Patents

Literature

71 results about "Sharkskin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sharkskin is a smooth worsted fabric with a soft texture and a two-toned woven appearance. Lightweight and wrinkle-free, sharkskin is ideal for curtains, tablecloths and napkins. Sharkskin fabric is popular for both men’s and women’s worsted suits, light winter jackets and coats. Sharkskin is commonly used as a liner in diving suits and wetsuits.

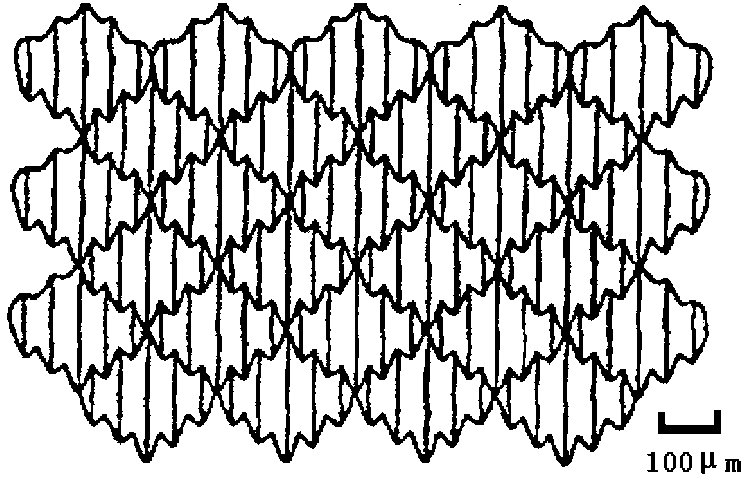

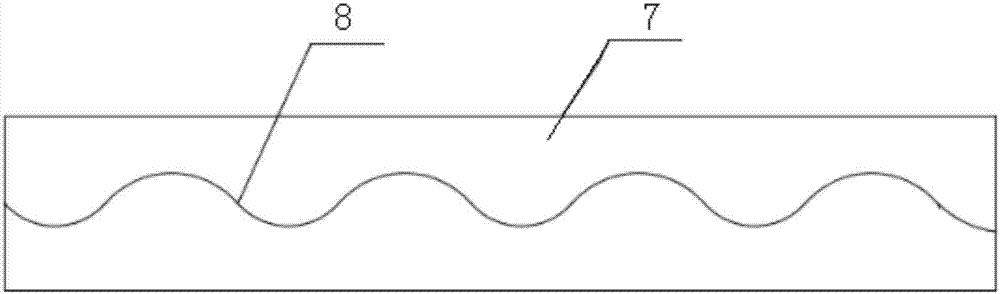

Method for copying sharkskin surface micro groove structure

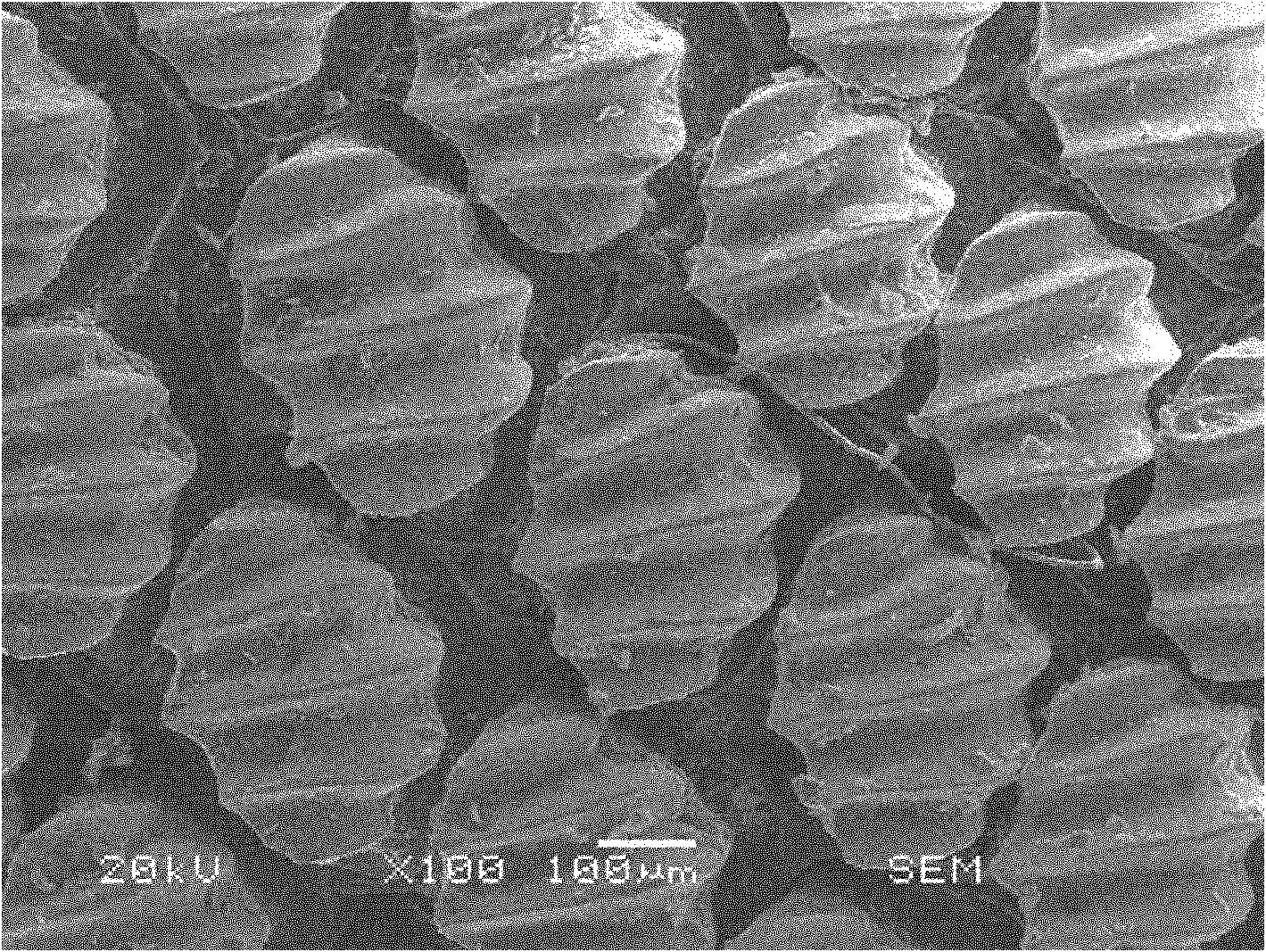

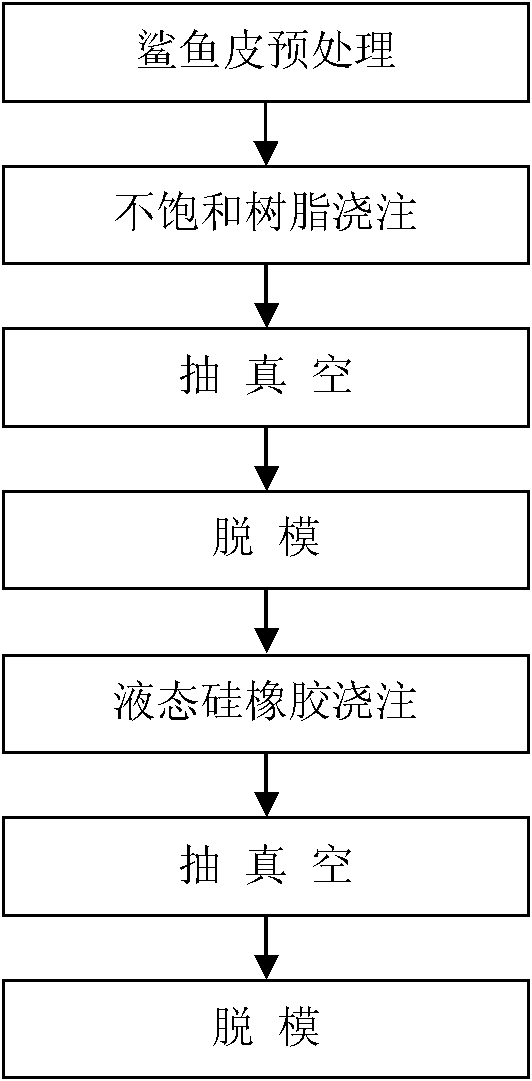

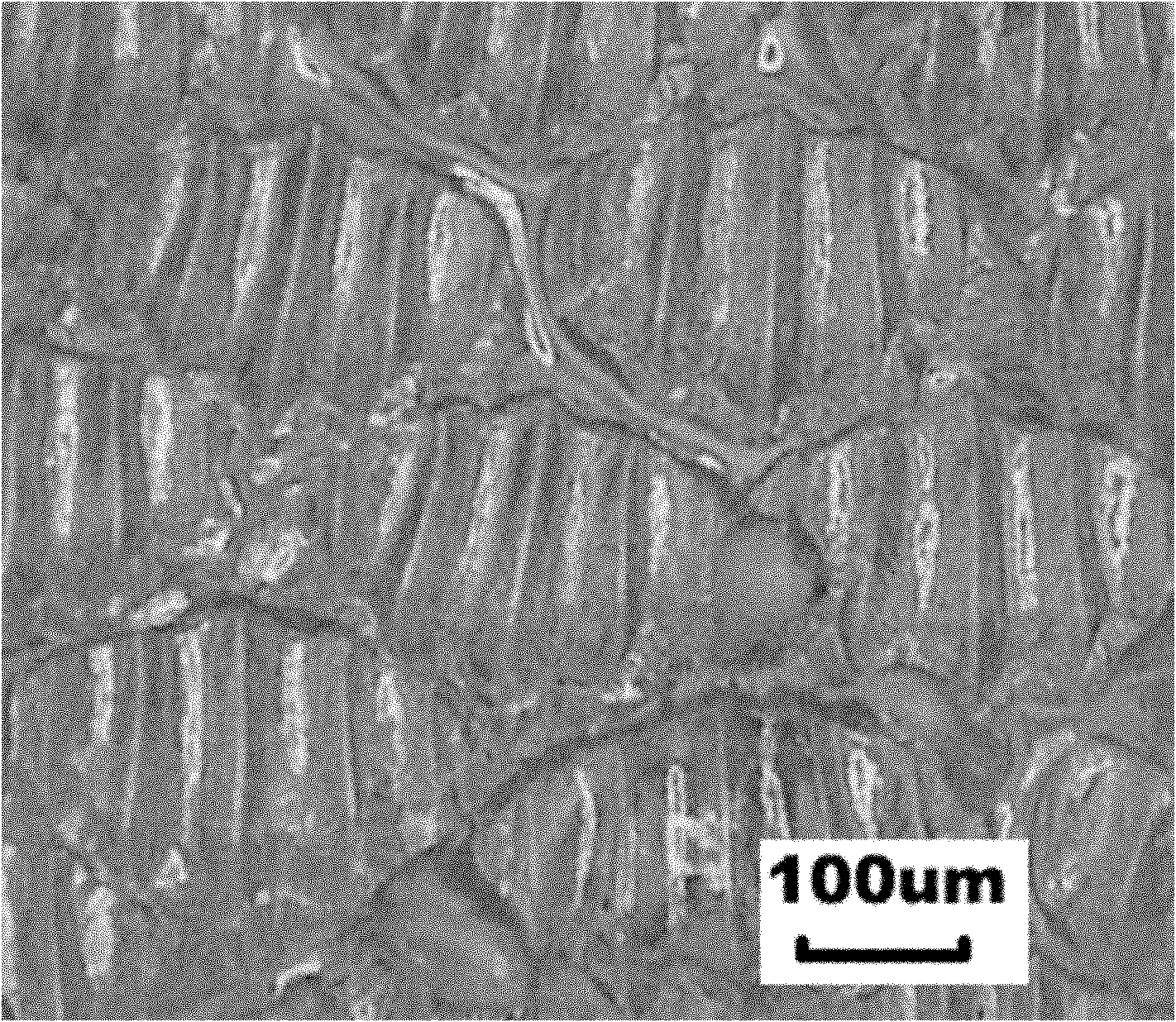

InactiveCN101966753ASolve the accuracy problemSolve the difficulty of strippingReplication methodSharkskin

The invention discloses a method for copying a sharkskin surface micro groove structure and belongs to the technical field of biological constraint molding. The method is characterized by comprising the following implementation steps: pretreating sharkskin; blowing mold release agent; pouring unsaturated resin; vacuumizing; releasing the unsaturated resin from a mold; blowing mold release agent; pouring liquid silicon rubber; vacuumizing; and releasing the liquid silicon rubber from a mold. The silicon rubber simulation sharkskin thin film obtained by the steps can copy the surface with a riblet micro groove structure of a shark completely and clearly and can be widely used in fields of resistance reduction in aircraft, ship and oil pipe projects and other projects.

Owner:DALIAN UNIV OF TECH

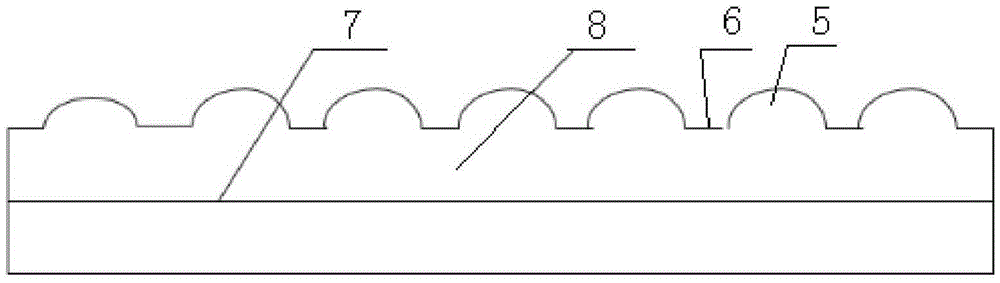

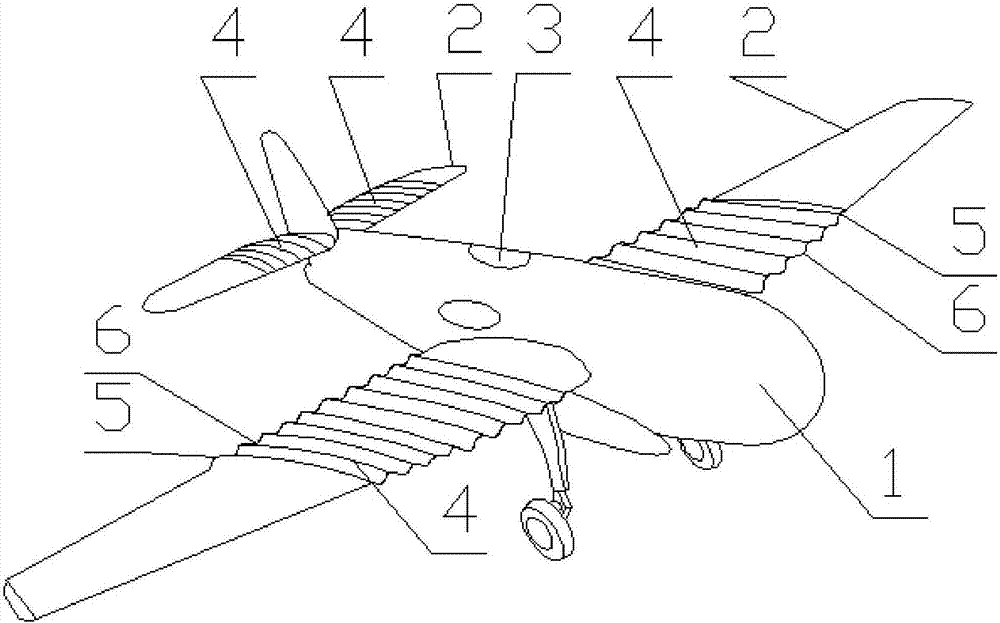

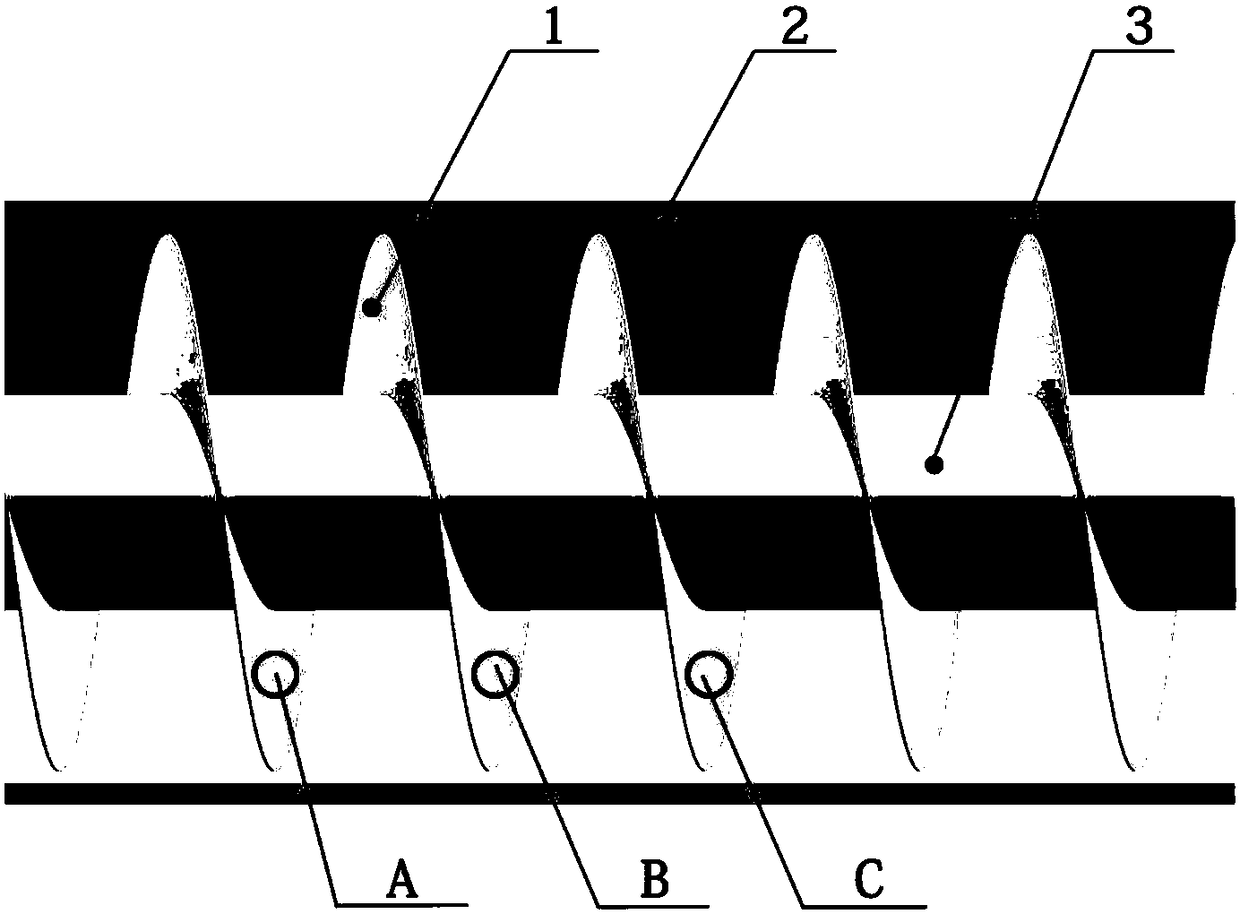

Sharkskin-imitating resistance-reducing wing

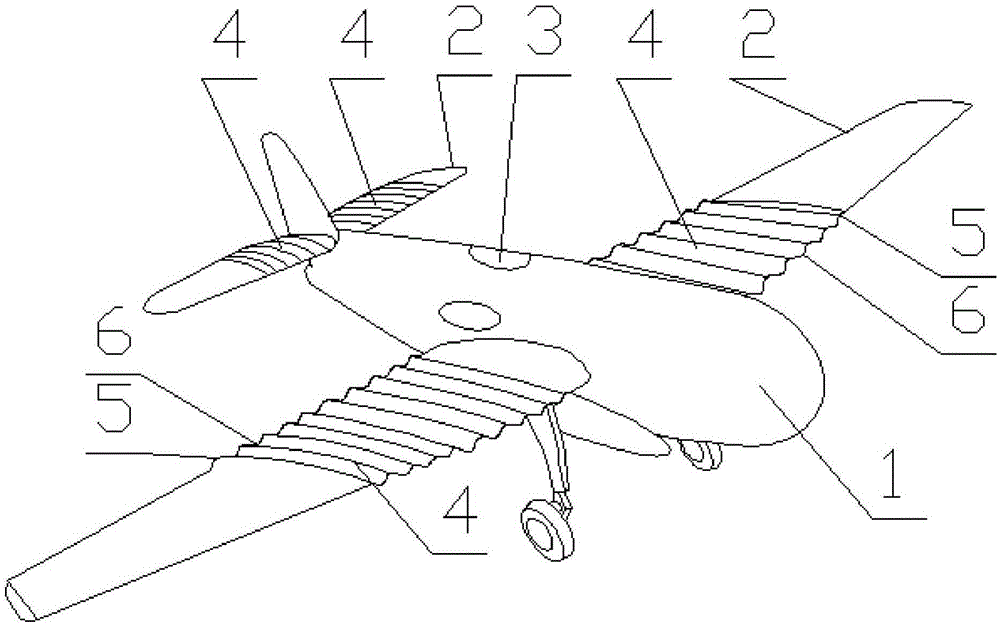

ActiveCN105644770AReduce resistanceLarge external forceSpars/stringersHeat reducing structuresSurface mountingEngineering

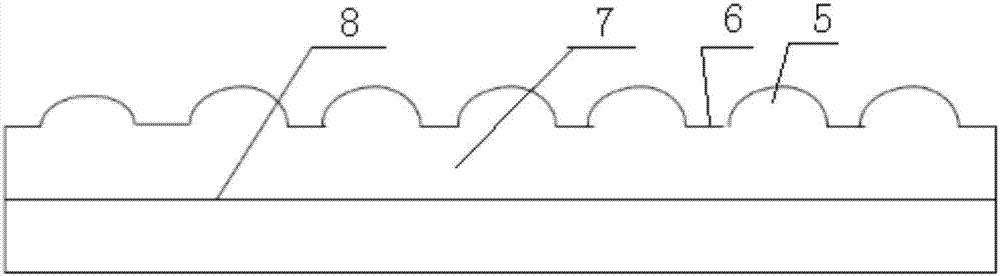

The invention provides a sharkskin-imitating resistance-reducing wing and belongs to the field of resistance-reducing wings. By the adoption of the sharkskin-imitating resistance-reducing wing, the problem that flying resistance is formed by vortexes on the surface of a plane is solved. According to the sharkskin-imitating resistance-reducing wing, a speed sensor (3) is installed on the surface of a plane body (1); a skin layer (4) adheres to the surface of a wing body (2); a set of arc-shaped protruding ribs (5) are arranged on the surface of the skin layer (4); and a groove (6) is formed between every two adjacent protruding ribs (5). A resistance reducing method of the sharkskin-imitating resistance-reducing wing comprises the steps that if the resistance measured by the speed sensor (3) is excessively large, the skin layer (4) is heated so that the temperature of the skin layer (4) can be increased, and a sharkskin-imitating rib structure is formed by means of the tensile force of a variable-trailing-edge wing body or a variable-chord wing body. According to the sharkskin-imitating resistance-reducing wing, the flow field characteristics around the plane are changed through the sharkskin-imitating rib structure, so that the resistance borne by the plane in the flying process is reduced.

Owner:HARBIN INST OF TECH

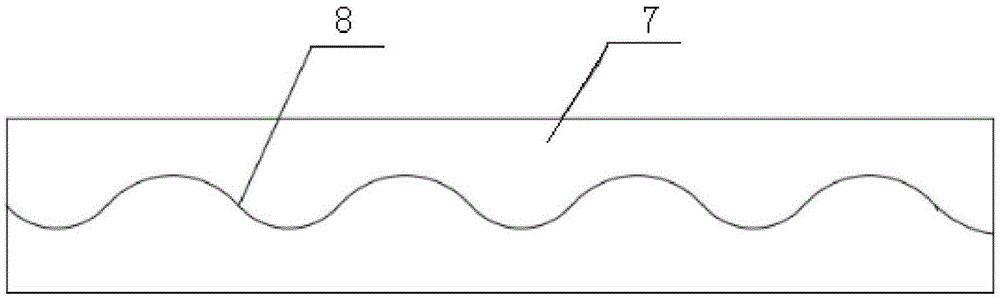

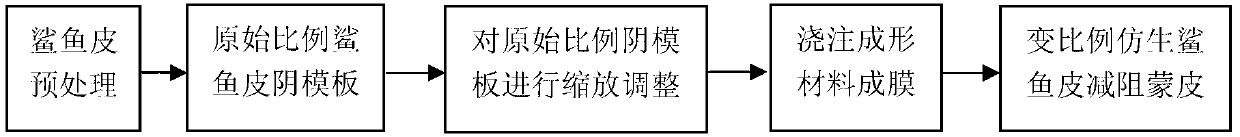

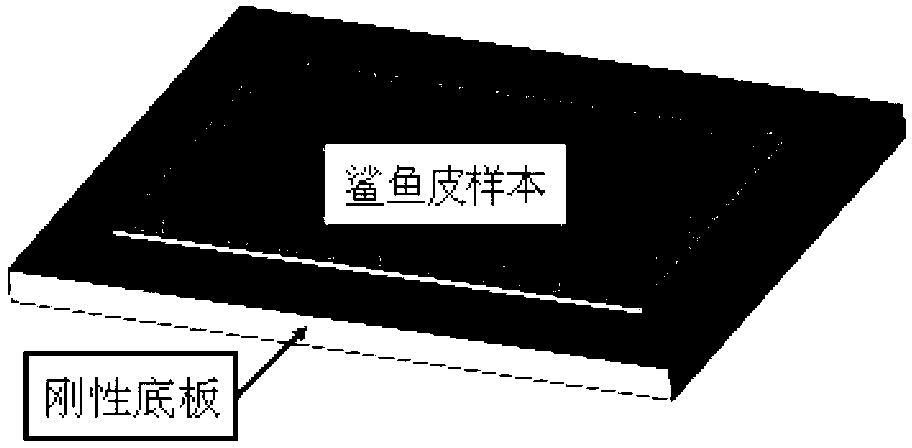

Controlled manufacturing method for shark imitated drag reduction surface structure under variable environment

ActiveCN102849205AImprove production efficiencyLow costFuselage bulkheadsEngineeringApplication object

The invention discloses a controlled manufacturing method for a shark imitated drag reduction surface structure under a variable environment. The method comprises the following steps of: 1, preparing an original-ratio sharkskin biological female template; 2, designing shape parameters of a deformed imitated shark required to be manufactured according to the requirement of an application environment; and 3, preparing a variable-proportion bionic drag reduction skin according to the application environment. The variable-proportion bionic sharkskin shaped drag reduction skin prepared by using the method has a functional structure completely in accordance with the original sharkskin shape, but has different shape parameters. By using the method for making the bionic drag reduction skin, the size of the surface shape of the skin can be adjusted according to the parameters such as common speed, different parts of the outer surface and the medium viscosity of an application object, so that the drag reduction effect of the shark imitated drag reduction skin is in an optimal state. The method has high practical value and broad application prospect in the technical field of bionic manufacturing.

Owner:BEIHANG UNIV

Method for producing super-imitated cotton warp knitting fabric with wicking function

InactiveCN103789920AGood moisture permeabilityImprove comfortFibre typesWarp knittingEngineeringSilicone oil

The invention relates to the technical field of textile, in particular to a method for producing super-imitated cotton warp knitting fabric with a wicking function. The method comprises the steps of material selection, beaming, warp knitting, dyeing and finishing in sequence. Raw materials are super-imitated cotton polyester fiber filaments and Y-shaped cross section type fine denier polyester filaments treated with elasticity enhancement. Warp knitting is conducted with dual-guide sharkskin stitches with the super-imitated cotton polyester fiber filaments serving as front guide bars and the Y-shaped cross section type fine denier polyester filaments serving as back guide bars. Hydrophilic soft finishing is conducted with block polyether amino-modified organic silicone oil finishing agents in the finishing step to enable the fabric to have both the original advantages of super-imitated cotton fabric and the wicking and dehumidification characteristics of the Y-shaped cross section type fine denier polyester filaments. Due to the fact that hydrophilic soft finishing is conducted with the block polyether amino-modified organic silicone oil finishing agents in the finishing step, the fabric is made softer, better in anti-pilling property, more fluffy and more comfortable.

Owner:ZHEJIANG QINGSONG TEXTILE

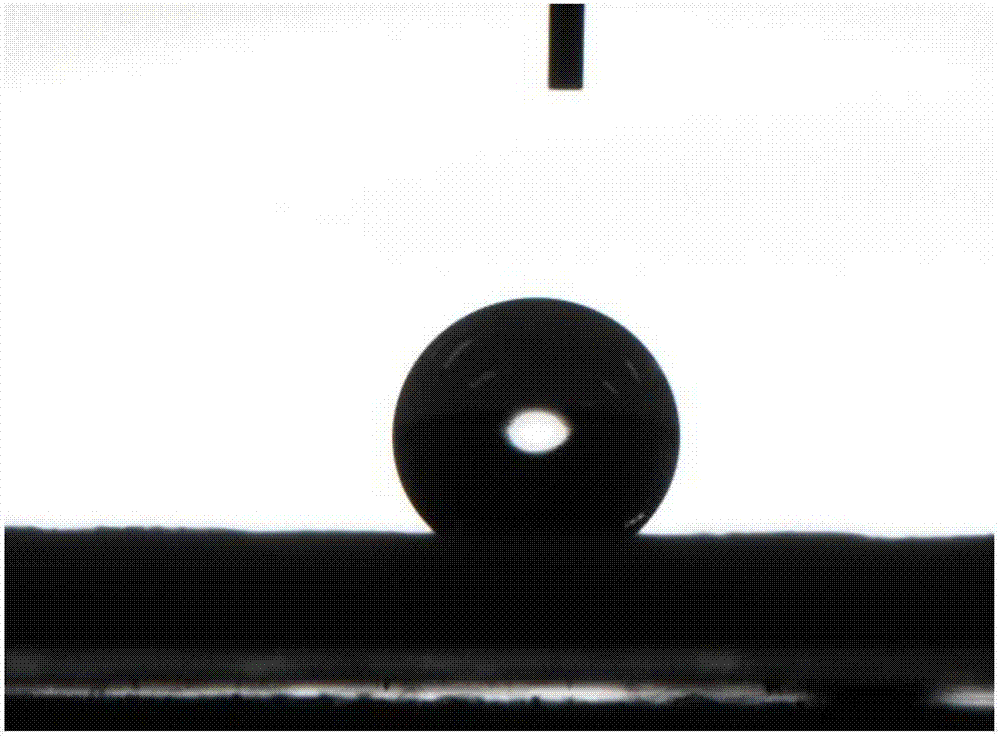

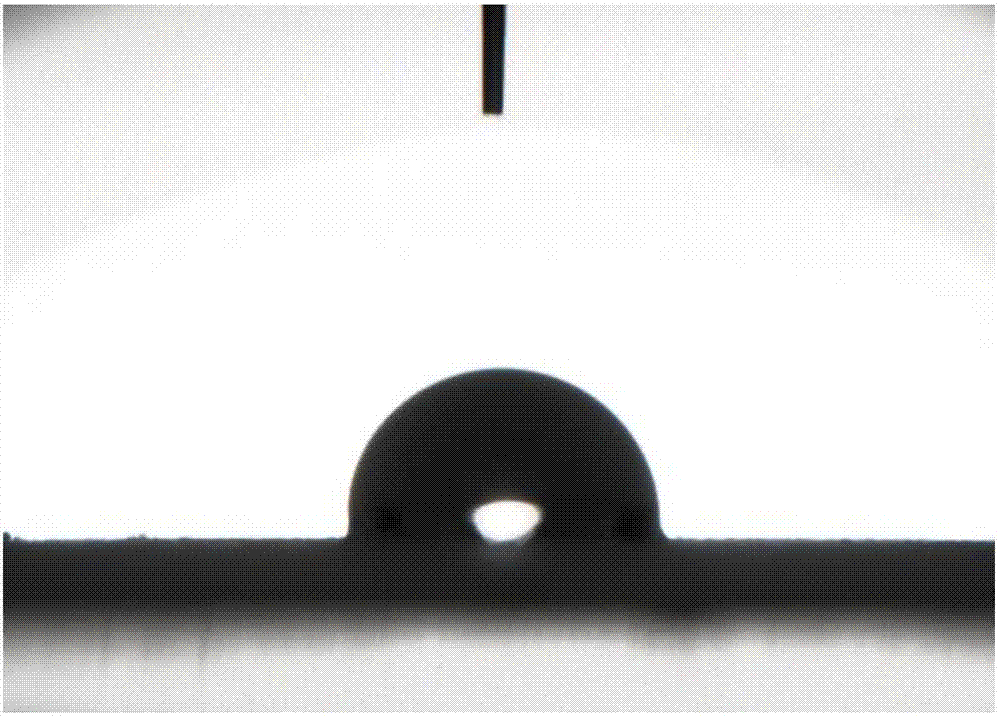

Self-repairing super-hydrophobic anti-drag elastomer thin film and preparation method thereof

ActiveCN107459668AHas super hydrophobic effectSelf-healing superhydrophobic propertiesMicro nanoElastomer

The invention relates to a self-repairing super-hydrophobic anti-drag elastomer thin film and a preparation method thereof. A sharkskin V-shaped groove structure is copied on the surface of an elastomer, and a polyarcylamide-polyfluoroalkyl acrylate segmented copolymer capable of self assembling and forming a micro-nano structure is further grafted on the surface of the elastomer; thus, the thin film has self-repair super-hydrophobic performance, a static water contact angle can reach 150 degrees or more, and a rolling angle is smaller than 10 degrees. When the anti-drag film is attached to a rotational viscometer rotor to perform an anti-drag performance test, drag reducing efficiency can reach 20%. The self-repairing super-hydrophobic anti-drag elastomer thin film disclosed by the invention has the advantages that 1, a super-hydrophobic anti-drag method and a bionic anti-drag method are combined together, so that the anti-drag film can have a better anti-drag effect under a laminar condition and a turbulent condition; 2, after surface chemical components of polyfluoroalkyl acrylate grated to the surface of the super-hydrophobic film are damaged, the polyfluoroalkyl acrylate can be self repaired after being soaked by a solvent or being heated under high temperature, so that the film can have a super-hydrophobic effect again.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

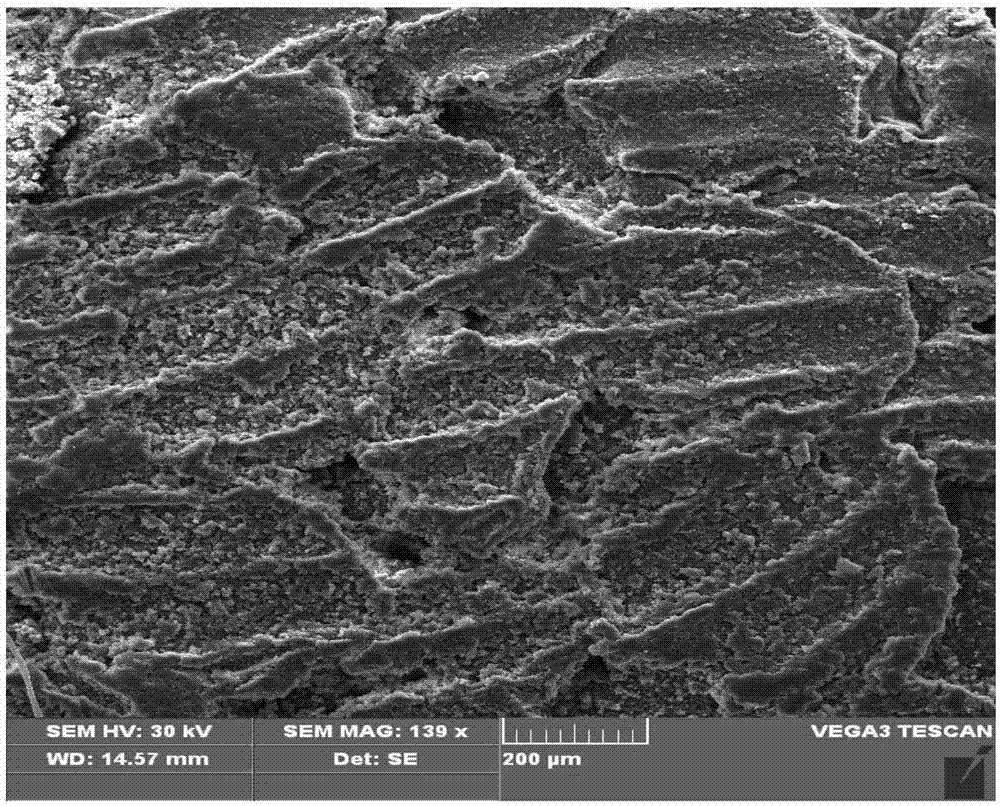

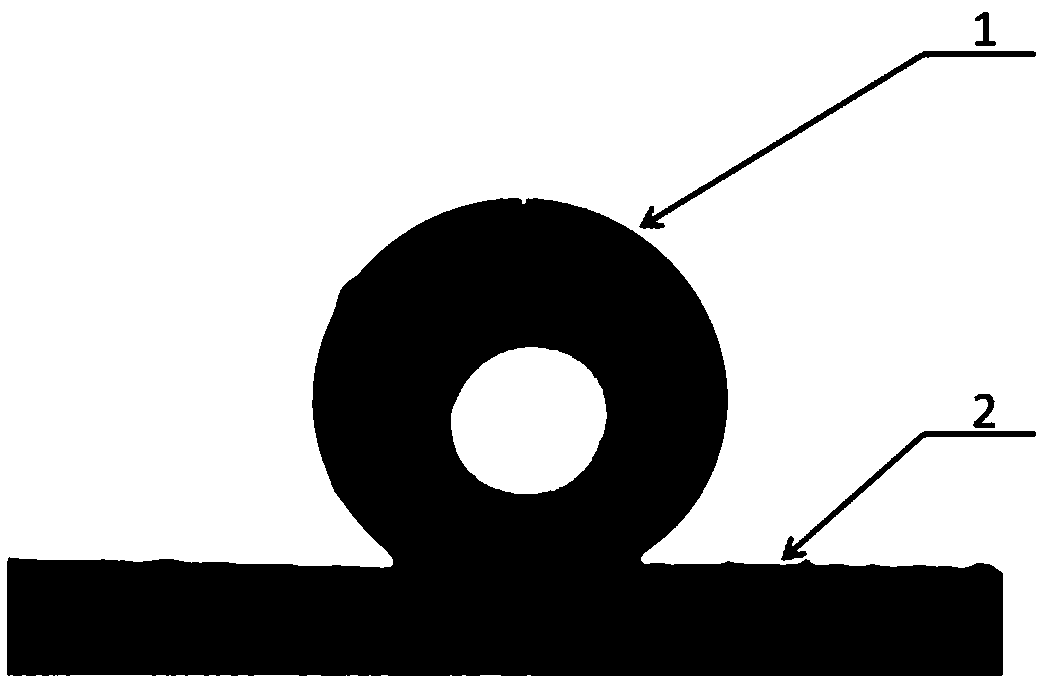

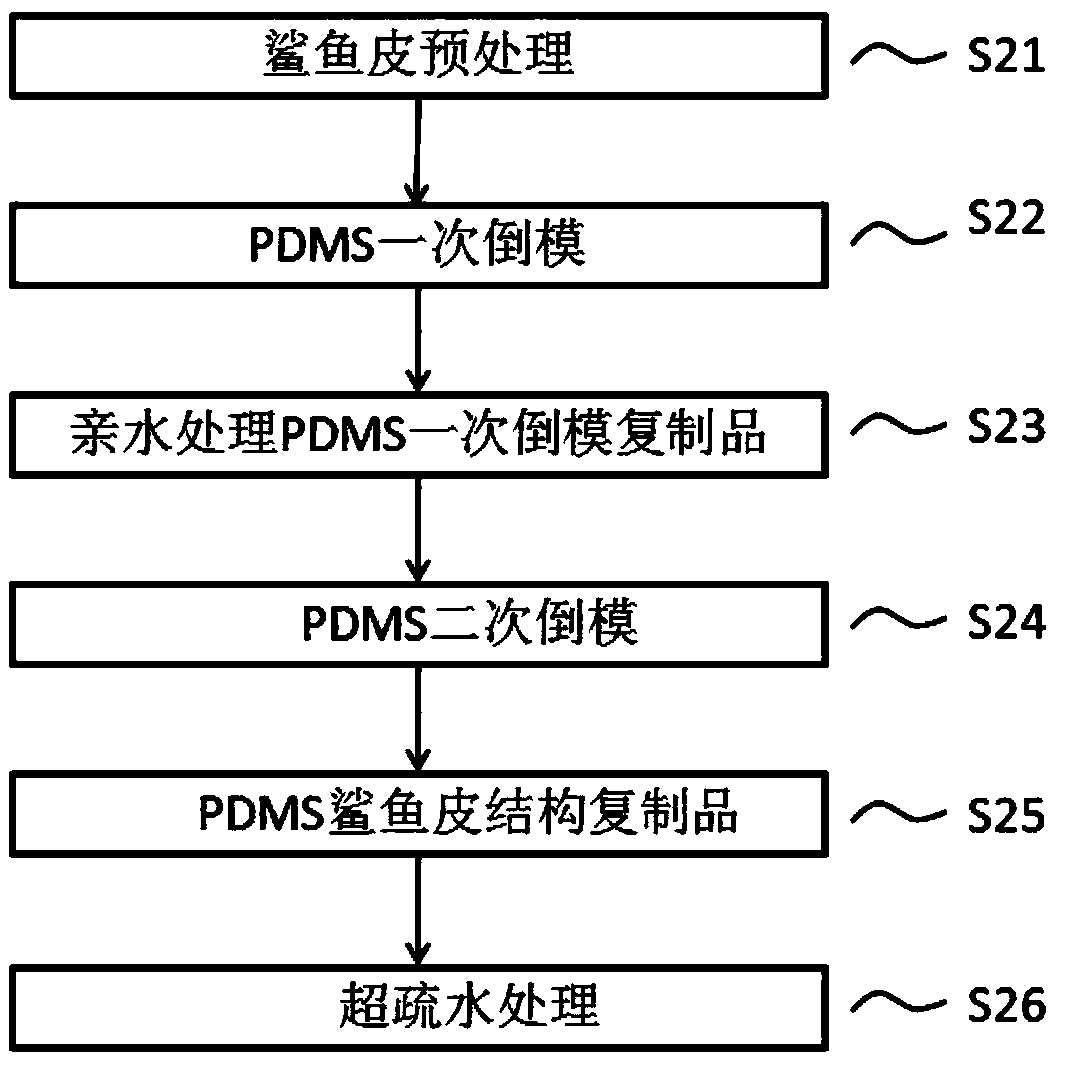

PDMS-based bionic sharkskin replica super-hydrophobic surface and preparation method thereof

The invention discloses a PDMS-based bionic sharkskin replica super-hydrophobic surface and a preparation method thereof and belongs to the technical field of hydrophobic surface preparation. According to the PDMS-based bionic sharkskin replica super-hydrophobic surface and the preparation method thereof, a sharkskin replica is obtained through twice mold changing of PDMS with a sharkskin as a template, and the surface of the sharkskin replica has a micron-scale groove structure; the PDMS sharkskin replica is put above a flame of an alcohol lamp or a lighter to be subjected to uniform combustion treatment, so that nano-particles generated during combustion are deposited on the PDMS sharkskin replica to enable the surface structure to become a micro-nano structure, and finally, the PDMS sharkskin replica is subjected to heating treatment. According to the super-hydrophobic surface preparation method provided by the invention, the contact angle of liquid drops is greater than 150 degrees, the rolling angle of the liquid drops is less than 10 degrees, and the material shows the super-hydrophobic property. The PDMS-based bionic sharkskin replica super-hydrophobic surface is simple in process, low in cost and easy to control and has good application prospects in the fields such as fog and ice prevention, self-cleaning, resistance reduction and oil-water separation.

Owner:BEIJING UNIV OF TECH

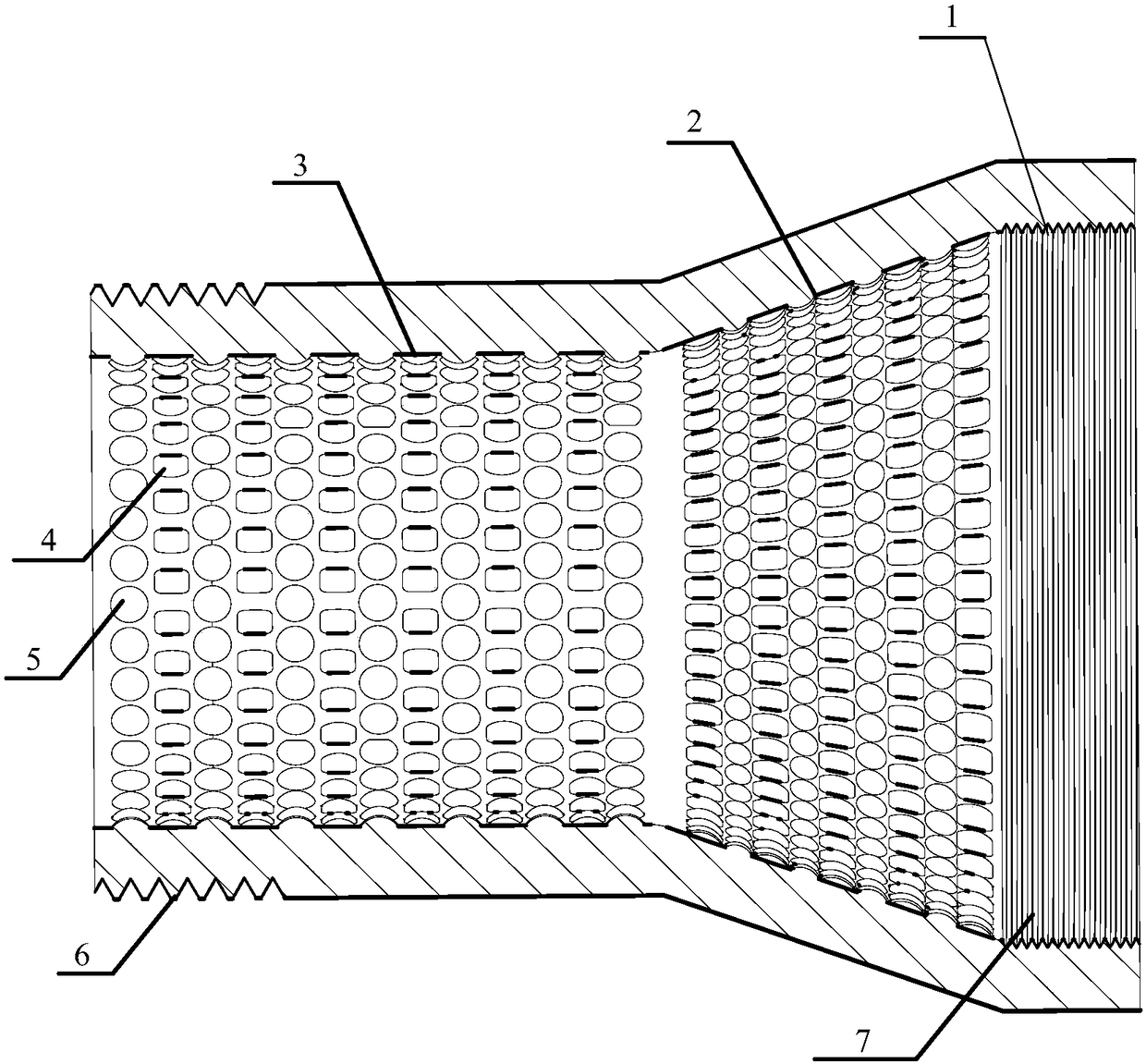

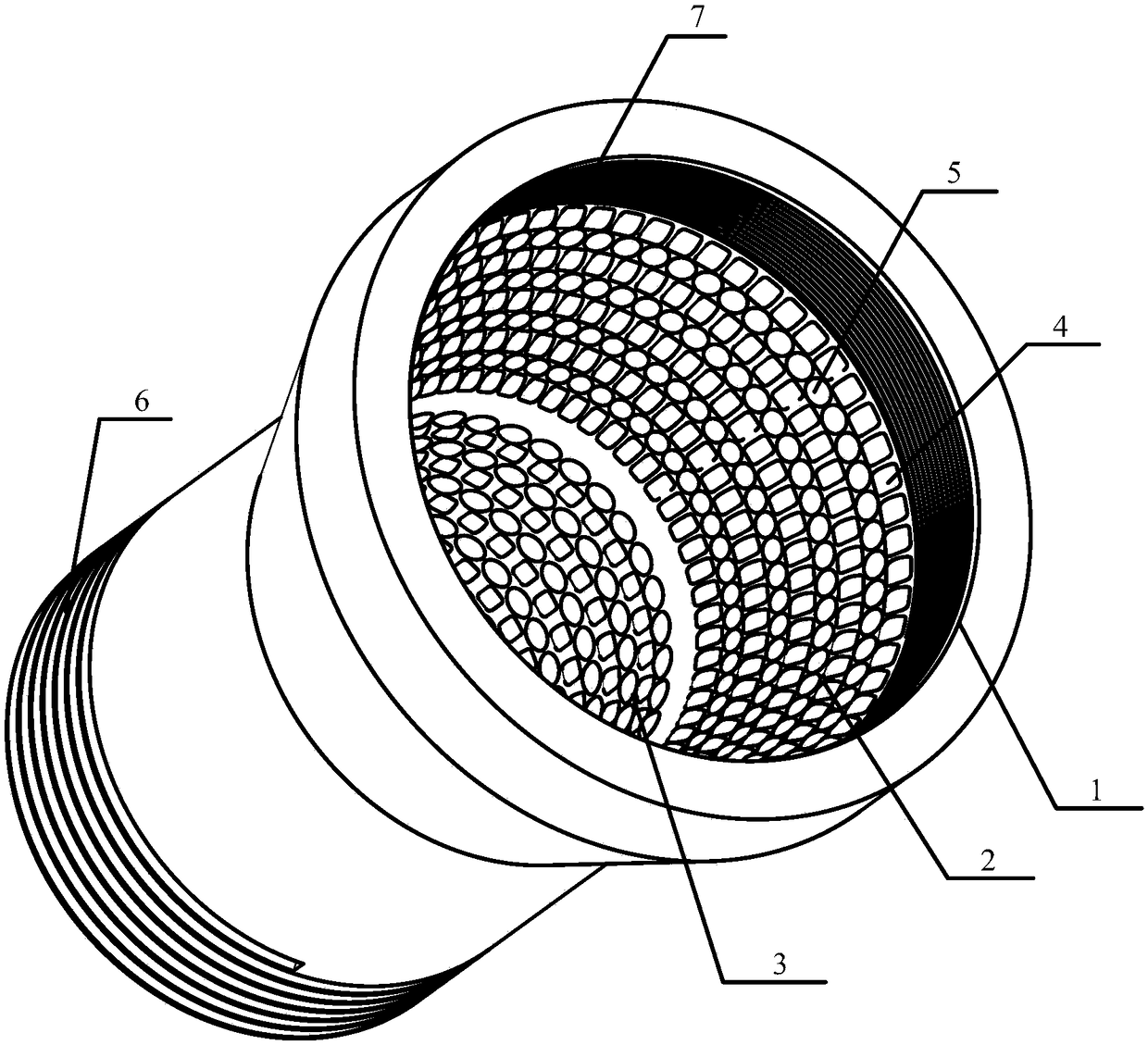

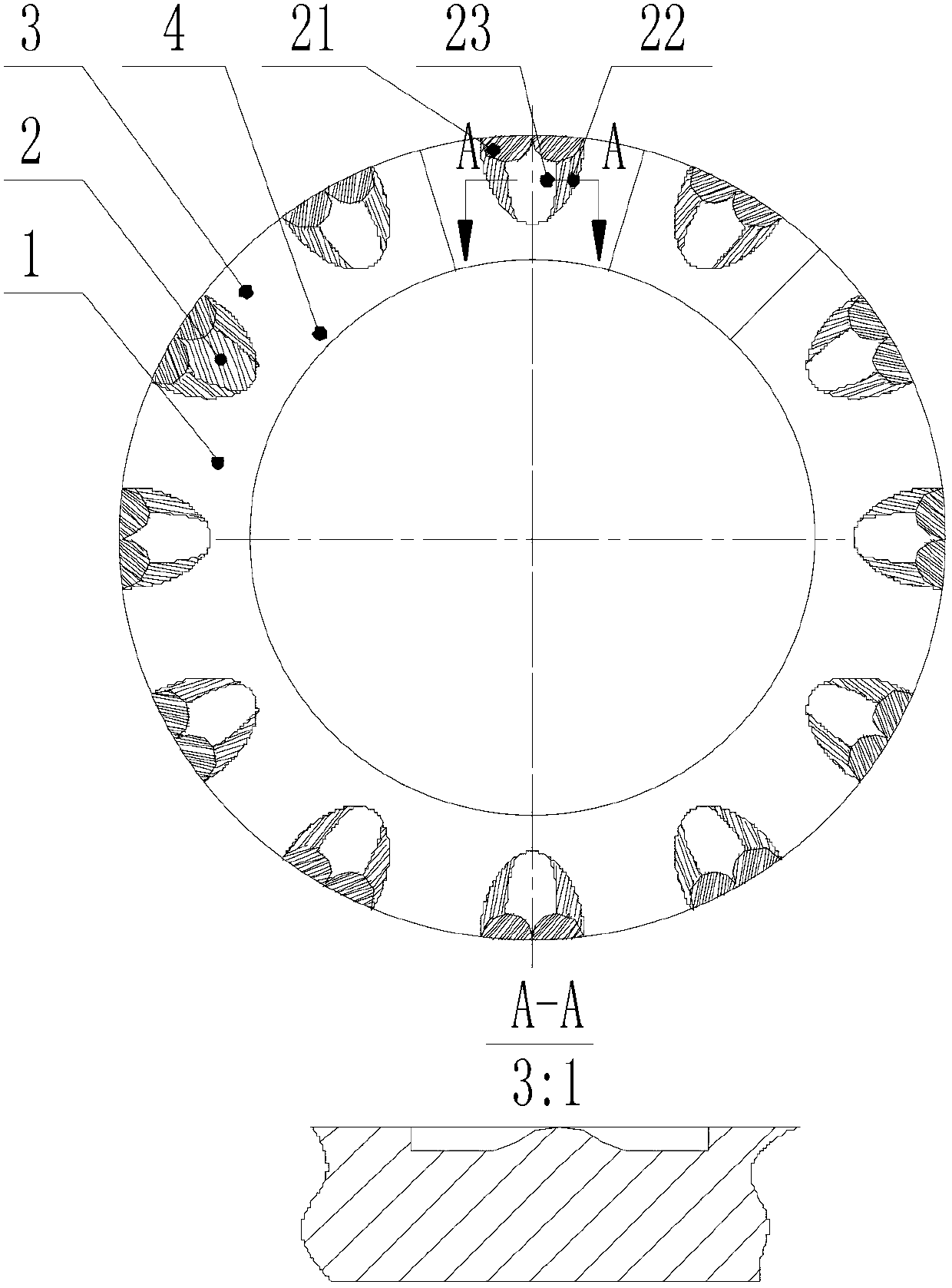

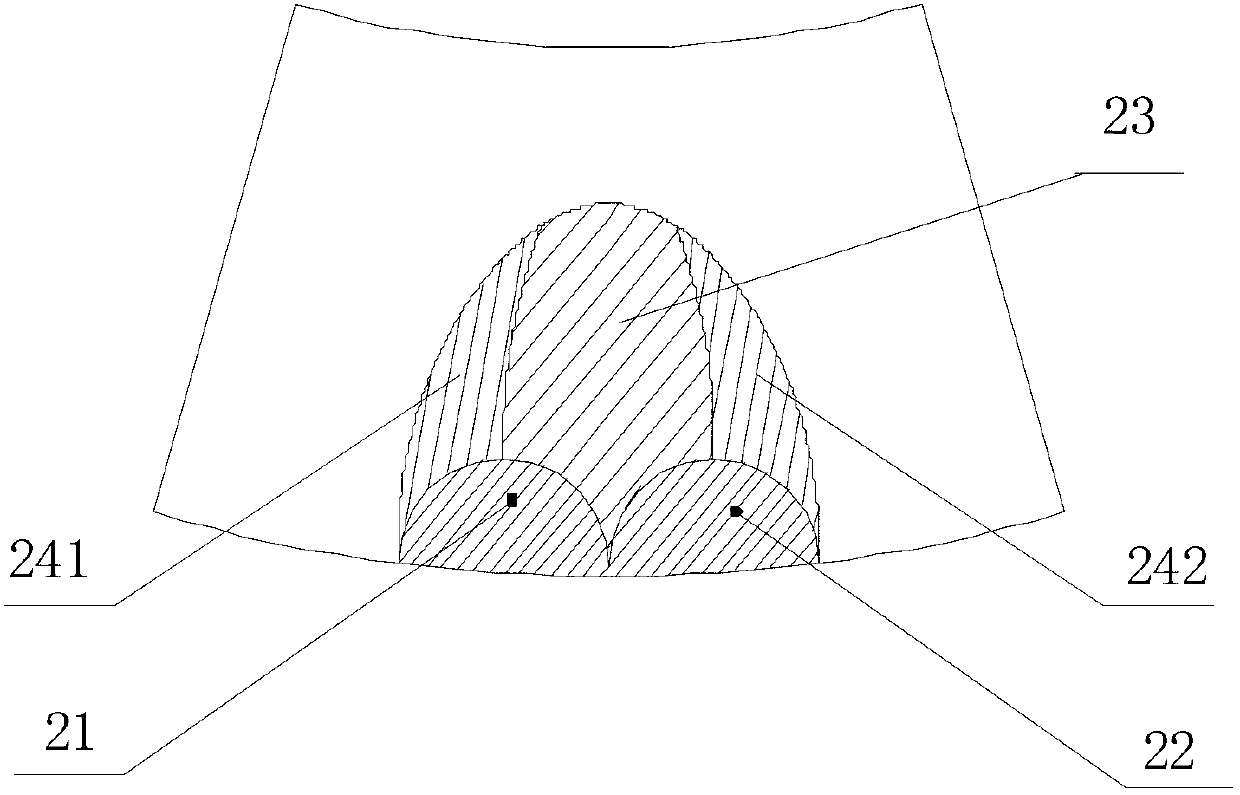

Composite bionic surface jet nozzle

A composite bionic surface jet nozzle is mainly composed of a truncated-cone-shaped contraction section and a circular-tube-shaped outlet section, the inner wall of the truncated-cone-shaped contraction section is a composite bionic surface composed of bionic sharkskin resistance reduction surfaces and bionic super-hydrophobic surfaces, the sharkskin resistance reduction surfaces are rectangular protrusions, long edges of the multiple identical rectangular protrusions are adjacent, in addition, the rectangular protrusions are distributed in the circumferential direction of the inner surface ofthe jet nozzle, and discontinuous bionic sharkskin resistance reduction convex rings are formed; the bionic super-hydrophobic surfaces are circular protrusions which are the same as the bionic sharkskin resistance reduction protrusions in height, the multiple circular protrusions which are the same as the bionic sharkskin resistance reduction convex rings in quantity are also distributed in the circumferential direction of the inner surface of the jet nozzle, discontinuous bionic super-hydrophobic convex rings are formed, and the bionic sharkskin resistance reduction convex rings and the bionic super-hydrophobic convex rings are sequentially arranged on the inner surface of the truncated-cone-shaped contraction section of the jet nozzle at intervals. According to the composite bionic surface jet nozzle, liquid resistance during jetting can be effectively reduced, thus, stable liquid jetting is achieved, the jetting distance is increased, and the energy saving effect is achieved.

Owner:YANSHAN UNIV

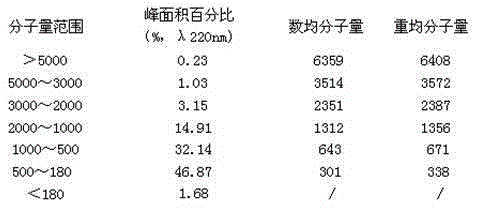

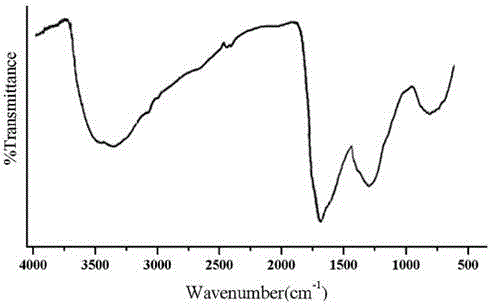

Technology for extracting collagen peptide, dermatan sulfate, hydroxyapatite and melanin from black sharkskin

The invention discloses a technology for extracting collagen peptide, dermatan sulfate, hydroxyapatite and melanin from black sharkskin. The technology comprises the following steps: conducting pre-treatment on the black sharkskin; carrying out enzymolysis; carrying out centrifugal separation to separate out a clear liquid and solid sediment; conducting ultrafiltration or resin adsorption on the clear liquid to obtain collagen peptide or dermatan sulfate respectively; treating the solid sediment with NaOH; conducting centrifugal separation on the treated solid sediment to obtain hydroxyapatite and melanin. The technology has the characteristics that collagen peptide, dermatan sulfate, hydroxyapatite and melanin are obtained continuously; the comprehensive utilization of the sharkskin is realized; the discharge of waste materials in the extraction and preparation processes is reduced; the production cost is reduced; the economic efficiency is improved; the technology is simple; industrialization can be realized.

Owner:福州宏东食品有限公司

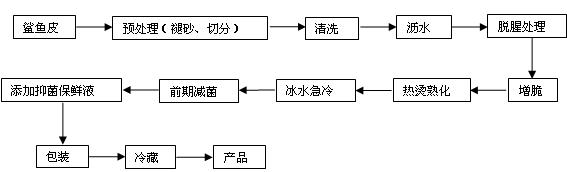

Refrigerated prepared instant sharkskin and preparation method thereof

The invention provides refrigerated prepared instant sharkskin and a preparation method thereof, wherein the refrigerated prepared instant sharkskin has a raw material recipe consisting of sharkskin and bacteriostatic fresh-keeping liquid according to a ratio of 1 / 1 (w / v). The sharkskin is used as raw materials, deodorization and embitterment treatment is carried out on the sharkskin, a cold sterilization process is used for carrying out early stage sterilization treatment on the sharkskin after hot blanching curing and ice water sharp quenching, then, the bacteriostatic fresh-keeping liquid is added to the sharkskin for keeping the freshness, and the refrigerated prepared instant sharkskin is obtained through refrigeration after package. The production process of the refrigerated prepared instant sharkskin of the invention can effectively eliminate the fishy smell of the sharkskin raw materials, can improve the crispy mouth feeling of the refrigerated prepared instant sharkskin products, can prolong the fresh-keeping shelf life of the refrigerated prepared instant sharkskin, and can develop the refrigerated prepared instant sharkskin products with nutrition, good taste, unique features, sanitation and safety.

Owner:FUJIAN AGRI & FORESTRY UNIV

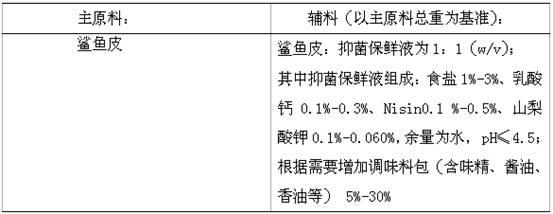

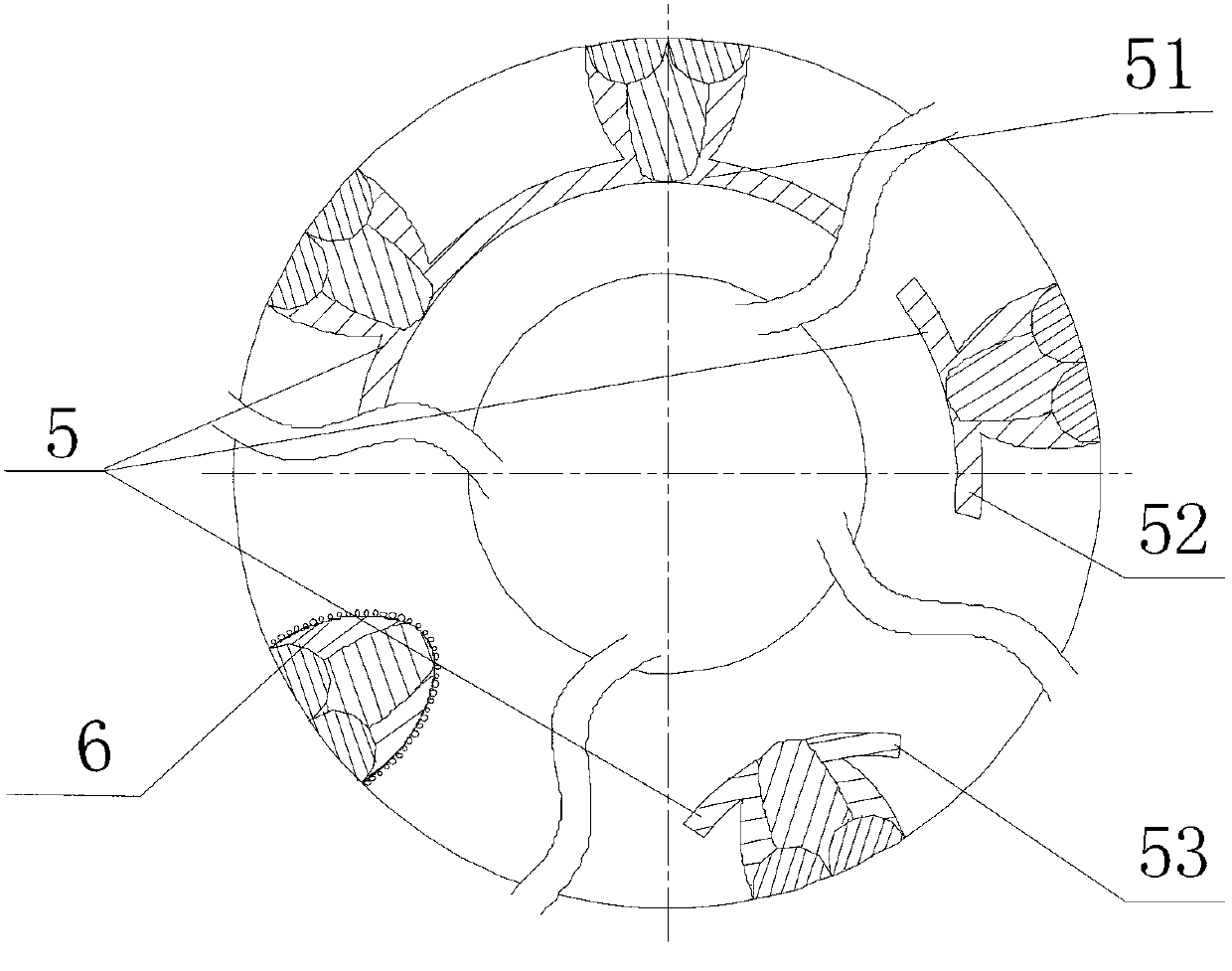

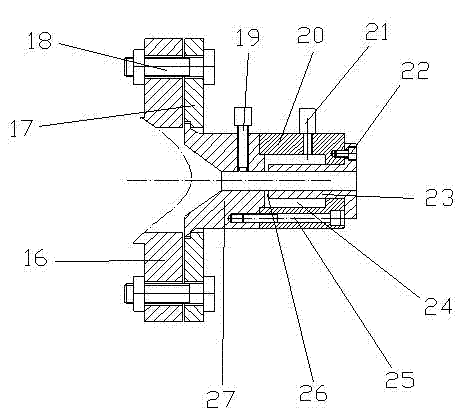

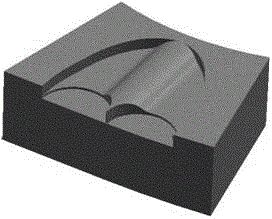

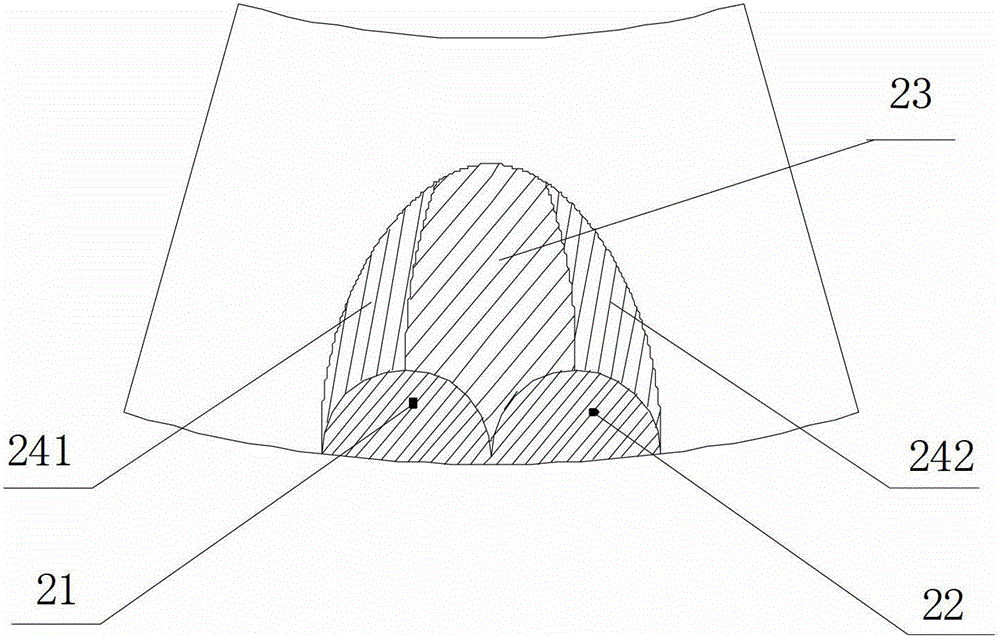

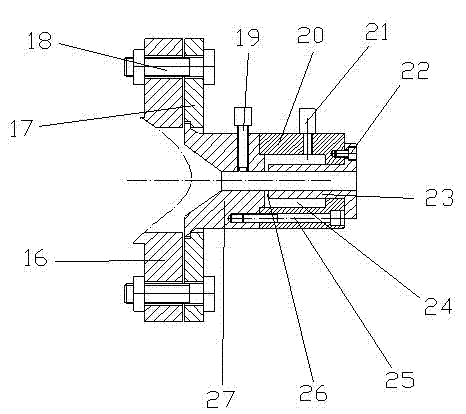

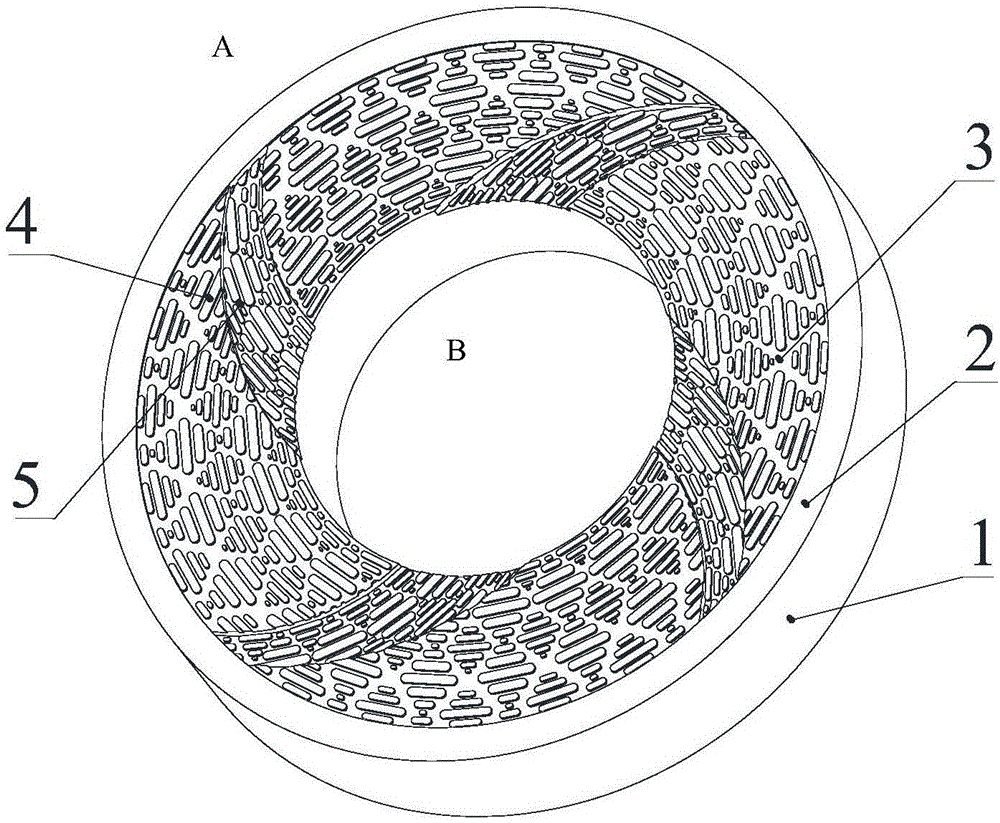

Sharkskin imitation streamline groove end face mechanical sealing structure

ActiveCN103122998ALarge dynamic pressure effectGreat effect of increasing resistance and reducing voltageEngine sealsEngineeringHigh pressure

Disclosed is a streamline groove end face mechanical sealing structure imitating a creased appearance of the surface of sharkskin. The streamline groove end face mechanical sealing structure comprises two mechanical sealing rings, namely a moving ring and a static ring, plural groups of streamline grooves imitating the creased appearance of the surface of the sharkskin and arranged along the peripheral direction are arranged at least one end face of the sealing rings of the moving ring and the static ring. Each biomimetic groove comprises a left circular groove and a right circular groove, a convex platform along the pressure drop direction in the groove and transitional parts between two sides of the convex platform and an outer contour line of the groove, so that the streamline grooves, namely sharkskin imitation streamline grooves, with the appearance imitating the creased surface of the sharkskin are formed. The sharkskin imitation streamline grooves are arranged on a high pressure side of an end face medium, namely an upper stream. The whole outlines of the sharkskin imitation streamline grooves are in a contracting shape along the pressure drop direction. The sharkskin imitation streamline grooves are arranged to form a groove annular belt along the circumference of the end face, and a plane annular belt area without grooves on the outer end face other than the groove annular belt is a sealing dam.

Owner:ZHEJIANG UNIV OF TECH

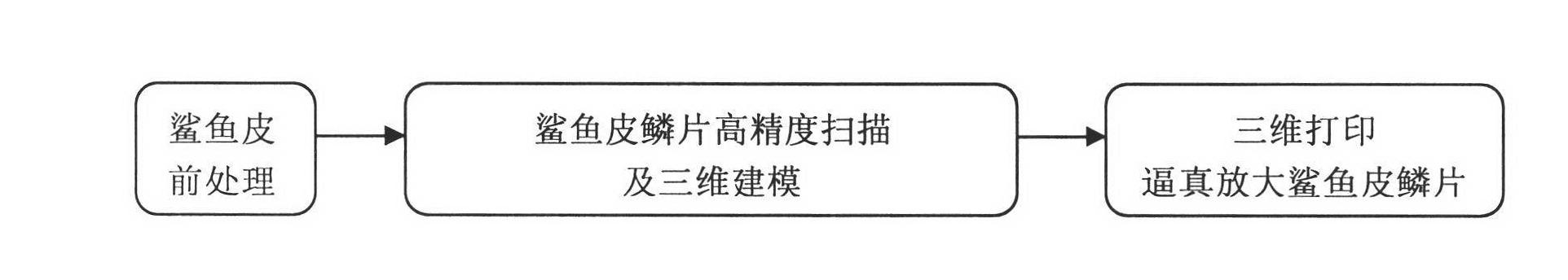

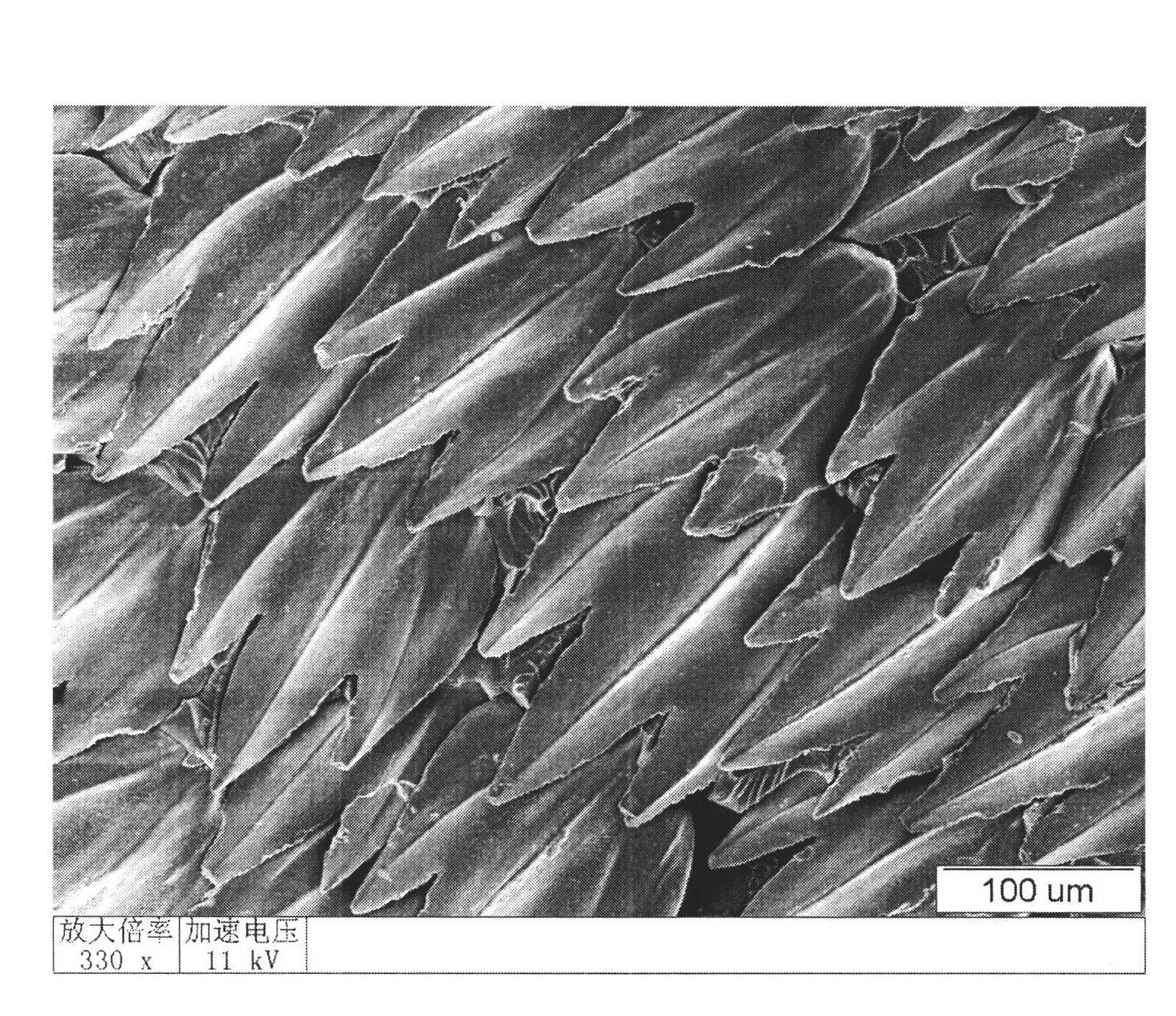

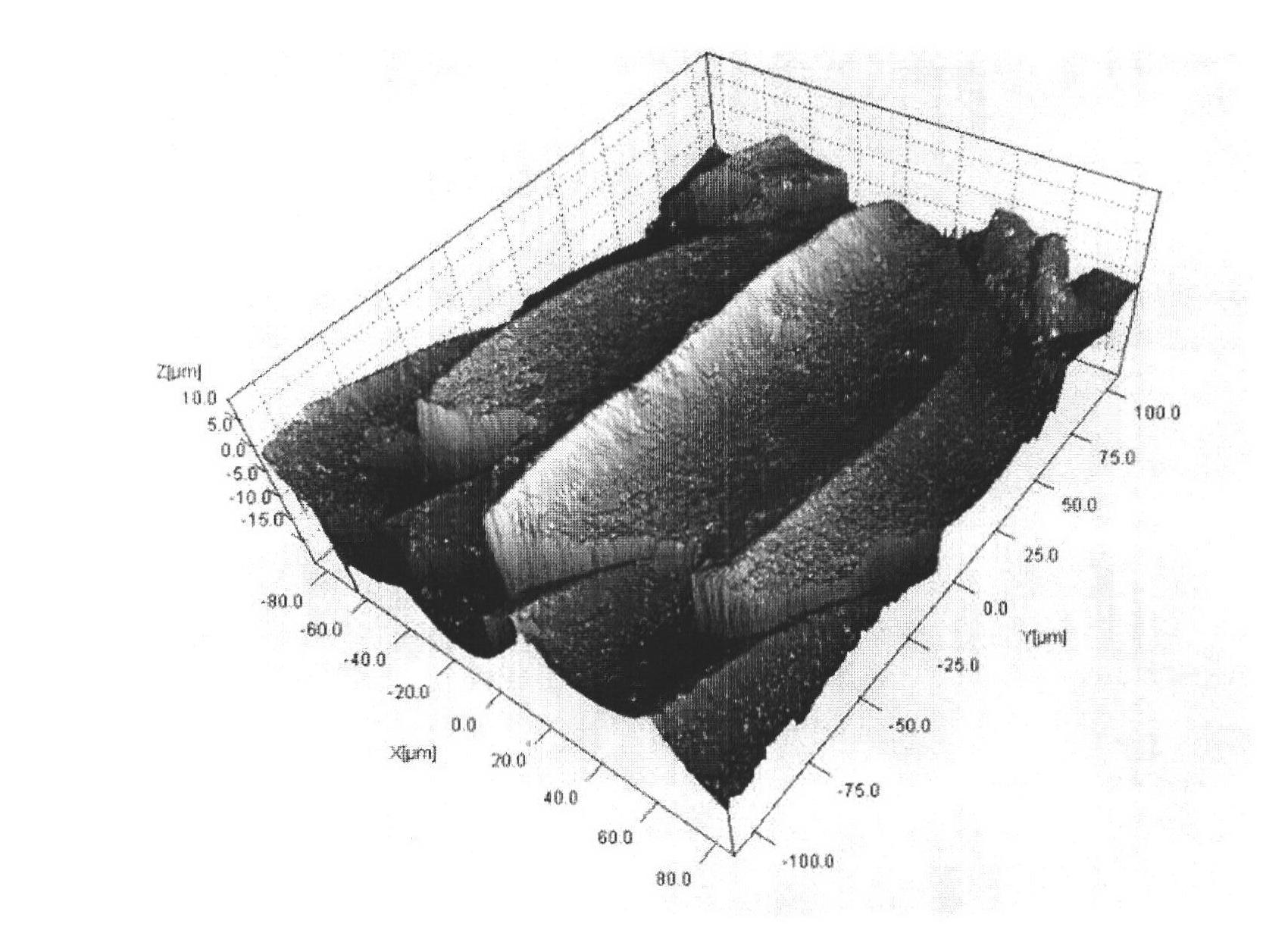

Method for manufacturing amplified vivid sharkskin squama

InactiveCN102102300ARealize arbitrary stretch deformationImprove drag reduction efficiencyTextiles and paperEngineeringViscosity

The invention relates to a method for manufacturing amplified vivid sharkskin squama, which comprises the following steps: 1) pre-treating the sharkskin; 2) precisely scanning the sharkskin squama and three-dimensionally modeling; and 3) three-dimensionally printing the vivid amplified sharkskin squama. By using the method, an amplified model of the vivid sharkskin squama can be acquired by usingthe techniques of high-precise scanning, three-dimensional printing and quick forming. The method is advanced. The vivid sharkskin squama can be directly viewed. In the fluid with high dynamic viscosity, the anti-dragging efficiency of the vivid sharkskin squama can be tested, thereby achieving the anti-dragging efficiency of the vivid sharkskin squama. The method is consistent with the development of the bionic anti-dragging surface manufacturing technique and has wide application prospect and high practical value.

Owner:BEIHANG UNIV

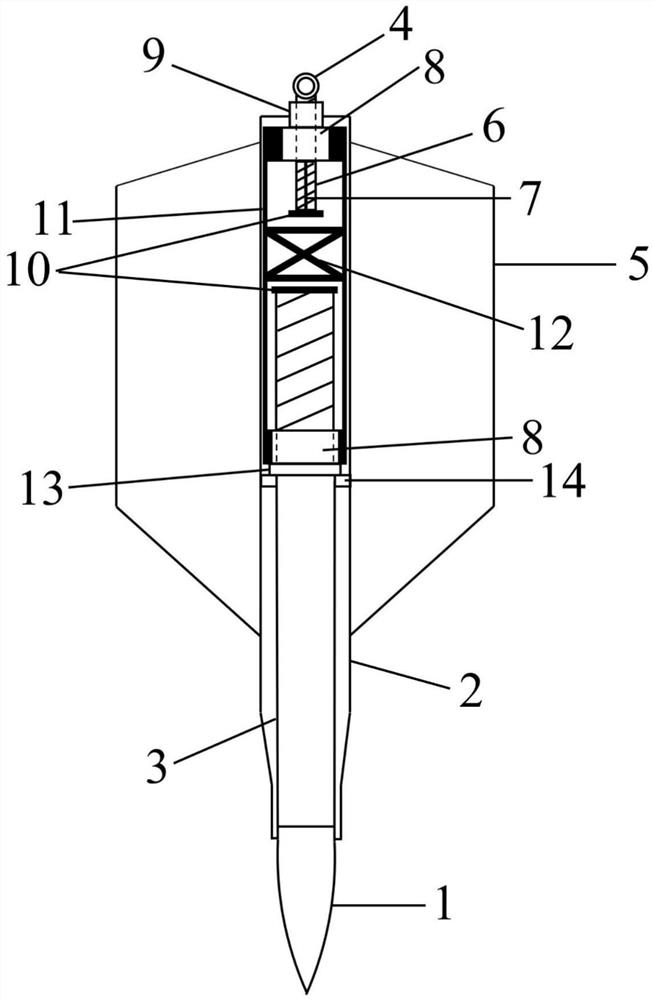

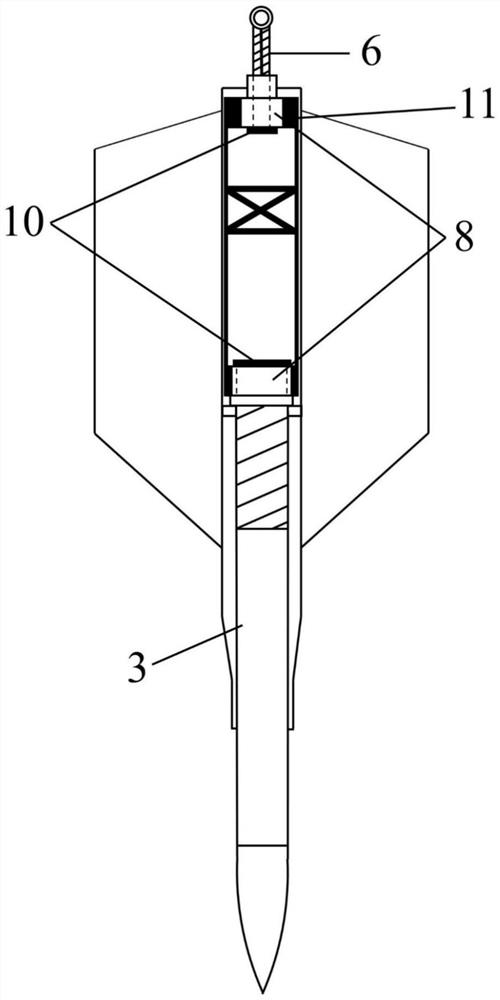

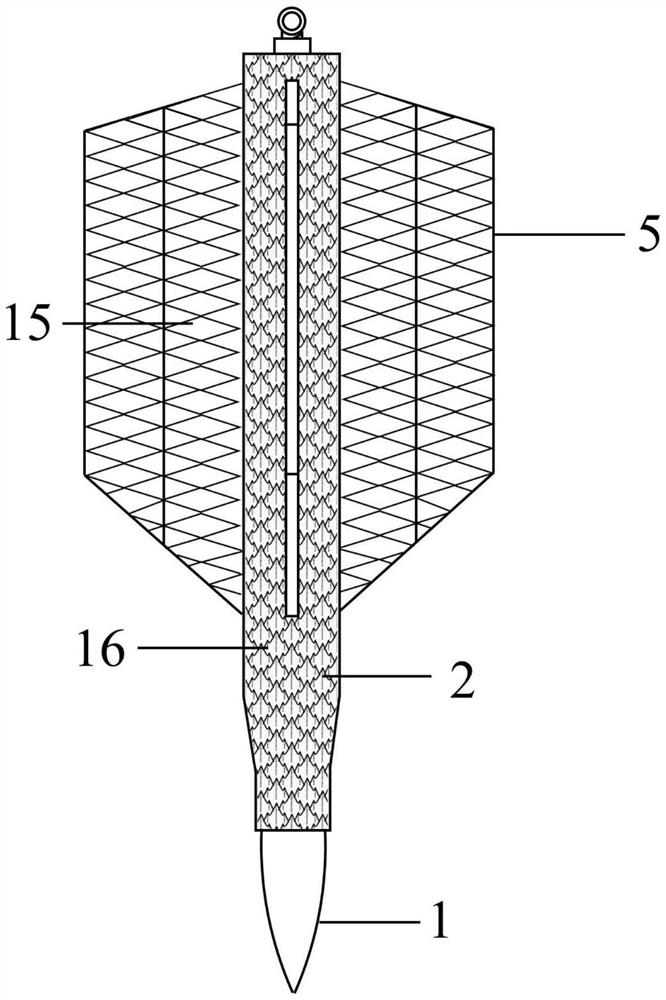

Novel torpedo anchor based on bionics and construction method thereof

ActiveCN112078728AImprove the pull-out capacityImprove stabilityAnchorsAnchoring arrangementsBiomimeticsWater flow

The invention provides a novel torpedo anchor based on bionics and a construction method thereof. The novel torpedo anchor is composed of an anchor body, an anchor rod, anchor wings, an anchor tip anda spiral extension mechanism. The anchor wings or the anchor body is additionally provided with negative poisson ratio materials, and the uplift bearing capacity of the torpedo anchor is improved byutilizing the characteristics of tension expansion and compression shrinkage of the negative poisson ratio materials; based on the sharkskin bionic principle, the surface structure of the anchor bodyis optimally designed, the water flow resistance in the installation and penetration process is reduced, and the frictional resistance between the anchor body and a seabed soil body is increased in the pull-up working state; the bionic principle of razor clam digging is used for reference, after initial penetration is completed, a working anchor chain is tensioned to be in linkage with the spiralextension mechanism, so that the anchor rod on the inside penetrates downwards, secondary penetration into the soil body is achieved, and the uplift bearing capacity and stability of the anchor body are improved.

Owner:DALIAN UNIV OF TECH

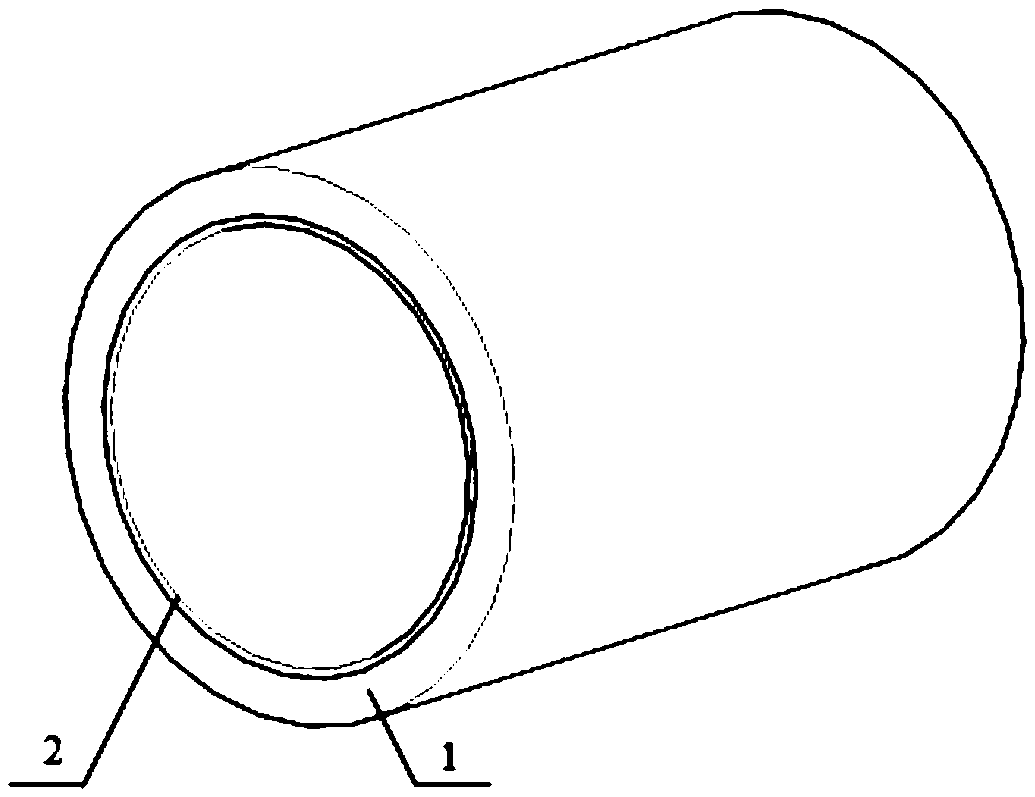

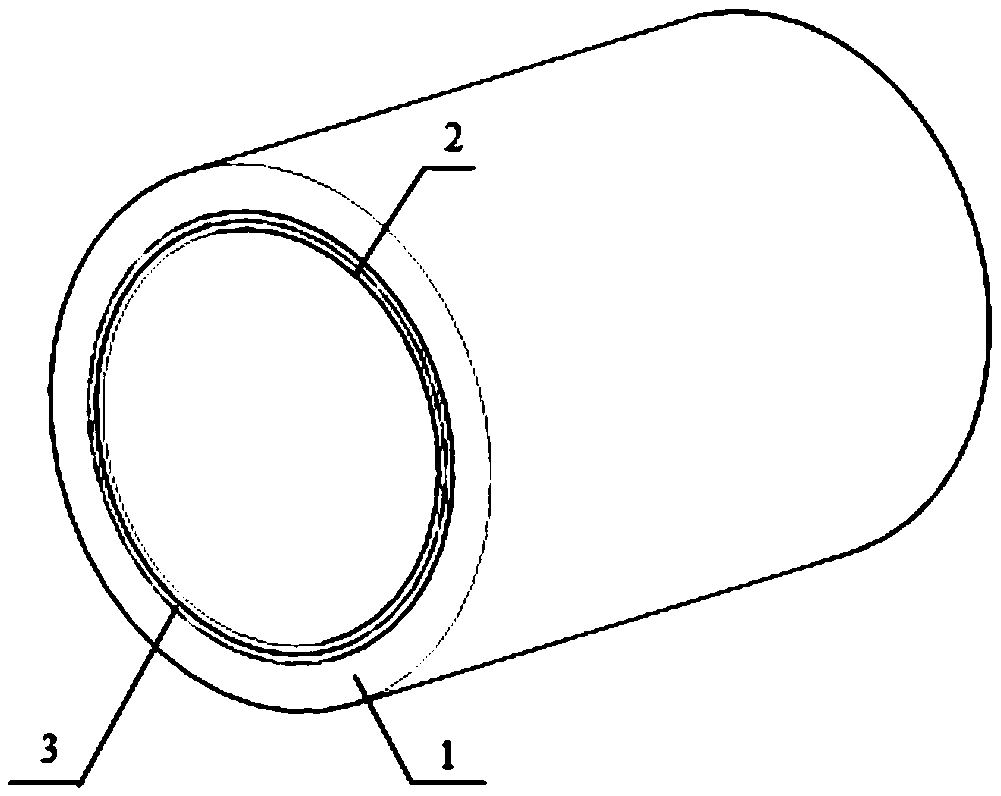

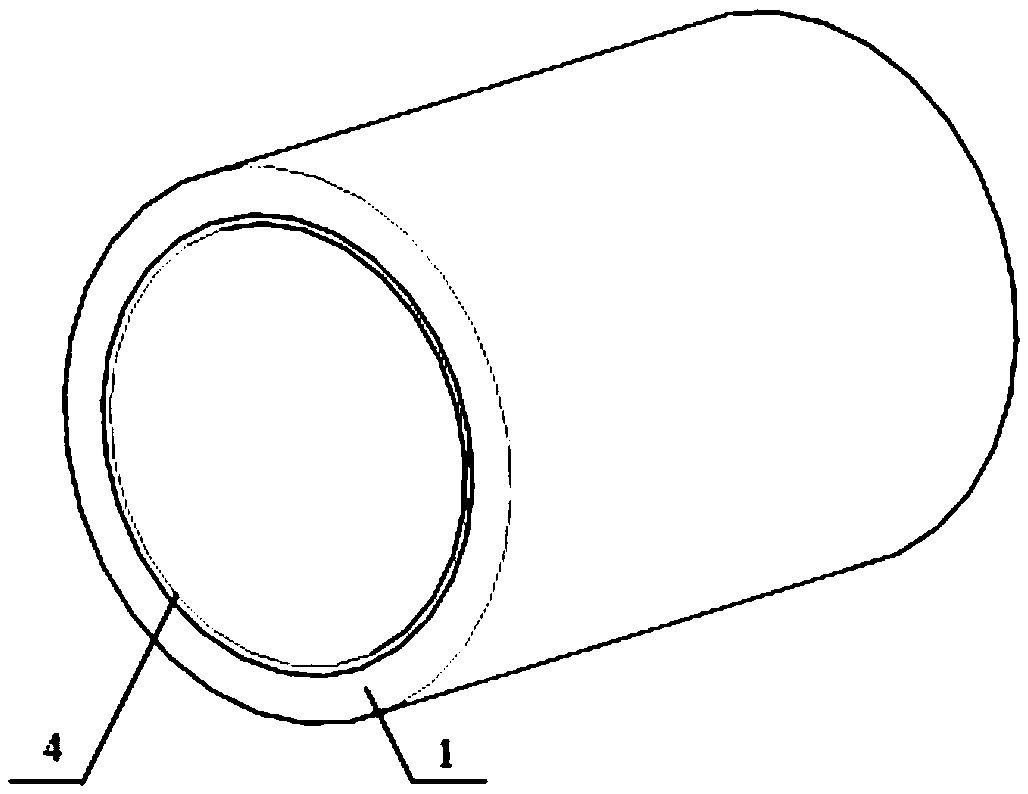

Method for lowering water conveying pipe head losses

InactiveCN105363656AReduce frictional resistanceReduce lossesPretreated surfacesCoatingsPipe waterLinear loss

The invention provides a method for lowering water conveying pipe head losses. An antifriction material is attached or coats the inner wall of a water conveying pipe. The antifriction material is a sharkskin simulating antifriction material or a nanometer super-hydrophobic material. The sharkskin simulating antifriction material can be directly stuck to the surface of the water conveying pipe, the surface of the water conveying pipe can also be coated with a substrate material layer at first so as to improve the bonding force between the sharkskin simulating material and the pipe wall; the surface of the water conveying pipe can be coated with the nanometer super-hydrophobic material directly and can also be coated with a substrate material layer at first so as to improve bonding force between the nanometer material and the pipe wall. The nanometer super-hydrophobic material can be mixed with the nanometer antifriction material for use so as to achieve the purposes of lowering frictional resistance and resisting corrosion; the method can lower the adhesive power and flow resistance of the solid-liquid surface, the hydrophobic performance of the surface of the water conveying pipe is effectively improved, and linear losses in the pipe water conveying process are reduced.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +1

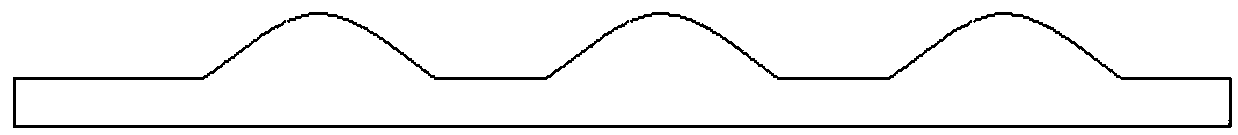

A method for reducing drag of a shark-skin-like drag-reducing wing

ActiveCN105644770BReduce resistanceLarge recoverable strainSpars/stringersHeat reducing structuresTrailing edgeFuselage

The invention provides a sharkskin-imitating resistance-reducing wing and belongs to the field of resistance-reducing wings. By the adoption of the sharkskin-imitating resistance-reducing wing, the problem that flying resistance is formed by vortexes on the surface of a plane is solved. According to the sharkskin-imitating resistance-reducing wing, a speed sensor (3) is installed on the surface of a plane body (1); a skin layer (4) adheres to the surface of a wing body (2); a set of arc-shaped protruding ribs (5) are arranged on the surface of the skin layer (4); and a groove (6) is formed between every two adjacent protruding ribs (5). A resistance reducing method of the sharkskin-imitating resistance-reducing wing comprises the steps that if the resistance measured by the speed sensor (3) is excessively large, the skin layer (4) is heated so that the temperature of the skin layer (4) can be increased, and a sharkskin-imitating rib structure is formed by means of the tensile force of a variable-trailing-edge wing body or a variable-chord wing body. According to the sharkskin-imitating resistance-reducing wing, the flow field characteristics around the plane are changed through the sharkskin-imitating rib structure, so that the resistance borne by the plane in the flying process is reduced.

Owner:HARBIN INST OF TECH

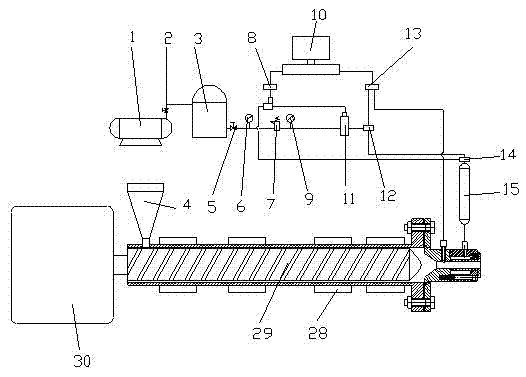

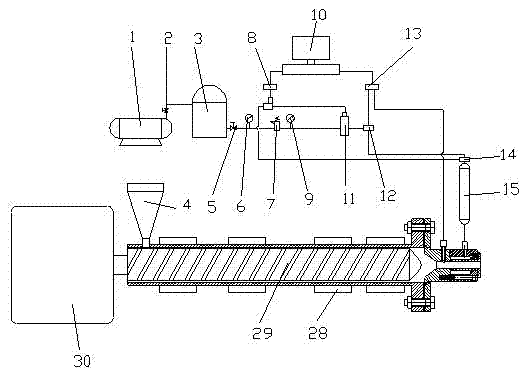

Gas-assistant extrusion molding device

InactiveCN102825752ASolve extrusion swellingSolve the large pressure drop of the extrusion dieThermodynamicsControl system

A gas-assistant extrusion molding device comprises an extruder, a gas control system and a gas-assistant extrusion molding die; during the extrusion molding process of polymer melt, a stable gas cushion film is formed between the inner wall of the extrusion die and the extruded melt, and thus the frictional resistance between the die wall surface and the extruded melt is reduced; therefore, the extrusion swelling phenomenon during the extrusion molding process is basically eliminated; the die pressure drop is reduced; and the surface quality problems of 'sharkskin', extrusion rupture phenomenon, and the like are prevented in the extrusion molding process.

Owner:NANCHANG UNIV

Instant sharkskin and preparation method thereof

The invention discloses an instant shark skin, which is produced by mixing, boiling and thickening the following raw materials with the following weight percents: 12 to 15 percent of fishy smell removed sharp skin, 3 to 5 percent of compounding material, and 80 to 85 percent of dripping seasoning. The compounding material is prepared by mushroom, black fungus, white fungus, veiled lady and dried scallop with a wet weight proportion of 3:3:6:6:2 after soaked. The dripping seasoning is prepared by the following dripping materials with the following weight percents and water: 10 to 15 percent of abalone juice, 0.3 to 0.5 percent of fresh chicken powder, 0.3 to 0.5 percent of white spirit, 0.1 to 0.3 percent of inosine monophosphate and guanosine monophosphate, 0.05 to 0.1 percent of salt, 0.01 to 0.05 percent of chicken extract, and 2 to 4 percent of starch. The invention has the advantages of convenient use, high nutritional value and good taste. The invention also discloses a preparation method of the instant sharp skin. The method has the advantage of good fishy smell removing effect; in addition, the compounding material and the dripping seasoning for the preparation of the sharp skin taste delicious and are rich in various nutrients.

Owner:NINGBO UNIV

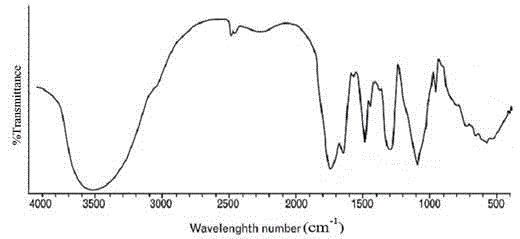

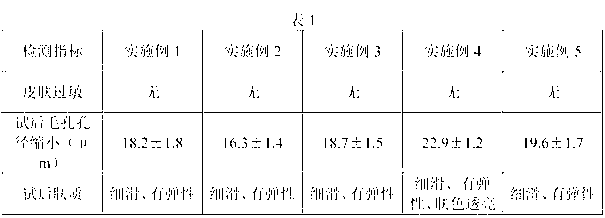

Cosmetic preparation for repairing aging rough skin and simultaneously repairing large pores

ActiveCN103169637AIncrease nutritionPromote healthy growthCosmetic preparationsToilet preparationsVitamin E AcetateD-alpha-Tocopheryl Acetate

The invention discloses a cosmetic preparation for repairing aging rough skin and simultaneously repairing large pores. The cosmetic preparation comprises the following raw materials in percentage by weight: 6.0-10.0% of sharkskin collagen peptide, 2.0-6.0% of squalane, 2.0-4.0% of water soluble lanum, 2.0-4.0% of sodium alginate, 1.0-2.0% of almond essential oil, 4.0-8.0% of vitamin E acetate, 4.0-8.0% of plant extract, 5.0-8.0% of emulsifier, 4.0-6.0% of wetting agent, 1.0-2.0% of essence, 0.5-1.0% of preservative and the balance of water. If the cosmetic preparation provided by the invention is continuously used for 8 weeks, the size of the face pores is obviously reduced (P less than 0.05), and the skin becomes fine and tight, and is transparent and white, and winkles become shallow and the skin is obviously improved.

Owner:广州中涵生物科技有限公司

Sharkskin lotus leaf imitation nano low resistance antifouling self-cleaning antiseize waterproof paint

InactiveCN101735726AImprove adhesionHigh hardnessAntifouling/underwater paintsPaints with biocidesAcrylic resinSolvent

The invention relates to a sharkskin lotus leaf imitation nano low resistance antifouling self-cleaning antiseize waterproof paint. The technical scheme of the invention includes that the paint is composed by the following components by parts by weight: 65-99 parts of component A containing 40-60 parts of hydroxyl acrylic resin, 20-25 parts of pigment, 3-5 parts of assistant and 20-30 parts of solvent, 1-35 parts of component B containing 1-35 parts of oxy-silicane and 1-5 parts of nano material silicone dioxide, and 5-25 parts of component C containing 5-35 parts of biuret or tripolymer; through crosslinking and solidifying of hydroxyl acrylic resin and oxy-silicane glue and biuret or tripolyme, the surface of formed paint film has extremely low friction coefficient the same as sharkskin and lotus leaf and extremely low surface energy, shows extremely good low resistance, antifouling, self-cleaning, antiseize waterproof properties and excellent mechanical strength, adhesion, acid-base resistance, temperature change resistance, weather ability and ageing resistance, is environmentally friendly and non-toxic and does not pollute marine environment. The invention can be widely applied to the building, home appliance, electricity and traffic fields, is energy-saving and environmentally friendly and fills the gap in the field.

Owner:秦中孝

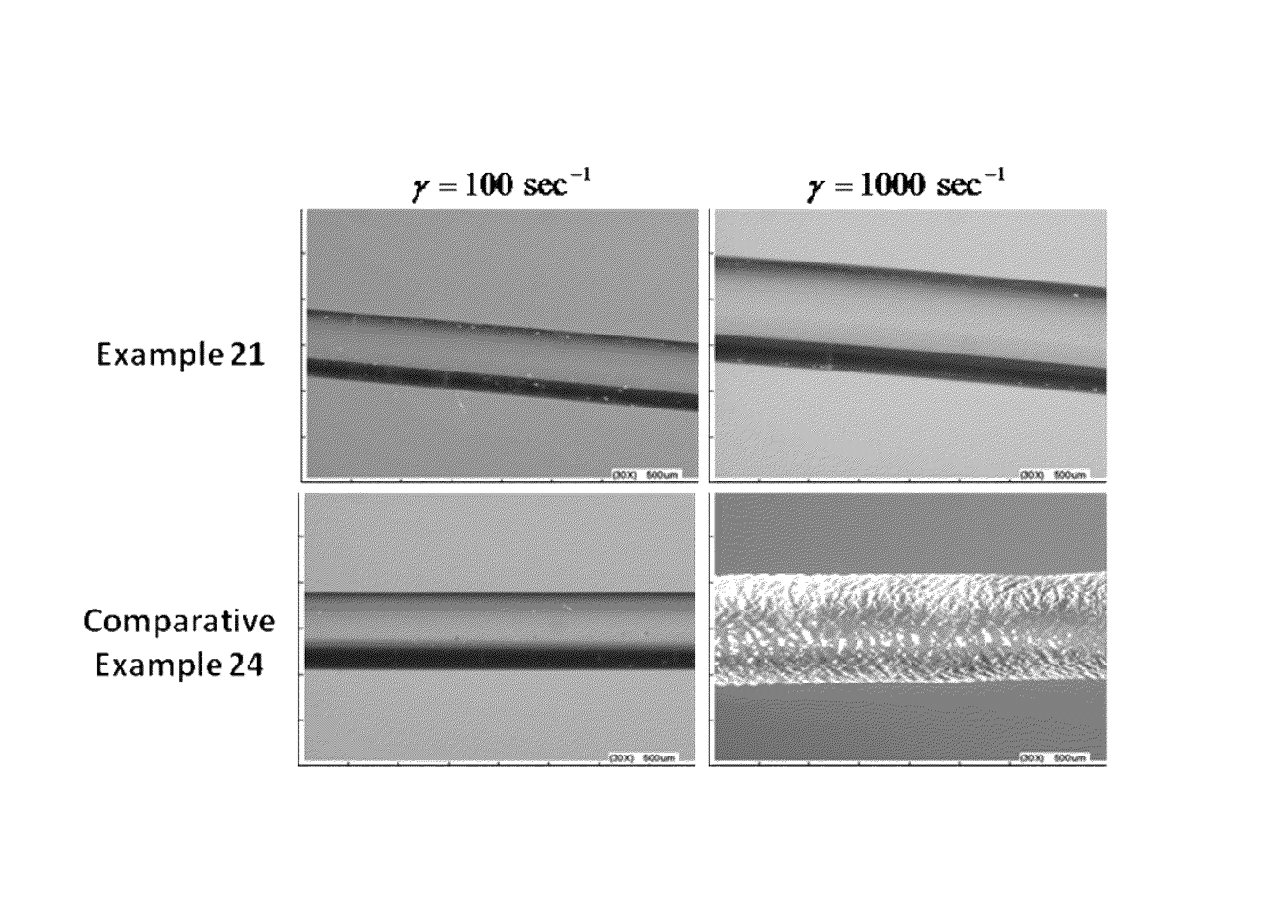

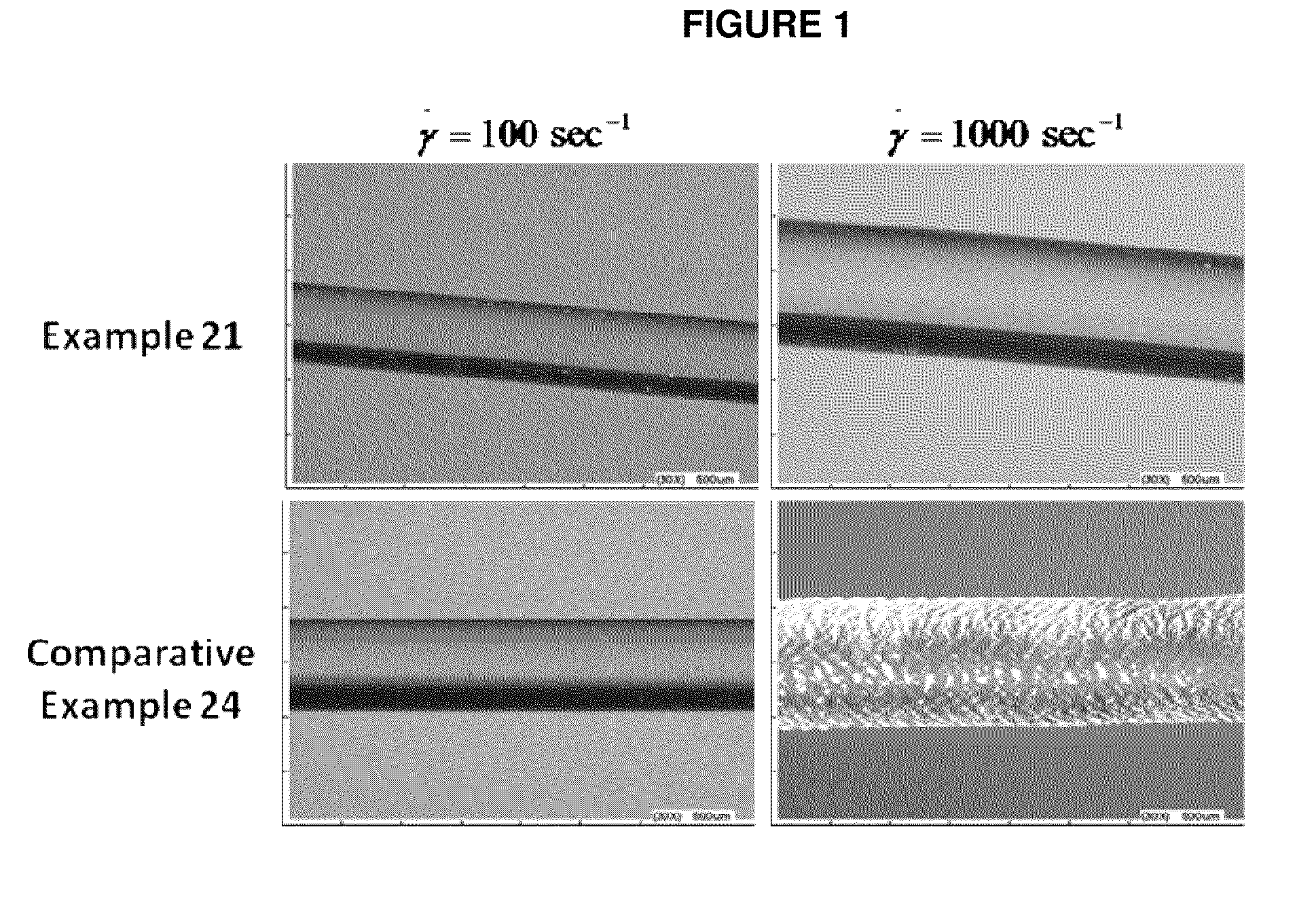

Extrusion blow molded articles

Extrusion blow molded (EBM) articles comprising a polyester having a dicarboxylic acid component and a glycol component. The dicarboxylic acid component comprises at least 90 mole % terephthalic acid residues. The glycol component comprises at least 75 mole % ethylene glycol residues and 15 to 25 mole % residues of a difunctional glycol such as, for example, 1,4-cyclohexanedimethanol. Such EBM articles can exhibit reduced haze, reduced sharkskin, and / or increased compatibility in PET recycling.

Owner:EASTMAN CHEM CO

Extrusion profile articles

Extrusion profile articles comprising a polyester having a dicarboxylic acid component and a glycol component. The dicarboxlyic acid component comprises at least 90 mole % terephthalic acid residues. The glycol component comprises at least 75 mole % ethylene glycol residues and 15 to 25 mole % residues of a difunctional glycol such as, for example, 1,4-cyclohexanedimethanol. Such extrusion profile articles can exhibit reduced haze, reduced sharkskin, and / or increased compatibility in PET recycling.

Owner:EASTMAN CHEM CO

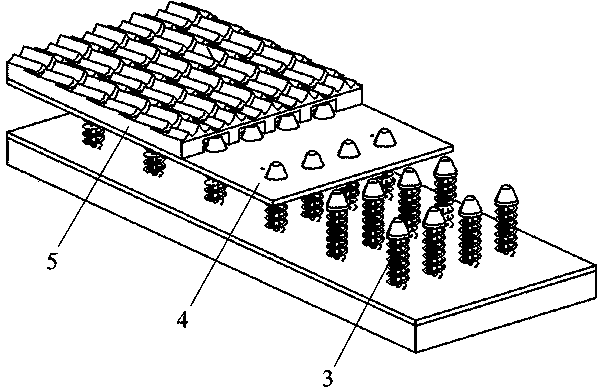

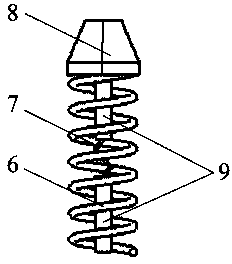

Bionic sharkskin making use of shape memory alloy artificial muscle longitudinally-injected drag reducer

InactiveCN103832539ASensitive workSensitive control methodWatercraft hull designHydrodynamic/hydrostatic featuresManufacturing technologyShape-memory alloy

The invention relates to the field of engineering bionic technology, in particular to bionic sharkskin making use of a shape memory alloy artificial muscle longitudinally-injected drag reducer. The bionic sharkskin making use of the shape memory alloy artificial muscle longitudinally-injected drag reducer comprises a supporting base, a hardened conductive layer I, artificial muscle flexible units, a hardened conductive layer II, a shark scale imitation skin layer and a drag reducer longitudinal injection device, wherein each artificial muscle flexible unit comprises a shape memory alloy artificial muscle spring, a pulling head, a two-section electric heating rod and a connection conductive wire, and each shape memory alloy artificial muscle spring has a certain amount of supporting strength. Compared with the prior art, the bionic sharkskin making use of the shape memory alloy artificial muscle longitudinally-injected drag reducer has the advantages that by the adoption of the design of shape memory alloy artificial muscle, a micro mucus secreting mechanism of the sharkskin is simulated by means of the unique material characteristic that the double-trip memory effect is presented under the driving of transformation temperature of the shape memory alloy artificial muscle, the working mode and control method of injecting a micro amount of the drag reducer are more sensitive, controllable and reliable compared with existing means, service life is guaranteed effectively, and a beneficial example is provided for the engineering bionic technology, especially the bionic drag reduction skin manufacturing technology, in the aspect of structure and function bionics.

Owner:SHANDONG UNIV OF TECH

Imitation shark skin streamlined groove end face mechanical seal structure

ActiveCN103122998BImprove the lubrication effectUniform pressure distributionEngine sealsHigh pressureEnd face mechanical seal

Disclosed is a streamline groove end face mechanical sealing structure imitating a creased appearance of the surface of sharkskin. The streamline groove end face mechanical sealing structure comprises two mechanical sealing rings, namely a moving ring and a static ring, plural groups of streamline grooves imitating the creased appearance of the surface of the sharkskin and arranged along the peripheral direction are arranged at least one end face of the sealing rings of the moving ring and the static ring. Each biomimetic groove comprises a left circular groove and a right circular groove, a convex platform along the pressure drop direction in the groove and transitional parts between two sides of the convex platform and an outer contour line of the groove, so that the streamline grooves, namely sharkskin imitation streamline grooves, with the appearance imitating the creased surface of the sharkskin are formed. The sharkskin imitation streamline grooves are arranged on a high pressure side of an end face medium, namely an upper stream. The whole outlines of the sharkskin imitation streamline grooves are in a contracting shape along the pressure drop direction. The sharkskin imitation streamline grooves are arranged to form a groove annular belt along the circumference of the end face, and a plane annular belt area without grooves on the outer end face other than the groove annular belt is a sealing dam.

Owner:ZHEJIANG UNIV OF TECH

Imitation sharkskin fabric and production method thereof

The invention relates to an imitation sharkskin fabric made by weaving warps and wefts. The imitation sharkskin fabric is characterized in that the wraps include first wraps and second wraps, and the wefts include first wefts and second wefts; the first wraps and first wefts are formed by wrapping a 100 Denier cationic low elastic polyester filament interlaced yarn formed by 48 single fibers and a 40 Denier spandexes through air before twisting; the second warps and second wefts are formed by compounding a 50 Denier polyester drawn yarn formed by 48 single fibers and a 50 Denier polyester pre-oriented yarn formed by 72 single fibers through air before twisting. The invention further discloses a production method of the fabric. Compared with the prior art, the imitation sharkskin fabric has the advantages that raw materials are polyurethane and polyester, so that the fabric has the advantages of wear resistance, wrinkle resistance, dimensional stability, good color fastness and the like; two layered weave, namely one face is in plain weave and the other face is in twill weave, is selected during weaving, and super elasticity and good air permeability are imparted to a fabric in dual directions of the warps and wefts.

Owner:正凯纺织有限公司

Extrusion blow molded articles

Extrusion blow molded (EBM) articles comprising a polyester having a dicarboxylic acid component and a glycol component. The dicarboxylic acid component comprises at least 90 mole % terephthalic acid residues. The glycol component comprises at least 75 mole % ethylene glycol residues and 15 to 25 mole % residues of a difunctional glycol such as, for example, 1,4-cyclohexanedimethanol. Such EBM articles can exhibit reduced haze, reduced sharkskin, and / or increased compatibility in PET recycling.

Owner:EASTMAN CHEM CO

Linear low-density polyethylene auxiliary-agent master batch and preparation method thereof

InactiveCN105273292AIncrease the critical shear rateGood optical performanceLow-density polyethyleneLinear low-density polyethylene

A linear low-density polyethylene (LLDPE) auxiliary-agent master batch and a preparation method thereof are disclosed and belong to the technical field of polyvinyl chloride processing master batch. The linear low-density polyethylene auxiliary-agent master batch is characterized by comprising the following compositions in parts by weight: 100 parts of LLDPE resin, 0.25-1.5 parts of an anti-oxidant, 0.3-1.0 part of an acid absorption agent, 0.2-1.0 part of hexagonal boron nitride, 0.3-4.0 parts of diundecyl phthalate, and 0.01-0.02 part of phthalocyanine blue. The LLDPE resin density is 0.91-0.92 g / cm<3>, and the melt mass flow rate is 2-10 g / 10 min. The preparation method comprises performing granulation on half LLDPE resin powder and diundecyl phthalate and on half LLDPE resin powder and hexagonal boron nitride, and then mixing according to the mass ratio of 1:1. By employing the technical scheme, the phenomena that the surface of a film is like a sharkskin and the film is broken when linear low density polyethylene is used to process the film are solved, and the processing efficiency is improved.

Owner:CHINA PETROLEUM & CHEM CORP

Gas-assistant extrusion molding method

InactiveCN102825753ADown to pressure dropRealize the effect of reducing viscosity and reducing dragPolymer scienceControl system

A gas-assistant extrusion molding method relates to polymer extrusion molding processing, and adopts a gas-assistant extrusion molding control system and a gas-assistant extrusion molding die to allow polymer melt to form a stable gas cushion film between the inner wall of the extrusion die and the extruded melt during the extrusion molding process of polymer melt, and thus the frictional resistance between the die wall surface and the extruded melt is reduced, and the gas-assistant extrusion molding is realized; therefore, the extrusion swelling phenomenon during the extrusion molding process is basically eliminated; the die pressure drop is reduced; and the surface quality problems of 'sharkskin', extrusion rupture phenomenon, and the like are prevented in the extrusion molding process.

Owner:NANCHANG UNIV

Method for separating and purifying collagen for biopharmaceutical use from sharkskin

InactiveCN101307093AAbundant raw materialsLow pricePeptide preparation methodsFreeze-dryingPhosphate

A method for obtaining collagen for biomedical use from shark skin through separation and purification adopts the raw material of the shark skin. The method has the following steps: steeping the shark skin in low-concentration phosphate buffer solution with a PH value of 7.4-7.6 to flush away squamae and residual flesh, chopping the shark skin in small pieces, and steeping and flushing the shark skin with deionized water for 3-5 times; steeping the clean shark skin in medium-concentration phosphate buffer solution which is five folds of the raw material amount with a PH value of 7.4-7.6 for 70-75 hours, then stirring the pulp evenly for 15 minutes with a temperature of 4 DEG C and a rotating speed of 10000rpm, and centrifuging the pulp for 15 minutes and taking supernatant; depositing and repeating the former step, mixing supernatant, adding ammonium sulphate to a saturation degree of 80 percent, a temperature of 4 DEG C and a rotating speed of 8000rpm, and centrifuging for 15 minutes and retaining deposit; dissolving the deposit in medium-concentration phosphate buffer solution with a PH value of 7.0; chromatographically fractionating the solution with G-75, 100, 150 glucan, collecting albumen digesting liquid with a temperature of 4 DEG C and a rotating speed of 10000rpm, centrifuging for 15 minutes, concentrating supernatant, and obtaining the collagen for biomedical use after freeze drying.

Owner:SHANGHAI FISHERIES UNIV

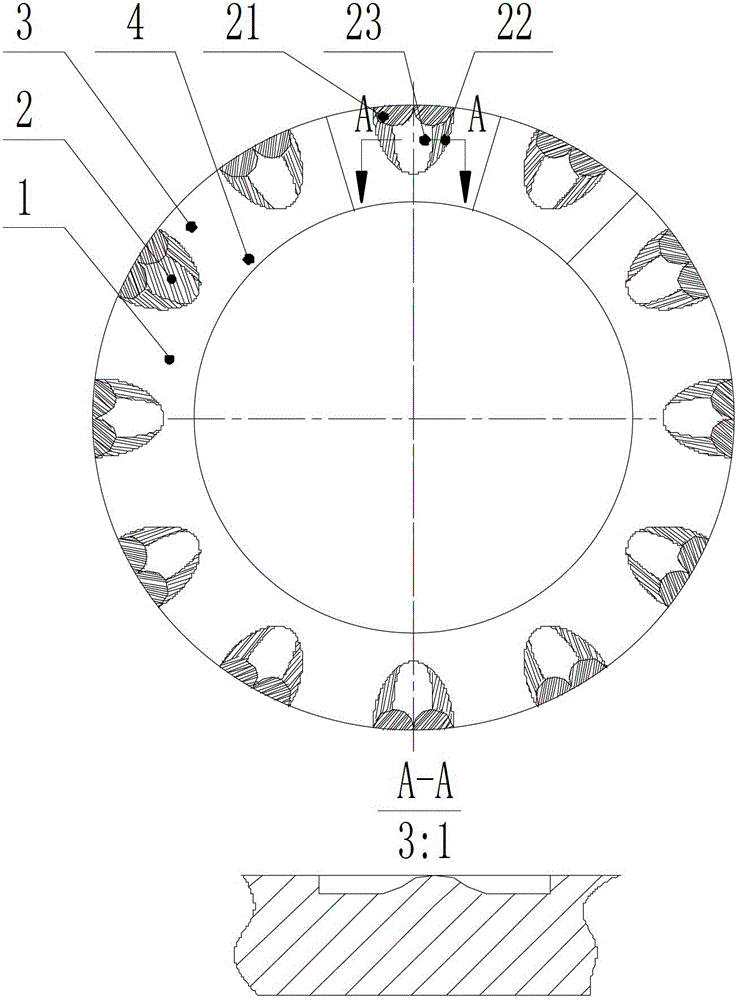

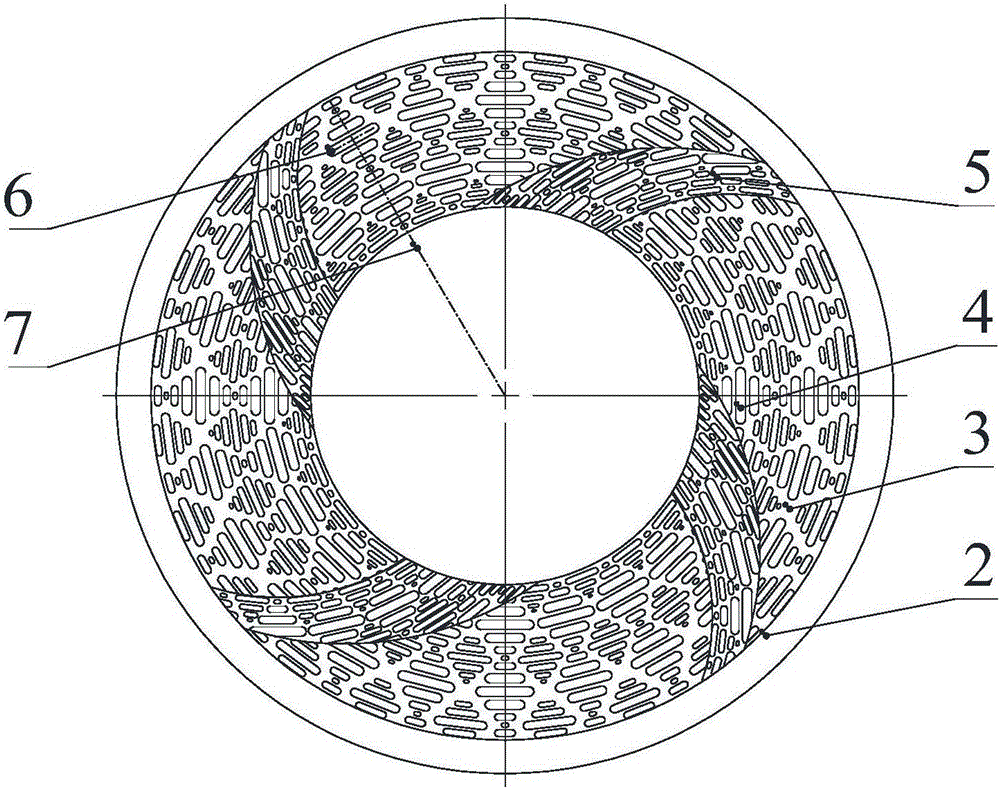

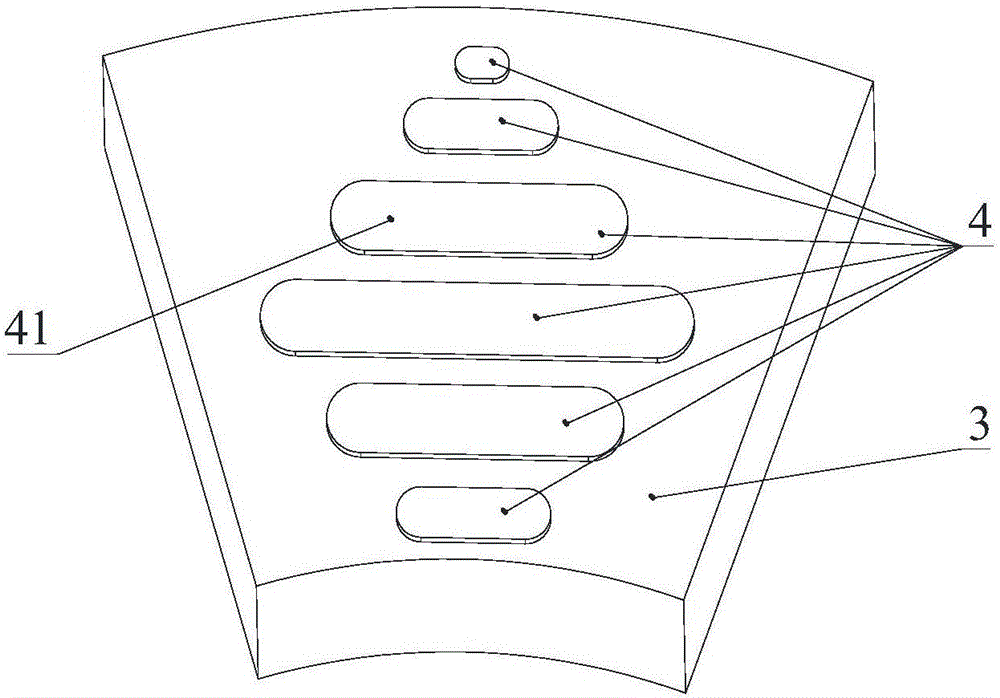

End-surface mechanical seal structure with sharkskin-imitated surface three-dimensional shape

ActiveCN106838323APrevent adhesionTo achieve the effect of enhanced heat dissipationEngine sealsThree dimensional shapeEngineering

The invention discloses an end-surface mechanical seal structure with a sharkskin-imitated surface three-dimensional shape. The end-surface mechanical seal structure comprises a moving ring or a fixed ring as mechanical seal, wherein the outer ends of the seal end surfaces of the moving ring and the fixed ring are taken as high-pressure sides, namely upstream parts, and the inner ends of the seal end surfaces are taken as low-pressure sides, namely downstream parts; a circle of closed seal dam is arranged at the upstream high-pressure side of at least one seal end surface in the moving ring or the fixed ring, a plurality of upstream pump grooves are uniformly arranged on the circumference of the surface of the seal end surface, a first end of each upstream pump groove extends to the high-pressure side of the seal end surface, and a second end extends to the low-pressure side of the seal end surface; an area between two adjacent upstream pump grooves is a seal weir; micro convex body clusters with the sharkskin-imitated surface shape are processed on the bottoms of the grooves and the surfaces of the seal weirs; the micro convex body clusters are arranged in a staggered manner until the micro convex body clusters uniformly bestrew the whole seal weirs and the bottoms of the upstream pump grooves; and the micro convex body clusters are formed by a plurality of parallel micro convex body units. The end-surface mechanical seal structure has the beneficial effects that attachment, drag reduction, wear resistance and enhanced heat dissipation of marine fouling organisms are prevented through the sharkskin-imitated surface three-dimensional shape.

Owner:ZHEJIANG UNIV OF TECH

Fluorine-containing polymer auxiliary master batch with effect of eliminating melt fracture

The invention discloses fluorine-containing polymer auxiliary master batch with an effect of eliminating melt fracture. By using the fluorine-containing polymer auxiliary master batch to improve the flowability of UHMWPE / PE alloy, the 'sharkskin' phenomenon in alloy extrusion is reduced. According to the technical scheme, the fluorine-containing polymer auxiliary master batch is prepared by usingfluorine-containing polymer auxiliaries as the additives and using different types of polyethylene materials as the matrix resin. The fluorine-containing polymer auxiliary master batch is prepared by,by mass percentage, 95-99% of polyethylene resin and 1-5% of fluorine-containing polymer auxiliaries. A preparation method of the fluorine-containing polymer auxiliary master batch includes the stepsof firstly, drying; secondly, weighing materials; thirdly, mixing; fourthly, performing extrusion granulation. The prepared fluorine-containing polymer auxiliary master batch is good in surface smoothness, capable of improving the 'sharkskin' phenomenon of the UHMWPE / PE alloy, capable of increasing productivity and lowering energy consumption and beneficial to the forming of UHMWPE / PE alloy pipes.

Owner:QUANGANG PETROCHEM RES INST OF FUJIAN NORMAL UNIV

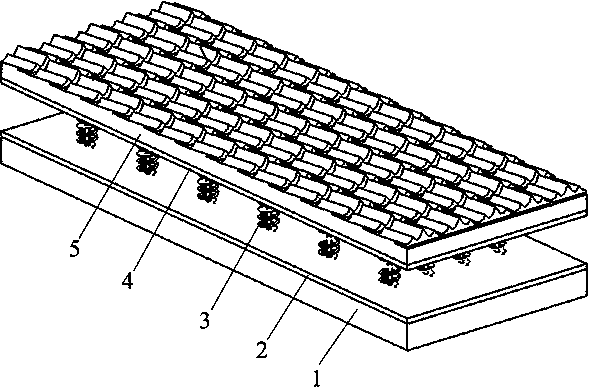

Feeder with bionic sharkskin placoid scale structure and manufacturing method of feeder

ActiveCN108147023AAlleviate or solve the problem of sticking screw bladesIncrease stickinessPackagingSpiral bladeScale structure

The invention discloses a feeder with a bionic sharkskin placoid scale structure and a manufacturing method of the feeder. The manufacturing method specifically comprises the steps that a shark placoid scale structure biological template is manufactured after pretreatment is conducted on a shark body skin, the relative positions and overall surface appearance data of a single shark placoid scale structure and a plurality of shark placoid scales in a large area are obtained through scanning, direct or indirect processing duplication is conducted on a spiral blade according to a certain scalingand ruler, the spiral blade with the bionic sharkskin placoid scale structure is mounted in a spiral feeder and used for conveying materials being high in viscidity, prone to caking, and poor in mobility, and thus the effects of reducing resistance and noise, prolonging the life of a feeding mechanism and guaranteeing smooth feeding are achieved.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com