Repeatable locking device for magnetically suspended flywheel

A technology of repeated locking and magnetic levitation, applied in the direction of the guidance device of the aerospace vehicle, can solve the problems of reduced reliability and forced unlocking of the flywheel, and achieve the effect of maintaining the locked state, convenient debugging and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

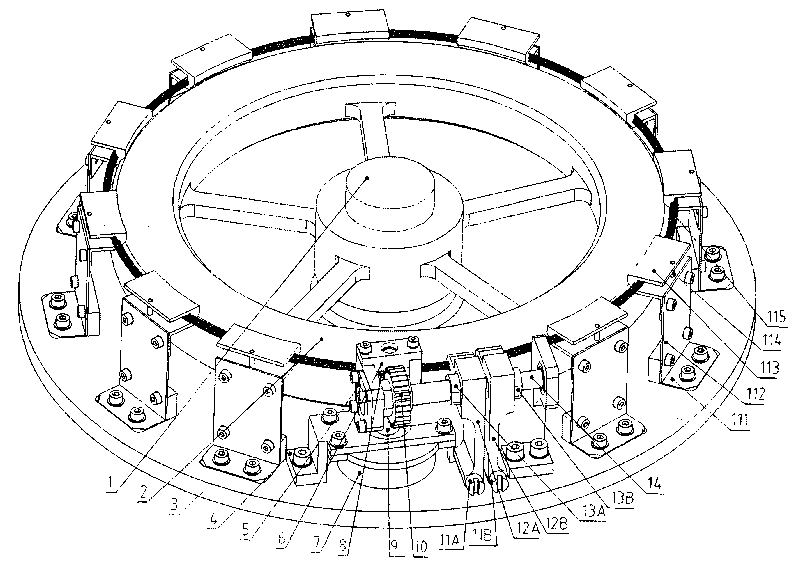

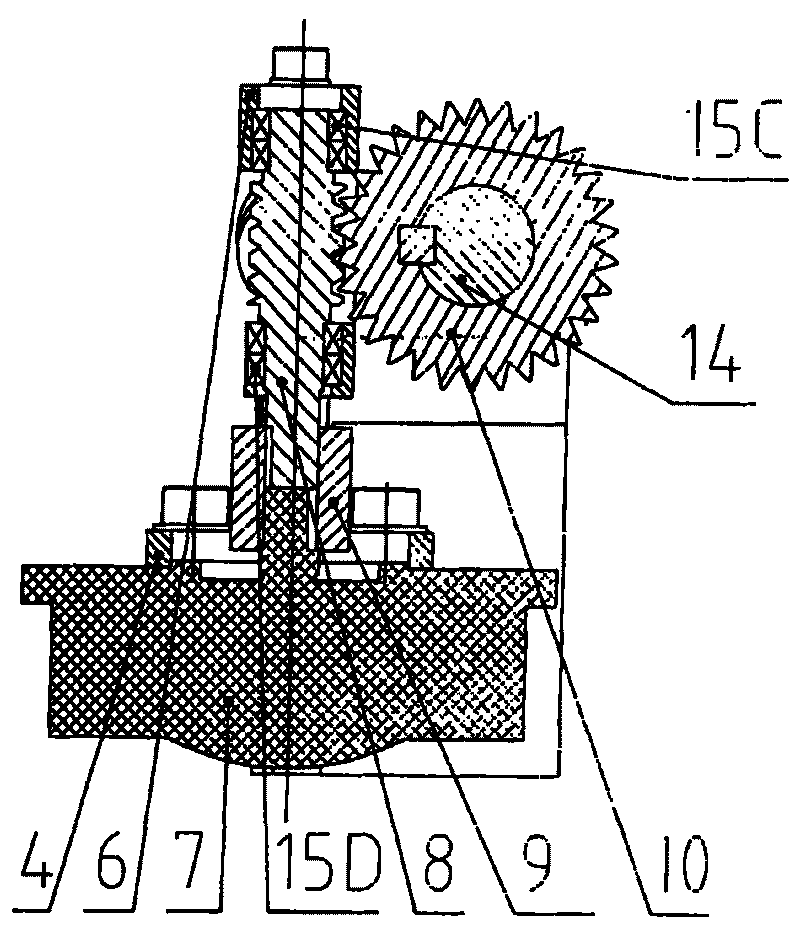

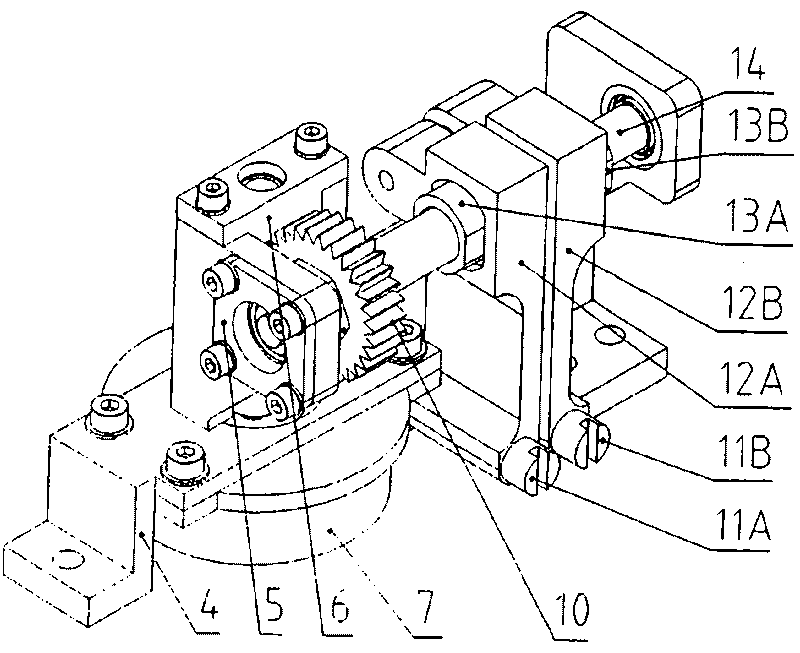

[0038] Such as figure 1 As shown, the present invention is mainly composed of a flywheel system, a transmission mechanism and a locking mechanism, wherein the flywheel system is mainly composed of a flywheel stator shaft 1, a flywheel rotor 2 and a base 3, and the transmission mechanism is mainly composed of a fixed plate 4, a left bearing pressure ring 5, Upper bearing pressure ring 6, motor 7, worm screw 8, coupling 9, worm wheel 10, left fixed column 11A, right fixed column 11B, left lock fork 12A, right lock fork 12B, left spherical nut 13A, right spherical nut 13B, Worm wheel linkage 14, left bearing 15A, right bearing 15B, upper bearing 15C and lower bearing 15D are made up of, and locking mechanism is mainly made up of shrapnel seat 111, shrapnel 112, shrapnel body 113, small column 114, steel wire rope 115, left connecting column 116A and The right connecting column 116B is composed, the flywheel stator shaft 1 is located on the radial inner side of the flywheel rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com