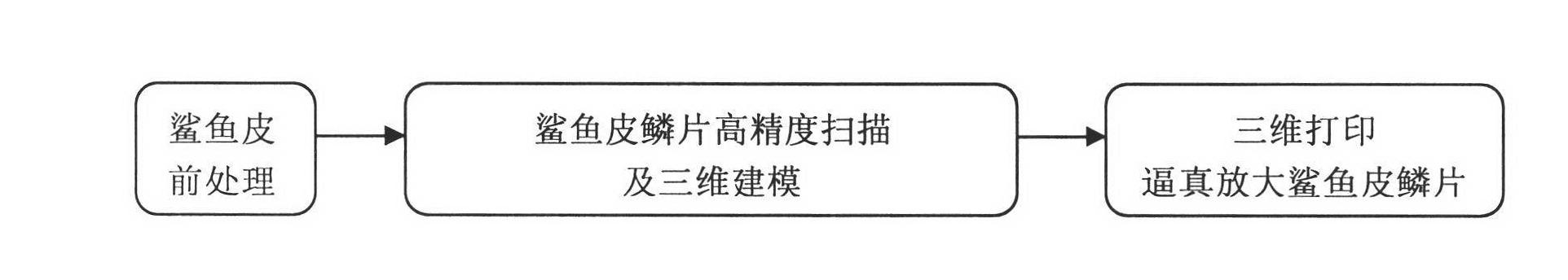

Method for manufacturing amplified vivid sharkskin squama

A technology of shark skin and scales, which is applied in the direction of textiles and papermaking, to achieve the effect of improving drag reduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

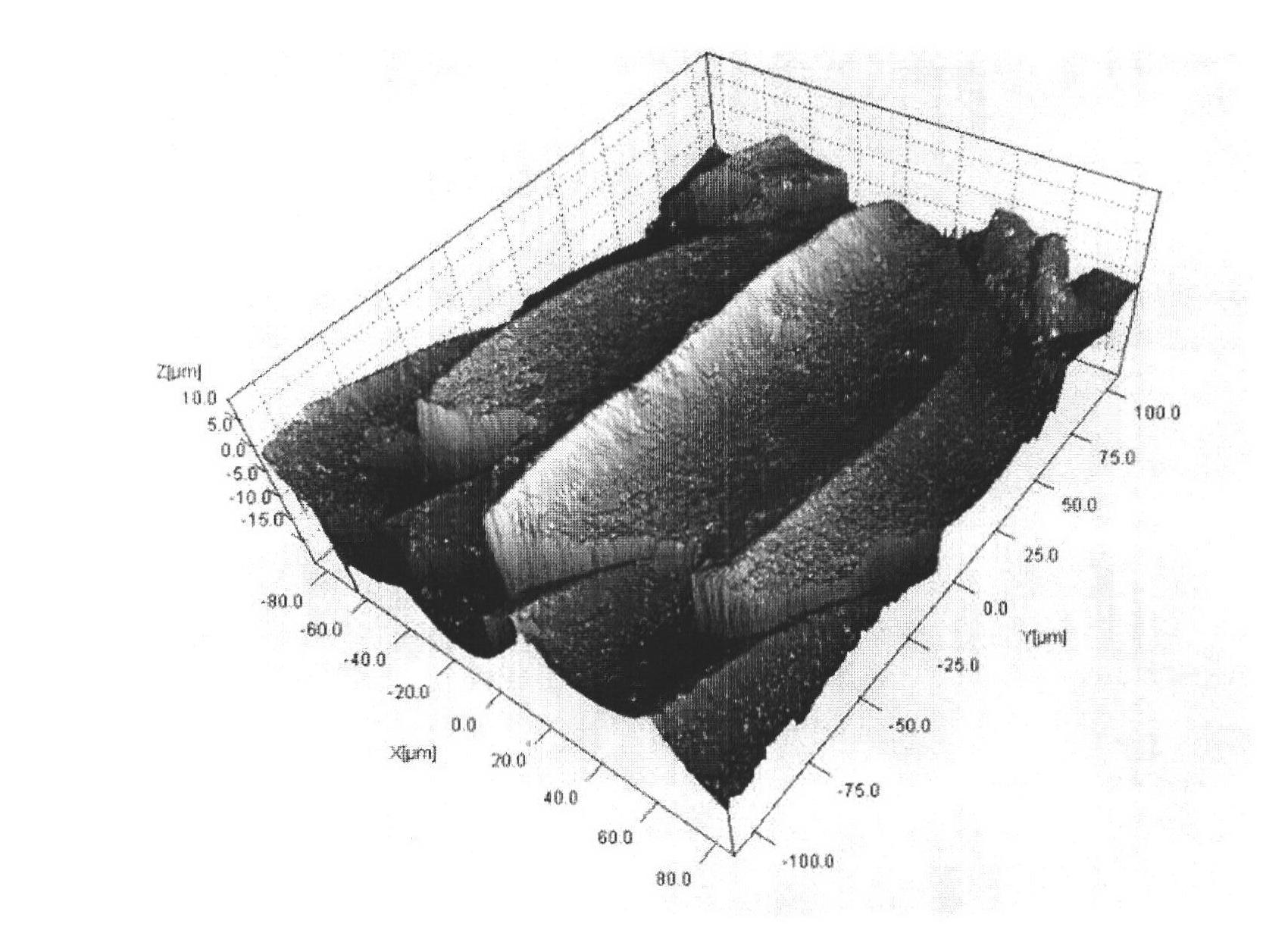

Method used

Image

Examples

Embodiment 1

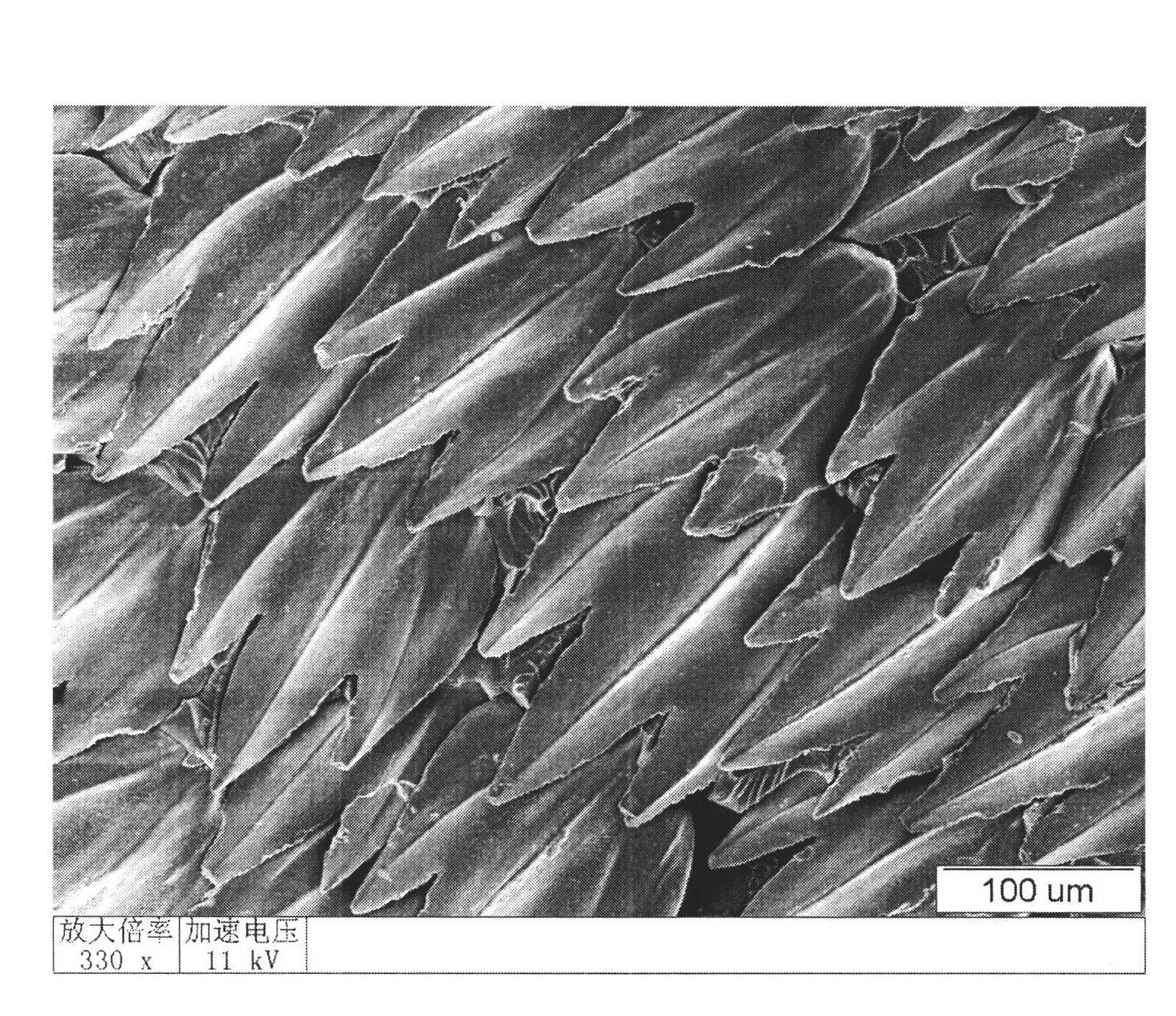

[0046] Selection of raw materials: The selected shark is the macaque. The experimental sample of the shark was purchased from Beijing Aquatic Products Company. The initial sample was in a frozen state, with a body length of 1.4m and a weight of 23Kg. 2.5% glutaraldehyde solution, 50%, 75%, 95, 100% ethanol, deionized water and other chemical reagents were purchased from Beijing Aoli Chemical Reagent Co., Ltd. The main material of shark scale printing is epoxy resin, and the model of auxiliary support material is FullCure705.

[0047] Step 1: Pre-treatment of shark skin

[0048](A) First thaw the frozen shark at natural normal temperature, then dissect and cut the shark skin. Rinse the cut shark skin 5 times with clean water and then 3 times with deionized water to remove the shark skin. Impurities such as mucus, silt, and blood stains attached to the skin surface were removed to obtain shark skin with a clean surface.

[0049] (B) The cleaned shark skin was completely soaked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com