Copper oil nozzle machining equipment

A processing equipment, copper oil technology, applied in the field of auto parts processing, can solve problems such as difficult grasping, difficulty in electroplating, immersion of fuel tank switch, etc., and achieve the effect of avoiding the waste of electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

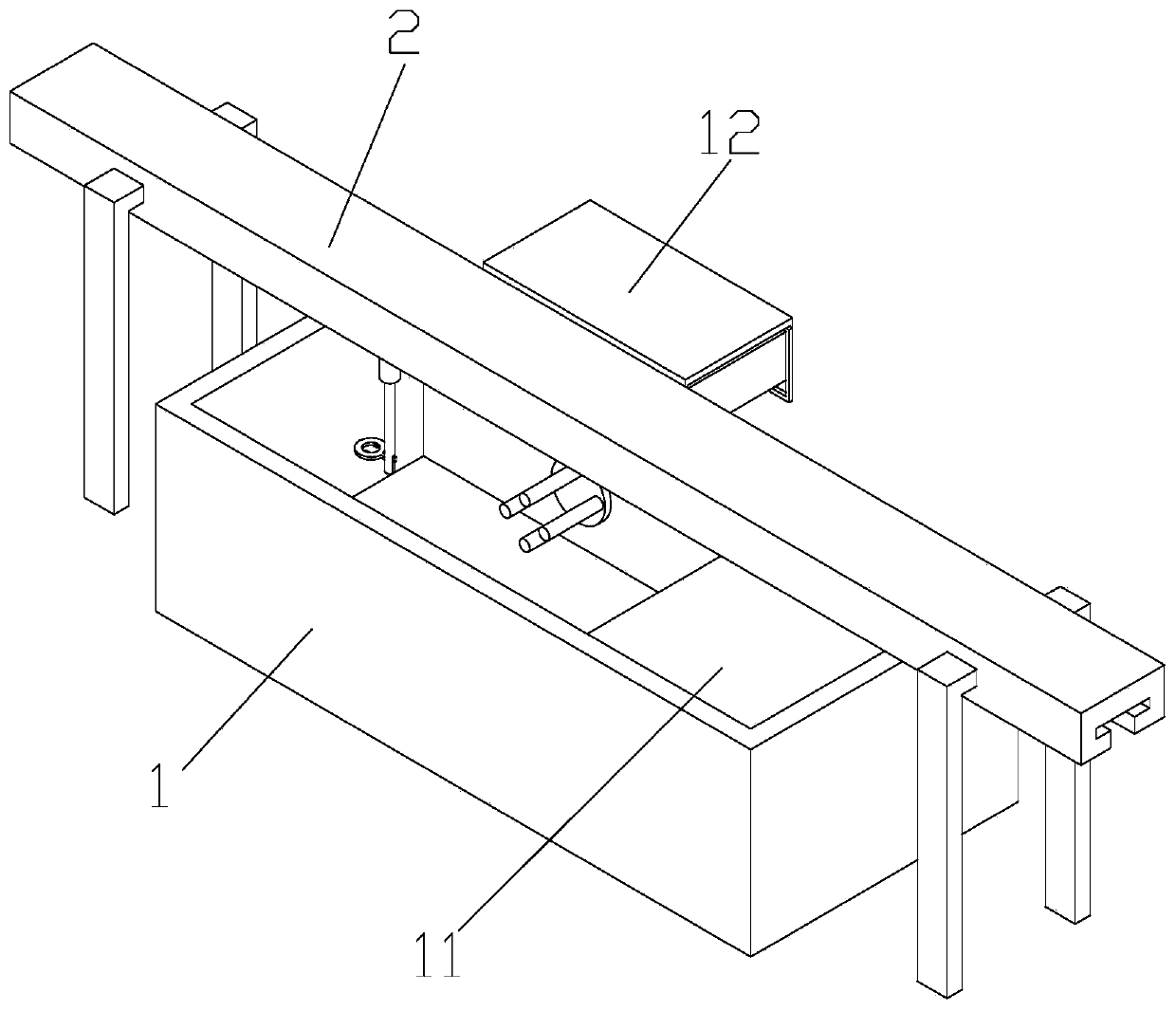

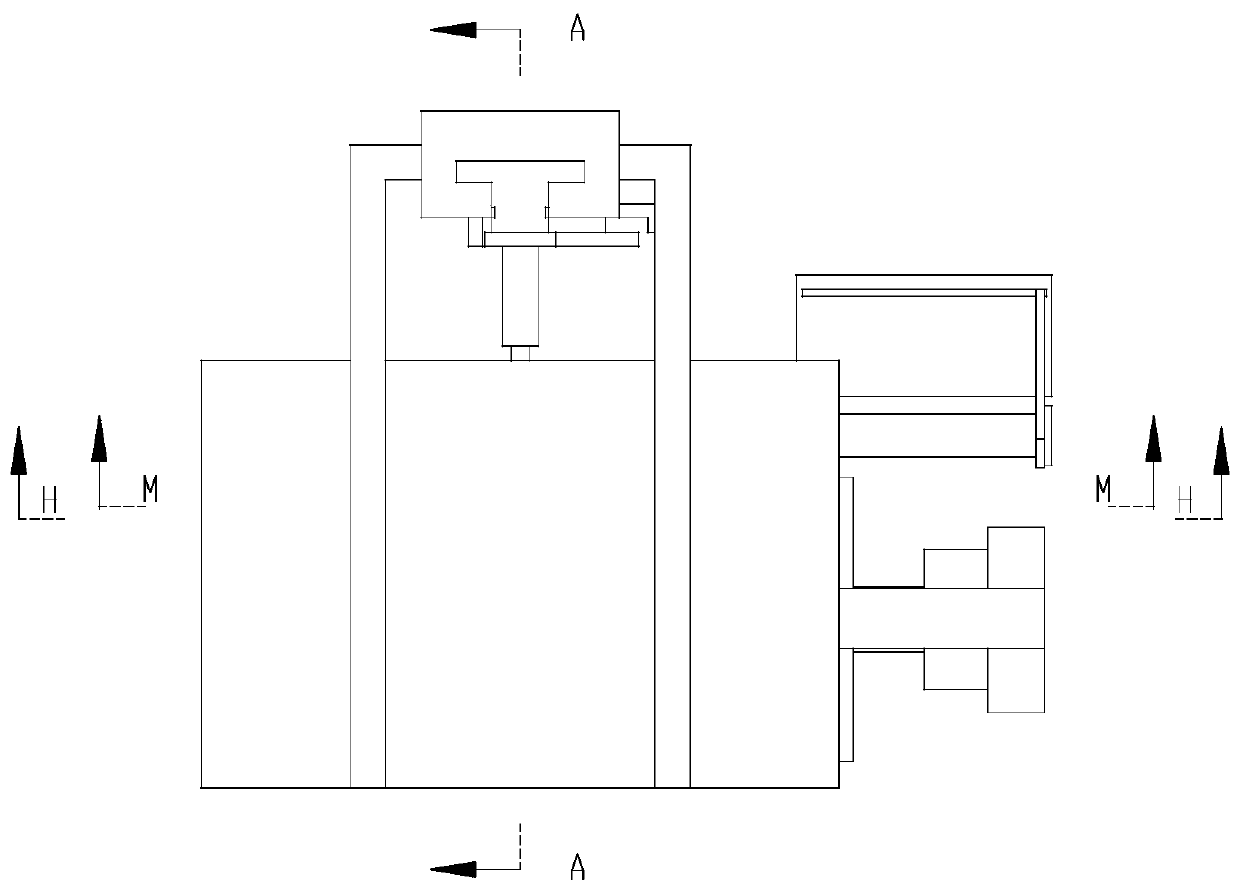

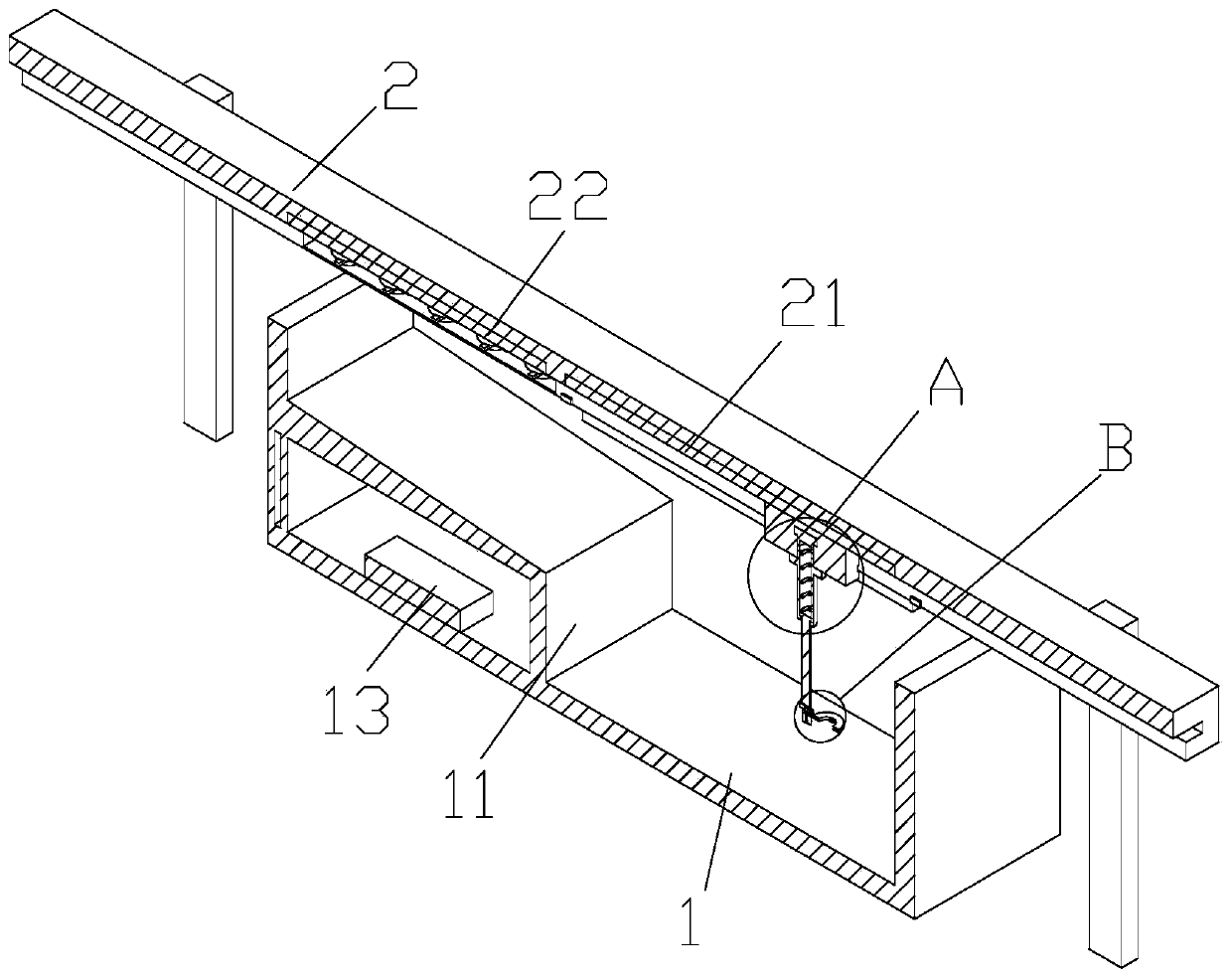

[0037] Such as Figure 1-22 As shown, a copper grease nozzle processing equipment includes an electroplating pool 1, a guide rail 2 arranged above the electroplating pool 1, and a guide block 3 arranged in the guide rail 2, and the guide block 3 is provided with a first connection A rod 31, the first connecting rod 31 is provided with a first movable chamber, the first movable chamber is pierced with a second connecting rod 32, and the top of the second connecting rod 32 is provided with a first limiting plate, The top of the first limiting plate is provided with a connecting spring 321, the first limiting plate is made of magnetic material, the top of the guide rail 2 is provided with a first groove, and a first groove is arranged in the first groove. Electromagnet 21, the first electromagnet 21 is arranged on the top of the electroplating pool 1; the side wall of the electroplating pool 1 is provided with a feeding device; when the throttle switch is galvanized, the fuel tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com