Space on-track repeated locking and releasing mechanism

A technique for repeatedly locking and releasing mechanisms, applied in mechanical equipment, fixtures, etc., can solve the problems of non-reusable use and excessive impact, and achieve the effect of simple structure, small impact, and no influence on attitude and stability control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

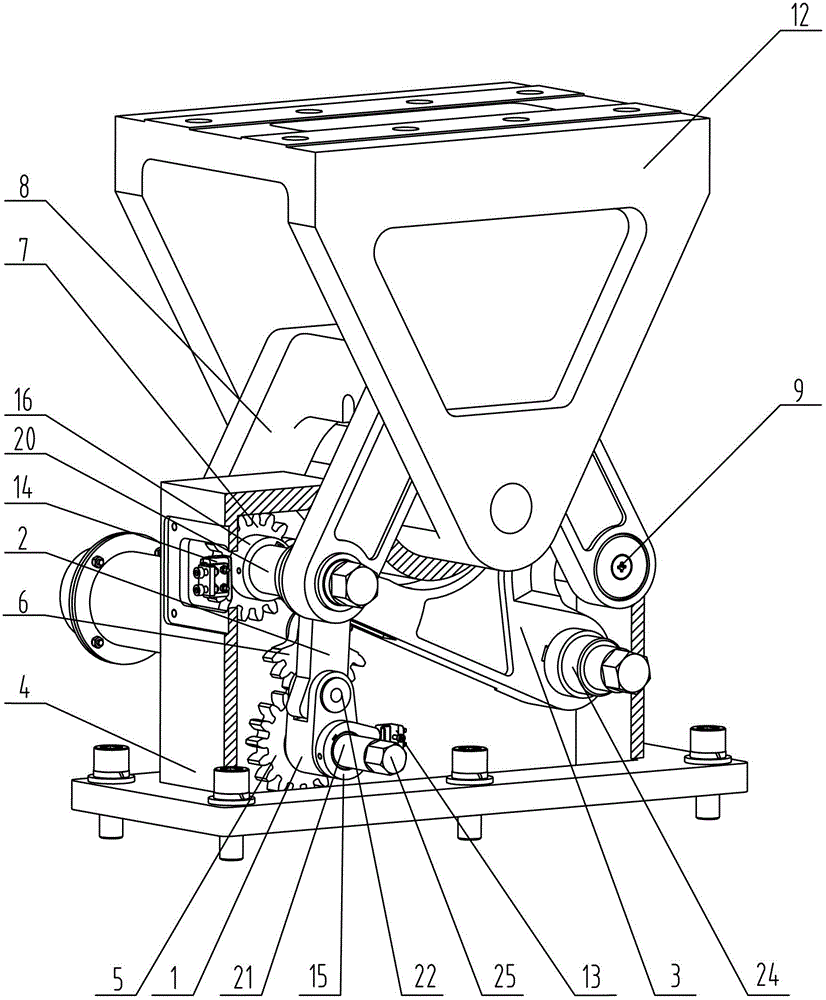

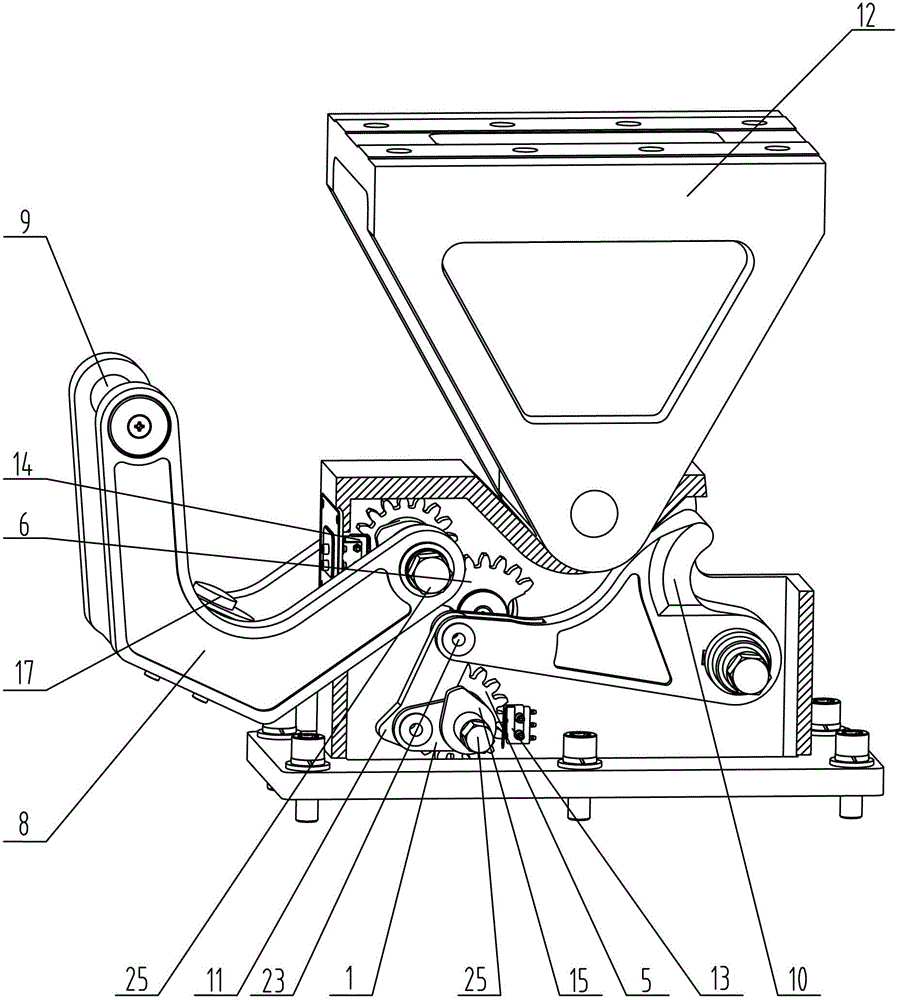

[0014] Specific implementation mode one: combine Figure 1-Figure 3 Describe this embodiment. A space-on-orbit repetitive locking and releasing mechanism in this embodiment includes a locking trunnion mechanism, a compression hook mechanism, a locking base mechanism, a crank rocker mechanism, and a drive gear mechanism. The locking trunnion The mechanism is arranged on the upper end of the locking base mechanism, and the driving gear mechanism is respectively connected with the locking hook mechanism and the crank rocker mechanism.

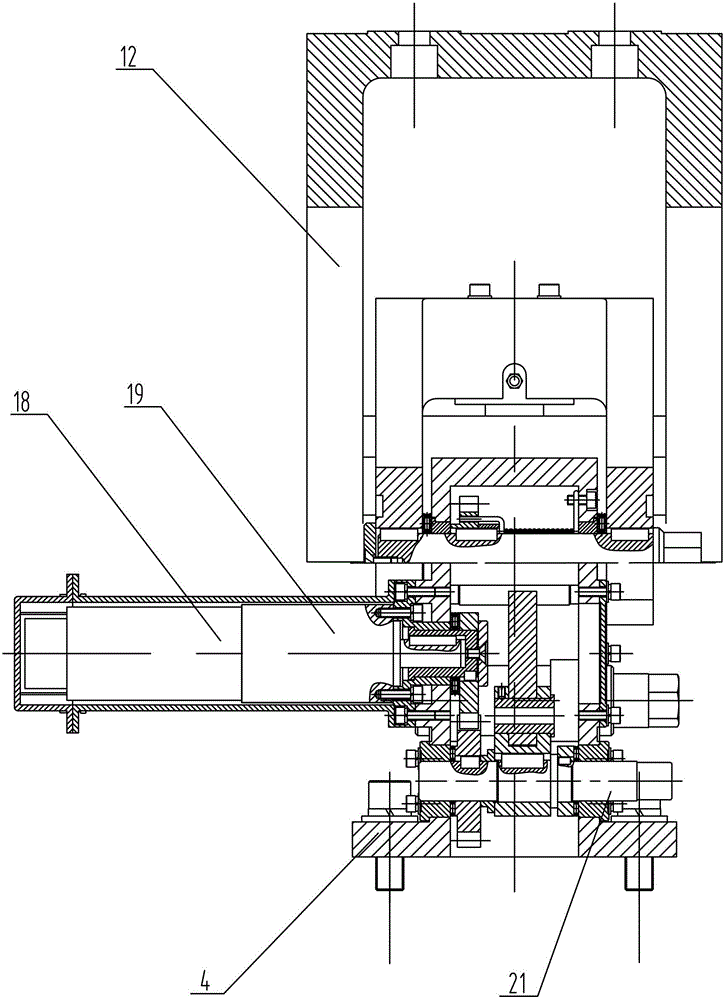

[0015] The locking base mechanism includes a base 4, the upper end of the base 4 is provided with a V-shaped groove, and the middle part of the base 4 is provided with a mechanism accommodating cavity,

[0016] The locking trunnion mechanism includes a trunnion 12, and the lower end of the trunnion 12 is arranged in a V-shaped groove on the base 4,

[0017] Described pressing lock hook mechanism comprises lock hook gear 7, lock hook body 8, first...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination figure 2 Referring to this embodiment, the compression lock hook mechanism of this embodiment further includes a pressure sensor 17, which is arranged on the lock hook body 8, and is used to measure the pressure of the locking state. Such setting is convenient for controlling whether the lock hook body 8 is locked. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Specific implementation mode three: combination figure 1 with figure 2 To illustrate this embodiment, the crank-rocker mechanism of this embodiment further includes a limiting device 11 , and the limiting device 11 is fixedly mounted on the connecting rod 2 . Such setting limits the extreme positions of the main crank rod 1 and the connecting rod 2 . Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com