Patents

Literature

615results about How to "Large locking force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Clip

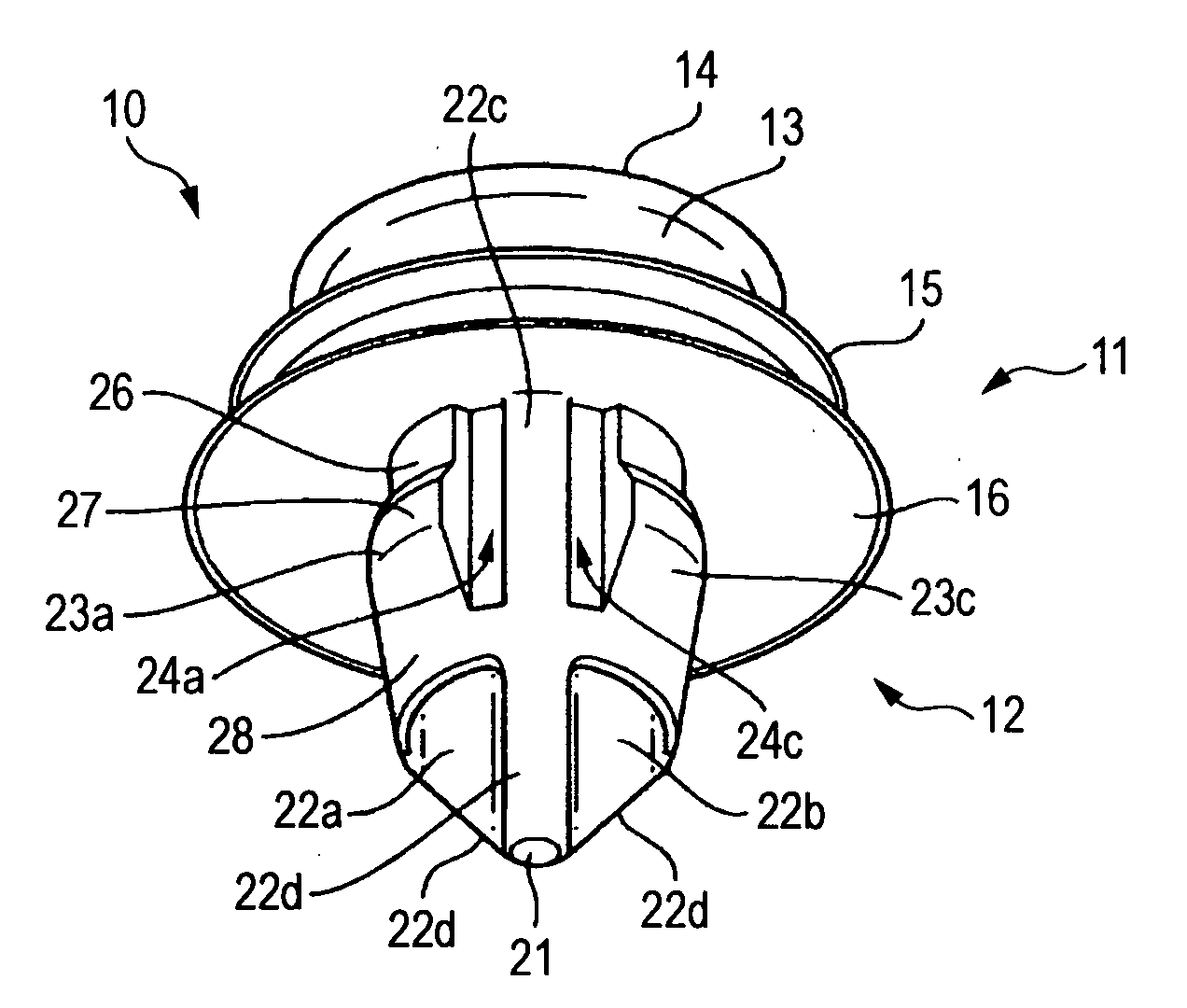

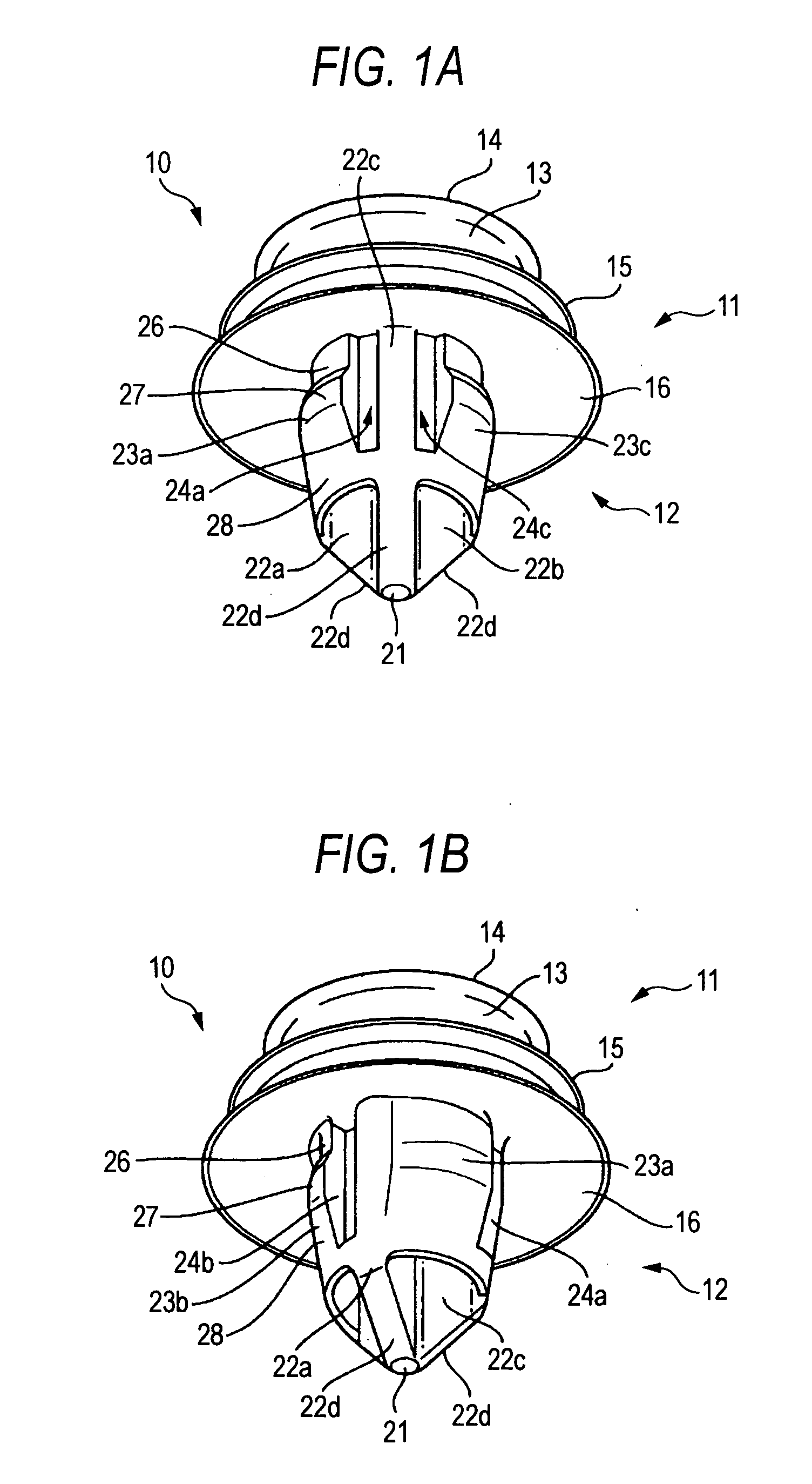

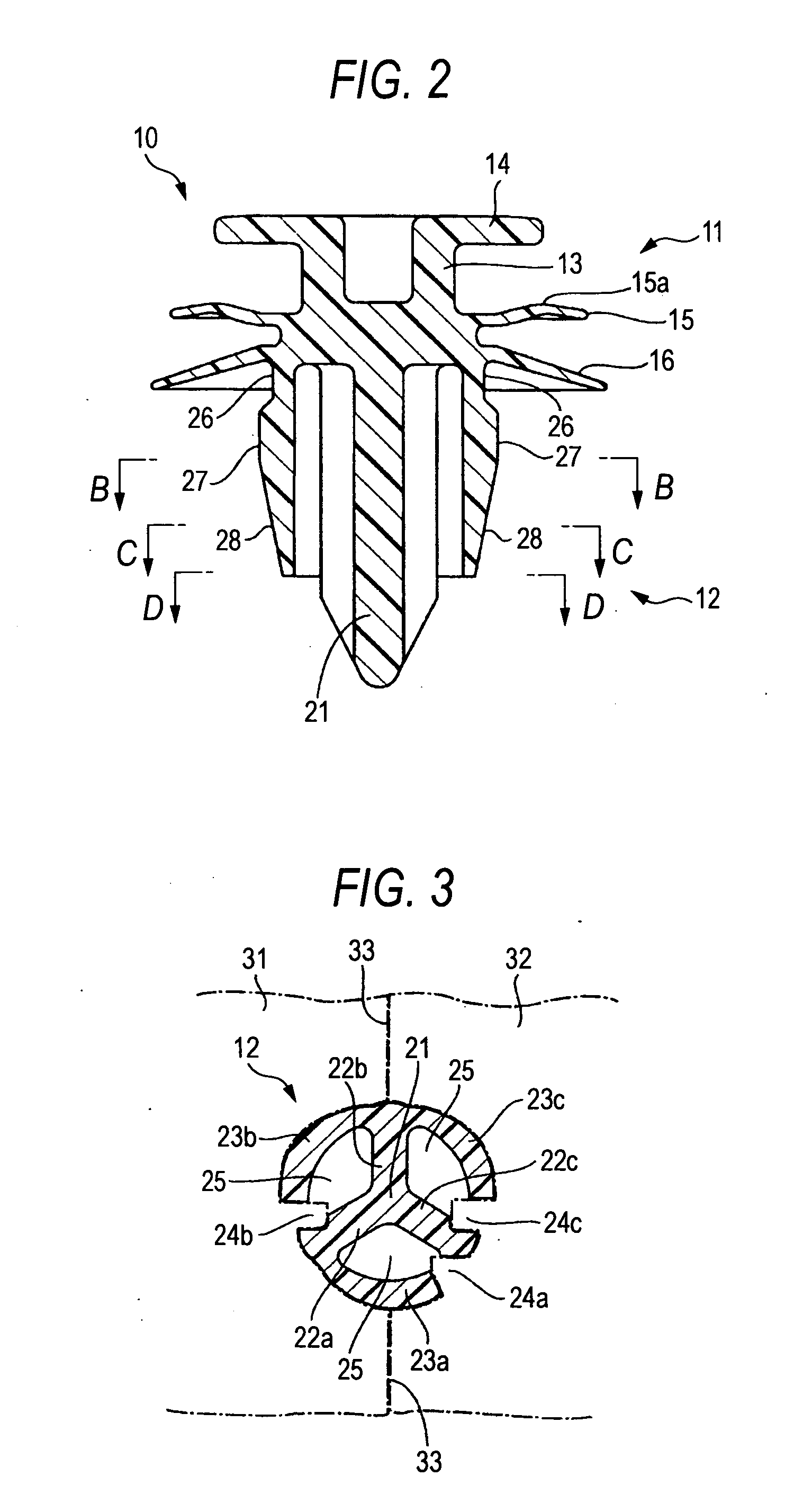

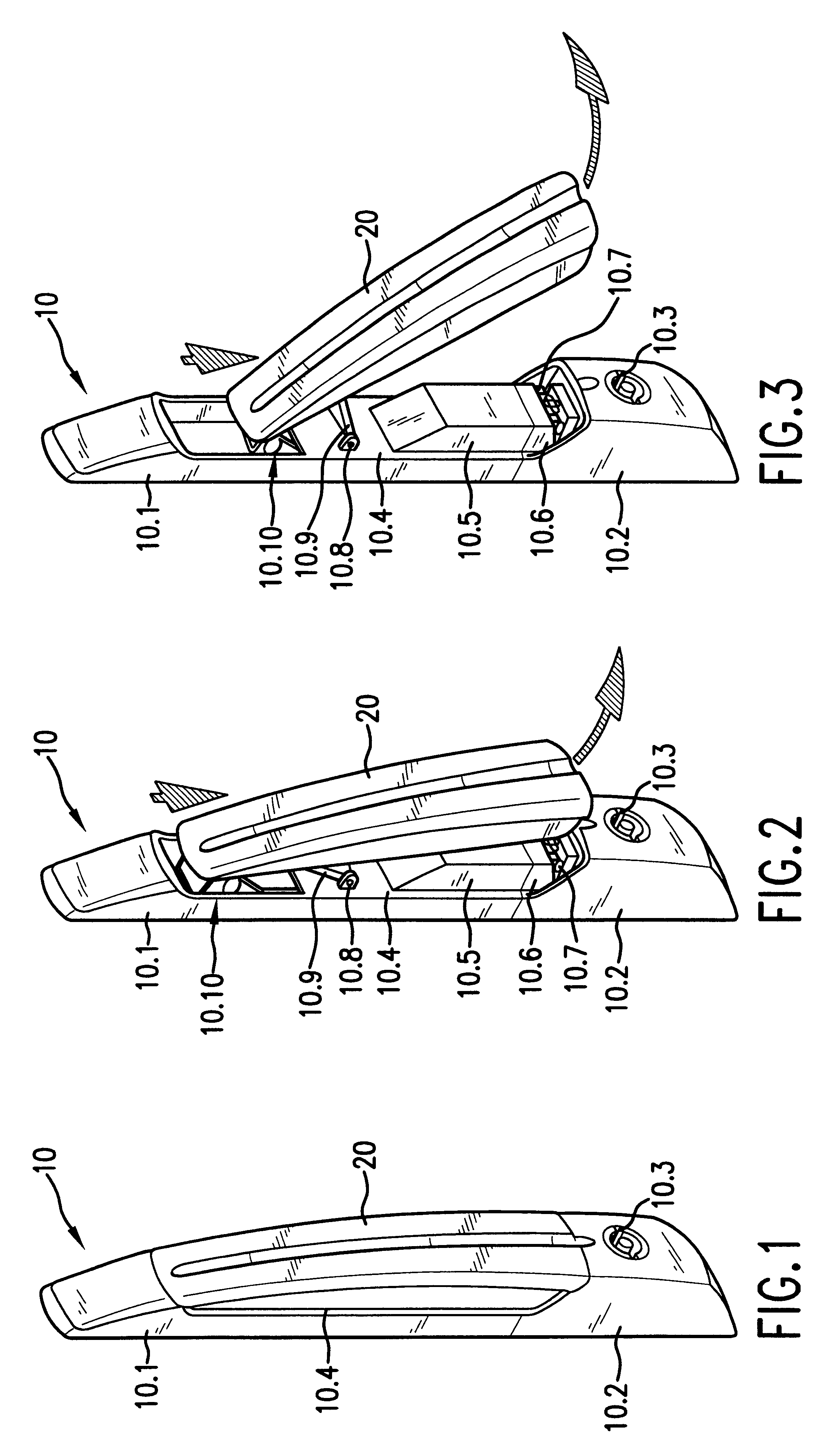

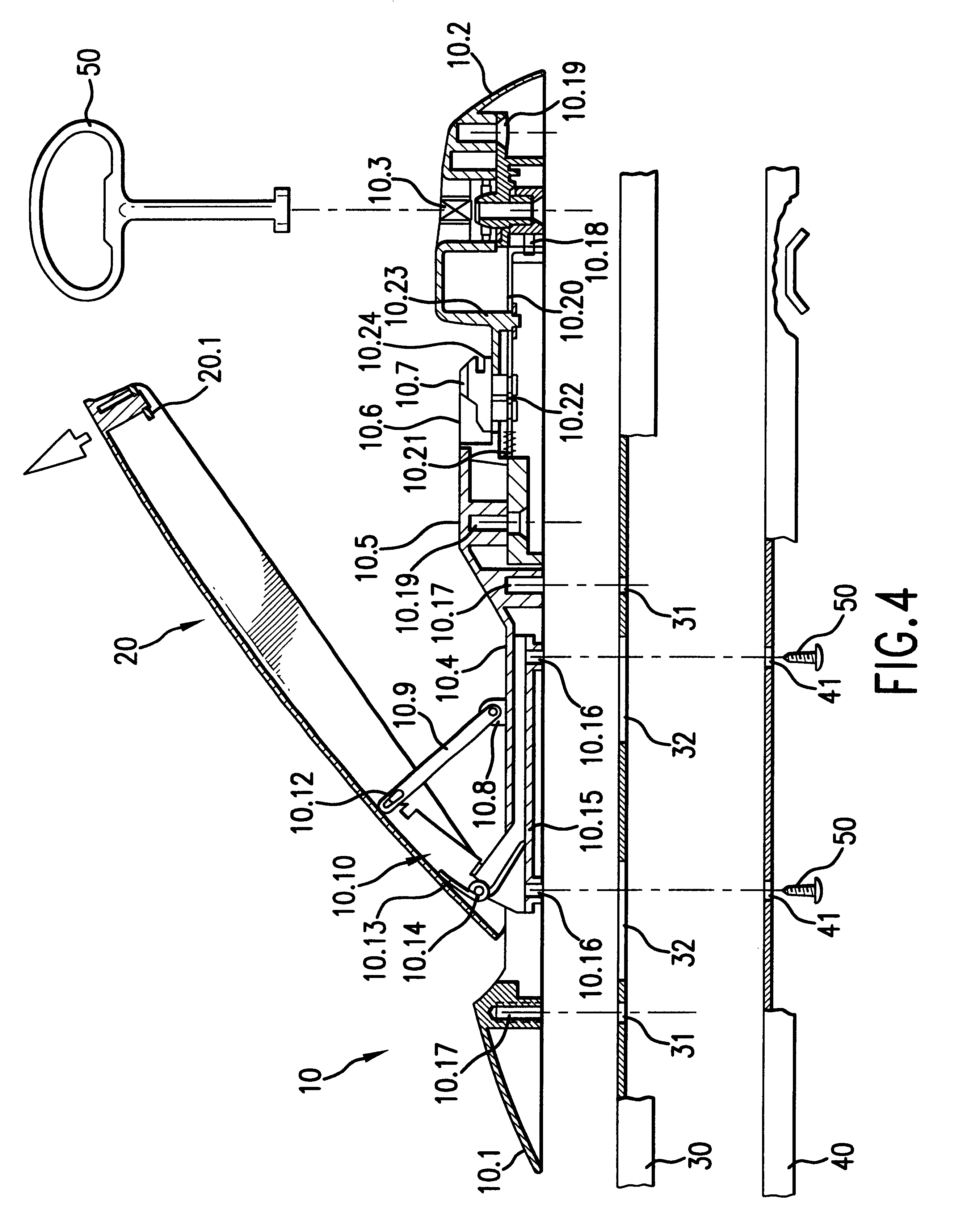

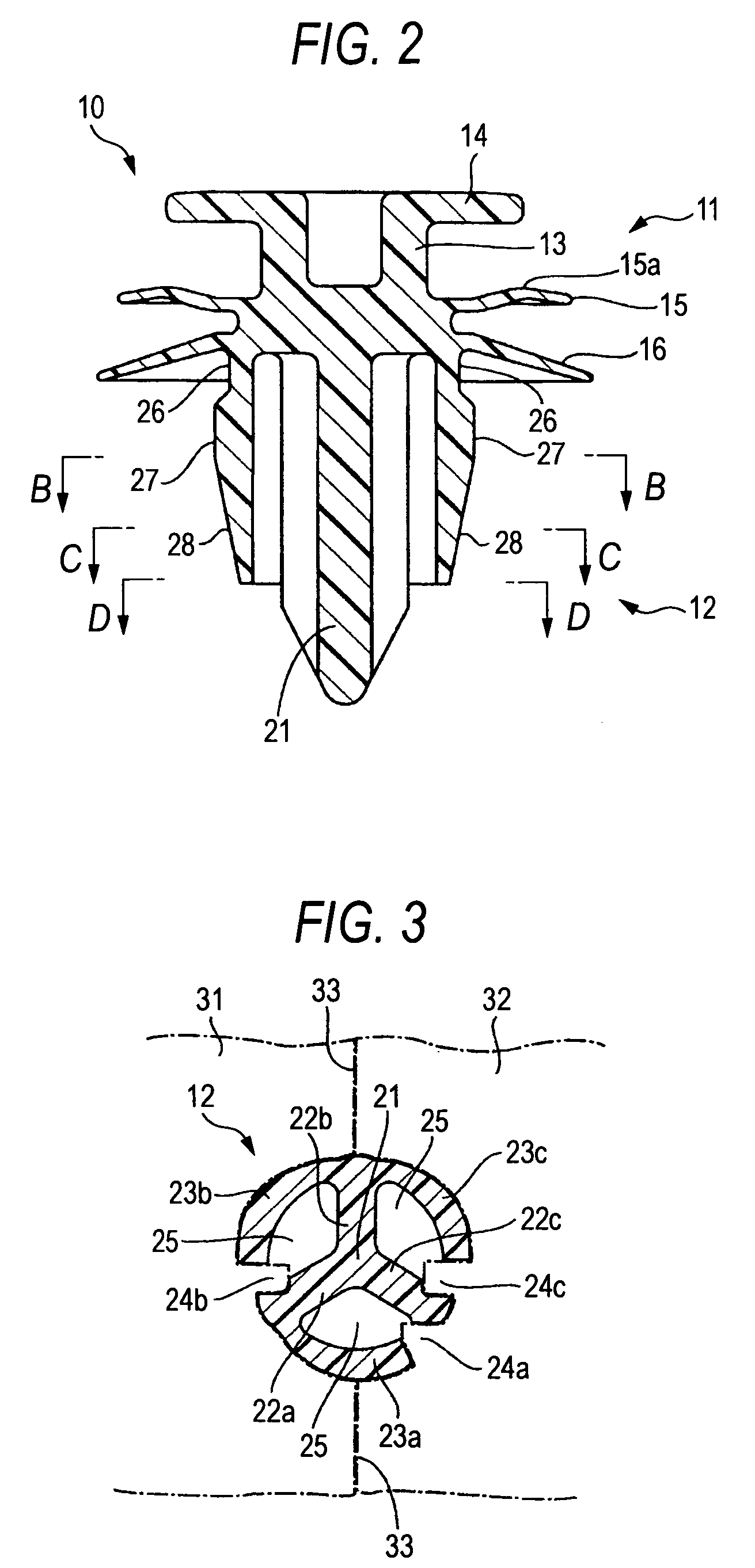

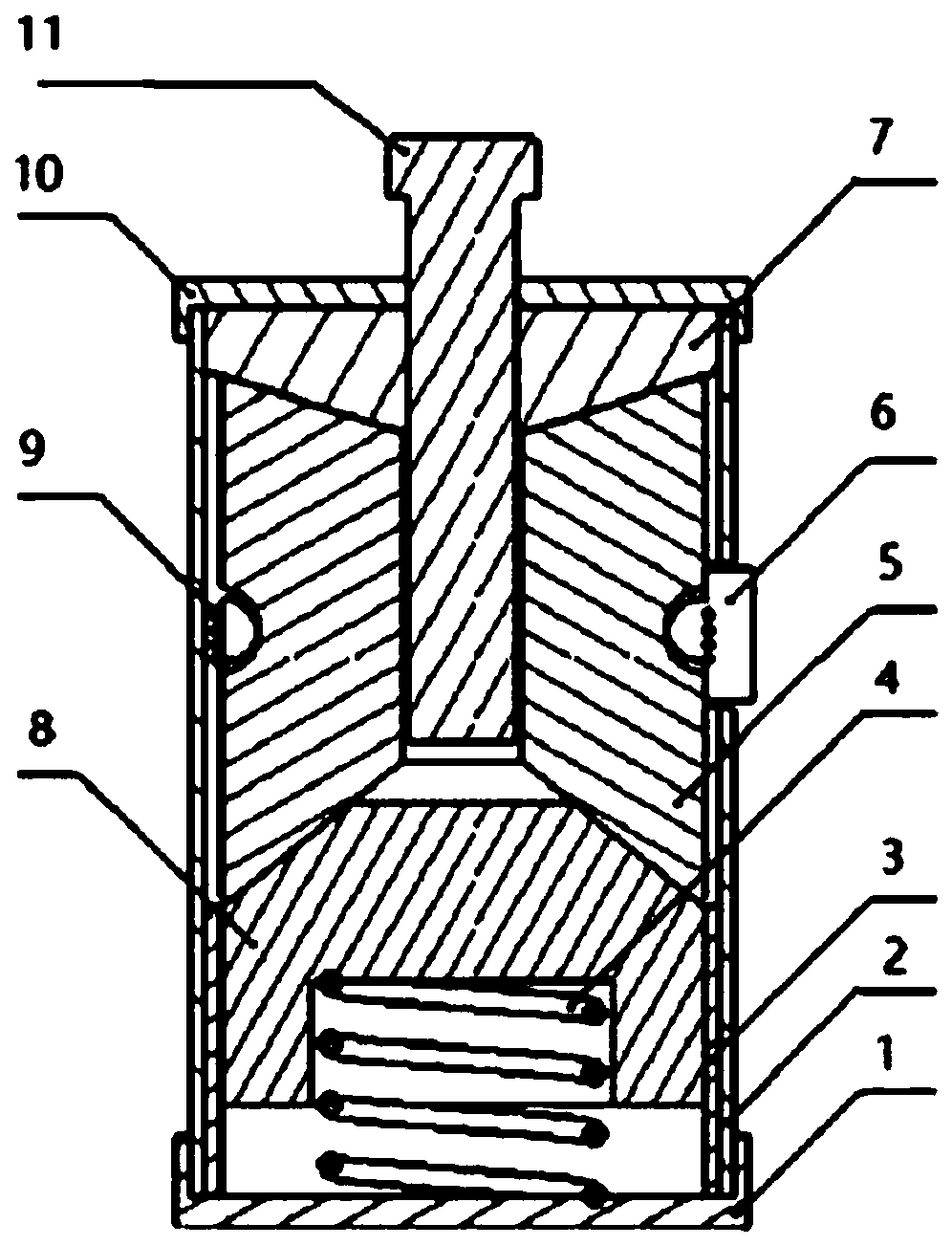

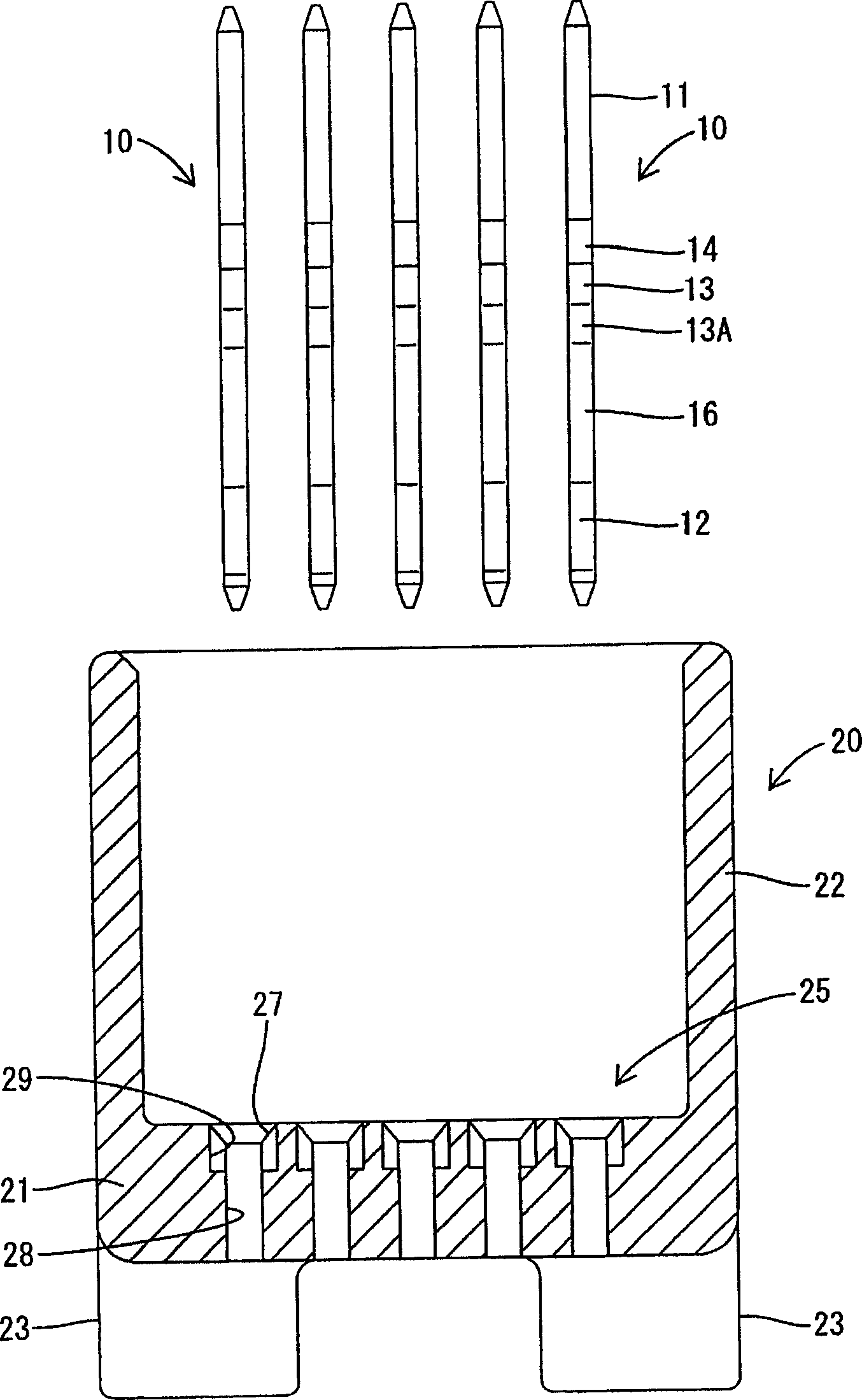

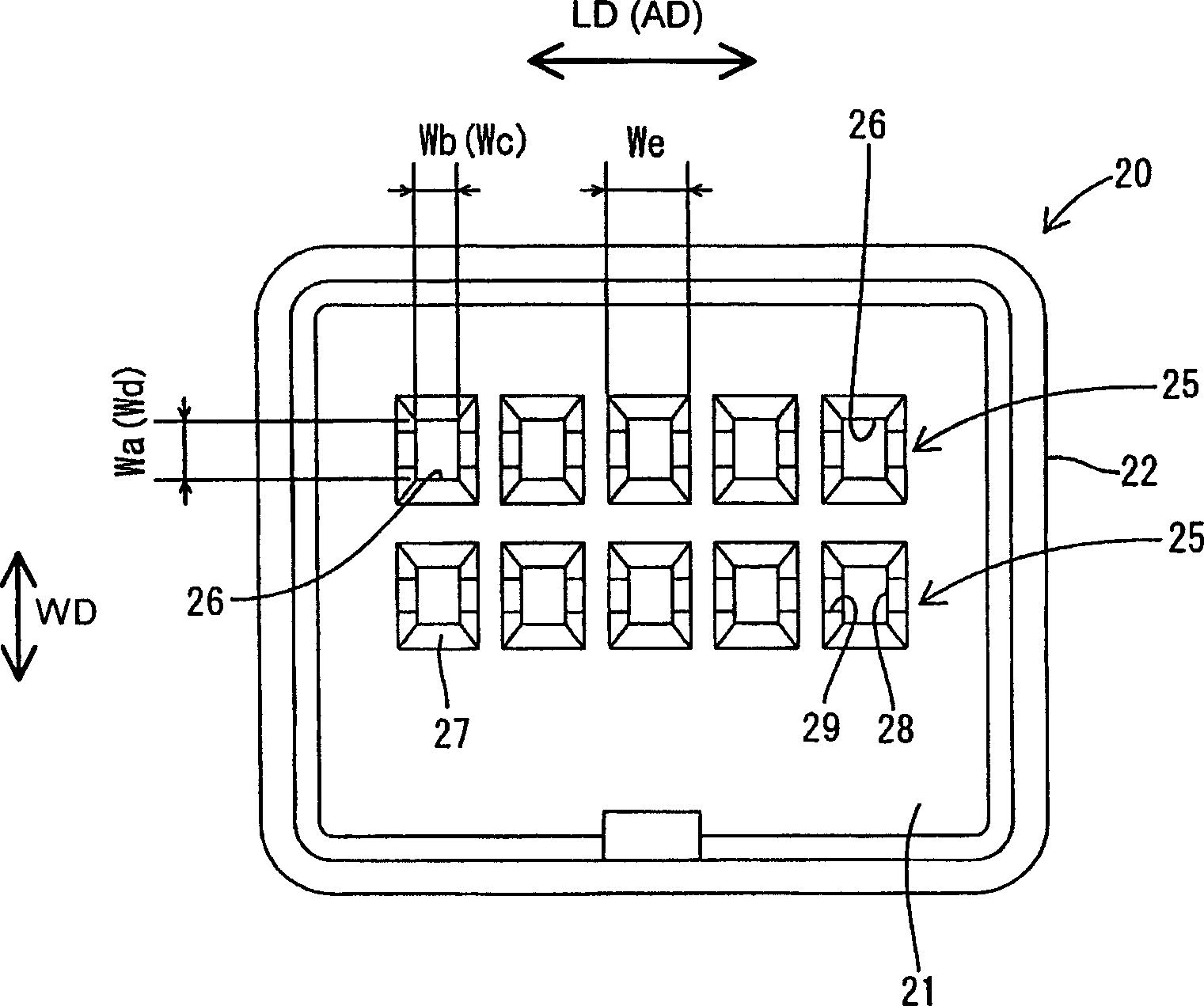

InactiveUS20050244250A1Large locking forceDisengagement of the clip can be preventedSnap fastenersFlow mixersEngineeringLower face

A clip has a head part adapted to be contacted with a peripheral edge of a fitting hole in a panel to be fitted, and a leg part adapted to be inserted into the fitting hole thereby to be engaged with the peripheral edge of the fitting hole. The leg part has a post suspended from a center of a lower face of the head part, at least three projections which are radially extended from the post in a diametrical direction and connected to the lower face of the head part at their upper ends, and engaging pieces which are extended from these projections in a circumferential direction to be respectively positioned between the projections. The engaging pieces are connected to the head part at their upper ends, and provided with slits between their circumferentially extended ends and the opposed projections.

Owner:PIOLAX CO LTD

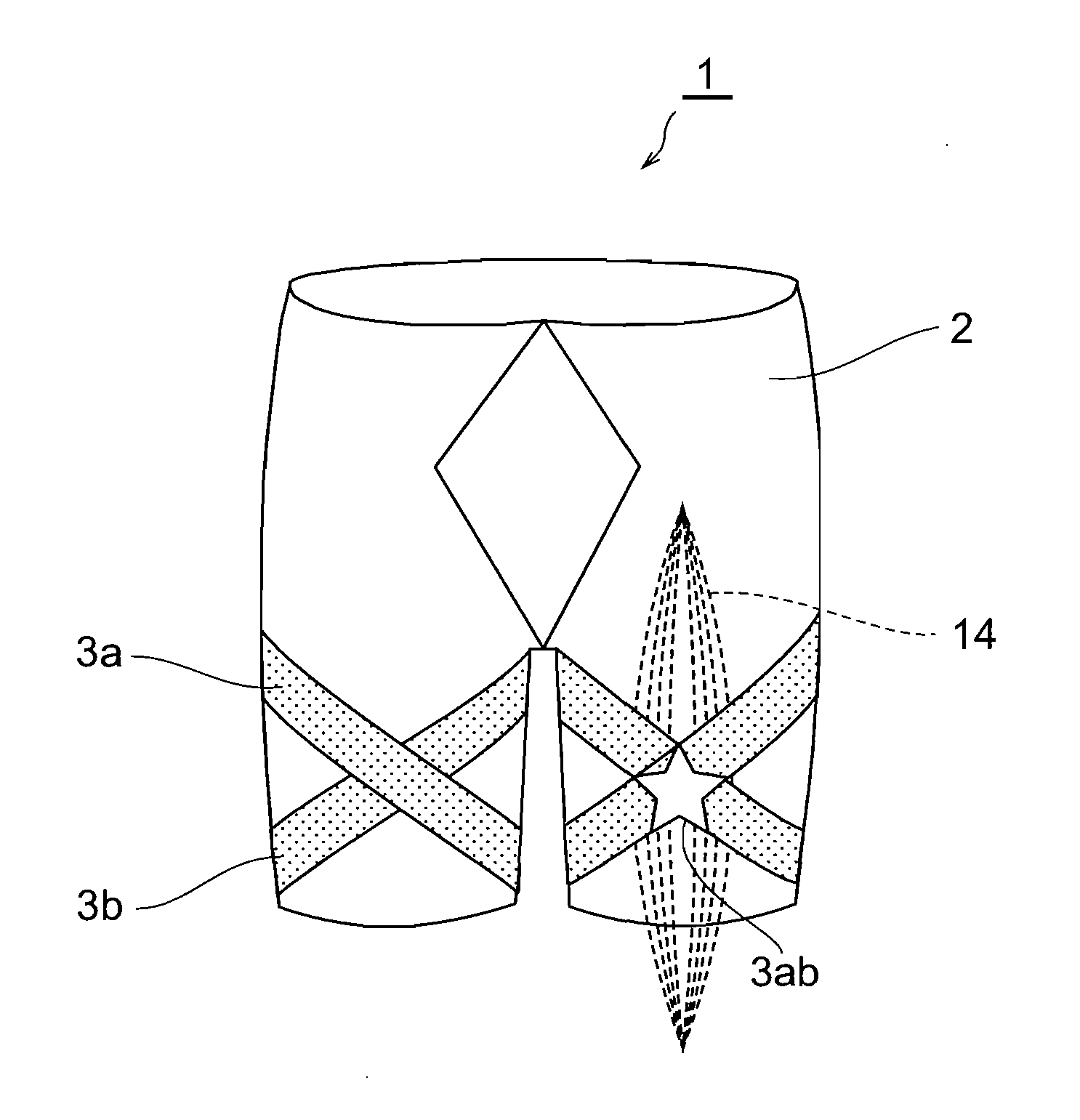

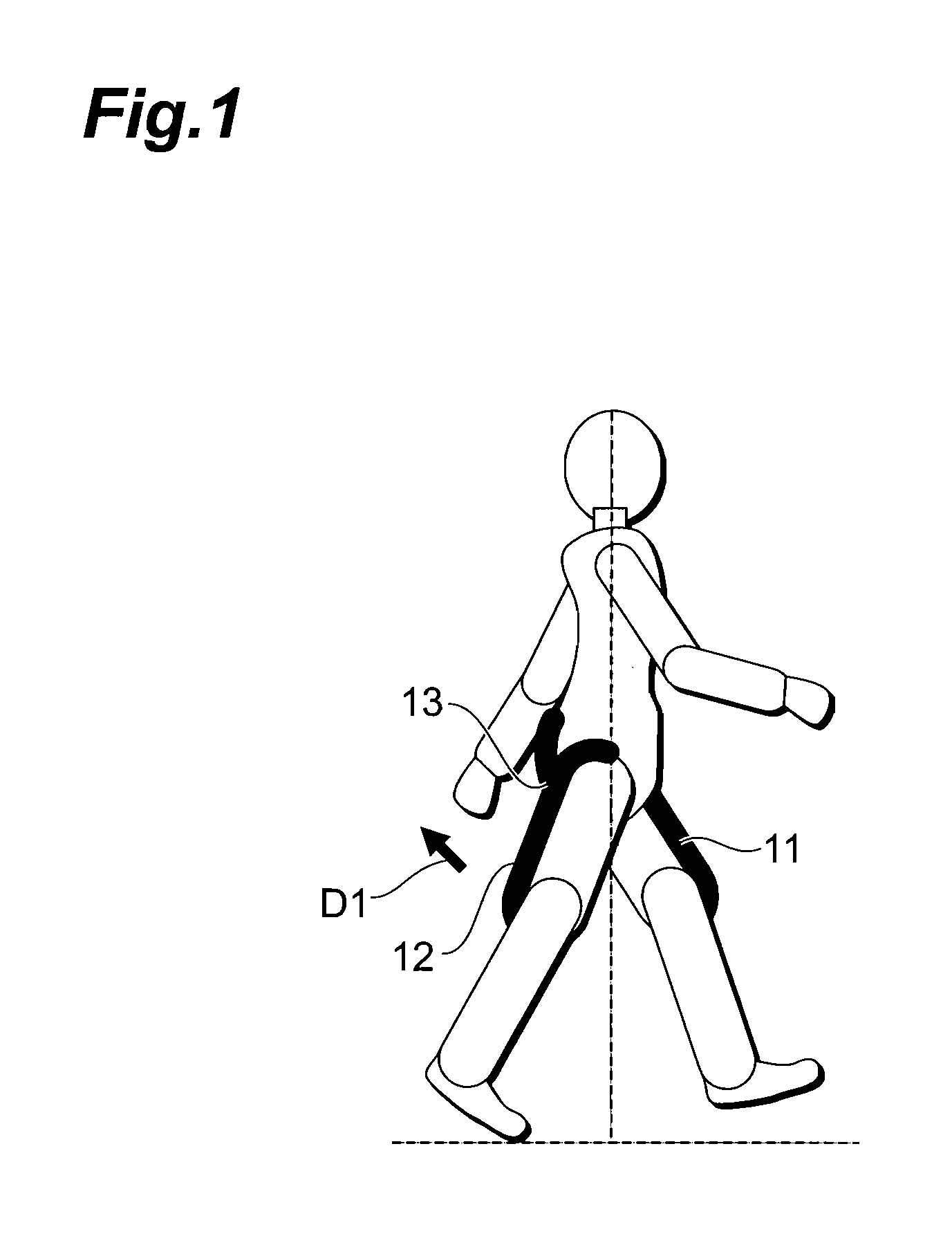

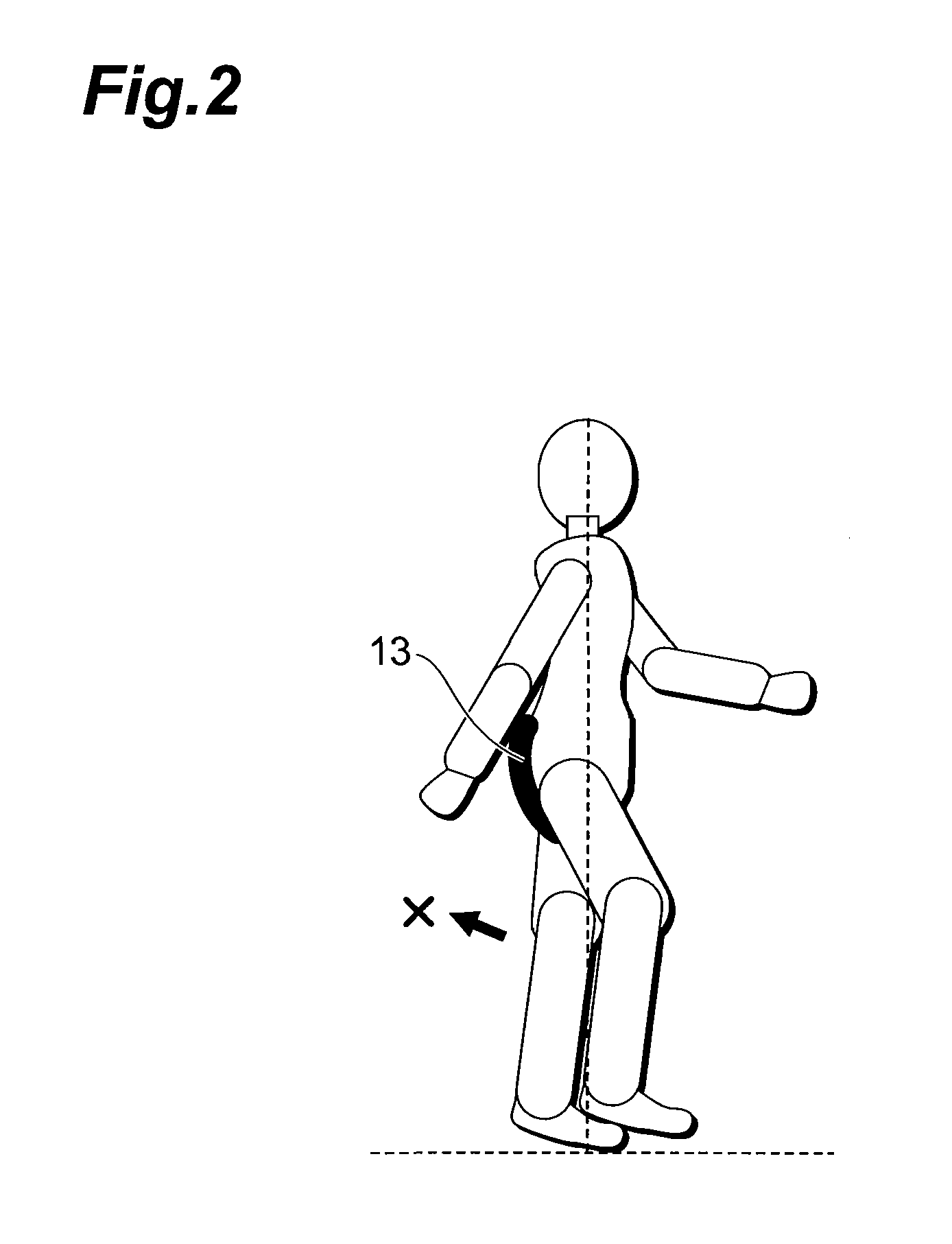

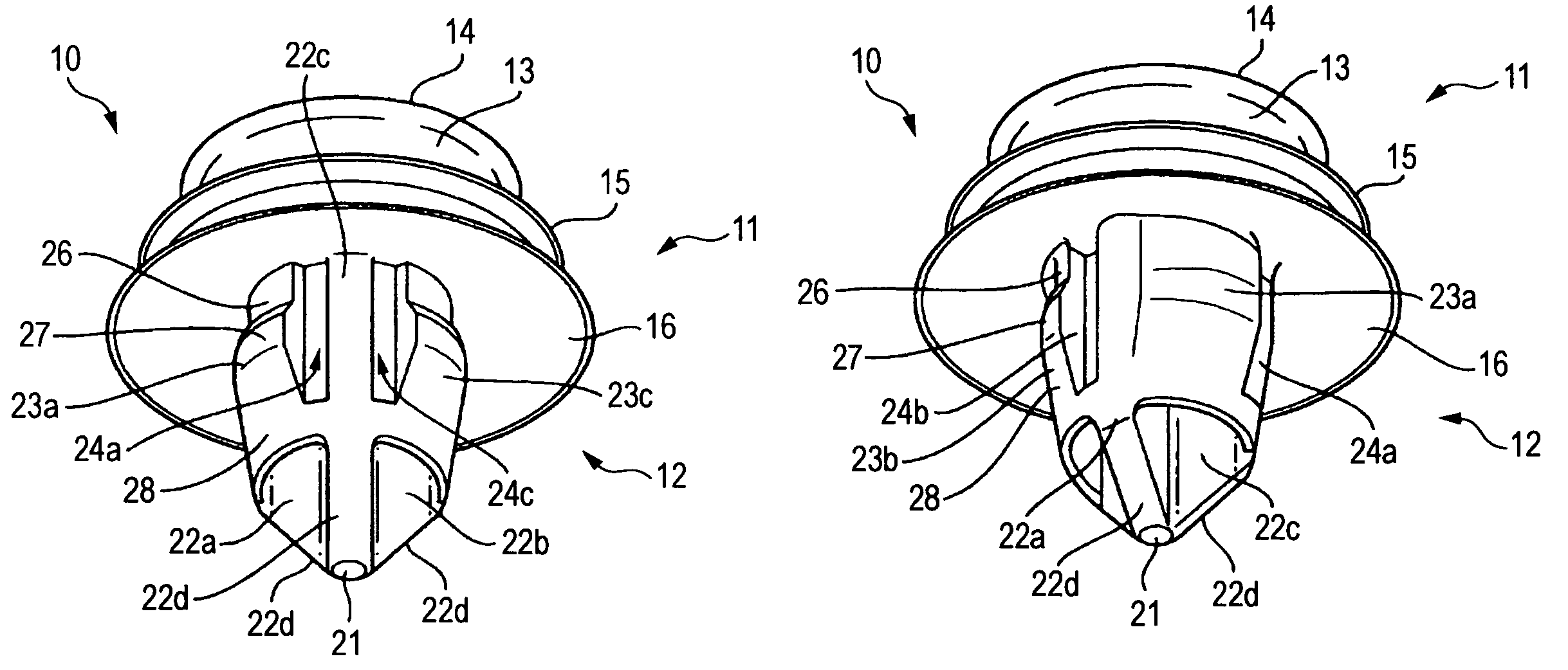

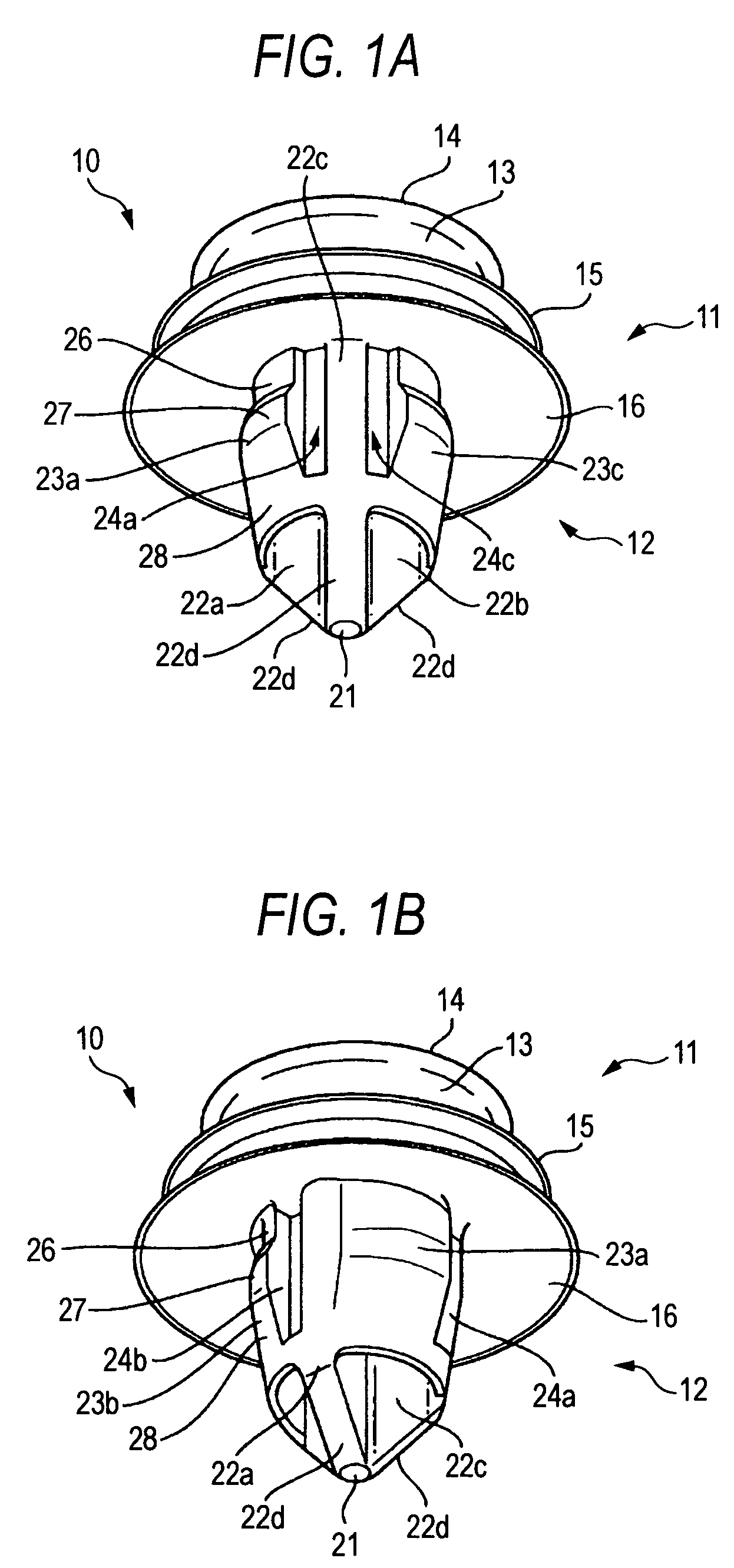

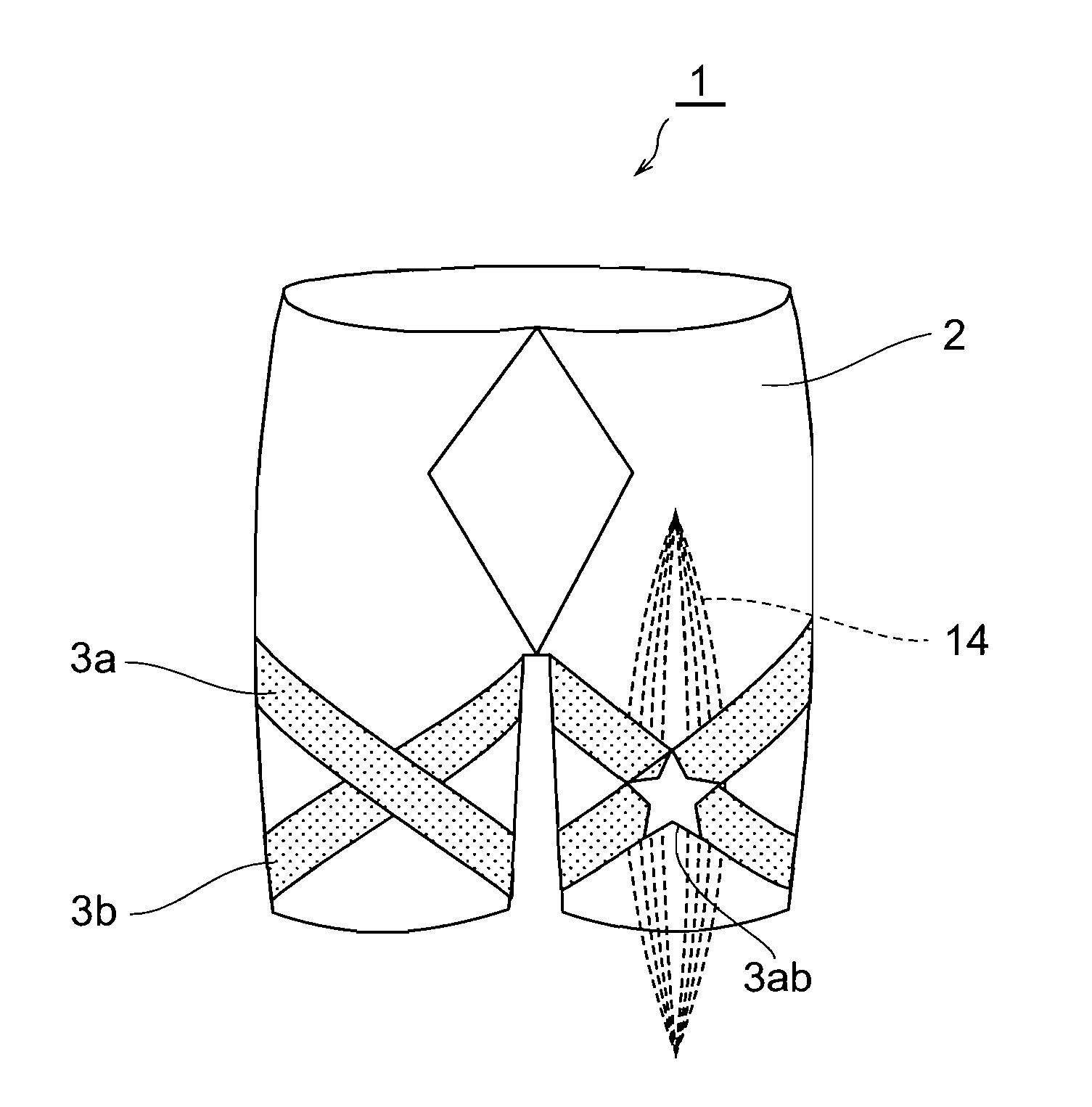

Bottom garment

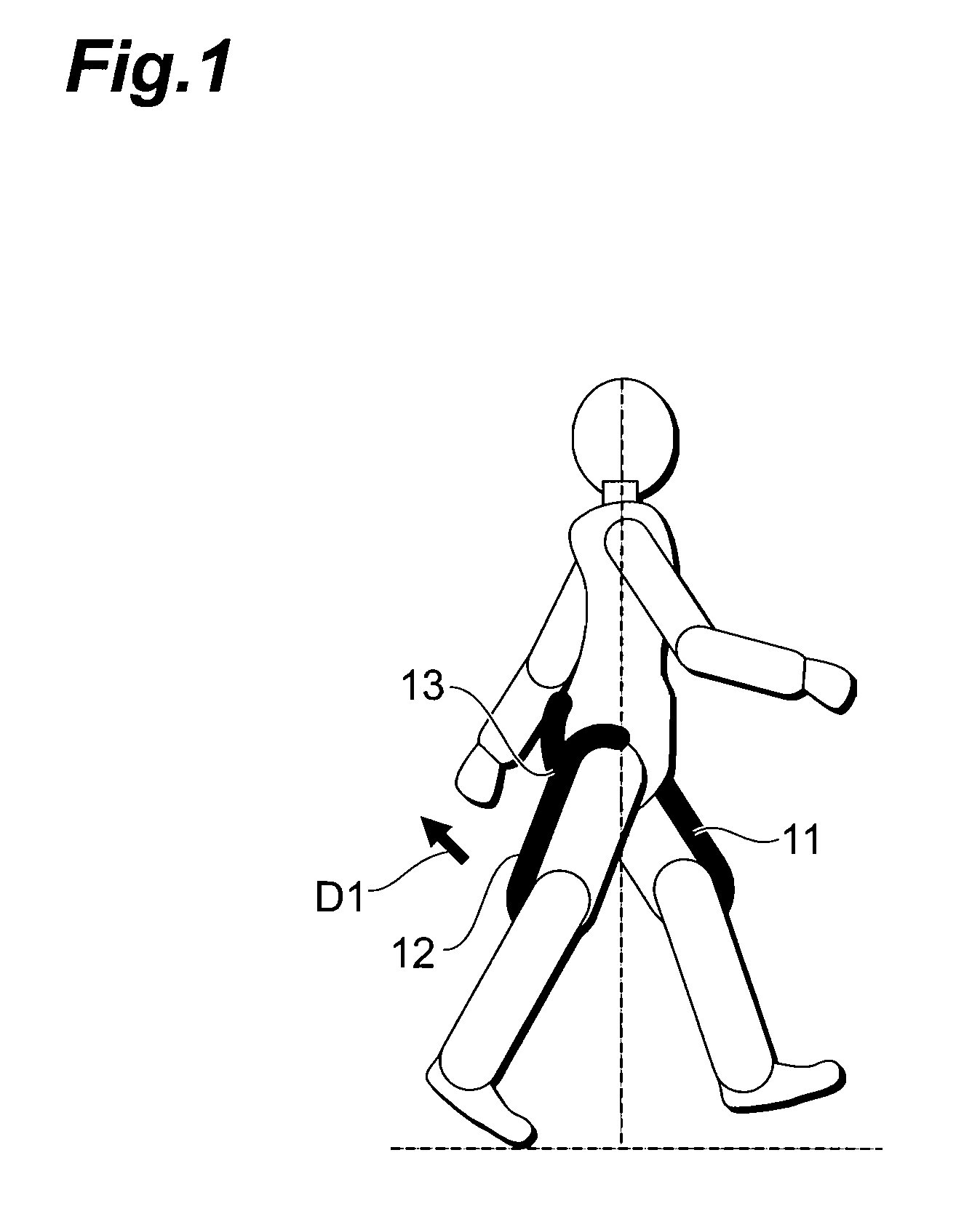

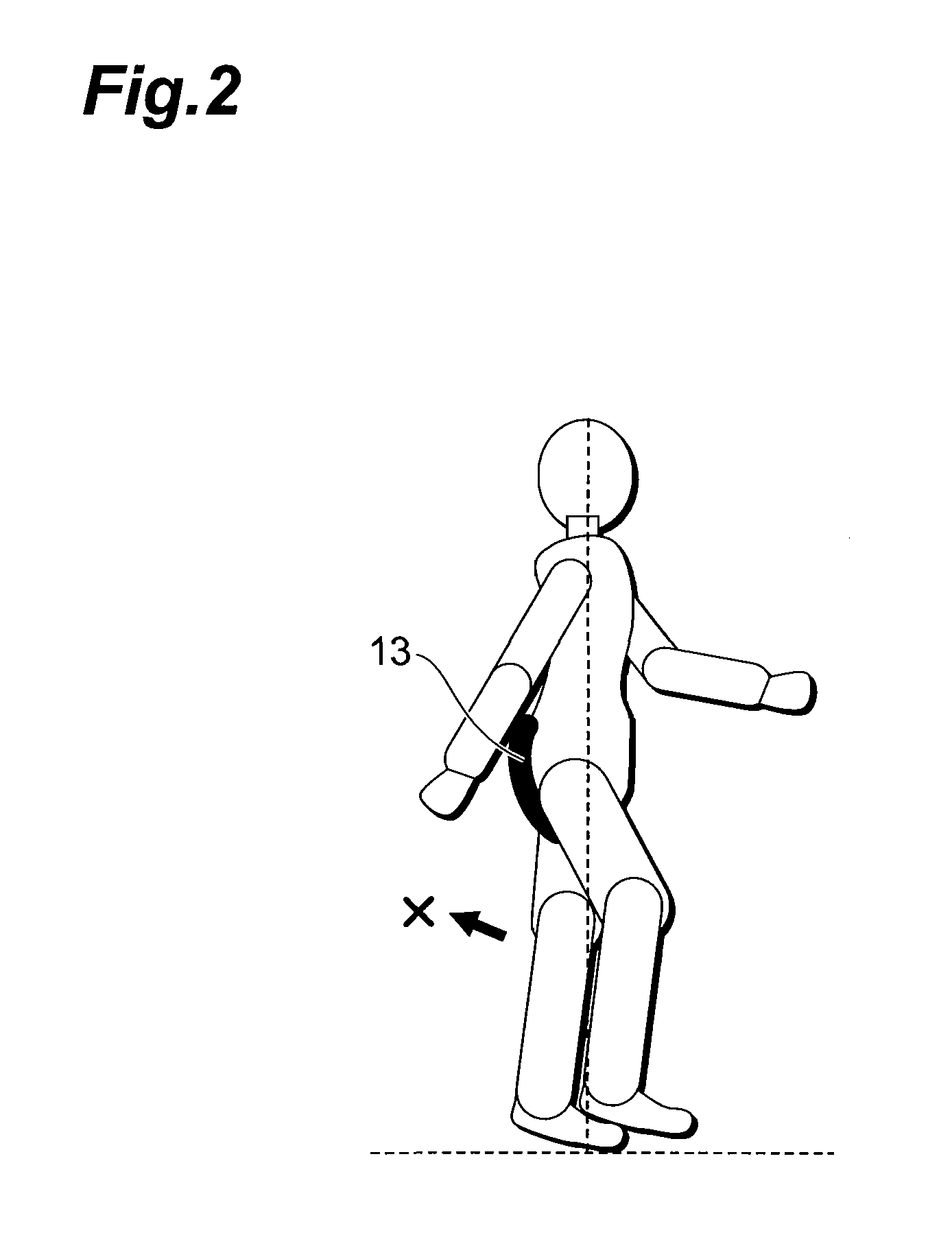

InactiveUS20070214541A1Effectively stimulateLarge locking forceGarment special featuresTrousersRectus femoris muscleEngineering

Filler clothes 3, which intersect with each other at a section corresponding to the middle point between the interspinal point and patellar midpoint of a human body, are formed on a front section of a bottom garment 1. The filler clothes 3which are formed in this manner stimulates the rectus femoris muscle 14 which is a part of the quadriceps of a wearer. When the quadriceps is stimulated while walking, the legs can be kicked backward significantly in a natural fashion, whereby the gluteus maximus muscles can be used efficiently.

Owner:WACOAL

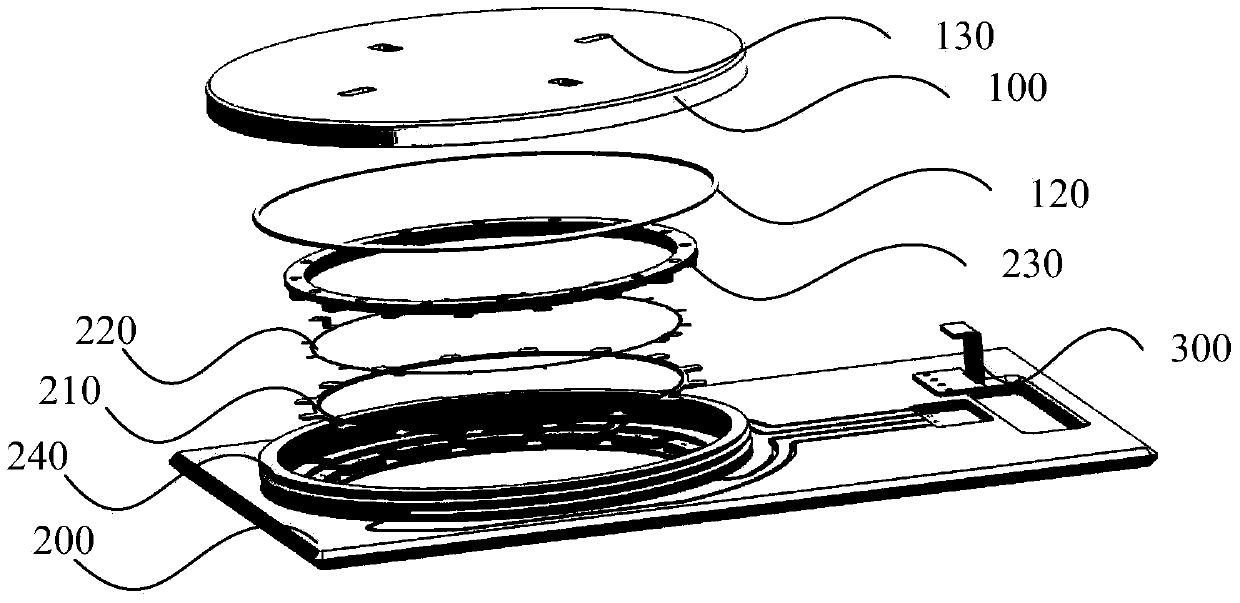

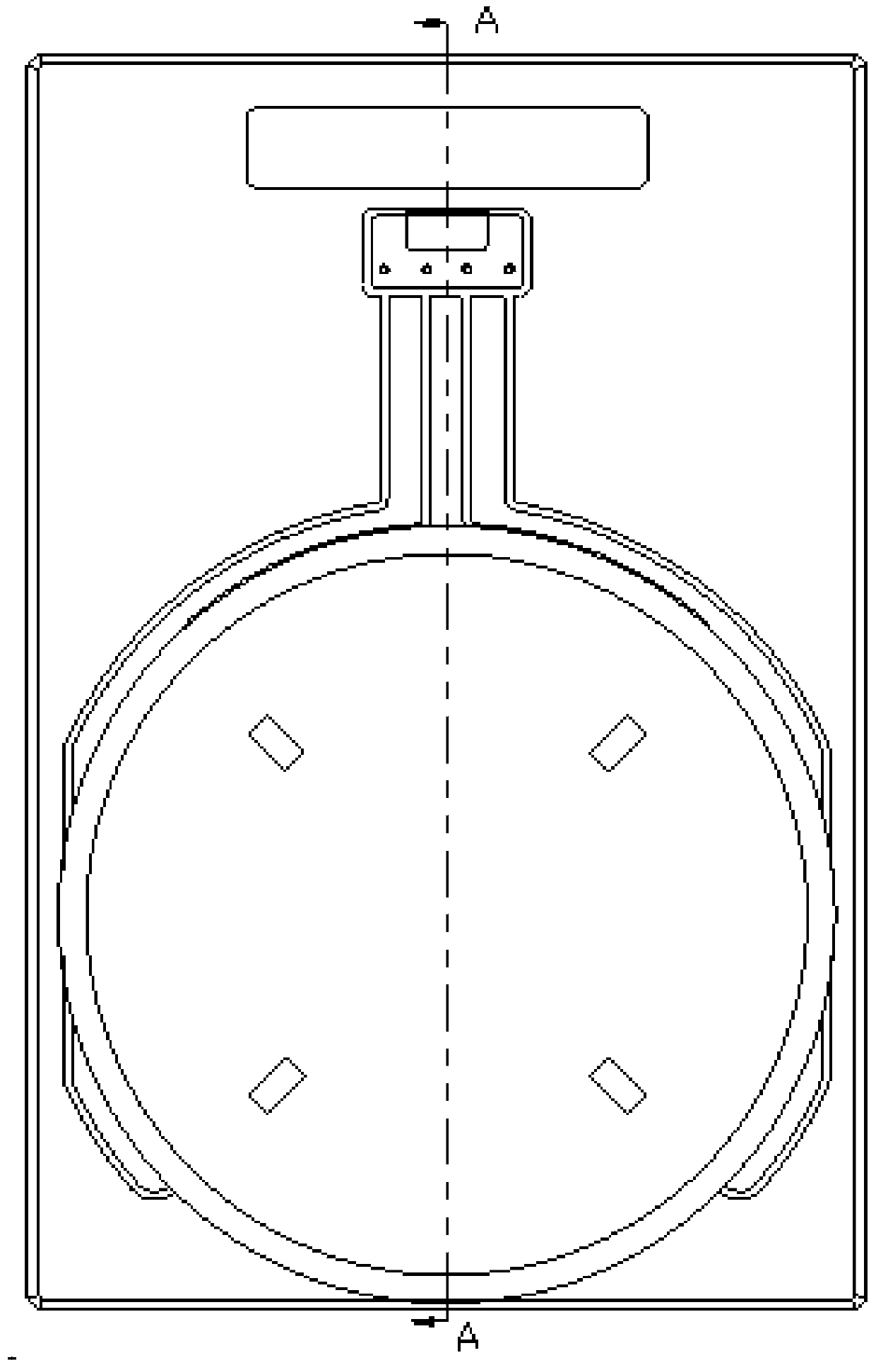

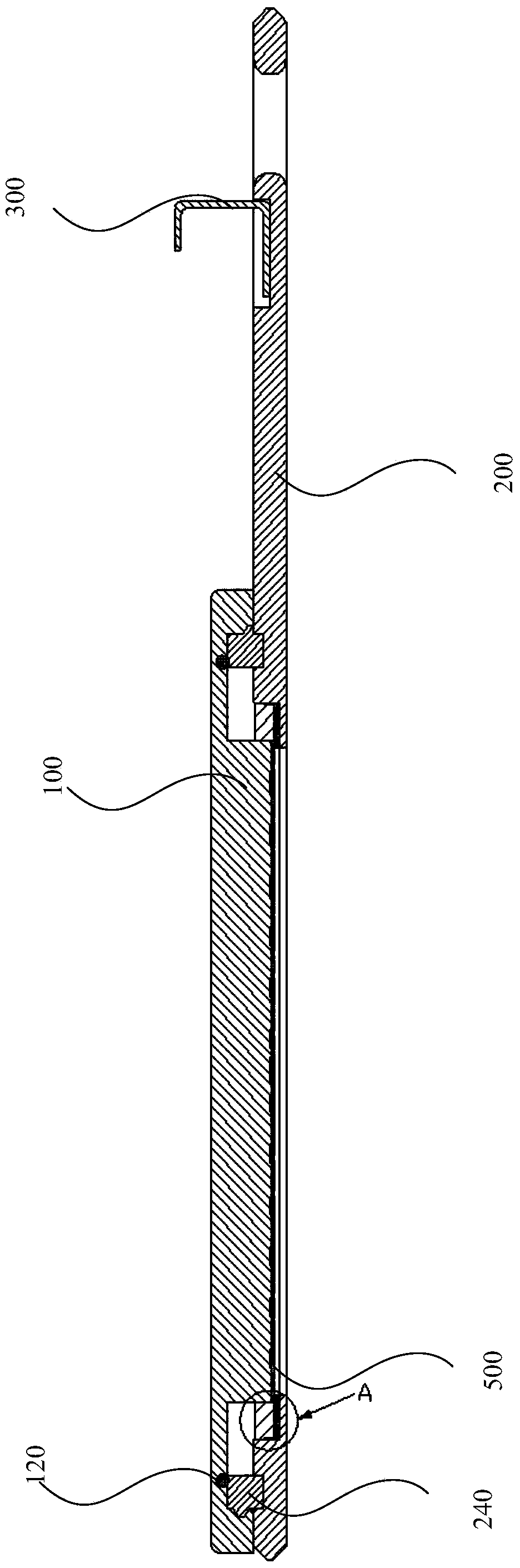

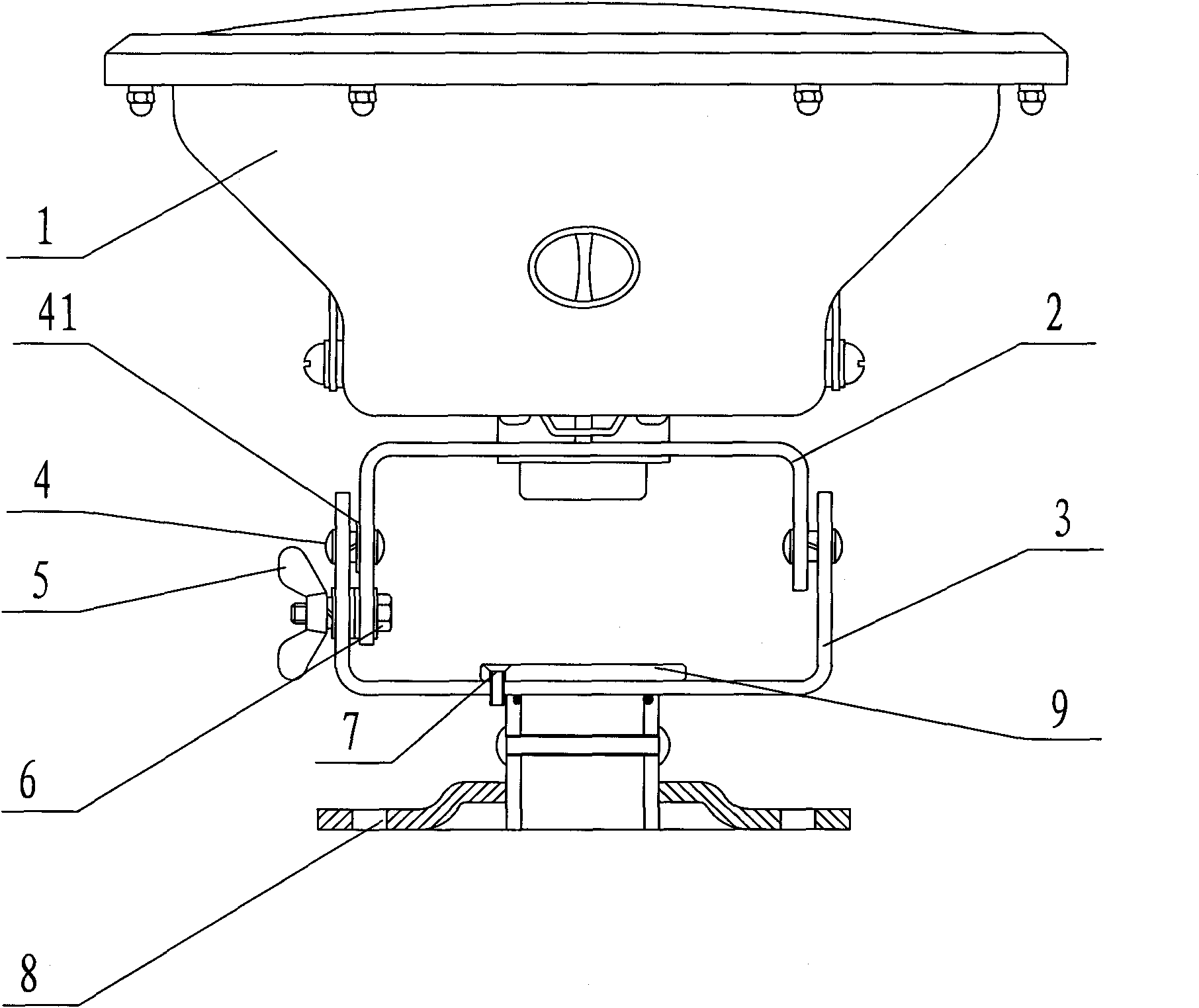

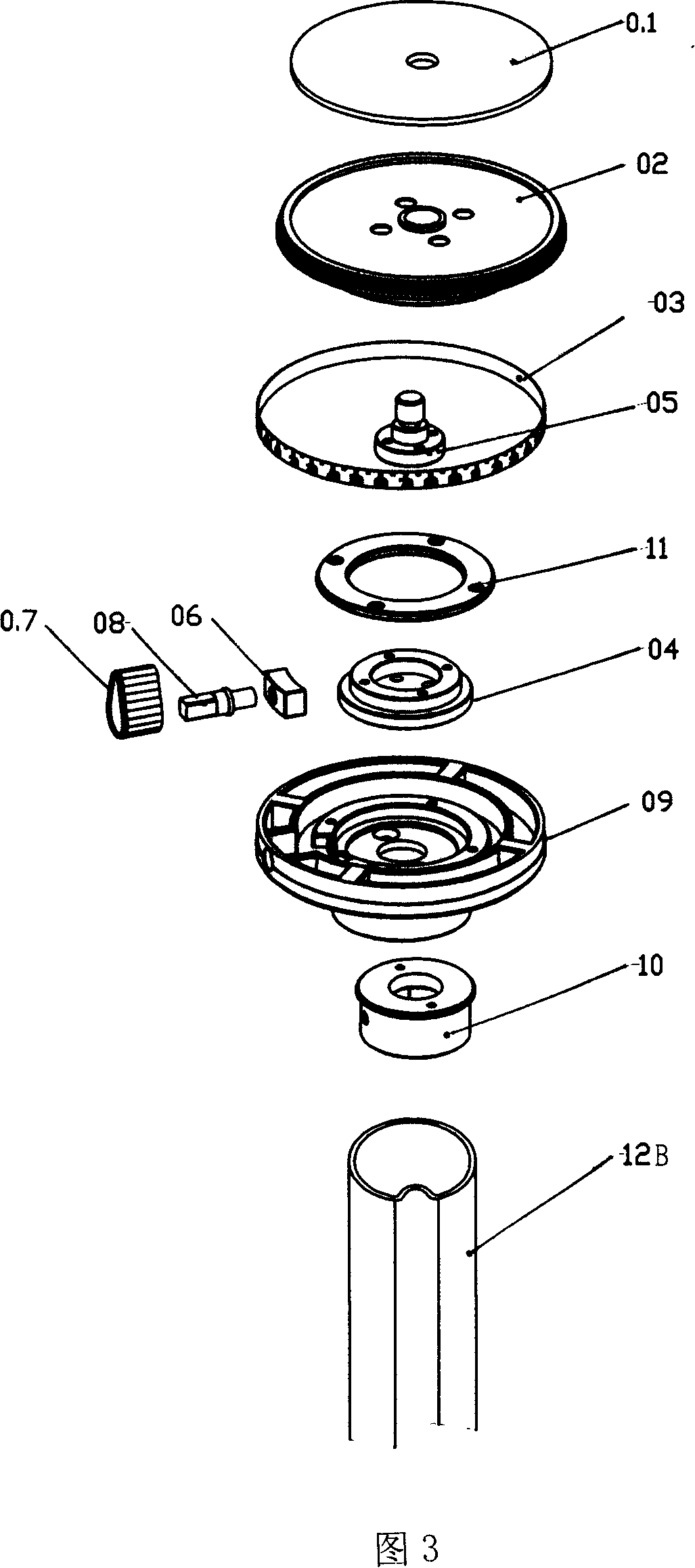

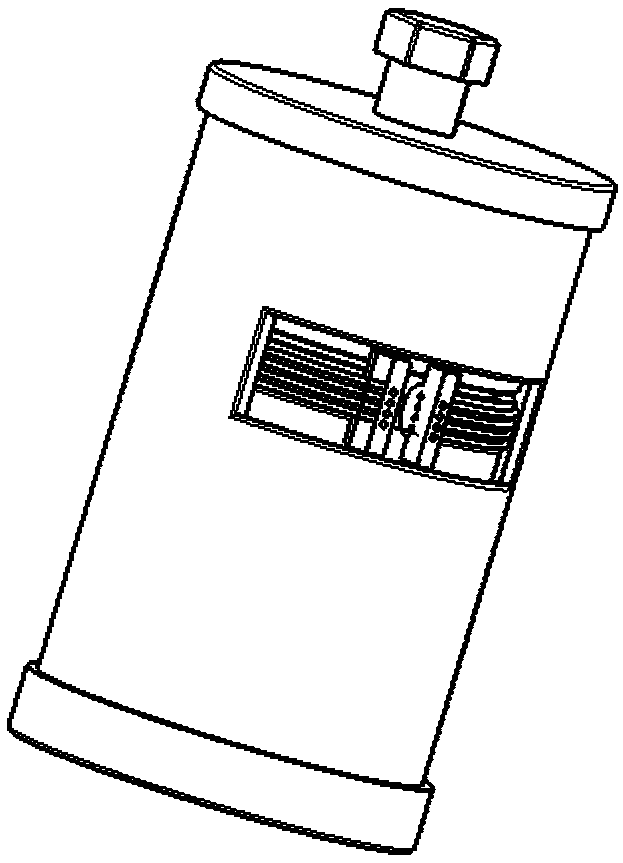

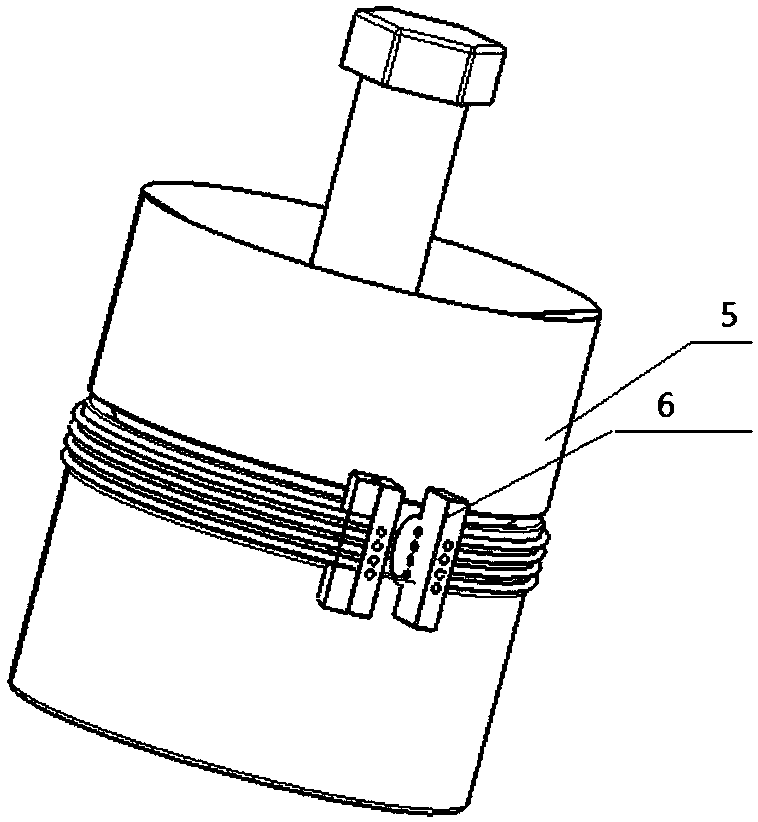

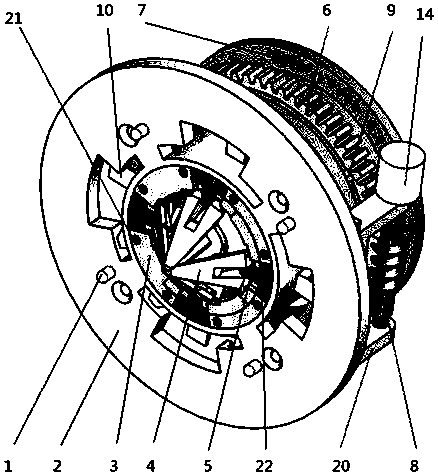

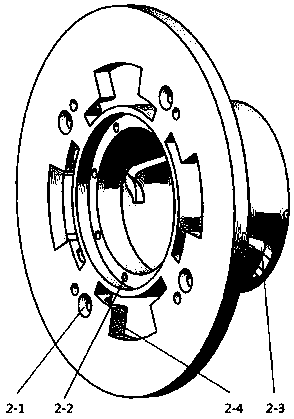

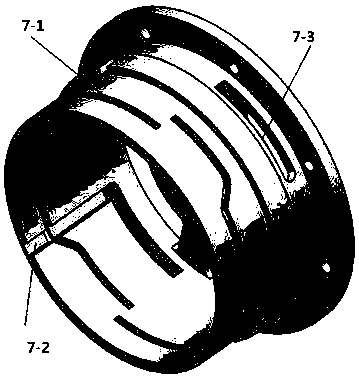

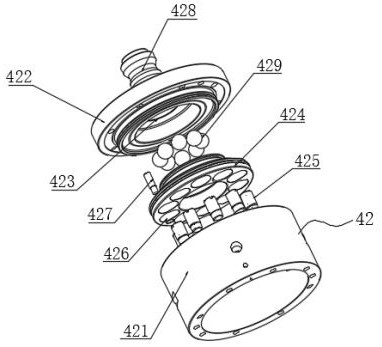

Hanging tool for wafer electroplating

ActiveCN103469271AUniform platingContact withElectrolysis componentsSemiconductor devicesEngineeringElectroplating

The invention discloses a hanging tool for wafer electroplating. The hanging tool comprises an upper cover, a lower plate and a metal conductive ring, wherein an inner thread is arranged on the inner wall of the upper cover, a wafer groove is formed in the lower plate, an electroplating hole is formed in the middle of the wafer groove, and an outer thread engaged with the inner thread is arranged on the outer wall of the wafer groove; a platform is arranged between the inner wall of the wafer groove and the electroplating hole; the metal conductive ring is arranged on the platform. The upper cover of the hanging tool for the wafer electroplating is locked in a rotary mode, and the need of manually disassembling screws is eliminated, so that the hanging tool is convenient to operate, uniform in force, good in electrical conductivity and sealing performance and uniform in water coating, thereby greatly saving the manpower and reducing the wafer scrapping risk.

Owner:江苏矽智半导体科技有限公司

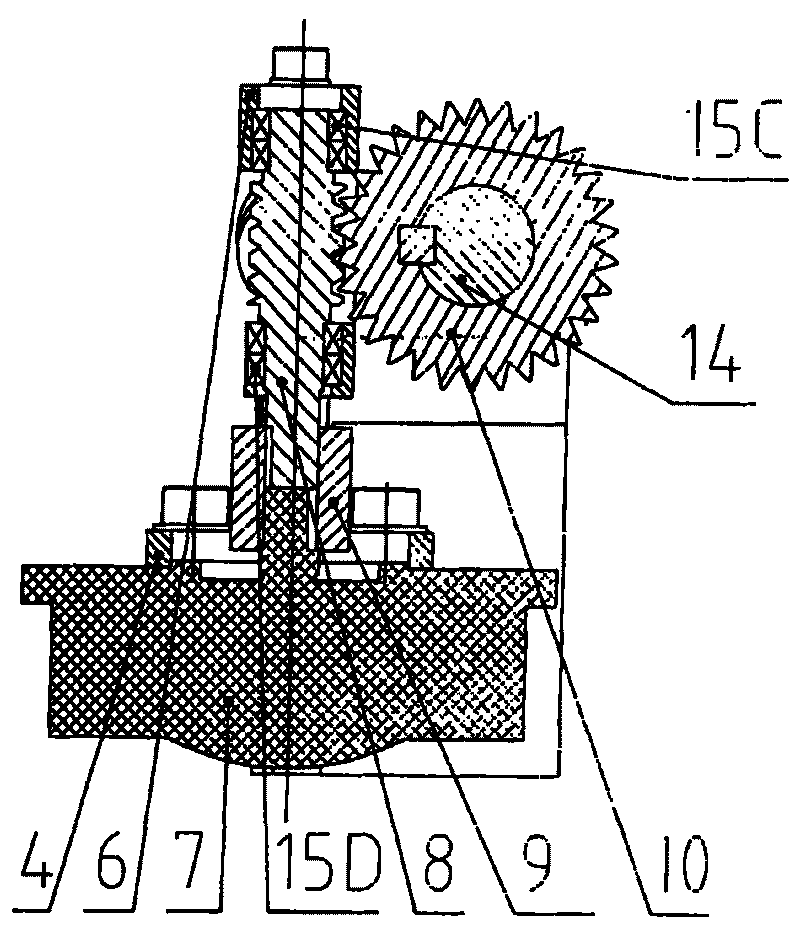

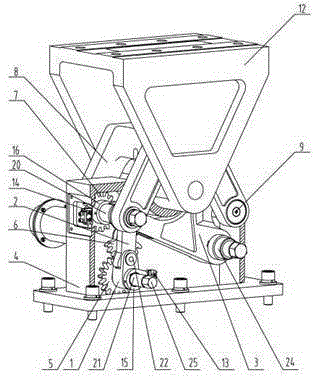

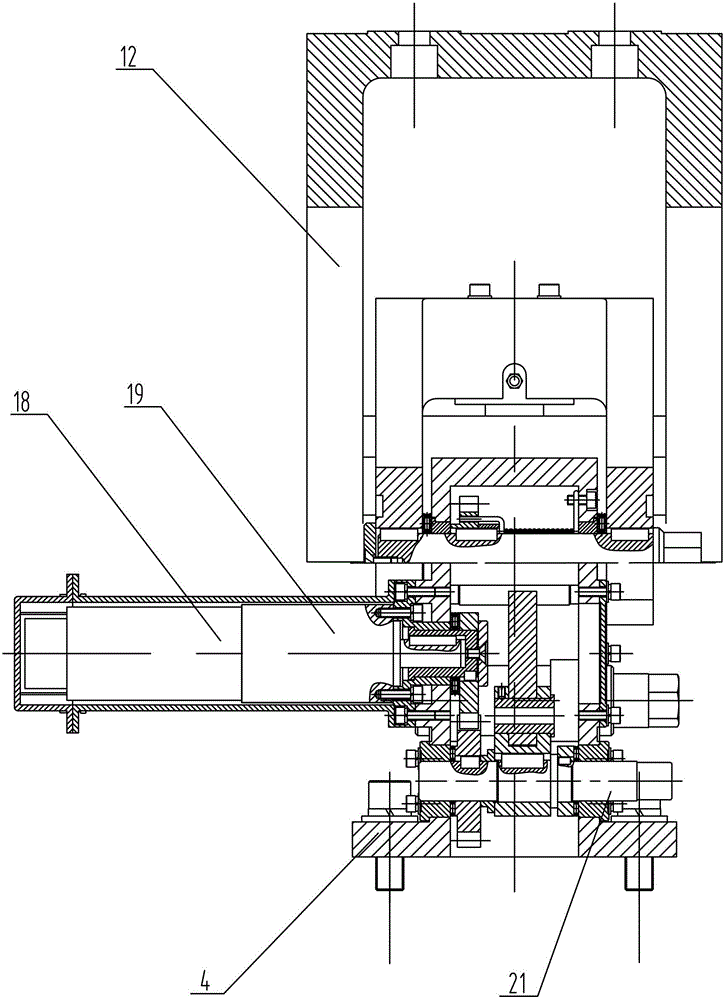

Repeatable locking device for magnetically suspended flywheel

InactiveCN101693472ARealize repeatable locking functionStay lockedSpacecraft guiding apparatusFreewheelLocking mechanism

The invention relates to a repeatable locking device for a magnetically suspended flywheel, which comprises a flywheel system, a driving mechanism and a locking mechanism, wherein the locking mechanism is arranged outside a flywheel rotor and is fixed to a flywheel base through a fastening bolt. The flywheel system mainly comprises a flywheel stator shaft, a flywheel rotor and a base; the driving mechanism mainly comprises a fixed plate, a left bearing pressure ring, an upper bearing pressure ring, a motor, a worm, a coupling joint, a worm wheel, a fixed pole, a locking fork, a spherical nut, a worm wheel link rod and a bearing; and the locking mechanism mainly comprises a spring chip seat, a spring chip, a spring chip body, a small pole, a steel rope and a connecting pole. The locking device protects a magnetically suspended flywheel system, and has the advantages of repeatable use, high reliability, simple structure and the like.

Owner:BEIHANG UNIV

Preparation method for asphalt concrete with conduction function

InactiveCN101215124ALow costAlleviate problems such as insufficient aggregateSolid waste managementForeign matterMaterials preparation

The invention relates to a process for preparing asphaltic concrete with conducting function, which is characterized in that the process includes the procedures of 1), preliminary treatment of aggregates, which means washing away the foreign matters of the steel slag with water. 2), raw materials preparation, which means that the percentage by weight of each component is that rough aggregates is 55%-80%, fine aggregates is 13%-30%, mineral filler is 7%-15%, the rough aggregates, fine aggregates and mineral filler are selected to reserve as aggregates, consumption of asphalt cement is 6%-8% of the weight of the aggregates, consumption of fabric stabilizer is 0.1%-0.5% of the gross weight of the aggregates and the asphalt cement, consumption of conducting material is 10-30% of the weight of the asphalt cement, and gradation design of SMA mixture is employed. 3), mixture blending, which means charging fractionally and blending multitime, the temperature is kept not lower 150 DEG C when molding. The preparing process has simple technique and low cost. The prepared asphaltic concrete has good conducting function and pavement using property.

Owner:WUHAN UNIV OF TECH

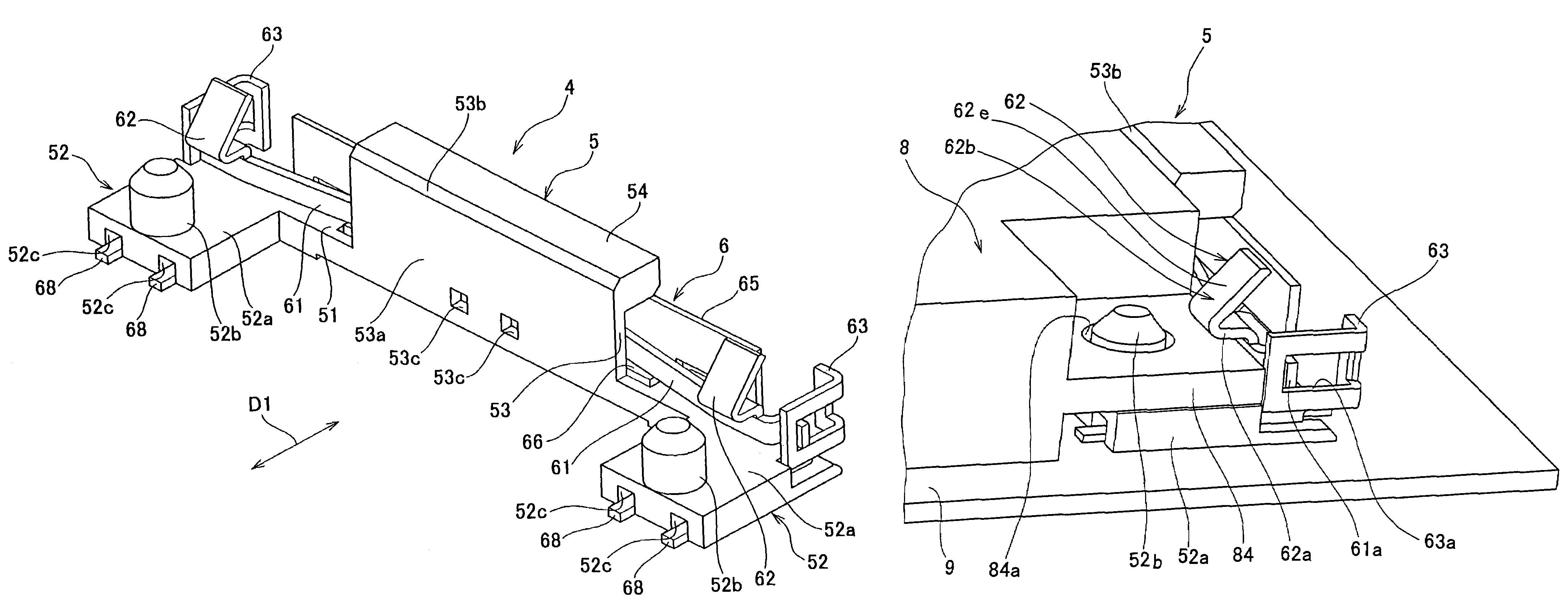

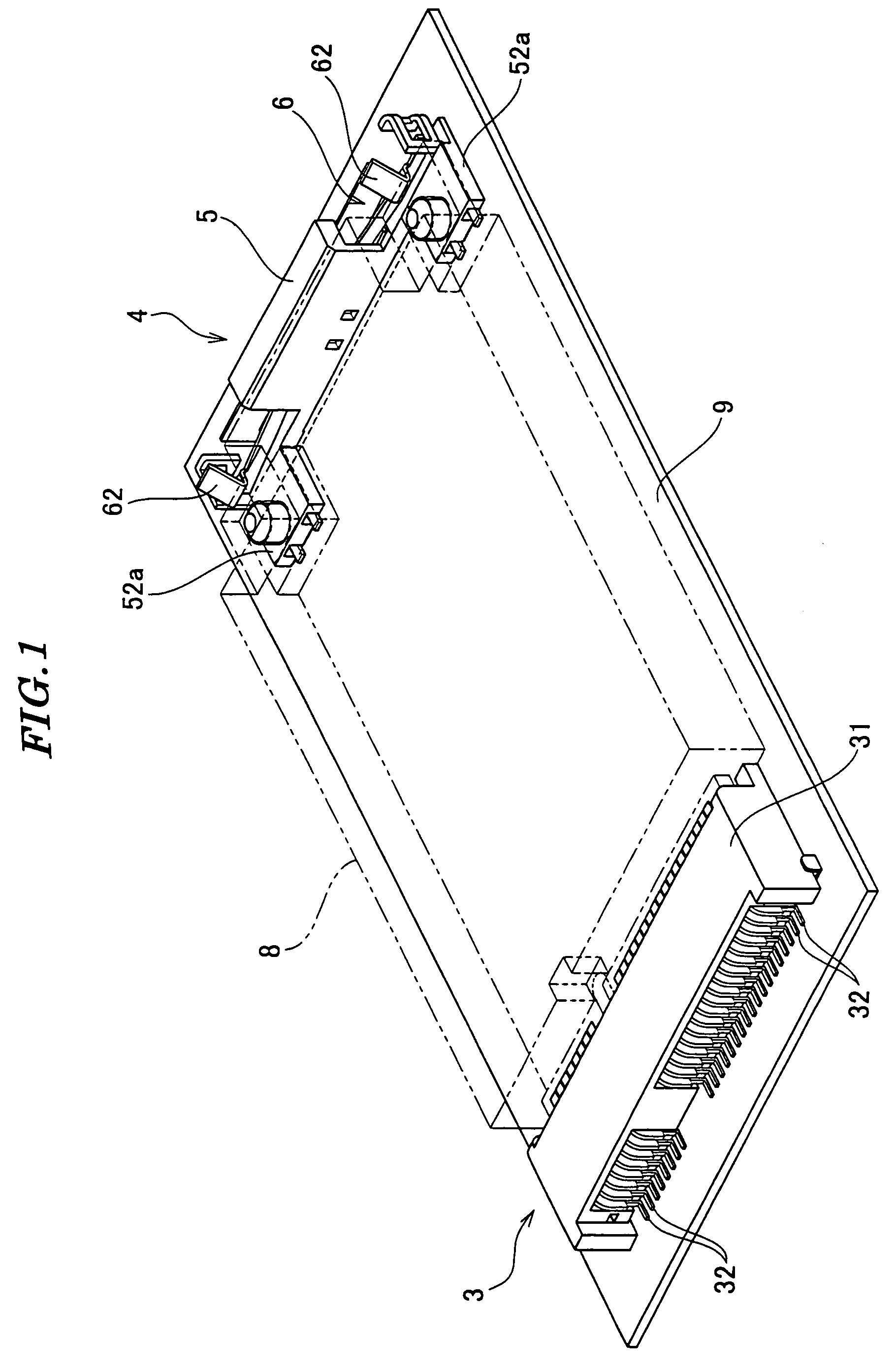

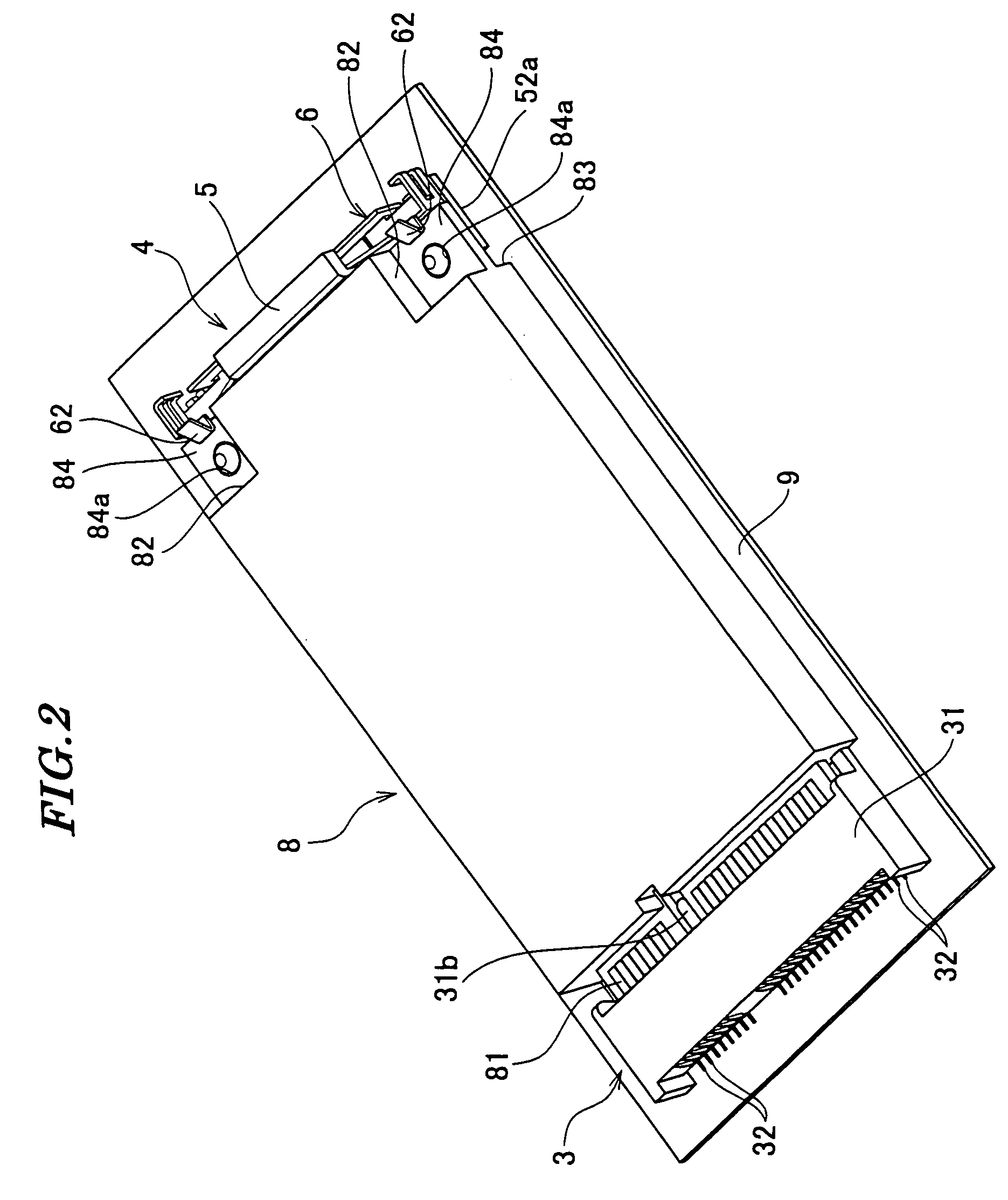

Locking device and connector provided with the same

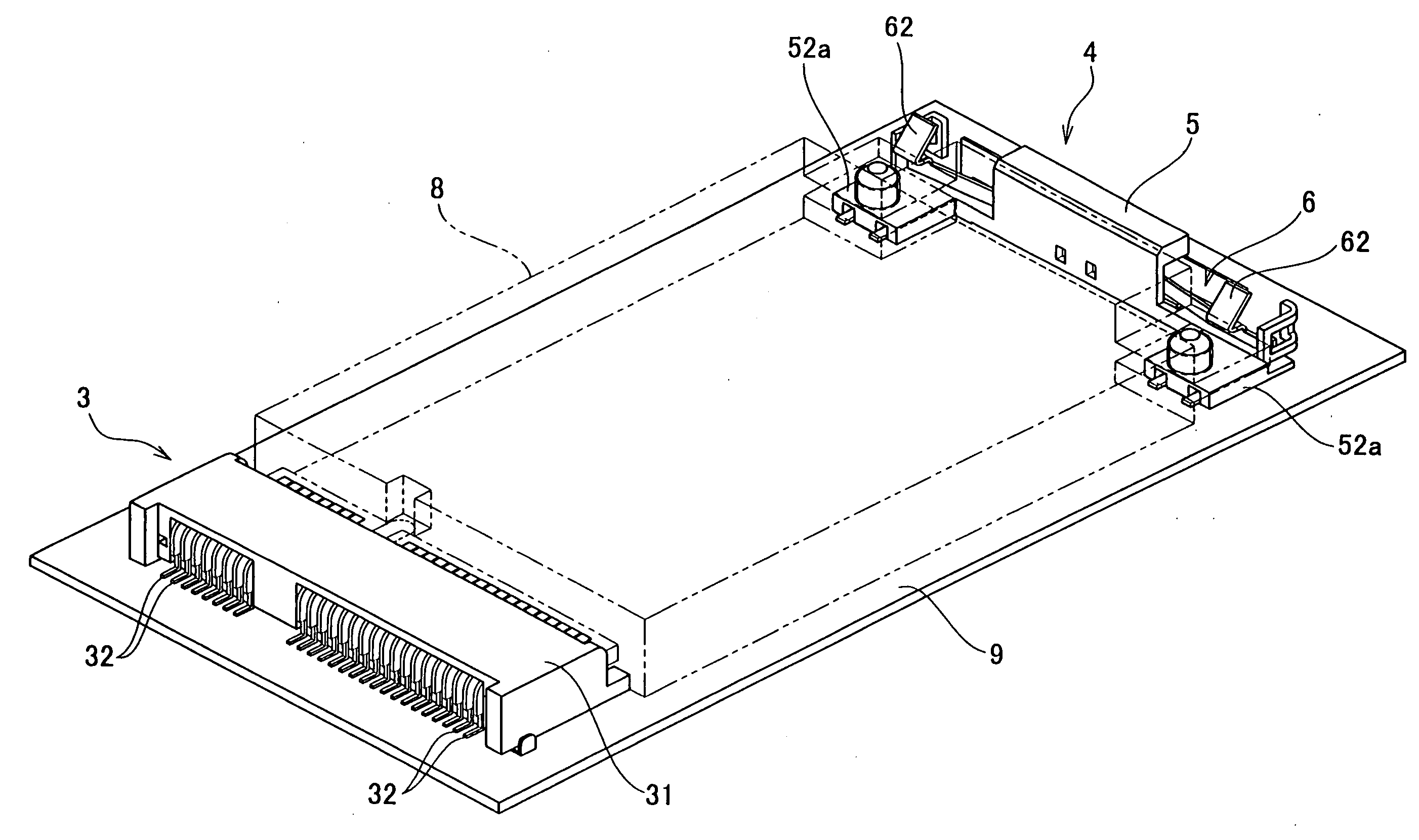

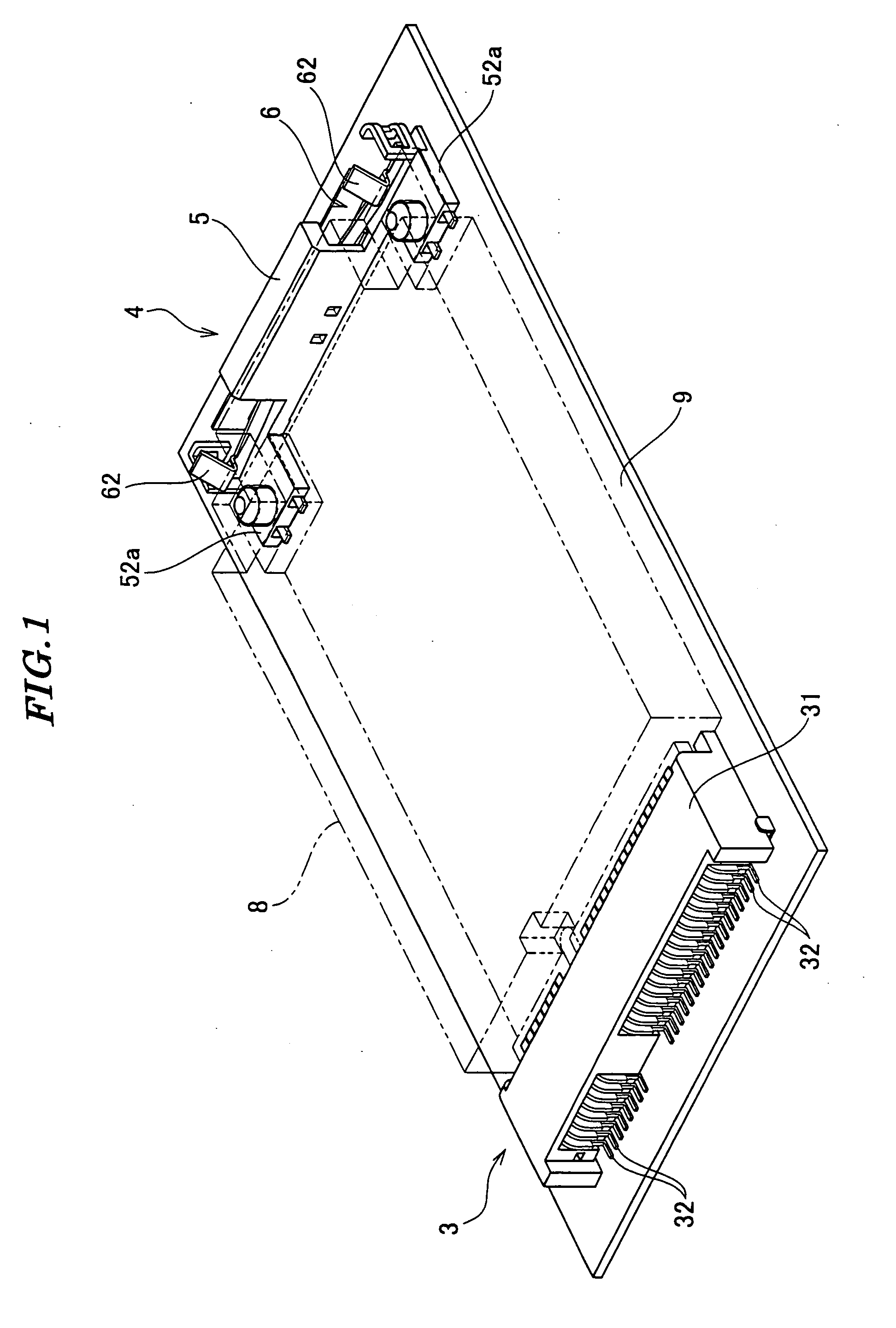

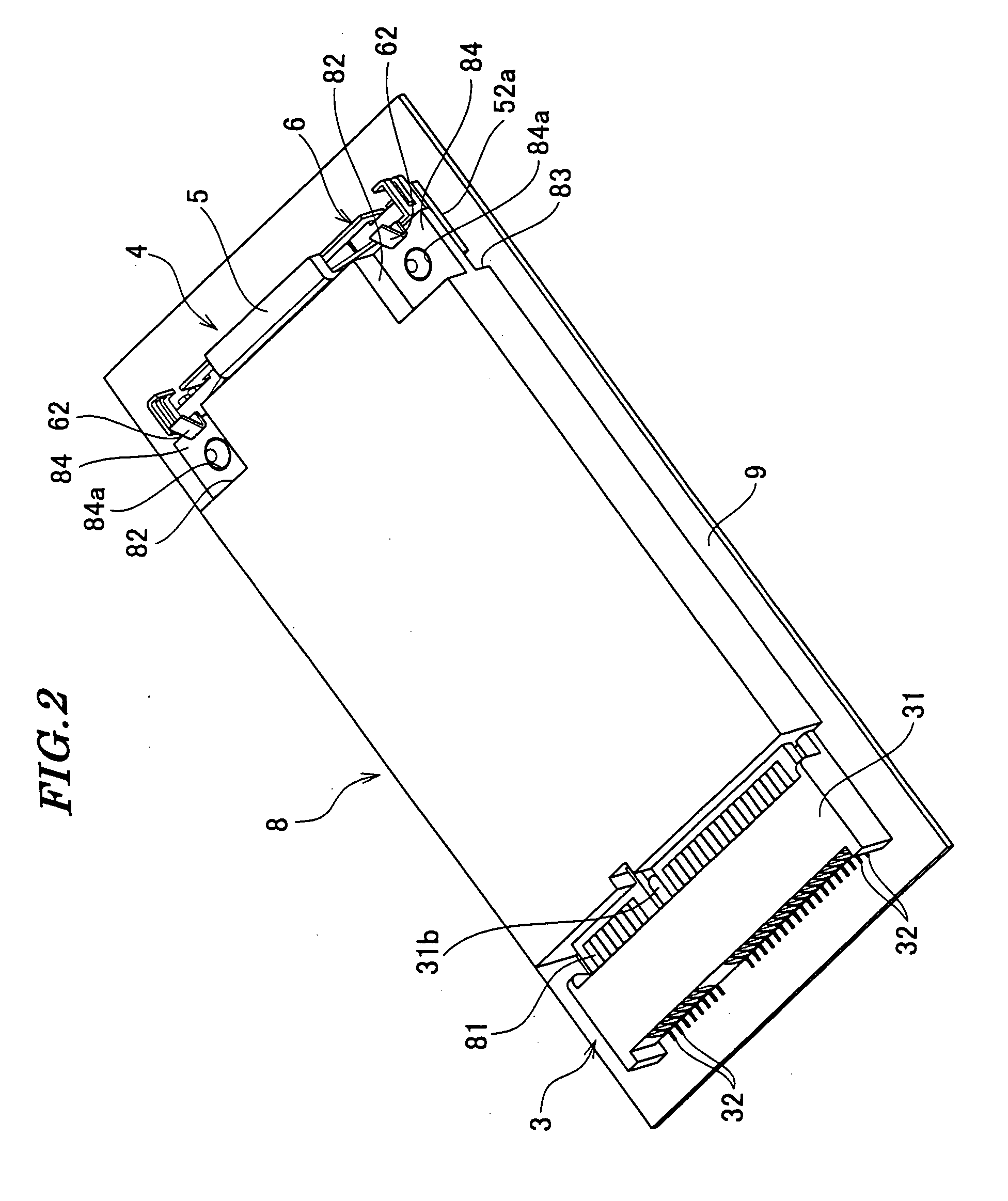

ActiveUS7470136B2Large locking forceAvoid breakingEngagement/disengagement of coupling partsIncorrect coupling preventionExpansion cardEngineering

A locking device which has a strong locking force and is difficult to be broken. Leaf springs bending in a direction toward or away from the rear end of a function expansion card are provided in a housing, and locking sections for locking the function expansion card are connected to the leaf springs. Guide sections are provided in the housing, for guiding the outer ends of the leaf springs in the direction of bending of the leaf springs.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

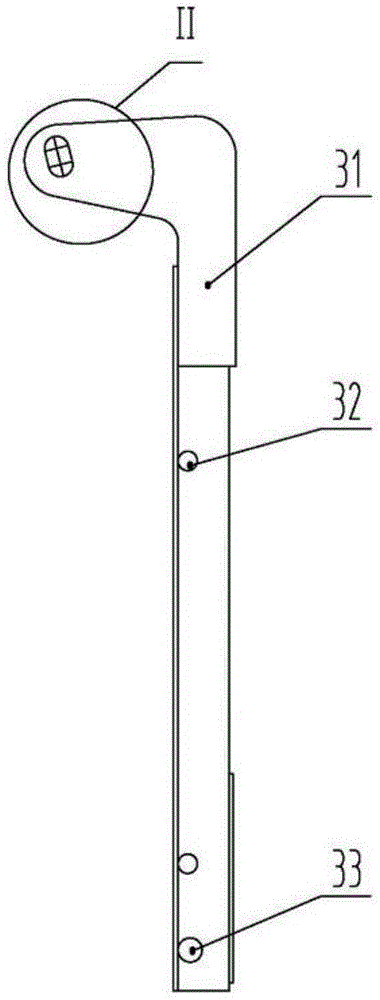

Slide rod locking device

InactiveUS6497437B1Large locking forceSmooth rotationWing handlesKeyhole guardsSwitchgearClassical mechanics

A slide rod locking system, especially for locking the door of a switchgear cabinet, having a handle which is coupled to a control element by a control mechanism. The handle can move around a pivotal axis running perpendicular to the plane of the cabinet door. The control element can move in a parallel position relative to the plane of the cabinet door as a result of the movement of the handle. The slide rod locking system transmits powerful locking forces and at the same time can have a low-height design structure by arranging a lever on an articulated joint of the handle at a distance from the pivotal axis. The lever enables the force introduced into the handle to be transmitted to the control element and can modify its angle position with respect to the handle when moved.

Owner:RITTALWERK RUDOLF LOH GMBH & CO KG

Clip

InactiveUS7549829B2Large locking forceDisengagement of the clip can be preventedSnap fastenersFlow mixersLower faceSurface plate

A clip has a head part adapted to be contacted with a peripheral edge of a fitting hole in a panel to be fitted, and a leg part adapted to be inserted into the fitting hole thereby to be engaged with the peripheral edge of the fitting hole. The leg part has a post suspended from a center of a lower face of the head part, at least three projections which are radially extended from the post in a diametrical direction and connected to the lower face of the head part at their upper ends, and engaging pieces which are extended from these projections in a circumferential direction to be respectively positioned between the projections. The engaging pieces are connected to the head part at their upper ends, and provided with slits between their circumferentially extended ends and the opposed projections.

Owner:PIOLAX CO LTD

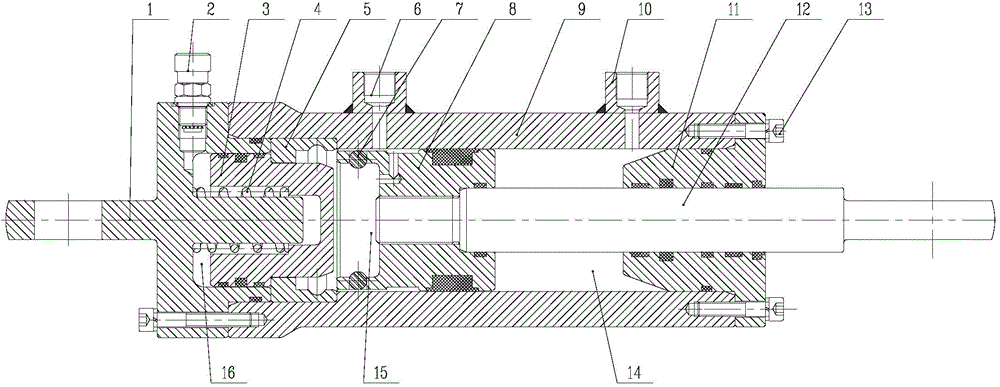

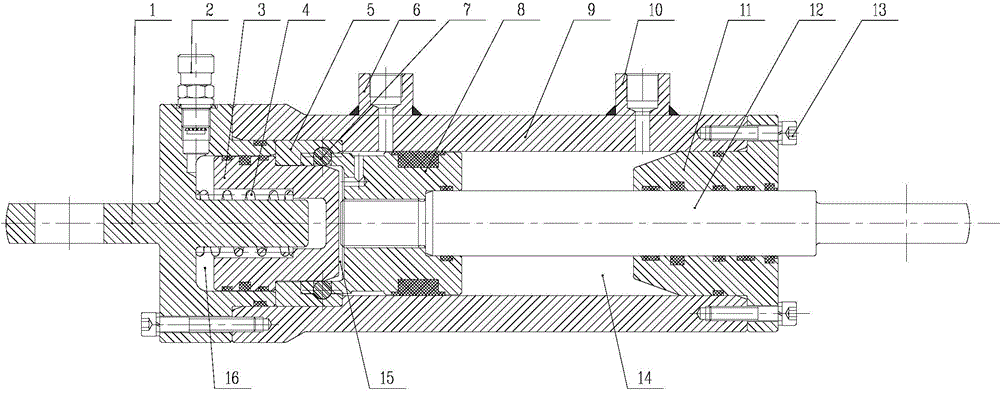

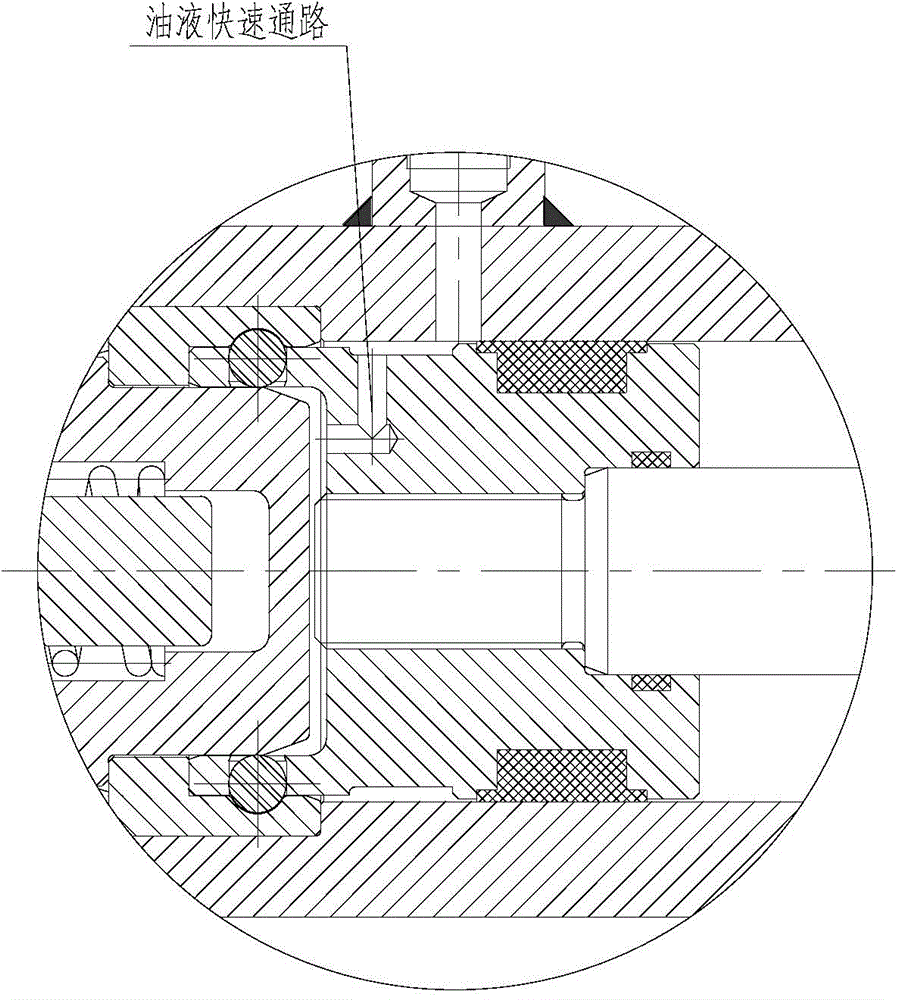

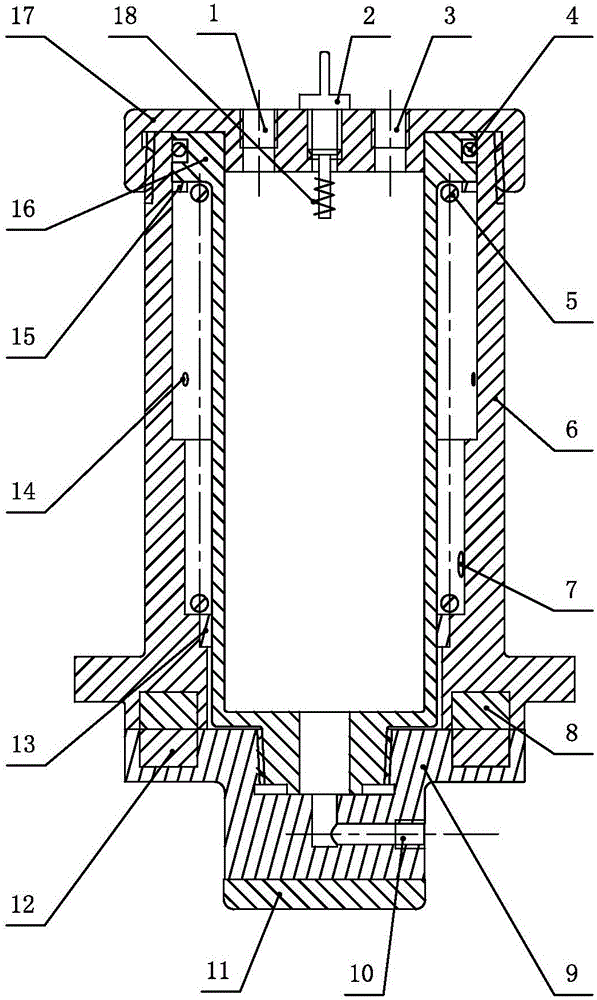

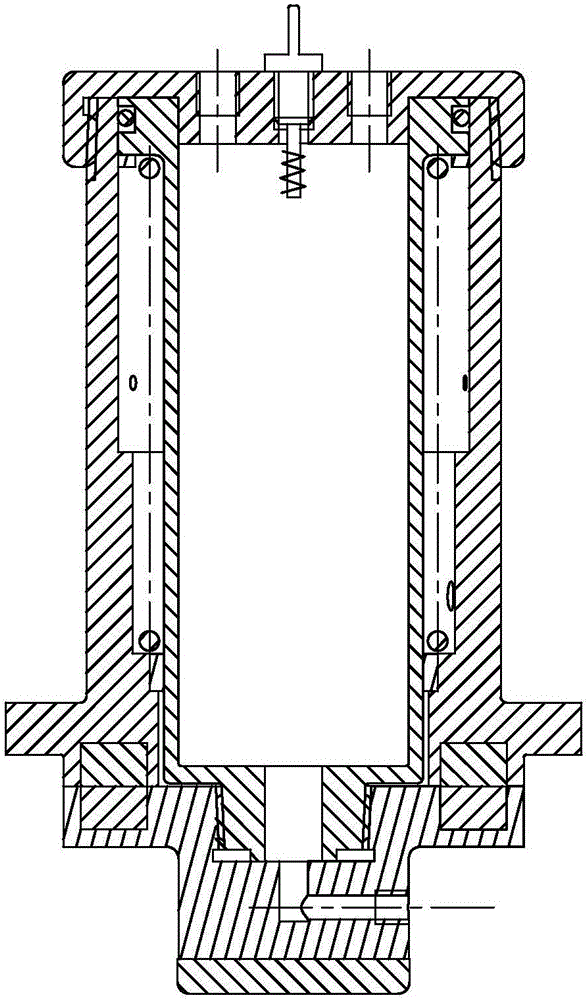

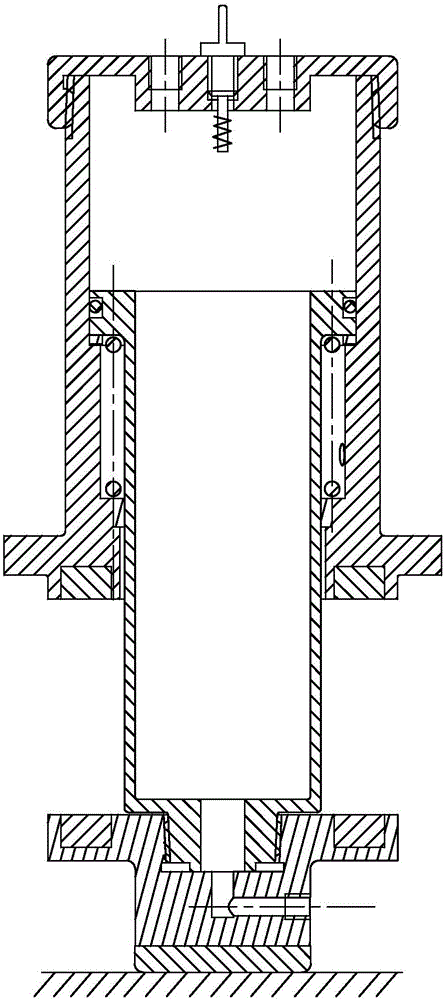

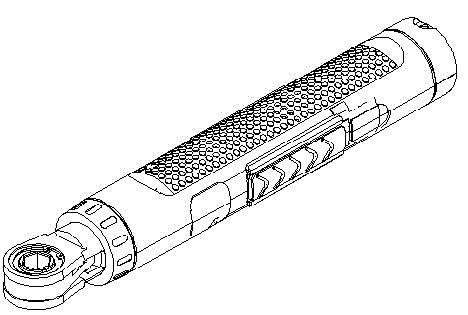

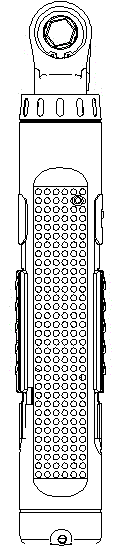

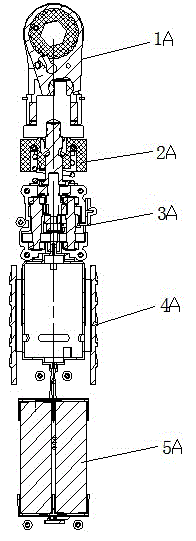

Powerful and mechanical automatic-locking hydraulic cylinder

InactiveCN104006033AReduced size spaceLock firmlyFluid-pressure actuatorsHydraulic cylinderPulp and paper industry

The invention discloses a powerful and mechanical automatic-locking hydraulic cylinder, and belongs to the technical field of hydraulic cylinders. The two ends of a cylinder barrel are sealed by a cylinder cover and a cylinder bottom respectively. A guiding column of the cylinder cover is sleeved with a spring. The spring is sleeved with a brake block. The two ends of the spring abut against the cylinder cover and the brake block respectively. The outer circumferential face of the large diameter of the brake block is in sealing fit with the inner circumferential face of the cylinder cover. The end face of the end, with a large-diameter hole, of a locking block abuts against the end face of the step of an inner hole of the cylinder barrel, and the other end face of the locking block abuts against the end face, located at the portion of the cylinder barrel, of the cylinder cover. After a steel ball is put into a steel ball installation hole of a piston, the steel ball installation hole of the piston is matched with an inner hole of the cylinder barrel, and an annular groove of the piston corresponds to a rodless cavity oil port in the cylinder barrel. One end of a piston rod is fixed to a piston rod installation hole of the piston, and the other end of the piston rod penetrates through the cylinder bottom to be located outside the cylinder barrel. According to the powerful and mechanical automatic-locking hydraulic cylinder, the requirement for automatic locking after the piston rod is completely retracted can be met, and the locking state can be kept for a long time under the situation that pressure relief of a hydraulic system is completed or leakage happens until unlocking is actively achieved.

Owner:CSIC ZHONGNAN EQUIP

Locking device and connector provided with the same

ActiveUS20070202732A1Large locking forceAvoid breakingEngagement/disengagement of coupling partsIncorrect coupling preventionExpansion cardLeaf spring

A locking device which has a strong locking force and is difficult to be broken. Leaf springs bending in a direction toward or away from the rear end of a function expansion card are provided in a housing, and locking sections for locking the function expansion card are connected to the leaf springs. Guide sections are provided in the housing, for guiding the outer ends of the leaf springs in the direction of bending of the leaf springs.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

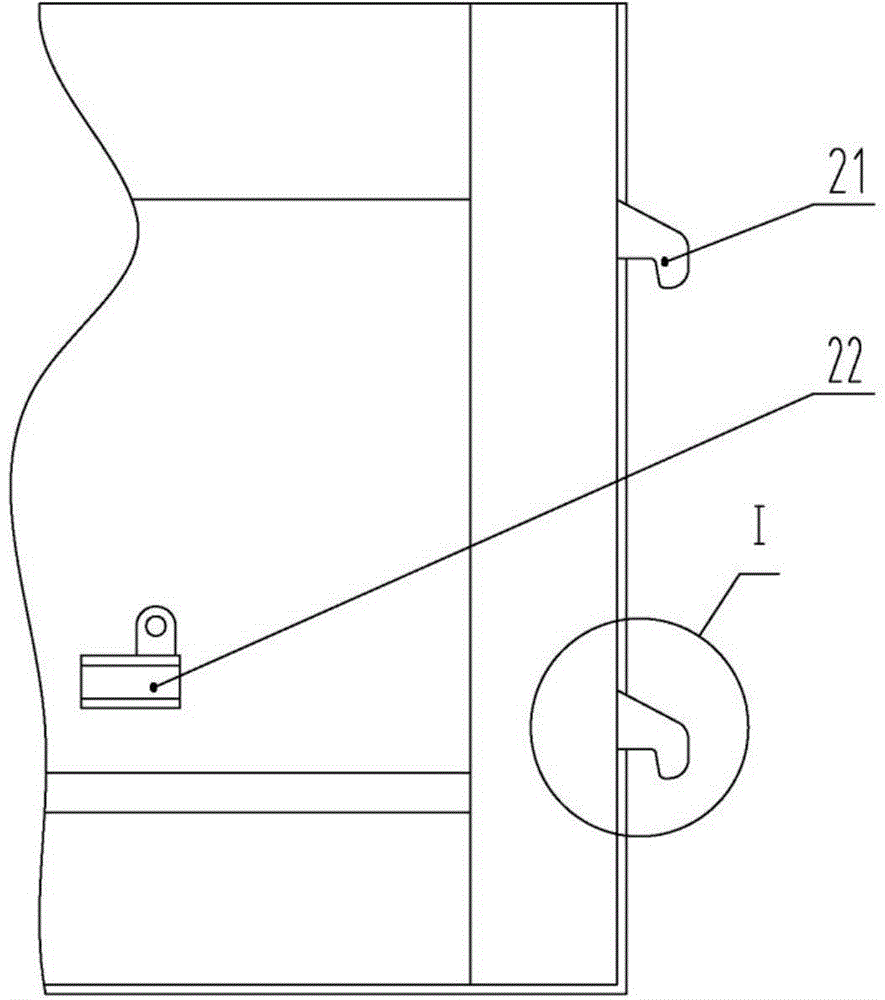

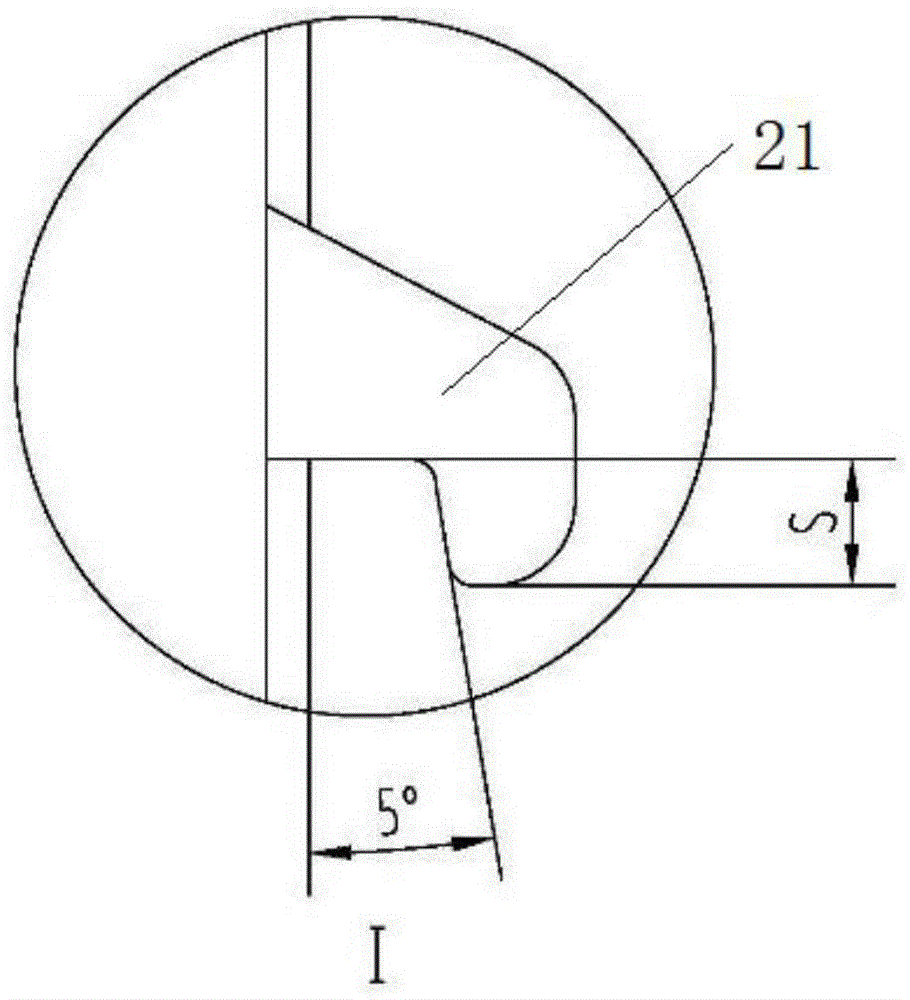

Lamp installing bracket and lamp thereof

InactiveCN101832532AEasy to useSimple structureLighting support devicesPulp and paper industryEngineering

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

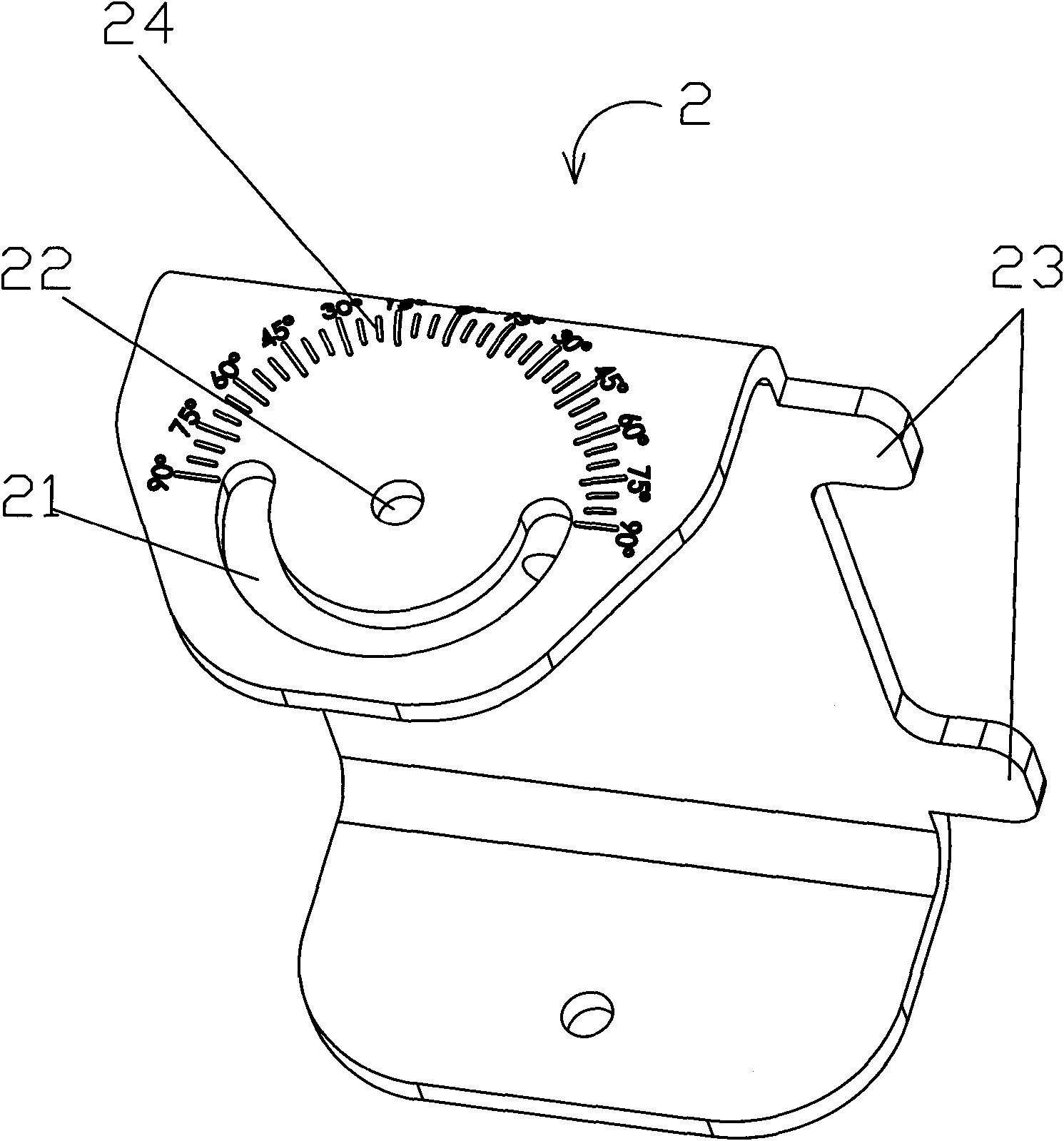

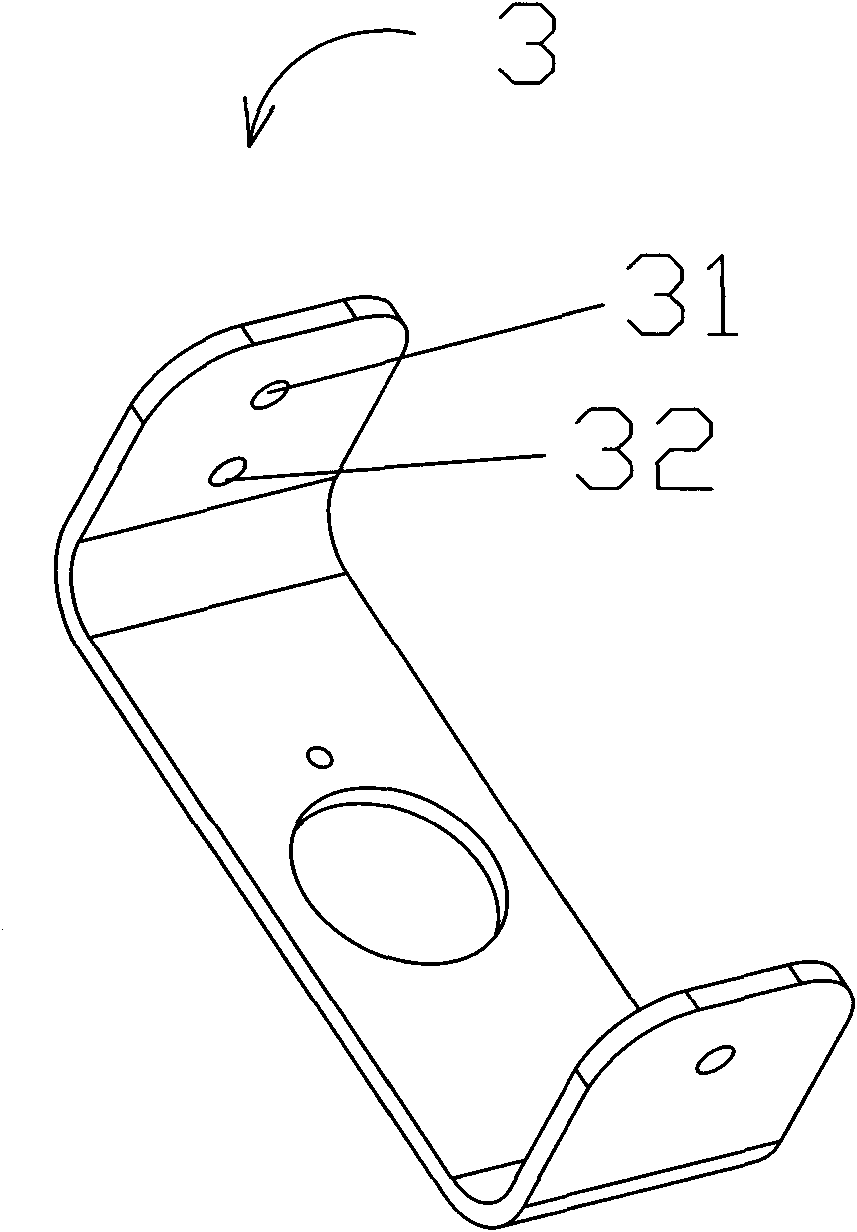

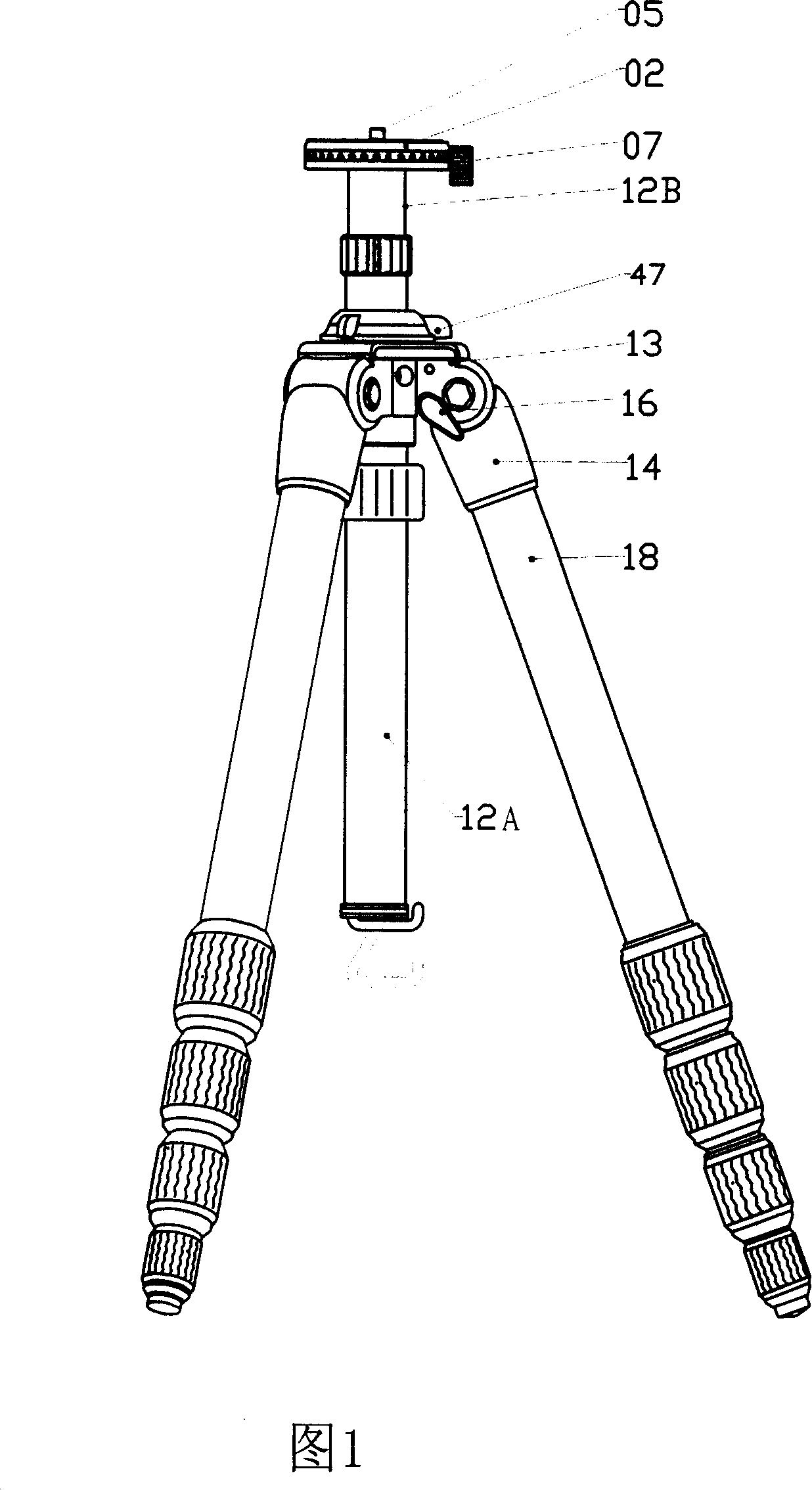

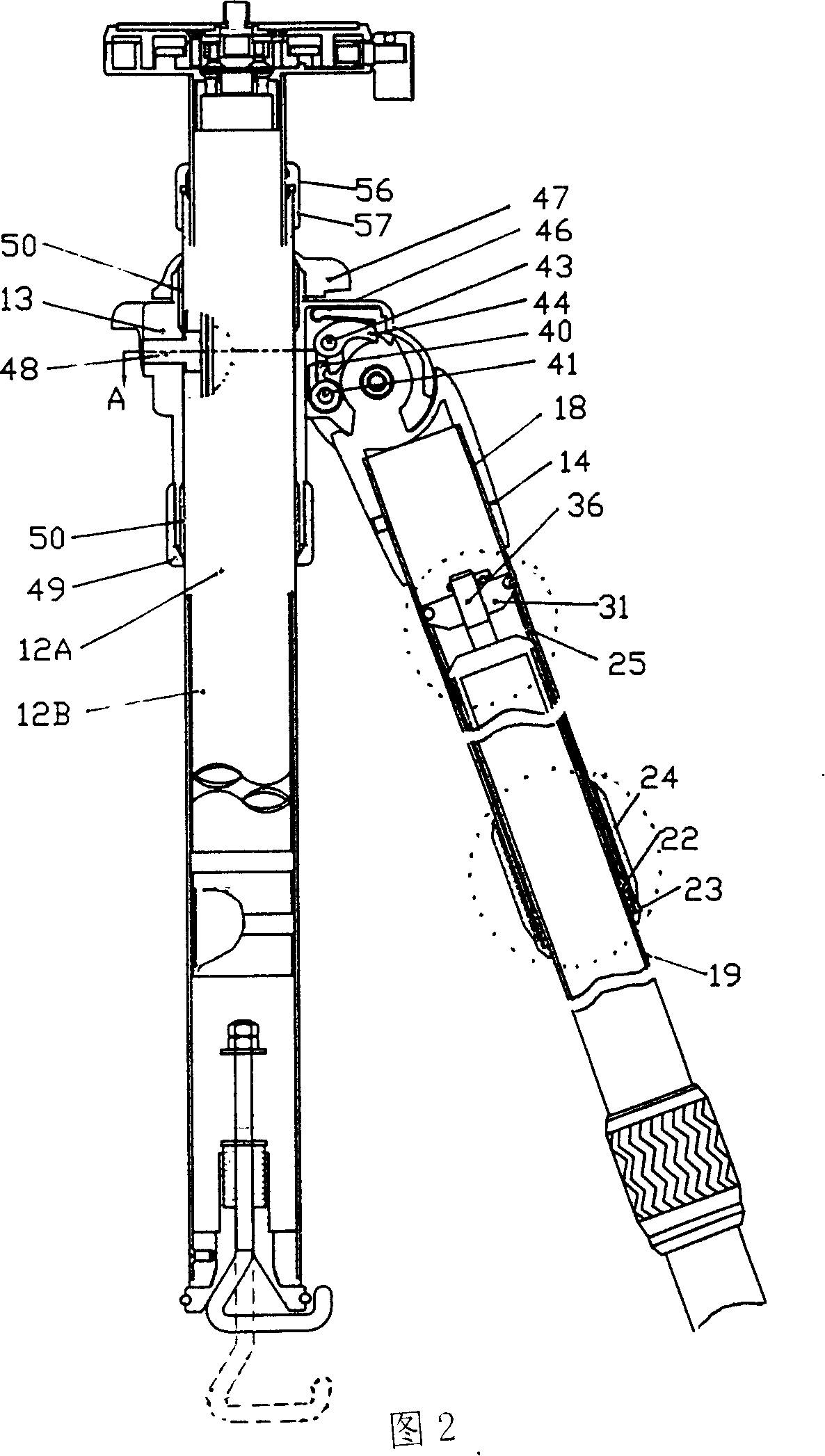

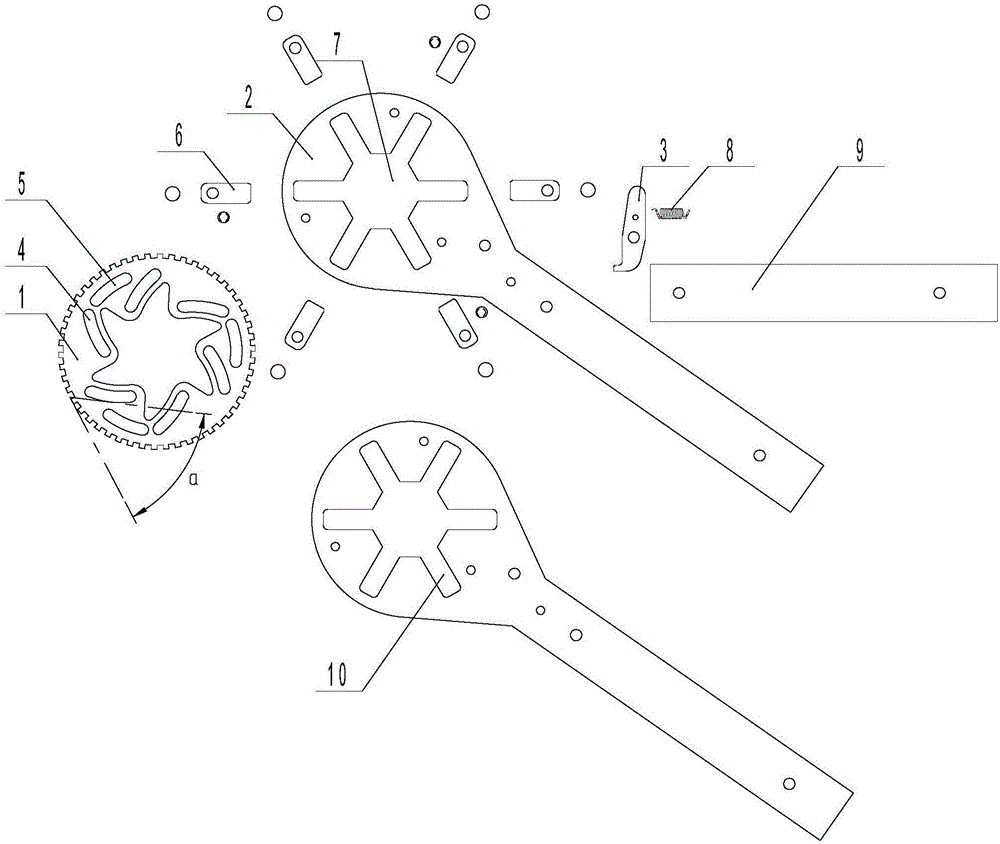

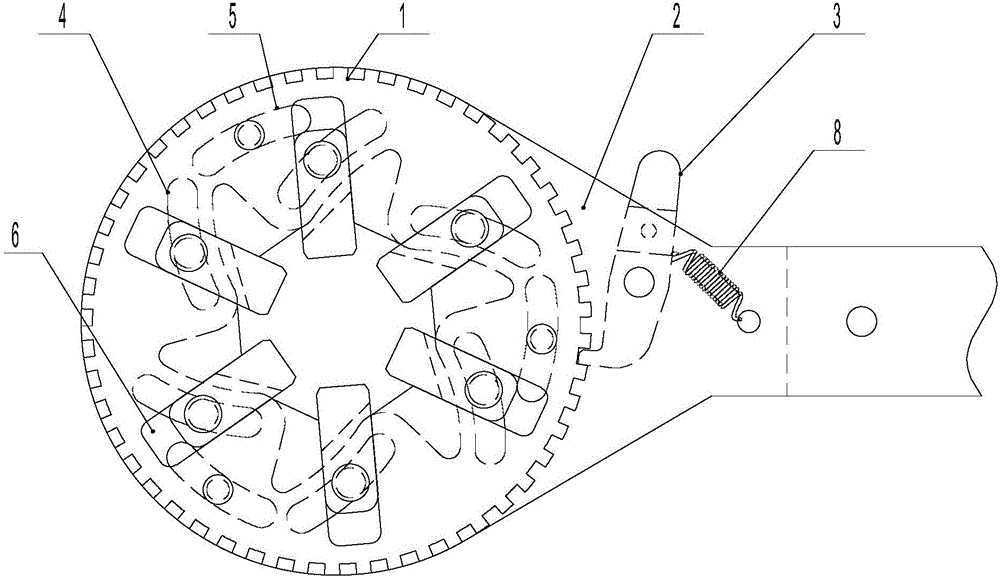

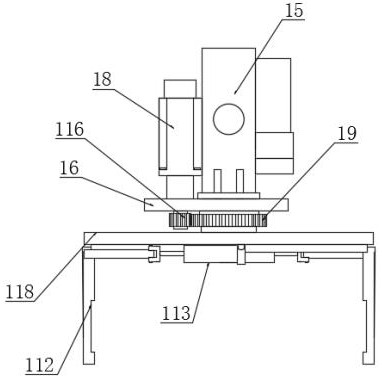

Tripod of camera

This invention is about a kind of camera tripod legs. In this invention there is an open and close regulator between the landing leg saddle and the main block that can fast adjust the open angle of the landing legs. The ratchets on the leg seat geared into the pawls, this can control the open angle of the landing legs. The taper screws and the taper nuts in the leg interacts together to control the locking and releasing of the legs. There is no measuring regulating figure plates on the top of centre shaft, but a pulled hooker on the bottom.

Owner:杨永坚

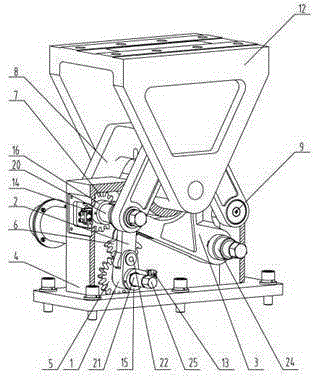

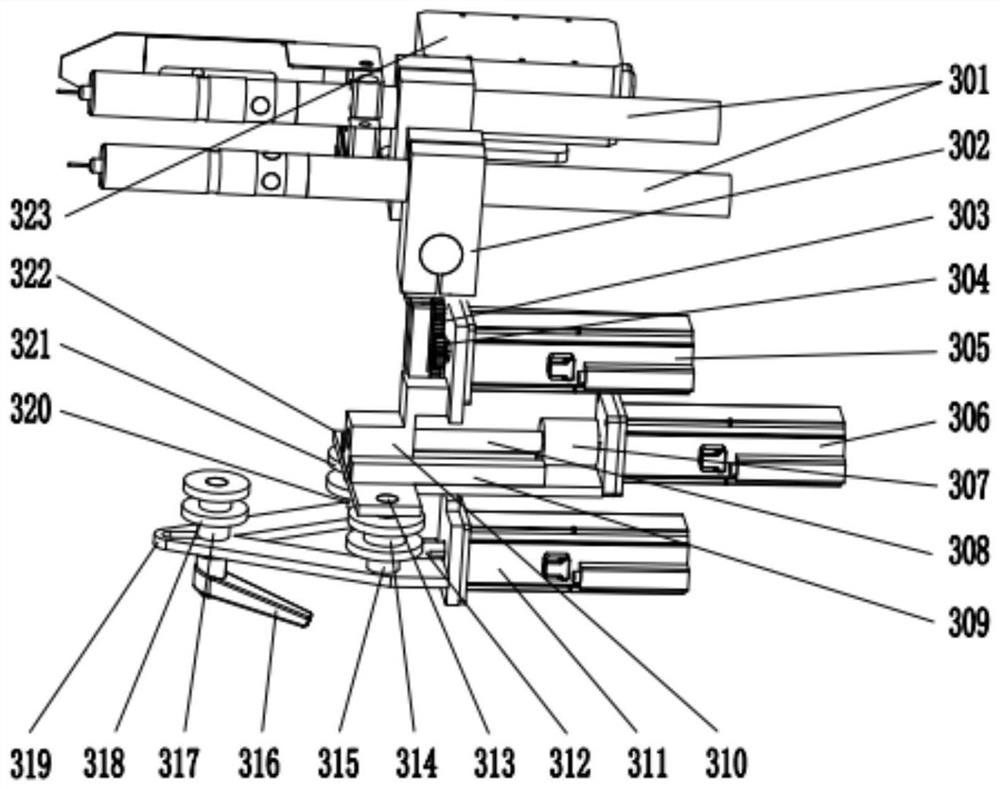

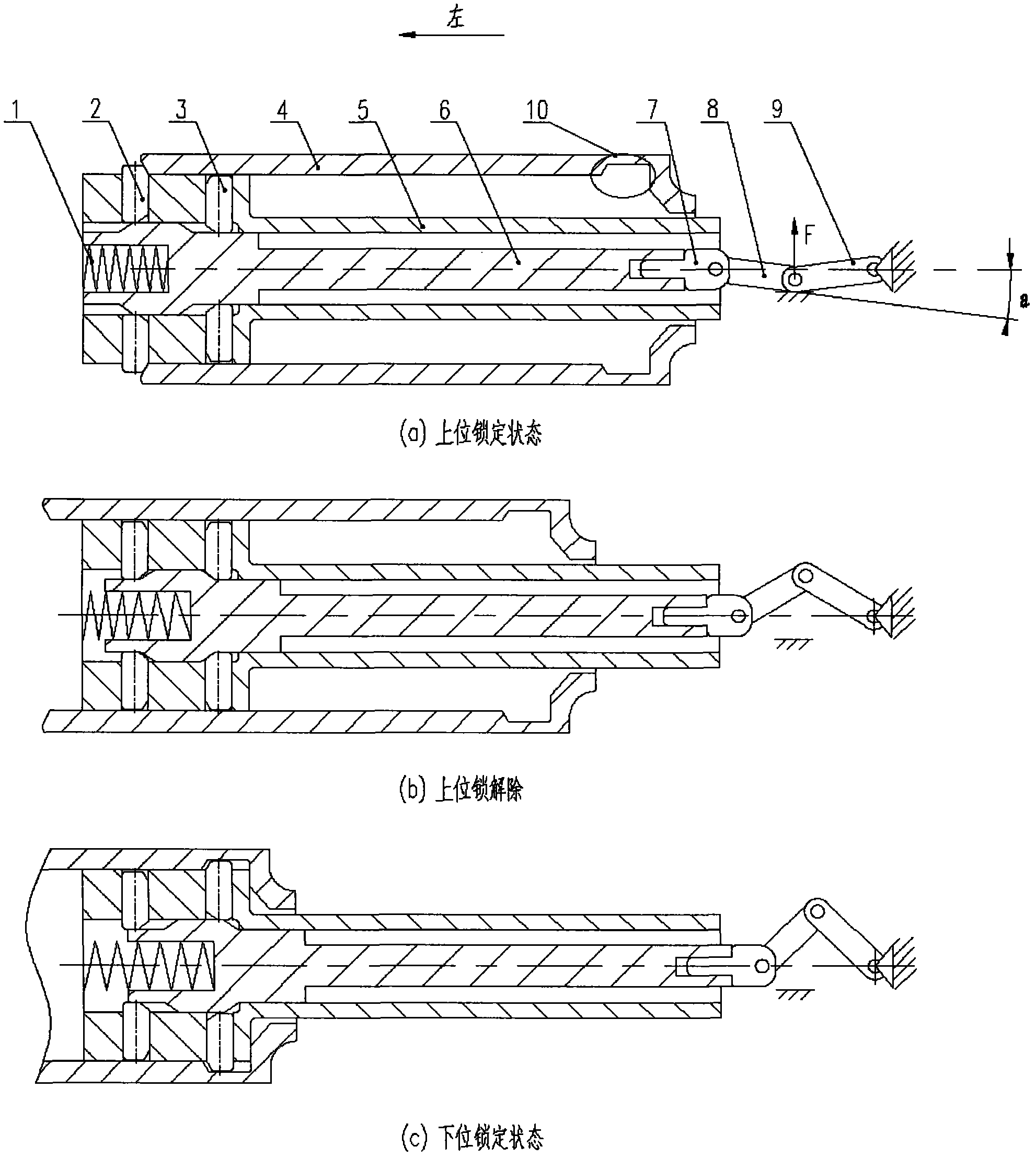

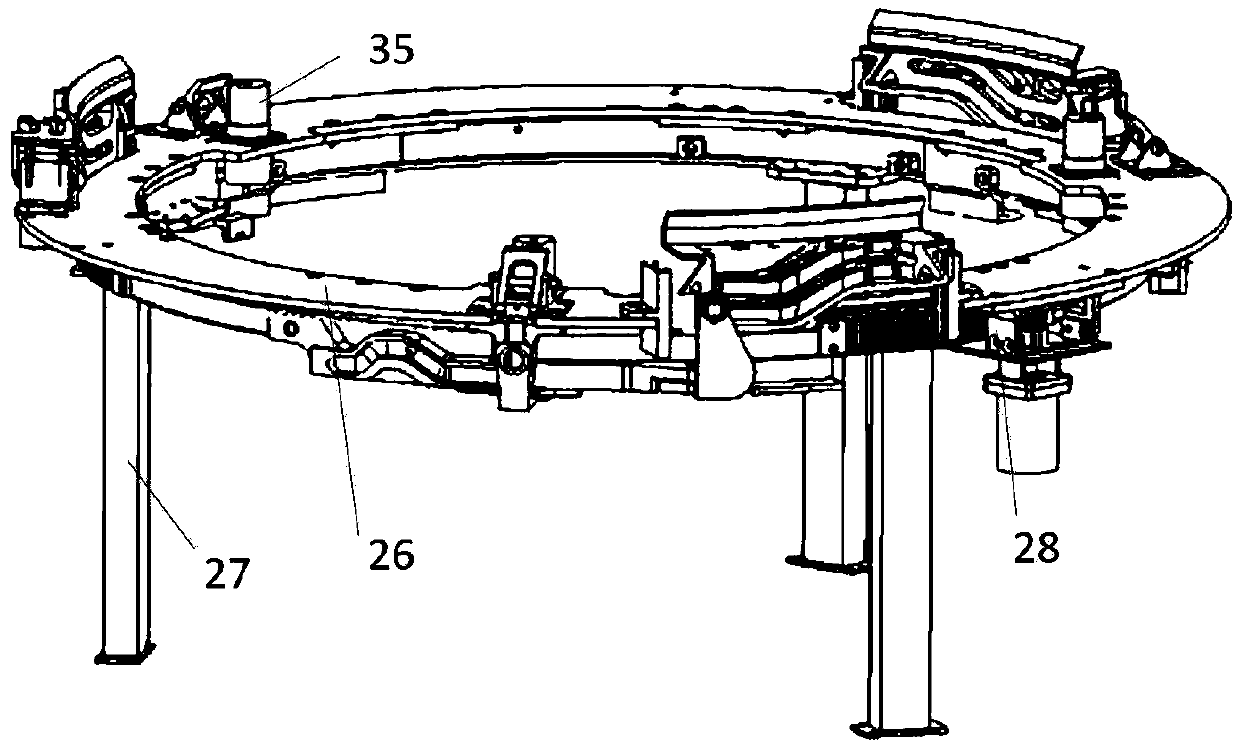

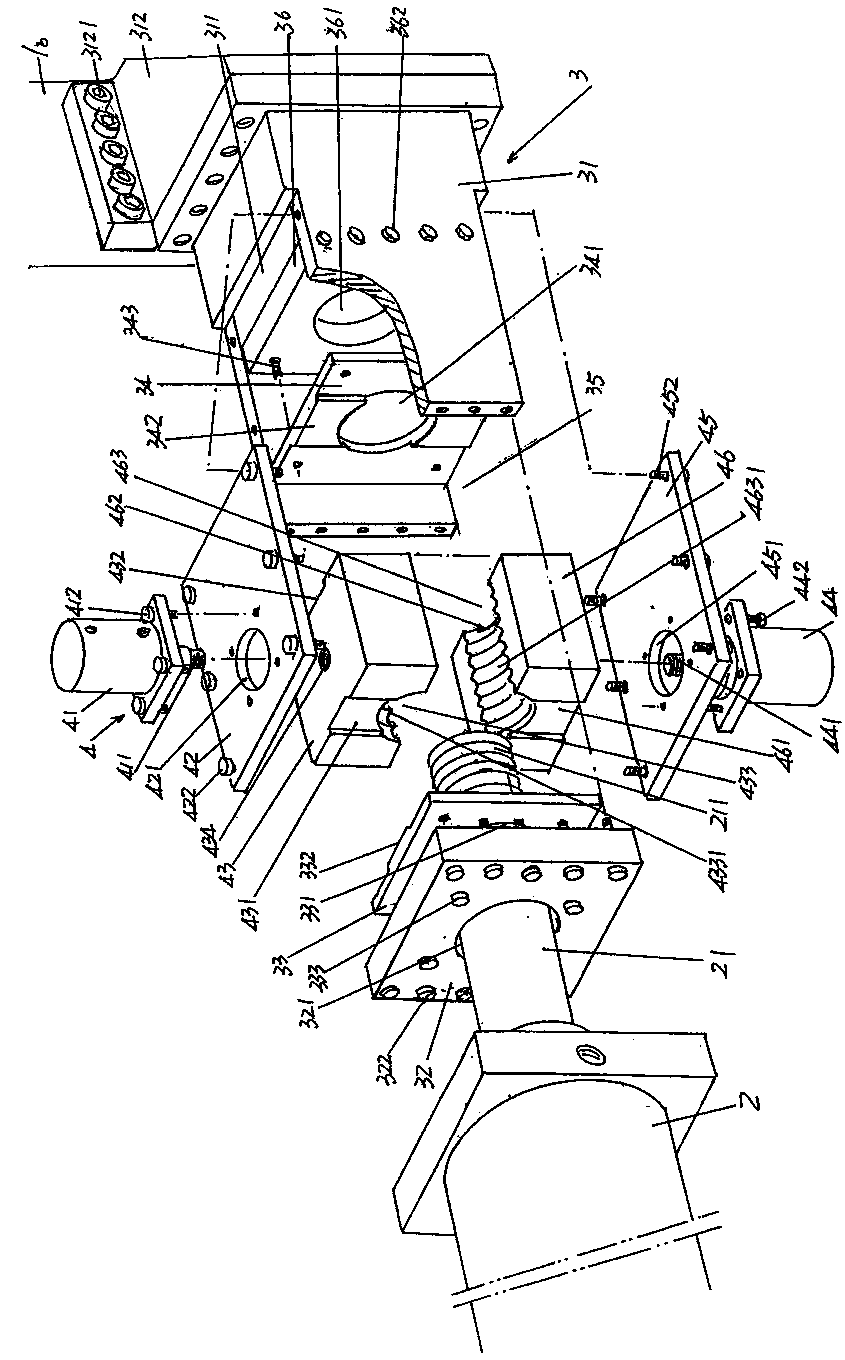

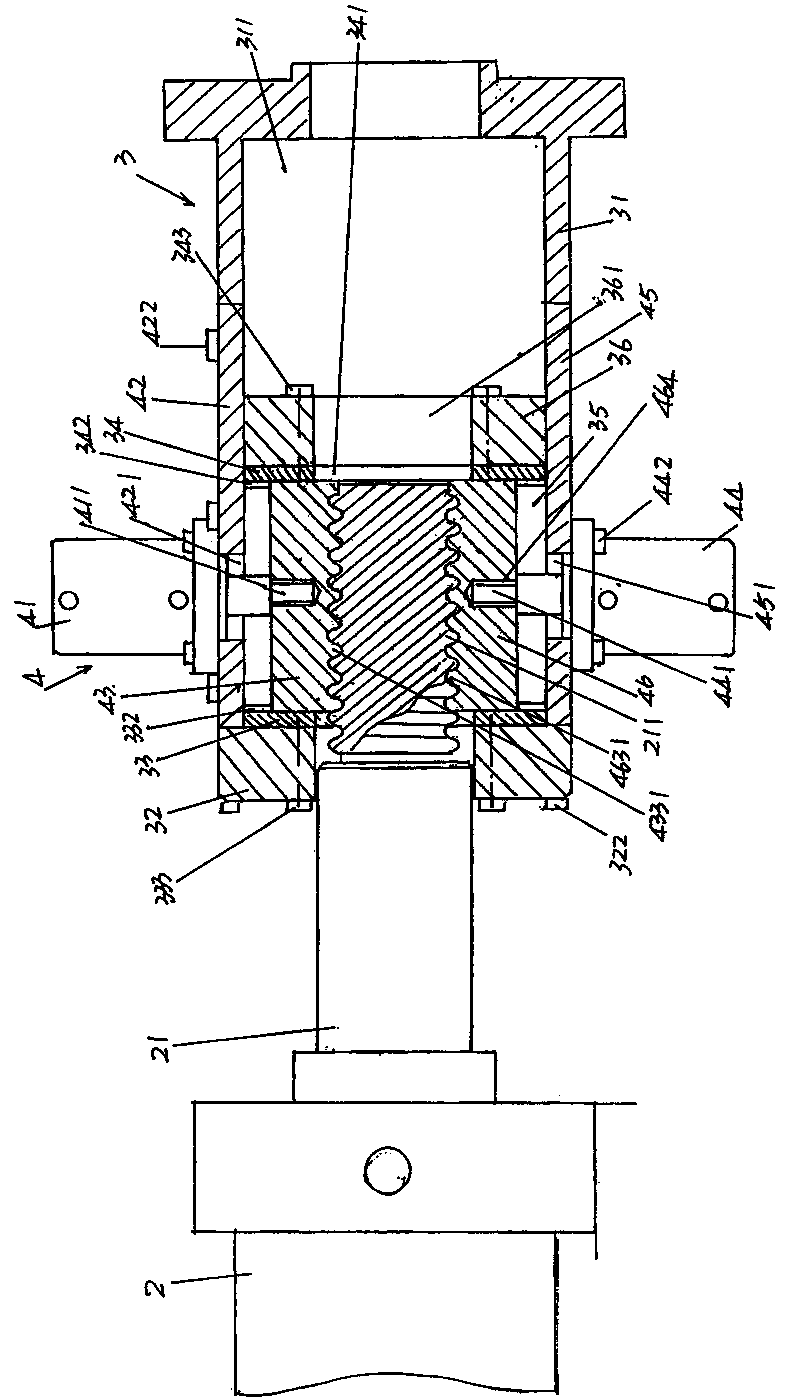

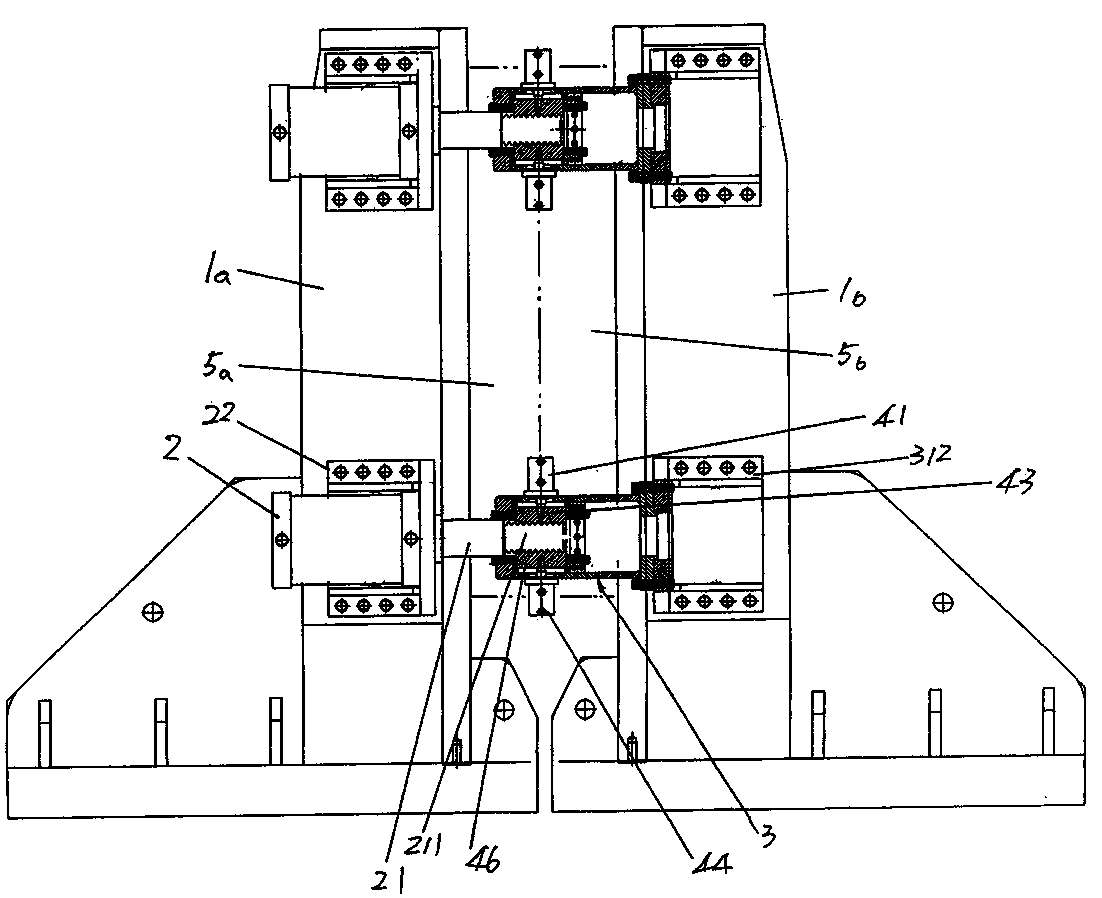

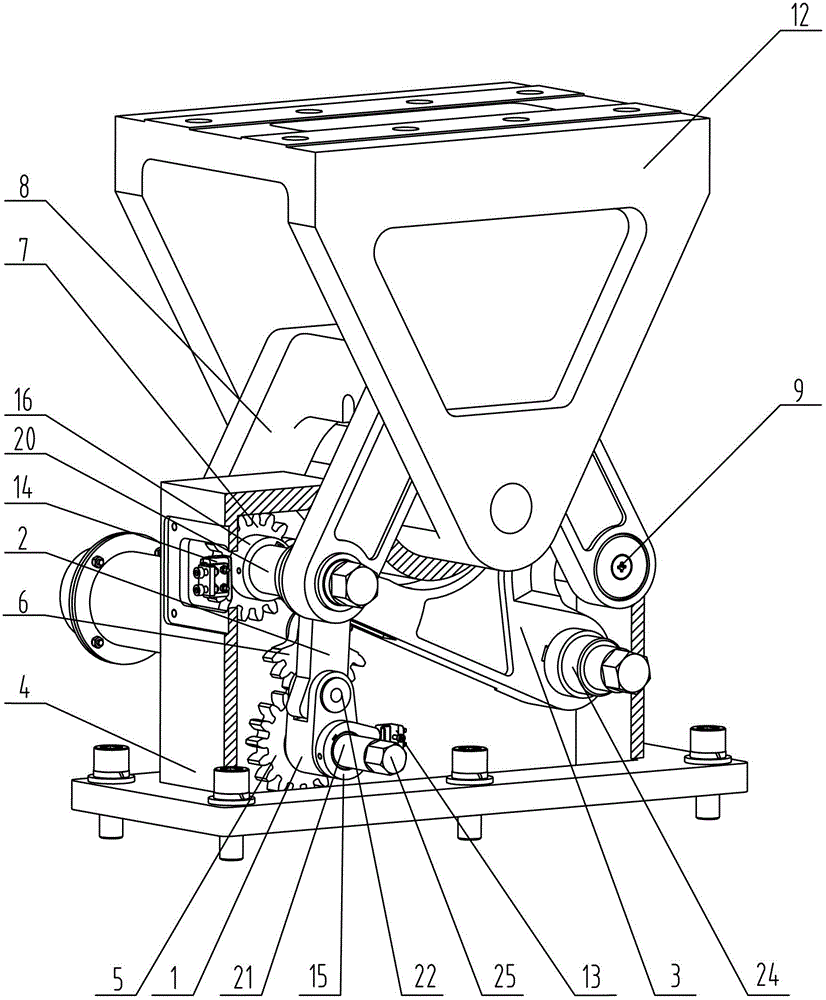

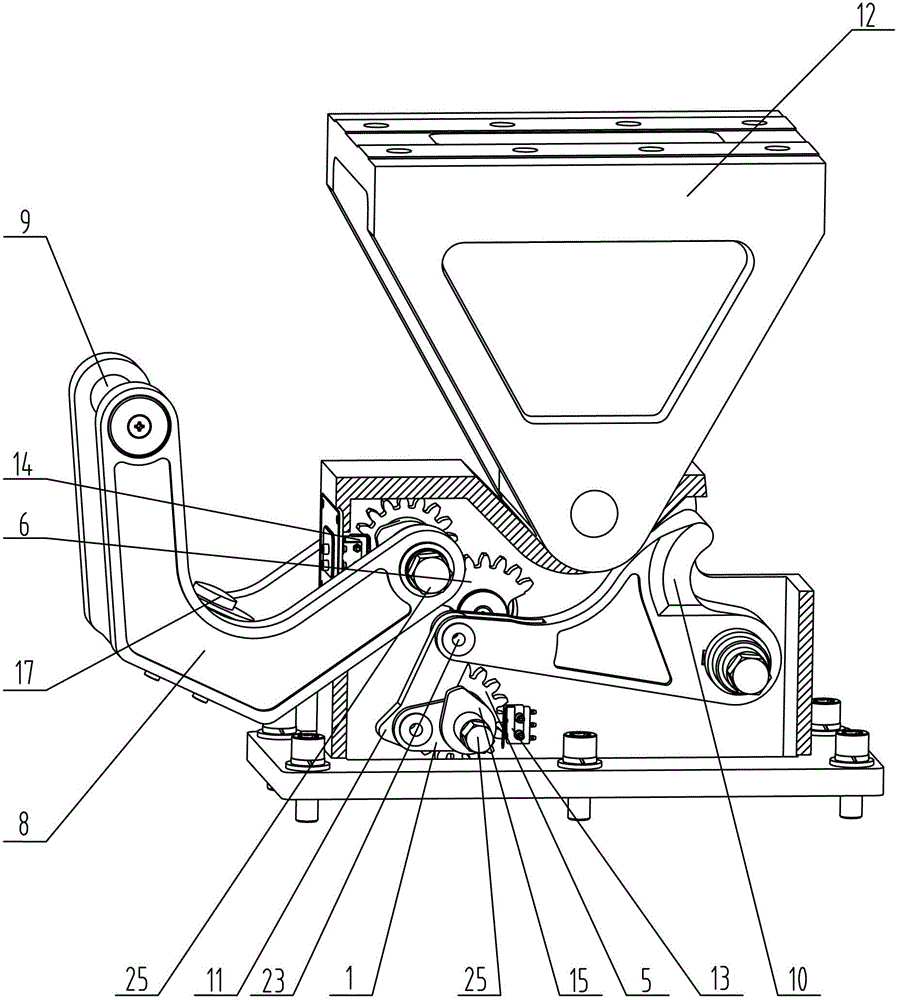

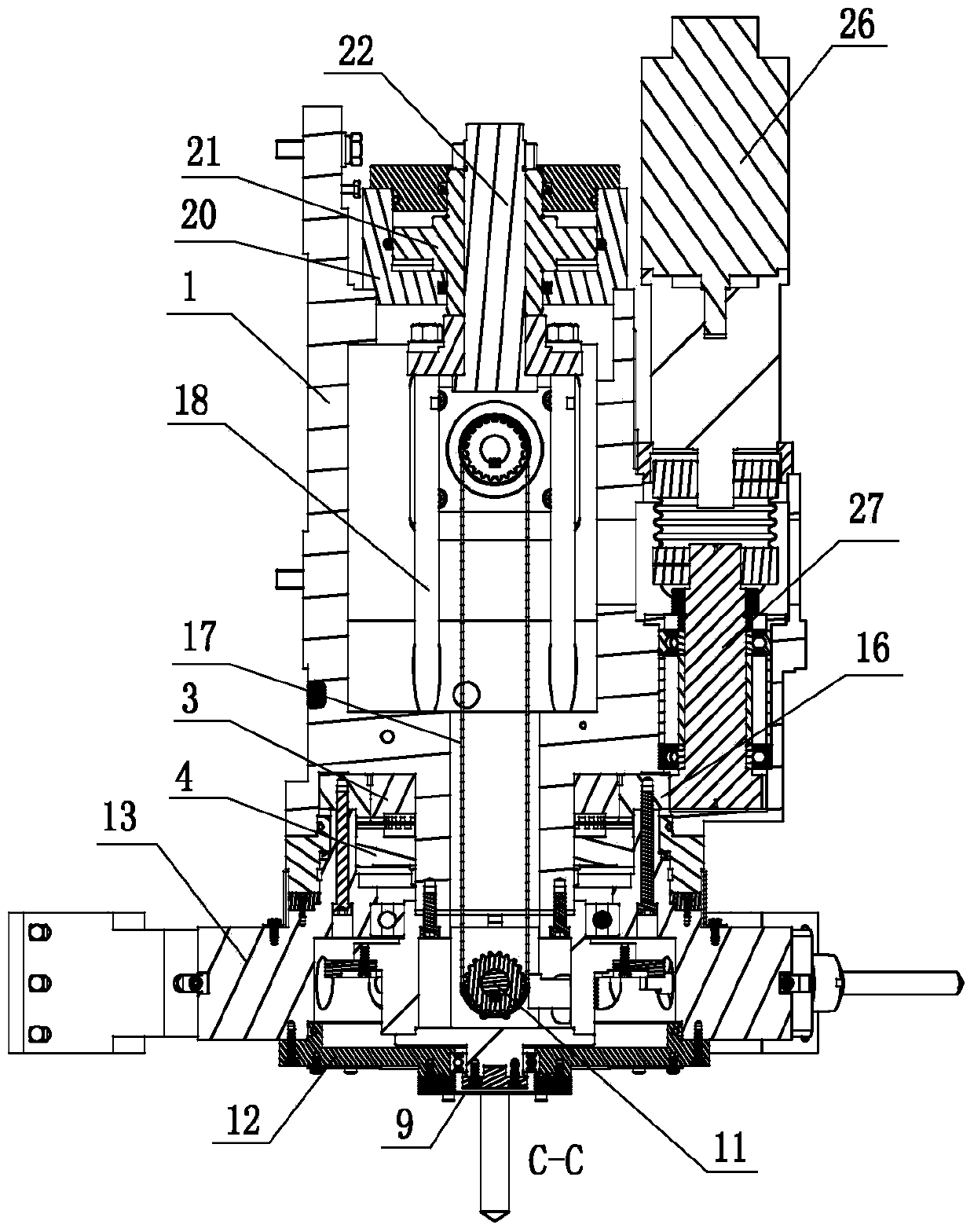

On-orbit repeated locking and releasing mechanism for space

InactiveCN106608373ARestricted degrees of freedomNon-affecting gestureCosmonautic component separationLocking mechanismEngineering

The invention relates to a repeated locking and releasing mechanism, in particular to an on-orbit repeated locking and releasing mechanism for space, and aims to solve the problem of repeated on-orbit locking and releasing of a large-scale actual load in a spacecraft. The on-orbit repeated locking and releasing mechanism comprises a trunnion locking mechanism, a lock hook compacting mechanism, a base locking mechanism, a crank and rocker mechanism and a driving gear mechanism, wherein the trunnion locking mechanism is arranged at the upper end of the base locking mechanism; and the driving gear mechanism is connected with the lock hook compacting mechanism and the crank and rocker mechanism. According to the on-orbit repeated locking and releasing mechanism disclosed by the invention, the trunnion locking mechanism, the lock hook compacting mechanism, the base locking mechanism, the crank and rocker mechanism and the driving gear mechanism are arranged in a crossed manner, so that the on-orbit repeated locking and releasing mechanism is simple and compact in structure; all the freedom degrees of a fixed object can be completely limited, and repeated locking can be realized; the maneuverability is good, so that the using requirement of on-orbit locking-releasing-relocking can be met. The on-orbit repeated locking and releasing mechanism disclosed by the invention is suitable for the technical field of aerospace and the technical field of electromechanical integration.

Owner:赵士野

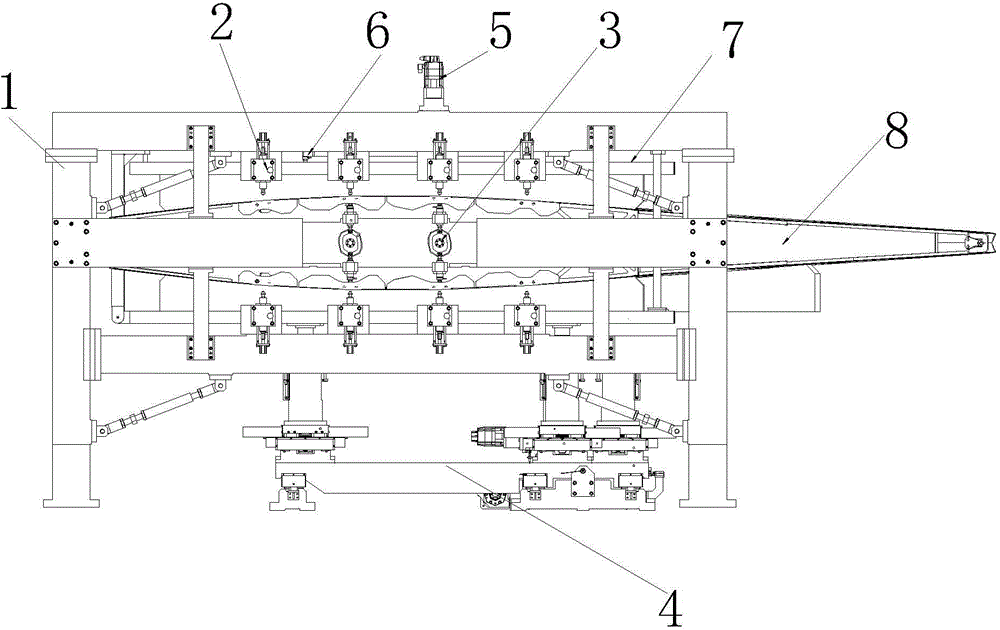

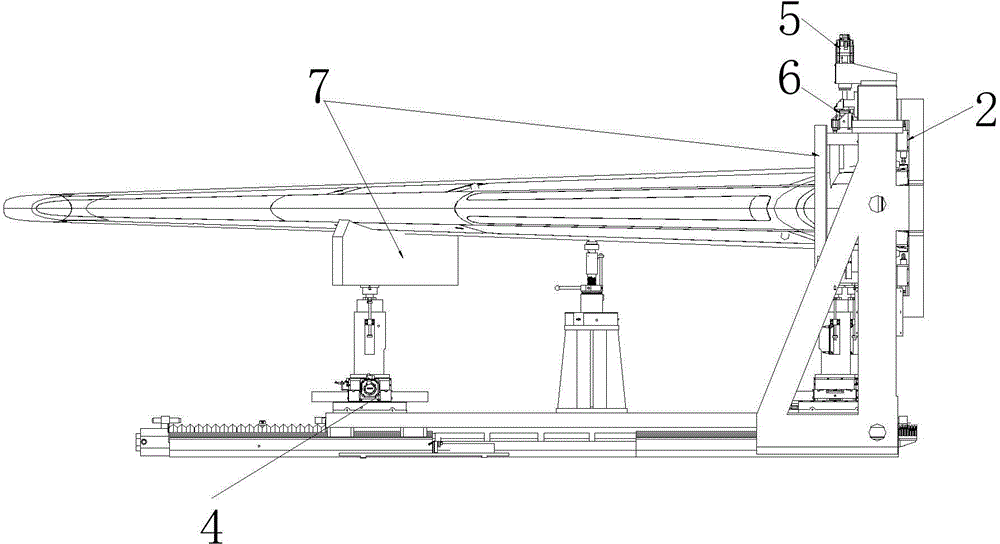

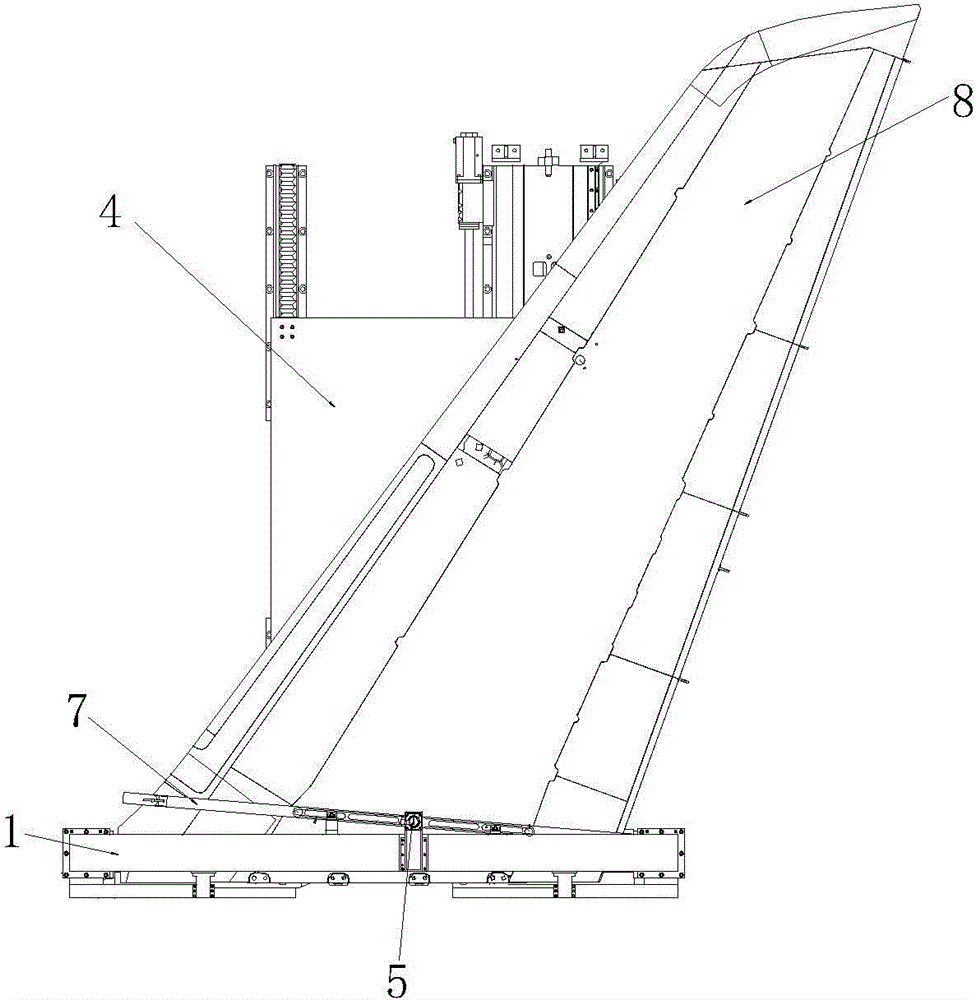

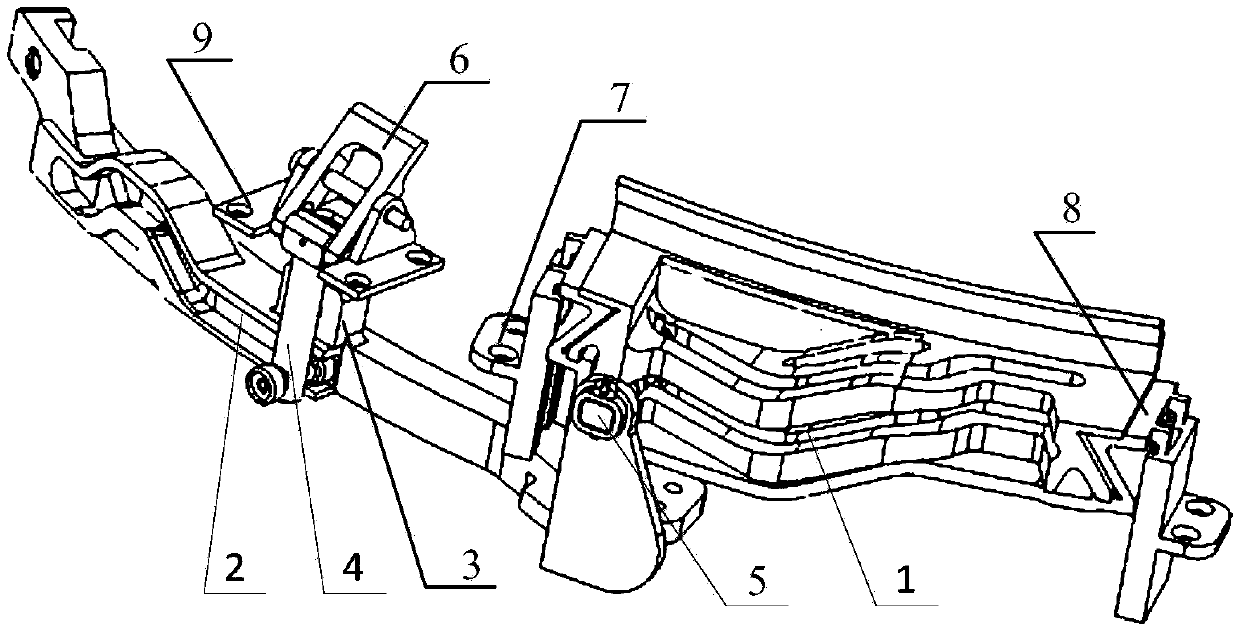

Clamp for processing vertical positioning surface of tail wing of airplane

ActiveCN104889775ARealize automatic positioning and clampingMeet the needs of positioning and clampingPositioning apparatusMetal-working holdersAirplane

The invention relates to a clamp for processing a vertical positioning surface of a tail wing of an airplane. The clamp comprises a bracket, and a gesture adjusting positioning device which is positioned at one side of the bracket and used for providing positioning supporting to the medium tail part of the tail wing; external supporting devices for compressing the outer side of the head part of the tail wing are mounted on an upper cross beam and a lower cross beam of the bracket; an inner supporting device for compressing the inner side of the head part of the tail wing is mounted on a medium cross beam of the bracket; a main clamping mechanism for fixing the head part of the tail wing is also mounted on the bracket. With the adoption of the clamp, the vertical positioning surface can be automatically positioned and clamped; the requirement on positioning and assembling of large and poor-rigidity parts can be met; after gesture adjusting, the clamping effect is outstanding; the parts are free of deformation due to clamping; the adjusting efficiency is high; the adjusting is flexible and stable.

Owner:WENZHOU UNIVERSITY

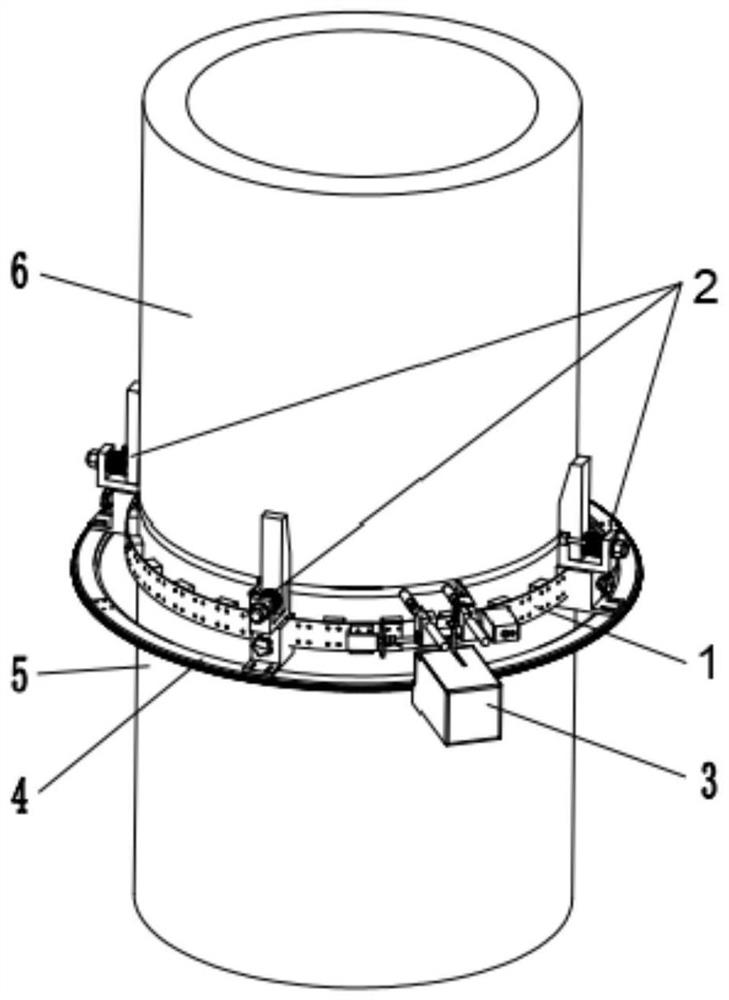

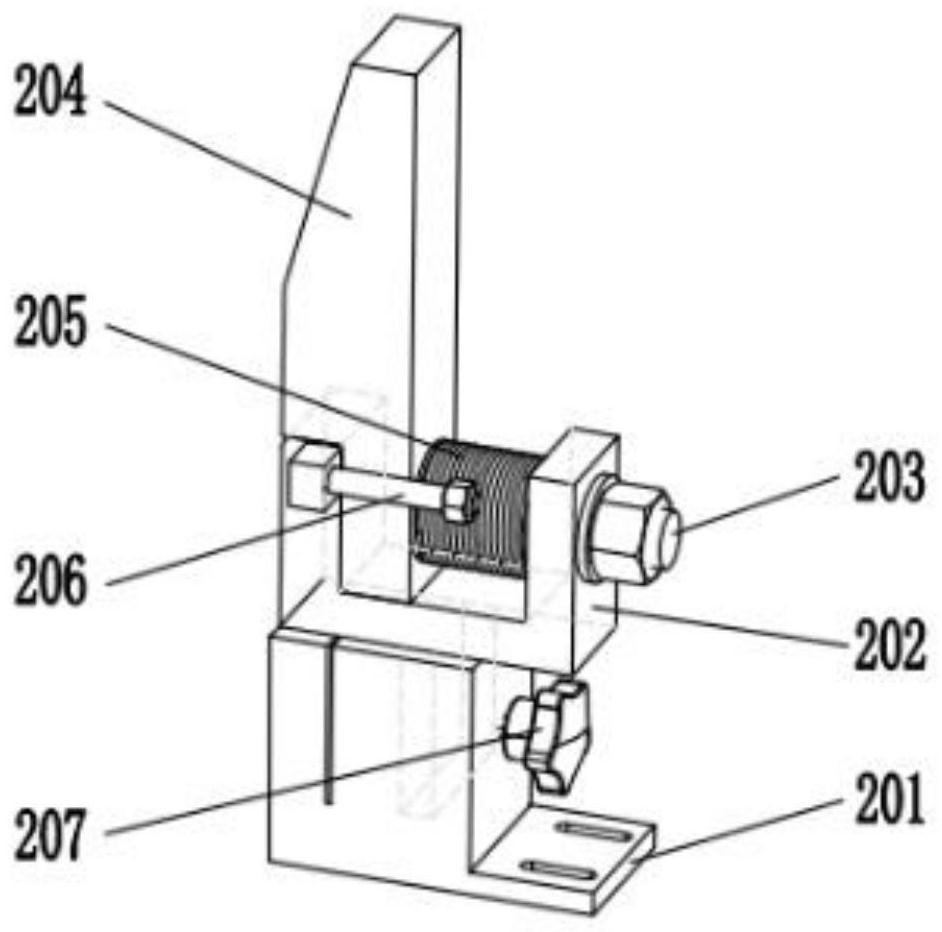

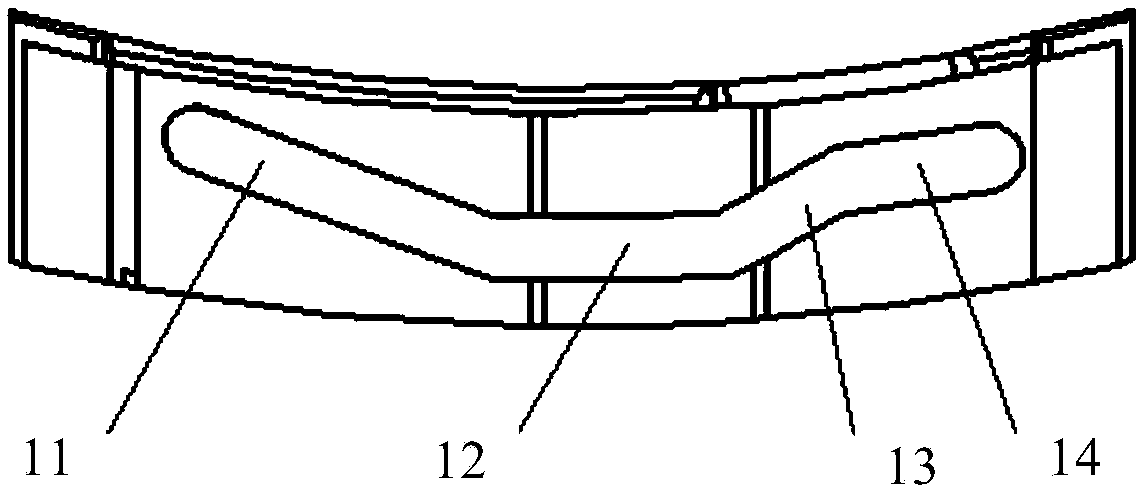

Quick abutting and automatic welding equipment for tubular pile

PendingCN111922620ALight structureLarge locking forceWelding/cutting auxillary devicesAuxillary welding devicesControl systemStructural engineering

The invention relates to the technical field of tubular pile welding, in particular to quick abutting and automatic welding equipment for a tubular pile. The equipment comprises a bed frame, a positioning adjusting mechanism, a guide rail, a welding trolley and a control system. The bed frame is fixed to the tubular pile, the positioning adjusting mechanism is mounted on the bed frame to abut twotubular piles quickly, the guide rail is mounted on the positioning adjusting mechanism, and the welding trolley is arranged on the guide rail and can move along the circumferential direction of the guide rail to weld the two tubular piles automatically. The equipment reduces the labor cost greatly, improves the welding efficiency and quality, and achieves quick welding and automatic welding.

Owner:上海雅跃智能科技有限公司

Adjustable spanner

Owner:王雨琪

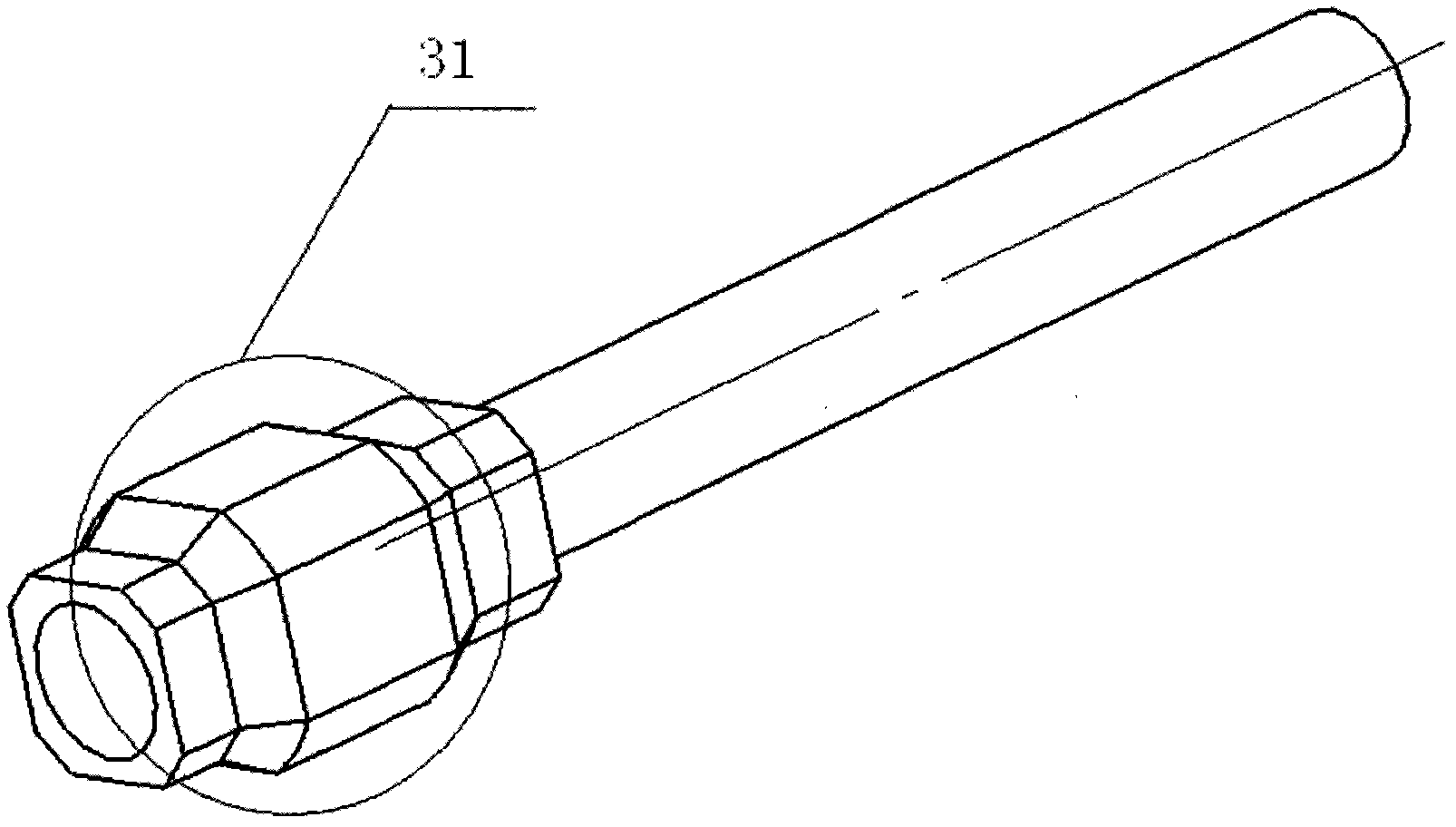

A spatial radial unlocking mechanism driven by a shape memory alloy SMA tow

ActiveCN109131951AGuaranteed synchronicityImprove unlocking precisionCosmonautic vehiclesCosmonautic component separationFixed frameShape-memory alloy

The invention provides a spatial radial unlocking mechanism driven by a shape memory alloy SMA tow, a base is fixed on the bottom of the outer cover of the mechanism and an upper cover is installed onthe top, the bolt is inserted through the through hole of the upper cover and is located above the top block, a locate block and two split nuts are sleeve on that outer periphery of the bolt, the outer periphery of the two split nut is provided with a groove, a rigid clamp is arranged in the groove of the two split nuts and an H-shaped fixing frame is arranged at the closed end of the two split nuts, and an SMA shape memory alloy wire bundle is wrapped around the outer periphery of the rigid clamp and fixed on the fixing frame. The invention solves the problem that the impact of the spatial radial unlocking mechanism in the prior art is large, a spatial radial unlocking mechanism driven by shape memory alloy SMA tow is provided, which adopts the radial driving mode of shape memory alloy SMA tow, and has the advantages of low impact, large driving displacement, high driving accuracy, short unlocking time, high moving accuracy, low friction and no pollution.

Owner:HARBIN INST OF TECH

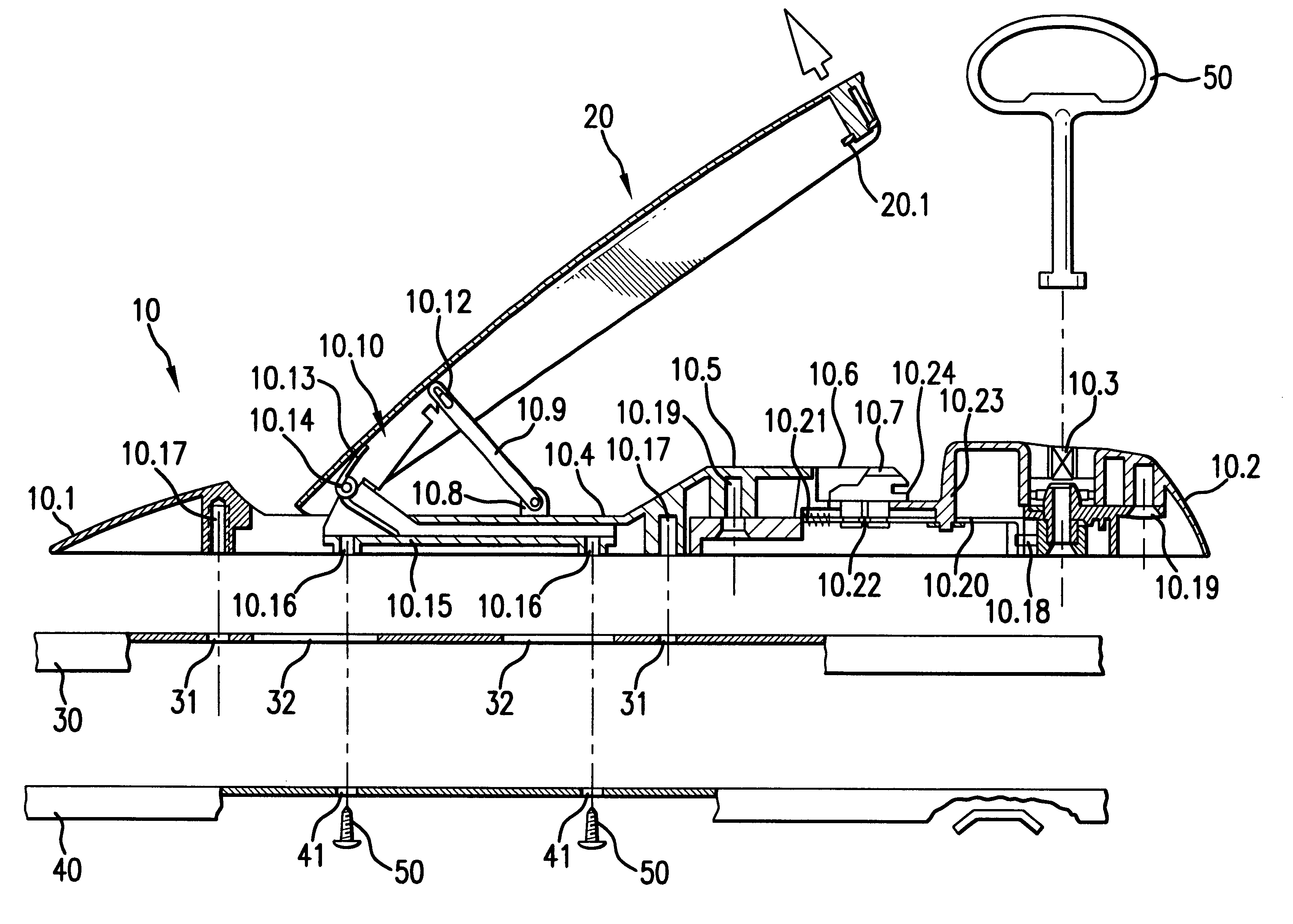

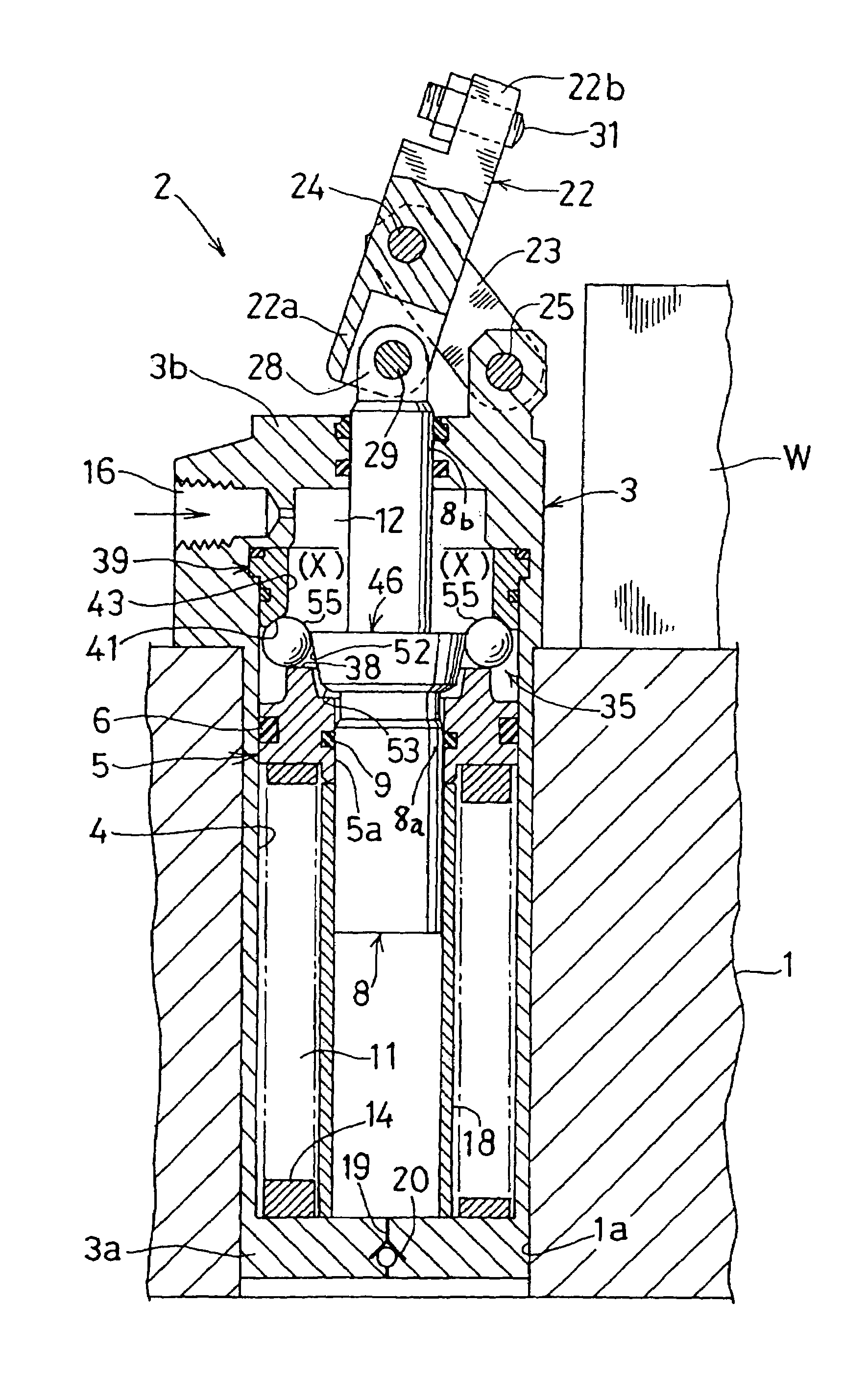

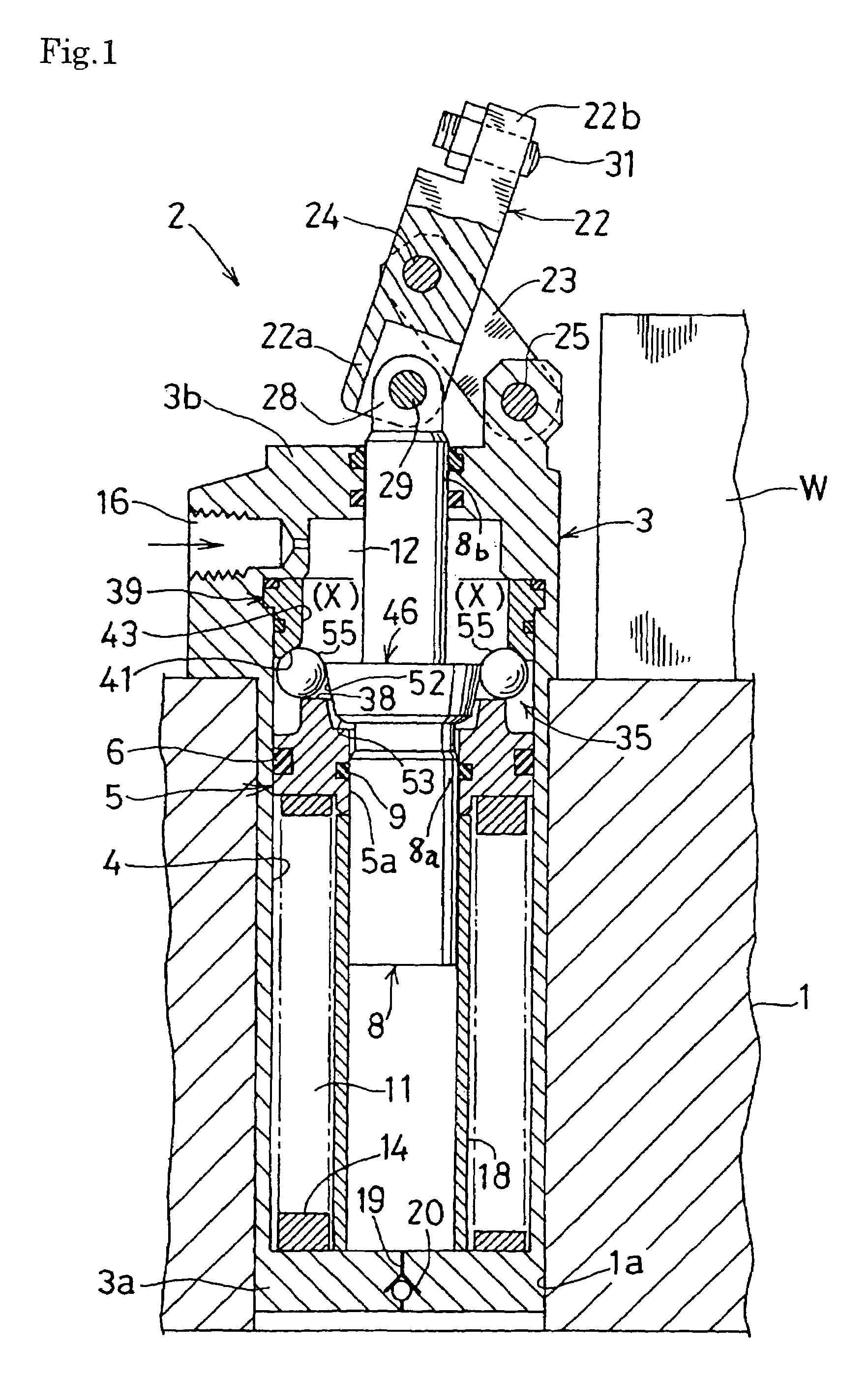

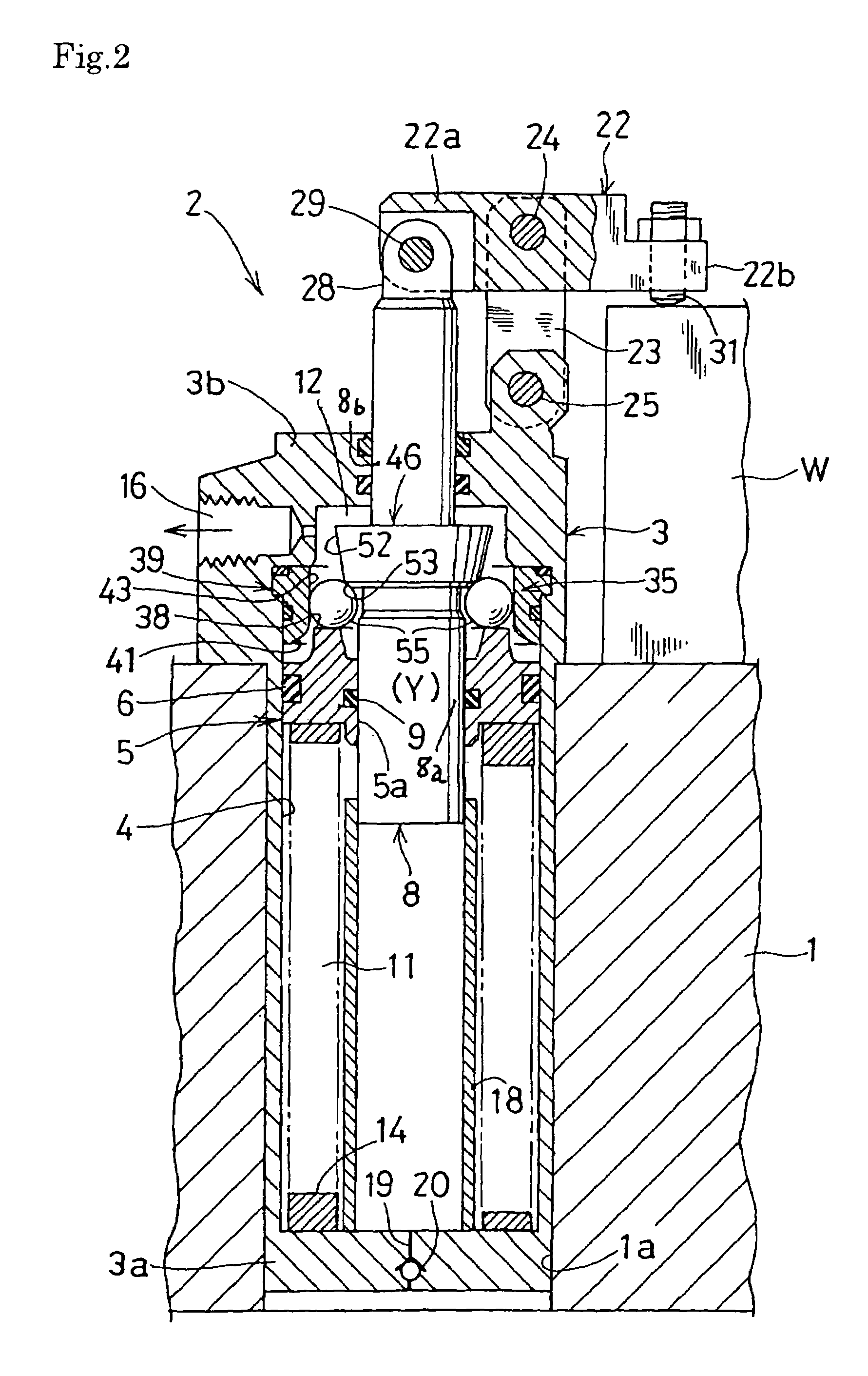

Spring-lock type clamp device

InactiveUS7175169B2Increase volumeLarge locking forceFluid-pressure actuatorsPositioning apparatusMechanical engineeringPiston

Into a housing (3) is hermetically inserted an annular piston (5), and into the annular piston (5) is hermetically inserted an output rod (8). A spring (14) located below the piston (5) moves the piston (5) upward for locking, pressurized oil in a release chamber (12) formed above the piston (5) moves the piston (5) downward for releasing. On an upper surface of the piston (5) is provided a pressing surface (38), on an inner periphery of a peripheral wall of the release chamber (12) is provided a first tapered surface (41), which narrows upward, and on an outer periphery of the output rod (8) is provided a second tapered surface (52), which narrows downward. Between the pressing surface (38), the first tapered surface (41) and the second tapered surface (52) are inserted a plurality of balls (55) circumferentially at intervals. Thereby, when the spring (14) moves the piston (5) upward for locking, a moving stroke of the output rod (8) is larger than that of the piston (5).

Owner:KOSMEK LTD (JP)

Gas-driving jumping device

The invention provides a gas-driving jumping device which comprises a cylinder body, a piston and at least one elastic element, wherein the top end of the cylinder body is sealed by an upper cylinder cover; an opening is formed on the bottom of the cylinder body; the cylinder body is fixedly connected with the upper cylinder cover; a pressure detection port, an exhaust port and an ignition device are arranged on the upper cylinder cover; the ignition device is located on the inner side of the upper cylinder cover; a first level step, a second level step and a third level step are respectively formed in a top-wide bottom-narrow form on an inner side wall of the cylinder body; the exhaust port is controlled by an exhaust solenoid valve; the piston is located in the cylinder body in a drawing form; the piston is hollow; the top of the piston is opening; the bottom of the piston is fixedly connected with a base; a gas inlet is formed on the side wall of the lower part of the base; the gas inlet is controlled by an inlet solenoid valve; a lug boss is arranged at the top end of the piston; the lug boss is connected with the top end of the elastic element; the bottom end of the elastic element is connected with the second level step. The gas-driving jumping device has the advantages that the locking force is large, the gas purity can be effectively ensured, the structure is compact, the mounting and dismounting are convenient, and the gas-driving jumping device has high-efficient ignition device and higher space use rate so that the robot has higher extreme obstacle-crossing ability and higher flexibility and maneuverability.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

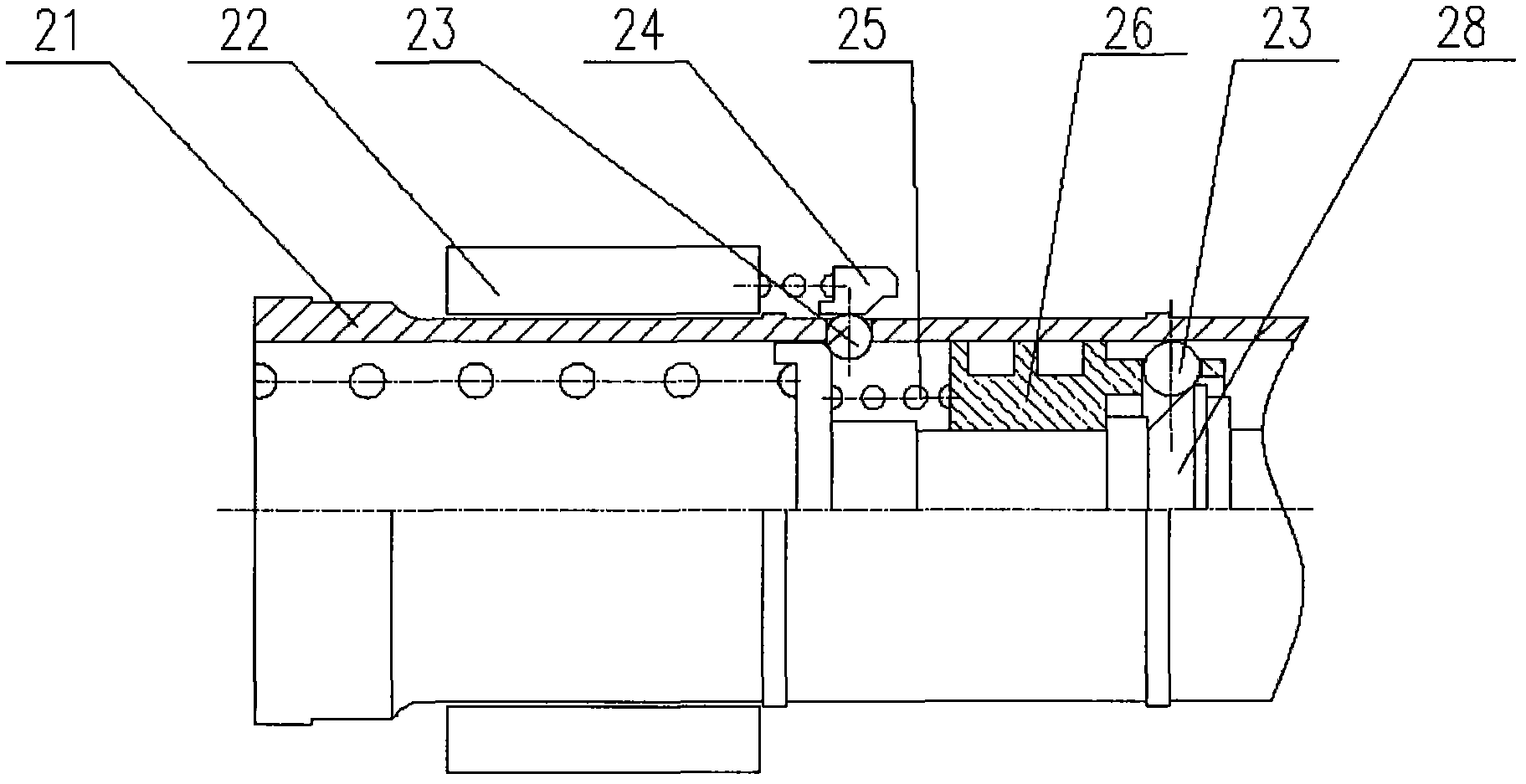

Actuator cylinder position locking and unlocking mechanism

InactiveCN102518621ALarge locking forceSmall unlocking forceFluid-pressure actuatorsPistonPneumatic actuator

The invention relates to an actuator cylinder position locking and unlocking mechanism, which comprises a cylinder body (4), a piston (5) and an ejector rod (6). The ejector rod (6) is mounted in the piston (5), a cavity is arranged at one end of the ejector rod (6), a spring (1) is mounted in the cavity, a hole is arranged at the other end of the ejector rod (6), the other end of the ejector rod is connected with a first connecting rod (7) with a cylindrical boss, the first connecting rod (7), a second connecting rod (8) and a third connecting rod (9) are hinged sequentially, and the other end of the third connecting rod (9) is fixed relatively. Radial holes (51) used for mounting an upper lock pin (2) and a lower lock pin (3) are arranged at one end of the piston (5) close to the cavity of the ejector rod (6) and are distributed circumferentially, and grooves are arranged in the radial holes (51). An annular groove (10) is arranged in the cylinder body (4) and the lower lock pin (3) can be clamped into the annular groove (10). The upper position and the lower position of a hydraulic / pneumatic actuator cylinder can be locked by the aid of the actuator cylinder position locking and unlocking mechanism which is high in locking force, low in unlocking force and high in reliability.

Owner:JINCHENG NANJING ELECTROMECHANICAL HYDRAULIC PRESSURE ENG RES CENT AVIATION IND OF CHINA

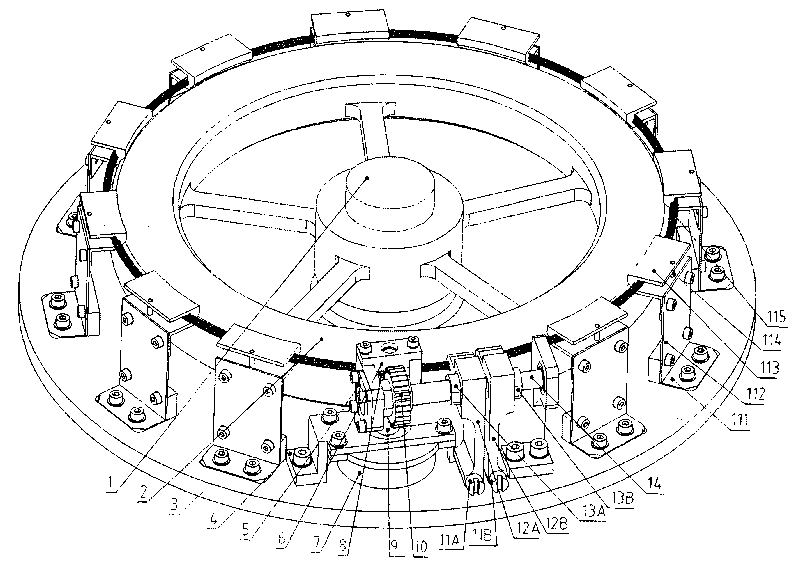

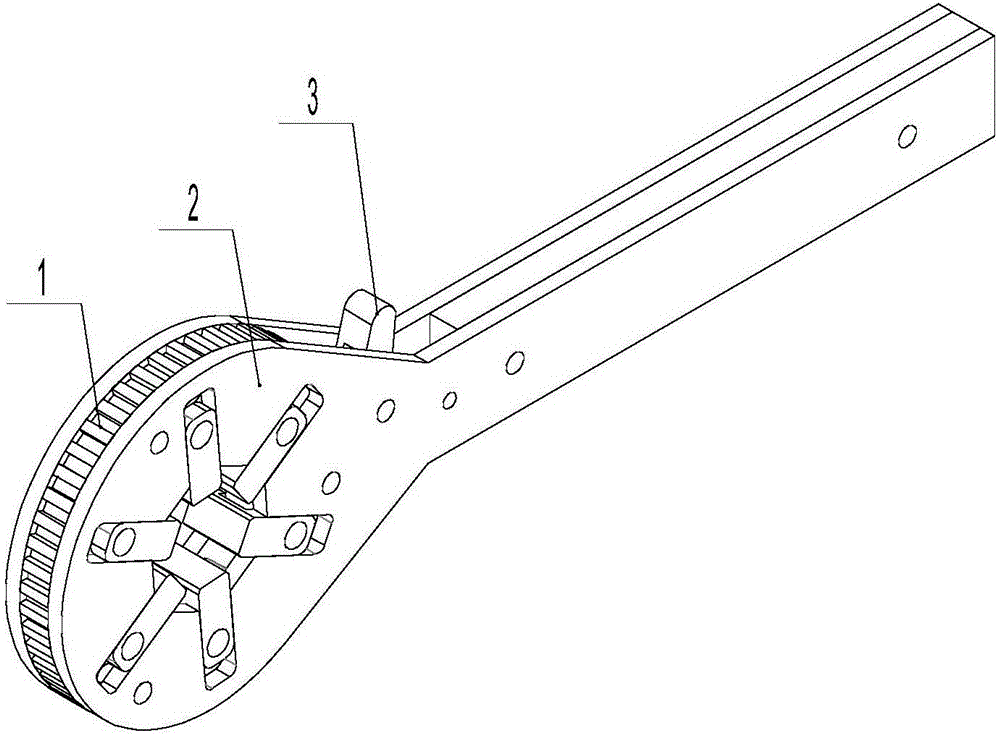

Locking release device applicable to satellite docking ring docking

ActiveCN105366077AAchieve closerSimple structureCosmonautic vehiclesCosmonautic component separationEngineeringCross pin

A locking release device applicable to satellite docking ring docking comprises a circular bracket (26), a transmission mechanism (28) and more than two sets of holding and compressing mechanisms. The circular bracket (26) is fixedly connected to a captured satellite. Each holding and compressing mechanism comprises a holding mechanism, a compressing mechanism and a rotating seat (2); the holding mechanism comprises a compressing member (1), a movement transfer member (8), a translation guide rail (7) and a cross pin shaft (5), and the compressing member (1) does radial or axial movement to compress a target satellite and draw the target satellite closer; and the compressing mechanism comprises a compressing plate (6), a compressing plate seat (9), an ejector pin (4) and an ejector pin guide rail (3), wherein up-and-down movement of the ejector pin (4) along the ejector pin guide rail (3) makes the compressing plate (6) rotate relative to the compressing plate seat (9) through four-stage pair connection, and one end of the compressing plate (6) is used for compressing or releasing a target satellite docking ring. With the device, a target satellite can be held, pulled closer, locked, released or retreated.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

Impact ratchet wrench

The invention discloses an impact ratchet wrench, which comprises a shell; the impact ratchet wrench further comprises a motor assembly, a transmission assembly, an impact assembly and a ratchet assembly, wherein the motor assembly, the transmission assembly, the impact assembly and the ratchet assembly are arranged inside the shell and are connected sequentially; the transmission assembly comprises a cylindrical gear train and is used for outputting a first rotation speed and a second rotation speed through gears in the gear train in a mode of transmission; the second rotation speed is lower than the first rotation speed; the impact assembly comprises an attacking piece and an output piece; and the attacking piece is used for intermittently providing increased torque to the output piece. With the adoption of the impact ratchet wrench, large torque desired by a fastening bolt is provided by an impact mechanism, so that relatively large fastening force is provided; a ratchet structure at the head part is small in size, so that the impact ratchet wrench is applicable for more working conditions; and the impact ratchet wrench is supplied with power through a battery, and is small in overall structure, light and applicable to carry over.

Owner:NANJING CHERVON IND

Dumper tail structure with hydraulic locking device

ActiveCN104691392AImprove fitPrevent leakageVehicle with tipping movementLoading-carrying vehicle superstructuresHydraulic cylinderEngineering

The invention discloses a dumper tail structure with a hydraulic locking device. The upper part of a back door body is a hinge plate which is hinged with a hinge seat, the hinge seat is arranged at the upper end of a dumper box body, an oblong hole is formed in a connection part between the hinge plate and the hinge seat and is matched with a connecting shaft on the hinge seat, and the connecting shaft and the oblong hole can generate relative movement; a latch hook clamping shaft is arranged at the lower part of the back door body, and a hook clamping shaft is arranged between the hinge plate and the latch hook clamping shaft on the back door body and is clamped with a hook on the side wall of the dumper box body. According to the dumper tail structure with the hydraulic locking device, a back door and the hydraulic locking device use cooperatively, the locking effect is excellent, the fitting degree of the back door and the box body can be improved, and material leakage can be effectively prevented; the hydraulic locking device can further prevent the back door from jumping up, and ensure the safety and the reliability of a vehicle during using; the hydraulic locking device can further increase the pushing force of a hydraulic cylinder, and provides a larger locking force; the dumper tail structure with the hydraulic locking device has the advantages of being simple in operation, safe, reliable and high in controllability.

Owner:SINO TRUK JINAN POWER

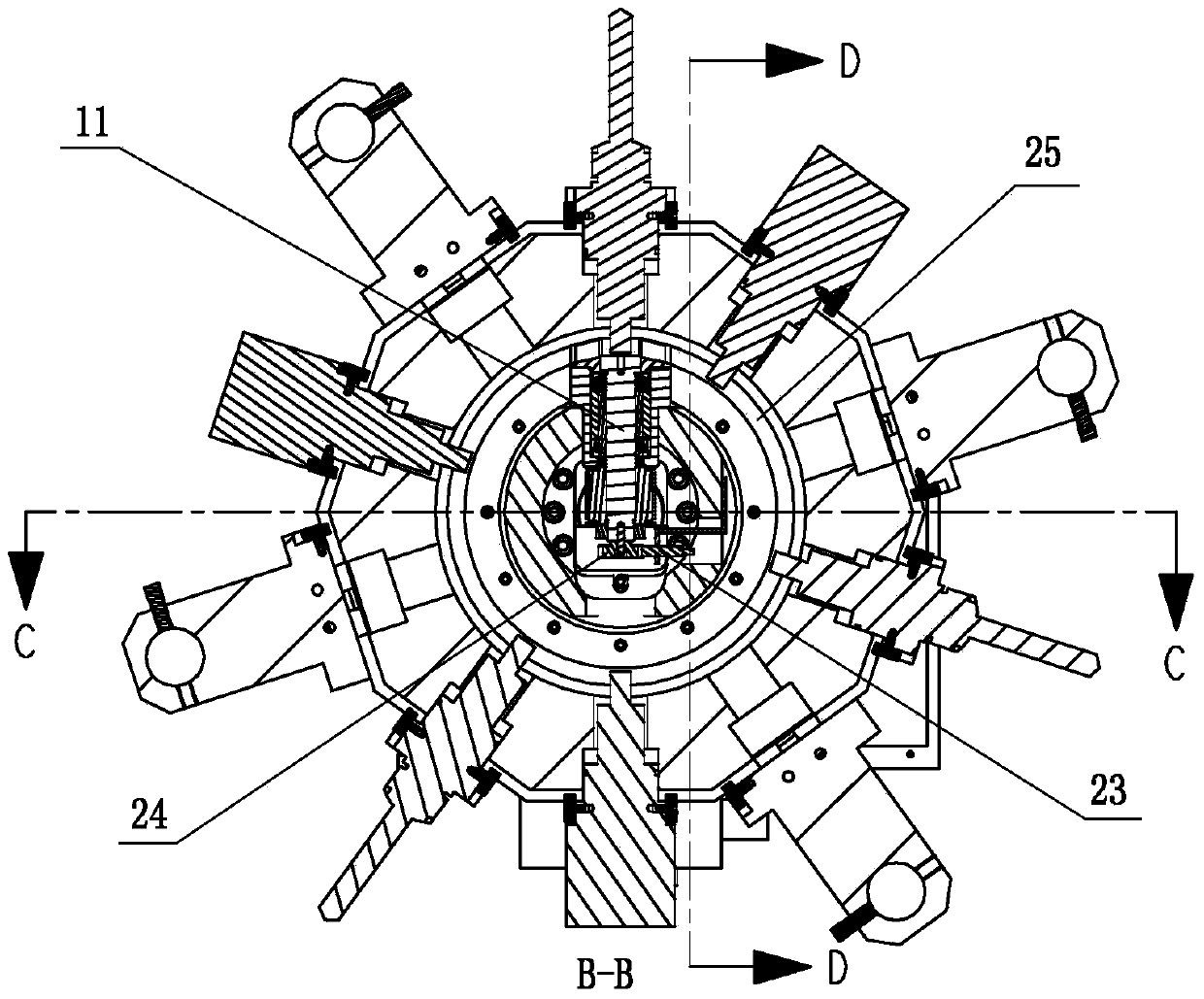

Self-oriented large-fault-tolerance isomorphic interface for spacecraft and using method thereof

ActiveCN110316404ALarge locking forceEasy to controlCosmonautic vehiclesCosmonautic component separationFault toleranceButt joint

The invention provides a self-oriented large-fault-tolerance isomorphic interface for a spacecraft and a using method thereof. A gear wheel is driven to rotate by a motor by means of a worm, a supporting sleeve is driven to rotate by the gear wheel by means of a gear wheel key, the supporting sleeve rotates to drive an inner rotating cylinder to rotate firstly, for the movement of the inner rotating cylinder, a guide plate is pushed out through a meshed guide plate driving rod, a guide plate pushing rod and a rotating pin, meanwhile, a locking positioning pin is pushed out by the supporting sleeve, after the locking positioning pin and the supporting sleeve reach a limit station, the motor stops, after the interface is aligned, the motor is started again, the supporting sleeve drives a meshed telescopic sleeve to move through the driving rod, and a connecting key is used for clamping a concave part of the locking sleeve so as to complete locking. According to the interface and the method in the invention, self-oriented fault-tolerant butt joint with large butt joint initial deviation between spacecrafts can be achieved, multi-angle butt joint under the condition of multi-face connection is achieved, the interface structure is simple, the locking force is large, the size is compact, and high-reliability and large-fault-tolerance butt joint of the spacecraft can be met; meanwhile, the control is simple, the energy consumption is low, and the task cost of actual spacecraft butt joint can be saved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Mold locking device of hollow plastic product forming machine

The invention relates to a mold locking device of a hollow plastic product forming machine, belonging to the field of a plastic product forming machine. The hollow plastic product forming machine comprises a left mold frame and a right mold frame, the mold locking device comprises a mold-locking actuating cylinder, a mold locking box and a mold-locking actuating cylinder grabbing mechanism, wherein the mold locking box comprises a mold locking box body, a cover plate, a first guide plate and a second guide plate; the mold-locking actuating cylinder grabbing mechanism comprises an upper actuating cylinder, an upper actuating cylinder seat plate, an upper engagement clamp block, a lower actuating cylinder, a lower actuating cylinder seat plate and a lower engagement clamp block; and the mold-locking actuating cylinder is horizontally arranged on the left mold frame, and cylinder column engagement teeth are formed at the surface of a mold-locking actuating cylinder column of the mold-locking actuating cylinder, at one end facing the mold locking box body. The mold locking device has the advantages that the closing effect of one pair of semi-molds can be ensured; the upper engagement clamp block and the lower engagement clamp block can be prevented from deflection to affect clamping forces on the mold-locking actuating cylinder column; the stability of vertical movement of the upper engagement clamp block and the lower engagement clamp block can be maintained in a long time; and the structure can be simplified, large locking forces for the mold-locking actuating cylinder column can be obtained with small mold locking forces, and electric energy can be saved.

Owner:SUZHOU TONGDA MACHINERY

Bottom garment

InactiveUS8245324B2Large locking forceWell formedGarment special featuresTrousersRectus femoris muscleEngineering

Filler clothes 3, which intersect with each other at a section corresponding to the middle point between the interspinal point and patellar midpoint of a human body, are formed on a front section of a bottom garment 1. The filler clothes 3 which are formed in this manner stimulates the rectus femoris muscle 14 which is a part of the quadriceps of a wearer. When the quadriceps is stimulated while walking, the legs can be kicked backward significantly in a natural fashion, whereby the gluteus maximus muscles can be used efficiently.

Owner:WACOAL

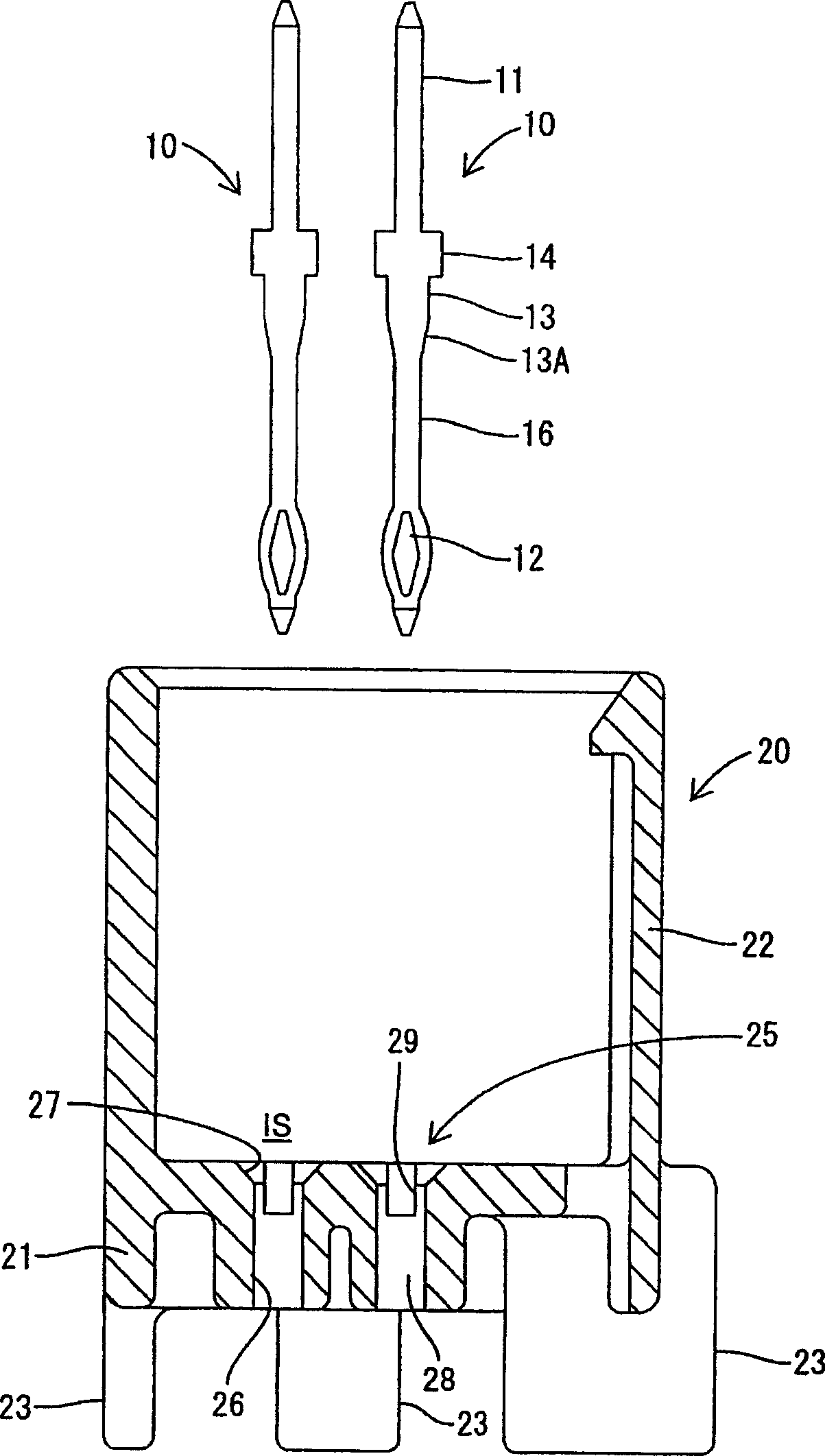

Connector for electrical equipment and electronic equipment and its assembling method

InactiveCN1713455AInhibit sheddingImprove connection reliabilitySecuring/insulating coupling contact membersFixed connectionsElectrical equipmentElectronic equipment

An object of the present invention is to reduce the interval between press-fit terminals while ensuring sufficient press-fit terminal holding force. Five insertion portions (25) are formed on each of the front and rear rows in the base wall (21) of the housing (20). Each insertion part (25) is formed with a relatively wide through hole (26) to allow the elastic protrusion part (12) of the press-fit terminal (10) to pass through, and a press-fit part (13) for press-fitting is also formed. ) relatively narrow press-in hole (28), wherein the width direction of the through hole (26) is consistent with the direction perpendicular to the arrangement direction of the terminals (10), and the width direction of the press-in hole (28) is consistent with the terminal ( 10) are arranged in the same direction. The elastic protrusion (12) of the press-fit terminal (10) first passes through the through hole (26) and then rotates 90° around its longitudinal axis. After that, the press-in portion (130) is pressed into the press-in hole (28), and the press-in is stopped when a stopper (14) comes into contact with the bottom surface of a receiving hole (29).

Owner:SUMITOMO WIRING SYST LTD

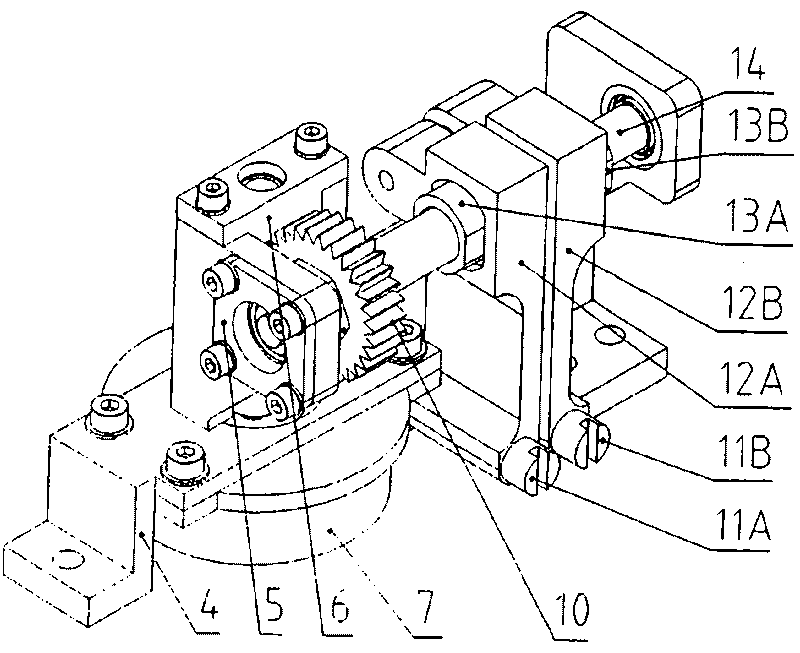

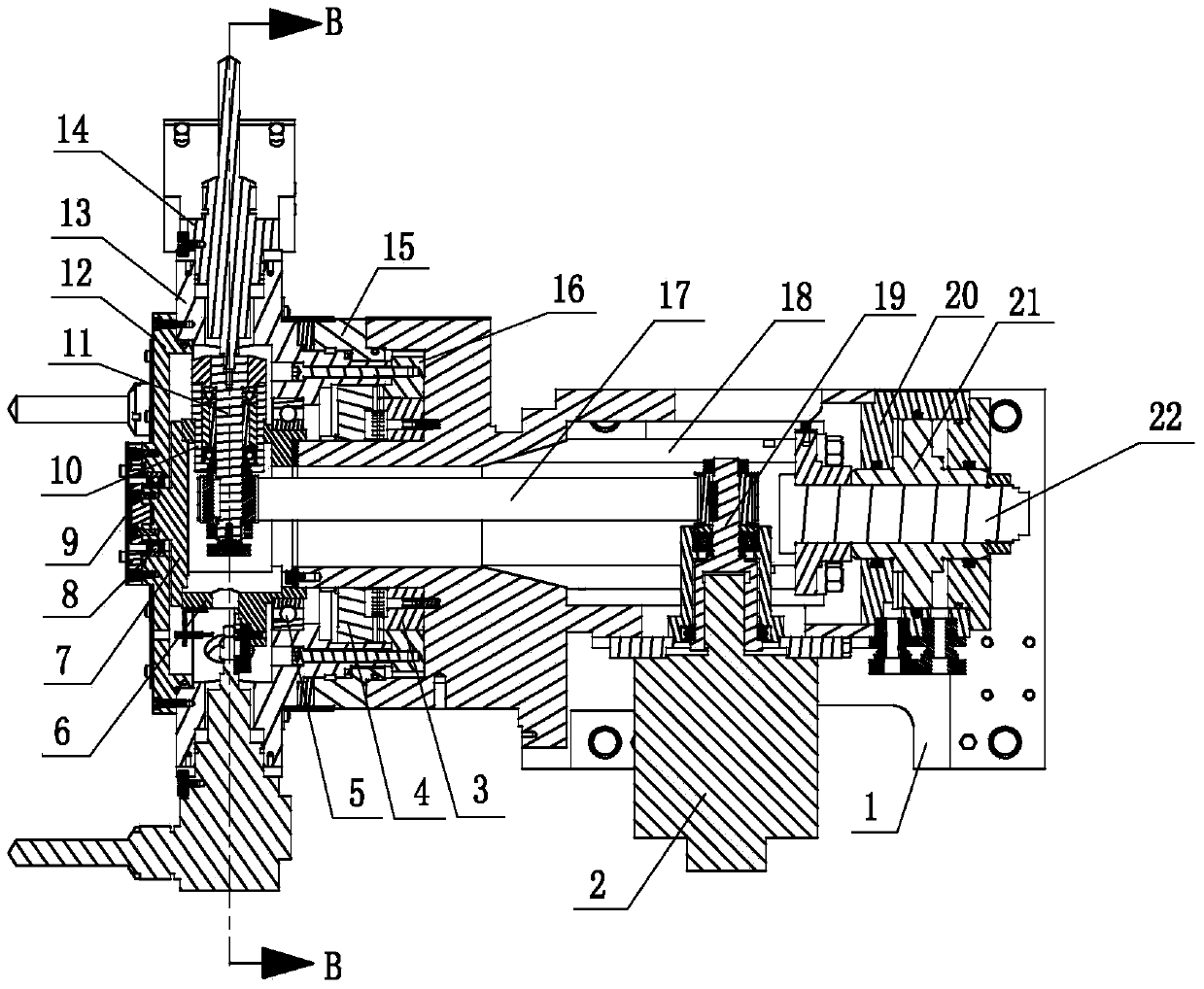

Space on-track repeated locking and releasing mechanism

ActiveCN102720733ARestricted degrees of freedomSimple structureSecuring devicesDegrees of freedomEngineering

The invention discloses a space on-track repeated locking and releasing mechanism, relating to a repeated locking and releasing mechanism. The invention aims to solve the problem in on-track repeated locking and releasing of large payload on spacecraft. The mechanism comprises a locking trunnion mechanism, a compaction lock hook mechanism, a locking base mechanism, a crank-rocker mechanism and a drive gear mechanism, wherein the locking trunnion mechanism is arranged at the upper end of the locking base mechanism; and the drive gear mechanism is connected with the compaction lock hook mechanism and the crank-rocker mechanism respectively. In the invention, the locking trunnion mechanism, the compaction lock hook mechanism, the locking base mechanism, the crank-rocker mechanism and the drive gear mechanism are crossed, the structure is simple and compact, all degrees of freedom of the fixed object can be completely limited, the repeated locking can be realized, the operability is good, and the using requirement of on-track locking-releasing-locking can be met. The mechanism disclosed by the invention is applicable to the technical field of aerospace and mechatronics.

Owner:HARBIN INST OF TECH

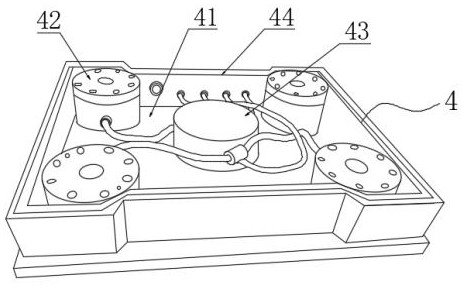

Combined machining hydraulic locking power tool table

ActiveCN104190973AAdapt to functional requirementsVersatileTool holdersPositioning apparatusDrive shaftControl engineering

The invention discloses a combined machining hydraulic locking power tool table, and belongs to machine tool parts. A plurality of power tool bases are arranged on a tool disc at intervals in the circumferential direction, the tool disc is fixedly connected with a transposition tooth disc and is supported through a bearing, and a gear shaft is meshed with a gear on the outer peripheral face of the transposition tooth disc for transmitting power of a tool changing drive motor. A lock oil cylinder piston is connected with a locking tooth disc through a connection piece to drive a tooth groove in the rear end face of the locking tooth disc to be correspondingly meshed with a tooth groove in the front end face of the transposition tooth disc and a tooth groove in the front end face of a fixing tooth disc fixed to a tool table base so as to achieve locking. A power drive motor transmits the rotating power to the power tool base through a drive shaft and a driven shaft which are connected in a transmission mode, the driven shaft and the power tool base are matched through a clamping groove and a clamping tenon, a driven shaft angle sensing mechanism feeds back signals to control the rotating angle of the driven shaft, the driven shaft is arranged in a radial driven shaft hole in a flange base through a bearing in a supported mode, and the tool table base is provided with a front transmission cavity and a rear transmission cavity which are used for passing of a transmission mechanism. The combined machining hydraulic locking power tool table is simple in structure and solves the problem that a traditional power tool table is complex in structure.

Owner:ZHEJIANG RIFA PRECISION MACHINERY

Intelligent production line for part manufacturing and working method thereof

ActiveCN112108929AFully automatedLarge locking forceMeasurement/indication equipmentsMetal working apparatusProduction lineRobot hand

The invention discloses an intelligent production line for part manufacturing and a working method thereof. The intelligent production line comprises a loading and unloading mechanism, a conveying mechanism, a production mechanism and a tray mechanism, wherein the conveying mechanism comprises a fixing frame and a truss rail which is fixed to the upper side of the fixing frame; the surface of thetruss rail is slidably connected with a mechanical arm assembly; and an inner cavity of the mechanical arm assembly is slidably connected with a lifting mechanical arm. The invention relates to the technical field of part machining. According to the intelligent production line for part manufacturing and the working method thereof, it is achieved that different parts are machined on a same device on the premise that a clamping way and cutting tools are not changed; by using a zero-point positioning module, the machined workpiece is fixed to a clamping tray; a truss robot grabs the clamping trayto place the clamping tray on a clamping base well fixed on a CNC machine; it is achieved that loading and unloading of the CNC machine are automatic; an operator clamps the workpiece on a loading table without occupying a machine tool; and it is achieved that one truss robot can be responsible for loading and unloading of multiple CNC machines.

Owner:AVIC POWER SCI & TECH ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com