Positioning method for machining workpiece and automatic clamp thereof

A positioning method and machining technology, applied in the field of machining, can solve the problems of complex shapes and the inability of stable clamping of workpieces, and achieve the effect of avoiding machining errors and stable and reliable positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A preferred embodiment of the positioning method includes the following steps:

[0051] A. Select the datum plane of the workpiece; in the designed drawings of the workpiece, it is usually the reference datum of other points, lines and surfaces. Generally speaking, a simple plane or curved surface that is not affected by the entire process can be selected as the datum plane. such as

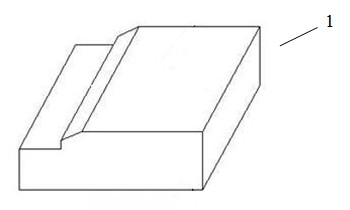

[0052] 1) When the workpiece surface is a regular surface, such as Figure 7A For the workpiece shown, the regular surface should be determined as the reference datum surface, and clamped by extension.

[0053] 2) When the machining surface of the workpiece is irregular and the opposite surface is regular, such as Figure 8A For the workpiece shown, the regular surface on the opposite side should be determined as the reference datum and clamped by shrinkage.

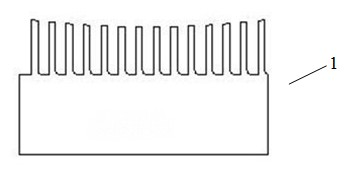

[0054] 3) When the workpiece processing surface and the opposite surface are irregular surfaces, such as Picture 9 For the workpiece shown...

Embodiment 2

[0060] As shown in FIG. 7, it is a schematic diagram of the positioning of the automatic clamp using the downward clamping method. The processing surface of the workpiece 1 to be processed and the selected reference surface are on the same side of the workpiece 1. The automatic fixture mainly includes a reference plate 31, a limiting component 33, a supporting component, and three groups of movable positioning blocks 32 and their power systems. The power system is a cylinder 41. The movable positioning block 32 is fixed on the top of the movable rod 42 of the cylinder 41 , Can move up and down with the movable rod 42. The supporting member includes a supporting seat 21 and left and right side walls 22; both ends of the side wall 22 are respectively connected to the supporting seat 21 and the reference plate 31, and an appropriate formation is formed between the side wall 22, the supporting seat 21 and the reference plate 31. Large and small space to pick and place the workpiece...

Embodiment 3

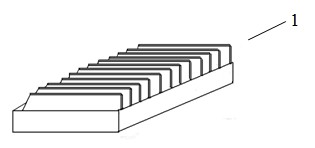

[0078] The difference between this embodiment and the second embodiment is mainly that the automatic clamp adopts a downward clamping method for positioning. As shown in FIG. 8, the processing surface of the workpiece 1 to be processed and the selected reference surface are on different sides of the workpiece 1. The workpiece 1 is placed on the support seat 21, the movable positioning block 32 is pressed down from above the workpiece 1, and the limit blocks 33 are respectively set at the appropriate positions on the front, rear, left and right sides of the reference plate 31 corresponding to the workpiece 1. . (Such as Figure 8B )

[0079] In this embodiment, because the processing surface of the workpiece 1 has a relatively large plane, the movable positioning block 32 is one, and a corresponding number of guide holes 311 are provided at the position of the movable positioning block 32 corresponding to the drilling of the workpiece 1 to further ensure the drilling The quality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com