Dumper tail structure with hydraulic locking device

A locking device and dump truck technology, which is applied to the upper structure of the truck, the upper structure, and the vehicle with inclined load movement, etc., which can solve the problem of loose locking, large gap between the rear door and the box body, and poor sealing of the rear door, etc. problems, to ensure safety and reliability, good locking effect, and prevent material leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

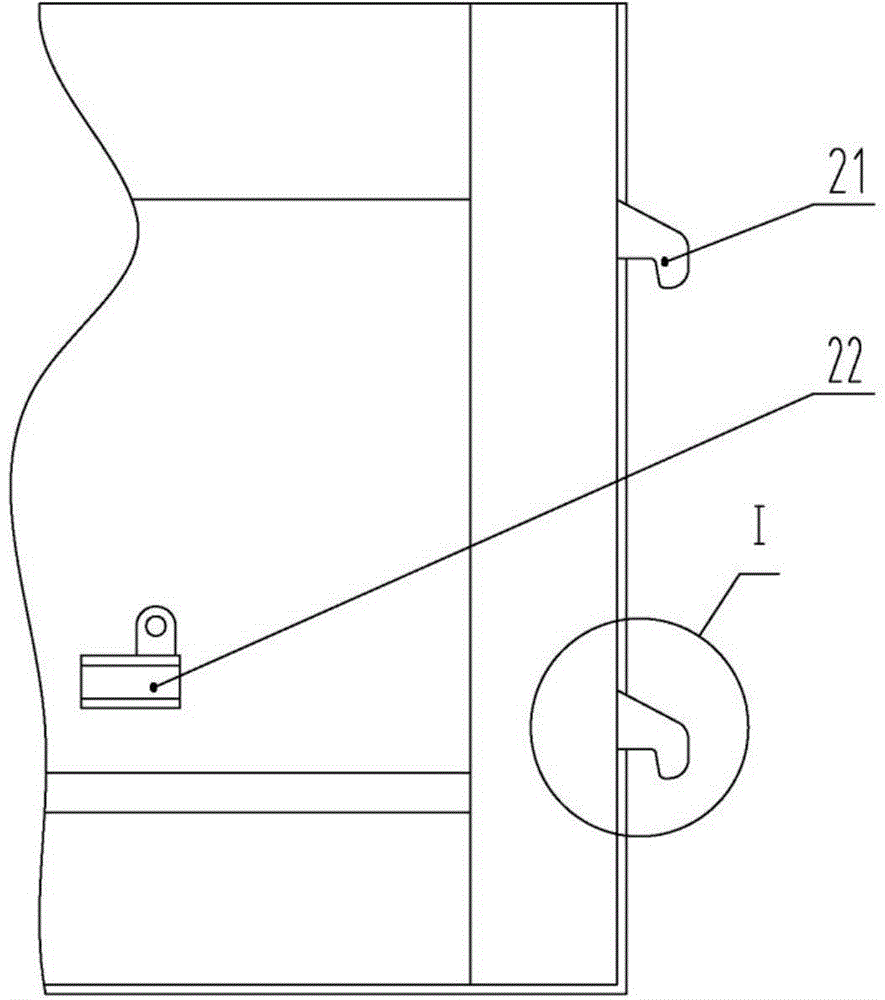

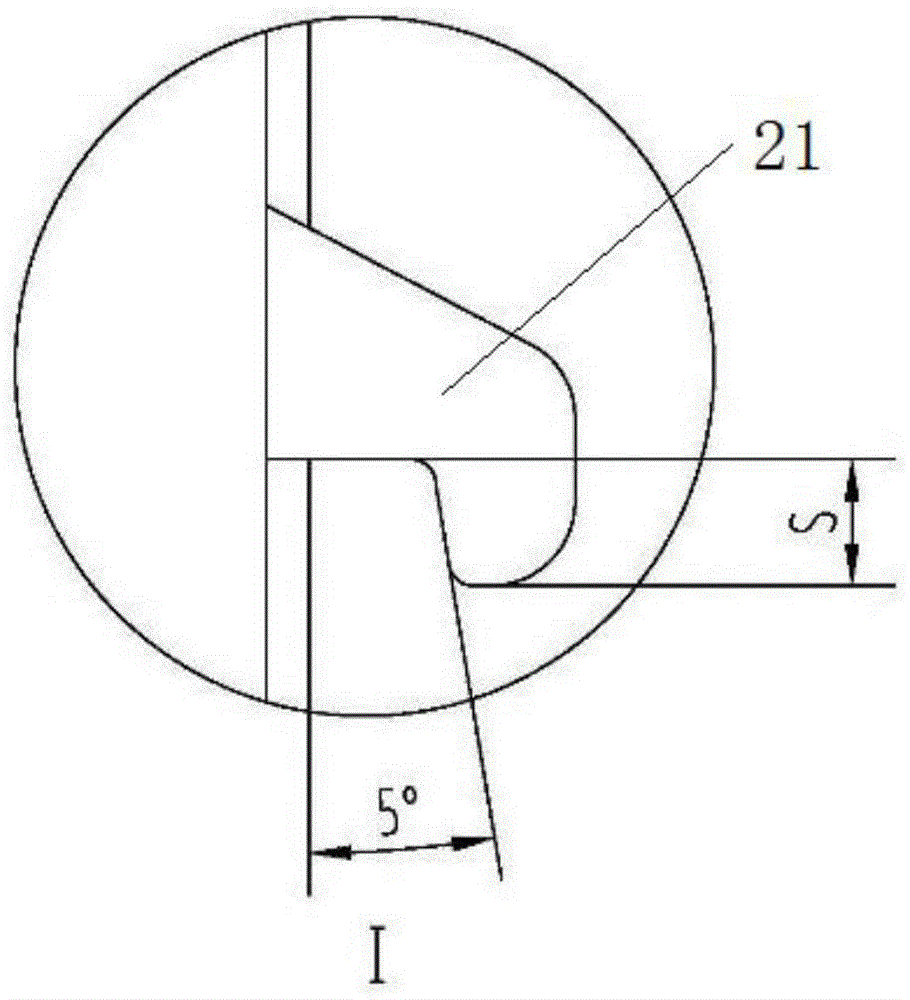

[0023] Such as figure 1 Shown, the dump truck casing, the casing 2 rear end is welded with hook 21, and the oil cylinder seat 22 and bearing pin 6 are welded at the appropriate place of side bottom.

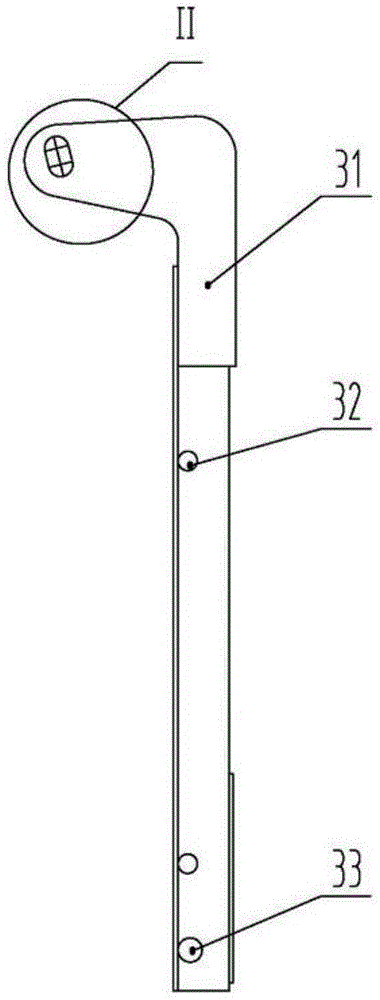

[0024] Such as image 3 Shown, rear door body, rear door 3 tops are welded with hinged plate 31, and both sides are welded with hook clamping shaft 32 and lock hook clamping shaft 33; There are oblong holes on the hinged plate, which can move up and down relative to the dump truck casing. Wherein there are two hook clamping shafts 32 on each side, and the hook clamping shafts 32 are matched with the hooks 21 fixed on the casing 2 .

[0025] Such as Figure 5 As shown, the front end of the double-acting hydraulic cylinder 4 is hinged on the cylinder seat 22 of the box body 2 through the hinge shaft 41, and the rear end is hinged on the upper part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com