Spray head used for MOCVD equipment

A sprinkler head and equipment technology, applied in the sprinkler head field, can solve problems such as poor deposition uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

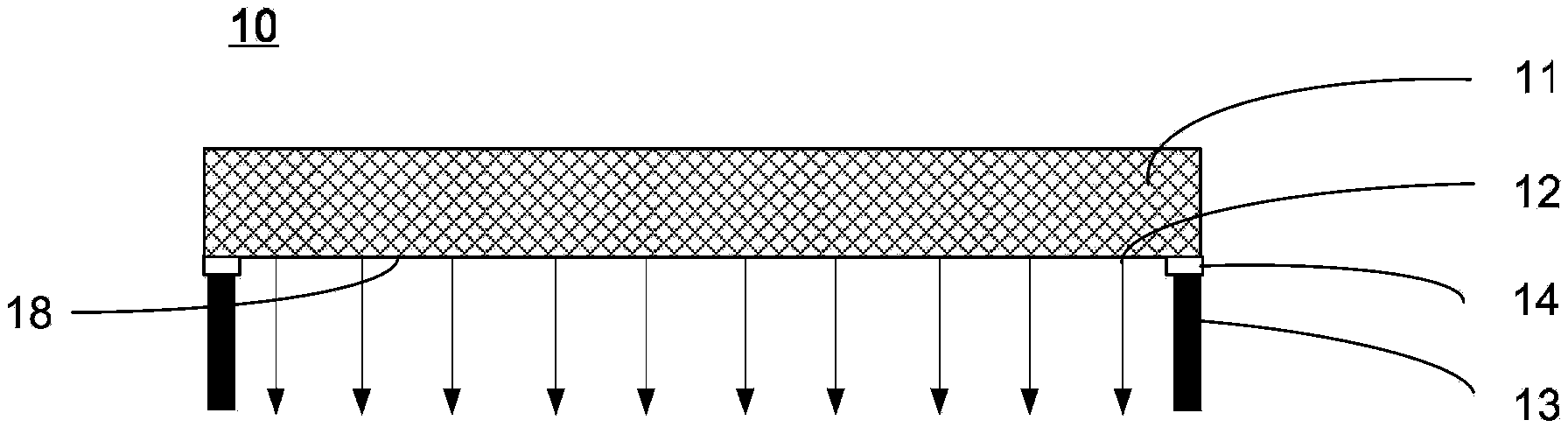

[0030] Please refer to figure 2 , which is a schematic structural diagram of the shower head of the MOCVD apparatus according to Embodiment 1 of the present invention. Such as figure 2 As shown, the shower head 10 of the MOCVD equipment is used to provide reaction gas to the substrate (not shown in the figure) located under the shower head 10. The shower head 10 of the MOCVD equipment includes: a main body layer 11, The side of the main body layer 11 close to the substrate is a gas outlet surface 18, and the reaction gas forms an airflow between the gas outlet surface 18 and the substrate; a restrictor ring 13, the restrictor ring 13 It is connected with the air outlet surface 18 and arranged around the air outlet surface 18 for controlling the direction of the air flow; a heat insulating layer 14 is provided between the restrictor ring 13 and the air outlet surface 18 .

[0031] Specifically, the main body layer 11 is generally made of metal material. The main body layer ...

Embodiment 2

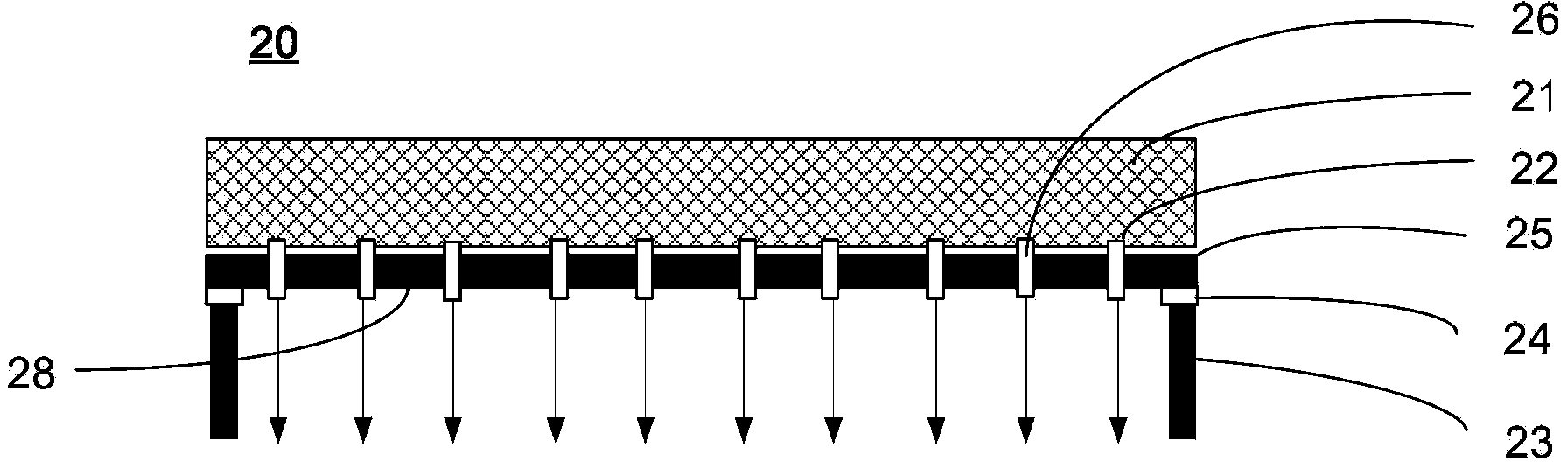

[0035] Please refer to image 3 , which is a schematic structural diagram of the shower head of the MOCVD apparatus according to Embodiment 2 of the present invention. Such as image 3 As shown, the shower head 20 of the MOCVD equipment is used to provide reaction gas to the substrate (not shown in the figure) located under the shower head 20. The shower head 20 of the MOCVD equipment includes: a main body layer 21, The side near the substrate in the main body layer 21 is a gas outlet surface 28, and the reaction gas forms an air flow between the gas outlet surface 28 and the substrate; a restrictor ring 23, the restrictor ring 23 It is connected with the air outlet surface 28 and arranged around the air outlet surface 28 for controlling the direction of the air flow; a heat insulation layer 24 is provided between the restrictor ring 23 and the air outlet surface 28 .

[0036] Specifically, the main body layer 21 is generally made of metal material. The main body layer 21 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com