Patents

Literature

60results about How to "Guaranteed plating effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

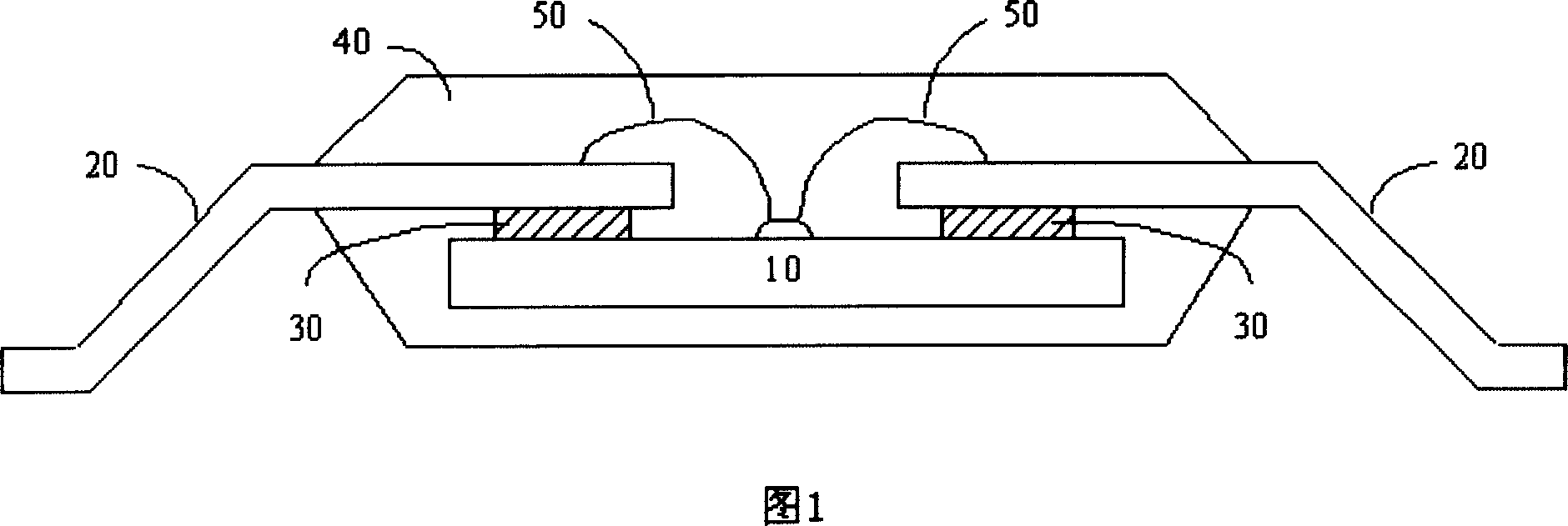

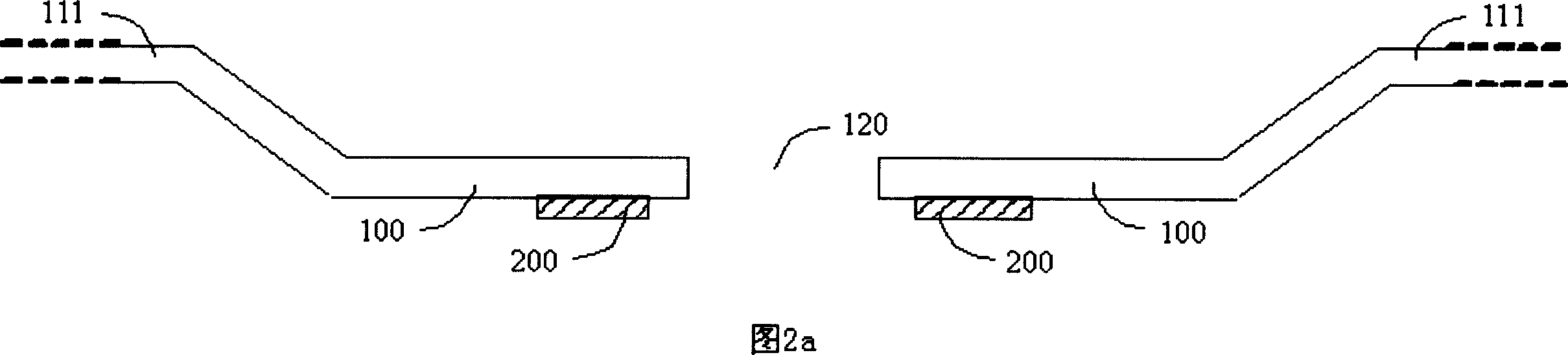

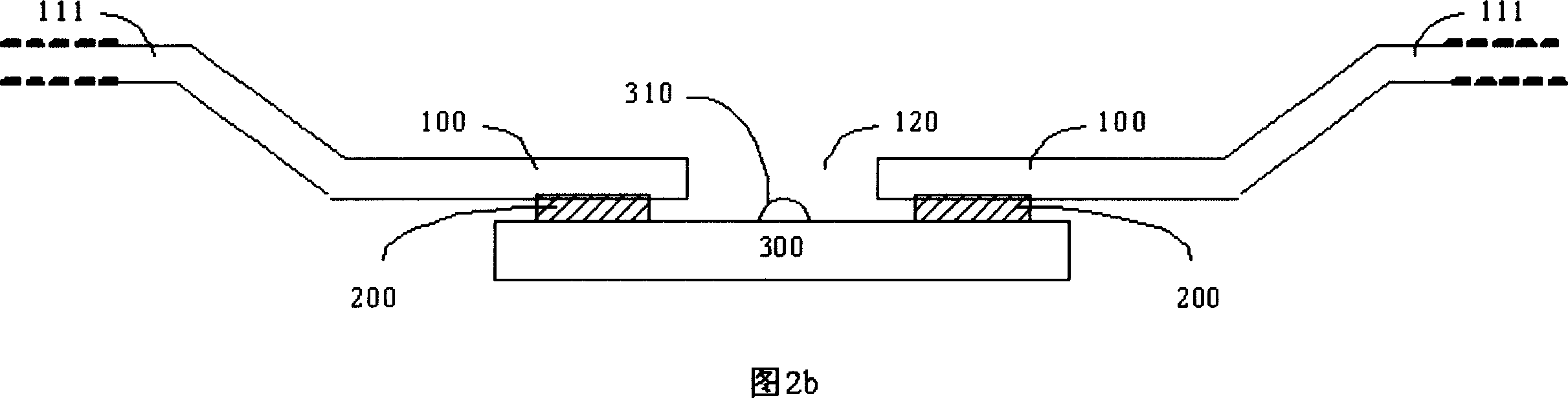

Lead frame chip-level encapsulation method

InactiveCN101055840AGuaranteed plating effectGuaranteed electrical stabilitySolid-state devicesSemiconductor/solid-state device manufacturingColloidLead frame

The invention proposes a lead frame type chip packaging method. The invention is similar to a conventional chip hook, but has a main difference that an inside pin of a lead frame is bended towords a side of the lead frame in addvance to form a space capable of supporting a chip and a lead, while an outside pin is directly exposed under a packaging colloid, and the outside pin is not bended and shaped when removing the frame. In addition, the packaged chip of the invention is face-down positioned on the lead frame, and the lead is connected to the lead frame via an opening of the lead frame by a solder pad positioned at a face of the chip, thereby the lead is under the lead frame. Another characteristic of the invention is that, after packaging, extravasated colloid or waste colloid are removed in a laser manner but only in a mechanical die or an electrolytic manner.

Owner:TITLE MAX TECH

Acid zinc-nickel alloy electroplating process applied to automobile parts

InactiveCN106011953AMild process conditionsImprove processing efficiencyMetallic material coating processesCorrosionAnode

The invention relates to an acid zinc-nickel alloy electroplating process applied to automobile parts. The electroplating process comprises the following steps: chemical deoiling, carrying out primary anode electrolysis, carrying out acid pickling, pre-plating zinc, carrying out acid pickling and deplating, ultrasonically deoiling, carrying out secondary anode electrolysis, activating, plating acid zinc nickel, carrying out bright dipping, passivating trivalent chromium, sealing, air shearing and drying. Compared with the existing process, the acid zinc-nickel alloy electroplating process applied to automobile parts has the advantages that deoiling is carried out twice and comprises chemical deoiling and ultrasonic deoiling; compared with the independent chemical deoiling, the process is mild in condition; the treatment efficiency is also greatly improved; and meanwhile, anode electrolysis is carried out after deoiling for each time, so that the corrosion caused in the deoiling process can be removed, thus the subsequent electroplating effect is ensured.

Owner:南通创源电化学科技有限公司

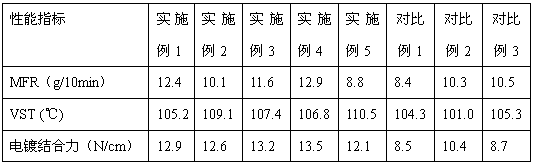

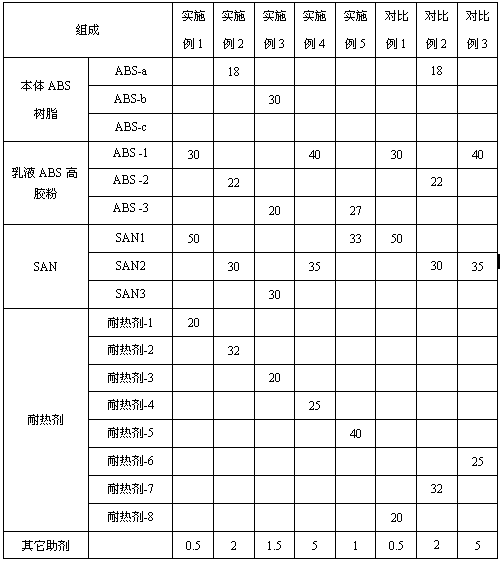

Heat-resisting ABS (Acrylonitrile-Butadiene-Styrene) resin applicable to electroplating and preparation method thereof

The invention relates to heat-resisting ABS (Acrylonitrile-Butadiene-Styrene) resin applicable to electroplating and a preparation method thereof. The heat-resisting ABS resin is prepared from the following ingredients in parts by weight: 0-30 parts of mass ABS resin, 20-40 parts of emulsion ABS rubber powder, 30-50 parts of styrene-acrylonitrile copolymer, 20-40 parts of heat resisting agent and 0.5-5 parts of other assistants, wherein the heat resisting agent is a quadripolymer based on four monomers including an N-phenyl maleimide monomer, an alpha-methyl styrene monomer, a styrene monomer and an acrylonitrile monomer, the weight percentage of the N-phenyl maleimide monomer is 5-20%, the weight percentage of the alpha-methyl styrene monomer is 40-70%, the weight percentage of the styrene monomer is 10-45%, the weight percentage of the acrylonitrile monomer is 10-45%, and the glass-transition temperature is 145-165 DEG C. According to the heat-resisting ABS resin applicable to electroplating and the preparation method thereof, through reasonably selecting the heat resisting agent, the heat resistance and plated layer binding force of the ABS resin are improved; and a heat-resisting master batch is not required to be prepared during preparation, so that the preparation is simple and easy to operate.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Zinc-nickel alloy electroplating process

The invention discloses a zinc-nickel alloy electroplating process. The zinc-nickel alloy electroplating process comprises the following steps: performing oil and rust removal, carrying out ultrasonic cleaning, electroplating, conducting hydrogen removal, performing hydrophobic treatment, washing with water and blow-drying. According to the process, the steps of oil removal and rust removal are integrated, so that the procedures are simplified, the cost is reduced, and the efficiency is improved; the step of ultrasonic cleaning is added, so that the whole pretreatment efficiency is high, and environmental protection and zero contamination are realized; in the electroplating process, the pH value of an electroplating solution is about 5, namely, weak acidity, electric current density of 50 mA / cm<2> is adopted, and silicon carbide particles with the particle diameters of 1-10 microns are added into the electroplating solution, so that the wearing resistance of a cladding subjected to electroplating is greatly enhanced, and the reduction is smaller than 0.02 micron under the condition that the friction speed is 15000 r / min.

Owner:太仓市金鹿电镀有限公司

Nickel-magnesium alloy electroplating technique

The invention discloses a nickel-magnesium alloy electroplating technique which comprises the following steps: deoiling and derusting, ultrasonic cleaning, electroplating, dehydrogenation, water repelling treatment, alcohol washing, water washing and blow-drying. The technique integrates the deoiling and derusting steps, thereby saving the procedure, lowering the cost and enhancing the efficiency. The ultrasonic cleaning step is added, so that the overall pretreatment is efficient, environment-friendly and pollution-free. In the electroplating process, the pH value of the electroplating solution is 5 or so which is weakly acidic, and the current density is 50 mA / cm<2>. The silicon carbide particles with the particle size of 1-10 mu m are added into the electroplating solution, so that the wear resistance of the final electroplating coating is greatly enhanced, and the reduction quantity is less than 0.02 mu m when the friction rotation speed is 15000 r / min.

Owner:太仓市金鹿电镀有限公司

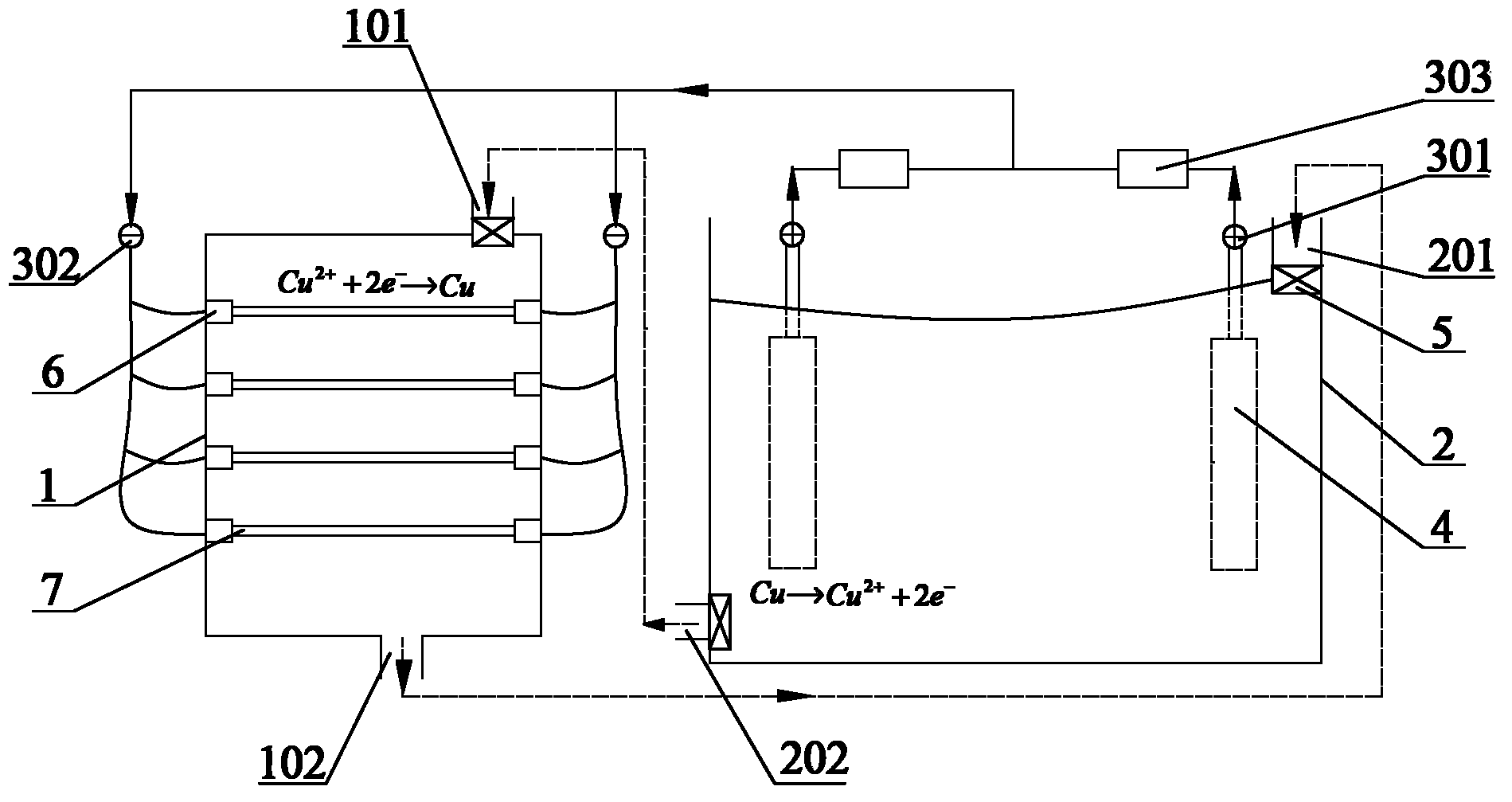

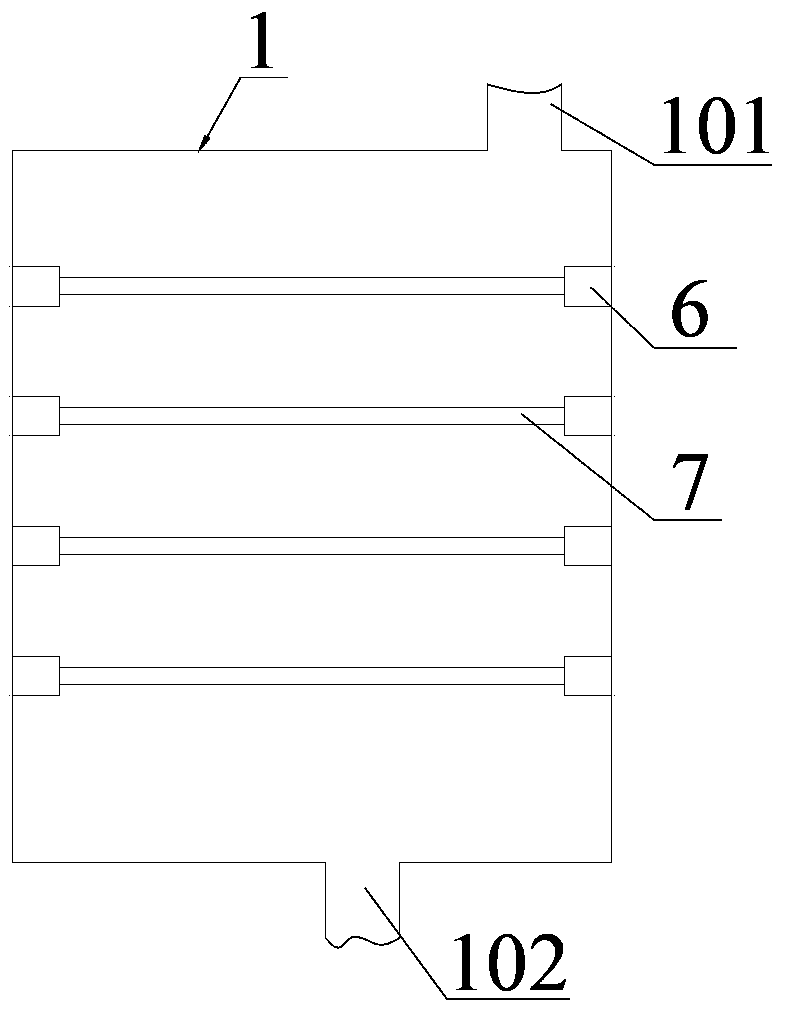

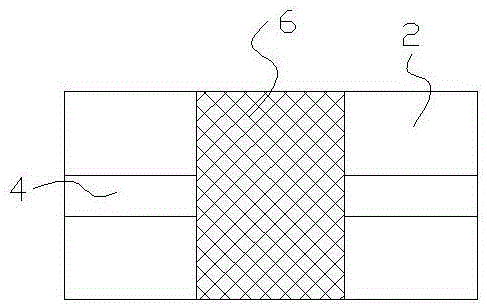

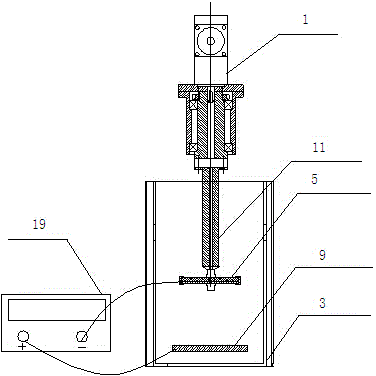

Electroplating device and method of plating copper in via hole of PCB (Printed Circuit Board)

InactiveCN103849915ANo pollution in the processAvoid enteringCellsPrinted element electric connection formationFine lineEngineering

The invention provides an electroplating device which comprises an electroplating bath and an auxiliary bath, wherein the anodic metal in the auxiliary bath is connected to a power supply device, a to-be-electroplated workpiece is connected to the cathode of the power supply device, the auxiliary bath is communicated with the electroplating bath and provides an electroplate liquid to the electroplating bath, the anodic metal immerges into the electroplate liquid, and the electroplating bath is used for plating metal to the to-be-electroplated workpiece. The invention further provides a method of plating copper into a via hole of a PCB (Printed Circuit Board). The electroplating device provided by the invention can electroplate PCBs with super ratio of thickness to radial dimension and fine lines.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

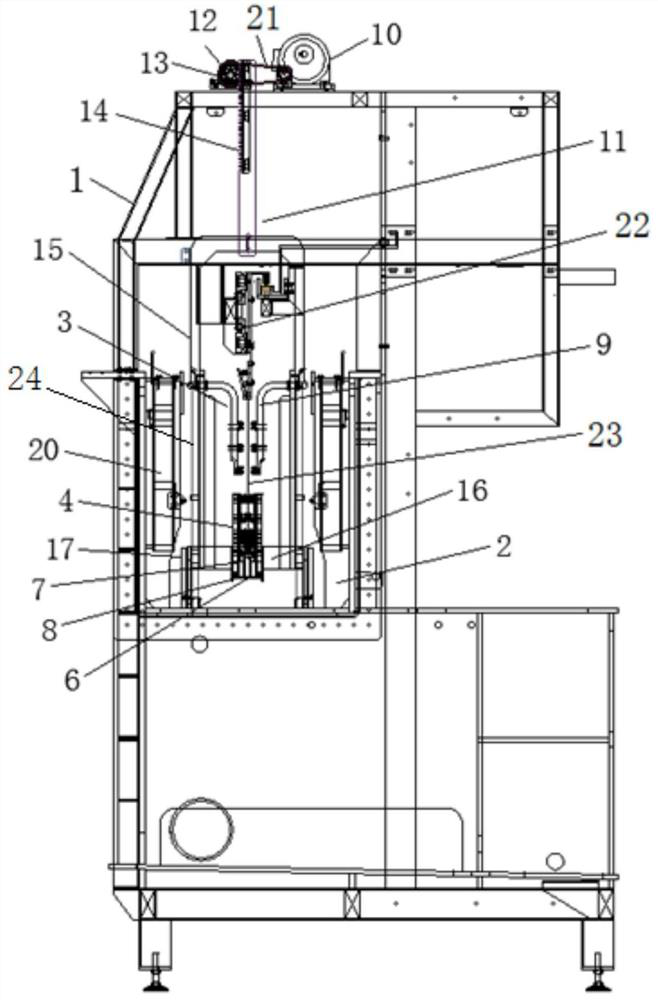

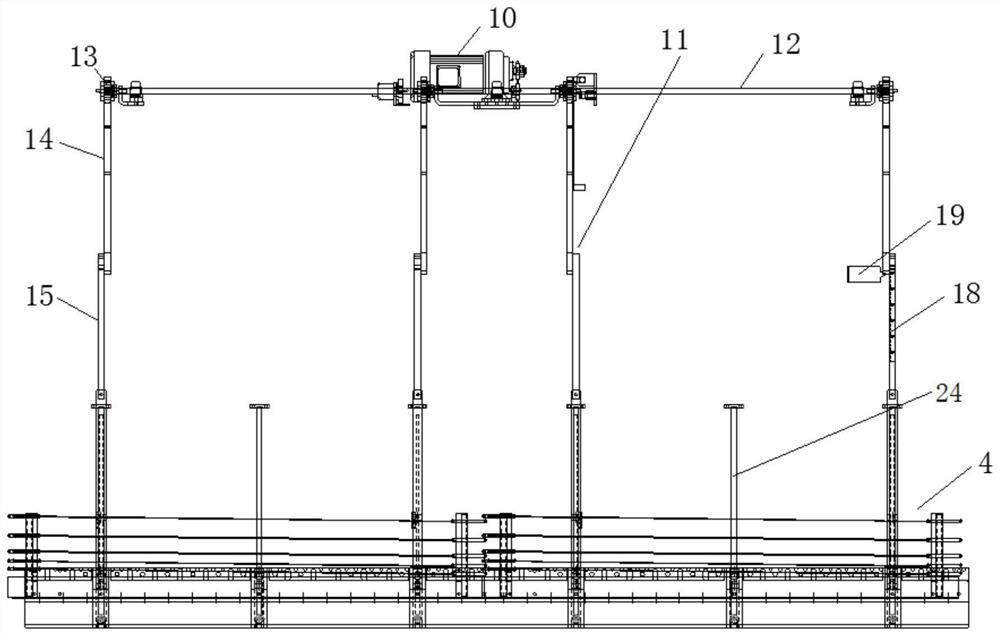

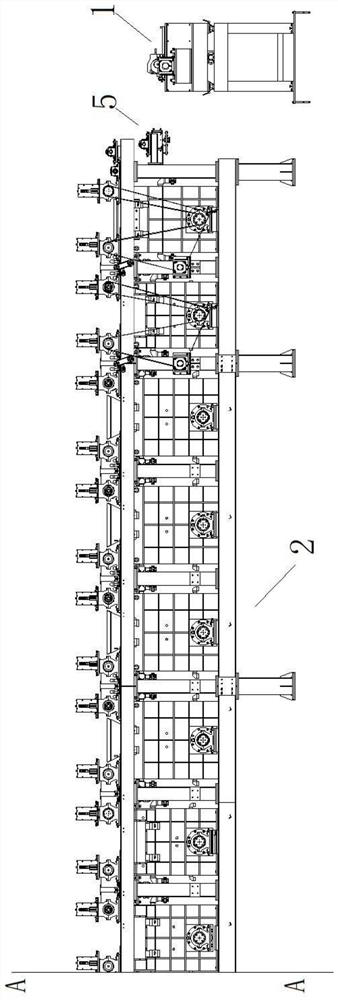

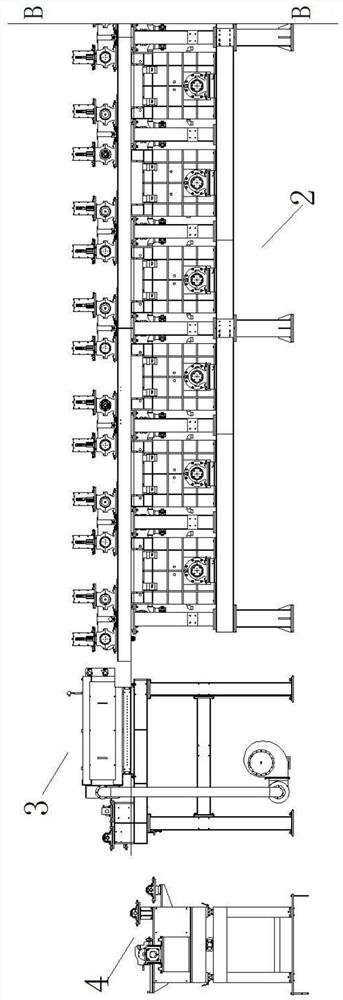

Electroplating device

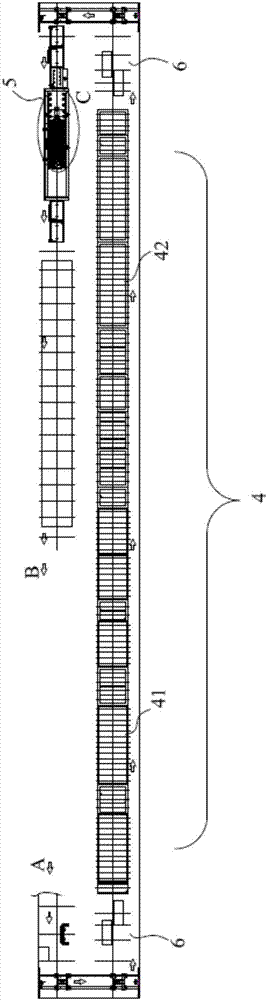

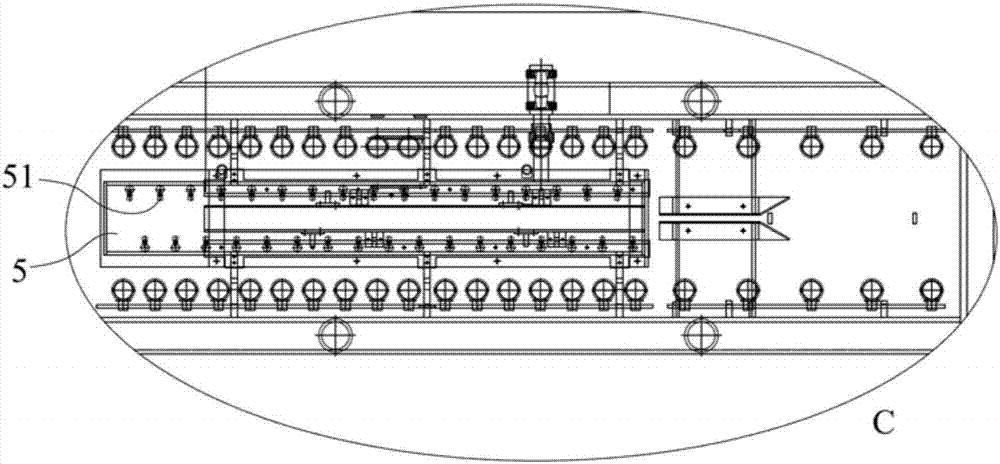

PendingCN107059097AImprove consistencyImprove preprocessing effectCellsProcess efficiency improvementMetallurgyMechanical engineering

The invention discloses an electroplating device which comprises a rail, a crown block, a hanging tool, pretreatment grooves and an electroplating groove. The crown block comprises a movement part and a lifting part, the movement part moves along the rail, and the lifting part is connected with the movement part; the hanging tool is used for bearing or clamping workpieces; the multiple pretreatment grooves are sequentially arranged along the rail in the length direction, the workpieces are subject to sinking placement in the pretreatment grooves by a certain time to complete pretreatment, and the length direction of the electroplating grooves is parallel to the rail transporting direction; and during workpiece electroplating, the hanging tool drives the workpieces to sequentially pass through the electroplating grooves at a certain rate, and the length direction of the workpieces is parallel to the length direction of the electroplating grooves during electroplating. The pretreatment grooves are arranged in the length direction in the rail paving direction, the length in the direction vertical to the rail can be decreased, and the floor area is reduced. The workpieces directly and sequentially pass through the electroplating grooves, and the workpiece electroplating consistency can be guaranteed.

Owner:JUNJIE MACHINERY SHENZHEN

Tourist souvenir furnishing article

InactiveCN105420769AAvoiding the Consequences of Serious PollutionImprove bindingCyanideCopper plating

The invention discloses a tourist souvenir furnishing article. The furnishing article is characterized in that a base material is produced by die-casting 2# zinc alloy, wherein a cyanide-free copper pre-plating layer, an acidic copper plating layer, a semi-bright nickel plating layer, a high sulfur nickel electroplating layer, a bright nickel electroplating layer and a chrome electroplating layer, which are correspondingly 3 to 5 microns, 1 to 2 microns, 0.5 to 1 microns, 2 to 3 microns, 1 to 2 microns, and 6 to 8 microns in thickness, are sequentially arranged on the outer surface of the base material.

Owner:张颖

Copper-manganese alloy electroplating technique

The invention discloses a copper-manganese alloy electroplating technique which comprises the following steps: deoiling and derusting, ultrasonic cleaning, electroplating, dehydrogenation, water repelling treatment, alcohol washing, water washing and blow-drying. The technique integrates the deoiling and derusting steps, thereby saving the procedure, lowering the cost and enhancing the efficiency; and the weakly alkaline conditions can produce less pollution to the environment. The ultrasonic cleaning step is added, so that the overall pretreatment is efficient, environment-friendly and pollution-free. In the electroplating process, an acidic system is adopted, and thus, can produce less pollution to the environment. By adding ascorbic acid, hydroquinone and other additives, the electroplating is performed under the conditions of proper current density and electroplating temperature, so the copper / manganese codeposition effect is good, and the finally obtained copper-manganese alloy electroplating coating has the advantages of uniform color, fine crystals, high film thickness (up to 10 mu m) and favorable wear resistance. After being rubbed 100 times by W40 sand paper in a single direction, the coating can not peel. The alloy coating has favorable electric conductivity, and can effectively prevent chromium in the stainless steel from outward transfer and dispersion.

Owner:太仓市金鹿电镀有限公司

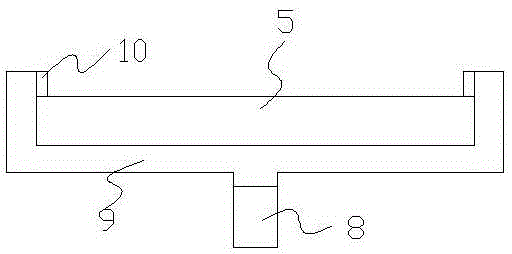

Plating tank plated evenly

InactiveCN105200499AEasy to install and disassembleEasy to replaceCellsTanksArchitectural engineeringElectroplating

The invention discloses a plating tank plated evenly. The plating tank comprises a tank body. Partition plates are fixedly connected to the tank body, and heating devices are further arranged on the tank body. Each partition plate is provided with an inclined plane, a sliding channel is formed in the corresponding partition plate, anode plates are connected in the sliding channels, and a filtering device is fixedly connected between the two partition plates, a water return pipe is arranged in the tank body. One end, located above the partition plates, of the water return pipe is connected with a telescopic pipe, the end, away from the water return pipe, of the telescopic pipe is connected with a tee pipe, the side faces of branch pipes of the tee pipe abut against the side faces the anode plates located on the partition plates penetrated by the water return pipe, and the outer side walls of the branch pipes are movably connected with blocking blocks. The positions of the anode plates can be adjusted according to requirements, the anode plates are convenient to assemble and disassemble, easy to replace and easy to locate in the mounting process, the plating bath foam temperature can be adjusted conveniently in the plating process, and plating bath foam can be recycled and filtered in real time.

Owner:ANHUI ZHONGZHI LIGHT SOURCE TECH

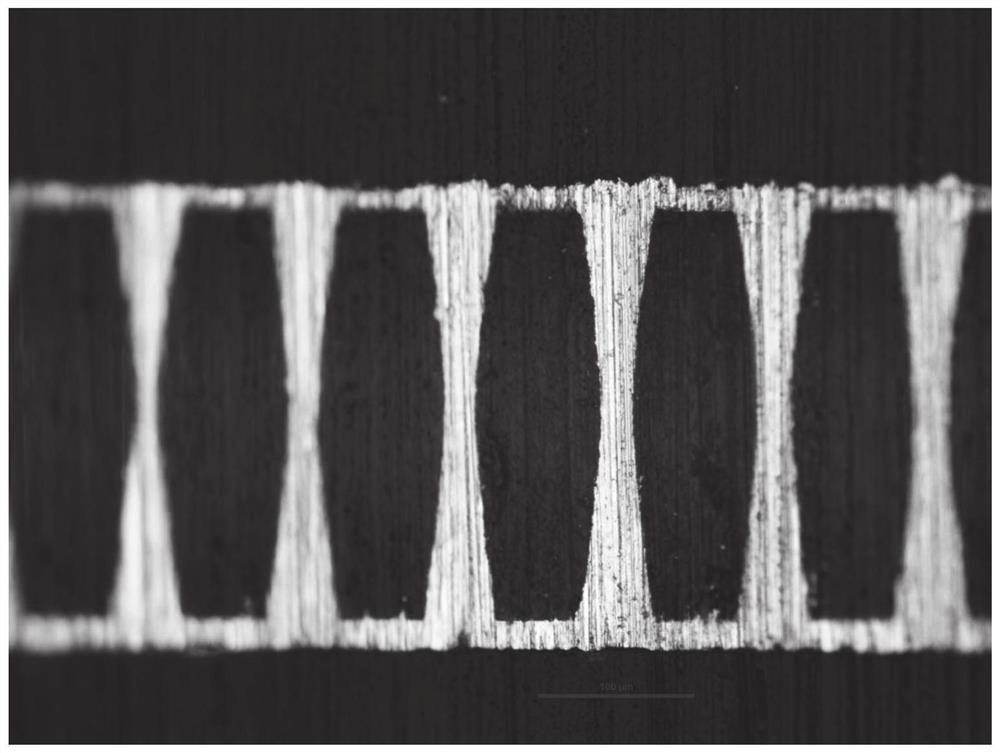

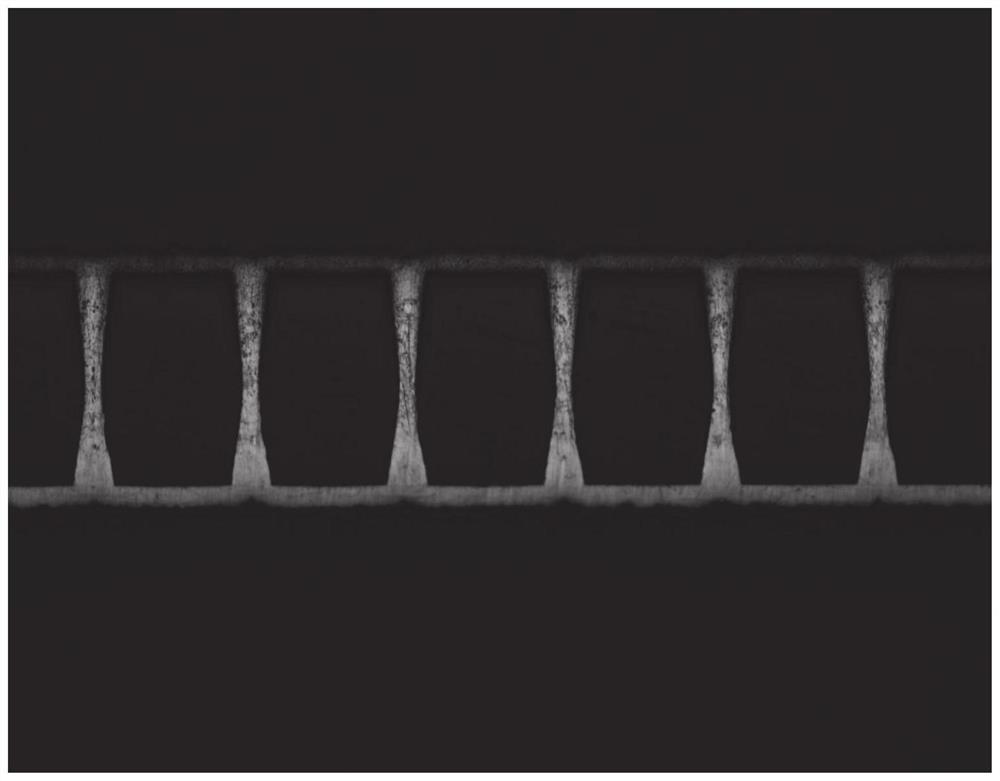

Method of manufacturing mechanical blind half hole

ActiveCN110121239AFull exchangeGuaranteed plating effectPrinted element electric connection formationEngineeringElectroplating

The invention discloses a method for manufacturing a mechanical blind half hole, and the method comprises the following steps: drilling a blind hole at the edge of a unit plate area on a production board, wherein a half of the blind hole is located in a forming line area on the production plate; drilling a through hole with the same aperture as the blind hole in the forming line area beside the blind hole, wherein the through hole is intersected with the blind hole; metalizing the hole through the processes of copper deposition and full-board electroplating; manufacturing an outer-layer circuit on the production board, firstly milling off the forming line area beside the blind hole in the production board in the process of manufacturing the outer-layer circuit after pattern electroplating,and then performing outer-layer etching to obtain the outer-layer circuit and the metalized blind half-hole. According to the invention, the risk that the bottoms of the blind hole semi-holes are free of copper can be effectively solved through the optimization of the production process, the problems of shawl and burrs on the edges of the blind hole semi-holes can be avoided, and the quality of circuit board products is guaranteed.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

Nickel-cobalt alloy electroplating technique

The invention discloses a nickel-cobalt alloy electroplating technique which comprises the following steps: deoiling and derusting, ultrasonic cleaning, electroplating, dehydrogenation, water repelling treatment, water washing and blow-drying. The technique integrates the deoiling and derusting steps, thereby saving the procedure, lowering the cost and enhancing the efficiency. The ultrasonic cleaning step is added, so that the overall pretreatment is efficient, environment-friendly and pollution-free. In the electroplating process, the pH value of the electroplating solution is 3 or so which is weakly acidic, and the current density is 110 A / dm<2>, so the wear resistance of the electroplating coating is greatly enhanced in the specific electroplating solution; under the condition that the friction rotation speed is 15000 r / min, the reduction quantity is less than 0.02 mu m, and the coating hardness is increased; and when the pulse period is 24ms, the maximum coating hardness is 609HV which is 1.5 times of the conventional nickel-cobalt coating, the surface is smooth, and the average grain size is 14nm or so.

Owner:太仓市金鹿电镀有限公司

Copper oil nozzle machining equipment

The invention discloses copper oil nozzle machining equipment which comprises an electroplating tank, a guide rail arranged above the electroplating tank and a guide block arranged in the guide rail.A first connecting rod is arranged on the guide block, a first movable cavity is arranged on the first connecting rod, a second connecting rod penetrates through the first movable cavity, a first limiting plate is arranged at the top of the second connecting rod, and a connecting spring is arranged at the top of the first limiting plate. The first limiting plate is made of magnetic materials, thetop of the guide rail is provided with a first groove, a first electromagnet is arranged in the first groove, the first electromagnet is arranged above the electroplating tank, and a feeding device isarranged on the side wall of the electroplating tank. An oil tank switch is machined in a mode that the guide rail and the guide block are matched with each other, so that the machining of the oil tank switch is automatically carried out, operators are prevented from directly contacting with an electroplating solution, the protection effect is played to the operators, the machining efficiency ofthe oil tank switch is greatly improved, and the machining difficulty of the oil tank switch is reduced.

Owner:绍兴市上虞区敏敏汽车配件有限公司

Copper electroplating process

The invention discloses a copper electroplating process. The copper electroplating process comprises the steps of deoiling and derusting, ultrasonic cleaning, electroplating, hydrogen removal, hydrophobic treatment, alcohol washing, water washing and blow-drying. As the two procedures of deoiling and derusting are integrated, the procedures are simplified, the cost is lowered, the efficiency is improved, and the weakly basic condition causes less environmental pollution; as the ultrasonic cleaning procedure is added, the integral pretreatment efficiency is high, and the environment-friendly and pollution-free purposes are achieved; in the electroplating process, as a cyanide-free alkali system is adopted, environmental pollution is small; hydroxyethyl acrylate, hydroxypropyl distarch phosphate, EDTA, hydroquinone and other additives are added, electroplating is performed under the conditions of appropriate current density and electroplating temperature, finally, a fully-bright, uniform, compact and no-microcrack copper coating with a relatively good binding force can be obtained, and the coating can be 10 [mu]m in thickness, excellent in wearing resistance and free of scales when rubbing for 100 times on W40 sand paper.

Owner:太仓市金鹿电镀有限公司

Environment-friendly electroplating liquid and electroplating process

The invention provides environment-friendly electroplating liquid. The environment-friendly electroplating liquid comprises 0.25-0.55 mol / L of chromic formate, 0.15-0.45 mol / L of ammonium formate, 0.15-0.45 mol / L of urea, 0.05-0.15 mol / L of malic acid, 65-75 g / L of boric acid, 155-165 g / L of ammonium sulfate, 8.5-9.5 g / L of sodium chloride, 1.5-2.5 g / L of a chromium walking agent, 1.0-1.5 g / L of a rare earth addition, 0.15-0.25 g / L of lauryl sodium sulfate and 0.15-0.25 g / L of sodium thiosulfate. The invention further provides an electroplating process which includes pretreatment, electroplating, dehydrogenation, hydrophobic treatment, washing and drying. By the adoption of the electroplating liquid and the electroplating process, the electroplating effect is good, and the electroplating liquid does not contain hexavalent chromium and is small in toxin and environmentally friendly.

Owner:太仓市金鹿电镀有限公司

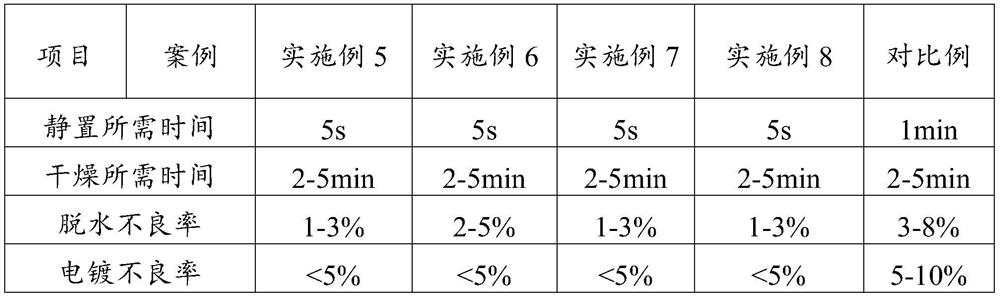

Dehydrating agent, preparation method of dehydrating agent, hydrocarbon water cutting agent and preparation method of hydrocarbon water cutting agent

InactiveCN112010773AEasy to dehydrateImprove efficiencyOrganic compound preparationCarboxylic acid amides preparationPtru catalystAlcohol

The invention discloses a dehydrating agent, a preparation method of the dehydrating agent, a hydrocarbon water cutting agent and a preparation method of the hydrocarbon water cutting agent, and relates to the technical field of chemical cleaning. The dehydrating agent comprises the following components in percentage by mass: 60-80% of an alcohol ether solvent, 5-10% of a phase transfer catalyst,10-20% of long-chain primary amine and 5-15% of short-chain carboxylic acid. The dehydrating agent provided by the invention has a good dehydrating effect and relatively high efficiency, the adsorption film on the surface of the part enables the part not to easily condense water and adsorb dust, and the dehydrating agent can be widely applied to electroplating pretreatment of the part, so that thesubsequent electroplating effect is ensured.

Owner:SHENZHEN XINJUNXIANG TECHCAL

Method for plating decorative chromium by die-cast zinc alloy part

InactiveCN105506690AAvoiding the Consequences of Serious PollutionImprove bindingCopper platingSulfur

The invention discloses a method for plating decorative chromium by a die-cast zinc alloy part. The method comprises the steps of: (1) treatment before plating ; (2) cyanide-free copper preplating; (3) acid copper plating; (4) electroplating of semi-bright nickel; (5) electroplating of high-sulfur nickel; (6) electroplating of bright nickel; and (7) electroplating of chromium. An obtained plating layer is uniform in plating film thickness, high in corrosion resistance, high in hardness, bright and smooth in surface, free of generation of scales, peeling, fading and color changing and suitable for decorative chromium plating treatment of decorative parts, artware and the like.

Owner:张颖

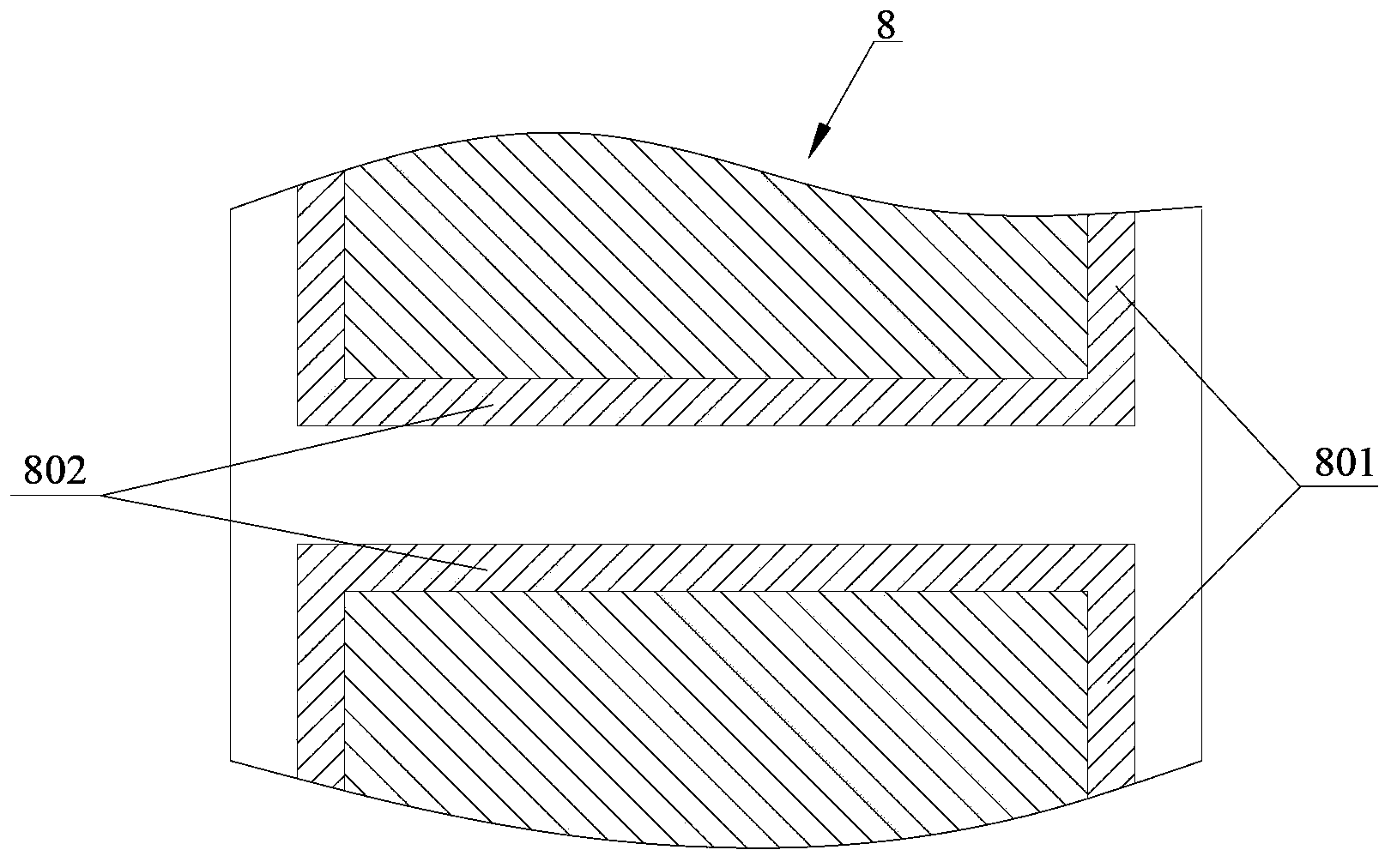

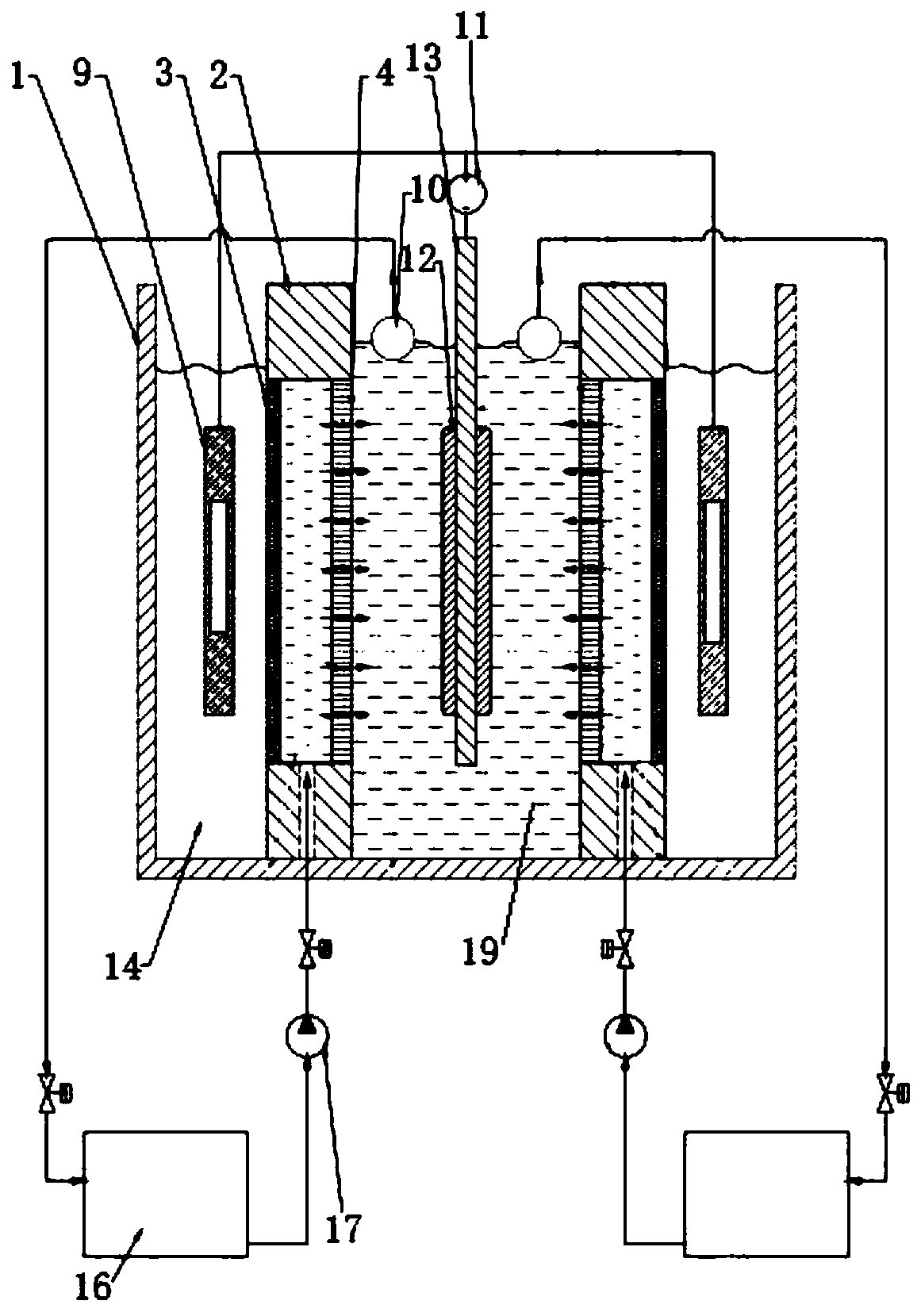

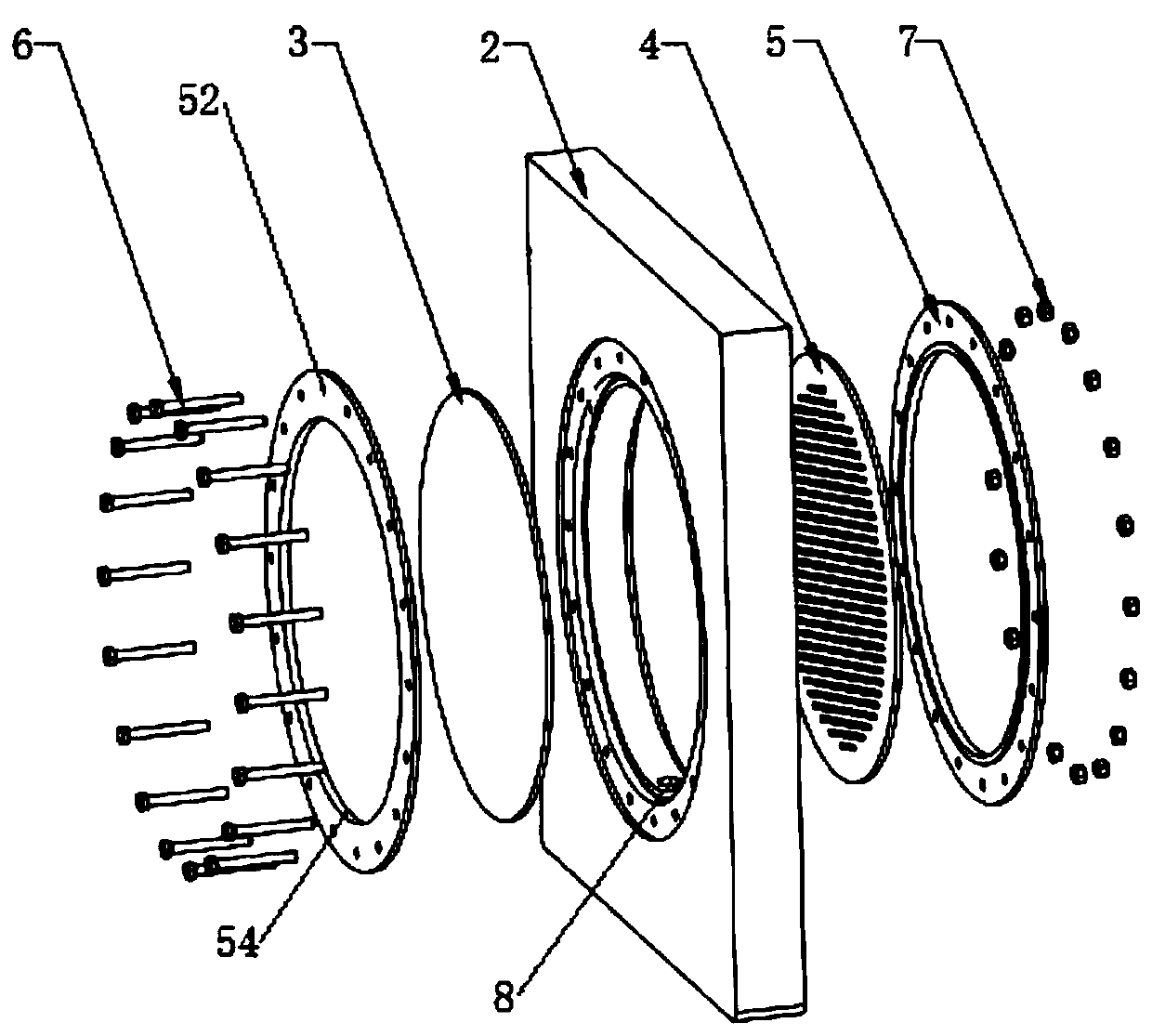

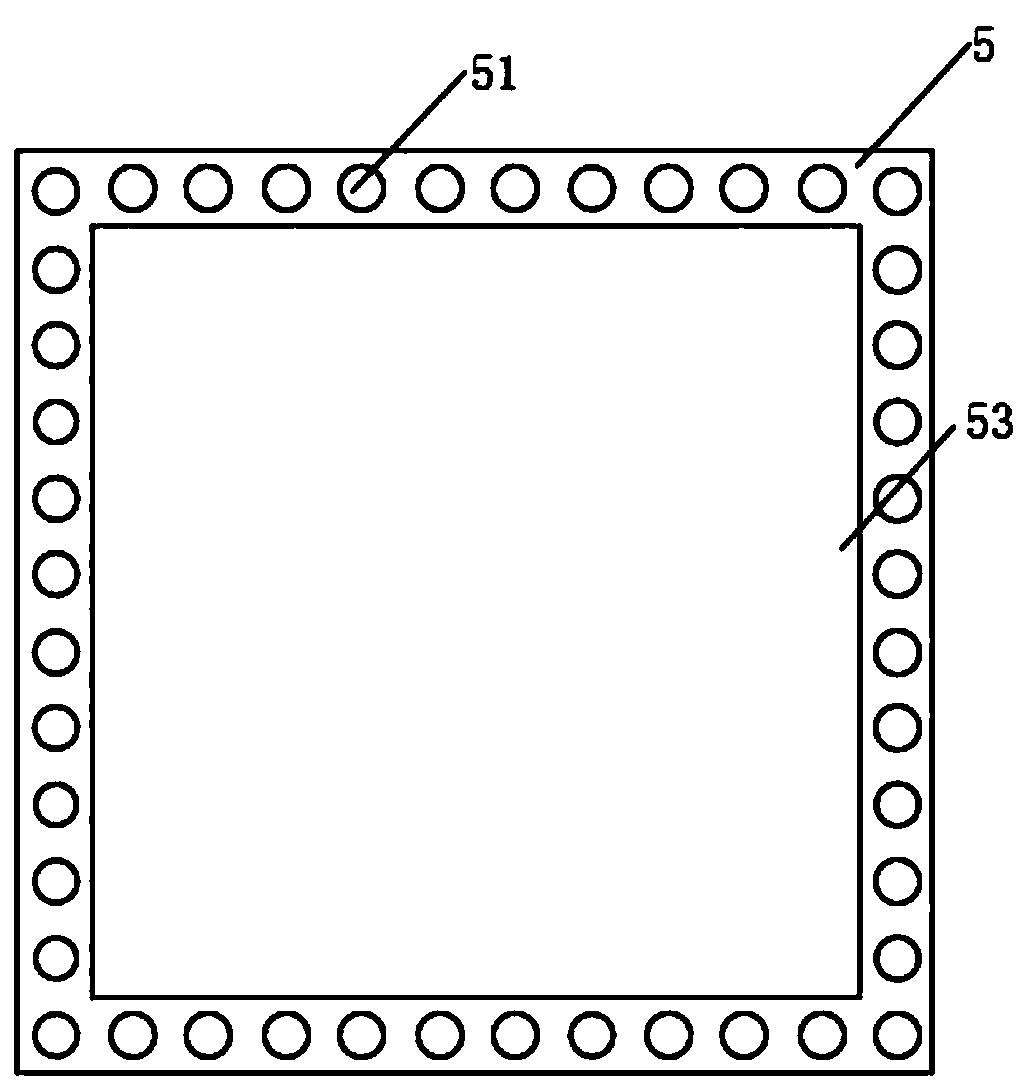

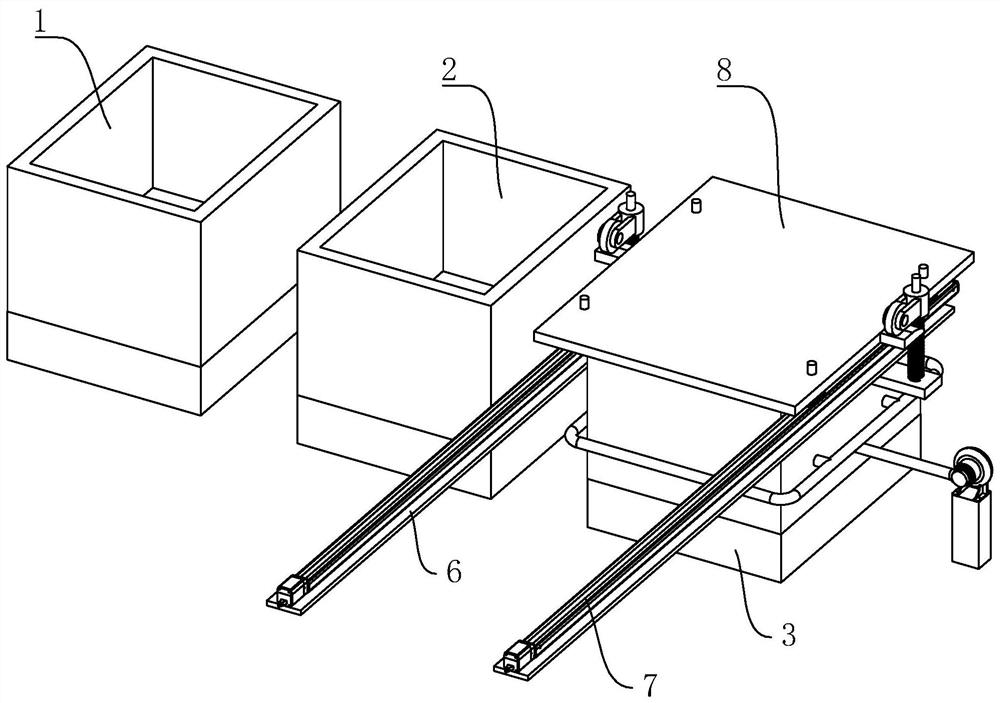

Jet flow type electrochemical deposition device

The invention discloses a jet flow type electrochemical deposition device. The device comprises an electroplating bath, wherein one or more jet flow mechanisms, cathodes and the anodes can be arrangedside by side in the electroplating tank, electrolysis on one or more substrates can be met, a substrate fixing frame is mounted in the electroplating tank, a substrate is mounted on the substrate fixing frame, the jet flow mechanisms are symmetrically arranged on the two sides of the substrate fixing frame, the jet flow mechanisms are provided with hollow shells, diaphragms and jet flow plates are mounted on the two sides of the jet flow mechanism respectively, cathode chambers are arranged on the side of the jet flow plates, and anode chambers are arranged on the side of the diaphragms. According to the device, through the design of the jet flow fixing plates, the diaphragms separate the catholyte in the cathode chamber and the anolyte in the anode chamber, an additive is not required tobe added in the solution in the anode chamber in the electrolysis process, the circular-shaped and the square-shaped jet flow plates are arranged, and the electrolysis of the plated objects in different shapes can be met, so that the electroplating effect of different plated objects is ensured.

Owner:ANHUI HONGSHI AUTOMATION EQUIP CO LTD

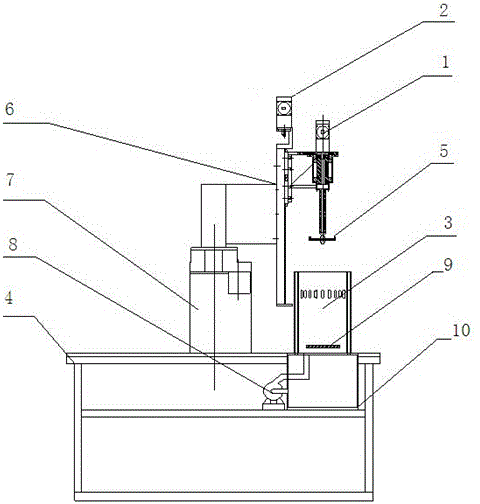

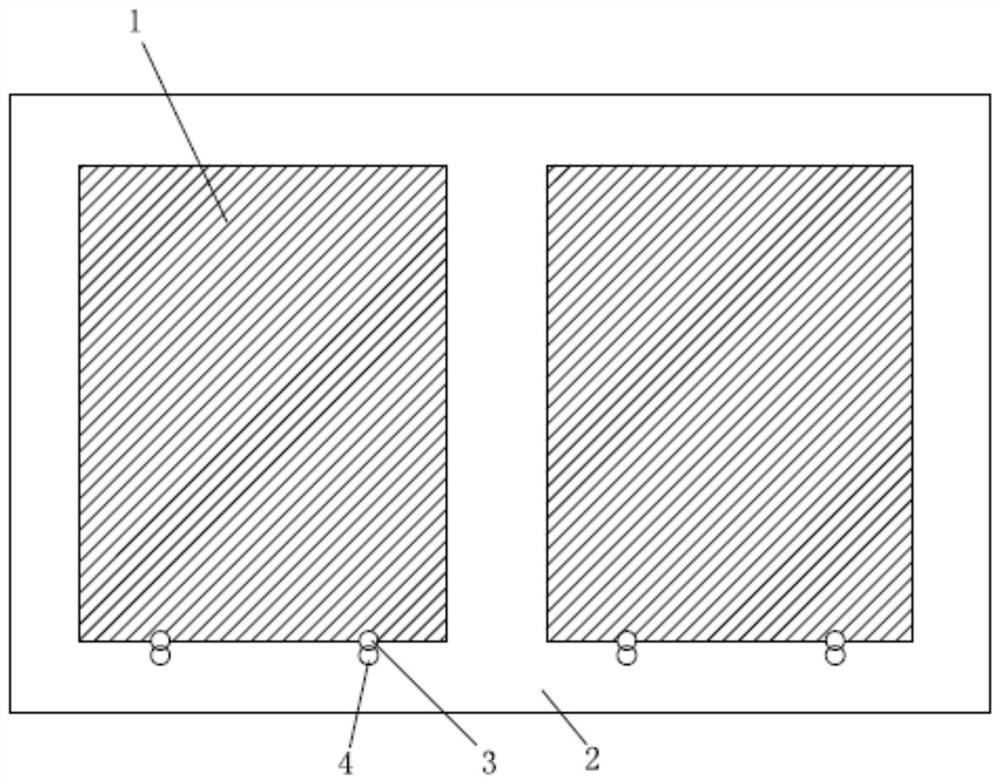

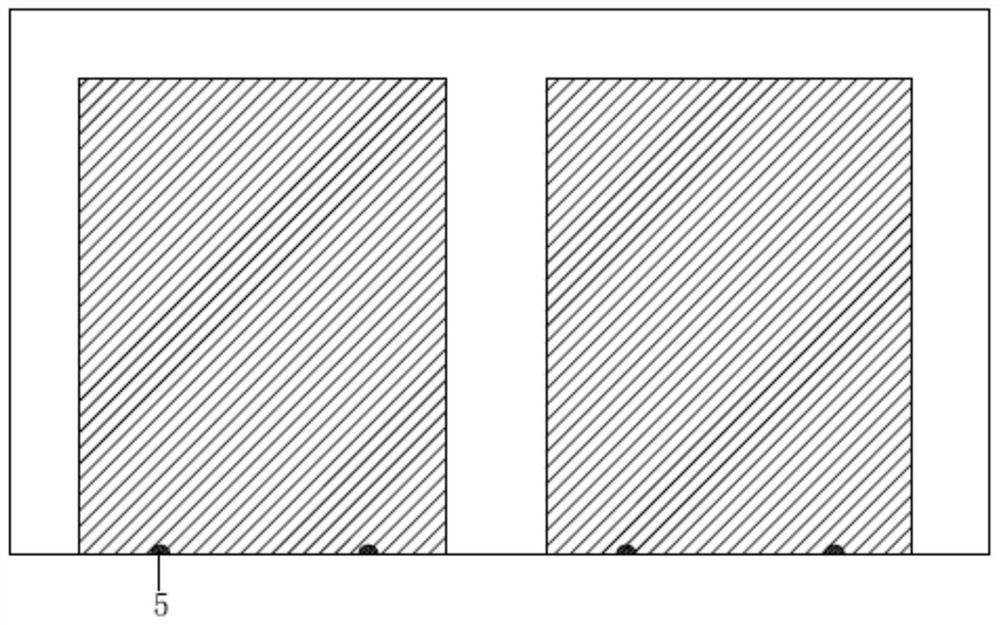

Aluminum alloy casting electroplating production equipment and production process thereof

InactiveCN111690964AOxidation will not occurGuaranteed plating effectGrinding machinesCleaning using liquidsAir pumpAluminium alloy

The invention relates to the technical field of aluminum alloy casting electroplating machining, in particular to aluminum alloy casting electroplating production equipment. The equipment comprises achemical oil removal pond, a cleaning pond and a machine body, all of which are sequentially arranged in the material running direction. A grinding cavity is arranged in the machine body. The upper end of the machine body is detachably connected with a sealing cover. An air pump is arranged on the outer side of the machine body. A suction pipe is connected to the air pump, and the suction pipe isconnected in the machine body in a penetrating and inserted manner and extends into the grinding cavity. A beating seat used for containing an aluminum alloy casting is arranged on the bottom wall ofthe grinding cavity, and grinding mechanisms are arranged in the grinding cavity. The equipment comprises the following steps of feeding, cleaning, chemical oil removal, cleaning and grinding. When the equipment grinds the aluminum alloy casting, the sealing cover and the machine body are matched, then the air pump is used for sucking air in the grinding cavity out, the aluminum alloy casting canbe ground under the vacuum state, an oxidation film on the surface of the aluminum alloy casting can be fully removed, and the electroplating effect is better.

Owner:太仓德丰五金制品有限公司

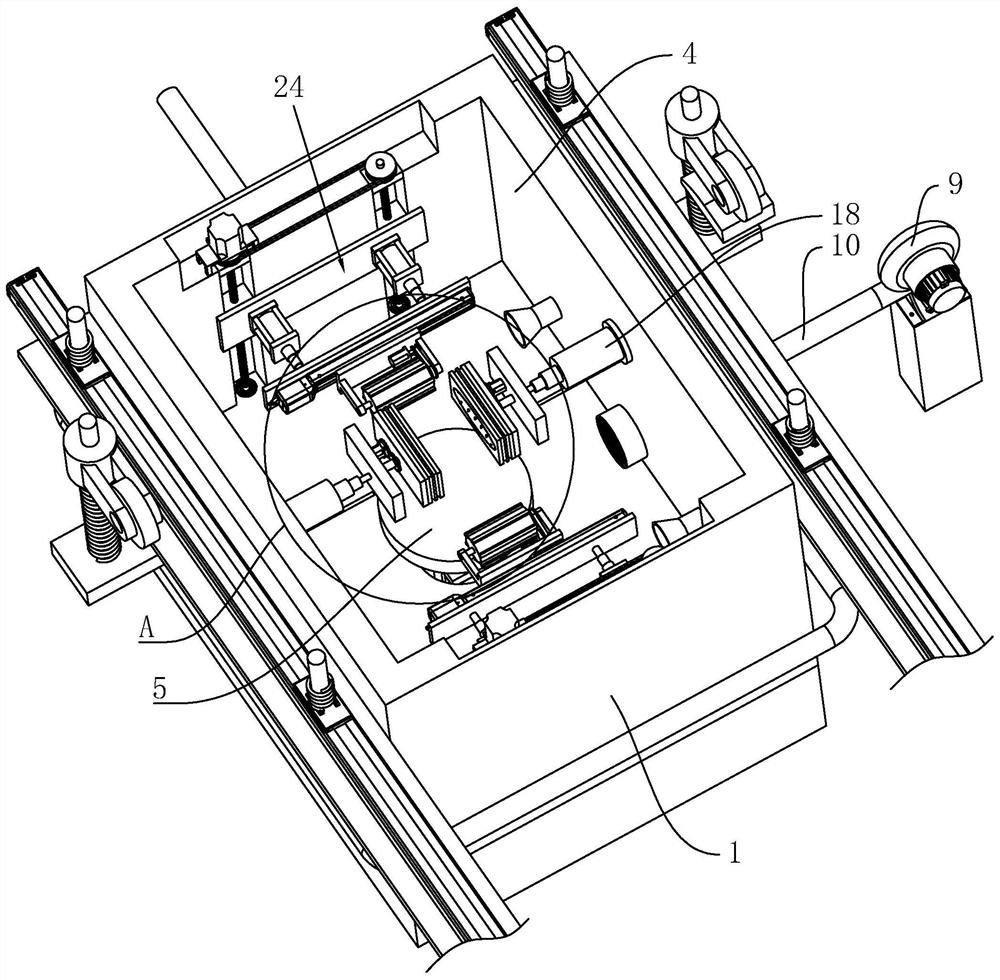

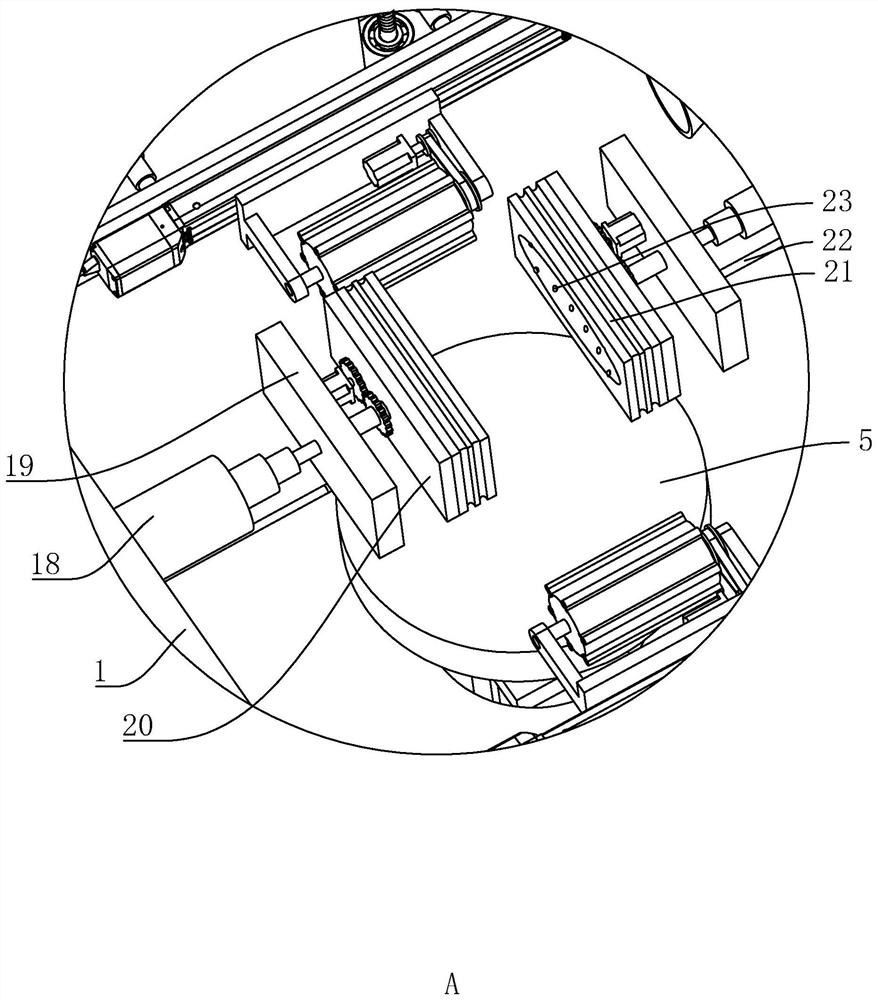

Special electroplating system for automobile clamp support

PendingCN107587184AEasy maintenanceEasy to replaceElectrolysis componentsProcess efficiency improvementEngineeringElectroplating

The invention relates to a special electroplating system for an automobile clamp support. The special electroplating system comprises a hanger main body, the hanger main body comprises a main body support, an electroplating support arranged in the main body support and a suspension support arranged at the upper end of the main body support; the electroplating support comprises a plurality of transverse electroplating rods, every transverse electroplating rod is provided with two electroplating hooks, and a spacing between the two electroplating hooks is adjustable; and the suspension support comprises two suspension arms, every suspension arm is provided with an adjusting fixed mechanism, and a suspension crossbeam is arranged between the two suspension arms. The system has the following advantages: the spacing between the two electroplating hooks on the same transverse electroplating rod is adjustable, so the spacing between the two electroplating hooks can be adjusted according to the dimension of the support to be electroplated, and the application range is wide; and the suspension arms are provided with the adjusting fixed mechanisms, so the transverse suspension beams are arranged on the adjusting fixed mechanisms, so subsequent maintenance and replacement are convenient.

Owner:浙江泛源科技股份有限公司

Electroplating processing device for inner bore and end faces of workpiece

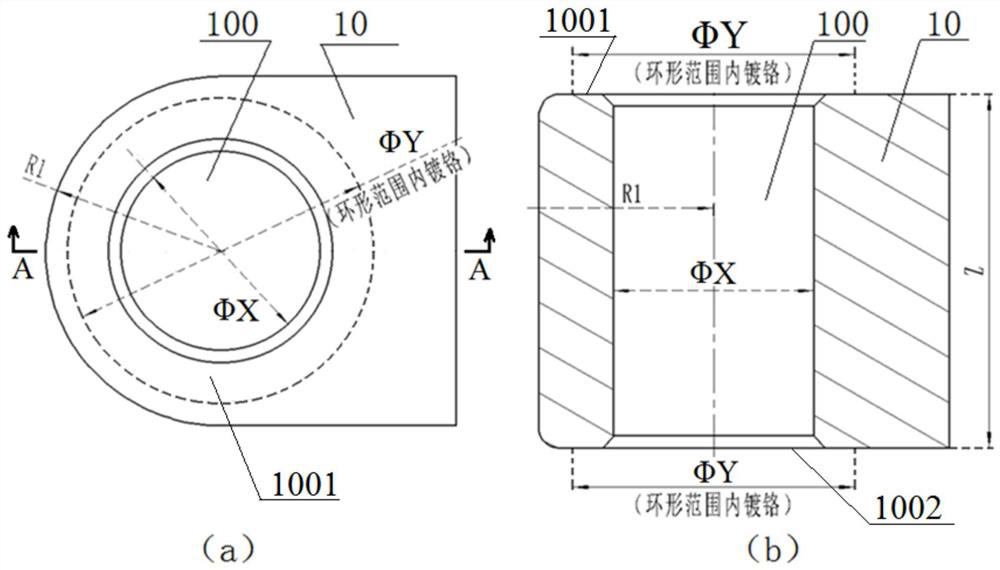

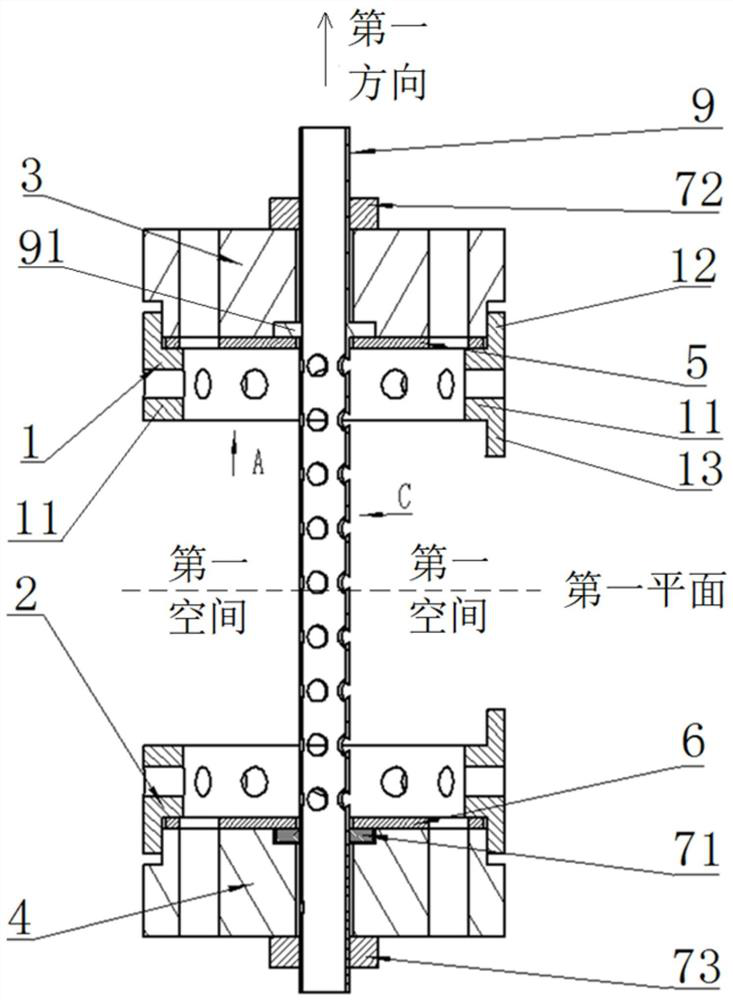

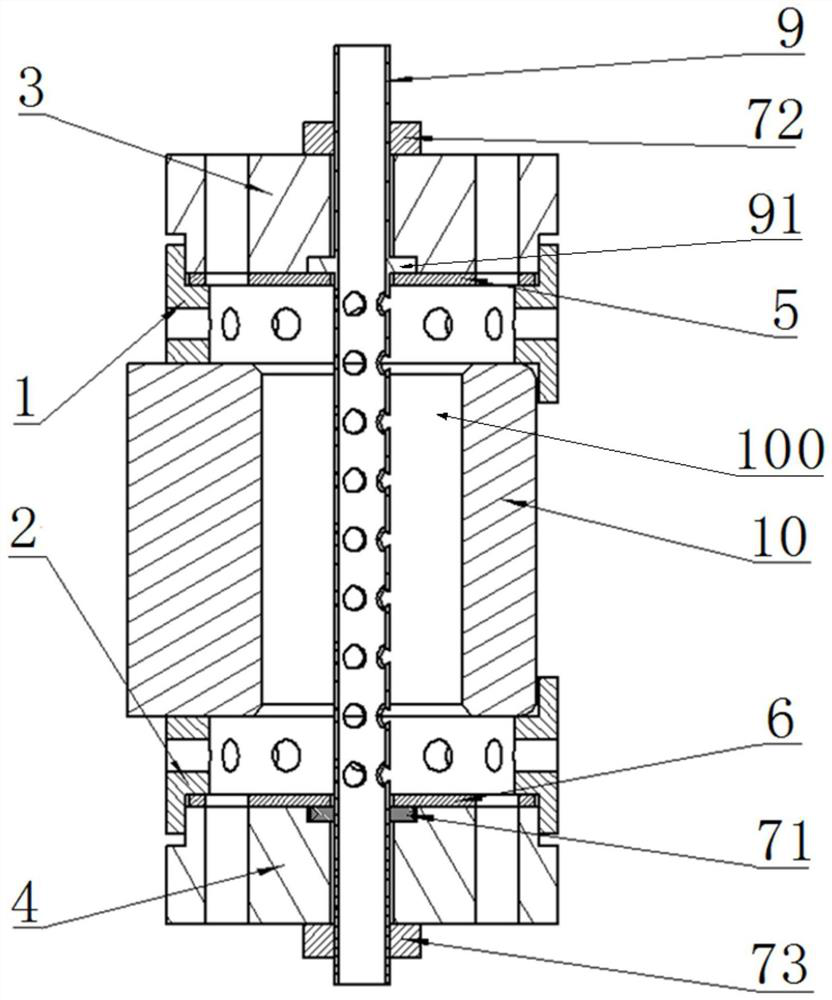

ActiveCN112342599AAvoid cathodic interactionsAchieve shieldingCurrent conducting devicesElectrodesEngineeringChrome plating

The invention provides an electroplating processing device for an inner bore and end faces of a workpiece. The inner bore is formed in the processed workpiece in the length direction; a processing device includes an anode bar, and the axis direction of the anode bar is defined as a first direction; the processing device further includes a fastening structure, and a first anode plate, a first fixing piece, a second fixing piece and a second anode plate which are sequentially arranged on the anode rod in a sleeving manner in the first direction; the first fixing piece and the second fixing pieceare arranged at an interval; a first through hole is formed in the first fixing piece; and when the processed workpiece is arranged on the anode bar in a sleeving manner and is contained in a first space, the inner wall face of the first through hole is located at the outer side of the boundary of the inner bore in a first end face, and a gap is present between the first anode plate and the firstend face as well as between the second anode plate and a second end face. The electroplating processing device can change the distribution of power lines in the electroplating process of the workpiece, and thus, uniform distribution of the current density of the electroplated surface of the workpiece is promoted, plating is evenly deposited on the surface of the workpiece, so that chromium plating of multiple parts of the inner bore and the end faces is completed at a time.

Owner:LANDING GEAR ADVANCED MFG

Pipe electroplating device

The invention provides a pipe electroplating device. The pipe electroplating device comprises an electroplating tank and a pipe body, wherein the inner part of the electroplating tank is filled with chemical liquid; the pipe body is arranged in the electroplating tank and is placed in the chemical liquid; the inner part of the pipe body forms an inner wall electroplating interval; the pipe electroplating device also comprises a feeding device for conveying the chemical liquid in the inner wall electroplating interval; the feeding device comprises an infusion pipe, a power pump and a chemical liquid tank, which are communicated with one another; the inner part of the chemical liquid tank is filled with the chemical liquid; the infusion pipe extends into the pipe body; a plurality of liquidoutlets are formed in the side of the infusion pipe; and the liquid outlets are distributed at intervals in the length direction of the infusion pipe.

Owner:FOSHAN SHUNDE DISTRICT JIEYONG ELECTRIC IND

Zinc-magnesium alloy electroplating technology

The invention discloses a zinc-magnesium alloy electroplating technology. The technology includes the following steps of oil and dust removing, ultrasonic cleaning, electroplating, hydrogen removing, hydrophobic treatment, washing and drying. According to the technology, the process of removing oil and the process of removing dust are combined into one, so that the processes are omitted, cost is reduced and efficiency is improved. In the electroplating process, additives such as SDMBA-Cl, polyethylene glycol and lauryl sodium sulfate are added in electroplating liquid, so that the deposition effect in the electroplating process is good, the self-corrosion current of an ultimate electroplated layer in a 3.5% sodium chloride solution is lowered, and the corrosion resistance is enhanced. Finally, the zinc-magnesium alloy electroplating technology is good in deposition effect, high in pretreatment efficiency and environmentally friendly.

Owner:太仓市金鹿电镀有限公司

Nickel plating protection clamp and nickel plating protection method

The invention relates to the technical field of electroplating, in particular to a nickel plating protection clamp and a nickel plating protection method. The nickel plating protection clamp comprises an upper supporting plate, wherein the upper end face is fixedly connected with a first lifting rod; an upper opening mechanism connected with the lower end face of the upper supporting plate; an upper clamp located below the upper opening mechanism and connected with the upper opening mechanism, wherein a wrapping groove is formed in the lower end face of the upper clamp, and the wrapping groove is attached to the upper half portion of the electroplated workpiece and used for clamping the upper half portion of the electroplated workpiece; and a lower clamp located below the upper clamp, wherein a wrapping groove is formed in the upper end face of the lower clamp. According to the nickel plating protection clamp, the upper clamp and the lower clamp are used for clamping the upper half portion and the lower half portion of the workpiece respectively, then the workpiece is placed in electroplating liquid for electroplating, half of the workpiece is electroplated in two times of electroplating, and therefore the electroplated area is not clamped by the clamp in the electroplating process, and the originally clamped area is electroplated as well; and therefore, the electroplating quality of the electroplated area of the workpiece is improved, and the using effect of the electroplating clamp is improved.

Owner:蒋昊良

Manufacturing method of tourist souvenir ornament

InactiveCN105624748AAvoiding the Consequences of Serious PollutionImprove bindingCopper platingZinc alloys

The invention discloses a manufacturing method of a tourist souvenir ornament. The manufacturing method comprises the following steps: (1) designing modeling of the tourist souvenir ornament by using a computer; (2) manufacturing a die casting metal mold according to the molding designed in the step (1); (3) selecting 2# zinc alloy and smelting; and meanwhile brushing coating on the mold obtained from the step (2) and pre-heating; (4) carrying out die casting molding by using a horizontal die casting machine; (5) carrying out demolding cleaning; and (6) electroplating, wherein electroplating comprises (1) treatment before plating, (2) cyanide-free copper pre-plating, (3) acid copper plating, (4) semi-bright nickel electroplating, (5), high sulfur nickel electroplating, (6) bright nickel electroplating and (7) chromium electroplating. A plating film of a plating layer obtained by the manufacturing method is uniform in thickness, high in corrosion resistance, high in hardness and bright and neat in surface, and the plating layer does not peel, fade or discolor.

Owner:张颖

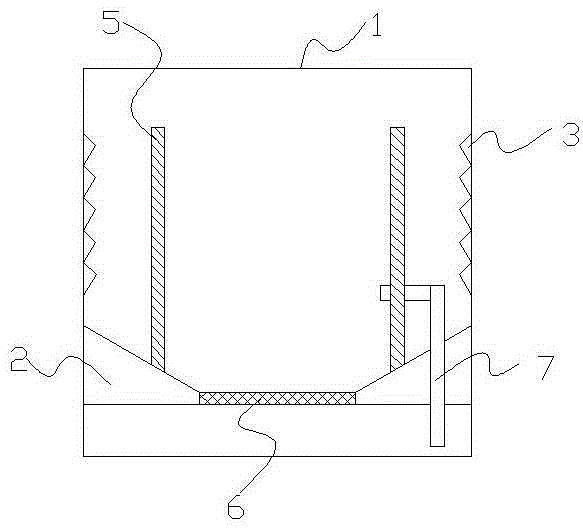

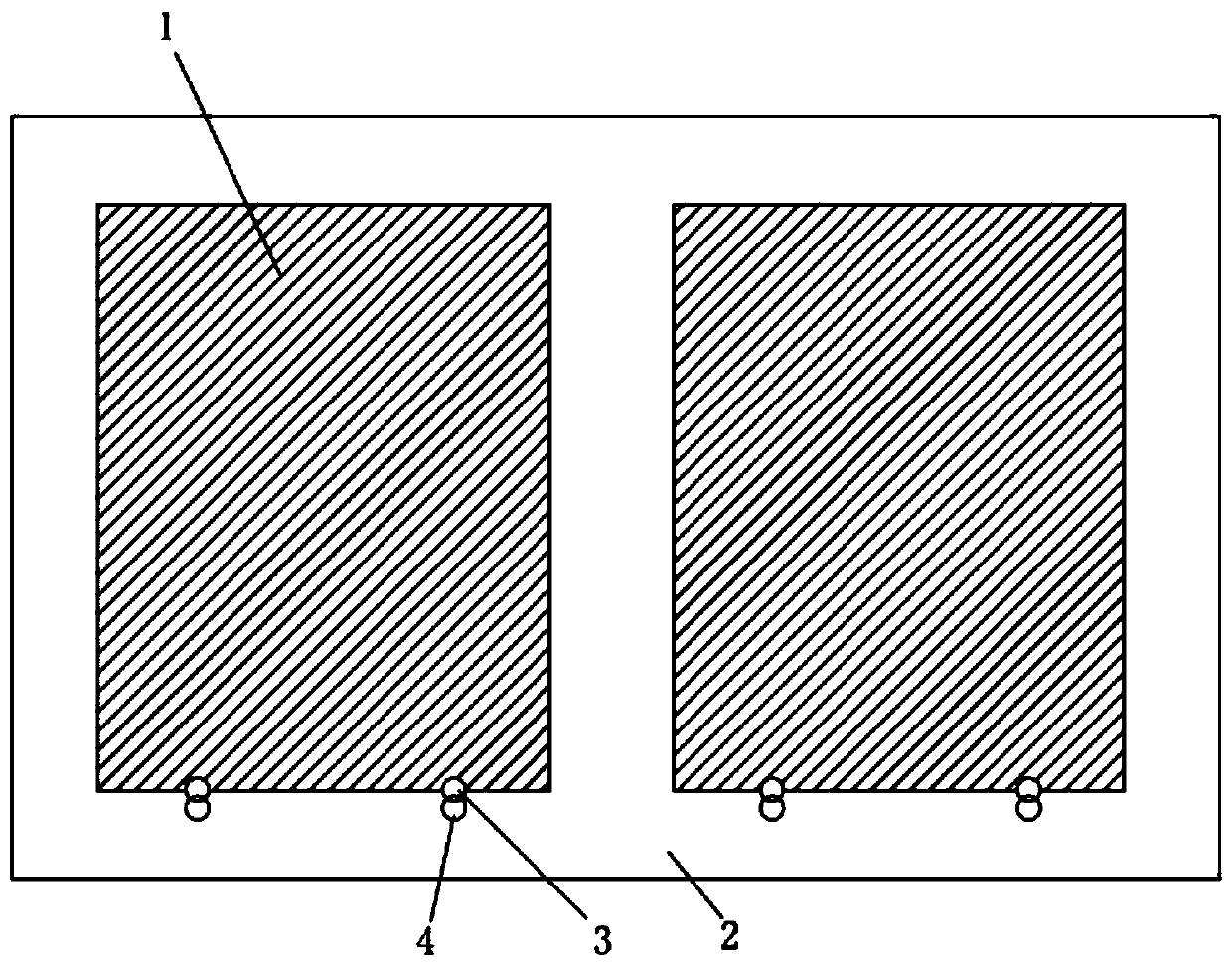

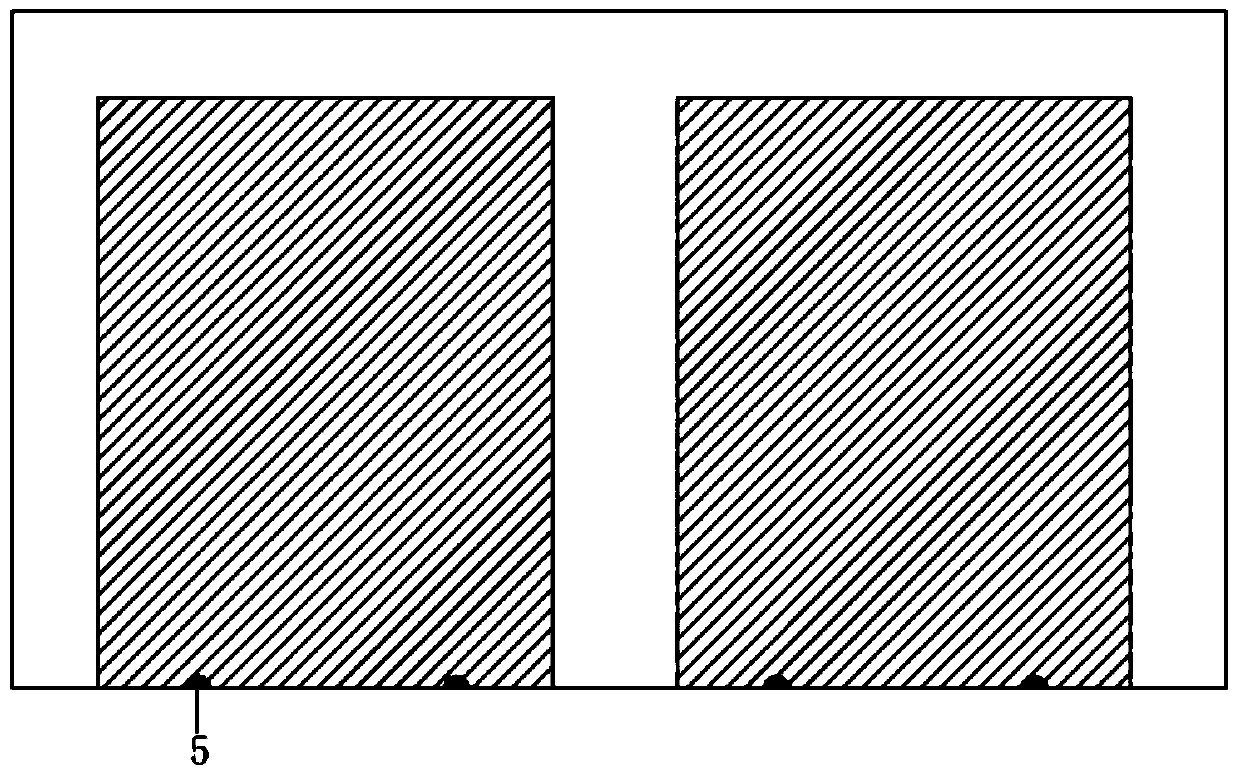

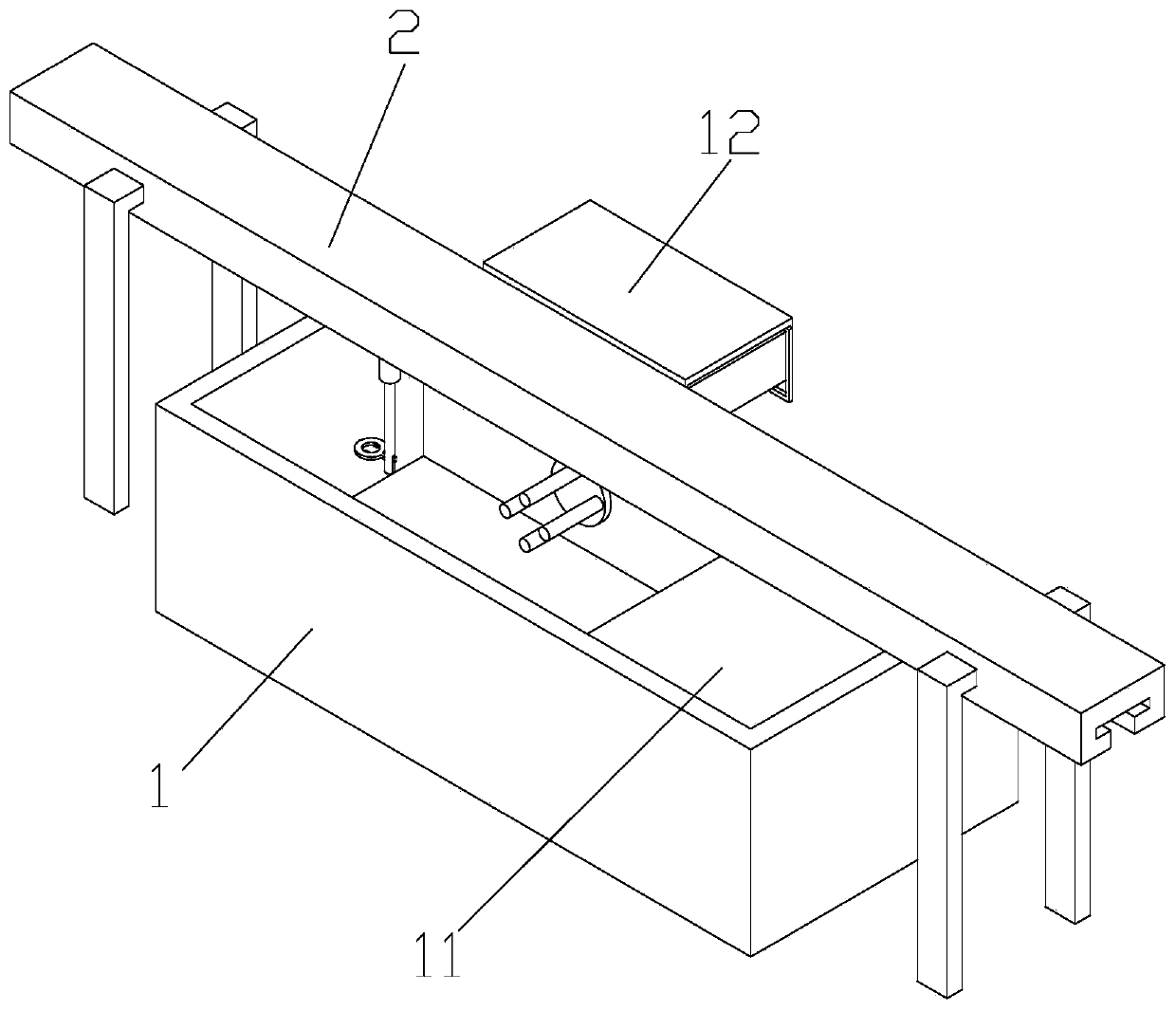

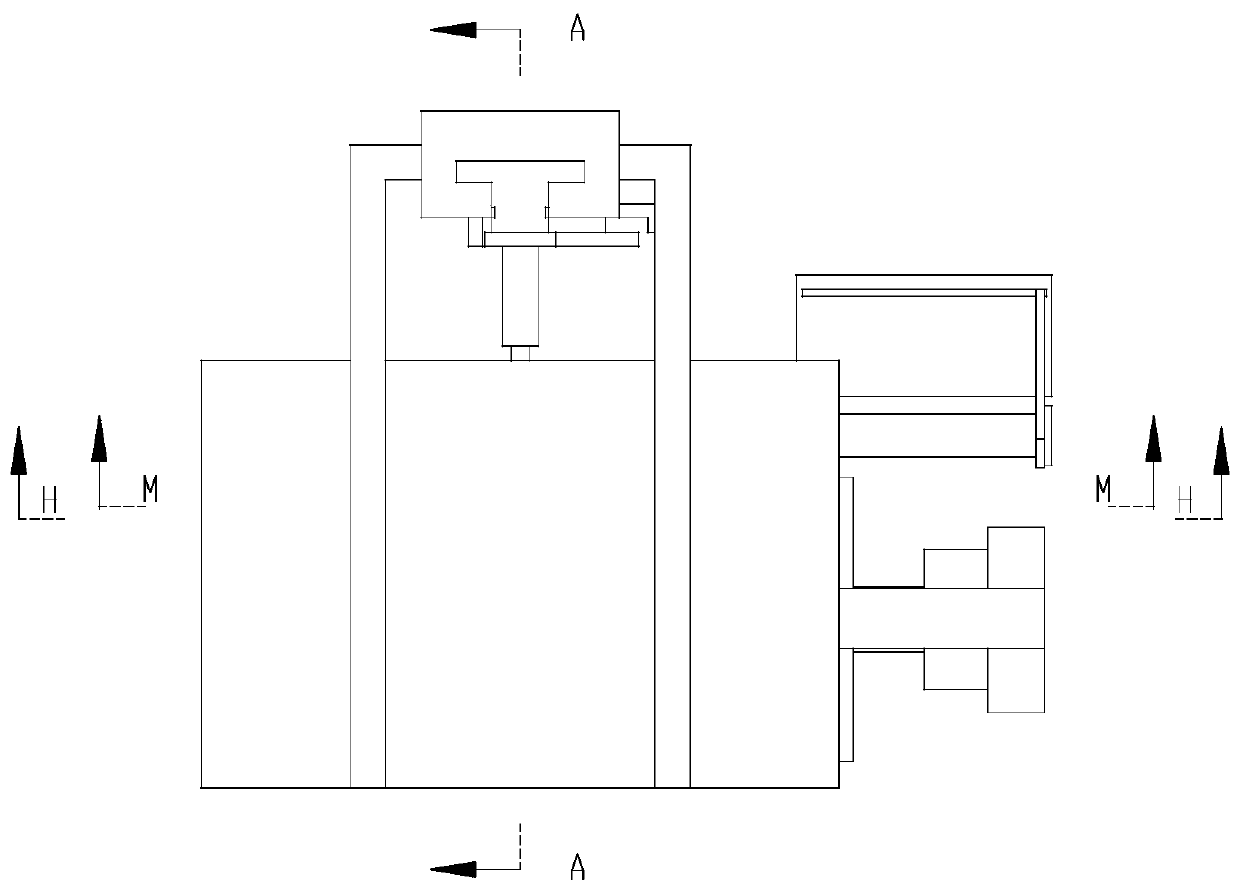

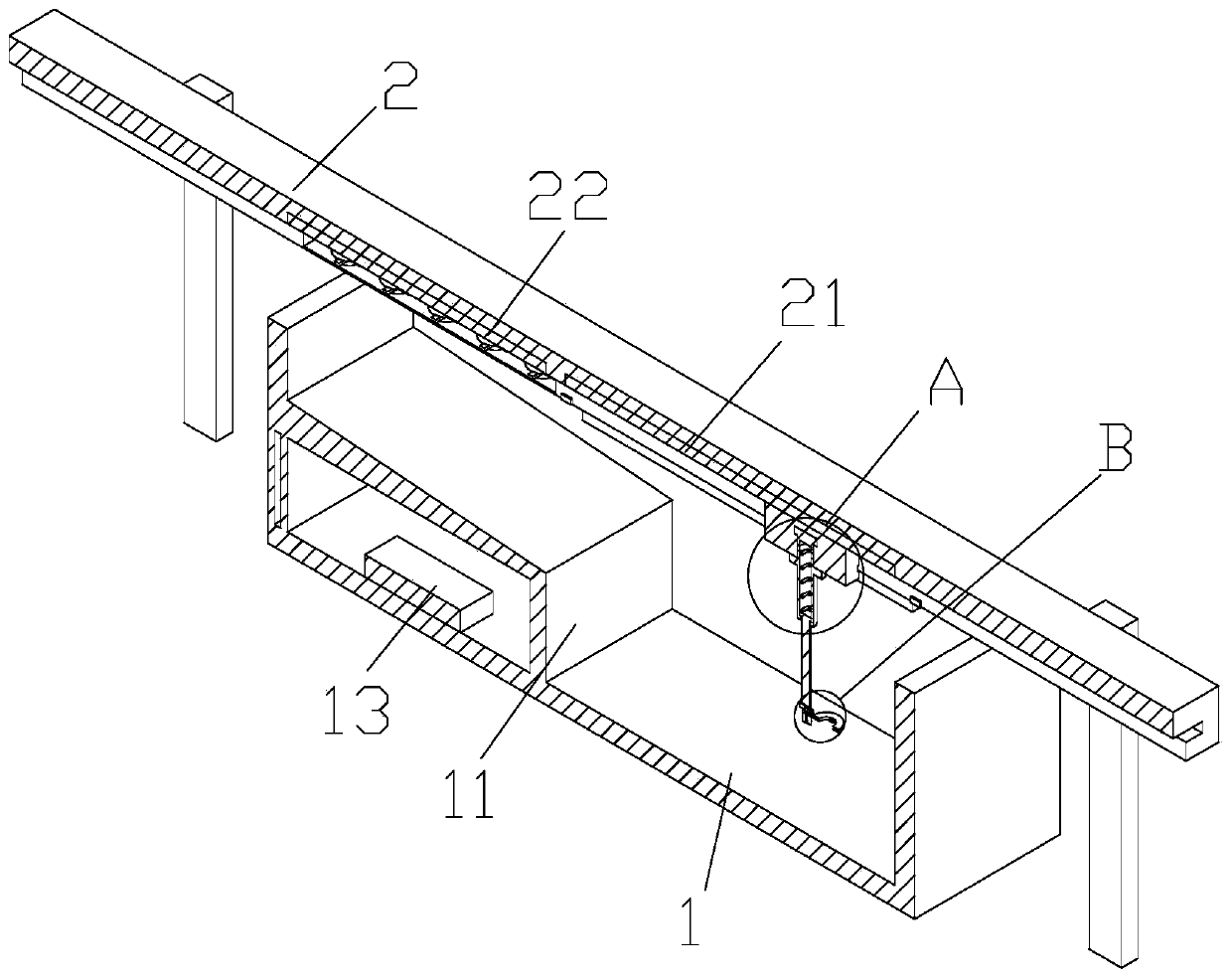

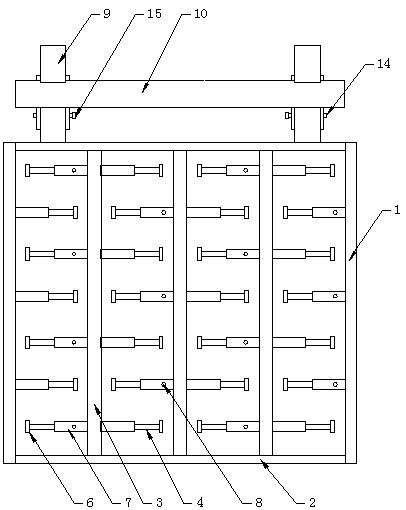

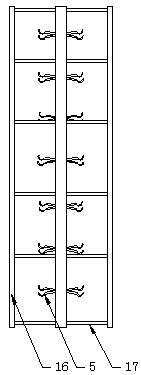

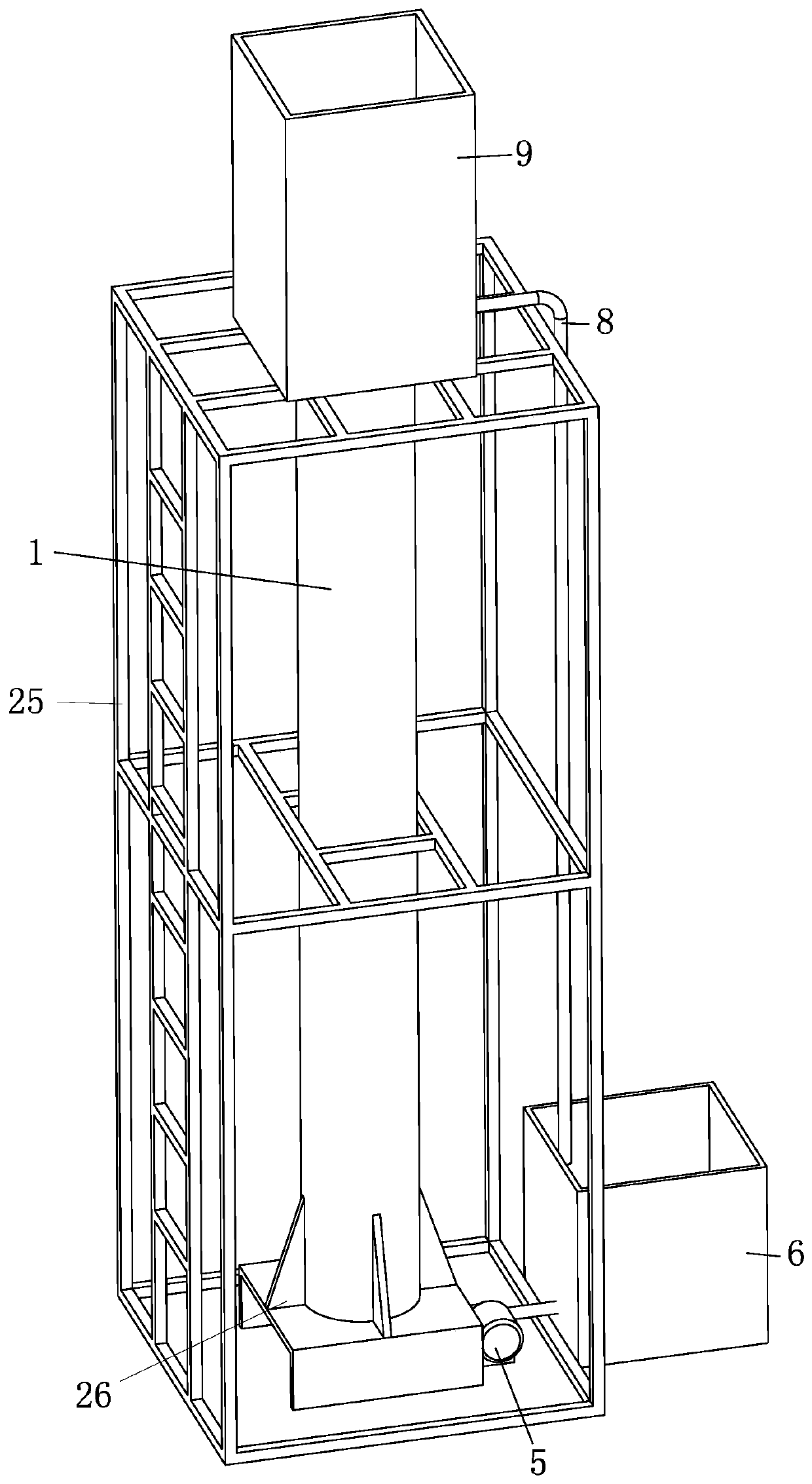

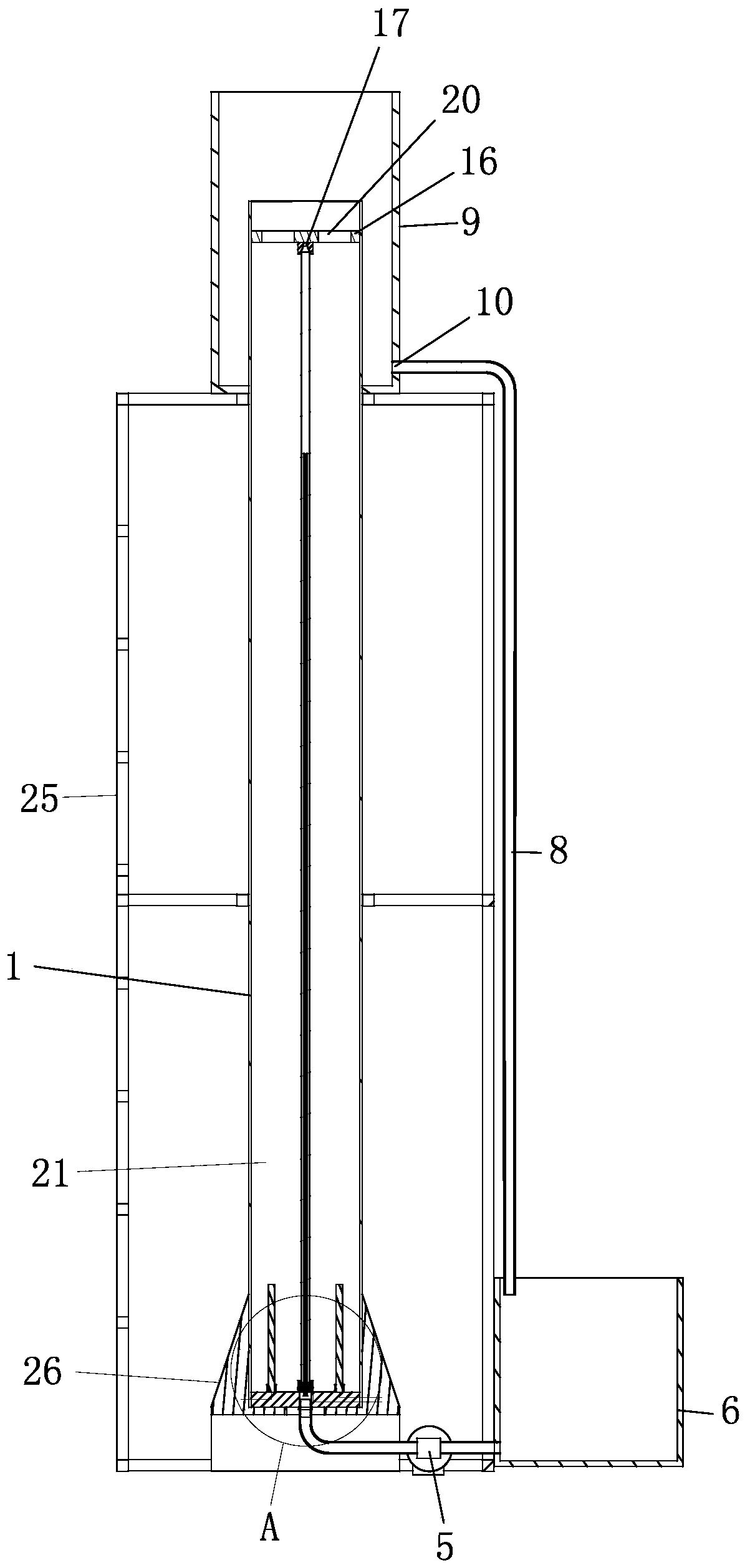

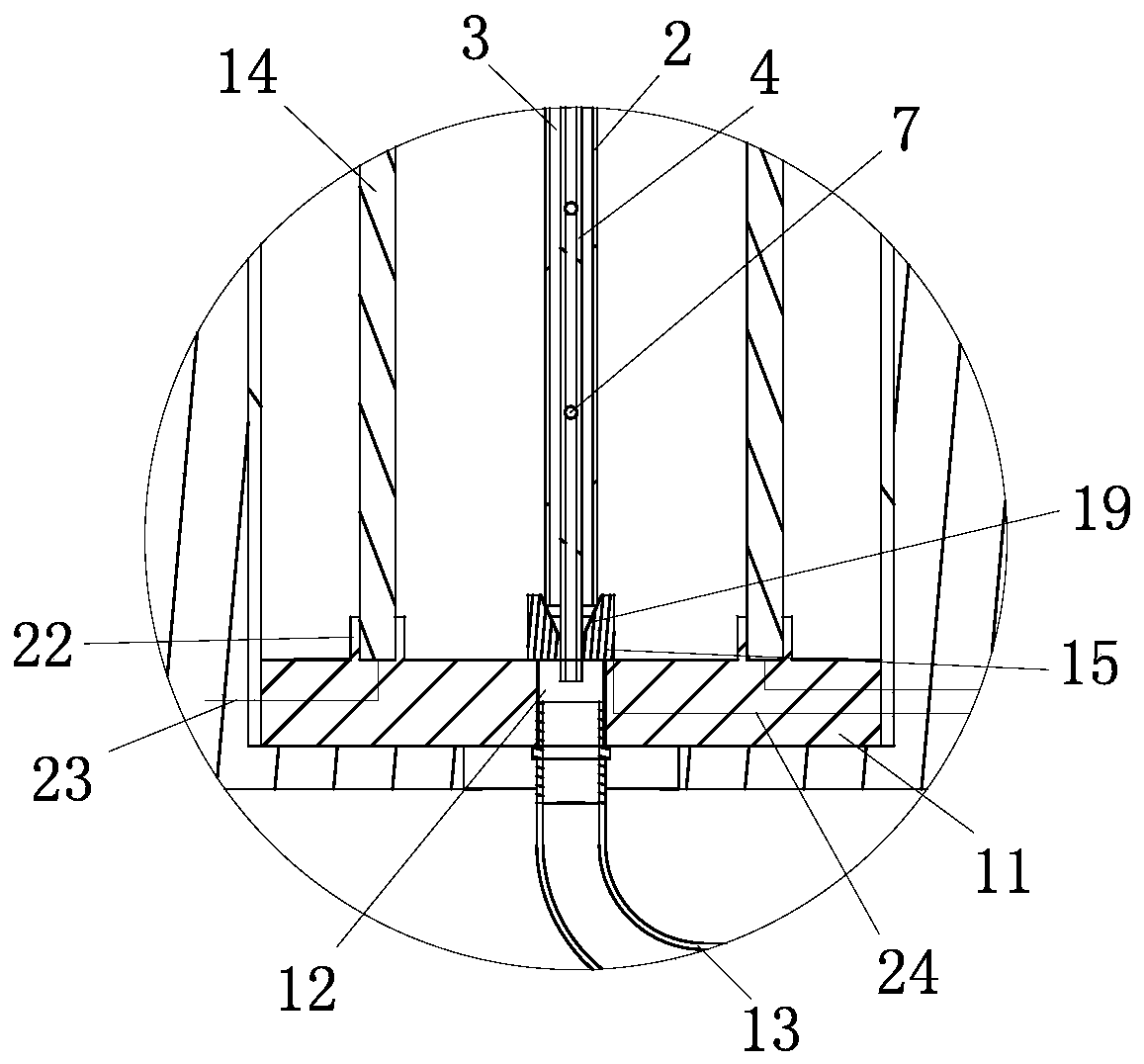

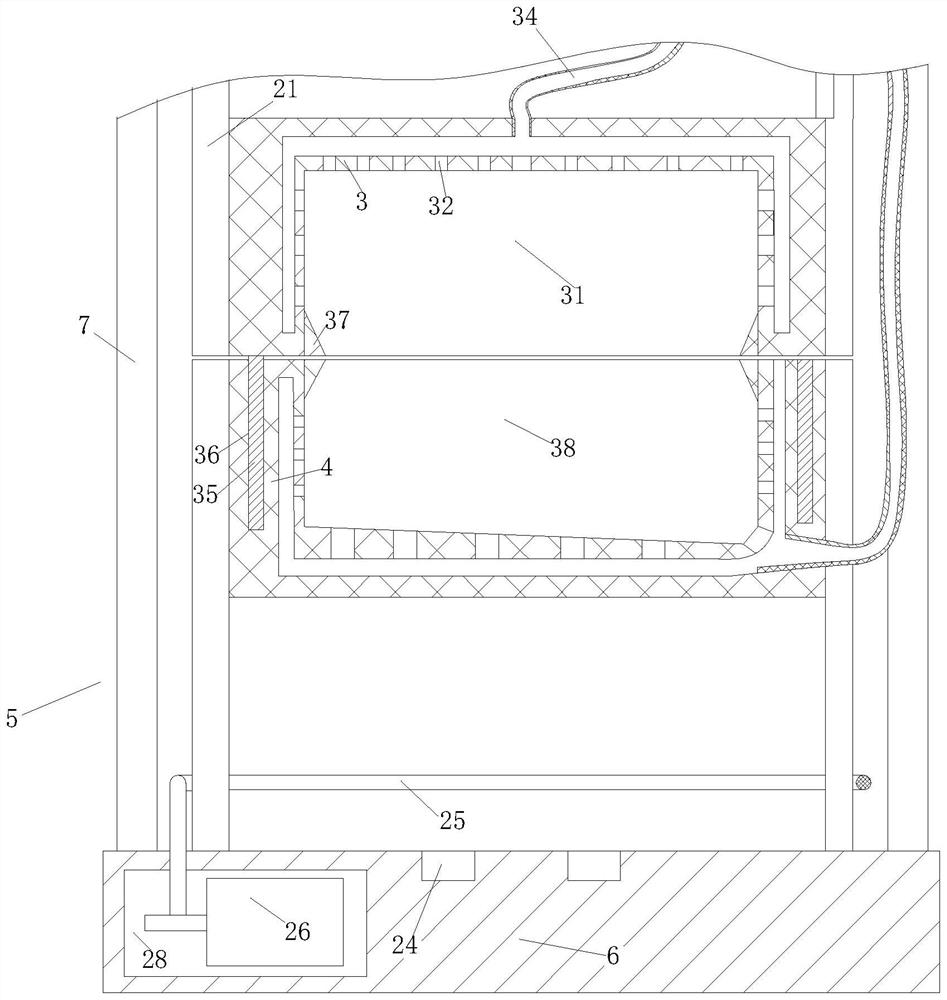

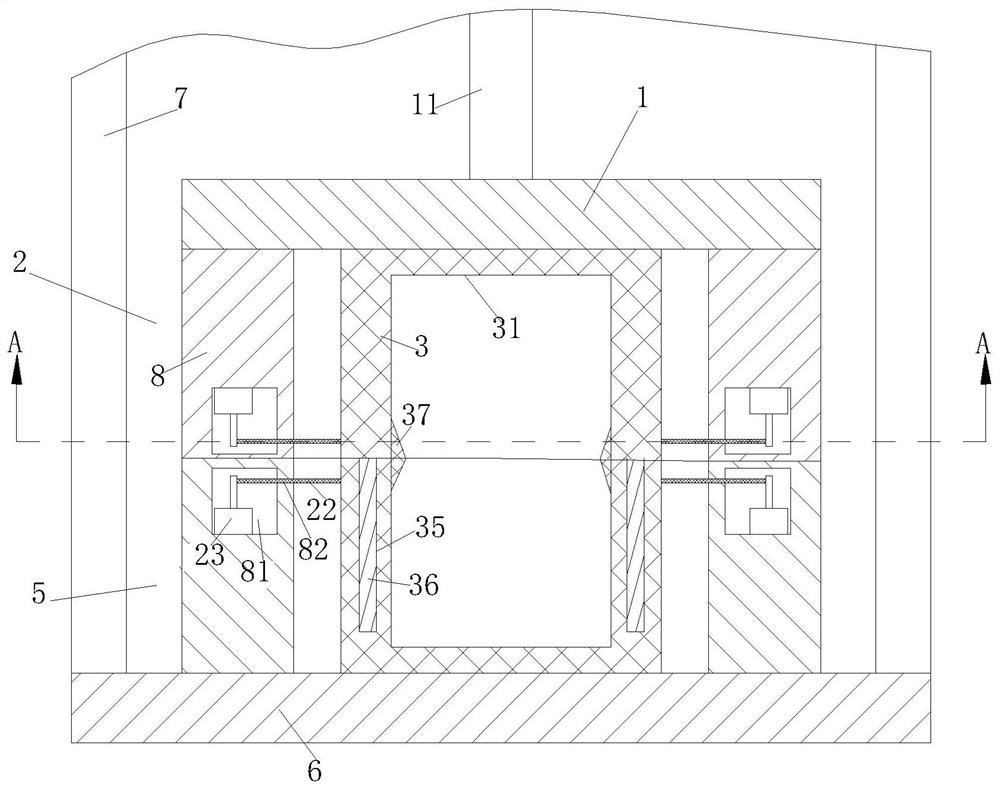

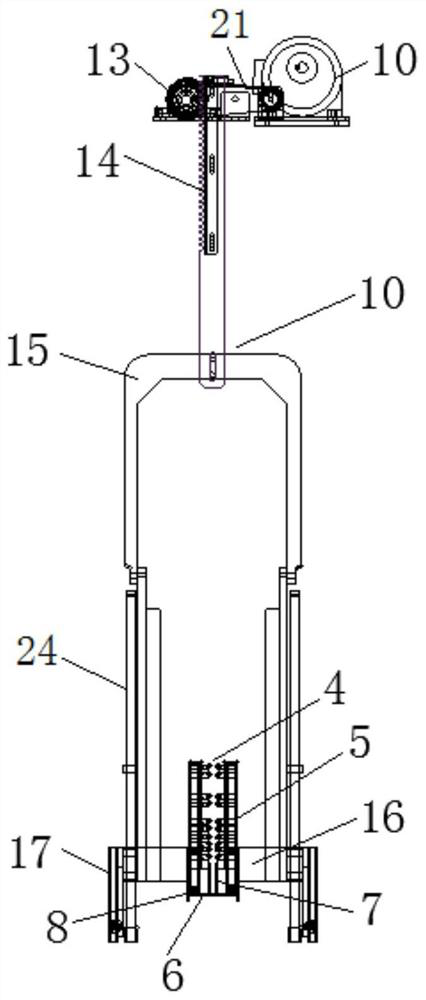

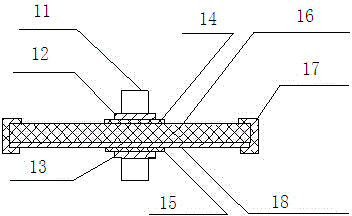

Lifting floating frame device for electroplating equipment

PendingCN111690974AGuaranteed OrientationGuaranteed plating effectCellsEngineeringStructural engineering

The invention discloses a lifting floating frame device for electroplating equipment. The lifting floating frame comprises a frame, a lifting mechanism and a guiding mechanism; the guiding mechanism is located in an electroplating tank, and comprises an upper guiding frame and a lower guiding frame that are arranged along the same vertical axis; the upper guiding frame is fixedly mounted on the frame; the lower guiding frame is mounted at the bottom of the lifting mechanism, can move in the vertical direction under the action of the lifting mechanism, and comprises two symmetrical lower guideplates; a lower guide rail is arranged in a gap between the two lower guide plates; the bottom end of the lower guide plate is provided with an inner cathode baffle and an outer cathode baffle relative to the inner and outer sides of the lower guide rail; a bottom cathode baffle is arranged at the bottom end of the inner cathode baffle; and two ends of the bottom cathode baffle are hermetically connected with the outer cathode baffle.

Owner:东莞市佳凡智能科技有限公司

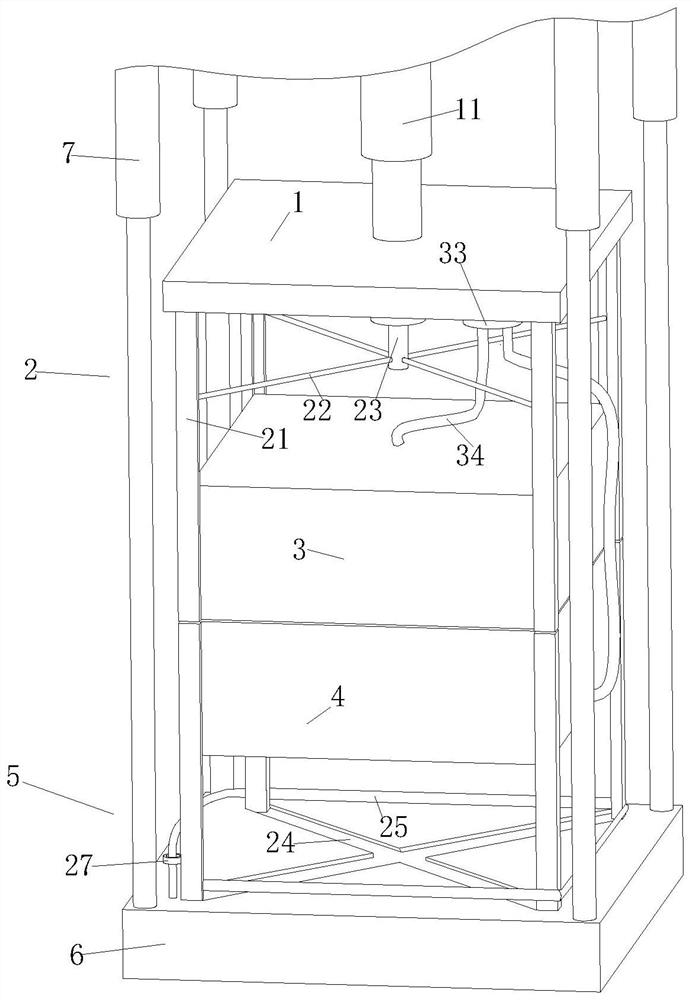

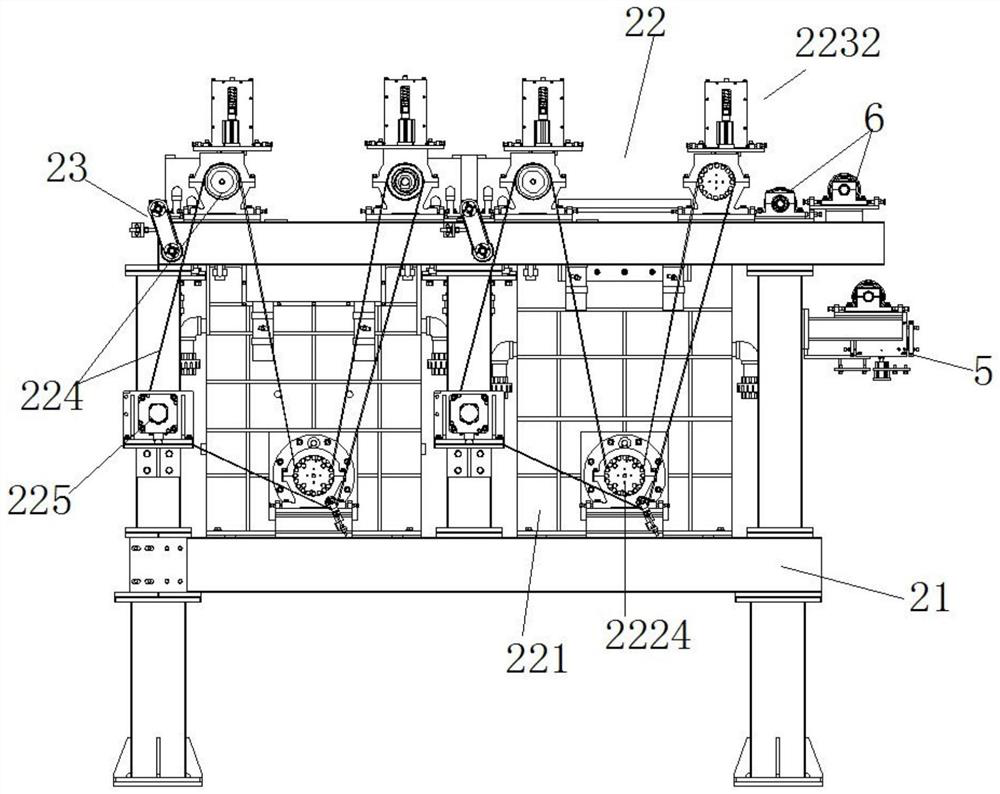

Electrolytic copper foil surface processor and working method thereof

PendingCN112522772AQuality assuranceStable transmissionCellsDrying machines with progressive movementsCopper foilElectrically conductive

The invention relates to an electrolytic copper foil surface processor. The electrolytic copper foil surface processor is mainly composed of an uncoiling device, an intermediate treatment groove section, a drying box, a coiling device and a control device, and the intermediate treatment groove section comprises a rack, a plurality of treatment devices arranged on the rack and tensioning roller mechanisms arranged between the adjacent treatment devices. Submerged rollers and conductive rollers are driven to rotate through magnetic force, it is guaranteed that tension of the multiple treatment devices is the same, and the production quality of copper foils is improved. The positions of anode plates are changed, the conveying positions of the copper foils are adjusted, the rough surfaces of the copper foils face the anode plates and make direct contact with the submerged rollers, the surfaces of the copper foils cannot be roughened through the conductive rollers, the smoothness of the surfaces of electroplated layers is improved, the electroplating efficiency is improved by arranging a partition plate between every two anode plates, liquid inlets are formed between the submerged rollers and the anode plates, so that the electroplating liquid between the anode plates and the copper foils can be supplemented more quickly, and the electroplating quality of the copper foils is guaranteed.

Owner:洪田科技有限公司

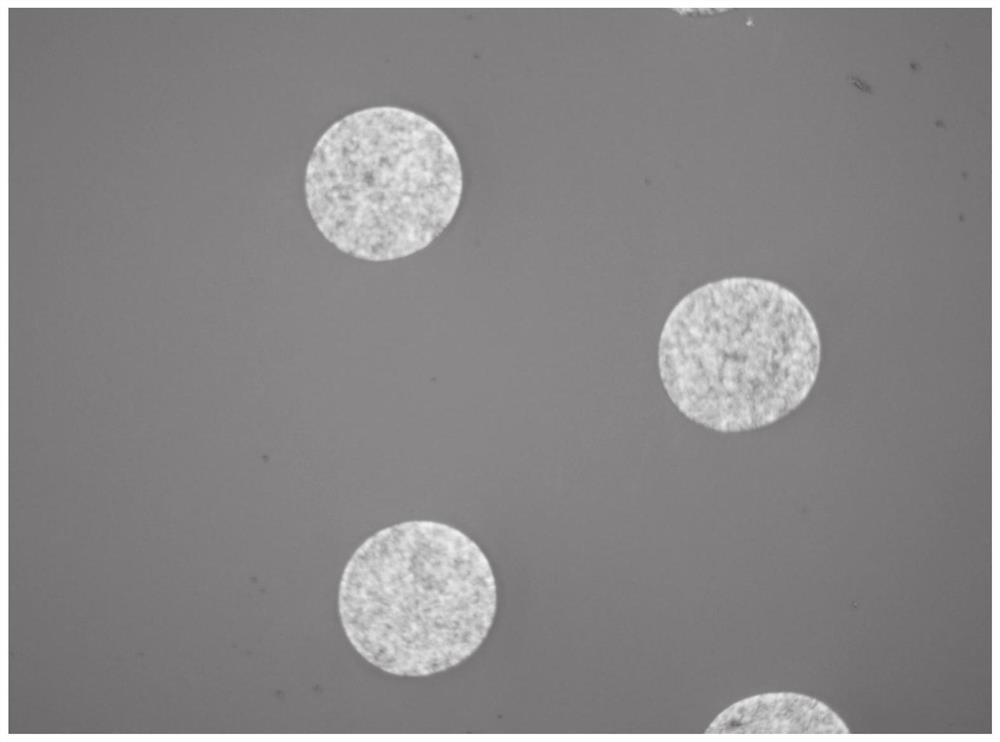

TGV deep hole filling method

ActiveCN113066758AImprove adhesion strengthInhibit sheddingSemiconductor/solid-state device manufacturingGlass productionElectroplatingMaterials science

The invention provides a TGV deep hole filling method. The TGV deep hole filling method comprises the following steps: A, cleaning a glass substrate; B, performing laser drilling on the glass substrate to obtain a plurality of glass through holes; C, corroding the glass substrate and the glass through hole by using a corrosive liquid; D, performing seed layer sputtering on the glass substrate and the glass through holes; G, soaking the glass substrate in a dilute sulfuric acid solution for activation; and F, electroplating. The glass substrate and the glass through hole are corroded, so that the surfaces of the glass substrate and the glass through hole become rough, the friction coefficient between the seed layer and the glass substrate and the friction coefficient between the seed layer and the glass through hole are increased, the adhesive strength of the seed layer can be enhanced, and in the subsequent activation and electroplating process, the seed layer can be prevented from falling off to a certain extent; therefore, the electroplating effect is ensured.

Owner:三叠纪(广东)科技有限公司

Continuous electroplating test device for simulating different linear speeds of strip steel

The invention relates to a continuous electroplating test device for simulating different linear speeds of strip steel. The continuous electroplating test device for simulating the different linear speeds of the strip steel is characterized in that the test device comprises a support; a workbench is arranged on the support, and working tanks are fixed to the workbench; the test device further comprises a working electrode system, a transmission shaft, an auxiliary electrode and a sample working electrode; the transmission shaft is connected with the working electrode system; both the auxiliary electrode and the working electrode system are connected with a rectifier, so that a closed loop is formed; the sample working electrode is installed on the working electrode system; the high-speed strip steel production process is simulated by adjusting the rotation of a motor. According to the test device, the whole continuous strip steel production process including the technological procedures such as alkali washing, acid washing, electroplating and passivating can be simulated; the whole process can be simulated, and a certain technological procedure can also be simulated; mutual interference between all simulation tests is avoided, and the test accuracy is further guaranteed.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

A kind of manufacturing method of mechanical blind hole and half hole

ActiveCN110121239BFull exchangeGuaranteed plating effectPrinted element electric connection formationEngineeringPhysics

The invention discloses a method for manufacturing mechanical blind holes and half holes, which comprises the following steps: drilling blind holes on the edge of a unit plate area on a production board, and half of the blind holes are located in the forming line area of the production board; Drill a through hole with the same diameter as the blind hole at the molding line area next to the blind hole, and the through hole intersects the blind hole; then metallize the hole through copper sinking and full board plating; make the outer circuit on the production board , and in the process of making the outer layer circuit, after pattern electroplating, the molding line area next to the blind hole on the production board is removed first, and then the outer layer is etched to obtain the outer layer circuit and the blind hole half hole after metallization. The method of the invention can effectively solve the risk of no copper at the bottom of the half-hole blind hole by optimizing the production process, and can avoid the problem of cloaks and burrs on the edge of the half-hole blind hole, thereby ensuring the quality of the circuit board product.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com