Patents

Literature

195results about How to "Uniform plating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

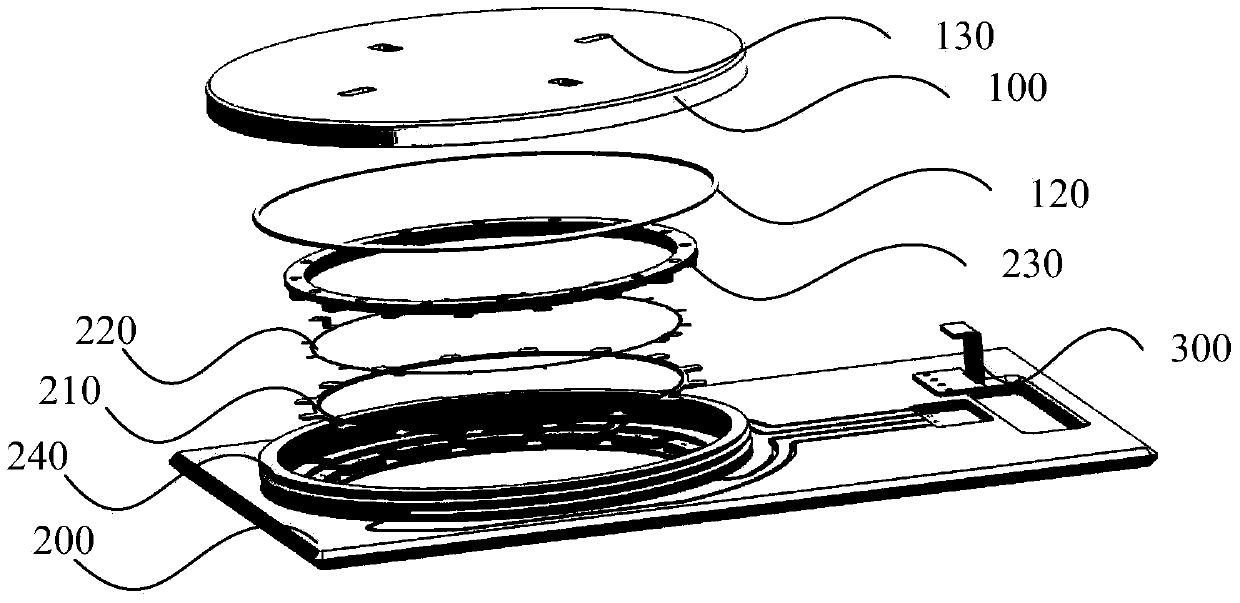

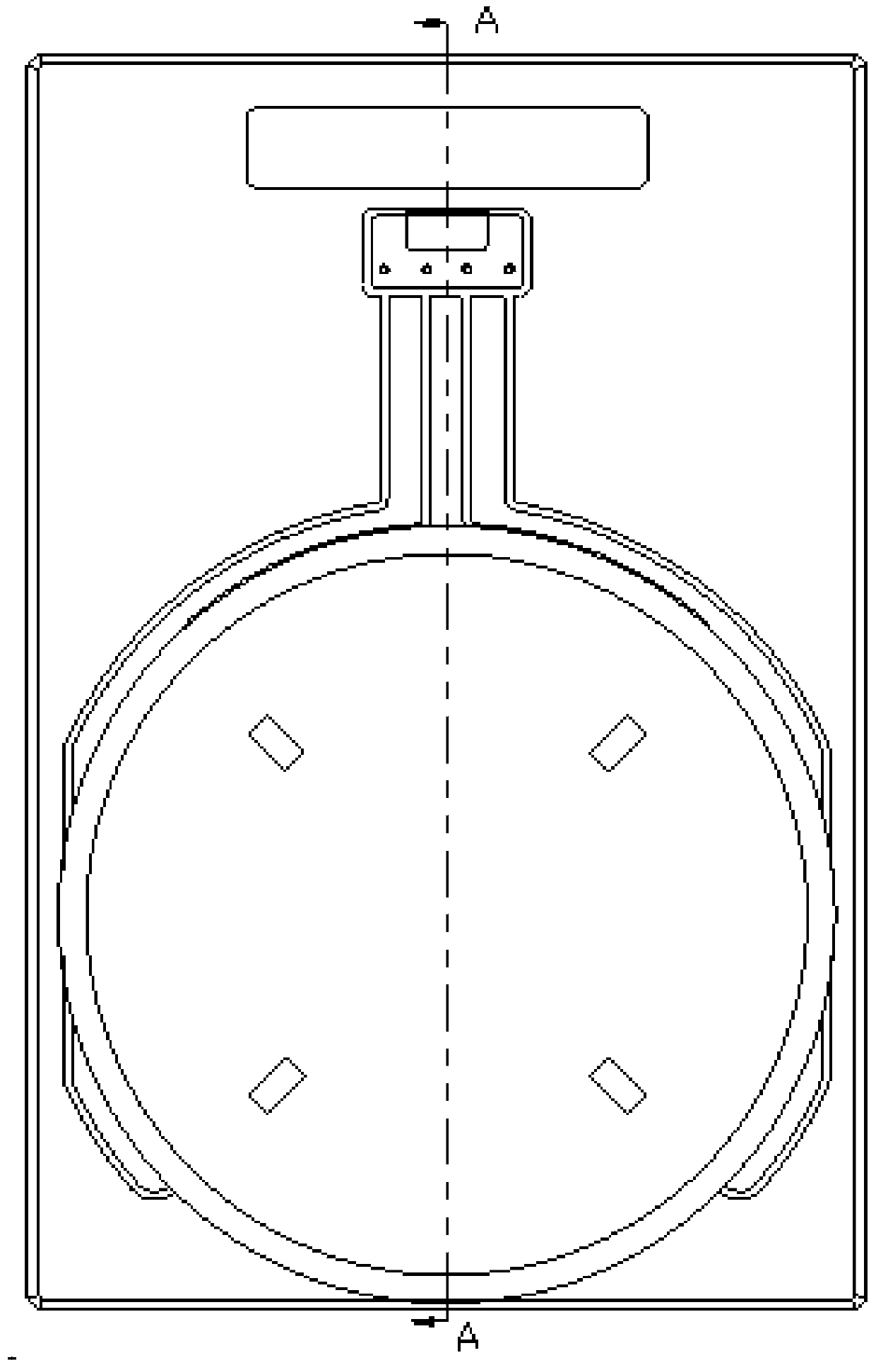

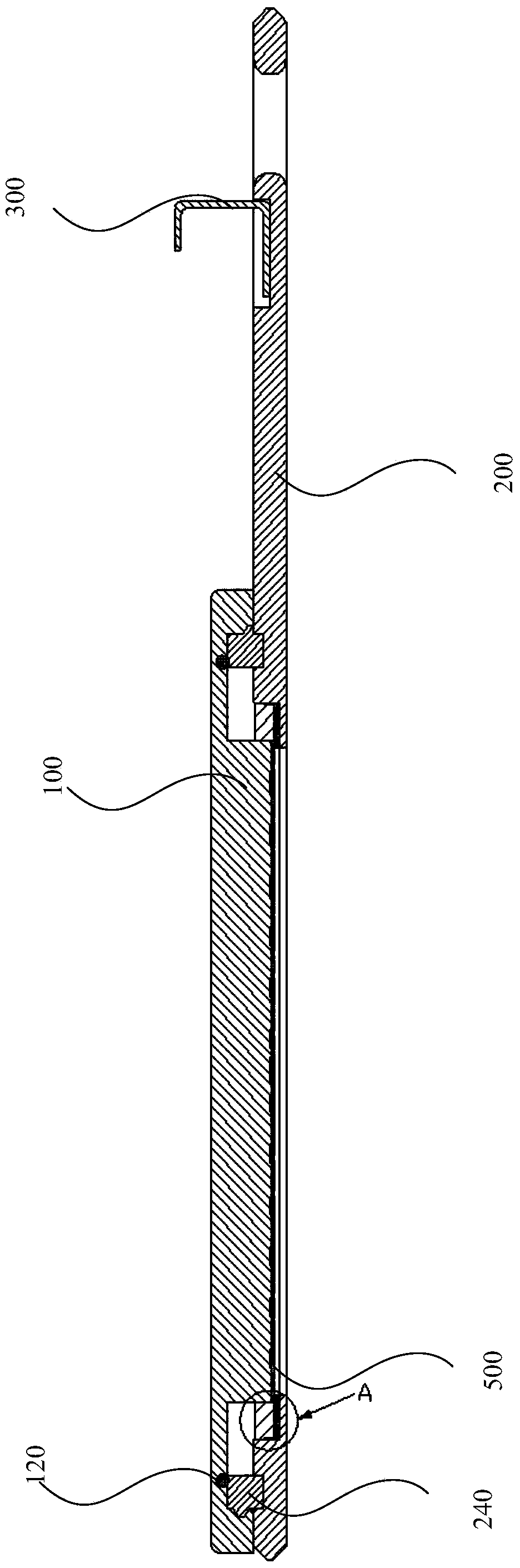

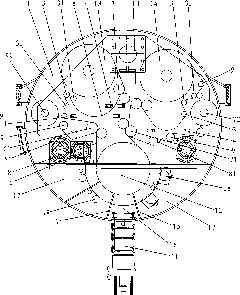

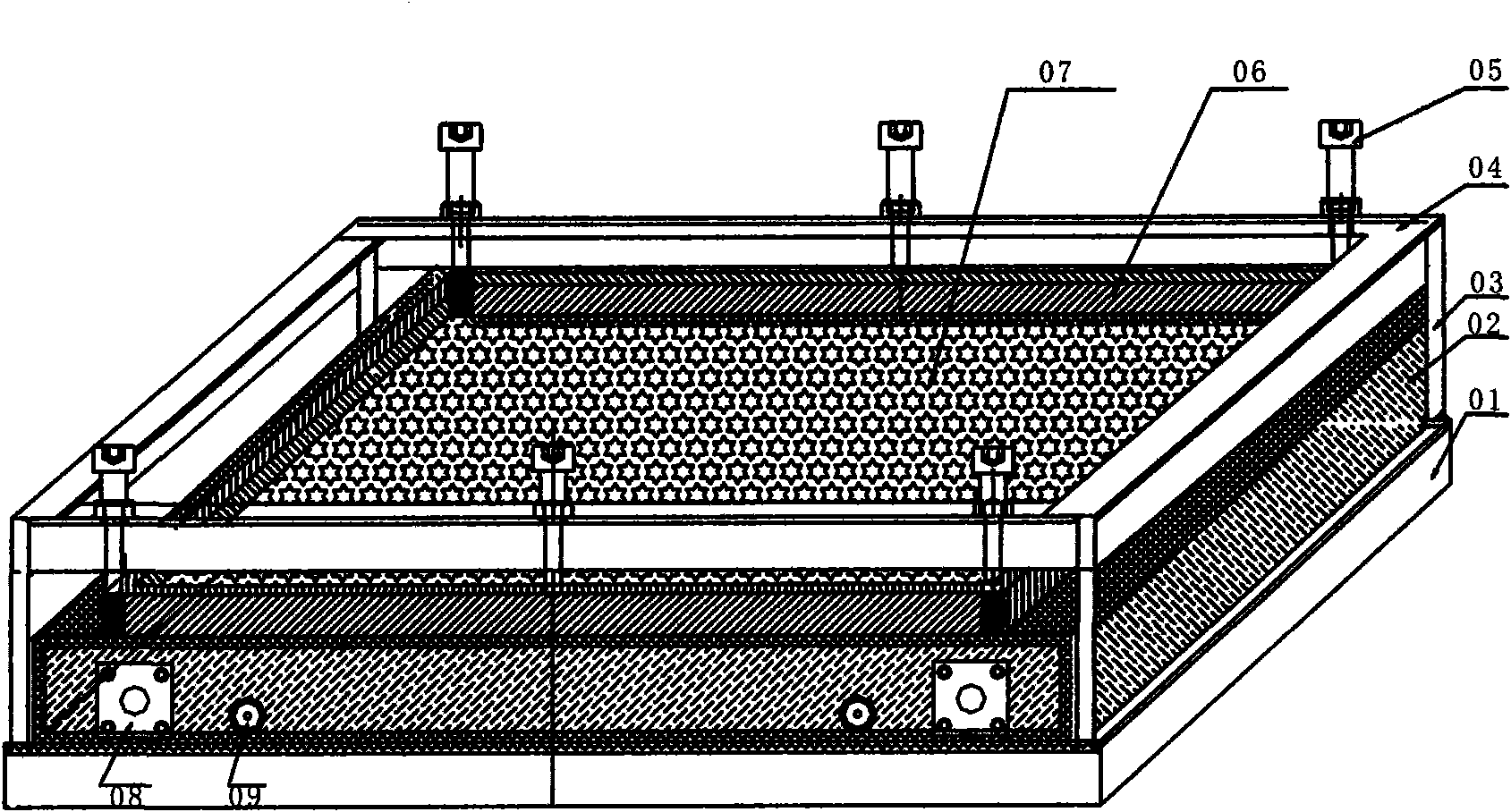

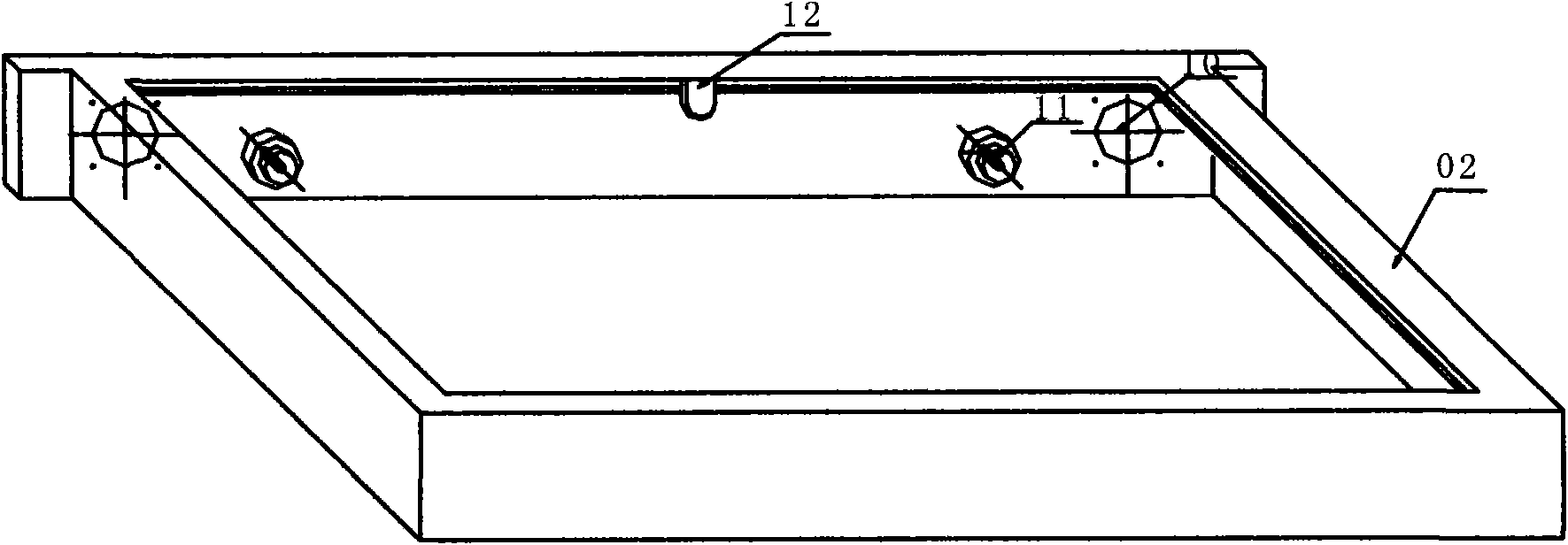

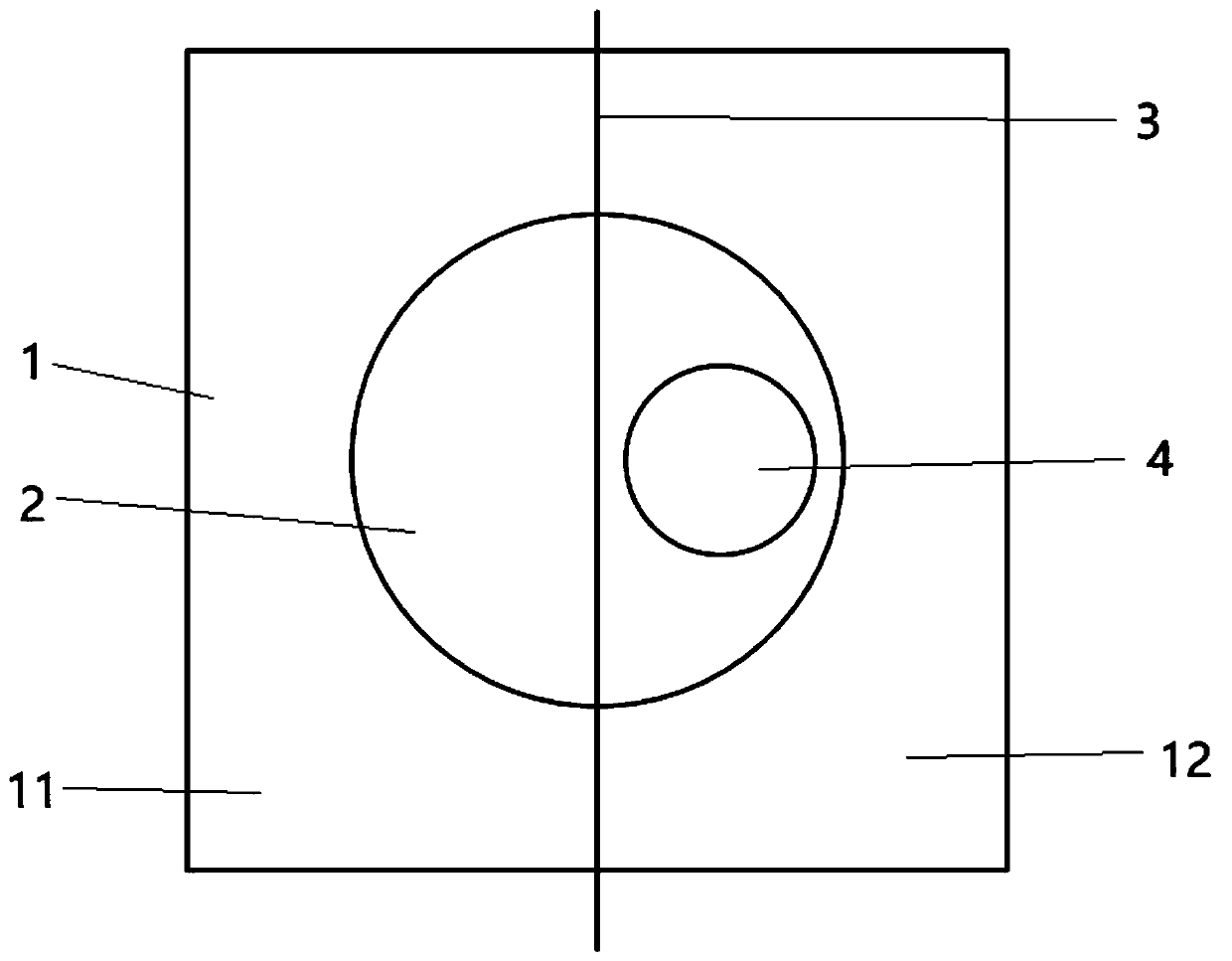

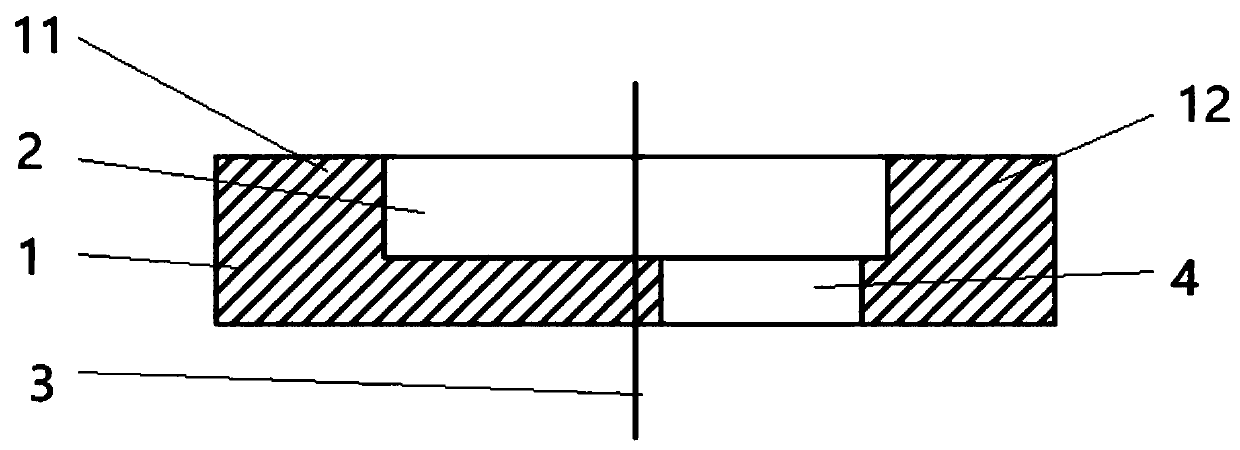

Hanging tool for wafer electroplating

ActiveCN103469271AUniform platingContact withElectrolysis componentsSemiconductor devicesEngineeringElectroplating

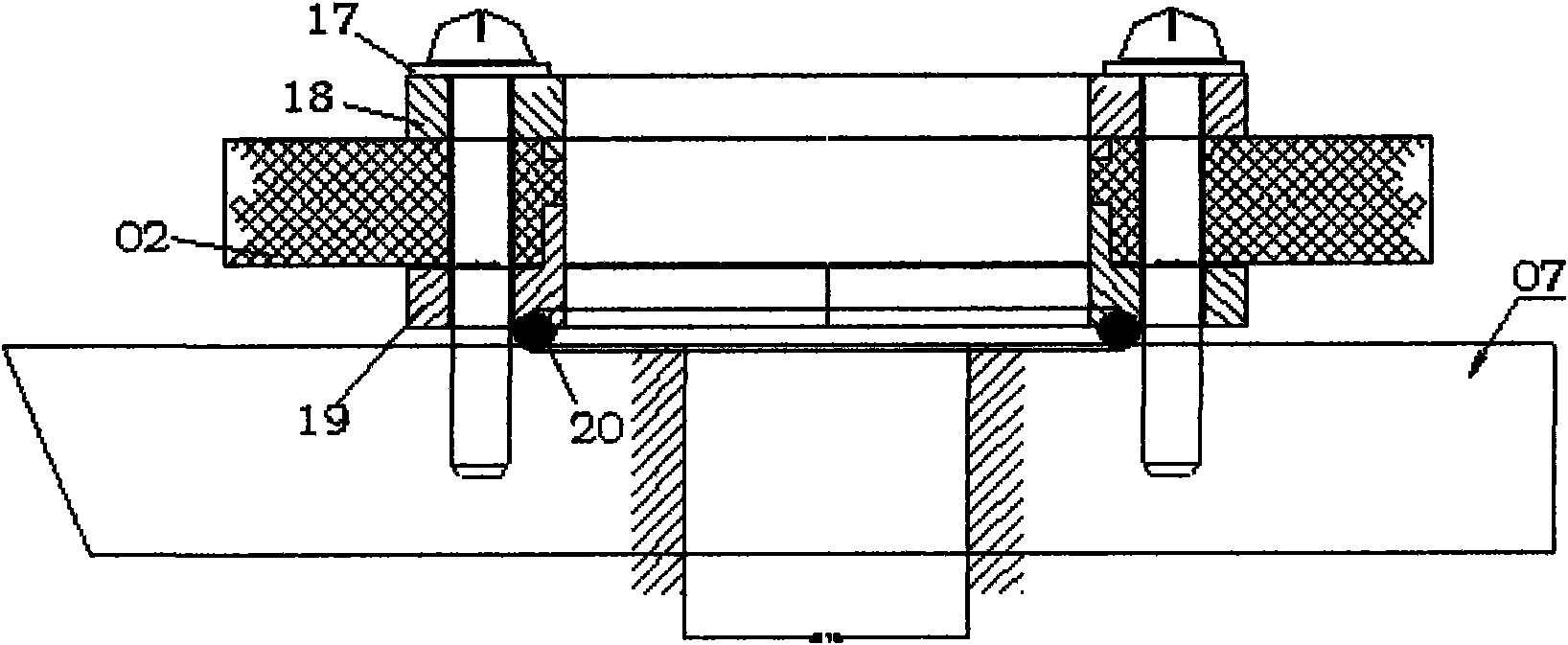

The invention discloses a hanging tool for wafer electroplating. The hanging tool comprises an upper cover, a lower plate and a metal conductive ring, wherein an inner thread is arranged on the inner wall of the upper cover, a wafer groove is formed in the lower plate, an electroplating hole is formed in the middle of the wafer groove, and an outer thread engaged with the inner thread is arranged on the outer wall of the wafer groove; a platform is arranged between the inner wall of the wafer groove and the electroplating hole; the metal conductive ring is arranged on the platform. The upper cover of the hanging tool for the wafer electroplating is locked in a rotary mode, and the need of manually disassembling screws is eliminated, so that the hanging tool is convenient to operate, uniform in force, good in electrical conductivity and sealing performance and uniform in water coating, thereby greatly saving the manpower and reducing the wafer scrapping risk.

Owner:江苏矽智半导体科技有限公司

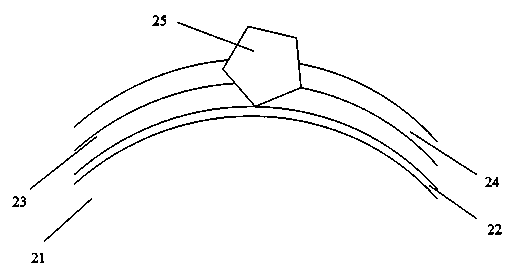

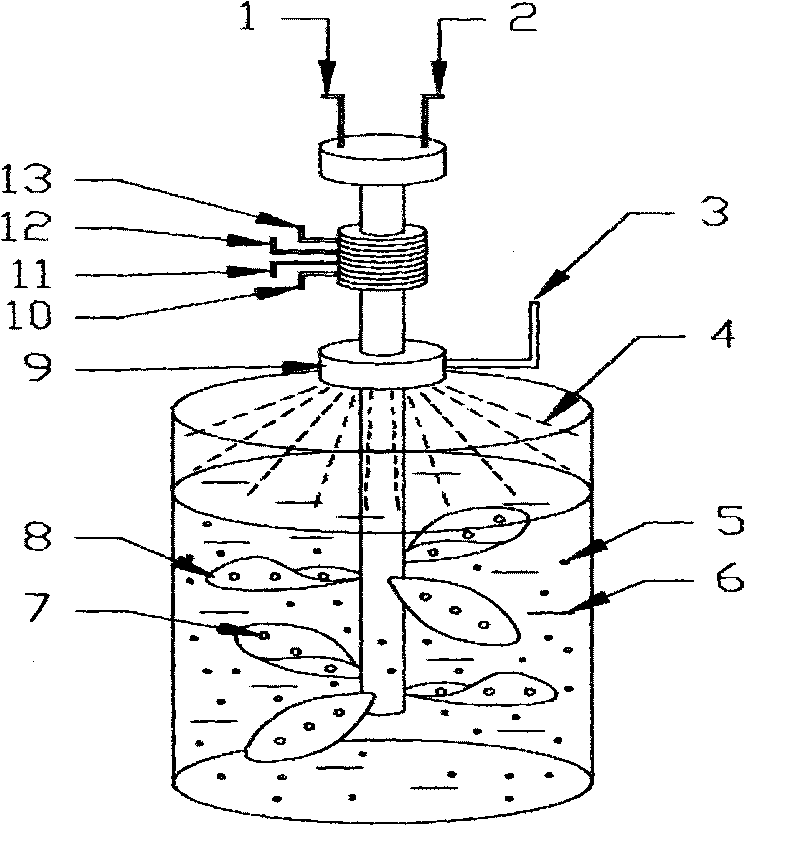

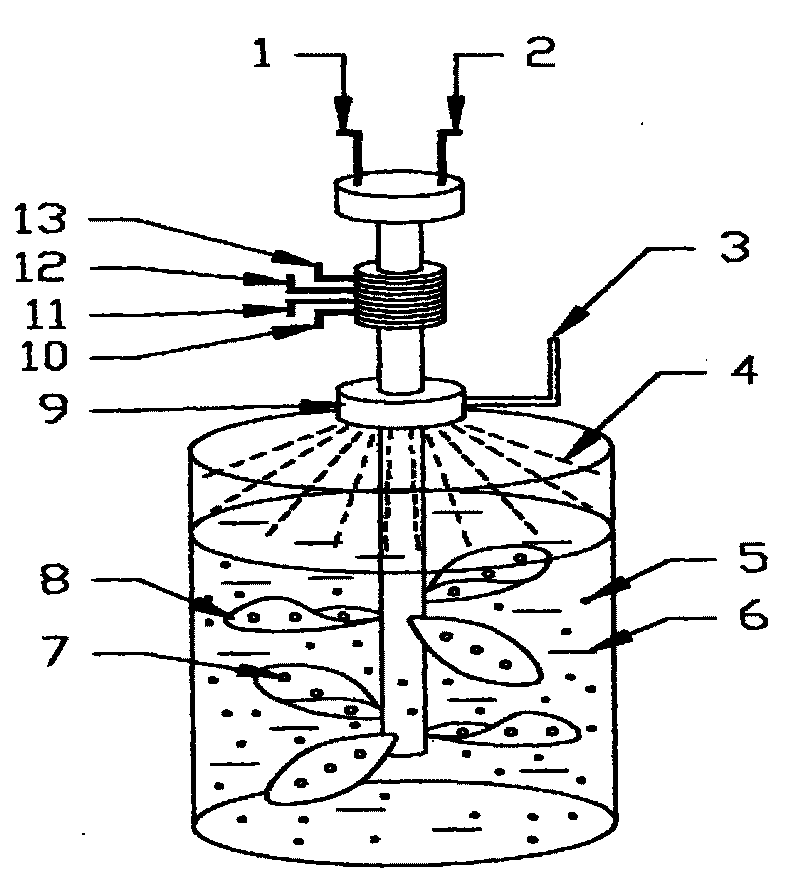

Preparation method of electroplating diamond fret saw

The invention relates to a preparation method of an electroplating diamond fret saw, comprising the following technological processes: 1. roughening processing is carried out to micrometer diamond particles in advance, nanometer diamond powder is added in cationic surface active agents according to the proportion of 1 : 3 by mass ratio, so as to prepare uniform and stable nanometer diamond powder suspending liquid, plating solution is arranged in an electroplating tank, after the weighted nanometer diamond powder suspending liquid is mixed with the micrometer diamond particles according to the proportion of 1 : 3 by mass ratio, and then the mixture is added in the plating solution, the plating solution is circulated continuously, and nickel aminosulfonate is main material in the plating liquid, and boracic acid and nickel chloride are additionally added, and a magnetic stirring device is arranged in the electroplating tank; 2. a steel wire continuously and uniformly passes through the electroplating tank, under the action of electrical current, nickel ions move to cathode from anode, so as to drive the nanometer diamond powder and the micrometer diamond particles to move to the steel wire, so as to lead the steel wire to be plated with the nanometer diamond powder and the micrometer diamond particles, meanwhile, chemical nickel-plating is carried out to the steel wire; 3. after the steel wire is separated from the electroplating tank, wires are wound up after being cleaned and dried. The method can continuously and quickly produce electroplating diamond fret saw, and the production efficiency is high.

Owner:JIANGSU FUNLIN SUPER HARD TOOLS

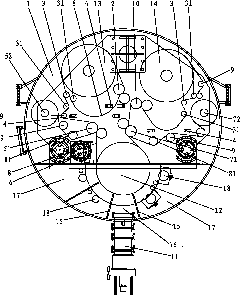

Winding-type vacuum coater

InactiveCN101798681AUniform platingConstant surface tensionVacuum evaporation coatingSputtering coatingEngineeringDrive motor

The invention relates to a winding-type vacuum coater which comprises a vacuum cavity, wherein the vacuum cavity is provided with an unwinding device, a coating chamber and a winding device; the coating chamber is provided with a coating roller connected with the output shaft of a drive motor; the unwinding device comprises an unwinding roller and an active feed rolling wheel pair; a tension release roller is arranged between the active feed rolling wheel pair and the coating roller and used for keeping the loose state of the material roll between the feed rolling wheel pair and the tension release roller; the winding device comprises an active winding roller; a feed rolling wheel pair is arranged between the coating roller and the winding roller; and a tension release roller is arranged between the feed rolling wheel pair and the winding roller. Since the material is kept loose between the feed rolling wheel pair and the tension release roller, the tension change of the unwinding roller and the winding roller due to the gradual change of the material roll diameter can not be transferred to the coating roller, thus, the surface tension of the coated material winding the coating roller is constant, so that the film is uniformly coated with favorable effect.

Owner:袁惠芬

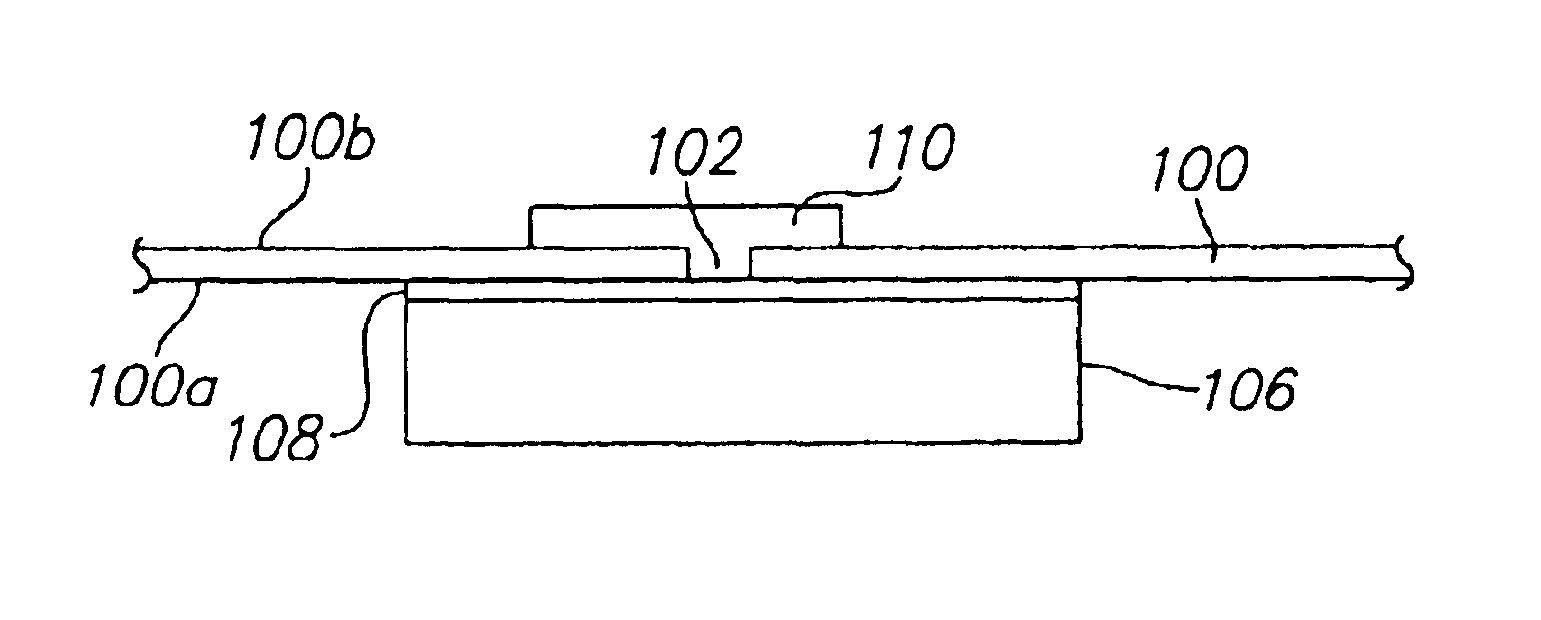

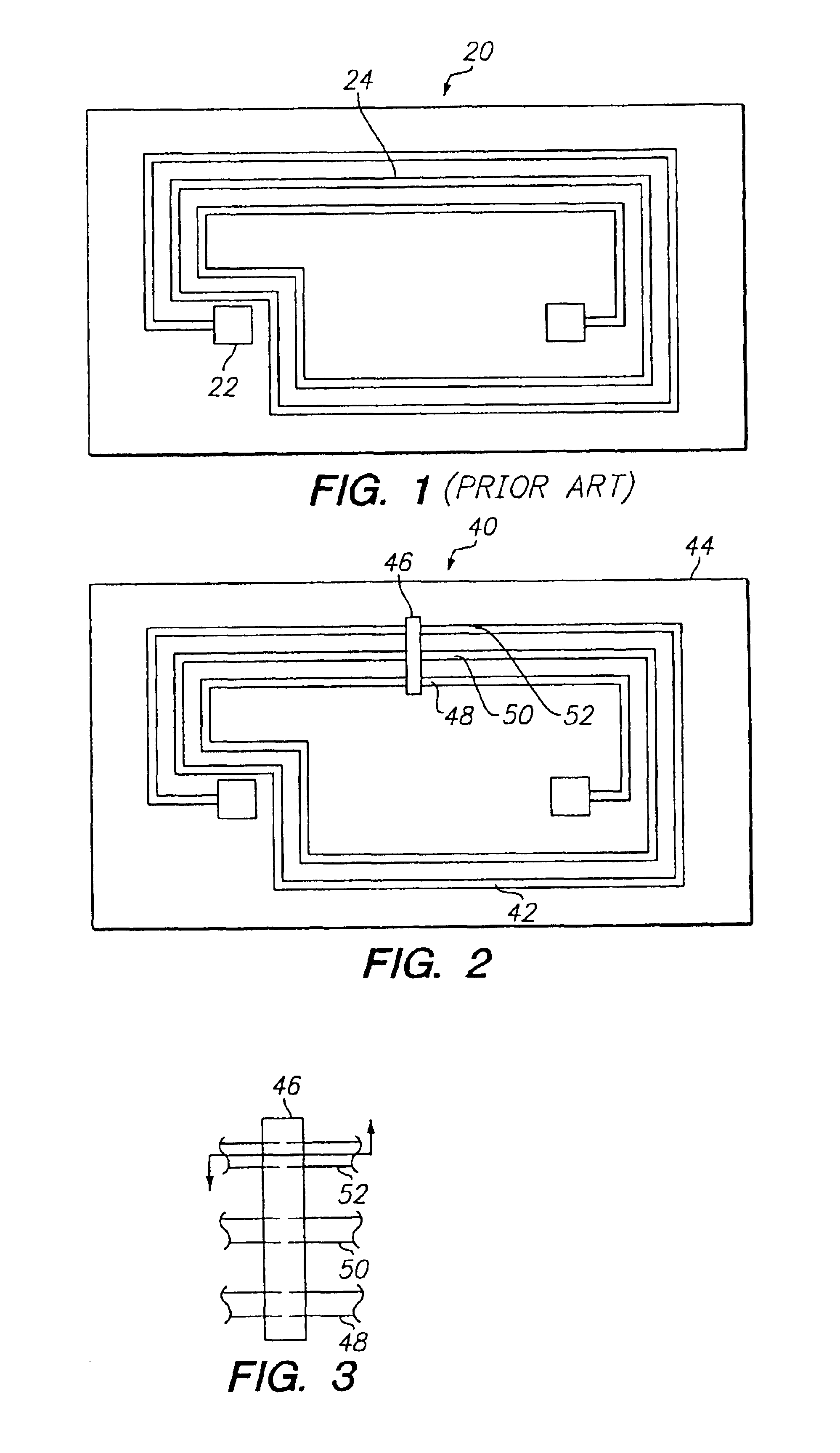

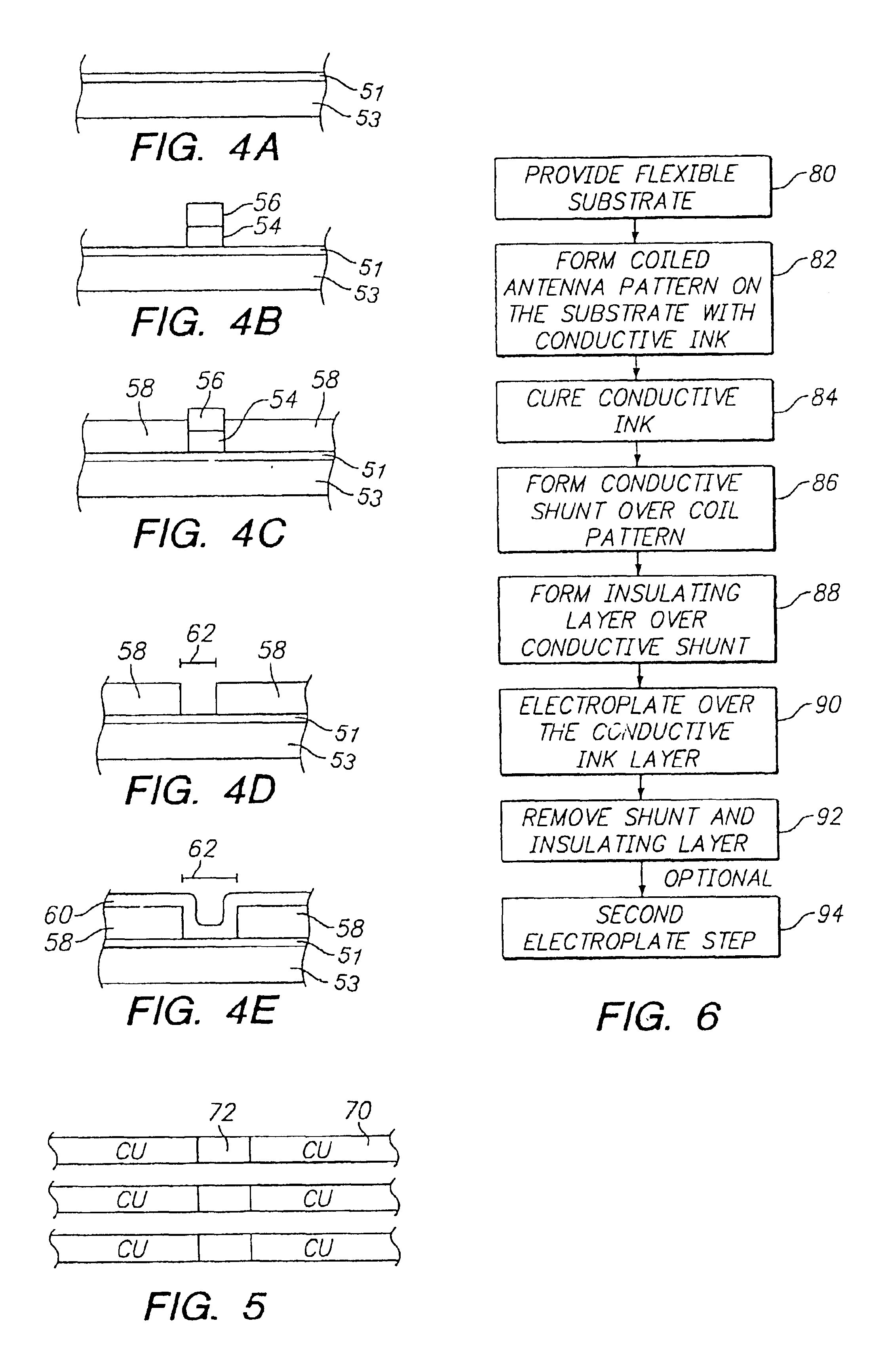

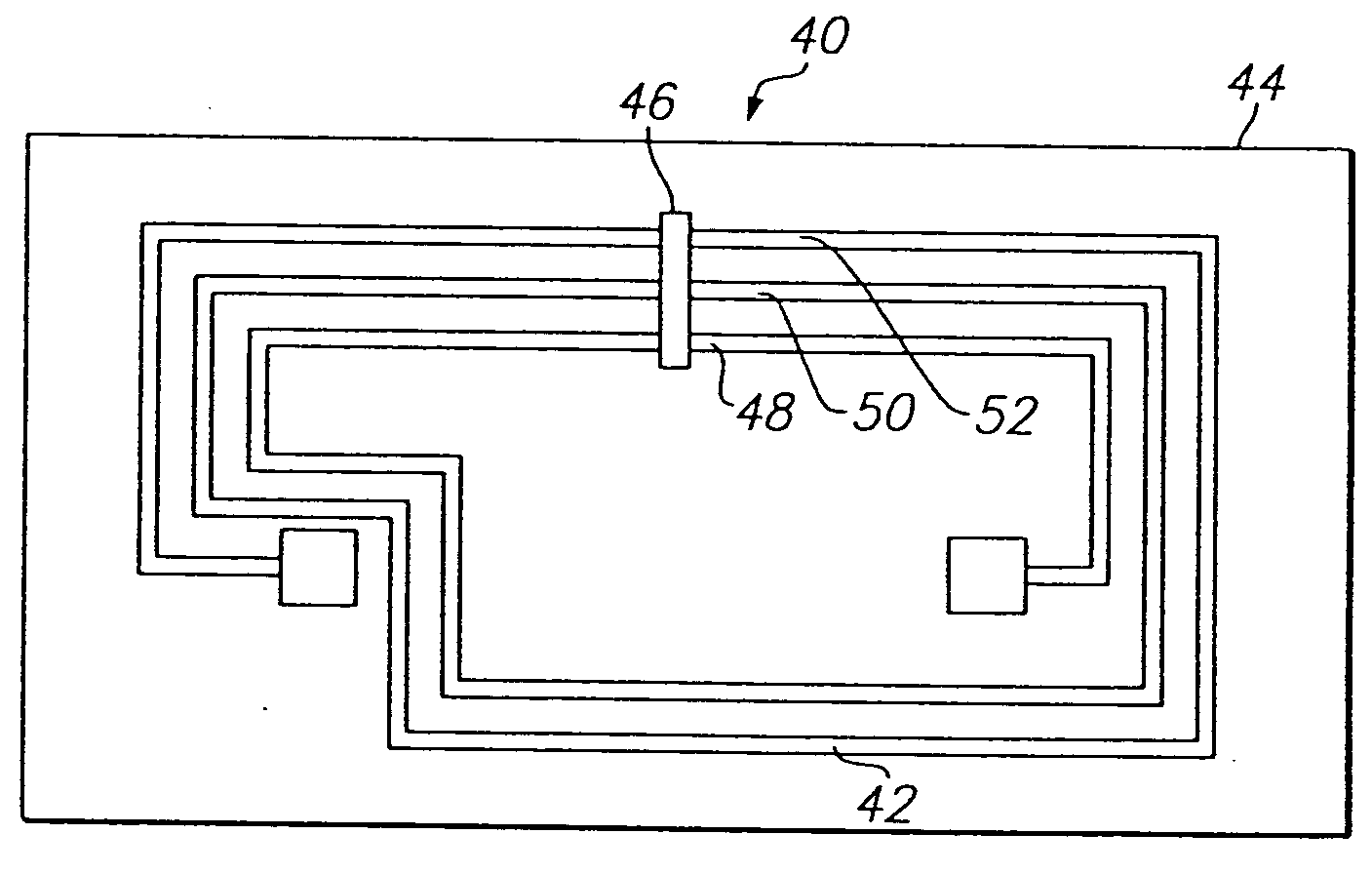

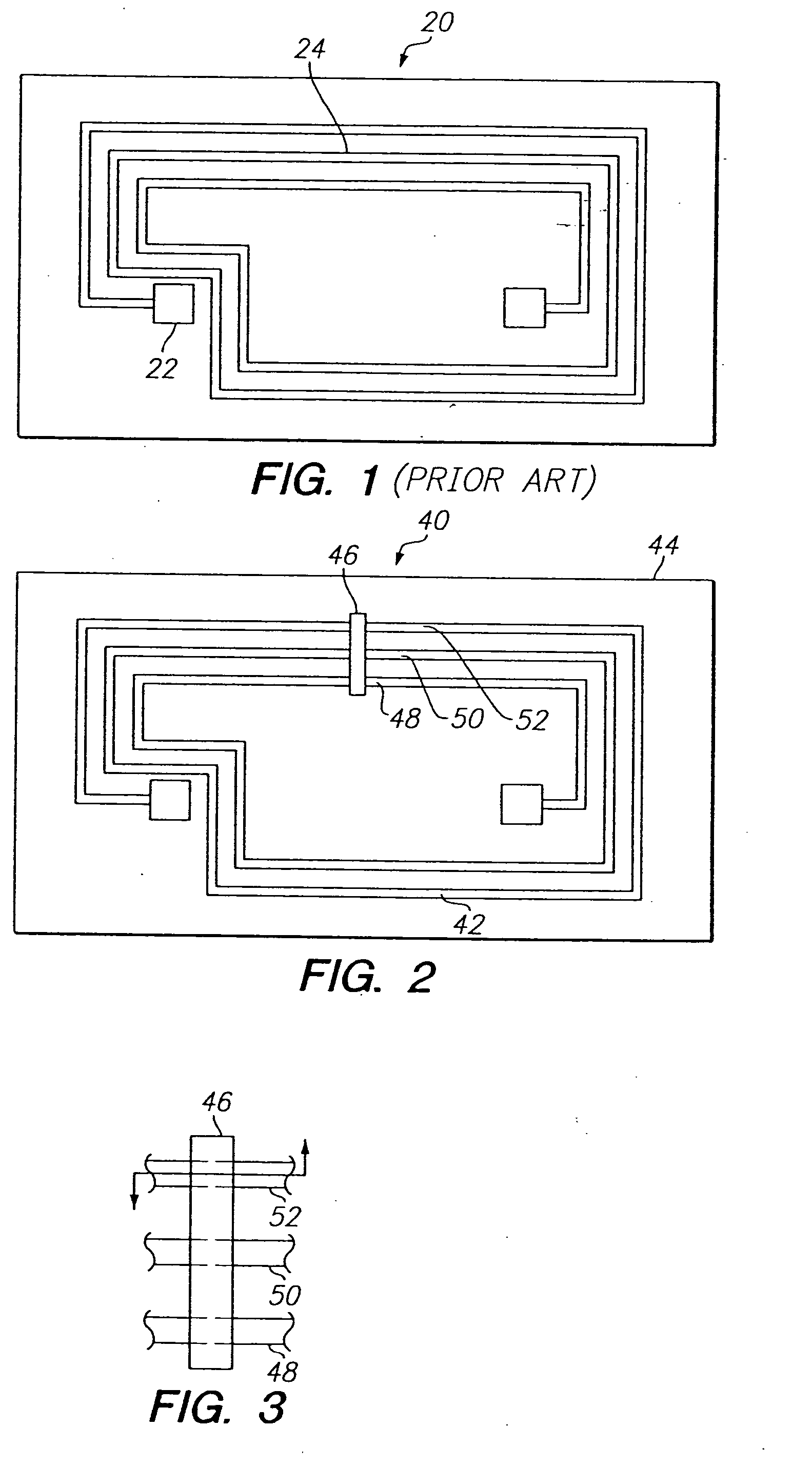

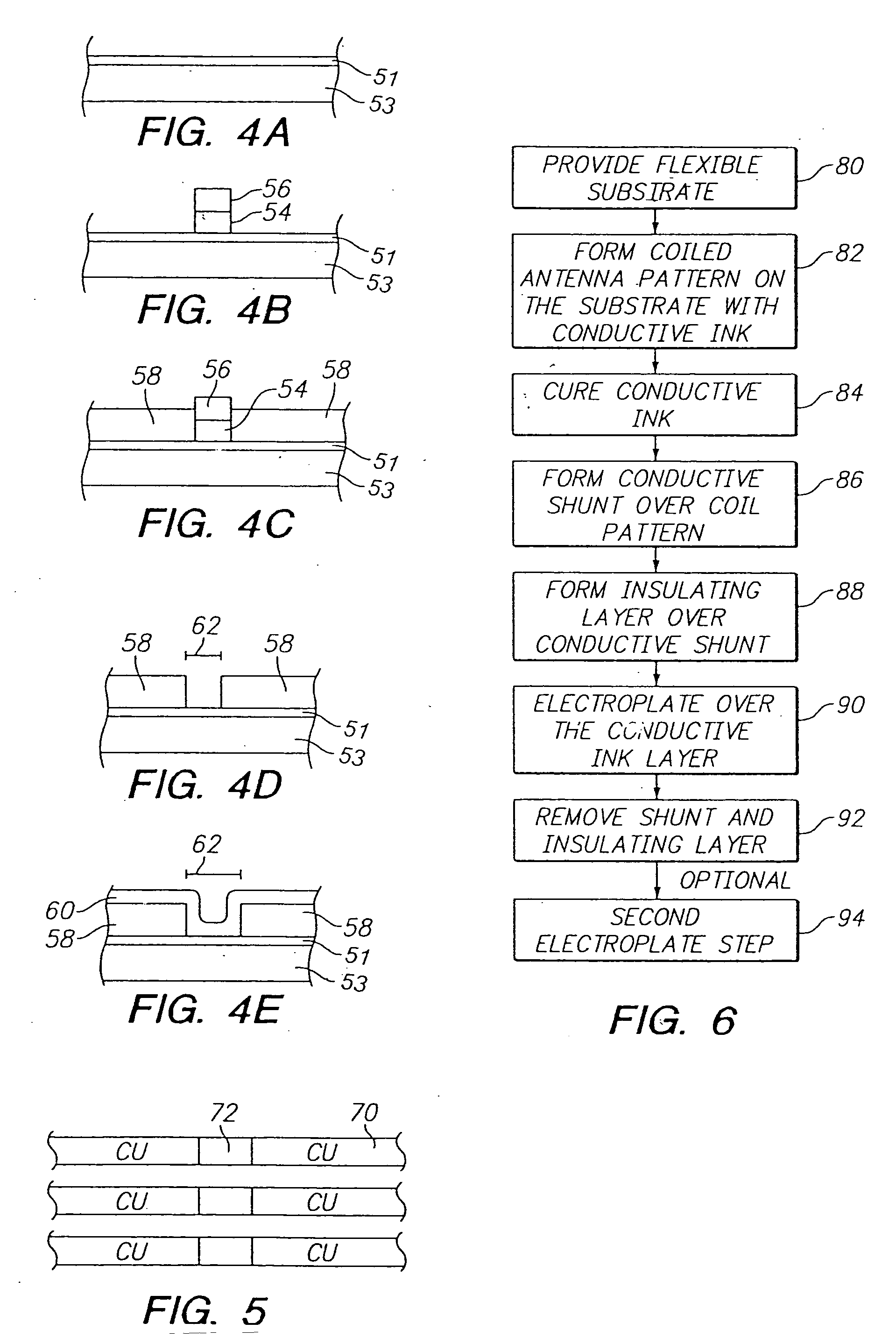

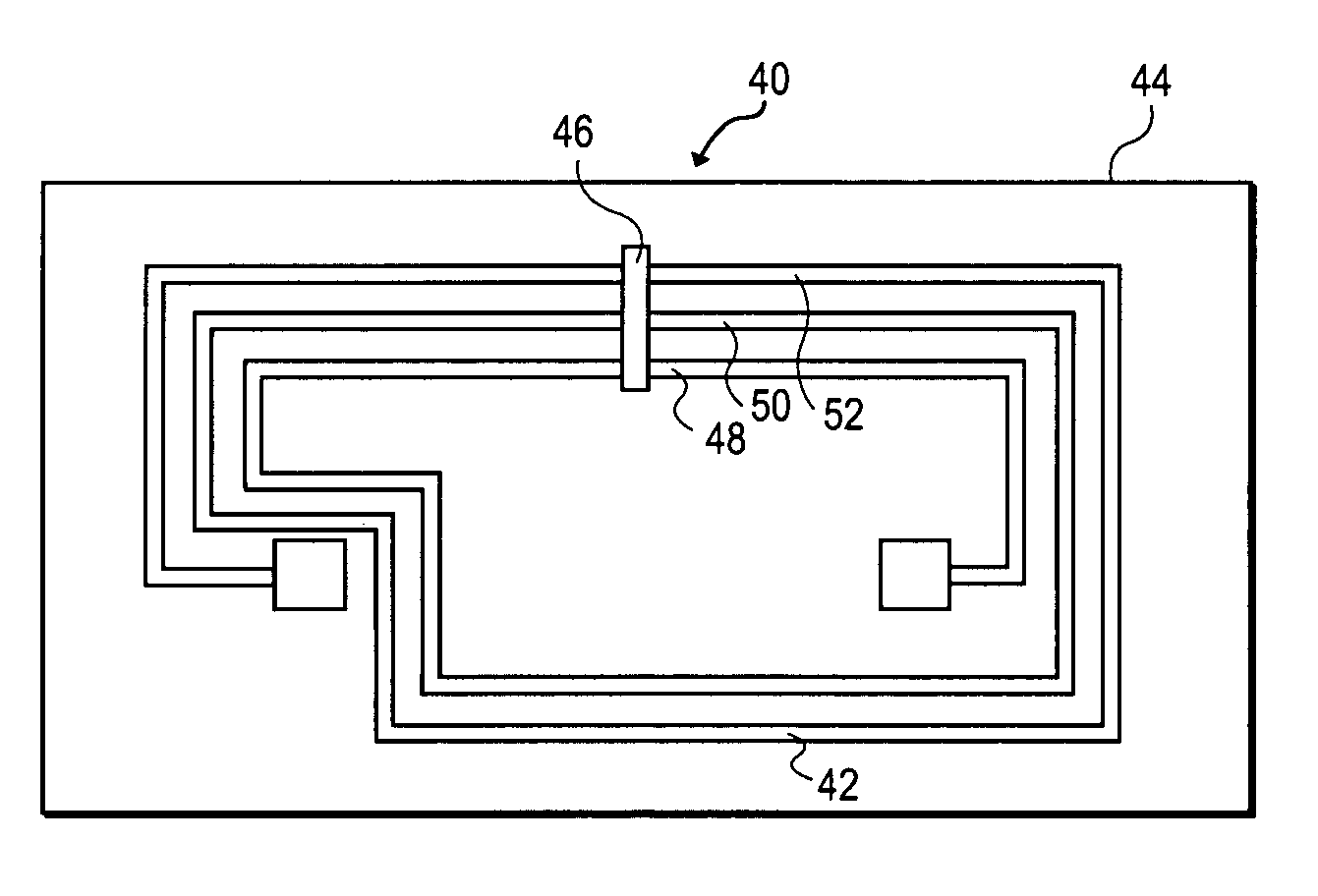

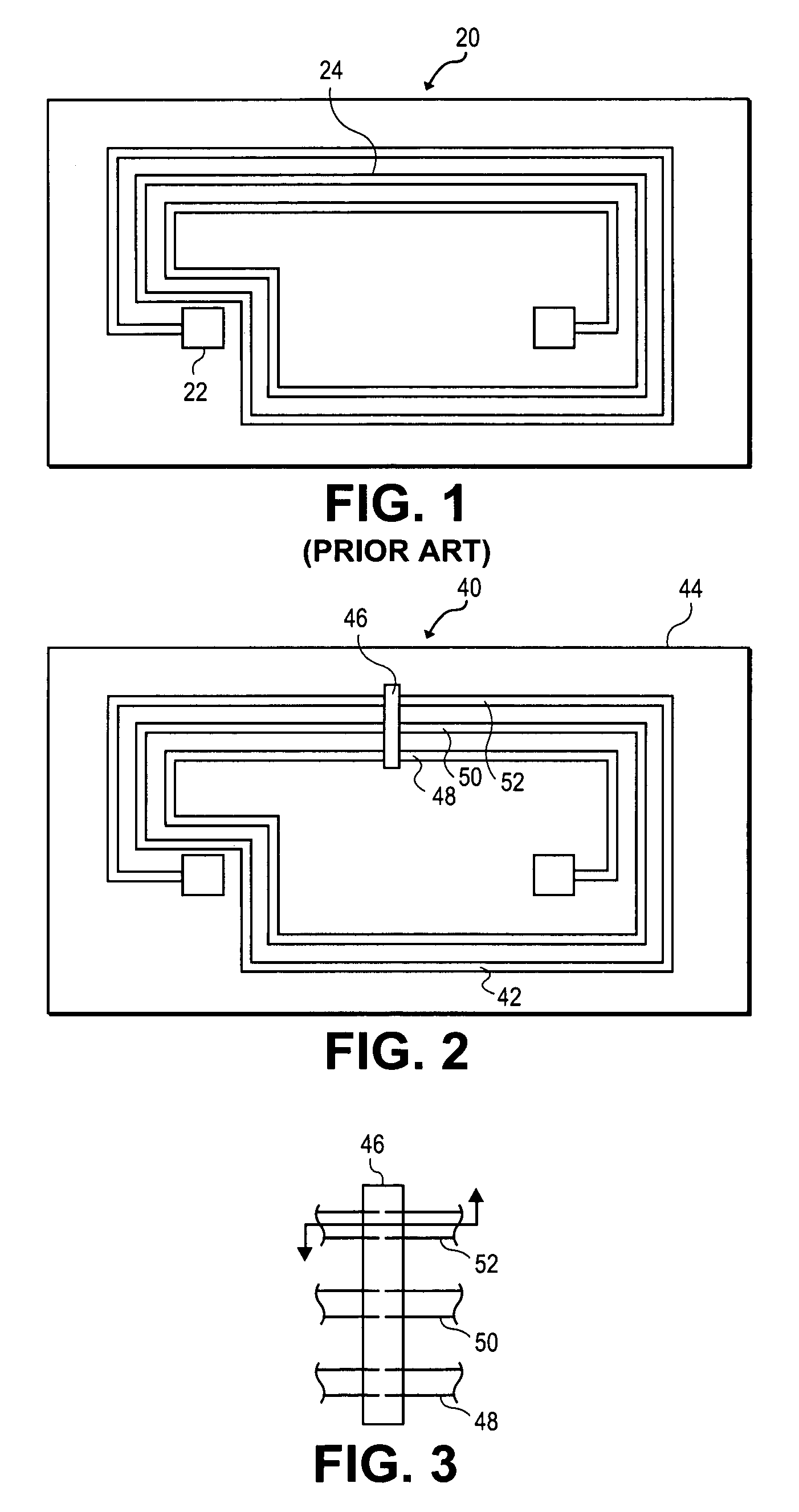

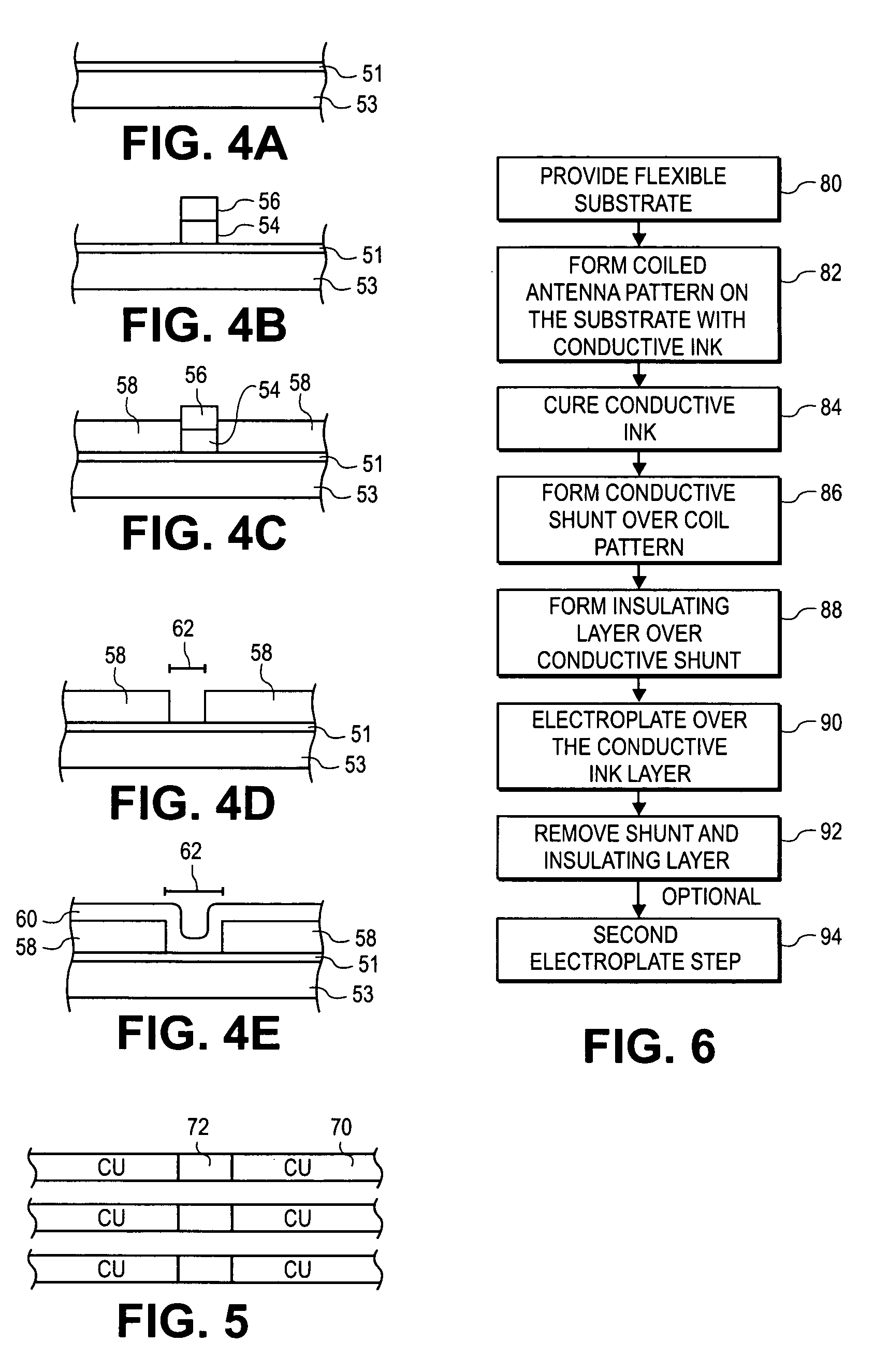

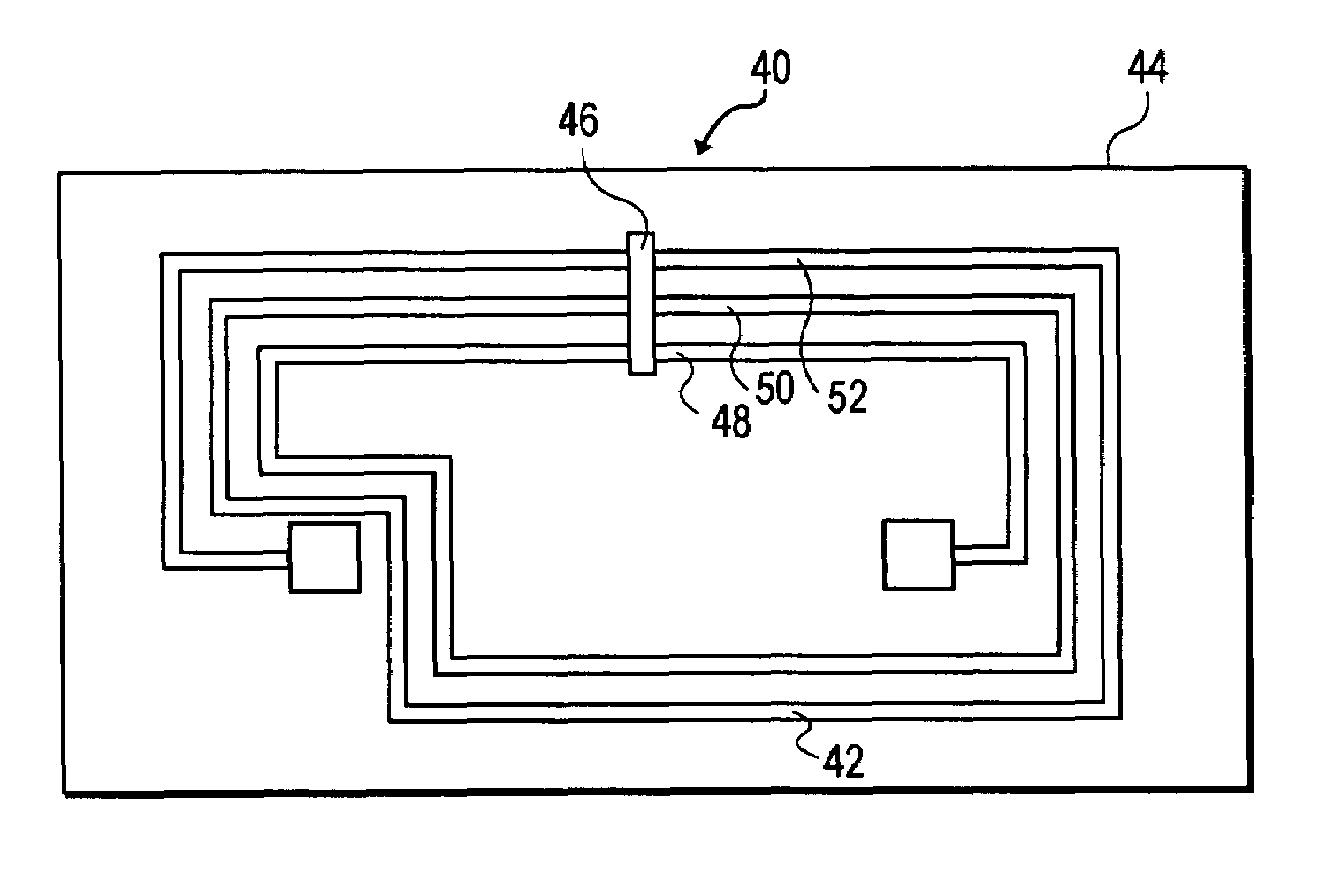

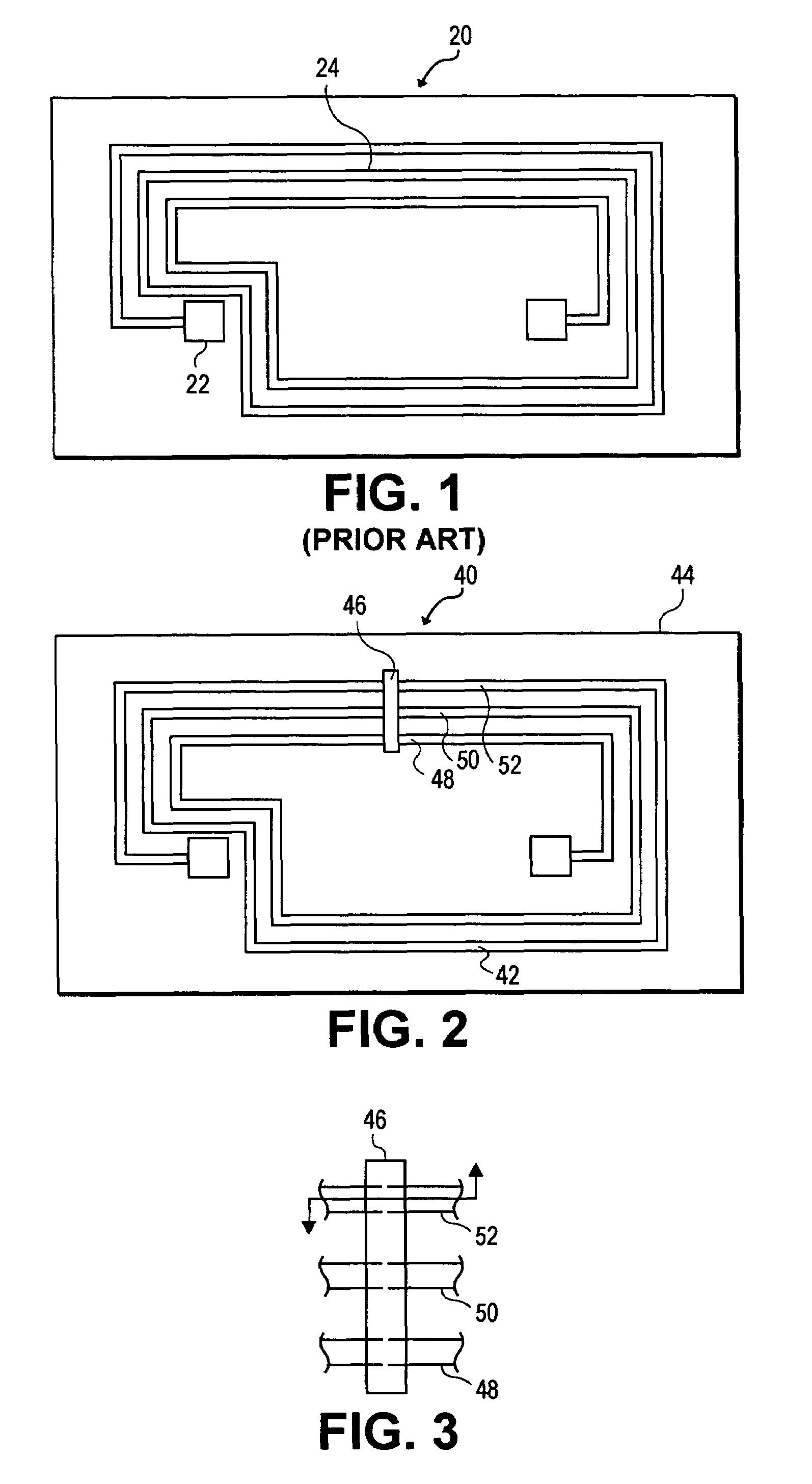

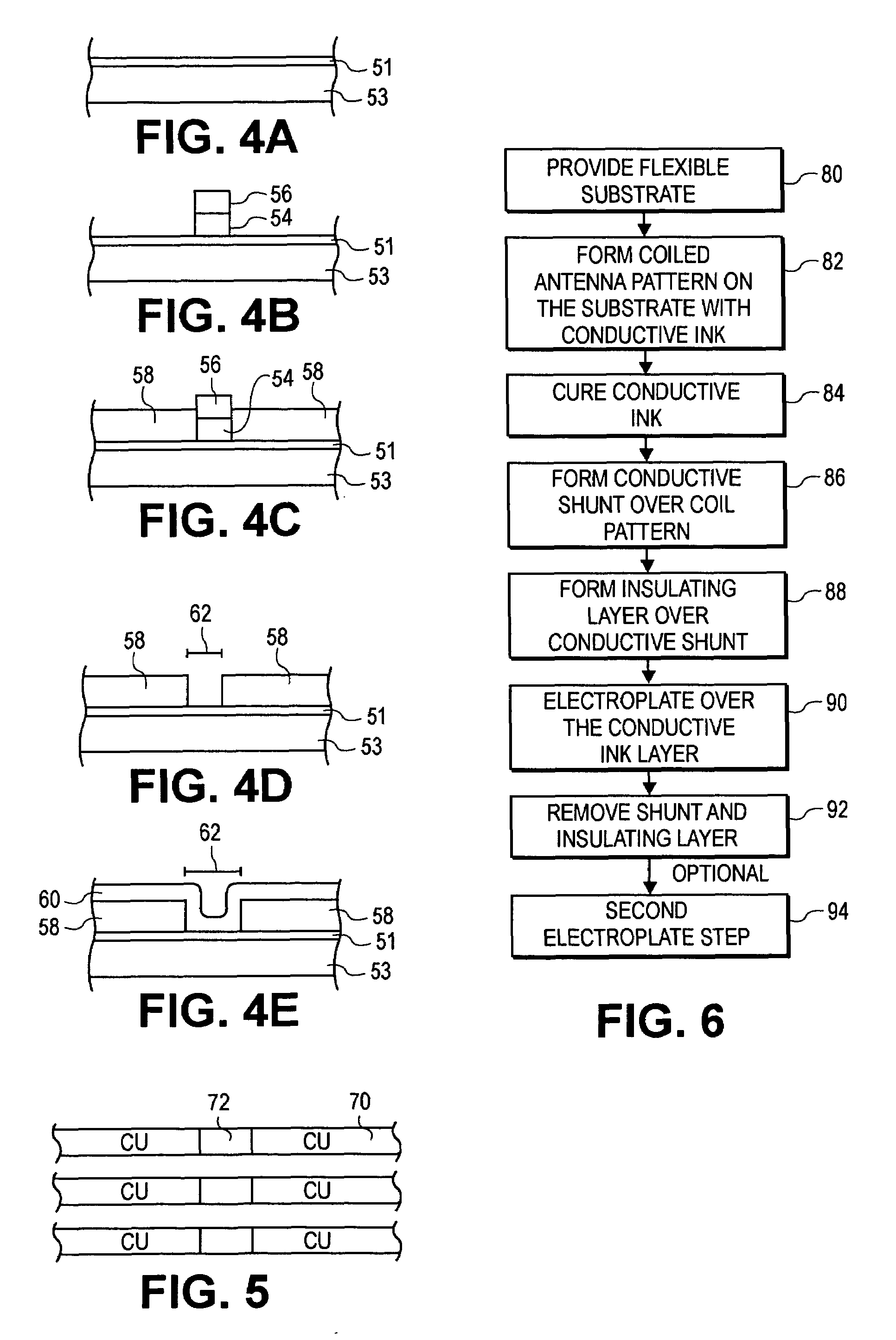

Method for forming radio frequency antenna

InactiveUS6933892B2Uniform platingResistanceSimultaneous aerial operationsAntenna supports/mountingsRadio frequencyElectroplating

A metalized circuit suitable for application as a radio frequency antenna is produced by forming an antenna coil pattern on a flexible substrate. The antenna coil pattern is formed using a conductive ink which is patterned on the substrate. The conductive ink is cured and an electrical-short layer is formed across the coils of the conductive ink pattern. An insulating layer is formed over top of the electrical-short layer, a metal layer electroplated on top of the conductive layer, and then the electrical-short layer is removed. The use of the electrical-short layer during the electroplating allows for the voltage at the different points on the conductive ink layer to be relatively similar, so that a uniform electroplate layer is formed on top of the conductive ink layer. This results in a better quality radio frequency antenna at a reduced cost.

Owner:RCD TECHNOLOGY

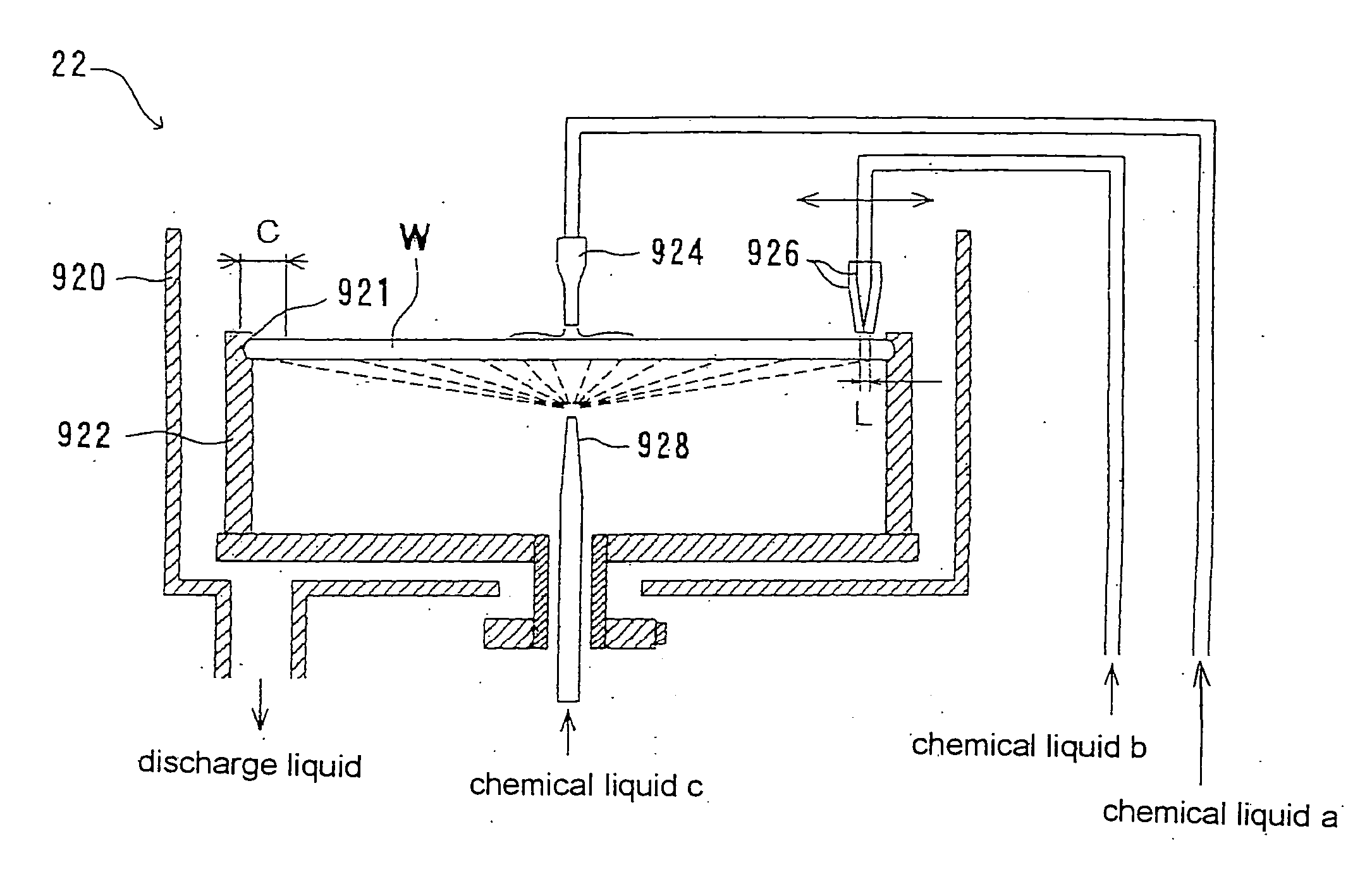

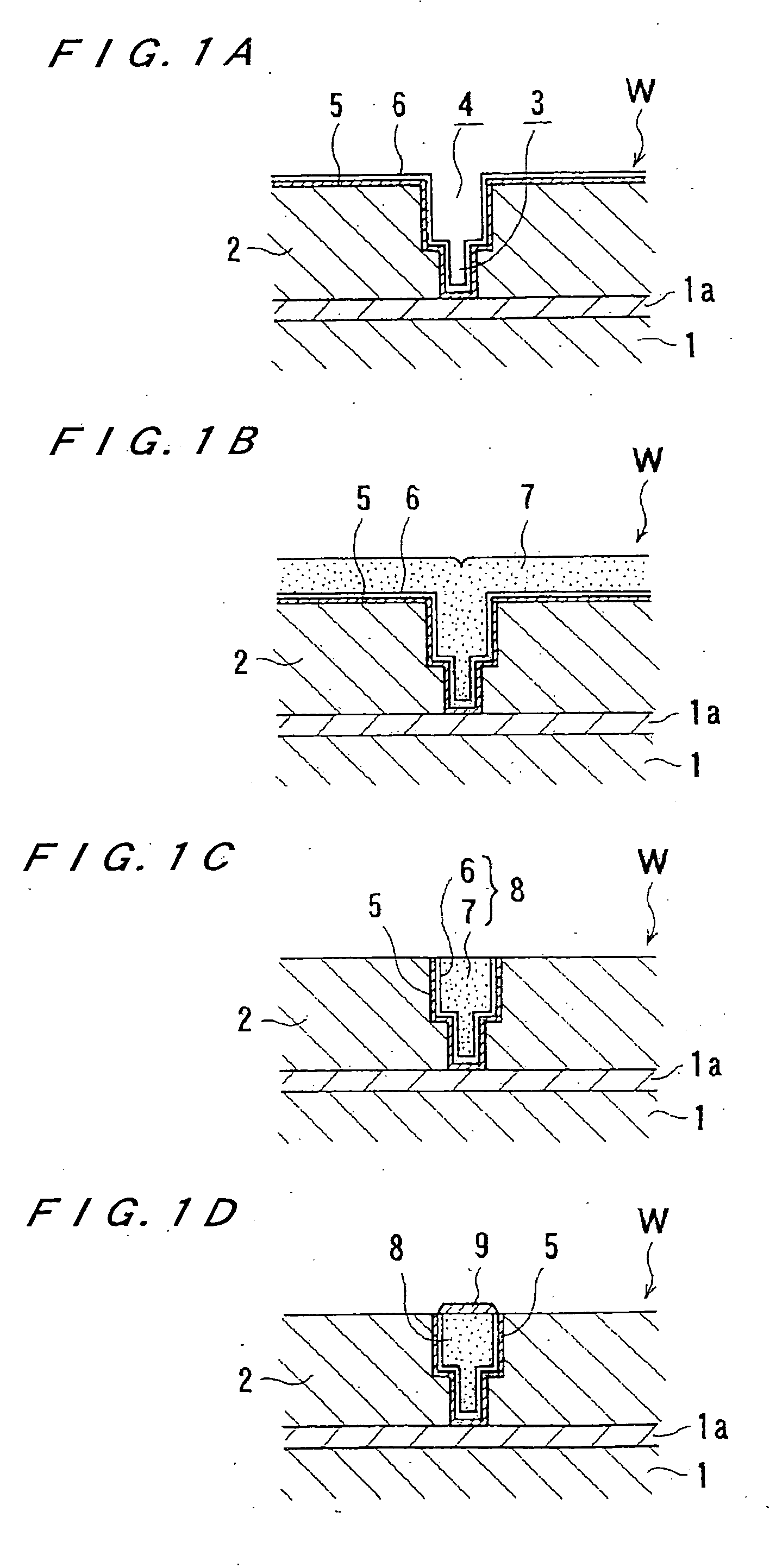

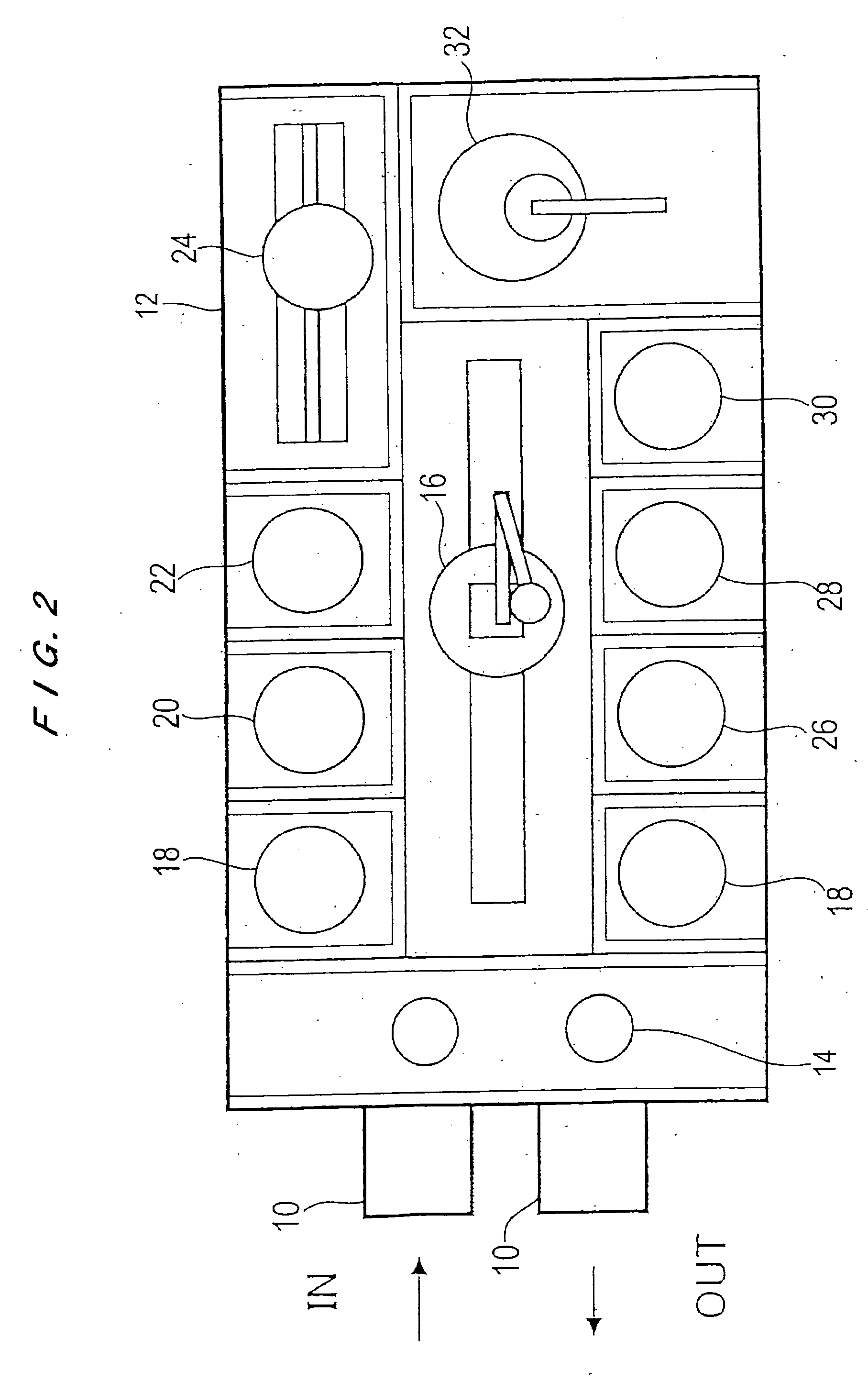

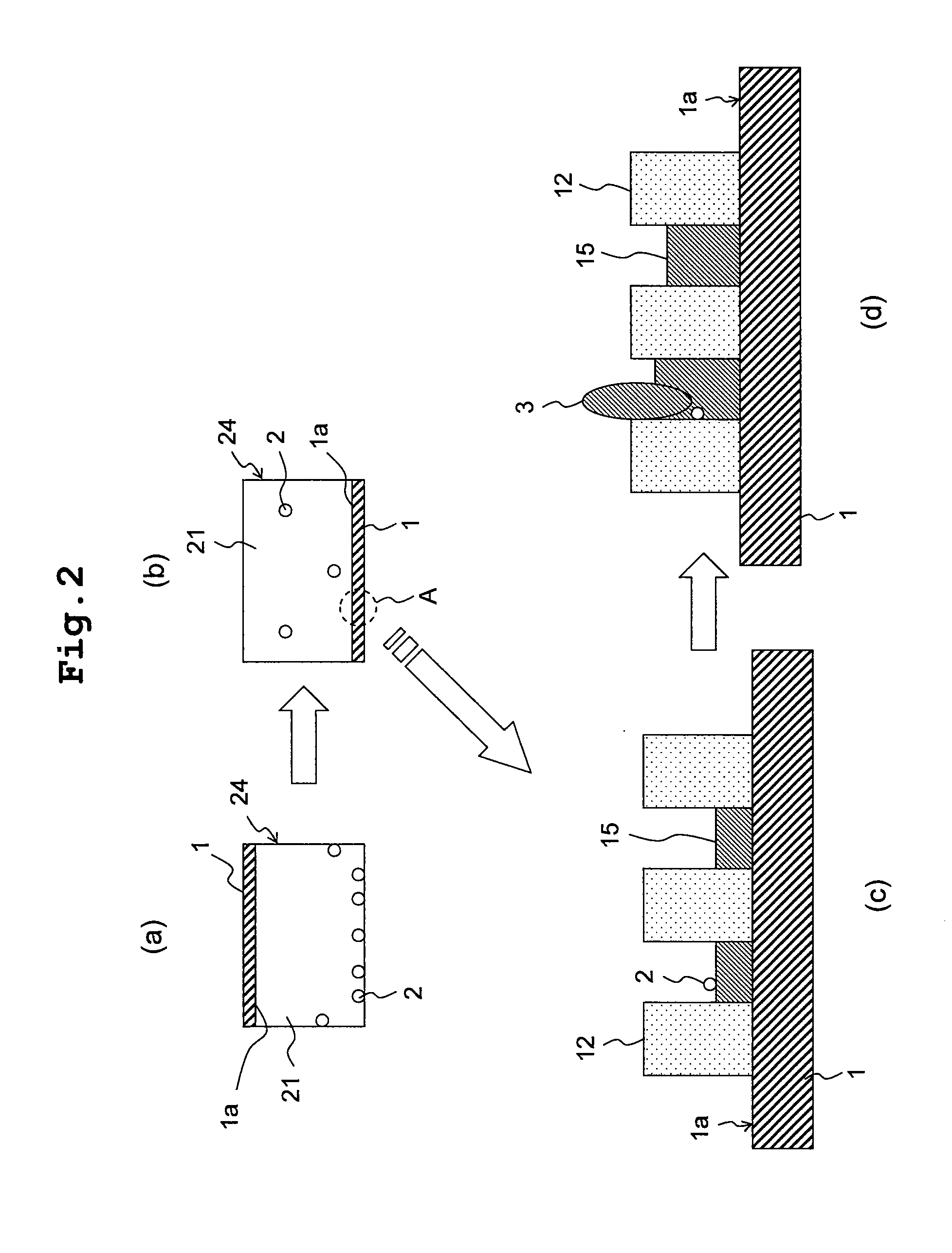

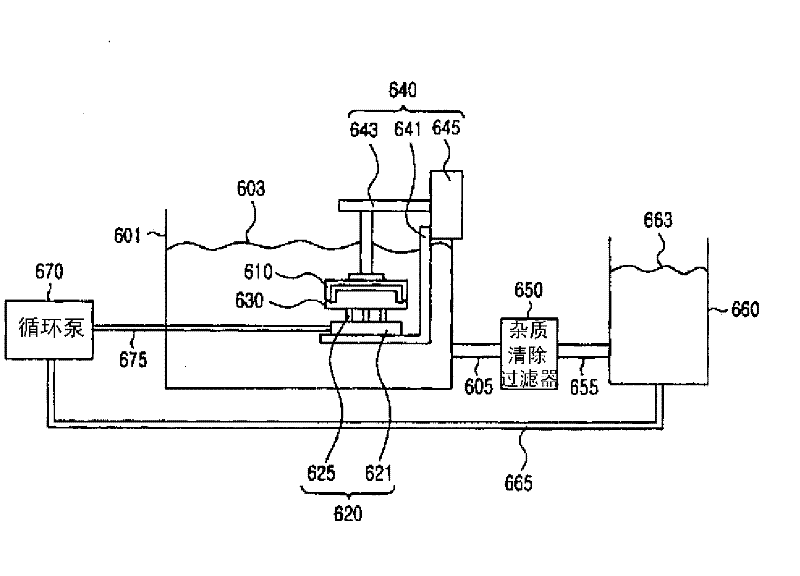

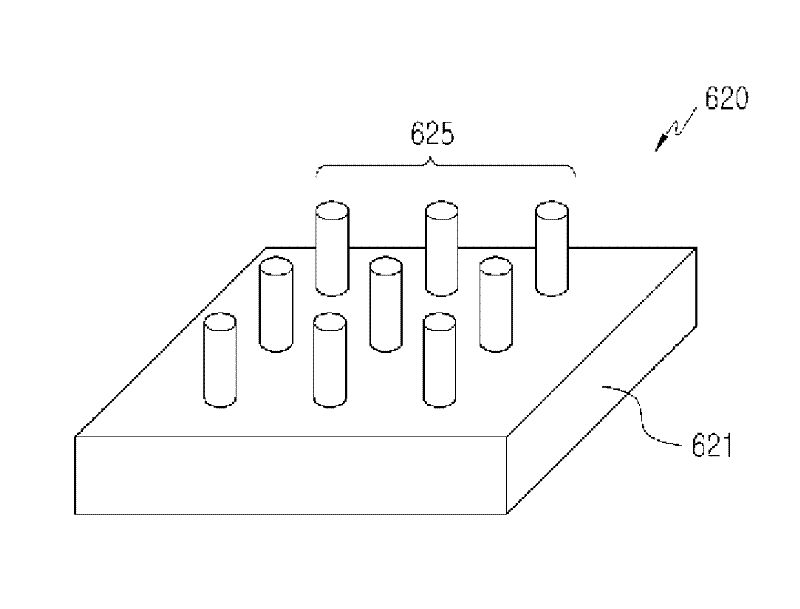

Plating device and planting method

InactiveUS20060113192A1Good reproducibilityTime of increase and decreaseCellsSemiconductor/solid-state device manufacturingCopperMaterials science

According to the present invention, there is provided a plating apparatus which can deposit a metal plated film such as a copper layer selectively in fine recesses for interconnects, such as trenches or via holes in a circuit form. The plating apparatus of the present invention includes an electrode head (701) having an anode (704), a plating solution impregnated material (703) for holding a plating solution, and a porous contact member (702) which is brought into contact with a surface of a substrate; a cathode electrode (712) which is brought into contact with the substrate to supply current to the substrate; a pressing mechanism (709) for pressing the porous contact member of the electrode head against the surface of the substrate under a desired pressure; a power source (723) for applying plating voltage between the anode and the cathode electrode; and a control unit (721) for correlating and controlling the state for pressing the porous contact member of the electrode head against the surface of the substrate, and the state of plating voltage applied between the anode and the cathode electrode.

Owner:IBM CORP +1

Method for forming radio frequency antenna

InactiveUS20050078035A1Uniform platingResistanceAntenna arraysSimultaneous aerial operationsRadio frequencyElectroplating

A metalized circuit suitable for application as a radio frequency antenna is produced by forming an antenna coil pattern on a flexible substrate. The antenna coil pattern is formed using a conductive ink which is patterned on the substrate. The conductive ink is cured and an electrical-short layer is formed across the coils of the conductive ink pattern. An insulating layer is formed over top of the electrical-short layer, a metal layer electroplated on top of the conductive layer, and then the electrical-short layer is removed. The use of the electrical-short layer during the electroplating allows for the voltage at the different points on the conductive ink layer to be relatively similar, so that a uniform electroplate layer is formed on top of the conductive ink layer. This results in a better quality radio frequency antenna at a reduced cost.

Owner:SQUARE 1 BANK

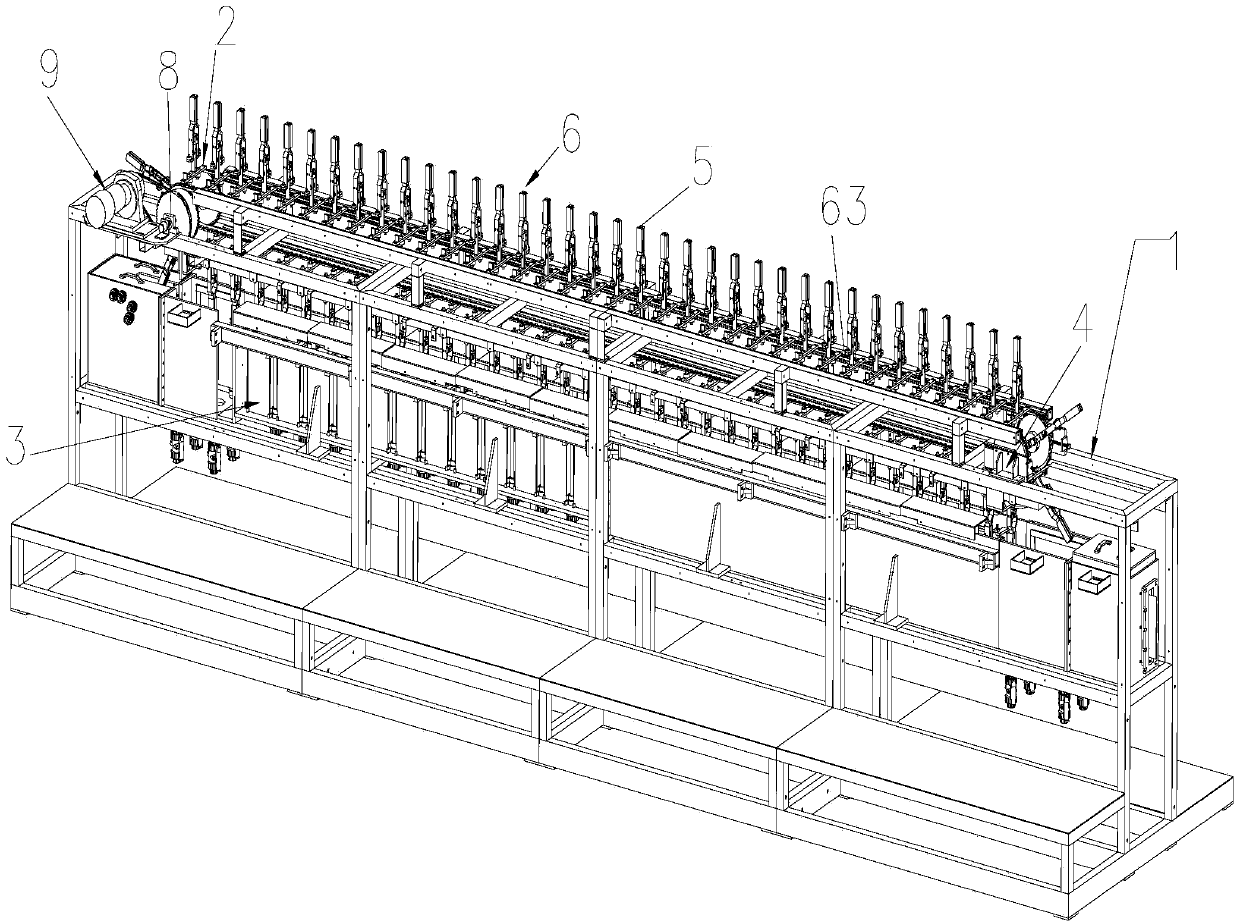

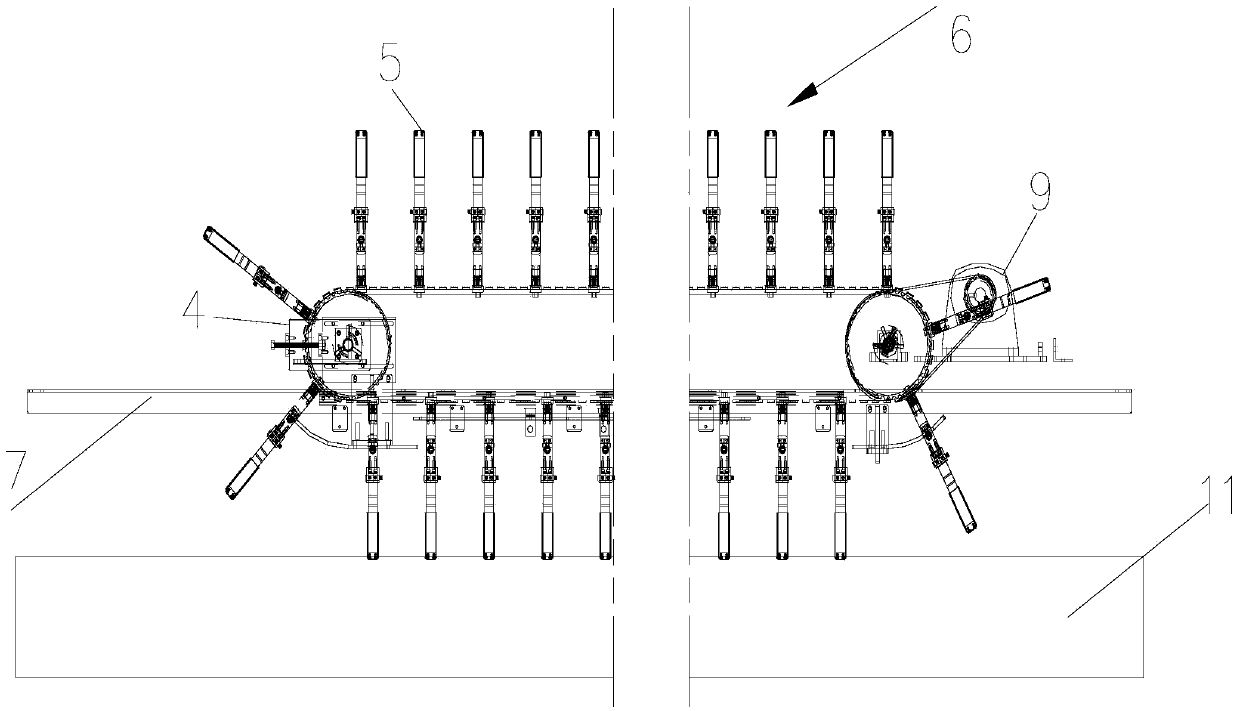

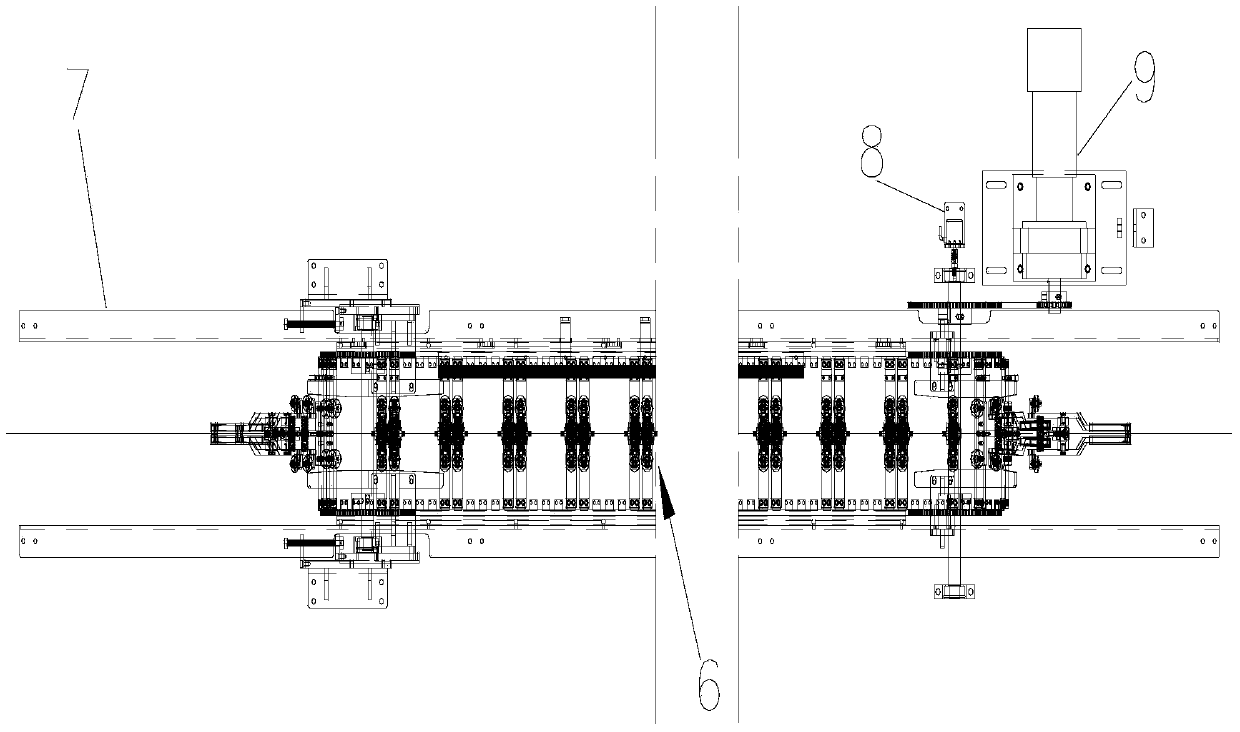

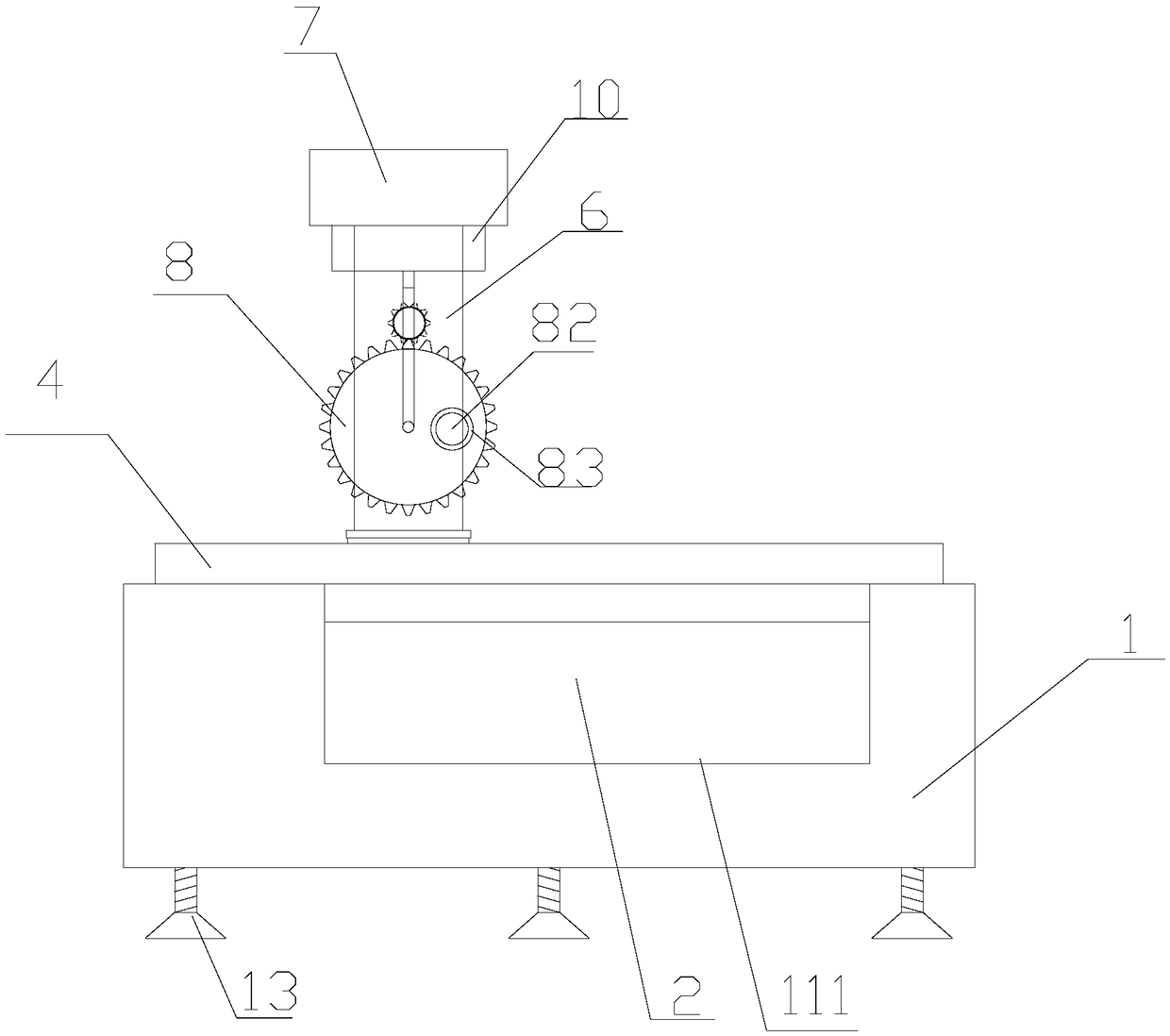

Automatic vertical continuous electroplating line main transmission device

An automatic vertical continuous electroplating line main transmission device is composed of a power supply, a chain-wheel transmission mechanism, and a plurality of electroplating clamps; wherein the chain-wheel transmission mechanism is a horizontal circular transmission mechanism which is composed of a group of chain wheels taken as the driving wheels, a group of chain wheels taken as the driven wheels, and a transmission chain driven by the chain wheels; and the electroplating clamps are alternately arranged on the transmission chain and circularly move along with the transmission chain in a vertical plane. The main transmission device is simple in structure, and the equipment width of the device can be largely reduced. The device can be used to carry out substrate electroplating, the electroplated substrate is more uniform, furthermore, the wrinkle happening rate is reduced, so the device is suitable for electroplating thinner substrates.

Owner:GREAT CHIEFTAIN ELECTRONICS MACHINERY

Aluminium-based light-type grid for plumbic acid cells and preparation method thereof

InactiveCN102315455AIncrease profitIncrease specific energyElectrode melt handlingElectrode carriers/collectorsChemical platingInternal resistance

The invention provides an aluminium-based light-type grid for plumbic acid cells and a preparation method thereof. The aluminium-based light-type grid comprises an open-cell porous aluminum or aluminium alloy (Al-Me) matrix with high specific surface area and a lead or lead alloy (Pb-Me') protective layer. The preparation technological flow of the protective layer mainly comprises four operationsof pretreatment, chemical plating of molten salt, metal bath and heat treatment. In comparison with traditional lead and lead alloy grids, the aluminium-based light-type grid prepared in the invention has high mechanical strength, good conductivity, large specific surface area, light weight and the like, and is used for positive and negative electrodes in plumbic acid cells so as to greatly reduce the weight of plumbic acid cells, improve the active substance utilization rate, specific energy, cycle life and seismic performance of plumbic acid cells, and minimize the internal resistance of cells. The preparation method provided by the invention is suitable for industrial application.

Owner:长沙灿能能源科技有限公司 +1

Method for forming radio frequency antenna

InactiveUS7298331B2ResistanceUniform platingSimultaneous aerial operationsPrinted circuit aspectsRadio frequencyElectroplating

A metalized circuit suitable for application as a radio frequency antenna is produced by forming an antenna coil pattern on a flexible substrate. The antenna coil pattern is formed using a conductive ink which is patterned on the substrate. The conductive ink is cured and an electrical-short layer is formed across the coils of the conductive ink pattern. An insulating layer is formed over top of the electrical-short layer, a metal layer electroplated on top of the conductive layer, and then the electrical-short layer is removed. The use of the electrical-short layer during the electroplating allows for the voltage at the different points on the conductive ink layer to be relatively similar, so that a uniform electroplate layer is formed on top of the conductive ink layer. This results in a better quality radio frequency antenna at a reduced cost.

Owner:SQUARE 1 BANK

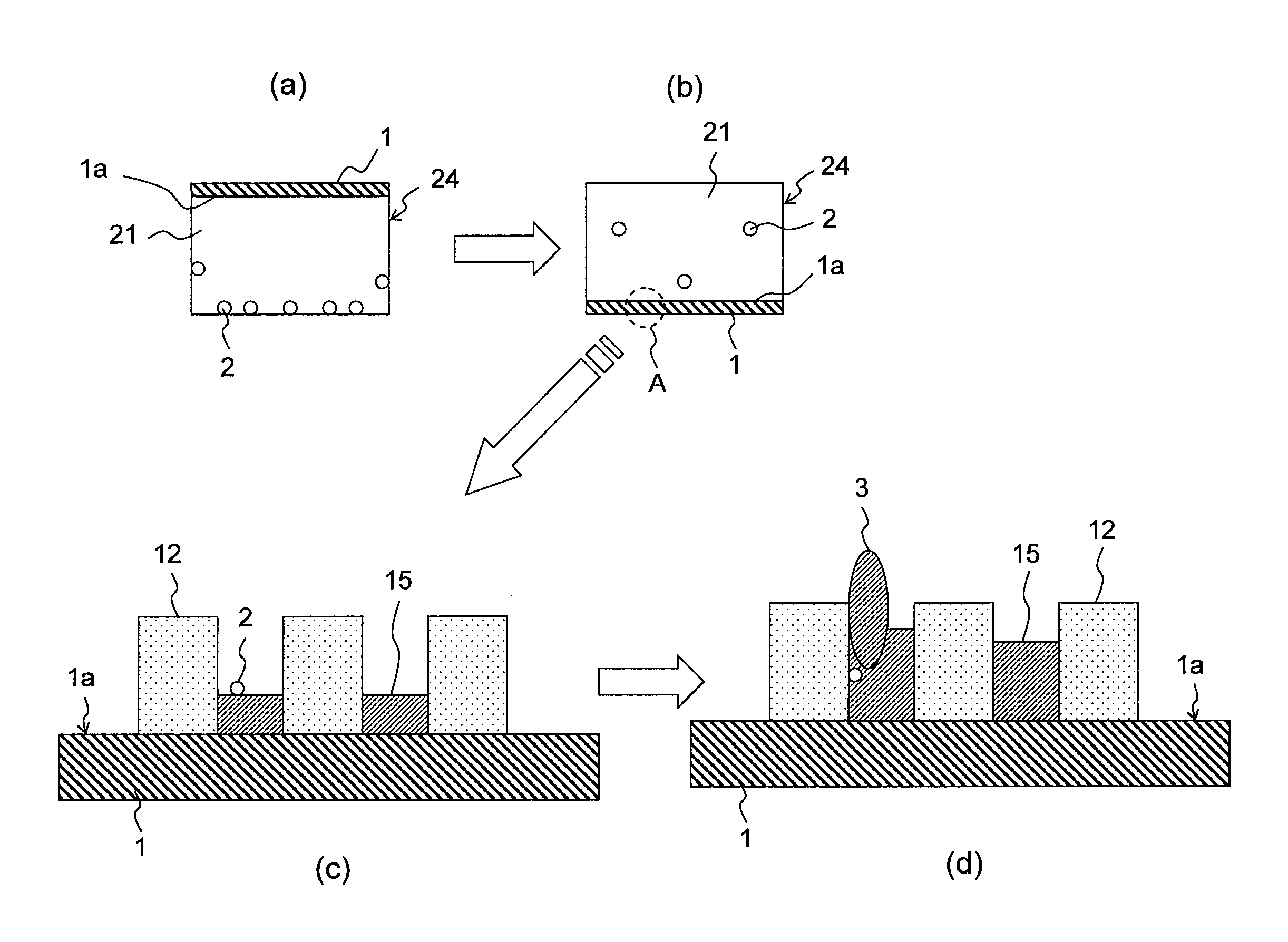

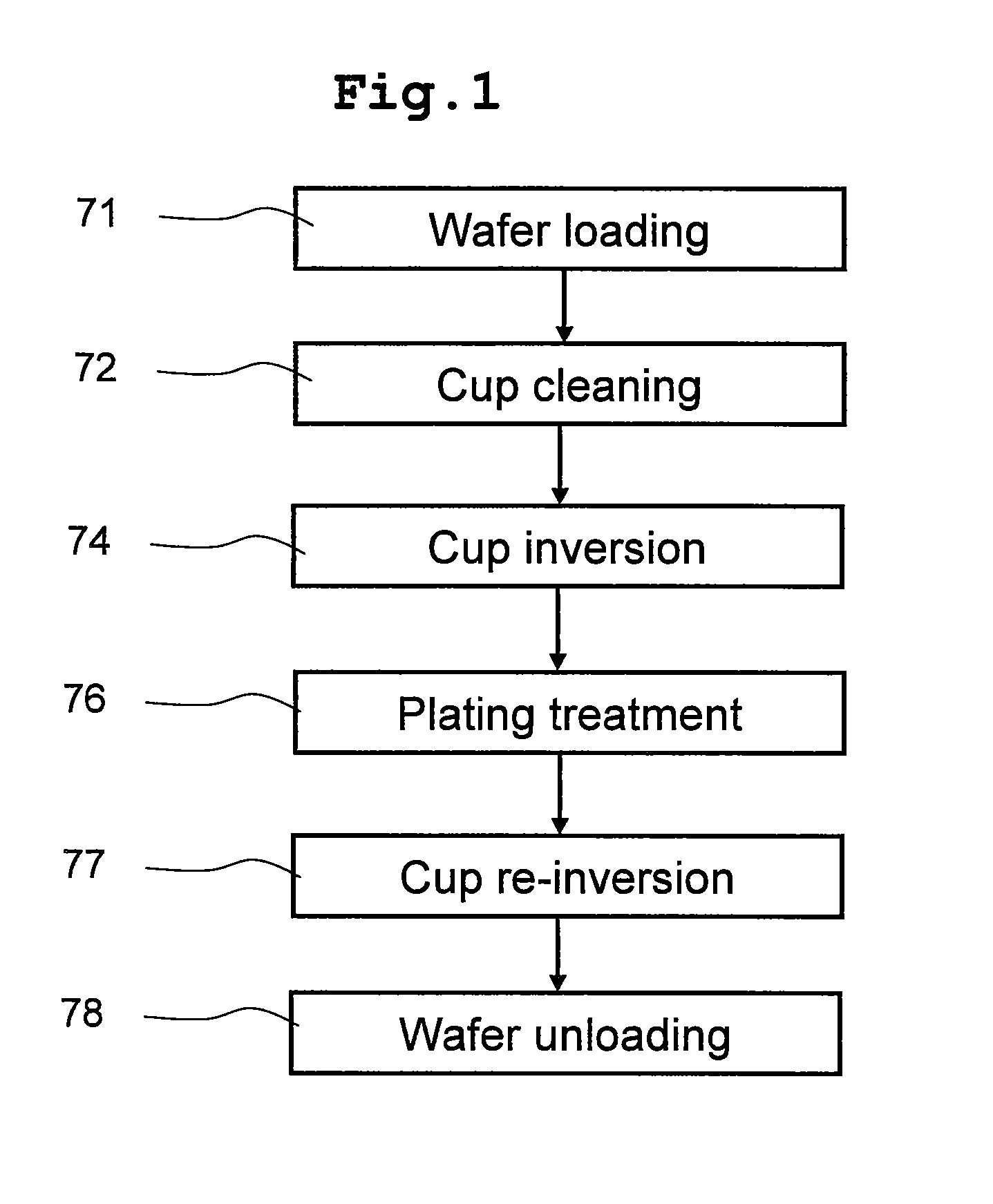

Manufacturing method of semiconductor integrated device

InactiveUS20090117730A1Avoid abnormal growthHighly uniform thicknessCellsAnodisationAbnormal growthsEngineering

Manufacture of semiconductor products such as LCD driver requires a bump plating step for forming a gold bump electrode having a size of from about 15 to 20 μm. This bump plating step is performed by electroplating with a predetermined plating solution, but projections intermittently appear on the bump electrode during a mass production process. In the invention, abnormal growth of projections over the gold bump electrode is prevented by adding, prior to the gold bump plating step, a step of circulating and stirring a plating solution while erecting a plating cup and efficiently dissolving / discharging a precipitate. This step is performed for each wafer to be treated.

Owner:RENESAS ELECTRONICS CORP

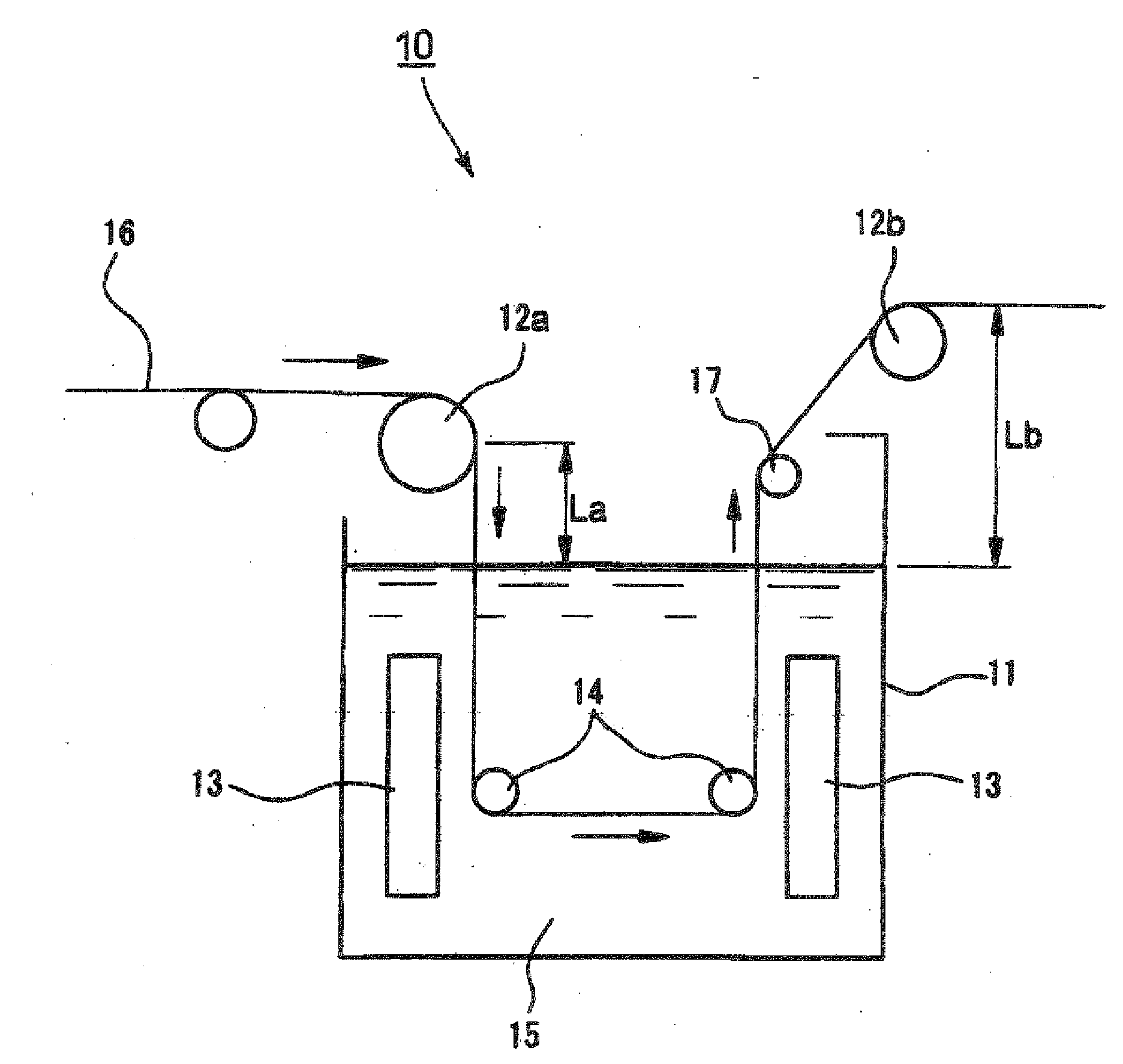

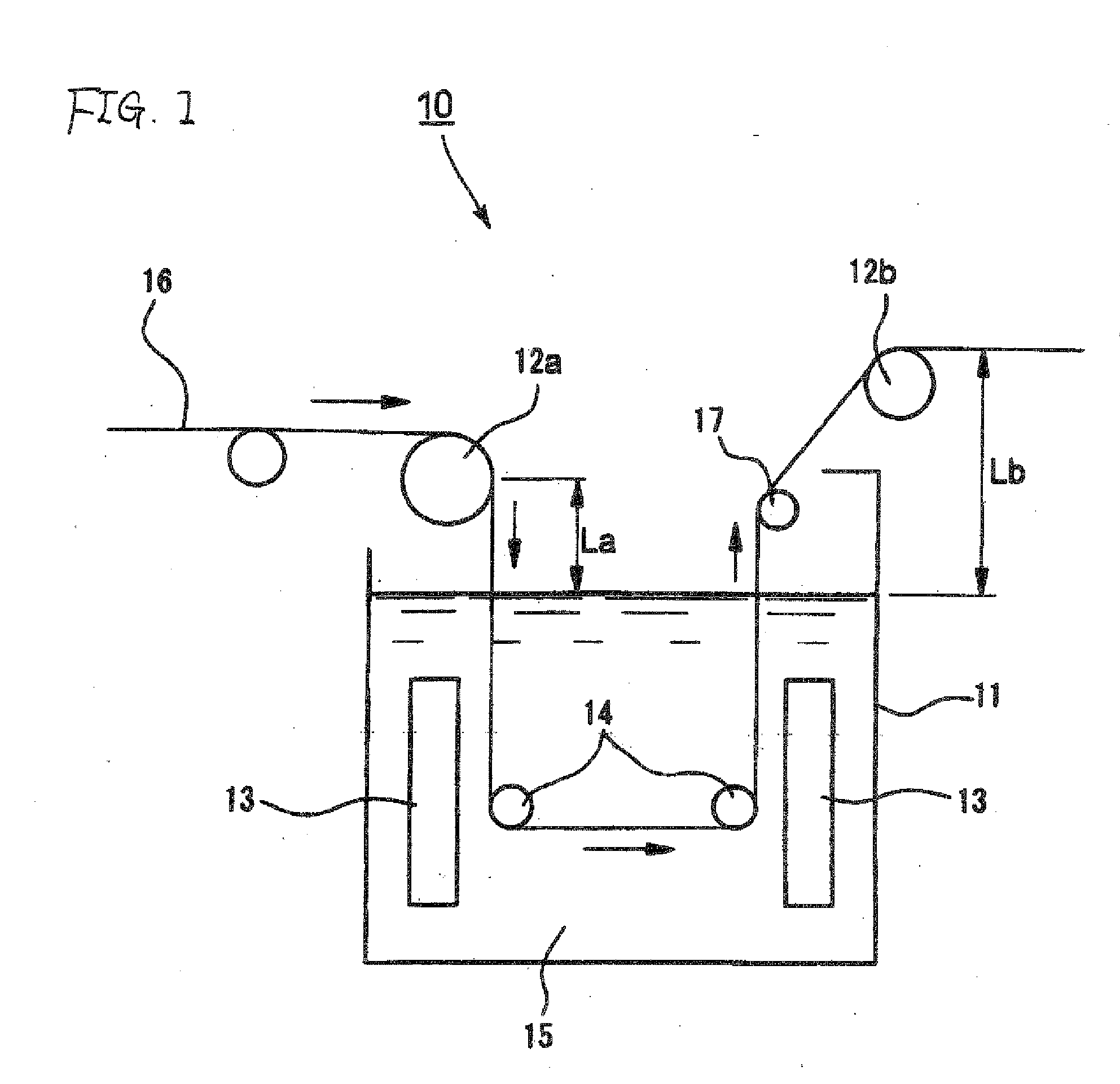

Plating processing method, light-transmitting conductive film and electromagnetic wave-shielding film

InactiveUS20090218127A1Uniform platingImprove productivityElectric discharge tubesMagnetic/electric field screeningSurface resistivityElectroplating

A plating processing method, which comprises continuously electroplating the surface of a film having a surface resistivity of from 1Ω / square to 1000Ω / square, wherein the transportation speed of the foregoing film is from 1 m / minute to 30 m / minute.

Owner:FUJIFILM CORP

Chemical aluminum plating solution and chemical aluminum plating method

InactiveCN101210319AImprove conductivityImprove thermal conductivityLiquid/solution decomposition chemical coatingCurrent distributionRoom temperature

The invention discloses a chemical aluminum plating solution and a chemical aluminum plating method. The chemical aluminum plating solution is composed of an aluminum-containing room-temperature molten salt and a reducer, wherein 0.05 to 2.5 mol reducer is contained in every liter of the aluminum-containing room-temperature molten salt. The method comprises the following steps of: soaking a workpiece to be plated in SnCl2 solution for sensitizing treatment, cleaning with water, and soaking in a PdCL2 solution for activation; or soaking a mixture solution containing SnCl2 and PdCl2 for activation; and chemically plating aluminum using the chemical aluminum plating solution in a dry inert atmosphere. According to the invention, aluminum can be separated out on the workpiece to be plated to achieve chemical aluminum plating by soaking the workpiece in the solution without electrifying. The invention can plate light-weight aluminum with excellent electrical conductivity and thermal conductivity not only on a metal base but also on an insulating workpiece to be plate. Moreover, the aluminum can be uniformly plated even for the workpiece with complex shape or for powder without considering the uniformity of current distribution since no electroplating is adopted. Accordingly, the invention has great practical value.

Owner:凌国平

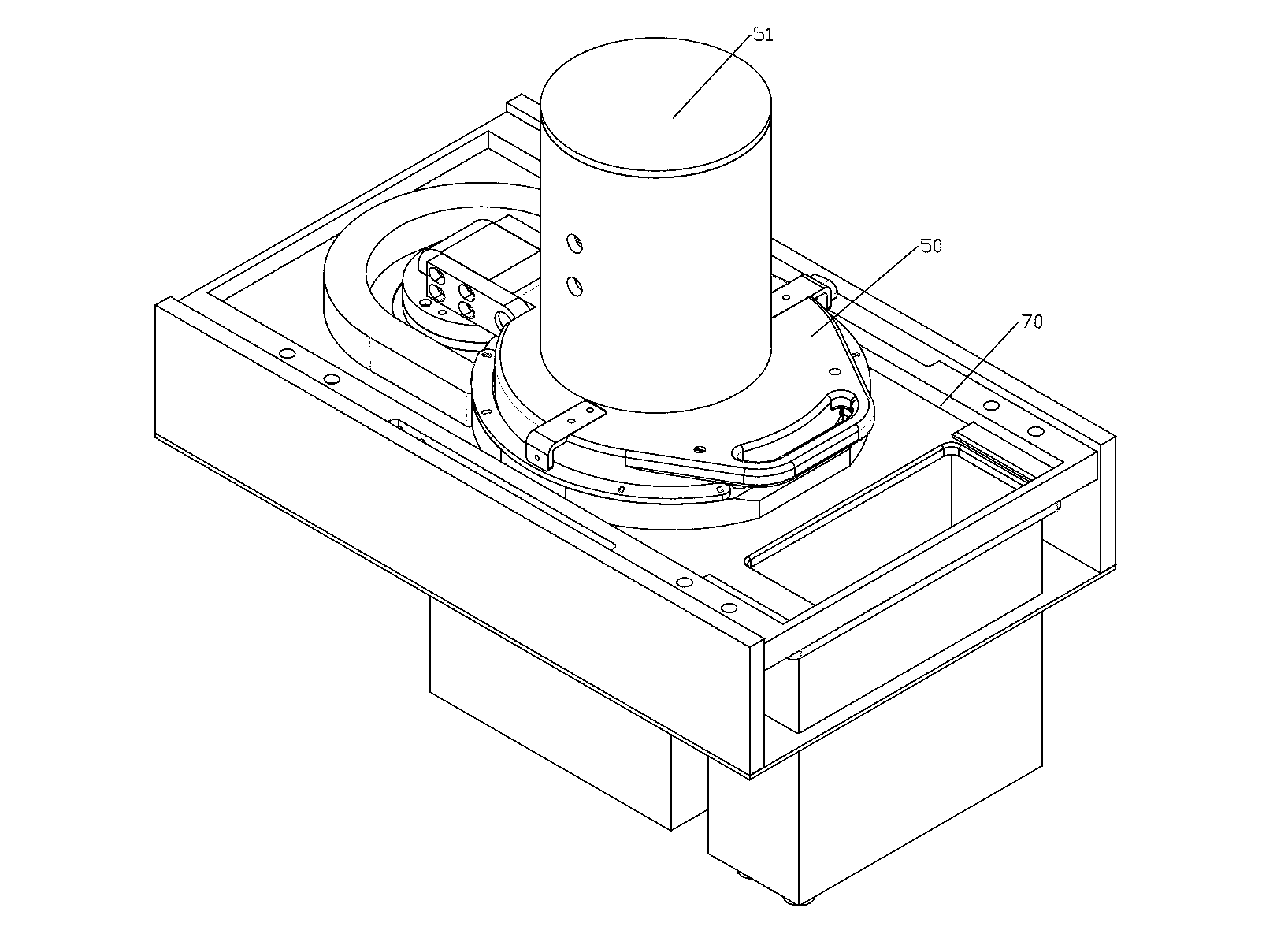

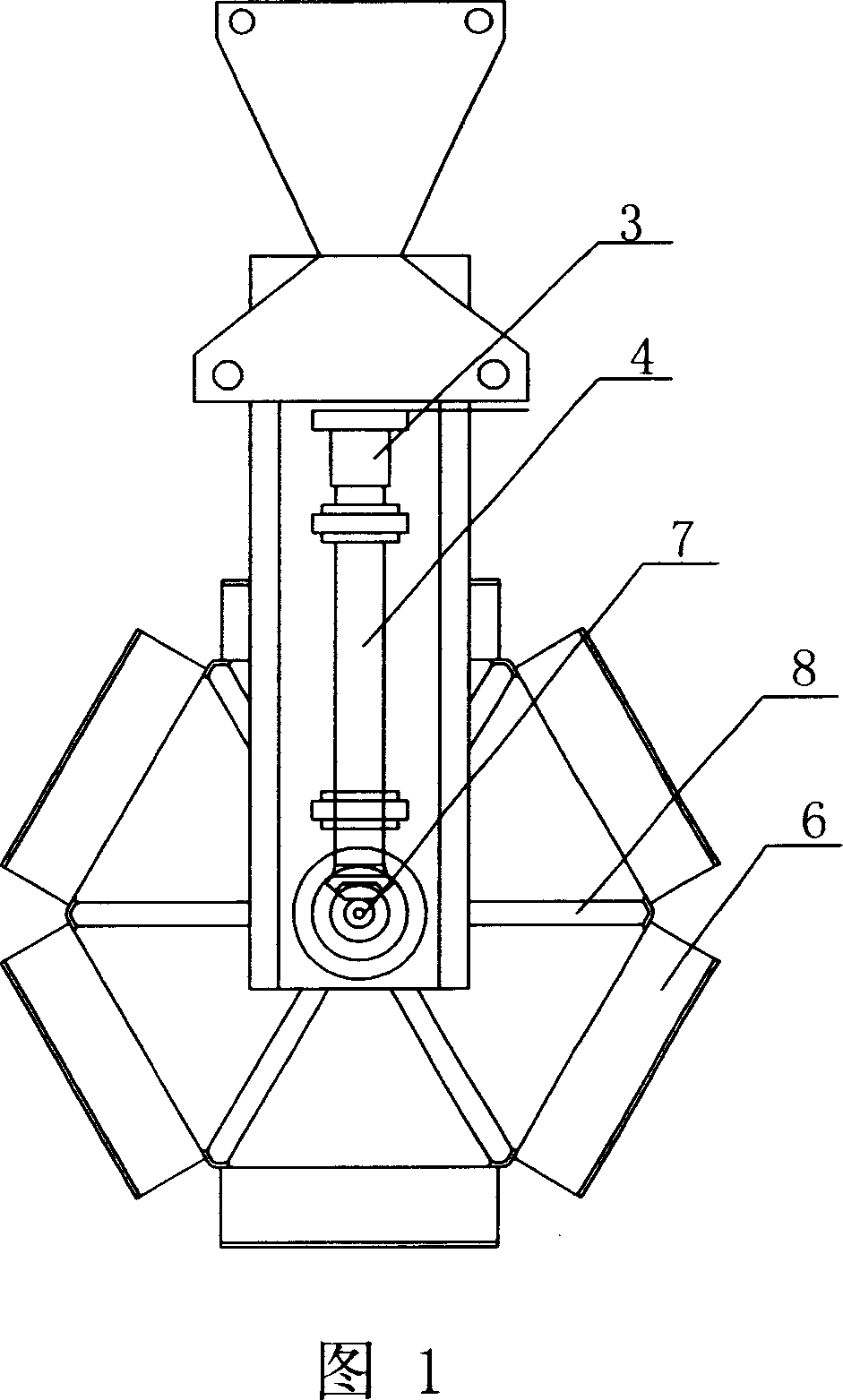

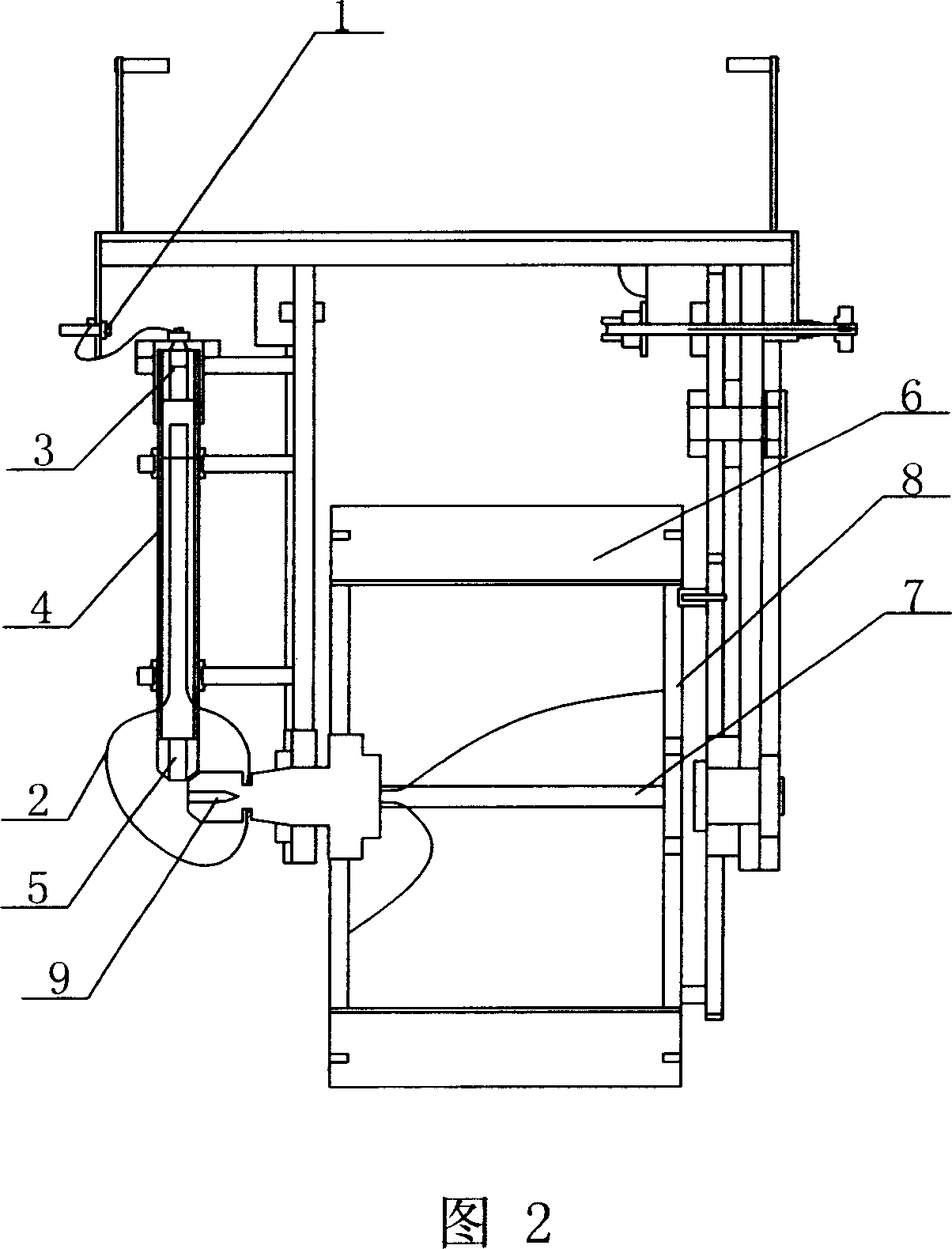

Method for local electroplating sheltering and hanging aluminium alloy cavity of communication filter

InactiveCN101555610AUniform platingIncrease productivityElectrolysis componentsFixed frameSilica gel

The invention discloses a method for local electroplating sheltering and hanging an aluminium alloy cavity of a communication filter. The method is characterized in that the method comprises the following steps: 1) facilitating a silicone waterproof jacket which is matched with the aluminium alloy cavity to be electroplated, sleeving the silicone waterproof jacket on the surface of the aluminium alloy cavity; 2) fixing the aluminium alloy cavity with the silicone waterproof jacket on a rotatable square fixed frame; and 3) hanging the square rotary fixed frame and the aluminium alloy cavity in an electroplating bath for rotary electroplating. The method adopts the silicone waterproof jacket to be matched with the square rotary fixed frame for use, the part of the shape which does not need to be electroplated uses the silicone waterproof jacket for sheltering, thereby exposing the part which needs to be electroplated; then the cavity with well arranged silicone waterproof jacket adopts a rapid press board and a stainless steel clamp to be fixed on the square rotary frame, thereby leading the cavity to carry out the adjustable-speed rotary electroplating in the electroplating bath, achieving the purposes of evenly electroplating the exposed part of the cavity and keeping the original color of the shape, further improving production efficiency, reducing production cost and improving product quality.

Owner:SUZHOU COPLATE SURFACE TREATMENT TECH

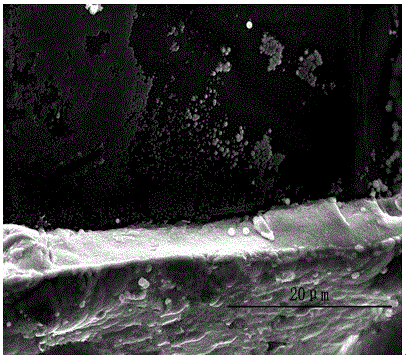

Diamond wire saw and rapid production method thereof

ActiveCN103388170AIncreased chance of collisionIncrease capture rateElectrolytic coatingsChemical platingHeat treated

The invention discloses a diamond wire saw and a rapid production method thereof. The surfaces of diamond grits are respectively coated with a nickel layer by chemical plating, the nickel layers are fixed on a copper-plated piano wire substrate pre-plated with a nickel layer through electroplating, and then the nickel layers are thickened, so that the diamond grits are solidified more firmly. The rapid production method of the diamond wire saw comprises the following steps of: 1, removing greases and oxides on the surfaces of diamond grits, and carrying out sensitization, activation and chemical nickel plating on the diamond grits; 2, removing greases and oxides on the surface of a metal substrate, and pre-plating nickel layers as buffer layers; and 3, carrying out composite electroplating, thickened electroplating and heat treatment on the diamond wire saw. According to the invention, diamond grits are subjected to chemical nickel plating to achieve an effect of electric conduction, so that the diamond grits carry out sequential movement under the action of an electric field, and chemical consolidation is realized; and in addition, intense agitation is introduced in an electroplating process, so that high-current / density electroplating is realized, and a highly efficient and rapid method is provided for the industrial production of diamond wire saws.

Owner:江西核工业兴中科技有限公司

Electroless copper plating solution and method for electroless copper plating

InactiveCN1867697APrevent excessive deposition reactionsUniform platingSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingCopper platingThiourea

An electroless copper plating solution characterized by using hypophosphorous acid or a hypophosphite salt as a second reducing agent together with a first reducing agent, and simultaneously using a stabilizer for inhibiting copper deposition. The first reducing agent includes formalin and glyoxylic acid, and the hypophosphite includes sodium hypophosphite, potassium hypophosphite, and ammonium hypophosphite. Stabilizers that inhibit copper deposition include 2,2'-bipyridine, imidazole, nicotinic acid, thiourea, 2-mercaptobenzothiazole, sodium cyanide, or thioglycolic acid. When electroless copper is plated on mirror surfaces (such as semiconductor wafers, etc.) where plating reactions are difficult to occur, the electroless copper plating solution can realize uniform plating at a reduced temperature.

Owner:JX NIPPON MINING & METALS CORP

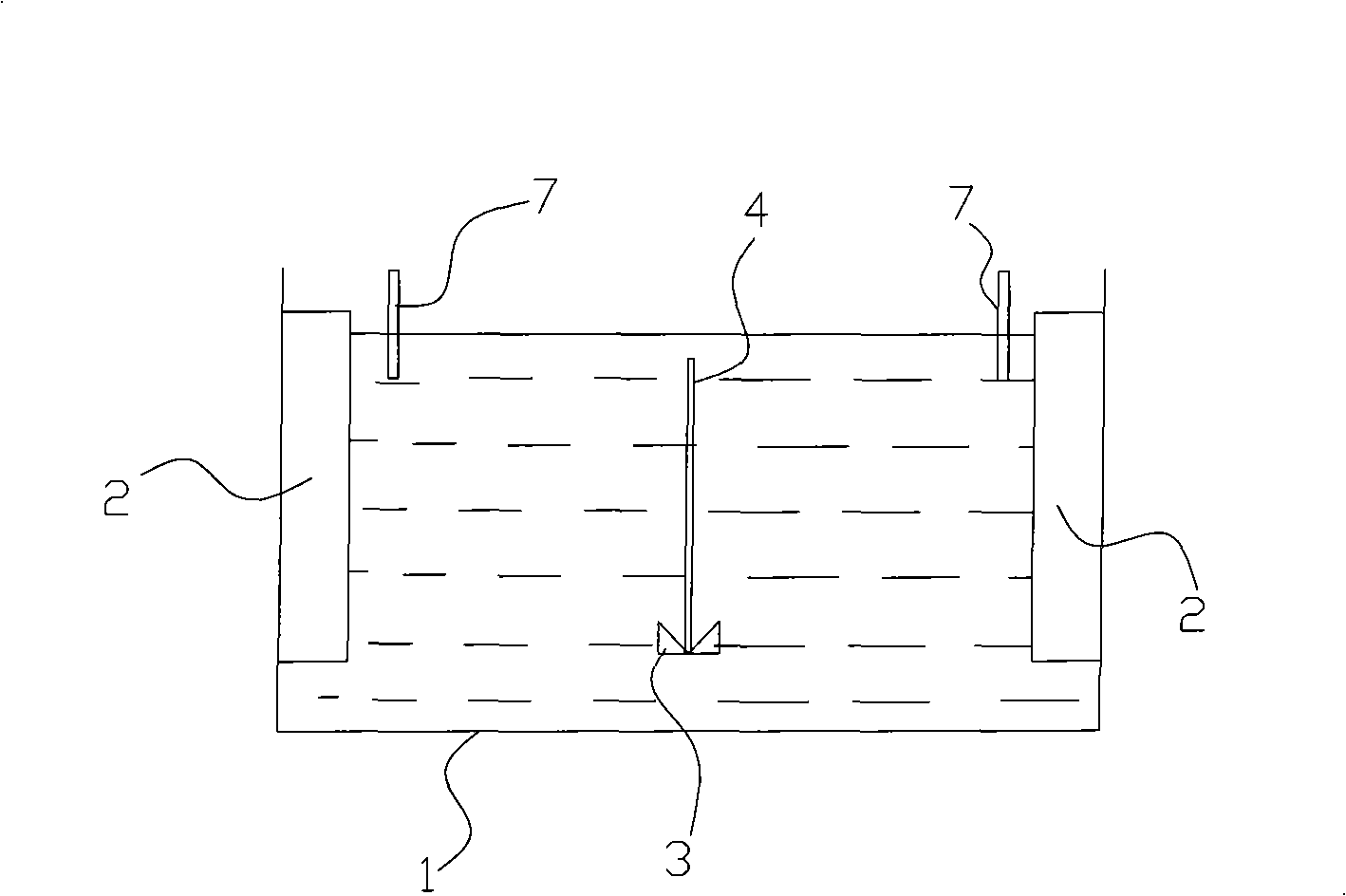

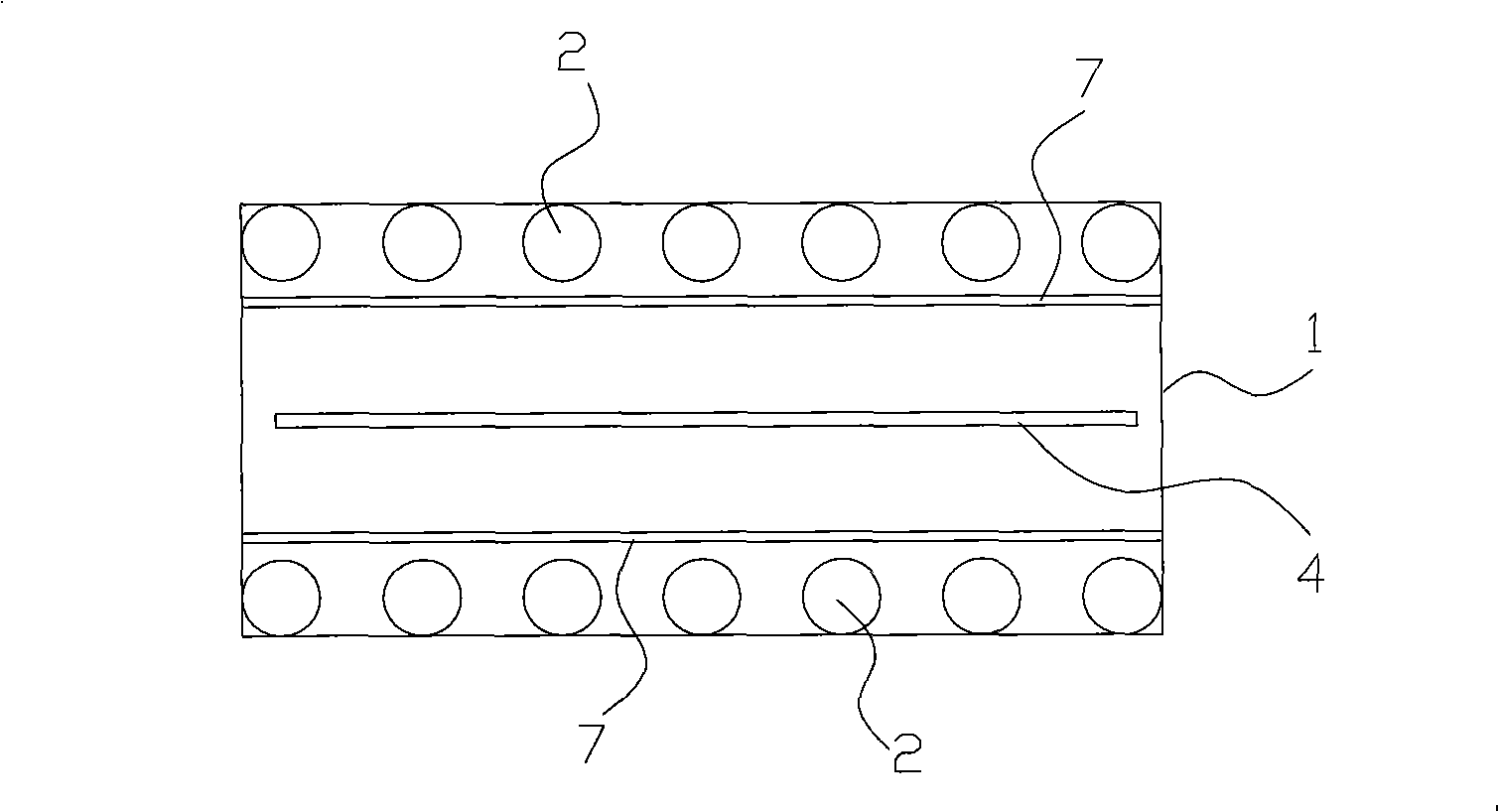

Electroplating device for printed breadboard

The invention discloses an electroplating device for a printed circuit board, wherein, two opposite anodes are arranged inside an electroplating bath and electrically connected with a positive electrode; a floating trough is arranged between the two anodes in the electroplating bath; the printed circuit board which is connected with a negative electrode is arranged on the floating trough; the floating trough comprises two side plates; the circuit board is positioned between the side plates; and side plate holes are uniformly arranged on the two side plates. The electroplating device for the printed circuit board readjusts a power line in the electroplating bath, thereby electroplating of the circuit board is more uniform and the electroplating effect is good.

Owner:SHENZHEN FASTPRINT CIRCUIT TECH

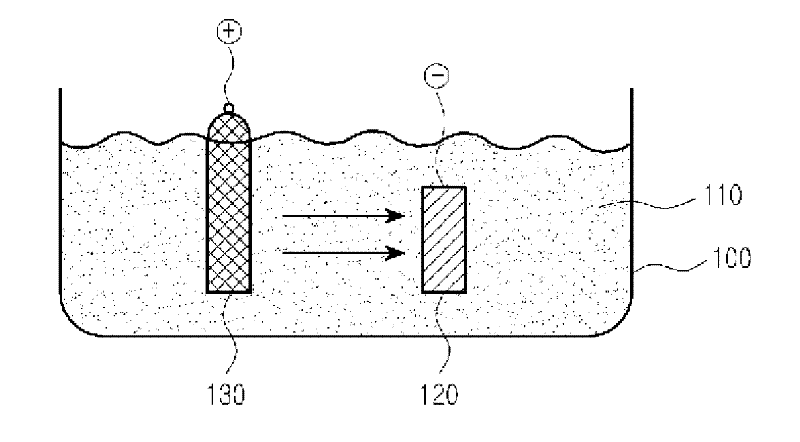

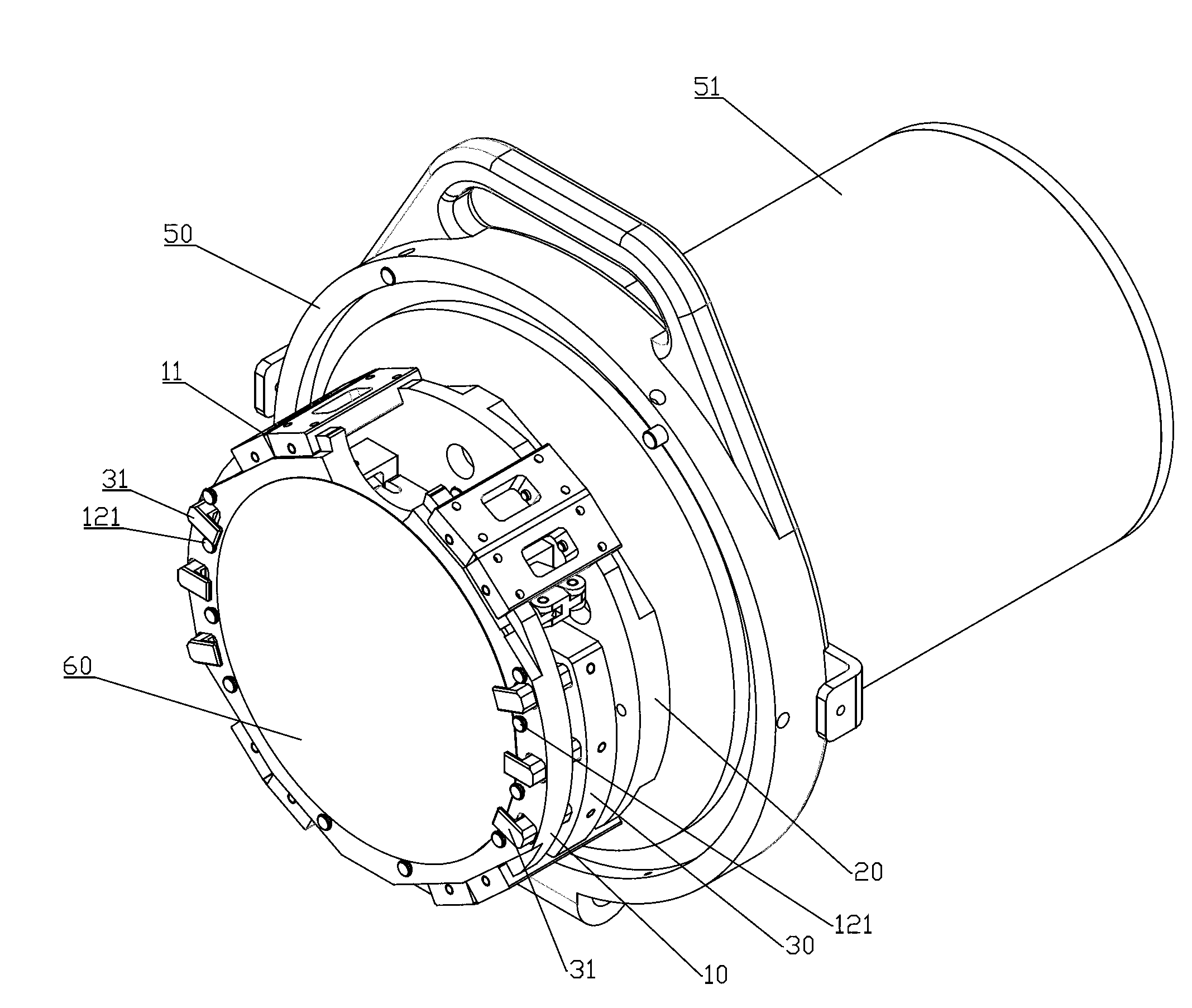

Electroplating apparatus

The present invention relates to an electroplating apparatus which comprises: a plating vessel containing electrolyte solution; and a supply unit which is connected to the plating vessel and which sprays the electrolyte solution containing metallic ions for electroplating onto specific parts of the object to be plated, wherein said supply unit is connected to an anode, and the object to be plated is connected to a cathode.

Owner:KMW INC

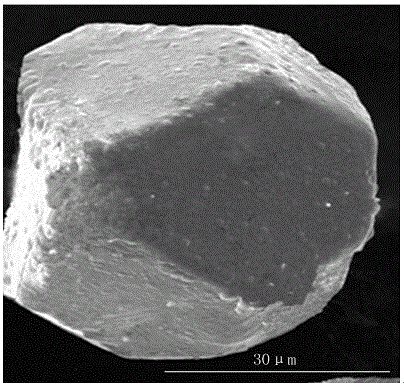

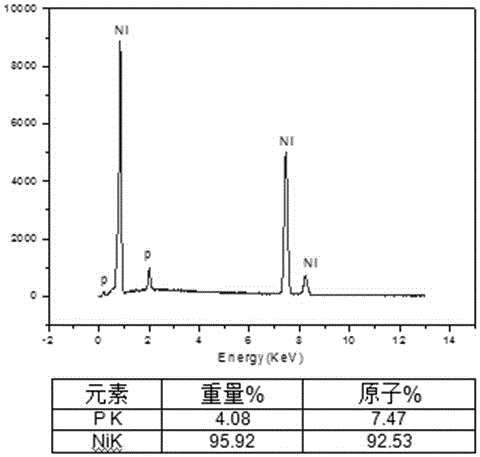

Method for chemically plating surface of diamond with Ni and P in microwave-ultrasound combined mode

InactiveCN105112891AReduce dosageLow costLiquid/solution decomposition chemical coatingChemical platingMicroparticle

The invention relates to a method for chemically plating the surface of diamond with Ni and P in a microwave-ultrasound combined mode and belongs to the technical field of diamond composites. The method includes the steps that firstly, grease and dirt of diamond particles are removed after the diamond particles are boiled in a NaOH solution, and then the surfaces of the diamond particles are roughened after the diamond particles are boiled in a dilute HNO3 solution; the diamond particles obtained after surface roughening are placed in a base colloid palladium solution for sensitization-activation; the diamond particles obtained after sensitization-activation are added into a sodium hypophosphite-water(1 / 2) solution with the concentration of 30 g / L for surface Pd2+ reduction of the diamond particles; and the diamond particles obtained after surface Pd2+ reduction are added into a chemical plating solution, are plated for 1-1.5 h under the microwave irradiation and ultrasound stirring conditions and stand still after being plated, and the diamond particles plated with Ni-P on the lower layer are washed with distilled water for vacuum drying. According to the method, the microwave irradiation heating technology and the ultrasound technology are combined to be applied to the Ni-P chemical plating process of the surface of the diamond, the quality of a coating is improved, and the coating is flat, smooth, dense, uniform and high in binding capacity and corrosion resistance.

Owner:KUNMING UNIV OF SCI & TECH

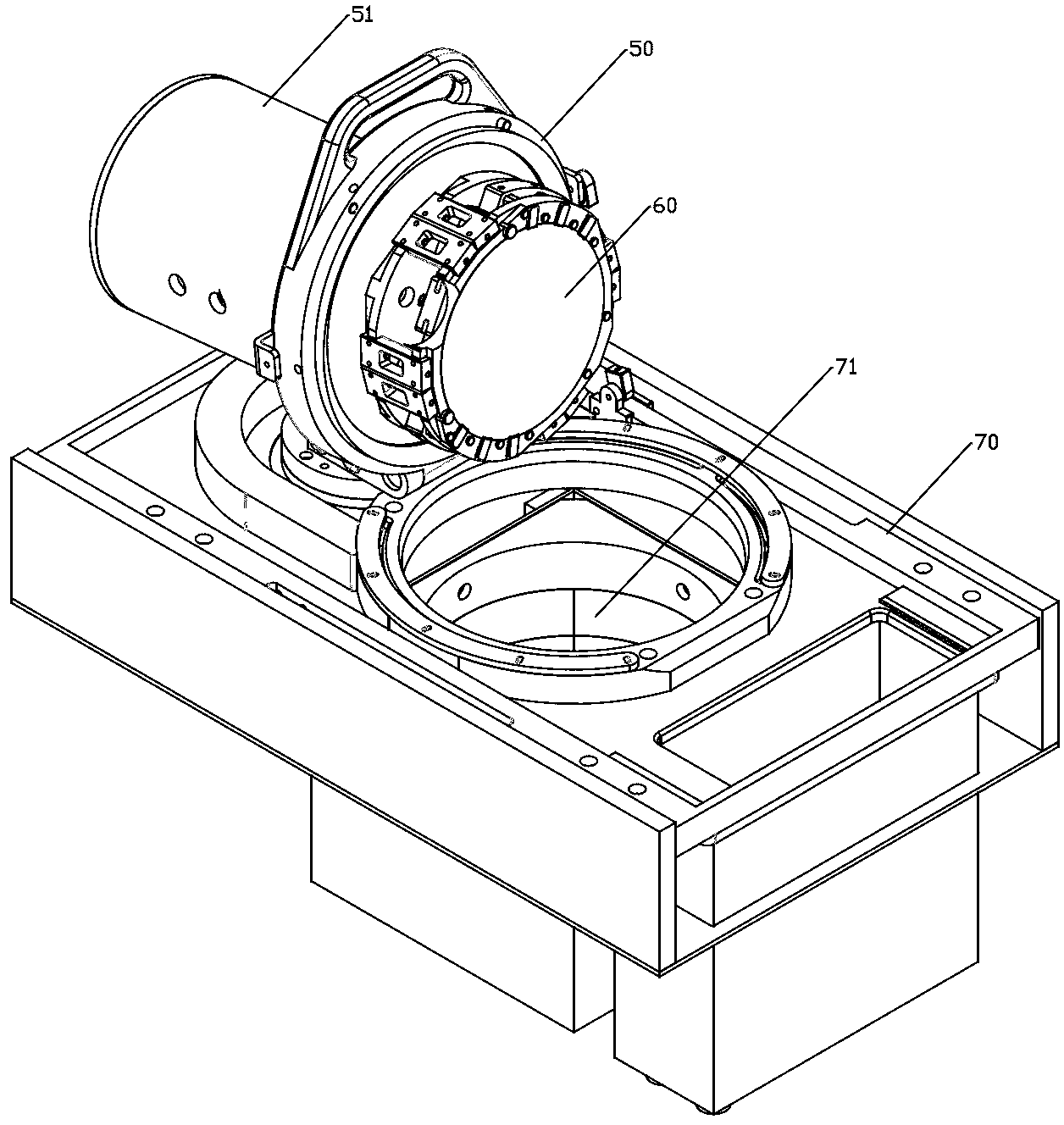

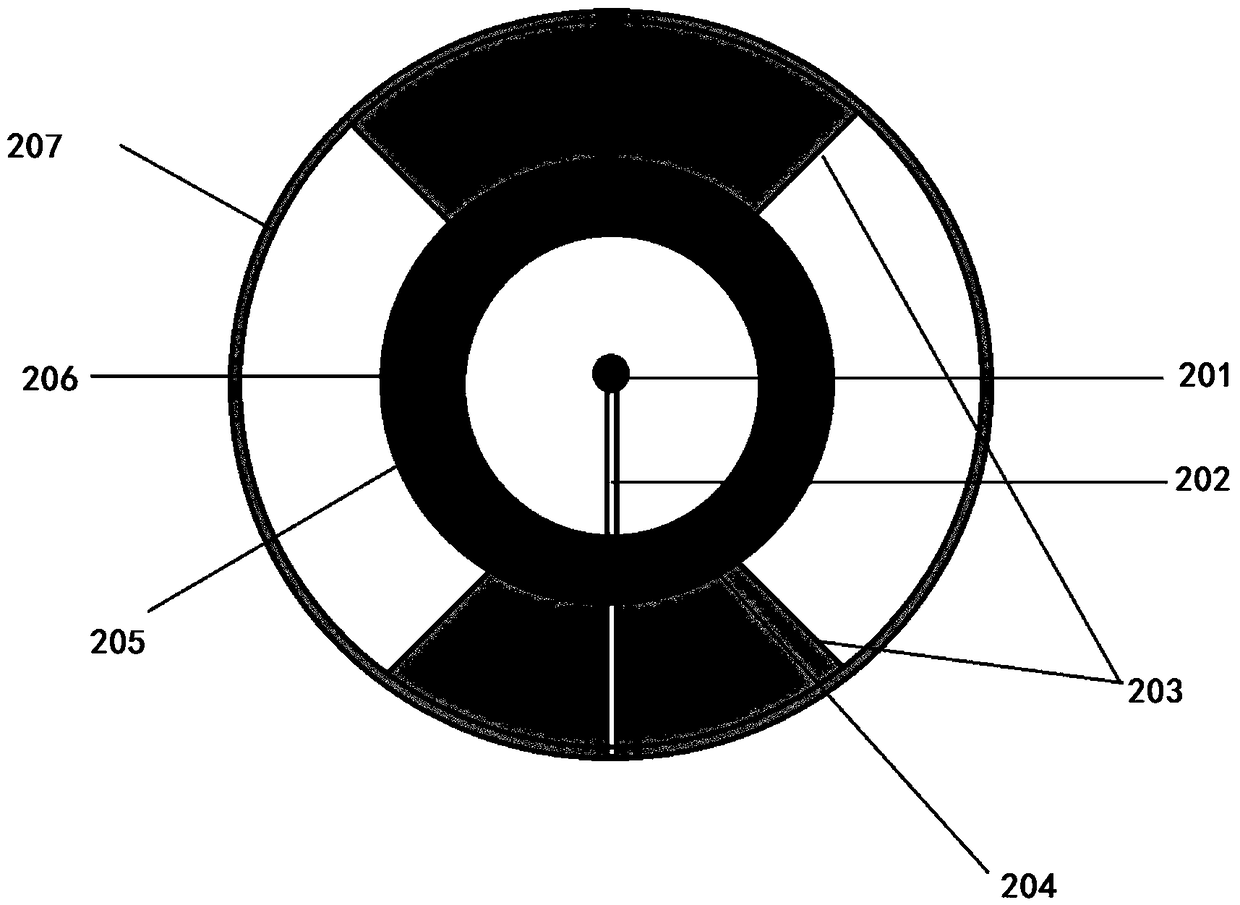

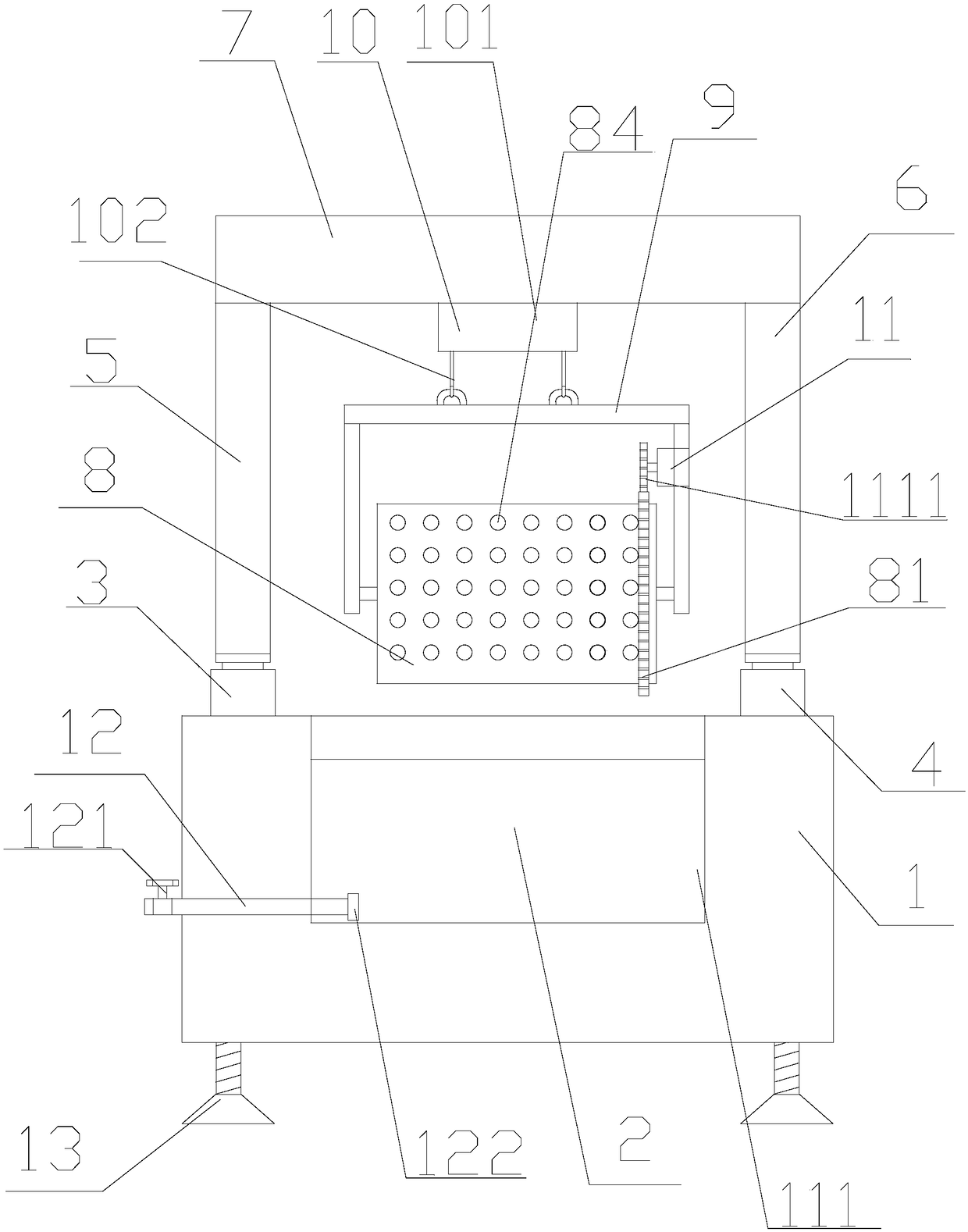

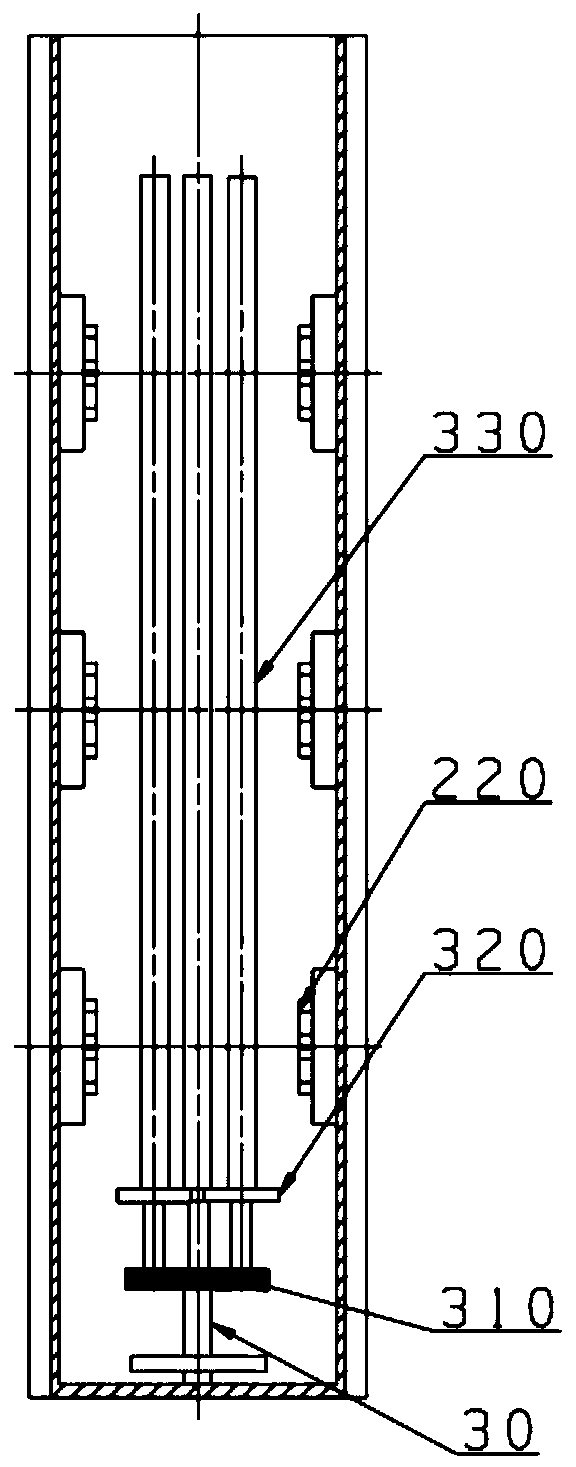

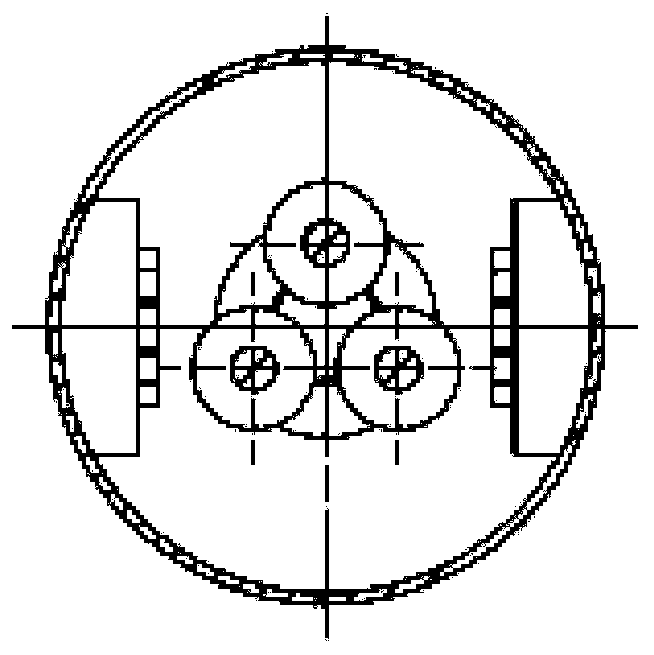

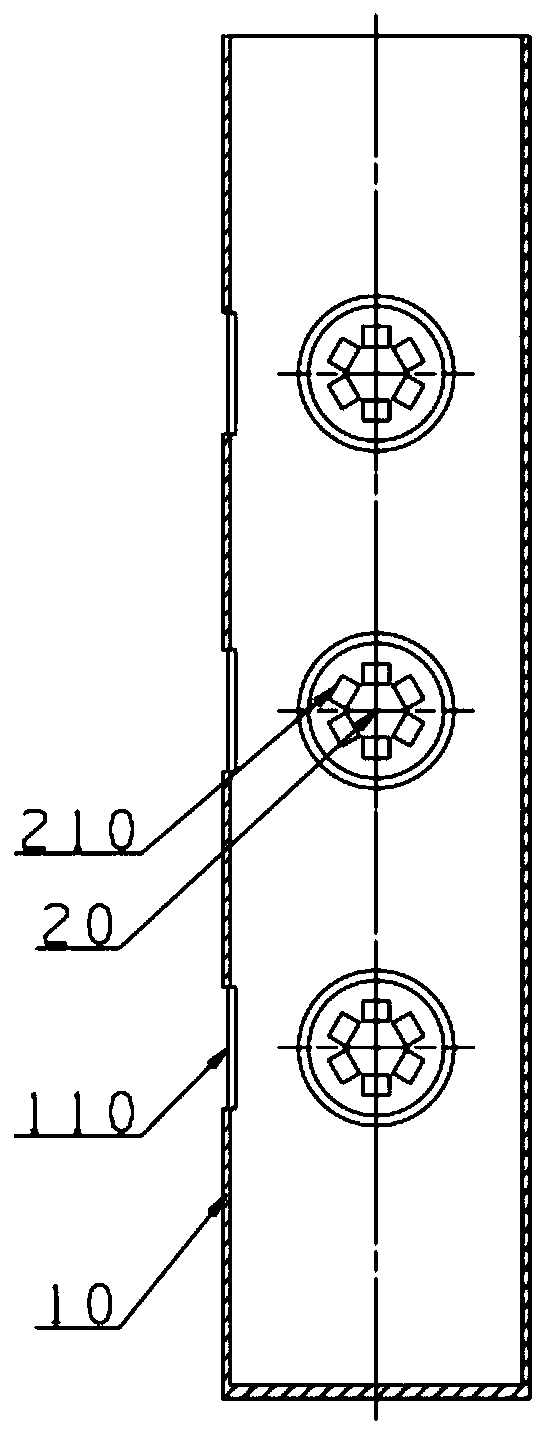

Wafer surface treatment device

ActiveCN103065996AUniform treatmentUniform platingSemiconductor/solid-state device manufacturingEtchingReciprocating motion

The invention discloses a wafer surface treatment device which is characterized by comprising a wafer clamping rotating device and a groove body. The groove body is provided with a groove cavity. The wafer clamping rotating device is hinged at the upper end of the groove body and arranged in a turning mode. The wafer clamping rotating device is composed of a lower base plate and a clamping clip, and the lower base plate is used for fixing a wafer and arranged in a rotating mode. The clamping clip consists of a hook body which extends toward the center of the base plate. The hook body is arranged below the lower base plate. The hook body which is driven to conduct motion toward the lower base plate and conduct reciprocating motion away from the lower base plate is arranged. The wafer surface treatment device not only fixes the wafer, but also drives the wafer to rotate. Even treatment on the surface of the wafer can be ensured after cleaning, galvanizing or etching. When cleaning is conducted, cleanout liquid does not need spraying the wafer, and risk of damage of the wafer can be reduced. When galvanizing or the etching is conducted, not only can each part of a galvanized or etched wafer be ensured, but also the galvanizing or the etching can be ensured. Meanwhile, the wafer surface treatment device is convenient to use.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

Method for forming radio frequency antenna

InactiveUS7268740B2ResistanceUniform platingAntenna arraysAntenna supports/mountingsRadio frequencyElectroplating

A metalized circuit suitable for application as a radio frequency antenna is produced by forming an antenna coil pattern on a flexible substrate. The antenna coil pattern is formed using a conductive ink which is patterned on the substrate. The conductive ink is cured and an electrical-short layer is formed across the coils of the conductive ink pattern. An insulating layer is formed over top of the electrical-short layer, a metal layer electroplated on top of the conductive layer, and then the electrical-short layer is removed. The use of the electrical-short layer during the electroplating allows for the voltage at the different points on the conductive ink layer to be relatively similar, so that a uniform electroplate layer is formed on top of the conductive ink layer. This results in a better quality radio frequency antenna at a reduced cost.

Owner:SQUARE 1 BANK

Method for chemical plating of metal on particle surface

InactiveCN101758230AImprove dispersion efficiencyEvenly dispersedLiquid/solution decomposition chemical coatingChemical platingFluid phase

The invention discloses a method for chemical plating of metal on the particle surface. An ultrasonic oscillation generator is put into a mechanical stirring paddle, a mechanical agitator is combined with a built-in ultrasonator, then the powder particles are fully dispersed by adding the reaction components by a liquid-phase spraying method, and the reaction in the plated area is uniform and stable, therefore, the purpose of uniformly-distributed coating powder particles is achieved. The method of combining the mechanical agitator and the built-in ultrasonator is adopted, thereby effectively improving the dispersion efficiency and solving the problem of powder particle agglomeration; and the method of adding the reaction components by liquid-phase spraying is adopted, therefore, the reaction in the chemical plating solution is uniform, and the defects of the unstable plating solution and the uneven surface plating of the powder particles can be avoided. The method has the advantages of simple and convenient operation, uniform dispersion of the powder particles, complete coating and the like, and effectively solves the problems of agglomeration, uneven surface coating and instability of the plating solution due to the excessively high plating speed during the chemical plating of the powder particles.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

Technology and equipment for coating film in deep hole

ActiveCN109295414AConvenient industrial application of internal platingImprove thickness uniformityVacuum evaporation coatingSputtering coatingMetallurgySurface cleaning

Owner:广东省广新离子束科技有限公司

Conduction system applicable to plating equipment

This invention relates to the conductive system of electroplating equipment. The system is composed of a copper conductive rod, conductive wires, and a conductive heat fixation cannula. The copper conductive rod is connected with the power supply. Besides, the copper conductive rod is also connected with the iron frame through the conductive heat fixation cannula via conductive wires, and through the power shaft of the roll frame, and is fixed on the wall. The conductive system can continuously supply electricity for work pieces during the electroplating, and does not limit the motion of work pieces. Besides, the conductive system is simple and convenient.

Owner:DONGGUAN CHAULEONG TELECOM TECH CO LTD

Method for machining semimetal blind hole with aspect ratio greater than 1

PendingCN110557890AAspect ratio greater than 1Uniform platingInsulating layers/substrates workingPrinted element electric connection formationSplit linesEngineering

The invention relates to a method for machining a semimetal blind hole with an aspect ratio greater than 1, which comprises the following steps: drilling a blind groove, namely, selecting a proper board and drilling a blind hole in the surface of the board, wherein the hole depth is greater than the hole diameter; drilling a flow guide hole, namely forming a reserved area and a cutting area on thetwo sides of the blind hole by taking the diameter of the blind hole as a division line and drilling a through hole in the hole bottom on one side of the cutting area, wherein the through hole does not cross the division line of the two areas; electroless plating copper and electroplating, namely, carrying out electroless plating copper and electroplating on the whole board, and forming uniform electroplated layers on the surface of the board and on the inner wall of the blind groove; carrying out milling and cutting, namely, transferring the board to a milling machine tool, milling and cutting the board by taking the division line delimited in S2 as a cutting line, and removing the cutting area; and completing machining, namely, completing the machining of the semimetal blind hole aftertrimming and post-processing. The problem that a bonding pad or cap copper cannot be manufactured in the semimetal blind hole due to falling of resin in the hole is avoided.

Owner:广州广合科技股份有限公司

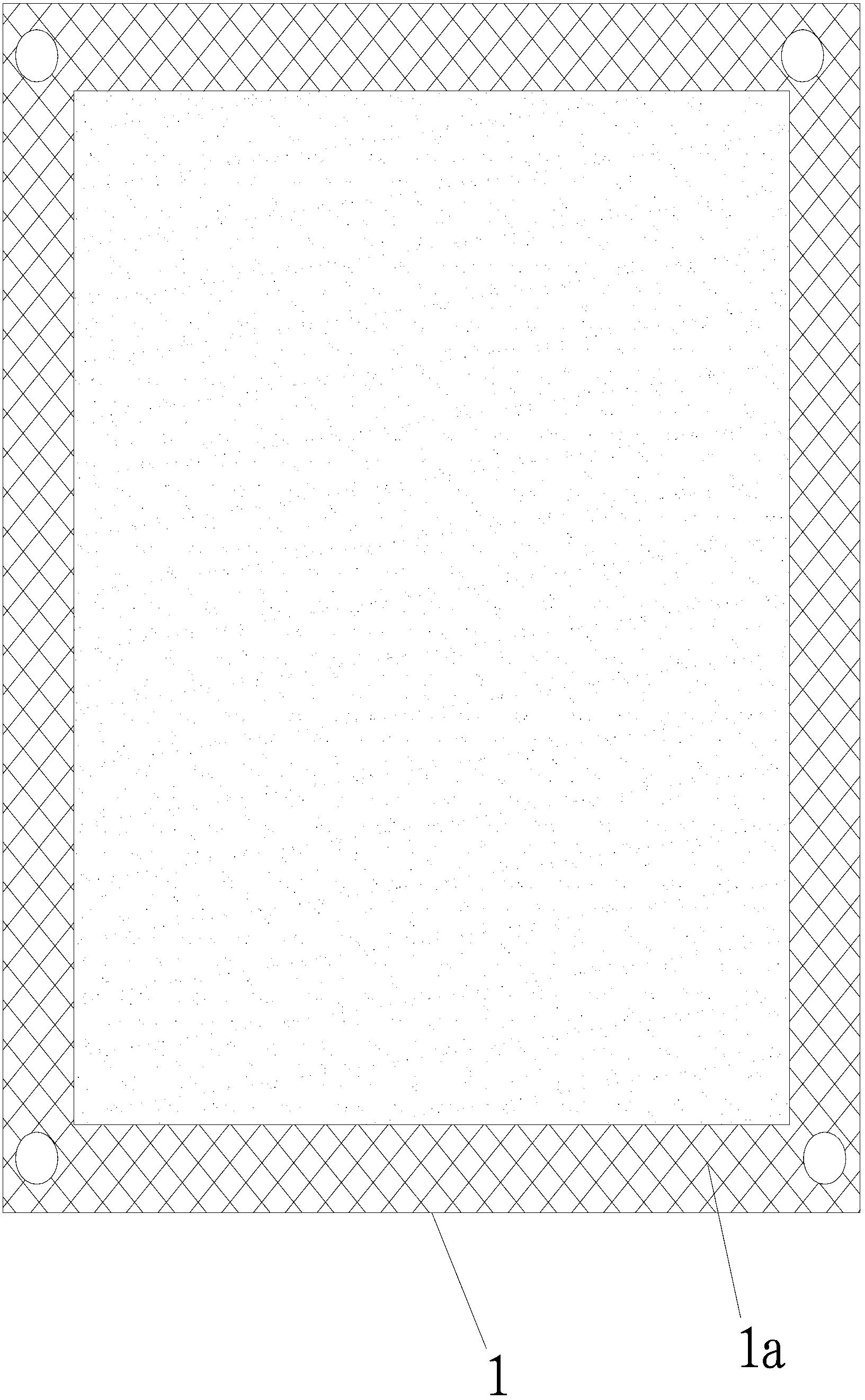

Electroplating process of circuit board of burning-resistant board

The invention discloses an electroplating process of a circuit board of a burning-resisting board. The electroplating process comprises the following steps: firstly, providing a base plate and coating a copper foil layer at the periphery of the plate surface of the base plate; and then, carrying out boring, first-time plate grinding, copper electroplating, second-time plate grinding, outer circuit manufacturing, and electroplating, wherein the copper foil layer is of a latticed structure; the current density is 15-20ASF during the electroplating process, and the electroplating time is 90-100 minutes. The copper foil layer is arranged at the periphery of the plate surface of the base plate, so that the electroplating is uniform without a plate burning phenomenon; a low-current density long-time electroplating way is adopted to ensure the uniform and stable current of the plate surface, so that the plate is not burnt due to excessive current, the binding force and structural cohesive force of the based copper and electroplated copper of the plate are kept, and the quality of the circuit board is ensured. Moreover, the latticed structure is arranged at the periphery of the plate surface for saving the copper, so that the electroplating area is reduced during the electroplating process, and the copper is further saved.

Owner:SHENZHEN XINGDA PCB

Novel electroplating barrel plating device

The invention discloses a novel electroplating barrel plating device comprising a main frame base, an electroplating liquid, a first electric cylinder, a second electric cylinder, a first pillar, a second pillar, a cross plate, a barrel plating bucket, a barrel plating bucket fixing bracket, a lifting device and a motor. The upper end of the main frame base is provided with an electroplating battery chamber, and the electroplating battery chamber is internally provided with the electroplating liquid; two sides, at the upper end of the main frame base, of the electroplating battery chamber areprovided with the first electric cylinder and the second electric cylinder respectively; the first electric cylinder and the second electric cylinder are relatively parallel to each other; the upper end of a sliding part of the first electric cylinder is provided with the first pillar. A workpiece is placed in the barrel plating bucket, hoisted into the electroplating battery chamber and processed; the workpiece is turned over by rotation of a roll barrel, the surface of the workpiece is electroplated more uniformly, all dead corners of the workpiece can be electroplated, and the electroplating effect cannot be affected by backlogging; the workpiece in the barrel plating bucket and the roll barrel is convenient to transport through the cooperation of the electric cylinders and the liftingdevice, the manpower is saved and the work efficiency is improved.

Owner:高益群

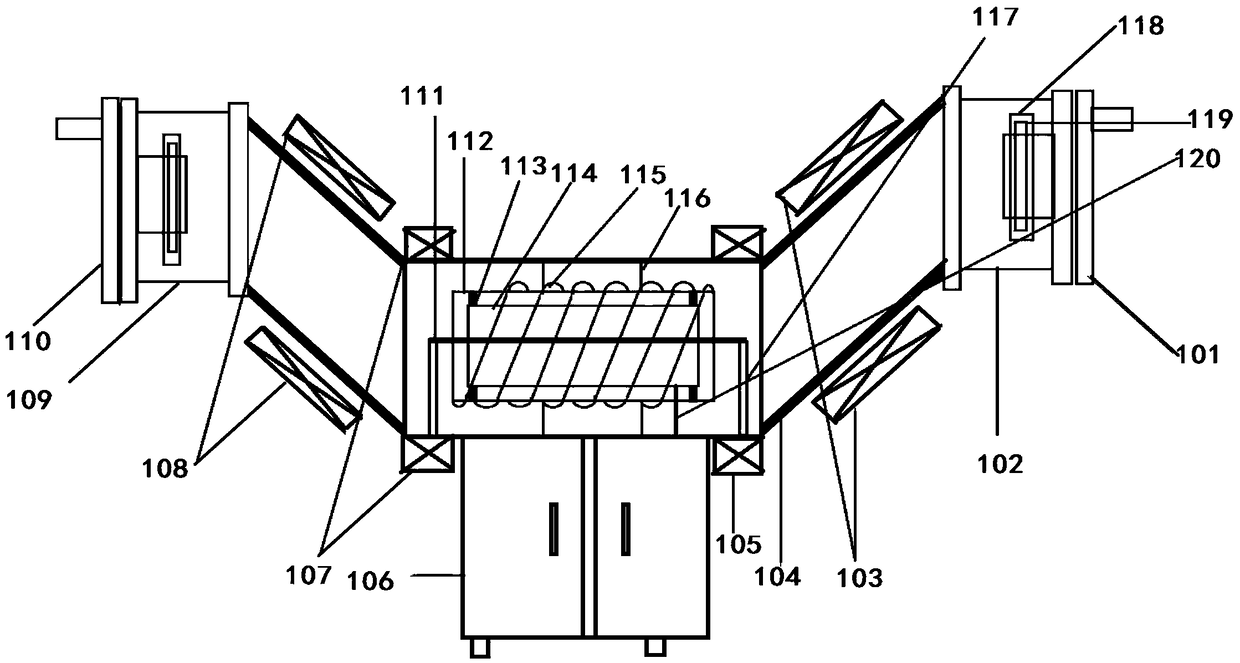

Vertical magnetron sputtering coating device for long outer cladding tube

ActiveCN110592544AExtended service lifeImprove efficiencyVacuum evaporation coatingSputtering coatingSputteringEngineering

The invention discloses a vertical magnetron sputtering coating device for a long outer cladding tube. The device comprises a shell, wherein the shell is provided with a cylindrical cavity with an opening at the top, a rotating device connected with a transmission device outside the shell is arranged at the bottom in the cavity, and a workpiece frame is arranged on the rotating device; a pluralityof pairs of target seat bottom discs are installed on the inner wall of the cavity along the axial direction thereof, a plurality of target seats are distributed on each target seat bottom disc, thetarget seats are used for installing metal target materials, a cavity door used for replacing the metal target materials is arranged beside each pair of target seat bottom discs, and shielding platesare arranged on the target seats; and an air inlet and outlet device and a high-pressure air outlet are formed in the top of the cavity, and during work, the metal target materials are connected witha negative electrode of an external circuit through seat electrodes, and the workpiece frame is connected with a positive electrode of the external circuit through the seat electrodes. According to the device, the structure is simple, the operation is convenient, a deposited film is uniform, when the target materials are subjected to magnetron sputtering, the atomic deposition rate of a cladding material is guaranteed due to the constraint of magnetic lines of force, raw materials are saved, and the production efficiency and the finished product quality are improved.

Owner:苏州思萃材料表面应用技术研究所有限公司

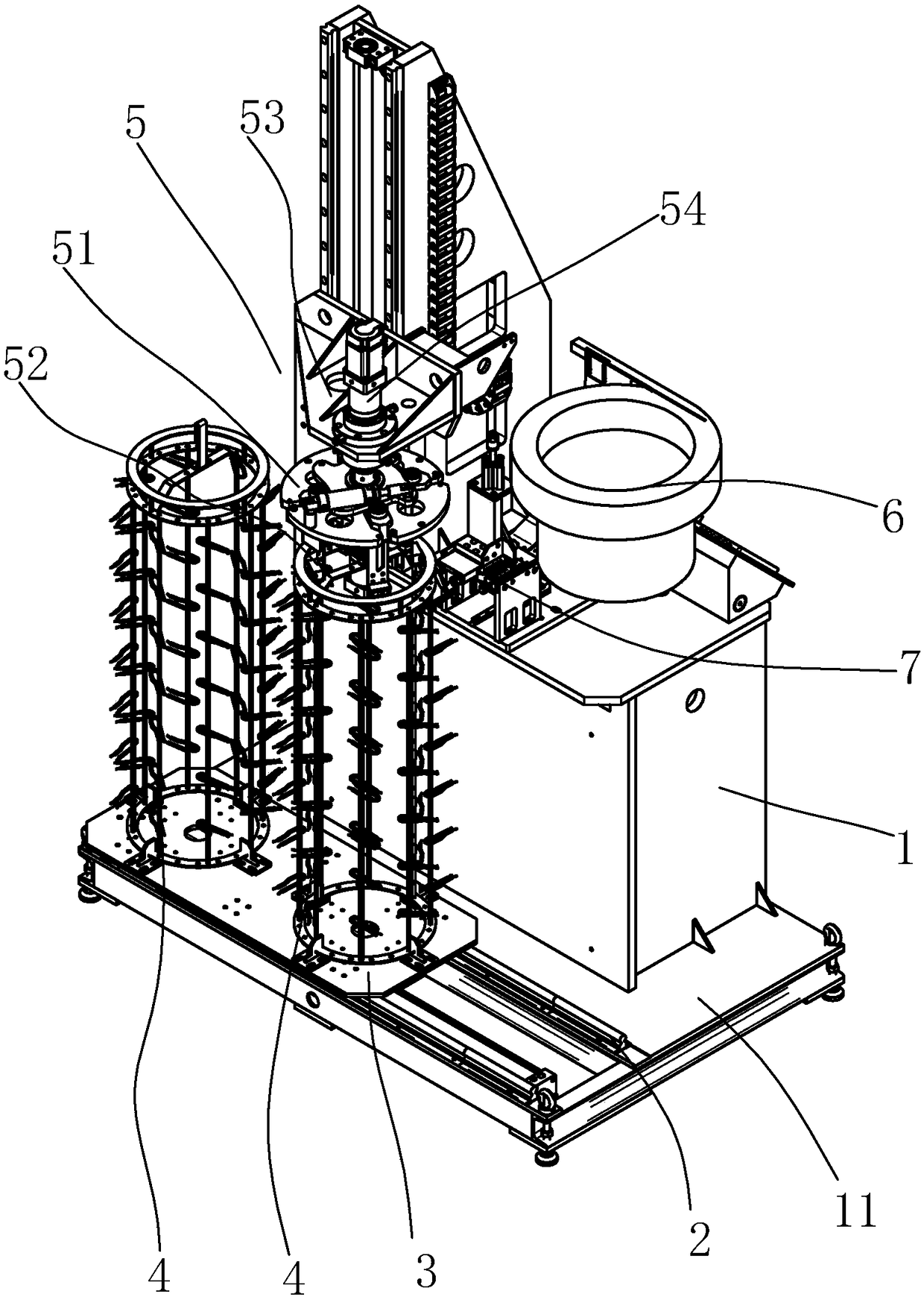

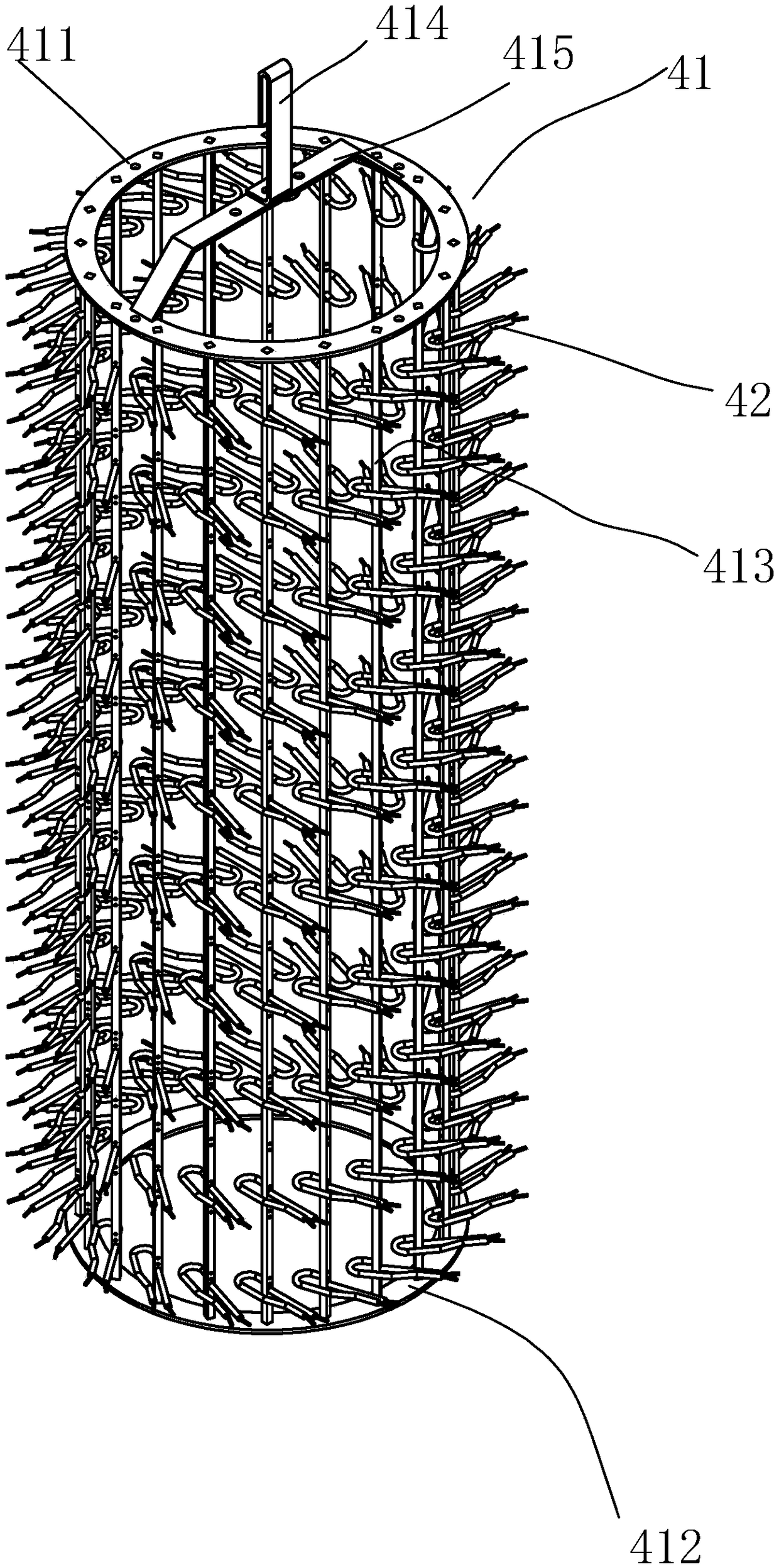

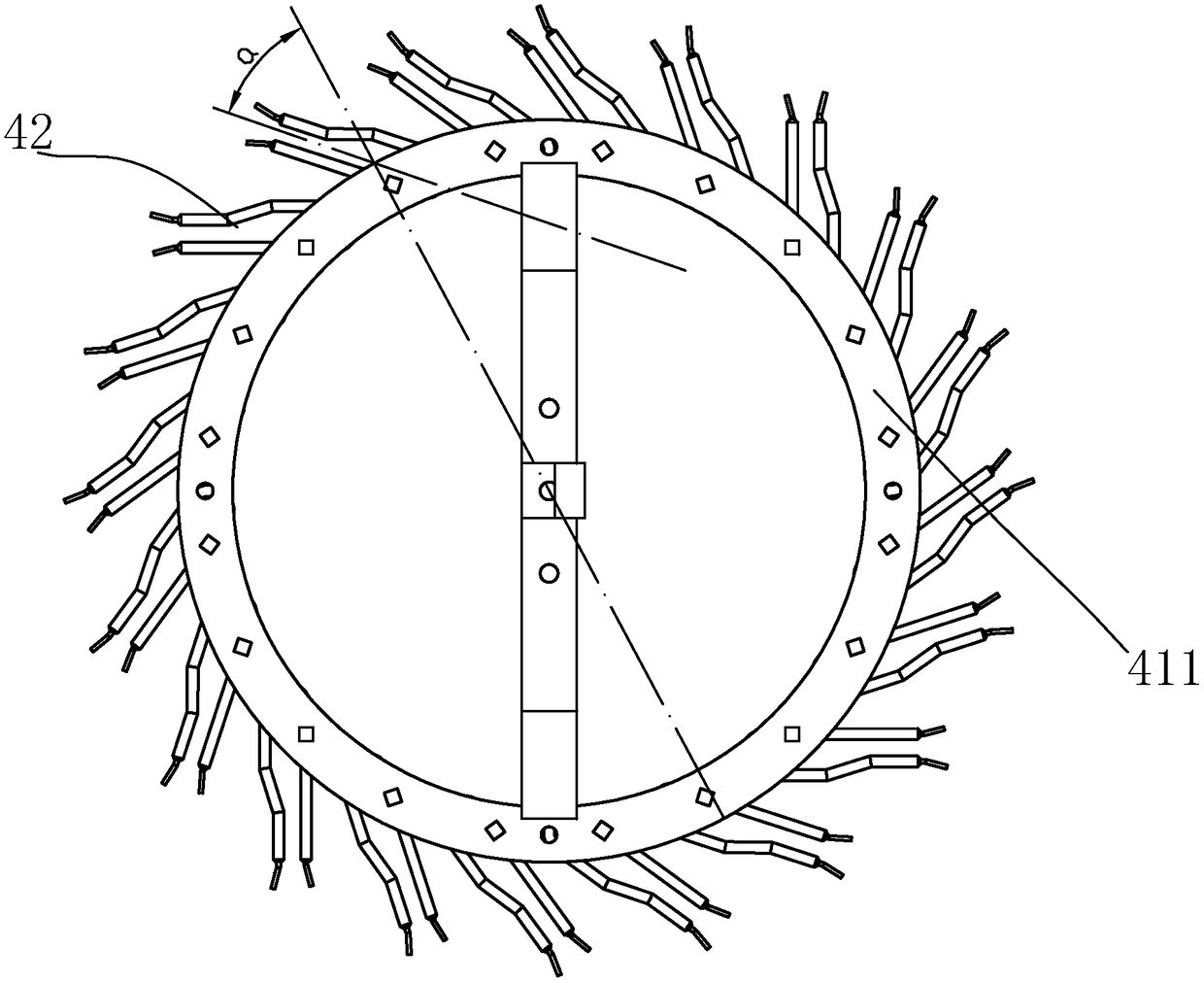

Automatic zipper head suspending machine

ActiveCN108221035AUniform platingGuaranteed continuityElectrolysis componentsSlide fastenersSlide plateElectroplating

The invention discloses an automatic zipper head suspending machine, which includes a machine frame having a pedestal. A sliding rail is arranged on the pedestal and is provided with a sliding board.At least two suspending cages are arranged on the sliding board. Each suspending cage has a cage body which is totally cylindrical in shape. A plurality of suspending members are arranged on the periphery of the cage body. Each suspending member has a working direction, wherein the included angle between the working direction and the normal direction of a point where the suspending member is arranged on the periphery of the cage body is 30-60 degrees. In the machine, more than two suspending cages are arranged on the pedestal, so that when the zipper heads are automatically suspended on one cage to full, the machine can instantly switch the cages, so that production continuity is guaranteed and production efficiency is increased. Meanwhile, by changing the included angle between the working direction and the normal direction of the suspending members, the zipper head can be electroplated more uniformly when being delivered to an electroplating device.

Owner:佛山市光立智能科技有限公司

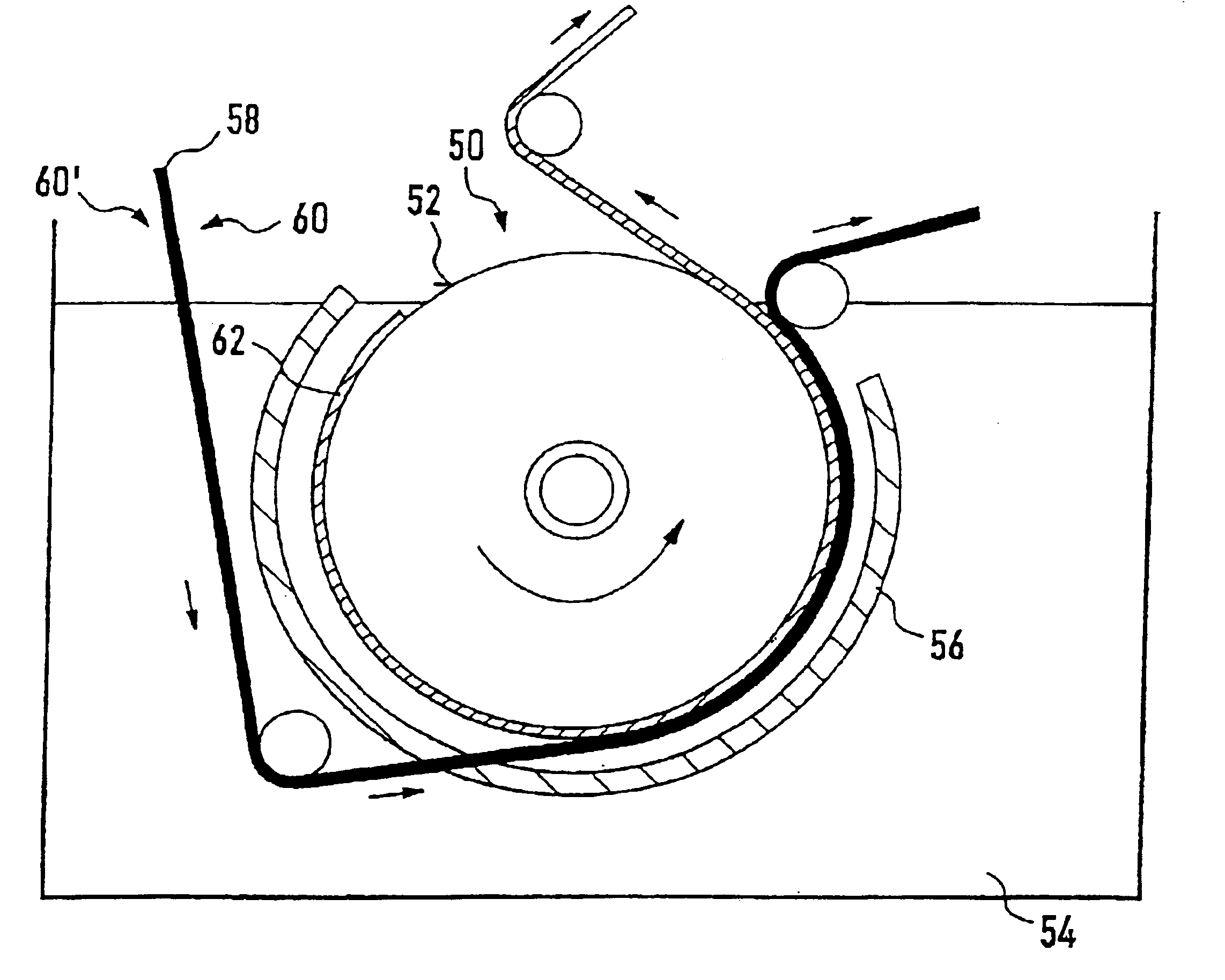

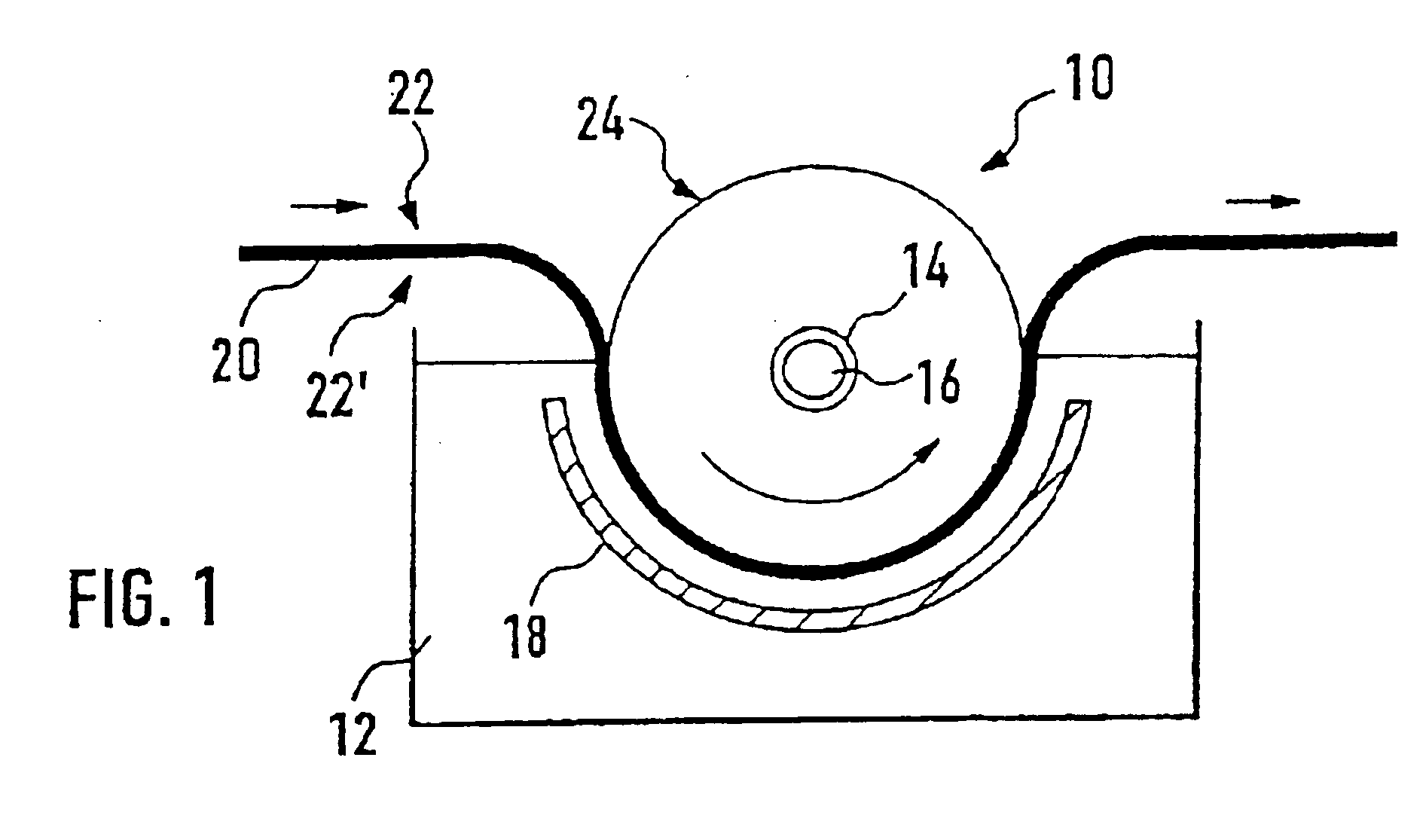

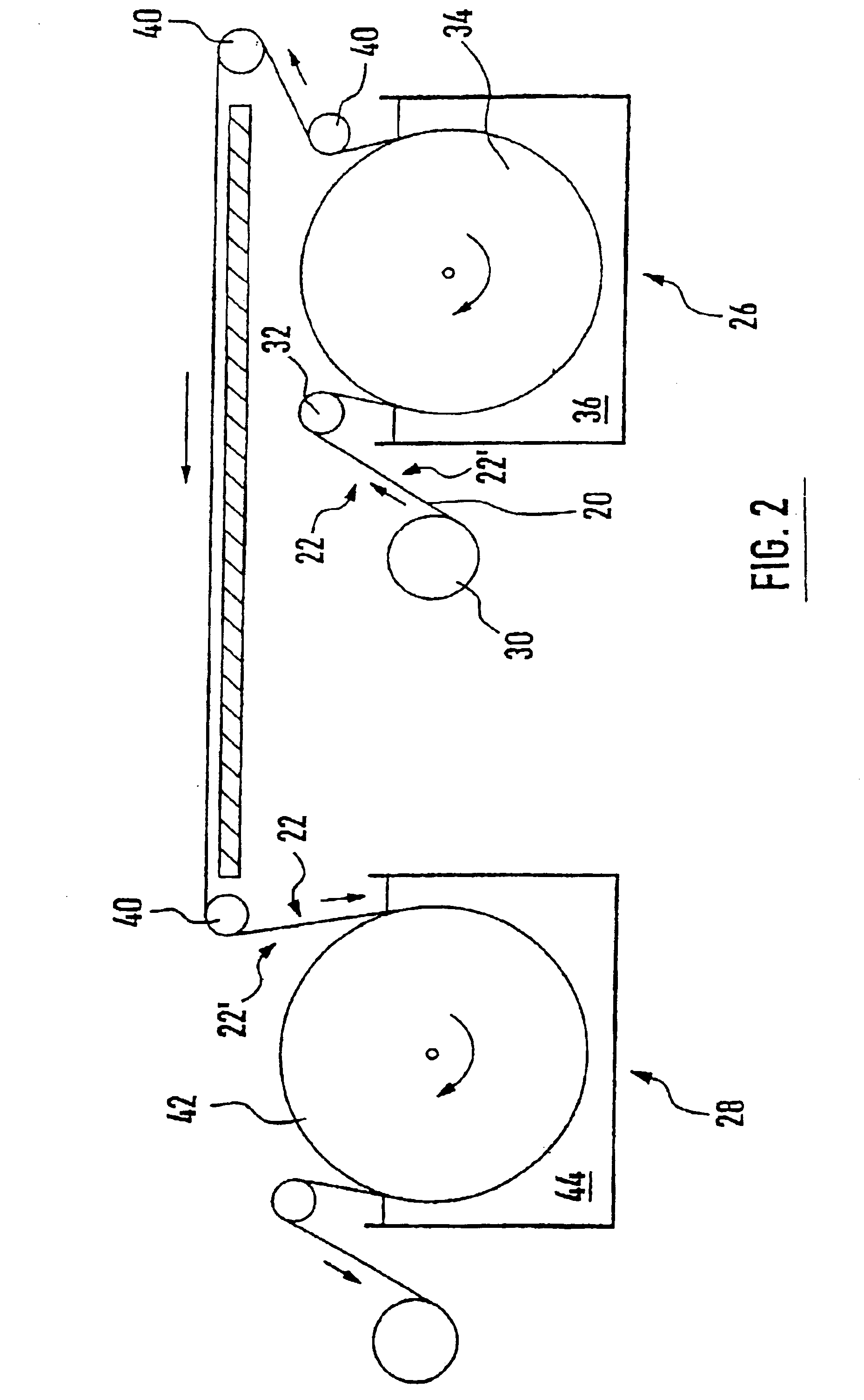

Method for electroplating a strip of foam

InactiveUS6942781B2Uniform platingElectrolysis componentsSurface reaction electrolytic coatingMetal foilElectroplating

A method for electroplating a strip of foam having two opposite sides and an electrically conductive surface, including:(a) continuously applying the strip of foam onto a moving cathode immersed in an electroplating bath so that the strip travels through the bath in contact with the moving cathode to electroplate metal on the strip of foam, a first side of the strip of foam facing a working surface of the moving cathode, and(b) continuously removing the electroplated strip of foam from the moving cathode when metal has been plated to a desired thickness;A metal foil is continuously formed by electrodeposition on the working surface of the moving cathode in such a way that the strip of foam is applied at step (a) onto the moving cathode over the metal foil; and, after step (b), the metal foil is continuously removed from the moving cathode.

Owner:CIRCUIT FOIL LUXEMBOURG R L

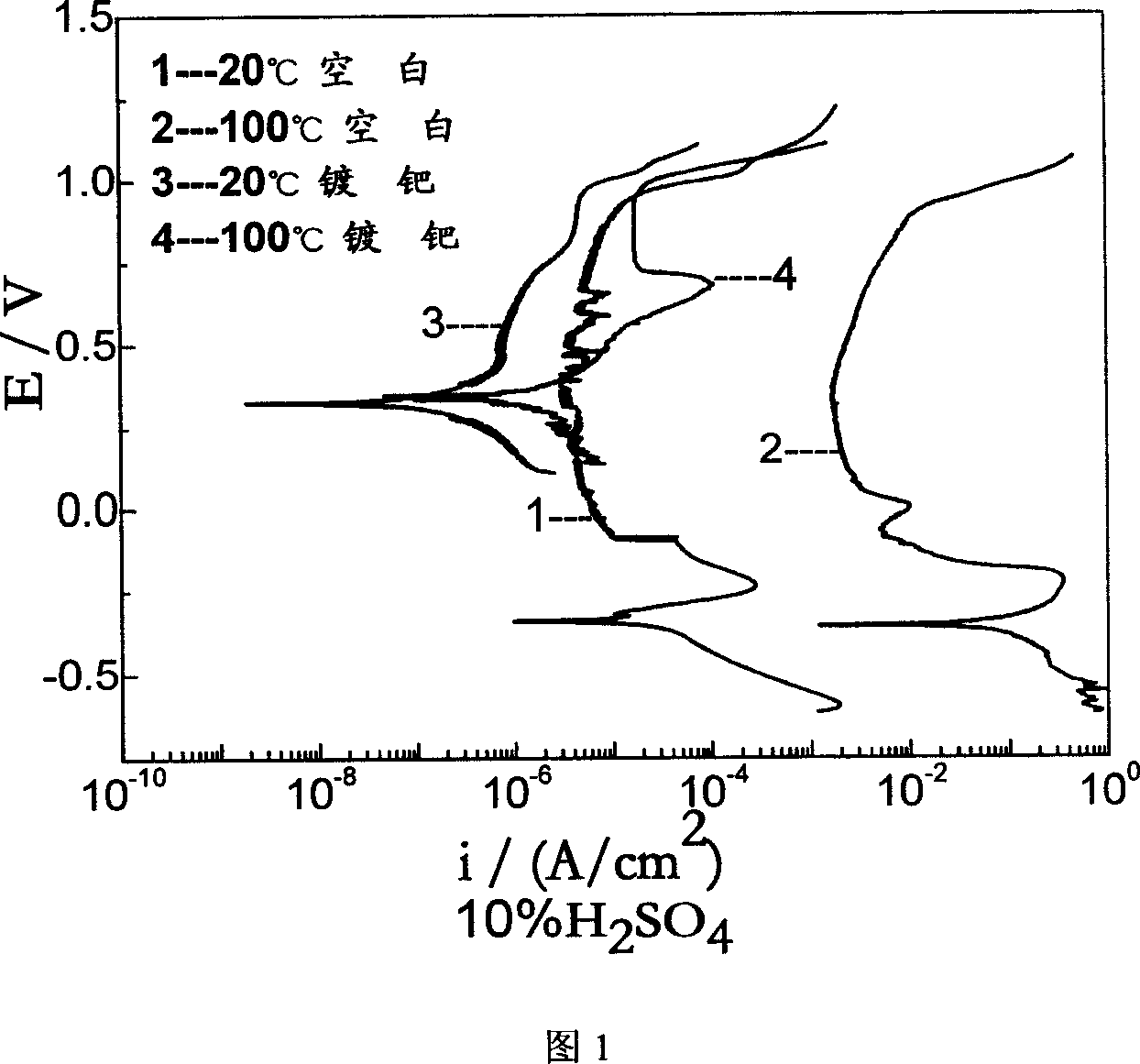

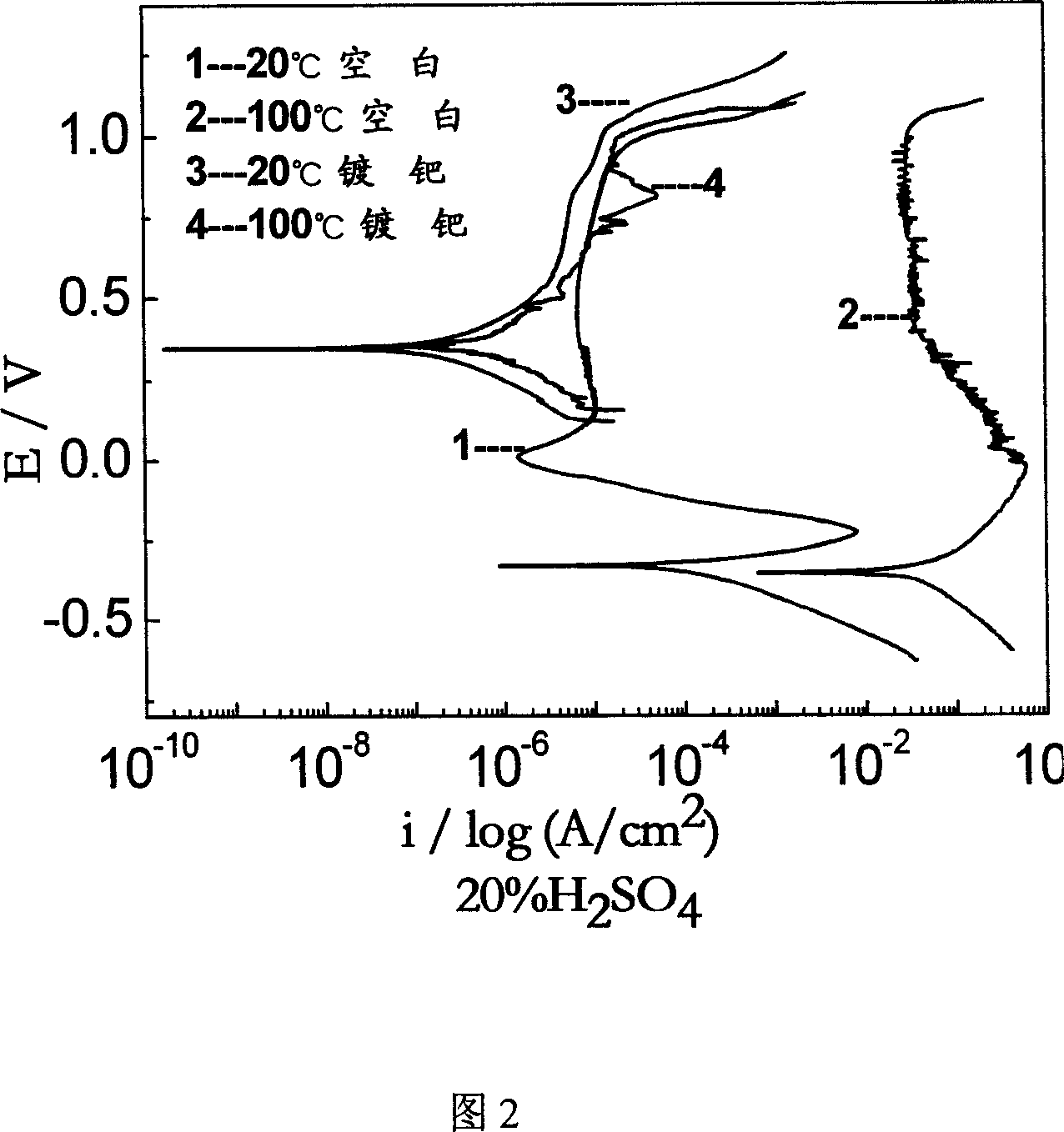

Chemical pd-plating process for stainless steel surface with excellent anticossive performance in non-oxidant medium

InactiveCN1932078AImprove passivation effectIncreased durabilityLiquid/solution decomposition chemical coatingChemical platingCompound (substance)

The present invention belongs to the field of surface treatment technology, and is especially chemical Pd-plating process for stainless steel surface with excellent anticorrosive performance in non-oxidant medium. The Pd-plated stainless steel is suitable for use in high temperature non-oxidant acidic medium environment. The chemical Pd-plating process includes surface pre-treatment and chemical plating, the surface pre-treatment includes deoiling and acid pickling, and chemical plating uses the plating solution comprising Pd salt Pd(NH3)4Cl2 in 1.5-5g / L accounting in PdCl2, stabilizer NH4Cl in 20-30 g / L, auxiliary complexing agent EDTA in 0-20g / L, surfactant Tween-20 in 0-0.002 ml / L, NH3 .H2O in 80-160 ml / L, reductant NaH2PO2 .H2O in 10-20g / L and water for the rest, of pH 9-10, for 30-60 min at 30-50 deg.c. The chemical Pd-plating process is simple.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com