Patents

Literature

2674results about How to "Lightweight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

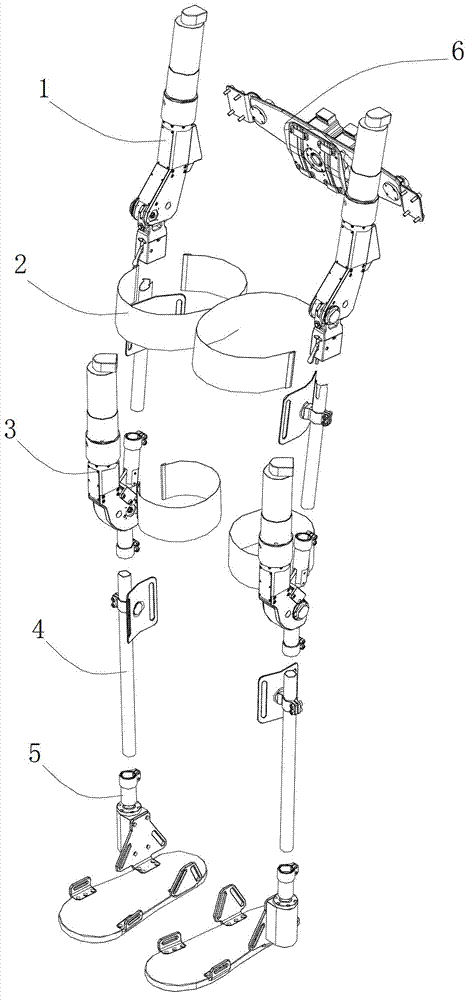

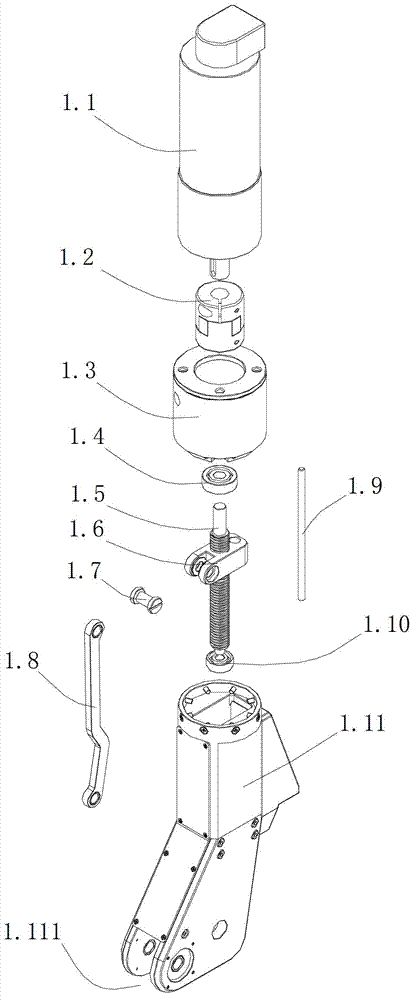

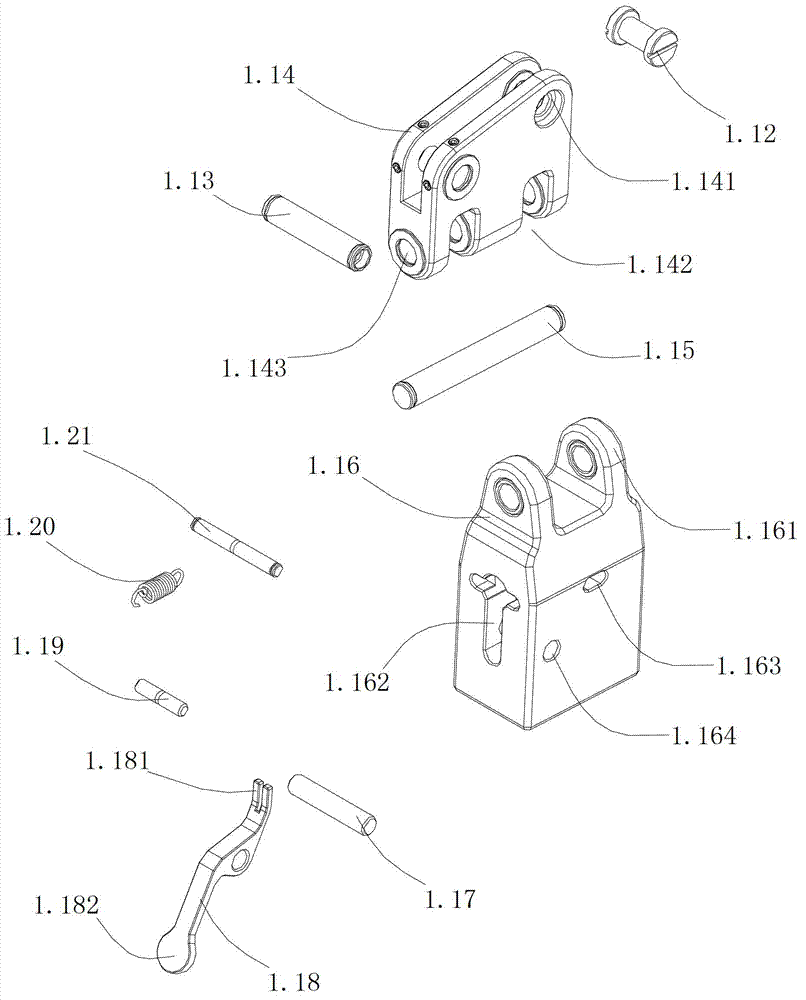

Portable and wearable exoskeleton robot for lower limb recovery and walking aid

The invention relates to a portable and wearable exoskeleton robot for lower limb recovery and walking aid. The exoskeleton robot comprises a hip joint part, a thigh support part, a knee joint part, a shank support part and an ankle joint and foot part which are connected in sequence. Motors are used to drive screw pairs in the hip joint part and the knee joint part so as to drive connecting rods, and accordingly joints are driven to move. Drive mechanisms are light and small in size. The exoskeleton robot is portable and suitable for wearing.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Method for preparing porcelain granules by using fly ash

InactiveCN101585698AImprove protectionSave natural resourcesFluid removalCeramic materials productionExpanded clay aggregateSlurry

The invention discloses a method for preparing porcelain granules by using fly ash, which comprises the following steps: putting fly ash, potassium feldspar and quartz as raw materials into a ball mill respectively, dry-milling the raw materials, sieving the milled raw materials respectively, removing iron from the sieved fly ash, putting the fly ash after iron removal, the sieved potassium feldspar and quartz and kaolin into the ball mill, and wet-milling and evenly mixing the materials to form mixed slurry; and granulating the mixed slurry by adopting a pressure type spray granulator, putting the granules into an alumina crucible, placing the alumina crucible into a silicon-carbon rod resistance furnace, sintering and naturally cooling the granules, and taking out the granules to obtain the high-strength porcelain granules. The method for preparing the porcelain granules by using the fly ash is not only favorable for saving natural resources and reducing the production cost, but also favorable for environmental protection. The fly ash does not need to be crushed by a high-power crusher, and the fly ash is mixed evenly. The production process is easy to control, and has little energy consumption; the strength of the prepared fly ash porcelain granules can reach 60 to 120MPa; and the porcelain granules have good properties of light weight, high temperature resistance, corrosion resistance and the like, and can be used as a fracturing propping agent for middle and deep layer oil-gas fields.

Owner:SHAANXI UNIV OF SCI & TECH

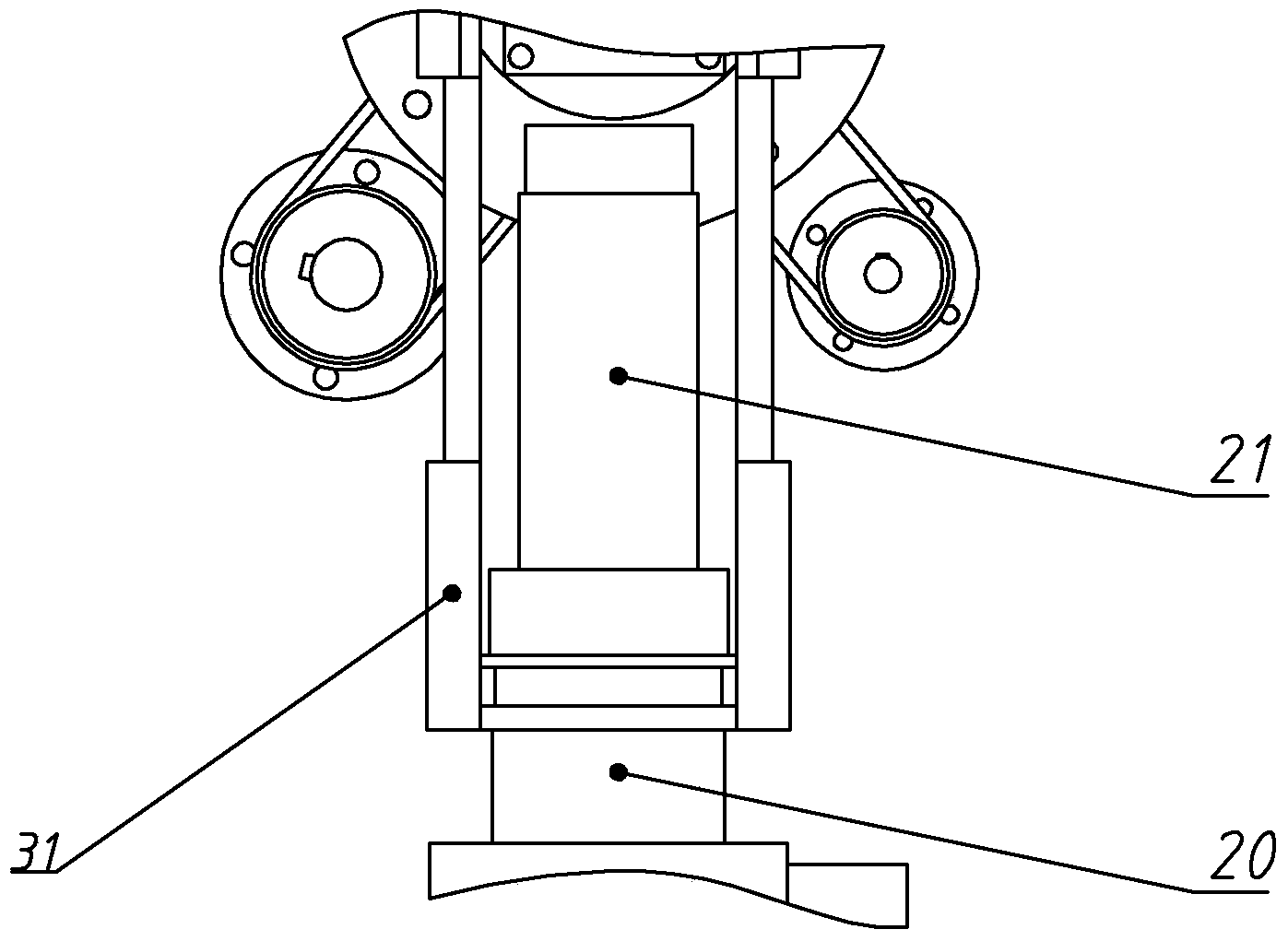

Six-degree-of-freedom humanoid robot arm

The invention discloses a six-degree-of-freedom humanoid robot arm, and relates to a robot arm. The invention aims to solve the problems that the existing robot arm is cumbersome in joint structure, heavy in self weight, low in load bearing ratio and complicated to control. A shoulder rotating joint, a shoulder joint, an upper arm, an elbow rotating joint, a elbow swing joint, a fore arm, a wrist rotating joint, a wrist swing and a hand are sequentially arranged from top to bottom, wherein an arm swing motor is connected with a worm by virtue of a conveyor belt, an arm rotating motor is connected with a shoulder swing support by virtue of a conveyor belt, an upper arm shell is arranged between a shoulder joint and an elbow joint, an elbow rotating drive motor and a speed reducer are sequentially arranged in the upper arm shell from top to bottom, an elbow swing joint motor is arranged in an elbow joint shell and is connected with an elbow joint conveyor belt, an elbow joint speed reducer is arranged in the elbow joint shell, a hand connecting support is arranged between the fore arm and the hand, a wrist joint swing motor is arranged on one side of the hand connecting support, and a wrist joint rotating motor is arranged at the upper end of the hand connecting support. The six-degree-of-freedom humanoid robot arm is applied to a humanoid robot.

Owner:HARBIN INST OF TECH

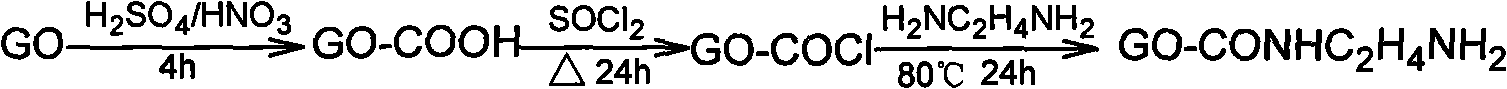

Method for preparing graphene functionalized alginate fibers

ActiveCN102181961AEffective orientationUniform and stable dispersionAlginate artificial filamentsWet spinning methodsFiberChemical reaction

The invention discloses a method for preparing graphene functionalized alginate fibers. The method comprises the following steps: firstly adding a defined amount of graphene to a sodium alginate solution to obtain a graphene / alginate spinning solution; or aminating the defined amount of graphene and then ensuring the aminated graphene to covalently bind with sodium alginate through a chemical reaction to obtain a graphene-alginate spinning solution; then ensuring the graphene / alginate spinning solution or the graphene-alginate spinning solution to respectively undergo a coagulation bath to obtain graphene / alginate as-spun fibers or graphene-alginate as-spun fibers; and then drawing, setting and oiling the graphene / alginate as-spun fibers or graphene-alginate as-spun fibers after ensuring the graphene / alginate as-spun fibers or graphene-alginate as-spun fibers to undergo a preheating bath and a drawing bath respectively to obtain graphene / alginate functionalized fibers or graphene-alginate functionalized fibers which are called graphene functionalized alginate fibers. The prepared graphene functionalized alginate fibers integrate the excellent performances of the graphene and the sodium alginate and have the excellent performances such as high tensile strength, good biocompatibility, antistatic performance, light weight, high elasticity, antibacterial performance and the like.

Owner:QINGDAO UNIV

Method for preparing conductive polyaniline electromagnetic interference screening paint

InactiveCN1632021AEquivalent EMI shielding performanceLightweightElectrically-conductive paintsPolyester coatingsElectromagnetic interferencePolyaniline

Disclosed is a method for preparing a conducting polyanion electromagnetic disturbance shielding coating, which uses conducting high molecular polyanion as the main conducting component, thermoplasticity resin as the mains film forming substance. The polyanion electromagnetic disturbance shielding coating has solved problems existing in that belongs to metal system,with advantages like light weigh,low prince good stability,convenient strange and constrction. Bsides,it does not need to used polyanion solution,making the application of conducting polyanion easier, more convenient and have lower cost. Mixing polyanion with different conductivity and inorganic filler can realize electromagnetic disturbance shielding with wider range of frequency, with higher shielding effect.

Owner:XI AN JIAOTONG UNIV

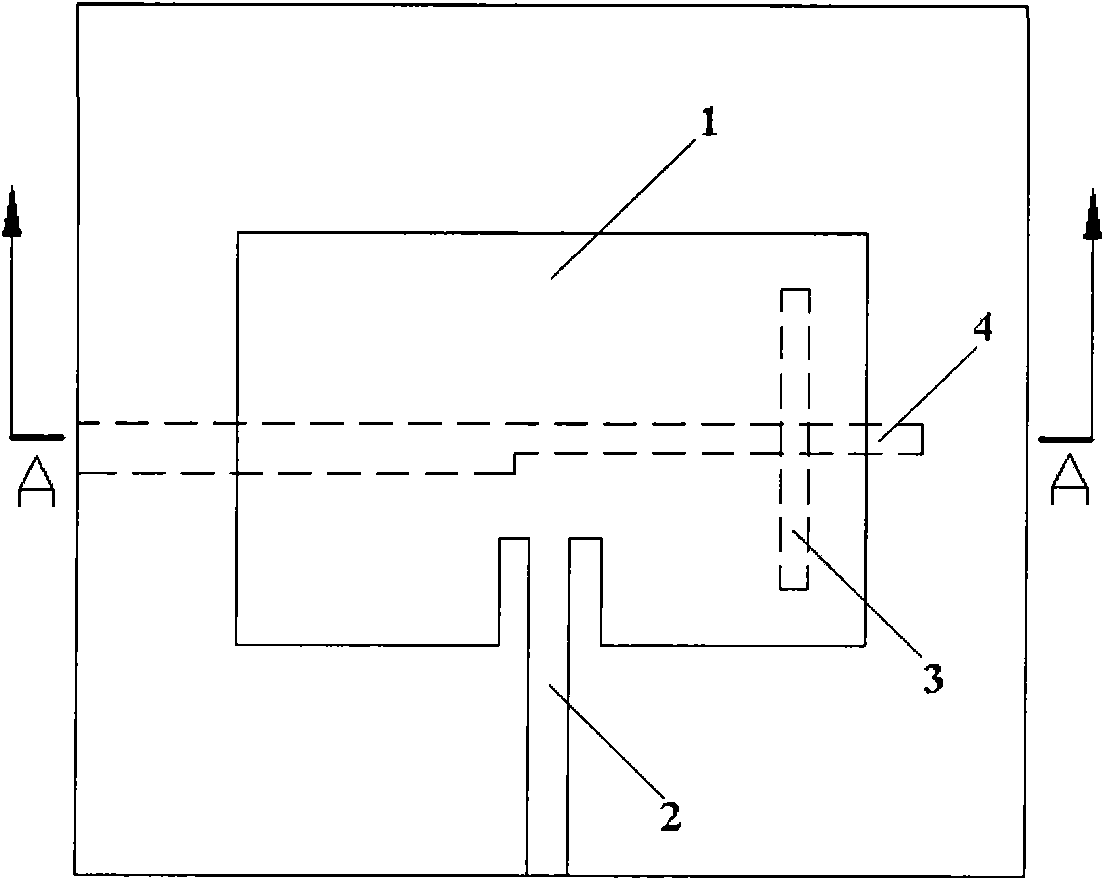

C/X dual-band microstrip antenna

InactiveCN101931122AAchieve Impedance MatchingIncrease output powerAntenna arraysSimultaneous aerial operationsPhysicsSatellite

The invention discloses a C / X dual-band microstrip antenna, and belongs to the technical field of antennas. The antenna adopts a dual-layer high-resistance silicon medium structure in which two frequency bands share a rectangular radiation patch; an upper layer of high-resistance silicon media bears a rectangular patch and an X frequency band feed line; an air cavity is etched on an upper layer of high-resistance silicon to reduce a composite dielectric constant of the high-resistance silicon; a lower layer of high-resistance media bear a C frequency band feed line; an X frequency band adopts microstrip coplanar feeding; and a C frequency band adopts slot coupling feeding. The C / X dual-band microstrip antenna or a C / X dual-band two-element microstrip antenna has the following advantages of: 1, singlechip and dual modes, simple structure and flexible design; 2, multiple frequencies; 3, miniaturization and light weight; and 4, integration. The C / X dual-band microstrip antenna can be widely applied to airborne point-to-point communication tools, such as satellite communications, control, guide and radars.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

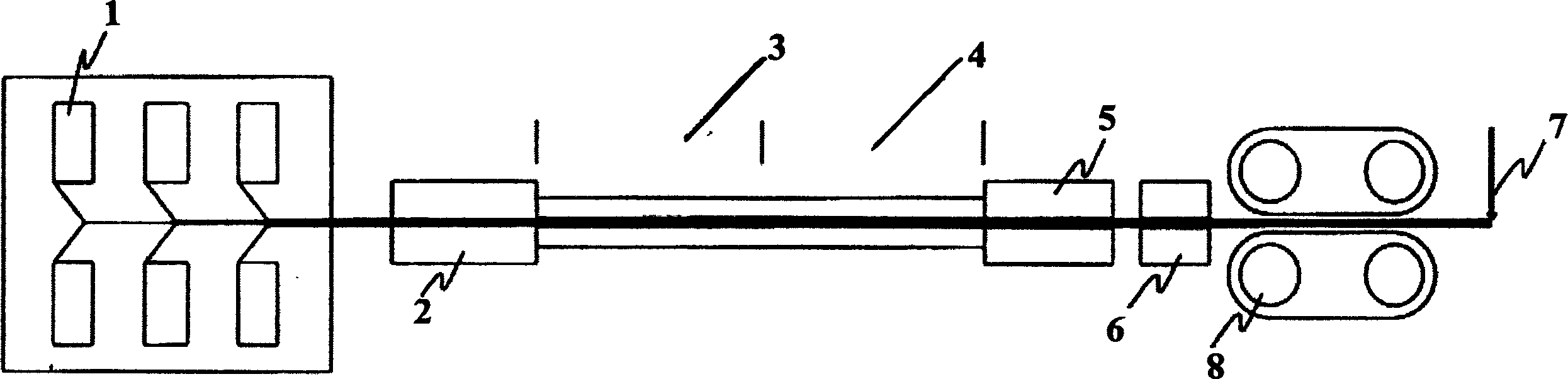

Composite interior material for motor car and preparation method thereof

InactiveCN102619022AGood compatibilityImprove functionalityNon-woven fabricsAdhesivesWork in processHot pressing

The invention relates to a composite interior material for a motor car and a preparation method thereof. The composite interior material comprises 60-80% of high performance fibers, 10-20% of flame retardant fibers and 10-20% of hot-melt fibers; and the preparation method comprises the following specific steps of: 1) opening the high performance fibers, the flame retardant fibers and the hot-melt fibers by a bale opener; reopening the high performance fibers, the flame retardant fibers and the hot-melt fibers by using a rough opener; and then mixing the high performance fibers, the flame retardant fibers and the hot-melt fibers by using a cotton blending machine; finely opening the mixture by using a fine opener; and combing the mixture by using a carding machine; 2) by using a nonwoven needle-punched machining technology, lapping the combed fibers in a cross way by a lapping machine; and then carrying out needle punching on the fibers by using a needle machine; and processing the fibers by using a singeing machine and a glazing calendar; and 3) carrying out composite hot pressing on a fiber felt which is a needle-punched, singed and calendared semi-finished product; and finally, forming the composite interior material together with a thermoplastic resin.

Owner:NANTONG UNIVERSITY +1

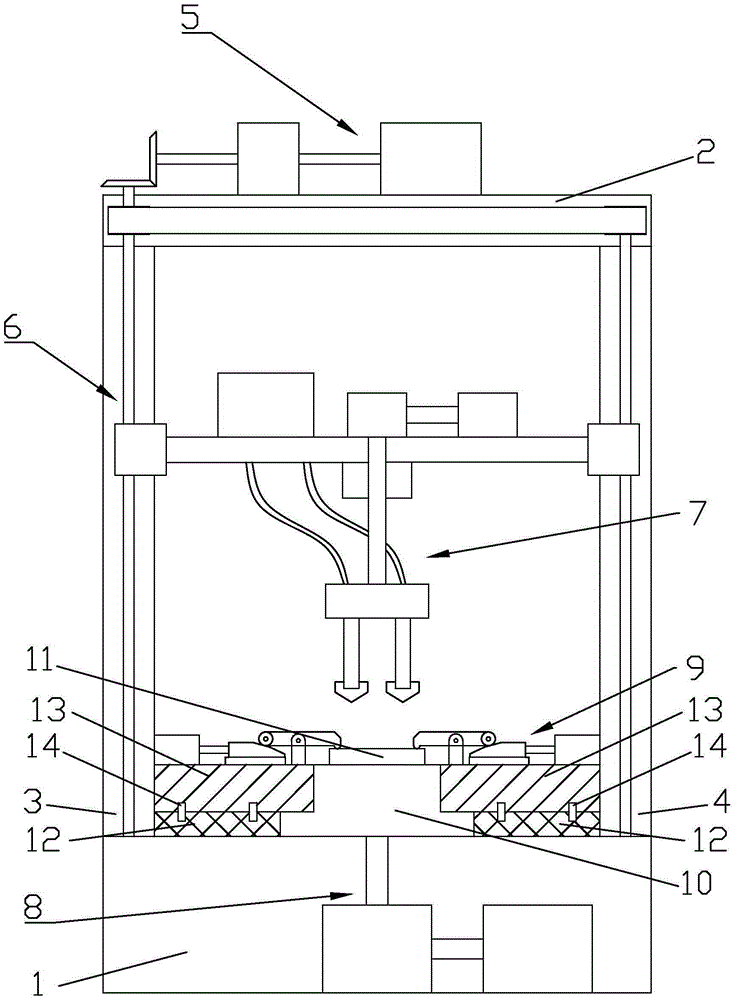

Drilling device applied to graphite mold production

InactiveCN105414599ASolving Drilling ProblemsStrong targetingWorkpiecesTurning toolsElectric machineryReducer

The invention discloses a drilling device applied to graphite mold production. The drilling device comprises a frame and a drilling table; drilling longitudinal frames and a drilling transverse frame are arranged on the frame; the drilling longitudinal frames are positioned at the two sides of the frame; the drilling transverse frame is positioned between the drilling longitudinal frames, and is provided with a lifting driving mechanism and a lifting mechanism; the lifting mechanism includes lifting platforms and lifting lead screws; the lifting lead screws are mounted in the drilling longitudinal frames, and are connected with lifting lead screw connecting bases; the lifting lead screw connecting bases are connected with the lifting platforms; drilling mechanisms are arranged on the lifting platforms, and include drilling motors and drilling lead screws; the drilling motors are connected with drilling motor output shafts; the drilling motor output shafts are connected with drilling speed reducers; the drilling speed reducers are connected with the drilling lead screws; the drilling lead screws are connected with drilling bases; and the drilling bases are connected with drill rods. The machine is simple in structure, strong in pertinency, precise in positioning and excellent in drilling effect, and preferably solves the drilling problem in the graphite mold production.

Owner:SHENGZHOU SIGMA TECH

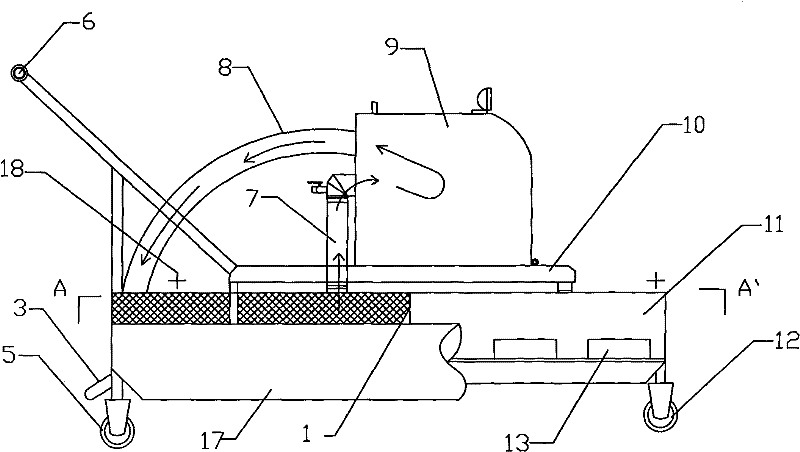

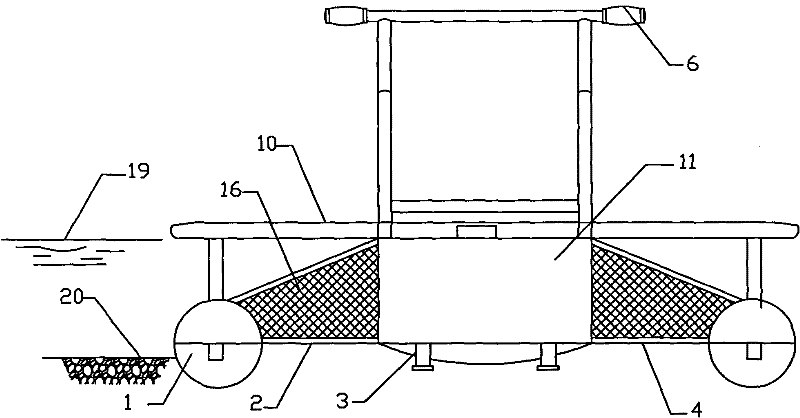

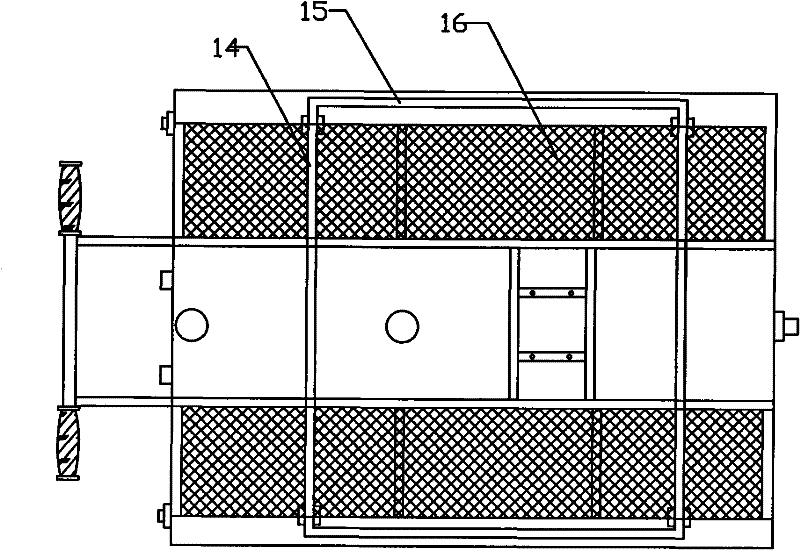

Floating barrel duckbilled lotus root digging machine

The invention discloses a floating barrel duckbilled lotus root digging machine, which comprises a chassis frame (14), a power water pump room (9), a pump fixing frame (10), a water inlet pipe (7), a high-pressure tube (8) and a high-pressure nozzle (3), and is characterized in that: the lotus root digging machine is provided with left and right sealed floating barrels (1); a working bin (11) is arranged between the left and right sealed floating barrels (1); bottom, front-back and top filtering nets (2, 4 and 16) are welded outside the working bin (11) and between the left and right sealed floating barrels (1); and the chassis frame (14) is welded with the left and right sealed floating barrels (1), the working bin (11), the pump fixing frame (10), an operating frame (6) and a lifting lever (15) into a whole. The lotus root digging machine is novel in structure, light and flexible in complete machine, low in manufacturing cost, easy to operate, high in efficiency, low in fault rate, easy to maintain, convenient to transfer and wide in application.

Owner:武汉兴盛农机技术开发有限公司

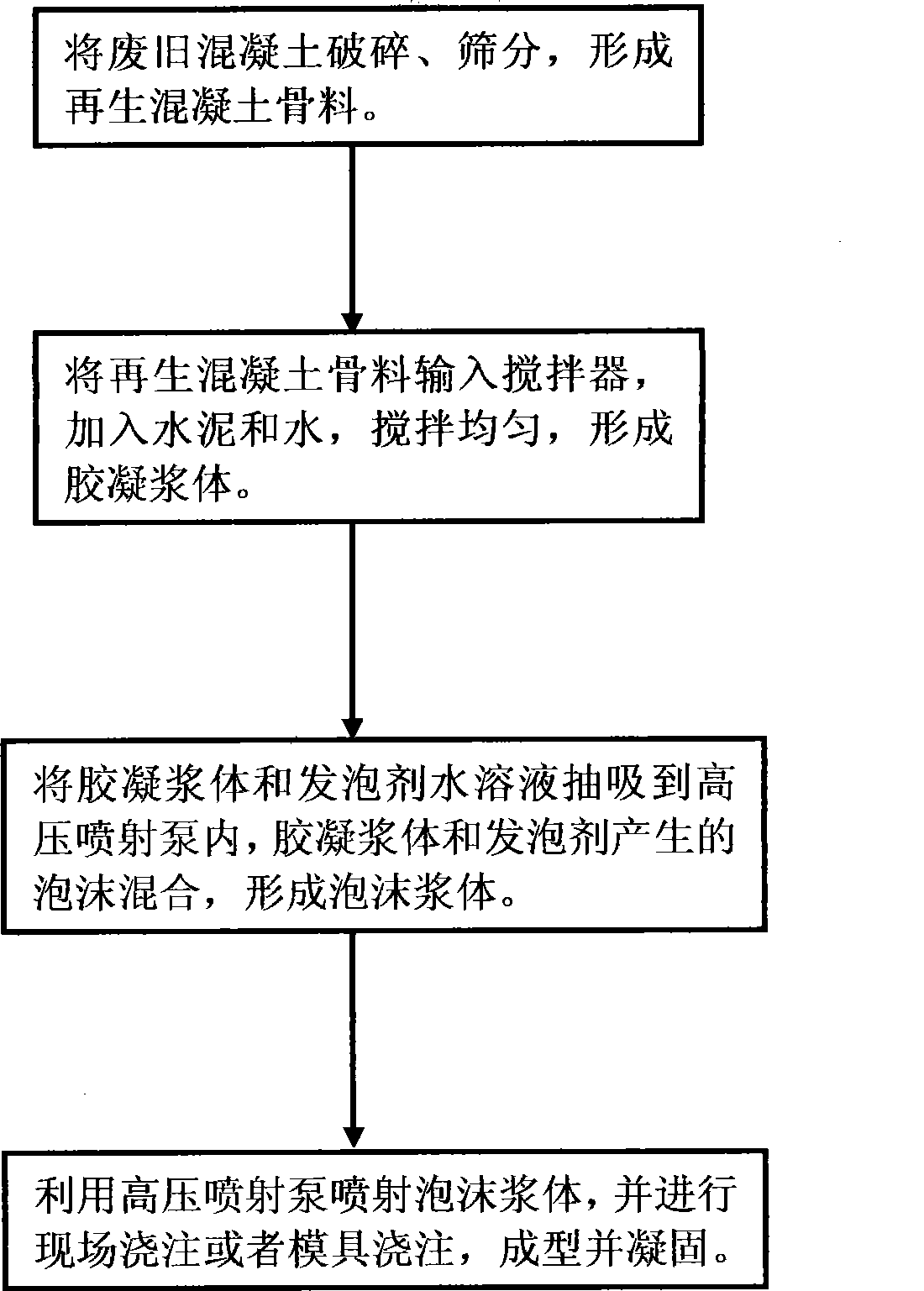

Foaming concrete made by waste and old concrete and production method thereof and use

InactiveCN101391902ASpeed up the solidificationGuaranteed continuitySolid waste managementCeramicwareUnderground pipelineSubgrade

The invention discloses light foaming concrete made by waste concrete, and the production method and application of the foaming concrete. The foaming concrete is formed by the mixing of regenerated foaming concrete aggregate formed after the smashing and screening of the waste concrete, jellous slurry formed by adding concrete, fly ash and water, and foam generated by a foaming agent. After on-spot injection, pouring or mould pouring, the foaming concrete can be used in a plurality of aspects in municipal infrastructure construction such as weak subgrade processing, high filling subgrade, road-widening subgrade, temporary subgrade, various underground pipeline foundation, narrow slot and small clearance space filling, road landslide emergency backfilling, building heat preservation, sound insulation walls and the like. The adoption of the waste concrete for making the foaming concrete has the advantages of utilizing the waste, being environment-friendly, saving energy and having low cost, and the like, and the produced foaming concrete has a plurality of good performances such as light weight, no lateral confinement compression resistance, self-compaction and vibro-free property, and the like.

Owner:BEIJING SIFANGRUGANG CONCRETE PROD

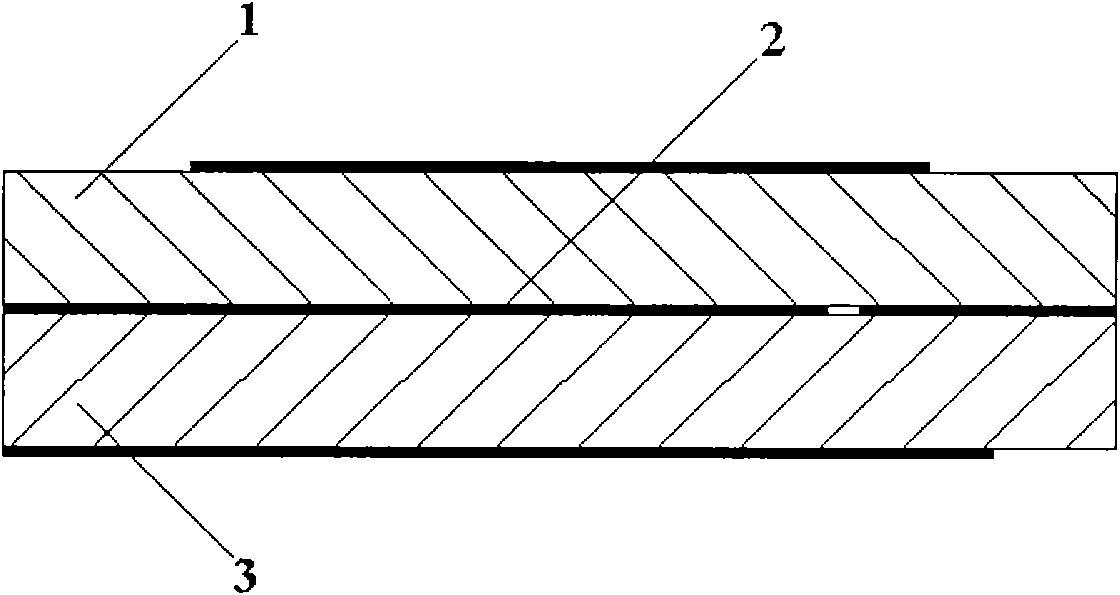

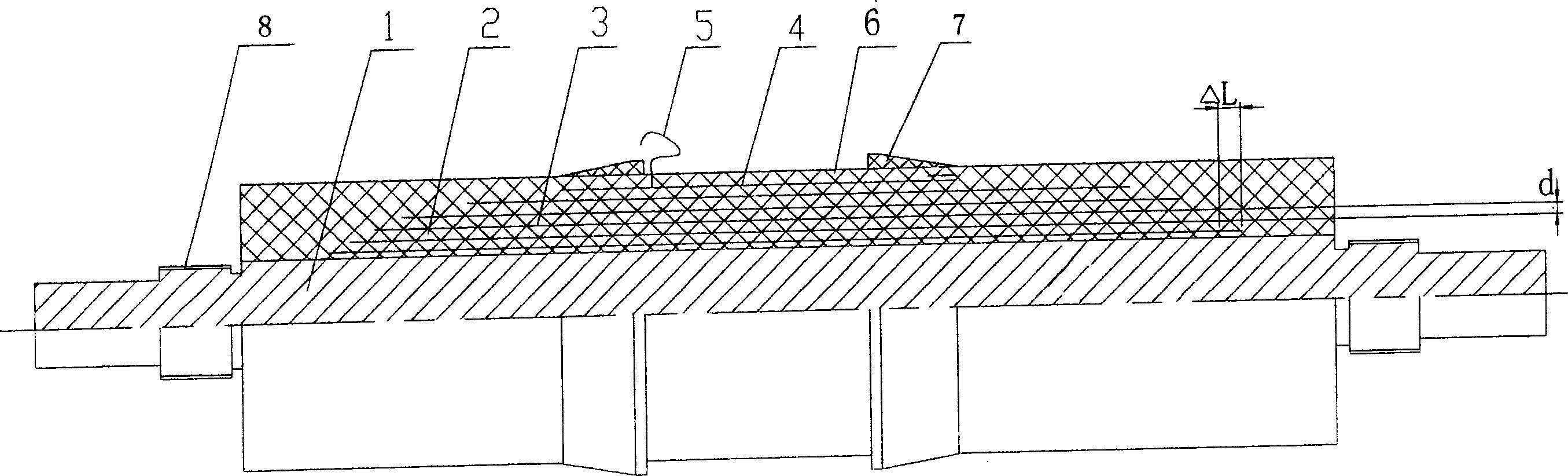

Dry type high-voltage capacitor core and making method thereof

InactiveCN1419250AImprove edge skin effectIncrease the corona onset voltageTransformers/inductances coils/windings/connectionsVoltage dividersFiberCapacitance

The present invention relates to a dry high-voltage capacitor core used in the high-voltage electric appliance of electric power system and the method thereof. The capacitor mandrel includes the carrying conductor, the insualting layer, the capacitor shroud, the gronding end shroud, the leading-out wire for measure and the outer insualting layer. Said inner insualting layer is formed by means of winding the insulating tows or band which is impregnated with binding solidified material. Said capacitor shroud is formed by means of uniformly winding the riband or two semiconducting material oral carbon fiber which is impregnated with binding solidified material and said capacitor shroud and said insulating layer are alternately winded together and are solidified into the concentric round in-series capacity voltage-sharing structure of multi-layer pure solid without interface.

Owner:NANJING ELECTRIC HIGH VOLTAGE BUSHING

Method for producing self-insulation baked brick by using pure coal gangue

InactiveCN101672083ASmall granularityImprove plasticity indexBuilding componentsCeramicwareCoal wasteCoal gangue

The invention relates to a method for producing self-insulation baked bricks by using pure coal gangue, comprising the following components in weight percent: 65-85 coal gangue, 2-10 coal dust, 10-25coal residue or fly ash and 3-15 pore forming agent. The method comprises the following processing steps: firstly crushing raw materials in particles with particle size being less than 3mm, wherein particles less than 0.5mm accounts for more than 60%; adding water of hole forming agents such as sawdust, rice hulls or straw and the like and evenly stirring; and obtaining finished products by aging,rolling and refining, extrusion molding, drying and roasting. The invention has the advantages of comprehensively using raw materials such as coal gangue, fly ash, sawdust and the like which are absolute waste in industry and agriculture, thus having important realistic significance in protecting environment and plowland, using the processes of jaw crushing, hammer crushing and screening to further lower the particle size of the coal gangue raw material, thus being favor of improving the plasticity indexes of raw materials and controlling lime bloating phenomenon, and has the effects of lightweight, heat preservation, heat insulation and sound insulation, thus completely satisfying the requirement of saving 50% of energy for buildings.

Owner:沈正

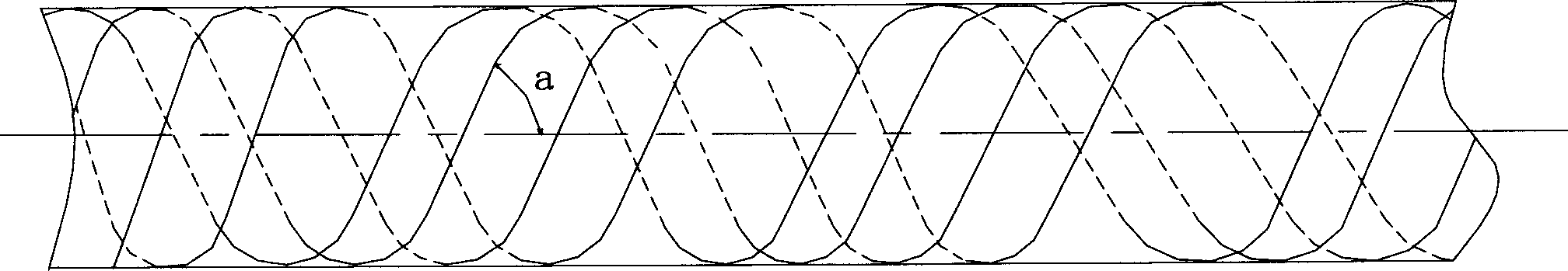

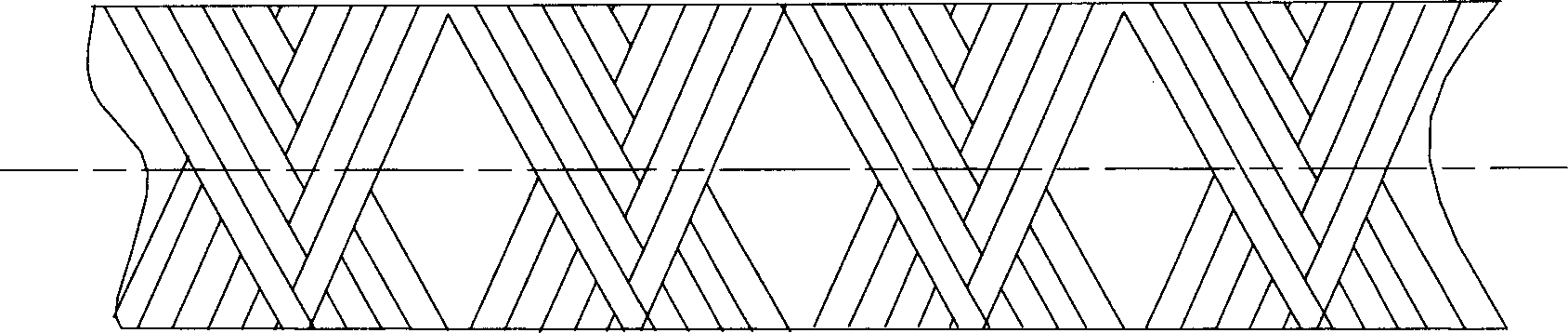

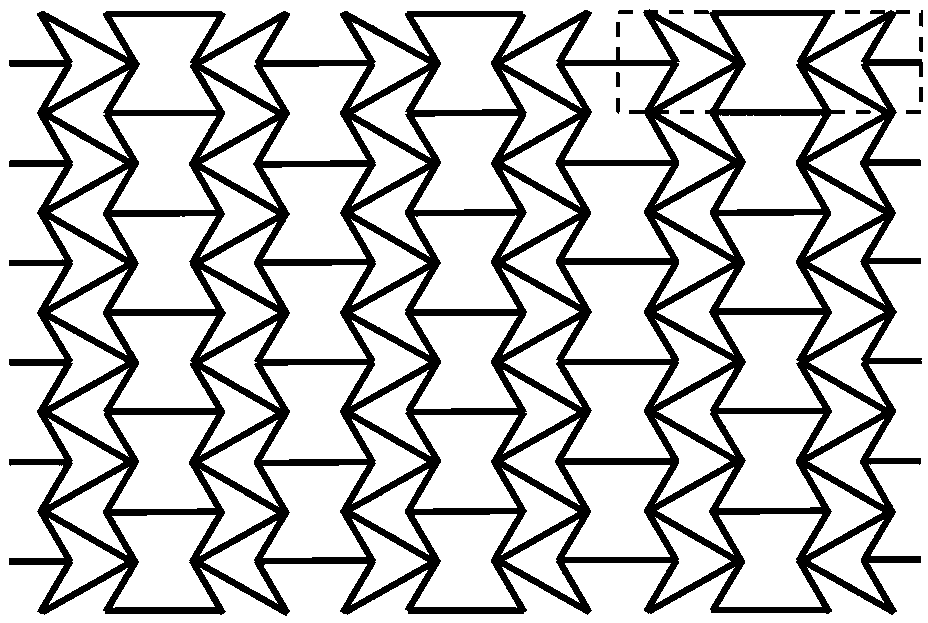

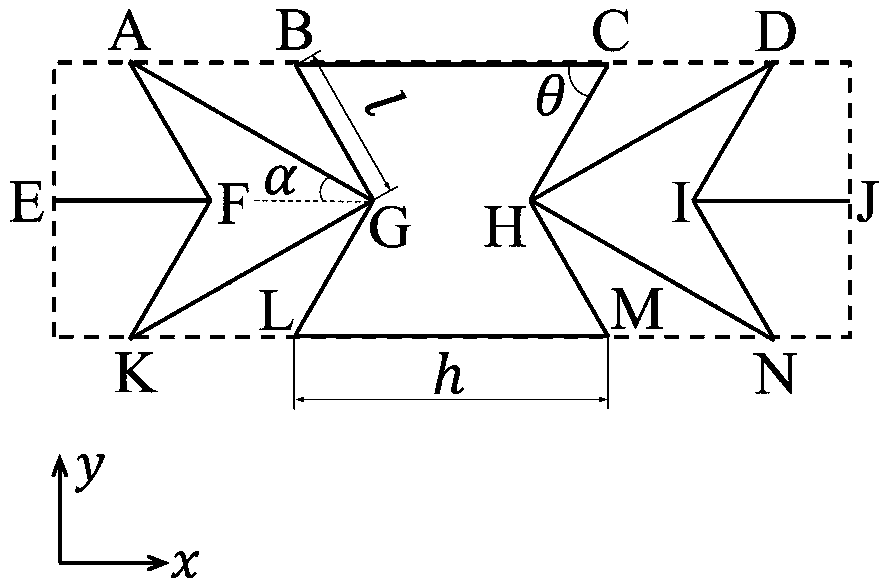

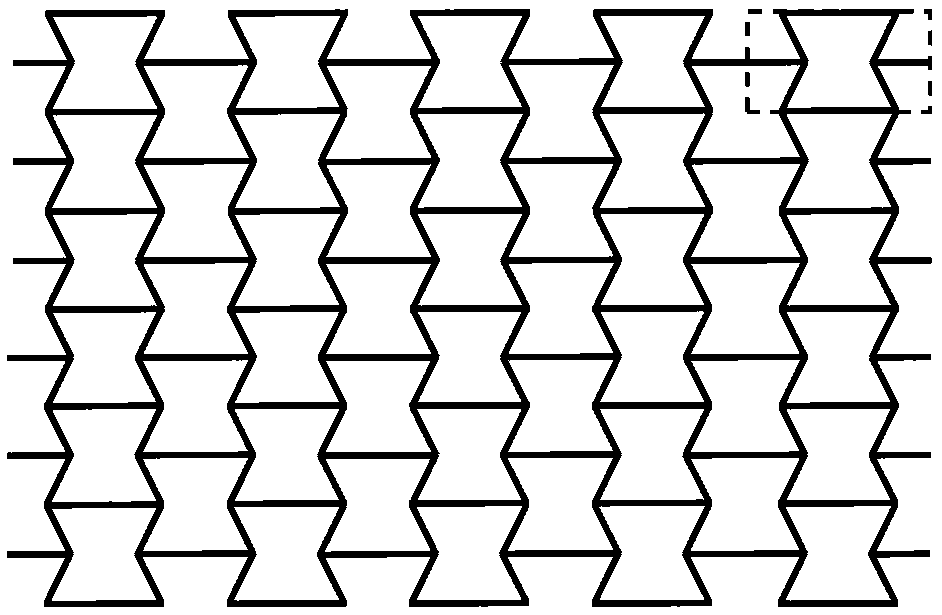

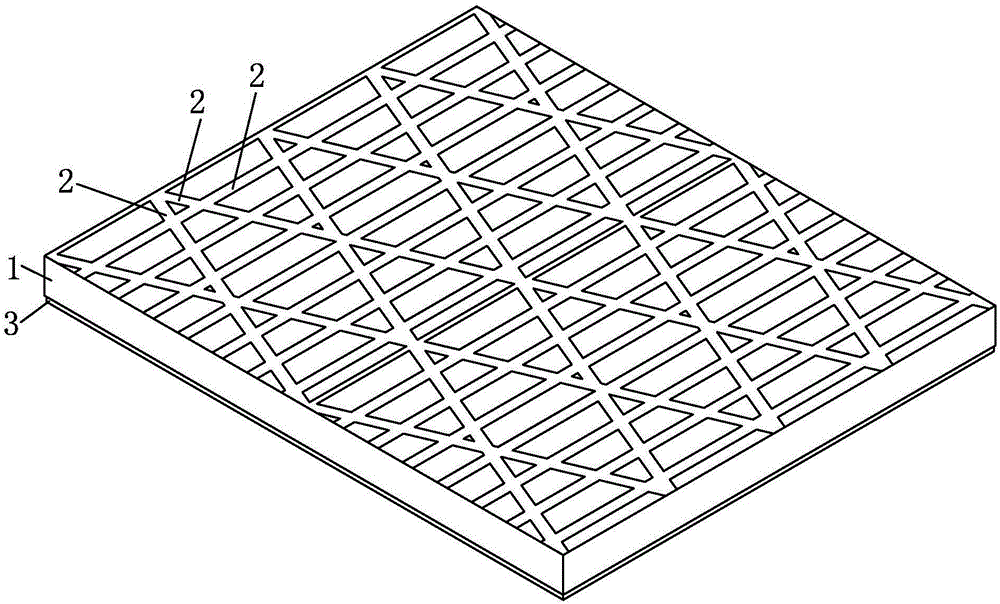

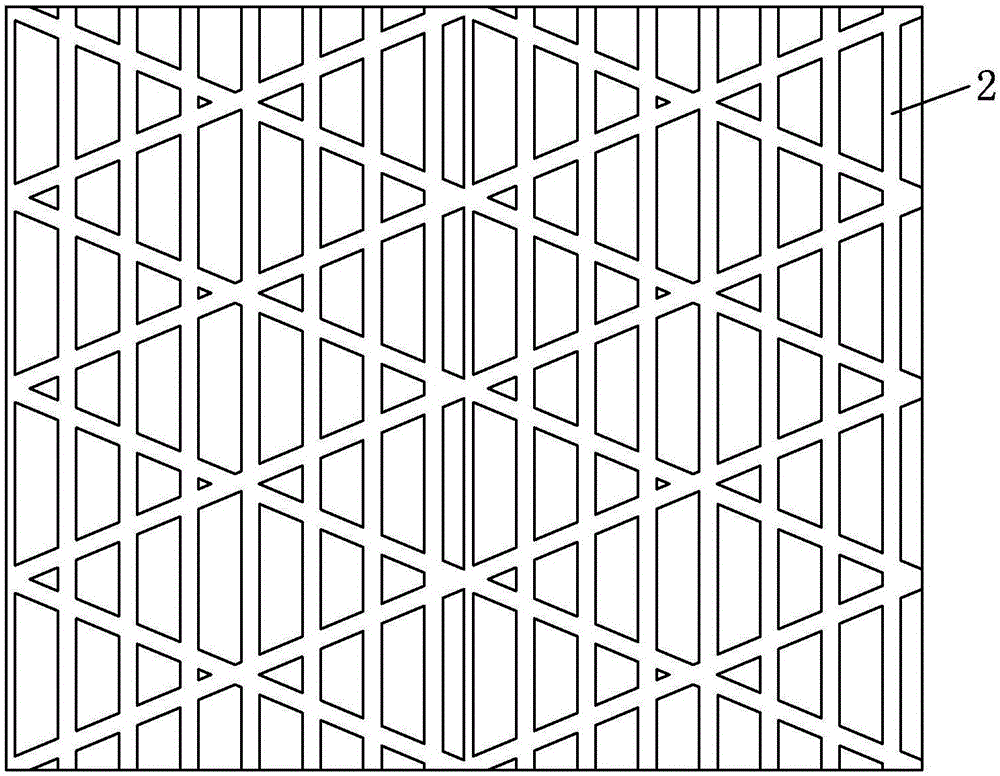

Pulled polycellular configuration and energy-absorbing structural member

InactiveCN108895108AImprove stress resistanceStrong impact resistanceElastic dampersShock absorbersShock resistanceEngineering

The invention discloses a pulled multicellular configuration and an energy-absorbing structure component, comprising a plurality of unit cell structures, wherein each unit cell is obtained by cleverlysplicing two typical concave characteristic structures and two arrow-shaped structures; the pulled multicellular configuration and the energy-absorbing structure component comprise a plurality of unit cell structures. The vertices of the concave corners on the left and right sides of the concave eigenstructure are connected with two arrow-shaped eigenstructures respectively, and the vertices of the concave corners of the two arrow-shaped eigenstructures are connected with half of the transverse bars of the other two concave eigenstructures, which together form a single cell structure with anexpanded multicellular configuration; the vertices of the concave corners of the left and right sides of the concave eigenstructures are connected with each other. Then the two-dimensional stretched polycyclic configuration is obtained by planar array. The polycellular material has negative Poisson's ratio property, which shrinks when compressed, thus locally densifying the compressed region. Thisunique deformation characteristic makes the polycellular material have stronger indentation resistance and impact resistance. In addition, by changing the slenderness ratio and inclination angle of the rod, the elastic properties and compression strength of the rod are adjusted.

Owner:BEIHANG UNIV

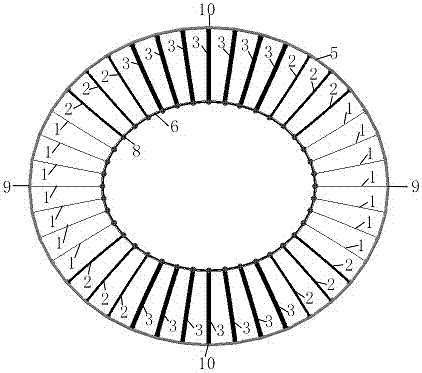

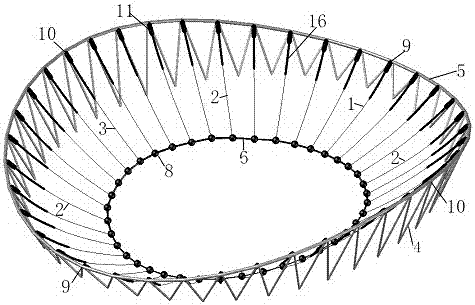

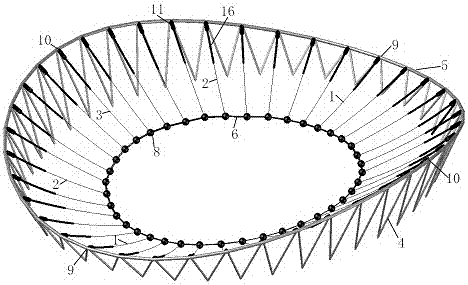

Construction method for integral lifting and batch step-by-step anchoring of spoke type single-layer cable net

InactiveCN106930538AReduced volume and work at heightLower requirementBuilding material handlingHeight differenceIndustrial engineering

The invention discloses a construction method for integral lifting and batch step-by-step anchoring of a spoke type single-layer cable net. A cable net structure mainly comprises vertical pillars, an outer pressing ring beam, an inner ring cable and radial cables. Obvious height differences exist in the outer end anchoring nodes of all the radial cables. According to the height differences of the anchoring nodes of the outer pressing ring beam, the radial cables are divided into different batches from a structural low point to a structural high point. The number of the batches is determined according to practical conditions. The integral cable net is lifted through a jack, all batches of the radial cables and the outer pressing ring beam are connected and anchored in batches step by step from the low point to the high point in the lifting process, and finally the structure is formed. According to the construction method, the construction support quantity and the upper air operation quantity can be reduced, the requirement quantity of a large-tonnage lifting system is reduced, installation cost is reduced, tool lightening is achieved, the construction period is shortened, and construction efficiency is improved.

Owner:SOUTHEAST UNIV

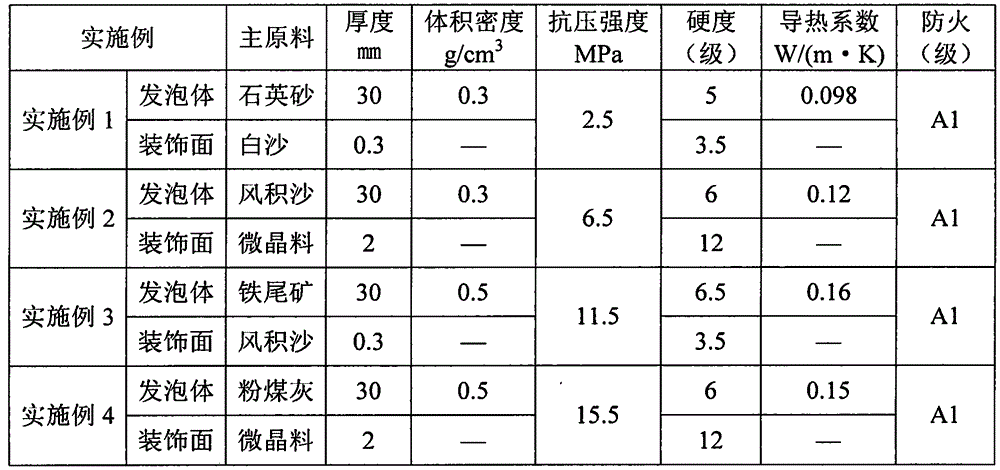

Microcrystalline foamed wall block produced by use of tailings and manufacturing method of microcrystalline foamed wall block

ActiveCN104631688AProduced noRelieve pressureBuilding componentsCeramicwareWeather resistanceSurface layer

The invention discloses a microcrystalline foamed wall block produced by use of tailings and a manufacturing method of the microcrystalline foamed wall block. According to the microcrystalline foamed wall block, a decorative surface layer is sintered on a tailing microcrystalline foamed base body manufactured by use of a tailing composite material at a high temperature. The manufacturing method comprises the following steps: (1) preheating, namely increasing the temperature to the range of 800-950 DEG C and preserving heat for 10-40 minutes; (2) integrated sintering, namely increasing the temperature to the range of 1000-1350 DEG C and preserving heat for 30-120 minutes; (3) annealing cooling, namely cooling to below 280 DEG C and then taking out of a kiln; (4) naturally cooling to below 100 DEG C and then performing mold stripping, thereby obtaining a microcrystalline foamed wall block board; naturally placing the microcrystalline foamed wall block board for more than 60 hours to eliminate stress, and then grinding or polishing, cutting and drying to obtain the microcrystalline foamed wall block. The microcrystalline foamed wall block has a plurality of functions of high strength, fire resistance, heat preservation and thermal insulation, moisture and water proofing, decoration, light weight, weathering resistance, environmental protection and the like.

Owner:BEIJING HUIERJIU MATERIAL TECH

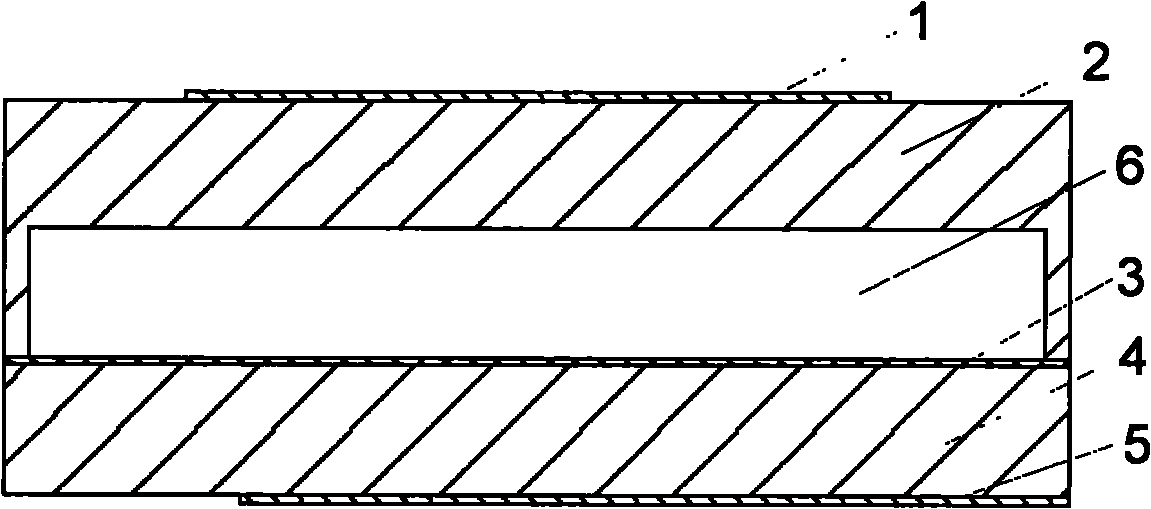

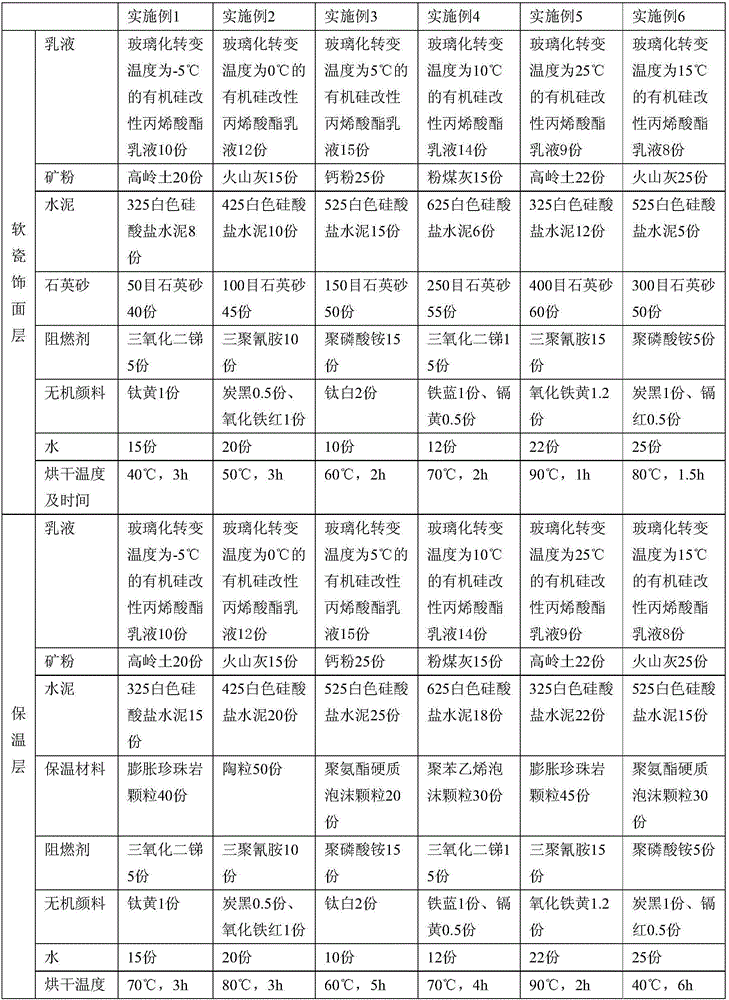

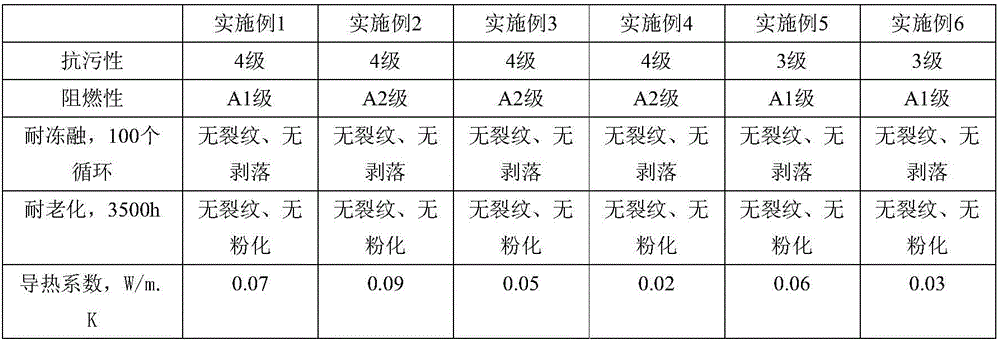

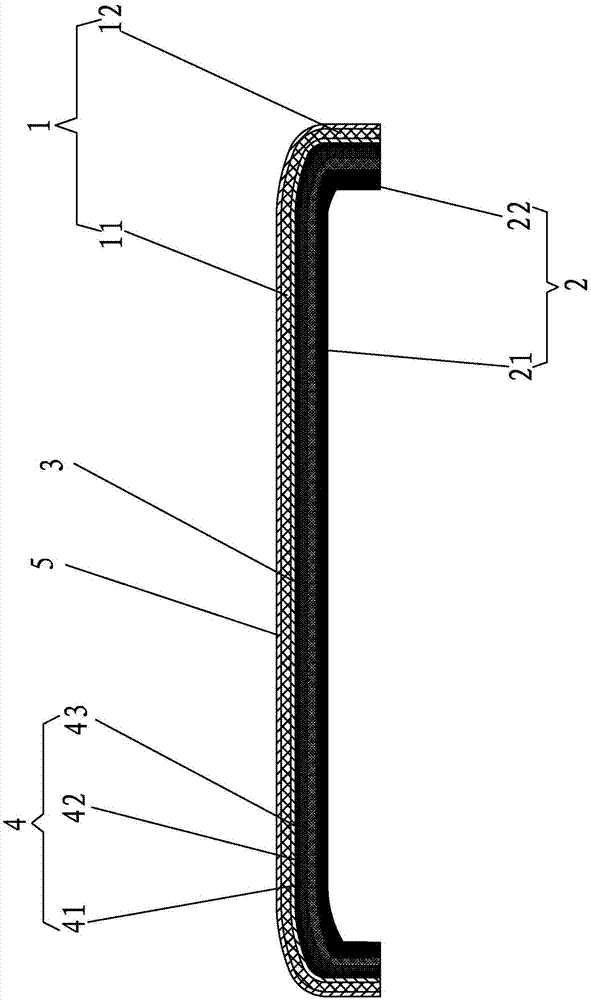

Heat preservation and decoration integrated facing tile and production method thereof

ActiveCN106495613AWith decorative functionWith heat preservation functionCovering/liningsGlass fiberEmulsion

The invention discloses a heat preservation and decoration integrated facing tile and a production method thereof. The heat preservation and decoration integrated facing tile comprises a soft porcelain decorative face layer and a heat preservation layer. The soft porcelain decorative face layer is composed of, by weight part, 8-15 parts of emulsion, 15-25 parts of mineral powder, 5-15 parts of cement, 40-60 parts of silica sand, 5-15 parts of flame retardant, 0.5-2 parts of inorganic pigment and 10-25 parts of water; the heat preservation layer is composed of the following components containing glass fiber gridding cloth and including, by weight part, 8-15 parts of emulsion, 15-25 parts of mineral powder, 15-25 parts of cement, 20-50 parts of heat preserving materials, 5-15 parts of flame retardant, 0.5-2 parts of inorganic pigment and 10-25 parts of water. The soft porcelain decorative face layer is good in hydrophobicity and stain-resistance and is connected with the heat preservation layer into a whole through mortar materials. The heat preservation and decoration integrated facing tile is light in weight and achieves both decorative and heat preservation functions, thereby being a heat preservation and decorative building material with excellent comprehensive performance.

Owner:万卓(江苏)新材料有限公司

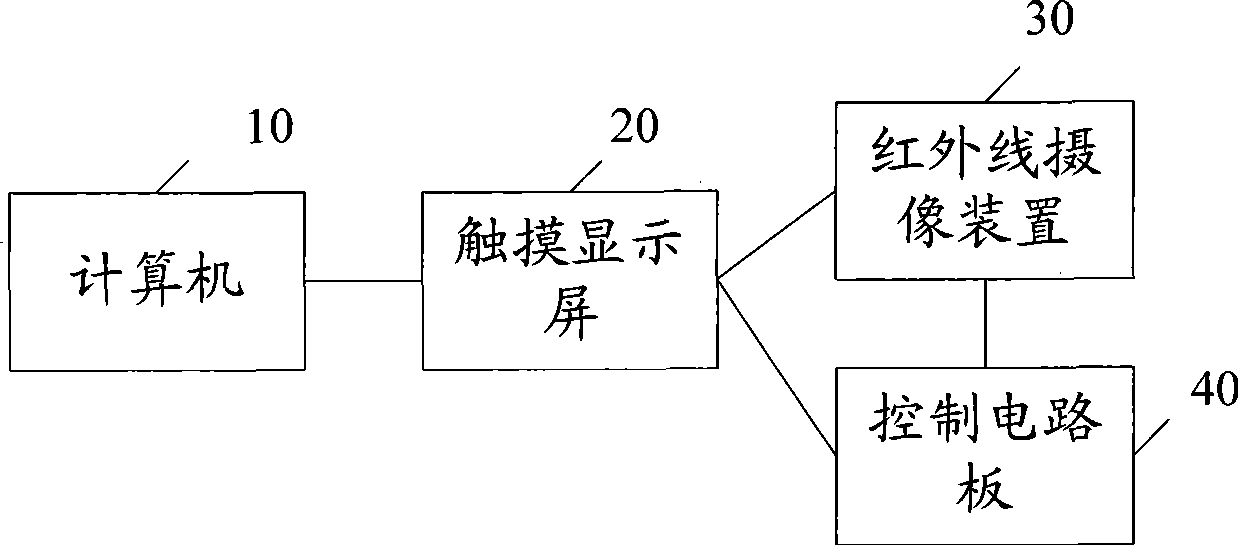

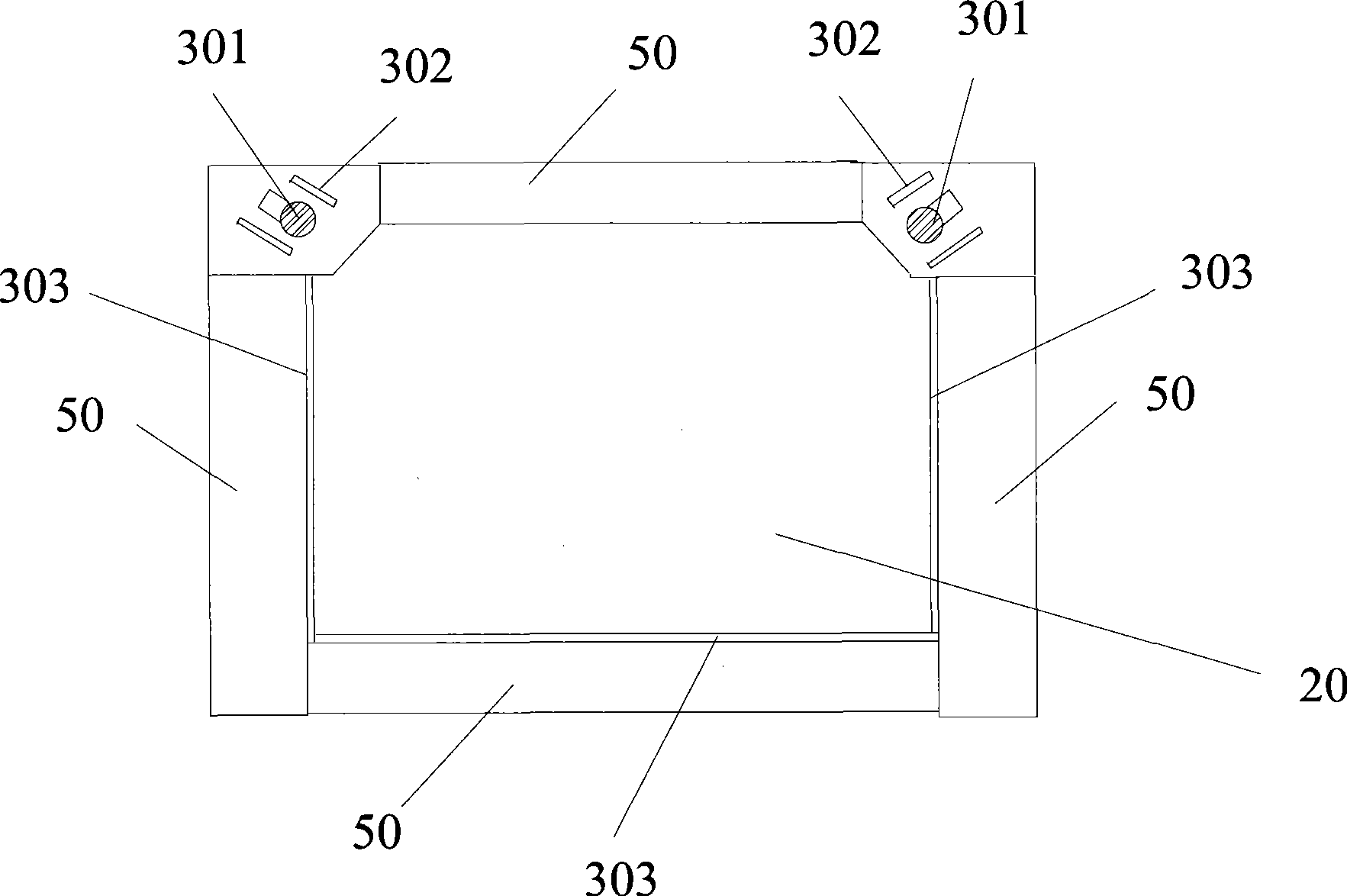

Touch display screen frame and system based on infrared videography, and its computing method

ActiveCN101498980AReduce volumeControl movementInput/output processes for data processingImage resolutionHuman–computer interaction

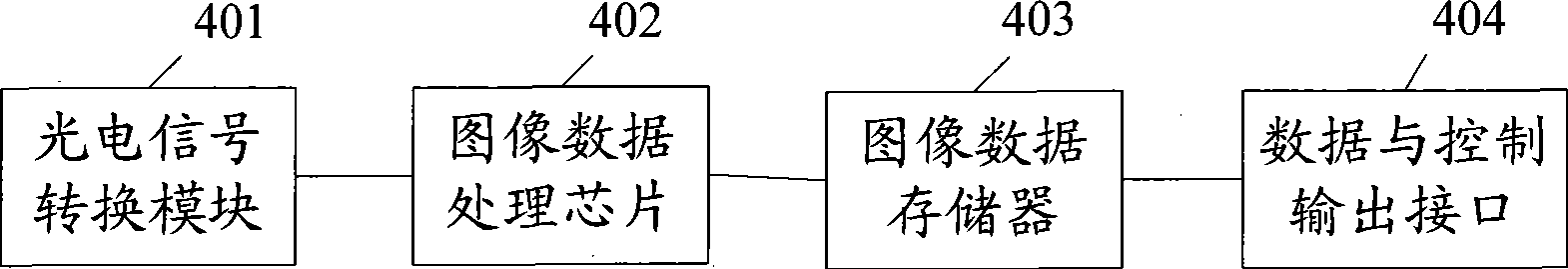

An embodiment of the invention discloses a touch display screen frame, system and calculating method based on infrared image pick-up; the system comprises a computer, a touch display screen, and an infrared image pick-up device and a control circuit board installed on the touch display screen frame, wherein the infrared image pick-up device comprises two high-resolution infrared cameras respectively at two ipsilateral angles of one rim of the touch display screen, infrared transmitting tubes installed at the tops or sides of the infrared cameras, and infrared refractive strips installed at the inner sides of the other three rims of the touch display screen; the four rims of the touch display screen are movably connected, and can be disassembled or folded from the touch display screen; the touch display screen frame can be independently and flexible configured, and the touch system can improve system resolution factor and computational accuracy of touch recognition point coordinates.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

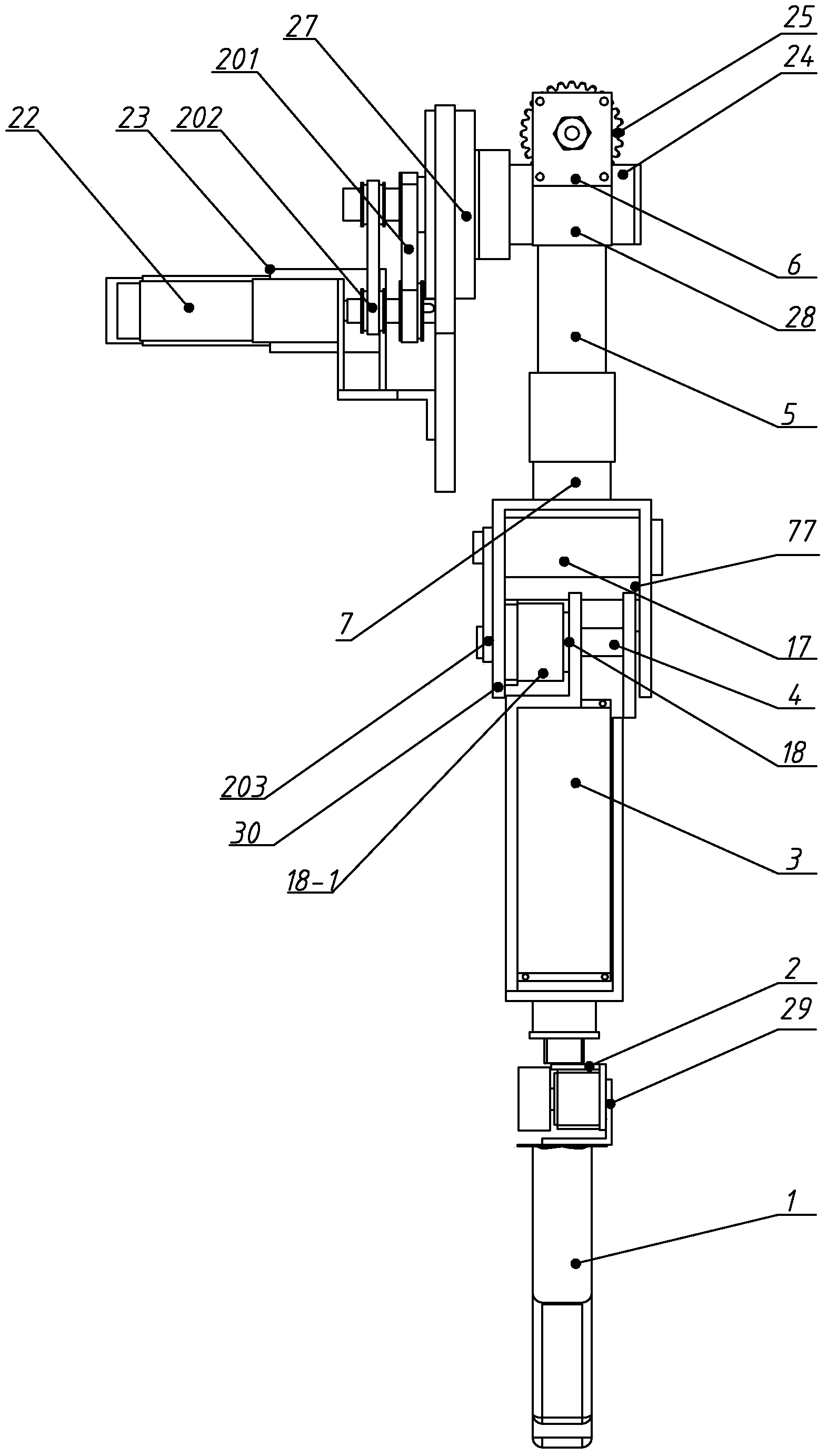

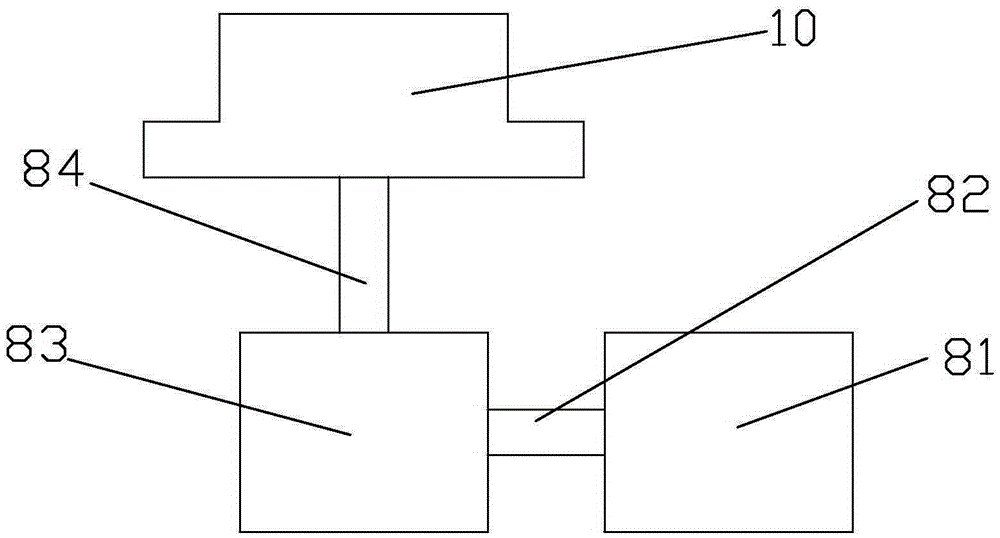

Lifting platform

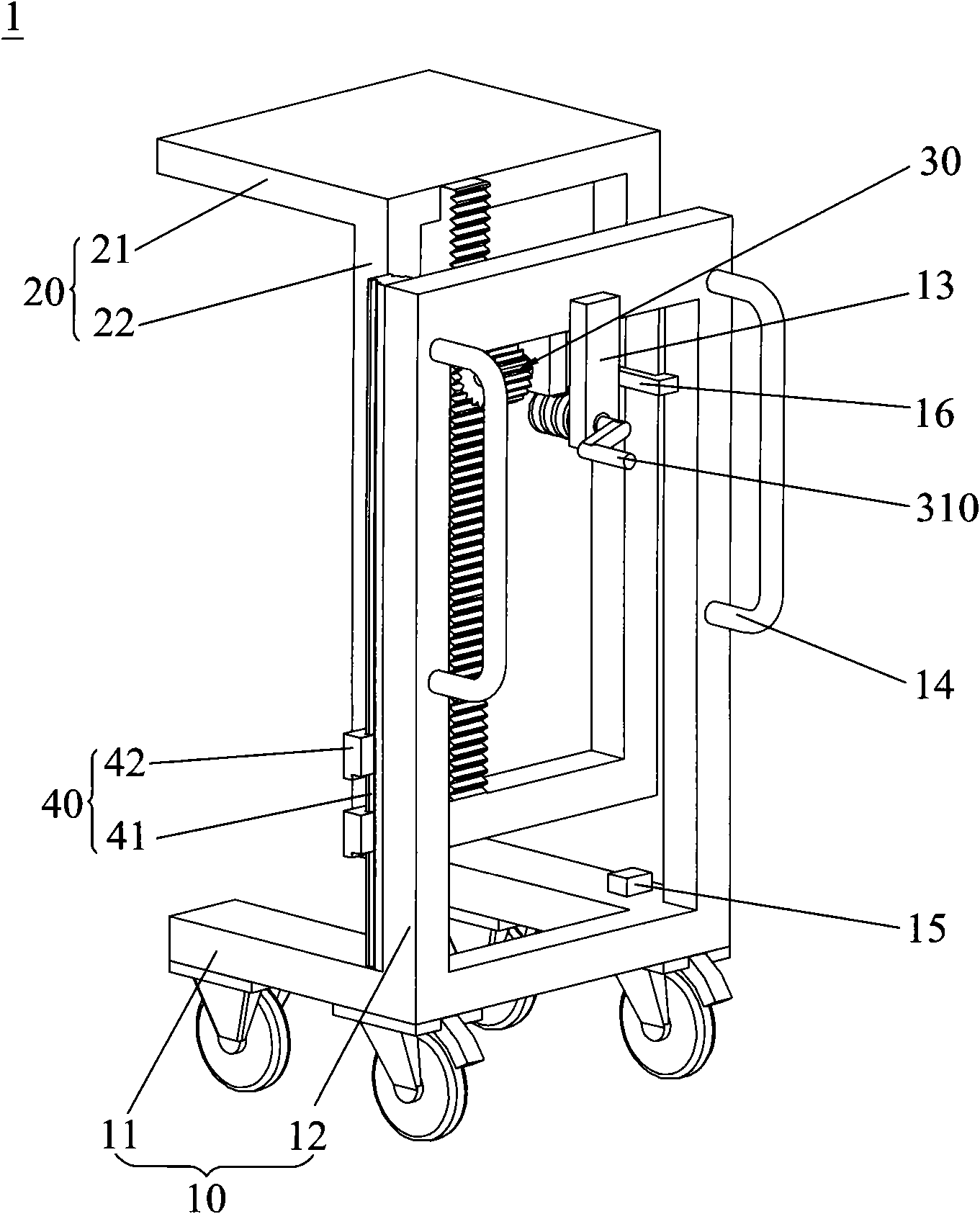

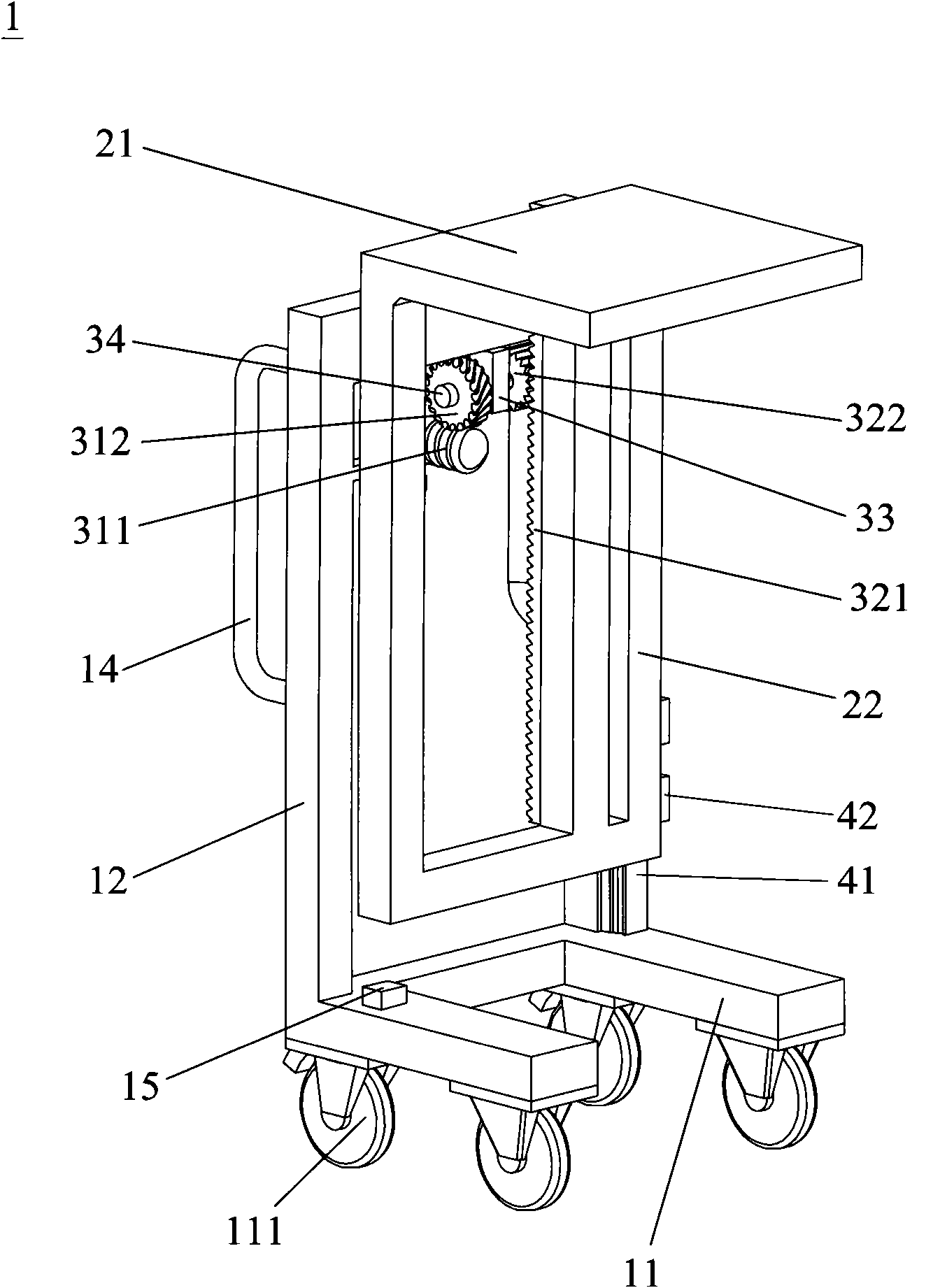

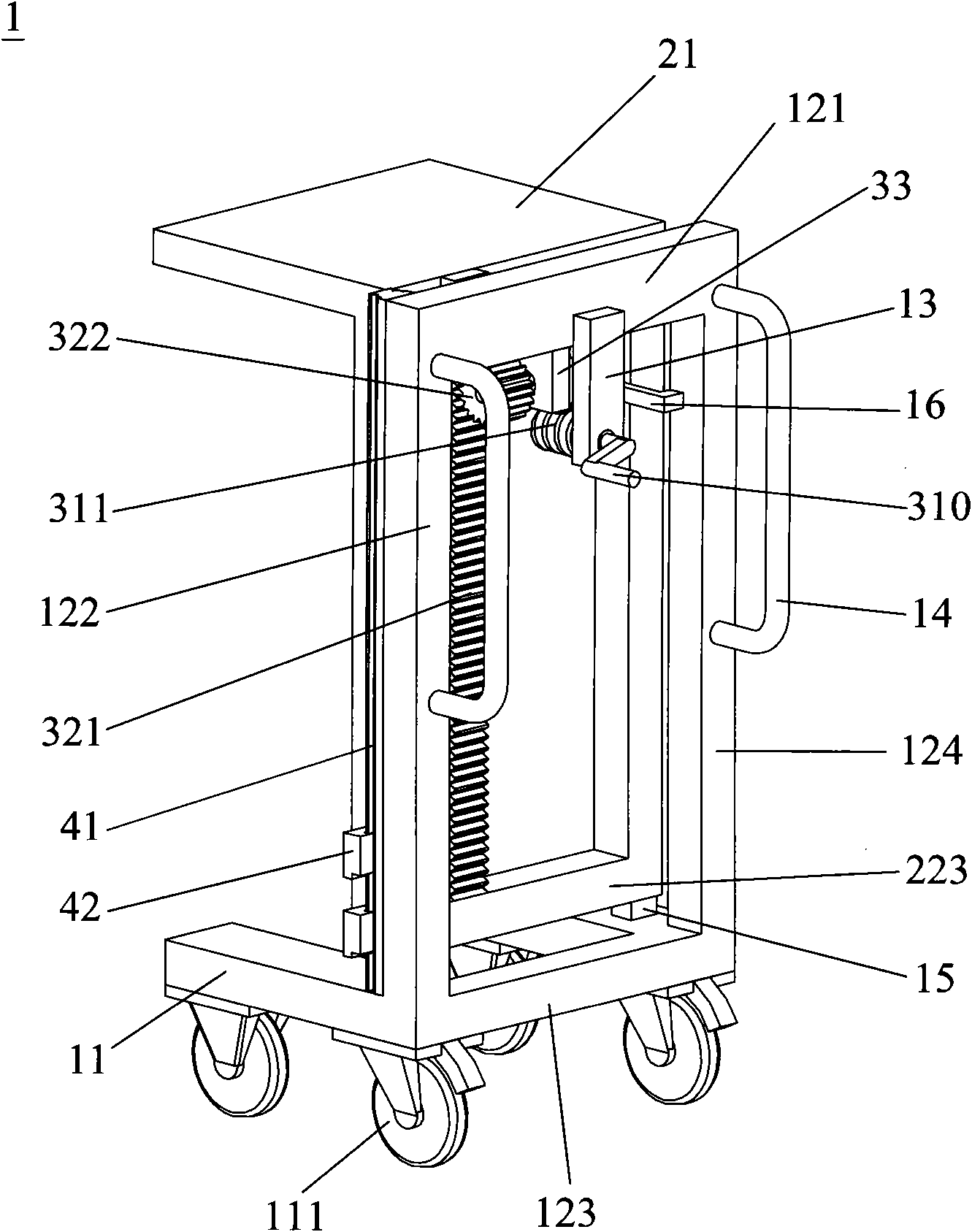

The invention discloses a lifting platform, comprising a supporting frame, a transmission mechanism, a sliding mechanism and a lifting bracket. The transmission mechanism comprises a first transmission assembly, a second transmission assembly, a fixed seat and a transmission shaft, wherein the fixed seat is arranged on the supporting frame, and the transmission shaft penetrates through the fixed seat and the two ends of the transmission shaft are respectively and fixedly connected with the first and second transmission assemblies; the first transmission assembly comprises a handle, a worm and a worm wheel, wherein the handle penetrates through the supporting frame and is pivoted with the supporting frame, the worm is fixedly connected with one end of the handle, and the worm wheel is fixedly connected with one end of the transmission shaft and is engaged with the worm; the second transmission assembly comprises a rack and a gear, wherein the rack is vertically arranged on the lifting bracket, and the gear is fixedly connected with the other end of the transmission shaft and is engaged with the rack; and the sliding mechanism comprises a guide rail and a sliding block, wherein the guide rail is arranged on the supporting frame and is parallel with the rack, and the sliding block is arranged on the lifting bracket and is clamped with the guide rail in a sliding manner. The lifting platform has the advantages of steady, safe and reliable lifting, high lifting precision, large stroke, no noise when in use, no pollution of environment, simple structure and compactness.

Owner:DONGGUAN ANWELL DIGITAL MASCH CO LTD

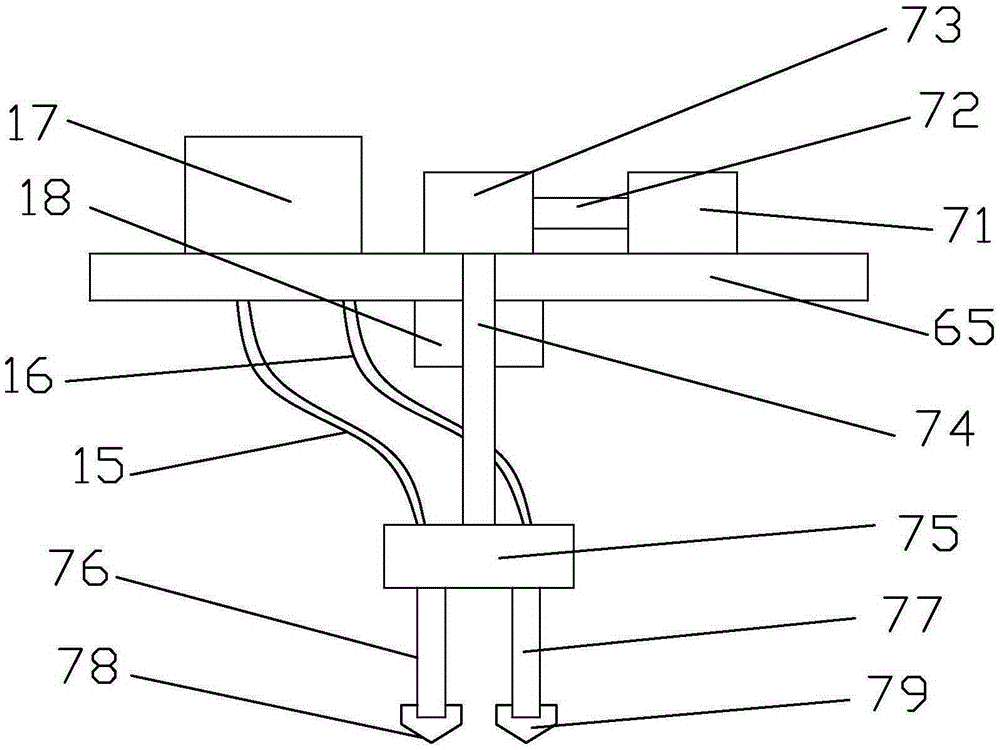

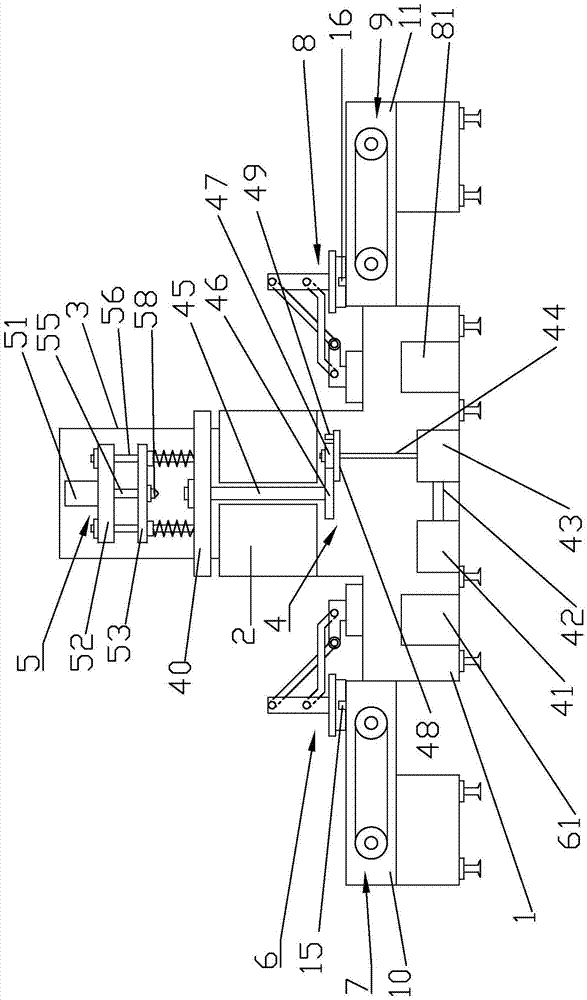

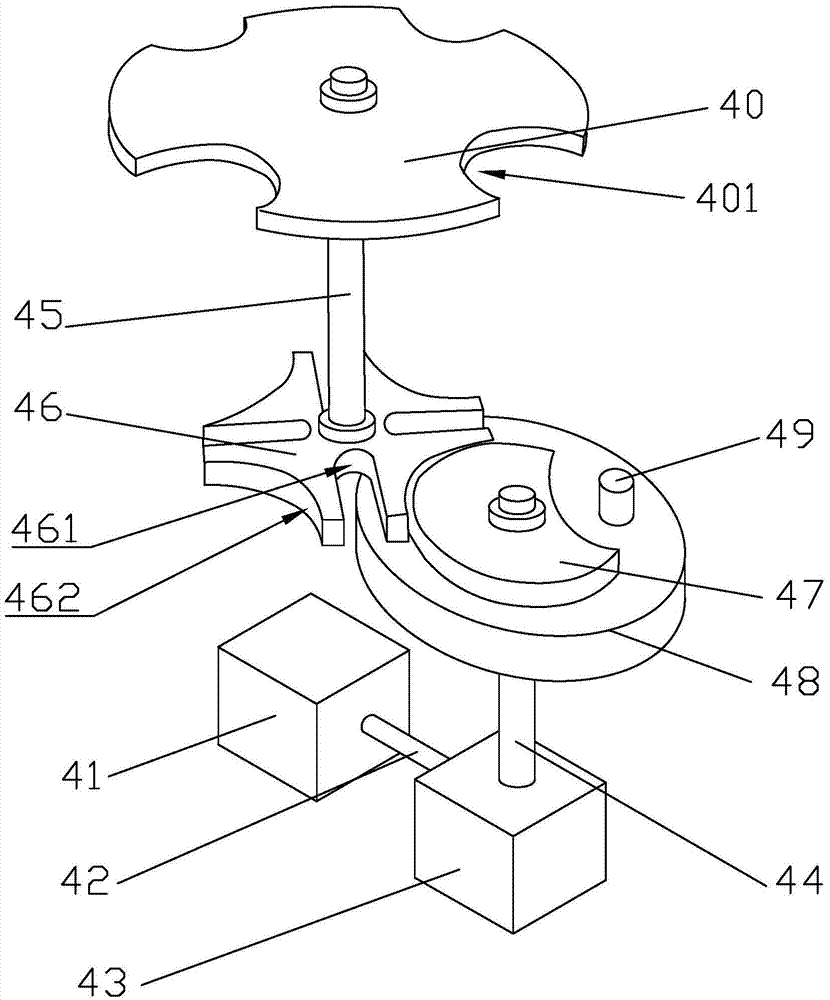

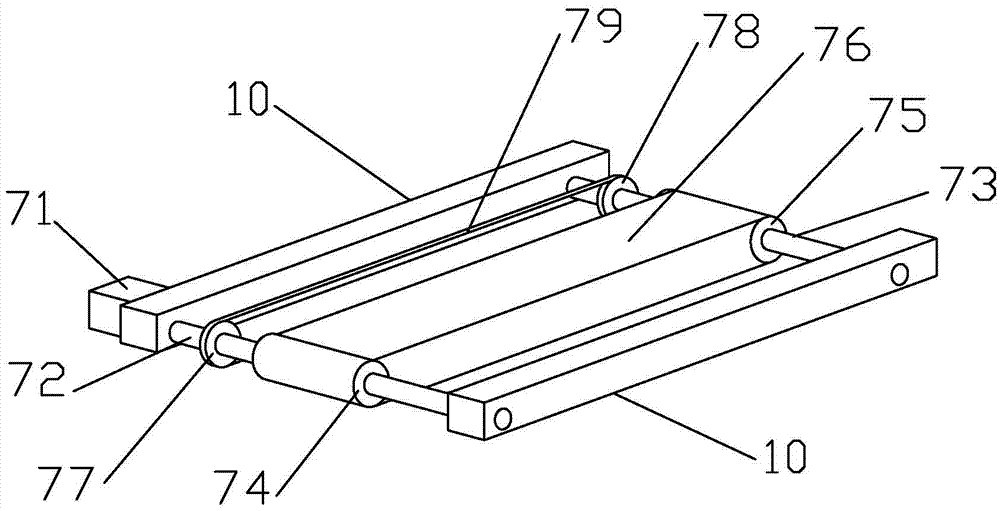

Full-automatic piercing apparatus applied to metal piece machining

ActiveCN105436289AGood precisionStable punching pressureMetal-working feeding devicesPositioning devicesEngineeringMachining

The invention discloses a full-automatic piercing apparatus applied to metal piece machining. The full-automatic piercing apparatus comprises a frame, a piercing platform and a piercing body; the piercing platform is located in the middle of the frame; the piercing body is mounted on an inner side of the piercing platform; a central through groove is formed in the center of the piercing platform; an intermittent rotating device is arranged in the central through groove; a loading platform and an unloading platform are arranged on the frame; a loading device is arranged on the loading platform, while an unloading device is arranged on the unloading platform; the loading device comprises a loading and conveying mechanism and a loading mechanism; the loading and conveying mechanism is connected with the loading mechanism and the loading mechanism is connected with the piercing platform; the unloading device comprises an unloading and conveying mechanism and an unloading mechanism; the unloading and conveying mechanism is connected with the unloading mechanism and the unloading mechanism is connected with the piercing platform. The apparatus is simple in structure, high in pertinence, high in piercing accuracy and good in piercing effect; automatic conveying and positioning are carried out, the entire piercing conveying operations are pipeline operations and the working efficiency is high; as a result, the piercing problem of metal piece machining is well solved.

Owner:南京自然机械制造有限公司

3D mobile phone back cover and molding process thereof

The invention discloses a 3D mobile phone back cover which comprises a body. The body comprises a glass back cover and a PET film. The glass back cover is integrally formed by a glass bending machine through hot bending. The PET film is punched and cut. The PET film is arranged in the glass back cover. The inner flat plate part coincides with a flat plate part. A side bending part coincides with an inner side bending part. The PET film is vacuum laminated with the glass back cover through a transparent optical adhesive layer. An ink pattern layer is arranged on one side, which fits the glass back cover, of the PET film. According to the 3D mobile phone back cover provided by the invention, the glass back cover and the PET film are free of signal interference, so that the signal of a mobile phone is strong; wireless charging is realized; the 3D mobile phone back cover is suitable for the application of a 5G network; the glass has the advantages of light weight, being thin, scratch resistance and heat dissipation, so that the mobile phone back cover has the corresponding effects of light weight, being thin, scratch resistance and heat dissipation; and the mobile phone is prevented from heating. The invention further discloses a molding process of the 3D mobile phone back cover.

Owner:FUJIAN SHISHI TONGDA ELECTRICAL APPLIANCE

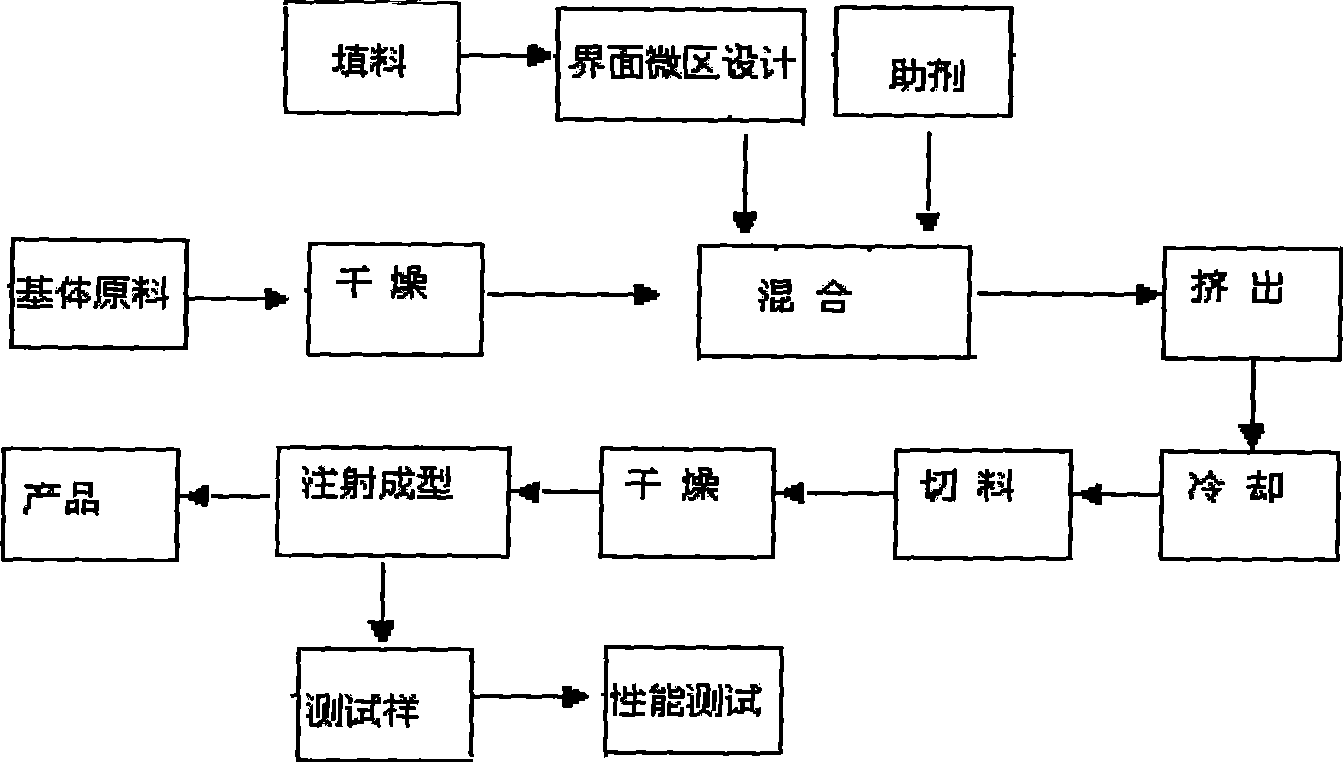

High performance polymer base composite material for support roller and preparation method

InactiveCN101423665AMeet the requirements for preparing idlersImprove corrosion resistanceGlass fiberAntistatic agent

The invention discloses a high performance polymer based composite material for carrier rollers and a method for preparing the same. The composite material comprises the following components in proportion: 50 to 80 percent of polycaprolactam, 5 to 30 percent of glass fiber, 0 to 30 percent of ceramic powder, 2 to 10 percent of lubricant, 1 to 15 percent of fire retarding agent, 0.05 to 1 percent of antistatic agent and 0.05 to 0.5 percent of anti-ageing agent; and, the adding amount of surface active is 5 percent of the weight of the ceramic powder. The composite material has the advantages of high strength, wearing resistance, high temperature resistance, electrostatic resistance, fire resistance, anti-ageing, environmental protection and the like.

Owner:CENT SOUTH UNIV +1

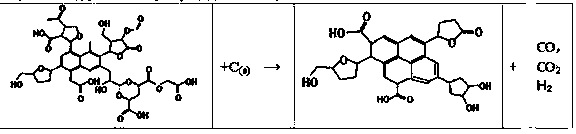

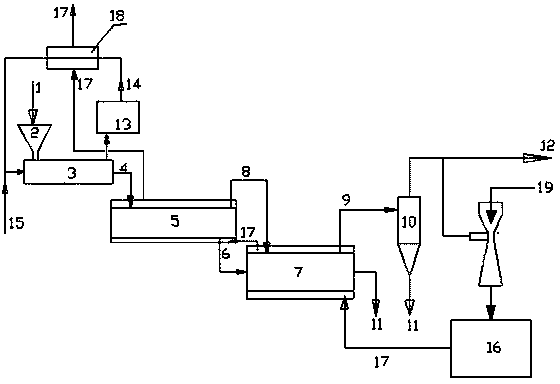

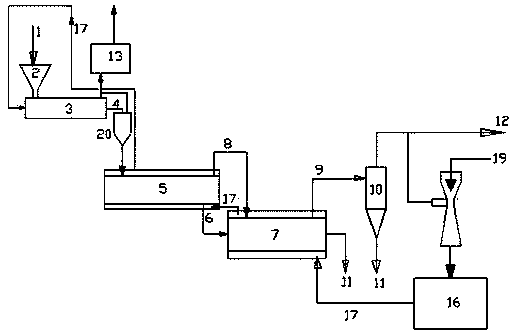

Waste pyrolysis system with adjustable oil, gas and carbon and method

ActiveCN104087340ALightweightLow viscositySolid waste disposalSludge treatment by pyrolysisThermodynamicsFlue gas

The invention relates to a waste pyrolysis system with adjustable oil, gas and carbon and a method. The system comprises a pre-reaction section, a main reactor, a conditioner and a particle separator. The front of the pre-reaction section is connected to a feeder and the tail of the pre-reaction section is connected to the main reactor. The conditioner is connected after the main reactor. The particle separator is connected after the conditioner. In specific, waste having a water content not more than 60% is fed into the pre-reaction section through the feeder, reacted waste is fed to the main reactor, residue coke generated after the reaction is finished is fed into the conditioner and a generated volatile material is discharged in a forced manner into the conditioner to be contacted, reacted and conditioned with the residue coke at the same time. The conditioner achieves conditioning of the residue coke and the volatile material at the same time. The volatile material after being conditioned is fed into the particle separator to output a clean volatile material. The residue coke after conditioning has a calorific value of 3.37-6.74 MJ / kg, and can be used as building raw materials or is conveyed to a sanitary landfill. The working temperature of the pre-reaction section is 105-298 DEG C and an inert gas or flue gas is fed into the pre-reaction section. The working temperature of the main reactor is 450-650 DEG C. The working temperature of the conditioner is 700-900 DEG C. The system and the method can obtain oil with better quality and more combustible gases and are adapt to changes of the water content of the waste.

Owner:上海济德能源环保技术有限公司

A coal ash-iron tailing based porous heat insulation material and a preparation method thereof

InactiveCN102167618AReduce pollutionImprove resource utilizationCeramic materials productionCeramicwareFoaming agentResource utilization

The invention belongs to the field of novel heat insulation material technology and specifically relates to a coal ash-iron tailing based porous heat insulation material and a preparation method thereof. The preparation method of the coal ash-iron tailing porous heat insulation material is characterized by mixing solid mixed powder and water, granulating and burning, wherein the water, by mass, accounts for 8% to 15% of the solid mixed powder, the solid mixed powder is prepared by mixing a powdery solid waste, a binder, a fluxing flexibilizer and a composite foaming agent, and the solid mixed powder comprises, by mass, 30% to 60% of the powdery solid waste, 30% to 50% of the binder, 5% to 20% of the fluxing flexibilizer and 5% to 10% of the composite foaming agent. The porous heat insulation material is characterized by high compressive strength, heat insulation and lightness and the method not only improves the use ratio of resources, but also reduces the environmental pollution caused by the waste.

Owner:WUHAN UNIV OF TECH

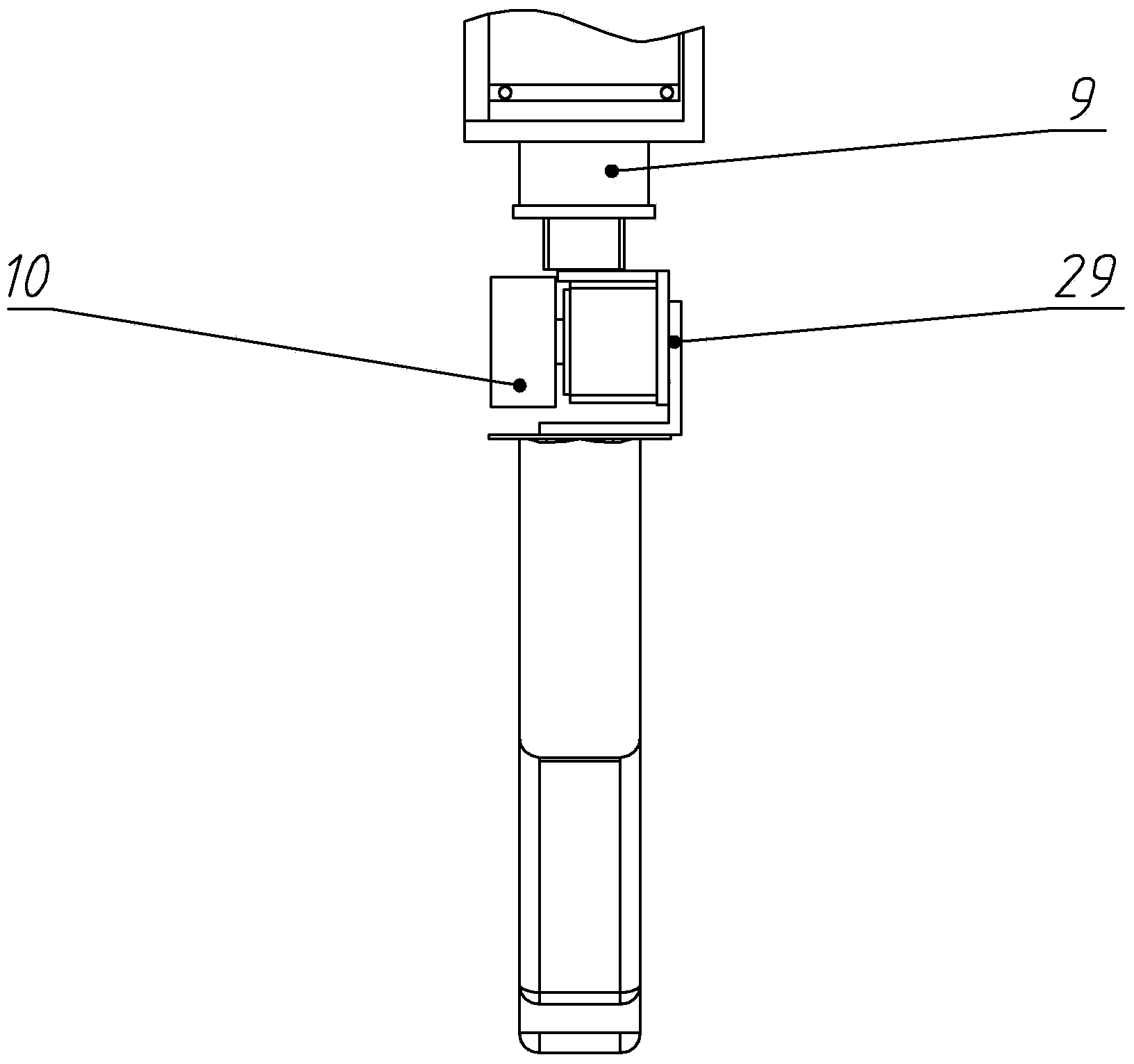

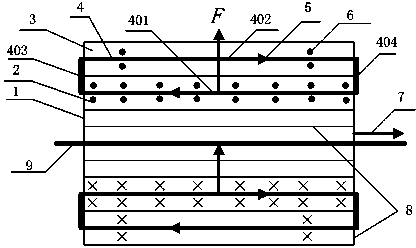

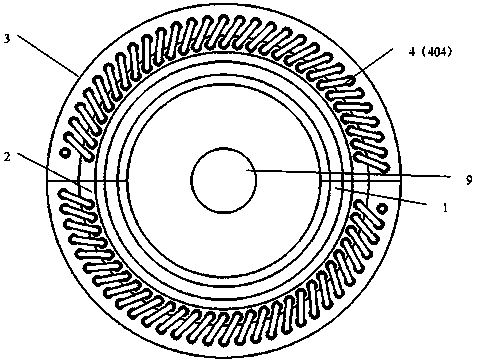

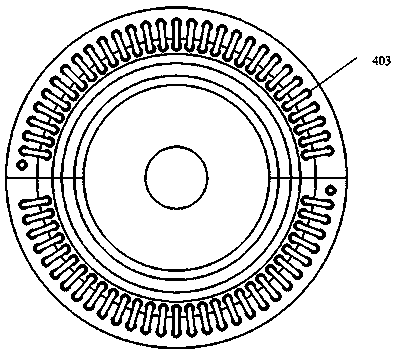

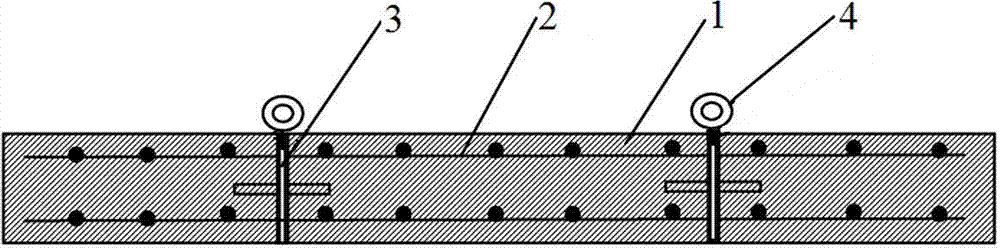

Magnetic force suspension robot for operation of overhead high-tension power transmission line

InactiveCN103595301AZero contactZero frictionMagnetic holding devicesApparatus for overhead lines/cablesMagnetic tension forceWeight trend

A magnetic force suspension robot for the operation of an overhead high-tension power transmission line comprises two suspension bushes (8), wherein the suspension bushes (8) can be opened or closed and are in central symmetry with a high-tension lead wire (9), each suspension bush (8) comprises a rectangular coil (4), an inner lining bush (1), a magnetic core (2) and an outer lining bush (3), and each inner lining bush (1), the corresponding magnetic core (2) and the corresponding outer lining bush (3) are arranged from inside to outside in sequence. The magnetic force suspension robot for the operation of the overhead high-tension power transmission line has the advantages that the robot can be suspended above the high-tension lead wire, zero contact and zero friction between the robot and the high-tension lead wire are achieved, and thus harmful abrasion and harmful moving loads are eliminated. Under the condition that driving force is available, the moving speed of the robot can be improved greatly through the zero contact and zero friction modes. Through the magnetic force suspension mode, the complexity of the moving mechanism of the robot can be lowered, and the light-weight trend of the robot can be achieved. A magnetic force suspension device is small in size, low in cost and easy to achieve.

Owner:HUBEI UNIV OF TECH

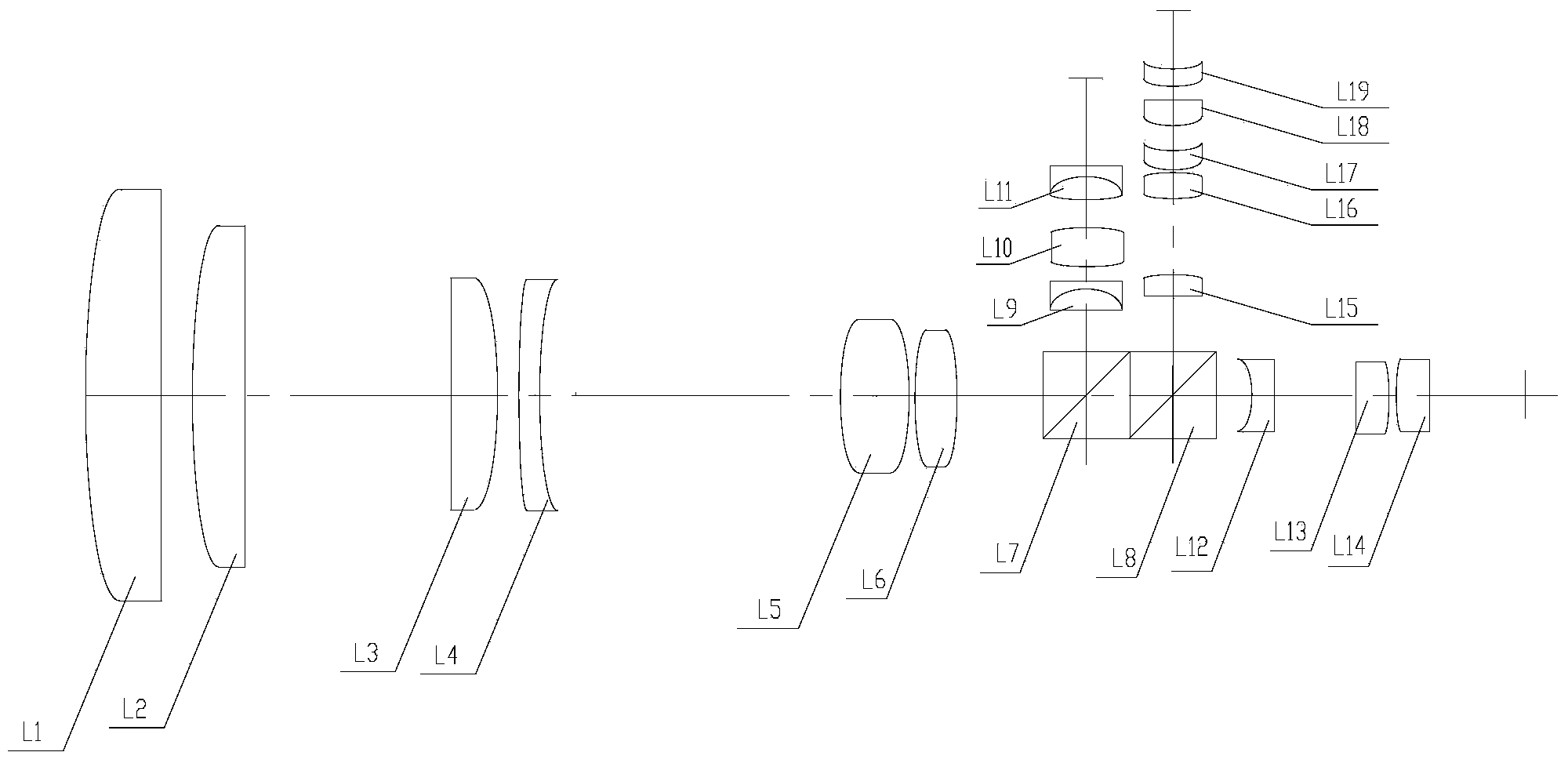

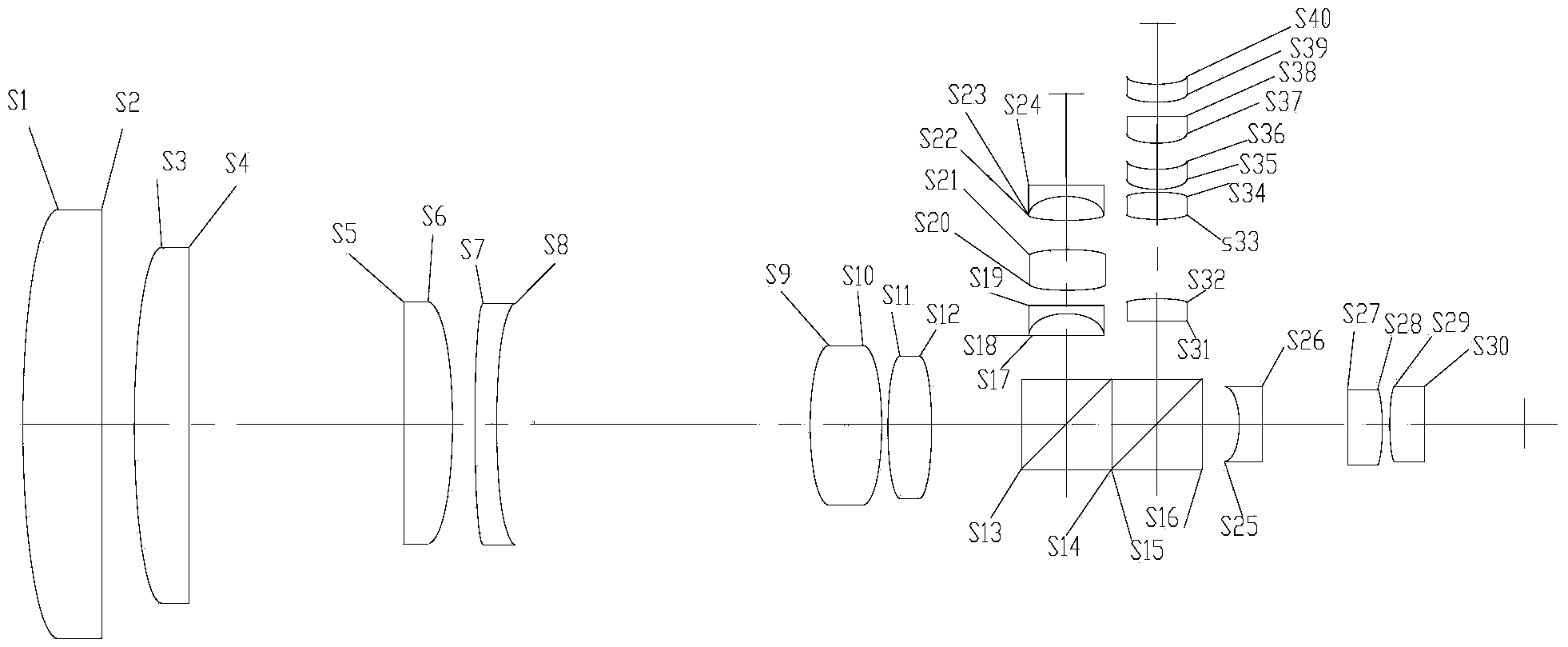

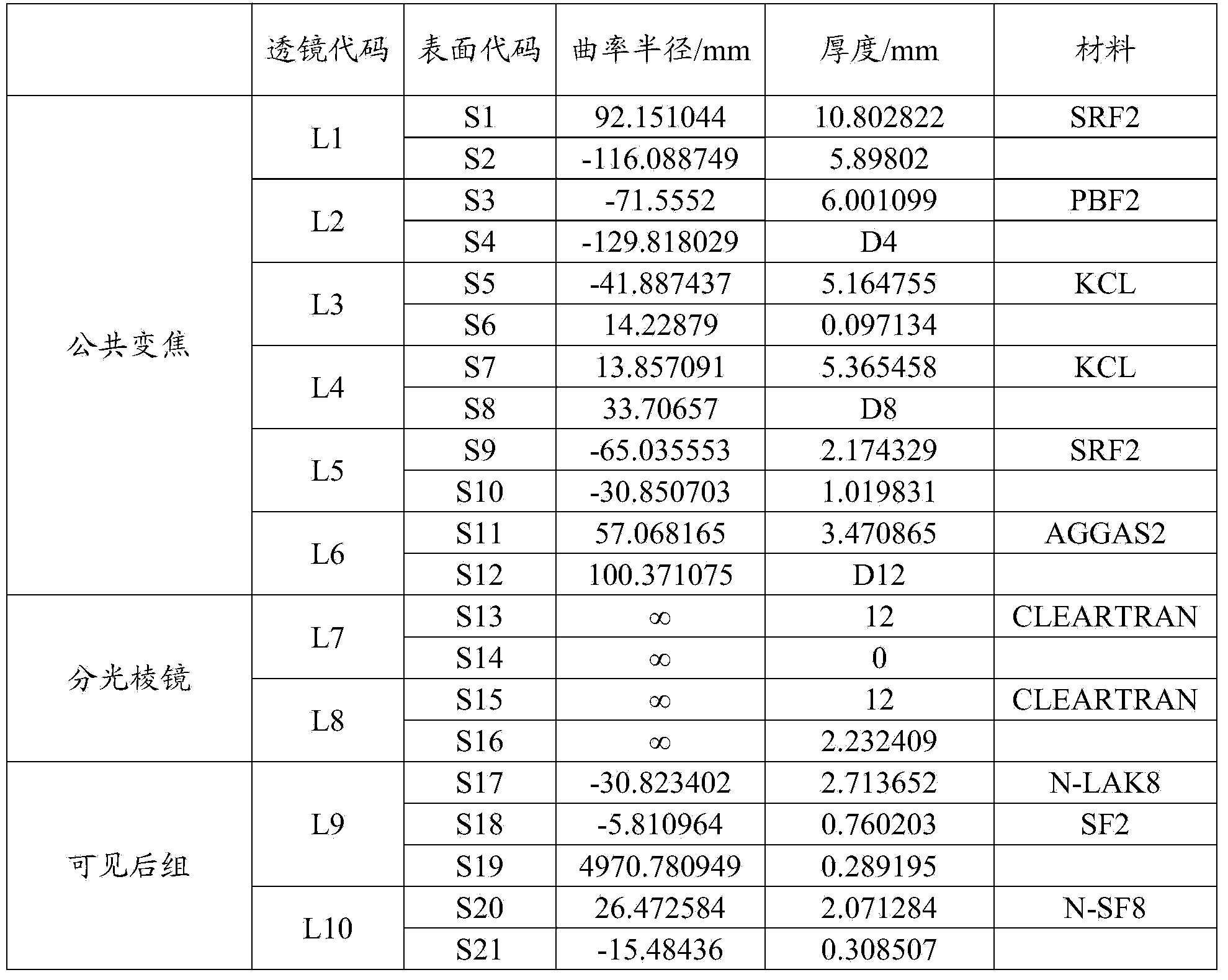

Integrated multi-waveband common-path synchronous continuous variable-focus optical system

The invention discloses an integrated multi-waveband common-path synchronous continuous variable-focus optical system. The optical system comprises a public front fixed group, a public zooming group and a public compensation group which are arranged in sequence along an optical axis, as well as a first group of beam splitter prisms for reflecting visible light and transmitting medium-wave infrared light and long-wave infrared light, and a second group of beam splitter prisms for reflecting long-wave infrared light and transmitting medium-wave infrared light. A common-caliber, common-path and common-variable-focus form is adopted, a visible waveband, a medium-wave waveband and a long-wave infrared waveband are zoomed synchronously and continuously along with the movement of the public zooming group in a zooming process, and the three wavebands are of the same focal lengths, zooming ratios and visual fields, thereby realizing synchronous observation, synchronous tracking and synchronous measurement of a target in the visible waveband, the medium-wave waveband and the long-wave infrared waveband. When different wavebands are needed for observing, path switching and new search of the target are unnecessary, thereby increasing the reaction speed of the optical system and preventing loss of a target moving at a high speed during path switching.

Owner:XIAN TECH UNIV

Bionic sharkskin structure capable of reducing drag

ActiveCN106585949AReduced wall shear stressMade softFuselage bulkheadsNanotechnologyConductive coatingAerospace engineering

The invention relates to wings of an aircraft and provides a bionic sharkskin structure capable of reducing drag to overcome the problems that conventional aircrafts cannot improve the off-line pneumatic performance of the whole flight bag in the case of different pneumatic environment conditions on the occasion of a disordered gas field and that the aircrafts encounter great flight drag and cannot meet the demand of flying at different flight speeds in the disordered gas field. The bionic sharkskin structure comprises a dielectric elastomer, a flexible electrode layer and nano-wire conductive coatings, wherein the dielectric elastomer is of a plate structure; one plate surface of the dielectric elastomer is coated with a plurality of the nano-wire conductive coatings; the plurality of the nano-wire conductive coatings are applied along a horizontal direction and along two oblique directions in oblique crossing with the horizontal direction to form a net structure; and other plate surface, opposite to the above plate surface, of the dielectric elastomer is coated with the flexible electrode layer. The bionic sharkskin structure capable of reducing drag in the invention is applied to wing roots.

Owner:HARBIN INST OF TECH

Continuous carbon fiber reinforced composite material for bone repair

The continuous carbon fiber reinforced composite material for bone repair is prepared with continuous carbon fiber, continuous carbon fiber felt or continuous carbon fiber, cloth through soaking in methyl methacrylate monomer or pre-polymer and subsequent extruding or bulk molding. The composite material of the present invention includes methyl methacrylate and carbon fiber, and the carbon fiber content is 20-80 wt%. The composite material may be used as the external fracture fixing material, internal fracture fixing material and bone repairing material. The composite material has the features of light weight, no interference on NMR examination and excellent biocompatibility. It may be implanted inside life body without negative effect on tissue, blood, etc.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

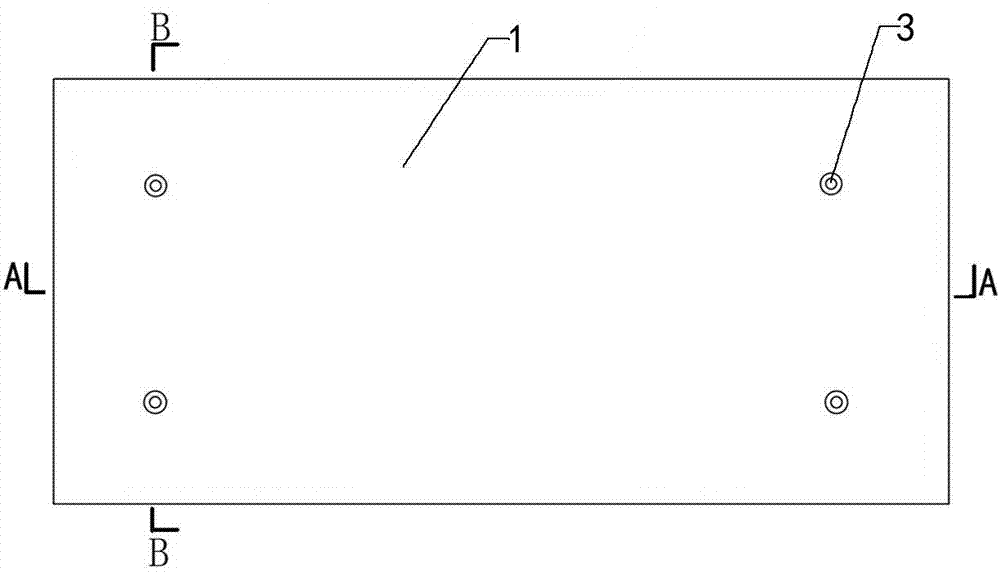

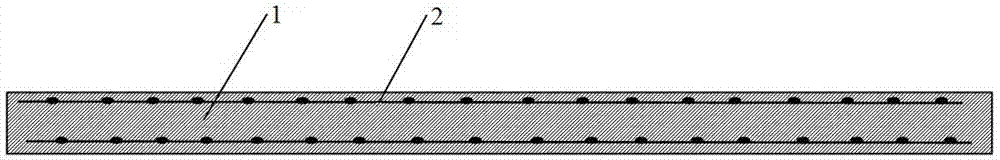

Fabricated type reactive powder concrete prefabricated pavement slab without reinforcing rib and manufacturing method thereof

ActiveCN104294728AStrong bending resistanceHigh compressive strengthSingle unit pavingsCeramic shaping apparatusWire gauzeWeather resistance

The invention discloses a fabricated type reactive powder concrete prefabricated pavement slab without a reinforcing rib and a manufacturing method thereof. A slab body is a material plate made from reactive powder concrete; layers of horizontal steel wire gauzes are respectively spread in the reactive powder concrete material plate and are close to upper and lower surfaces; hoisting embedded parts which run through in the vertical direction are respectively arranged at the four corners, wherein the two ends of the hoisting embedded parts are connected with lifting appliances. When the fabricated type reactive powder concrete prefabricated pavement slab without the reinforcing rib is manufactured, the fluidity of the reactive powder concrete is controlled to avoid deformation of the pavement slab in the later-period manufacturing process, and the fabricated type reactive powder concrete prefabricated pavement slab without the reinforcing rib is maintained naturally indoors to ensure the total quality of the pavement slab. Compared with a common concrete pavement slab, the pavement slab has the advantages of no reinforcing rib in structure, small thickness, portability, light weight, convenience in transportation and installation, high intensity, wear resistance, high bearing capability, good anti-impact performance, good anti-fatigue performance, good weather resistance, and fast and efficient construction, repeated use, and can be widely applied to road construction of temporary building living quarters.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

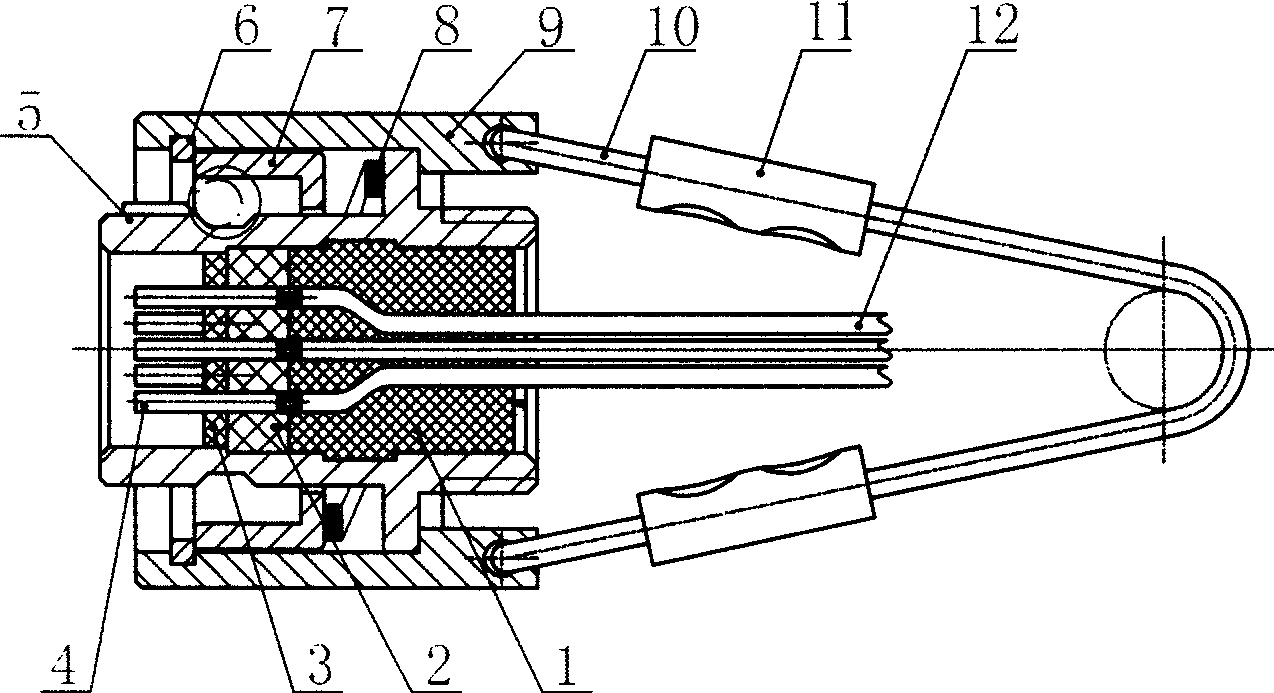

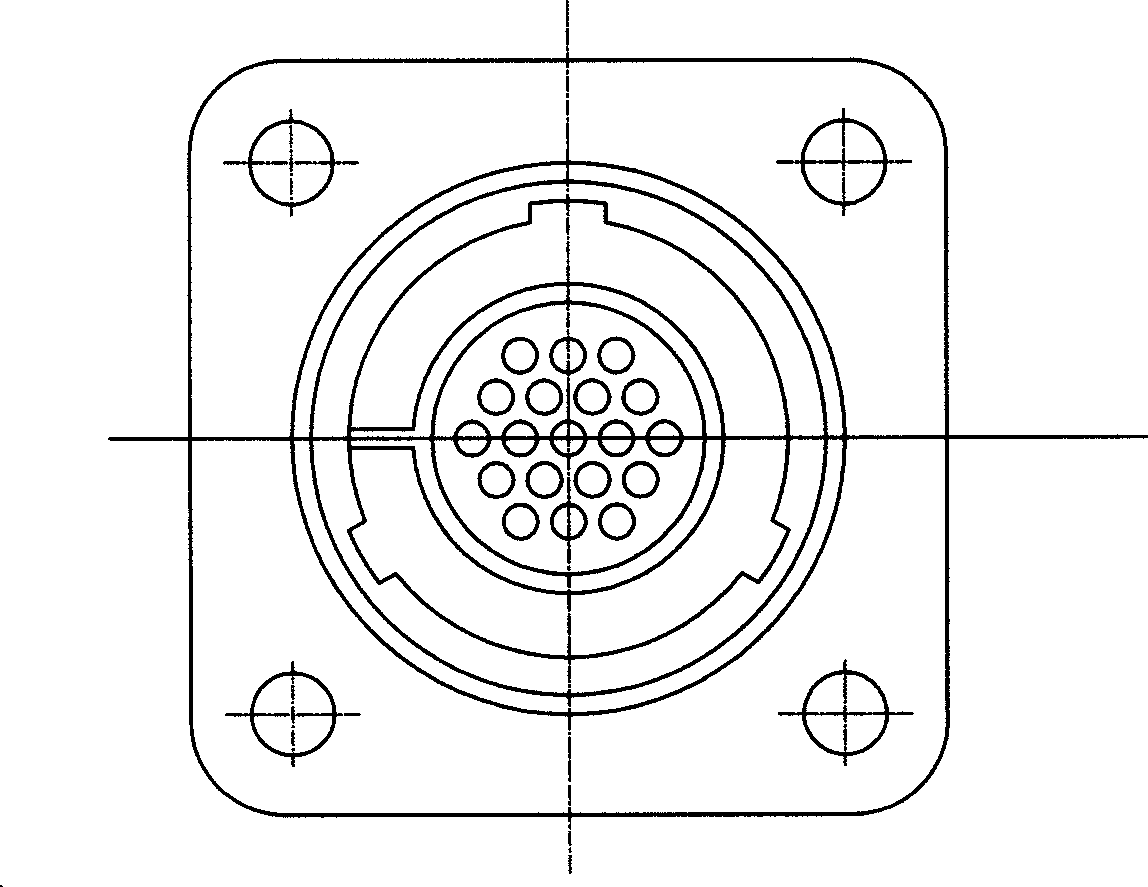

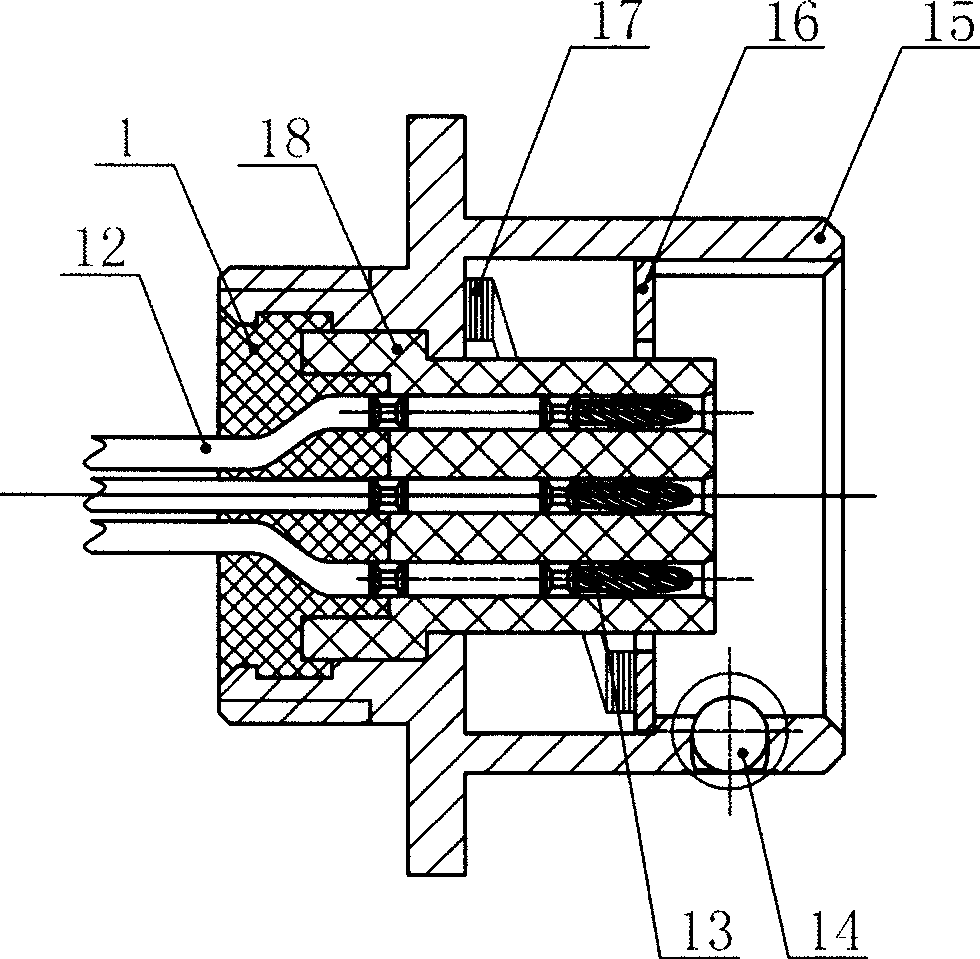

Micro separated electric connector

InactiveCN101447626AQuick lockEasy to separateIncorrect coupling preventionCouplings bases/casesMiniaturizationSteel ball

A micro separated electric connector is composed of a plug and a socket; the plug is composed of a rigid glue, an insulator interface gasket, a jack, a plug shell, a collar, a lock sleeve, a wave washer, an unblock sleeve, a pull wire, a compression sleeve and a lead wire; the socket is composed of a rigid glue, a contact pin, a steel ball, a socket shell, a collar, a wave washer and an insulator; the tail of a rigid jack is connected with the lead wire; the rigid glue is filled and sealed for fixing; the gasket is arranged at the end face of the plug; a positioning key is arranged on the plug shell to be matched with a socket location notch; a V-shaped trough is arranged under the positioning key, in which the steel ball is pressed; the lock sleeve is arranged on the wave washer; the pull wire penetrates in the hole of the unlock sleeve to be connected; and the steel ball is arranged in the step hole of the socket shell. The micro separated electric connector is miniaturized and light and takes small space.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

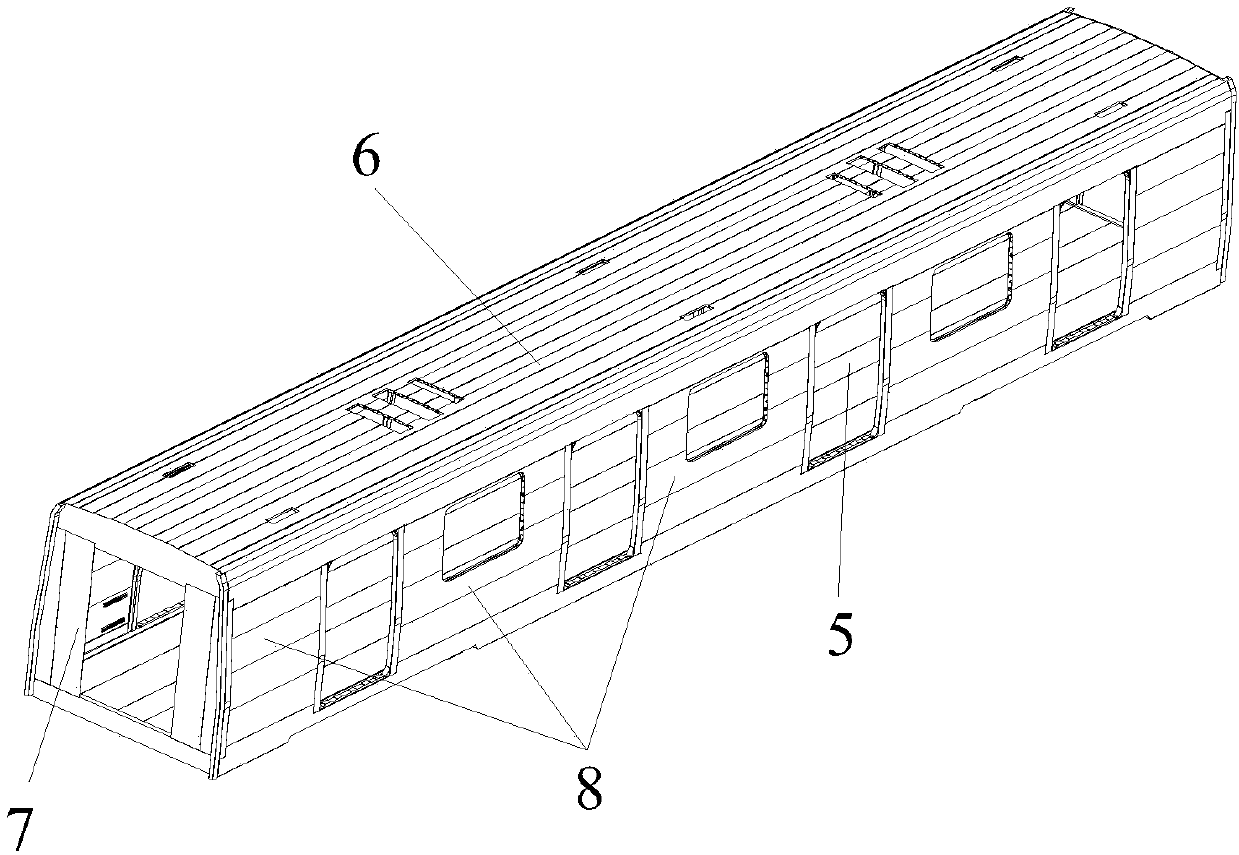

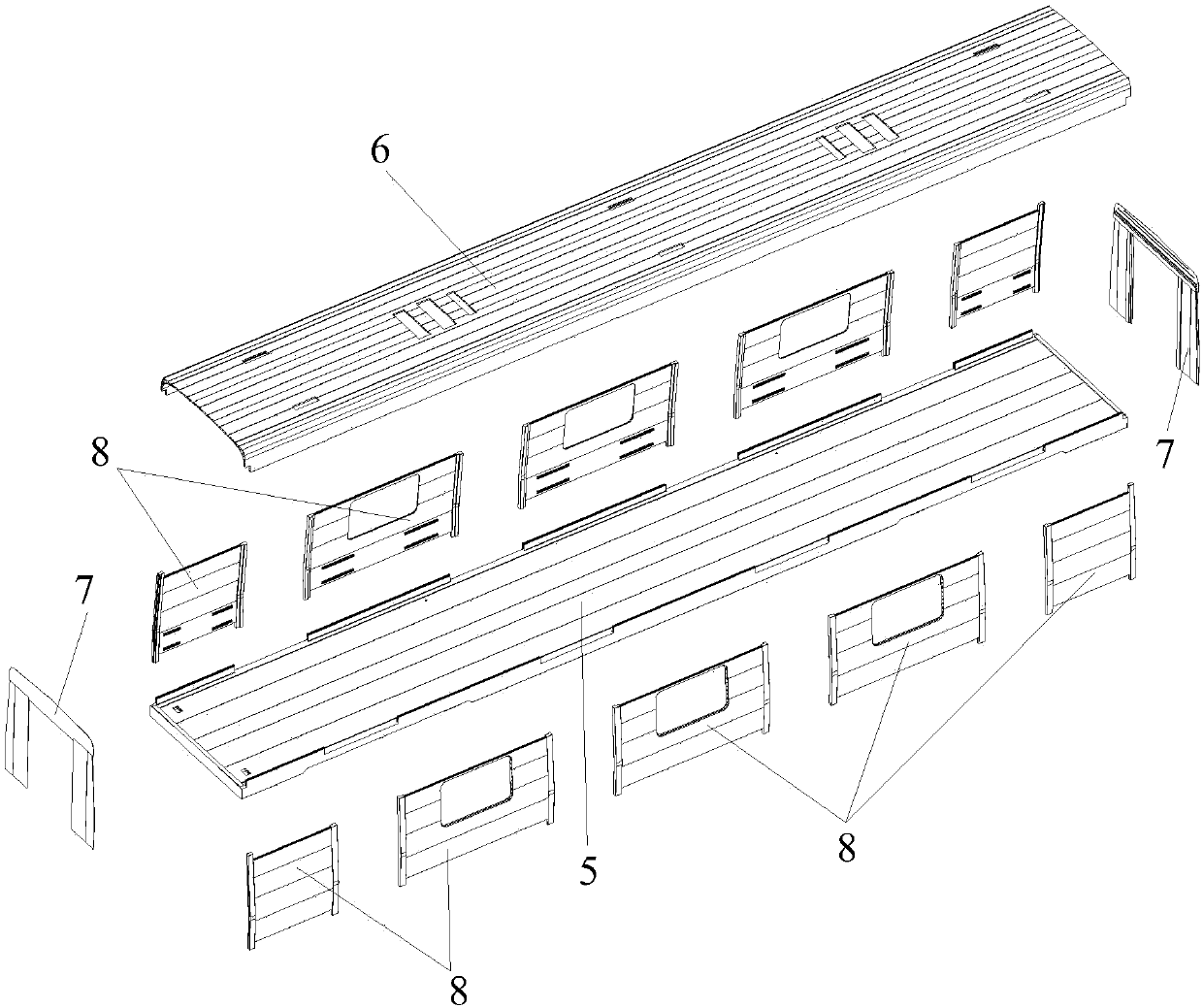

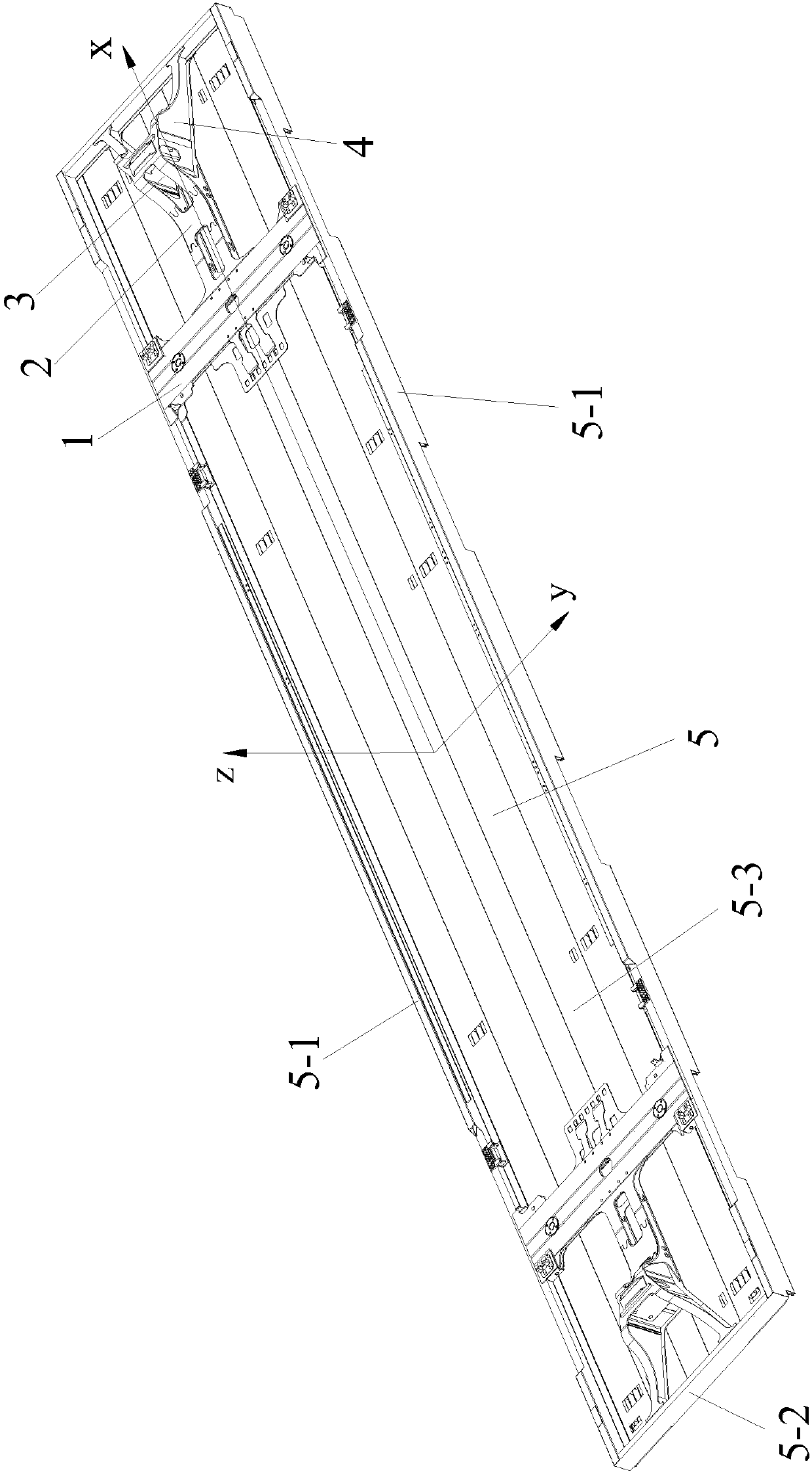

Light-weight metro vehicle body with novel traction sleeper buffer structure

ActiveCN107856688AImprove accessibilityImprove welding qualityRailway roofsUnderframesEngineeringUltimate tensile strength

The invention provides a light-weight metro vehicle body with a novel traction sleeper buffer structure and belongs to the field of full-aluminum product metro vehicle body devices. The light-weight metro vehicle body comprises a chassis, a vehicle roof, two end walls, multiple side wall boards and a full-aluminum product traction sleeper buffer device. The chassis comprises a rectangular floor frame jointly defined by two side beams and two end beams and a floor located in the floor frame. The traction sleeper buffer device comprises a sleeper beam, a traction beam, a draw gear installation seat and two buffer beams. A traction beam lower cover plate and a buffer beam lower cover plate of the full-aluminum product traction sleeper buffer device of the light-weight metro vehicle body are both made of a profile aluminum plate material which is low in density, light in weight and good in bending performance, the draw gear installation seat is made from aluminum plates high in yield stress, other straight plate structures are all made of an aluminum plate material high in yield stress, overall selected materials of the traction sleeper buffer device meet the strength standard, and theprocessing property of welding and manufacturing of the traction sleeper buffer device is the best; and all lightening holes can be simultaneously used as auxiliary holes in the inner cavity weldingoperation process, so that the accessibility and welding quality of inner cavity welding joints are improved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com