Circumferential tooth gap measuring and coloring positioning device for bevel gear pair

A technology of bevel gear pair and positioning device, which is applied in the testing of measuring devices, transmission parts, mechanical parts, etc., can solve the problems of difficult operation, small space, low measurement repeatability, etc., and achieve the effect of stable and reliable positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

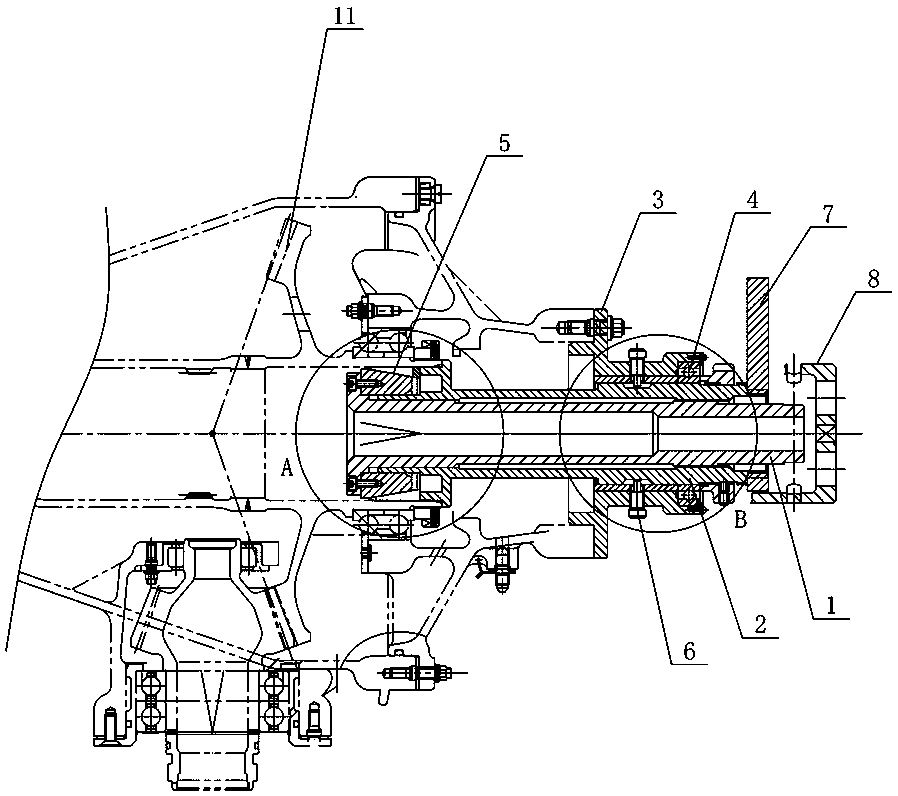

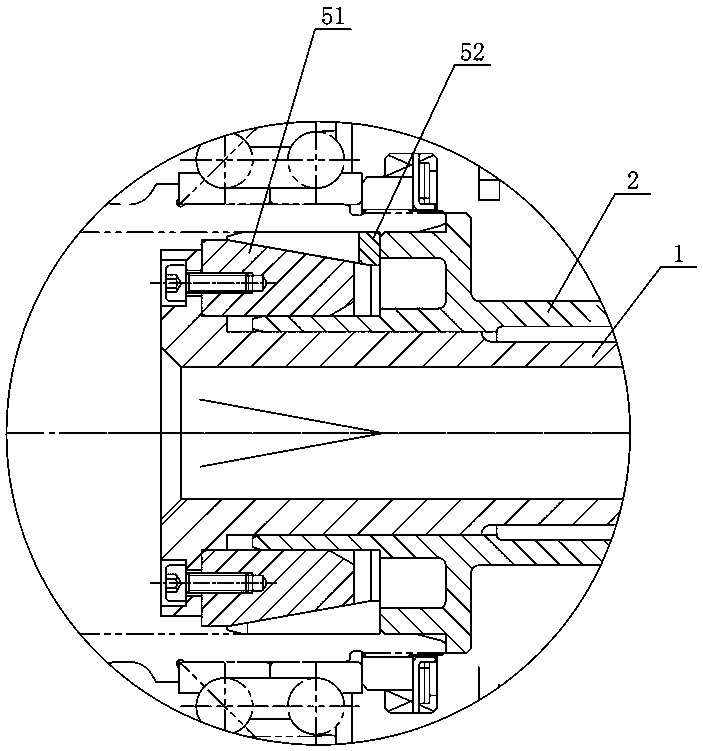

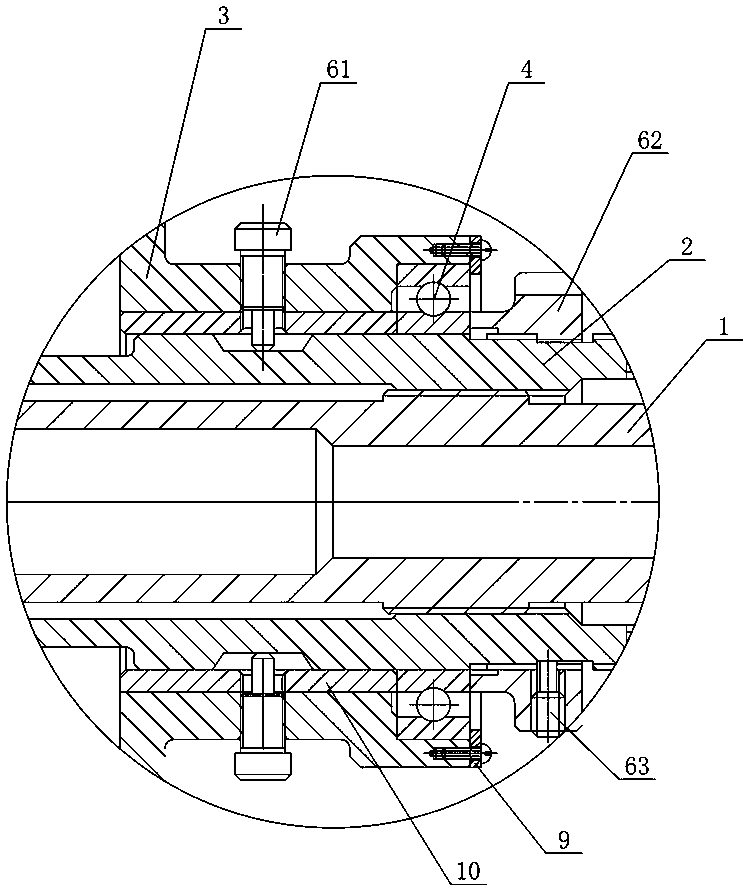

[0023] Figure 1 to Figure 3 It shows an embodiment of the present invention's circumferential backlash measurement and coloring positioning device for bevel gear pairs, including tension shaft 1, compression shaft 2, fixed frame 3, bearing 4, expansion group 5 and locking Group 6, the fixed frame 3 is fixed on the housing of the reducer at the output end, the bearing 4 is installed on the fixed frame 3, the pressing shaft 2 is socketed with the bearing 4 and extends into the output gear 11, and the tensioning shaft 1 is installed on the The compression shaft 2 is connected with the compression shaft 2 by threads, the end of the tension shaft 1 close to the output gear 11 exceeds the compression shaft 2, and the expansion group 5 is installed on the excess end of the tension shaft 1 and connected to the inner wall of the output gear 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com