Buffering positioning device of book sewing machine

A technology of positioning mechanism and sewing machine, which is applied in book binding, compound continuous process of book processing, printing, etc. It can solve the problems of many uncertain factors, pinched signatures, easy to pull, etc., and achieves good cushioning effect , Reliable positioning and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

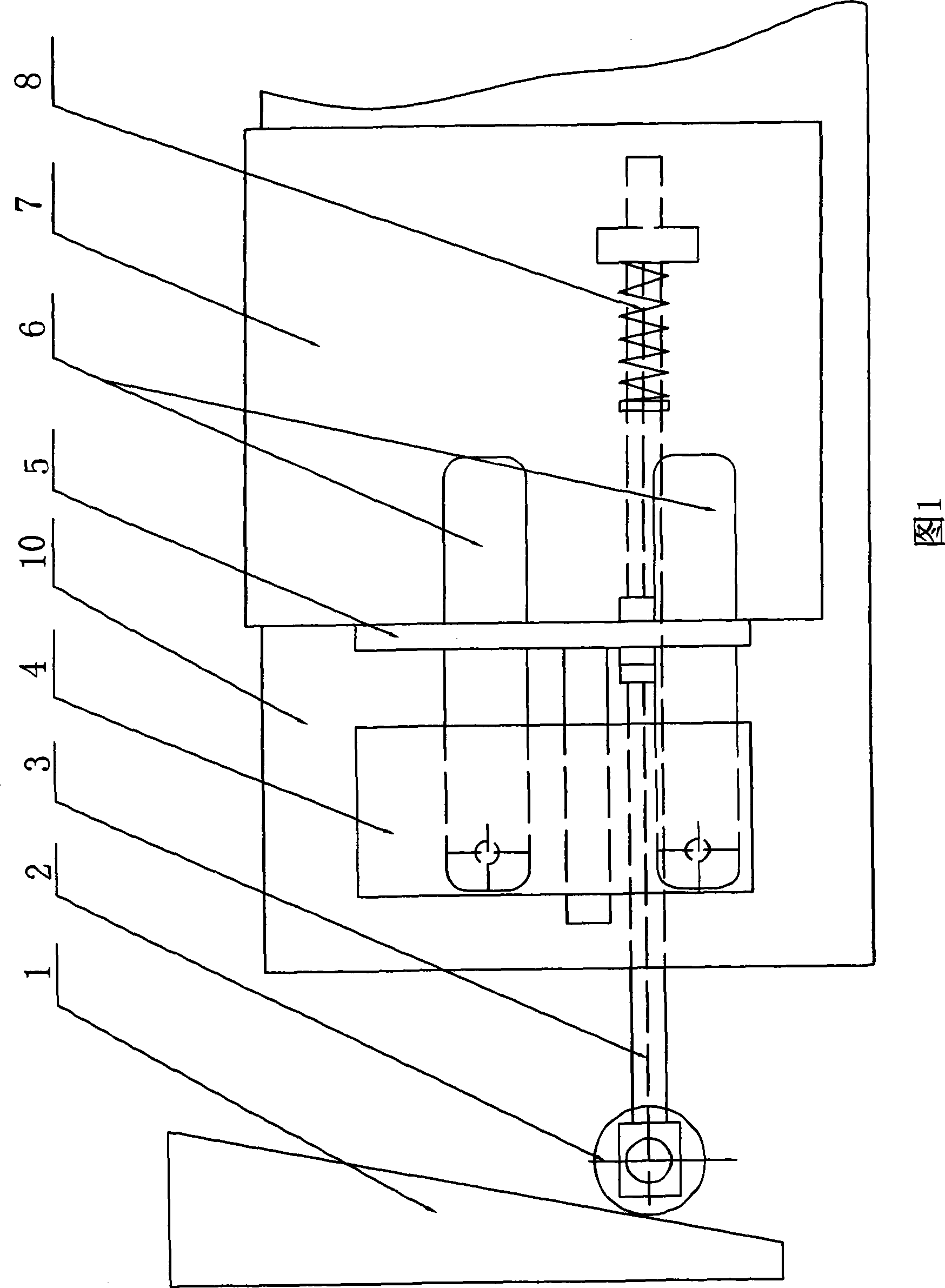

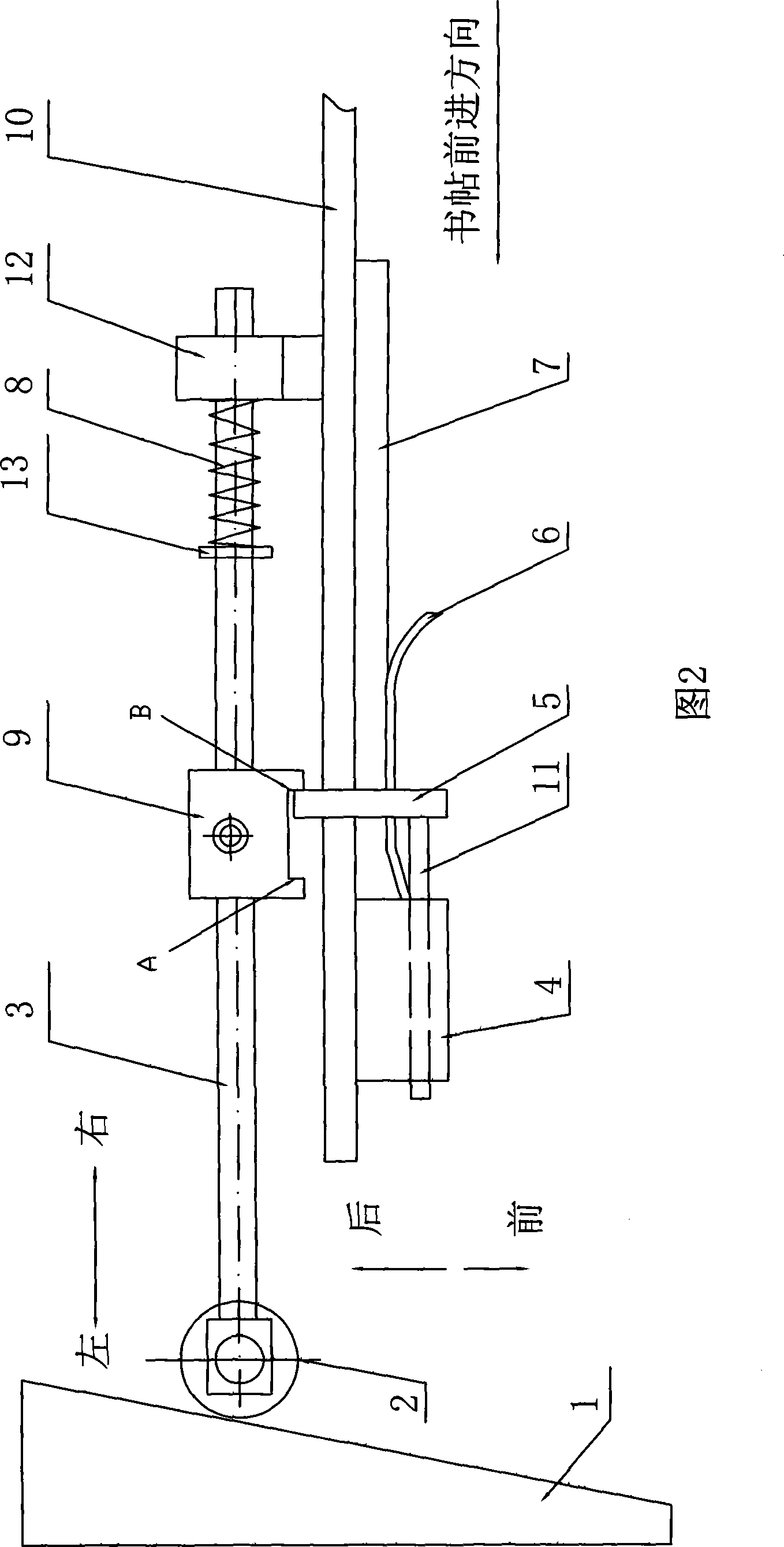

[0011] The embodiment as shown in Fig. 1 and Fig. 2 includes an inclined rail 1 fixed on the frame of the sewing machine, a book shelf 10, a pull rod 3, a fixed seat 4 fixed on the book shelf 10, a retaining rail 5, an upper and lower Two pieces of pressure reed 6, spring 8, buffer groove block 9, pull rod 3 is movably supported on the book shelf by two sleeves 12 (only one is drawn in the figure, the other is at the extension position of the pull rod and the book shelf) 10 and can be moved laterally, the end of the pull rod 3 in sliding contact with the inclined rail 1 is equipped with a roller 2, the roller 2 is in contact with the inclined rail 1 and rolls, the pull rod 3 is provided with a spring support seat 13, and the two ends of the spring 8 are respectively supported on the spring On the end faces of the support seat 13 and the sleeve 12, one end of the retaining rail 5 is provided with a guide plate 11, and moves along the guide groove in the fixed seat 4 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com