Mold locking device of hollow plastic product forming machine

A technology for a plastic product and a clamping device, which is applied in the field of clamping device of a hollow plastic product molding machine, can solve the problems of troublesome maintenance and replacement, affecting the clamping force, breaking away from the semicircular locking groove, etc., so as to save power consumption and simplify the structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

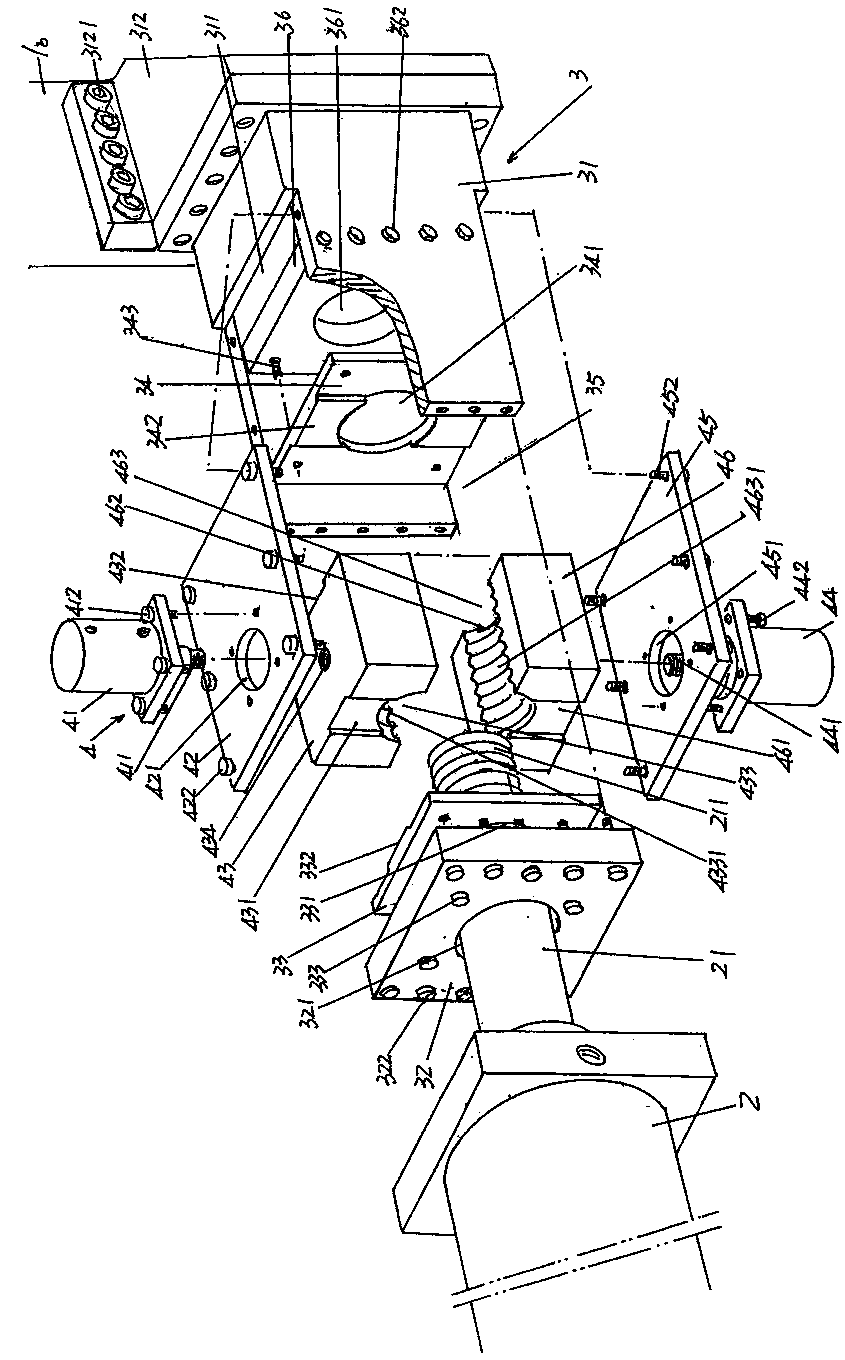

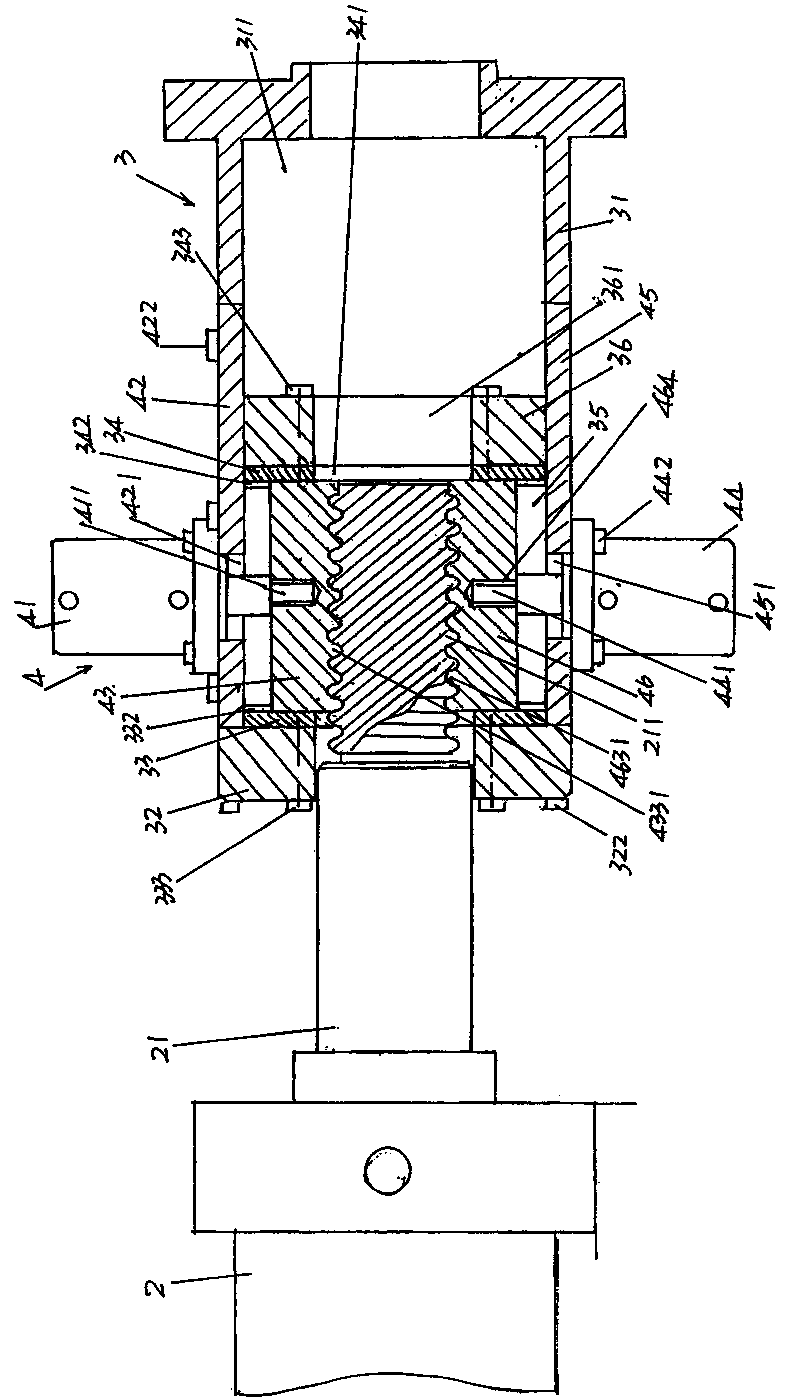

[0025] See figure 1 and figure 2 , what the applicant needs to explain is: in the following descriptions, all directional expressions such as left, right, up, and down are for the position status of the current illustration, so it cannot and should not be based on this. The technical solutions provided by the present invention constitute limitations.

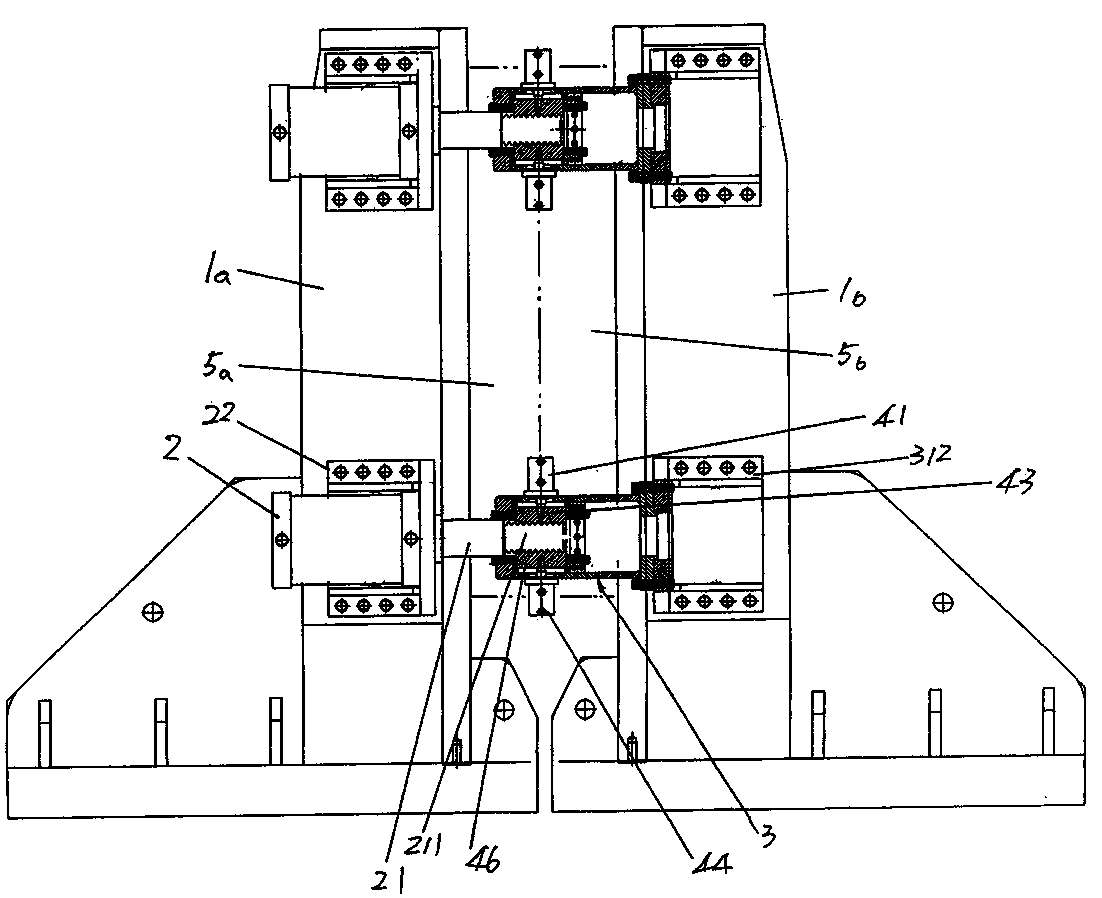

[0026] Since the clamping device mentioned in the present invention is applied to a molding machine for hollow plastic products, and according to known techniques, the molding machine for hollow plastic products has a left mold frame 1a ( image 3 shown) and right formwork 1b ( figure 1 and image 3 Shown), so the clamping device is set between the left and right mold bases 1a, 1b. Also, according to the known technology, for example, according to the teaching of paragraph 0025 of the description of CN101890805B mentioned by the applicant in the above background technology column, 4 or 6 identical structures can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com