Conduction system applicable to plating equipment

A technology of electroplating equipment and conductive heads, which is applied in the field of conductive systems, can solve the problems of small application range, easy winding, production danger, etc., and achieve the effects of guaranteed electroplating effect, convenient connection and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

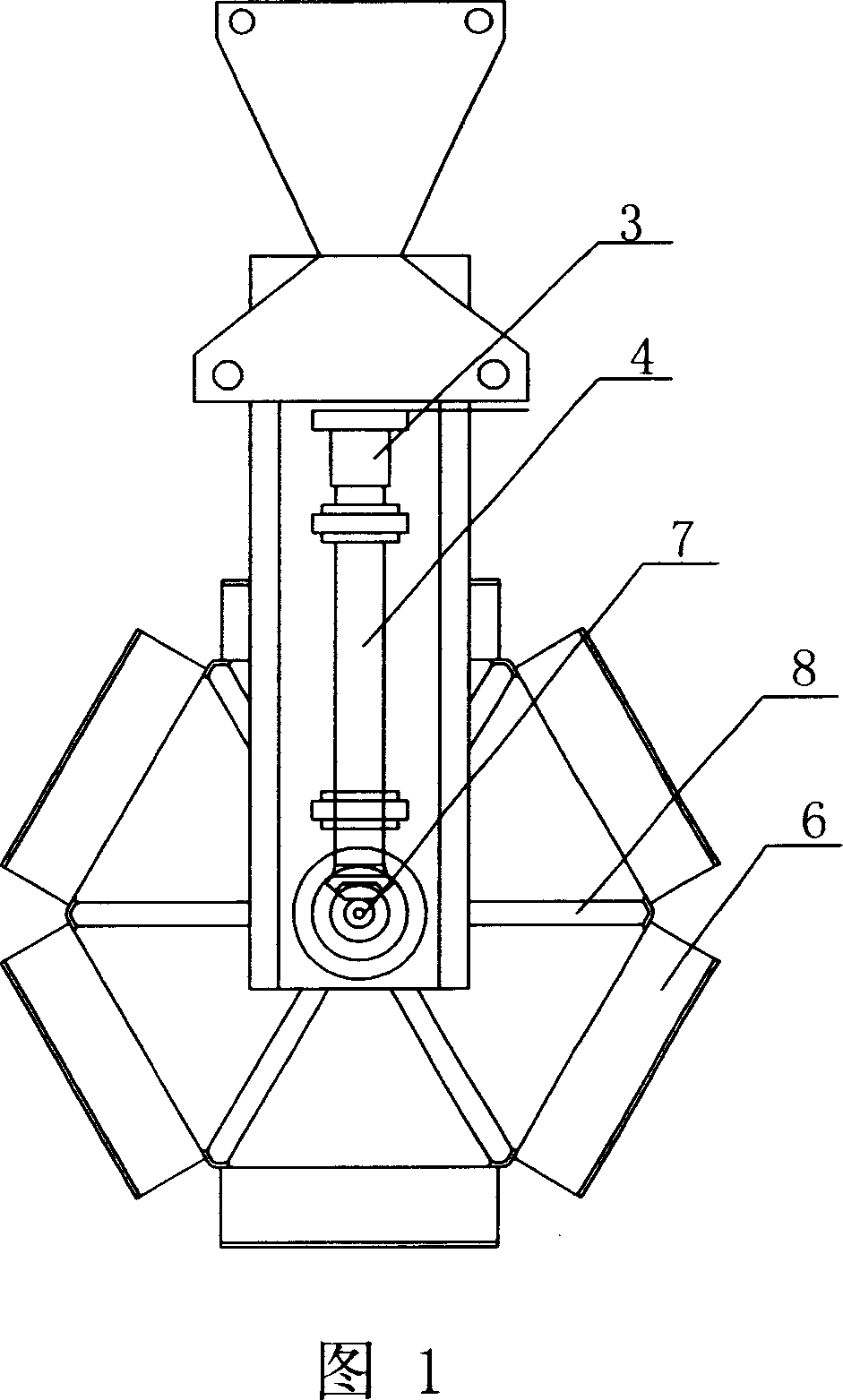

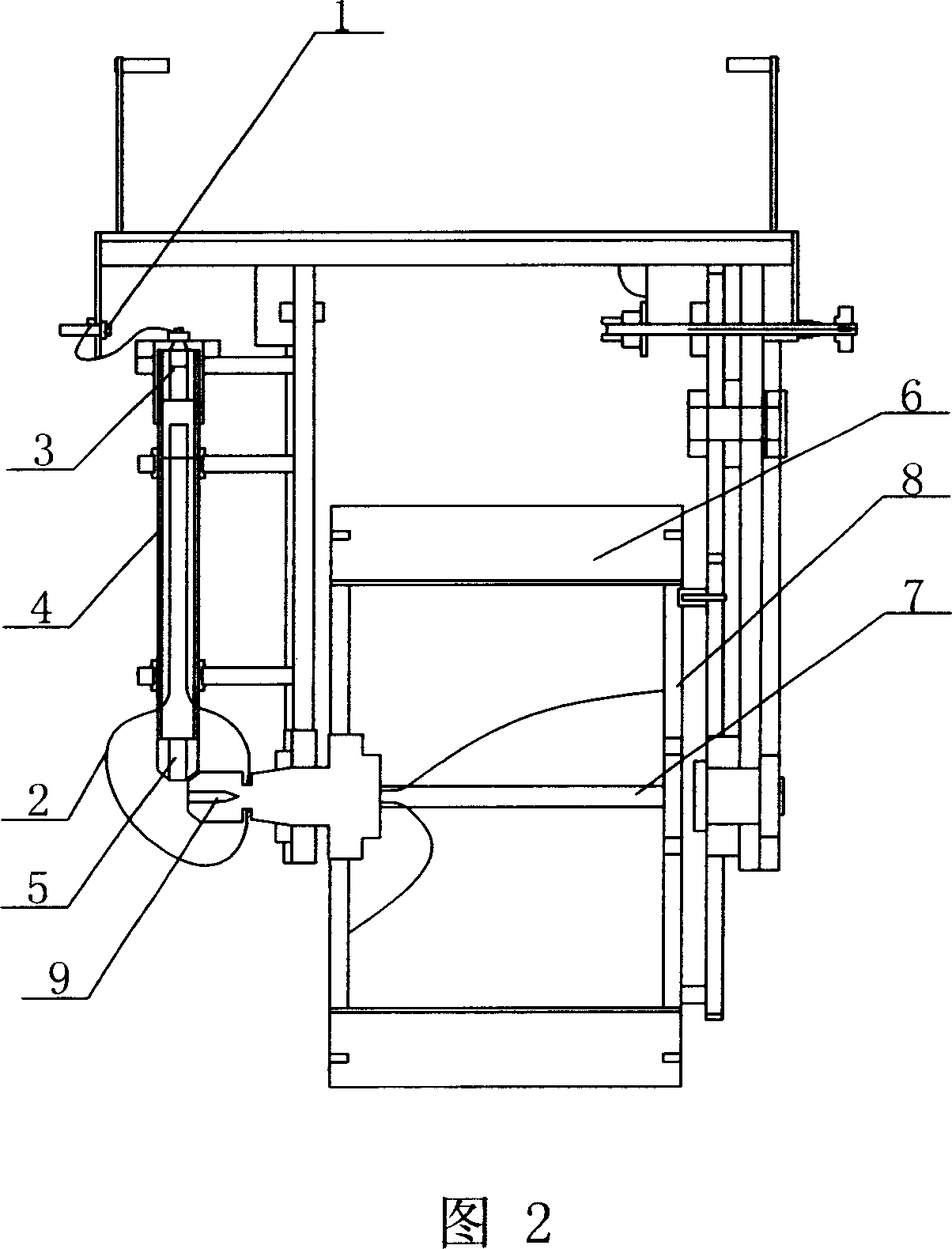

[0009] Below in conjunction with accompanying drawing, the present invention is further described: as shown in Figure 1, a kind of conductive system that is applied to electroplating equipment comprises copper conductive rod 1, flexible wire 2, mercury conductive device 3 and conductive head fixed sleeve 4 and steering cone Gear 5, the negative electrode of the power supply is connected to the cathode hook of the workpiece holder through them. The copper conductive rod 1 is connected to the power supply, and is connected with the transmission shaft 7 and the hexagonal iron frame 8 of the workpiece fixing frame 6 through the wire 2. In order to prevent the wire from being kinked when the workpiece fixing frame 6 rotates, the bottom of the conductive head fixing sleeve 4 is equipped with The bevel gear 9 that turns to the bevel gear 5 and the shaft end socket of the transmission shaft 7 of the hexagonal iron frame 8 forms a bevel gear transmission, and the conductive head fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com