Connector for electrical equipment and electronic equipment and its assembling method

A technology of electronic equipment and connectors, which is applied to the parts, connections, and fixed connections of connection devices, and can solve the problems of limiting the distance between press-fit terminals 3 and shrinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

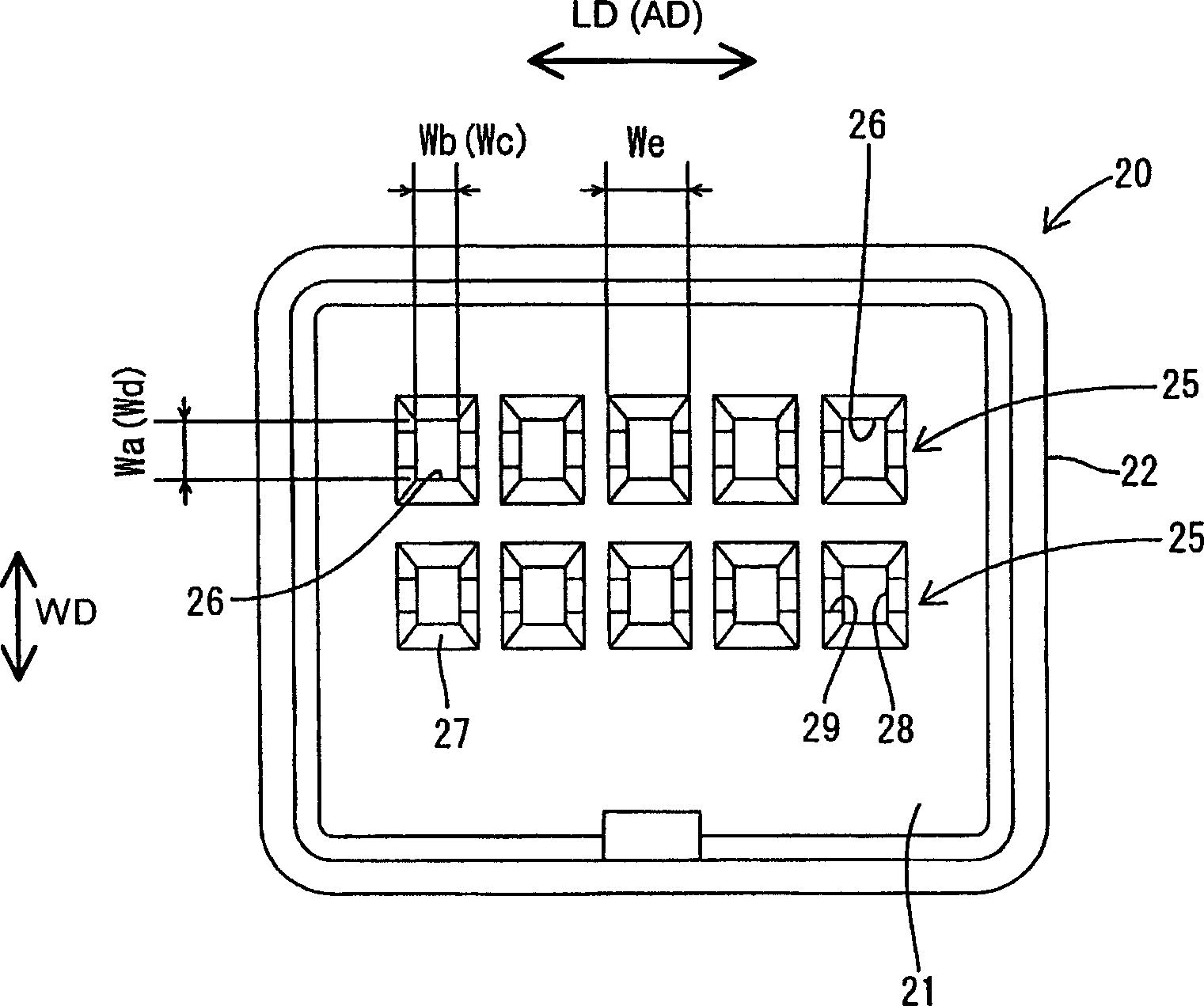

[0045] In the following, see Figure 1-10A preferred embodiment of the present invention is described.

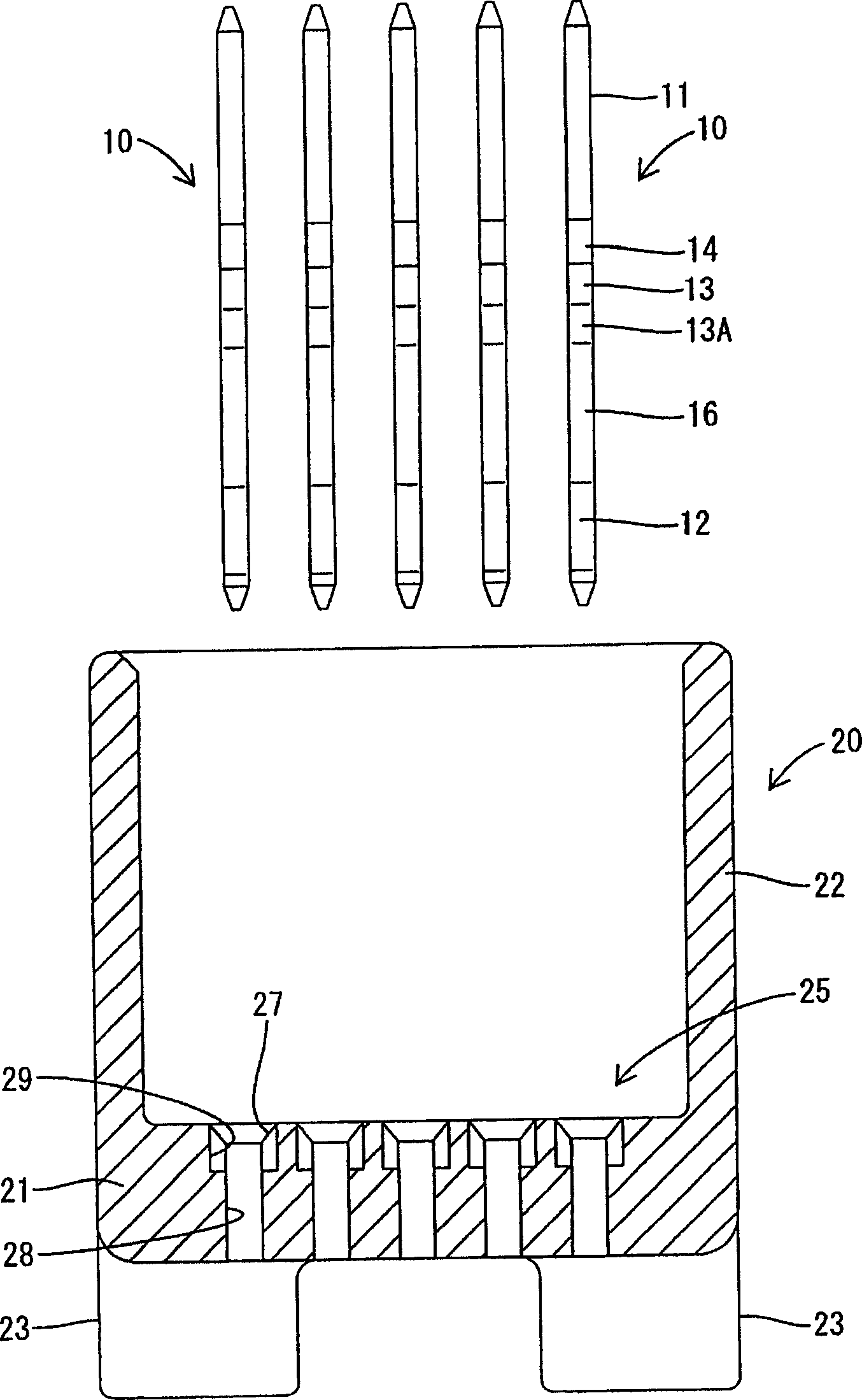

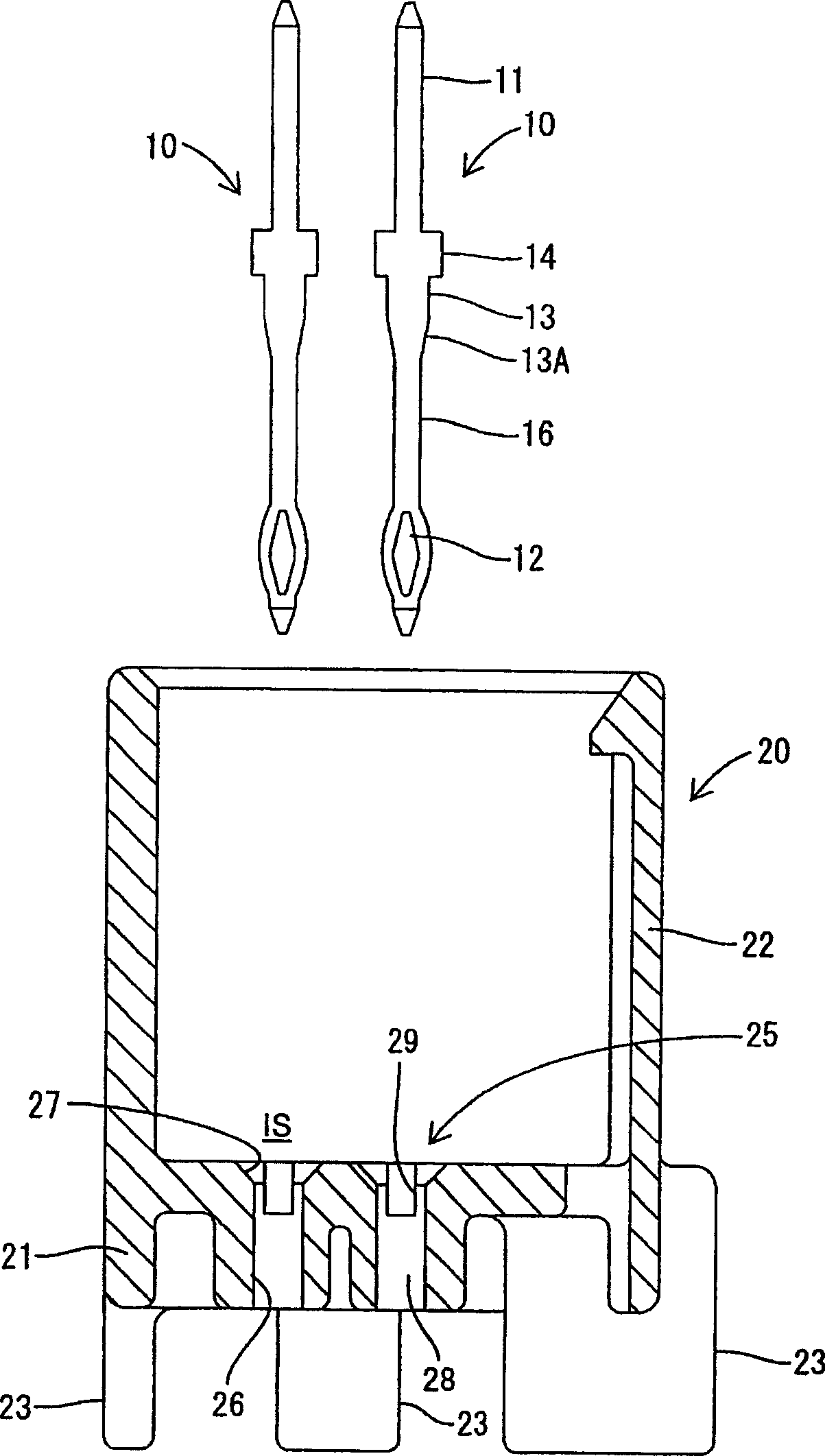

[0046] The circuit board connector of the present embodiment (as a preferred connector for connection with electrical and / or electronic equipment) is constructed in such a way that one or more, for example 10, press-fit terminals 10 are at least partially inserted, preferably Press in or assemble into as figure 1 with figure 2 The connector housing 20 (hereinafter referred to as "housing 20") is shown, and the connector will be mounted on a printed circuit board 30 (as a preferred electrical and / or electronic device, see Figure 9 , and hereinafter referred to as "circuit board 30").

[0047] Each press-fit terminal 10 is preferably formed into a shape as shown in FIGS. 5(A)-5(C) by punching or press-working a conductive (preferably metal) plate having excellent conductivity. As a whole, the press-fit terminal 20 is substantially in the form of a narrow and long recta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com