Modified TPU film fabric compound and preparation method thereof

A compound and modification technology, applied in the field of materials, can solve problems such as stress cannot be eliminated, edge warping, poor dispersion effect, etc., and achieve the effect of solving excessive processing temperature difference, good tensile strength, and increasing barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

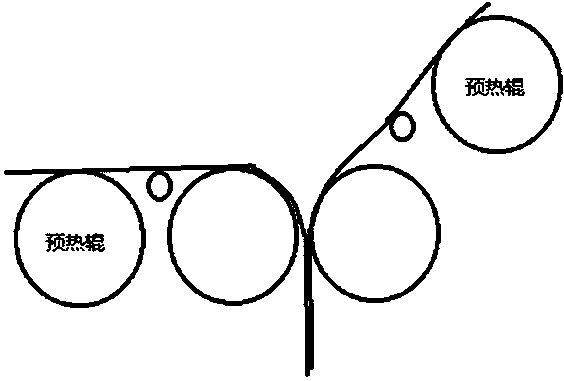

Method used

Image

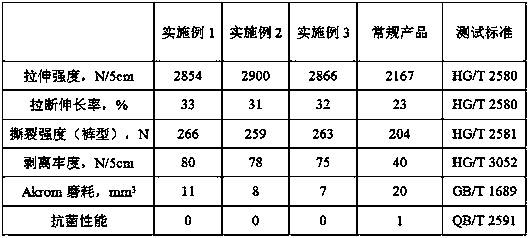

Examples

Embodiment 1

[0028] A modified TPU film fabric composite, which includes a modified TPU film layer, a PU face adhesive layer, polyethylene fiber reinforced nylon base cloth, a PU bottom adhesive layer, and a modified TPU bottom film layer;

[0029] Both the modified TPU mask layer and the modified TPU bottom film layer are made of the following components in parts by weight: 4 parts of TPU modifier and 100 parts of polyether TPU resin.

[0030] Described TPU modifying agent is graphene oxide and polyether type TPU resin extrusion blend compound, and its preparation method is: graphene oxide, polyether type TPU resin, Licowax E lubricant are by mass ratio 50:100: 15 mixing, made by co-rotating twin-screw extrusion granulation.

[0031] The polyether-type TPU has a soft segment PTMEG molecular weight of 1100-1200 for synthesis, a hydroxyl value of 110-115 mgKOH / g, a Shore hardness of 90A-95A, a weight-average molecular weight of 100,000-110,000, and a melting range of 190 ~200°C.

[0032] ...

Embodiment 2

[0042] A modified TPU film fabric composite, which includes a modified TPU film layer, a PU face adhesive layer, polyethylene fiber reinforced nylon base cloth, a PU bottom adhesive layer, and a modified TPU bottom film layer;

[0043] Both the modified TPU mask layer and the modified TPU bottom film layer are made of the following components in parts by weight: 6 parts of TPU modifier and 100 parts of polyether TPU resin.

[0044]Described TPU modifying agent is graphene oxide and polyether type TPU resin extrusion blend compound, and its preparation method is: graphene oxide, polyether type TPU resin, Licowax E lubricant are by mass ratio 50:100: 15 mixing, made by co-rotating twin-screw extrusion granulation.

[0045] The polyether-type TPU has a soft segment PTMEG molecular weight of 1100-1200 for synthesis, a hydroxyl value of 110-115 mgKOH / g, a Shore hardness of 90A-95A, a weight-average molecular weight of 100,000-110,000, and a melting range of 190 ~200°C.

[0046] T...

Embodiment 3

[0056] A modified TPU film fabric composite, which includes a modified TPU film layer, a PU face adhesive layer, polyethylene fiber reinforced nylon base cloth, a PU bottom adhesive layer, and a modified TPU bottom film layer;

[0057] Both the modified TPU mask layer and the modified TPU bottom film layer are made of the following components in parts by weight: 8 parts of TPU modifier and 100 parts of polyether TPU resin.

[0058] Described TPU modifying agent is graphene oxide and polyether type TPU resin extrusion blend compound, and its preparation method is: graphene oxide, polyether type TPU resin, Licowax E lubricant are by mass ratio 50:100: 15 mixing, made by co-rotating twin-screw extrusion granulation.

[0059] The polyether-type TPU has a soft segment PTMEG molecular weight of 1100-1200 for synthesis, a hydroxyl value of 110-115 mgKOH / g, a Shore hardness of 90A-95A, a weight-average molecular weight of 100,000-110,000, and a melting range of 190 ~200°C.

[0060] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Melting range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com