Composite negative electrode material, negative electrode, lithium ion battery and preparation method

A negative electrode material and negative electrode technology, applied in the field of electrochemical materials, can solve the problems of poor initial charge-discharge capacity and cycle performance, and achieve the effects of reducing local current density, improving deposition uniformity, and improving lithophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of composite negative electrode material:

[0030] Step 1. Cut the commercial melamine foam resin into a shape of 5cm×5cm×3cm, put it into a tube furnace, and carbonize it at 1200°C for 2h under the protection of nitrogen atmosphere, wash it with absolute ethanol after cooling, and dry it at 60°C , and then cut to obtain a foamed carbon matrix of 5cm×5cm×0.1cm;

[0031] Step 2: Put the metal lithium foil into the crucible, heat to 250°C to completely melt the metal lithium foil to obtain molten lithium; immerse the foamed carbon matrix in the molten lithium for 2 minutes, take it out and let it cool naturally to obtain the composite Negative material.

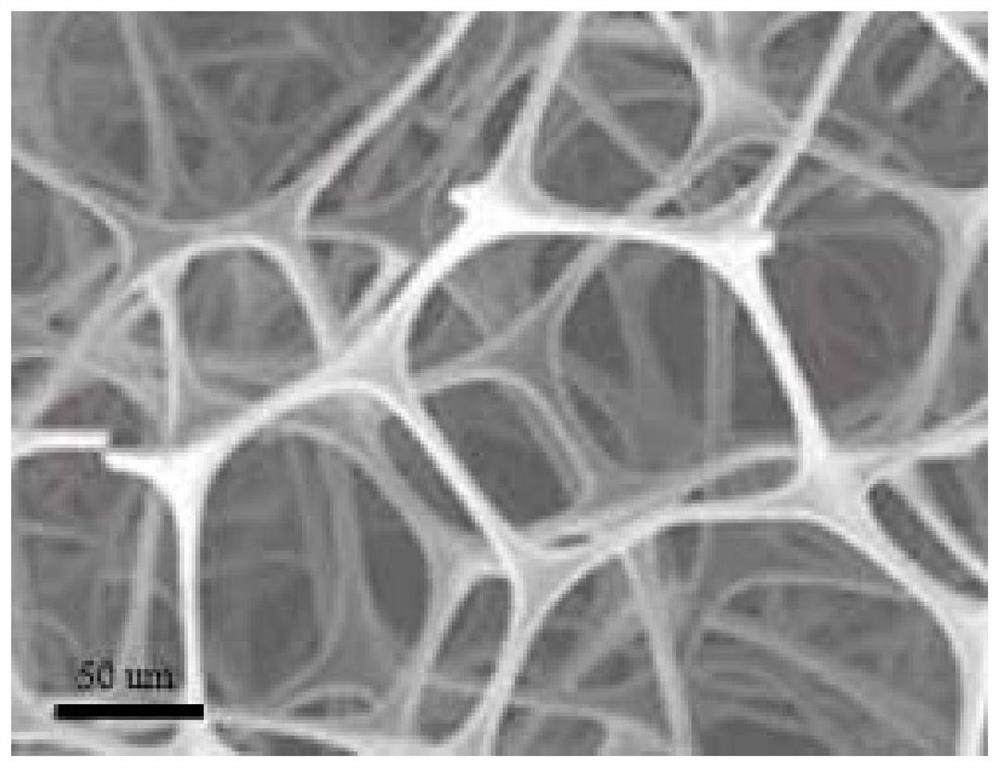

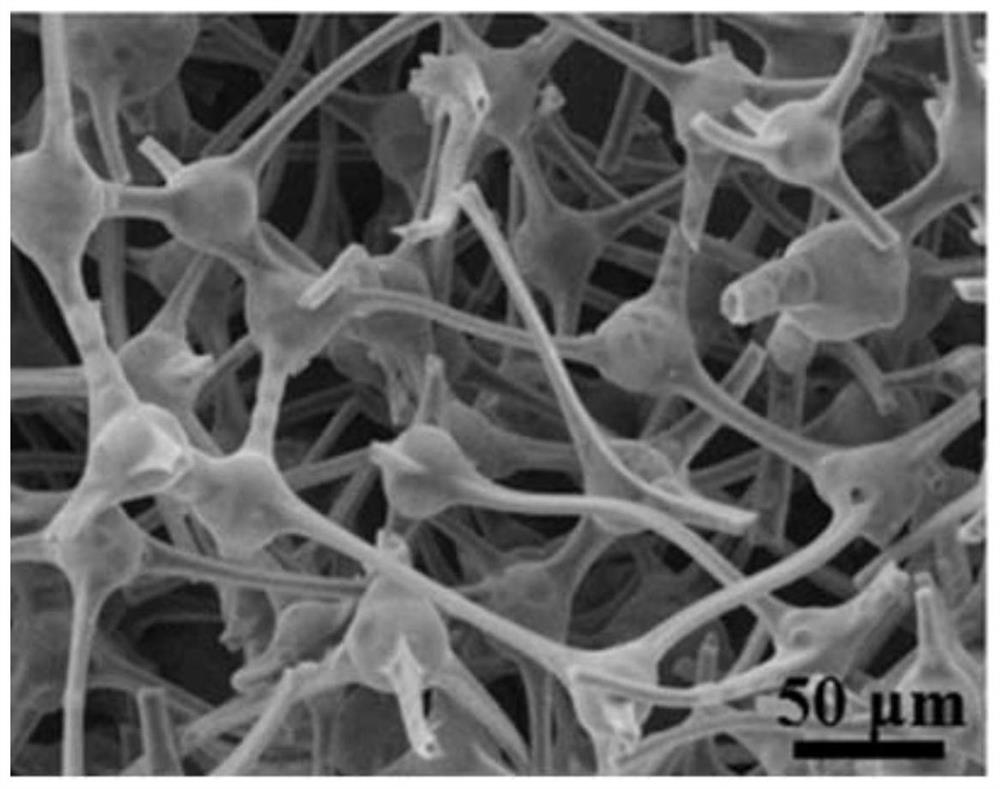

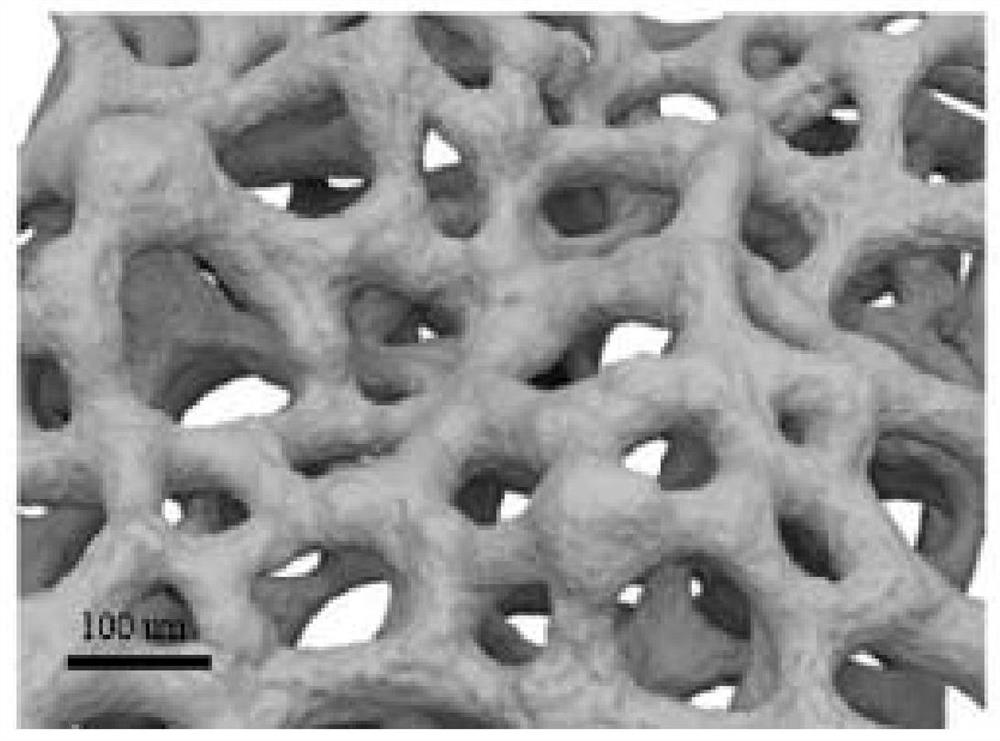

[0032] figure 1 Be the SEM figure of described melamine foam resin, figure 2 It is the SEM picture of carbonized foamed carbon matrix. It can be seen from the figure that the prepared foamed carbon matrix has a high open porosity, the open porosity can reach 99%, and the distribution of pores is ...

Embodiment 2

[0039] A preparation method of composite negative electrode material:

[0040] Step 1. Cut the commercial melamine foam resin into a shape of 5cm×5cm×3cm, put it into a tube furnace, and carbonize it at 1000°C for 4h under the protection of nitrogen atmosphere, wash it with absolute ethanol after cooling, and dry it at 60°C , and then cut to obtain a foamed carbon matrix of 5cm×5cm×0.1cm;

[0041] Step 2: Put the metal lithium foil into the crucible, heat to 180°C to completely melt the metal lithium foil to obtain molten lithium; immerse the foamed carbon matrix in the molten lithium for 4 minutes, take it out and let it cool naturally to obtain the composite Negative material.

Embodiment 3

[0043] A preparation method of composite negative electrode material:

[0044] Step 1. Cut the commercial melamine foam resin into a shape of 5cm×5cm×3cm, put it into a tube furnace, and carbonize it at 1300°C for 3h under the protection of nitrogen atmosphere, wash it with absolute ethanol after cooling, and dry it at 60°C , and then cut to obtain a foamed carbon matrix of 5cm×5cm×0.1cm;

[0045] Step 2: Put the metal lithium foil into the crucible, heat to 500°C to completely melt the metal lithium foil to obtain molten lithium; immerse the foamed carbon matrix in the molten lithium for 6 minutes, take it out and let it cool naturally to obtain the composite Negative material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com