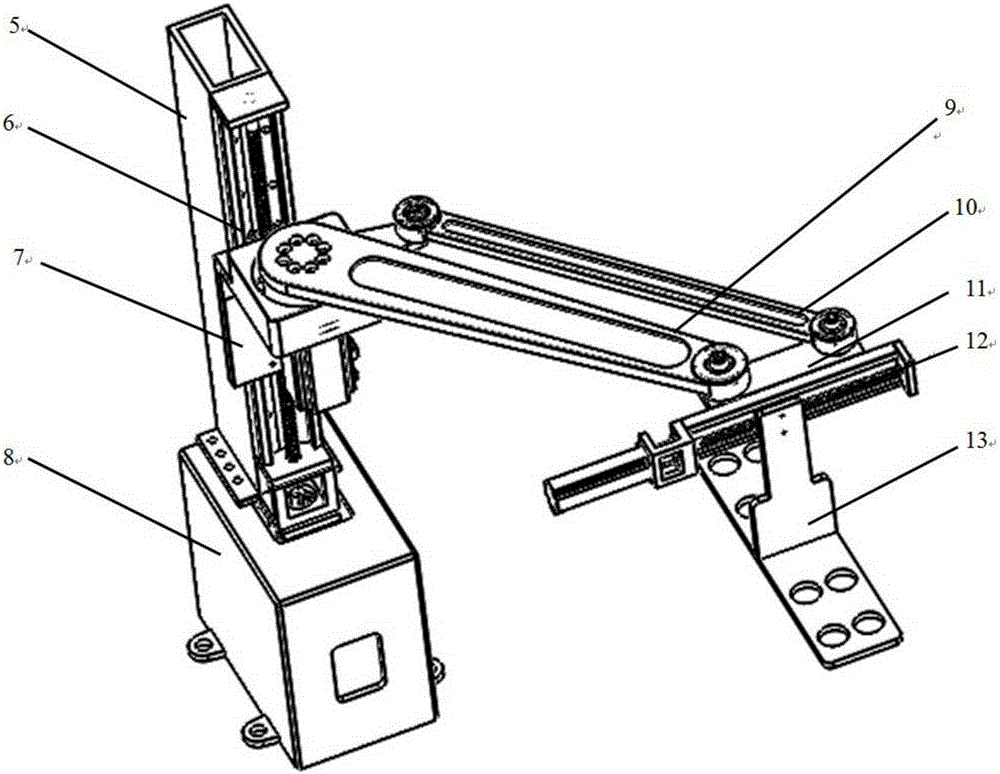

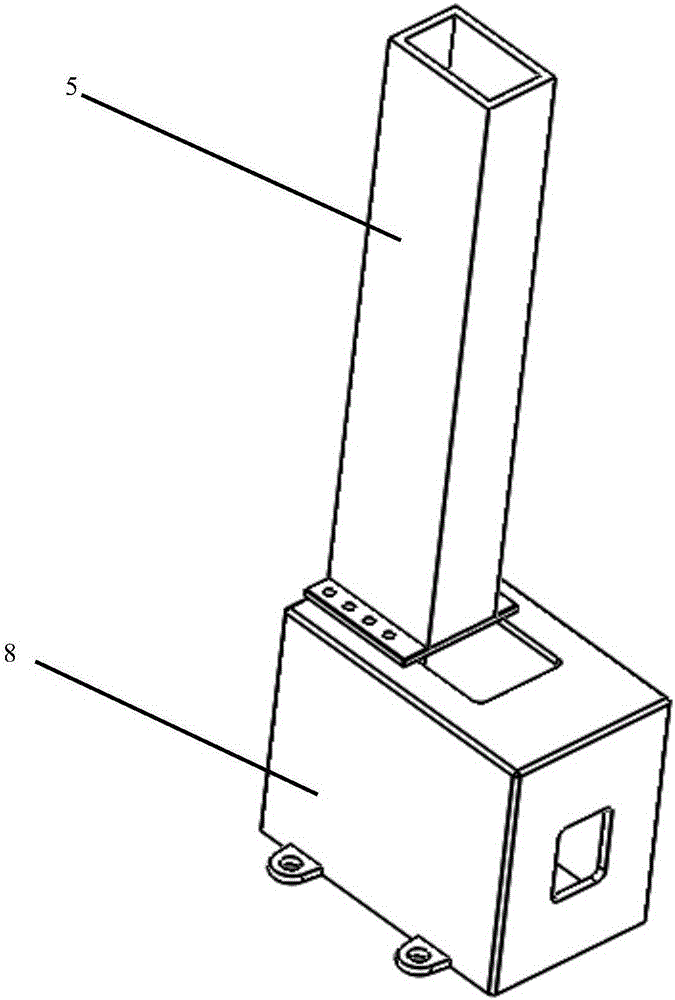

Transverse double-connecting rod type carrying pin mobile mechanism for crane

ActiveCN101214910AHigh reliability and high efficiency requirementsEasy to assemble and disassembleCranesEngineeringMechanical engineering

The invention discloses a horizontal double connecting rod bearing pin insert-draw mechanism for cranes; a first pin drawing plate (1) and a second pin drawing plate (13) are respectively fixed on a bearing pin (12) and a second bearing pin (14); an expansion oil cylinder (15) is provided with a power oil cylinder (9); the piston rod of the power oil cylinder (9) is hinged with a first connecting rod (5) and one end of a second connecting rod (19) and provided with a spring reset mechanism and a limit mechanism; the expansion oil cylinder (15) is hinged with a first swing rod (2)and a second swing rod (16); one end of the first swing rod (2) is drivingly connected with the first pin drawing plate (1), and the other end is hinged with the first connecting rod (5); one end of the second swing rod (16) is drivingly connected with the second pin drawing plate (13) and the other end is hinged with the second connecting rod (19). The invention is a horizontal double connecting rod bearing pin insert-draw mechanism for cranes which has the advantages of simple and compacted structure, convenience in installation and maintenance, stable and reliable performance, and the improved efficiency of the complete machine, and is widely applicable in the series products of large-tonnage crane.

Owner:ZOOMLION HEAVY IND CO LTD

Clamping device

InactiveCN104875152AIncrease clamping pointRestricted degrees of freedomWork holdersEngineeringMechanical engineering

Owner:SHENGRUI TRANSMISSION

Ink-jet printer and printing method thereof

The invention discloses an ink-jet printer and a printing method thereof. The ink-jet printer comprises a printing module, supporting beams, a printing platform, an ink-scraping maintenance device and a control system. The printing module is installed above the supporting beams, a sprayer is installed at the lower end of the printing module, and the printing platform is arranged below one ends of the supporting beams. The ink-scraping maintenance device is arranged below the other ends of the supporting beams, the control system is used for controlling work of the printing module, the ink-scraping maintenance device and the sprayer. The ink-jet printer is characterized in that the ink-scraping maintenance device comprises a lifting device, and the lifting device can make lifting movement on the whole in the vertical direction, namely in the Z-axis direction; by controlling overall lifting of the ink-scraping maintenance device and horizontal movement of the printing module in the direction of the supporting beams, ink-scraping or maintenance operation of the sprayer is completed, the lifting device is skillful in structure design, and lifting smoothness and steadiness are high; and in the ink-scraping maintenance process, by approaching a sensor for automatic detection and controlling the distance between the sprayer and the ink-scraping maintenance device, accuracy can be improved, and quick and convenient ink-scraping maintenance is achieved.

Owner:BEIJING MEIKEYI

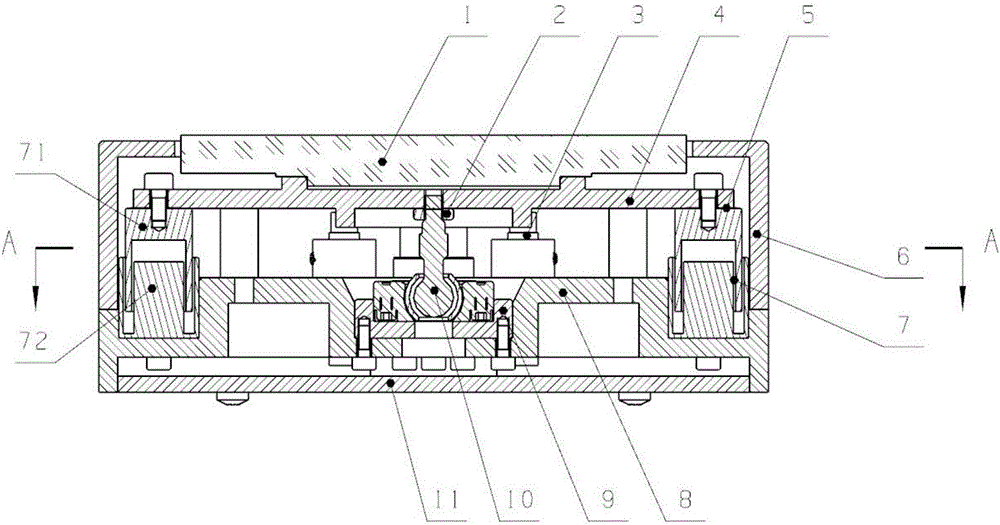

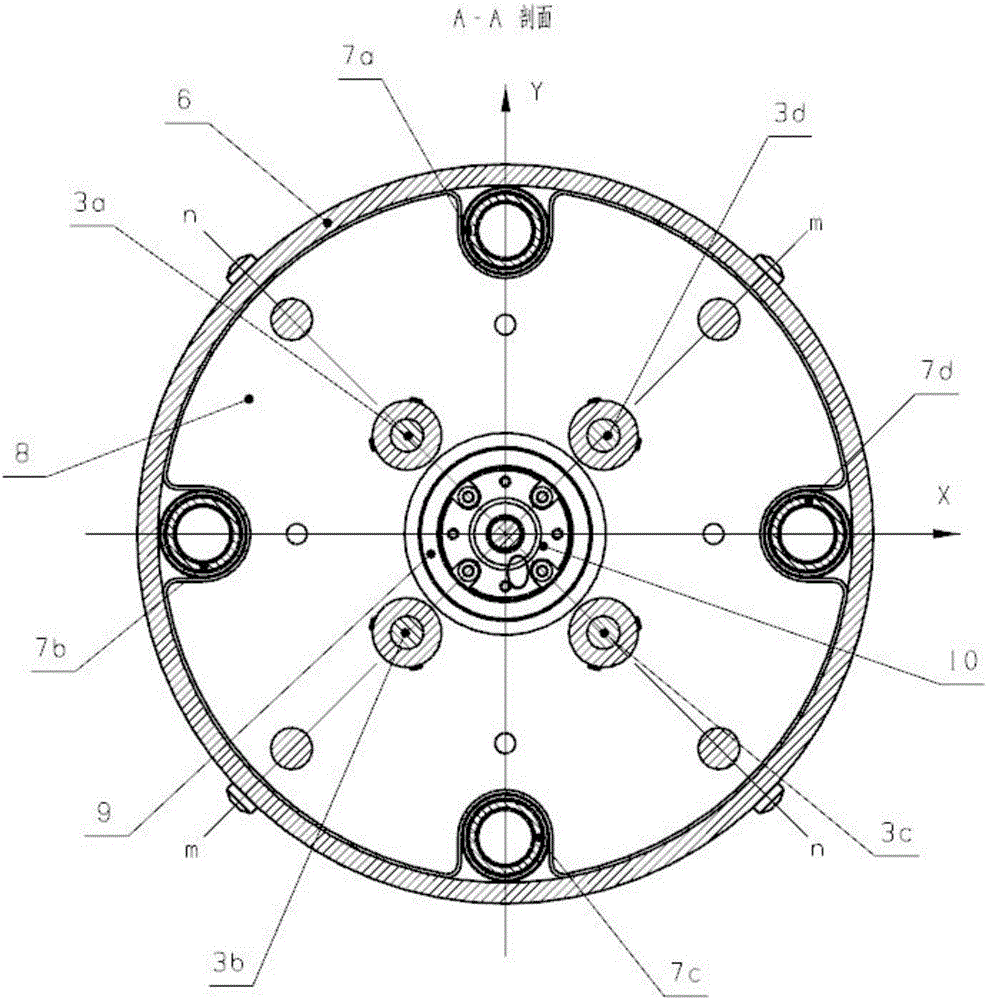

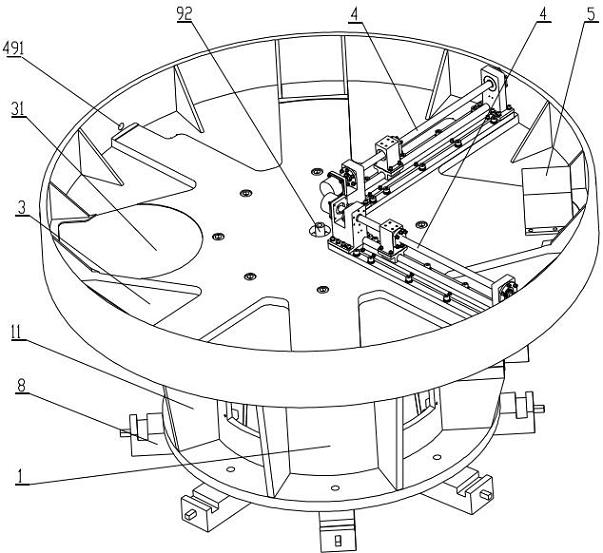

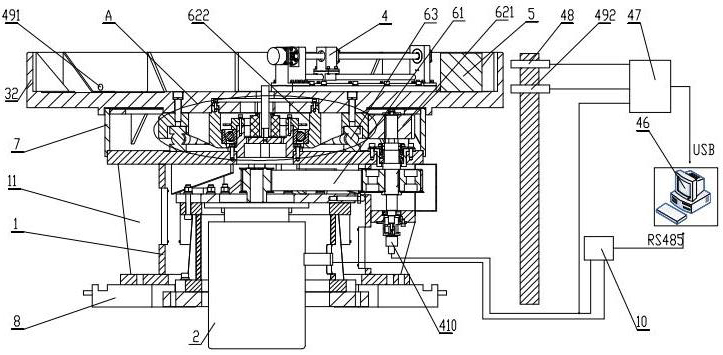

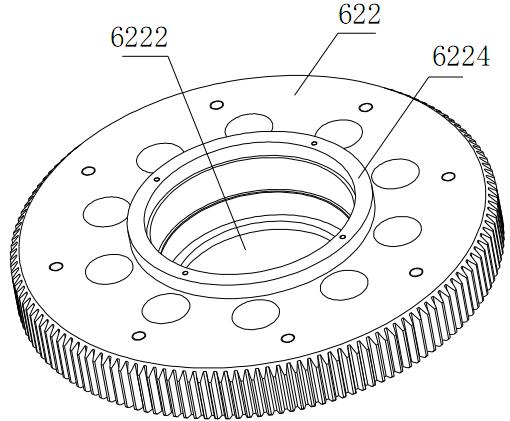

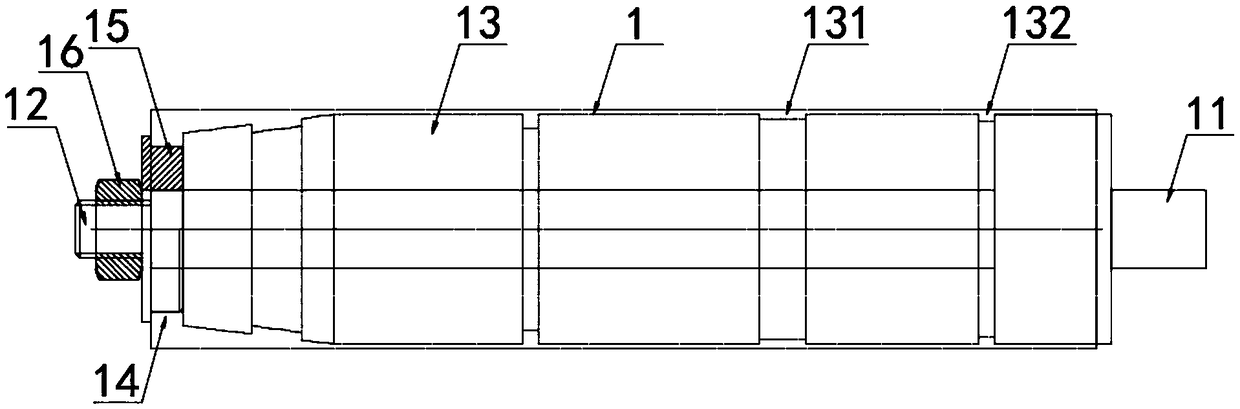

Centrifuge used in multi-parameter complex test environment

InactiveCN101915653ARestricted degrees of freedomReduce quality problemsWeather/light/corrosion resistanceStatic/dynamic balance measurementBall bearingDynamic balance

The invention discloses a centrifuge used in a multi-parameter complex test environment. The centrifuge comprises a stand, a driving motor, an arm, a transmission mechanism and a dynamic balance executing mechanism, wherein the arm is provided with a web plate; the transmission mechanism comprises a belt transmission mechanism and a gear mechanism; the gear mechanism comprises a pinion which is coaxial with a driven pulley and a bull gear which is fixedly connected with the arm; the upper surface of the bull gear is contacted with the bottom surface of the arm; the lower surface of the bull gear is provided with an annular groove for accommodating a thrust ball bearing capable of providing axial support for the bull gear; the bull gear is connected with the stand through the thrust ball bearing; a gap is reserved between the lower surface of the bull gear and the stand; the bull gear is provided with a through hole; the bottom of the through hole is extended inwards to form a step for arranging an angular contact ball bearing; a cover plate which is fixedly connected with the stand to compress the angular contact ball bearing is arranged above the angular contact ball bearing; and the driving motor and the transmission mechanism are arranged in the stand. The centrifuge has the advantages of small space occupied by the body, high capacity of the arm and capability of carrying various environmental chambers and realizing adaptive dynamic balance of the arm.

Owner:ZHEJIANG UNIV

Thin-wall shell processing method

ActiveCN109396766ARestricted degrees of freedomGuarantee quality requirementsWork clamping meansPositioning apparatusEngineeringThermal treatment

The invention discloses a thin-wall shell processing method which comprises a tool clamp, wherein the tool clamp comprises a mandrel; one end of the mandrel is equipped with a mounting column; the outer part of the mandrel is fixedly equipped with an outer ring body in a sleeving mode; a wide ring-shaped slot and a narrow ring-shaped slot are formed in the outer ring body; a step is arranged between one end of the outer ring-shaped body and the mandrel; an auxiliary pressure plate is arranged on the outer part of the step in the sleeving mode; one side of the auxiliary pressure plate is equipped with a nut; and the nut is in threaded connection with the mounting column. The thin-wall shell processing method comprises the following specific steps: step I, outer wall rough turning; step II,high-temperature tempering; step III, left end surface turning; step IV, right end surface turning; step V, clamp mounting; step VI, outer wall fine turning; and step VII, appearance processing. The thin-wall shell processing method performs processing through a high-efficiency machine tool, and a thermal-treatment tempering distressing process is added to release part processing inner stress; andthe necessity of designing a special clamp is combined, so that processing deformation is prevented, and part processing quality requirements are guaranteed.

Owner:河南红宇精密机械有限公司

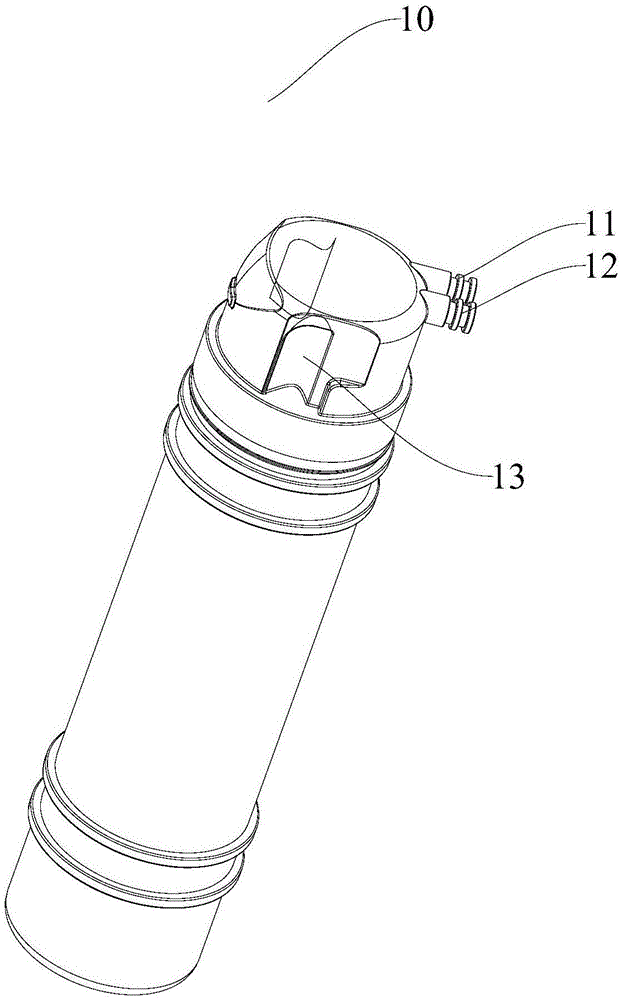

Water purifier

ActiveCN106345168AEasy to fixSimple structureMembrane filtersFiltration separationWorking pressureWaste management

The invention discloses a water purifier. The water purifier comprises a shell, a filter core assembly, a water path board and a filter core fixing structure, wherein the filter core assembly is arranged on the shell and comprises a filter core; a water inlet and a water outlet are formed in the filter core, and the water inlet and the water outlet are respectively formed in the side parts of the filter core; a water path is limited in the water path board, and a direct inserting type filter core interface connected with the water inlet and the water outlet is formed in the water path board; the filter core fixing structure is detachably connected to the water path board or the shell and is connected with the filter core so as to fix the position of the filter core relative to the water path board. According to the water purifier disclosed by the embodiment of the invention, by inserting the filter core in the water path board and fixing the position of the filter core relative to the water path board through the filter core fixing structure, the filter core can be effectively locked, the degree of freedom of the filter core relative to the water path board is limited, and the filter core is further prevented from being thrown away from the water path board due to larger working pressure of the water inlet and the water outlet or the action of an external force, the filter core or the water path board is prevented from being destroyed, the connection reliability is ensured, and the cost is reduced.

Owner:FOSHAN MIDEA CHUNGHO WATER PURIFICATION MFG +1

Workpiece fixing mechanism used for riveting pressure assembly machine

ActiveCN103157984ARestricted degrees of freedomRealize six-point complete positioningWork holdersMetal working apparatusPistonAssembly machine

The invention discloses a workpiece fixing mechanism used for a riveting pressure assembly machine. The workpiece fixing mechanism used for the riveting pressure assembly machine is used for fixing a shell body. The workpiece fixing mechanism used for the riveting pressure assembly machine comprises a positioning plate fixed above a working plane, a side top cylinder and a set of pressing plates, wherein the side top cylinder is arranged at one side of the positioning plate and the set of the pressing plates are arranged at one side of the fixing plate. A cylinder boss and a positioning pin are arranged on the positioning plate, and the cylinder boss and the holes arranged at the bottom of the shell body are matched with each other. The motion direction of the side top cylinder piston is parallel to the working plane. The pressing plates are driven by a locking cylinder connected at the lower surface of the working plane. According to the workpiece fixing mechanism used for the riveting pressure assembly machine, the side top cylinder is arranged at one side of the positioning plate, when the side top cylinder works, a ejector rod stretches out, the ejector rod abuts against the shell body and moves in a clockwise mode, and therefore reliable contact of the side face of the shell body and the positioning pin is ensured.

Owner:SUZHOU INST OF INDAL TECH

Chromatic aberration corrector for charged particles and charged-particle optical apparatus using the corrector

ActiveUS7211804B2Restricted degrees of freedomImprove aberrationStability-of-path spectrometersMaterial analysis using wave/particle radiationMolecular physicsCharged particle beam

The present invention provides an aberration corrector functioning under a condition outside the setting optical condition of an incorporated charged particle beam apparatus.An intermediate potential region different from the ground potential of an aberration corrector is provided in the space between the stages of multipole lenses constructing the aberration corrector to adjust a potential. Using this, when selecting an incident (outgoing) condition, an outgoing (incident) condition can be adjusted.

Owner:HITACHI HIGH-TECH CORP

Space on-track repeated locking and releasing mechanism

ActiveCN102720733ARestricted degrees of freedomSimple structureSecuring devicesDegrees of freedomEngineering

The invention discloses a space on-track repeated locking and releasing mechanism, relating to a repeated locking and releasing mechanism. The invention aims to solve the problem in on-track repeated locking and releasing of large payload on spacecraft. The mechanism comprises a locking trunnion mechanism, a compaction lock hook mechanism, a locking base mechanism, a crank-rocker mechanism and a drive gear mechanism, wherein the locking trunnion mechanism is arranged at the upper end of the locking base mechanism; and the drive gear mechanism is connected with the compaction lock hook mechanism and the crank-rocker mechanism respectively. In the invention, the locking trunnion mechanism, the compaction lock hook mechanism, the locking base mechanism, the crank-rocker mechanism and the drive gear mechanism are crossed, the structure is simple and compact, all degrees of freedom of the fixed object can be completely limited, the repeated locking can be realized, the operability is good, and the using requirement of on-track locking-releasing-locking can be met. The mechanism disclosed by the invention is applicable to the technical field of aerospace and mechatronics.

Owner:HARBIN INST OF TECH

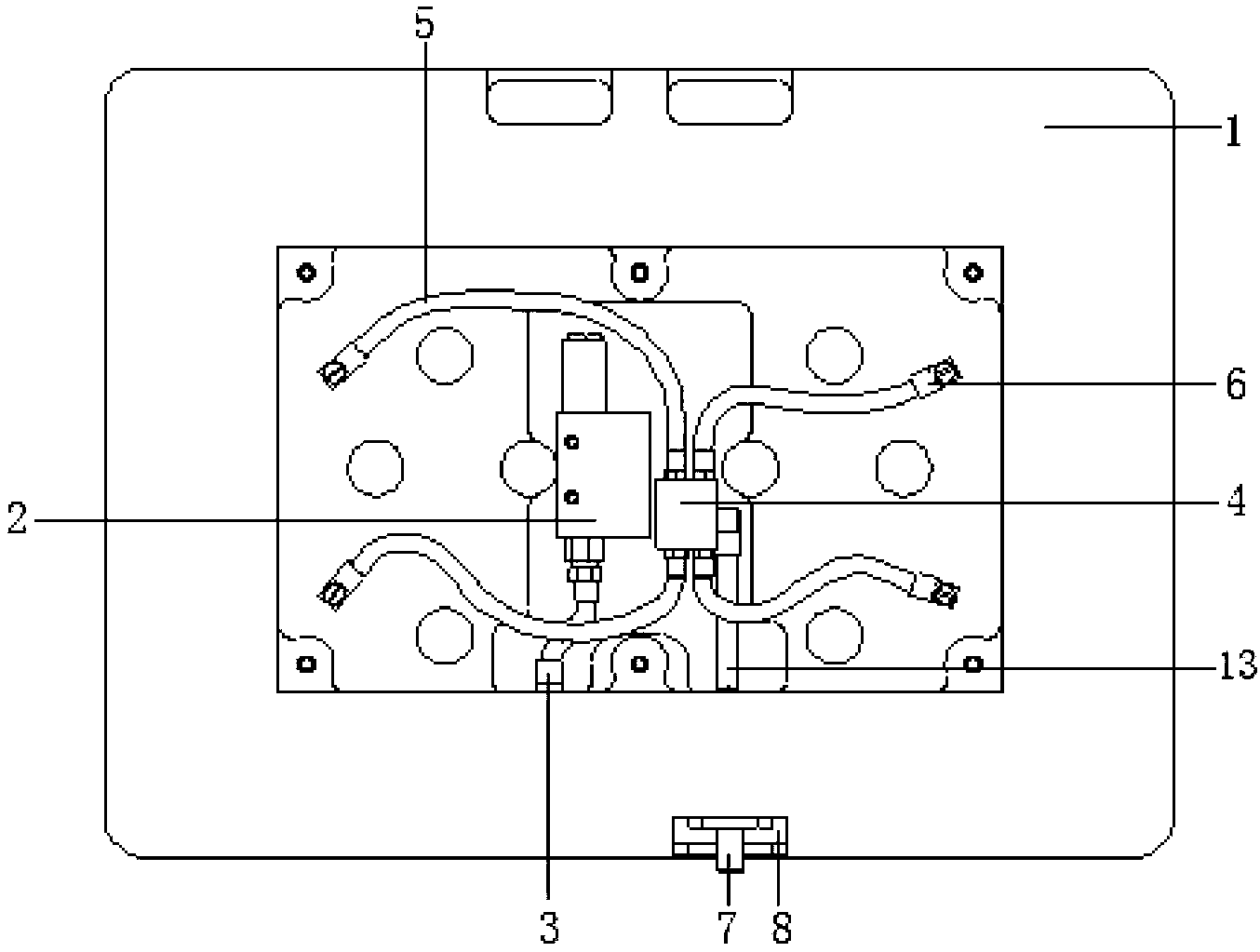

Adsorption jig with built-in vacuum generator

InactiveCN102837212AGuaranteed interchangeabilityGuaranteed interchangeability of replacement positioning postsPositioning apparatusMetal-working holdersEngineeringVacuum pump

The invention discloses an adsorption jig with a built-in vacuum generator; the adsorption jig comprises a tooling plate, the vacuum generator, a fast connector, a shunt block, first air pipes, L-shaped connectors, hardware and suckers; the vacuum generator is connected with an external air source with stable pressure through the fast connector which is connected with the vacuum generator, and is communicated with the shunt block; at least two first air pipes are connected onto the shunt block; the port of each first air pipe is connected with the L-shaped connector; through holes are arranged in the tooling plate; one end of each through hole is provided with the L-shaped connector and is connected with the shunt block through the first air pipe, and the other end of each through hole is provided with the hardware; the suckers in the same number with the first air pipes are assembled on the hardware; the surface of the tooling plate is provided with a positioning side and at least two positioning columns; the built-in vacuum generator replaces an external vacuum pump to work; and the vacuum generator has a small size and a simple structure, and is low in cost, can be arranged in the tooling plate only by leaving a smaller space in the internal structure of the tooling plate to form a complete integral design, so that not only is the performance excellent but also the appearance is attractive and generous.

Owner:SUZHOU GAMMA AUTOMATION TECH

Grabbing and placing device for deburring

InactiveCN105196165ASmall inertiaIncrease freedomGrinding feedersThree degrees of freedomEngineering

The invention discloses a grabbing and placing device for deburring, which belongs to the technical field of industrial robot application. The grabbing and placing device comprises an input conveyor belt, a brush machine, an output conveyor belt and a moving support three-degree-of-freedom transfer robot, wherein the input conveyor belt is horizontally arranged; the brush machine is positioned under a sucking disc mounting plate when an active arm of an arm conveying device of the moving support three-degree-of-freedom transfer robot is positioned at the middle position; the output conveyor belt and the input conveyor belt are symmetrically arranged relative to the brush machine. The grabbing and placing device disclosed by the invention has the advantages of high production efficiency, high automatic degree and capabilities of realizing full-automatic collection, conveying and grabbing operations.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

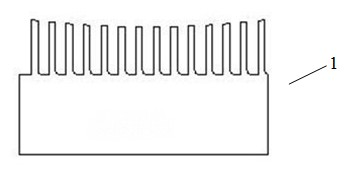

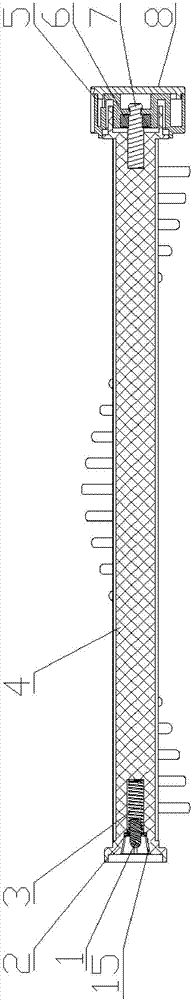

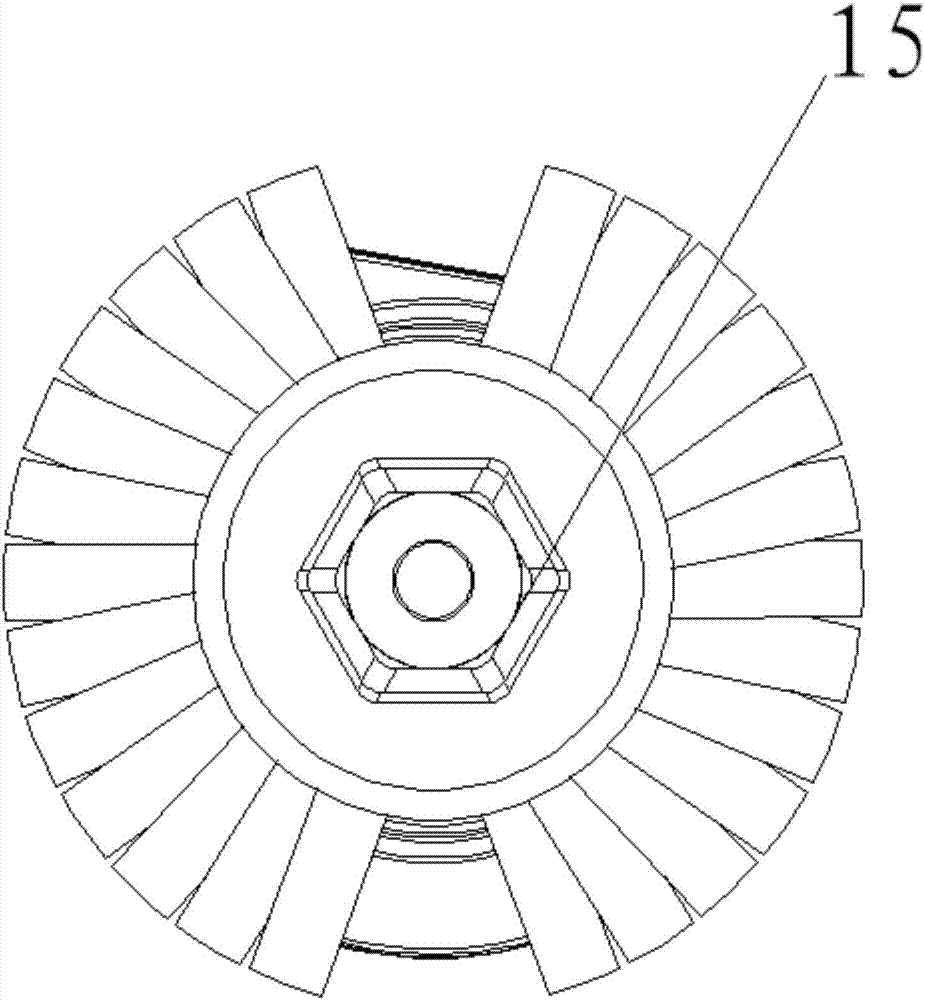

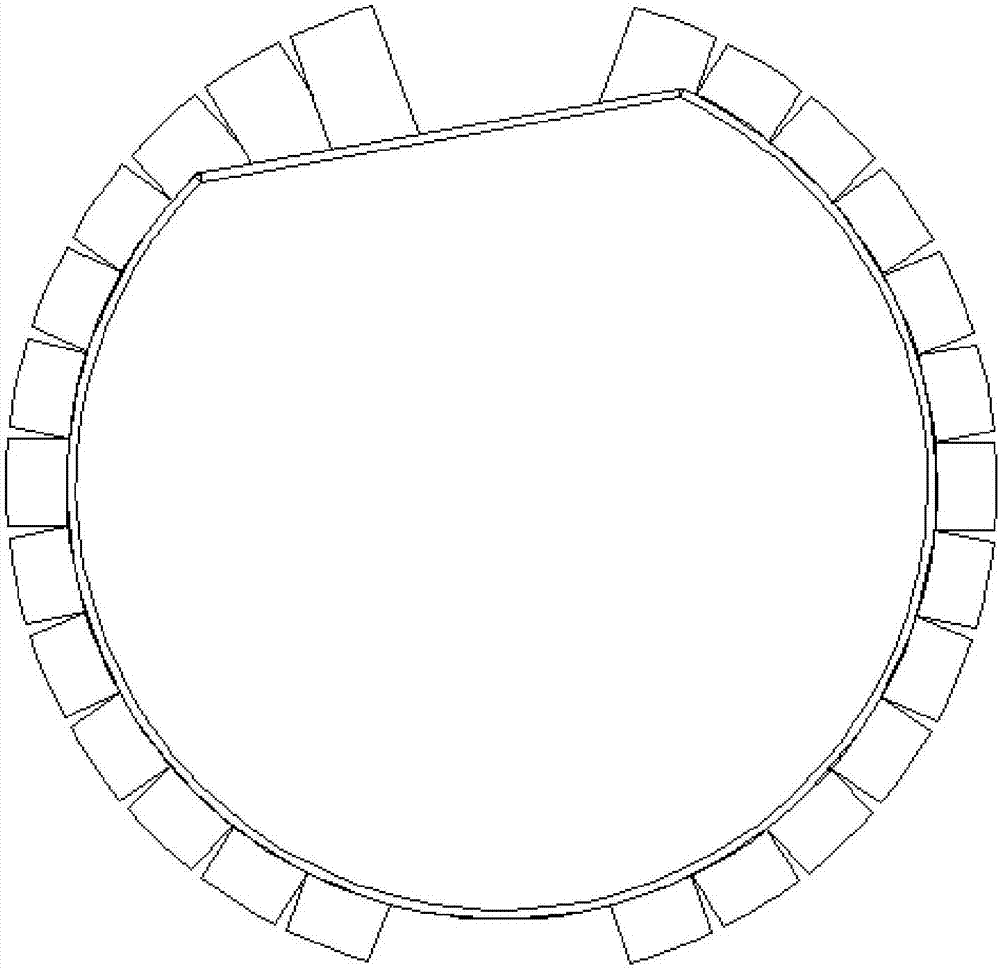

Split-type brake disc

ActiveCN103591193ARestricted degrees of freedomImprove cooling effectBraking discsFriction liningEngineeringRadiation

The invention discloses a split-type brake disc. The split-type brake disc comprises a disc hub, friction blocks and installation pins. The disc hub is provided with a middle hole. The number of the friction blocks is an odd number larger than three; each friction block comprises two friction plates and a plurality of radiation ribs, wherein the radiation ribs are located between the two friction pieces, and the two friction plates and the radiation ribs of the friction block are integrally formed or fixedly connected. Flanges of the disc hub are located between the two friction plates of each friction block. Each friction plate is provided with an installation boss, and the installation bosses are provided with installation holes. The flanges of the disc hub are provided with flange holes. The installation pins penetrate through the installation holes in the installation bosses and the flanges holes in the flanges so that the friction blocks can be fixedly connected with the disc hub. The friction blocks are installed on the disc hub in an annularly-arrayed mode, and a gap exists between every two adjacent friction blocks. The split-type brake disc is good in thermal stress relief effect, reliable in installation and convenient to disassemble and assemble.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com